Page 1

Model 286.31 Transient Permeability

Pore Pressure Intensifier

Product Information

l

015-018-201 C

Page 2

Copyright information © 2007 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation.

Contact information MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255 (within the U.S. or Canada)

Phone: 952-937-4000 (outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

Publication information

Manual Part Number Publication Date

015-018-201 B

015-018-201 C

July 1992

August 2007

Page 3

Contents

Introduction 5

Major Components 6

Control Panel Valves 7

Specifications 9

How the Pressure Intensifier Works 10

The Area Ratio 11

Operation 13

Operating the Control Panel Valves 15

Purging and Filling the Fluid Lines 16

Fill the Fluid Reservoir 17

Purge and Fill the Pressure Intensifier 20

Pressurize the Intensifier 22

Purge and Fill the Lower Pore Line 24

Purge and Fill the Reference Volume 1 Lines 26

Purge and Fill the Balance and Upper Pore Lines 29

Purge and Fill the Reference Volume 2 Lines 32

Purge and Fill the Low Pressure Reservoir Line 35

Purge and Fill the Reservoir Return Line 38

Refill the Pressure Intensifier 41

Running a Steady State Flow Test 44

Fill the Pressure Intensifier 45

Purge and Fill the Pore Pressure Lines 49

Refill the Pressure Intensifier 53

Prepare to Run a Test 56

End the Test 58

Running a Transient Permeability Flow Test 59

Fill the Pressure Intensifier 60

Purge and Fill the Pore Pressure Lines 63

Refill the Pressure Intensifier 67

\Prepare to Run the Test 70

End the Test 77

Maintenance 81

286.31 Transient Permeability Pore Pressure Intensifier

3

Page 4

4

286.31 Transient Permeability Pore Pressure Intensifier

Page 5

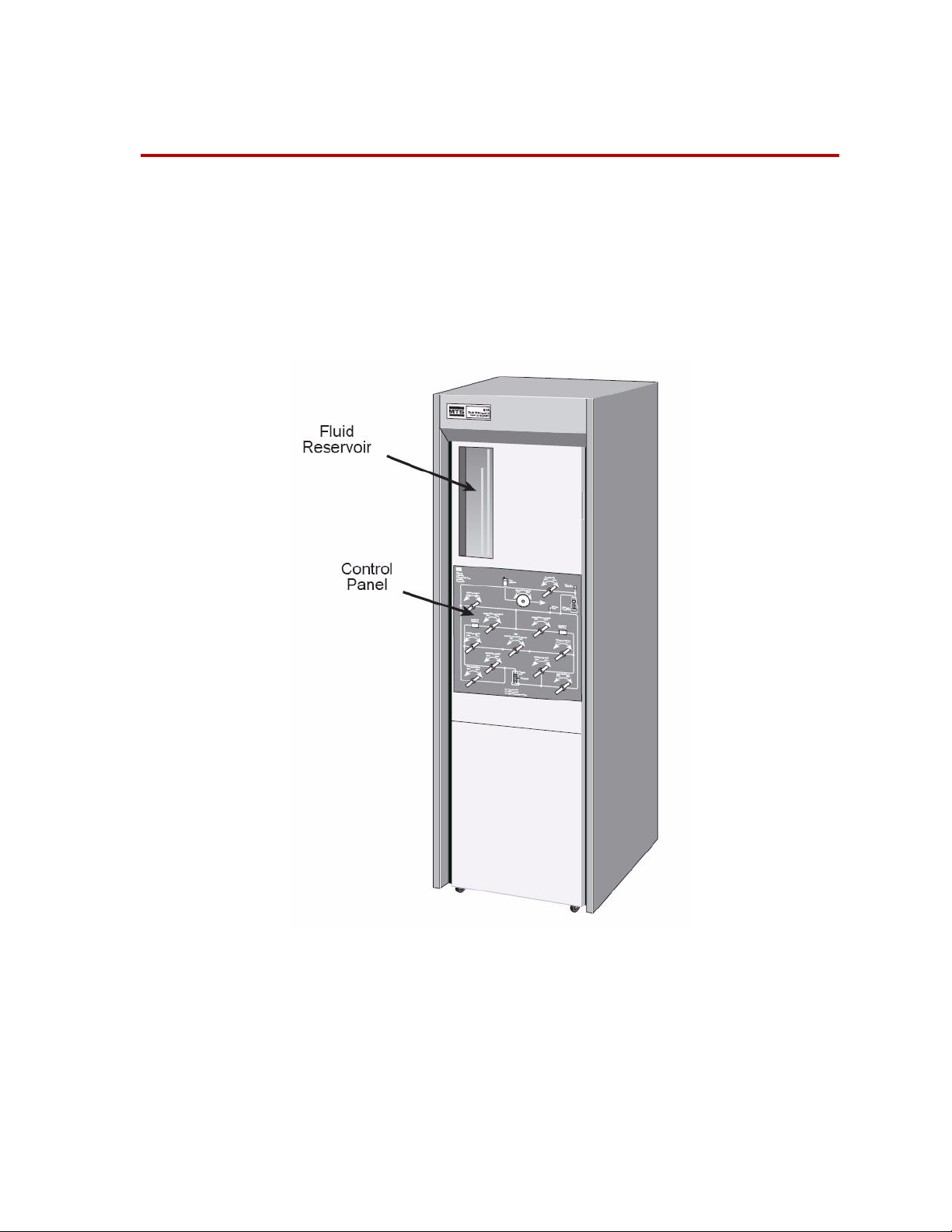

Introduction

This manual documents the Model 286.31 Transient Permeability Pore Pressure

Intensifier.

The 286.31 pressurizes fresh, distilled water up to 10,000 psi (69 MPa). The

pressurized fluid is applied to a specimen installed in a triaxial cell to test its

permeability characteristics.

286.31 Transient Permeability Pore Pressure Intensifier Introduction

5

Page 6

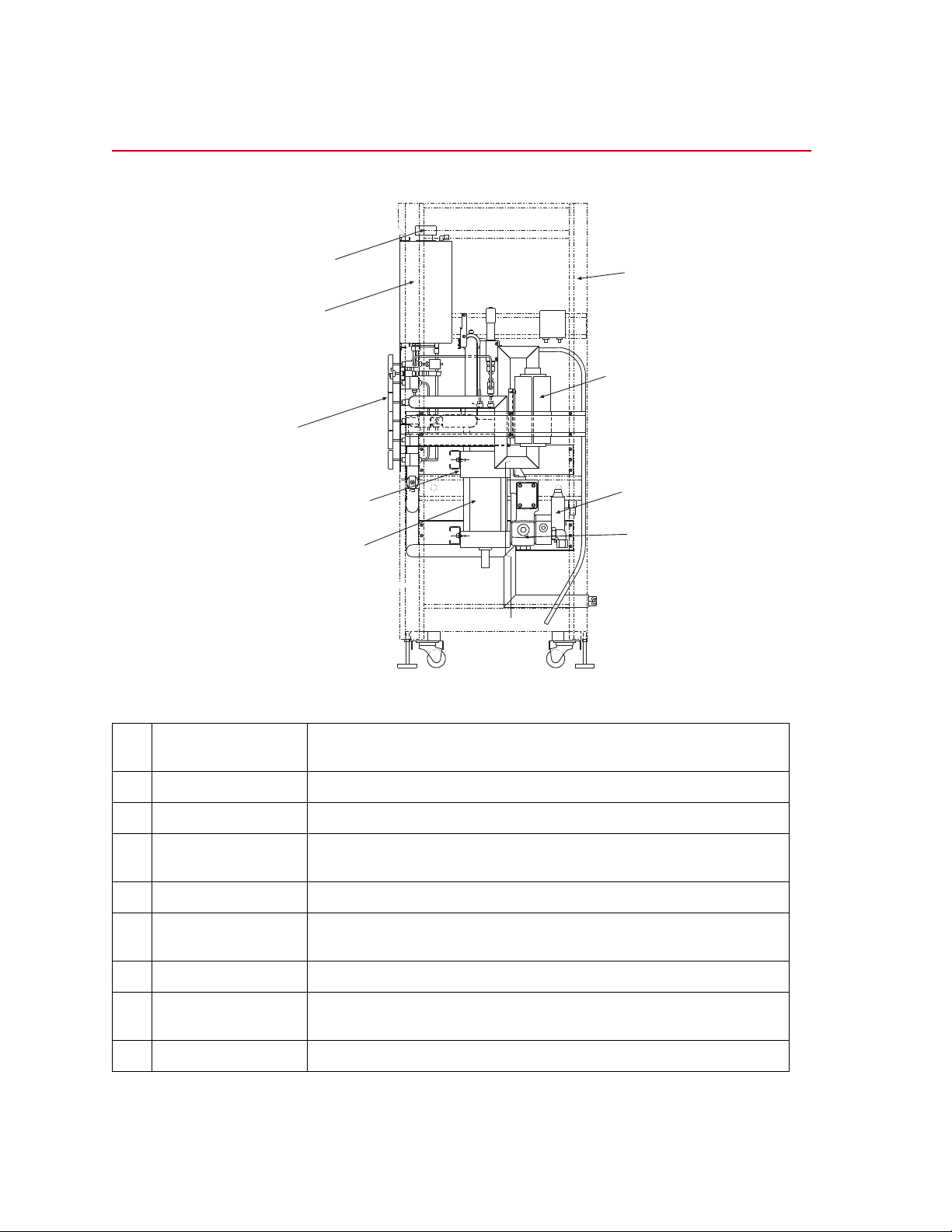

Major Components

1

2

3

4

5

6

7

8

9

Major Components

vent

1

is a removable cap that allows air trapped in the system to escape; also the

fill point for manually filling the reservoir.

cabinet

2

fluid reservoir

3

control panel

4

identification label

5

pressure intensifier

6

actuator manifold

7

servovalve

8

houses the 286.31. It has leveling casters and a rear access door.

holds the system’s distilled water in a clear acrylic container.

has the valves needed to operate the 286.31. Valves are identified by name

and placed in front of a hydraulic schematic of the 286.31 and T riaxial Cell.

lists unit specifications such as pressure, reservoir capacity, and fluid type.

is an servovalve controlled actuator that operates a pump which boosts pore

pressure fluid up to 10,000 psi (69 MPa).

is the connection point for hydraulic components.

responds to system control signals to operate the pressure intensifier’s

piston.

reference volumes

9

6

Introduction

are two high pressure reservoirs used during transient permeability tests.

286.31 Transient Permeability Pore Pressure Intensifier

Page 7

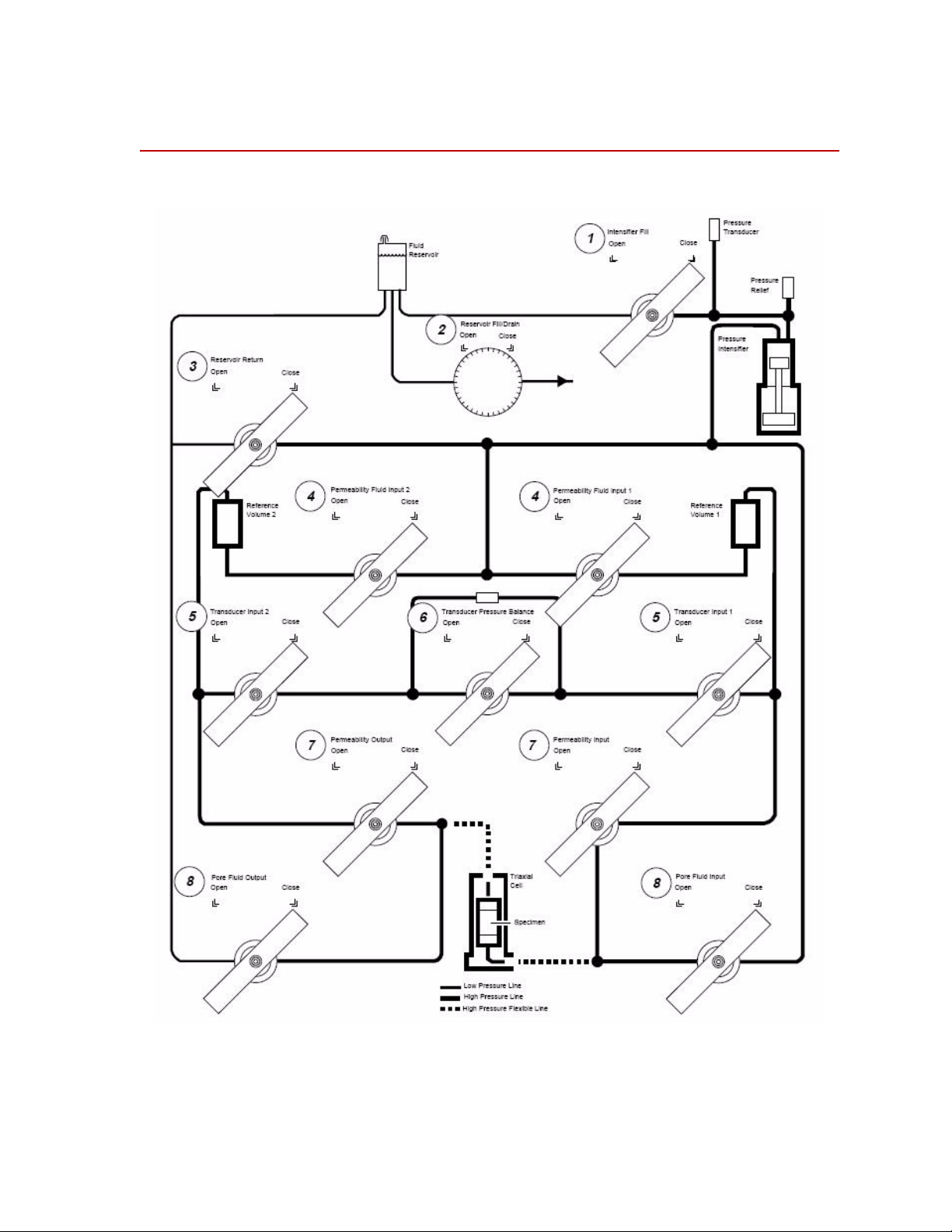

Control Panel Valves

Control Panel Valves

286.31 Transient Permeability Pore Pressure Intensifier Introduction

7

Page 8

Control Panel Valves

1 Intensifier Fill

2 Reservoir Fill/Drain

3 Reservoir Return

4 Permeability Fluid Input 1

Permeability Fluid Input 2

5 Transducer Input 1 Transducer

Input 2

6 Transducer Pressure Balance

7 Permeability Input Permeability

Output

8 Pore Fluid Input Pore Fluid

Output

controls the flow of fluid from the Reservoir into the Pressure

Intensifier.

controls the flow of fluid into the Fluid Reservoir when the 286.31 is

connected to a fluid supply.

is normally kept closed.

control the filling and pressurization of Reference Volumes 1 and 2.

apply Reference Volume 1 and 2 pressures to the Pressure Transducer

when open.

protect the pressure transducer from damaging high pressures. It is

normally left open. When closed it exposes this transducer to the

pressure differential between Reference Volumes 1 and 2.

apply Reference Volume 1 and 2 pressures to the specimen in the

triaxial cell when open.

bypass the permeability fluid circuit when open.

8

Introduction

286.31 Transient Permeability Pore Pressure Intensifier

Page 9

Specifications

Console Dimensions

height

width

depth

Weight 1000 lb 454 kg

74 in.

24 in.

32 in

1880 mm

610 mm

813 mm

Specifications

Reservoir capacity

Intensifier capacity

Controllable output pressure 12,000 psi

Max. fluid temperature 167°F 75°C

Fluid type distilled water

Hardline fittings F375C (female)

1.6 gal (369 in

0.09 gal (20 in

20,000 psi

3

) 6.1 litre (6050 cm3)

3

) 0.34 litre (340 cm3)

80 MPa

140 MPa

286.31 Transient Permeability Pore Pressure Intensifier Introduction

9

Page 10

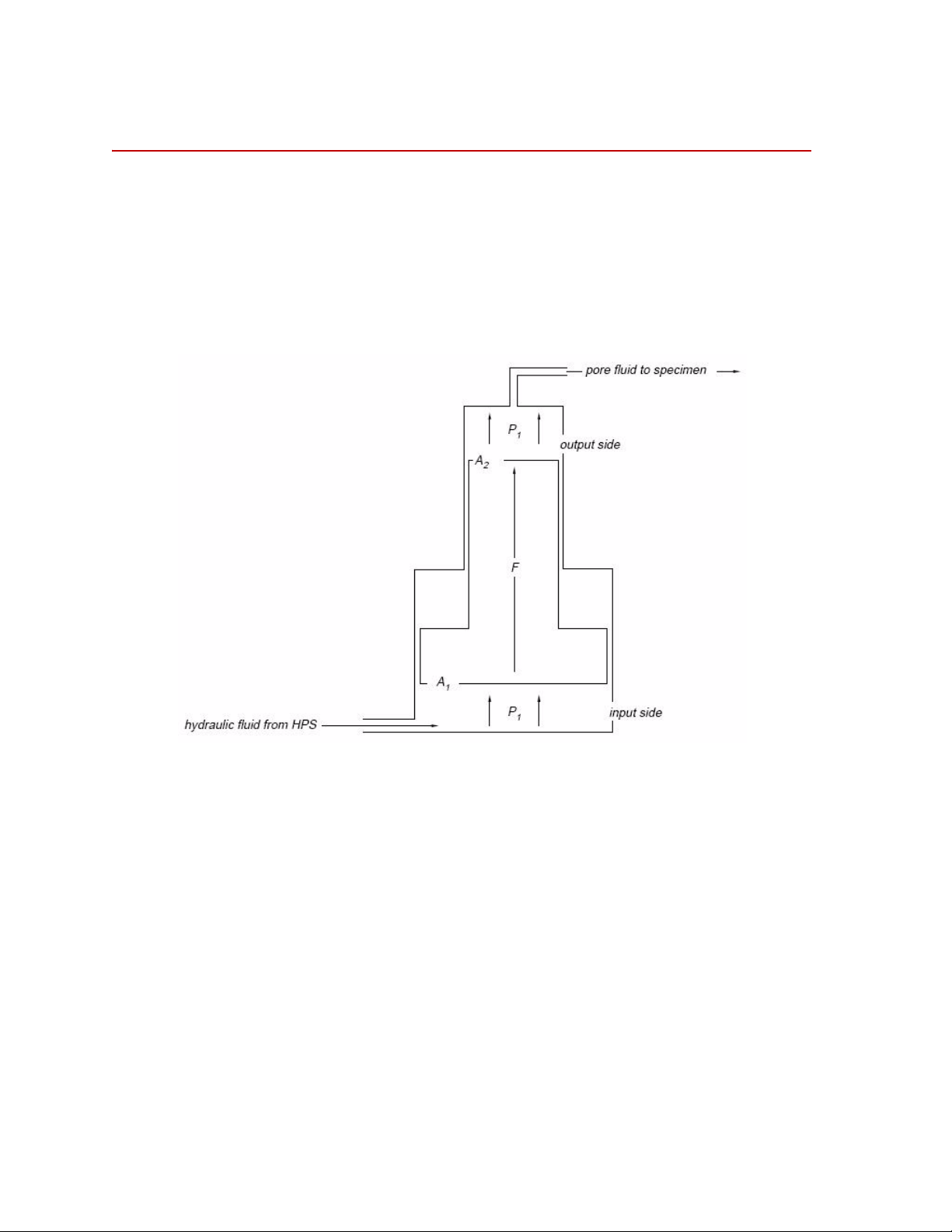

How the Pressure Intensifier Works

FA1P1×=

P

2

F

A

2

------=

How the Pressure Intensifier Works

The 286.31’s Pressure Intensifier develops the 10,000 psi (69 MPa) pressures

applied to your specimen. The pressure transformer is the part of the Intensifier

that develops this pressure.

The pressure transformer’s principle: low pressure applied to a large area

produces a large force. Apply this force over a smaller area and you will produce

a higher pressure.

The hydraulic power supply forces hydraulic fluid into the transformer’s low

pressure input side. The resulting force (F) is the product of the supply side’s

large piston area (A

HPS (P

):

1

) multiplied by the pressure of the hydraulic fluid from the

1

The force produced (F) transfers to the fluid in the output side. The resulting

pressure (P2) is the product of the force (F) divided by the output side’s smaller

piston area (A

Introduction

10

):

2

286.31 Transient Permeability Pore Pressure Intensifier

Page 11

The Area Ratio

area ratio

A

1

A

2

------=

How the Pressure Intensifier Works

The area ratio is the ratio of the input pressure to the output pressure. It

determines how much the input pressure boosts the output pressure. It is

The identification label on your 286.31 gives its area ratio.

For example, your label says the area ratio is 3.33:1. This means a 3000 psi input

pressure will produce a 10,000 psi output pressure.

286.31 Transient Permeability Pore Pressure Intensifier Introduction

11

Page 12

How the Pressure Intensifier Works

12

Introduction

286.31 Transient Permeability Pore Pressure Intensifier

Page 13

Operation

Operation of the 286.31 Intensifier consists of —

• Purging and Filling the Fluid Lines

• Running a Steady State Flow Test

• Running a Transient Permeability Flow Test

Note Complete purging needs only to be done when —

• You first install the 286.31.

• You accidentally draw air into the Pressure Intensifier

Special equipment needed —

• distilled water — at least 2 gallons (8 litres)

• 1% Triton® wetting solution

• Teflon® thread sealing tape

The 286.31 is designed to operate as part of an integrated system that typically

includes —

• a Test Controller with closed-loop control electronics

• a hydraulic power supply

• a triaxial cell or pressure vessel installed in a load unit

• a confining fluid pressure intensifier

T o become familiar with your system, make a trial run of the test you want to run.

Familiarize yourself with the controls and indicators used in each step, without

actually doing the step.

286.31 Transient Permeability Pore Pressure Intensifier Operation

13

Page 14

The following warning, caution, and note apply during all steps.

WARNING

CAUTION

You will be working with very high pressures — The spray from a leak could

cut your skin.

The 286.31 develops intensely high pressures (10000 psi/69 MPa). Broken lines

or fittings could produce a skin cutting spray.

Stop if you can’t build up to test pressure. You may have a leak somewhere.

Reduce pressure to zero, then find and repair the leak.

Fluid hotter than 165°F/75°C can damage the acry lic flui d res erv oi r an d its

hoses.

Watch the temperature of the confining fluid in your triaxial cell —

especially if your cell has heaters. The confining fluid will heat the pore

fluid.

Wait for the confining fluid temperature to cool below 165°F/75°C before

drawing the pore fluid back into the 286.31 reservoir.

Use only distilled water in the 286.31—

Use any other fluid and you can wreck its seals.

Note Adding a 1% T riton wetting solution to the distilled water will lubricate the

286.31’s seals and make them last longer.

14

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 15

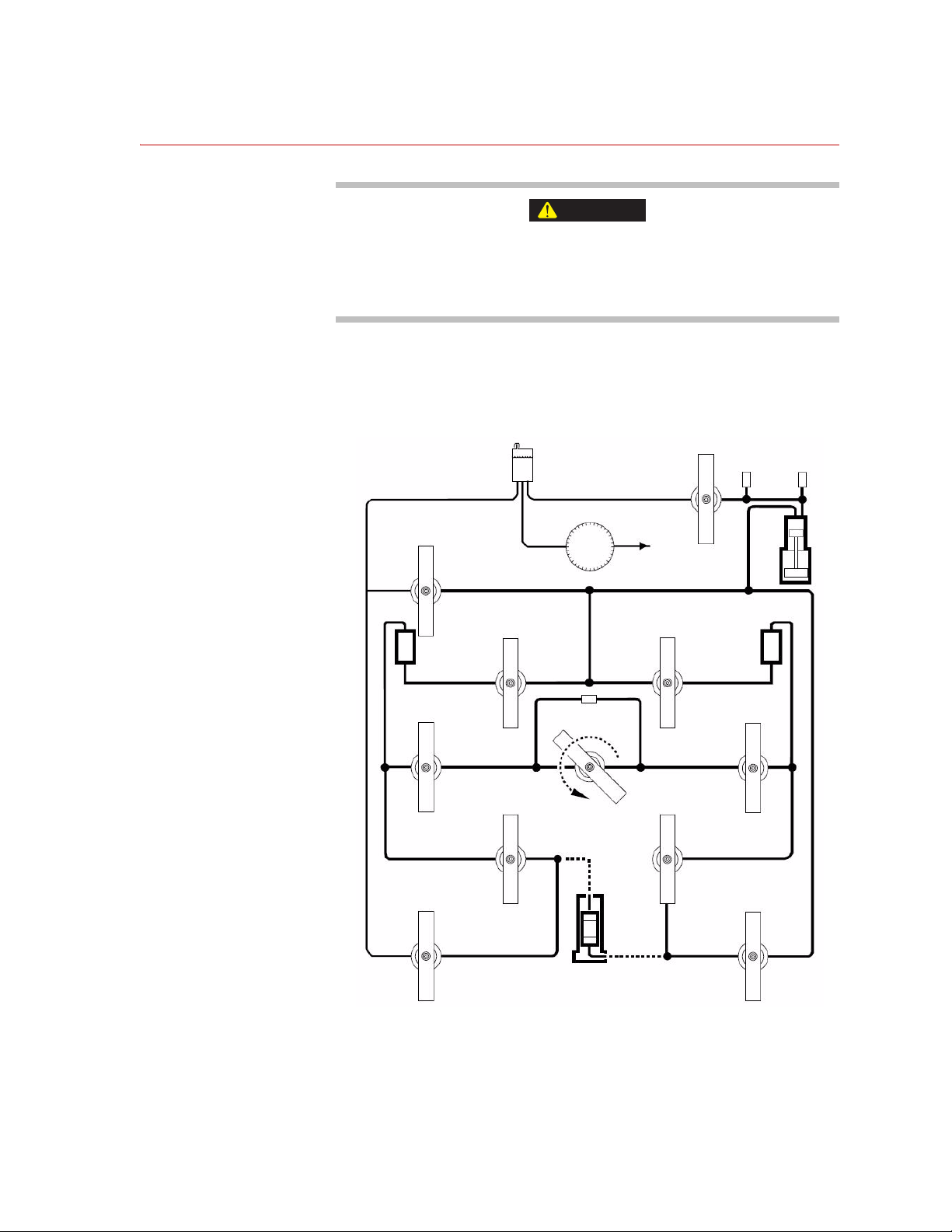

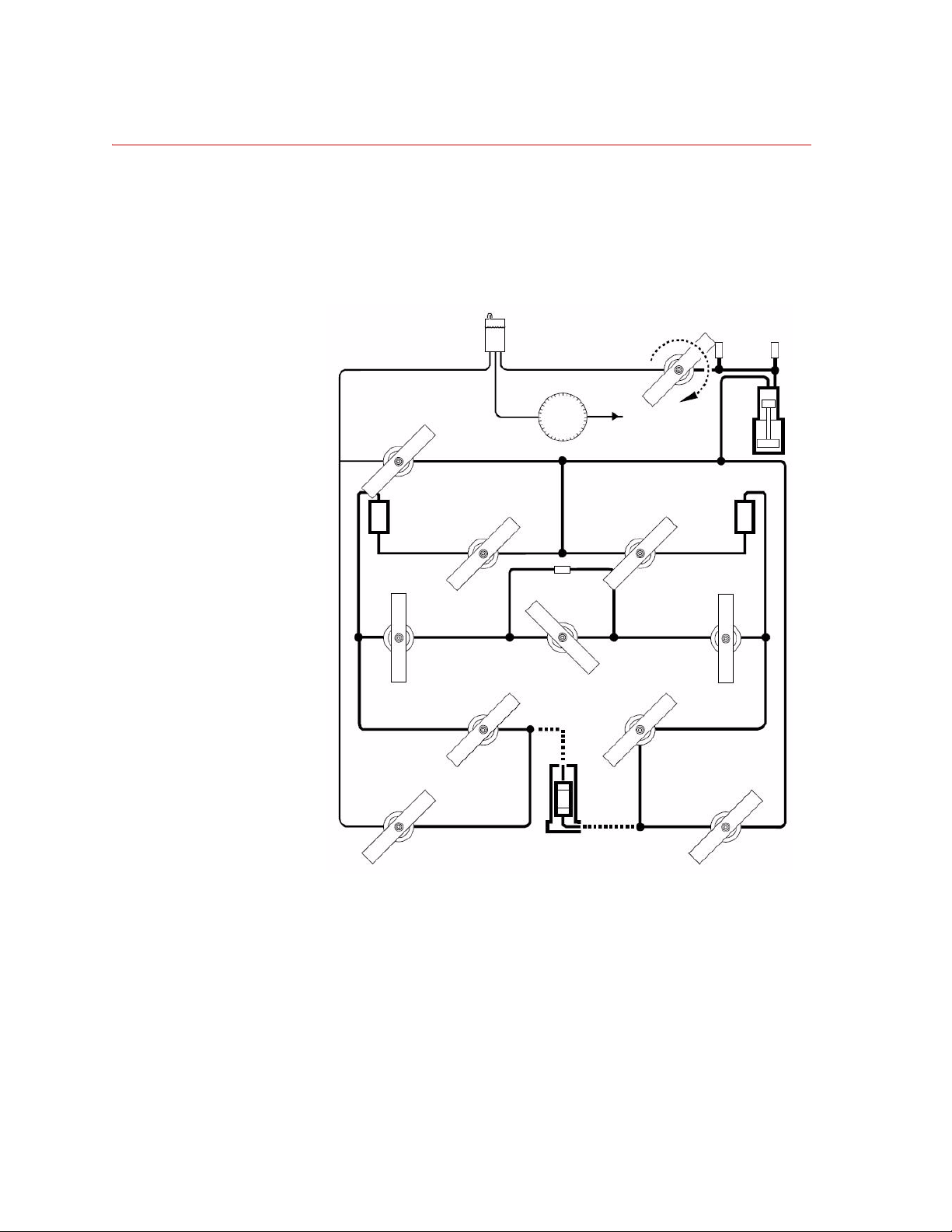

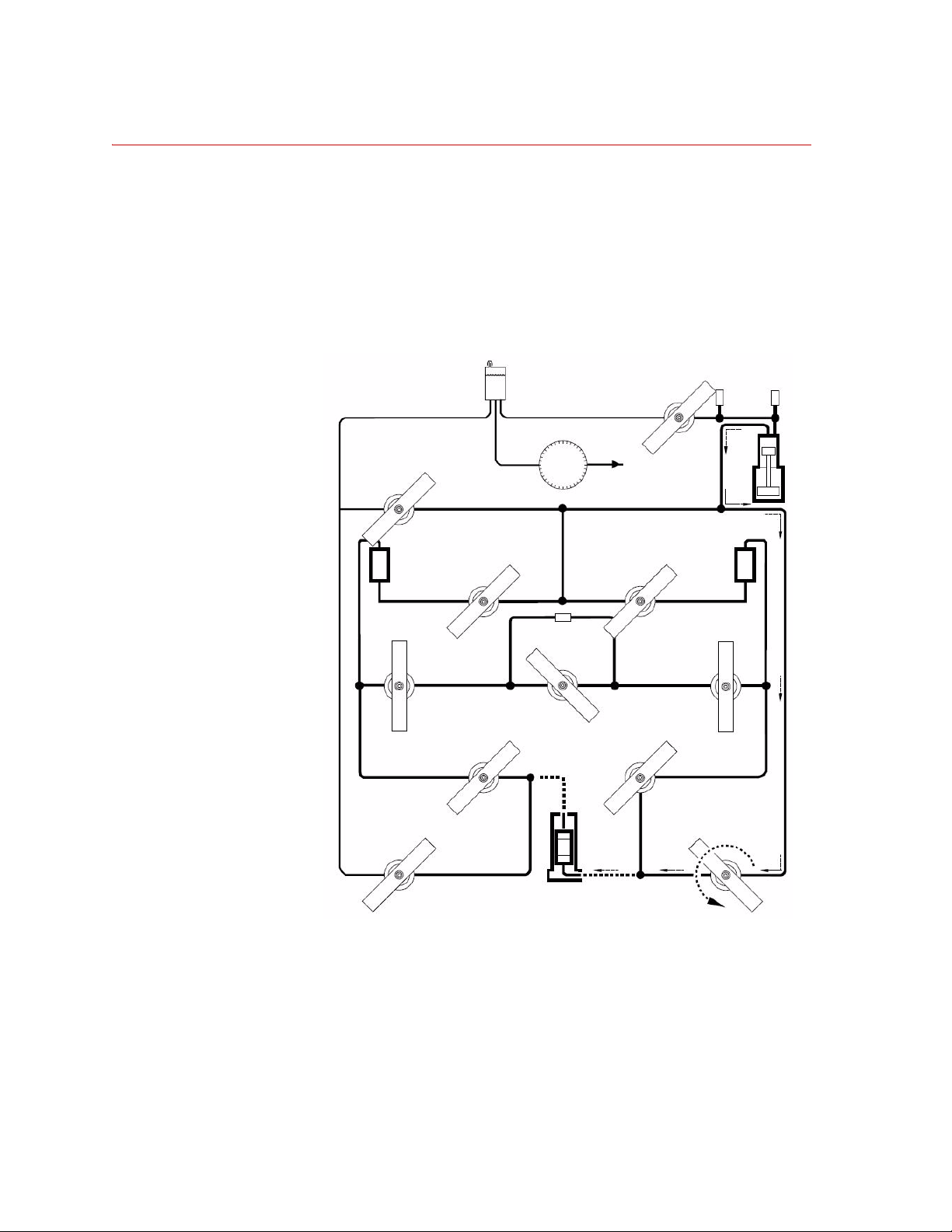

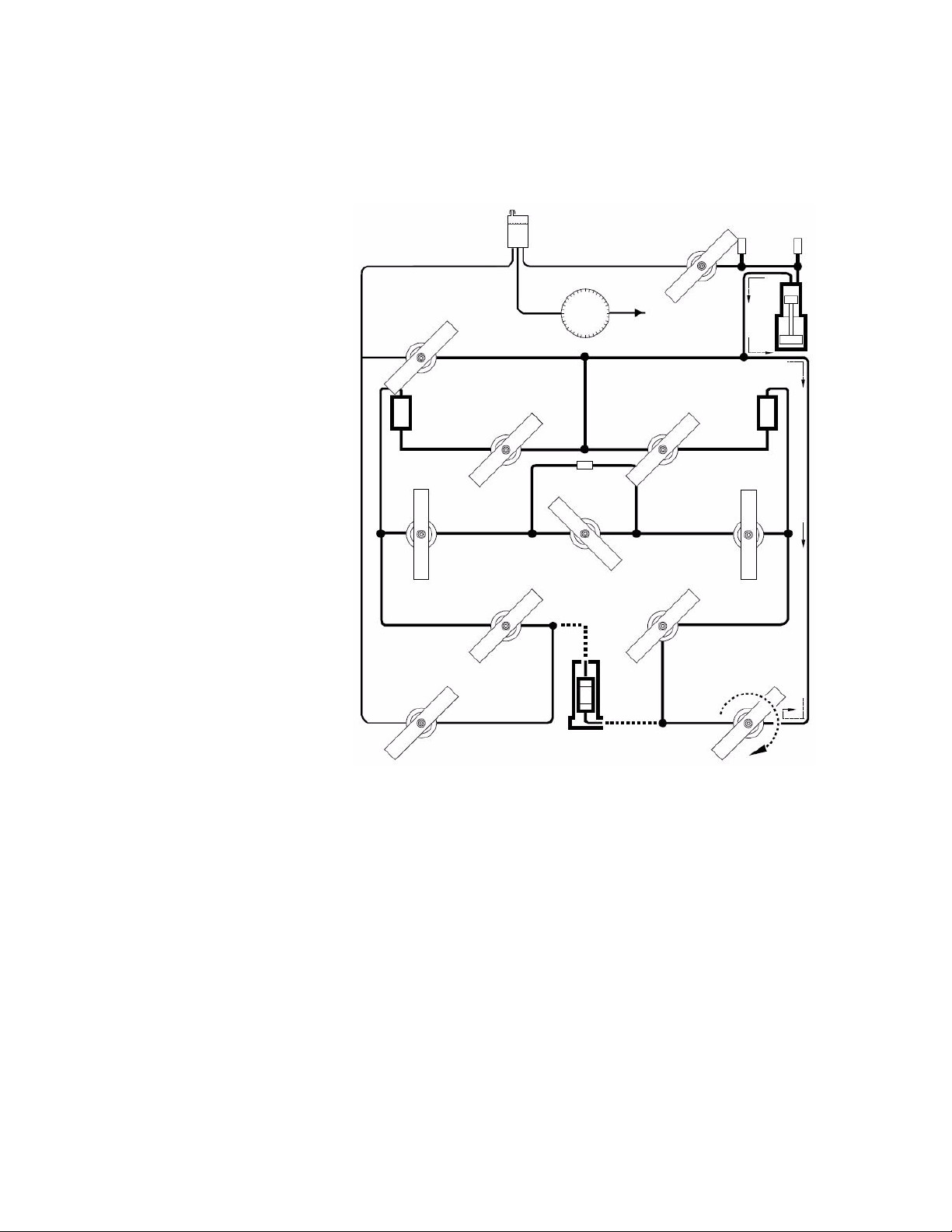

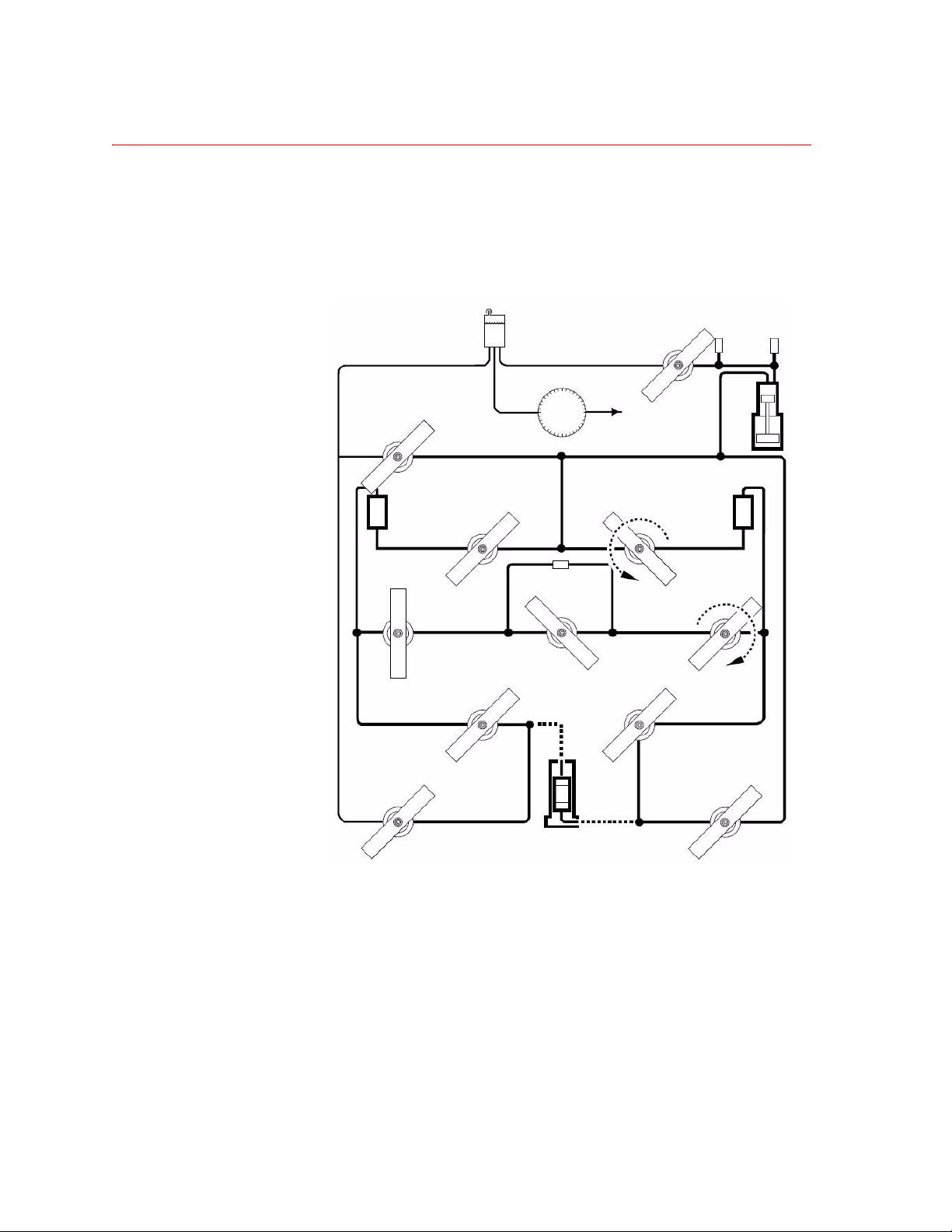

Operating the Control Panel Valves

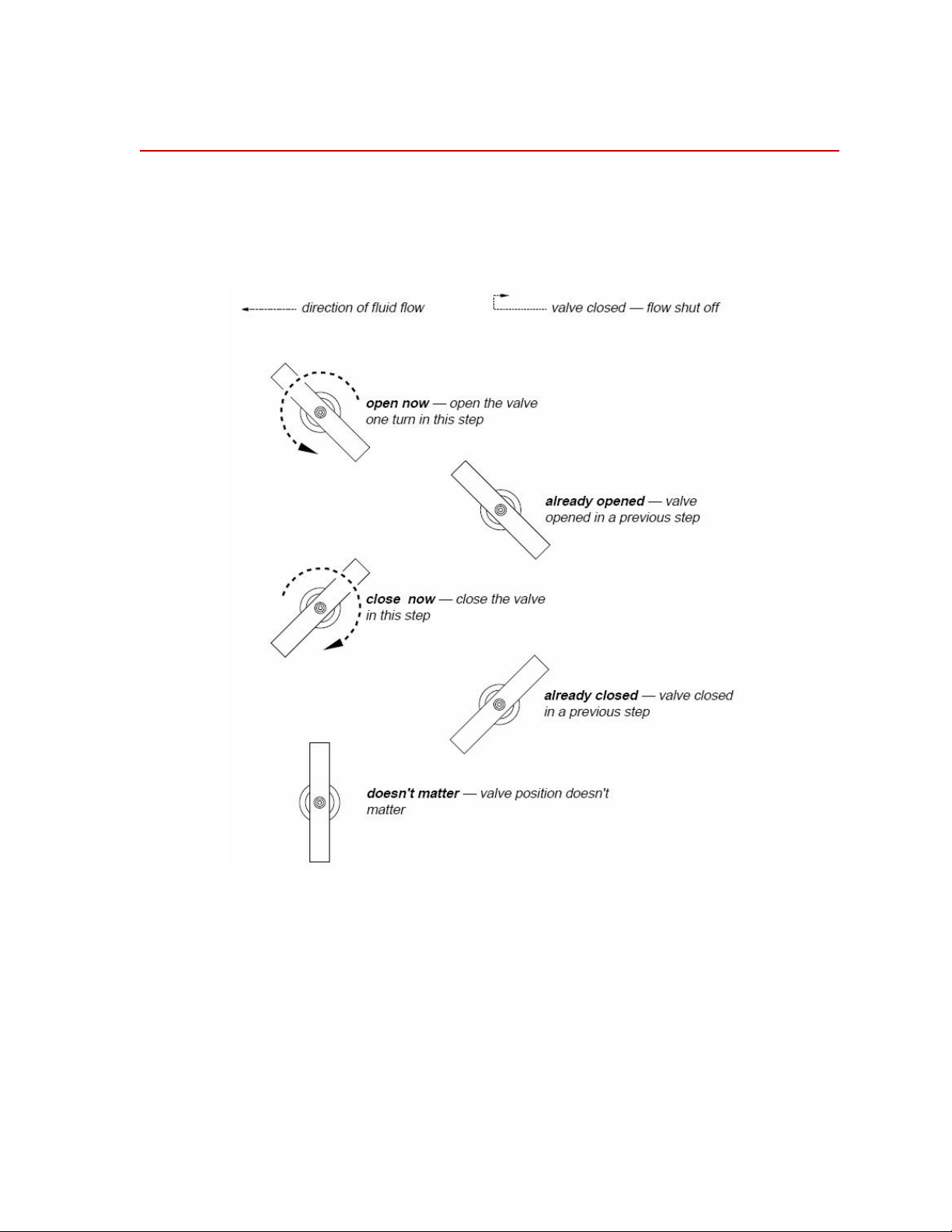

Most of the steps in this section involve opening and closing valves on the

286.31’s control panel. The pictures that follow in this section will show you

which valves to open and close. The figure below is the key to these pictures.

Operating the Control Panel Valves

A full turn opens a valve completely but still lets you shut it quickly. It takes only

light force to shut the valve completely, though using more force won’t hurt it.

286.31 Transient Permeability Pore Pressure Intensifier Operation

15

Page 16

Purging and Filling the Fluid Lines

Purging and Filling the Fluid Lines

In this section you’ll purge the 286.31’s lines of air and fill them with distilled

water.

You only need to do this after installing the 286.31 or if you’ve accidentally

drawn air into the Pressure Intensifier through a dry Fluid Reservoir.

Note Before you start purging and filling, make sure your Triaxial Cell is open.

Purging and filling has ten major tasks, which must be done in order

• Fill the Fluid Reservoir

• Purge and Fill the Pressure Intensifier

• Pressurize the Intensifier

• Purge and Fill the Lower Pore Line

• Purge and Fill the Reference 1 Lines

• Purge and Fill the Balance and Upper Pore Lines

• Purge and Fill the Reference 2 Lines

• Purge and Fill the Low Pressure Reservoir Line

• Purge and Fill the Reservoir Return Line

• Refill the Pressure Intensifier

16

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 17

Fill the Fluid Reservoir

CAUTION

An open Transducer Pressure Balance valve protects the differential

pressure transducer from damaging high system pressures —

Keep this valve open except when told to close it.

1. Protect the differential pressure transducer .

Tur n the Transducer Pressure Balance valve to the Open position.

Purging and Filling the Fluid Lines

286.31 Transient Permeability Pore Pressure Intensifier Operation

17

Page 18

Purging and Filling the Fluid Lines

2. If there is a specimen installed in the triaxial cell, remove it. Lines cannot be

purged and filled with a specimen in place.

You will find instructions for removing the specimen in your Triaxial Cell

manual.

3. Prepare to fill the Fluid Reservoir.

Turn the Pore Fluid Output, Por e Fluid Input, Permeability Output, and

Permeability Input valves to the Close position.

18

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 19

Purging and Filling the Fluid Lines

4. Fill the Fluid Reservoir.

If your 286.31 is connected to a distilled water supply —

Tur n the Reservoir Fill/Drain valve to the Open position.

When the Fluid Reservoir is about 3/4 full, turn the Reservoir Fill/

Drain valve to the Close position.

If your 286.31 is not connected to a distilled water supply —

Remove the filler plug at the top of the 286.31’s cabinet.

Open the console’s rear door . Unscrew one of the hex–head plugs in the

Reservoir. (This allows air to vent more easily out of the Reservoir.)

Use a funnel to fill the Fluid Reservoir about 3/4 full.

Seal the filler cap and hex–head plug with Teflon thread sealing tape

and reinstall them.

286.31 Transient Permeability Pore Pressure Intensifier Operation

19

Page 20

Purging and Filling the Fluid Lines

Purge and Fill the Pressure Intensifier

1. Switch on electrical power at the control console.

2. Set up the test controller to control the 286.31’s Pressure Intensifier from the

Manual Control on the RCS (Remote Station Controller).

3. Select the pore pressure control channel’s most sensitive operating range.

4. Select pore pressure as the active control mode.

5. Apply high hydraulic pressure to the 286.31.

20

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 21

Purging and Filling the Fluid Lines

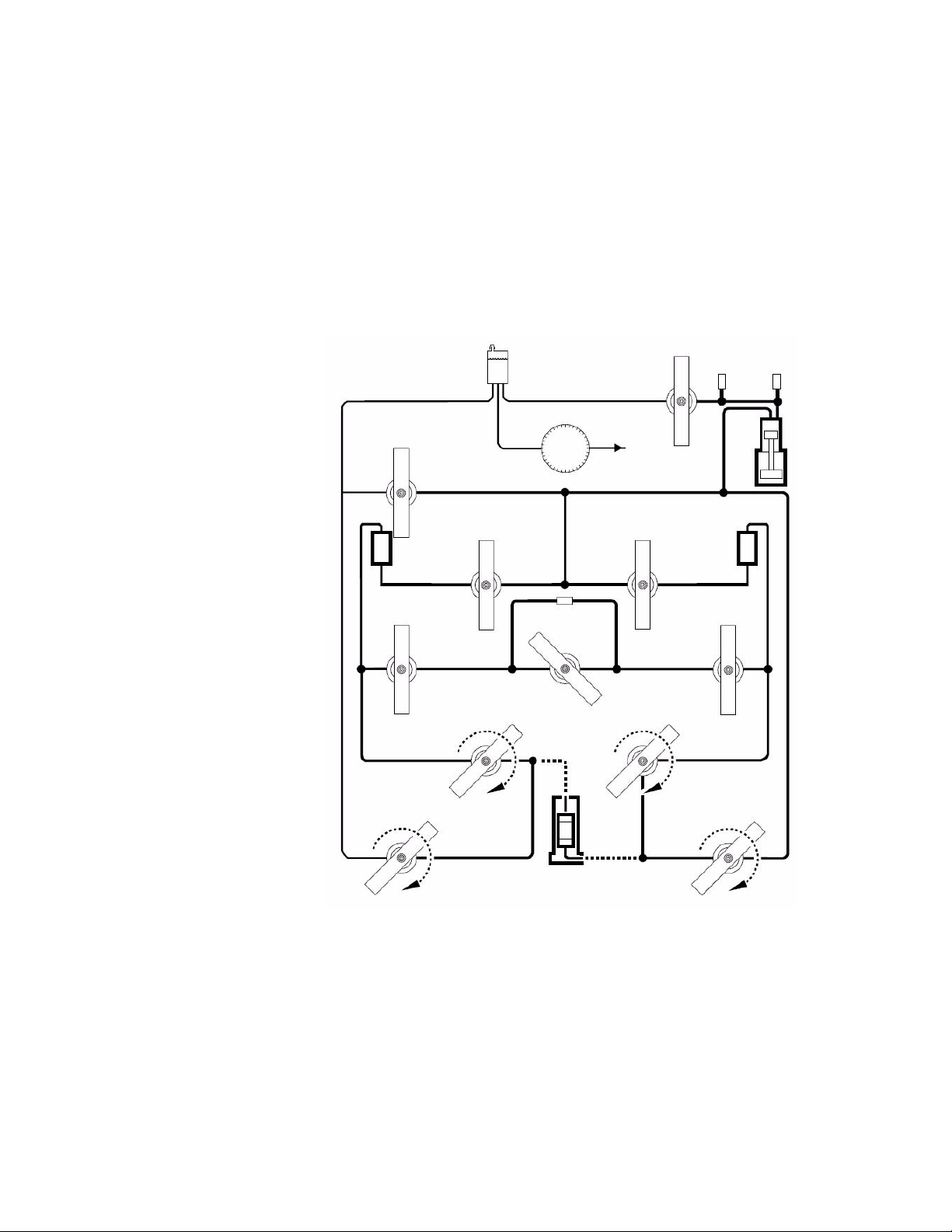

6. Prepare to purge the Pressure Intensifier of air and fill it with fluid.

Tur n the Permeability Fluid Input 1, Permeability Fluid Input 2, and

Reservoir Return valves to the Close position.

Tur n the Intensifier Fill val ve to the Open position.

7. On the test controller, monitor the displacement sensor output.

8. Purge the Pressure Intensifier of air and fill it with fluid.

Slowly turn the Manual Control clockwise, then counterclockwise to fully

stroke the Intensifier’s piston.

Watch the displacement signal to make sure you fully stroke the piston.

When the bubbling at the Fluid Reservoir stops, use the Set Point or

Manual Control to fully retract the Intensifier’s piston.

286.31 Transient Permeability Pore Pressure Intensifier Operation

21

Page 22

Purging and Filling the Fluid Lines

Pressurize the Intensifier

1. On the test controller, monitor the pressure sensor output.

2. Prepare to pressurize the fluid in the 286.31.

Tur n the Intensifier Fill val ve to the Close position.

22

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 23

Purging and Filling the Fluid Lines

3. Extend the Pressure Intensifier’s piston to pressurize the fluid.

On the RSC, slowly turn the Manual Control to develop a slight positive

pressure.

While purging, keep the pressure as low as practical but positive all the

time. Keep watching the pore pressure as you purge the lines.

If pressure starts dropping and extending the piston does not raise the

pressure, you will have to stop and refill the Pressure Intensifier.

Note If the Intensifier needs refilling during this procedure —

1. Shut off any valve that is draining fluid out of the 286.31.

2. Turn the Permeability Fluid Input 1, Permeability Fluid Input 2,

and Reservoir Return valves to the Close position.

3. Do the steps in “Refill the Pressure Intensifier” on page 41.

4. Return to the step where you were when the Intensifier ran dry.

5. Turn the Permeability Fluid Input 1, Permeability Fluid Input 2,

and Reservoir Return valves back where they were.

286.31 Transient Permeability Pore Pressure Intensifier Operation

23

Page 24

Purging and Filling the Fluid Lines

Purge and Fill the Lower Pore Line

1. Purge the lower pore pressure line of air and fill it with fluid.

Tur n the Pore Fluid Input valve to the Open position.

Fluid and bubbles will come out of the triaxial cell's lower pore pressure

port.

As soon as the bubbles stop, go on to step 2.

24

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 25

Purging and Filling the Fluid Lines

2. Shut off the flow to the triaxial cell.

Tur n the Pore Fluid Input valve to the Close position.

286.31 Transient Permeability Pore Pressure Intensifier Operation

25

Page 26

Purging and Filling the Fluid Lines

Purge and Fill the Reference Volume 1 Lines

1. Prepare to purge the Reference Volume 1 lines of air and fill them with fluid.

Tur n the Permeability Fluid Input 1 valve to the Open position.

Tur n the Transducer Input 1 valve to the Close position.

26

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 27

Purging and Filling the Fluid Lines

2. Purge the Reference Volume 1 lines of air and fill them with fluid.

Tur n the Permeability Input valve to the Open position.

As soon as the fluid coming out at the triaxial cell’s lower pore pressure port

becomes bubble-free, go on to step 3.

286.31 Transient Permeability Pore Pressure Intensifier Operation

27

Page 28

Purging and Filling the Fluid Lines

3. Shut off the flow to the triaxial cell.

Tur n the Permeability Input valve to the Close position.

28

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 29

Purging and Filling the Fluid Lines

Purge and Fill the Balance and Upper Pore Lines

1. If your triaxial cell has a upper pore pressure valve, open it now.

2. Prepare to purge the Transducer Pressure Balance and upper pore pressure

lines of air and fill them with fluid.

Tur n the Transducer Input 1 and Transducer Input 2 valves to the Open

position.

286.31 Transient Permeability Pore Pressure Intensifier Operation

29

Page 30

Purging and Filling the Fluid Lines

3. Purge the Transducer Pressure Balance and upper pore pressure port lines of

air and fill them with fluid.

Tur n the Permeability Output to the Open position.

As soon as the fluid coming out at the triaxial cell’s upper pore pressure port

becomes bubble-free, go on to step 4.

30

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 31

Purging and Filling the Fluid Lines

4. Shut off the fluid flow to the triaxial cell.

Tur n the Permeability Output valve to the Close position.

286.31 Transient Permeability Pore Pressure Intensifier Operation

31

Page 32

Purging and Filling the Fluid Lines

Purge and Fill the Reference Volume 2 Lines

1. Prepare to purge the Reference Volume 2 lines of air and fill them with fluid.

Tur n the Permeability Fluid Input 2 valve to the Open position.

Turn the T ransducer Inpu t 2 and Permeability Fluid Input 1 valves to the

Close position.

32

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 33

Purging and Filling the Fluid Lines

2. Purge the Reference Volume 2 lines of air and fill them with fluid.

Tur n the Permeability Output to the Open position.

As soon as bubble-free fluid starts coming out at the triaxial cell’s upper

pore pressure port, go on to step 3.

286.31 Transient Permeability Pore Pressure Intensifier Operation

33

Page 34

Purging and Filling the Fluid Lines

3. Stop the flow to the triaxial cell.

Tur n the Permeability Output valve to the Close position.

34

Operation

4. If your Triaxial Cell has an upper pore pressure valve, close it now.

286.31 Transient Permeability Pore Pressure Intensifier

Page 35

Purging and Filling the Fluid Lines

Purge and Fill the Low Pressure Reservoir Line

1. Prepare to purge the low pressure Fluid Reservoir line of air and fill it with

fluid.

Tur n the Pore Fluid Output valve to the Open position.

Air in this line will come out at the Fluid Reservoir.

286.31 Transient Permeability Pore Pressure Intensifier Operation

35

Page 36

Purging and Filling the Fluid Lines

2. Purge the low pressure Fluid Reservoir line of air and fill it with fluid.

If your triaxial cell doesn’t have a shut off valve for the upper pore pressure

line, plug this line at its triaxial cell output. Cap it or plug it with your finger

(or a helper’s).

Tur n the Permeability Output valve to the Open position.

As soon as the fluid entering the Fluid Reservoir becomes bubble-free, go

on to step 3.

36

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 37

Purging and Filling the Fluid Lines

3. Stop the flow to the Fluid Reservoir.

Tur n the Permeability Output valve to the Close position.

4. Uncap the Triaxial Cell’s upper pore pressure line if you have plugged it.

286.31 Transient Permeability Pore Pressure Intensifier Operation

37

Page 38

Purging and Filling the Fluid Lines

Purge and Fill the Reservoir Return Line

1. Prepare to purge the Reservoir Return line of air and fill it with fluid.

Tur n the Pore Fluid Output and Permeability Fl uid Input 2 valves to the

Close position.

Air purged from this line will bubble out at the Fluid Reservoir.

38

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 39

Purging and Filling the Fluid Lines

2. Purge the reservoir return line of air and fill it with fluid.

Tur n the Reservoir Return valve to the Open position.

As soon as bubbles stop coming out at the Fluid Reservoir, go on to step 3.

286.31 Transient Permeability Pore Pressure Intensifier Operation

39

Page 40

Purging and Filling the Fluid Lines

3. Stop the flow to the Fluid Reservoir.

Tur n the Reservoir Return valve to the Close position.

40

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 41

Refill the Pressure Intensifier

1. On the RSC, turn the Manual Control until pressure drops to zero.

2. On the test controller, monitor the displacement sensor output.

3. Prepare to refill the Pressure Intensifier. Turn the Intensifier Fill valve to

the Open position.

Purging and Filling the Fluid Lines

286.31 Transient Permeability Pore Pressure Intensifier Operation

41

Page 42

Purging and Filling the Fluid Lines

4. Refill the Pressure Intensifier with fluid.

On the RSC, slowly turn the Manual Control to retract the Intensifier’s

piston.

Stop when the displacement signal shows a fully retracted piston.

5. Make sure the Pressure Transducer line is fully purged so air bubbles will

not be forced into the pore lines.

On the RSC, slowly turn the Manual Control to extend the Intensifier’s

piston.

Stop when bubble-free fluid begins flowing back into the Reservoir.

Now turn the Manual Control to fully retract the Intensifier’s piston .

6. On the test controller, monitor the pressure sensor output.

42

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 43

Purging and Filling the Fluid Lines

7. Prepare to pressurize the 286.31's lines.

Tur n the Intensifier Fill val ve to the Close position.

8. On the RSC, slowly turn the Manual Control to produce a positive

pressure.

286.31 Transient Permeability Pore Pressure Intensifier Operation

43

Page 44

Running a Steady State Flow Test

Running a Steady State Flow Test

Running a steady state flow test has five major tasks

• Fill the Pressure Intensifier

• Purge and Fill the Pore Pressure Lines

• Refill the Pressure Intensifier

• Prepare to Run the Test

• End the Test

Note If you have just done a complete purge of the 286.31, skip ahead to

“Prepare to Run a Test” on page 56.

44

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 45

Fill the Pressure Intensifier

1. If you have a specimen installed in the triaxial cell, remove it now. Your

triaxial cell manual has the details on doing this.

2. Turn the valves to match the positions shown in the Step 3 picture.

3. Skip this step if the Reservoir is already 3/4 full.

Fill the Fluid Reservoir.

If your 286.31 is connected to a distilled water supply —

Tur n the Reservoir Fill/Drain valve to the Open position.

When the Fluid Reservoir is about 3/4 full, turn the Reservoir Fill/

Drain valve to the Close position.

If your 286.31 is not connected to a distilled water supply —

Remove the filler plug at the top of the 286.31.

Open the console’s rear door . Unscrew one of the hex–head plugs in the

Reservoir. (This allows air to vent more easily out of the Reservoir.)

Running a Steady State Flow Test

Use a funnel to fill the Fluid Reservoir about 3/4 full.

Seal the filler cap and hex–head plug with Teflon thread sealing tape

and reinstall them.

286.31 Transient Permeability Pore Pressure Intensifier Operation

45

Page 46

Running a Steady State Flow Test

4. Switch on electrical power at the control console.

5. Set up the test controller to control the 286.31’s Pressure Intensifier from

Manual Control on the RSC.

6. Select pore pressure as the active control mode.

7. Select the pore pressure control channel’s most sensitive operating range.

8. Apply high hydraulic pressure to the 286.31.

9. Prepare to purge the Pressure Intensifier of air and fill it with fluid. Turn the

Intensifier Fill valve to the Open position.

46

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 47

Running a Steady State Flow Test

10. On the test controller, monitor the displacement sensor output.

11. Purge the Pressure Intensifier of air and fill it with fluid.

On the RSC, slowly turn the Manual Control clockwise, then

counterclockwise to fully stroke the Intensifier’s piston.

Watch the displacement signal to make sure you fully stroke the piston.

When the bubbling at the Fluid Reservoir stops, use the RSC Manual

Control to fully retract the Intensifier’s piston.

12. On the test controller, monitor the pressure sensor output.

286.31 Transient Permeability Pore Pressure Intensifier Operation

47

Page 48

Running a Steady State Flow Test

13. Prepare to pressurize the fluid in the 286.31. Turn the Intensifier Fill valve

to the Close position.

48

Operation

14. Pressurize the fluid in the 286.31 by extending the Intensifier ’s piston.

On the RSC, slowly turn the Manual Control to develop a positive

pressure.

As you purge the pore pressure lines, keep the pressure low but positive all

the time. Keep an eye on the pressure as you purge the lines.

286.31 Transient Permeability Pore Pressure Intensifier

Page 49

Purge and Fill the Pore Pressure Lines

1. Purge and fill the lower pore pressure line.

Tur n the Pore Fluid Input valve to the Open position.

As soon as bubble-free fluid comes out at the triaxial cell’s lower pore

pressure port, go on to step 2.

Running a Steady State Flow Test

286.31 Transient Permeability Pore Pressure Intensifier Operation

49

Page 50

Running a Steady State Flow Test

2. Shut off the flow of fluid to the triaxial cell.

Tur n the Pore Fluid Input valve to the Close position.

50

Operation

3. If your triaxial cell has an upper pore pressure valve, open it now.

286.31 Transient Permeability Pore Pressure Intensifier

Page 51

Running a Steady State Flow Test

4. Purge and fill the upper pore pressure line.

Tur n the Reservoir Return and Pore Fluid Output valves to the Open

position.

Go on to step 5 as soon as bubble–free fluid comes out of the upper pore

pressure line.

286.31 Transient Permeability Pore Pressure Intensifier Operation

51

Page 52

Running a Steady State Flow Test

5. Turn the Reservoir Return and Pore Fluid Output valves to the Close

position.

52

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 53

Refill the Pressure Intensifier

1. Refill the Fluid Reservoir.

You can skip this step if the Reservoir is already 3/4 full.

If your 286.31 is connected to a distilled water supply —

Tur n the Reservoir Fill/Drain valve to the Open position.

When the Fluid Reservoir is about 3/4 full, turn the Reservoir Fill/

Drain valve to the Close position.

If your 286.31 is not connected to a distilled water supply —

Remove the filler plug at the top of the 286.31.

Open the console’s rear door . Unscrew one of the hex–head plugs in the

Reservoir. (This allows air to vent more easily out of the Reservoir.)

Use a funnel to fill the Fluid Reservoir about 3/4 full.

Seal the filler cap and hex–head plug with Teflon thread sealing tape

and reinstall them.

Running a Steady State Flow Test

286.31 Transient Permeability Pore Pressure Intensifier Operation

53

Page 54

Running a Steady State Flow Test

2. On the test controller, monitor the displacement sensor output.

3. Prepare to refill the Pressure Intensifier with fluid. Turn the Intensifier Fill

valve to the Open position.

54

Operation

4. Fill the Pressure Intensifier with fluid.

On the RSC, slowly turn the Manual Control to fully retract the

Intensifier’s piston.

Watch the displacement signal to make sure you have fully retracted the

piston.

286.31 Transient Permeability Pore Pressure Intensifier

Page 55

Running a Steady State Flow Test

5. Prepare to pressurize the fluid in the 286.31.

Tur n the Intensifier Fill val ve to the Close position.

286.31 Transient Permeability Pore Pressure Intensifier Operation

55

Page 56

Running a Steady State Flow Test

CAUTION

Prepare to Run a Test

1. Install your specimen in the triaxial cell.

If pore pressure becomes higher than confining pressure — even for a

second — your specimen will be damaged.

Always keep confining pressure higher than pore pressure.

2. If your Triaxial Cell has an upper pore pressure shut off valve, make sure it’s

3. Apply a confining pressure to the specimen.

For the details on doing this step, see the installation section of your triaxial

cell manual.

open.

Confining pressure must always be higher than the pore pressure.

For the details on doing this step, see the operation section of your confining

pressure intensifier manual.

4. Pressurize the pore fluid to the desired starting pressure.

On the RSC, turn the Manual Control control slowly until you reach the

desired pore pressure.

5. If the rest of your system is ready, start your data acquisition procedure.

56

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 57

Running a Steady State Flow Test

6. Begin the steady state flow test

Tur n the Pore Fluid Input and Pore Fluid Output valves to the Open

position.

Fluid will slowly flow through the specimen and into the Fluid Reservoir,

discharging at atmospheric pressure.

286.31 Transient Permeability Pore Pressure Intensifier Operation

57

Page 58

Running a Steady State Flow Test

End the Test

1. On the test controller, monitor the pressure sensor output.

2. Remove pressure from the lines.

On the RSC, turn the Manual Control control slowly until pressure

becomes zero.

3. Isolate the triaxial cell.

Turn the Pore Fluid Output and Pore Fluid Input valves to the Close

position.

58

Operation

4. If your triaxial cell has an upper pore pressure valve, close it.

286.31 Transient Permeability Pore Pressure Intensifier

Page 59

Running a Transient Permeability Flow Test

Running a Transient Permeability Flow Test

Performing a permeability flow test has five major tasks

• Fill the Pressure Intensifier

• Purge and Fill the Pore Pressure Lines

• Refill the Pressure Intensifier

• Prepare to Run the Test

• End the Test

Note If you have just done a complete purge of the 286.31, skip ahead to

Section 2.3.4. It begins on page 2-96.

286.31 Transient Permeability Pore Pressure Intensifier Operation

59

Page 60

Running a Transient Permeability Flow Test

Fill the Pressure Intensifier

1. If you have a specimen installed in the triaxial cell, remove it now. Your

triaxial cell manual has the details on doing this.

2. Turn the valves to match the positions shown in the Step 3 picture.

3. Fill the Fluid Reservoir. Skip this step if the reservoir is 3/4 full.

If your 286.31 is connected to a distilled water supply —

Tur n the Reservoir Fill/Drain valve to the Open position.

When the Fluid Reservoir is about 3/4 full, turn the Reservoir Fill/

Drain valve to the Close position.

If your 286.31 is not connected to a distilled water supply —

Remove the filler plug at the top of the 286.31.

Open the console’s rear door . Unscrew one of the hex–head plugs in the

Reservoir. (This allows air to vent more easily out of the Reservoir.)

Use a funnel to fill the Fluid Reservoir about 3/4 full.

Seal the filler cap and hex–head plug with Teflon thread sealing tape

and reinstall them.

60

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 61

Running a Transient Permeability Flow Test

4. Switch on electrical power at the control console.

5. Set up the test controller to control the 286.31’s Pressure Intensifier from the

RSC (Remote Station Controller).

6. Select the pore pressure control channel’s most sensitive operating range.

7. Select pore pressure as the active control mode.

8. Apply high hydraulic pressure to the 286.31.

9. Prepare to purge the Pressure Intensifier of air and fill it with fluid. Turn the

Intensifier Fill valve to the Open position.

10. On the test controller, monitor the displacement sensor output.

286.31 Transient Permeability Pore Pressure Intensifier Operation

61

Page 62

Running a Transient Permeability Flow Test

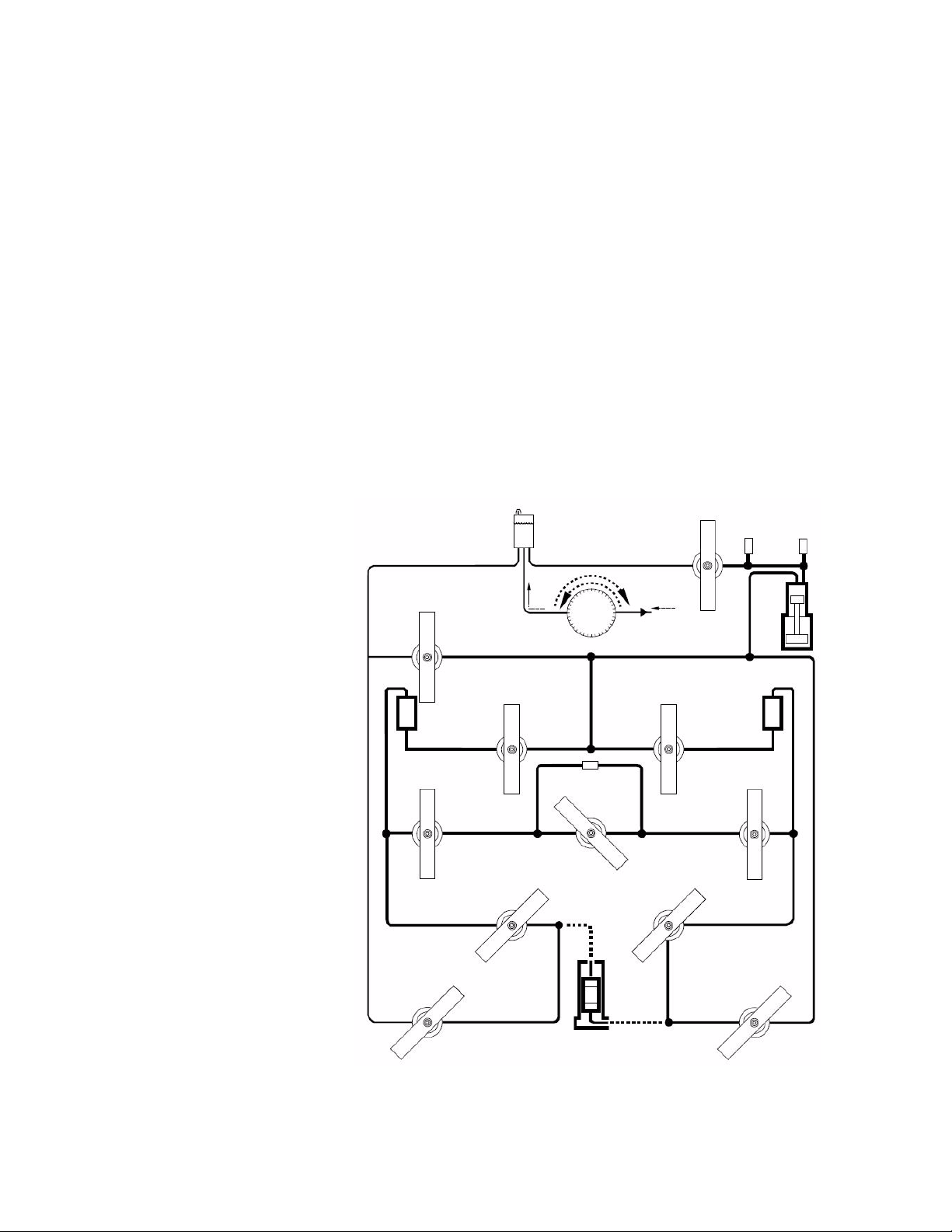

11. Purge the Pressure Intensifier of air and fill it with fluid.

On the RSC, slowly turn the Manual Control clockwise, then

counterclockwise to fully stroke the Intensifier’s piston.

Watch the displacement signal to make sure you fully stroke the piston.

When the bubbling at the Fluid Reservoir stops, use the Manual Control to

fully retract the Intensifier’s piston.

12. On the test controller, monitor the pressure sensor output.

13. Prepare to pressurize the fluid in the 286.31. Turn the Intensifier Fill valve

to the Close position.

62

Operation

14. Pressurize the fluid in the 286.31 by extending the Intensifier ’s piston.

On the RSC, slowly turn the Manual Control to develop a positive

pressure.

As you purge the pore pressure lines, keep the pressure low but positive all

the time. Keep an eye on the pressure as you purge the lines.

286.31 Transient Permeability Pore Pressure Intensifier

Page 63

Purge and Fill the Pore Pressure Lines

1. Purge and fill the lower pore pressure line.

Tur n the Pore Fluid Input valve to the Open position.

As soon as bubble-free fluid comes out at the triaxial cell’s lower pore

pressure port, go on to step 2.

Running a Transient Permeability Flow Test

286.31 Transient Permeability Pore Pressure Intensifier Operation

63

Page 64

Running a Transient Permeability Flow Test

2. Shut off the flow of fluid to the triaxial cell.

Tur n the Pore Fluid Input valve to the Close position.

64

Operation

3. If your triaxial cell has an upper pore pressure valve, open it now.

286.31 Transient Permeability Pore Pressure Intensifier

Page 65

Running a Transient Permeability Flow Test

4. Purge and fill the upper pore pressure line.

Tur n the Reservoir Return and Pore Fluid Output valves to the Open

position.

Go on to step 5 as soon as bubble–free fluid comes out of the upper pore

pressure line.

286.31 Transient Permeability Pore Pressure Intensifier Operation

65

Page 66

Running a Transient Permeability Flow Test

5. Turn the Reservoir Return and Pore Fluid Output valves to the Close

position.

66

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 67

Refill the Pressure Intensifier

1. Refill the Fluid Reservoir.

You can skip this step if the Reservoir is already 3/4 full.

If your 286.31 is connected to a distilled water supply —

Tur n the Reservoir Fill/Drain valve to the Open position.

When the Fluid Reservoir is about 3/4 full, turn the Reservoir Fill/

Drain valve to the Close position.

If your 286.31 is not connected to a distilled water supply —

Remove the filler plug at the top of the 286.31.

Open the console’s rear door . Unscrew one of the hex–head plugs in the

Reservoir. (This allows air to vent more easily out of the Reservoir.)

Use a funnel to fill the Fluid Reservoir about 3/4 full.

Seal the filler cap and hex–head plug with Teflon thread sealing tape

and reinstall them.

Running a Transient Permeability Flow Test

286.31 Transient Permeability Pore Pressure Intensifier Operation

67

Page 68

Running a Transient Permeability Flow Test

2. On the test controller, monitor the displacement sensor output.

3. Prepare to refill the Pressure Intensifier with fluid. Turn the Intensifier Fill

valve to the Open position.

68

Operation

4. Fill the Pressure Intensifier with fluid.

On the RSC, slowly turn the Manual Control to fully retract the

Intensifier’s piston.

Watch the displacement signal to make sure you have fully retracted the

piston.

286.31 Transient Permeability Pore Pressure Intensifier

Page 69

Running a Transient Permeability Flow Test

5. Prepare to pressurize the fluid in the 286.31.

Tur n the Intensifier Fill val ve to the Close position.

286.31 Transient Permeability Pore Pressure Intensifier Operation

69

Page 70

Running a Transient Permeability Flow Test

CAUTION

\Prepare to Run the Test

1. Install your specimen in the triaxial cell.

For the details on this procedure, refer to the installation section of your

triaxial cell manual.

If pore pressure becomes higher than confining pressure — even for a

second — your specimen will be damaged.

Always keep confining pressure higher than pore pressure.

2. Apply a confining pressure to the specimen.

Always keep confining pressure higher than pore pressure.

For details on this step, refer to the operation section of confining pressure

intensifier's manual.

3. If your triaxial cell has pore pressure valves, make sure they are open.

70

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 71

Running a Transient Permeability Flow Test

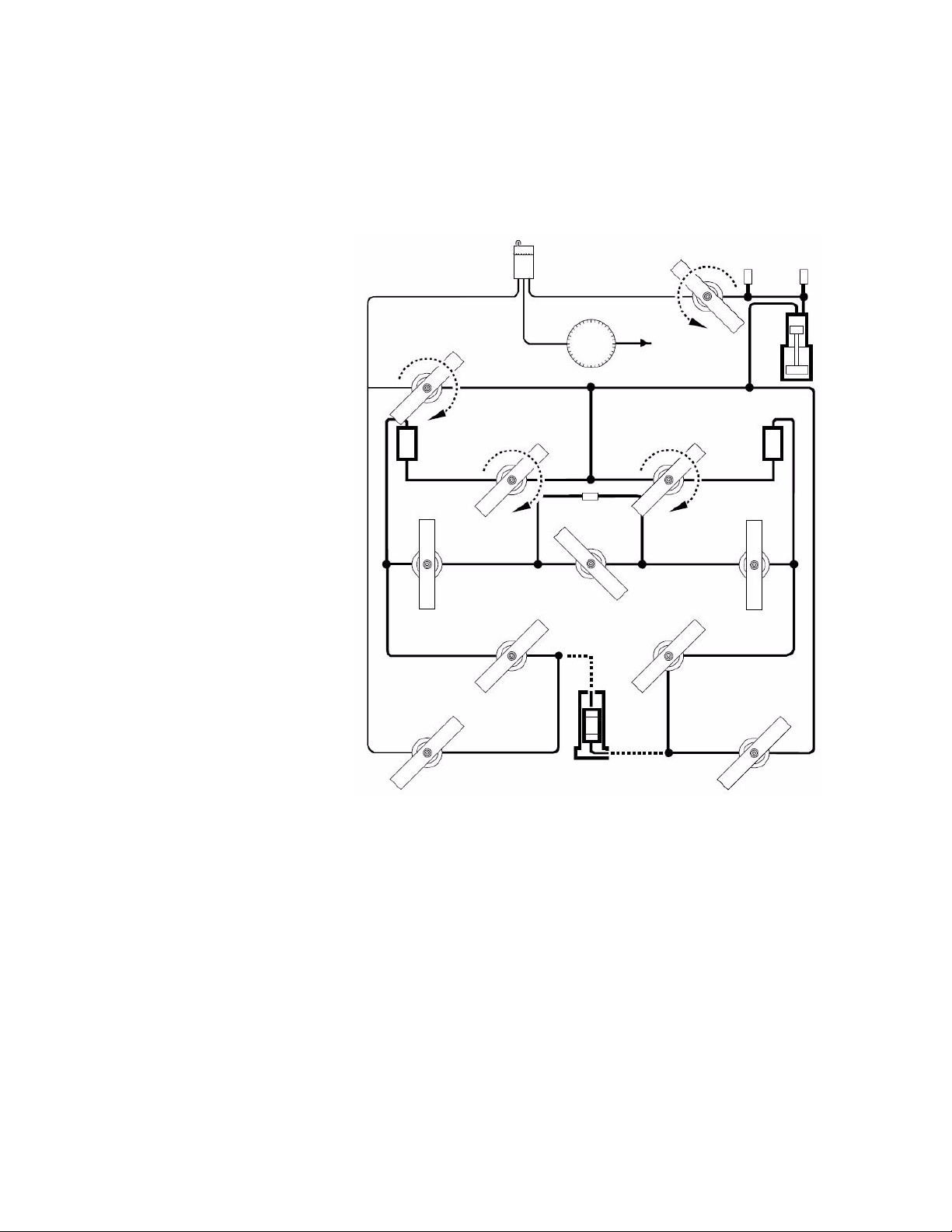

4. Prepare to pressurize Reference Volume 2.

Tur n the Permeability Fluid Input 1, Permeability Fluid Input 2, and

Transducer Input 2 valves to the Open position.

5. Pressurize Reference Volume 2.

On the RSC, slowly turn the Manual Control to develop the Reference

Volume 2 pressure you want.

286.31 Transient Permeability Pore Pressure Intensifier Operation

71

Page 72

Running a Transient Permeability Flow Test

6. Apply Reference Volume 2 pressure to the specimen.

Turn the Permeability Input and Permeability Output valves to the Open

position.

72

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 73

Running a Transient Permeability Flow Test

CAUTION

7. Separate Reference Volume 2 from Reference Volume 1.

Tur n the Permeability Input, Transducer Pressure Balance, and

Permeability Fluid Input 2 valves to the Close position.

You are now applying pressure to the 286.31's differential pressure

transducer.

8. Monitor the pressure differential transducer’s pressure signal.

The 286.31's pressure differential transducer will be damaged if the

difference in pressure between Reference Volumes 1 and 2 exceeds the

transducer's operating limit.

286.31 Transient Permeability Pore Pressure Intensifier Operation

73

Page 74

Running a Transient Permeability Flow Test

9. Compress the Reference Volume 1 fluid some more to create the pressure

differential between Volumes 1 and 2.

On the RSC, turn the Manual Control to create the pressure differential you

want.

10. Isolate Reference Volume 1 from the Pressure Intensifier.

Tur n the Permeability Fluid Input 1 valve to the Close position.

74

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 75

Running a Transient Permeability Flow Test

11. If needed, fine-tune the pressure differential between Reference Volume 1

and Reference Volume 2.

Adjust the Transducer Input 1, Transducer Input 2, and Permeability

Output valves. Do not close them, but turn them enough to change their

valve positions.

This can be done now and when you are running the test.

12. If the rest of your system is ready, start your data ac qu isition procedure.

286.31 Transient Permeability Pore Pressure Intensifier Operation

75

Page 76

Running a Transient Permeability Flow Test

13. Start the transient permeability flow test.

Tur n the Permeability Input valve to the Open position.

76

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 77

End the Test

Running a Transient Permeability Flow Test

1. Bypass the differential pressure transducer.

Tur n the Transient Pressure Balance valve to the Open position.

286.31 Transient Permeability Pore Pressure Intensifier Operation

77

Page 78

Running a Transient Permeability Flow Test

2. Prepare to reduce pore pressure to zero.

Tur n the Permeability Input 1 and Permeability Input 2 valves to the

Open position.

78

Operation

3. On the test controller, monitor the pressure sensor output.

4. Reduce pore pressure to zero.

On the RSC, slowly turn the Manual Control to reduce pressure to zero.

286.31 Transient Permeability Pore Pressure Intensifier

Page 79

Running a Transient Permeability Flow Test

5. Isolate the triaxial cell.

Turn the Permeability Output and Permeability Input valves to the Close

position.

6. If your triaxial cell has an upper pore pressure valve, close it.

286.31 Transient Permeability Pore Pressure Intensifier Operation

79

Page 80

Running a Transient Permeability Flow Test

80

Operation

286.31 Transient Permeability Pore Pressure Intensifier

Page 81

Maintenance

Prevent bacteria from growing in the pore fluid. Do this by adding a bactericide

to the fluid and by changing the pore fluid frequently.

Pore fluid lines can be flushed with a mild detergent solution. Use the steps in

“Purging and Filling the Fluid Lines” on page 16 to flush the lines. Follow the

detergent flush with a thorough fresh water flush.

Check the accumulators’ precharge pressures at least once a month. Your Series

111 Accumulator manual has details on accumulator maintenance.

286.31 Transient Permeability Pore Pressure Intensifier Maintenance

81

Page 82

82

Maintenance

286.31 Transient Permeability Pore Pressure Intensifier

Page 83

Page 84

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

ISO 9001:2000 Certified QMS

Loading...

Loading...