Page 1

Installation Instructions

ControlNet Modules

Catalog Numbers 1756-CN2, 1756-CN2R, 1756-CN2RK, 1756-CN2RXT, 1756-CNB, 1756-CNBR, 1768-CNB, 1768-CNBR

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, CompactLogix, CompactLogix-XT, ControlFLASH, ControlLogix-XT, ControlLogix, FLEX I/O-XT, Logix5000, Logix-XT, RSLinx, R SLogix, R SNetWorx, Rockwell Soft ware, Rockwell Automation,

RSLogix 5000 , RSLinx Classic, RSNetWorx for ControlNet, and Studio 5000 are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

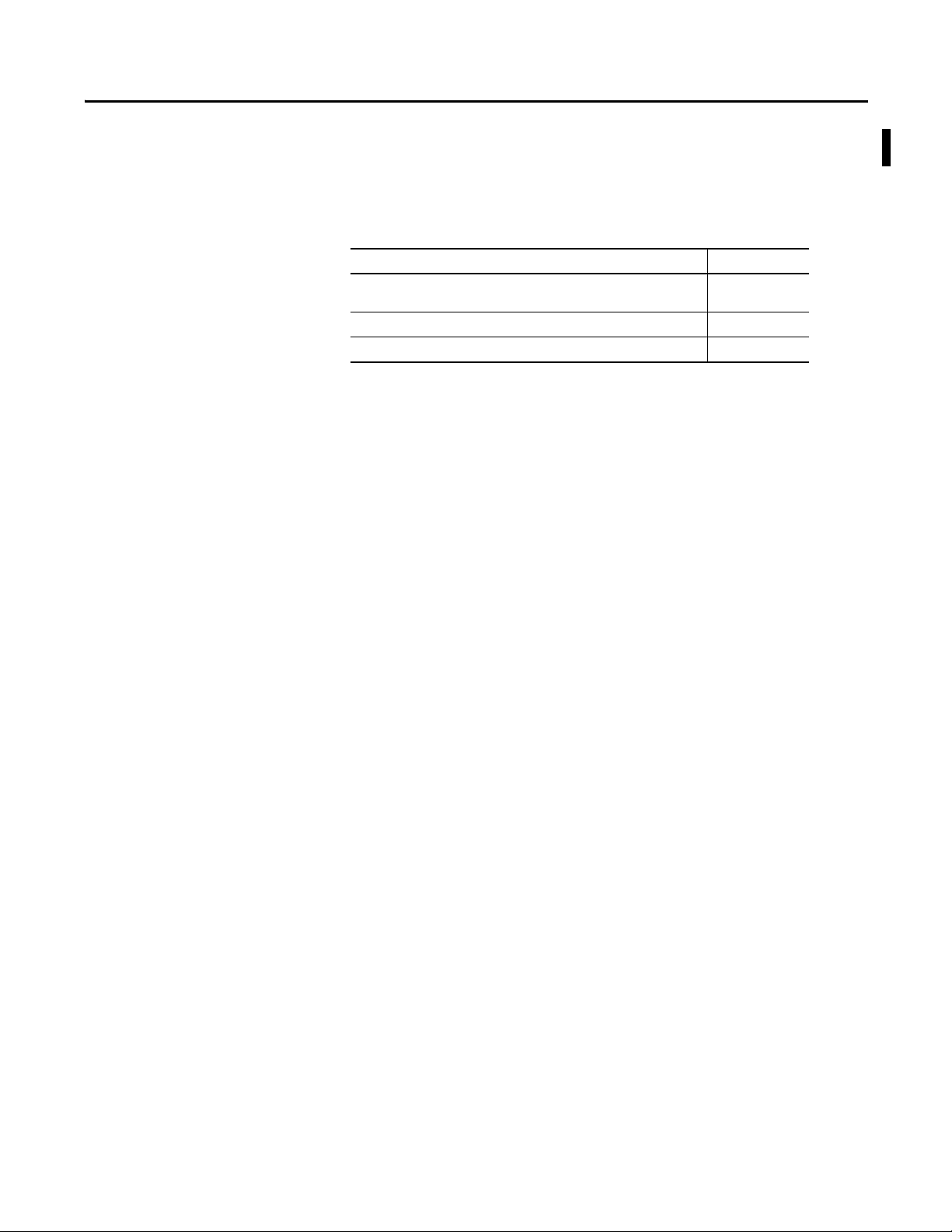

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Updated art work to illu strate module redesign Throughout

document

Updated EDS file and firmware download procedures Chapters 1, 2, and 3

Updated 1756 status indicators Appendix A

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 5

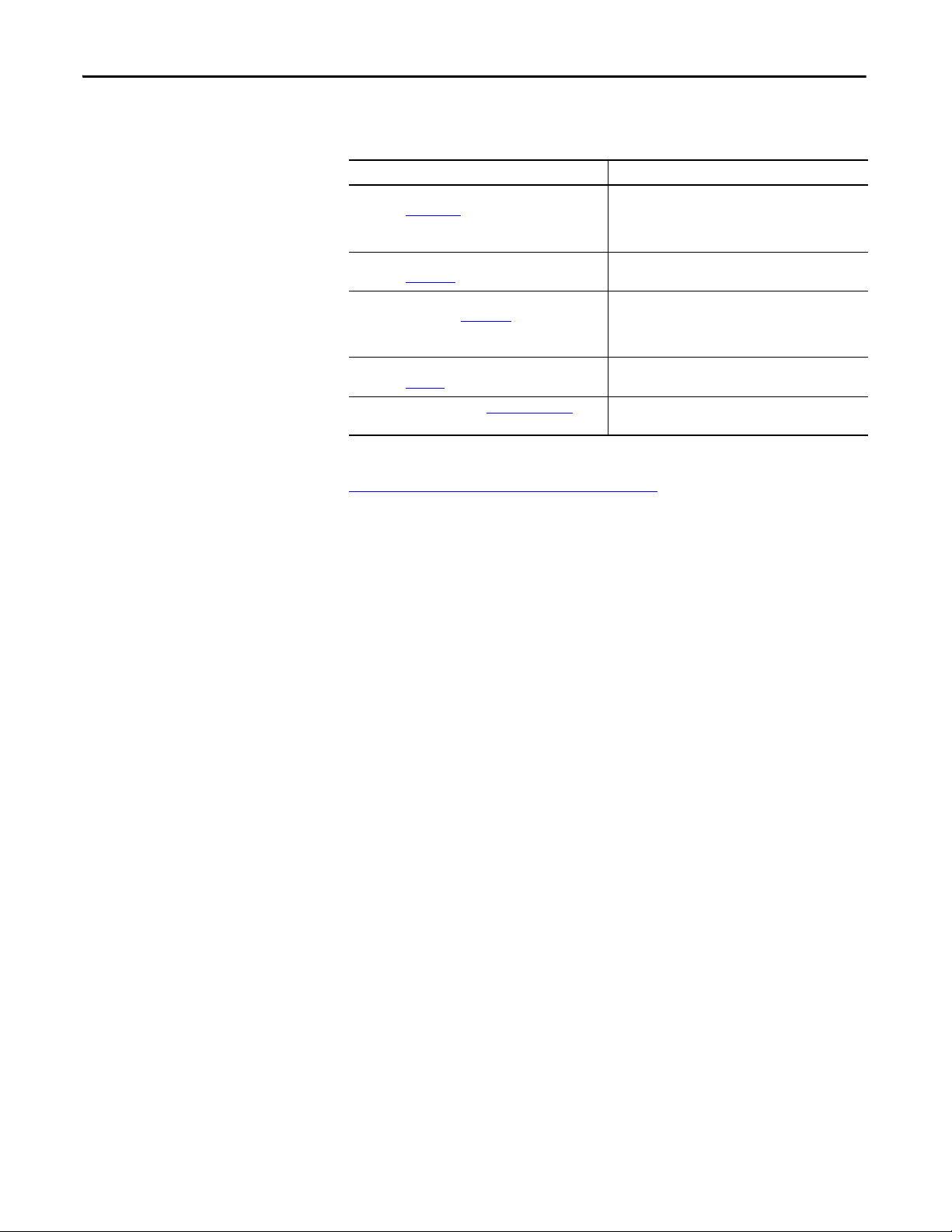

Table of Contents

Preface

Install a 1756 ControlNet

Communication Module

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

ControlLogix-XT Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ControlLogix-XT with Traditional ControlLogix Components. . 11

Redundant Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Determine Module Slot Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Set the Node Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connect the Module to a ControlNet Network . . . . . . . . . . . . . . . . . . . . 15

Remove the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reset the Module to the Original Factory Settings. . . . . . . . . . . . . . . 18

Keeper Configuration—Automatic Keeper Crossload . . . . . . . . . . . 18

Install the EDS File and Get Firmware Updates. . . . . . . . . . . . . . . . . . . . . 19

Download the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connect a Programming Terminal to the Network

with a 1786-CP Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connect to the Module via the USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Install a 1768 ControlNet

Communication Module

Redundant Media

Chapter 2

Redundant Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installation Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Grounding Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Set the Node Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Install the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

If You Use Screws to Mount the Module . . . . . . . . . . . . . . . . . . . . . . . 26

Mount on a DIN Rail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connect the Module to a ControlNet Network . . . . . . . . . . . . . . . . . . . . 28

Remove the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Install the EDS File and Get Firmware Updates. . . . . . . . . . . . . . . . . . . . . 31

Download the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 3

Use Redundant Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 5

Page 6

Table of Contents

Appendix A

1756 ControlNet Status Indicators

USB Communication

1768 ControlNet Module Status

Indicators

Index

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Interpret the OK Status Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Interpret the Network Channel Status Indicators . . . . . . . . . . . . . . . 38

1756-CN2, 1756-CN2R,

1756-CN2RXT, and

1756-CN2RK ControlNet Communication Modules. . . . . . . . . . . . . . . 38

OK Status Indicator and Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Network Channel Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1756-CNB/E and

1756-CNBR/E ControlNet Communication Modules. . . . . . . . . . . . . . 43

OK Status Indicator and Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Network Channel Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Appendix B

Set Up a USB Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Appendix C

1768-CNB and 1768-CNBR ControlNet Modules . . . . . . . . . . . . . . . . . 51

OK Status Indicator and Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Network Channel Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 7

Preface

This manual describes how to install and start up ControlNet modules with

Logix5000 ™ controllers.

You should use this manual if you program applications that use the ControlNet

network with one of these Logix5000 controllers:

™

• CompactLogix

• ControlLogix

You should also understand the following:

• Networking concepts

• How to the use Studio 5000

• How to use RSLinx

®

™

environment

®

Classic programming software

Studio 5000 Environment

The Studio 5000 Automation Engineering and Design Environment combines

engineering and design elements into a common environment. The first element

in the Studio 5000 environment is the Logix Designer application. The Studio

™

5000 Logix Designer application is the rebranding of RSLogix

5000 software

and continues to be the product to program Logix5000 controllers for discrete,

process, batch, motion, safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell

Automation

engineering design tools and capabilities. This environment is the

one place for design engineers to develop all of the elements of their control

system.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 7

Page 8

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

ControlNet Network Configuration User Manual,

publication CNET-UM001

ControlNet Coax Media Planning and Installation Guide,

publication CNET-IN002

ControlNet Standard and High-flex Coax Cable Installation

Instructions, publication 1786-IN009

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other

Provides details about how to use ControlNet

communication modules with Logix5000

controllers and communicate with other devices

on the ControlNet network.

Describes the required components of a ControlNet coax

media system.

Provides application information you need to consider

when you install standard RG-6 (catalog number

1786-RG6/A) and high-flex RG-6 (catalog number

1786-RG6F/A) coax cable in your ControlNet network.

Provides general guidelines for installing a Rockwell

Automation industrial system.

certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

8 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 9

Chapter 1

Install a 1756 ControlNet Communication

Module

Top ic Pa ge

ControlLogix-XT Systems 11

Redundant Media 12

Installation Summary 12

Determine Module Slot Location 12

Set the Node Address 13

Install the Module 14

Connect the Module to a ControlNet Network 15

Remove the Module 17

Install the EDS File and Get Firmware Updates 19

Connect a Programming Terminal to the Network with a 1786-CP Cable 20

Connect to the Module via the USB Port 21

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as

defined in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide adequate protection to radio

communication services in such environments.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application if nonmetallic. The interior of the enclosure must

be accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding

specific enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

, for additional installation requirements.

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 9

Page 10

Chapter 1 Install a 1756 ControlNet Communication Module

North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I Division 2 Groups

A, B, C, D, Haza rdous Locations a nd nonhazardous locations only. Each product is supplied

with markings on the rating nameplate indicating the hazardous location temperature

code. When combining products within a system, the most adverse temperature code

(lowest "T" number) may be used to help determine the overall temperature code of the

system. Combinations of equipment in your system are subject to investigation by the

local Authority Having Jurisdiction at the time of installation.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une utilisation en

environnements de Classe I Division 2 Groupes A, B, C, D dangereux et non dangereux.

Chaque produit est livré avec des marquages sur sa plaque d'identification qui indiquent

le code de température pour les environnements dangereux. Lorsque plusieurs produits

sont combinés dans un système, le code de température le plus défavorable (code de

température le plus faible) peut êt re utilisé pour déterminer le code de température

global du système. Les combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de l'installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this

equipment unless power has been removed or

the area is known to be nonhazardous. Secure

any external connections that mate to this

equipment by using screws, sliding latches,

threaded connectors, or other means provided

with this product.

• Substitution of components may impair

suitability for Class I, Division 2.

• If this product contains batteries, they must only

be changed in an area known to be

nonhazardous.

European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to comply with the Essential Health and

Safety Requirements relating to the design and construction of Category 3 equipment intended for use in Zone 2 potentially explosive atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN 60079-0.

WARNING: RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher les connecteurs. Fixer tous les

connecteurs externes reliés à cet équipement à

l'aide de vis, loquets coulissants, connecteurs

filetés ou autres moyens fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

WARNING:

• This equipment must be installed in an enclosure providing at least IP54 protection when applied in Zone 2 environments.

• This equipment shall be used within its specified ratings defined by Rockwell Automation.

• Provision shall be made to prevent the rated voltage from being exceeded by transient disturbances of more than 40% when

applied in Zone 2 environments.

• This equipment must be used only with ATEX certified Rockwell Automation backplanes.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other means

provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

10 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 11

Install a 1756 ControlNet Communication Module Chapter 1

IMPORTANT

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

ATTENTION: Personnel responsible for the application of safety-related programmable electronic systems (PES) shall be aware

of the safety requirements in the application of the system and shall be trained in using the system.

ControlLogix-XT Systems

The ControlLogix-XT™ products include control and communication system

components that, when used with FLEX I/O-XT™ products, provide a complete

control system solution that can be used in environments where temperatures

range from -20…70 °C (-4…158 °F).

When used independently, the ControlLogix-XT system can withstand

environments where the temperature ranges from -25…70 °C (-13…158 °F).

ControlLogix-XT with Traditional ControlLogix Components

ControlLogix-XT system components are rated for extreme

environmental conditions only when used properly with other LogixXT system components. The use of ControlLogix-XT components with

traditional ControlLogix system components nullifies extreme-environment

ratings.

If a ControlLogix-XT module is used with traditional ControlLogix products that

are not designed for extreme environments, the ControlLogix-XT module can

withstand only the environments specified for the traditional ControlLogix

version of the module. For example, if a 1756-CN2RXT module is used in a

traditional 1756-A10 chassis, the 1756-CN2RXT module can withstand only the

environment specified for the traditional 1756-CN2R module.

The ControlLogix-XT system components are designed to meet the same and

greater operational and environmental requirements as traditional

ControlLogix products.

When a ControlLogix-XT component is used as a replacement for a traditional

ControlLogix component, the functional and environmental requirements of

the traditional ControlLogix component apply.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 11

Page 12

Chapter 1 Install a 1756 ControlNet Communication Module

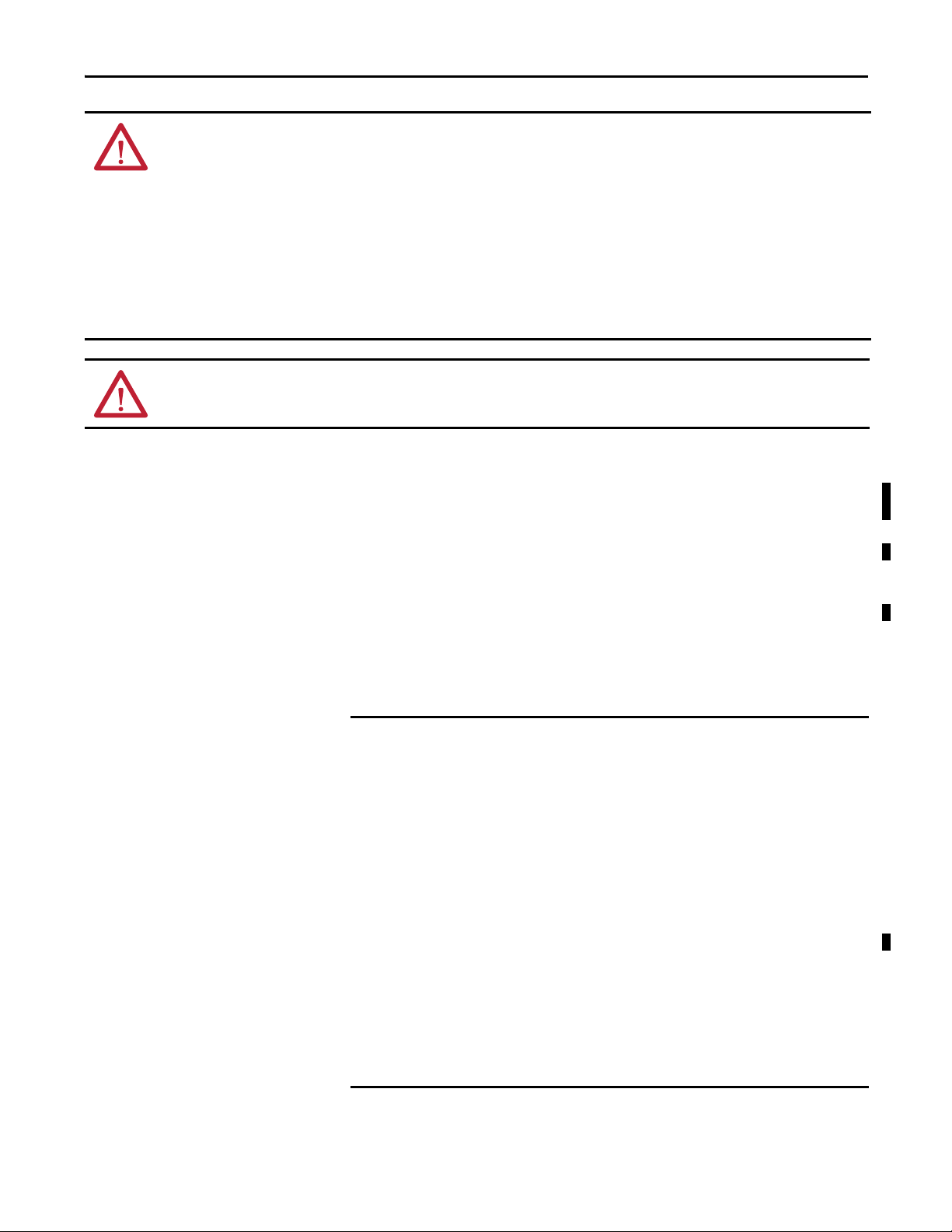

1

4

5

6

2

3

Item Description

1Power supply

2 Chassis

3Slot 0

4Slot 1

5Slot 2

6Slot 3

20806

Redundant Media

Installation Summary

These 1756 ControlNet bridge modules have two ControlNet ports to support

redundant media:

• 1756-CN2R

• 1756-CNBR

• 1756-CN2R

• 1756-CN2RXT

• 1756-CN2RK

For information about using these modules with redundant media, see

Redundant Media on page 33

.

To install a communication module in a 1756 ControlLogix chassis, complete

these steps.

1. Determine Module Slot Location

2. S

et the Node Address.

3. Install the Module

.

4. Connect the Module to a ControlNet Network

.

.

Determine Module Slot Location

5. Remove the Module

6. Install the EDS File and Get Firmware Updates

7. C

onnect a Programming Terminal to the Network with a 1786-CP Cable.

8. Connect to the Module via the USB Port

.

.

.

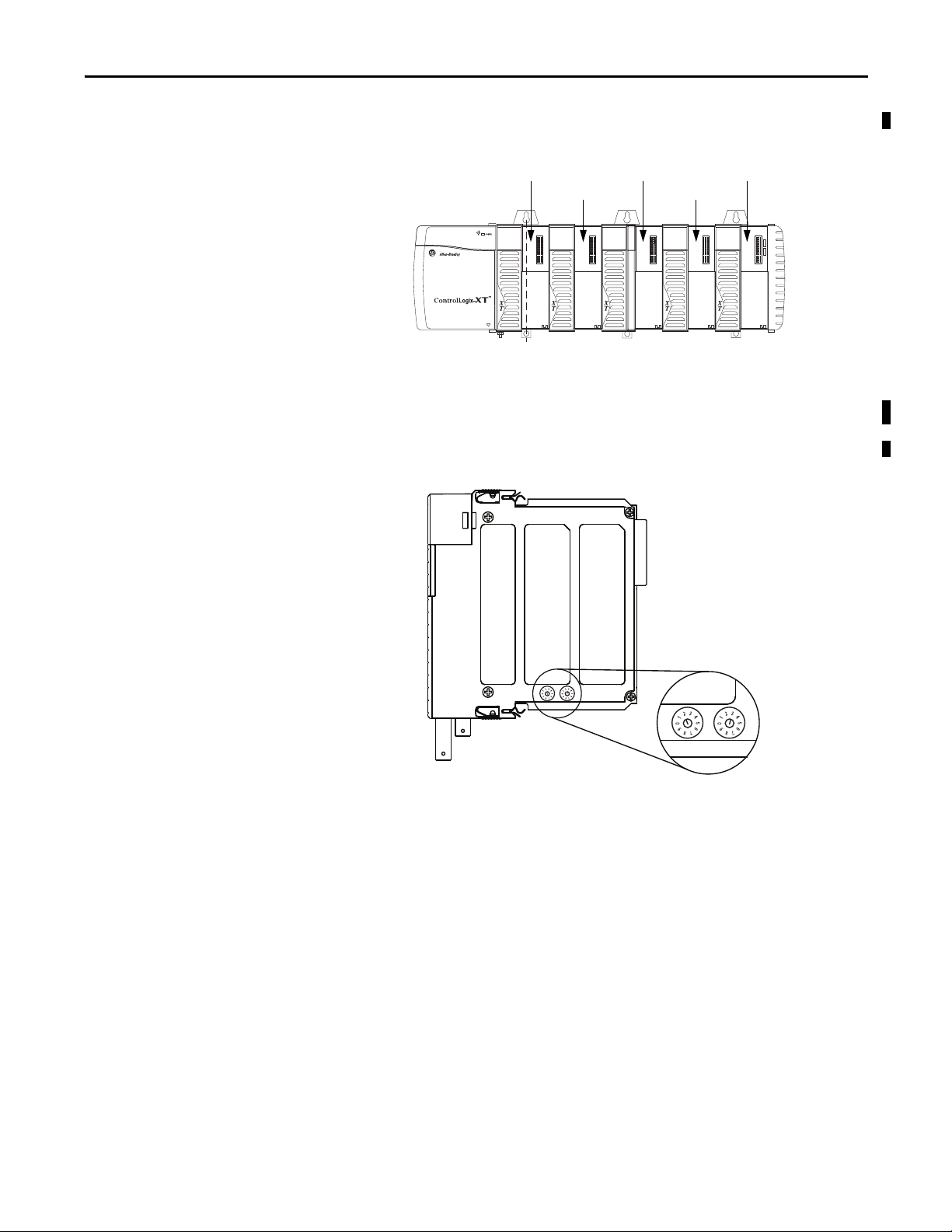

Install the communication module in any slot in the ControlLogix chassis. You

can install multiple communication modules in the same chassis. This example

shows chassis slot numbering in a 4-slot chassis. Slot 0 is the first slot and is always

the leftmost slot in the rack.

12 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 13

Install a 1756 ControlNet Communication Module Chapter 1

Slot 0

Slot 1

Slot 2

Slot 3

Slot 4

Side of Module

Front of Module

This module’s node address is 23

This example shows chassis slot numbering in a ControlLogix-XT chassis.

Set the Node Address

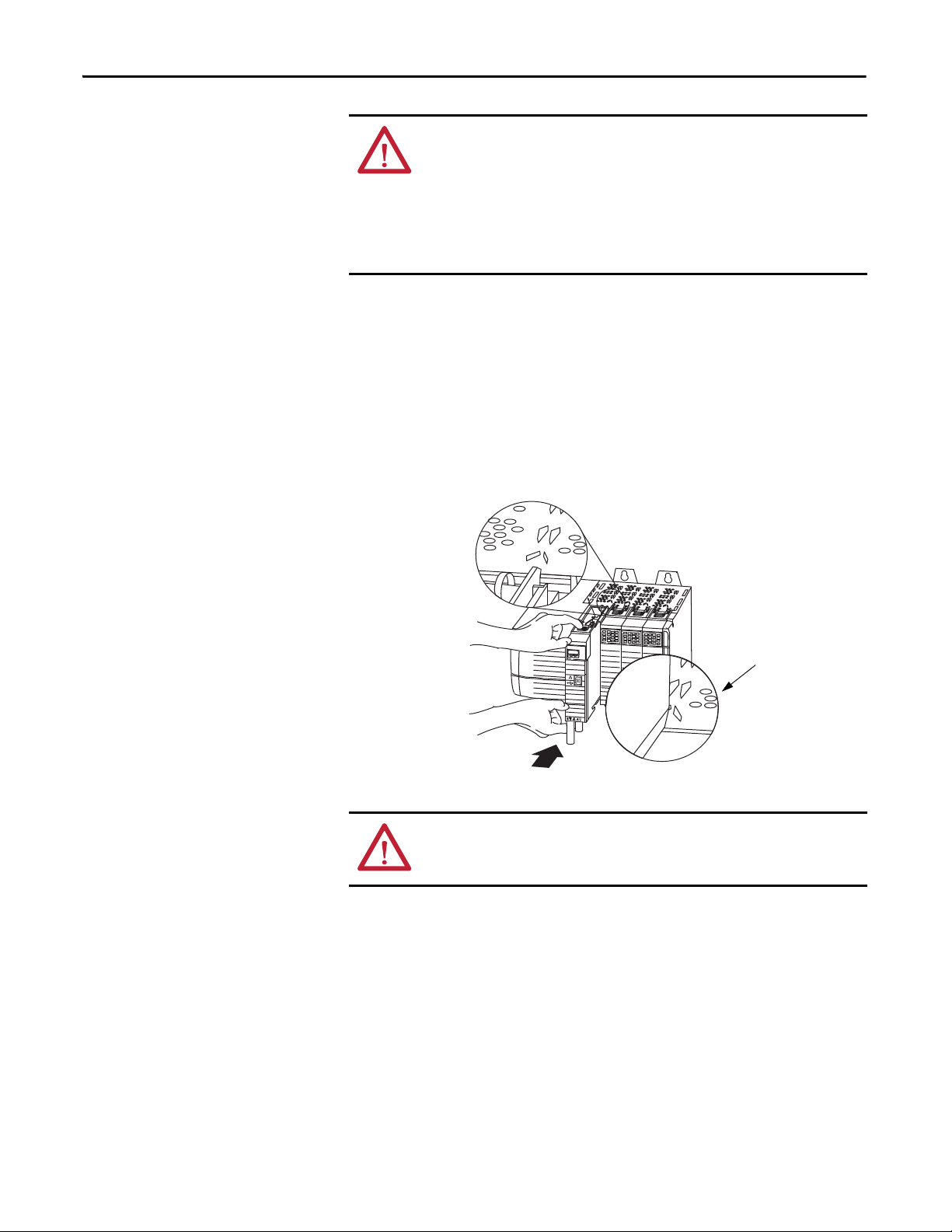

Use a small screwdriver to set the module’s node address switches. You must

specify a unique ControlNet node address. You can select an address of 01…99.

Address 00 is an invalid ControlNet node address.

32462-M

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 13

Page 14

Chapter 1 Install a 1756 ControlNet Communication Module

32463-M

Circuit

Board

Install the Module

WARNING: When you insert or remove the module while backplane power is

on, an electrical arc can occur. This could cause an explosion in hazardous

location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the module

and its mating connector. Worn contacts may create electrical resistance that can

affect module operation.

To install the module, follow this procedure.

1. Align the circuit board with the top and bottom guides in the chassis.

2. Slide the module into the chassis making sure the module backplane

connector properly connects to the chassis backplane.

The module is properly installed when it is flush with the power supply or

other installed modules.

ATT EN TI ON : Do not force the module into the backplane connector. If you

cannot seat the module with firm pressure, check the alignment. Forcing the

module into the chassis can damage the backplane connector or the module.

14 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 15

Install a 1756 ControlNet Communication Module Chapter 1

1756-CN2R Module in a

1756-A4 Chassis

ControlNet Node

Redundant Media

(Opt ional )

ControlNet Node

ControlNet Link

TIP

Connect the Module to a ControlNet Network

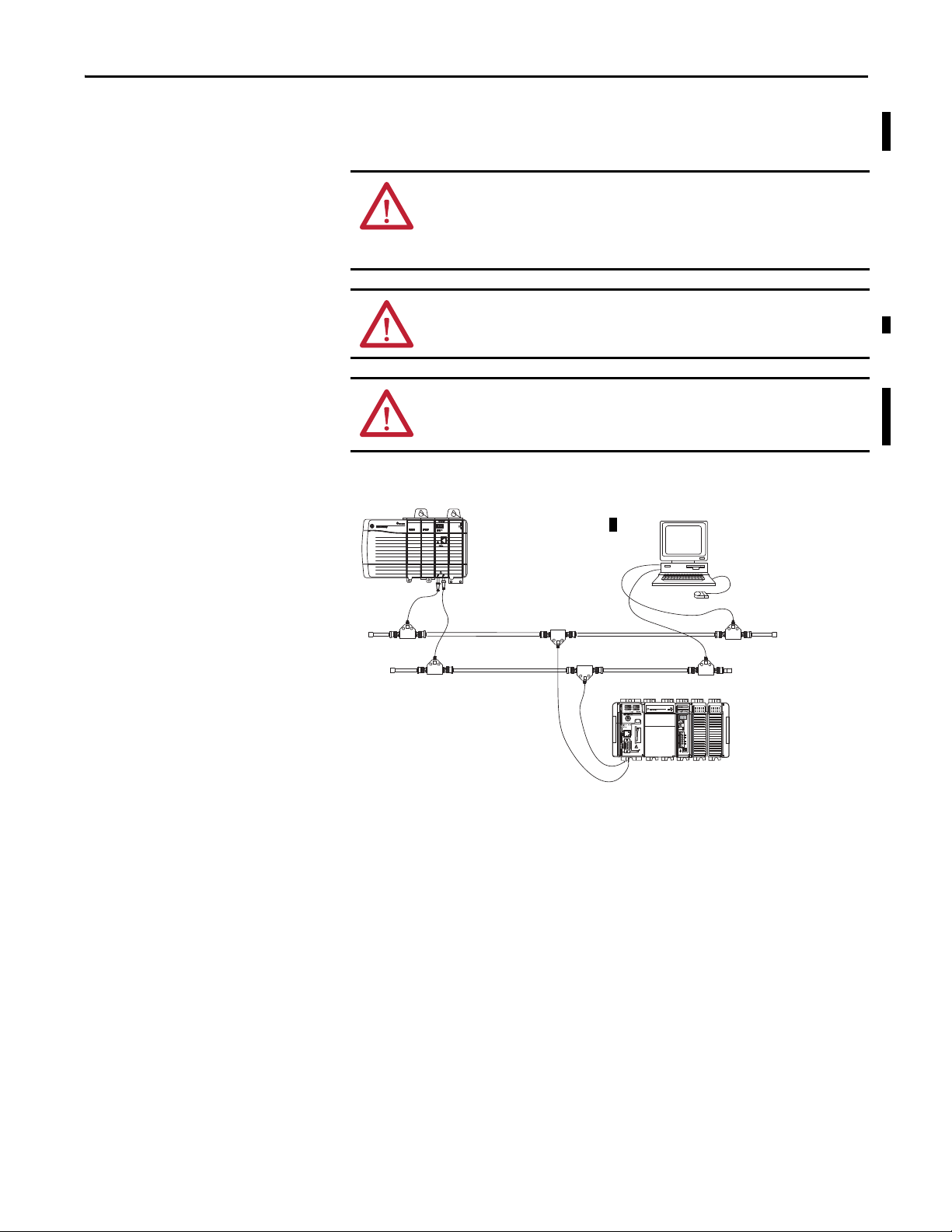

You can connect the module to the ControlNet network by using a tap, catalog

numbers 1786-TPR, 1786-TPS, 1786-TPYR, 1786-TPYS, or 1786-TCT2BD1.

WARNING: If you connect or disconnect the communication cable with power

applied to this module or any device on the network, an electrical arc can occur.

This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

WARNING: Do not use the USB port in hazardous locations.

ATTENTION: The USB port is intended only for temporary local programming

purposes and is not intended for permanent connection. The USB cable is not to

exceed 3.0 m (9.84 ft) and must not contain hubs.

This example shows a ControlNet network using redundant media.

For network connections, we recommend taps with a straight connector

(catalog number 1786-TPS or 1786-TPYS) because of the location of the BNC

connectors on the bottom of the module.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 15

Page 16

Chapter 1 Install a 1756 ControlNet Communication Module

IMPORTANT

Tru nkl ine A

Tru nkl ine B

1756-CN2 Trunkline A

1756-CN2R Trunklines A and B

Dust Cap

Dust Cap

32464

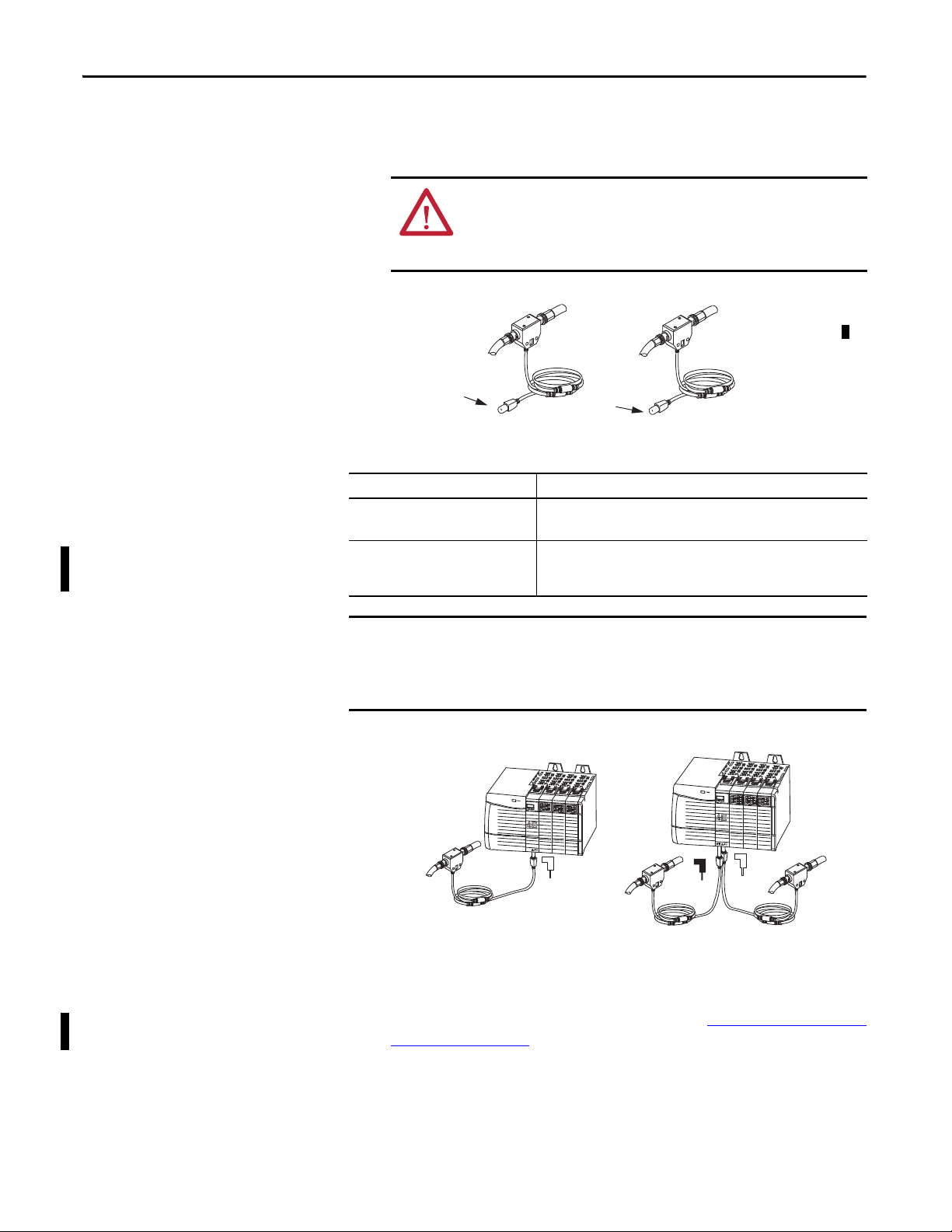

Nonredundant Media

Redundant Media

Tap

Tap

Tap

Network

Network

To connect the module to the network with a tap, perform this procedure.

1. Remove and save the dust caps from the ControlNet taps.

ATTENTION: Do not allow any metal portions of the tap to contact any

conductive material. If you disconnect the tap from the module, place

the dust cap back on the straight or right-angle connector to prevent

the connector from accidentally contacting a metallic grounded surface.

2. Connect the tap’s straight or right-angle connector to the module’s BNC

connector.

If your network supports Then connect the tap’s connector

Nonredundant media

(all 1756-CNx modules)

Redundant media

(1756-CNBR, 1756-CN2R, 1756-CN2RXT,

and 1756-CN2RK modules)

From trunkline A to channel A on the module.

From trunkline A to channel A on the 1756-CN2R module.

From trunkline B to channel B on the 1756-CN2R module.

To avoid accidentally reversing the tap connections, before making your

connection, check the tap drop cable for the label indicating the attached

segment. Accidental connection reversals produce incorrect status displays and

require troubleshooting.

3. Apply power to the module and check the status indicators to determine

whether the power supply and module are operating properly.

For more information about status indicators, see 1756 ControlNet Status

Indicators on page 37.

16 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 17

Install a 1756 ControlNet Communication Module Chapter 1

X

T

Remove the Module

You can install or remove this module while chassis power is applied.

WARNING: When you insert or remove the module while backplane power is

on, an electrical arc can occur. This could cause an explosion in hazardous

location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the module

and its mating connector. Worn contacts may create electrical resistance that can

affect module operation.

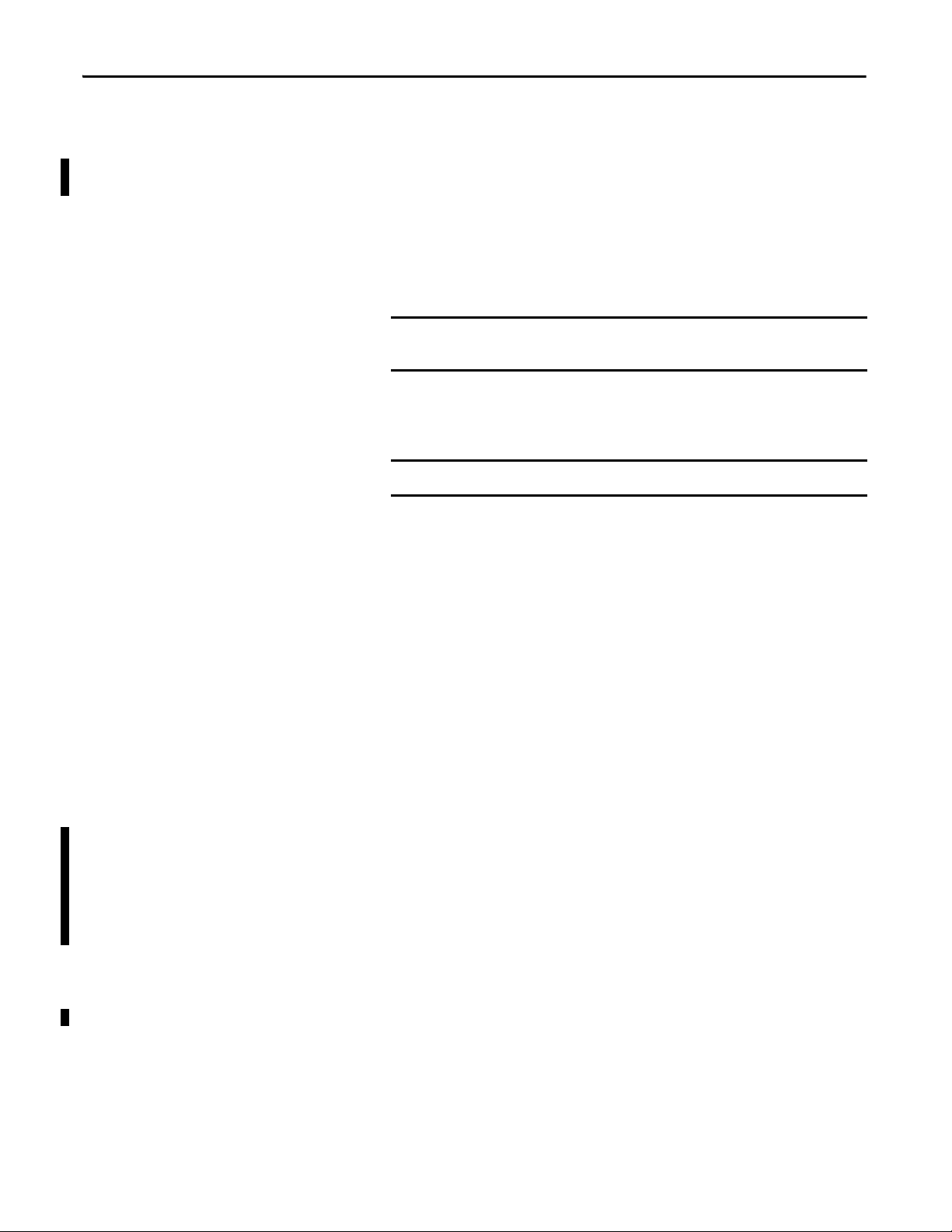

To remove or replace the module, use this procedure.

1. Push on the upper and lower module tabs to disengage them.

2. Slide the module out of chassis.

The figure shows the removal of a 1756-CN2RXT module.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 17

Page 18

Chapter 1 Install a 1756 ControlNet Communication Module

IMPORTANT

IMPORTANT

Reset the Module to the Original Factory Settings

If you are using a 1756-CN2, 1756-CN2R, 1756-CN2RXT or 1756-CN2RK

communication module, you can reset the module to its original settings and

clear all keeper information.

To reset a module to its factory settings, complete these steps.

1. Remove power from the chassis.

Removing power from the chassis before removing the module is only

necessary if the module is in a Class I, Division 2 hazardous location.

2. Remove the module from the chassis.

3. Reset the switches to 00.

Do not use the 00 switch setting during normal module operation.

4. Replace the module in the chassis.

5. Apply power to the chassis.

6. After the module status display reads ‘Reset Complete—Change Switch

Settings’, remove power from the chassis.

7. Remove the module from the chassis.

8. Set the switches to their final value.

9. Replace the module in the chassis.

10. Apply power to the chassis.

Keeper Configuration—Automatic Keeper Crossload

The 1756-CN2, 1756-CN2R, 1756-CN2RXT, and 1756-CN2RK

communication modules are keeper capable modules. If a keeper capable module

has a valid configuration and has the lowest address among the keeper capable

nodes on the network, it becomes the active keeper. The active keeper is the node

that distributes network configuration information to other nodes as the

network is formed or as nodes are added to the network.

When the module is first removed from the box or is reset to the original factory

settings, it will automatically attempt to crossload configuration information

from the current active keeper. If an active keeper with a valid network

configuration is present on the active network, the configuration crossload will

succeed. No user intervention is needed. However, if an active keeper does not

exist or does not have a valid network configuration, you must use RSNetWorx

for ControlNet software to download the network configuration information.

18 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 19

Install a 1756 ControlNet Communication Module Chapter 1

Install the EDS File and Get Firmware Updates

For the 1756-CN2, 1756-CN2R, 1756-CN2RXT, and 1756-CN2RK modules,

the EDS file can be uploaded directly from the module. This feature lets you

register the EDS file for your module from within RSLinx software.

Use the steps below to register the EDS file from within RSLinx software.

1. Open RSLinx software and browse for the module.

Before you begin, make sure you have the correct version of RSLinx

software.

ControlNet Module Required Version of RSLinx Software

1756-CN2RXT or 1756-CN2RK 2.55 or later

1756-CN2/C or 1756-CN2R/C 2.55 or later

1756-CN2/B or 1756-CN2R/B 2.51 or later

2. Right-click the module and choose Upload EDS file from device.

The Upload EDS wizard opens.

3. Complete the EDS wizard to register the EDS file.

Download the Firmware

Complete these steps to download and install the firmware.

1. Go to the Rockwell Automation Web site at

http://www.rockwellautomation.com/

2. From the Support tab, product Product Compatibility & Download

Center.

3. On the Get Downloads tab, click Find Product Downloads.

4. Enter your search criteria and click Go.

.

5. Select the module from the list then click the Find Downloads button at

the bottom of the Selections tab.

6. Click the download graphic .

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 19

Page 20

Chapter 1 Install a 1756 ControlNet Communication Module

ControlNet Link

1756-CNBR/E

1784-KTC, 1784-KTCx,

1784-PCC, 1784-PCIC,

1784-PKTCS or 1784-PCICS

Card

1786-CP Cable

The Available Downloads window opens.

7. From the bulleted list, choose the firmware name.

The End User License Agreement opens.

8. Review the agreement and click I Agree.

The Rockwell Automation Download Manager opens and the download

begins. The location of the downloaded file is shown under the progress

bar.

9. When the downloaded is complete, click Close.

10. Locate the downloaded .zip file and extract it to a temporary directory.

11. Use the ControlFlash utility to install the firmware.

Connect a Programming Terminal to the Network with a 1786-CP Cable

To connect a programming terminal to the network using a 1786-CP cable, you

have the following options:

• Use a 1784-KTC, 1784-KTCx, 1784-PCC, 1784-PCIC, 1784-PKTCS,

or 1784-PCICS communication card and a 1786-CP cable.

• Use a 1770-KFC communication interface, a serial or parallel connection,

and a 1786-CP cable.

20 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 21

Install a 1756 ControlNet Communication Module Chapter 1

1756-CNBR/E

1770-KFC

ControlNet Link

Serial or Parallel Connections

1786-CP Cable

The 1786-CP cable can be plugged into any ControlNet network product’s NAP

to provide programming capability on the ControlNet network. A programming

terminal connected through this cable is counted as a node and must have a

unique network address.

Connect to the Module via the USB Port

ATT EN TI ON : Use a 1786-CP cable when connecting a programming terminal to

the network through an NAP. Using a commercially available RJ-style cable

could result in network failure.

WARNING: The NAP is intended only for temporary local programming

purposes and is not intended for permanent connection. If you connect or

disconnect the NAP cable with power applied to any device on the network, an

electrical arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

The 1756-CN2, 1756-CN2R, 1756-CN2RXT, and 1756-CN2RK

communication modules include a USB port. For more information about USB

setup and configuration, see USB Communication on page 47

.

WARNING: Do not use the USB port in hazardous locations.

ATTENTION: The USB port is intended only for temporary local programming

purposes and is not intended for permanent connection. The USB cable is not to

exceed 3.0 m (9.84 ft) and must not contain hubs.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 21

Page 22

Chapter 1 Install a 1756 ControlNet Communication Module

IMPORTANT

The USB port on ControlNet modules uses a Type B receptacle. The port is

USB 1.1-compatible and runs at 12 Mbps.

See Table 7 - RSLinx Software Versions on page 47

for more information about

using the correct version of RSLinx software.

Use a USB cable to connect your computer to the USB port. The connection lets

you download programs to controllers and configure other devices, which are

accessible by the module, directly from your computer.

Do not simultaneously upgrade the firmware for more than one module at a

time through a USB port. If you do, one or more of the updates may fail in the

middle of the upgrade.

For more information about setting up a USB port, see USB Communication on

page 47.

22 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 23

Chapter 2

Install a 1768 ControlNet Communication

Module

Top ic Pa ge

Redundant Media 25

Installation Summary 25

Set the Node Address 25

Install the Module 26

Connect the Module to a ControlNet Network 28

Remove the Module 29

Install the EDS File and Get Firmware Updates 31

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as

defined in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR 11. Without appropriate precautions,

there may be difficulties with electromagnetic compatibility in residential and other environments due to conducted and radiated

disturbances.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA, V2, V1, V0 (or equivalent) if non-metallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures

, for additional installation requirements

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 23

Page 24

Chapter 2 Install a 1768 ControlNet Communication Module

North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I Division 2 Groups

A, B, C, D, Hazardous Locations and nonhazardous locations only. Each product is supplied

with markings on the rating nameplate indicating the hazardous location temperature

code. When combining products within a system, the most adverse temperature code

(lowest "T" number) may be used to help determine the overall temperature code of the

system. Combinations of equipment in your system are subject to investigation by the

local Authority Having Jurisdiction at the time of installation.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une utilisation en

environnements de Classe I Division 2 Groupes A, B, C, D dangereux et non dangereux.

Chaque produit est livré avec des marquages sur sa plaque d'identification qui indiquent

le code de température pour les environnements dangereux. Lorsque plusieurs produits

sont combinés dans un système, le code de température le plus défavorable (code de

température le plus faible) peut être utilisé pour déterminer le code de température

global du système. Les combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de l'installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this

equipment unless power has been removed or

the area is known to be nonhazardous. Secure

any external connections that mate to this

equipment by using screws, sliding latches,

threaded connectors, or other means provided

with this product.

• Substitution of components may impair

suitability for Class I, Division 2.

• If this product contains batteries, they must only

be changed in an area known to be

nonhazardous.

WARNING: RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher les connecteurs. Fixer tous les

connecteurs externes reliés à cet équipement à

l'aide de vis, loquets coulissants, connecteurs

filetés ou autres moyens fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

24 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 25

Install a 1768 ControlNet Communication Module Chapter 2

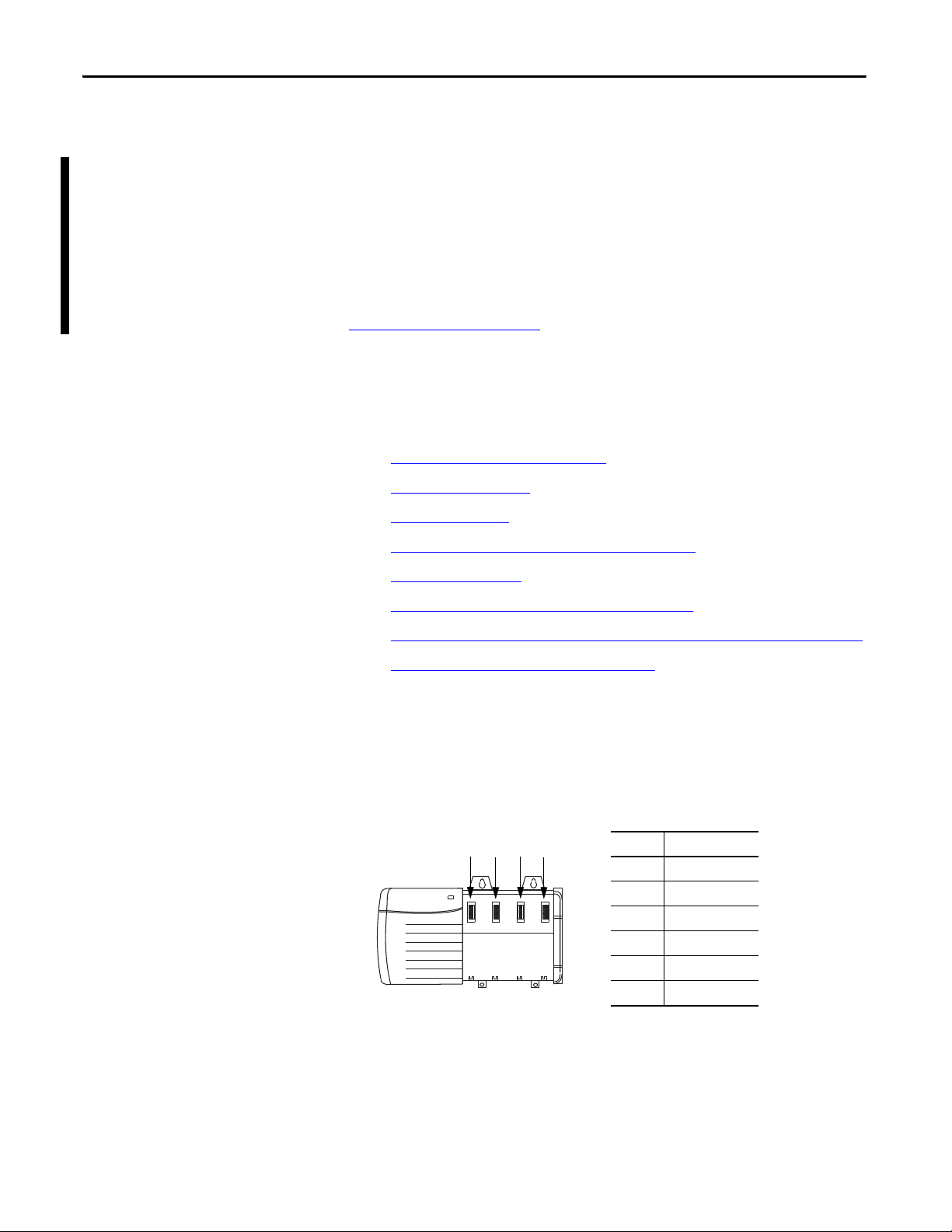

NETWORK

ADDRESS

31651- M

50

60

6

8

7

70

9

0

4

3

2

1

5

80

90

00

10

20

30

40

NETWORK

ADDRESS

50

60

6

8

7

70

9

0

4

3

2

1

5

80

90

00

10

20

30

40

Top of Module

Back of Module

This module’s node address is 21.

Redundant Media

Installation Summary

The 1768-CNBR bridge module has two ControlNet ports to support

redundant media. For information about using the module with redundant

media, see Redundant Media on page 33

.

To install a communication module in a 1768 ControlLogix chassis, complete

these steps.

1. Set the Node Address

2. Install the Module

3. Connect the Module to a ControlNet Network

.

.

.

Grounding Considerations

ATT EN TI ON : This product is grounded through the DIN rail to chassis ground.

Use zinc-plated yellow-chromate steel DIN rail to assure proper grounding. The

use of other DIN rail materials (for example, aluminum or plastic) that can

corrode, oxidize, or are poor conductors, can result in improper or intermittent

grounding. Secure DIN rail to mounting surface approximately every 200 mm

(7.87 in.) and use end-anchors appropriately.

Set the Node Address

Use a small screwdriver to set the module’s node address switches. You must

specify a unique ControlNet node address. You can select an address of 01…99.

Address 00 is an invalid ControlNet node address.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 25

Page 26

Chapter 2 Install a 1768 ControlNet Communication Module

IMPORTANT

Install the Module

To install the module, follow this procedure.

If You Use Screws to Mount the Module

Do not use screws and DIN rail to mount the module. It is possible to break off

the mounting tabs if you screw the module to the panel while they are on DIN

rail.

The instructions show how to mount the module on DIN rail. If you are using

screws instead of DIN rail, make these changes to the instructions.

Refer to Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

, for additional information.

1. Use the module as a template and mark pilot holes on your panel.

2. Drill the pilot holes for M4 or #8 screws.

3. Use M4 or #8 screws to mount the module to your panel.

Use 1.16 N•m (10 lb•in) of torque.

4. Ground the module on a ground bus with a dedicated earth ground stake.

5. Connect the ground bus to a functional earth ground on the DIN rail or

panel.

26 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 27

Install a 1768 ControlNet Communication Module Chapter 2

(front)

(rear)

1768-CNB Module

1768-CNBR Module

31646A-M

31646AB-M

Mount on a DIN Rail

Follow these steps to install the module on a DIN rail.

1. Mount the DIN rail in a suitable location.

ATTENTION: This product is grounded through the DIN rail to chassis

ground. Use zinc-plated yellow-chromate steel DIN rail to assure proper

grounding. The use of other DIN rail materials (for example, aluminum

or plastic) that can corrode, oxidize, or are poor conductors, can result in

improper or intermittent grounding. Secure DIN rail to mounting

surface approximately every 200 mm (7.8 in.) and use end-anchors

appropriately.

2. Mount the module on the DIN rail, as shown.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 27

Page 28

Chapter 2 Install a 1768 ControlNet Communication Module

Tru nkl ine A

Tru nkl ine B

1768-CNB Trunkline A

1768-CNBR Trunklines A and B

Dust Cap

Dust Cap

Connect the Module to a ControlNet Network

You can connect the module to the ControlNet network by using a tap (catalog

number 1786-TPR, 1786-TPS, 1786-TPYR, 1786-TPYS, or 1786-TCT2BD1)

or a network access cable (catalog number 1786-CP).

See the ControlNet Coax Media Planning and Installation Guide, publication

CNET-IN002

, for additional information.

WARNING: If you connect or disconnect the communication cable with power

applied to this module or any device on the network, an electrical arc can occur.

This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

ATT EN TI ON : 1768 modules are not designed for removal and insertion under

power. Removal or insertion of a 1768 module while power is applied can result

in module damage or unintended operation.

The 1768-CNB and 1768-CNBR modules have a network access port (NAP)

available.

WARNING: The NAP is intended for temporary local programming purposes

only and not intended for permanent connection. If you connect or disconnect

the NAP cable with power applied to this module or any device on the network,

an electrical arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Perform the following steps to connect the module to the network by using a tap.

1. Remove and save the dust caps from the ControlNet network taps.

ATTENTION: Do not allow any metal portions of the tap to contact any

conductive material. If you disconnect the tap from the module, place

the dust cap back on the straight or right-angle connector to prevent

the connector from accidentally contacting a metallic grounded surface.

28 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 29

Install a 1768 ControlNet Communication Module Chapter 2

IMPORTANT

05

06

6

8

7

07

9

0

4

3

2

1

5

08

09

00

01

02

03

04

NETWORK

ADDRESS

31653- M

05

06

6

8

7

07

9

0

4

3

2

1

5

08

09

00

01

02

03

04

NETWORK

ADDRESS

Network 1

Network 2

Nonredundant Media

Redundant Media

A

A

B

Tap

Tap

Tap

IMPORTANT

2. Connect the tap’s straight or right-angle connector to the module’s BNC

connector.

If your network supports Connect the tap’s connector

Nonredundant media

From trunkline A to channel A on the module.

(1768-CNx modules)

Redundant media

(1768-CNBR modules)

• From trunkline A to channel A on the 1768-CNBR module.

• From trunkline B to channel B on the 1768-CNBR module.

To avoid accidentally reversing the tap connections on 1768-CNBR

installations, before making your connection, check the tap drop cable for the

label indicating the attached segment. Accidental connection reversals

produce incorrect status displays and require troubleshooting.

Remove the Module

To remove or slide a module, turn off the power and pull out the DIN rail

connectors on the module. After you turn off the power, wait for all of the lights

on the power supply and controller to turn off before you disconnect any

modules.

3. Apply power to the module and check the status indicators to determine

whether the power supply and module are operating properly.

ATT EN TI ON : 1768 modules are not designed for removal and insertion under

power. Removal or insertion of a 1768 module while power is applied can result

in module damage or unintended operation.

When you turn the CompactLogix power supply off, make sure you wait for all

status indicators on the power supply and controller to turn off before

disconnecting any part from the system.

If you disconnect the CompactLogix system while the controller is still writing

its program to memory, the program write will not be completed and you will

lose your program.

• When you turn off the power, the controller writes its project to memory.

• If you don’t wait for the lights to turn off, you will lose your project.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 29

Page 30

Chapter 2 Install a 1768 ControlNet Communication Module

Remove a module as shown below.

30 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 31

Install a 1768 ControlNet Communication Module Chapter 2

Install the EDS File and Get Firmware Updates

For the 1768-CNB and 1768-CNBR modules, the EDS file can be uploaded

directly from the module. This feature lets you register the EDS file for your

module from within RSLinx software.

Use the steps below to register the EDS file from within RSLinx software.

1. Open RSLinx software and browse for the module.

2. Right-click the module and choose Upload EDS file from device.

The Upload EDS wizard opens.

3. Complete the EDS wizard to register the EDS file.

Download the Firmware

Complete these steps to download and install the firmware.

1. Go to the Rockwell Automation Web site at

http://www.rockwellautomation.com/

2. From the Support tab, product Product Compatibility & Download

Center.

.

3. On the Get Downloads tab, click Find Product Downloads.

4. Enter your search criteria and click Go.

5. Select the module from the list then click the Find Downloads button at

the bottom of the Selections tab.

6. Click the download graphic .

The Available Downloads window opens.

7. From the bulleted list, choose the firmware name.

The End User License Agreement opens.

8. Review the agreement and click I Agree.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 31

Page 32

Chapter 2 Install a 1768 ControlNet Communication Module

The Rockwell Automation Download Manager opens and the download

begins. The location of the downloaded file is shown under the progress

bar.

9. When the downloaded is complete, click Close.

10. Locate the downloaded .zip file and extract it to a temporary directory.

11. Use the ControlFlash utility to install the firmware.

32 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 33

Redundant Media

IMPORTANT

Top ic Pag e

Use Redundant Media 33

These ControlNet bridge modules support redundant media:

• 1756-CN2R

• 1756-CN2RK

• 1756-CN2RXT

• 1756-CNBR/E

• 1768-CNBR

Chapter 3

Use Redundant Media

You can run a second trunk cable between ControlNet nodes for redundant

media. With redundant media, nodes send signals on separate trunks. The

receiving node compares the quality of the two signals and permits use of the

better signal while retaining the other signal on a back-up cable should the

primary trunk cable fail.

Trunk cables on a redundant cable link are defined by the segment number and

the redundant trunk-cable letter.

Actual ControlNet products are labeled with these icons:

The shaded icon represents redundant media.

In this example, the redundant trunk cable is trunk cable B.

ControlNet redundant media can tolerate only one fault. If there is a fault on

both channel A and B, network integrity is not guaranteed.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 33

Page 34

Chapter 3 Redundant Media

Node

Tru nk C abl e A

Tru nk C abl e B

Node

Node

To use redundant media, all nodes must support redundant media.

Figure 1 - Redundant Media Example

Observe these guidelines when planning a redundant media system in a

hazardous area:

• Route trunk cables A and B differently to reduce the chance of both cables

being damaged simultaneously.

– Trunk cables A and B may contain different lengths of cable if you are

using 1786-RPA/B repeater adapters. However, the difference in length

must not exceed 800 m (2640 ft).

– Trunk cables A and B must have identical configurations. Each segment

must contain the same number of taps, nodes, and repeaters. Connect

nodes and repeaters in the same relative sequence on both trunk cables.

• Each node on a redundant-cable link must support redundant coax

connections and be connected to both trunk cables at all times. Any nodes

connected to only one side of a redundant-cable link will result in media

errors on the unconnected trunk cable.

• Install the cable system so that the trunk cables at any physical device

location can be easily identified and labeled with the appropriate icon or

letter. Each redundant ControlNet device is labeled so you can connect it

to the corresponding trunk cable.

34 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 35

Redundant Media Chapter 3

IMPORTANT

We recommend that you do not mix cable connections when using redundant

cabling, such as connecting trunk cable A to the B connector on the node.

Mixing cable connections makes it difficult to interpret cable fault indications

and locate a bad cable segment.

When in Redundant Cable mode, each node independently decides whether to

use channel A or channel B. This decision is based on error counters internal to

each node. Redundant cabling is only valid if there is only one fault on the

network. In other words, if you have a proper redundant cabling system and

you remove node 3 on trunk A and node 4 on trunk B, the system will not

operate correctly because a double failure has occurred.

Additional Resources

For more information, see the ControlNet Standard and High-flex Coax Cable

Installation Instructions, publication 1786-IN009

.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 35

Page 36

Power

OUT

24Vdc NOMINA L

120W

Ter m in at o rs

Ter m in at o rs

Ter m in at o rs

Ter m i na t o rs

Tru nk Ca ble A

Tru nk C abl e B

Node

Node

Repeater A

Repeater B

Node

Node

Chapter 3 Redundant Media

Figure 2 - Redundant Media System

36 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 37

Appendix A

32468-M

Network Channel

Status Indicators

OK Status Indicator

1756 ControlNet Status Indicators

Top ic Pa ge

1756-CN2, 1756-CN2R, 1756-CN2RXT, and 1756-CN2RK ControlNet Communication Modules 38

1756-CNB/E and 1756-CNBR/E ControlNet Communication Modules 43

The 1756 ControlNet communication modules and adapters support these

status indicators.

Status Indicator Description

OK status indicator Indicates the module’s current state.

Network channel status indicators Indicates the status of network channels A and B.

Status Indicators

The 1756 ControlNet communication modules and adapters support these

status indicators.

Status Indicator Description

B Indicates the Network Channel Status, Channel B.

A Indicates the Network Channel Status, Channel A.

OK OK, indicates the current state of the module.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 37

Page 38

Appendix A 1756 ControlNet Status Indicators

IMPORTANT

IMPORTANT

Interpret the OK Status Indicator

The OK status indicator reflects the module state, such as the running of a selftest, the updating of firmware, and normal operation without an established

connection.

When you view the status indicators, always view the OK status indicator first

to determine the state of the module. This information may help you to

interpret the network channel status indicators. As a general practice, view all

status indicators together to gain a full understanding of the module’s status.

Interpret the Network Channel Status Indicators

The network channel status indicators appear in one of these states:

• Steady—The indicator is on continuously in the defined state.

• Alternating—The two indicators alternate between the two defined states

at the same time (applies to both indicators viewed together). The two

indicators are always in opposite states, out of phase.

1756-CN2, 1756-CN2R, 1756-CN2RXT, and 1756-CN2RK ControlNet Communication Modules

• Flashing—The indicator alternates between the two defined states (applies

to each indicator viewed independent of the other). If both indicators

flash, they must flash together, in phase.

When you connect the 1756-CNB/E and 1756-CNBR/E modules to a ControlNet

network by using only the NAP, the channel A and channel B indicators are

meaningless.

This section provides the following information about status indicators:

• To understand the OK status indicator and display messages, refer to

Tab le 1 on pa ge 39

• For information about viewing the network channel status indicators

together, refer to Ta bl e 2 on pa ge 42

• For information about viewing the network channel status indicators

individually, refer to Tab le 3 on pa ge 42

.

.

.

38 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 39

1756 ControlNet Status Indicators Appendix A

OK Status Indicator and Display

Table 1 - OK Status Indicator and Display

Status Display Description

Off None The module is not communicating due to a power supply fault or internal fault.

Do any of the following:

• Check the power supply.

• Check the cable connectors.

• Make sure the module is firmly seated in the chassis.

• If the indicator remains off, replace the module.

Steady Red Reset Complete—Change Switch Settings The module’s network address is set to 00, an invalid ControlNet address.

Remove the module from the chassis, and set the network address to a valid value. For more

information, see Install a 1756 ControlNet Communication Module

FAIL This code is displayed when the power-up test fails.

Replace the module.

Backplane Init

Stop Service Received A nonredundant module is placed into a redundant secondary chassis. The module was

Flashing red Image update Needed The Boot image is running.

DUPLICATE NODE DETECTED The module’s network address is the same as another module’s on the link.

Flash in progress A firmware upd ate is in progress.

TEST The module is executing a power-up test.

(1)

The module is waiting for the redundant module to complete powerup.

commanded to stop functioning by the redundancy module (RM2/RM/SRM).

Remove the nonredundant module from the redundant secondary chassis, and then replace the

nonredundant module with the redundant module.

This could occur if a 1756-CN2 or 1756-CN2R module running Boot code is inserted into a chassis

along with a 1756-SRM or 1756-RM module.

For use in an enhanced redundancy system, the 1756-CN2/B or 1756-CN2/C modules are designed

to interoperate with a 1756-RM or 1756-RM2 module. It should not be used with a 1756-SRM

module.

Insert the module into a chassis that does not contain a 1756-SRM, 1756-RM or 1756-RM2 module,

and then update the module’s firmware with ControlFLASH software.

Update the module’s firmware with Contro lFLASH soft ware.

Remove the module from the chassis, and set the network address to a unique value. For more

information, see Install a 1756 ControlNet Communication Module on page 9.

If communication to the module is lost during an update, this message will continue to be

displayed even though the module will not be able to finish the update.

Remove power from the module to recover, and then perform the update again.

If the display persists for more than 45 seconds, replace the module because it has failed.

on page 9.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 39

Page 40

Appendix A 1756 ControlNet Status Indicators

Table 1 - OK Status Indicator and Display

Status Display Description

Steady Green OK This is normal operation. There is at least one connection to or through the module.

INIT The module is initializing.

PASS This message is displayed momentarily upon completion of a successful power-up test.

(1)

CMPT

(1)

DSNP

(1)

PwDS

(1)

PQgS

(1)

PwQS

(1)

PwNS

(1)

QgS

(1)

QS

A#xx This message is the node address where xx is an address from 01...99.

MACID SWITCH ERROR Node address switch changed after you cycled power.

Steady green or flashing green CPU=xx% This message is the CPU utilization rate where xx is the amount of CPU used, ranging from 0...99%.

OK The module is operating normally.

Flashing green OK This is normal operation. No connections to or through the module exist.

Invalid Network Configuration ControlNet configuration error.

NET ERR A network cabling error exists, or there are no other ac tive nodes on the network.

Rev xx.xx When you start the module, its major and minor revisions are disclosed causing this message to

The secondary module is compatible with its partner.

The secondary module is disqualified with no partner.

Check the corresponding slot of the primary chassis for the module type and revision.

The module is primary with a dis qualified secondar y partner.

Check the type and revision of the 1756-CN2/B module.

The module is primary with a qualifying secondary partner.

The module is primary with a qualified secondary partner.

The module is primary with no secondary partner.

Check corresponding slot of secondary chassis for correct module.

The secondary module is qualifying.

The secondary module is qualified.

We recommend that you either return switches to their original settings or replace the module, as

this could indicate a latent ha rdware anomaly.

This message occurs only if the CPU utilization exceeds 80%.

Recheck the configuration.

Verify that the module’s net work address is less than or equal to the maximum unscheduled

network address (UMAX).

Recheck your network cabling and make sure another node on the network is active (online).

briefly appear.

The display shows these revisions where the major revision appears to the left of the decimal point,

and the minor revision appears to the right.

40 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 41

1756 ControlNet Status Indicators Appendix A

Table 1 - OK Status Indicator and Display

Status Display Description

Any Keeper: Unconfigured The network configuration data maintained in memory by the keeper object has been erased or

Keeper: Unconfigured (data format

changed)

Keeper: Unconfigured (slot changed) After the keeper object’s network-configuration data was downloaded, the module was moved to a

Keeper: Unconfigured (net address

changed)

Keeper: Signature Mi smatch The networ k configuration data maintained in memory by the keeper object does not match the

Keeper: None Valid on Network The network configuration data maintained in memory by the keeper object does not match the

corrupted.

Do any of the following:

• Use RSNetWorx software to download or update the keeper object in the module.

• Reset the module to the original factory settings, as described on page 14

.

The network configuration data maintained in memory by the keeper object is in a format

incompatible with the current revision of firmware.

Do any of the following:

• Use RSNetWorx software to download or update the keeper object in the module.

• Reset the module to the original factory settings, as described on page 14

.

different spot in the rack.

Do any of the following:

• Return the module to the proper slot.

• Use RSNetWorx software to download or update the keeper object in the module.

• Reset the module to the original factory settings, as described on page 14

.

The network address switches on the module have been changed since the keeper object’s

network-configuration data was downloaded.

Do any of the following:

• Return the network address switches to their original setting.

• Use RSNetWorx software to download or update the keeper object in the module.

• Reset the module to the original factory settings, as described on page 14

.

current network configuration.

There is a valid active keeper on the network.

Do any of the following:

• Use RSNetWorx software to download or update the keeper object in the module.

• Reset the module to the original factory settings, as described on page 14

.

current network configuration, and there is no valid active keeper on the network.

Use RSNetWorx software to download or update the keeper object in the module.

Important: The Install the Module

on page 14 procedure does not work. There is no valid active

keeper from which to crossload data.

(1) ControlLogix enhanced redundancy systems only.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 41

Page 42

Appendix A 1756 ControlNet Status Indicators

Network Channel Status Indicators

Table 2 - Network Channel Status Indicators A and B

Status Description

Off There is no power.

Steady red Unit has faulted.

Cycle power or reset unit. If the fault persists, contact a Rockwell Automation representative or distributor.

Alternating red/green A self-test is being conducted.

Alternating red/off Node has been configured incorrectly.

Check network address and other ControlNet configuration parameters.

Table 3 - Network Channel Status Indicators A or B

Status Description

Off Channel has been disabled.

Program the network for redundant media, if required.

Steady green This is normal operation.

Flashing green/off Temporary errors exist. The unit will self-correct.

Node is not configured to go online.

Make sure that the configuration manager node (keeper) is present and working and the selected address is not greater

than the maximum unscheduled node address (UMAX).

Flashing red/off A media fault exists.

Check media for broken cables, loose connectors, or missing terminators.

No other nodes are present on the network.

Add other nodes to the network.

(1)

(1) The configuration manager node (keeper) is the node responsible for distributing ControlNet configuration data to all nodes on the network.

42 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 43

1756 ControlNet Status Indicators Appendix A

1756-CNB/E and

1756-CNBR/E ControlNet

This section provides the following information about status indicators:

• To understand the OK status indicator and display messages, see Ta b l e 4

Communication Modules

• For information about viewing the network channel status indicators

together, see Table 5 on page 46

• For information about viewing the network channel status indicators

individually, see Tabl e 6 o n pa ge 4 6

OK Status Indicator and Display

Table 4 - OK Status Indicator and Display

Status Display Description

Off None The module is not communicating due to a power supply fault or internal fault.

Do any of the following:

• Check the power supply.

• Check the cable connectors.

• Make sure the module is firmly seated in the chassis.

• If the status indicator remains off, replace the module.

Steady red Msg scrolls

Flashing red BOOT The module has invalid firmware.

(1)

BPA# ERR The module has detected a different slot address from that latched in when the module was started. Excessive noise on the

BPRX ERR Too many CRC errors are being generated by the multicast backplane receiver, so the backplane multicast receivers have

BPIC ERR Hardware within the module has faulted.

CNIC ERR

DUPL NODE For enhanced redundancy systems, this may be a temporary condition during chassis switchover. Otherwise, the module’s

RACK ERR The module cannot read the backplane EEPROM, or the rack/slot address is incorrect.

STOP The 1756-CNB/E module was commanded to stop functioning by the redundancy module. This occurs when a non-

(2)

WAI T RM

or

(2)

WAI T SRM

ROM UPDT A firmware update is in progress.

SNGL KPR! The module has detected that it has been connected to a ControlNet single-keeper network, version 1.0 or 1.25.

The module’s network address is set to 00, an invalid ControlNet address, or 99, an invalid ControlNet address if you are

using enhanced redundancy control. See the footnote at the end of the table.

Remove the module from the chassis, and set the network address to a valid value. For more information,

see Install a 1756 ControlNet Communication Module

backplane causes this error.

Replace the chassis or module.

been shut off.

Replace the module.

Replace the module.

network address is the same as another module’s on the link.

For enhanced redundancy systems only, wait 10 seconds. If the condition persists, remove the module from the chassis,

and set the switches to a unique address. For more information,

see Install a 1756 ControlNet Communication Module

Replace the chassis.

redundancy-compliant 1756-CNB/E module is placed into a redundant secondary chassis.

Remove the nonredundancy-compliant 1756-CNB/E module from the redundant secondary chassis and replace it with a

redundant 1756-CNBR/E module.

The 1756-CNB/E module is waiting for the redundancy module to be started.

Update t he module’s firmware with Cont rolFLASH software.

Update the firmware of module at node address 01 and reschedule the network.

.

.

on page 9.

on page 9.

.

Rockwell Automation Publication CNET-IN005C-EN-P - July 2014 43

Page 44

Appendix A 1756 ControlNet Status Indicators

Table 4 - OK Status Indicator and Display (Continued)

Status Display Description

Steady green OK Normal operation is occurring. At least one connection has been made to or through the module.

INIT The module is initializing.

BW >MAX The module is receiving too much network traffic and connections are timing out. The network bandwidth has been

(2)

CMPT

(2)

DSNP

(2)

PwDS

(2)

PwQg

(2)

PwQS

(2)

PwNS

(2)

Qfng

(2)

QS

SW ERR The node address switch changed after the module was started.

Flashing green CNFG ERR The ControlNet network was configured incorrectly.

NET ERR A network cabling error exists, or no other active nodes exist on the net work.

OK Normal operation is occurring. No connections have been made to or through the module.

exceeded.

No action is required because this is a temporary condition.

If this happens frequently, add another module and split the traffic between them.

The secondary 1756-CNB/E module is compatible with its partner.

The 1756-CNB/E module is disqualified without a partner.

Check corresponding slot of primary chassis for type and revision of module.

The 1756-CNB/E module is primary with a disqualified secondary partner.

Check the type and revision of the module.

The 1756-CNB/E module is primary with a qualifying secondar y partner.

The 1756-CNB/E module is primary with a qualified secondary part ner.

The 1756-CNB/E module is primary with no secondary partner.

Check the corresponding slot of the secondary chassis for the correct module.

The secondary 1756-CNB/E module is qualifying.

The secondary 1756-CNB/E module is qualified.

We recommend that you either return the switches to their original settings or replace the module, since this condition

could indicate a latent hardware anomaly.

Recheck the ControlNet network configuration.

Recheck your network cabling and make sure another node on the network is active (online).

44 Rockwell Automation Publication CNET-IN005C-EN-P - July 2014

Page 45

Table 4 - OK Status Indicator and Display (Continued)

Status Display Description

SO_2

SO_3

SN_1

SN_2

SN_3

?Cpt

!Cpt

(2)

Old primary switchover phase 1 is in progress.

If the display shows this message for more than 3 seconds, then the 1756-CNB/E module failed during transition from one

redundancy phase to another. Replace one or both redundancy modules.

(2)

Old primary switchover phase 2 is in progress.

If the display shows this message for more than 3 seconds, then the 1756-CNB/E module failed during transition from one

redundancy phase to another. Replace one or both redundancy modules.

(2)

Old primary switchover phase 3 is in progress.

If the display shows this message for more than 3 seconds, then the 1756-CNB/E module failed during transition from one

redundancy phase to another. Replace one or both redundancy modules.

(2)

New primary switchover phase 1 is in progress.

If the display shows this message for more than 3 seconds, then the 1756-CNB/E module failed during transition from one

redundancy phase to another. Replace one or both redundancy modules.

(2)

New primary switchover phase 2 is in progress.

If the display shows this message for more than 3 seconds, then the 1756-CNB/E module failed during transition from one

redundancy phase to another. Replace one or both redundancy modules.

(2)

New primary switchover phase 3 is in progress.

If the display shows this message for more than 3 seconds, then the 1756-CNB/E module failed during transition from one

redundancy phase to another. Replace one or both redundancy modules.

(2)

The 1756-CNB/E module has not determined if it is compatible.

If the display shows this message for more than 3 seconds, then the 1756-CNB/E module failed during transition from one

redundancy phase to another. Replace one or both redundancy modules.

(2)

The 1756-CNB/E module has determined that it is not compatible.

Replace the 1756-CNB/E module with one of the correct type and revision.

Steady green or off SO_1

1756 ControlNet Status Indicators Appendix A