Remington 482 Operating Instructions Manual

Important :

Read this manual and all labels carefully before operating your powder actuated tool.

This manual should always accompany the tool and be transferred with it upon change

of ownership.

REMINGTON®

Operating

Instructions

Model 482

Powder Actuated

Fastening Tool

REMINGTON

2

106088

INDEX

Warning: Safety Precautions............................................................................. 2-11

Why a Fastener Holds.......................................................................................... 12

Selecting Fasteners and Power Loads ................................................................ 13

Operation ....................................................................................................... 14, 15

Maintenance......................................................................................................... 16

Troubleshooting ............................................................................................. 16, 17

Parts Central ........................................................................................................ 17

Parts List .............................................................................................................. 18

Accessories.......................................................................................................... 19

Tool Disassembly and Assembly ................................................................... 19, 20

Buffer and Piston Replacement ........................................................................... 21

Application Chart............................................................................................ 22, 23

Warranty.................................................................................................Back Cover

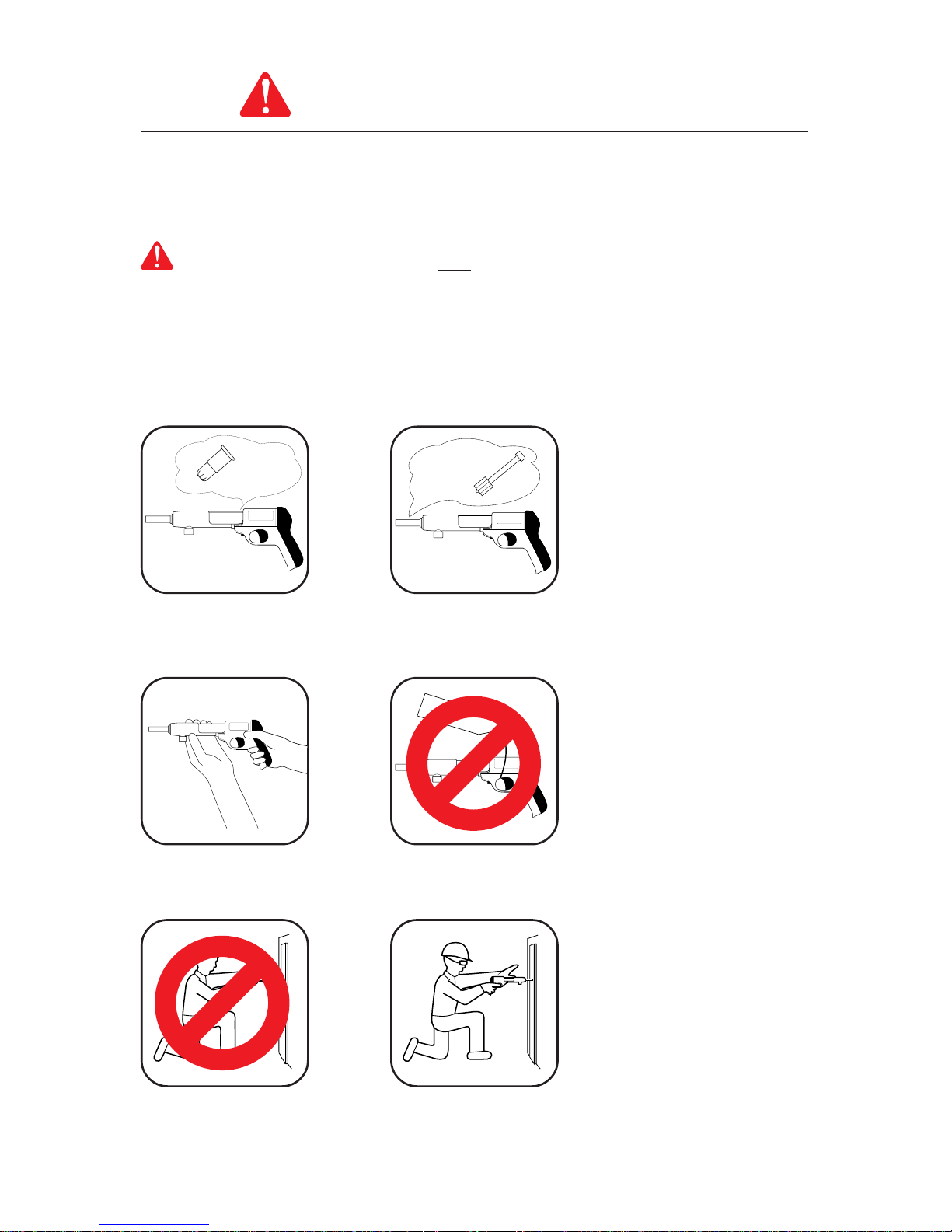

* Not provided with tool.

REMINGTON

Power Fastener*

Barrel

Assembly

Trigger

Maximum 2

1

/2" - Model 482

Power Load*

Muzzle

Spall Shield

Recommended

Approved Goggles

REMINGTON

Model 482 Powder Actuated Fastening Tools

The Remington Model 482 Powder Actuated Fastening Tool is designed for use

with Remington 22 caliber Type A crimped loads and Remington Power Fasteners. Remington Power Fasteners are manufactured from special steel and heat

treated to produce a very hard yet ductile fastener.

3

106088

Warning: Safety Precautions

The following pages contain detailed warnings, cautions, and rules of safe operation.

Read carefully and become familiar before operating to avoid serious injury. We

expressly disclaim any liability for any injury to persons or damage to property which

result from your failure to take the precautions contained in this manual.

WARNING: This tool is designed only for use by qualified operators. Qualification

is obtained through a thorough understanding of the Safety Warnings and operating

instructions as defined in this operating manual. NOTE: Your local labor regulations may

require that the operator of this tool on a job site be thoroughly trained and certified for

competence prior to operating this tool. For certification procedures, call 1-800-626-2237

(U.S.A.) or 1-905-826-8010 (Canada)

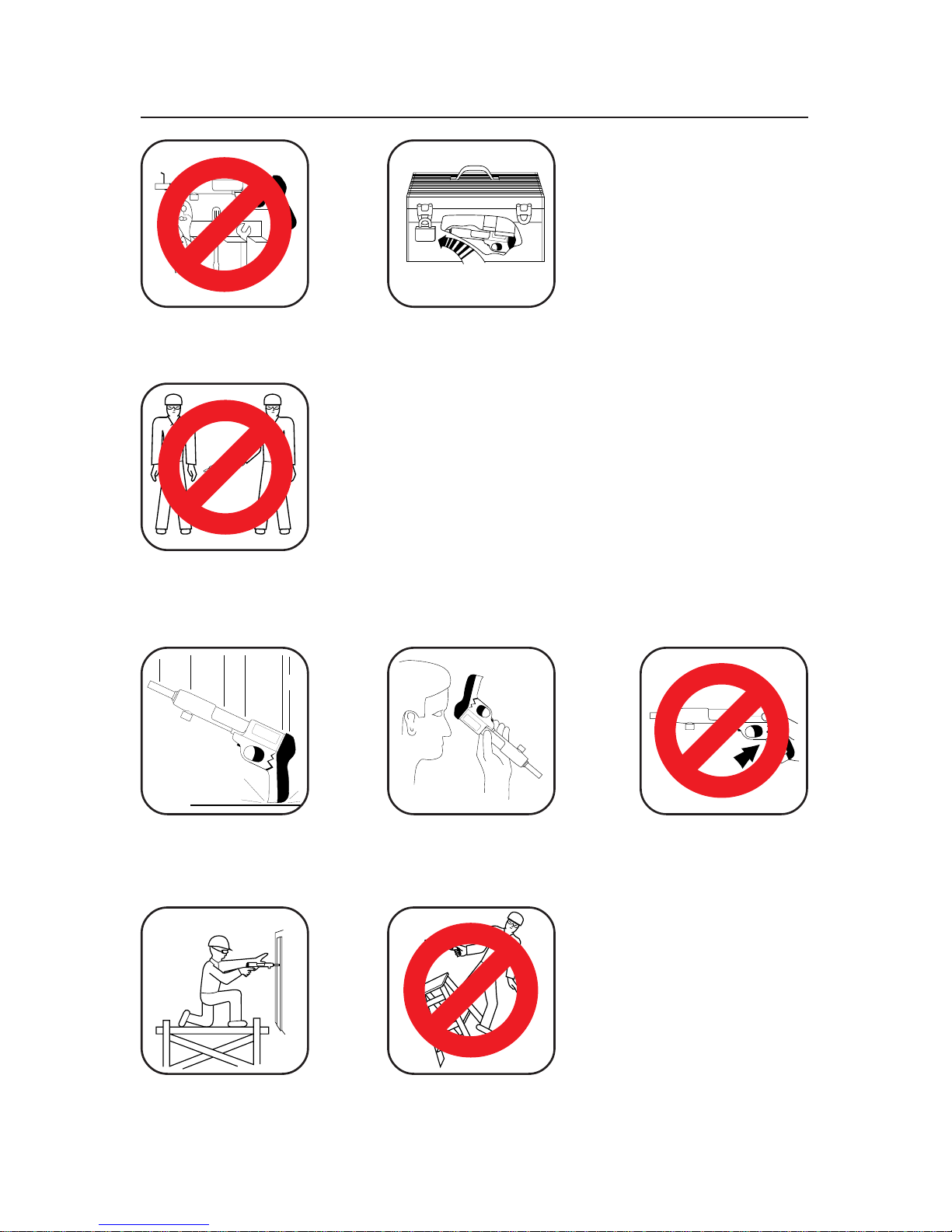

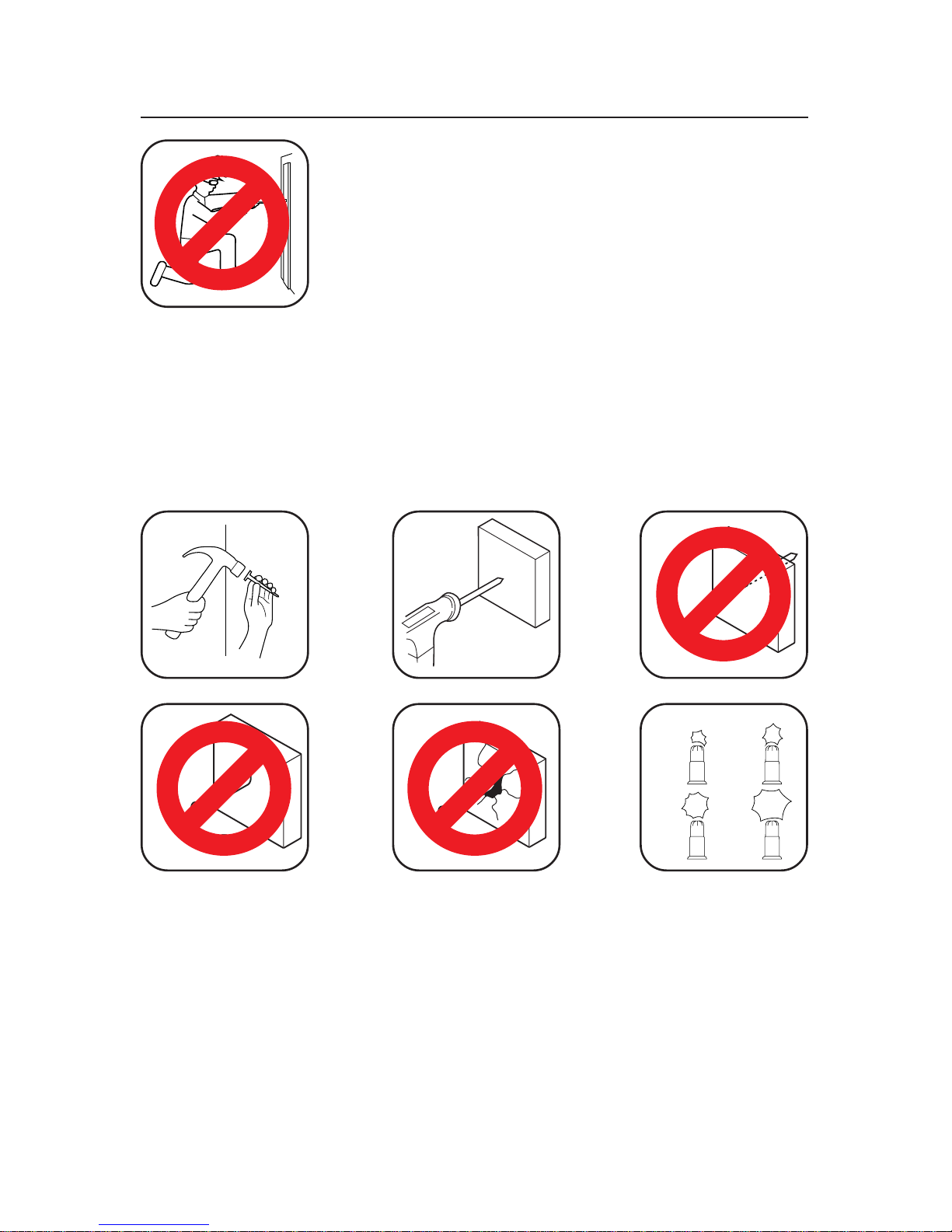

BEFORE USING

DEFECTIVE

3. Operators and bystanders must ALWAYS wear goggles and hearing protection

which meet or exceed the accepted standards for adequate protection in your

country. In the U.S., refer to ANSI standards. In Canada, refer to CSA standards.

2. ALWAYS inspect to make sure the tool is working properly. If the tool does not work

properly, remove from service and tag DEFECTIVE. DO NOT use the tool again until

it has been properly repaired.

1. ALWAYS handle the tool as if it were loaded. Before starting work, check that the

tool is unloaded and the muzzle is clear. NEVER load a tool unless it is going to be

used.

?

?

4

106088

Safety Precautions

4. ALWAYS clear the work area on all sides and post appropriate warning signs on job

sites.

5. ALWAYS make sure the work area is clean from loose material and debris.

HANDLING THE TOOL

1. NEVER place your hand over the muzzle. Accidental discharge can cause serious

injury.

2. NEVER place your finger on the trigger until the tool’s muzzle is against the work

surface.

PISTOLETS DE

SCELLEMENT

EN USAGE

ATTENTION

!

5

106088

Safety Precautions

3. ALWAYS store UNLOADED powder actuated tool and power loads in a locked

container. Keep power loads of different power levels in separate containers.

4. NEVER carry or pass a loaded powder actuated tool. NEVER point a powder

actuated tool at anyone.

6. ALWAYS take precaution to maintain your balance while operating a powder

actuated tool.

5. If the tool is dropped, inspect for damage and repair it before continuing to work.

NEVER use a damaged tool.

POW

DER

LOADS

POWD

LOAD

6

106088

Safety Precautions

TOO BRITTLE

Surface

shatters

482-30

CENTER

PUNCH TEST

482-27

7. An operator taking medication should take extra precautions while handling the tool.

NEVER drink alcoholic beverages or take medications which impair your vision,

balance or judgement before using a powder actuated tool.

1. ALWAYS know the thickness and type of base material into which you are fastening.

NEVER GUESS. Test the base material by using the Center Punch Test. The Center

Punch Test is performed by using a hammer to test drive the particular power

fastener to be used into the material. If the point penetrates easily, the material is

too soft. If the point becomes blunt, the material is too hard. If the material fractures,

cracks or shatters, the material is too brittle. Test fastenings can be made if the

material shows a clear fastener impression and the fastener point is not blunted.

ALWAYS start with the lowest power load (Gray-Level 1) and proceed with the order

shown in the lower right-hand figure above. Always wear approved goggles.

KNOW YOUR FASTENING BASE MATERIAL

TOO HARD

Point

flattens

482-29

TOO SOFT

Sinks in

with

average

hammer

blow

482-28

Start

1

GRAY

3

GREEN

4

YELLOW

2

BROWN

482-31

?

?

?

?

?

?

?

7

106088

482-34

482-37

Safety Precautions

482-36

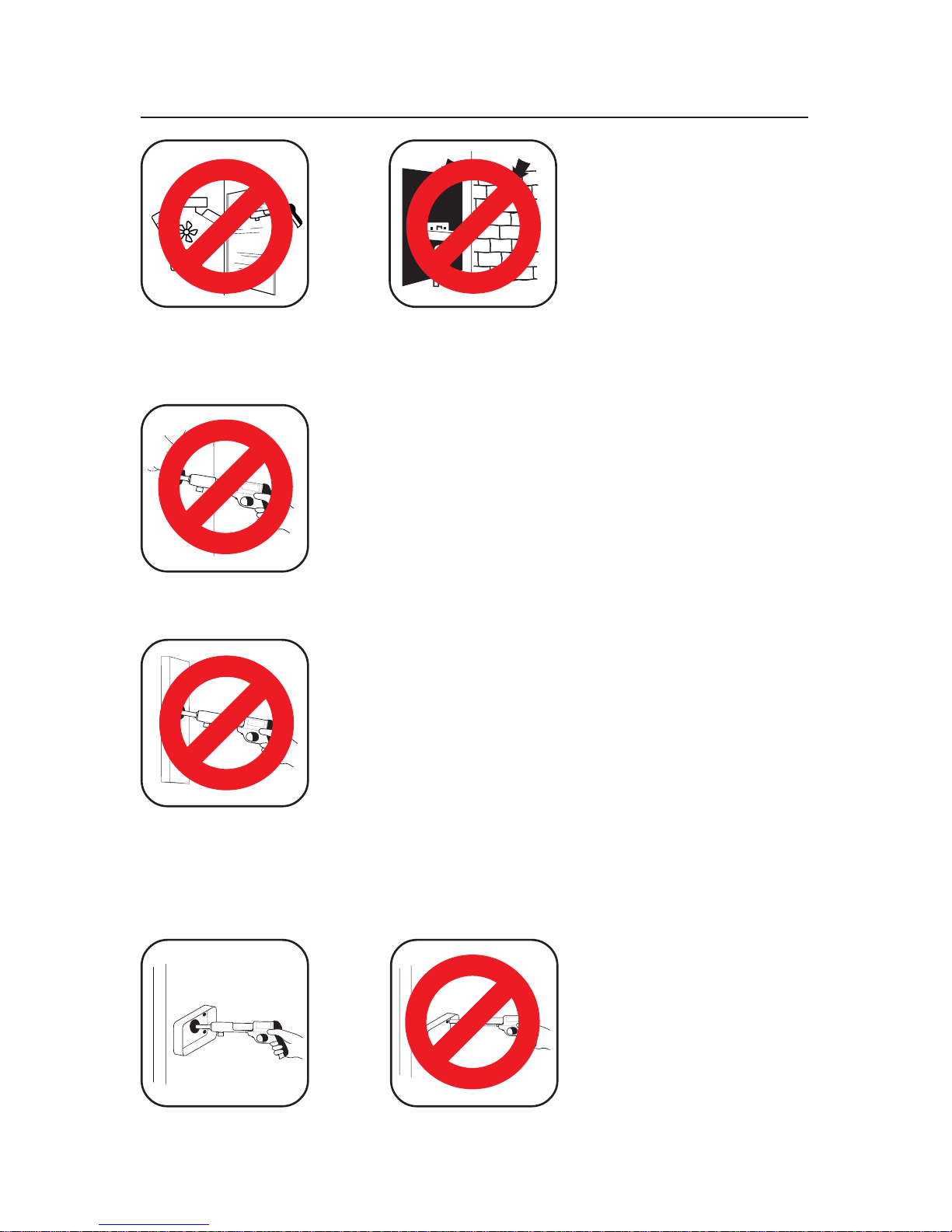

3. NEVER make fastenings in spalled or cracked areas.

5. DO NOT fasten through or within 1/2" of predrilled or pre-punched holes.

4. NEVER drive power fasteners into thin or easily penetrated materials unless it is

backed by concrete or steel. When in doubt, such as when base material is

concealed, conduct a Center Punch Test (See page 6). Check continually to avoid

fastening into unsuitable material, especially in older buildings.

482-35

CAST IRON GLASS

2. NEVER attempt to drive power fasteners into very hard or brittle materials including,

but not limited to cast iron, glass, tile, stone, brick, or hardened steel. Materials of

this type tend to shatter and create hazard from flying particles.

TILE

BRICK

482-33

8

106088

NO

90

482-44

3/16" MIN

1/2"

1"

482-41

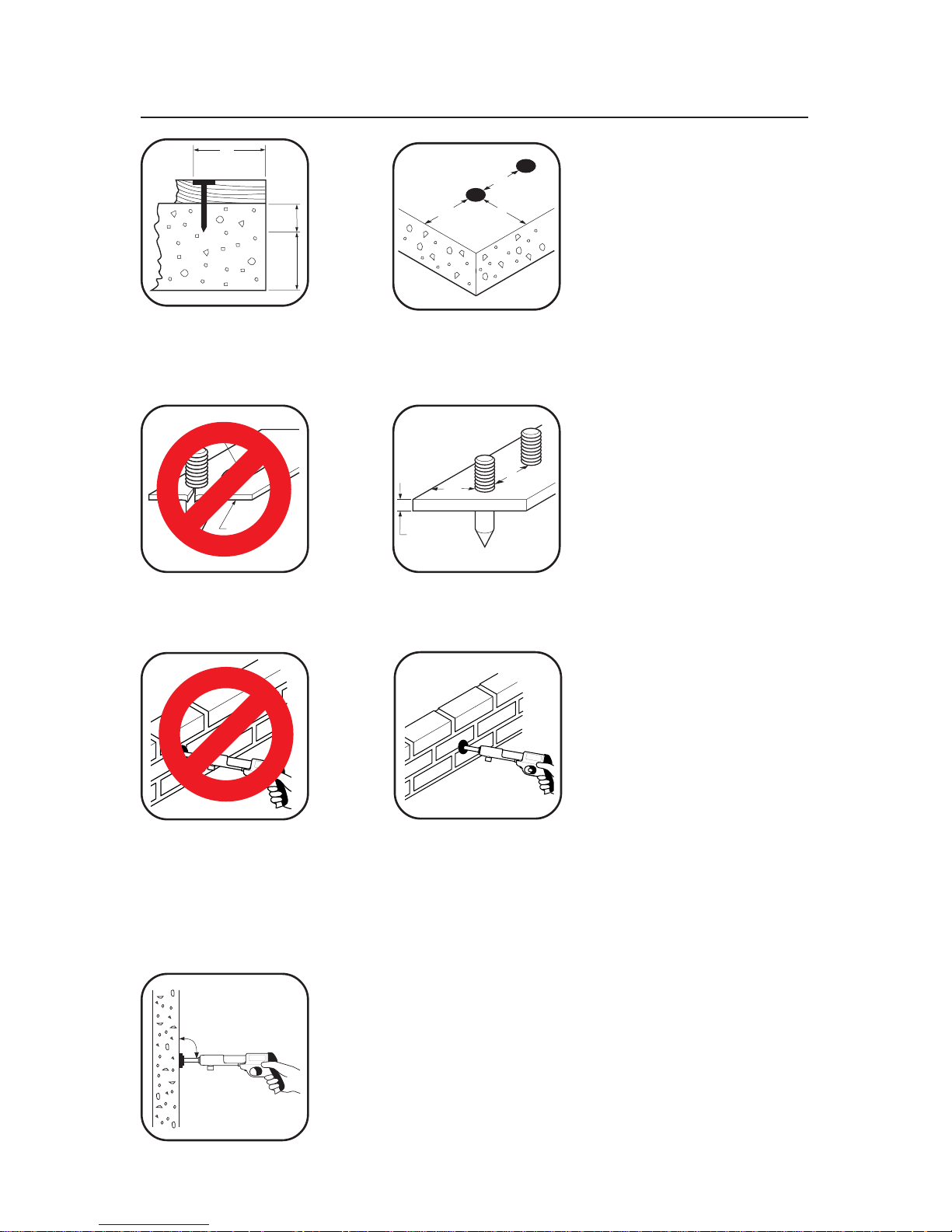

6. DO NOT drive power fasteners into concrete less than three times as thick as the

intended fastener penetration, within 3" of the edge, within 3" of another power

fastener or within 3" of a failed power fastener.

7. DO NOT drive power fasteners into steel base material less then 3/16" thick, within

2" of a weld, within 1/2" of the edge or within 1" of another power fastener.

8. When fastening into masonry walls, always drive into horizontal mortar joints, never

into vertical mortar joints. BE CAREFUL. A poorly laid joint may permit too much

penetration, and/or unsatisfactory holding power.

OPERATING THE TOOL

1. ALWAYS hold tool perpendicular to work surface.

3"

3"

3"

482-39

TOO THIN

WELD

482-40

3"

3X

1X

482-38

YES

Safety Precautions

Loading...

Loading...