Omega Products PX540 Installation Manual

®

PX540 Series

Pressure Transducers

Operator’s Manual: M1137/0698

General Description

The OMEGA® PX540 Pressure Transducer consists of a pressure connection section with welded stainless steel diaphragm and a case for housing the electronic equipment and the electrical connection. The piezoresistive pressure sensor is installed behind the diaphragm, with the intervening space filled with silicone oil as pressure transmission liquid.

The pressure sensor’s signal is converted by an amplifier to a signal of 4 to 20 mA. The pressure connection DIN 3852 is used as a seal behind threads by means of the added NBR O-ring. (No flush-mounted seal).

Characteristics of this transducer include:

•4 to 20 mA current output which is ideal for long distance signal transmitting and industrial environments.

•High accuracy and repeatability.

•Corrosion resistant, and

•Rugged NEMA=12 dust-tight/drip-tight enclosure.

How To Adjust Zero and Span

NOTE:

Unit has been factory calibrated. No adjustment is required upon delivery from OMEGA Engineering.

Zero adjustment must be performed at no pressure and the output reading must be 4 mA.

Span adjustment must be performed at full scale pressure and the output reading must be 20 mA.

If you do not get either of these readings at the required no pressure or full scale pressure, go through the following procedure to get to the screws.

Remove the connector from the body of the transmitter as described in steps 1 and 2 in the Wiring Section.

Adjust the zero screw so the output reading is 4 mA at no pressure. At full scale pressure, the output must be 20 mA; if it is not, adjust the span screw.

The Zero screw is marked with a white dot. The span screw is marked with a red dot. Refer to Figure 1.

Figure 1.

Location of Adjustment

Screws

Wiring

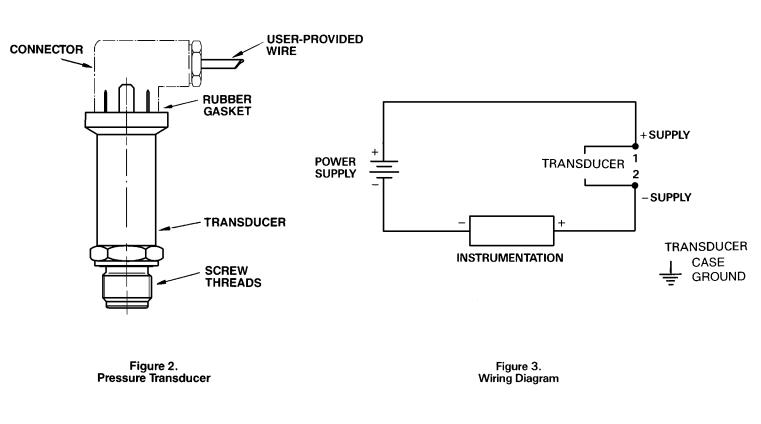

To access the screw terminals and wire the transducer, refer to Figure 2, and the following procedure.

1.Locate the screw at the top of the transducer and unscrew.

2.Separate connector from the rest of the transducer body. Remove the screw and rubber gasket from the connector and set aside.

3.Using a small blade screwdriver, insert it in the corner slot and pry off square cover (and terminals).

4.Insert cable into hole (not screw hole) and feed through into square part of assembly. Wire terminals in terminal block using wiring diagram (refer to Figure 3).

5.Replace terminal block and snap in place.

6.Put rubber gasket on unit.

7.Connect larger part of transducer to wired unit observing positions of blades.

8.Insert screw in screw hole and tighten two parts to each other.

Figure 2. |

|

Figure 3. |

Pressure Transducer |

|

Wiring Diagram |

|

|

|

Loading...

Loading...