Page 1

Model 286.20 Confining Pressure Intensifier

l

Product Information

015-020-201 B

Page 2

Copyright information © 2007 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation.

Contact information MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255 (within the U.S. or Canada)

Phone: 952-937-4000 (outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

Publication information

Manual Part Number Publication Date

015-020-201 A

015-020-201 B

June 1991

August 2007

Page 3

Contents

Preface 5

About This Manual 6

Conventions 7

Technical Support 8

Introduction 13

Overview Of Typical Confining Pressure Control System 14

Description of Major Components 16

Specifications and Dimensions 18

Operation 19

Control Panel 20

High Pressure Precaution 22

High Temperature Precaution 22

Confining System Operation Considerations 23

Operating Procedures 27

Filling the Reservoir From An External Source 28

Filling the Pressure Intensifier From an External Container 30

Filling the Pressure Intensifier From The Reservoir 32

Filling the Triaxial Cell 34

Heating The Triaxial Cell 36

Pressurizing and Depressurizing The Confining Fluid 37

Cooling The Triaxial Cell and Confining Fluid 41

Emptying the Triaxial Cell 42

Draining the Reservoir to an External Location 44

manual name Contents

3

Page 4

4

Contents

manual name

Page 5

Preface

Safety first! Before you attempt to use your MTS equipment in your test system, read and

Contents About This Manual 6

understand the Safety manual. Like an automobile, your test system is very

useful—but if misused, it is capable of deadly force. You should not be afraid of

your test system, but you should always maintain a healthy respect for it.

Improper installation, operation, or maintenance of MTS equipment in your test

system can result in hazardous conditions that can cause severe personal injury or

death, and damage to your equipment and specimen. Again, read and understand

the Safety manual before you continue. It is very important that you remain aware

of hazards that apply to your test system.

Conventions 7

Technical Support 8

286.20 Pressure Intensifier Preface

5

Page 6

About This Manual

About This Manual

Purpose This manual provides detailed information about the Model 286.20 Confining

Pressure Intensifier. The information includes an overview and operation.

Summary This manual includes the following sections.

Introduction This section provides an overview of typical confining pressure control system, a

description of major components, and specifications.

Operation This section contains procedures for operations involving the flow and

pressurization of confining fluid.

Preface

6

286.20 Pressure Intensifier

Page 7

Conventions

Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions Hazard notices are embedded in this manual and contain safety information that

is specific to the task to be performed. Hazard notices immediately precede the

step or procedure that may lead to an associated hazard. Read all hazard notices

carefully and follow the directions that are given. Three different levels of hazard

notices may appear in your manuals. Following are examples of all three levels.

Note For general safety information, see the Safety manual included with your

system.

Danger notices Danger notices indicate the presence of a hazard which will cause severe personal

injury, death, or substantial property damage if the danger is ignored.

Warning notices Warning notices indicate the presence of a hazard which can cause severe

personal injury, death, or substantial property damage if the warning is ignored.

Caution notices Caution notices indicate the presence of a hazard which will or can cause minor

personal injury, cause minor equipment damage, or endanger test integrity if the

caution is ignored.

Other conventions Other conventions used in your manuals are described below:

Notes Notes provide additional information about operating your system or highlight

easily overlooked items.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

286.20 Pressure Intensifier Preface

7

Page 8

Technical Support

Technical Support

Start with your

manuals

Technical support

numbers

MTS web site

www.mts.com

E-mail: General information:info@mts.com

Telephone HELPLine 800-328-2255

The manuals supplied by MTS provide most of the information you will need to

use and maintain your equipment. If your equipment includes MTS software, you

should look for README files for additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, telephone, or fax to contact MTS for assistance. You can also

fill out the Problem Submittal Form that is available on the MTS web site and in

the back of many MTS manuals that are distributed in paper form.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Problem Submittal Form and a Technical Support link.

• Problem Submittal Form:

www.mts.com > Contact MTS > Problem Submittal Form

• Technical Support:

www.mts.com > Contact Us > Service & Technical Support

Weekdays 7:00 A.M. to 6:00 P.M.,

Central Time

Fax 952-937-4515

Please include an MTS contact name if possible.

Preface

8

286.20 Pressure Intensifier

Page 9

Technical Support

Before you

contact MTS

Know your site number

and system number

Know information from

prior technical

assistance

MTS can help you more efficiently if you have the following information

available when you contact us for support.

The site number contains your company number and identifies your equipment

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system project number identifies

which system you are calling about. You can find your project number in the

papers sent to you when you ordered your system.

Example system project number: US1.30123

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions.

Know relevant computer

information

• How long has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model and serial numbers of the suspect equipment?

If you are experiencing a computer problem, have the following information

available.

• Manufacturer’s name and model number

• Operating software type and service patch information. Examples:

– Windows XP Service Pack 1 (SP1)

– Windows 2000 Service Pack 3 (SP3)

• Amount of system memory. Example: 512 MB of RAM.

• Amount of free space on the hard drive in which the application resides.

Example: 11.2 GB free space, or 72% free space.

• Current status of hard-drive fragmentation. Example: 3% total

fragmentation.

286.20 Pressure Intensifier Preface

9

Page 10

Technical Support

Know relevant software

information

If you contact MTS

by phone

For MTS software application problems, have the following information

available.

• TestWorks 4 version; for example Version 4.09

• Names of other non-MTS applications that are running on your computer,

such as screen savers, keyboard enhancers, print spoolers, and so forth

Your call will be registered by a HELPLine agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, your agent will ask you for your site number, name, company,

company address, and the phone number where you can normally be reached.

Identify system type To assist your HELPLine agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• • Electromechanical materials test system

• • Hydromechanical materials test system

• • Vehicles test system

• • Vehicles component test system

• • Aero test system

Be prepared to

troubleshoot

Prepare yourself for troubleshooting while on the phone.

• Call from a telephone close to the system so that you can try implementing

suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

10

Preface

286.20 Pressure Intensifier

Page 11

Technical Support

Write down relevant

information

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

Problem Submittal

Form in MTS manuals

Prepare yourself in case we need to call you back.

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again.

In addition to the Problem Submittal Form on the MTS web site, there is also a

paper version of this form (postage paid) in the back of many MTS manuals. Use

this form to forward problems you are experiencing with your MTS equipment,

whether it be software, hardware, manuals, or service. This form includes check

boxes that allow you to select when you expect us to respond to your input. We

guarantee a timely response—your feedback is important to us.

286.20 Pressure Intensifier Preface

11

Page 12

Technical Support

12

Preface

286.20 Pressure Intensifier

Page 13

Introduction

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

815

Fluid

Resivoir

Control

Panel

This section describes the Model 286.20 Confining Pressure Intensifier (CPI), its

role in the typical rock mechanics test system and other system components

typically used with the Confining Pressure Intensifier. Specifications and

dimensions are also included.

The Model 286.20 Confining Pressure Intensifier is designed to provide a source

of fluid at pressures suitable for use in the confining pressure chamber of a

triaxial cell. The CPI is used to fill the triaxial cell with confining fluid,

pressurize the fluid, control the pressure, and empty the fluid from the triaxial

cell at the conclusion of a test.

Some model versions produce confining pressures up to 140 MPa (20,000 psi).

When connected to a fluid-filled triaxial cell, the maximum fluid volume that can

flow during pressurization of the external device and its specimen can be as high

as 1300 cubic centimeters (80 cubic inches). See “Specifications and

Dimensions” on page 18 for specifications for all models.

286.20 Pressure Intensifier Introduction

13

Page 14

Overview Of Typical Confining Pressure Control

Overview Of Typical Confining Pressure Control System

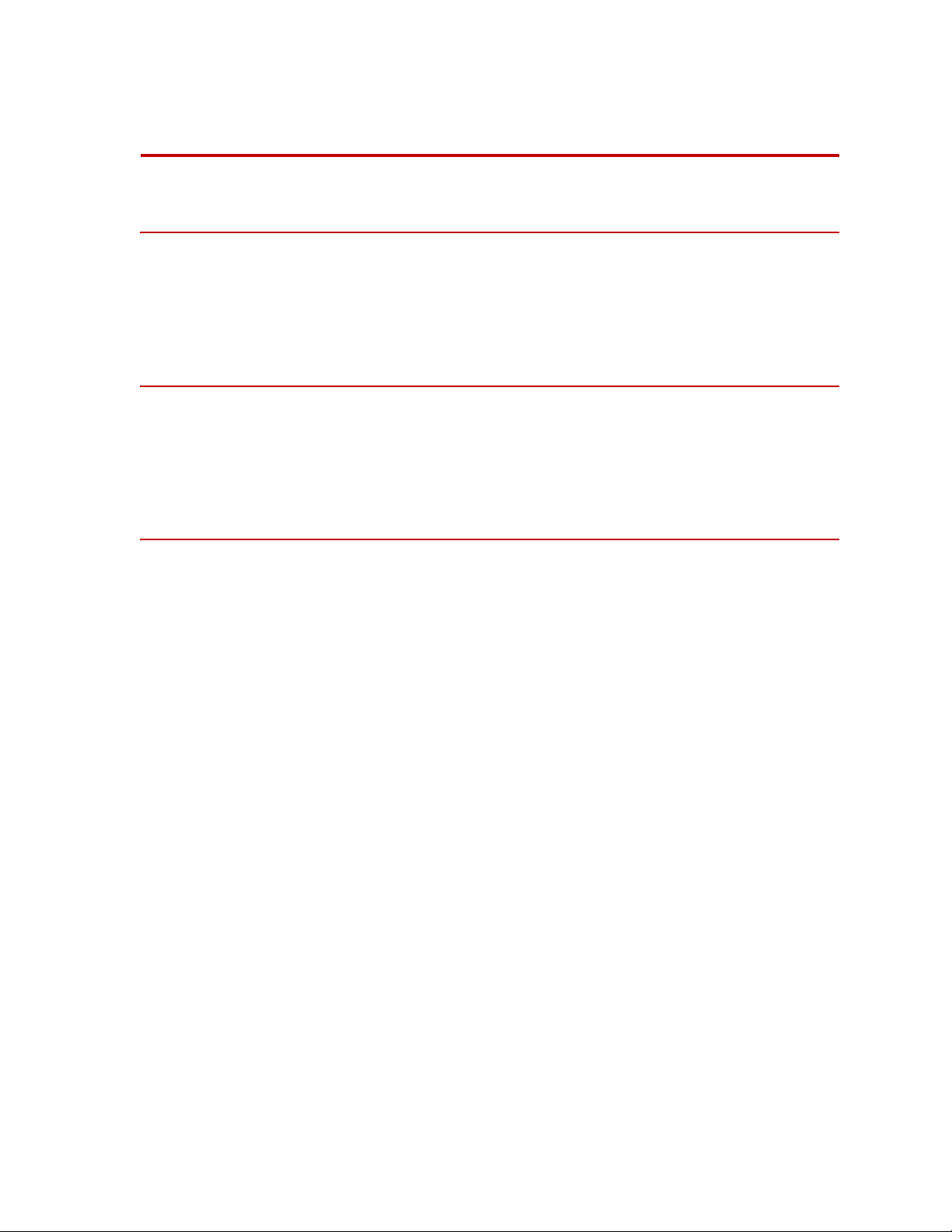

The major system components typically used with the Confining Pressure

Intensifier are shown in the following figure.

14

Introduction

As shown in the figure, a separate hydraulic power supply acts as the primary

power source for the Confining Pressure Intensifier. Hydraulic fluid pressures up

to 21 MPa (3,000 psi) are translated into confining fluid pressures up to 140 MPa

(20,000 psi) under servo control provided by separate electronic controller

equipment.

Compressed air, driving a small fluid pump, provides the power to cause

confining fluid to flow between various system components before and after

pressurizing operations, while filling and/or emptying the triaxial cell, the

pressure intensifier, the reservoir, etc. The pump can also cause fluid to flow

between an external fluid container and either the CPI or the triaxial cell.

286.20 Pressure Intensifier

Page 15

Overview Of Typical Confining Pressure Control

Pressure and displacement transducers in the CPI provide signals proportional to

their respective variables, enabling the external electronic controller equipment

to measure these variables and to control either the pressure produced by the CPI,

or the linear displacement of the pressure intensifiers piston relative to a fixed

reference.

While the displacement transducer output signal is proportional to the

displacement of the pressure intensifiers piston, relative to a reference point, the

electronic control equipment associated with this transducer is usually calibrated

in units of volumetric displacement, cubic inches or cubic centimeters, a function

of linear displacement multiplied by the area of the pressure intensifiers piston

rod.

286.20 Pressure Intensifier Introduction

15

Page 16

Description of Major Components

1

2

4

3

5

6A

8

7

9

6B

Description of Major Components

The following figure and table identify and describe the major components of the

Model 286.20.

TEM COMPONENT DESCRIPTION

I

1 Cabinet

2 Reservoir

3 Operator control panel

Enclosure mounted on casters. Includes leveling legs for

stability and a hinged rear access door.

Clear acrylic container. Includes filler port with strainer

which also acts as a vent for escaping gases.

Panel contains all the valves used during operation and a

pressure gage which reads confining pressure. The panel

includes a schematic of the unit to aid in operation.

16

Introduction

286.20 Pressure Intensifier

Page 17

Description of Major Components

4 Pressure transducer

5 Pressure relief valve

6 Pressure intensifier

7 Hydraulic service manifold

8 Servovalve

9 Linear transducer

Provides a signal which represents the level of confining

fluid pressure being applied to the triaxial cell. The

signal is used by the electronic controller equipment as

feedback when pressure is the controlled variable.

Relieves pressure in the system if pressure exceeds the

CPI’s pressure rating by a certain amount.

Actuator which uses servovalve controlled hydraulic

fluid to pressurize the confining fluid. The top end,

identified as “6A,” is the high pressure, confining fluid

part of the actuator. The lower part, “6B,” is the low

pressure, hydraulic end.

Provides an interface between the external hydraulic

power supply and the pressure intensifier. Provides

mounting for various hydraulic components such as

accumulators and the servovalve.

Controls flow and pressure of hydraulic fluid applied to

the input side of the pressure intensifier.

Provides a signal to the test controller.

286.20 Pressure Intensifier Introduction

17

Page 18

Specifications and Dimensions

Specifications and Dimensions

The following tables list the dimensions, weights, and specifications for the

Model 286.20 Confining Pressure Intensifier.

Dimensions and Weights

P

ARAMETER ALL MODELS

Height 1825 mm (72 in.)

Width 600 mm (23.6 in.)

Depth 845 mm (33.3 in.)

Weight 454 kg (1000 lb.)

Reservoir Capacity 11.4 liters (3.0 gallon)

PARAMETER MODEL 286.20-08 MODEL 286.20-10

Maximum Output

Pressure, MPa/PSI

Output Volume

cu. cm/in.

Recommended

Fluids

Maximum Fluid

Temperature

Air Driven Pump

Compressed Air

Requirement

80/12,000

655/40

Refined mineral oil (i.e., PG1¨, or Multitherm¨) or

Silicone oil for triaxial testing to +200

75 °C (165 °F)

Note Many triaxial cells are capable of heating

confining fluid to a temperature exceeding

this value. Therefore, it is imperative that the

fluid be allowed to cool to 75

less, before recirculating it into the Pressure

Intensifier.

0.6 MPa (90 psi), clean and dry

140/20,000

980/60

°C/400 °F

°C/165 °F, o r

18

Introduction

286.20 Pressure Intensifier

Page 19

Operation

This section contains procedures for all operations involving the flow and

pressurization of confining fluid. All operating controls on the Confining

Pressure Intensifier (CPI) are described.

In addition to the Confining Pressure Intensifier, a confining pressure system

typically includes a hydraulic power supply, some type of electronic controller

equipment, and a triaxial cell. Before attempting to operate the CPI, become

familiar with each component of the confining pressure system by reading the

introduction sections of the manuals that apply.

Pressurization and depressurization of confining fluid is primarily under the

control of the electronic controller equipment. Because of the variety of

electronic controller equipment that can be used with a confining pressure

system, information provided in this manual is limited to that which will enable

you to relate CPI parameters, such as fluid pressure and fluid volumetric

displacement, to controller functions such as the command, readout and limit

functions.

A typical procedure for operating the Confining Pressure Intensifier would be:

1. Filling the reservoir; see “Filling the Reservoir From An External Source”

on page 28.

2. Filling the pressure intensifier; see “Filling the Pressure Intensifier From an

External Container” on page 30 and “Filling the Pressure Intensifier From

The Reservoir” on page 32.

3. Filling the triaxial cell; see “Filling the Triaxial Cell” on page 34.

4. Heating the triaxial cell (if applicable); see “Heating The Triaxial Cell” on

page 36.

5. Pressurizing and depressurizing the confining fluid; see “Pressurizing and

Depressurizing The Confining Fluid” on page 37.

6. Cooling the triaxial cell; see “Cooling The Triaxial Cell and Confining

Fluid” on page 41.

7. Emptying the triaxial cell to the reservoir; see “Emptying the Triaxial Cell”

on page 42.

8. Emptying the reservoir to an external container; see “Draining the Reservoir

to an External Location” on page 44.

Before operating the system for the first time, simulate the desired operation.

Locate the controls involved with each step, without actually performing the

adjustment. In this way, you will become familiar with the information that is

required or the decisions that must be made before beginning actual operation.

286.20 Pressure Intensifier Operation

19

Page 20

Control Panel

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

1

2

4

3

5

6

8

7

Control Panel

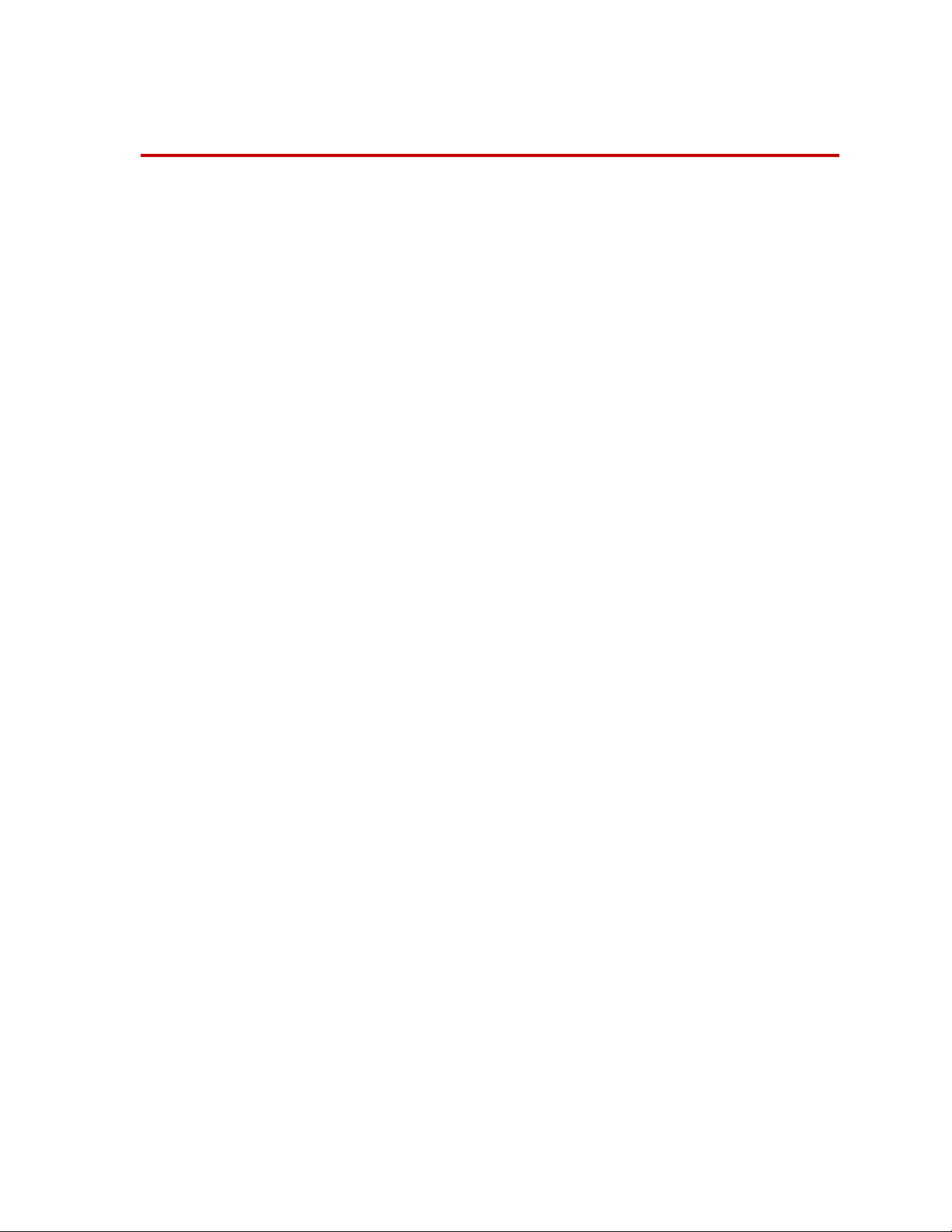

The following figure shows the operational controls, superimposed on the front

panel hydraulic schematic. The following table describes items 1 through 8,

shown in the figure.

The table lists the operational effects of each individual control. However, note

that performing the various operations listed in the table usually involves the

manipulation of two or more of the controls.

TEM CONTROL FUNCTION

I

1 Confining Fluid

Output

2 Confining Pressure

gage

20

Operation

Adjustable hand-valve. Turning the valve counterclockwise toward Open

allows air to be vented from the triaxial cell to the reservoir when filling the

cell with fluid. The valve must be closed before pressurizing the triaxial cell.

Analog gage. Indicates pressure inside the Triaxial Cell, scaled in pounds

per square inch (psi).

286.20 Pressure Intensifier

Page 21

Control Panel

3 Air Direction

4 Confining Fluid

Input

5 Fluid Direction

6 Fluid Transfer Pump

Control

7 Reservoir Fill

Two position hand-valve. Position “A” enables air to escape from the

triaxial cell to the reservoir when filling the triaxial cell with confining fluid.

Position “B” allows compressed air to force confining fluid from the triaxial

cell to the reservoir, when emptying fluid from the triaxial cell.

(If the valve handle is positioned mid-way between “A” and “B,” the valve

is turned off.)

Adjustable hand-valve. Turning the valve counterclockwise toward Open

allows fluid to flow into or out of the triaxial cell, or it allows cell fluid to be

pressurized by the pressure intensifier. Turning the valve fully clockwise to

Close closes the input to the triaxial cell.

Three position hand valve.

Position “A” allows fluid to flow from the reservoir to the pressure

intensifier or triaxial cell.

Position “B” allows fluid to flow from the reservoir to an external container

when draining the reservoir.

Position “C” allows the air-driven hydraulic pump to pump fluid from an

external container into the reservoir.

Adjustable valve allows compressed air to operate the air-driven hydraulic

pump. (The pump is used only when transferring fluid from one location to

another, not while pressurizing the confining fluid.)

Adjustable hand-valve. Turning the valve counterclockwise toward Open

allows confining fluid to flow from the triaxial cell to the reservoir when

emptying the cell, or from an external container to the reservoir when filling

the reservoir. The valve must be closed before pressurizing the triaxial cell.

8 Intensifier Fill

Adjustable hand-valve. Turning the valve counterclockwise toward Open

allows confining fluid to flow from the reservoir to the pressure intensifier.

The valve must be closed before pressurizing the triaxial cell.

286.20 Pressure Intensifier Operation

21

Page 22

High Pressure Precaution

WARNING

CAUTION

High Pressure Precaution

Confining fluid can attain very high pressures. High pressure fluid can

cause severe injury or death.

Ensure pressure gage reads zero before opening the Confining Fluid Output

valve. Follow all procedures provided by this manual.

The Model 286.20 Confining Pressure Intensifier is capable of producing very

high pressures. If mishandled or improperly adjusted, it is capable of seriously

injuring and/or killing personnel, damaging itself, and damaging surrounding

equipment. If care is taken however, the unit can provide prolonged service

without incidents.

High Temperature Precaution

Temperature of fluid in the triaxial cell can exceed the temperature rating of

the Confining Pressure Intensifier. This could damage the Confining

Pressure Intensifier.

Temperature will increase when applying pressure. So if heated to maximum

temperature before pressure is applied, increasing pressure too fast can cause

the temperature to increase to a point where it can damage the equipment;

primarily the transducers.

Also allow fluid in the triaxial cell to cool to 75 °C (167 °F) or less before emptying

the triaxial cell back to the reservoir of the Confining Pressure Intensifier.

The Model 286.20 Confining Pressure Intensifier has a temperature rating of

°C (167 °F). Many triaxial cells have higher temperature ratings. Therefore,

75

the confining fluid in the triaxial cell must be allowed to cool to 75

or below, before being recirculated into the Confining Pressure Intensifier. If

fluid having a temperature higher than 75

the CPI, the acrylic reservoir and associated flexible tubing can be damaged.

°C (167 °F) is allowed to circulate into

°C (167 °F),

22

Operation

286.20 Pressure Intensifier

Page 23

Confining System Operation Considerations

Confining System Operation Considerations

The following paragraphs provide some general information about operation of

the CPI.

Closed-Loop Control Modes Used For Pressurizing Confining Fluid

When pressurizing the confining fluid, the pressure intensifier inside the CPI

operates under closed-loop control principles. External electronic controller

equipment receives signals from a pressure transducer in the CPI, and also from a

linear displacement transducer, which indicates current pressure intensifier piston

position relative to a reference position. The amplitudes of the two signals are

proportional to their respective variables.

Pressure control mode Calibration of the electronic controller equipment is such that the signal from the

pressure transducer relates directly to pressure inside the triaxial cell, in psi or

MPa, depending on how the controller equipment was calibrated. When the

output of the pressure transducer is chosen as a feedback signal for the controller,

pressure becomes the controlled, or independent, variable, and displacement

becomes a dependent, or uncontrolled, variable. This is usually referred to as the

pressure control mode.

Displacement control

mode

The pressure control mode is the preferred control mode.

The signal from the CPI’s linear displacement transducer. When the output of the

displacement transducer is chosen as a feedback signal for the controller,

volumetric displacement becomes the controlled, or independent, variable and

pressure becomes a dependent, or uncontrolled, variable. This is usually referred

to as the displacement control mode.

The displacement control mode is less desirable for use than the pressure control

mode because very small changes in displacement cause very large changes in

pressure. Also, if the displacement control mode were used while the triaxial cell

was being heated, the controller would be insensitive to fluid expansion due to

increasing temperature and very high pressures could result.)

If the triaxial cell is equipped with heaters, it is important to remain aware of the

effects of thermal expansion of the fluid when the Confining Pressure Intensifier

is in operation. This is described under the following heading.

286.20 Pressure Intensifier Operation

23

Page 24

Confining System Operation Considerations

Effects of Thermal Expansion of Confining Fluid

When heaters are used to heat the triaxial cell, the specimen and the confining

fluid, the confining fluid expands.

Thermal expansion

when operating in

pressure control mode

Thermal expansion

when operating in

displacement control

mode

If the confining pressure system is being operated in the pressure control mode

while the triaxial cell is being heated, pressure inside the triaxial cell normally

will not increase as temperature rises. This is because any tendency for pressure

to increase, as a result of thermal expansion or any other cause, will be

automatically corrected by the controller. The piston of the CPI’s pressure

intensifier will simply retract, as required to maintain the correct pressure, in

spite of increasing thermal expansion, assuming that the pressure intensifier’s

piston does not reach the physical end of its stroke in the process. If the piston

cannot retract sufficiently to maintain the programmed pressure, confining

pressure will increase rapidly with further thermal expansion.

If the confining pressure system is being operated in the displacement control

mode, while the triaxial cell is being heated, pressure inside the triaxial cell will

increase rapidly as thermal expansion occurs, because, except for various

monitoring devices such as limit detectors, the controller is insensitive to

pressure changes.

(Properly executed operating procedures can avoid either of the situations that

are described under this heading, where pressure increases undesirably because

of thermal expansion. They are described here to indicate that such situations can

develop and to provide a basis for describing the use of the controller’s error

detectors and limit detectors, which follows.)

24

Operation

286.20 Pressure Intensifier

Page 25

Confining System Operation Considerations

Use of Error Detectors and Limit Detectors While Pressurizing

Information under heading Effects of Thermal Expansion of Confining Fluid

describes two situations in which confining pressure can be, or can become, an

uncontrolled variable. These situations, and actually all “normal” pressurizing

procedures, warrant the use of whatever devices are available, on the electronic

controller equipment, that enable system conditions to be monitored and system

operation to be shut down in the event abnormal or undesirable operating

conditions occur.

In the first situation described under heading Effects of Thermal Expansion of

Confining Fluid, the controller is controlling pressure but is unable to

compensate for additional pressure increase caused by further thermal expansion

because the piston of the pressure intensifier has bottomed out and cannot retract

any further. In this case, two monitoring circuits, common to most controllers,

would afford some protection, if properly pre-adjusted.

Error detectors Error detectors monitor the amplitude of the controller’s error signal

(proportional to the difference between command and feedback) and are

therefore always associated with the controlled variable. In the situation where

the controller becomes unable to compensate for further thermal expansion

(because the pressure intensifier is unable to retract any further), the error signal

will begin to increase in magnitude as soon as the controller can no longer

compensate, if further thermal expansion occurs. If the error detectors had been

adjusted to be sensitive to small error levels, the pressurization procedure would

be terminated very soon after the problem occurred.

Limit detectors Limit detectors can be set up to monitor the level of variables, whether the

variables are independent (controlled) or dependent (uncontrolled). In the first

situation described under heading Effects of Thermal Expansion of Confining

Fluid, the controller’s limit detector could also have been set up to terminate the

pressurization procedure in the event that pressure exceeded some preestablished limit. With both error detectors and limit detectors in use monitoring

the controlled variable, the pressurization procedure would be terminated by

whichever detector reacted first.

In the second situation described under heading Effects of Thermal Expansion of

Confining Fluid, with volumetric displacement the controlled variable, the error

detector could be adjusted to react to some unusual level of error (associated with

the controlled variable, volumetric displacement) and the limit detector could be

set up to actuate if the dependent variable, pressure, exceeded some undesired or

unanticipated level.

Since an unanticipated high pressure level is nearly always of greater concern

than is high volumetric displacement (although a displacement limit could be

caused by a leak, which could be extremely dangerous), pressure should always

be monitored by either limit detectors or error detectors, or both. Limit detectors

provide some advantage over error detectors in that precise limit levels are easily

established. Error detectors actuate when feedback (the actual level of the

controlled variable) deviates from command (the desired level of the controlled

variable) by some presettable amount and they can detect such errors regardless

of the level of the controlled variable. Both detector types offer unique

advantages and should be used simultaneously and judiciously according to the

test situation at hand.

286.20 Pressure Intensifier Operation

25

Page 26

Confining System Operation Considerations

Effects of Air In The System

The operating procedures provided in this section include instructions for

removing air from the pressurized parts of the system before pressurizing the

confining fluid.

A large volume of air can affect system response time, when operating in the

pressure control mode, or it can affect the expected relationship between pressure

and volumetric displacement, when operating in the displacement control mode,

especially when low pressures are involved.

Fluid Capacity Considerations

The CPI’s reservoir has sufficient capacity for normal operation with any MTS

triaxial cell. If the CPI is to be used with pressure vessels requiring greater

capacities, a separate container of confining fluid is usually used.

When a separate fluid storage container is used to increase reservoir capacity

during CPI operating procedures, the container is typically used as the source for

the volume of fluid required to fill the pressure vessel and the CPI’s reservoir is

used as the source for the CPI’s pressure intensifier. When used in this manner,

the CPI’s air-driven hydraulic pump is used to fill the pressure vessel, directly

from the storage container. When the pressure vessel must be emptied, fluid is

forced from the vessel by compressed air applied through the Air Direction

control, although the expelled fluid must first go through the CPI’s reservoir, then

to the external container via the Fluid Direction valve.

Frothing

Certain procedures which involve air flow into the bottom of the fluid reservoir,

such as “Emptying the Triaxial Cell” on page 42, can cause frothing of the fluid

in the reservoir.

Frothing can quickly cause fluid in the reservoir to overflow.

Always observe the reservoir while emptying the triaxial cell and take steps to

avoid overflow:

A. Open the reservoir fill valve one turn, or less.

B. Slow or shut off the flow of air before overflow occurs.

26

Operation

286.20 Pressure Intensifier

Page 27

Operating Procedures

WARNING

The operating procedures, which follow, are presented in the usual order of

occurrence. The first, “Filling the Reservoir From An External Source” on page

28, assumes the reservoir is to be filled for the first time, or that fluid quantity in

the reservoir needs to be replenished. Subsequent procedures assume that the

condition of the system is as established by the successful performance of the

immediately preceding procedure.

Hydraulic power will be applied during some operating procedures.

Conditions hazardous to life and equipment exist on all systems or

equipment that might be connected to the same hydraulic power source.

Before turning on hydraulic power, first make sure that all systems or equipment

that use the same hydraulic power source are in appropriate condition for

application of hydraulic power.

Operating Procedures

Make certain no one is performing work on other systems or equipment sharing

the same hydraulic power source. Inform other people in the vicinity that you are

about to turn on hydraulic power.

286.20 Pressure Intensifier Operation

27

Page 28

Operating Procedures

Filling the Reservoir From An External Source

The following procedure will fill the reservoir from an external fluid container.

The following figure shows the sequence of actions described in the procedure.

Note The fluid to be added must be a recommended type (see “Specifications

and Dimensions” on page 18) and the same as any fluid currently in the

Confining Pressure Intensifier. (Don’t mix fluid types.)

Preliminary steps A. Connect a filler hose between the connector on the lower side of the

Fluid Direction valve (rear side of control panel) and the external fluid

container. Immerse the container end of the hose in the fluid.

B. Connect a source of clean, compressed air to the quick-disconnect

connector on the Fluid Transfer Pump Control (rear of control panel).

Required pressure is 90 psi (0.6 MPa).

Procedure 1. Turn the Fluid Transfer Pump Control fully clockwise to the Off position.

2. Turn the Fluid Direction valve to position C.

3. Turn the Confining Fluid Input valve fully clockwise to the Close position.

4. Turn the Intensifier Fill valve fully clockwise to the Close position.

5. Set the Reservoir Fill valve a turn or two counterclockwise, in the Open

direction.

6. Actuate the air-driven hydraulic pump by rotating the Fluid Transfer Pump

Control counterclockwise.

7. Watch the fluid as it fills the reservoir. Set the Fluid Transfer Pump Control

to the Off position when fluid in the reservoir reaches the desired fill level

(typically three-quarters full).

8. Turn the Reservoir Fill valve fully clockwise (towards Close).

Note It might be desirable to fill the pressure intensifier from the same external

container, next. See “Filling the Pressure Intensifier From an External

Container” on page 30.

28

Operation

286.20 Pressure Intensifier

Page 29

Operating Procedures

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

4 - Close

5 - Open

8 - Close

2 - C

1 - Off

6 - On

7 - Off

7 - Watch

level

3 - Close

Filling the Reservoir From An External Source

286.20 Pressure Intensifier Operation

29

Page 30

Operating Procedures

Filling the Pressure Intensifier From an External Container

Note This procedure is used only when filling the pressure intensifier for the

first time. It is used after filling the reservoir for the first time and it

purpose is to establish operating fluid levels in the CPI.

For filling the pressure intensifier during daily operation of the CPI, see

“Filling the Pressure Intensifier From The Reservoir” on page 32.

Purpose of this

procedure

If the CPI’s pressure intensifier is being filled for the first time, it may be

desirable to fill it from an external fluid container, as described here, to avoid

lowering the level of fluid in the reservoir, especially when the volumetric

displacement rating of the pressure intensifier is 980 cm

3

), or more.

(80 in.

This procedure fills the pressure intensifier only to the extent allowed by the

position of the pressure intensifier’s piston rod. For example, if the pressure

intensifier’s piston is at mid-stroke, the volume of fluid the pressure intensifier

will be able to contain is approximately half the pressure intensifier’s volumetric

rating. But, the procedure will expel all air from the pressure intensifier and fill

the available space with confining fluid. “Filling the Pressure Intensifier From

The Reservoir” on page 32 describes how to fully fill the pressure intensifier

from the reservoir prior to pressurizing operations.

Note The fluid used must be a recommended type (see Specifications) and

the same as any fluid currently in the CPI. (Don’t mix fluid types.)

3

(60 in.3), or 1300 cm3

Preliminary steps A. Connect a filler hose between the connector on the lower side of the

Fluid Direction valve (rear side of control panel) and the external fluid

container. Immerse the container end of the hose in the fluid.

B. Connect a source of clean, dry compressed air to the quick-disconnect

connector on the Fluid Transfer Pump Control (rear of control panel).

Required pressure is 90 psi (0.7 MPa).

Procedure 1. Turn the Reservoir Fill valve fully clockwise to the Close position.

30

Operation

2. Turn the Confining Fluid Input valve fully clockwise to the Close position.

3. Turn the Fluid Direction valve to the “C” position.

4. Open the Intensifier Fill valve a turn or two counterclockwise.

5. Turn the Fluid Transfer Pump Control counterclockwise just enough to run

the air-driven hydraulic pump at low speed.

6. Watch for air bubbles to stop and/or an increase of fluid level in the

reservoir. When the reservoir fluid level starts to increase beyond its

previous level, turn the Fluid Transfer Pump Control fully clockwise to Off.

7. Put the Fluid Direction valve in the “A” position.

8. Turn the Fluid Transfer Pump Control counterclockwise a turn or two to run

the air-driven pump.

9. When no more bubbles are seen the entering the reservoir, turn the Fluid

Transfer Pump Control fully clockwise to the Off position.

10. Turn the Intensifier Fill valve fully clockwise to the Close position.

286.20 Pressure Intensifier

Page 31

Operating Procedures

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

4 - Open

10-Close

1 - Close

3 - C

7 - A

5 - On

6 - Off

8 - On

9- Off

6 - Watch

for bubbles

and fluid

level

2 - Close

Filling the Pressure Intensifier From an External Container

286.20 Pressure Intensifier Operation

31

Page 32

Operating Procedures

Filling the Pressure Intensifier From The Reservoir

Note If you are filling the pressure intensifier for the first time, perform the

procedure under heading “Filling the Pressure Intensifier From an

External Container” on page 30. This procedure is used for normal, day-

to day use prior to pressurizing operations.

Purpose of this

procedure

The purpose of this procedure is to establish three simultaneous conditions in

preparation for pressurizing the confining fluid:

A. To fill the high pressure end of the pressure intensifier with confining

fluid.

B. To expel all air from the high pressure end of the pressure intensifier.

C. To place the pressure intensifier’s piston near the start of its

displacement range

Procedure 1. Make sure the Reservoir Fill valve is turned fully clockwise to the Close

position.

2. Open the Intensifier Fill valve a turn or two counterclockwise.

3. Turn the Confining Fluid Input valve fully clockwise to Close.

4. Configure the confining system’s controller for the displacement control

mode.

5. At the CPI’s control equipment, turn on hydraulic pressure.

6. At the displacement controller, cause the pressure intensifier’s piston rod to

slowly stroke to the lower end of it’s travel (piston fully retracted, zero

displacement position). This will draw fluid from the reservoir, into the

pressure intensifier.

32

Operation

7. Actuate the air-driven hydraulic pump by rotating the Fluid Transfer Pump

Control counterclockwise.

8. Watch the reservoir and note any air bubbles escaping from the intensifier.

When the air bubbles cease, set the Fluid Transfer Pump Control to the Off

position.

9. At the displacement controller, cause the pressure intensifier’s piston rod to

stroke slowly

action forces any air out of the intensifier lines. When air bubbles cease to

appear, stop the motion of the pressure intensifier’s piston rod.

10. At the displacement controller, cause the pressure intensifier’s piston rod to

stroke slowly downward again to about 10% of its displacement range. This

will draw fluid back into the pressure intensifier.

11. Turn the Intensifier Fill valve fully clockwise to Close.

12. Turn off hydraulic power.

upward while observing the reservoir for air bubbles. This

286.20 Pressure Intensifier

Page 33

Operating Procedures

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

2 - Open

11-Close

1 - Close

7 - On

8 - Off

Steps 4 through 6, 9, and 10 are

performed on the test controller

and not shown here

3 - Close

Filling the Pressure Intensifier From The Reservoir

286.20 Pressure Intensifier Operation

33

Page 34

Operating Procedures

Filling the Triaxial Cell

Note Before starting this procedure, decide whether the triaxial cell (or

Preliminary step A. If you are filling the triaxial cell from an external container, connect a

Procedure 1. Set the Fluid Direction valve to the desired source of confining fluid:

• Position “A” selects fluid from the reservoir.

• Position “C” selects fluid from the external container.

2. Turn the Reservoir Fill valve fully clockwise to Close.

3. Turn the Intensifier Fill valve fully clockwise to Close.

pressure vessel) will be filled from the reservoir or from an external fluid

container. See Heading 2.5.5. Normal operating procedure when

operating with an MTS triaxial cell, is to fill the triaxial cell from the CPI’s

fluid reservoir.

filler hose between the connector on the lower side of the Fluid

Direction valve (rear side of control panel) and the external fluid

container. Immerse the container end of the hose in the fluid.

4. Turn the Confining Fluid Input valve a turn or two counterclockwise to

Open.

5. Turn the Confining Fluid Output valve a turn or two counterclockwise to

Open.

6. Open the confining fluid valve on the triaxial cell. See the lower sketch in

the following figure. (The CPI’s Confining Fluid Input valve is connected

by high pressure hose to the triaxial cells lower confining fluid valve. The

CPI’s Confining Fluid Output valve is connected to the triaxial cell’s

pressure relief valve.)

7. Set the Air Direction valve to position A.

8. Actuate the air-driven hydraulic pump by rotating the Fluid Transfer Pump

Control counterclockwise. Watch the reservoir. Regulate the speed of the

air-driven pump to avoid frothing of the fluid in the reservoir. Excessive

frothing can cause fluid to overflow from the reservoir (on early CPI

versions only).

Note Fluid will flow into the triaxial cell, forcing air out to the reservoir.

On later CPI versions, the line from the Air Direction control expels air/

fluid into the reservoir from above the reservoir’s fluid level -- watch for

bubble-free fluid to flow into the reservoir. On earlier CPI versions the

line from the Air Direction control enters into the bottom of the reservoir -

- watch for the bubble stream to stop flowing.

34

Operation

9. Watch for fluid flow into the reservoir and note any air bubbles. When air

bubbles cease to appear, turn the Fluid Transfer Pump Control to the Off

position.

286.20 Pressure Intensifier

Page 35

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

3 - Close

2 - Close

8 - On

9 - Off

4 - Open

Filling the Triaxial Cell

1 - A

or C

5 - Open

9 - Watch

for bubbles

and fluid

level

6 - Open the

confining

pressure

valve

7 - A

Operating Procedures

286.20 Pressure Intensifier Operation

35

Page 36

Operating Procedures

WARNING

Heating The Triaxial Cell

Some users choose to heat the triaxial cell before applying test pressures to the

cell. Others apply test pressures while the cell is heating. In either case, the CPI

must be operated in pressure control mode during the heating process. Also, the

Confining Fluid Output valve on the CPI’s front panel should be closed to

prevent hot fluid from entering, and damaging, the reservoir.

Pressure inside the triaxial cell could reach high levels while the cell is

being heated.

This could cause personal injury or death or damage to the equipment or

specimen.

Always operate the CPI in pressure control mode during the heating process.

The process of heating the triaxial cell is included as a step in the following

procedure (“Pressurizing and Depressurizing The Confining Fluid” on page 37).

36

Operation

286.20 Pressure Intensifier

Page 37

Operating Procedures

WARNING

Pressurizing and Depressurizing The Confining Fluid

This procedure describes how to pressurize and depressurize the triaxial cell and

indicates the proper time to heat and cool the triaxial cell.

Purpose of this

procedure:

This procedure describes how (and when):

A. To make sure the pressure intensifier’s piston is properly positioned for

pressurizing the triaxial cell.

B. To heat and pressurize the triaxial cell.

C. To cool and depressurize the triaxial cell at the end of the test.

Note This procedure requires that hydraulic pressure be applied to the

pressure intensifier’s servovalve to enable the pressure intensifier’s

piston to be stroked under closed loop control. Explicit instructions

cannot be provided for these steps because of the large variety of

electronic controller equipment in use. Refer to the system operation

manual.

Hydraulic power will be applied during this procedure.

Conditions that can be hazardous to life and equipment can exist on all

systems or equipment that are connected to the same hydraulic power

source.

Before turning on hydraulic power, make sure that all systems or equipment that

use the same hydraulic power source are in an appropriate condition before you

turn on hydraulic power.

Make certain no one is performing work on other systems or equipment that share

the same hydraulic power source as the CPI. If people are working on other

systems or equipment, inform them that you intend to turn on hydraulic power.

Inform other people in the vicinity that you are about to turn on hydraulic power.

286.20 Pressure Intensifier Operation

37

Page 38

Operating Procedures

WARNING

Procedure: 1. Configure the confining pressure system’s controller for the displacement

control mode. (The pressure control mode will be used later while

pressurizing the triaxial cell.)

to position the pressure

intensifier’s piston

2. On the triaxial cell, close the lower confining pressure valve. (Leave the

triaxial cell’s upper valve open.)

3. On the CPI, open the Intensifier Fill valve.

4. Make sure the CPI’s Reservoir Fill valve is fully clockwise to the Close

position.

5. At the CPI’s electronic control equipment, turn on low hydraulic pressure.

6. At the CPI’s displacement controller, adjust the position of the pressure

intensifier’s piston for 10% displacement.

Placing the piston at 10% displacement allows a 10% margin for piston

retraction, if required, while still providing a 90% displacement stroke, if

necessary, while pressurizing the triaxial cell.

7. Close the CPI’s Intensifier Fill valve.

High hydraulic pressure will be applied during the following steps.

Conditions that may be hazardous to life and equipment can exist on all

systems or equipment that are connected to the same hydraulic power

source.

pressurizing the

triaxial cell

Steps 9 and 10 provide some information about how to minimize the hazards of

turning on high hydraulic pressure. However because of the variety of electronic

controller equipment in use, explicit instructions cannot be given here.

8. On the electronic control equipment, perform the operations necessary to

switch from displacement control mode to pressure control mode.

With certain types of electronic control equipment, it might be necessary to

turn off hydraulic power while converting to pressure control mode. Other

equipment types allow manual mode switching with hydraulic power on

and, if a computer is included, via the keyboard. Refer to your test controller

documentation.

9. On the triaxial cell, open the lower confining pressure valve.

10. On the CPI, make sure the Confining Fluid Input valve is open.

11. If the triaxial cell is to be heated, set up the temperature controller

equipment as required to bring the triaxial cell to operating temperature.

This process will usually take at least several hours, depending on the

temperature to be reached.

38

Operation

286.20 Pressure Intensifier

Page 39

Operating Procedures

12. On the CPI’s pressure controller, perform the operations necessary to bring

triaxial cell confining pressure to test level.

The CPI’s confining pressure gage will provide an approximate indication of

confining pressure but the readout capabilities of the CPI’s electronic controller

should by used where any precision is required.

cooling and

depressurizing the

triaxial cell

13. After the test is over, perform the operations necessary at the CPI’s pressure

controller to reduce triaxial cell confining pressure to a low level.

14. If the triaxial cell has been heated, adjust the temperature controller

equipment to allow the triaxial cell to cool. See “Cooling The Triaxial Cell

and Confining Fluid” on page 41. It will take several hours for the triaxial

cell to cool, depending on the temperature of the triaxial cell.

15. After the triaxial cell has cooled to, at most, 167°F (75°C), perform the

operations necessary at the CPI’s pressure controller to reduce triaxial cell

confining pressure to zero.

16. After you are certain that confining pressure has been reduced to zero, turn

the Confining Pressure Input valve fully clockwise to Close.

17. At the electronic controller equipment, turn off hydraulic power to the CPI.

18. Slowly open the CPI’s Confining Pressure Output valve to vent residual

pressure, if any, from the triaxial cell.

286.20 Pressure Intensifier Operation

39

Page 40

Operating Procedures

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

3 - Open

7 - Close

4 - Close

10 - Open

16 - Close

Pressurizing and Depressurizing The Confining Fluid

18 - Open

2 - Close the

confining

pressure

valve

9 - Open the

confining

pressure

valve

Operation

40

286.20 Pressure Intensifier

Page 41

Cooling The Triaxial Cell and Confining Fluid

CAUTION

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

Cooling the Triaxial Cell and Confining Fluid

CAUTION

Do not allow hot fluid (above 167°F (75°C)

to be recirculated back into the CPI.

Temperature of fluid in the triaxial cell can exceed the temperature rating of

the Confining Pressure Intensifier.

This could damage the Confining Pressure Intensifier.

Always allow fluid in the triaxial cell to cool to 167∞F (75∞C) or less before

emptying the triaxial cell back to the reservoir of the Confining Pressure

Intensifier.

The CPI has a temperature rating of 167°F (75°C). Many triaxial cells have

higher temperature ratings. Confining fluid in the triaxial cell must be allowed to

cool to 167°F (75°C), or below, before being recirculated into the Confining

Pressure Intensifier. If fluid having a temperature higher than 167°F (75°C) is

allowed to circulate into the CPI, the acrylic reservoir and associated flexible

tubing can be damaged.

Operating Procedures

There are no operational steps involved in allowing the triaxial cell and its

confining fluid to cool. Do not operate the CPI or cause hot fluid to flow into the

CPI while the triaxial cell is cooling.

286.20 Pressure Intensifier Operation

41

Page 42

Operating Procedures

CAUTION

Emptying the Triaxial Cell

Temperature of fluid in the triaxial cell may exceed the temperature rating of

the Confining Pressure Intensifier.

This could damage the Confining Pressure Intensifier

Always allow fluid in the triaxial cell to cool to 167∞F (75∞C) or less before

emptying the triaxial cell back to the reservoir of the Confining Pressure

Intensifier.

Procedure: 1. Verify that the triaxial cell has cooled to 167°F (75°C) or less.

2. Make sure the Air Direction valve is in position “A”.

3. Adjust the electronic controller equipment to reduce pressure in the triaxial

cell to a small, but positive, pressure (e.g., 10 psi).

4. Open the Confining Fluid Output valve one turn.

The pressure intensifier will extend to the end of its stroke as fluid is expelled

from the pressure intensifier, up through the triaxial cell and into the reservoir.

Leave hydraulic power applied to the CPI, with the pressure intensifier fully

extended.

5. Open the Reservoir Fill valve one turn only.

Note Be prepared to perform step 8 and 9 immediately after step 7, in order to

avoid frothing and overflow of fluid from the reservoir.

6. Turn the Air Direction valve to the “B” position.

Compressed air applied to the top of the cell will cause fluid to flow from the

cell, up through the Reservoir Fill valve and into the reservoir.

7. When the reservoir is about half full, turn the Air Direction valve to the

neutral or off position (valve handle pointing straight up.)

Remaining air pressure in the cell will continue to empty the cell.

8. Watch for the first air bubbles to enter the reservoir (from the bottom) and,

when bubbles are seen, immediately

turn the Reservoir Fill valve off to

avoid frothing and overflow of fluid from the reservoir.

42

Operation

9. Bleed any remaining air pressure from the cell by turning the Air Direction

valve to the “A” position.

286.20 Pressure Intensifier

Page 43

Operating Procedures

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

5 - Open (one turn)

8 - Watch for bubbles

8 - Close

Emptying the Triaxial Cell

7 - Watch

the reservoir

2 - A

6 - C

7 - Off

9 - A

4 - Open

(one turn)

286.20 Pressure Intensifier Operation

43

Page 44

Operating Procedures

Triaxial

Cell

Open Close

Confining Fluid Input

Open Close

Confining Fluid Output

Open Close

Reservoir Fill

Fluid

Reservoir

Open Close

Intensifier Fill

Pressure

Intensifier

Low Pressure

Relief

Pressure

Transducer

Low pressure line

High pressure line

286.20

Confining

Pressure

Intensifier

r

Fluid Filter

Off

Fluid Transfer Pump Control

Air supply in

100 psi max.

Air Driven

Hydraulic

Pump

Fluid Direction

A

B

C

C

A

B

Empty

Reservoir

From fluid

supply or to

empty fluid

Fill system from

fluid supply

using pump

Fill system

from reservoir

using pump

Confining

Pressure

AB

A

B

Air Direction

Air supply into empty

traxial cell.

Bleed air into reservoir

when filling triaxial cell.

psi

bar

High Pressure

Relief

Air Pressure

Relief

Draining the Reservoir To An External Container

2 - B

Draining the Reservoir to an External Location

Procedure: 1. Connect a hose between the connector on the lower side of the Fluid

Direction valve (rear side of control panel) and the external fluid container.

2. Set the Fluid Direction valve to position B. Confining fluid in the fluid

reservoir will flow into the container by means of gravity.

Operation

44

286.20 Pressure Intensifier

Page 45

Page 46

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

ISO 9001:2000 Certified QMS

Loading...

Loading...