Philips DigitalDiagnost User manual

12.18.07

Philips Medical Systems

www.medical.philips.com/us

Note for Architects and/or Contractors: "If revisions are listed, these drawings must be thoroughly reviewed so that all changes can be incorporated into your project"

Rev.

Level

Date Revision Descriptions By

Revisions

Table of Contents

Section A - Equipment Plan

General Notes -------------------------------------- AN

Equipment Plan ------------------------------------- A1

Equipment Details ----------------------- AD1 - AD2

Transport Details --------------------------------- AD3

Section S - Support Plan

Support Notes --------------------------------------- SN

Support Plan - Floor and Wall ------------------- S1

Support Plan - Ceiling------------------------------ S2

Support Details --------------------------- SD1 - SD2

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Quote Number O.A. Number

Drawn By

Section E - Electrical Plan

Electrical Notes ------------------------------------ EN

Electrical Plan -------------------------------- E1 - E2

Electrical Details --------------------------------- ED1

Section N - Network Plan

Network Diagram ---------------------------------- N1

Check List ----------------------------------------- CHK

N-SRD040005

Project Number

C1

Sheet 1 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

HVAC Requirement for General Equipment Locations

Heating, ventilation, air conditioning requirement for general equipment locations must

maintain temperature at 75° +/- 11° fahrenheit (24° +/- 6° celsius) and non-condensing

relative humidity at 47%, +/- 28%.

Electrical Requirements

Optimus 65/80/C

Supply Configuration: 3 phase, 3 wire power and ground. Delta or wye

Nominal Line Voltage: 400, 440, 460 or 480 VAC, 60 Hz

Branch Power Requirement: 150 KVA

Circuit Breaker: 3 pole, 100 Amps (@ 480V)

(03.0)

(06.0)

Minimum Site Preparation Requirements

A smooth efficient installation is vital to Philips and its' customers. Understanding what the

minimum site preparation requirements are will help achieve this goal. The following list clearly

defines the requirements which must be fulfilled before the installation can begin.

1. Walls to be painted or covered, baseboards installed, floors to be tiled and/or covered,

ceiling shall have grid tiles and lighting fixtures installed.

2. Doors and windows, especially radiation protection barriers, installed and finished with

locksets operational.

3. All electrical convenience, conduit, raceway and junction boxes installed.

4. Incoming mains power operational and connected to room x-ray breaker.

5. 115v convenience outlets operational.

6. All support structures correctly installed. All channels, pipes, beams and/or other supporting

devices should be level, parallel, and free of lateral or longitudinal movements.

7. All contractor supplied cables pulled and terminated.

8. A dust-free environment in and around the procedure room.

9. All HVAC (heating, ventilating and air conditioning) installed and operational as per

specifications.

10. Architectural features such as computer floor, wood floor, casework, bulkheads, installed

and finished. When technical cabinets are installed in a closet with doors, it is suggested that

the customer install a temperature alarm in the event of an air conditioning failure.

11. All plumbing installed and finished.

12. Philips does not install or connect developing tanks, automatic processors or associated

equipment, built in illuminators, cassette pass boxes, loading benches and cabinets, lead

protective screens, panels or lead glass window and frame. This is to be done by the

customer/contractor.

13. Clear door openings for moving equipment into the building must be 42" (1067mm) w x 82"

(2083mm) h min. 48" (1219mm) w x 82" (2083mm) h rec., or larger contingent on an 8'-0"

(2438mm) corridor width.

Note

Once Philips has moved equipment into the suite and started the installation, the contractor

shall schedule his work around the Philips installation team on site. It is suggested that a

telephone be provided in the room to receive telephone calls. This would alleviate facility staff

from answering calls for Philips personnel.

Remote Service Diagnostics

Medical imaging equipment to be installed by Philips Medical is equipped with a service

diagnostic feature which allows for remote and on site service diagnostics. To establish this

feature, a dedicated direct-distance - dialing, voice-grade line must be installed as shown on

plan. All costs with this feature are the responsibility of the customer.

(00.1)

General Specifications

1. Responsibility

The customer shall be solely responsible, at its expense for preparation of site, including any

required structural alterations. The site preparation shall be in accordance with plans and

specifications provided by Philips. Compliance with all safety, electrical, and building codes

relevant to the equipment and its installation is the customer's responsibility. Sufficiency of

such plans and specifications, specifically including, but not limited to the accuracy of the

dimensions described therein, shall be the sole responsibility of customer. The customer shall

advise Philips of conditions at or near the site which could adversely affect the carrying out of

the installation work and shall ensure that such conditions are corrected and that the site is fully

prepared and available to Philips before the installation work is due to begin. The customer

shall provide all necessary plumbing, carpentry work, or conduit wiring required to attach and

install products ready for use.

2. Permits

Customer shall obtain all permits and licenses required by federal, state/provincial or local

authorities in connection with the construction, installation and operation of the products and

shall bear any expense in obtaining same or in complying with any related rules, regulations,

ordinances and statutes.

3. Radiation Protection

The customer or his contractor, at his own expense, shall obtain the service of a licensed

radiation physicist to specify radiation protection. For the purpose of the radiation protection

design for the suite, the physicist should assume a maximum kVp x-ray tube output of 150.

4. Asbestos and Other Toxic Substances

Philips assumes no hazardous waste (i.e., pcb's in existing transformers) exists at the site. If

any hazardous materials are found, it shall be the sole responsibility of the customer to properly

remove and dispose of this material at its expense. Any delays caused in the project for this

special handling shall result in Philips time period for completion being extended by like period

of time. Philips assumes that no asbestos material is involved in this project in any ceilings,

walls or floors. If any asbestos material is found anywhere on the site, it shall be the

customer's sole responsibility to properly remove and/or make safe this condition, at the

customer's sole expense.

5. Labor

In the event local labor conditions make it impossible or undesirable to use Philips' regular

employees for such installation and connection, such work shall be performed by laborers

supplied by the customer, or by an independent contractor chosen by the customer at the

customer's expense, and in such case, Philips agrees to furnish adequate engineering

supervision for proper completion of the installation.

6. Schedule

The general contractor should provide Philips with a schedule of work to assist in the

coordination of delivery of Philips supplied products which are to be installed by the contractor

and delivery of the primary equipment.

7. Extended Installation or Turnkey Work by Philips.

Any room preparation requirements for Philips equipment indicated on these drawings is the

responsibility of the customer. If an extended installation or turnkey contract exists between

Philips and the customer for room preparation, then additional work required for the equipment

will not be represented on these drawings. Some of the responsibilities of the customer as

depicted in these drawings may be assumed by Philips. In the event of a conflict between the

work described in the turnkey contract workscope and these drawings, the turnkey contract

workscope shall govern.

(00.0)

12.18.07

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

AN

Sheet 2 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

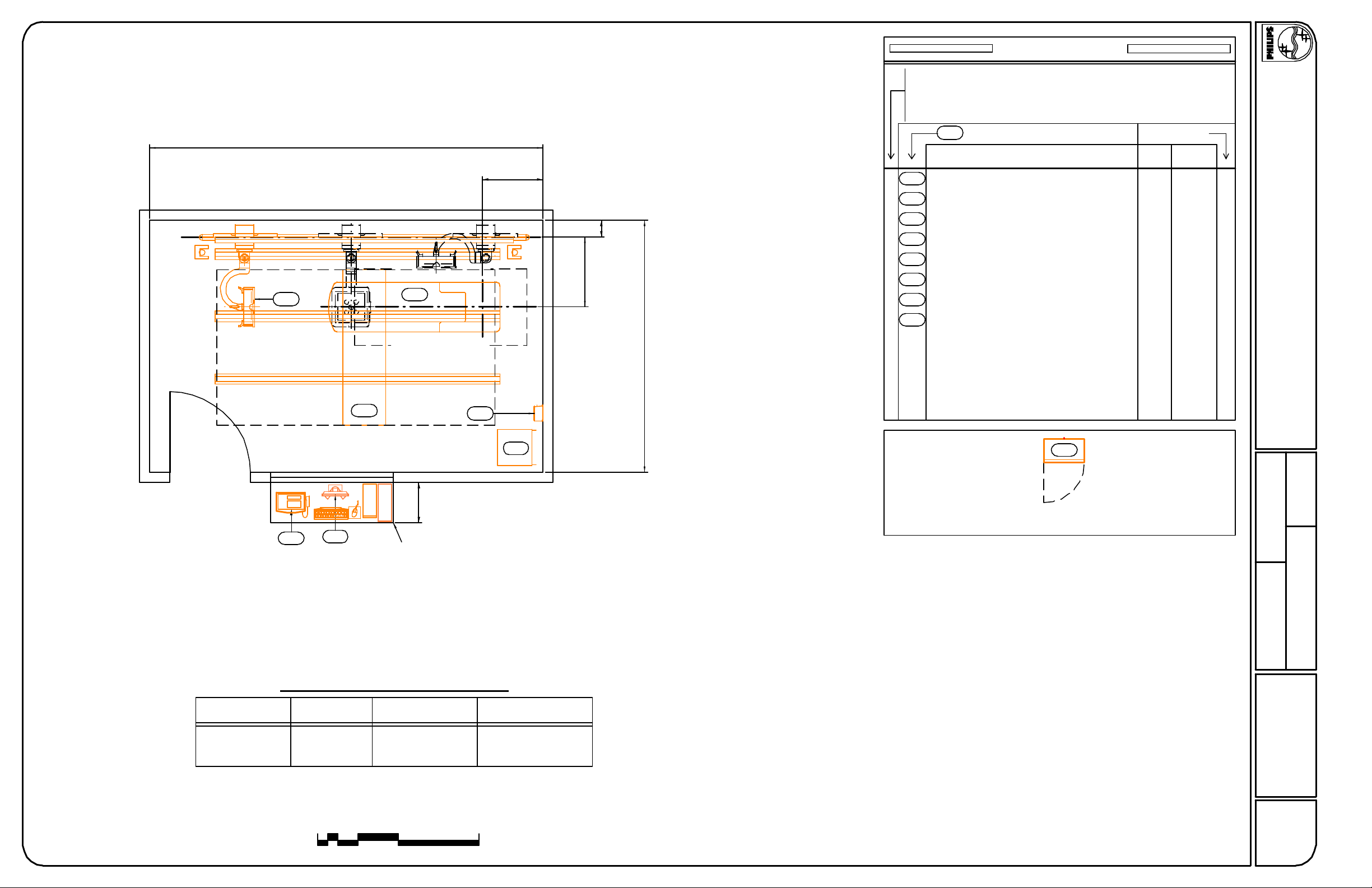

19'-6"

Table Floorplate Centerline

3'-0"

Equipment Legend

A

Furnished and installed by Philips

B

Furnished by customer/contractor and installed by customer/contractor

C

Installed by customer/contractor

Furnished by Philips and installed by contractor

D

E

Existing

F

Future

G

Option

Equipment Designation

Description

A

Detail Sheet

Weight

Heat Load

(btu/hr)(lbs)

1707462Optimus 80 Control Cabinet (40E Rack)ME

12.18.07

AD1

4' Wide Patient Entry

(Recommended)

DVM

PBC

DDW

MU

MS

2'-0"

Counter provided and

installed by customer

SCU

ME

10"

Floor Rail

Centerline

3'-5 1/2"

Table Longitudinal Centerline

12'-6"

A

A

A

A

A

A

A

MSC

Final location to be coordinated with the customer and architect of record.

AD1

1379Optimus Control PanelPBC

AD1

1297810CS 2 Tube Crane w/ Cable Carrier RailMU

AD1

060Manual Storage CabinetMSC

AD1

11914Segment Control UnitSCU

AD2

444753Digital Diagnost VM (Left)DVM

AD2

2083176Digital Diagnost WorkstationDDW

AD2

341472Single Sided Table TH-SMS

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Equipment Layout

Wall Stand Tube Position

Digital

Diagnost VM

Reported Existing Ceiling Height : None

Ceiling heights (from finished floor to bottom of Unistrut) other than

recommended may impact equipment functionality; consult with Philips.

0 8'1'

Minimum/Preferred

Ceiling Height

2'

4'

9' - 10 1/8" (3000mm)8' - 8 3/8" (2650mm)Upper Position

11' - 1 3/4" (3400mm)9' - 11 3/4" (3040mm)Lower Position

Maximum

Ceiling Height

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

A1

Sheet 3 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

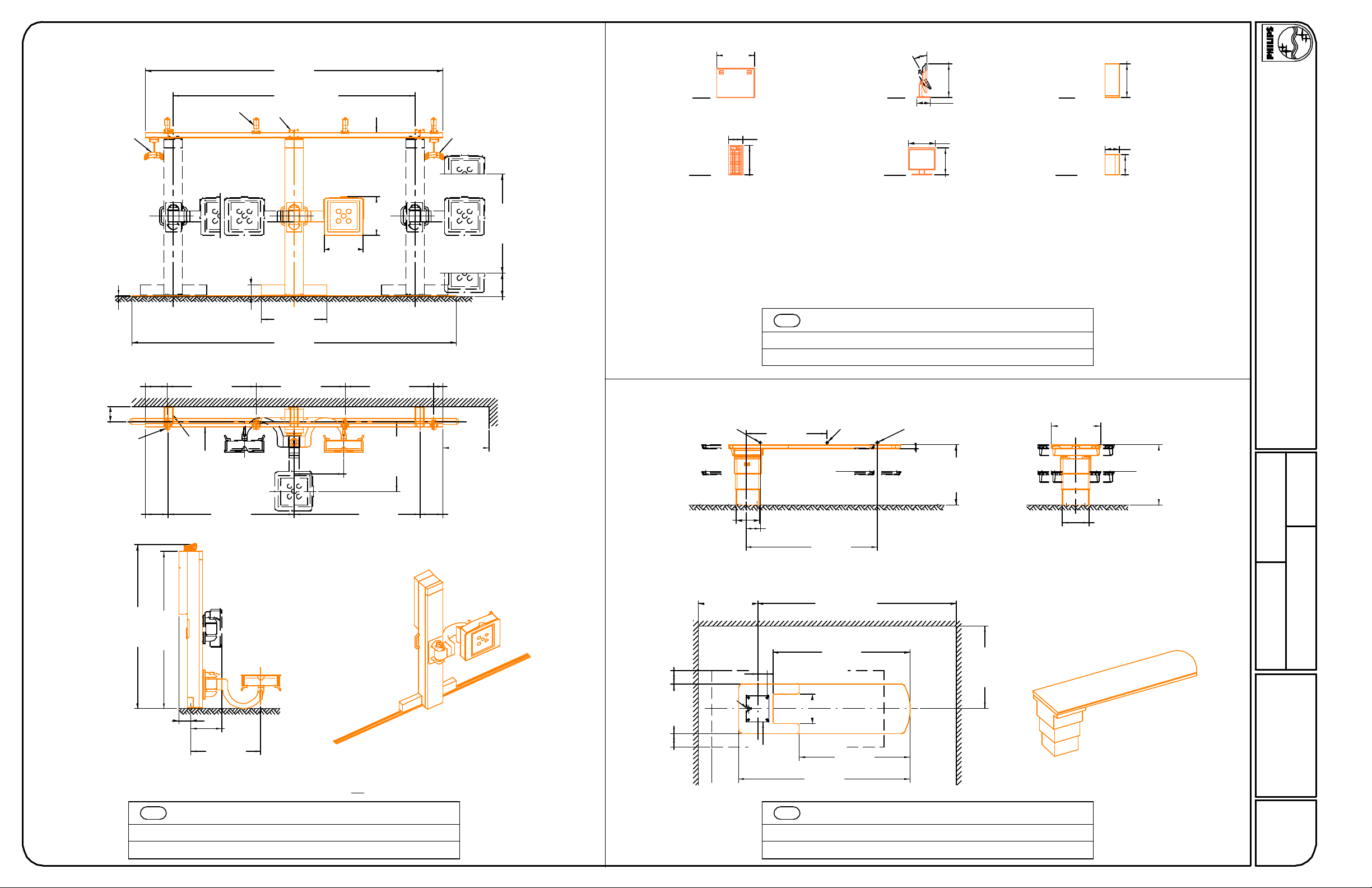

Optional Wall Mounting Bracket

12.18.07

max.

107.47"

2730mm

25.59"

650mm

8.27"

210mm

min.

49.22"

1250mm

90°

90°

Option:

Tomo

Option:

Tomo

92.13"

9.57"

243mm

max.

2340mm

33.86"

min.

860mm

14.96"

380mm

92.76"

2356mm

34.41"

874mm

Option:

Tomo

57.87"

1470mm

9.49"

241mm

*

Option:

Tomo

25.59"

36.00"

914mm

9.49"

241mm

650mm

Option:

Rail for

Cable Carrier

4.49"

114mm

3.07"

78mm

6.00"

152mm

PBC

Weight

Heat Dissipation

15.75"

400mm

16.93"

430mm

Optimus Control Panel

9 lbs (4 kg)

137 Btu/hr (35 kcal/hr)

11.03"

13.19"

335mm

280mm

.79"

20mm

(07.0)

24.02"

610mm

30.00"

762mm

Max. weight of cabinet with manuals = 260 lbs. (118 kg)

MSC

Weight

Heat Dissipation

Manual Storage Cabinet

14.02"

356mm

60 lbs (27 kg)

0 Btu/hr ( 0 kcal/hr)

2.56"

65mm

(03.0)

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

8x45º

11.81"

300mm

Option:

Tomo

Supporting Arm UpSupporting Arm Down

* Column movement range = 1260mm (49.61");

standard range of 1470mm reduced by 210mm

(8.28") to allow optional cable carrier to be

mounted on transverse carriage.

* Optional cable carrier can be mounted on

longitudinal rail, causing 210mm (8.28") of

tube crane coverage loss (foot or head-end).

MU

Weight

Heat Dissipation

* Extension Rails are an additional 113lbs (51kg).

CS 2 Tube Crane

8x45º

Longitudinal

Rail

(368 kg)810 lbs

(326 kcal/hr)1297 Btu/hr

Transverse

Carriage

Option:

Cable Carrier

(07.1)

5.47"

139mm

8.94"

227mm

Cable

Openings

SCU

Weight

Heat Dissipation

21.06"

535mm

1.97"

50mm

42.50"

1080mm

±

Segment Control Unit

14 lbs (6 kg)

119 Btu/hr (30 kcal/hr)

(07.0)

2.76"

70mm

Clear Area

Around Cabinet

ME

Weight

Heat Dissipation

20.48"

520mm

21.66"

550mm

Optimus 50/65/80 Control Cabinet

2.76"

70mm

7.88"

200mm

76.98"

1955mm

462 lbs (210 kg)

1707 Btu/hr (430 kcal/hr)

Filler Panel

(07.0)

Date

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

AD1

Sheet 4 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

22.44"

177.17"

4500mm

143.70"

A

3650mm

B

max.

guide rail

570mm

Side

Side

30°

max

19.92"

506mm

8.07"

205mm

Top

20.32"

516mm

12.18.07

cable carrier

for CS 2/4

.63"

13.27"

337mm

min.

max.

9.06"

230mm

13.38"

340mm

13.78"

350mm

16mm

A

52.83"

1342mm

B

guide rail

74.80"

1900mm

User side left User side right (default)

22.64"

575mm

23.46"

596mm

6.89"

175mm

39.37"

1000mm

192.91"

4900mm

52.83"

1342mm

52.83"

1342mm

29.53"

750mm

74.80"

1900mm

41.54"

1055mm

cable carrier

for wall stand

min.

5.39"

137mm

27.56"

700mm

13.78"

350mm

59.06"

1500mm

13.78"

350mm

Required for insertion

of column

8.07"

205mm

Front

17.52"

445mm

CPU (Sun Ultra 25)

Weight: 60 lbs (27 kg)

Heat Dissipation: 1707 btu/hr (430 kCal/hr)

DDW

Weight

Heat Dissipation

center of gravity

table

13.80"

350mm

48.31"

1227mm

8.66"

220mm

center of gravity

table & patient

78.27"

1988mm

15.91"

404mm

Front

15.98"

406mm

19 " LCD Color Monitor

Weight: 16 lbs (8 kg)

Heat Dissipation: 171 btu/hr (43 kCal/hr)

Digital Diagnost Workstation

center of gravity

patient

2.13"

54mm

max.

min.

20.08"

510mm

35.83"

910mm

8.31"

211mm

Front

12.01"

305mm

UPS

Weight: 100 lbs (46 kg)

Heat Dissipation: 205 btu/hr (93 kCal/hr)

(07.0)

(81 kg)176 lbs

(566 kCal/hr)2083 Btu/hr

29.53"

750mm

35.83"

910mm

max.

20.08"

510mm

15.87"

403mm

min.

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

97.64"

2480mm

93.70"

2380mm

7.22"

183mm

Guide rail to be supported using ceiling holders (A) OR wall holders (B)

DVM

Weight

Heat Dissipation

18.10"

460mm

41.54"

1055mm

Digital Diagnost VM

(342 kg)753 lbs

(112 kcal/hr)444 Btu/hr

(06.0)

wall clearance required for

installation and service of table base

7.87"

200mm

29.53"

750mm

7.87"

200mm

min.

cable

outlet

15.75"

400mm

35.43"

900mm

5.55"

141mm

floor plate

Weight

Heat Dissipation

wall clearance required for insertion of tabletop

118.11"

min.

3000mm

81.89"

2080mm

17.72"

450mm

66.14"

1680mm

102.36"

2600mm

MS

Single Sided Table TH-S

472 lbs (214 kg)

341 Btu/hr (86 kcal/hr)

49.21"

1250mm

wall clearance required for

installation and service of table base

(06.0

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

AD2

Sheet 5 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

4'-8.30"

1430mm

2'-11.43"

900mm

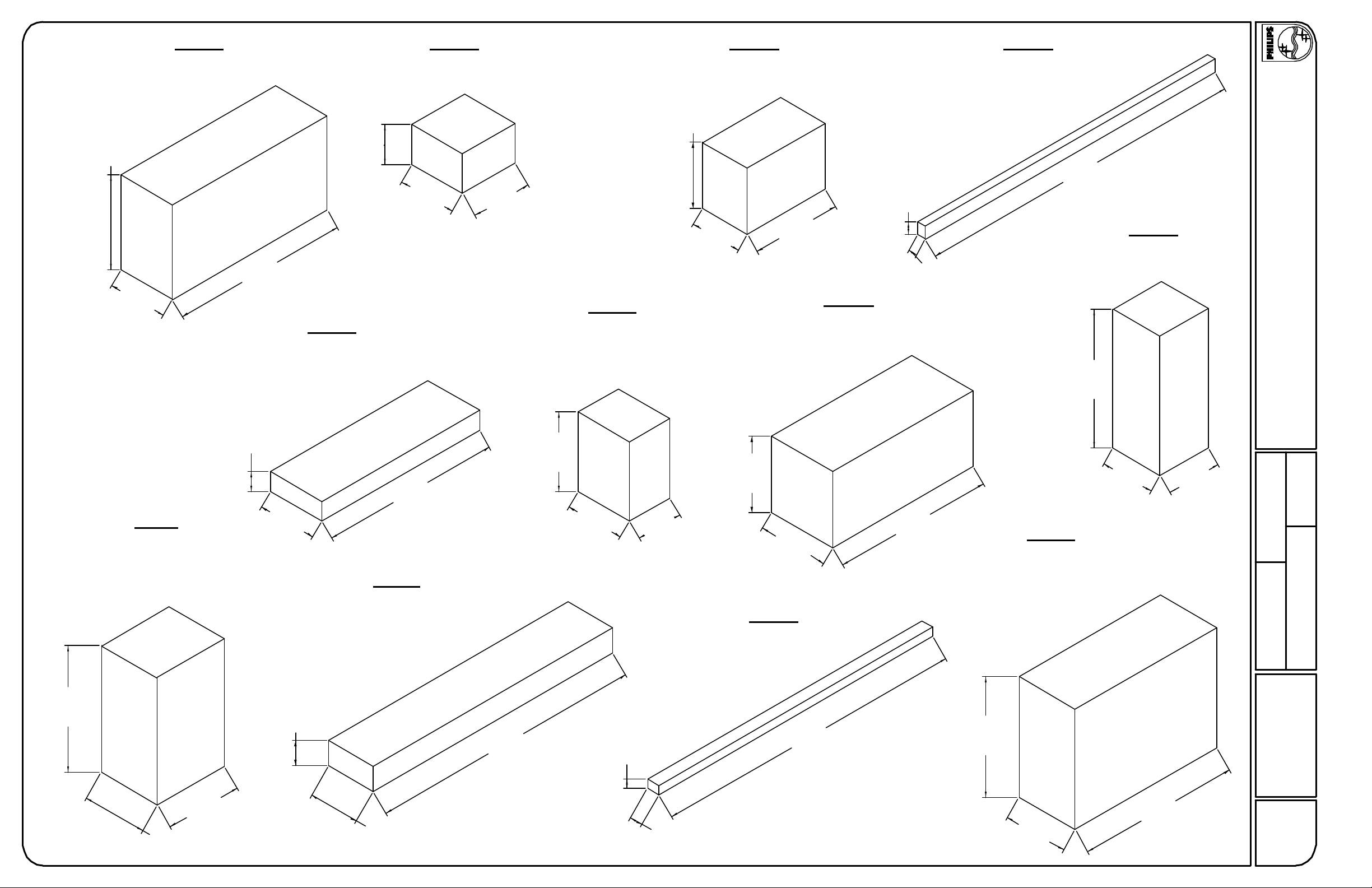

Crate A

Moveable Column

Weight: 629 lbs.

8'-10.30"

2700mm

1'-11.62"

600mm

Crate E

Single Sided Table TH-S

Table Top

Weight: 270 lbs.

Crate B

Flat Detector

Weight: 99 lbs.

2'-10.65"

880mm

3'-.22"

920mm

Digital Bucky Unit with Swivelling Arm

Crate F

Single Sided Table TH-S

Table Base

Weight: 450 lbs.

Crate C

Weight: 281 lbs.

3'-3.37"

1000mm

2'-6.71"

780mm

7.87"

200mm

4'-5.54"

1360mm

5.12"

130mm

Crate G

Single Sided Trolley TF-M

Weight: 584 lbs.

Crate D

Floor Rail and Guide Rail

Weight: 135 lbs.

16'-6.82"

5050mm

Generator Cabinet

6'-10.68"

12.18.07

Crate H

Weight: 508 lbs.

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

2100mm

Crate I

CS4 Transverse Carriage

Weight: 562 lbs.

Tomography (option)

Additional Weight: 67 lbs.

6'-3.59"

1920mm

11.81"

300mm

2'-11.43"

900mm

9'-.27"

2750mm

Crate J

CS4 Longitudinal Carriage

Weight: 429 lbs.

1'-2.97"

380mm

13'-8.56"

4180mm

3'-11.24"

1200mm

2'-11.43"

900mm

5.50"

140mm

2'-3.56"

700mm

3'-9.28"

1150mm

3'-6.13"

1070mm

Crate K

CS Base Rails 4.3 m

Weight: 198 lbs.

15'-8.19"

4780mm

8'-.46"

2450mm

2'-8.28"

820mm

Crate L

CS2 Complete

Weight: 931 lbs.

Tomography (option)

Additional Weight: 67 lbs.

5'-11.65"

1820mm

2'-9.07"

840mm

Date

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

3'-2.58"

980mm

3'-10.06"

1170mm

2'-6.72"

780mm

7.88"

200mm

3'-2.59"

980mm

8'-1.25"

2470mm

(06.0)

AD3

Sheet 6 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Loading...

Loading...