Page 1

DC-6/DC-6T/DC-6Vet

Diagnostic Ultrasound System

Service Manual

Page 2

Page 3

CONTENTS

1 General Description .............................................................................. 1-1

1.1 System Characteristics ........................................................................................... 1-1

1.2 Applicable Scope .................................................................................................... 1-1

2 System Overview .................................................................................. 2-1

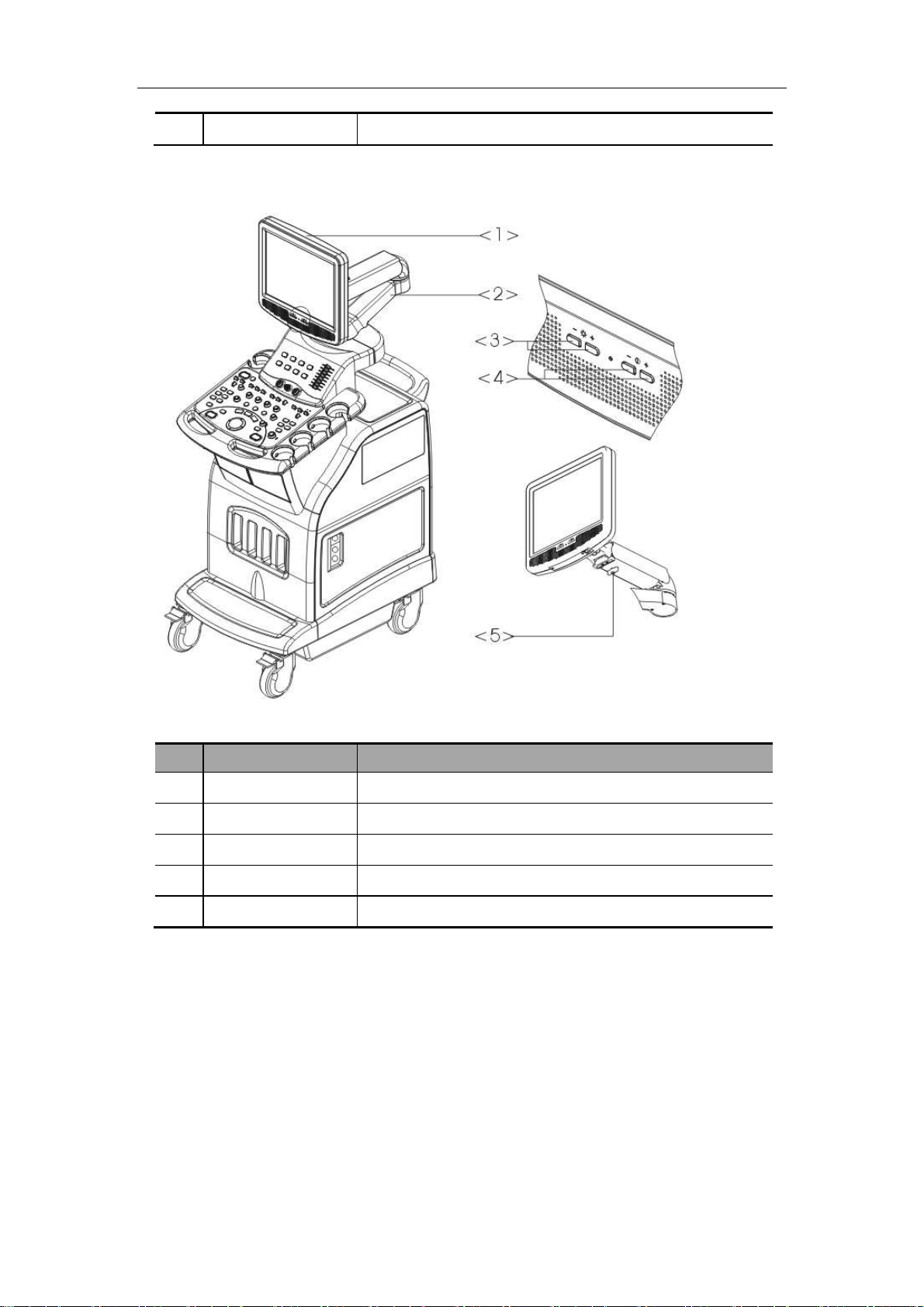

2.1 System Appearance ............................................................................................... 2-1

2.1.1 Complete System with CRT Monitor ........................................................................ 2-1

2.1.2 Complete System with LCD Monitor ........................................................................ 2-3

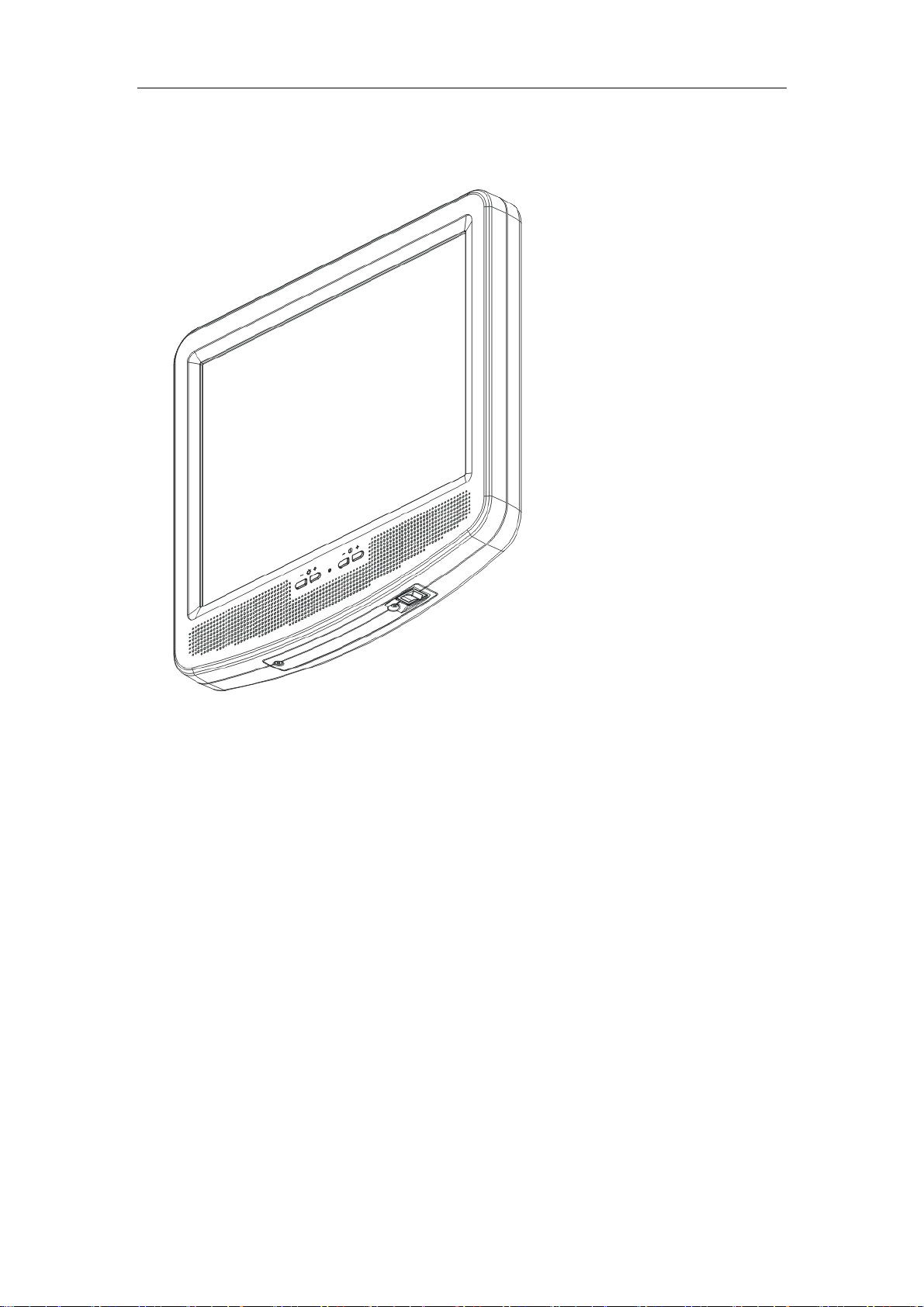

2.2 LCD Monitor ........................................................................................................... 2-4

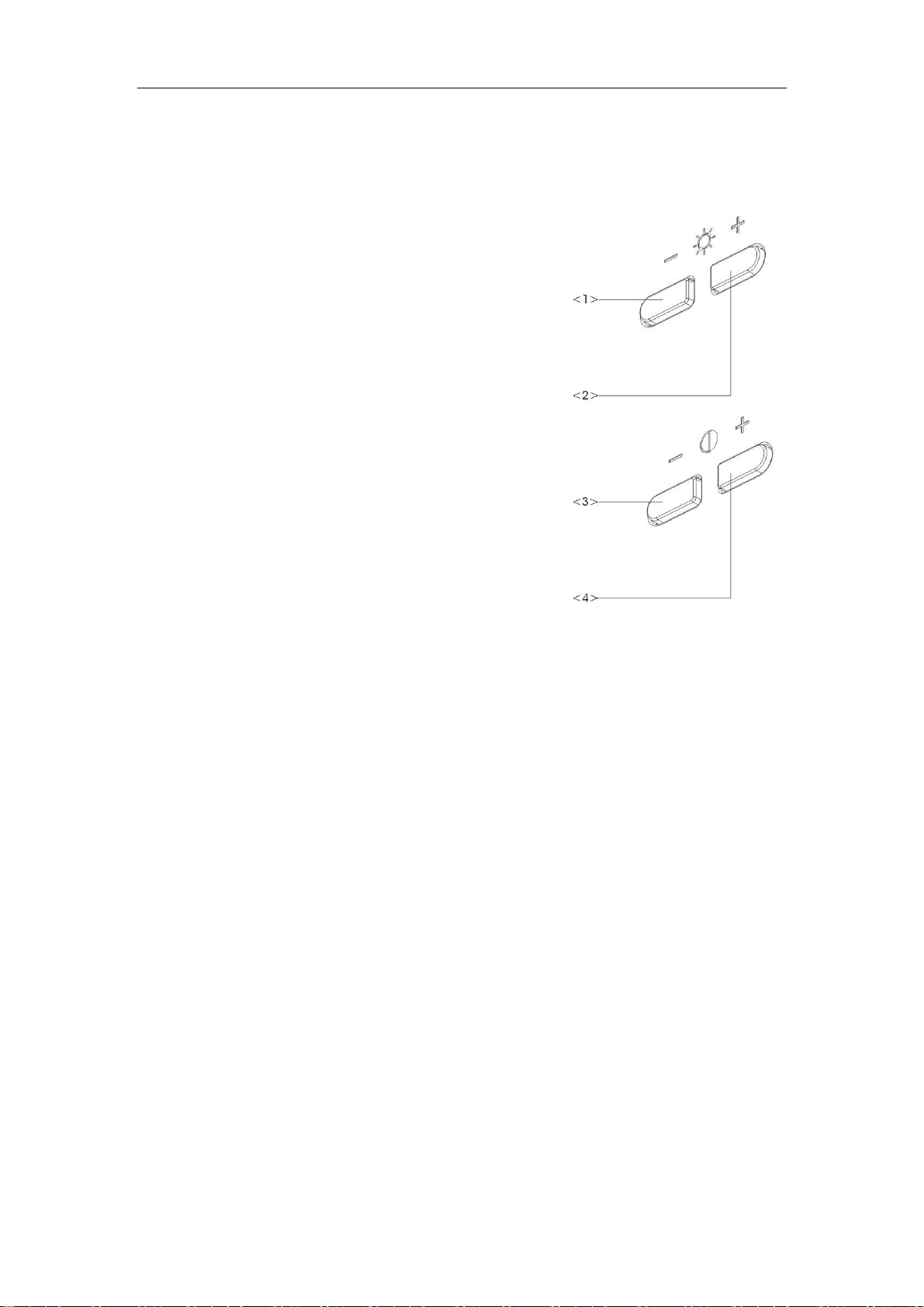

2.2.1 Brightness and contrast buttons............................................................................... 2-5

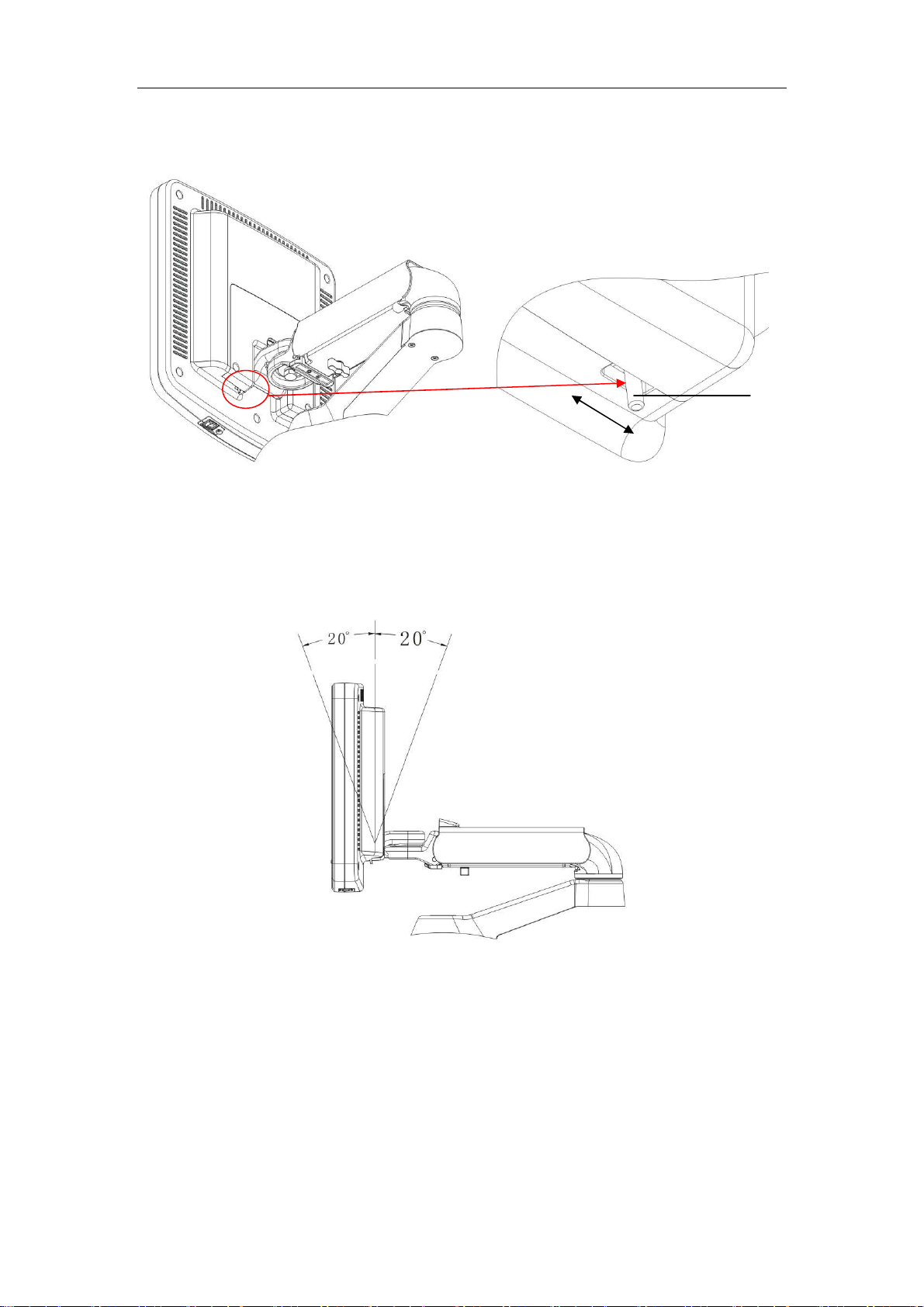

2.2.2 Up/down adjusting lever ........................................................................................... 2-6

2.2.3 Lever of upper support arm ...................................................................................... 2-7

2.3 I/O Panel ................................................................................................................. 2-8

2.4 Power Panel ........................................................................................................... 2-9

2.5 ECG Panel............................................................................................................ 2-10

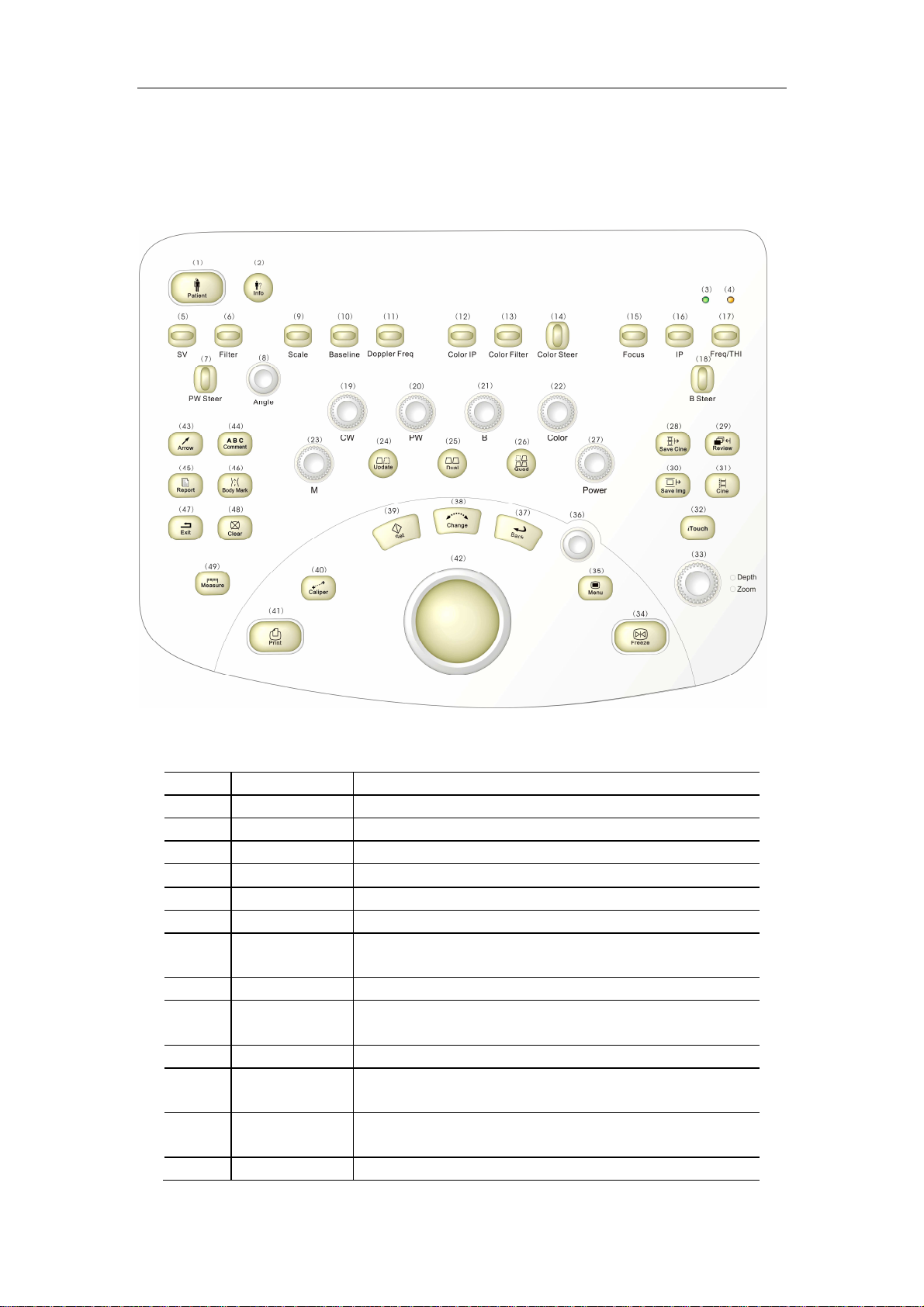

2.6 Control Panel ........................................................................................................ 2-11

2.6.1 Main panel .............................................................................................................. 2-11

2.6.2 Minor panel ............................................................................................................. 2-14

2.6.3 Keyboard ................................................................................................................ 2-15

2.7 Symbols ................................................................................................................ 2-18

3 Principle Description ............................................................................ 3-1

3.1 Electric Principle of the System .............................................................................. 3-1

3.2 Principle of Boards ................................................................................................. 3-2

3.2.1 Transducer Board ..................................................................................................... 3-2

3.2.2 Transmission board .................................................................................................. 3-3

3.2.3 Amplifier board ......................................................................................................... 3-3

3.2.4 Beamformer board ................................................................................................... 3-4

3.2.5 DSP board ................................................................................................................ 3-5

3.2.6 System motherboard ................................................................................................ 3-7

3.2.7 CW board ................................................................................................................. 3-8

3.2.8 Built-in PC module ................................................................................................... 3-9

3.2.9 IO module ............................................................................................................... 3-12

3.2.10 ECG module ......................................................................................................... 3-13

i

Page 4

3.2.11 Control panels and keyboard ............................................................................... 3-14

3.2.12 Detection board of Power Output ......................................................................... 3-15

3.2.13 CRT monitor ......................................................................................................... 3-16

3.2.14 LCD monitor ......................................................................................................... 3-17

3.3 Power Supply Principle ........................................................................................ 3-19

3.3.1 Power supply system ............................................................................................. 3-19

3.3.2 Principle of power boards ....................................................................................... 3-22

3.4 System Software .................................................................................................. 3-26

3.4.1 Structure ................................................................................................................. 3-26

3.4.2 Principle .................................................................................................................. 3-27

4 System Structure and Assembly/Disassembly .................................. 4-1

4.1 Exploded View of Complete System ...................................................................... 4-1

4.2 Exploded View of LCD Monitor and Support Arm .................................................. 4-3

4.3 Disassembly and Replacement .............................................................................. 4-4

4.3.1 Disassembly of the monitor ...................................................................................... 4-4

4.3.2 Replacement of the bottom light .............................................................................. 4-8

4.3.3 Replacement of spring damping parts ..................................................................... 4-9

4.3.4 Disassembly of the main panel .............................................................................. 4-14

4.3.5 Disassembly of the minor panel ............................................................................. 4-16

4.3.6 Replacement of the trackball .................................................................................. 4-18

4.3.7 Replacement of the main panel PCBA .................................................................. 4-19

4.3.8 Replacement of the keyboard PCBA ..................................................................... 4-22

4.3.9 Replacement of the keyboard ................................................................................ 4-23

4.3.10 Replacement of the light control PCBA ................................................................ 4-25

4.3.11 Replacement of the keyboard slide tracks ........................................................... 4-26

4.3.12 Replacement of the snap-close (lock head and lock seat) .................................. 4-27

4.3.13 Replacement of the travel switch (with the cable) ............................................... 4-29

4.3.14 Disassembly of the system boards ...................................................................... 4-30

4.3.15 Remove built-in PC module ................................................................................. 4-37

4.3.16 Remove HDD ....................................................................................................... 4-40

4.3.17 Remove the DVD-R/W assembly ......................................................................... 4-41

4.3.18 Remove the ECG assembly ................................................................................. 4-43

4.3.19 Remove the transducer board.............................................................................. 4-47

4.3.20 Replace the inlet dust net ..................................................................................... 4-49

4.3.21 Remove the transformer ...................................................................................... 4-51

ii

Page 5

4.3.22 Remove the fan assembly .................................................................................... 4-52

4.3.23 Replace casters ................................................................................................... 4-55

4.4 Installation of Peripherals ..................................................................................... 4-57

4.4.1 Installation of black/white video printer .................................................................. 4-57

4.4.2 Installation of color video printer ............................................................................ 4-59

4.4.3 Installation of VCR.................................................................................................. 4-63

5 Maintenance Requirements ................................................................. 5-1

5.1 Tools Required ....................................................................................................... 5-1

5.1.1 Tools/measurement devices and consumables ....................................................... 5-1

5.1.2 Standard configuration of tools and consumables ................................................... 5-2

5.2 Maintenance Personnel .......................................................................................... 5-3

6 Checks ................................................................................................... 6-1

6.1 Equipment condition Inspection ............................................................................. 6-1

6.1.1 Inspection Schedule ................................................................................................. 6-1

6.1.2 Checks before inspection ......................................................................................... 6-1

6.2 Function checks ..................................................................................................... 6-2

6.2.1 Flowchart for function checks................................................................................... 6-2

6.2.2 Content of the function checks ................................................................................. 6-2

6.3 Safety Checks ........................................................................................................ 6-4

6.3.1 Electric safety ........................................................................................................... 6-4

6.3.2 Checks for mechanical safety .................................................................................. 6-5

6.4 Image Checks ........................................................................................................ 6-8

6.4.1 B/W image phantom data checks and image records ............................................. 6-8

6.4.2 Check phantom data ................................................................................................ 6-8

6.4.3 Final operation checks and image archive ............................................................... 6-9

6.4.4 Checking color flow images ..................................................................................... 6-9

7 System Maintenance ............................................................................ 7-1

7.1 Cleaning ................................................................................................................. 7-1

7.1.1 Flowchart for cleaning .............................................................................................. 7-1

7.1.2 Content of the cleaning ............................................................................................ 7-1

7.2 Software Maintenance ............................................................................................ 7-4

7.2.1 Back up the preset data ........................................................................................... 7-4

7.2.2 Restore the preset data ............................................................................................ 7-5

7.2.3 Upgrade the software ............................................................................................... 7-7

7.2.4 System recovery .................................................................................................... 7-10

iii

Page 6

7.2.5 Hard disk recovery ................................................................................................. 7-12

7.2.6 Install and uninstall the software of optional devices ............................................. 7-13

7.2.7 Monitor test............................................................................................................. 7-15

7.2.8 Self-test .................................................................................................................. 7-17

8 Troubleshooting .................................................................................... 8-1

8.1 Troubleshooting for Power ..................................................................................... 8-1

8.2 Troubleshooting for Monitor ................................................................................... 8-1

8.3 Troubleshooting for the Power-up Process ............................................................ 8-2

8.4 Troubleshooting for the Operation Process............................................................ 8-3

8.5 Troubleshooting for Software ................................................................................. 8-3

8.6 Troubleshooting for Others ..................................................................................... 8-4

Appendix A Spare Part List ....................................................................... A-1

Appendix B Interface Definition and Function List ................................. B-1

Appendix C Initial Data of the Hard Disk .................................................. C-1

Appendix D Electrical Safety Inspection ................................................. D-1

iv

Page 7

© 2006-2012 Shenzhen Mindray Bio-Medical Electronics Co., Ltd. All rights Reserved.

For this Operator’s Manual, the issue date is 2012-09.

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called

Mindray) owns the intellectual property rights to this Mindray product and this manual.

This manual may refer to information protected by copyright or patents and does not

convey any license under the patent rights or copyright of Mindray, or of others.

Mindray intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the

written permission of Mindray is strictly forbidden.

Release, amendment, reproduction, distribution, rental, adaptation, translation or any

other derivative work of this manual in any manner whatsoever without the written

permission of Mindray is strictly forbidden.

,

WATO, BeneHeart, are the trademarks, registered or otherwise, of Mindray in

China and other countries. All other trademarks that appear in this manual are used

only for informational or editorial purposes. They are the property of their respective

owners.

, , , , BeneView,

Responsibility on the Manufacturer Party

Contents of this manual are subject to change without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not be

liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this manual.

Mindray is responsible for the effects on safety, reliability and performance of this

product, only if:

all installation operations, expansions, changes, modifications and repairs of this

product are conducted by Mindray authorized personnel;

the electrical installation of the relevant room complies with the applicable

national and local requirements; and

the product is used in accordance with the instructions for use.

Upon request, Mindray may provide, with compensation, necessary circuit diagrams,

calibration illustration list and other information to help qualified technician to maintain

and repair some parts, which Mindray may define as user serviceable.

Note

I-I

Page 8

This equipment is not intended for family usage.

This equipment must be operated by skilled/trained medical professionals.

Warning

It is important for the hospital or organization that employs this equipment to carry out a

reasonable service/maintenance plan. Neglect of this may result in machine breakdown

or injury of human health.

Warranty

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

Exemptions

Mindray's obligation or liability under this warranty does not include any transportation or

other charges or liability for direct, indirect or consequential damages or delay resulting

from the improper use or application of the product or the use of parts or accessories

not approved by Mindray or repairs by people other than Mindray authorized personnel.

This warranty shall not extend to:

Any Mindray product which has been subjected to misuse, negligence or accident;

Any Mindray product from which Mindray's original serial number tag or product

identification markings have been altered or removed;

Any product of any other manufacturer.

Safety, Reliability and Performance

Mindray is not responsible for the effects on safety, reliability and performance of the product

if:

Assembly operations, extensions, re-adjusts, modifications or repairs are carried out by

persons other than those authorized by Mindray.

Personnel unauthorized by Mindray repairs or modifies the instrument.

II

Page 9

Return Policy

Manufacturer:

Shenzhen Mindray

Bio-Medical Electronics Co., Ltd.

Address:

Tel:

Fax:

Return Procedure

In the event that it becomes necessary to return this product or part of this product to

Mindray, the following procedure should be followed:

1. Obtain return authorization: Contact the Mindray Service Department and obtain a

Customer Service Authorization (Mindray) number. The Mindray number must appear

on the outside of the shipping container. Returned shipments will not be accepted if the

Mindray number is not clearly visible. Please provide the model number, serial number,

and a brief description of the reason for return.

2.

Freight policy: The customer is responsible for freight charges when this product is

shipped to Mindray for service (this includes customs charges).

3. Return address: Please send the part(s) or equipment to the address offered by

Customer Service department

Company Contact

Mindray Building, Keji 12th Road South, Hi-tech Industrial Park,

Nanshan, ShenZhen 518057, P.R.China,

+86 755 26582479 26582888

+86 755 26582934 26582500

EC-Representative: Shanghai International Holding Corp. GmbH(Europe)

Address: Eiffestraβe 80, Hamburg 20537, Germany

Tel: 0049-40-2513175

Fax: 0049-40-255726

III

Page 10

Safety Precautions

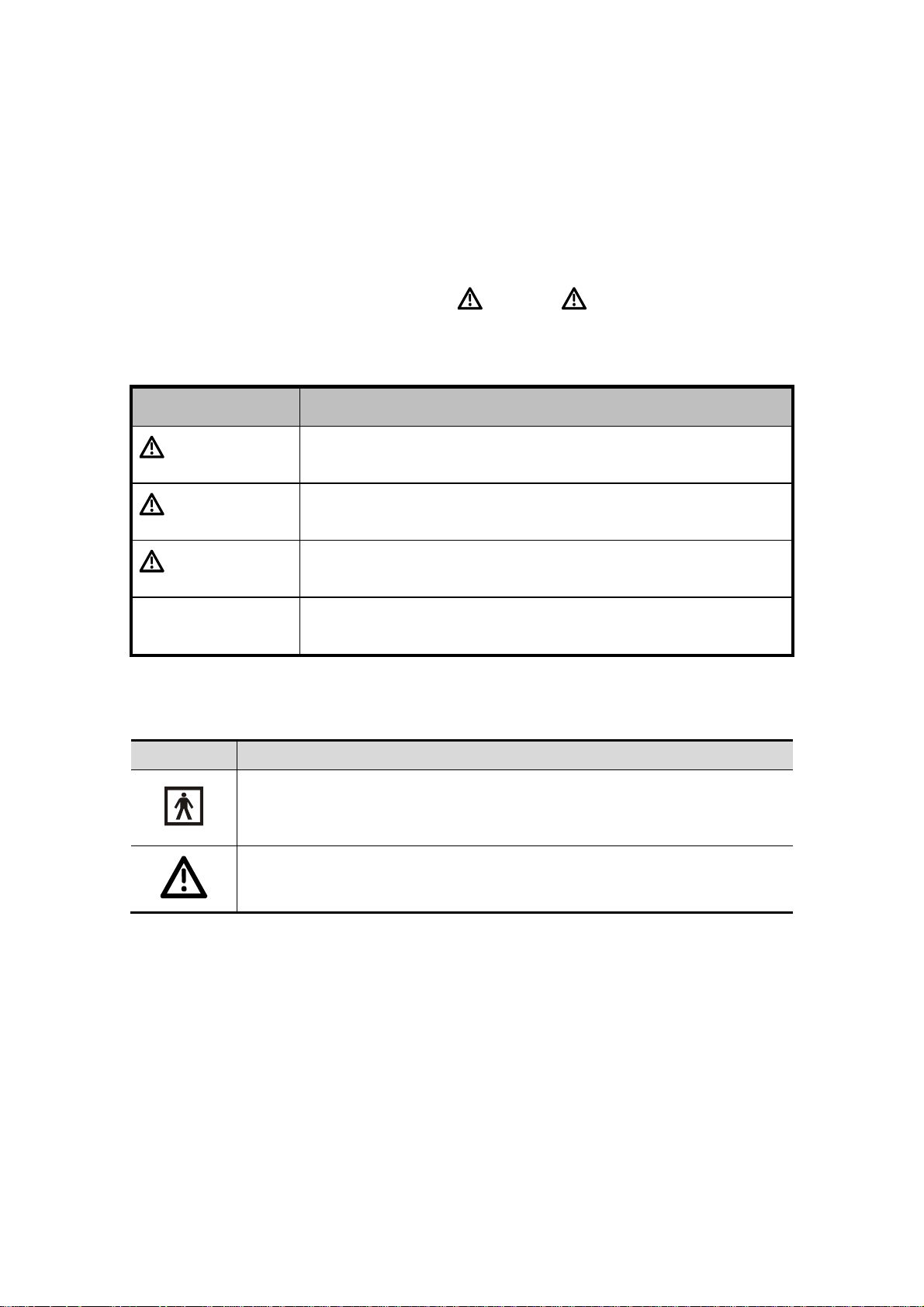

1. Meaning of Signal Words

In this operator’s manual, the signal words DANGER, WARNING and NOTE are

used regarding safety and other important instructions. The signal words and their meanings

are defined as follows. Please understand their meaning before reading this manual.

Signal word Meaning

DANGER

WARNING

CAUTION

NOTE

Indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Indicates a potentially hazardous situation that, if not avoided, may

result in property damage.

2. Meaning of Safety Symbols

Symbols Description

Type-BF applied part

The ultrasound transducers connected to this system are Type-BF applied

parts.

"Attention" indicates the points that you should pay attention to. Be sure to

read the operator’s manual concerning these points before using the

system.

IV

Page 11

3. Safety Precautions

Please observe the following precautions to ensure patient and operator safety when using

this system.

DANGER:

WARNING:

1. Do connect the plug of this equipment to the wall receptacle, and

2.... Be sure to connect the potential-equalization lead wire before

Do not use flammable gasses such as anesthetic gas, oxygen or

hydrogen, or flammable liquids such as ethanol, near this product,

because there is danger of explosion.

the plug must meet the ratings indicated on the rating nameplate.

Using an adapter or multi-functional receptacle may affect the

system grounding performance and thus causing the leakage

current to exceed safety requirements.

In addition, do connect the video printer to the auxiliary power

socket of this system. And use the printing cable provided by this

system to connect the printer. Otherwise, it may cause electric

shock.

inserting the equipment power plug into the receptacle. Also, be

sure to remove the equipment power plug from the receptacle

before disconnecting the wire to avoid electric shock.

3....Connect the earth conductor only before turning ON the system.

Disconnect the grounding cable only after turning OFF the system.

Otherwise, electric shock may result.

4.... For the connection of power and grounding, follow the appropriate

procedures described in this operation manual. Otherwise, there is

risk of electric shock. Do not connect the grounding cable to a gas

pipe or water pipe, otherwise functional grounding may not be

effective or there may be risk of a gas explosion.

5....Before cleaning the system, be sure to disconnect the power cable

from the outlet. If the system is defective, there is risk of electric

shock.

V

Page 12

6.... No waterproof device is applied to this equipment. Do not use this

equipment in any place with the possibility of water ingress. There

is risk of electric shock if any water is sprayed on or into the

equipment. If carelessly spray any water onto the equipment,

contact the Mindray sales office, customer service department or

representative.

7.... Use the transducer carefully. In case that the body contacts the

scratched transducer surface, immediately stop using the

transducer and contact the Mindray sales office, customer service

department or representative. There is risk of electric shock if using

the scratched transducer.

8.... Be careful not to let the patient contact the live parts of the

ultrasound equipment or other devices, such as signal I/O ports. If

the ultrasound equipment is defective, there is risk of electric

shock.

9. Do not use the transducers other than those specified by Mindray.

Otherwise, the equipment and the transducer may be damaged,

causing an accident such as a fire in the worst case.

10.

Do not subject the transducers to knocks. Use of defective

transducers may cause an electric shock.

11. Do not open the shell or front panel. If you open the shell when the

system is powered on, there may be a short circuit or electric

shock.

12. Do not use this system with using equipment at the same time such

as an electrosurgical unit, high-frequency therapy equipment, or a

defibrillator, etc. otherwise it may result in electric shock to the

patient.

13. Use only the ECG leads provided with the ECG module, otherwise it

may result in electric shock.

14. If this system needs to be moved, please hold the handle. If other

parts of the system are held, it may cause damage due to the

abnormal force. Do not push the system from the left/right side;

otherwise it may be toppled over.

VI

Page 13

15. Accessory equipment connected to the analogue and digital

interfaces must be complied with the relevant IEC standards (e.g.,

IEC 60950 Safety of information technology Equipment Standard

and IEC 60601-1 Medical Equipment standard). Furthermore all

configurations should comply with the standard IEC60601-1-1. Any

person, who connects additional equipment to the signal input or

output ports and configures a medical system, is responsible for

ensuring that the system complies with the requirements of

IEC60601-1-1. If you have any problem, consult the technical

services department of your local representative.

16. Prolonged and repeated use of keyboards can result in hand or

arm nerve disorders for some individuals. Observe the local safety

or health regulations concerning the keyboard use.

CAUTION:

(1) This system must be used only by qualified professionals.

(2) This operation manual does not describe clinical

2....Malfunctions due to radiowaves:

(1) Use of radiowave-emitting devices in the proximity of this

(2) If a person brings a device that generates radio waves near

3.... Precautions concerning installation and movement of the system:

(1) Ensure to install the equipment horizontally and lock up the

1....Precautions concerning clinical examination techniques:

examination techniques. Selection of the proper clinical

examination technique must be based on specialized

training and clinical experience.

medical electronic system may interfere with its operation.

Do not bring or use devices that generate radio waves, such

as cellular telephones, transceivers, and radio controlled

toys, in the room where the system is installed.

the system, ask him/her to immediately turn OFF the device.

casters securely. Otherwise, it may move to cause injury.

(2) Do not move the equipment from its sides; otherwise it may

be toppled over and may injure people.

(3) When you move the equipment on a slope, it shall be moved

slowly by two people; otherwise it may happen to slide and

severely injure people.

(4) Do not sit on the equipment, because it may move and make

people lose balance and fall.

VII

Page 14

(5) Dot not place any object on the monitor, because it may fall

and injure people.

(6) Fasten the peripheral devices before moving the equipment.

Otherwise, the peripheral devices may fall and injure people.

(7) When moving the equipment on steps, you shall prevent it

from being toppled.

4....Do not vibrate the equipment excessively (when moving the

equipment); otherwise the mechanical parts (such as casters) may

be damaged. If the equipment is often moved on a bumpy floor,

contact the Mindray sales office, customer service department or

representative.

5. Do not connect this system to outlets with the same circuit breakers

and fuses that control the current of devices such as life-support

systems. If this system malfunctions and generates an

overcurrent, or when there is an instantaneous current at power ON,

the circuit breakers and fuses of the building’s supply circuit may

be tripped.

6....Always keep the machine dry. Avoid transporting this machine

quickly from the cold place to the warm place; otherwise

condensation or water drops may be formed, causing short circuit.

7....If the circuit breaker is tripped, it indicates that the machine or the

peripheral devices have problems. In these cases, you cannot repair

by yourself but should contact the Mindray sales office, customer

service department or representative.

8.... There is no risk of high-temperature burns during routine

ultrasound examinations, even if, due to environment temperature

and exam modes, the surface temperature of the transducer exceeds

the body temperature of the patient. To prevent high-temperature

burns, do not apply the transducer to the same region on the patient

for a long time. Apply the transducer only for as long as required

time for diagnosis.

9....This device and its accessories are not disinfected and sterilized

when they are out of the factory, so the user shall disinfect and

sterilize transducers or biopsy brackets as per the manuals prior to

use of transducers or biopsy brackets. After the sterilization or

disinfection of accessories, chemicals must be washed out or gases

must be discharged thoroughly from the accessories. Remaining

residual chemicals or gases will not only result in damage to the

accessories but also can be harmful to human bodies.

VIII

Page 15

10....Before examining a new patient, press the key to delete

the patient information and data recorded in the image memory for

the previous patient. Otherwise, the new data may be confused

with the data of the previous patient.

11. Do not connect/disconnect the system and its accessories (such as

printers or DVD recorder) without turning OFF the power; otherwise

it may cause damage of the equipment or electric shock.

12. Do not turn OFF the power supply of the system during printing,

saving, or invoking; otherwise these processes may not be

completed normally or files may be lost.

13. During operation, if the system is improperly powered off, it may

result in data damage of the hard disk or system failure.

IX

Page 16

NOTE: 1. Do not use the machine in the vicinity of strong electromagnetic field (such

as the transformer), which may affect the performance of the machine.

2. Do not use the machine in the vicinity of high-frequency radiation source,

which may affect the performance of the machine or even lead to failure.

3. To avoid damaging the machine, do not use the machine in following

environment:

(1) Locations exposed to direct sunlight;

(2) Locations subject to sudden changes in temperature;

(3) Dusty locations;

(4) Locations subject to vibration;

(5) Locations near heat generators;

(6) Locations with high humidity.

4. Turn ON the system only after the power has been OFF for more than 20

seconds. If the system is turned ON immediately after being turned OFF,

the system may malfunction.

5. Turn OFF the auxiliary power switch or stop transmission through the

『Freeze』 key before connecting or disconnecting a transducer. If a

transducer is connected or disconnected with an image displayed, the

system and/or the transducer may malfunction.

X

Page 17

6. After using the transducer, remove the ultrasound gel on it and place the

transducer on the transducer holder. Otherwise, water in the gel may enter

the acoustic lens, thus adversely affecting the performance and safety of the

transducer.

7. You can record the registration data (including the hospital data and patient

data). To ensure the security of the data, be sure to back up the data on

external storage media. Data stored in the equipment may be lost due to

improper operation or an accident.

8. Do not apply external force to the control panel (e.g. leaning against it).

Otherwise it may damage the system.

9. If the system is used in a small room, the room temperature may rise.

Therefore, proper ventilation shall be provided.

10. When disposing the system or any part of it, contact your Mindray

representative. Do not dispose of this system without consulting Mindray.

Mindray would bear no responsibility for damages resulting from disposal of

this system without consulting Mindray.

11. Degradation of electrical and mechanical safety characteristics (such as

generation of a leakage current or deformation/abrasion of mechanical

parts) and of image sensitivity and resolution may occur after a period of

time. To ensure normal operation of the system, it is recommended to sign a

maintenance and service agreement to prevent accidents.

12. Output power outlet in the system is used to supply power for the

recommended peripheral devices. Do not connect other devices to the

outlet, otherwise the rated output power may be exceeded and failure may

result. Maximum output power of the power outlet for peripheral devices is

350VA.

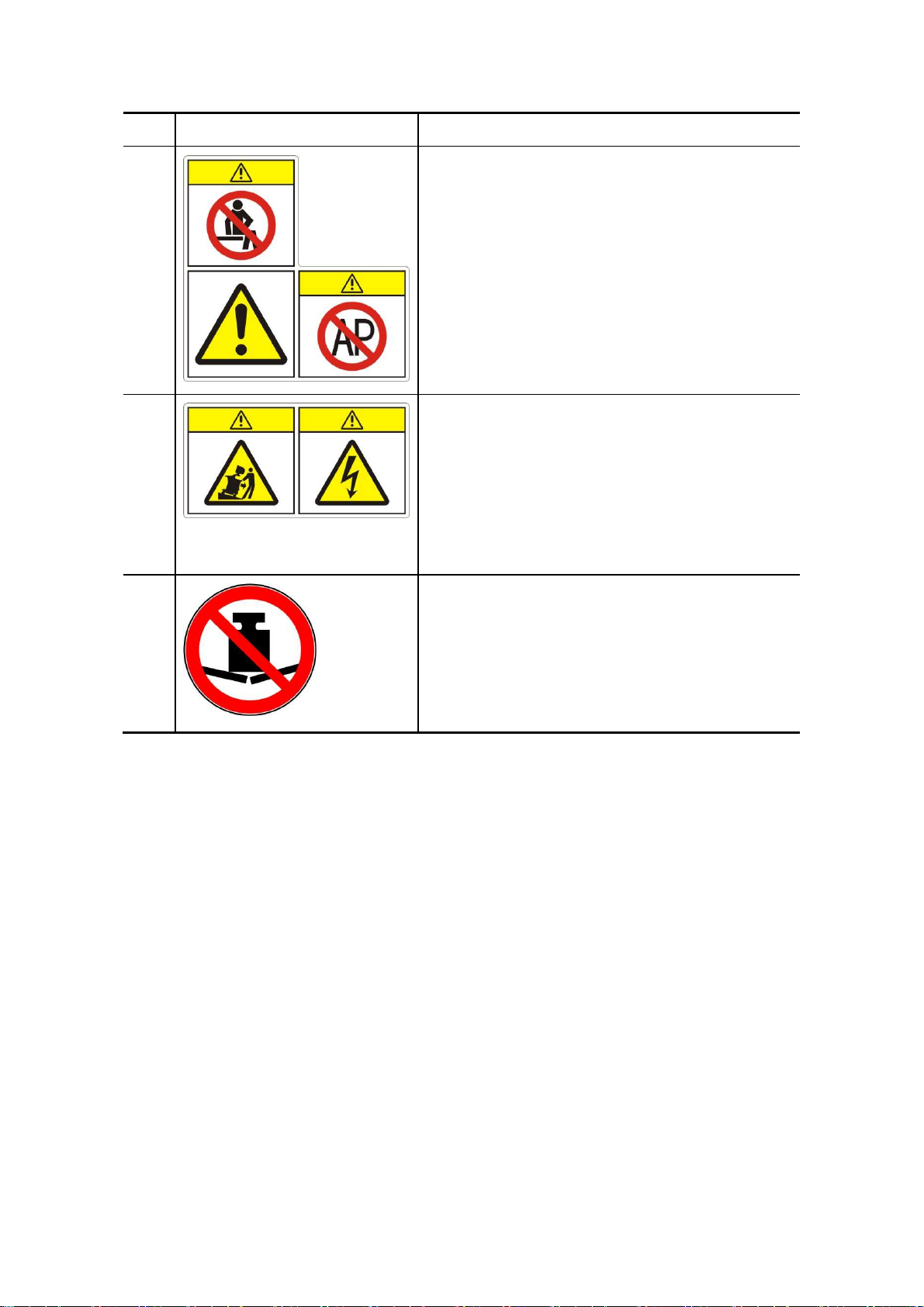

4. Warning Labels

Various warning labels are attached to this system in order to call the user's attention to

potential hazards.

The symbol

on the warning labels indicates safety precautions. The warning labels

use the same signal words as those used in the operation manual.

Detailed information about the warning labels is given in the operation manual. Read

operation manual carefully before using the system.

The name, pattern and the meaning of each warning label are described as follows:

XI

Page 18

No.

<1>

<2>

Label Meaning

(a) CAUTION: Do not sit on the system.

(b) Before using the system, be sure to carefully

read the relevant content of this operation

manual.

(c) DANGER: The system must not be used around

flammable gasses.

(a) CAUTION: Do not place the system on a sloped

surface. Otherwise the system may slide

unexpectedly, resulting in person injury or the

system malfunction. The system should be

moved over a sloped surface by two persons to

ensure safety.

(b) CAUTION: The system shells must not be

opened, because the high voltage inside may

cause electric shock.

<3>

Beware of excessive stress exerted to the system.

XII

Page 19

1

1.1

The DC-6/DC-6T/DC-6Vet Diagnostic Ultrasound System is a color Doppler system with

features of all-digital architecture and whole-body application, which is designed based on

clinical needs. The system supports a wide range of transducers, and its imaging modes

include B Mode, M mode, Pulsed Wave Doppler (PW), Continuous Wave Doppler (CW), Color,

and Power, Smart3D, iScape and Free Xros M. It supports single-frame files such as formats

of DICOM, BMP and JPEG, and Cine files such as CIN and AVI; the silicone keyboard and

flexible trackball are adopted for the system; the high-performance ICs are used to realize the

front-end transmission and reception and back-end software functions; the system is suitable

for a wide variety of hospitals and clinics.

1.2

System Characteristics

Applicable Scope

General Description

The DC-6/DC-6T Diagnostic Ultrasound System is applicable for adults, pregnant women,

pediatric patients and neonates, and it is intended for use in abdominal, cardiac, small parts

(breast, testes, thyroid, etc.), peripheral vascular, fetal, transrectal, transvaginal, pediatric,

neonatal cephalic, musculoskeletal (general and superficial), and intraoperative (liver,

gallbladder, pancreas) exams.

The DC-6Vet Diagnostic Ultrasound System is intended for use in abdominal, cardiac,

obstetric, small parts, peripheral vascular, transrectal, musculoskeletal (general and

superficial), and intraoperative exams for animals, such as dog, cat, equine, bovine and ovine,

etc.

1-1

Page 20

2

2.1

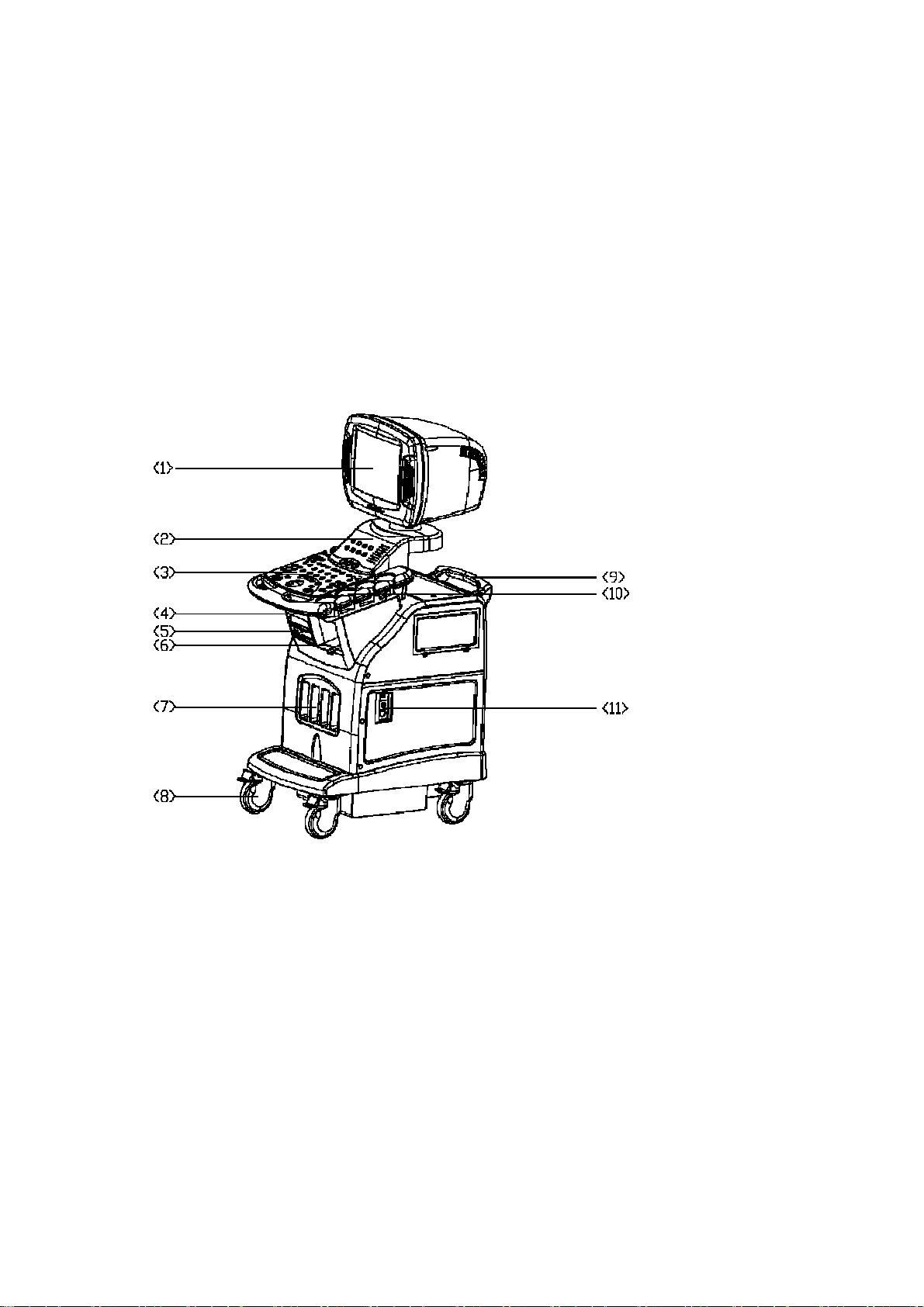

2.1.1 Complete System with CRT Monitor

System Appearance

System Overview

2-1

Page 21

System Overview

No

Name Function

<1> Monitor Displays the images and parameters during scanning

<2> Minor panel Human-machine interface, operation control

<3> Main panel Human-machine interface, operation control

<4> Keyboard Human-machine interface, operation control

<5> DVD-R/W Rewritable CD drive

<6> Space for placing

Used for placing B/W video printer

video printer

<7> Transducer socket Interface connecting transducers and the main unit

There are 3 active sockets and one dummy socket

<8> Casters Used for fixing or moving the system

<9> Handle Used for pushing the system

<10> Transducer holder Used for placing transducers temporarily

<11> ECG panel Used for connecting the ECG cable and footswitch, etc.

<12> Table for placing

Used for placing color video printer

color printer

<13> I/O panel Interface panel for input and output signals

<14> Power panel Electrical interface panel

<15> USB interface Used for USB devices

<16> MIC interface Used for connecting a microphone

<17> Space for placing

Used for placing VCR

VCR

2-2

Page 22

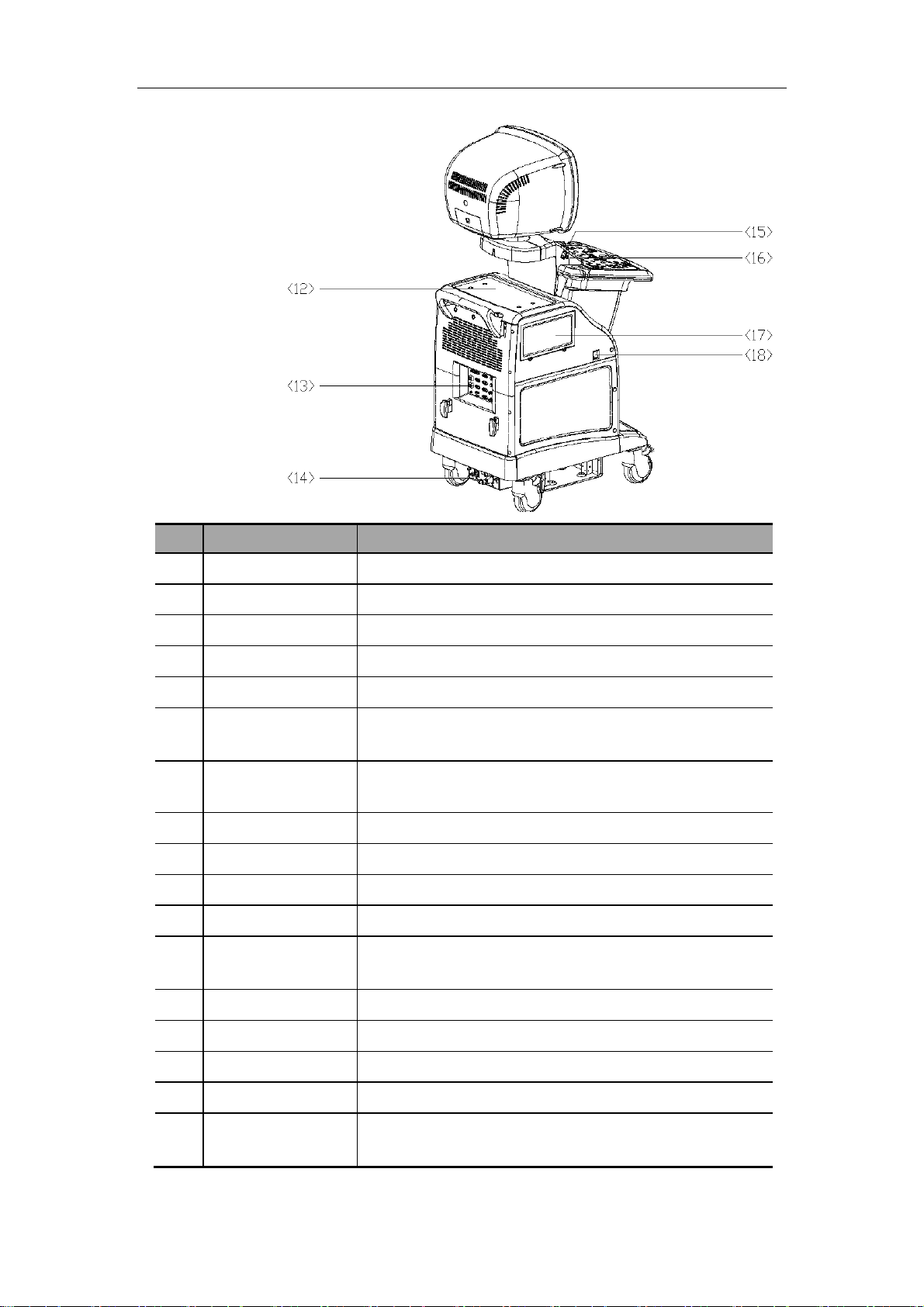

<18> Power switch Used for turning on/off the power supply

2.1.2 Complete System with LCD Monitor

System Overview

No

<1> Monitor Displays the images and parameters during scanning

<2> Monitor support arm Supports and adjusts height and position of LCD monitor

<3> Brightness buttons Adjust brightness of LCD monitor

<4> Contrast buttons Adjust contrast of LCD monitor

<5> Locking lever Locks the monitor in the lowest status

Name Function

2-3

Page 23

System Overview

2.2

LCD Monitor

2-4

Page 24

2.2.1 Brightness and contrast buttons

In the figure at the right side, 1> and <2> are

brightness-adjusting buttons, above which is a

sun symbol. A “-” symbol above the <1>

button indicates the button is used to

decrease brightness. A “+” symbol above the

<2> button indicates the button is used to

increase brightness.

<3> and <4> are contrast-adjusting

buttons, above which is a lune symbol. A “-”

symbol above the <3> button indicates the

System Overview

button is used to decrease contrast. A “+”

symbol above the <4> button indicates the

button is used to increase contrast.

Press both <2> and <3> buttons at the same time and hold for more than 3s, the default

brightness and contrast settings will be recovered.

Press both <1> and <4> buttons and hold for more than 3s to pop up the service menu of the

monitor, select “zoom select” to choose the image size to display; the default value is “user”.

NOTE: <1> and <2> are used to move the cursor up and down; <3> is used as “cancel” and

<4> is used as “OK”.

2-5

Page 25

2.2.2 Up/down adjusting lever

System Overview

left

right

As shown in the figure above, the lever is located at the lower left of the monitor back. Only

when the lever is placed in the rightmost position can it be used for up/down adjustment of the

monitor. (Note: if there is no lever for another type of monitor, you can adjust it directly.)

The monitor can be tilted 20 degrees downward or upward. See the figure below.

lever

When the system is packed for transportation or moved to another place, push the lever to the

left side and push down the monitor so that the monitor is placed in the horizontal position.

See the figure below.

2-6

Page 26

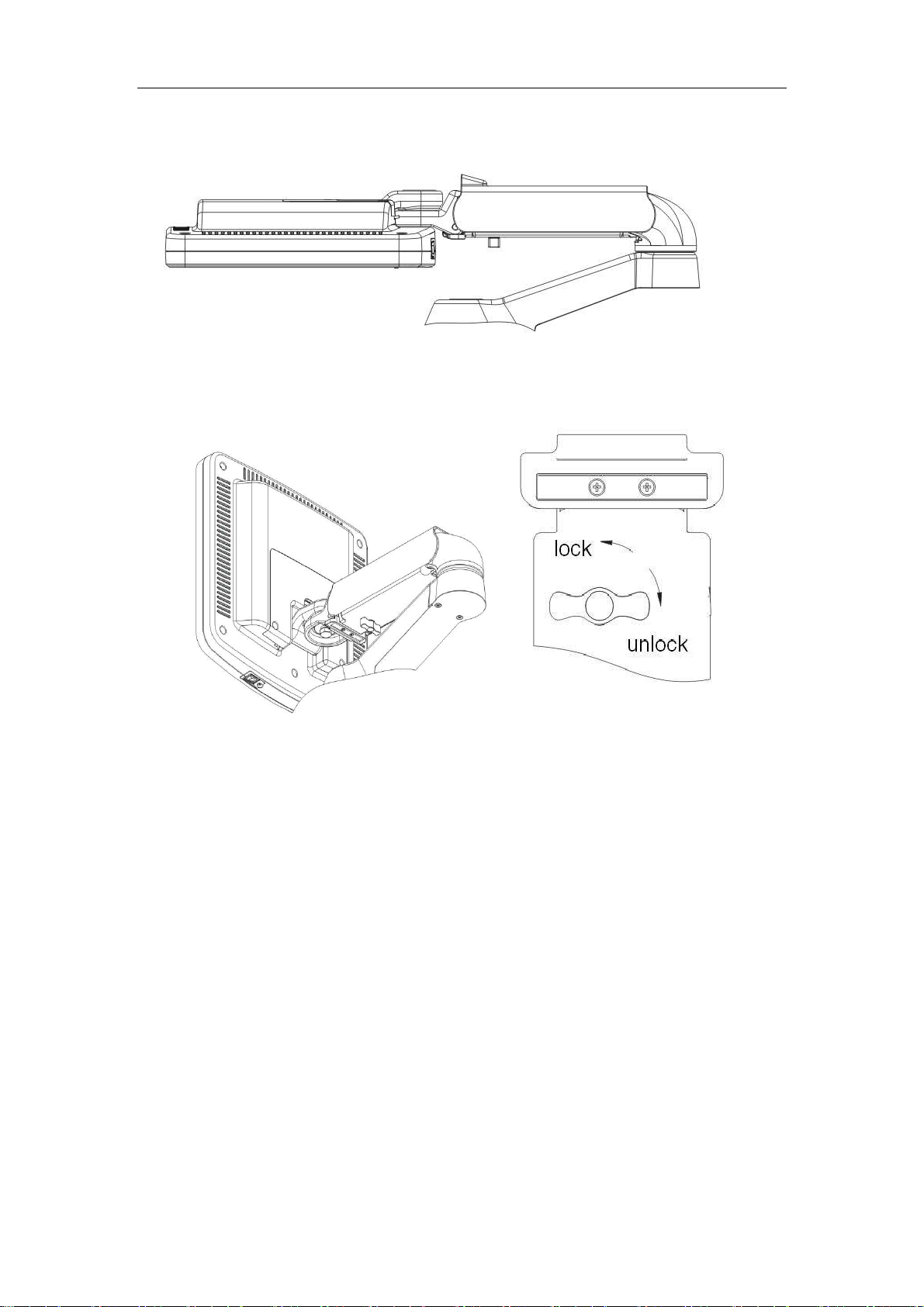

2.2.3 Lever of upper support arm

System Overview

2-7

Page 27

System Overview

>

>

9>

16>

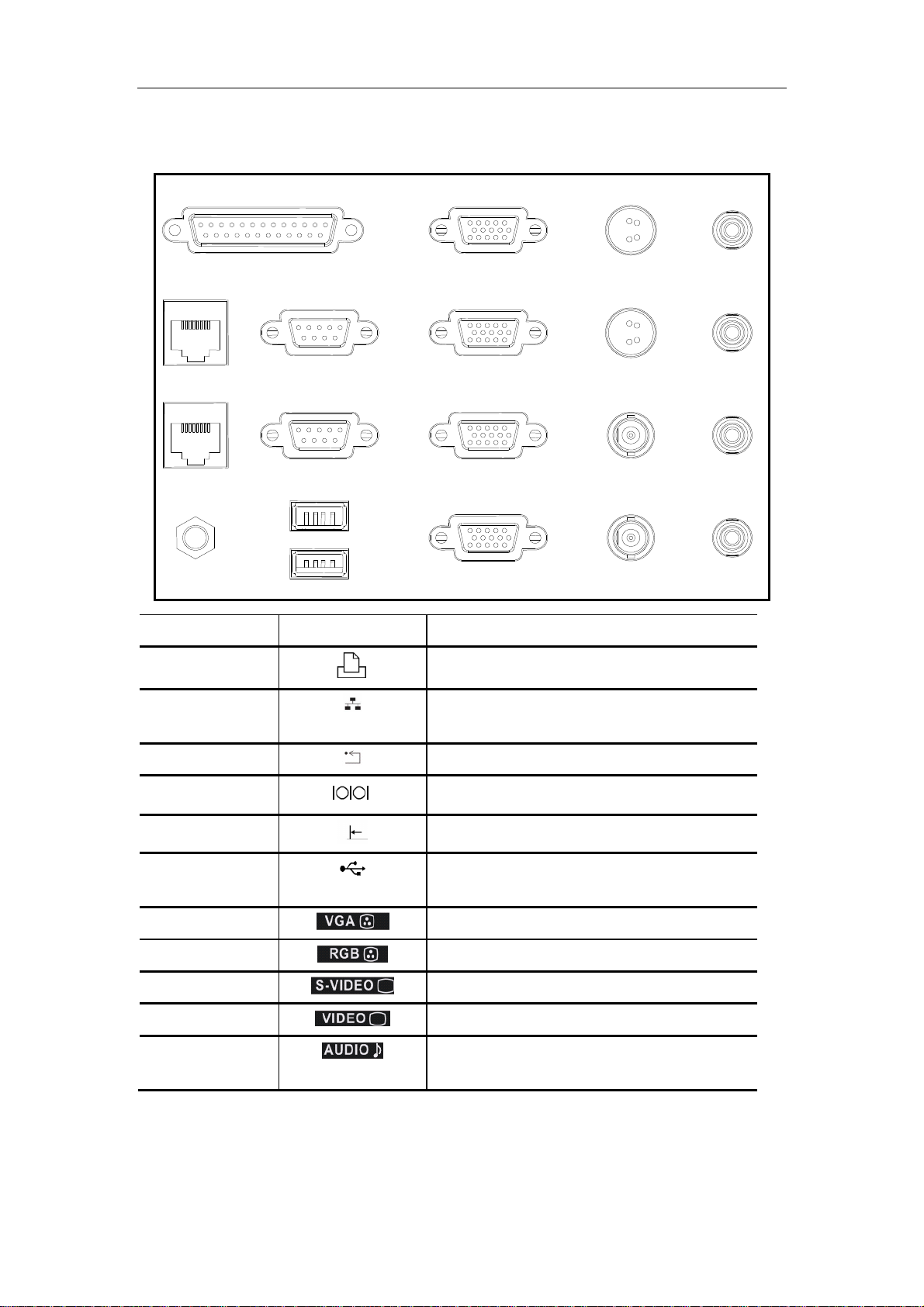

2.3

I/O Panel

<2>

<3>

<4>

<1> <9>

<5> <10> <14

<6> <11>

<7>

<8>

<12>

<13> <17

<18>

<15> <1

<

<20>

No Symbol Function

<1>

Used for system recovery

<2>, <3>

Ethernet interface (<2> is reserved for future

use; <3> can be used now.)

<4>

<5>

<6>

<7>, <8>

Control port for color video printer

USB port (<8> is used for USB devices, while

System reset

Serial port

<7> is for expansion.)

<9>,<10>

<11>,<12>

<13>,<14>

<15>,<16>

Used for RGB component video I/O

Used for VGA I/O

Used for separate video I/O

Used for composite video I/O

<17>,<18>

<19>,<20>

2-8

Used for stereo audio I/O

Page 28

System Overview

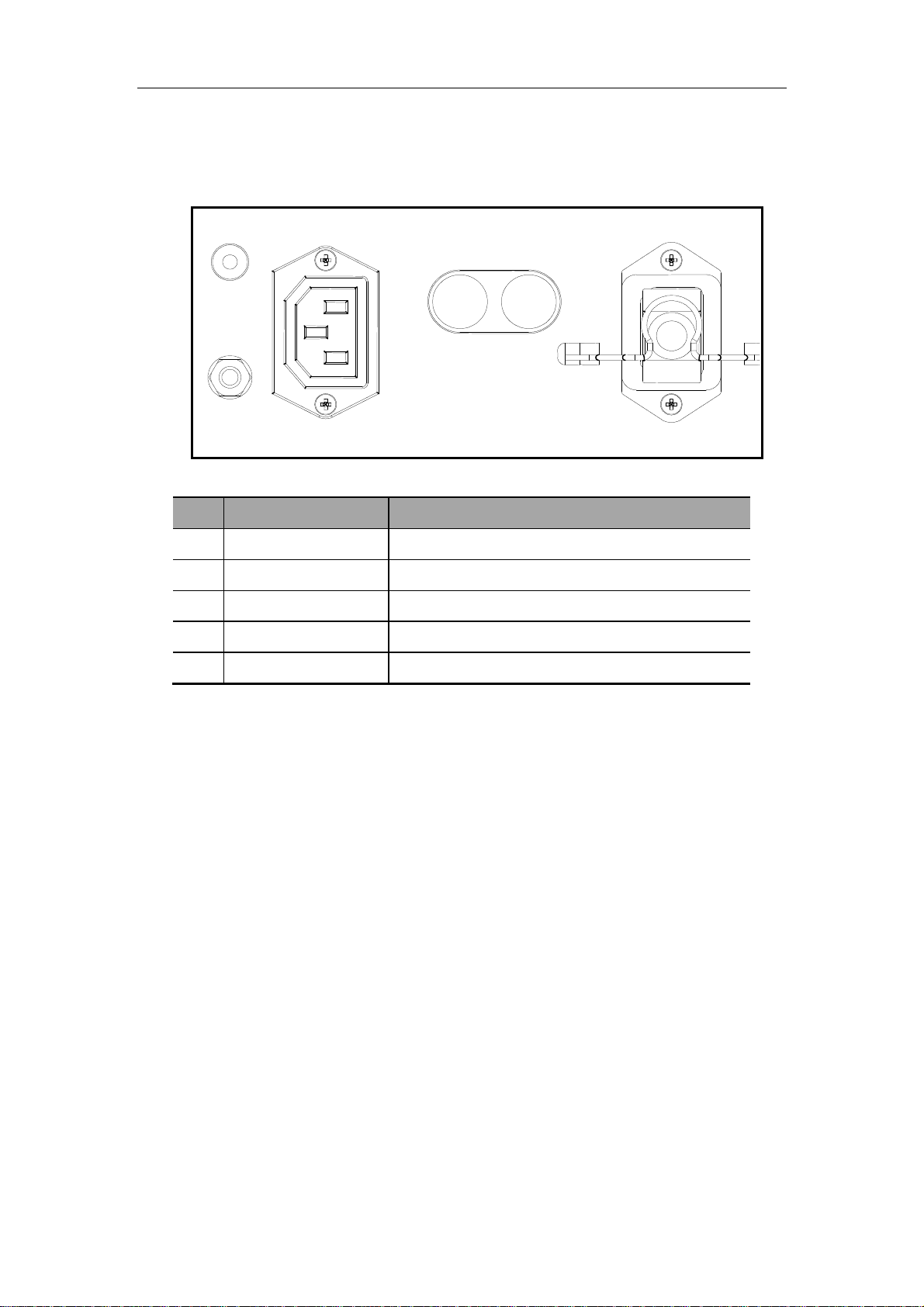

2.4

Power Panel

<1> <3>

<4>

<2>

No Name Function

<1> Ground terminal Used for grounding connection

<2> Equipotential terminal Used for equipotential connection

<5>

<3> Power outlet Power supply for optional peripheral devices

<4> Circuit breaker Used for cutting off power supply of the system

<5> Power inlet AC power inlet

2-9

Page 29

System Overview

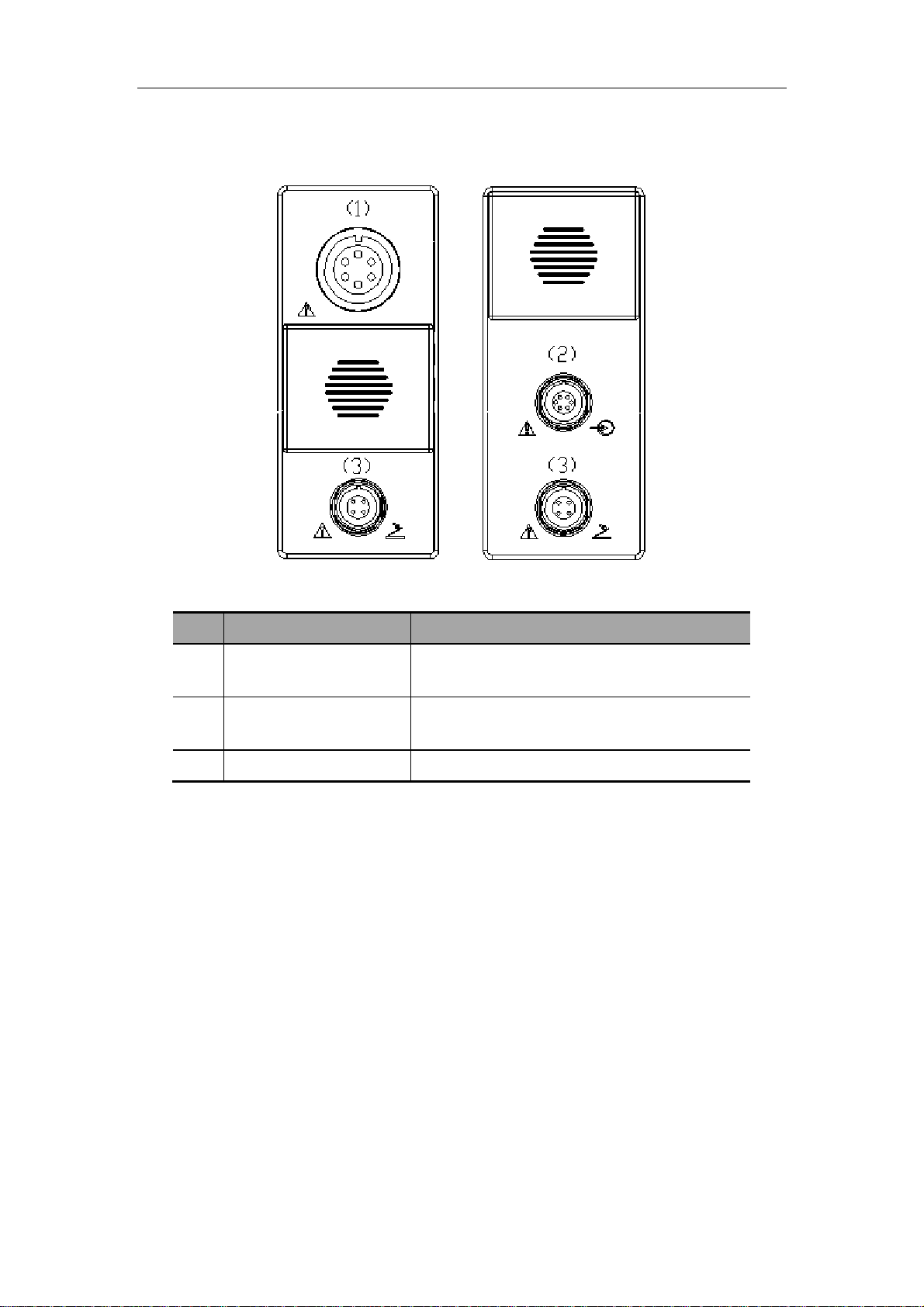

2.5

ECG Panel

No Name Function

<1> ECG lead signal input

interface

<2> External ECG signal

input port

<3> Footswitch interface Used for connecting the footswitch

Used for connecting ECG leads and acquiring

ECG signals

Used for connecting the signal output port of

ECG monitor

2-10

Page 30

System Overview

2.6

Control Panel

2.6.1 Main panel

No English Name

<1> Patient Press to start an exam of a new patient.

<2> Info Press to enter the patient information input screen.

<3> / Power indicator

<4> /

<5> SV Toggle to adjust the size of sample volume.

<6> Filter Toggle to adjust wall filter frequency in the PW mode.

<7> PW Steer Toggle to adjust SV steering angle of a linear transducer

<8> Angle Toggle to adjust SV corrected angle in the PW mode.

<9> Scale Toggle to adjust pulse repetition frequency in the

<10> Baseline Toggle to adjust baseline position in the PW/Color mode.

<11> Doppler Freq Toggle to adjust transmit frequency in the

<12> Color IP Toggle to select IP parameter combinations in the

<13> Color Filter Toggle to select wall filter in the Color/Power mode.

Hard disk indicator

in the PW mode.

Color/Power/PW mode.

Color/Power/PW mode.

Color/Power mode.

Function

2-11

Page 31

System Overview

<14> Color Steer Toggle to adjust ROI steering angle of a linear transducer

in the Color/Power mode.

<15> Focus Toggle to adjust focus position for B images.

<16> IP Toggle to select IP for B images.

<17> Freq/THI Toggle to adjust the current transducer frequency and

harmonic frequency.

<18> B Steer Toggle to adjust steering scan of a linear transducer or

trapezoid imaging.

<19> CW Press to enter the CW mode; rotate to adjust gain of a

CW image.

<20> PW Press to enter the PW mode; rotate to adjust gain of a

PW image.

<21> B Press to enter the B mode; rotate to adjust gain.

<22> Color Press to enter the Color Doppler mode; rotate to adjust

gain.

<23> M Press to enter the M mode; rotate to adjust gain of an M

image.

<24> Update Press to switch between image windows in M/B mode,

PW/B or CW/B mode., Press to start or end image

capture in the 3D mode.

<25> Dual Enters dual-split screen display, or changes the live

image window in Dual.

<26> Quad Enters the quad-split screen display, or changes the live

image window in the Quad mode.

<27> Power Press to enter the Power Doppler mode; rotate to adjust

gain.

<28> Save Cine Quickly saves cine files to the default region of the

internal hard disk in the preset image format.

<29> Review Reviews the image files of the current patient or the last

patient.

<30> Save Img Quickly saves image files to the default region of the

internal hard disk in the preset image format.

<31> Cine Enters the cine review status.

<32> iTouch Press to optimize images.

<33> Depth/Zoom When the Depth indicator lights on, the knob is used for

adjusting image depth by turning it; when the knob is

pressed down and the Zoom indicator lights on, the knob

is used for adjusting magnification factor by turning it.

<34> Freeze Freezes or unfreezes an image.

<35> Menu Invokes or closes the menu corresponding to the current

status.

<36>

Multifunction knob: it functions differently depending upon

different statuses. Refer to the relevant sections for

specific functions.

<37> Back Returns to the previous operation.

<38> Change Changes the active point of the caliper during

measurement; or opens the comment library in the

comment status.

2-12

Page 32

<39> Set Confirms an operation, equivalent to the left-button of the

mouse.

<40> Caliper Starts general measurement function.

<41> Print Prints the screen image (video print control).

<42> Trackball Adjusts the cursor’s position on the screen.

<43> Arrow Adds comment arrows, and the arrow orientation is

adjusted through the multifunction knob.

<44> Comment Press to start the comment function and the system

enters the comment status.

<45> Report Enters the current patient report.

<46> Body Mark Enters the body mark status.

<47> Exit Exits the current status.

<48> Clear Clears all comments, measurement calipers,

and the selected body marks on an image.

<49> Measure Starts application measurement functions.

System Overview

2-13

Page 33

2.6.2 Minor panel

System Overview

No English Name Function

<1> / Reserved for future use, can be defined

<2> / Reserved for future use, can be defined

<3> / Reserved for future use, can be defined

<4> / Reserved for future use, can be defined

<5> Record Used for data recording, can be defined

<6> ECG Entering or exiting the ECG menu

<7> iStation Entering the patient files management

<8> Probe Switching between effective transducers connected

and its exam mode.

<9> TGC Adjusting time gain compensation

<10> A.Power Adjusting Acoustic Output

<11> ECG Adjusting ECG signal position and ECG gain

<12> Volume Adjusting Doppler sound volume

2-14

Page 34

2.6.3 Keyboard

Ejection of the keyboard

System Overview

Push the edge of the keyboard inward slightly, and then the keyboard automatically ejects

outward. At this time the light under the main control panel is bright automatically to lighten

the keyboard.

Retraction of the keyboard

Push the keyboard inward, and when a click sound is heard, the keyboard is retracted.

2-15

Page 35

Functions of the keys

No Key Function

System Overview

<1> Enter

<2> Esc

<3> Tab Jumping to the next operation

<4> Space Inserting a space

<5> Caps Lock Switching between upper and lower case letters

<6> Num Lock Switching between numeric and other characters

<7> Shift

<8> Ctrl

<9> Alt Combined key

<10> Pause/Break /

<11> Home

<12> End

<13> PgUp Turning pages upward or leftward

<14> PgDn Turning pages downward or rightward

<15> Arrow Moving the cursor position

<16> Ins Switching between insertion and overwrite

<17> Del Deleting characters after the cursor

<18> Back Space Deleting characters before the cursor

<19> PrtSc /

<20> Win Logo /

<21> Application /

Receiving the input data; or moving the cursor to the head of

next row of the text or the input field.

Same as that of the『Exit』key

Press the『Shift』key and another key simultaneously, and then

upper and lower case letters or upper and lower characters can

be switched; Shift+ +Set;

Combined shortcut, Ctrl+ +Set;

Moving the cursor to the head of the row, or the leftmost side of

an edit unit.

Moving the cursor to the tail of the row, or the rightmost side of

an edit unit.

NOTE: ”/” symbols represent the keys are undefined.

2-16

Page 36

Functions of the keys F1 to F12

Quickly starting the patient information screen (identical to the

Quickly starting the diagnosis report screen (identical to the

ment status (identical to the

No Key Function

<1> F1 /

<2> F2

『Info』 key)

<3> F3

『Report』 key)

<4> F4 Quickly starting the com

『Comment』 key)

<5> F5 /

<6> F6 /

<7> F7 /

<8> F8 /

<9> F9 Switching to the video replay menu

System Overview

<10> F10 Quickly starting preset function

<11> F11 Turning on/off the display of biopsy guide line

<12> F12 /

NOTE: for the keys undefined, the user can define functions for them as per needs and habit.

Refer to the “Preset” chapter for details.

2-17

Page 37

System Overview

2.7

explained as well. Refer to “Safety Precautions” for safety symbols.

Symbols

This system uses the symbols listed in the following table, and their meanings are

Symbol Meaning

!

Type-BF device

Refer to relevant content in the Operation Manual, to avoid

safety accidents

Dangerous voltage

AC (alternate current)

Functional earth

Equipotentiality

Protective earth

Breaker ON/OFF

Power ON/OFF

Footswitch

Transducer socket

Network port

Parallel port

Serial port

S-VIDEO signal interface

VIDEO signal interface

VGA signal

RGB signal

External signal input

Remote control port

USB

2-18

Page 38

System Overview

System reset

Audio signal

Microphone input jack

Product serial number

Manufacture date

Manufacturer

2-19

Page 39

3

3.1

Electric Principle of the System

Principle Description

The system consists of transducer module, transmission module, reception module, CW

module, beamformer module, B/M-mode signal processing module, color flow signal

processing module, Doppler signal processing module, DSC module, CPU system, ECG

module, and input/output module, etc.

Transducer

board

Transducer

interface

board

POUT

Scan control

signal

Data bus

Transmission

Connector

board

CW board

Scan control

Amplifier

board

ECHO

Front-end FPGA

configuration bus

signal

Front-end control bus

Beamformer

B , M

C, CM

PW, CW

DSP

board

IO connecting

board

Hardwired

Hardwired

IO

board

LED board

Fan

isolation

transformer

Power

external

power

input

PHV1

A+5V

-PHV1

A-100V

PHV2

A+100V

-PHV2

A+5V

A-5V

A+12V

D+3.3V

D+5V

D-12V

Fan connecting

board

connecting

board

external

adapter board

auxiliary

output

A+5V

A-5V

D+3.3V

A+12V

PHV1

-PHV1

D+5V

system motherboard

PFC board +5V board

auxiliary

output

peripheral output

A+5V

A-5V

Power output detecting board

Power motherboard

D+5V

D+3.3V

-5V board

D+5V

D+3.3V

D+12V

A-5V

A+5V

HDD

PHV board

3-1

Page 40

Principle Description

3.2

Principle of Boards

3.2.1 Transducer Board

The block diagram of the transducer board is shown as follows:

Relay-EN2

Relay-EN1

Relay-EN0

Relay-EN3

The transducer board is designed for switching between the transducers and recognition of

the transducer IDs. The transducer switching signal controls the relays to switch between

the transducers, and the ID reading circuit is independent of the transducer switching circuit

and can read out the IDs of the transducers.

For A, B, C, and D transducers, the channel, double-pole double-throw relays are respectively

adopted to control the status of the transducer. Now take relay drive of the transducer A as an

example to describe the principle of the transducer switching. After the transducer select

control signal D_Relay-ENA is driven by 245, the four-channel signal D_Relay-ENA is

obtained. The four-channel signals are respectively driven by four relays to generate the

eight-channel signals A The A signals respectively control channel relays, so that the element

of the transducer A can be selected.

The transducer ID codes are selected by the signal CS and read into CPLD. After the system

reads out a transducer’s ID code, the system software will set the D_Relay-ENX (X

3-2

Page 41

Principle Description

represents A, B or C) signal to select the corresponding transducer. Since the system may

read multiple transducer ID codes simultaneously, the system software will select the

corresponding transducer based on the current exam.

When transducers are disconnected or connected, the interrupt signal will be automatically

generated to notify the system software, so that the system software can obtain the current

status of transducer connection and provide the prompt message accordingly.

3.2.2 Transmission board

The block diagram of the transmission board is shown as follows:

The transmission board is designed for generation of high-voltage pulse and transmission

sequence. The transmission circuit consists of two parts: transmission sequence and

transmission drive. The transmission sequence circuit generates low-voltage transmission

pulse, which passes the transmission drive circuit and is converted to high-voltage pulse. The

transmission board is provided with four programmable transmission voltages by the power

supply, so that the board can generate different transmission waveforms depending on the

needs of the system.

3.2.3 Amplifier board

The block diagram of the amplifier board is shown as follows:

The amplifier board is designed for voltage-controlled gain amplification of small signal echo.

3-3

Page 42

Principle Description

The amplifier board consists of high-voltage isolation circuit, channel select circuit, primary

voltage-controlled gain amplification circuit and secondary fixed gain amplification circuit. The

control signal of the channel select logic is derived from the beamformer board, and this

signal controls the on-off of the reception channel. The primary gain amplification circuit

consists of AD8332 and the peripheral circuits. The AD8332 is a dual-channel

voltage-controlled gain amplifier, and the gain voltage is derived from DA conversion from the

beamformer board and ranges between 0.04V and 1V. The secondary fixed gain amplification

circuit consists of AD8132 and the peripheral circuits.

3.2.4 Beamformer board

The block diagram of the beamformer board is shown as follows:

The beamformer board consists of beamformer module, signal processing FPGA module, and

signal processing DSP module. The beamformer board is designed for AD sampling,

beamforming, radio frequency signal processing, Doppler signal processing, flow signal

processing, video signal processing, and generation of scan control signal, etc.

The channel difference analog signal, transmitted from the system motherboard, passes the

low-pass filter to avoid aliasing of subsequent AD sampling. The cut-off frequency is 15 MHz.

After the signal is filtered and passes 8 pieces of high-speed AD for sampling, the sampled

data is sent to FPGA U46 and U65 for beamforming.

The data, after beamforming, is sent to FPGA U4 for B/W signal processing.

3-4

Page 43

Principle Description

At the same time the data is sent to FPGA U59 for color flow signal processing and partial

Doppler signal processing. Subsequently part of data is sent to FPGAU83 for remaining color

flow signal processing, and the other part of the data is sent to DSP U78 for remaining

Doppler signal processing. Then the B/W signal, color flow signal, Doppler signal pass the

system motherboard and are sent to the DSP board for the subsequent processing.

3.2.5 DSP board

The DSP board consists of Cine module (Cine), digital scan conversion module (DSC),

back-end display module (Display), and data capture module (Capture) and CPU system. Its

block diagram is shown as follows:

The Cine, DSC, 3D data capture and back-end display modules are designed for post

processing, and the FPGA is adopted for these functions.

The MCF5474 is used as the system CPU, to control the modules and whole system.

The functions of the modules are described as follows:

3.2.5.1

Pre-processing of echo data

Cineloop storage and review in each mode

DDR internal memory used for Cineloop storage

The Cine and DSC modules both have 4 parallel data channels for 2-D image, M image,

Doppler image and ECG waveform.

3.2.5.2

The DSC module is designed for conversion from echo data format to VGA data format.

3.2.5.3

The up USB interface is used for transferring original image data to the PC platform.

Cine module

DSC module

Capture module

The down USB interface is used for storage of 3D data calculated by the PC in the RAM.

3-5

Page 44

The USB interface HDD can be realized.

Connector

Description

Status

Remarks

Connector

Description

Connector

Description

Principle Description

3.2.5.4

Processing of graphic and image integration and provision of control interface for main

The graphic memory is directly accessed by CPU.

Interface control of video input and output

3.2.5.5

The CPU system is the control core of the ultrasound system, consisting of hardware

Communicating with other MCU or DSP, and configuring, initializing, and monitoring each

Initialization configuration for system FPGA and DSP;

System control: parameter control for FPGA; management for system controllers; on-line

Display module

CPU to graphic memory

CPU system

system and software system. The hardware provides support for functions of the system

software, and the software realizes the control of hardware modules. The functions of the

CPU system include: image display and measurements, and human-machine interaction.

hardware module;

upgrading of each MCU.

3.2.5.6

J1 USB IDE HDD interface Not supported

J2 Reserved FPGA serial port Not welded

J4 Reserved 1561 USB Host port Not supported

J6 CPU BDM and JTAG select

J7 Small HDD socket Not supported Either HDD socket or CF

J10 JTAG link of PLD Supported For JTAG configuration of

J11 JTAG link of CPU and PLD Not supported

J14 USB Device interface of CPU Not supported

J15 BDM socket interface of CPU Supported For CPU system debugging

J166 CF card socket Not supported

JP1-4 Used for connecting CPU’s

Connectors of the DSP board

jumper

JTAG link and PLD’s JTAG

link

No jumper for

BDM

Not supported

socket is welded

CPLD and FPGA

and program downloading

3.2.5.7

D1 3.3V power indicator D27 FPGA configuration

Functions of LED indicators

indicator

3-6

Page 45

Principle Description

ISP1161 test output

D2 5V power indicator D30

indicator

D7 -5V power indicator D31-D34 Connection indicator of

network control

D8,D14,D15 FPGA debugging indicator D37,D39-D41 DSC FPGA debugging

indicator

D9,D10,D25 ISP1561 USBVBUS

indicator

D11,D18,D36 Cine FPGA debugging

indicator

D12 DSC FPGA configuration

indicator

D13 12V power indicator D49 Capture FPGA

D17, D26 CPU debugging indicator D50-D51 CPLD debugging status

D19-D24 ISP1561 status indicator

D38 Cine FPGA configuration

status indicator

D42-D44 ISP1583 Suspending

status indicator

D45-D48 Capture FPGA debugging

status indicator

configuration status

indicator

indicator

3.2.6 System motherboard

The system motherboard, serving as platform of the hardware system, provides power

channels and signal channels for modules.

The IO signal connection diagram of the system motherboard is shown as follows:

3-7

Page 46

Principle Description

Category

Interface

Socket

Use

I/O interface definition of the system motherboard:

number

Interfaces with

boards

Transducer

connecting board

ECG module Soft-wired 1 2 serial ports

PC module Hard-wired

USB, microphone Soft-wired 3 3 USB (one reserved), 1 microphone

Footswitch signal Soft-wired 1 To ECG board

Power control

signal

Power signal Hard-wired

Hard-wired

Hard-wired

Hard-wired

5 Connecting transmission board, amplifier

board, beamformer board, DSP board, and

the board reserved

1 Transducer signal

power signal

footswitch

Powered by power supply

1 1 serial port

3 USB ports

S-Video signal

Status signal and PC power signal

Powered by power supply

interface

1 1 serial port, for power control

SW, SW-EN soft switch signal, PW-OFF

4 For each channel of power

3.2.7 CW board

The CW board diagram is shown below, which consists of four portions: transmission,

reception, power and control.

3-8

Page 47

Principle Description

eception

Reception

Tissue

3.2.7.1

Transmit

converter

R

converter

Transmit

amp

RF amp

Transmit

beamformer

Waveform

generator

Quadrat

ure

demo

beamform

Transmission

The transmission signal flow graph is shown as follows:

er

filter

Audio

amp

Result

display

Signal

process

AD

convert

er

3.2.7.2

The high voltage isolation circuit is used to protect the reception circuit. Although a relay is

placed in the front-end of the reception circuit to isolate from the transducer, if fault occurs for

the relay control, the high voltage may be applied to the front-end of the reception circuit.

Therefore the high voltage isolation is necessary.

The band pass filter is used to filter extremely low frequency component and sum frequency

component in the signal demodulated. It consists of two-level active high-pass filter and

four-level active low-pass filter.

Reception

The reception signal flow graph is shown as follows:

3.2.8 Built-in PC module

3.2.8.1

The built-in PC module is used for background processing of 3D and iScape data. The image

data is transferred from ultrasound system to PC system via a USB2.0 interface, for the

System function

3-9

Page 48

Principle Description

purpose of analysis, such as 3D imaging. In the figure below, the broken line stands for

control flow, while the real lines stand for data streams. The main CPU control

communicates with the built-in PC via a serial port. The built-in PC initiates USB2.0 main

control of the PC system and USB2.0 slave of the ultrasound system. The data is transferred

via USB2.0, and the main CPU system determines that the results are to be displayed

whether by the ultrasound system or by the built-in PC.

Data before DSC processing

main CPU

control

USB2.0 for data transfer

Graph/image Circuit

Image capture

MonitorMoSwitchS

Built-in PC

3.2.8.2

PC carry board

The industrial control PC has advantages in the aspects of reliability, signal interface methods,

power supply categories, and power consumption, so it is used as the built-in PC. The built-in

PC module consists of PC carry board, industrial control board, memory stick, HDD and fan.

The PC carry board is introduced as follows:

The data transfer between the PC carry board and the digital processing board is completed

via 2-channel USB2.0 interface;

The PC carry board communicates with the digital processing board 5474 via a serial port;

The S-VIDEO interface is used for maintaining mode display;

The USB and kilomega Ethernet interface is used for connecting the IO-BOX;

HDD supporting SATA interface is used to store 3D system data;

CPLD is used to manage the system power system;

The PC carry board obtains power of 12V, 5V or 3.3V from the mother board;

The PC carry board interfaces are shown as follows:

3-10

Page 49

Principle Description

3.2.8.3

The ZPACK110 socket is used for connecting the PC carry board and mother board, and

signals are defined as follows:

Interface definition

3-11

Page 50

Principle Description

PA SIG.DES

PB

SIG.DES

PC

SIG.DES

PD

SIG.DES

PE

SIG.DES

Model: 110Pin PC platform

PA.1 GND PB.1 DM-SIG PC.1 DP-SIG PD.1 GND PE.1 VBUS-SIG

PA.2 GND PB.2 DM-PC2 PC.2 DP-PC2 PD.2 GND PE.2 VBUS-PC2

PA.3 VBUS-PC1 PB.3 DM-PC1 PC.3 DP-PC1 PD.3 GND PE.3 GND

PA.4 PC-YIN PB.4 PC-CIN PC.4 GND PD.4 GND PE.4 GND

PA.5 PW-STS PB.5 BOARD-DETECT PC.5 NC PD.5 NC PE.5 NC

PA.6 GND PB.6 GND PC.6 GND PD.6 GND PE.6 GND

PA.7 RXD-PC PB.7 TXD-PC PC.7 PS-DATA PD.7 PS-CLK PE.7 /

PA.8 GND PB.8 GND PC.8 GND PD.8 GND PE.8 GND

PA.9 GND PB.9 GND PC.9 GND PD.9 GND PE.9 GND

PA.10

PA.11

PA.12

PA.13

PA.14

PA.15

PA.16

PA.17

PA.18

PA.19

PA.20

PA.21

PA.22

D+5 PB.10

D+5 PB.11

D+5 PB.12

GND PB.13

GND PB.14

D+3.3 PB.15

D+3.3 PB.16

GND PB.17

A-5 PB.18

GND PB.19

GND PB.20

D+12 PB.21

D+12 PB.22

D+5 PC.10

D+5 PC.11

D+5 PC.12

GND PC.13

GND PC.14

D+3.3 PC.15 D+3.3 PD.15 D+3.3 PE.15

D+3.3 PC.16 D+3.3 PD.16 D+3.3 PE.16

GND PC.17

A-5 PC.18

GND PC.19

GND PC.20

D+12 PC.21 D+12 PD.21 D+12 PE.21

D+12 PC.22 D+12 PD.22 D+12 PE.22

D+5 PD.10

D+5 PD.11

D+5 PD.12

GND PD.13 GND PE.13

GND PD.14 GND PE.14

GND PD.17 GND PE.17

A-5 PD.18

GND PD.19 GND PE.19

GND PD.20 GND PE.20

D+5 PE.10

D+5 PE.11

D+5 PE.12

A-5 PE.18

D+5

D+5

D+5

GND

GND

D+3.3

D+3.3

GND

A-5

GND

GND

D+12

D+12

Interfaces between the PC carry board and IOBOX: 1 USB port, 1 network port.

3.2.9 IO module

The IO module consists of IO connecting board, IO adapter board, and IO interface board.

The connection relation between these boards is shown as follows:

1. One end of the IO connecting board is connected to the DSP board, and the other end is

connected to the IO adapter board; the standard 40PIN IDE HDD interface and 4PIN

power interface are provided, and the power socket for HDD cooling fan is reserved.

2. One end of the IO adapter board is connected to the IO connecting board, and the other

end is connected to the IO interface board; the adapter board serves as an extension

board.

3. The IO interface board is connected to the IO adapter board, and provides IO interfaces

and the power of the system; the IO interfaces are divided into internal IO (invisible for

the user) and external IO (visible for the user).

The block diagram of the IO module is shown as follows:

3-12

Page 51

Principle Description

DSP

board

IO connecting board

Hard-wired

Hard-wired

Hard-wired

HDD

IO adapter board

IO interface board

PARALLEL

COM 1

ETHERNET 1/2

USB 1/2

VGA OUT 1

REMOTE 1

RGB OUT 1

S-VIDEO OUT 1

VIDEO OUT

AUDIO OUT 1

RGB IN

VIDEO IN 1

S-VIDEO IN 1

AUDIO IN 1

RESET

VGA IN

TO DVD RW (S-VIDEO IN, S-VIDEO OUT,

AUDIO IN, AUDIO OUT, SERIAL PORT)

TO CD-RW (IDE)

TO monitor (VGA, AUDIO-PW OUT)

TO VCR (S-VIDEO IN, S-VIDEO OUT,

AUDIO IN, AUDIO OUT, SERIAL PORT)

TO B/W VIDEO PRINTER (VIDEO OUT, REMOTE 1)

TO TOUCHSCREEN (SERIAL PORT, VGA)

LCD

LCD

KEYBOARD

CD RW

Note: other modules are in the broken lines

DVD

TOUCHSCREEN

3.2.10 ECG module

The ECG module is designed for monitoring of ECG signals and display of ECG waveforms,

which serve as reference of ultrasound images. The ECG module can synchronously trigger

display of 2-D images and color flow images. After the ECG signal is amplified, filtered and

sampled, through the RS232 serial port, the signal is sent to the DSC module; at the same

time the R-wave is detected, and the detected ECG-triggering signal is sent to the system

controllers through interrupt, to start the scan transmission. The ECG module communicates

with the main CPU system through the RS232 serial port.

The ECG signal can be inputted to the system, through an interface compatible with Mindray’s

monitoring products.

3-13

Page 52

Principle Description

ECG lead

DC IN

Footswitch

Front

interface

board

Amplifier

ECG module

Filter

Sampling

HR

detect

Main CPU system

DSC module

System

control

3.2.11 Control panels and keyboard

The control panels and keyboard are designed for key scanning, indicator control, buzzer

control, receiving and processing for encoder data, STC data, PS/2 data, and they

communicate with the main unit through serial ports. The control panels and keyboard consist

of main panel, minor panel, encoder panel, and light control board, etc. The block diagram is

shown as follows:

The block diagram of the main panel is shown as follows:

3-14

Page 53

Principle Description

enclosure

protective

earth

TGC

adjustment (8-

segment)

serial

comm

interface

5V/3.3V

DC/DC

converter

ATmega64L

RS232

serial

level

converter

LED drive/control

DC/DC

converter

74HC373

EPM570T144

rotary encoder

74HC14

buzzer

4 independent

keys

65-key matrix

rotary encoder

knob value

The keyboard plays an important role in information communication between the ultrasound

system and environment, and on the basis of functions it consists of: CPU circuit, DC/DC

conversion circuit, key control circuit, trackball control circuit, encoder control circuit, LED

drive circuit and STC A/D sampling circuit. The CPU circuit consists of one MCU chip and the

peripheral circuit, and it is the core of the keyboard, to process various types of information.

The DC/DC circuit is used to provide different levels required by the keyboard. The key

control circuit refers to the key processing hardware, which consists of CPLD and the

peripheral circuit. The trackball control circuit and encoder control circuit are used to convert

the external mechanical actions to signals which are recognizable by MCU, and the circuits

consist of trackball, encoder, waveform shaping circuit and hardware processing circuit. The

LED control circuit is used to indicate statuses of LEDs. The STC A/D sampling circuit

consists of sliding potentiometer, amplifier and AD sampling circuit, and it is used to convert

the analog signal from the sliding potentiometer to the digital signal which can be accepted by

MCU.

3.2.12 Detection board of Power Output

The detection board of power output is designed to precisely adjust the programmable

high-voltage and monitor other output voltage.

The programmable high-voltage is divided into PHV1, -PHV1, PHV2 and -PHV2, and the

adjustment ranges are between +5V and +80V and between -5V and -80V, and the

adjustment precision is 1%.

For other voltages, the digital voltages include: D+12V, D+5V, D+3.3V and D-12V; the analog

voltages include: A+100V, A-100V, A+12V, A+5V and A-5V.

3-15

Page 54

The block diagram of the detection board is shown as follows:

Principle Description

power

output

module

HPV1

-HPV1

HPV2

-HPV2

CON1

CON2

CON3

CON4

+D3P3V

+D5V

+A5V

-D12V

+D12V

voltage

divider

voltage

divider

voltage

divider

voltage

divider

ADT7516

voltage

divider

voltage

divider

voltage

divider

voltage

divider

voltage

divider

follow

backward

follow

backward

lowpass

lowpass

lowpass

backward

lowpass

lowpass

lowpass

lowpass

SPI

ADT7516_VREF

lowpass

lowpass

AD7928

SPI

+D5V

-A5V

POWER

VREF

clock

+5V

A5V

-A5V

Max6066

REF3040

232

voltage

divider

voltage

divider

backward

MAX3243

lowpass

lowpass

TTL

Atmega

64L

JTAG

SPI

download

interface

-A100V

+A100V

CONNECTOR

3.2.13 CRT monitor

The CRT monitor is used to convert electric signal, transmitted from the main board, to

high-speed electrons for impacting fluorescent screen, thus generating light signal to make

images seen on the screen. The external indicator of the CRT is designed to judge if the

monitor works normally. Generally if there is synchronous signal, this indicator is green;

otherwise it is yellow.

3-16

Page 55

3.2.14 LCD monitor

Principle Description

3.2.14.1

parts.

No Components Name Qty

1 15 inch TFT LCD PANEL-LQ150X1LW71N 1

2 15 inch LCD control board- LQ150X1LW71N 1

3 15 inch LCD LVDS connecting wire 1

4 Connecting wire between 15 inch LCD power board

5 15 inch LCD OSD board 1

6 15 inch LCD OSD connecting wire 1

7 15 inch LCD light board-12v 1

8 15 inch LCD power inverter board 1

9 15 inch LCD light switch and connecting wire 1

Components of LCD monitor module

LCD module consists of 15 inch LCD display screen, boards and cards, wires and metal

The components of the LCD module are shown as follows:

1

and drive board

10 LCD fixing bracket 1

11 Reinforced plate 1

12 Shielding mask bracket 1

13 Left plate of shielding mask 1

14 Right plate of shielding mask 1

15 LCD fixing bracket 1

16 Wire strip CHS-3X80mm nylon 2

17 Cross panhead screw GB/T9074.8 M3X8 coated with

rust-proof nickel

18 Aluminum sunk screwφ3.2*7(GB/T 12617) 21

The 15 inch LCD display screen is a specified model, LQ150X1LW71N made by SHARP;

the boards, cards and wires are customized according to structure and interface

specifications.

29

3-17

Page 56

Principle Description

3.2.14.2

CCFL

Function diagram

15" LCD panel

Audio L +/-

Inverter & Power LCD drive

12v

Speaker(right)Speaker(left)

Audio R +/-

LVDS

Signal , 12v

Key OSD board

12v

AC 90-260V VGA Audio L/R

Auxiliary output

AC 90-260V

3.2.14.3

Interface definition

Definition of LVDS signal output pins:

Drive voltage 3.3V, LVDS interface.

PIN SIGNAL PIN SIGNAL

1 VCC 11 RX2-

IO interface board

Light board

12v

Toggle

switch

12v

2 VCC 12 RX2+

3 GND 13 GND

4 GND 14 CK5 RX0- 15 CK+

6 RX0+ 16 GND

3-18

Page 57

7 GND 17 RX38 RX1- 18 RX3+

9 RX1+ 19 GND

10 GND 20 GND

Definition of speaker signal pins:

PIN NUMBER SIGNAL