Page 1

User Manual

Compact GuardLogix Controllers

Catalog Numbers 1768-L43S, 1768-L45S

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation

® sales office or online at http://www.rockwellautomation.com/literature/) describes some

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Rockwell Automation, Allen-Bradley, TechConnect, ControlLogix, GuardLogix, CompactBlock Guard I/O, ControlFLASH, Log ix5000, RSLogix, RSNetWorx, CompactLogix, Compact I/O, DriveLogix, Integrated

Architecture, KwikLink, MicroLogix, PanelView, PhaseManager, POINT Guard I/O, POINT I/O, PowerFlex, Rockwell Software, SLC, and RSLinx are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

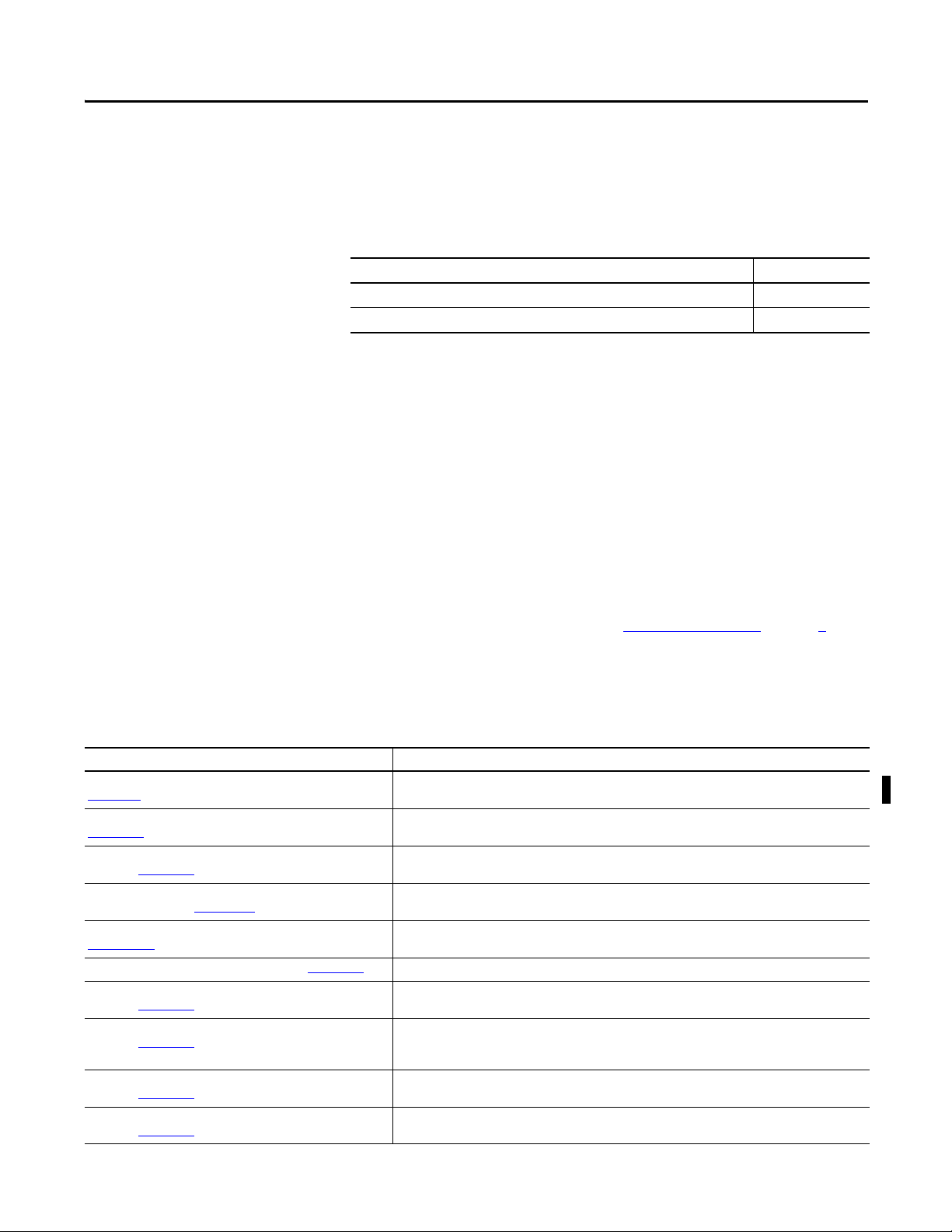

Summary of Changes

The information below summarizes the changes to this manual since the last

publication.

To help you find new and updated information in this release of the manual, we

included change bars as shown to the right of this paragraph.

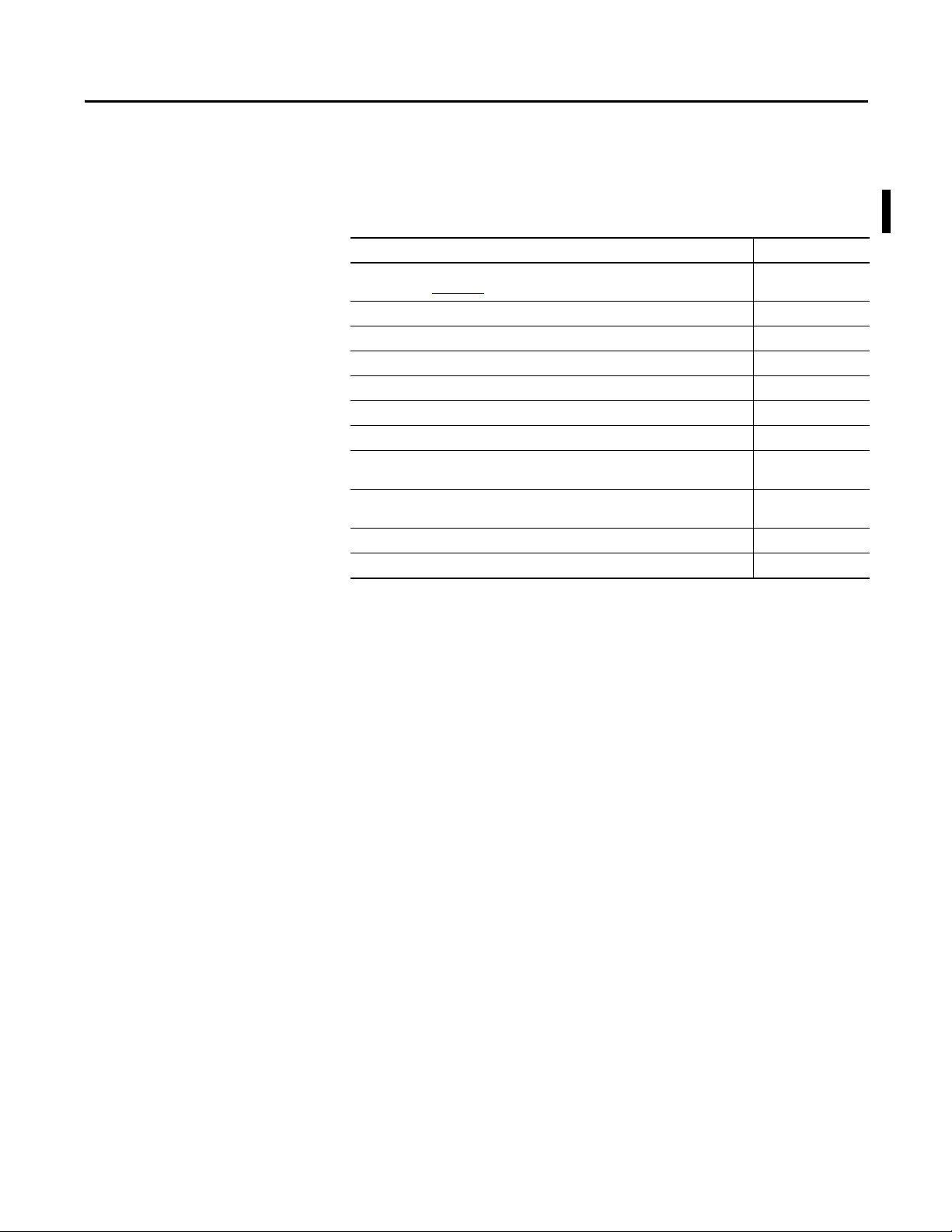

Top ic Pa ge

Specifications and certifications are in the CompactLogix Controller Specifications Technical

Data, publication 1769-TD005

Added information on using unicast connections for I/O modules on EtherNet/IP networks 16, 57

Added installation information Chapter 2

Added information on Run mode protection for the safety task signature 36, 90, 91

Updated I/O replacement procedures to include various replacement scenarios 65…71

Updated Requested Packet Interval maximum value 75

Added DCA_INPUT and DCAF_INPUT data types to list of valid types for safety tags 78

Restructured information on produced and consumed safety tags and configuring peer

safety controllers so that all information is together in Chapter 6

Moved status indicator description tables to an appendix and added troubleshooting

information

Added information on changing to a 1756-L7xS controller 125

Added History of Changes appendix 127

.

—

81

Appendix B

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 5

System Overview

Install the Controller

Table of Contents

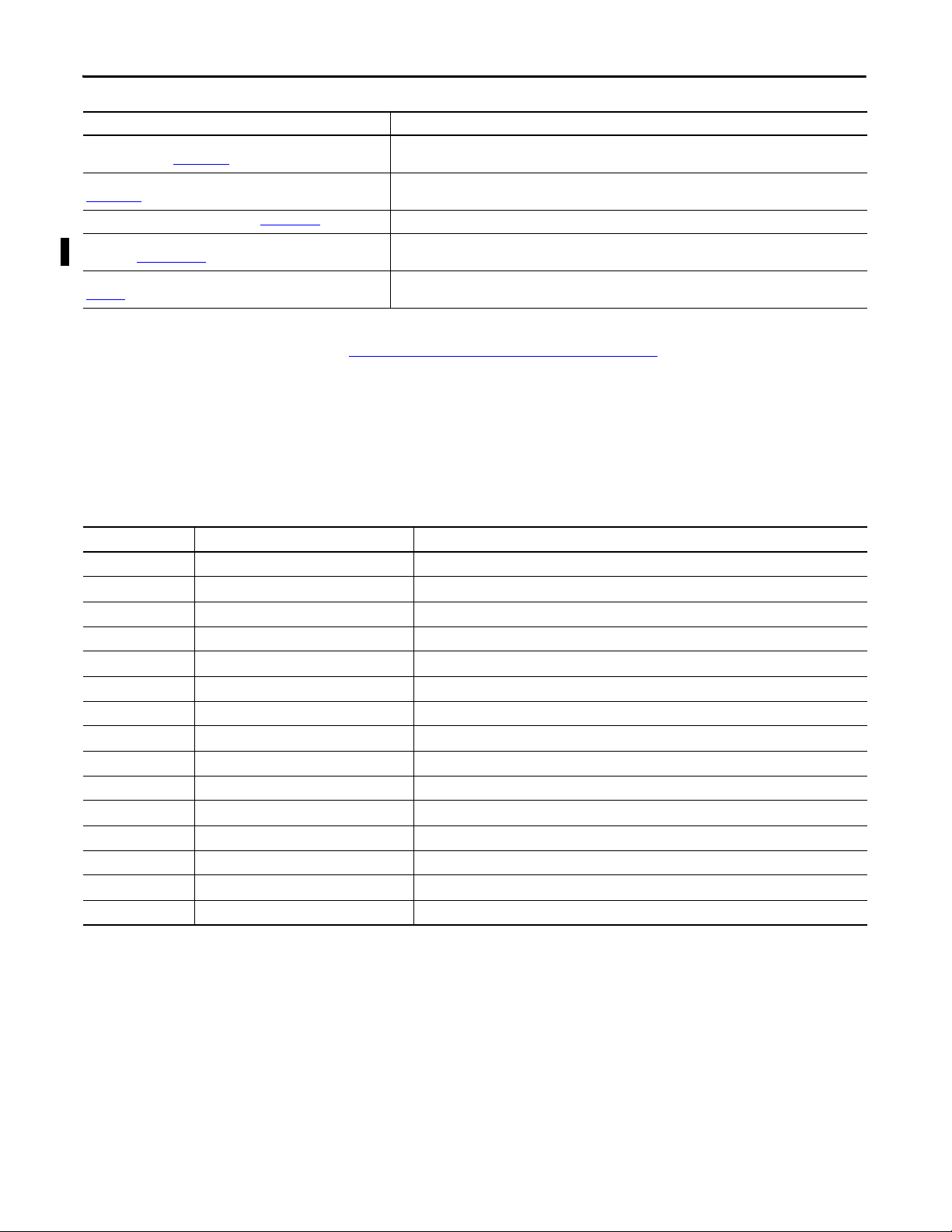

Preface

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Understanding Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

Safety Application Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Network Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Task Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Distinguishing Between Standard and Safety Components . . . . . . . . . . 12

HMI Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Controller Data Flow Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Selecting System Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Selecting Safety I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Selecting Communication Networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Programming Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Environment and Enclosure Information. . . . . . . . . . . . . . . . . . . . . . . 17

Programmable Electronic Systems (PES) . . . . . . . . . . . . . . . . . . . . . . . 18

North American Hazardous Location Approval. . . . . . . . . . . . . . . . . 18

European Hazardous Location Approval . . . . . . . . . . . . . . . . . . . . . . . 19

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Required System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Module Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mount the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Panel Mount the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mount the Controller on a DIN Rail. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Confirm the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Insert or Remove a Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Make Communication Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Update the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Install Firmware via ControlFlash Software. . . . . . . . . . . . . . . . . . . . . 28

Install Firmware via AutoFlash Software. . . . . . . . . . . . . . . . . . . . . . . . 29

Install Firmware via a CompactFlash Card. . . . . . . . . . . . . . . . . . . . . . 29

Remove a 1768 or 1769 Module from the DIN Rail . . . . . . . . . . . . . . . . . 30

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 5

Page 6

Table of Contents

Chapter 3

Configure the Controller

Communicate over Networks

Create a Controller Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Set Passwords for Safety-locking and -unlocking . . . . . . . . . . . . . . . . . . . . 35

Protecting the Safety Task Signature in Run Mode. . . . . . . . . . . . . . . . . . 36

Handling I/O Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Enable Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Configure a Peer Safety Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 4

The Safety Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Managing the Safety Network Number (SNN). . . . . . . . . . . . . . . . . . 39

Assigning the Safety Network Number (SNN). . . . . . . . . . . . . . . . . . 41

Changing the Safety Network Number (SNN). . . . . . . . . . . . . . . . . . 41

EtherNet/IP Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Producing and Consuming Data via an EtherNet/IP Network . . . 45

Connections over the EtherNet/IP Network . . . . . . . . . . . . . . . . . . . 45

EtherNet/IP Communication Example . . . . . . . . . . . . . . . . . . . . . . . . 46

EtherNet/IP Connections for CIP Safety I/O Modules. . . . . . . . . . 47

Standard EtherNet/IP Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ControlNet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Producing and Consuming Data via a ControlNet Network . . . . . 48

Connections over the ControlNet Network . . . . . . . . . . . . . . . . . . . . 48

ControlNet Communication Example . . . . . . . . . . . . . . . . . . . . . . . . . 49

ControlNet Connections for Distributed I/O . . . . . . . . . . . . . . . . . . 50

Standard DeviceNet Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Serial Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 5

Add, Configure, Monitor, and Replace

CIP Safety I/O

6 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Adding CIP Safety I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Configure CIP Safety I/O Modules via RSLogix 5000 Software . . . . . . 56

Setting the Safety Network Number (SNN) . . . . . . . . . . . . . . . . . . . . . . . . 57

Using Unicast Connections on EtherNet/IP Networks. . . . . . . . . . . . . . 57

Setting the Connection Reaction Time Limit. . . . . . . . . . . . . . . . . . . . . . . 57

Specify the Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . 58

View the Maximum Observed Network Delay . . . . . . . . . . . . . . . . . . 58

Setting the Advanced Connection Reaction Time Limit

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Understanding the Configuration Signature. . . . . . . . . . . . . . . . . . . . . . . . 61

Configuration via RSLogix 5000 Software . . . . . . . . . . . . . . . . . . . . . . 61

Different Configuration Owner (listen only connection) . . . . . . . . 62

Reset Safety I/O Module Ownership. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Addressing Safety I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Monitor Safety I/O Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Resetting a Module to Out-of-box Condition. . . . . . . . . . . . . . . . . . . . . . . 65

Replacing a Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Page 7

Develop Safety Applications

Table of Contents

Replacement with ‘Configure Only When No Safety Signature

Exists’ Enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Replacement with ‘Configure Always’ Enabled. . . . . . . . . . . . . . . . . . 70

Chapter 6

The Safety Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Safety Task Period Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Safety Task Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Safety Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Safety Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Safety Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Tag Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Data Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Constant Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

External Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Produced/Consumed Safety Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Configure the Peer Safety Controllers’ Safety Network Numbers . 81

Produce a Safety Tag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Consume Safety Tag Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Safety Tag Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Create Tag Mapping Pairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Monitor Tag Mapping Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Safety Application Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Safety-lock the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Generate a Safety Task Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Software Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Go Online with the Controller

Chapter 7

Connecting the Controller to the Network. . . . . . . . . . . . . . . . . . . . . . . . . 93

Connect the Controller via a Serial Network. . . . . . . . . . . . . . . . . . . . 93

Connect Your EtherNet/IP Device and Computer. . . . . . . . . . . . . . 94

Connect Your ControlNet Communication Module and Your

Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Configuring the Network Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Configure a Serial Communication Driver. . . . . . . . . . . . . . . . . . . . . . 95

Configuring an EtherNet/IP or ControlNet Driver . . . . . . . . . . . . . 95

Understanding the Factors that Affect Going Online. . . . . . . . . . . . . . . . 95

Project to Controller Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Firmware Revision Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Safety Status/Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Safety Task Signature and Safety-locked and -unlocked Status . . . . 97

Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Upload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Go Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 7

Page 8

Table of Contents

Chapter 8

Monitor Status and Handle Faults

Store and Load Projects Using

Nonvolatile Memory

Viewing Status via the Online Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Monitoring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

All Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Safety Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Monitoring Status Flags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Monitoring Safety Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Controller Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Nonrecoverable Controller Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Nonrecoverable Safety Faults in the Safety Application . . . . . . . . . 106

Recoverable Faults in the Safety Application . . . . . . . . . . . . . . . . . . . 107

Viewing Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Developing a Fault Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Program Fault Routine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Controller Fault Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Use GSV/SSV Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Chapter 9

Using Memory Cards for Nonvolatile Memory . . . . . . . . . . . . . . . . . . . . 113

Storing a Safety Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Loading a Safety Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Manage Firmware with Firmware Supervisor . . . . . . . . . . . . . . . . . . . . . . 116

Status Indicators

Change Controller Type in RSLogix

5000 Projects

History of Changes

Appendix A

Compact GuardLogix Controller Status Indicators . . . . . . . . . . . . . . . . 117

Clear a Major Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Clear a Nonrecoverable Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Troubleshoot a Nonresponsive Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Troubleshoot System Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Examine the Power Supply PWR Status Indicator. . . . . . . . . . . . . . 120

Examine the Controller PWR Indicator . . . . . . . . . . . . . . . . . . . . . . . 121

Examine the I/O PWR Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Appendix B

Changing from a Standard to a Safety Controller . . . . . . . . . . . . . . . . . . 123

Changing from a Safety to a Standard Controller . . . . . . . . . . . . . . . . . . 124

Changing from a 1756 GuardLogix Controller to a 1768 Compact

GuardLogix Controller or Vice Versa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Changing from a 1756-L7xS Controller to a 1756-L6xS or 1768-L4xS

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Appendix C

Index

8 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 9

Preface

Top ic Pa ge

Additional Resources 9

Understanding Terminology 10

This manual is a guide for using Compact GuardLogix™ controllers. It describes

the Compact GuardLogix-specific procedures you use to configure, operate, and

troubleshoot your controller.

Use this manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that use Compact GuardLogix controllers.

You must have a basic understanding of electrical circuitry and familiarity with

relay logic. You must also be trained and experienced in the creation, operation,

and maintenance of safety systems.

For detailed information on related topics like programming your

Compact GuardLogix controller, SIL 3/PLe requirements, or information on

standard Logix components, see the list of Additional Resources

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

CompactLogix Controllers Specifications Technical Data, publication

1769-TD005

GuardLogix Controller Systems Safety Reference Manual, publication

1756-RM093

GuardLogix Safety Application Instruction Set Reference Manual,

publication 1756-RM095

CompactBlock Guard I/O EtherNet/IP Safety Modules Installation

Instructions, publication 1791ES-IN001

Guard I/O EtherNet/IP Safety Modules User Manual, publication

1791ES-UM001

CompactLogix Controllers User Manual, publication 1768-UM001

Logix5000 Controllers General Instruction Set Reference Manual,

publication 1756-RM003

Logix5000 Controllers Common Procedures Programming Manual,

publication 1756-PM001

EtherNet/IP Modules in Logix5000 Control Systems User Manual,

publication ENET-UM001

ControlNet Modules in Logix5000 Control Systems User Manual,

publication CNET-UM001

Provides specifications, dimensions, and certification information for Compact GuardLogix controllers

Contains detailed requirements for achieving and maintaining SIL 3/PLe with the GuardLogix controller system

Provides information on the GuardLogix Safety ap plication instruction set

Provides information on installing CompactBlock ™ Guard I/O™ EtherNet/IP Safety modules

Provides information on using Guard I/O EtherNet/IP Safety modules

Provides information on using CompactLogix™ controllers in standard applications

Provides information on the Logix5000™ instruction set

Provides access to the Logix5000 Controllers set of programming manuals, which covers managing project files,

organizing tags, ladder logic programming, testing routines, creating Add-On Instructions, controller status

data, handling faults, importing and exporting project components and more

Provides information on using EtherNet/IP communication modules in a Logix5000 control system

Provides information on using the 1756-CNB module in Logix5000 control systems

on page 9.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 9

Page 10

Preface

Resource Description

Logix5000 Controllers Execution Time and Memory Use Reference

Manual, publication 1756-RM087

Logix5000 Controllers Import Export Reference Manual, publication

1756-RM084

PhaseManager User Manual, publication LOGI X-U M001

SERCOS and Analog Motion Configuration and Startup Manual,

publication MOTION-UM001

Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

Provides information on estimating the execution time and memor y use for instructions

Provides information on using RSLogix™ 5000 Import/Export utility

Provides information on programming the controller to use equipment phases in a standard application

Provides information on configuring the controller for motion axes, coordinate system, and motion modules in

standard applications

Provides in-depth information on grounding and wiring programmable controllers

You can view or download publications at

http://www.rockwellautomation.com/literature

technical documentation, contact your local Allen-Bradley® distributor or

Rockwell Automation sales representative.

. To order paper copies of

Understanding Terminology

This table defines terms used in this manual.

Table 1 - Terms and Definitions

Abbreviation Full Term Definition

1oo2 One Out of Two Refers to the behavioral design of a multi-processor safety system.

CIP Common Industrial Protocol A communication protocol designed for industrial automation applications.

CIP Safety Common Industrial Protocol – Safety Certified SIL 3/PLe rated version of CIP.

DC Diagnostic Coverage The ratio of the detected failure rate to the total failure rate.

EN European Norm. The official European standard.

GSV Get System Value An instruction that retrieves specified controller-status information and places it in a destination tag.

— Multicast The transmission of information from one sender to multiple receivers.

PFD Probability of Failure on Demand The average probability of a system to fail to perform its design function on demand.

PFH Probability of Failure per Hour The probability of a system to have a dangerous failure occur per hour.

PL Performance Level ISO 13849-1 safety rating.

RPI Requested Packet Interval The expected rate in time for production of data when communicating over a network.

SNN Safety Network Number A unique number that identifies a section of a safety network.

SSV Set System Value An instruction that sets controller system data.

— Standard An object, task, tag, program, or component in your project that is not a safety-related item.

— Unicast The transmission of information from one sender to one receiver.

10 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 11

System Overview

Top ic Pag e

Safety Application Requirements 11

Distinguishing Between Standard and Safety Components 12

Controller Data Flow Capabilities 13

Selecting System Hardware 14

Selecting Safety I/O Modules 14

Selecting Communication Networks 14

Programming Requirements 15

Chapter 1

Safety Application Requirements

The Compact GuardLogix controller system is certified for use in safety

applications up to and including Safety Integrity Level (SIL) 3 and Performance

Level (e) in which the de-energized state is the safe state. Safety application

requirements include evaluating probability of failure rates (PFD and PFH),

system reaction-time settings, and functional-verification tests that fulfill

SIL 3/PLe criteria.

For SIL 3 and PLe safety system requirements, including functional validation

test intervals, system reaction time, and PFD/PFH calculations, refer to the

GuardLogix Controller Systems Safety Reference Manual, publication

1756-RM093

operating a Compact GuardLogix SIL 3, PLe safety system.

Compact GuardLogix-based SIL 3/PLe safety applications require the use of at

least one safety network number (SNN) and a safety task signature. Both affect

controller and I/O configuration and network communication.

Refer to the GuardLogix Controller Systems Safety Reference Manual,

publication 1756-RM093

. You must read, understand, and fulfill these requirements prior to

, for details.

Safety Network Number

The safety network number (SNN) must be a unique number that identifies

safety subnets. Each safety subnet that the controller uses for safety

communication must have a unique SNN. Each CIP Safety device must also be

configured with the safety subnet’s SNN. The SNN can be assigned

automatically or manually.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 11

Page 12

Chapter 1 System Overview

For information on assigning the SNN, see Managing the Safety Network

Number (SNN) on page 39.

Safety Task Signature

The safety task signature consists of an ID number, date, and time that uniquely

identifies the safety portion of a project. This includes safety logic, data, and

configuration. The Compact GuardLogix system uses the safety task signature to

determine the project’s integrity and to let you verify that the correct project is

downloaded to the target controller. Creating, recording, and verifying the safety

task signature is a mandatory part of the safety-application development process.

Distinguishing Between Standard and Safety Components

See Generate a Safety Task Signature

Slots in the Compact GuardLogix backplane may be populated with other

CompactLogix I/O modules that are certified to the Low Voltage and EMC

Directives. Refer to http://www.ab.com/certification/ce

certificate for the Programmable Control – CompactLogix Product Family and

determine which modules are certified.

You must create and document a clear, logical, and visible distinction between the

safety and standard portions of the application. To aid in creating this distinction,

RSLogix 5000 programming software features safety identification icons to

identify the safety task, safety programs, safety routines, and safety components.

In addition, the RSLogix 5000 software uses a safety class attribute that is visible

whenever safety task, safety programs, safety routine, safety tag, or safety

Add-On Instruction properties are displayed.

The controller does not allow writes to safety tag data from external HMI devices

or via message instructions from peer controllers. RSLogix 5000 software can

write safety tags when the Compact GuardLogix controller is safety-unlocked,

does not have a safety task signature, and is operating without safety faults.

on page 90 for more information.

to find the CE

The 1768 CompactLogix Controllers User Manual, publication 1768-UM001

provides information on using 1768 CompactLogix controllers in standard

(non-safety) applications.

HMI Devices

HMI devices can be used with Compact GuardLogix controllers. HMI devices

can access standard tags just as with a standard controller. However, HMI devices

cannot write to safety tags; safety tags are read-only for HMI devices.

12 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

,

Page 13

System Overview Chapter 1

IMPORTANT

Compact GuardLogix Controller

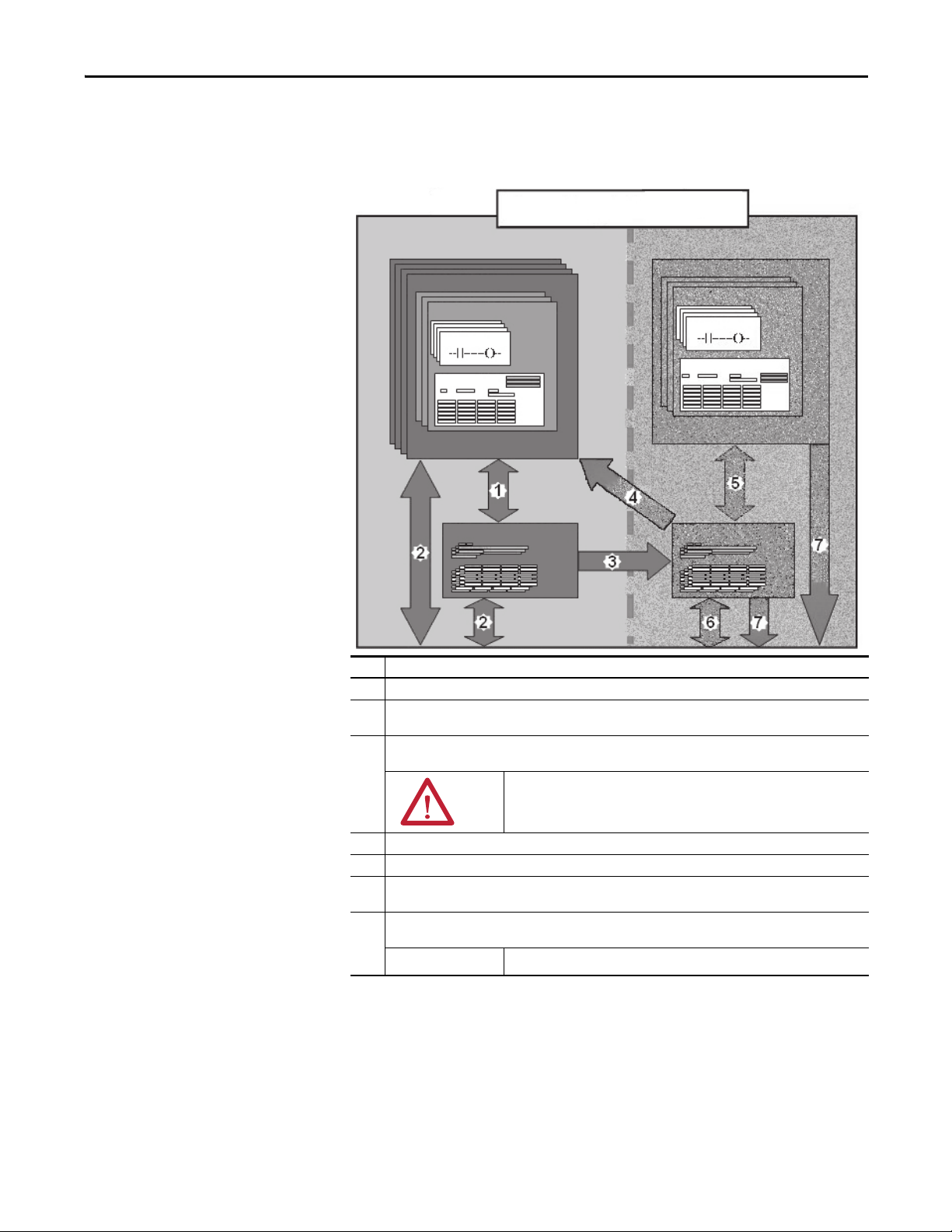

Controller Data Flow Capabilities

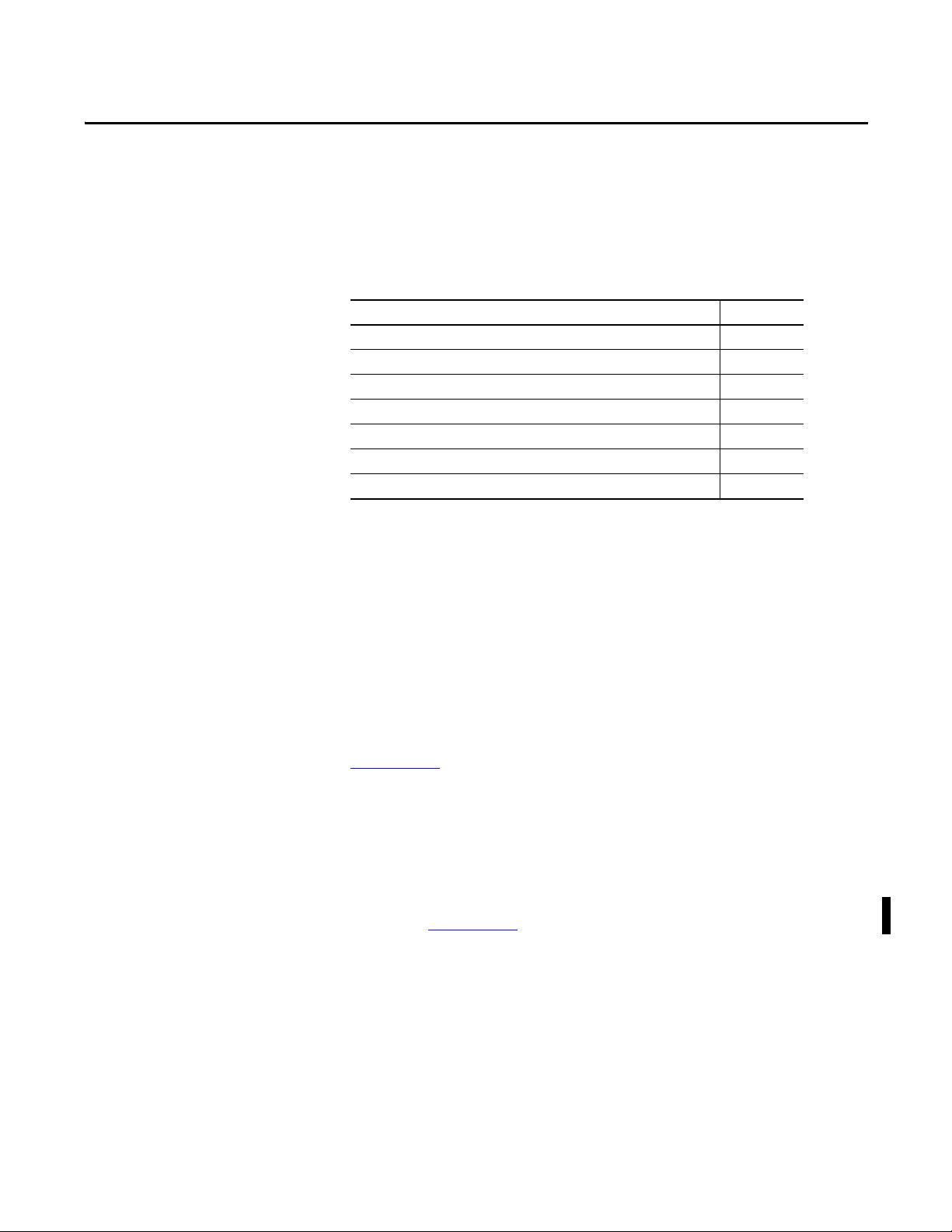

This illustration explains the standard and safety data-flow capabilities of the

Compact GuardLogix controller.

Figure 1 - Data Flow Capabilities

Standard Safety

Standard Tasks

Standard Programs

Standard Routines

Program Data

Controller Standard Tags

Safety Task

Safety Programs

Safety Routines

Program Safety Data

Controller Safety Tags

No. Description

1 Standard tags and logic behave the same way they do in the standard Logix platform.

2 Standard tag data, program- or controller-scoped, can be exchanged with external HMI devices, personal

3 Compact GuardLogix controllers are integrated controllers with the ability to move (map) standard tag data

4 Controller-scoped safety tags can be read directly by standa rd logic.

5 Safety tags can be read or written by safety logic.

6 Safety tags can be exchanged between safety controllers over Ethernet or ControlNet networks, including 1756

7 Safety tag data, program- or controller-scoped, can be read by external devices, such as HMI devices, personal

computers, and other controllers.

into safety tags for use within the safety task.

ATT EN TI ON : This data must not be used to directly control a SIL 3/PLe

output.

and 1768 GuardLogix controllers.

computers, or other standard controllers.

Once this data is read, it is considered standard data, not SIL 3/PLe data.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 13

Page 14

Chapter 1 System Overview

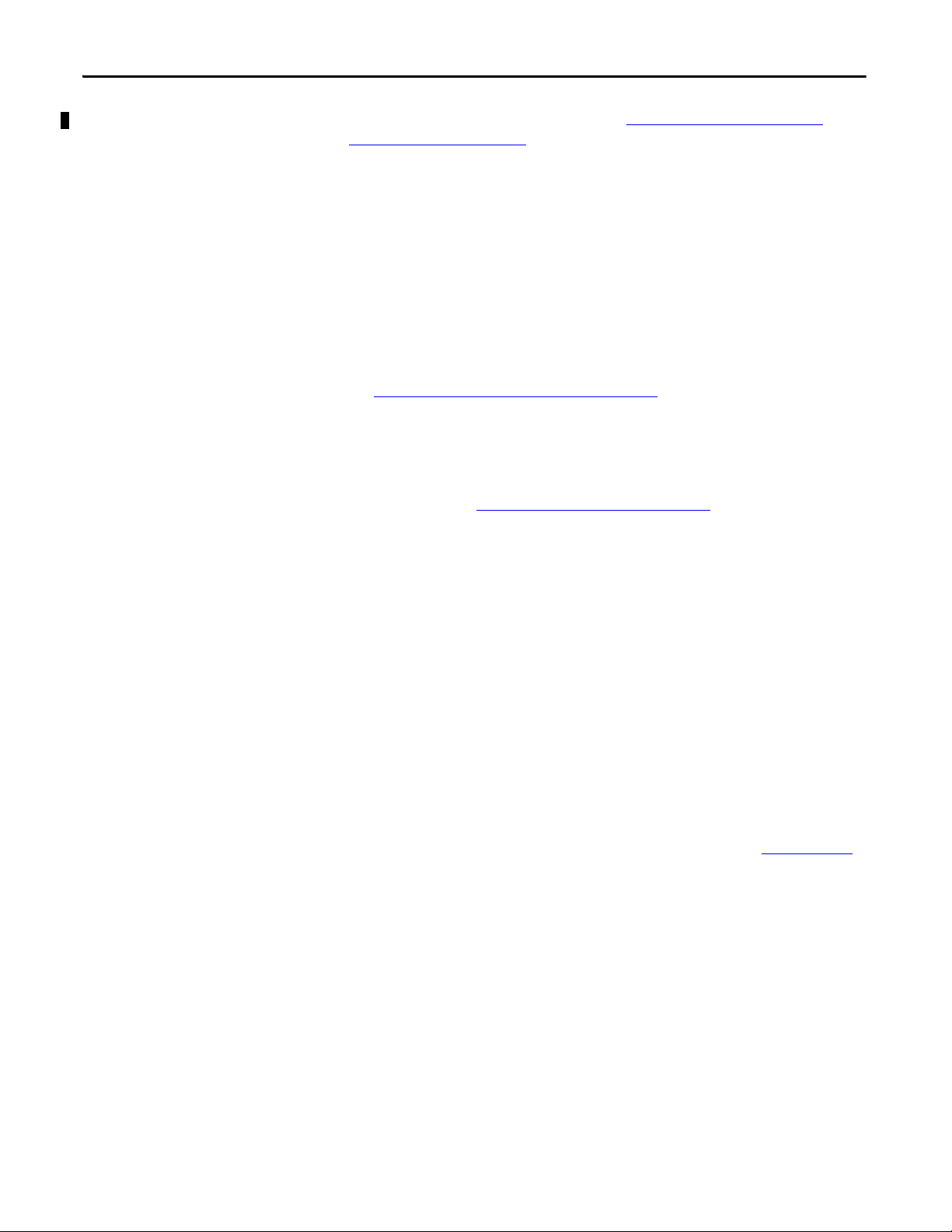

Selecting System Hardware

The Compact GuardLogix system supports SIL 3 and PLe safety applications.

Controller

1768-L43S and 1768-L45S controllers feature one built-in serial port. A

keyswitch on the front panel lets you change controller modes: RUN, PROGram

and REMote. The 1768 Compact GuardLogix controllers combine a 1768

backplane with a 1769 backplane. This combination includes all the advantages

of the 1768 architecture for safety applications while retaining the 1769 I/O

support for standard applications.

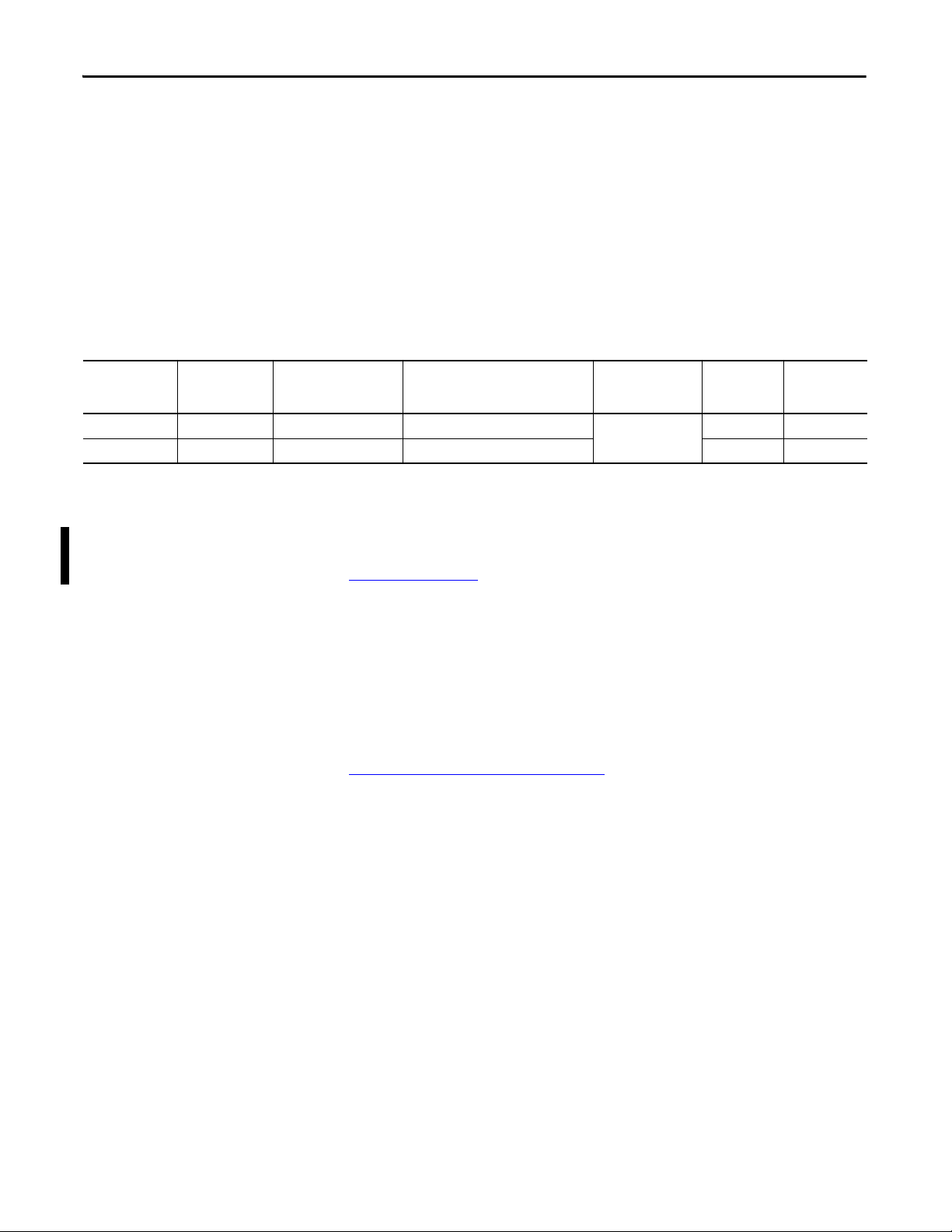

Controller Available 1768

Slots

1768-L43S 2 2 16 Modules in 3 Banks 250 0.5 MB 2 MB

1768-L45S 4 2 30 Modules in 3 Banks 1 MB 3 MB

Number of 1768

Communication

Modules

Maximum Local 1769 I/O Modules

Supported

Number of

Connections

Supported

Safety Task

Memory

In addition, Compact GuardLogix controllers support 1768-M04SE SERCOS

modules for motion control in standard (non-safety) applications. For

information on developing motion applications, refer to the SERCOS and

Analog Motion Configuration and Startup Manual, publication

MOTION-UM001

.

Standard

Memory

Selecting Safety I/O Modules

Selecting Communication Networks

Safety input and output devices can be connected to CIP Safety I/O on

EtherNet/IP networks, allowing output devices to be controlled by a Compact

GuardLogix controller system via EtherNet/IP communication.

For the most up-to-date information on available CIP Safety I/O catalog

numbers, certified series, and firmware revisions, see

http://www.ab.com/certification/safety

.

The Compact GuardLogix controller supports communication that lets it do the

following:

• Distribute and control Safety I/O on EtherNet/IP networks.

• Produce and consume safety tag data between 1756 and 1768 GuardLogix

controllers across EtherNet/IP or ControlNet networks.

• Distribute and control standard I/O on EtherNet, ControlNet, or

DeviceNet networks.

14 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 15

System Overview Chapter 1

Use these communication modules to provide an interface between Compact

GuardLogix controllers and network devices.

Use this module To interface between

1768-ENBT, series A, revision 3

1768-CNB, series A, revision 3

(1) This or later.

(1)

(1)

The Compact GuardLogix controller and EtherNet/IP devices

Controllers on the ControlNet network

The Compact GuardLogix controller can connect to RSLogix 5000

programming software via a serial connection, an 1768-ENBT EtherNet module,

or a 1768-CNB ControlNet module.

Programming Requirements

See the Additional Resources

on page 9 for more information on using network

communication modules.

RSLogix 5000 software is the programming tool for Compact GuardLogix

controller applications.

Use Ta bl e 2

to identify the minimum software versions for use with your

Compact GuardLogix controllers.

Table 2 - Software Versi ons

Cat. No. RSLogix 5000 Software

1756-L43S, 1756-L45S 18 Any version

(1) This version or later.

(2) RSLinx Classic version 2.59 or later is required with RSLogix 5000 software version 20 or later.

Versi on

(1)

RSLinx® Classic Software

(1)

Vers ion

(2)

Safety routines include safety instructions, which are a subset of the standard

ladder logic instruction set, and safety application instructions. Programs

scheduled under the safety task support only ladder logic.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 15

Page 16

Chapter 1 System Overview

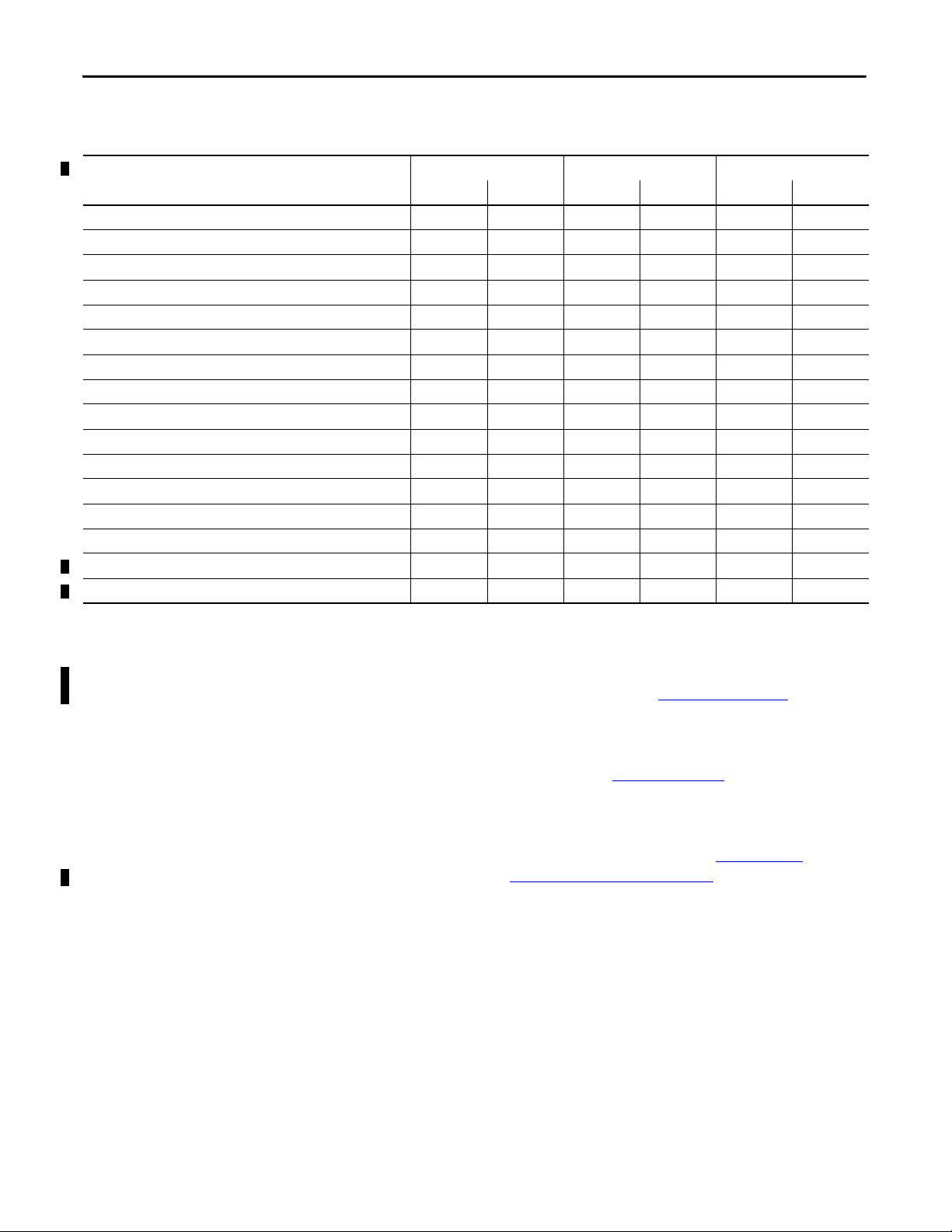

Table 3 - Supported Features by RSLogix 5000 Software Version

Featu re

Safety Task Standard Task Safety Task Standard Task Safety Task Standard Task

Add-On instructions XXXXXX

Alarms and events X X X

Constant value tags XXXXXX

Equipment phase routines X X X

External Access XXXXXX

Event tasks X X X

Firmware Supervisor XXXXXX

Function block diagrams (FBD) X X X

Integrated motion X X X

Ladder logic XXXXXX

Language switching XXXXXX

Online import and export of program components X X X

Sequential function char t (SFC) routines X X X

Structured text XXX

Unicast connections for produced and consumed safety tags XXXX

Unicast connections for safety I/O modules XX

Version 18 Version 19 Version 20

Compact GuardLogix controllers support 1768-M04SE SERCOS modules for

motion control in standard (non-safety) applications. For information on

developing motion applications, refer to the SERCOS and Analog Motion

Configuration and Startup Manual, publication MOTION-UM001

.

Compact GuardLogix controllers also support PhaseManager™ programs, which

let you add equipment phases to standard controller applications. Refer to the

PhaseManager User Manual, publication LOGIX-UM001

, for more

information.

For information on using these features, refer to the Logix5000 Controllers

Common Procedures Programming Manual, publication 1756-PM001

publications listed in the Additional Resources

on page 9, and RSLogix 5000

, the

software online help.

16 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 17

Install the Controller

Top ic Pag e

Precautions 17

Required System Components 20

Clearance Requirements 20

Module Placement 20

Mount the Controller 22

Insert or Remove a Memory Card 26

Make Communication Connections 26

Update the Controller 28

Remove a 1768 or 1769 Module from the DIN Rail 30

Chapter 2

Precautions

Read and follow these precautions for use.

Environment and Enclosure Information

ATTENTION: This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II

applications (as defined in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR Publication 11. Without appropriate

precautions, there may be difficulties with electromagnetic compatibility in residential and other environments due to

conducted as well as radiated disturbances.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of

flame, complying with a flame spread rating of 5VA or be approved for the application if non-metallic. The interior of the

enclosure must be accessible only by the use of a tool. Subsequent sections of this publication may contain additional

information regarding specific enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures

, for additional installation requirements

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 17

Page 18

Chapter 2 Install the Controller

Programmable Electronic Systems (PES)

AT TE NT IO N: Personnel responsible for the application of safety-related

Programmable Electronic Systems (PES) shall be aware of the safety

requirements in the application of the system and shall be trained in using

the system.

North American Hazardous Location Approval

The following information applies when operating this

equipment in hazardous locations:

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class

I Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous

locations only. Each product is supplied with markings on the rating

nameplate indicating the hazardous location temperature code.

When combining products within a system, the most adverse

temperature code (lowest "T" number) may be used to help

determine the overall temperature code of the system. Combinations

of equipment in your system are subject to investigation by the local

Authority Having Jurisdiction at the time of installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is

known to be nonhazardous. Secure any external

connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or

other means provided with this product.

• Substitution of components may impair suitability

for Class I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Informations sur l'utilisation de cet équipement en

environnements dangereux:

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à

une utilisation en environnements de Classe I Division 2 Groupes A, B,

C, D dangereux et non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d'identification qui indiquent le code de

température pour les environnements dangereux. Lorsque plusieurs

produits sont combinés dans un système, le code de température le

plus défavorable (code de température le plus faible) peut être utilisé

pour déterminer le code de température global du système. Les

combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de

l'installation.

AVERTISSEMENT: RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que l'environnement

est classé non dangereux avant de débrancher

l'équipement.

• Couper le courant ou s'assurer que l'environnement

est classé non dangereux avant de débrancher les

connecteurs. Fixer tous les connecteurs externes

reliés à cet équipement à l'aide de vis, loquets

coulissants, connecteurs filetés ou autres moyens

fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

18 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 19

Install the Controller Chapter 2

European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by

European Union Directive 94/9/EC and has been found to comply with the Essential Health and

Safety Requirements relating to the design and construction of Category 3 equipment intended

for use in Zone 2 potentially explosive atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by

compliance with EN 60079-15 and EN 60079-0.

ATTENTION: This equipment is not resistant to sunlight or other sources of

UV radiation.

WARNING:

• This equipment must be installed in an enclosure providing at least IP54

protection when applied in Zone 2 environments.

• This equipment shall be used within its specified ratings defined by

Rockwell Automation.

• Provision shall be made to prevent the rated voltage from being exceeded by

transient disturbances of more than 40% when applied in Zone 2

environments.

• Secure any external connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or other means provided with

this product.

• Do not disconnect equipment unless power has been removed or the area is

known to be nonhazardous.

Prevent Electrostatic Discharge

ATT EN TI ON : This equipment is sensitive to electrostatic discharge, which

can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in

use.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 19

Page 20

Chapter 2 Install the Controller

IMPORTANT

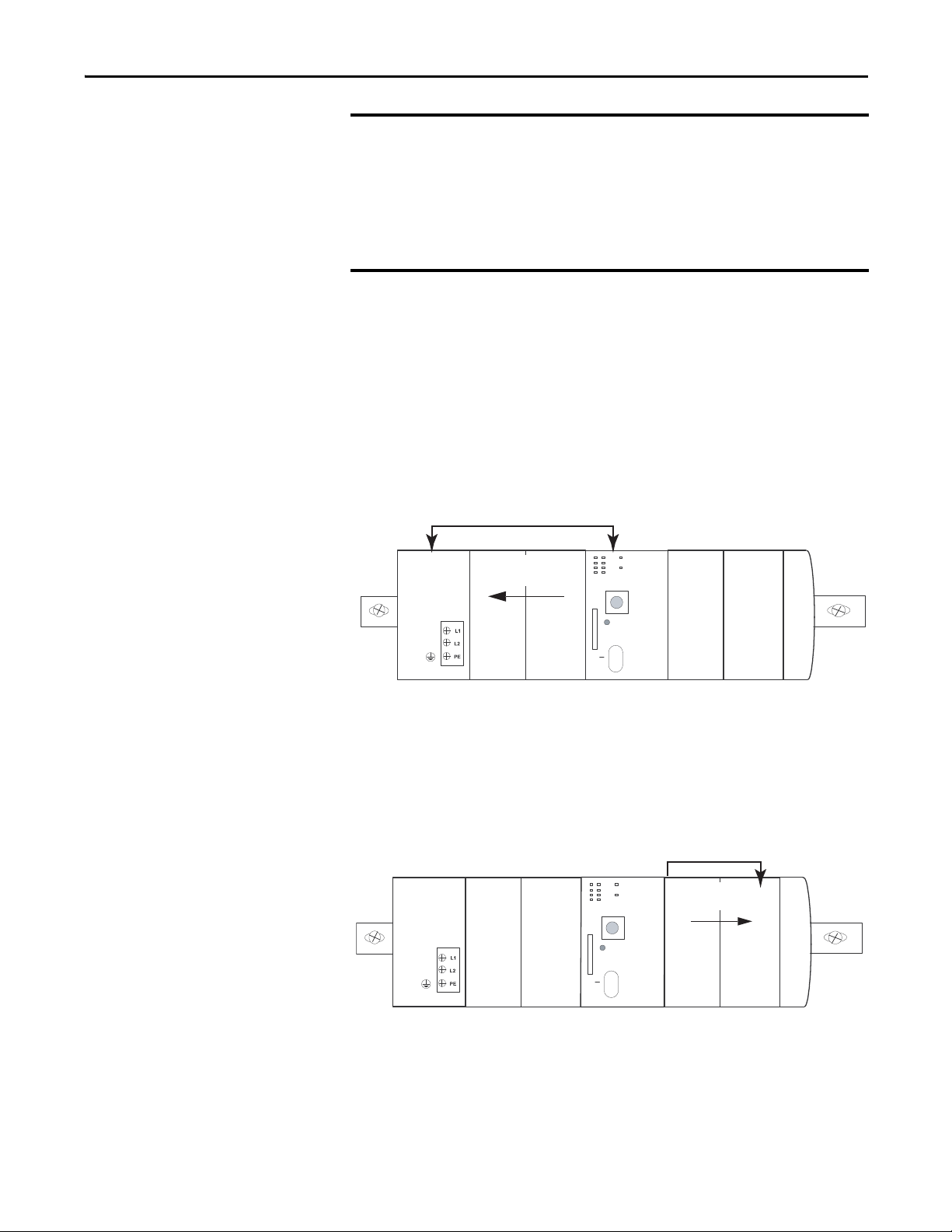

31609-M

Power

OUT

L1

L2/N

90 mm

(3.54 in.)

105 mm (4.13 in.)

90 mm

(3.54 in.)

105 mm (4.13 in.)

1768 Backplane (local)

1768 Controller, Power Supply, and I/O Modules

Remote Bank

1769 Power Supply and

I/O Modules

1769 Backplane

Required System Components

Clearance Requirements

You need these parts when installing your controller:

• 1768-L43S or 1768-L45S Compact GuardLogix controller

• 1768-PA3 or 1768-PB3 power supply

• 1769-ECR end cap

• Mounting screws (M4 or #8 panhead) or one of these

EN 50 022 DIN rails:

– 35 x 7.5 mm (1.38 x 0.30 in.)

– 35 x 15 mm (1.38 x 0.59 in.)

• 1756-CP3 serial cable (or make your own)

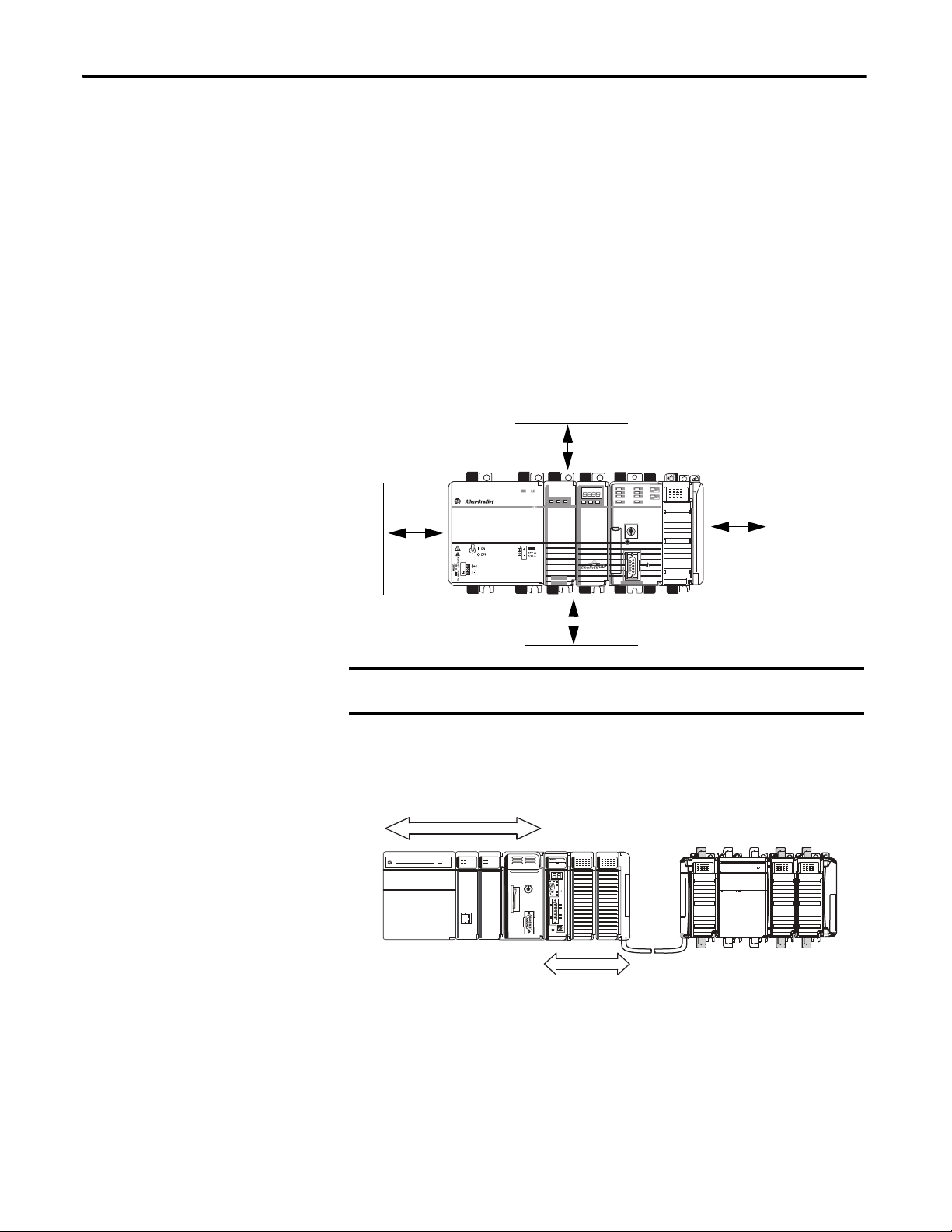

Allow for the minimum clearance from enclosure walls, wireways, and other

equipment.

Module Placement

20 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

These minimum clearances keep the modules cool enough in most situations.

The operating temperature range is 0…60 °C (32…140 °F).

Page 21

Install the Controller Chapter 2

IMPORTANT

1768 Backplane

1768 Modules

1768-L43S

Slot 2 Slot 1 Slot 0

1769 Backplane

1769 Modules

1768-L43S

Slot 2Slot 1Slot 0

CompactLogix System Distance Ratings

Because the 1768 CompactLogix power supply works with the controller to

power a 1768 system, the distance rating in a 1768 CompactLogix system

differs from that in a 1769 CompactLogix system.

In the 1768 system, the distance rating is the distance between 1769 I/O

modules and the controller. In the 1769 system, the distance rating is the

distance between 1769 I/O modules and the power supply.

Follow these requirements to determine proper placement of your 1768

controller, power supply, 1768 I/O modules, and 1769 I/O modules:

• Place the 1768-L4xx controller so that it is the last module (furthest away

from the power supply) in the 1768 backplane.

• The 1768 CompactLogix power supply distributes power from the right

side of the supply and must be the leftmost module in the system.

• The local bank is powered by a 1768 power supply.

• Up to eight 1769 I/O modules can reside in the local bank.

• 1768 slots are numbered right to left, starting with the controller as slot 0.

• Up to two remote banks of 1769 I/O modules may be connected by using

1769-CRLx extension cables.

• Remote banks are powered by a standard 1769 power supply.

• Each I/O bank must have its own 1769 power supply.

• 1769 slots are numbered from left to right, starting with the controller as

slot 0.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 21

Page 22

Chapter 2 Install the Controller

IMPORTANT

IMPORTANT

• Up to eight 1769 Compact I/O modules can reside on each side of a 1769

power supply in a remote bank. Consult the module’s specifications for its

distance rating.

1769 power supplies must be separated from the 1768 series

processor by a bus extension cable. Never put a 1769 power supply in

the 1768 backplane or the controller will generate a major fault that

cannot be cleared until you remove the 1769 power supply.

• The type of controller determines the maximum number of 1768 modules

that can reside in the local bank and the maximum number of 1769 I/O

modules that can reside in one local and up to two remote banks.

Controller Max Local 1768 Modules Max 1769 I/O Modules (local and remote)

1768-L43S 2 16

1768-L45S 4 30

Mount the Controller

You can mount the controller to a panel or on a DIN rail.

Do not use screws if using a DIN rail to mount the controller. You can

break the mounting tabs if you screw the controller to a panel while it

is on a DIN rail.

Panel Mount the Controller

Follow these steps to mount your controller by using the panhead screws.

1. Connect the CompactLogix modules together as shown in Mount the

Controller on a DIN Rail on page 23.

2. Use the controller as a template and mark pilot holes on your panel.

3. Drill the pilot holes for M4 or #8 screws.

ATTENTION: During mounting of all devices, be sure that all debris

(such as metal chips or wire strands) is kept from falling into the

controller or I/O modules. Debris that falls into the controller or

modules could cause damage while the controller is energized.

4. Use M4 or #8 screws to mount the controller to your panel with 1.16 N•m

(10 lb•in) of torque.

5. Ground the module on a ground bus with a dedicated earth ground stake.

6. Connect the ground bus to a functional earth ground on the panel or a

DIN rail.

22 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 23

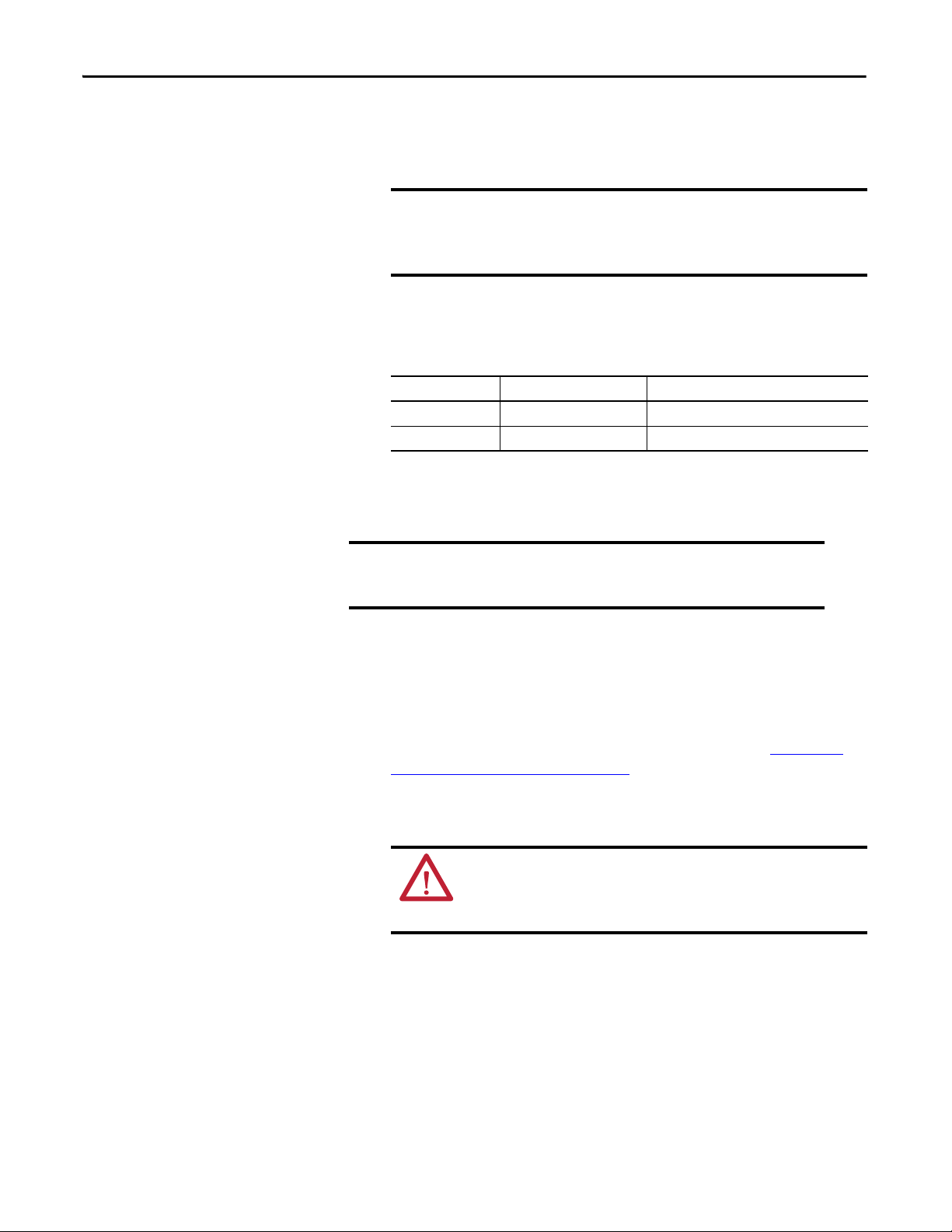

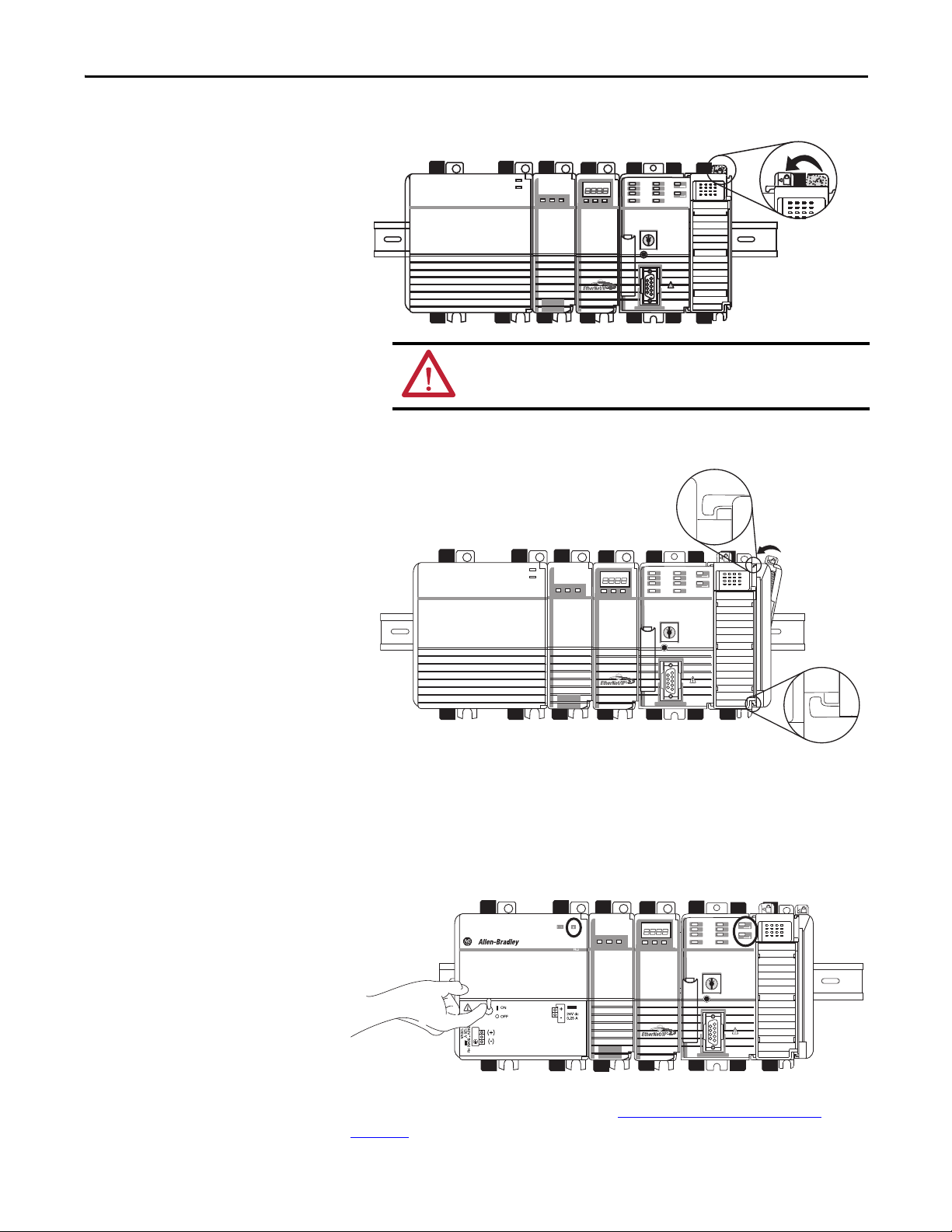

Mount the Controller on a DIN Rail

31595-M

a.

b.

b.

c.

a.

a.

c.

AT TE NT IO N: This product is grounded through the DIN rail to chassis ground.

Use zinc plated yellow-chromate steel DIN rail to assure proper grounding. The

use of other DIN rail materials (for example, aluminum and plastic) that can

corrode, oxidize, or are poor conductors, can result in improper or intermittent

grounding. Secure DIN rail to the mounting surface approximately every

200 mm (7.87 in.) and use end anchors appropriately.

Mount 1768 Components

Follow these steps to mount the controller.

1. Mount the controller on the DIN rail.

Install the Controller Chapter 2

31596 -M

2. Mount additional 1768 modules to the left of the controller.

31597-M

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 23

Page 24

Chapter 2 Install the Controller

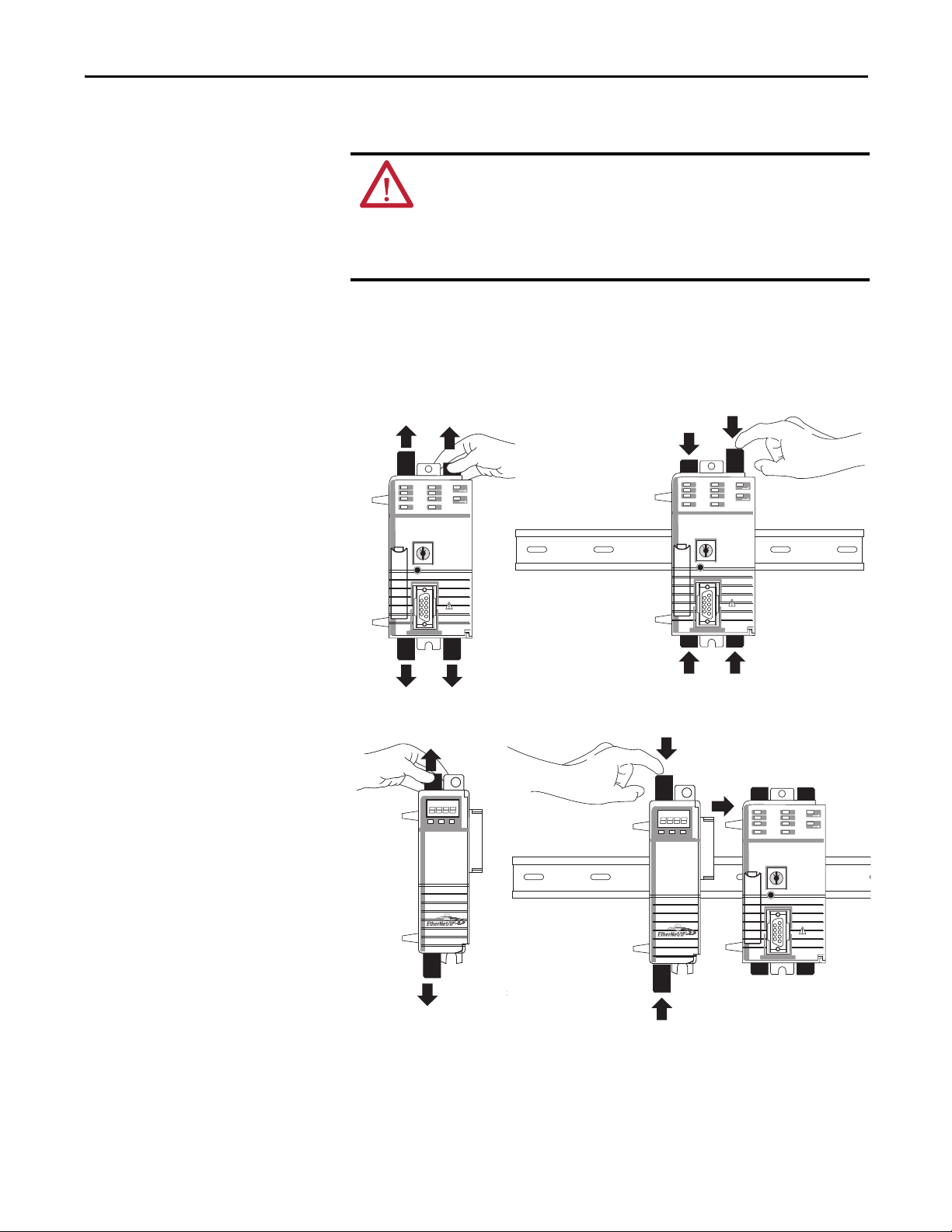

31599-M

3. Mount the 1768 power supply and other 1768 modules.

Mount 1769 I/O Modules

Follow these steps to mount 1769 I/O modules to the right of the controller.

1. Align the upper and lower tongue-and-groove slots and slide the module

back toward the DIN rail until the bus levers line up.

2. Close the DIN rail latches.

24 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 25

Install the Controller Chapter 2

a.

b.

a.

Power

OUT

L1

L2/N

3. Slide the bus lever to the left to lock the modules together.

ATTENTION: When attaching I/O modules, it is very important that the

bus connectors are securely locked together for proper electrical

connection.

4. Attach the end cap by using the tongue and groove slots (a) and locking the

bus lever (b).

Confirm the Installation

After you have installed the controller and applied power, check that the PWR

and I/O PWR status indicators are solid green.

If the indicators are in any other state, see Troubleshoot System Power

page 120.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 25

on

Page 26

Chapter 2 Install the Controller

Workstation Controller

1 DCD

2 RDX

3 TXD

4 DTR

COMMO N

6 DSR

7 RTS

8 CTS

9

1 DCD

2 RDX

3 TXD

4 DTR

COMMO N

6 DSR

7 RTS

8 CTS

9

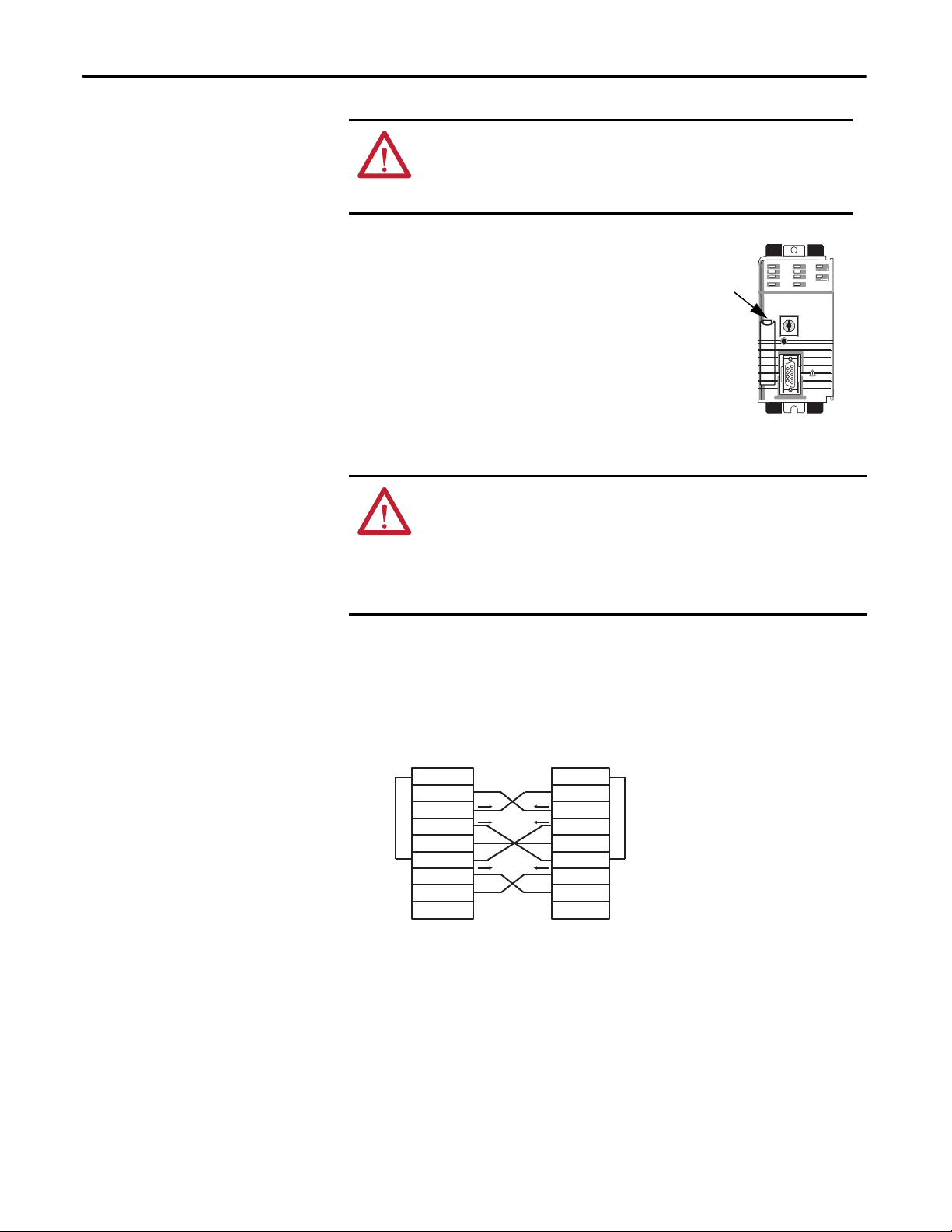

Insert or Remove a Memory Card

Make Communication Connections

WARNING: When you insert or remove the memory card when power is

on, an electrical arc can occur. This could cause an explosion in hazardous

location installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

Follow these steps to insert or remove a CompactFlash

card.

1. Press the memory-card door latch on the

controller front panel and pivot the door down

toward you.

2. Insert or remove the card from the slot.

3. Close the memory card door.

WARNING: If you connect or disconnect the serial cable with power

applied to this module or the serial device on the other end of the cable,

an electrical arc can occur. This could cause an explosion in hazardous

location installations.

Make sure that power is removed or the area is nonhazardous before

proceeding.

Connect the 1756-CP3 serial cable to the controller’s serial port and to your

workstation.

If you make your own cable, follow these guidelines.

• Wire the connectors as shown.

• Limit the cable length to 15.2 m (50 ft).

• Attach the shield to both connectors.

26 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 27

Install the Controller Chapter 2

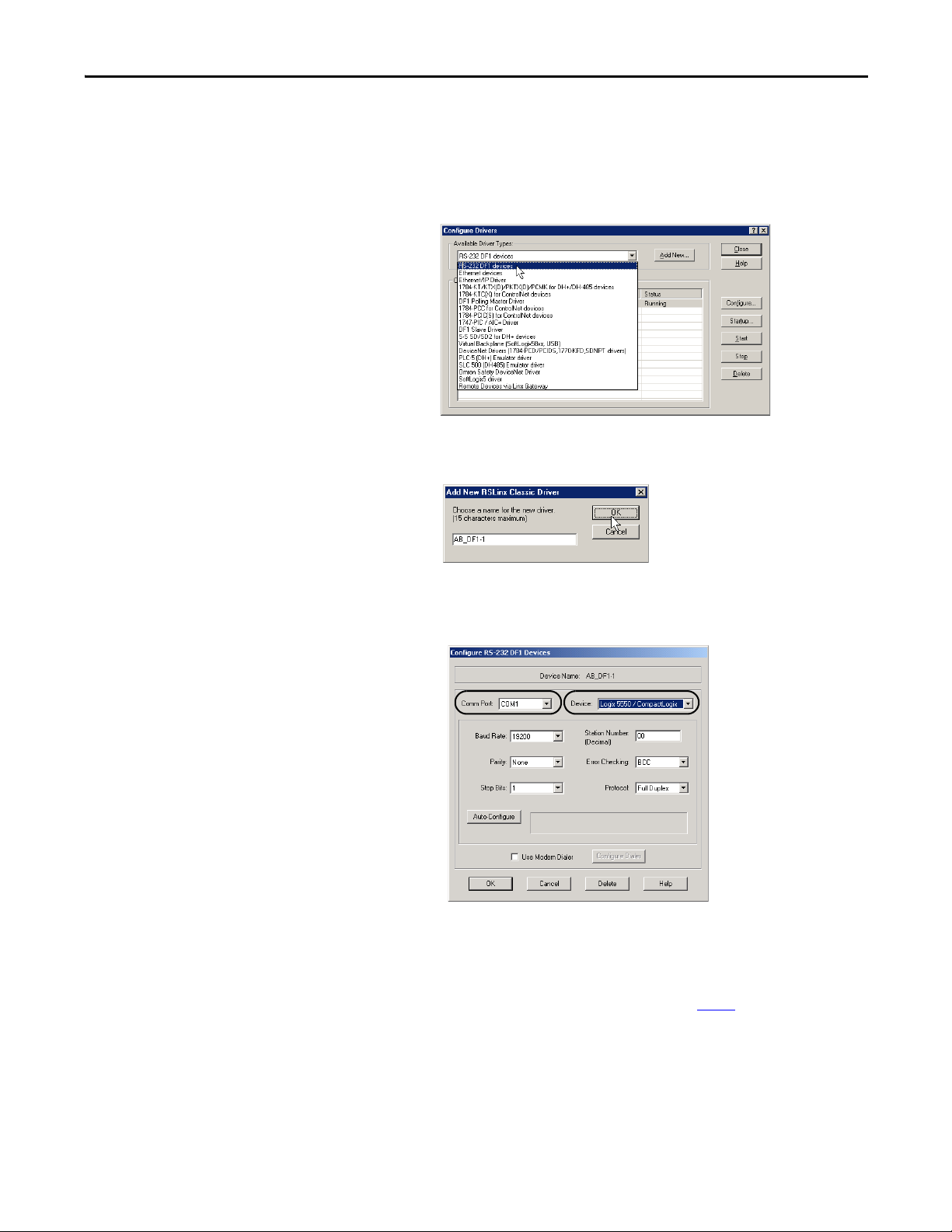

Use RSLinx software to configure the driver for serial communication.

1. From the Communications menu, choose Configure Drivers.

2. From the Available Driver Types pull-down menu, choose the RS-232

DF1 devices driver.

3. Click Add New.

4. Type a name for the driver and click OK.

5. From the Comm Port pull-down menu on the Configure Devices dialog

box, choose the serial port on the workstation to which your cable is

connected.

6. From the Device pull-down menu, choose Logix5550/CompactLogix.

7. Click Auto-Configure.

a. Click OK if the Auto Configuration Successful dialog box appears.

b. If the dialog box does not appear, go back to step 5

and verify that you

selected the correct comm port.

8. Click Close.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 27

Page 28

Chapter 2 Install the Controller

IMPORTANT

TIP

Update the Controller

The controllers ship without firmware. Controller firmware is packaged with

RSLogix 5000 programming software. In addition, controller firmware is also

available for download from the Rockwell Automation Technical Support

website at: http://www.rockwellautomation.com/support/

.

When installing or updating controller firmware, do not interrupt the update

process in any way. Interrupting the firmware update may result in an

inoperable controller. Inoperable controllers must be returned to Rockwell

Automation.

To install firmware, you can use any of the following.

Method Page

ControlFlash, version 8 or later, software that ships with RSLogix 5000 software 28

AutoFlash software that runs within RSLogix 5000 software 29

A 1784-CF64 or 1784-CF128 CompactFlash card with valid firmware already loaded 29

Updating your controller firmware via ControlFlash or AutoFlash software

requires either a serial or other network connection to the controller.

Updating via an Ethernet connection is faster, but you must first install a 1768ENBT Ethernet module to connect to the controller via the Ethernet network.

For information on installing, configuring, and operating a 1768-ENBT module,

refer to the EtherNet/IP Modules in Logix5000 Control Systems User Manual,

publication ENET-UM001

.

Install Firmware via ControlFlash Software

1. Make sure the network is connected.

2. Start ControlFlash software.

3. When the Welcome dialog box appears, click Next.

4. Select the catalog number of the controller and click Next.

5. Expand the network until you see the controller.

If the required network is not shown, first configure a driver for that

network in RSLinx software.

6. Select the controller and click OK.

7. Select the desired revision level and click Next.

8. To start the update, click Finish and then Yes.

9. The OK status indicator flashes red to show that the update is in progress.

The status box indicates when the update is complete and the OK status

indicator is solid green.

10. Click OK.

11. Click Cancel and then Yes to close ControlFlash software.

28 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 29

Install the Controller Chapter 2

TIP

Install Firmware via AutoFlash Software

1. Make sure the network is connected.

2. Using RSLogix 5000 software, attempt a download to a controller project.

3. AutoFlash software launches if the required firmware is not loaded on the

controller.

4. Select the catalog number of the controller and click Next.

5. Expand the network until you see the controller.

If the required network is not shown, first configure a driver for that

network in RSLinx software.

6. Select the controller and click OK.

7. Select the desired revision level and click Next.

8. To start the update, click Finish and then Yes.

9. The OK status indicator flashes red to show that the update is in progress.

The status box indicates when the update is complete and the OK status

indicator is solid green.

10. Click OK.

11. Click Cancel and then Yes to close AutoFlash software.

Install Firmware via a CompactFlash Card

Follow these steps to use RSLogix 5000 software to store the controller program

and firmware of an already-configured controller to the CompactFlash card. The

firmware is automatically stored on your CompactFlash card when you store the

program.

1. With the CompactFlash card installed on the configured controller, on the

Controller Properties dialog box, click the Nonvolatile Memory tab.

2. Click Load Image On Powerup to save to the card.

3. Remove the card and insert it into the controller onto which you want to

load the firmware and user program.

4. Start the new controller and the image stored on the CompactFlash card

loads.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 29

Page 30

Chapter 2 Install the Controller

IMPORTANT

Power

OUT

L1

L2/N

Off

Power

OUT

L1

L2/N

a.

b.

31607-M

Powe r

OUT

L1

L2/N

c.

d.

c.

a.

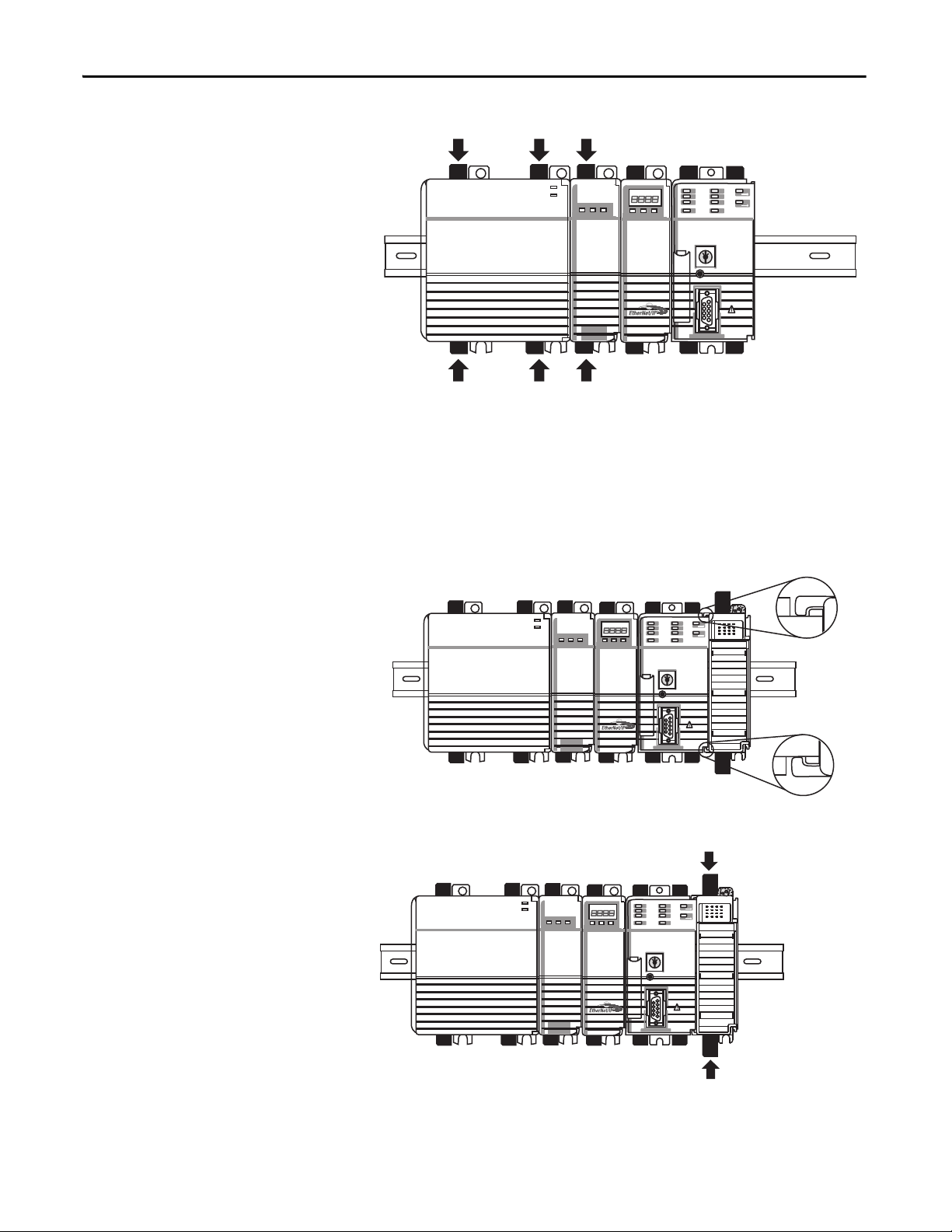

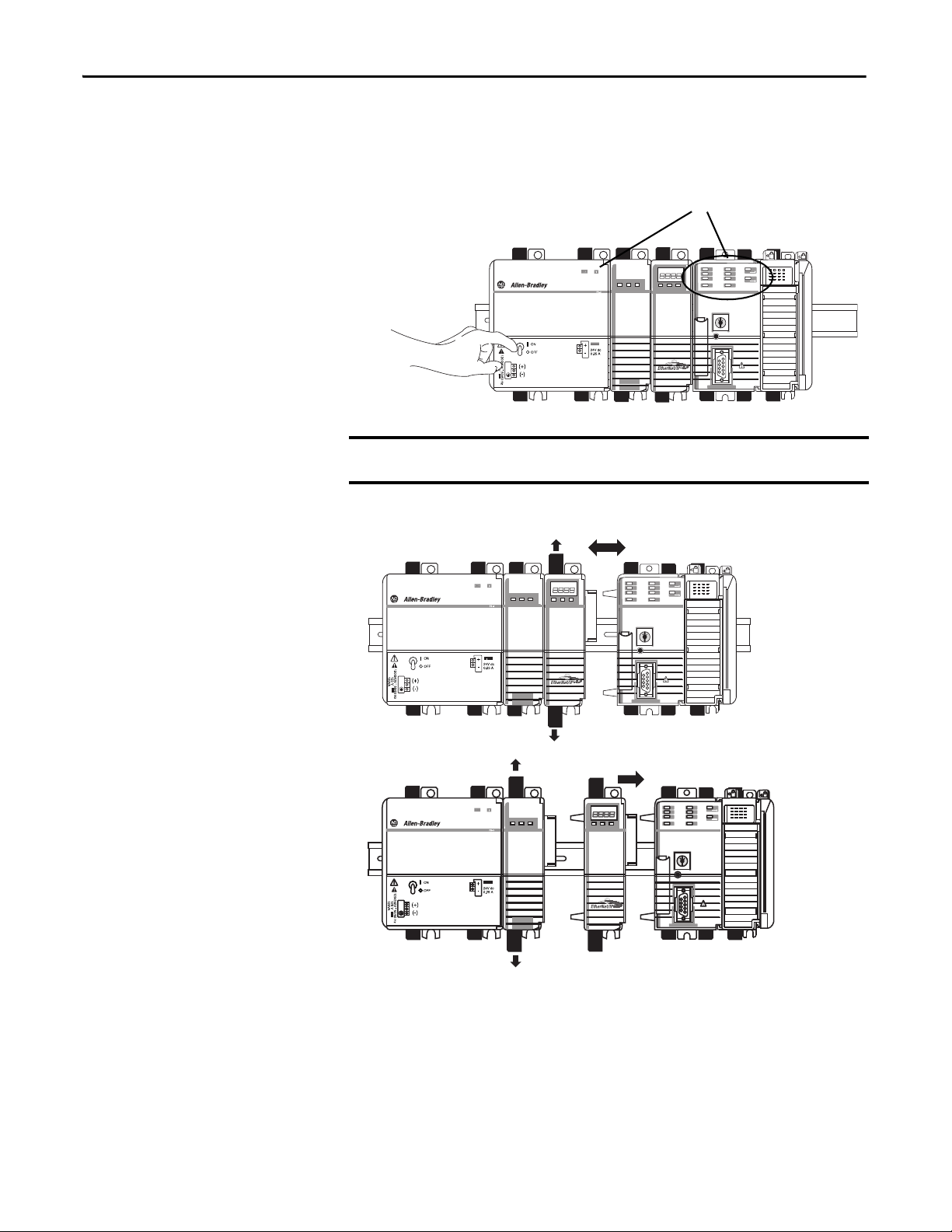

Remove a 1768 or 1769 Module from the DIN Rail

If you need to remove a module from the DIN rail, follow these steps.

1. Remove power from the controller and wait for all status indicators on the

power supply and controller to turn off.

If you disconnect any part of the system while the controller is still writing its

program to memory, you will lose your program.

2. Remove the 1768 module.

30 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 31

Install the Controller Chapter 2

b.

a.

b.

3. Remove the 1769 module by unlocking the bus lever (a) and DIN rail

latches (b).

Power

L1

L2/N

OUT

4. Slide the module away from the DIN rail along the tongue and groove

slots.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 31

Page 32

Chapter 2 Install the Controller

32 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 33

Configure the Controller

Top ic Pa ge

Create a Controller Project 33

Set Passwords for Safety-locking and -unlocking 35

Handling I/O Module Replacement 37

Enable Time Synchroniz ation 37

Configure a Pee r Safety Controller 38

Chapter 3

Create a Controller Project

To configure and program your controller, use RSLogix 5000 software to create

and manage a project for the controller.

1. Create a project in RSLogix 5000 software by clicking the New button on

the main toolbar.

2. From the Type pull-down menu, choose a Compact GuardLogix

controller:

• 1768-L43S CompactLogix5343S Safety Controller

• 1768-L45S CompactLogix5345S Safety Controller

3. Enter the major revision of firmware for the controller.

4. Type a name for the controller.

When you create a project, the project name is the same as the name of the

controller. However, you can rename either the project or the controller.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 33

Page 34

Chapter 3 Configure the Controller

5. Specify the folder in which to store the safety controller project.

6. For RSLogix 5000, version 20 or later, choose a Security Authority option.

For detailed information on security, refer to the Logix5000 Controllers

Security Programming Manual, publication 1756-PM016

.

7. Click OK.

RSLogix 5000 software automatically creates a safety task and a safety program.

A main ladder logic safety routine called MainRoutine is also created within the

safety program.

Figure 2 - Safety Task in the Controller Organizer

A red bar under the icon distinguishes safety programs and routines from

standard project components in the RSLogix 5000 Controller Organizer.

When a new safety project is created, RSLogix 5000 software also automatically

creates a time-based safety network number (SNN).

This SNN defines the Compact GuardLogix controller as a safety subnet. It can

be viewed and modified via the General tab on the Controller Properties dialog

box.

For most applications, this automatic, time-based SNN is sufficient. However,

there are cases in which you might want to enter a specific SNN.

34 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 35

Figure 3 - Safety Network Number

TIP

Configure the Controller Chapter 3

Set Passwords for Safetylocking and -unlocking

You can use the Controller Properties dialog box to change the controller

from standard to safety or vice versa by clicking Change Controller.

However, standard and safety projects are substantially affected.

See Appendix

B, Change Controller Type in RSLogix 5000 Projects, for

details on the ramifications of changing controllers.

Table 4 - Additional Resources

Resource Description

Chapter

6, Develop Safety Applications. Contains more information on the safety task, safety

Chapter 4, Communicate over Networks Provides more information on managing the SNN

programs, and safety routines

Safety-locking the controller helps protect safety control components from

modification. Only safety components, such as the safety task, safety programs,

safety routines, and safety tags are affected. Standard components are unaffected.

You can safety-lock or -unlock the controller project when online or offline.

The safety-lock and -unlock feature uses two separate passwords. Passwords are

optional.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 35

Page 36

Chapter 3 Configure the Controller

Follow these steps to set passwords.

1. Choose Tools > Safety > Change Password.

2. From the What Password pull-down menu, choose either Safety Lock or

Safety Unlock.

3. Type the old password, if one exists.

4. Type and confirm the new password.

5. Click OK.

Passwords may be from 1…40 characters in length and are not casesensitive. Letters, numerals, and the following symbols may be used: ‘ ~ !

@ # $ % ^ & * ( ) _ + , - = { } | [ ] \ : ; ? / .

Protecting the Safety Task Signature in Run Mode

You can prevent the safety task signature from being either generated or deleted

while the controller is in Run or Remote Run mode, regardless of whether the

safety application is locked or unlocked, by checking Protect Signature in Run

Mode on the Safety tab of the Controller Properties dialog box.

36 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 37

Configure the Controller Chapter 3

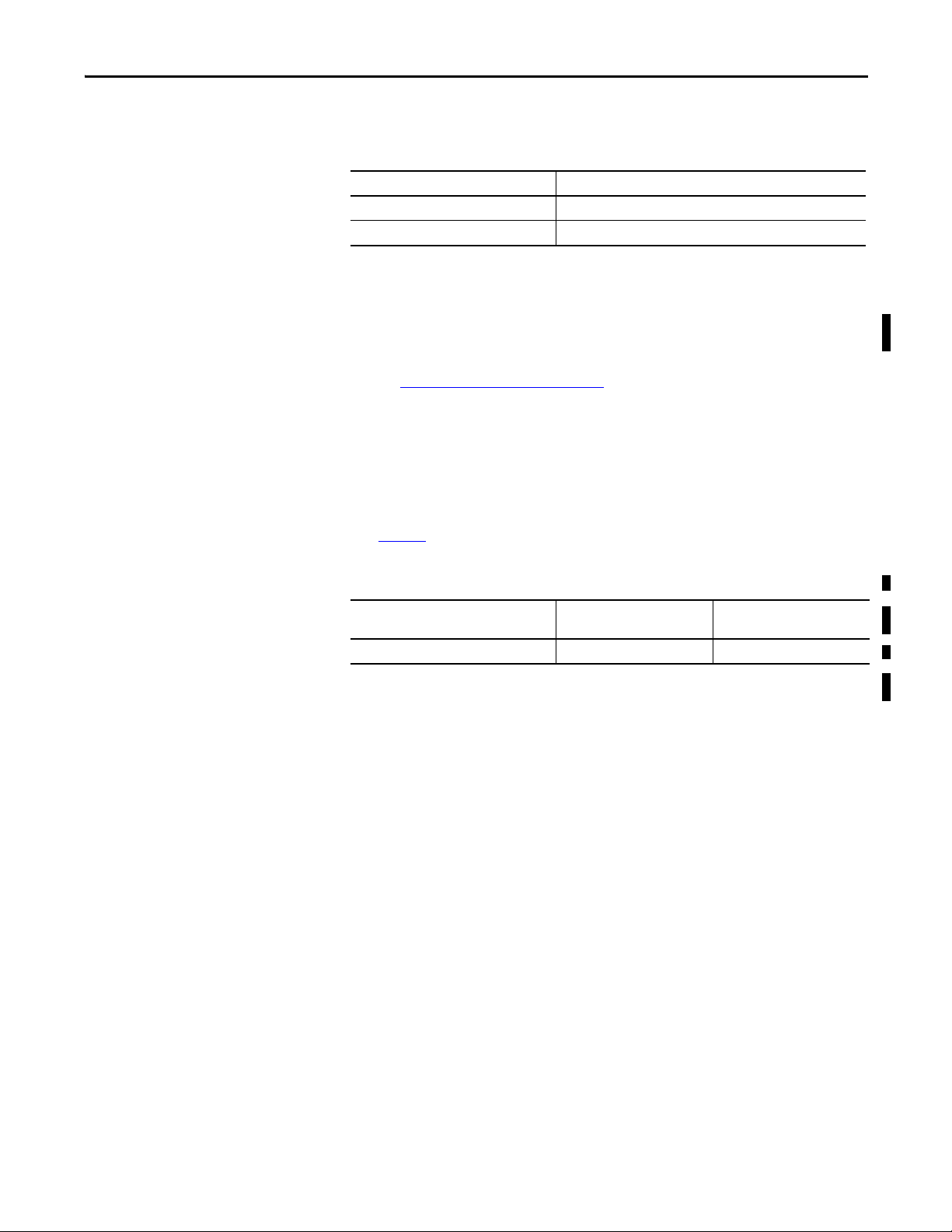

Handling I/O Module Replacement

The Safety tab of the Controller Properties dialog box lets you define how the

controller handles the replacement of an I/O module in the system. This option

determines whether the controller sets the safety network number (SNN) of an

I/O module to which it has a connection and for which it has configuration data

(1)

when a safety task signature

Figure 4 - I/O Module Replacement Options

exists.

Enable Time Synchronization

ATTENTION: Enable the Configure Always feature only if the entire

routable CIP Safety Control System is not being relied on to maintain

SIL 3 during the replacement and functional testing of a module.

See Chapter

5, Add, Configure, Monitor, and Replace CIP Safety I/O for more

information.

In a Compact GuardLogix controller system, Time Synchronization must be

enabled for the controller. To allow the controller to become the CST master,

enable Time Synchronization on the Date/Time tab of the Controller Properties

dialog box. Time Synchronization provides a standard mechanism to synchronize

clocks across a network of distributed devices.

(1) The safety task signature is a number used to uniquely identify each project’s logic, data, and configuration, thereby protecting the

system’s safety integrity level (SIL). See Safety Task Signature

information.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 37

on page 12 and Generate a Safe ty Task Signature on page 90 for more

Page 38

Chapter 3 Configure the Controller

Figure 5 - Date/Time Tab

Configure a Peer Safety Controller

For more information on Time Synchronization, refer to the Integrated

Architecture™ and CIP Sync Configuration Application Solution, publication

IA-AT003

You can add a remote peer safety controller to the I/O configuration folder of

your safety project to allow standard or safety tags to be consumed. To share

safety data between peer controllers, you produce and consume controller-scoped

safety tags.

For details on configuring the peer safety controllers and producing and

consuming safety tags, see Produced/Consumed Safety Tags

.

on page 81.

38 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 39

Communicate over Networks

TIP

Top ic Pag e

The Safety Ne twork 39

EtherNet/IP Communication 45

Control Net Communi cation 48

Standard DeviceNet Communication 51

Serial Communication 52

Additional Resources 53

Chapter 4

The Safety Network

The CIP Safety protocol is an end-node to end-node safety protocol that allows

routing of CIP Safety messages to and from CIP Safety devices through bridges,

switches, and routers.

To maintain high integrity when routing through standard bridges, switches, or

routers, each end node within a routable CIP Safety Control System must have a

unique reference. This unique reference is a combination of a safety network

number (SNN) and the node address of the network device.

Managing the Safety Network Number (SNN)

The SNN assigned to safety devices on a network segment must be unique. You

must be sure that a unique SNN is assigned to each CIP Safety network that

contains safety devices.

Multiple safety network numbers can be assigned to a CIP Safety subnet or

a ControlBus chassis that contains more than one safety device. However,

for simplicity, we recommend that each CIP Safety subnet have

one, and only one, unique SNN.

The SNN can be software-assigned (time-based) or user-assigned (manual).

These two formats of the SNN are described in the following sections.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 39

Page 40

Chapter 4 Communicate over Networks

Time-based Safety Network Number

If the time-based format is selected, the SNN value that is generated represents

the date and time at which the number was generated, according to the personal

computer running the configuration software.

Figure 6 - Time-based Format

Manual Safety Network Number

If the manual format is selected, the SNN represents entered values from 1…9999

decimal.

Figure 7 - Manual Entry

40 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 41

Communicate over Networks Chapter 4

IMPORTANT

Assigning the Safety Network Number (SNN)

You can allow RSLogix 5000 software to automatically assign an SNN, or you

can assign the SNN manually.

Automatic Assignment

When a new controller or module is created, a time-based SNN is automatically

assigned via the configuration software. Subsequent new safety-module additions

to the same CIP Safety network are assigned the same SNN defined within the

lowest address on that CIP Safety network.

Manual Assignment

The manual option is intended for routable CIP Safety systems where the

number of network subnets and interconnecting networks is small, and where

users might like to manage and assign the SNN in a logical manner pertaining to

their specific application.

See Changing the Safety Network Number (SNN)

If you assign an SNN manually, make sure that system expansion does not

result in duplication of SNN and node address combinations.

on page 41.

Automatic Versus Manual

For typical users, the automatic assignment of an SNN is sufficient. However,

manual manipulation of the SNN is required if the following is true:

• Safety consumed tags are used.

• The project consumes safety input data from a module whose

configuration is owned by some other device.

• A safety project is copied to another hardware installation within the same

routable CIP Safety system.

Changing the Safety Network Number (SNN)

Before changing the SNN you must do the following:

• Unlock the project, if it is safety-locked.

See Safety-lock the Controller

on page 88.

• Delete the safety task signature, if one exists.

See Delete the Safety Task Signature

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 41

on page 91.

Page 42

Chapter 4 Communicate over Networks

Change the Safety Network Number (SNN) of the Controller

1. In the Controller Organizer, right-click the controller and choose

Properties.

2. On the General tab of the Controller Properties dialog box, click to

the right of the safety network number to open the Safety Network

Number dialog box.

3. Click Time-based and then Generate.

4. Click OK.

Change the Safety Network Number (SNN) of Safety I/O Modules on the CIP Safety Network

This example uses an EtherNet/IP network.

1. Find the first EtherNet/IP communication module in the I/O

Configuration tree.

2. Expand the safety I/O modules available through the EtherNet/IP

communication module.

42 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 43

Communicate over Networks Chapter 4

3. Double-click the first safety I/O module to view the General tab.

4. Click to the right of the safety network number to open the Safety

Network Number dialog box.

5. Choose Time-based and click Generate to generate a new SNN for that

EtherNet/IP network.

6. Click OK.

7. Click Copy to copy the new SNN to the Windows Clipboard.

8. Open the General Tab of the Module Properties dialog box of the next

safety I/O module under that EtherNet/IP module.

9. Click to the right of the safety network number to open the Safety

Network Number dialog box.

10. Choose Time-based and click Paste to paste that EtherNet/IP network’s

SNN into that device.

11. Click OK.

12. Repeat steps 8

…10 for the remaining safety I/O modules under that

EtherNet/IP communication module.

13. Repeat steps 2

…10 for any remaining network communication modules

under the I/O Configuration tree.

Rockwell Automation Publication 1768-UM002C-EN-P - April 2012 43

Page 44

Chapter 4 Communicate over Networks

Copy and Paste a Safety Network Number (SNN)

If the module’s configuration is owned by another controller, you may need to

copy and paste the SNN from the configuration owner into the module in your

I/O configuration tree.

1. In the software configuration tool of the module’s configuration owner,

open the Safety Network Number dialog box for the module.

2. Click Copy.

3. Click the General tab on the Module Properties dialog box of the I/O

module in the I/O Configuration tree of the consuming controller project.

This consuming controller is not the configuration owner.

4. Click to the right of the safety network number to open the Safety

Network Number dialog box.

5. Click Paste.

6. Click OK.

44 Rockwell Automation Publication 1768-UM002C-EN-P - April 2012

Page 45

Communicate over Networks Chapter 4

EtherNet/IP Communication

For CIP Safety communication, including Safety I/O module control, choose a

1768-ENBT module, series A, revision 3 or later.

For standard EtherNet/IP communication, choose a 1768-ENBT or

1768-EWEB communication module, series A, revision 3 or later.

EtherNet/IP communication modules provide the following features:

• Support for messaging, produced/consumed tags, HMI, and distributed

I/O.

• Encapsulated messages within standard TCP/UDP/IP protocol

• A common application layer with ControlNet and DeviceNet networks

• Interface via RJ45, category 5, unshielded, twisted-pair cable

• Support for half/full duplex 10 M or 100 M operation

• Work with standard switches

• No network scheduling required

• No routing tables required

These software products are available for EtherNet/IP networks.

Table 5 - Software for EtherNet/IP Modules

Software Purpose Required

RSLogix 5000 programming

software

BOOTP/DHCP utility This utility comes with RSLogix 5000 software. You can use this

RSNetWorx™ for EtherNet/IP

software

RSLinx software You can use this software to configure devices, establish

This software is required to configure the controller project and

define EtherNet/IP communication.

utility to assign IP addresses to devices on an EtherNet/IP network.

You can use this software to configure EtherNet/IP devices by IP

addresses and/or host names.

communication between devices, and provide diagnostics.

Yes

No

No

Yes

Producing and Consuming Data via an EtherNet/IP Network

The controller supports the ability to produce (send) and consume (receive) tags

over an EtherNet/IP network. Produced and consumed tags each require

connections. The total number of tags that can be produced or consumed is

limited by the number of available connections.

Connections over the EtherNet/IP Network

You indirectly determine the number of connections the safety controller uses by

configuring the controller to communicate with other devices in the system.