Raymarine 465 User Manual

Distributed by

Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the

Raytheon Company.

Echo Sounding

How it Works

Your eyes underwater

An “echo sounder” or “sonar” unit sends high-frequency sound waves down into the water below a boat. These sounds hit the bottom of the lake or sea and bounce back. The display unit measures the time delay as the signal goes out and returns. The FishFinder uses this information to display a graphic image of the bottom conditions. The system also uses this same principle to detect fish or other objects in the water, and display their size and location. This display is like a “window” which allows you to look into the underwater world.

About the transducer

The transducer transmits the sound waves down into the water. It also receives the waves as they return. One type of transducer can be mounted on the transom

of the boat, as shown here. Other types of transducers can be installed through a hole in the hull, or mounted inside the hull.

|

The Sidelooker |

|

|

transducer |

|

|

The optional Sidelooker is a |

|

|

special type of transducer |

|

|

which allows the Fish- |

|

|

Finder to detect fish beside |

|

|

the boat. The Sidelooker |

The Sidelooker transducer uses a |

|

produces two powerful hori- |

special plastic material called “PVDF,” |

|

zontal beams which ex- |

which was developed by Raytheon |

|

tend to either side, just |

Naval Systems. This allows the Side- |

|

below the surface of the |

looker to give you the clearest possible |

|

water. |

picture of conditions underwater. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FishFinder 465

“Out of the box” operation

Because of a number of automatic features, the FishFinder 465 unit is ready to operate “right out of the box.” This unit includes automatic settings for the most important controls – range, sensitivity, and zoom. Because these settings are automatic, the FishFinder will provide useful displays right from the start. Once you become more comfortable with the operation of the unit, you can adjust these settings.

Features and functions

PWR

F I S H F I N D E R

SETUP

CLEAR

ZOOM

A-SCP

BOT

LOCK

465

Excellent ability to find fish

To a sonar unit like the FishFinder, the water includes a lot of background “noise.”

There are many conditions which could confuse a sonar unit – bubbles and wakes in the water, temperature differences between water layers, and so on. It can be difficult for a sonar unit to detect fish against this background of noise.

Because of its advanced circuitry, the 465 is especially good at telling the difference.

Dual frequency operation

“Frequency” is a measure of how fast the sound waves change or “vibrate.” The

FishFinder uses sound waves with two different frequencies – 50 kHz and 200 kHz. The 50 kHz frequency scans a wide area, and penetrates the water well. This frequency is best for use in deep water.

The 200 kHz frequency scans a narrower area but produces a more detailed view. This frequency is best for seeing fish near the bottom, or fish which are close together. The FishFinder can also use both frequencies at the same time. This provides good depth penetration and good detail in the display.

Fish symbols and alarms

The unit provides fast, positive identification of fish in the water. It even indicates the size of a fish using eight different fish symbols. The 465 includes alarms for shallow warning, deep warning and fish warning.

Clear LCD display

The FishFinder display produces continuous pictures of bottom conditions and fish in the water. The display unit may be turned or tilted to the best viewing angle. The FishFinder unit can be easily removed from the boat for storage in a safe place.

Totally waterproof

The FishFinder 465 meets U.S. Coast

Guard specifications for waterproofing, so it can stand up to the hard service required on small boats. The rugged construction and sophisticated sealing methods used in this unit will ensure many years of reliable service.

Before you begin

This manual contains very important information on the installation and operation of your FishFinder 465. For best results as you use this unit, please take the time to read this manual thoroughly.

IMPORTANT NOTICE

THIS DEVICE IS ONLY AN AID TO NAVIGATION. ITS ACCURACY CAN BE AFFECTED BY MANY FACTORS, INCLUDING EQUIPMENT FAILURE, DEFECTS, ENVIRONMENTAL CONDITIONS AND IMPROPER HANDLING OR USE.

IT IS THE USER’S RESPONSIBILITY TO EXERCISE COMMON PRUDENCE AND NAVIGATIONAL JUDGMENT. THIS DEVICE SHOULD NOT BE RELIED UPON AS A SUBSTITUTE FOR SUCH PRUDENCE AND JUDGMENT.

Warranty card

Before you go any further, please take a few minutes to fill out the warranty card. It is very important that you return the warranty card soon after your purchase. This will ensure that you receive the full benefits offered by the warranty.

Service information

In the unlikely event that your unit is ever in need of service, please refer to the section on “Maintenance and Troubleshooting” at the back of this manual. See the information on “How to Contact Apelco.”

Special terms

In this manual, we will use some special terms which have to do with boats and boating. These are explained in a Glossary at the end of the manual. If you do not recognize a word which appears in this manual, check the Glossary.

ii

FishFinder 465

Instruction Manual

Contents

Echo sounding – How it works (inside front cover) FishFinder 465 – Features and functions i

For information and service ii

1 Introduction 1

About the FishFinder 465 |

1 |

|

|

|

|

System Components |

2 |

|

|

|

|

Standard Equipment |

2 |

|

|

|

|

Standard Transducers |

2 |

|

|

|

|

Optional Accessories |

2 |

|

|

|

|

2 Installation 4 |

|

|

|

|

|

About the Transducer |

4 |

|

|

|

|

Selecting the Correct Type of Transducer |

5 |

|

|||

Assembling the Transducer Bracket |

6 |

|

|

||

Positioning the Transom-Mount Transducer |

6 |

|

|||

Mounting the Transom-Mount Transducer |

9 |

|

|||

Mounting the Optional Sidelooker Transducer |

10 |

||||

Installation Notes – Thru-Hull Transducer |

10 |

|

|||

Installation Notes – In-Hull Transducer 12 |

|

|

|||

Installation Notes – Trolling Motor Transducer |

12 |

||||

Installation Notes – |

|

|

|

|

|

Transducer for Speed and Temperature Only |

13 |

||||

EMC Installation Guidelines 13 |

|

|

|

||

Mounting the Display Unit – Standard Mount |

15 |

||||

Mounting the Display Unit – Flush Mount |

17 |

|

|||

Installing the Transducer Cable 18 |

|

|

|

||

Installing the Transducer Cable – Sidelooker Option 20 |

|||||

Installing the Transducer Cable – |

|

|

|

||

Separate Speed and Temperature Sensors |

20 |

||||

Making the DC Power Connections |

21 |

|

|

||

Calibrating the Sensors |

23 |

|

|

|

|

3 Operating Instructions 25

Controls on Display Unit 25

Turning the Power On and Off 27

Setup Memory 27

Lamp/Contrast Display 28

iv

Operating Pages 29

FishFinder Page 31

Choosing a Frequency 36

Fish Indications 37

Bottom Indications 38

Window Page 40

Sidelooker Page 42

Digital Page 46

Performance Modes 49

Zoom Mode 49

A-Scope (Bottom Coverage) Mode 51

Bottom Lock Mode 53

4 Setup Instructions 55

The Setup Menu |

55 |

|

|

|

|

|

Range Setting |

56 |

|

|

|

|

|

Sensitivity Setting |

57 |

|

|

|

||

Chart Speed Setting |

59 |

|

|

|

||

Frequency Setting |

60 |

|

|

|

||

Resetting the Log |

62 |

|

|

|

||

System Setup Menu |

63 |

Shallow Alarm 66 |

||||

Simulator |

64 |

|

Deep Alarm |

67 |

||

Language |

64 |

Fish Alarm |

67 |

|||

Fish Symbol |

64 |

Buzzer |

68 |

|

||

White Line |

64 |

Depth Units |

69 |

|||

VRM |

65 |

|

|

Speed Units |

69 |

|

Sidelooker |

65 |

Temp Units |

69 |

|||

Speed Cal |

65 |

Speed |

69 |

|

||

Temp Cal |

66 |

|

Log 69 |

|

|

|

Depth Digits 66 |

Temp 69 |

|

|

Setup Menus for Zoom Mode 70 |

|

|

|

Zoom Select Menu |

70 |

|

|

Zoom Screen Split/Full Menu Item |

71 |

||

Setup Menus for Bottom Lock Mode |

72 |

|

|

Bottom Lock Range Menu Item |

72 |

||

Bottom Lock Split/Full Menu Item |

73 |

||

Setup Menu for Window and Digital Pages 74

Resetting from the Digital Page |

75 |

Setup Instructions for Sidelooker |

75 |

Sidelooker Range Menu Item 76

v

5

6

Sidelooker Sensitivity Menu Item 77 Sidelooker Chart Speed Menu Item 77 Sidelooker View Menu item 78 Combining Displays 79

Resetting the Unit to Factory Defaults 80 Default Settings 81

Maintenance and Troubleshooting 82

Cleaning Instructions 82 Troubleshooting Suggestions 82 Servicing a Thru-Hull Transducer 86 How to Contact Apelco 86

Specifications 89

General Information 89

FishFinder Functions 90

Connector Diagrams 91

Glossary of Terms 92

vi

List of Figures

Figure |

|

|

Page |

|||||||||||

|

Unit in Use |

Inside front cover |

|

|

|

|

|

|

|

|

|

|

|

|

|

Front Panel |

|

i |

|

|

|

|

|

|

|

|

|

|

|

1-1 |

Typical Installation |

|

1 |

|

|

|

|

|

|

|

|

|

||

2-1 |

Transducer Types |

|

5 |

|

||||||||||

2-2 |

Assembling the Transducer Bracket |

|

6 |

|

||||||||||

2-3 |

Transducer Mounted on Transom |

|

7 |

|

|

|

|

|||||||

2-4 |

Transducer Bracket, Side View |

|

7 |

|

|

|

|

|||||||

2-5 |

Correct Mounting Position |

|

8 |

|||||||||||

2-6 |

Mounting the Transducer |

|

8 |

|

|

|

|

|

|

|

|

|||

2-7 |

Installing the Sidelooker Transducer |

|

10 |

|

|

|

|

|

|

|

||||

2-8 |

Suppression Ferrites |

|

14 |

|

|

|

|

|

|

|

|

|

|

|

2-9 |

Installation on Bracket |

|

15 |

|

|

|

|

|

|

|

||||

2-10 |

Dimensions |

|

16 |

|

|

|

||||||||

2-11 |

Flush-Mount Installation |

|

17 |

|

|

|

|

|||||||

2-12 |

Disassembling from Bracket |

|

18 |

|

|

|

|

|||||||

2-13 |

Installing Cable on Transom |

|

19 |

|

|

|

|

|

||||||

2-14 |

Cable for Sidelooker Transducer |

|

20 |

|

|

|

|

|||||||

2-15 |

Cable for Speed and Temperature Sensor |

21 |

|

|

||||||||||

2-16 |

DC Power Connections |

|

22 |

|

|

|

||||||||

3-1 |

Display Panel |

|

25 |

|

|

|

|

|

|

|||||

3-2 |

Lamp/Contrast Menu |

|

28 |

|

|

|

|

|||||||

3-3 |

Operating Pages |

|

30 |

|

|

|||||||||

3-4 |

FishFinder Mode Page |

|

31 |

|

|

|

|

|

|

|||||

3-5 |

Fish Indications |

|

37 |

|

|

|||||||||

3-6 |

Bottom Conditions |

|

39 |

|

|

|

||||||||

3-7 |

Window Page |

|

40 |

|

|

|

|

|||||||

3-8 |

Options for Window Page |

|

41 |

|

|

|

|

|

|

|

||||

3-9 |

Sidelooker Feature |

|

42 |

|

|

|||||||||

3-10 |

Sidelooker Page |

|

43 |

|

|

|||||||||

3-11 |

Digital Page |

|

46 |

|

|

|||||||||

3-12 |

Performance Modes |

|

48 |

|

|

|

||||||||

3-13 |

Zoom Mode |

|

49 |

|

|

|

|

|||||||

3-14 |

A-Scope Mode |

|

51 |

|

|

|

|

|

||||||

3-15 |

Bottom Lock Mode |

|

53 |

|

|

|

|

|

|

|

||||

4-1 |

Setup Menu Items |

|

55 |

|

|

|||||||||

4-2 |

Range Menu Item |

|

56 |

|

||||||||||

4-3 |

Sensitivity Menu Item |

|

57 |

|

|

|

||||||||

4-4 |

Changing the Chart Speed Setting |

|

59 |

|

|

|

|

|

|

|

|

|

||

4-5 |

Chart Speed Menu Item |

|

60 |

|

|

|||||||||

4-6 |

Frequency Menu Item |

|

60 |

|

||||||||||

4-7 |

Log Reset Menu Item |

|

62 |

|

||||||||||

vii

4-8 |

Reaching the System Setup Menu |

63 |

|

|

|

|

|

4-9 |

System Setup Menu |

63 |

|

|

|

|

|

4-10 |

Zoom Select Menu Item |

70 |

|

|

|

|

|

4-11 |

Zoom Screen Split/Full Menu Item |

71 |

|

|

|

|

|

4-12 |

Bottom Lock Range Menu Item |

72 |

|

||||

4-13 |

Bottom Lock Split/Full Menu Item |

73 |

|

||||

4-14 |

Digital Setup Menu Item |

74 |

|

|

|||

4-15 |

Sidelooker Range Menu item |

76 |

|

|

|||

4-16 |

Sidelooker Sensitivity Menu Item |

77 |

|

|

|||

4-17 |

Sidelooker Chart Speed Menu Item |

77 |

|

|

|

||

4-18 |

Sidelooker View Menu Item |

78 |

|

|

|

||

4-19 |

Split FishFinder Page with A-Scope Mode |

79 |

|

|

|

|

|

4-20 |

Window Page with Option G Selected |

|

|

|

|

|

|

|

and Zoom Enabled |

80 |

|

|

|||

5-1 |

Sample Mailing Label |

88 |

|

|

|||

6-1 |

Connector Diagrams |

91 |

|

||||

viii

1 – Introduction

About the FishFinder 465

The FishFinder 465 is a system that uses sound waves (“sonar”) to detect fish and show the bottom of a lake or sea. The system includes a transducer and a display unit, connected by a cable. The transducer sends high-frequency sound waves down into the water. These sounds strike fish, the bottom, or other objects in the water, and return as echoes. The FishFinder then interprets these echoes and presents a display.

The FishFinder 465 can handle many different jobs:

•detect the presence of fish below the boat

•trigger an alarm when fish are found

•measure the depth of the water

•set alarms for minimum and maximum depth

•show the shape of the bottom

•determine whether the seabed is hard or soft

•measure the speed of the boat and the distance traveled

•show the water temperature

We are sure you will find the FishFinder 465 to be one of the most useful devices on your boat.

FishFinder 465

Display Unit

465

Optional Thru Hull

Transducer

Transducer mounted

in quick release Fig. 1-1 transom bracket

Typical Installation

Introduction |

1 |

System Components

The FishFinder 465 consists of a compact display unit connected to a transducer. The transducer is attached to the boat and extends into the water.

Standard Equipment

When you unpack your FishFinder 465, you should find the following standard equipment in the carton. If any items are missing, please notify your Apelco dealer immediately, or contact the Customer Service Department at Apelco at 1-800-539-5539, ext. 2120. Please provide the serial number of the FishFinder when reporting any missing items.

Description |

Part No. |

FishFinder 465 display unit |

M78954 |

|

|

Quick-release swivel-mount bracket |

|

(with mounting hardware) |

G623996-1 |

|

|

DC power cable |

M99-146 |

|

|

Instruction manual |

81146-1 |

|

|

Four #10 x 3/4” ss mounting screws |

— |

|

|

Standard Transducers

Depending on which model of the 465 you have purchased, the box will include one of the transducers listed below:

Description |

Part No. |

Transom-mount transducer (with speed |

|

and temperature sensors, including |

|

mounting bracket and hardware) |

M78898 |

|

|

Bronze thru-hull transducer (with |

|

speed and temperature sensors) |

M78923 |

|

|

Optional Accessories

Optional accessories and parts can be purchased directly from Apelco Marine. For prices and ordering information, please call the Parts Department at (800) 539-5539 ext. 2120.

2 Introduction

Description |

Part No. |

Sidelooker transom-mount transducer |

M78930 |

|

|

Sidelooker transducer for trolling motor |

|

(all-in-one unit senses depth below boat, |

|

with Sidelooker and temperature sensor, |

|

including mounting hardware) |

M78929 |

|

|

Extension for transducer cable (15 ft., 5 m) |

M99-140 |

|

|

Extension for transducer cable, |

|

for Sidelooker transducer (15 ft., 5 m) |

M99-139 |

|

|

Flush-mounting kit (with hardware and |

|

mounting template) |

M99-138 |

|

|

Fairing block for M78923 thru-hull |

|

transducer (Lexan®) |

M99-142 |

Low profile plastic thru-hull transducer |

|

(Valox® plastic, sensor for depth only) |

M78922 |

Bronze thru-hull transducer |

|

(sensor for depth only) |

M78921 |

|

|

In-hull/trolling motor transducer (for installation in |

|

fiberglass hull only, or mounting on trolling motor, |

|

including hardware for either installation) |

M78928 |

|

|

Angled in-hull transducer (for installation |

|

in fiberglass hull only, where deadrise |

|

angle is 10° to 22°) |

M78946 |

|

|

Plastic thru-hull transducer (Valox® plastic, with |

|

speed and temperature sensors, used with depth- |

|

only transducers M78922, M78928, M78946) |

M78937 |

|

|

Transom-mount speed and temperature |

|

sensor (used with depth-only transducers |

|

M78922, M78928, M78946) |

M78936 |

|

|

Replacement transom transducer |

|

mounting bracket kit |

M99-148 |

|

|

Transducer switch box (select between two 465 |

|

FishFinder displays, using one transducer) |

M99-136 |

|

|

Replacement paddle wheel kit (for transom- |

|

mount transducer) |

M99-143 |

|

|

Replacement paddle wheel kit |

|

(for thru-hull transducer) |

D234 |

|

|

Replacement paddle wheel kit |

|

(for bronze thru-hull transducer) |

D144 |

|

|

Introduction |

3 |

2 – Installation

The installation process has four parts:

•Mounting the transducer

•Mounting the display unit

•Connecting the cables for the transducer and power supply

•Calibrating the display unit

About the Transducer

Several different kinds of transducers can be used with this unit. The transom-mount type is used most often. Other types are shown in Fig. 2- 1.

Most transducer types can measure the water depth. Some of the transducers also have two other sensors: a paddle wheel which detects the speed of the boat, and a sensor for the water temperature. The display unit uses the speed information to calculate the distance the boat has traveled.

The transducer is very important to the operation of the FishFinder. It is also important that you mount the transducer correctly. The transducer will give the most reliable readings if it looks into water which is smooth and undisturbed. If you place the transducer so bubbles or turbulence flow across the face of the unit, the system may give inaccurate readings.

There are three important rules for placing any type of transducer:

•The transducer should be continuously covered by water when the boat is moving. (If the transducer is mounted near the side of the boat, it may be exposed when the boat is turning.)

•The transducer should be placed where turbulence or bubbles will not pass directly over the face of the unit. Don’t place the transducer behind any running strakes, intakes, or thru-hull fittings which create turbulence.

•The transducer should be mounted where it will not be affected by the wash from the propeller(s).

4 |

Installation |

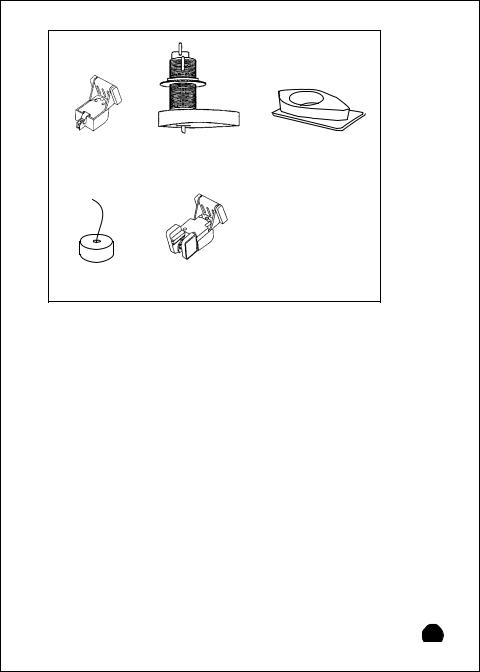

Transom-mount |

Thru-hull |

Fairing for |

transducer |

transducer |

thru-hull transducer |

In-hull |

Sidelooker |

Fig. 2-1 |

|

Transducer |

|||

transducer |

transducer |

||

Types |

|||

|

|

Selecting the Correct Type of Transducer

Before you begin the installation, double-check to be sure you have the correct type of transducer. Each kind of transducer is designed for a particular type of use. In this manual we will include detailed mounting instructions for the transom-mount transducer. We will also include some general information on the other types. For detailed information on these other transducers, see the instructions which are packaged with the unit.

Use a transom-mount transducer if –

your boat has an outboard or inboard-outboard engine(s) only. This type of transducer must be mounted ahead of or beside the propeller(s). Don’t use this type of transducer on a boat with a straight-shaft inboard engine.

Use a thru-hull transducer if –

your boat has a straight-shaft inboard engine. This type of transducer is installed in a hole drilled through the hull.

Use an in-hull transducer if –

you have a high-speed boat or if, for some reason, you cannot use a transom-mount or thru-hull transducer. The hull may be no more than 1" thick.

Installation |

5 |

Use a trolling motor transducer if –

you want to attach the transducer to a trolling motor.

Use a Sidelooker transducer if –

you need a way of searching for fish on either side of the boat. This type of transducer is attached to the bracket of the transom-mount transducer.

Assembling the Transducer Bracket

Fit together the two parts of the transducer bracket as shown in Fig. 2-2. When the installation is complete, the parts snap together as shown.

LIKE THIS! |

NOT THIS! |

Attach the |

Bracket is installed |

two parts |

upside down |

Lower the transducer and snap in the release clip

Fig. 2-2

Assembling

the Transducer

Bracket

Positioning the Transom-Mount Transducer

Begin by finding the best location for the mounting bracket. Here are the rules:

•If your boat has one propeller (outboard or inboard-outboard), mount the transducer about 18” (455 mm) to the side of the centerline of the boat. See Fig. 2-3. Choose the side that is on the downstroke of the propeller. (This is usually the starboard side of the boat.) This will reduce any interference caused by air bubbles.

•If your boat has twin propellers (outboard or inboard-outboard), place the transducer near the centerline of the boat.

•If the propeller can be turned to steer the boat, allow at least 2" (50

mm)beyond the swing radius of the propeller. This will prevent the

6 |

Installation |

Allow a clearance of at least 10 inches (254 mm)

10" (254 mm)

Fig. 2-3

Transducer

Mounted on

Transom

Transducer in released position

Fig. 2-4

Transducer

Bracket,

Side View

propeller from damaging the transducer when it is turned.

•Do not mount the transducer behind any hull fittings, intakes, or other parts which extend from the hull. These may cause turbulence or air bubbles.

•The bracket has a quick-release mechanism. This prevents damage by allowing the transducer to flip up if it hits any debris or the bottom. See Fig. 2-4. Allow enough clearance above the transducer so that it can swing upward completely. This is about 10" (254 mm) measured from the bottom of the transom.

Installation |

7 |

Average transom angle– |

Vertical transom – |

Sloping transom– |

no wedge necessary |

place wedge this way |

place wedge this way |

2°to 5° |

2°to 5° |

2°to 5° |

For fiberglass hull – 1/8" to 1/4" (3.2 to 6 mm)

For aluminum hull – 1/4" to 3/8" (6 to 9 mm)

No! |

No! |

No! |

The bow of the transducer |

Rivets on the hull are |

is above the bottom of the |

creating bubbles. |

transom, creating |

Lower the transducer |

cavitation. |

a bit. |

1 2 3

Insert screws 1 and 3 1/4" from the bottom of

slots, and screw 2 1/4" from the top of the

slot to allow room for

adjustment. Correct

adjustment. Correct

alignment

If screws are inserted this way, it won’t be possible to make the height adjustment.

Incorrect alignment

The rear of the transducer is too high, creating cavitation.

Fig. 2-5

Correct Mounting

Position

Fig. 2-6

Mounting

the Transducer

8 |

Installation |

•If the boat will be carried on a trailer, be sure the transducer will not hit any rollers, bunks or fittings on the trailer.

Mounting the Transom-Mount Transducer

1.On a boat with a fiberglass hull, the leading edge of the transducer should extend 1/8" (3.2 mm) to 1/4" (6 mm) below the bottom edge of the hull. See Fig. 2-5. On an aluminum hull, the transducer should extend a bit more – 1/4" (6 mm) to 3/8" (9 mm). If the boat will be operated at high speeds, the transducer may be mounted closer to the centerline of the hull.

2.The lower surface of the transducer should tilt down toward the rear at a slight angle (2° to 5°). The mounting bracket includes a wedge. Depending on the angle of the transom on your boat, you may need this wedge to get the correct angle for the bottom of the transducer.

3.Looking at the rear of the boat, be sure the bracket is vertical (perpendicular to the water line).

4.Hold the bracket (and the wedge, if used) against the transom and trace the positions of the screw slots.

5.Remove the bracket. See Fig. 2-6. The screws in the outer slots should be placed about 1/4" (6 mm) up from the bottom of each slot. The screw in the center slot should be placed 1/4” (6 mm) down from the top. (This will allow you to adjust the bracket up or down a bit.) Drill pilot holes 3/4" (19.1 mm) deep. Use a 9/64" (3.6 mm) drill bit. To prevent drilling too deeply, wrap masking tape around the drill bit about 7/8" (22 mm) from the tip. Drill in only as far as the tape marker.

If you are attaching the bracket to a fiberglass hull, you can minimize any surface cracking of the gel coat. Before drilling each pilot hole, drill a shallow hole (chamfer) at each location about 1/16" (1.5 mm) deep. Use a 1/4" (6 mm) drill bit.

6.Attach the bracket to the hull using the panhead screws with flat washers. Before you tighten the screws, apply a good-quality marine sealant to the pilot holes. This will protect the hull from water penetration. Do not tighten the screws completely yet.

7.Move the bracket up or down so that the leading edge of the transducer has the clearance shown in Fig. 2-5.

8.Once the bracket is in the correct position, you can tighten the screws.

Installation |

9 |

Mounting the Optional Sidelooker Transducer

1.The Sidelooker transducer allows the display unit to check the water to either side of the boat. This is helpful when you are looking for fish near river banks, or under docks or piers.

2.The Sidelooker transducer is attached to the same mounting bracket used with the transom-mount transducer. See Fig. 2-7. Begin by installing the transom-mount bracket as described earlier.

Fig. 2-7

Installing the

Sidelooker

Transducer

3.Attach the Sidelooker transducer to the top of the transom mounting bracket. Use the four panhead screws supplied. The fit should be snug, but do not overtighten the screws.

4.If you are installing the optional Sidelooker transducer, there will be two transducer cables. Run the second cable beside the cable for the transom-mount transducer.

Installation Notes – Thru-Hull Transducer

Detailed instructions for this installation will be included with the transducer. In this section, we will note just a few important points.

1.Earlier we listed three general rules for placing transducers. All of these rules apply when you are mounting a thru-hull transducer. Here are some other rules for selecting the best mounting location:

10 |

Installation |

For planing hulls – Install in the flat planing area near the stern. Always install forward of the propeller(s) and shaft(s).

For small displacement hulls – Install near the centerline of the hull and 1/3 of the way forward from the stern. Always install forward of the propeller(s) and shaft(s).

For large displacement hulls – Install near the centerline of the hull and 1/3 of the way aft from the bow. Always install forward of the propeller(s) and shaft(s).

For sailboats – Install forward of the leading edge of the keel, to one side and near the centerline of the hull.

2.Choose a location where you can easily reach the transducer from inside the boat. This will allow you to service the unit. Allow at least 6" (152 mm) of headroom above the transducer.

3.When choosing a mounting location, drill a small pilot hole (1/8" or 3.2 mm) from the inside of the hull. Before you drill the hole, be sure you will be able to reach the large nut on the top of the unit, and that there will be enough clearance for the cable. If there is a strake or other feature on the hull, drill from the outside of the hull instead. (This small hole can be filled easily if the mounting location is not suitable.)

4.The position of the transducer is especially critical on high speed boats (capable of more than 20 knots). Check the locations of the transducers on similar boats before installing the transducer in your own boat. Choose the location which will offer the best performance.

5.If the bottom of the hull at the mounting location is flat, you can mount the transducer directly through the hull. If the hull rises at an angle (the “deadrise angle”) of more than 10°, you must include a mounting block or “fairing.” The transducer must be mounted in a vertical position. Attach the fairing block to the hull as firmly as possible. This fairing block must be able to resist the drag of the water against the hull, and must also be completely waterproof.

6.If the hull of the boat has a core-type hull, you will need to follow special mounting procedures. The core material must be protected from any water which may leak from the inside of the boat. (If the core material is remains wet, it may rot and weaken the hull.)

7.When working with the transducer, support it by holding the body of the unit or the rings. Do not hang the transducer from the cable.

Installation |

11 |

8.It is very important to seal the opening around the transducer using a high-quality marine sealant suitable for underwater use. After installation, do not leave your boat in the water for any amount of time without checking for leaks.

Installation Notes – In-Hull Transducer

Detailed instructions for this installation will be included with the transducer. In this section, we will note just a few important points.

1.Choose the best mounting location:

For outboard powerboats – Install as far aft as possible

For inboard/outboard powerboats – Install close to the engine(s)

For inboard powerboats – Install forward of the propeller(s) and shaft(s)

For sailboats – Install near the centerline of the hull and forward of the leading edge of the keel

2.An in-hull transducer may only be installed in a fiberglass hull which is no more than 1" (25 mm) thick. The in-hull transducer may not be installed in wood or aluminum hulls.

3.Use the standard in-hull transducer if it will be installed in a flat part of the hull, or a section with no more than 10° of deadrise. Use the angled in-hull transducer if the mounting location has up to a 22° of deadrise.

4.Do not try to compensate for the angle of the hull by fairing the epoxy adhesive on the face of the transducer.

5.Use the epoxy supplied with the in-hull transducer, or an equivalent epoxy glue. Do not use any other type of adhesive, including silicone or RTV adhesive.

Installation Notes – Trolling Motor Transducer

Detailed instructions for this installation will be included with the transducer. This type of transducer is attached to the horizontal gear case of the trolling motor. The installation is simple, but is important to keep the transducer away from the wash from the propeller, and from turbulence caused by parts of the hull.

12 |

Installation |

Installation Notes – Transducer for Speed and Temperature Only

This type of transducer may be used with a thru-hull transducer which reads depth only. The speed/temperature transducer is attached to the transom of the boat. Detailed instructions for this installation will be included with the transducer. The cable for this transducer uses a “Y” connector. See the notes on “Installing the Transducer Cable.”

EMC Installation Guidelines

When different types of marine electronic equipment are mounted closely together in a tight space, they may interfere with each other. The design and manufacture of this unit follow industry standards for “Electromagnetic Compatibility” (EMC). However, it is important to install the unit correctly to ensure the best possible performance. Below is a list of some of the factors which could affect the operation of the product. Some of these factors may affect the way you install the FishFinder and the wiring cables.

•Place the display unit and the power and signal cables at least 3 ft. (1m) from any equipment transmitting radio signals, or any cables carrying radio signals. This includes VHF radios, cables and antennas. In the case of SSB radios, the distance should be increased to 7 ft. (2m).

•Allow a space of at least 7 ft. (2m) from the path of a radar beam. Normally, a radar beam will spread about 20° above and below the radiating element.

•The power for the display unit should be supplied from a different battery than the one used to start the engine. If the voltage to the

FishFinder unit drops below +10.8 V DC, this could cause the unit to reset. This will not damage the equipment, but it may cause the loss of some information, and it can change the operating mode.

Avoid running the FishFinder power wires near the power wiring for any radar, radio, or Loran-C units. If possible, wire the FishFinder power wires to a separate circuit breaker.

•If the transducer cable runs near another electrical wire, it may pick up electrical interference or “noise.” To reduce this, try to keep the transducer cable separated as far as possible from all other wires.

Installation |

13 |

This is especially important with wiring for the boat’s ignition, alternator, or tachometer. It is also helpful to keep the transducer cable away from the FishFinder power cable. If it is necessary to run the transducer cable across any wires, make the crossing at a right angle.

•Use only genuine Raytheon cables. During the installation, do not cut the transducer cable or remove the connector. Do not try to shorten or splice the cable. The transducer cable includes several wires, along with shielding and insulation. If the cable is cut, it cannot be repaired. (Cutting the cable will also void the warranty.) During installation, if you need to drill any holes for the cable, they must be large enough to accept the connector. This will allow you to make the installation without cutting the wire.

•A “suppression ferrite” may be attached to one of the cables. See Fig. 2-8. If you must remove the ferrite during installation, be sure to reassemble it in the same position.

Fig. 2-8 |

Suppression |

Ferrites |

14 |

Installation |

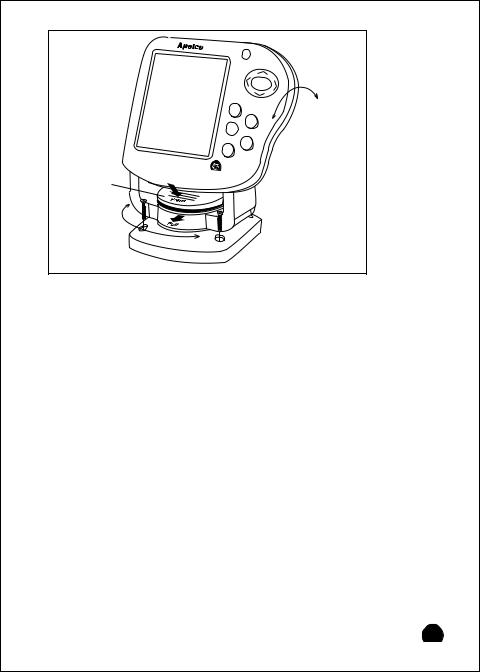

To release the display from the base, press here.

The display can be turned from side to side.

PWR

SETUP

CLEAR ZOOM

A-SCP BOT LOCK

The angle of the display

can be changed.

Fig. 2-9

Installation on Bracket

Mounting the Display Unit – Standard Mount

You may mount the display unit on any flat surface using the bracket supplied. See Fig. 2-9. (There is also an optional kit which allows you to flush-mount the display in a flat panel or dashboard). Follow these instructions if you are using the standard mounting bracket:

1.The “LCD” type display used on this unit is easier to see from certain angles. Before selecting a permanent mounting location, make temporary power connections and turn on the unit. This will allow you to test the visibility of the display from several different angles.

2.Remove the display unit from the bracket by pressing on the large button in the center of the bracket. See Fig. 2-9.

3.Mount the base of the bracket using the supplied screws.

4.Slide the display unit back into the bracket.

5.Adjust the display unit for the best viewing angle. You can turn the display from side to side, and tilt it up or down.

Installation |

15 |

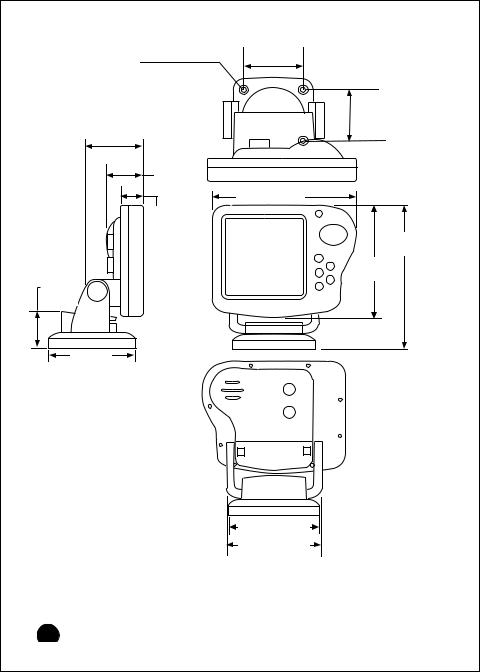

Hole 3/16" (5 mm) |

2-25/32" |

(70 mm) |

|

|

2-21/32" |

2-27/32" |

(67 mm) |

|

|

(72 mm) |

|

1-3/4" |

|

(45 mm) |

6-5/8" (169 mm) |

|

|

1-15/32" |

|

(37 mm) |

8-1/4" |

|

|

|

(210 mm) |

|

5-13/16" |

|

(147 mm) |

1-3/4" |

|

(44 mm) |

|

4-9/32" |

|

(109 mm) |

|

|

3-29/32"(99 mm) |

|

4-7/32"(107 mm) |

|

Fig. 2-10 |

|

Dimensions |

16 |

Installation |

Mounting the Display Unit – Flush Mount

In order to do this installation, you will need the optional flush mounting kit (part no. M99-138). See Fig. 2-11.

1.Select a mounting location on the dashboard or control panel. Choose a clear, flat area at least 7" x 7" (180 mm x 180 mm). Be sure you will also have at least 6" (152 mm) of clearance behind the area where the display unit will be mounted. It is a good idea to drill a small pilot hole in the center of the mounting area. Be sure there are no hidden electrical wires or other items behind the point where you plan to mount the display unit.

2.A mounting template is supplied with the flush mounting kit. Tape this over the selected location on the panel and trace around the edges.

3.Make the cutout for the display. Drill a series of 1/2" (13 mm) holes at the points shown around the edges of the cutout area.

4.Drill the two small holes for the threaded studs as shown on the mounting template. Use a 7/32" (5.5 mm) drill bit.

5.Remove the template and draw straight lines between the 1/2" holes. Cut along each of the lines with a small saw.

Gasket

Mounting hole cut according to template

Screw holes

Fasten with threaded studs and wing nuts

Fig. 2-11

Flush-mount

Installation

Installation |

17 |

6.Separate the display unit from the mounting bracket. (See Fig. 2-12.) Press the large button in the center of the bracket to separate the bracket arms. The display unit is attached to the arms by two screws. Each screw is covered by a cap. Locate the small slot beside each cap and pry upward using a small screwdriver. Remove the caps, then the two screws and the two wave washers. Save these parts in case you ever want to use the mounting bracket.

PWR

SETUP

CLEAR

ZOOM

A-SCP

BOT

LOCK

465

To pry up the cap, insert a small screwdriver here.

Fig. 2-12

Disassembling from Bracket

7.Screw the threaded studs into the holes on the rear of the display unit.

8.Set the display unit into place to be sure that it will fit correctly. Thread the wing-nuts onto the threaded studs to hold the display unit in place temporarily.

9.Once the DC wiring is complete, finish the installation. Hold the gasket in place around the opening. Fit the display into the cutout again. From the rear, screw the thumbscrews securely onto the threaded studs to hold the unit in place.

Installing the Transducer Cable

A 20 foot length of cable, with the connector attached, is supplied with the transducer.

18 |

Installation |

Cable feed-thru cap

Cable clamp

1" (25 mm)

Hull projections

Fiberglass: 1/4" (6mm)

Aluminum: 1/2" (13 mm)

Fig. 2-13

Installing Cable on Transom

1.Route the cable up and over the top edge of the transom. See Fig. 2-13. Secure the cable using cable clamps. (These clamps are available from your local marine equipment supplier.)

If you do not want to expose the cable on the deck, you may drill a new hole (3/4" or 19 mm) through the transom for the cable. (Remember–this hole must be large enough to accept the cable with the connector attached. Do not cut the cable!) To seal the opening, use a feed-thru cap where the cable passes through the transom.

2.Run the cable through the interior of the boat. If the transducer cable runs near another electrical wire, it may pick up electrical interference or “noise.” To reduce this, try to keep the transducer cable separated as far as possible from all other wires. This is especially important with wiring for the boat’s ignition, alternator, or tachometer. Also try to keep the transducer cable away from the antenna and power cables for VHF or FM radios. It is also helpful to keep the transducer cable away from the FishFinder power cable. If it is necessary to run the transducer cable across any wires, make the crossing at a right angle.

3.Be careful not to tear the cable jacket when passing it through bulkheads and other parts of your boat. Secure the cables using tywraps or lacing twine. Coil the extra cable and tie it out of the way.

4.If the 20 foot transducer cable is not long enough, a 15 foot extension cable (5M) is available from your Apelco dealer (PN: M99-140).

Installation |

19 |

Loading...

Loading...