Mitsubishi Electronics SDP-ECO 1630 III User Manual

III

USERS MANUAL

Before attempting to operate this product, you should thoroughly read and fully understand all the contents of this manual.

Administrators and supervisors shall not instruct anyone to operate or inspect this machine unless he/she is familiar with all the contents of this document.

For Your Safety

-This manual must be thoroughly read and understood by all operators before they attempt to use SDP-Eco 1630 III.

-This manual provides general guidelines, precautions and warnings for the safe operation of this machine. Very serious accidents may occur if this machine is utilized without following this manual and we shall bear absolutely no liability or responsibility for the consequences.

-The warning labels for hazard prevention area attached to dangerous parts or areas of the machine. Study and understand all the specific dangers involved and how they can be avoided.

-Keep this manual available and near the machine at all times so that it can be immediately referred to whenever necessary.

-Look up the name, address and phone number of our nearest dealer or branch office (listed on the back page of this manual), and post the information prominently for quick reference.

-Please make sure that this manual reaches everyone charged with operating this machine.

Warning

Warning

Machine operators must thoroughly read Chapter 1. Do not turn on the machine's power supply until all of the precautions have been read and understood. Very serious accidents may occur if this instruction is not observed.

Administrators and supervisors shall not instruct anyone to operate or inspect the SDPEco 1630 III unless he/she is familiar with all the contents of this document.

i

Compliance with CISPR Rules

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures.

Compliance with FCC Rules

Notice for the USA

This machine has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the machine is operated in a commercial environment. This machine generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this machine in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at their own expense.

Changes or modifications not expressly approved by Mitsubishi Paper Mills Limited could void the user's authority to operate the machine.

Notice for Canada

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Unit Regulations.

Cet appareil numérique de la Class A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

When export the machine

International transfer of this product, any of its parts, components and/or software must be carried out in compliance with the relevant laws and ordinance of the country of export and the country of product end-use. We do not assume any responsibility of liability for product transferred without regard to proper export/import regulations or procedures.

Limit of responsibility

Please note that machine specifications are subject to change without notice for updates and improvements. This may cause inconsistencies between the contents of this manual and the machine you currently possess.

We shall not be held responsible for any damage caused by conditions beyond our control such as customer modification, disassembly or misuse of our machine, programs or software, or their use in a defective or deficient environment.

We assume no responsibility or liability for any damage or consequential and/or indirect losses resulting from any accident or malfunction that might occur during the operation of this machine.

Copyright

©2005: Mitsubishi Paper Mills Limited.

The copyright for this entire manual belongs to Mitsubishi Paper Mills Limited.

Copying, reprinting, or reproduction of this manual in whole or in part in any medium without our express consent infringes upon the copyright and the rights of the publisher.

ii

Introductory Note

Thank you very much for choosing our product. We sincerely hope that you will enjoy using the SDP-Eco 1630 III, and fully utilize all its functions and capabilities.

This users manual describes how to safely operate this machine and explains all the basic procedures for data setting, maintenance, inspections, etc.

As noted below, however, it is the client's obligation to obtain or prepare all the necessary material safety data sheets ("MSDS") for any chemical substances used during the client's operation on this machine. Although great care has been taken in preparing this manual, if you find that certain points seem unclear or in error, please contact Mitsubishi Paper Mills Limited.

This manual contains the following sections:

Chapter 1 "On Safety"

This chapter describes instructions to be observed for the safest possible operation of the product. Please make sure to read this chapter before turning on the power to the product.

Chapter 2 to 6

These chapters provide relevant knowledge and reference information for machine operation. Please read them carefully before attempting to operate the machine.

Chapter 7 to 9

These chapters describe daily maintenance procedures and troubleshooting methods as well as supplying various technical information. Please read through them as necessary.

iii

About this manual

In this manual, important supplementary remarks are classified as either WARNINGs, CAUTIONs, Cautions, or Notes.

Since remarks under WARNING and CAUTION headlines call attention to conditions and operations that may result in accidents or physical injuries, be sure to thoroughly read and observer their instructions.

Indicates a potentially hazardous situation which, if not  Warning avoided or properly handled, could possibly result in

Warning avoided or properly handled, could possibly result in

death or serious injury.

Indicates a potentially hazardous situation which, if not  Caution avoided or properly handled, could possibly result in

Caution avoided or properly handled, could possibly result in

minor or moderate injury.

Caution

Note

Indicates a situation that could either cause damage to the machine, destroy data necessitate extensive reduplicated effort. Strictly follow the noted instructions.

Provides supplementary information or information to prevent incorrect operations.

iv

Contents

Chapter 1 On Safety

1.1When using the machine ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••1

1.2Warning labels and attachment positions ••••••••••••••••••••••••••••••••••••••••••••4

1.3Handling processing chemicals ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••6

1.4Before connecting the power cable•••••••••••••••••••••••••••••••••••••••••••••••••••••8

1.5Operation precautions ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9

1.6Precautions during transport and installation •••••••••••••••••••••••••••••••••••••10

1.7SDP-Eco 1630 III Installation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10

1.8Maintenance ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••12

1.9Machine disposal••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••13

Chapter 2 Names of Machine Components and Parts

2.1Main unit ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••15

2.2Operation panel••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••17

2.3Safety switch••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••18

Chapter 3 Handling plates

3.1Plate setting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••19

3.2Plate end processing ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••23

Chapter 4 Operation

4.1Cable connection check••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••25

4.2Turning ON the power switch ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••26

4.3Initialization ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••26

4.4Data input for the set plate (This procedure is necessary when

loading the plate.)•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••27

4.5Execution of Pre. Feed command (This procedure is necessary

when loading the plate.)••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••28

4.6Exposure••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••29

4.7Processor section•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••31

4.8Collecting exposed plates •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••34

4.9Turning OFF the power supply and inspection at shutdown •••••••••••••••34

v

Chapter 5 Menus and panel displays

5.1User menu •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••37

5.2Panel operation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••39

Chapter 6 User menu

6.1Plate data•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••41

6.2Laser menu ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••42

6.3Pre. Feed menu •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••44

6.4Image Data menu•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••44

6.5Mode menu ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••44

6.6Maintenance menu •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••45

6.7Rinse •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••45

Chapter 7 Maintenance

7.1Cutter blade replacement••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••47

7.2Cylindrical lens cleaning •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••48

7.3Filter cleaning•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••49

7.4Punch dust removal••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••50

7.5Cleaning the processor section •••••••••••••••••••••••••••••••••••••••••••••••••••••••••51

7.6Cleaning the washing tank••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••59

7.7Replacing the diffusion sheet (SLM-EAC, SLM-EST)•••••••••••••••••••••••••63

7.8List of expendable parts••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••65

7.9How to order parts••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••65

Chapter 8 Message

8.1Message ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••67

8.2Displaying and clearing errors•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••67

8.3Status display•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••68

8.4Warning display••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••68

8.5List of error messages ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••69

8.6Jam removal procedure ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••71

Chapter 9 Specifications

9.1Basic specifications ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••73

9.2Overview diagram ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••74

vi

Chapter1 On Safety

Chapter 1 On Safety

SDP-Eco 1630 III was designed and manufactured with special attention to safety considerations. However, it is impossible either to eliminate all potential sources of danger from such products or to anticipate all possible hazards and misuses. It is therefore critical that you both familiarize yourself, all your operators and other relevant personnel with all of the noted precautions, countermeasures and related procedures, and take maximum care when operating this machine.

1.1When using the machine

•Grounding connection

-In order to prevent electric shock at the AC power supply unit, be sure to connect the ground in accordance with operation site regulations (resistance: less than 100 ohms) using the SDP-Eco 1630 III exclusive wire.

-Even when the user's present facility outlet can

be with the SDP-Eco 1630 III power plug with ground, make sure that the ground pole on the outlet is connected with ground in accordance with operation site regulations (resistance: less than 100 ohms)

Following all relevant local wiring regulations, prepare a grounded  Warning (less than 100 ohms) power supply outlet that can accept this

Warning (less than 100 ohms) power supply outlet that can accept this

machine's power plug.

•Power supply

-Prepare a power supply that satisfies all the requirements stipulated in the specification sheet.

-Always provide circuit breakers for unit or devices that use water or chemicals.

-Please entrust all wiring, connections and other electrical work to an authorized electrician.

•Maintenance and safe passage during emergencies

A minimum of 60 cm clearance is required around the machine at all times to afford adequate space for maintenance and safe passage during emergencies. Never allow this space to become blocked with any objects, wires, or other obstacles.

- 1 -

SDP-Eco1630 III USERS MANUAL |

Chapter 1 On Safety |

• This machine incorporates a power supply unit.

Do not use a bubble type extinguisher when a fire occurs. It may cause electric shocks. Place a powder type extinguisher near the machine.

• The SDP-Eco 1630 III is equipped with a leakage circuit breaker.

If a short circuit occurs in the machine, the breaker is automatically activated and shuts off the circuit.

Occasionally the main unit will not activate when you turn ON the Power Switch because the leakage breaker inside the main unit

Warning has turned itself OFF.

In such a case, contact your local dealer where you purchased the machine and ask a service person to check out the condition.

• This machine incorporates high current electrical circuits.

Touching the electrical circuits of this machine with any part of your body can cause serious injury or death. Please contact the dealer where you purchased this machine when maintenance or inspections are required.

• Safety switches

To ensure operator safety, this machine is provided with safety switches. If a front door is opened while the machine is running, a safety switch is activated and operation is immediately stopped.

(Refer to "Chapter 2 Names of Machine Component and Parts".)

- 2 -

Chapter 1 On Safety

• LASER SAFETY.

The SDP-Eco1630 III is certified as a Class 1 laser product under the U.S. Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health and Safety Act of 1968. This means that the recorder does not produce hazardous laser radiation.

Since radiation emitted inside the SDP-Eco1630 III is completely confined within protective housings and external covers, the laser beam can not escape from the machine during any phase of user operation.

• CDRH REGULATIONS.

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration implemented regulations for laser products on August 2, 1976. Compliance is mandatory for products marketed in the United States. The level shown in the figure indicates compliance with the CDRH regulations and must be attached to laser products marketed in the United States.

• For European model

The SDP-Eco1630 III is classified as a CLASS 1 LASER PRODUCT in accordance with IEC Pub 1.1 825 1984.

Ordinary operation will not release laser radiation into the work environment. Do not remove any of the safety covers for this product or release any of its interlock switches. Laser radiation may cause injuries to your body (e.g. weakened eyesight, skin cancer).

- 3 -

SDP-Eco1630 III USERS MANUAL |

Chapter 1 On Safety |

1.2 Warning labels and attachment positions

Warning labels are attached to dangerous parts or areas of the machine. All operators and maintenance personnel must follow the instructions written on these labels.

-Do not remove or deface any of these warning labels.

-Labels must always be clearly visible without any obstacles shielding or obscuring them.

-If a label is removed or defaced, replace it with a new warning label as soon as possible. Please contact the dealer where you purchased this machine for new labels.

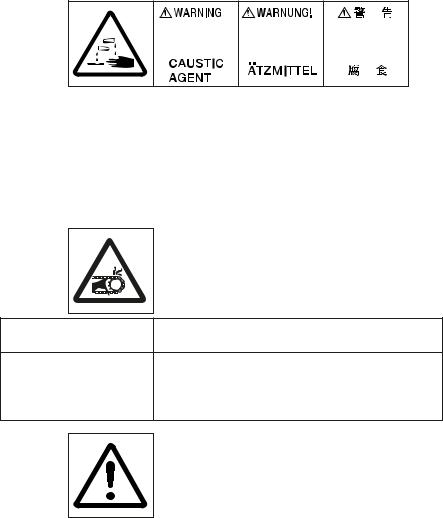

•Types of warning labels

(1)Caustic

agent

Hazard |

Safe handling method |

|

|

|

|

Contains processing |

Always wear protective gear such as safety glasses, |

|

chemicals. Direct contact |

rubber gloves, masks, and rubber aprons. |

|

with these chemicals due |

||

Read all instructions and warnings for processing |

||

to splashing or overflow |

||

may result in skin. |

chemicals. |

|

irritation, blindness, or |

||

|

||

burns. |

|

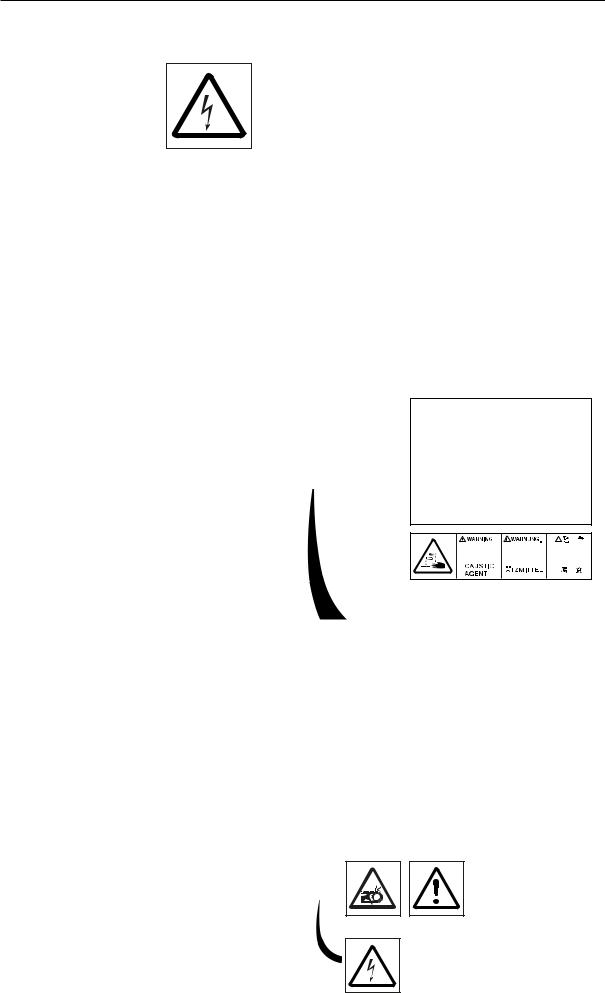

(2) Hazardous |

|

Moving |

|

Section |

|

Hazard |

Safe handling method |

Hands or fingers may get |

Keep hands, fingers and the rest of the body away |

caught. |

during operation. Always turn OFF the main power |

|

supply and the power switch on the machine before |

|

approaching. |

(3) Caution

Hazard |

Safe handling method |

|

|

Sections marked with this |

Keep hands, fingers and the rest of the body away |

label contain functions or |

from the machine while it is running. If you must |

components which could |

physically touch the machine, always turn the |

cause personal injury. |

power supply OFF beforehand. |

|

|

- 4 -

Chapter 1 On Safety

(4)Electric shock

Hazard |

Safe handling method |

|

|

|

|

There are sections where |

The parts or sections marked with this label should |

|

the voltages are |

be avoided. Be careful not to touch them with your |

|

dangerously high. Direct |

||

bare bands or any part of your body. |

||

contact with these sections |

||

|

||

(marked with this label) can |

|

|

cause severe shock and |

|

|

potentially fatal injuries. |

|

|

|

|

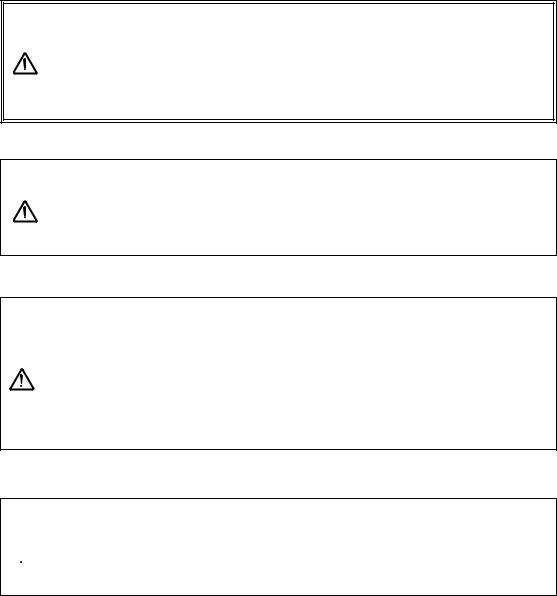

• The locations of the machine's warning labels are shown below.

(1)

Cutter blade replacement procedure

Cutter blade replacement procedure

(2) |

(3) |

(4) |

- 5 -

SDP-Eco1630 III USERS MANUAL |

Chapter 1 On Safety |

1.3 Handling processing chemicals

The SDP-Eco 1630 III uses processing chemicals to activate and stabilize exposed plates. The processing chemicals used in this Warning machine are not generally dangerous to humans, but failure to use them in the correct manner is dangerous. Be sure to handle all

processing chemicals with care.

Cautions for use of processing chemicals

Cautions for use of processing chemicals

Inflammation may occur if processing chemicals come in contact

with the eyes or skin, so be sure to wear protective gear (safety Caution goggles and rubber gloves) when handling the chemicals.

Keep out of reach of children.

What to do in case of emergency

What to do in case of emergency

If chemicals come in contact with the eyes, immediately rinse with clean running water for at least 15 minutes. If the inflammation persists, consult an eye specialist.

Caution If chemicals come in contact with the skin, immediately rinse under clean running water.

If chemicals are swallowed, immediately consult a physician. Report the ingredients of the chemical or solution to the physician.

Cautions for handling waste chemicals

Cautions for handling waste chemicals

These chemicals have high COD and pH levels (especially the activator) and cannot be disposed of by simply pouring them down  Caution the drain. Please have processing chemicals removed by a

Caution the drain. Please have processing chemicals removed by a

certified waste management specialist.

- 6 -

Chapter 1 On Safety

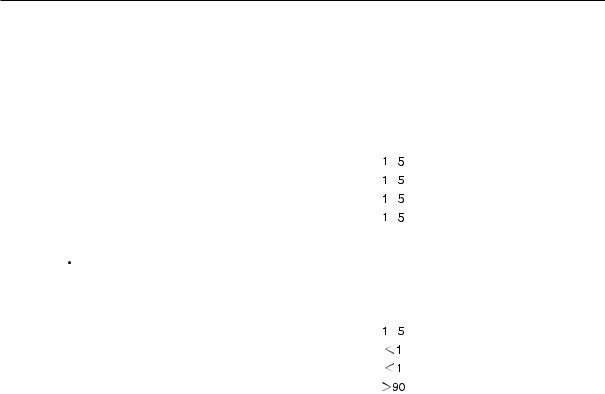

Processing chemical components

Processing chemical components

Activator (SLM-EAC) Mixture: (aqueous chemical) pH: approx. 13.4

Activator (SLM-EAC) Mixture: (aqueous chemical) pH: approx. 13.4

Composition |

CAS No. |

Percentage |

||

Potassium hydroxide |

1310-58-3 |

|

|

|

|

|

|

||

Potassium sulfite |

7646-93-7 |

|

|

|

|

|

|

||

Sodium sulfite |

7757-82-6 |

|

|

|

|

|

|

||

N-amino ethyl ethanolamine |

111-41-1 |

|

|

|

|

|

|

||

Stabilizer (SLM-EST) |

|

|

|

|

Mixture: (aqueous chemical) |

|

|

|

|

pH: approx. 6.0 |

|

|

|

|

Composition |

CAS No. |

Percentage |

||

Phosphate |

7778-77-0 |

|

|

|

|

|

|

||

Tri-ethanol amine |

102-71-6 |

|

|

|

Heavy sodium sulfite |

7631-90-5 |

|

|

|

Water |

7732-18-5 |

|

|

|

- 7 -

SDP-Eco1630 III USERS MANUAL |

Chapter 1 On Safety |

1.4Before connecting the power cable

•Power supply

-Check that the power switch on the SDP-Eco 1630 III is turned OFF before connecting the power plug to the user's power outlet. (Refer to "Chapter 2: Names of Machine Component and Parts".)

Power plug with earth wire

•Power cables

-Always use grounded power cables when connecting to this machine.

-If you find anything that might indicate power cable damage such as unusual deformations or surface flaws, immediately turn OFF the power supply, pull the power plug from its outlet and

contact the dealer where you purchased this machine.

-Do not place heavy objects or articles with sharp blades anywhere on the power cable or forcefully pull at it.

-Never connect the power cable to a shared or overloaded outlet or distribution socket.

-Please contact our nearest dealer before attempting to extend the power cable.

If you notice any problems with the power cable such as scratches  Warning or deformities, immediately turn OFF the main power supply switch

Warning or deformities, immediately turn OFF the main power supply switch

and contact the dealer where you purchased this machine.

- 8 -

Chapter 1 On Safety

1.5Operation precautions

•Do not turn the machine's power supply ON or start operation until this manual has been thoroughly read and fully understood.

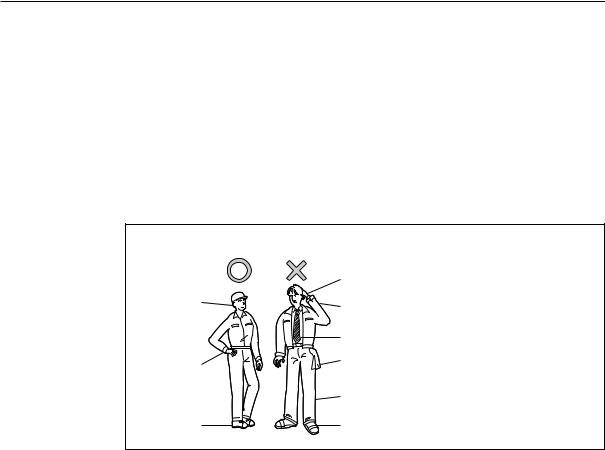

•All operators must wear appropriate work clothing and should never wear necklaces, scarves, or other accessories which could be caught by moving parts and cause accidents.

Appropriate

Cap

Buttoned

Safety shoes (preferable)

Unacceptable

Gloves

(or wet hands) Always avoid clothing, gear, or accessories that could in any way

Open cuffs be caught up in the machine.

Loose or dangling necktie

Items hanging from clothes

Over-long trousers

Slippers or sandals

•Do not operate the machine if you feel in anyway sick, nauseous or unsteady.

•If you notice that the machine is in any way abnormal, immediately report the situation to your supervisor for appropriate action.

•The SDP-Eco 1630 III can perform continuous automatic operation, but it must not be operated continuously without an operator in attendance.

An operator trained to take appropriate initial corrective actions should always be in attendance to deal immediately with any emergencies that may arise.

•When your SDP-Eco 1630 III will not be operated for an extended period of time, be sure to unplug the power cord. Check for any dust or contamination in the outlet, power plug, and/or the AC power socket on your SDP-Eco 1630 III at least once a year.

•During operation, do not open any of the unit's doors or covers. Opening these doors or covers may be hazardous to the safety of operators and other persons working in the vicinity, and may also damage the machine.

•Power failure

If a power failure occurs due to an external reason, immediately turn OFF the power switch and the SDP-Eco 1630 III.

When power is recovered, supply power again, referring to "4.2 Turning ON the power switch".

-9 -

SDP-Eco1630 III USERS MANUAL |

Chapter 1 On Safety |

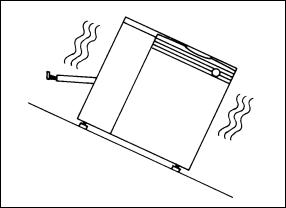

1.6Precautions during transport and installation

•The weight of the SDP-Eco 1630 III is described in "Chapter 9: Specifications"Make sure the floor is fully capable of handling 2500 N/m2 (approx. 55 lbs/ft2) or heavier loading before installing the SDP-Eco 1630 III .

•Transport and installation

This machine's transport and installation must always be handled by engineers and contractors assigned by Mitsubishi Paper Mills Limited. We shall bear no responsibility whatever for any unit breakage, damage, or malfunctions caused by or during transport or installation performed by anyone other than the above specified personnel. Whenever your machine must moved, transferred, or reinstalled, please entrust all procedures to our nearest branch office or dealer.

1.7 SDP-Eco 1630 III Installation

• Installation environment

Installing the machine in the following locations may cause machine damage or malfunctions. Do not install the machine anywhere that is exposed or subject to:

*Locations with strong and/or persistent vibration

*Locations with an uneven floor

- 10 -

Chapter 1 On Safety

*Locations in direct sunlight

*Locations with high temperature and/or humidity (outside the normal range of Temp.: 18 to 28˚C, Rel.humidity: 50 to 70%)

*Locations where dew condensation is a factor

*Locations with sudden, drastic temperature changes

*Locations where excessive dirt, grime or dust are factors

*Locations in the vicinity of flammable gases or liquids

*Locations having corrosive chemical vapors, mists, or gases

*Locations with a nearby heat source (such as a radiator or heater)

*Locations with electrical interference such as voltage fluctuations or line noise.

*Locations with devices which emit sparks or electromagnetic radiation

•Ventilation

Please ensure sufficient ventilation during the operation of the equipment to avoid odor in high density.

- 11 -

SDP-Eco1630 III USERS MANUAL |

Chapter 1 On Safety |

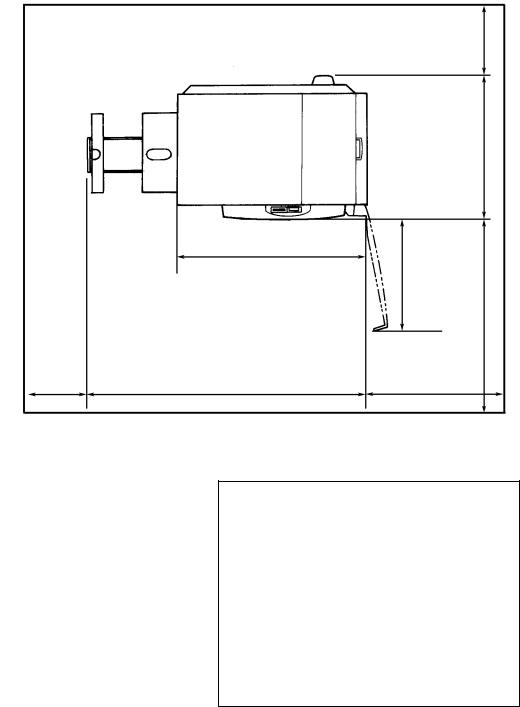

• Installation space

As shown in figure below, clearance is required around the machine at all times to assure adequate space for maintenance and safe passage during emergencies.

(Unit: cm)

40 or longer

79.5

100

66.9 |

100 or longer |

40 or |

|

|

longer |

146.5 |

70 or longer |

1.8Maintenance

•Maintenance that requires tools may only be performed by persons who have been specially

trained with our authorized

curriculum. |

Power switch |

•During machine maintenance, the operator must make it clear that the machine should not be turned ON and prevent any person other than our authorized technician(s) from touching the machine.

•Be sure to turn OFF the power switch and remove the power plug from the outlet before you start maintenance, cleaning or repairs.

-12 -

Chapter 1 On Safety

1.9Machine disposal

•To protect the environment, always commission a special authorized contractor to dispose of your old machine(s).

•Commission an ordinary contractor to dispose of parts discarded or replaced during the repair processing.

- 13 -

SDP-Eco1630 III USERS MANUAL

- 14 -

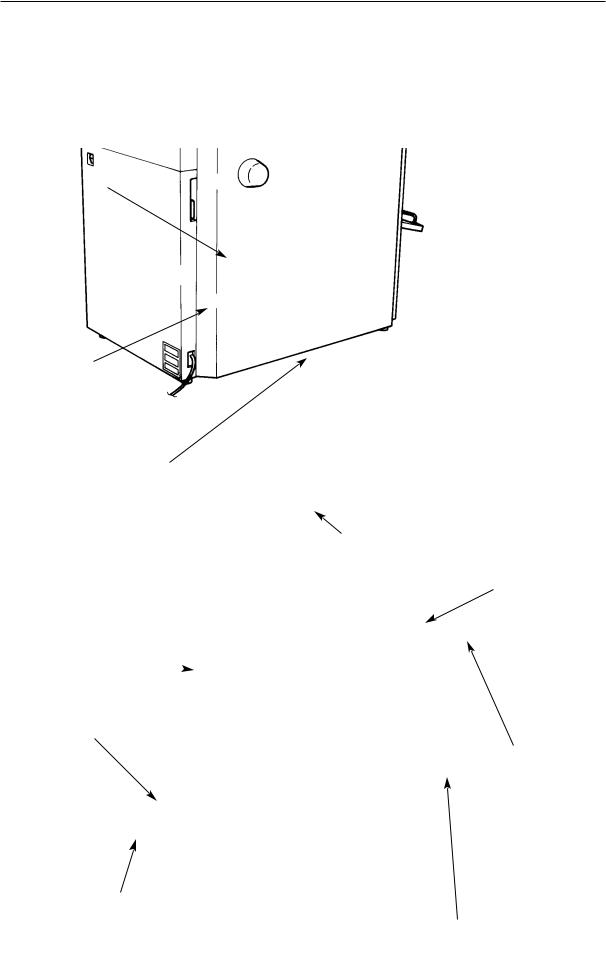

Chapter 2 Names of Machine Components and Parts

Chapter 2 Names of Machine Components and Parts

The SDP-Eco 1630 III consists of the following parts.

2.1 Main unit

Plate setting cover

Power switch

Wide SCSI connector

AC power socket

Operation panel

Filter

Plate receiving tray

Nip roller clearance handle

Arm

Front door

- 15 -

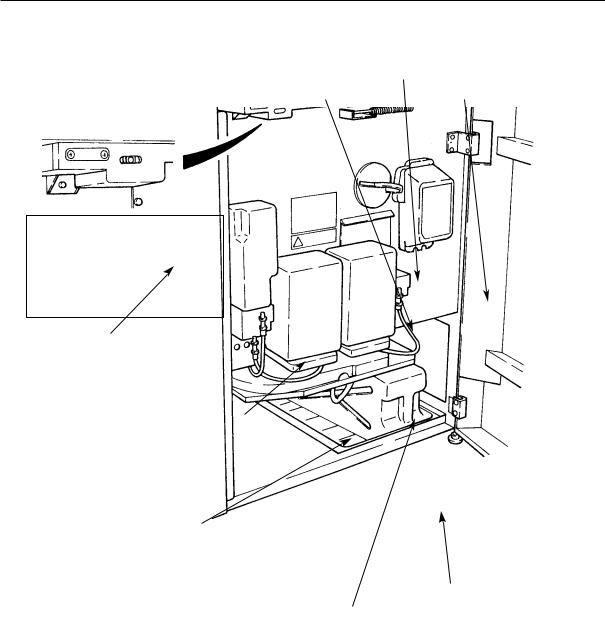

SDP-Eco1630 III USERS MANUAL

Cylindrical lens

Plate take up unit |

Cutter unit |

Safety switch

Rinse water replenisher bottle

EST replenisher bottle (stabilizer)

Waste chemical tank

EAC replenisher bottle (activator)

- 16 -

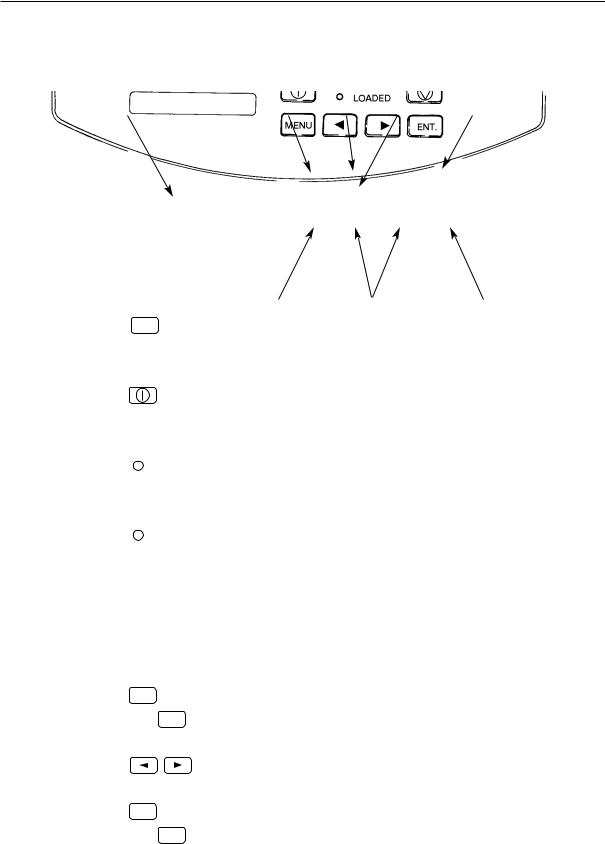

Chapter 2 Names of Machine Components and Parts

2.2 Operation panel

(1) |

(2) |

(3) |

(4) |

(5) |

|

(6) |

(7) |

(8) |

(1) |

Display panel |

|

|

|

The operation mode, error messages, and setting values for various |

||

|

parameters are displayed on this panel. |

|

|

(2) |

Power ON/OFF key |

|

|

|

The power ON/OFF key is used to turn OFF the power after a processor |

||

|

cleaning operation. This key is used for the usual ON/OFF operation. |

||

(3) |

ON LINE lamp |

|

|

|

The ON LINE lamp is lit during transmission or standby status between |

||

|

the SDP-Eco 1630 III and host computer. |

|

|

(4) |

LOADED lamp |

|

|

|

The LOADED lamp lights when a film is loaded and at its exposure |

||

|

position. |

|

|

(5) Stop key (Reset)

Stop key (Reset)

The STOP key is used to interrupt the exposure of a plate. If the exposure is interrupted, the plate will be cut and discharged. This key is also used to cancel errors and to turn OFF the error buzzer.

(6)MENU key

|

The |

MENU key is used to switch the user's mode between remote and local. |

|

Also it returns the menu to the upper level. |

|

(7) |

|

Select key |

|

The SELECT key is used to move the cursor or change parameters. |

|

(8) |

|

key |

|

The |

key is used to enter parameters or to execute various |

|

commands. |

|

- 17 -

Loading...

Loading...