Page 1

BS-300

Chemistry Analyzer

Service Manual

Page 2

Page 3

© 2006 Shenzhen Mindray Bio-medical Electronics Co., Ltd. All rights Reserved.

For this Service Manual, the issued Date is 2006-06 (Version: 1.0).

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called

Mindray) owns the intellectual property rights to this Mindray product and this

manual. This manual may refer to information protected by copyrights or patents and

does not convey any license under the patent rights of Mindray, nor the rights of

others. Mindray does not assume any liability arising out of any infringements of

patents or other rights of third parties.

Mindray intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the

written permission of Mindray is strictly forbidden.

Release, amendment, reproduction, distribution, rent, adaption and translation of this

manual in any manner whatsoever without the written permission of Mindray is

strictly forbidden.

, , , , are the registered

trademarks or trademarks owned by Mindray in China and other countries. All

other trademarks that appear in this manual are used only for editorial purposes

without the intention of improperly using them. They are the property of their

respective owners.

Responsibility on the Manufacturer Party

Contents of this manual are subject to changes without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not

be liable for errors contained herein nor for incidental or consequential damages in

connection with the furnishing, performance, or use of this manual.

Mindray is responsible for safety, reliability and performance of this product only in

the condition that:

all installation operations, expansions, changes, modifications and repairs of this

product are conducted by Mindray authorized personnel;

the electrical installation of the relevant room complies with the applicable

national and local requirements;

the product is used in accordance with the instructions for use.

WARNING:

It is important for the hospital or organization that employs this

equipment to carry out a reasonable service/maintenance plan.

Neglect of this may result in machine breakdown or injury of human

health.

NOTE:

This equipment is to be operated only by medical professionals trained

and authorized by Mindray or Mindray-authorized distributors.

I

Page 4

Warranty

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR ANY PARTICULAR PURPOSE.

Exemptions

Mindray's obligation or liability under this warranty does not include any

transportation or other charges or liability for direct, indirect or consequential

damages or delay resulting from the improper use or application of the product or the

use of parts or accessories not approved by Mindray or repairs by people other than

Mindray authorized personnel.

This warranty shall not extend to:

any Mindray product which has been subjected to misuse, negligence or

accident;

any Mindray product from which Mindray's original serial number tag or product

identification markings have been altered or removed;

any product of any other manufacturer.

Return Policy

Return Procedure

In the event that it becomes necessary to return this product or part of this product to

Mindray, the following procedure should be followed:

1 Obtain return authorization: Contact the Mindray Service Department and

obtain a Customer Service Authorization (Mindray) number. The Mindray

number must appear on the outside of the shipping container. Returned

shipments will not be accepted if the Mindray number is not clearly visible.

Please provide the model number, serial number, and a brief description of

the reason for return.

2 Freight policy: The customer is responsible for freight charges when this

product is shipped to Mindray for service (this includes customs charges).

3 Return address: Please send the part(s) or equipment to the address offered

by Customer Service department

Company Contact

Manufacture: Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Address:

Phone:

Fax:

Mindray Building, Keji 12th Road South, Hi-tech Industrial Park,

Nanshan, Shenzhen, P.R.China, 518057

+86 755 26582479 26582888

+86 755 26582500 26582501

II

Page 5

Preface

Who Should Read This Manual

This manual is written for service professionals authorized by Mindray.

Conventions Used in This Manual

Safety Symbols

This chart explains the symbols used in this manual.

When you see … Then …

WARNING:

Read the statement following the symbol. The

statement is alerting you to an operating hazard

that can cause personal injury.

BIOHAZARD:

CAUTION:

NOTE:

Read the statement following the symbol. The

statement is alerting you to a potentially

biohazardous condition.

Read the statement following the symbol. The

statement is alerting you to a possibility of

system damage or unreliable results.

Read the statement following the symbol. The

statement is alerting you to information that

requires your attention.

Graphics

All graphics, including screens and printout, are for illustration purpose only and

must not be used for any other purposes.

i

Page 6

Page 7

Contents

Contents

Preface........................................................................................................................................... i

Who Should Read This Manual .............................................................................................. i

Conventions Used in This Manual .......................................................................................... i

1 Specifications....................................................................................................................1-1

1.1 System Feature...................................................................................................1-1

1.2 Loading System Feature .....................................................................................1-1

1.3 Analysis System Feature.....................................................................................1-2

1.4 Others..................................................................................................................1-2

2 System Installation...........................................................................................................2-1

2.1 Check before Installation.....................................................................................2-1

2.2 Installation Procedure..........................................................................................2-1

3 System Descriptions ........................................................................................................3-1

3.1 Dispensing System..............................................................................................3-1

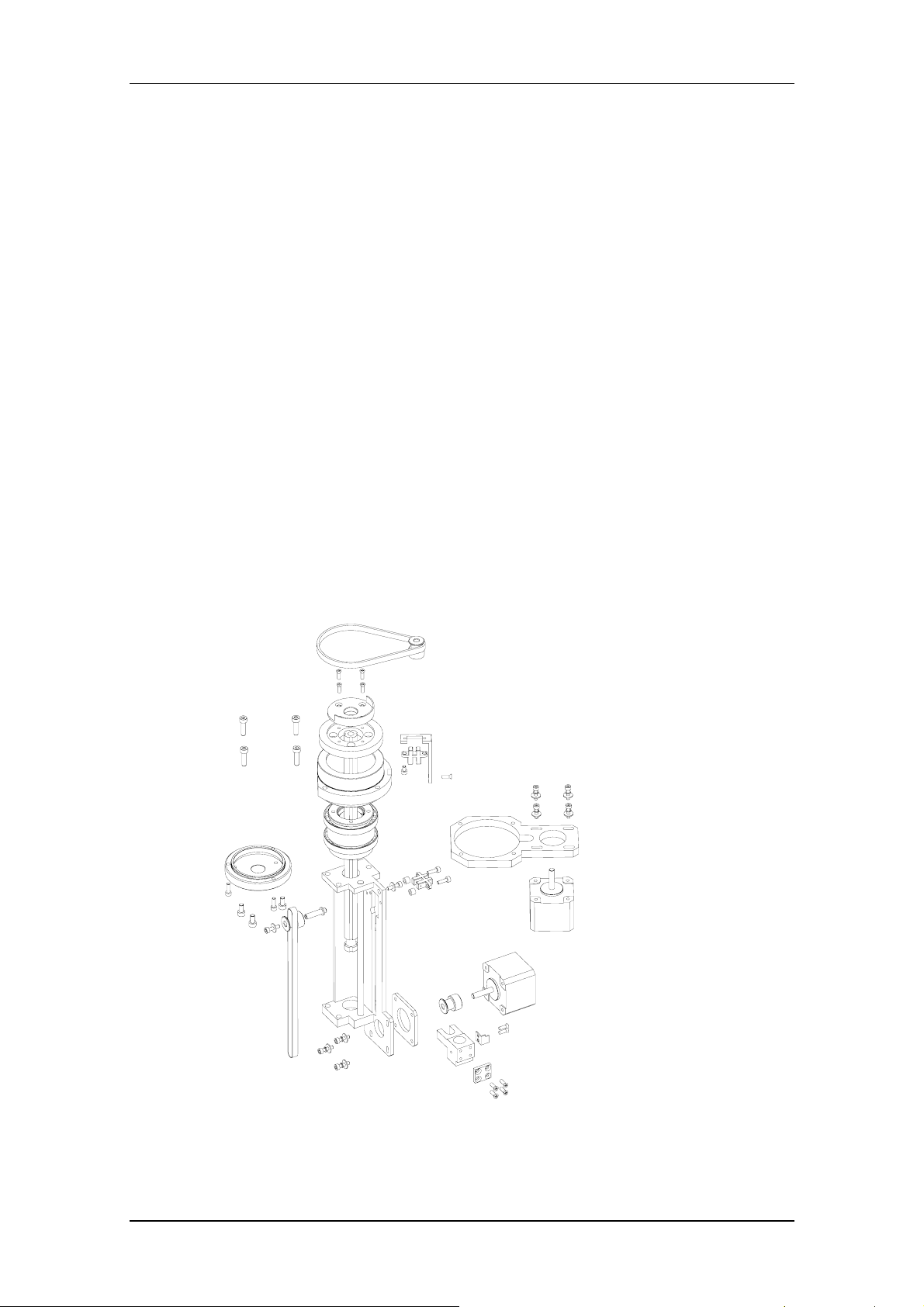

3.1.1 Probe assemblies.................................................................................3-1

3.1.2 Disk assemblies ...................................................................................3-2

3.2 Feeder .................................................................................................................3-3

3.2.1 Feeder assemblies...............................................................................3-3

3.2.2 Manipulator...........................................................................................3-4

3.3 Temperature Control System...............................................................................3-5

3.3.1 Temperature control assembly.............................................................3-5

3.3.2 Reagent preheating..............................................................................3-6

3.3.3 Reagent refrigeration............................................................................3-7

3.4 Photometric System ............................................................................................3-8

3.5 Fluid System........................................................................................................3-8

3.6 ISE Module (optional)........................................................................................3-10

Functions of Boards.........................................................................................................4-1

4

4.1 Main Control Board..............................................................................................4-1

4.2 Power Drive Board ..............................................................................................4-2

4.3 A/D Conversion Board.........................................................................................4-2

4.4 Reagent Refrigeration Board...............................................................................4-2

4.5 Level Detection Boards .......................................................................................4-3

4.6 Feeder Connection Board ...................................................................................4-3

4.7 Manipulator Connection Board............................................................................4-3

4.8 Probes Connection Board ...................................................................................4-4

4.9 Power Supply Assembly......................................................................................4-4

5 Maintenance and Service.................................................................................................5-1

5.1 Replacing Light Filter Assembly ..........................................................................5-1

5.2 Replacing Optical Fiber.......................................................................................5-4

5.3 Adjusting Reaction Disk, Manipulator and Feeder..............................................5-7

5.4 Adjusting Probes and Disks.................................................................................5-8

5.5 Replacing Components of ISE Unit (optional)...................................................5-10

5.5.1 Replacing Tubing................................................................................5-10

5.5.2 Replacing Pumps...............................................................................5-13

5.5.3 Replacing ISE Module........................................................................5-13

6 Software Introduction.......................................................................................................6-1

1

Page 8

Contents

6.1 System Software..................................................................................................6-1

6.1.1 System initialization..............................................................................6-1

6.1.2 Shutdown processing...........................................................................6-2

6.2 Control Software..................................................................................................6-2

7 Service Flow......................................................................................................................7-1

7.1 Fluid Level Detection Failure of Reagent Probe..................................................7-1

7.2 Fluid Level Detection Failure of Sample Probe...................................................7-2

7.3 Liquid Dropping From Probes..............................................................................7-3

7.4 Failing to Detect Level of Water for Washing Exteriors.......................................7-4

7.5 Abnormal Results................................................................................................7-5

7.5.1 All Results Being Abnormal..................................................................7-5

7.5.2 Some Results Being Abnormal.............................................................7-5

7.5.3 Several Results Being Abnormal..........................................................7-6

7.6 Insufficient Light Intensity of Lamp......................................................................7-7

7.7 Temperature Control Failure................................................................................7-8

7.8 Bar Code Scanner (optional) Failure...................................................................7-9

7.9 Feeder Failure ................................................................................................... 7-11

7.9.1 Transducer Distribution of the Feeder................................................7-11

7.9.2 Feeder Failure....................................................................................7-12

7.9.3 Manipulator Failure.............................................................................7-13

7.10 Troubleshooting of ISE Unit (optional)...............................................................7-13

8 Mechanical Structure .......................................................................................................8-1

9 Tools and Parts.................................................................................................................9-1

9.1 Service Tools .......................................................................................................9-1

9.2 Parts ....................................................................................................................9-1

10

Maintenance And Test Software....................................................................................10-1

General..............................................................................................................10-1

10.1

Command ..........................................................................................................10-3

10.2

10.2.1 Single Command Area.......................................................................10-3

10.2.2 Macroinstruction Area.......................................................................10-10

10.3 PARA and Speed.............................................................................................10-13

10.4 Temperature.....................................................................................................10-19

10.5 Photoelectric....................................................................................................10-20

Appendix A Board s Connection Diag rams.............................................................................. A-1

Appendix B Test Points of Boards............................................................................................ B-1

2

Page 9

1 Specifications

X

1.1 System Feature

Dimension: 980mm × 710mm × 1200mm (W × D × H)

Weight: 175kg

Power supply: AC100-130V ± 10% or 200-240V ± 10%

Input power: 1000VA

System: optional, multi-channel, multi-test

Scope: Clinical chemistries

Test types: end-point, kinetic and fixed-time. All support double-reagent and

double-wavelength

Calibration type: Linear (single-point, two-point and multi-point), Logistic 4P,

Logistic 5P, Exponential 5P, Polynominal 5P, Parabola, Spline

QC rules: Westgard multi-rule,

Twin-plot

Tests analyzed simultaneously: 48 (single-reagent) / 24 (double-reagent); if the

ISE unit (optional) is connected, 3 (Na, K and Cl included) or 4 (Na, K, Cl and Li

included) tests are added

Throughput: maximum 300tests/h; if the ISE (optional) is connected, maximum

420tests/h (Na, K and Cl included) or maximum 480 tests/h (Na, K, Cl and Li

included)

Specifications

−

-R, Cumulative sum check, Cumulative error,

1.2 Loading System Feature

Sample volume: 3µl~45µl; Precision: 0.5µl; for the ISE (optional), 70µl serum,

70µl plasma, 140µl diluted urine

Sample disk: general sample disk, including the inner circle and the outer circle

Sample tube position: 60 positions, including 6 calibrator positions, 3 control

positions, 5 for STAT sample positions; 5 virtual disks for maximum 300 samples

Sample probe: with a built-in level detector; equipped with auto safeguard;

capable of tracking sample level

Washing function: automatically washing interior and exterior of sample probe;

carryover no more than 0.1%

Pre-dilution: 4 ≤ dilution rate ≤ 150, taking reaction cuvettes as the container

Reagent volume: 30-450ul; Precision: 1ul

Reagent disk: including the inner circle and the outer circle

Reagent position number: 25/50 reagent positions. Each reagent position is

available for containing one Hitachi 7060 bottle, one Hitachi 7170 bottle, one

Mindray inner-circle bottle or one Mindray outer-circle bottle.

Reagent probe: One independent probe which has a built-in level detector; is

equipped with auto safeguard and capable of tracking reagent level

Washing function: automatically washing interiors and exteriors of reagent probes;

carryover no more than 0.1%

1-1

1-

Page 10

Specifications

Mixing bar: for single-reagent tests, it functions after sample dispensing; for

double-reagent tests, it functions after the dispensing of the sample and the

second reagent.

1.3 Analysis System Feature

Lamp house: 50w lamp

Light splitting mode: Splitting by optical fiber, filtering by an interference filter.

Half band-width: 10±2nm

Wavelength: 340, 405, 450, 510, 546, 578, 630, 670, 700nm

Absorbance range: -0.1~5, 10mm optical path conversion

Reaction cuvette: 5 × 6 × 25mm, optical path 5mm. Material: PP, disposable.

Volume: 750uL

Reaction liquid volume: 180-500µl

Max. reaction time: 20 minutes

Reaction temperature: 37±0.3℃ with fluctuation of ±0.1℃

1.4 Others

Operating system: Windows 2000 or Windows XP

Display: optional

System interface: RS-232

Printer: optional

Built-in bar code scanner: optional

ISE module: optional

1-2

Page 11

2 System Installation

NOTE:

The analyzer should be installed or moved to another place by

Mindray-authorized personnel only.

2.1 Check before Installation

The user should provide the environment that meets the requirements mentioned in

the Operation Manual. Check if the environment meets the requirements before

installing the analyzer . Refer to the chapter 2 of the Operation Manual for details.

2.2 Installation Procedure

System Installation

1 Ensure available installation fields and environments in hospitals.

2 Confirm the reagents and calibrators.

3 Go to the installation field, and then check the delivery list for acceptance.

4 Install the four handles on the four angles of the analyzer. Move the analyzer

to the installation field, fix the casters, and then remove the handles.

5 Insta ll the computer, display and printer.

6 Open the front plate, and check whether cable connections are loose. Open

the top plate, check whether the probe assemblies, reagent disk and sample

disk are intact and in good performance.

7 Connect the communication cable, power cable, grounding wire, waste tank

and deionized water tank. Install the used-cuvette bucket, reagent probe,

sample probe and mixing bar.

8 Top up the deionized water tank with deionized water.

9 Put reaction cuvettes in the feeder. Remember to check whether the surfaces

of the cuvettes are smooth. In case of any bump, remove it before loading the

cuvette to the compartment. Do not touch the light transmission part of the

cuvette in which the colorimetric reading is taken.

10 Load acid and alkaline detergents to positions 46 and 47, and distilled water

to positions 49 on the reagent disk. Load distilled water to position 60 on the

sample disk.

11 Switch on the analyzer as follows: POWER → ANALYZING UNIT POWER

→display → computer → printer.

12 After Windows is started, double-click the icon of BS-300 on the desktop to

start the system software. The system program will automatically finish the

self-test, become online and warm up the reaction cuvettes within about 30

minutes.

13 Select the [System/Status] menu, and then observe the system status and

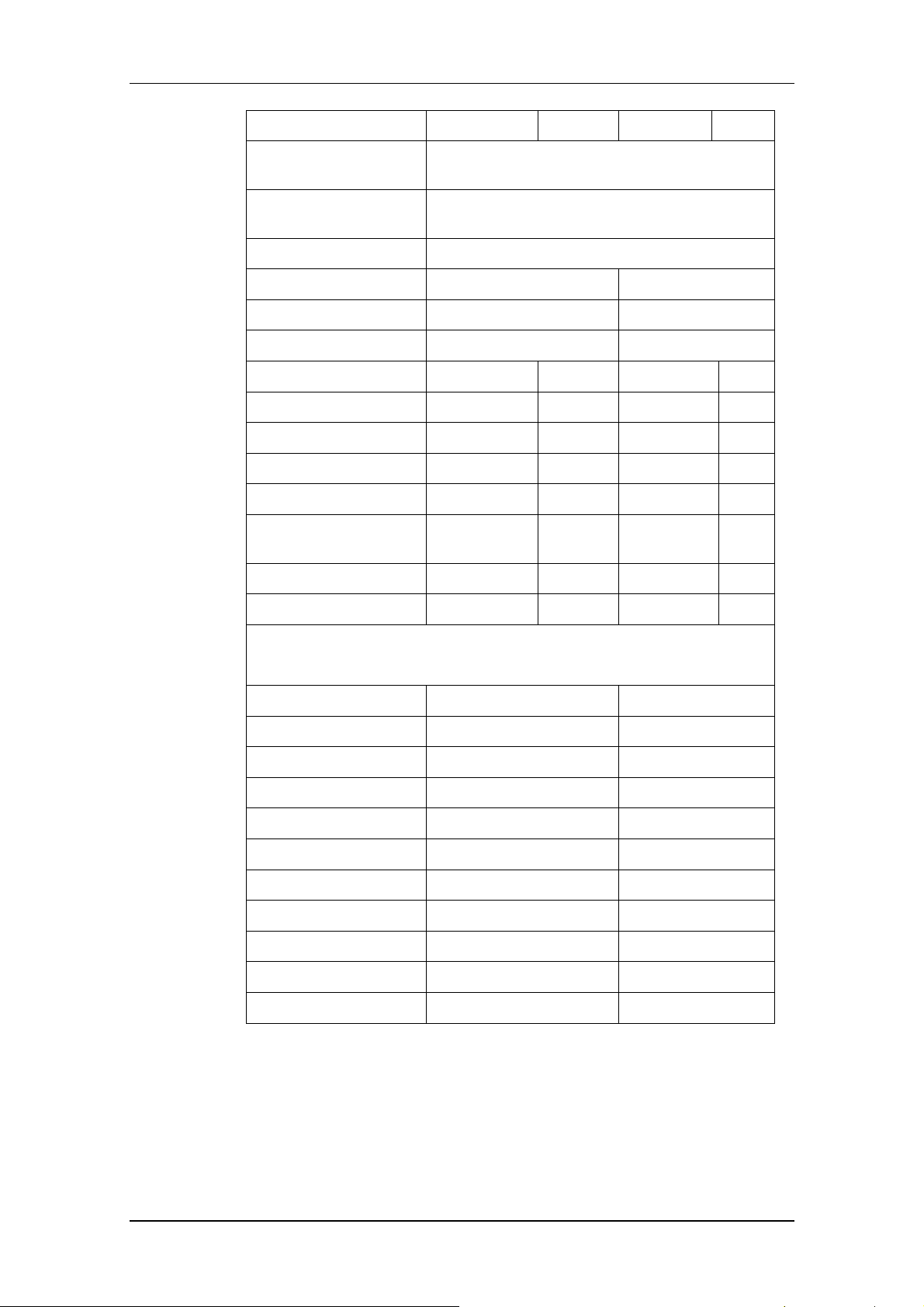

record it in the table below:

2-1

Page 12

System Installation

Feeder status Unconnected Full Half full Empty

Reaction disk

temperature

Reagent disk

temperature

Ambient temperature

Waste tank status Abnormal (full) Normal (not full)

Detergent status Abnormal (empty) Normal (available)

Printer status No printer Normal

Main control unit Unconnected Idle Running

Reaction disk unit Unconnected

Reagent disk unit Unconnected

Sample disk unit Unconnected

Loading/unloading unit Unconnected

Temperature control

unit

Lamp

Unconnected

Network connection Unconnected

Wavelength Dark current Light source base

340

405

450

510

546

578

630

670

700

Reference light system

14 Select the [System/Maintenance] menu. Then select the Motion tab page,

and implement all sub-steps of each unit to see whether they are normal. In

case of any exception, adjust it.

15 Wash the interiors and exteriors of the sample probe, reagent probe and

mixing bar for several times to make the fluid circuit filled.

16 Set parameters for test, reagent and calibration under the Parameters menu.

2-2

Page 13

System Installation

17 Request for calibration and samples, run and then debug the results.

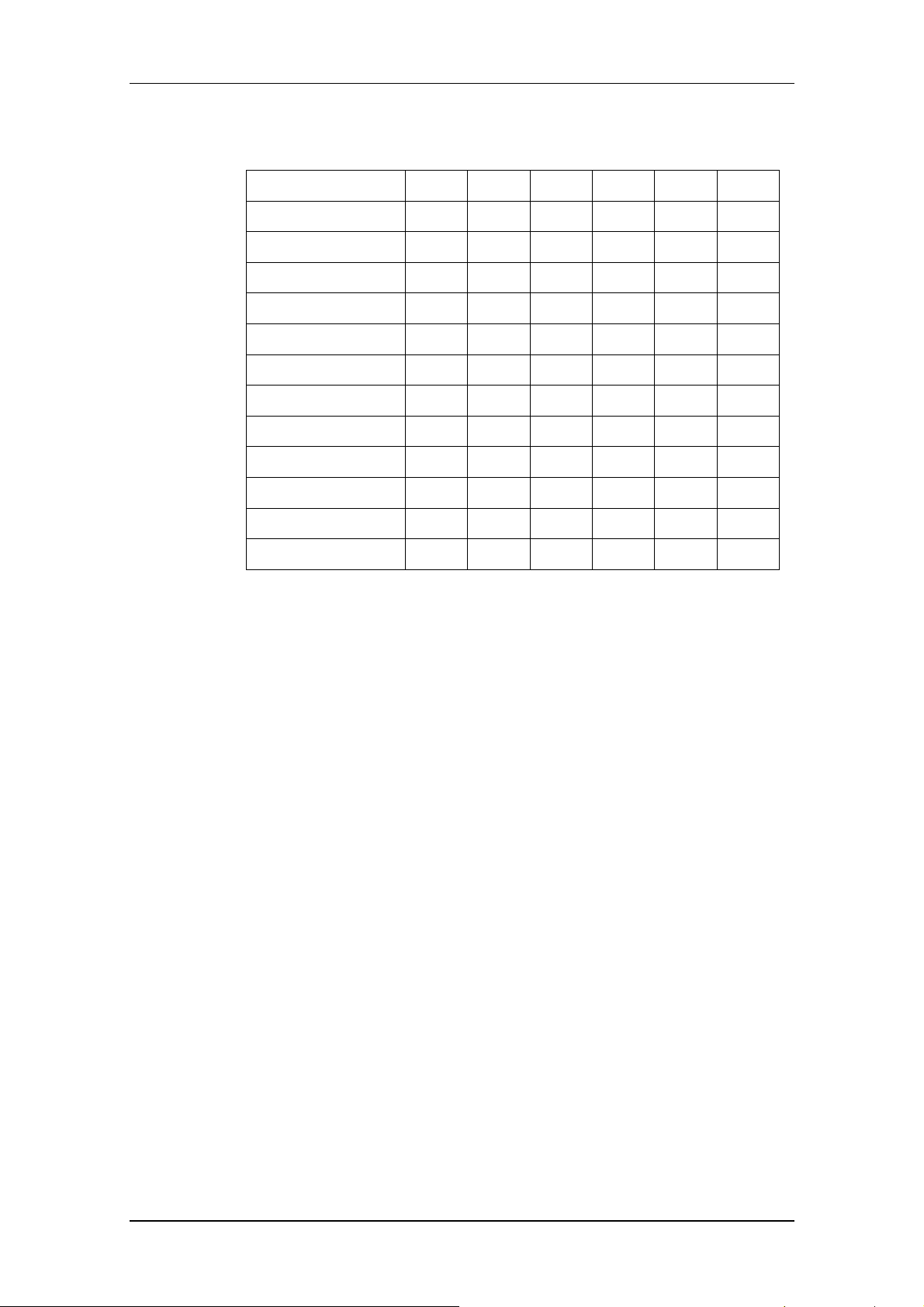

18 After debugging the results, fill them in the table below:

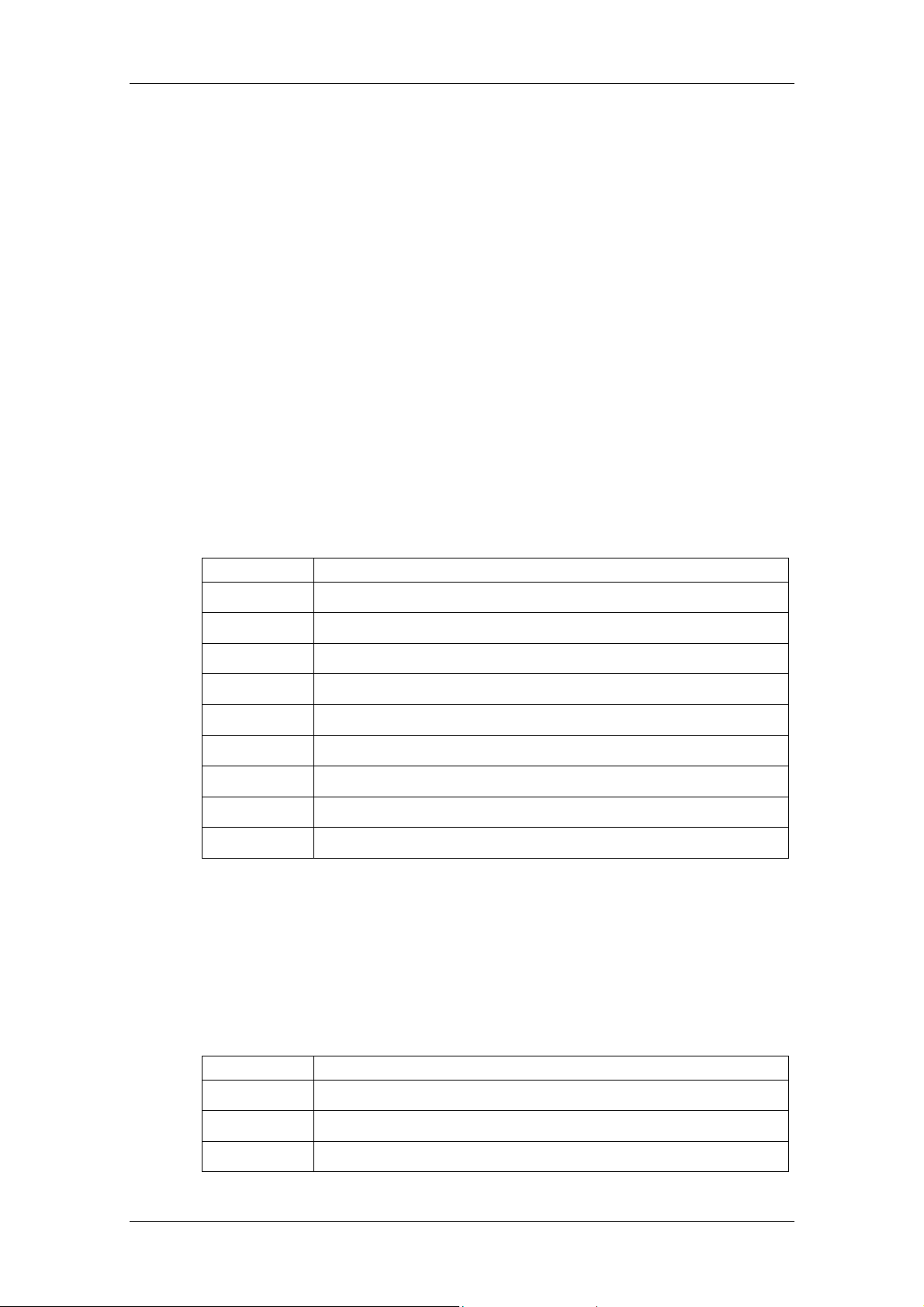

Test ALT CREA BUN

Target value

2sd range

Test value 1

Test value 2

Test value 3

Test value 4

Test value 5

Test value 6

Test value 7

Test value 8

Test value 9

Test value 10

19 Training

Can the user complete daily tests? Yes □ No □

Is the user familiar with the analytical methods such as

kinetic, two-point, endpoint?

Is the user familiar with the daily, weekly and monthly

maintenance and relevant maintenance methods?

Is the user skilled in washing dust screens? Yes □ No □

Is the user skilled in cleaning and replacing the probes

and the mixing bar?

Is the user skilled in replacing the plunger assemblies

of syringes?

Is the user skilled in replacing the lamp? Yes □ No □

Is the user skilled in maintenance of built-in bar code

scanner?

Is the user skilled in maintenance of ISE unit? Yes □ No □

Does the user know the positions, roles and

preparation methods of distilled water and acid and

alkaline detergents?

Yes □ No □

Yes □ No □

Yes □ No □

Yes □ No □

Yes □ No □

Yes □ No □

2-3

Page 14

Page 15

3 System Descriptions

The BS-300 analyzer consists of the analyzing unit, operation unit and output unit.

The analyzing unit consists of the dispensing system, feeder, temperature control

system, photometric system and fluid system.

3.1 Dispensing System

The dispensing system consists of the probe assemblies (including the reagent

probe assembly, sample probe assembly and mixing bar assembly), reagent disk,

sample disk and reaction disk.

3.1.1 Probe assemblies

System Descriptions

Among the probe assemblies, the mixing bar assembly is the same as the reagent

probe assembly and the sample probe assembly, except that the knurled axis is

30cm shorter.

Every probe assembly has a horizontal photoelectric switch and a vertical

photoelectric switch. These switches are used for defining horizontal and vertical

3-1

Page 16

System Descriptions

initial positions of probe assemblies. The horizontal and vertical step motors

precisely control the horizontal and vertical movements of the probe assemblies, and

the synchronizing belts serve as the gearing.

The shaft and the bushing must corporate with each other precisely, so they cannot

be used confusedly.

3.1.2 Disk assemblies

The three disk assemblies are different in their coders. The coder corresponds to the

position where disks should stop. There is an initial-position mark under every coder.

The three coders of the three disks have three coder transducers. Each transducer

has two photoelectric switches for inducing the rotation and initial position of the

disk.

The step motors control the disk assemblies, and the synchronizing belts serve as

the gearing.

3-2

Page 17

System Descriptions

There is a build-in bar code scanner to the left of the sample disk. The scanner is

optional.

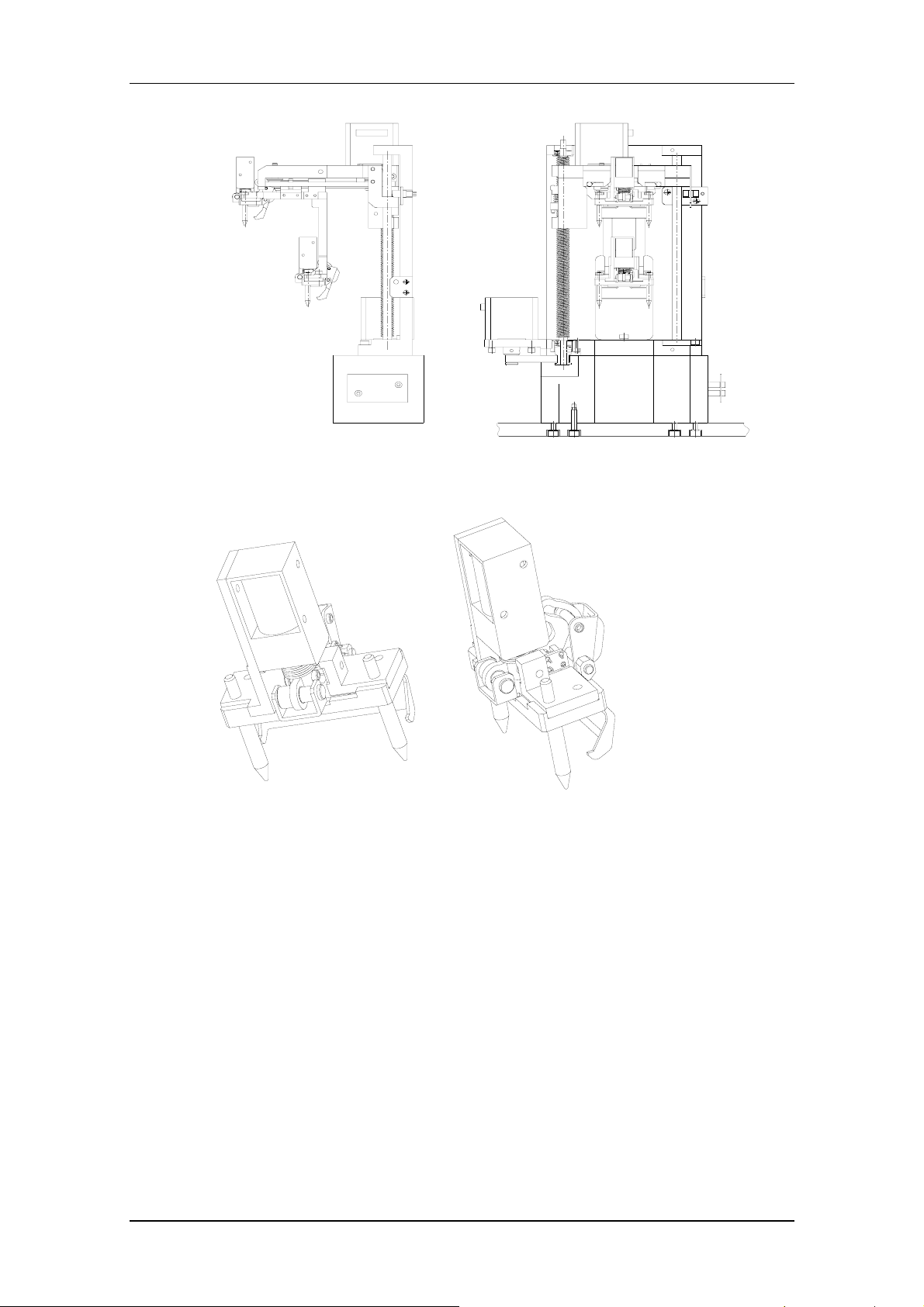

3.2 Feeder

The feeder consists of the feeder assemblies and the manipulator. It is designated to

send cuvette segments to the reaction disk, take out the used ones and abandon

them to the used-cuvette bucket.

3.2.1 Feeder assemblies

The feeder assemblies include the gearing assembly, cuvette compartment

assembly, cuvette-pushing assembly and no-cuvette detection assembly (see the

following figure).

The supporting plate of the feeder assemblies is a square piece of steel that is

connected to the analyzing unit by its four poles, which are secured by four nuts.

Unscrewing the nuts, you can disassemble the feeder assemblies from the analyzing

unit easily.

Sample probe assemblyBuild-in bar code scanner

3-3

Page 18

System Descriptions

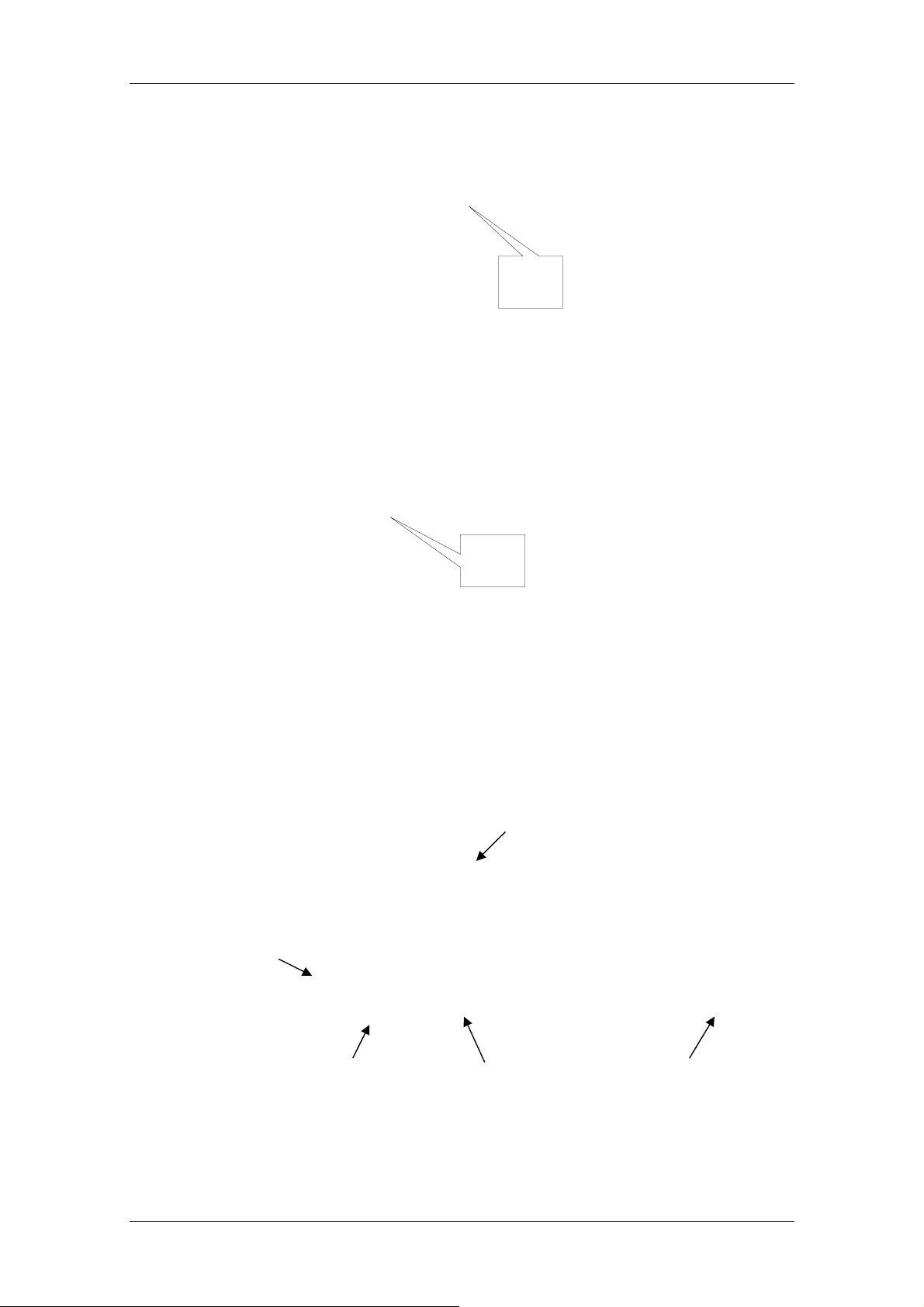

There are five transducers that are shown in the figure below.

The no-cuvette transducer is used to detect whether there is a cuvette segment at

the loading position. The insufficient-cuvette transducer is used for determine

whether there are less than 10 reaction cuvettes in the compartment or not. If yes,

the analyzer will give a prompt.

Pressure Transducer

No-Cuvette

Transducer

3.2.2 Manipulator

Two step motors (horizontal and vertical) supply power for horizontal and vertical

movements of the manipulator.

The upper finger and lower finger are same in their structures. They work together to

replace used cuvette segments with new ones.

The manipulator runs in a relatively complicated way. There are four transducers on

it: vertical transducer, horizontal transducer and two finger transducers.

Cuvette-Pushing

Limit Transducer

Insufficient-Cuvette

Transducer

Cuvette-taking limit

transducer

3-4

Page 19

System Descriptions

3.3 Temperature Control System

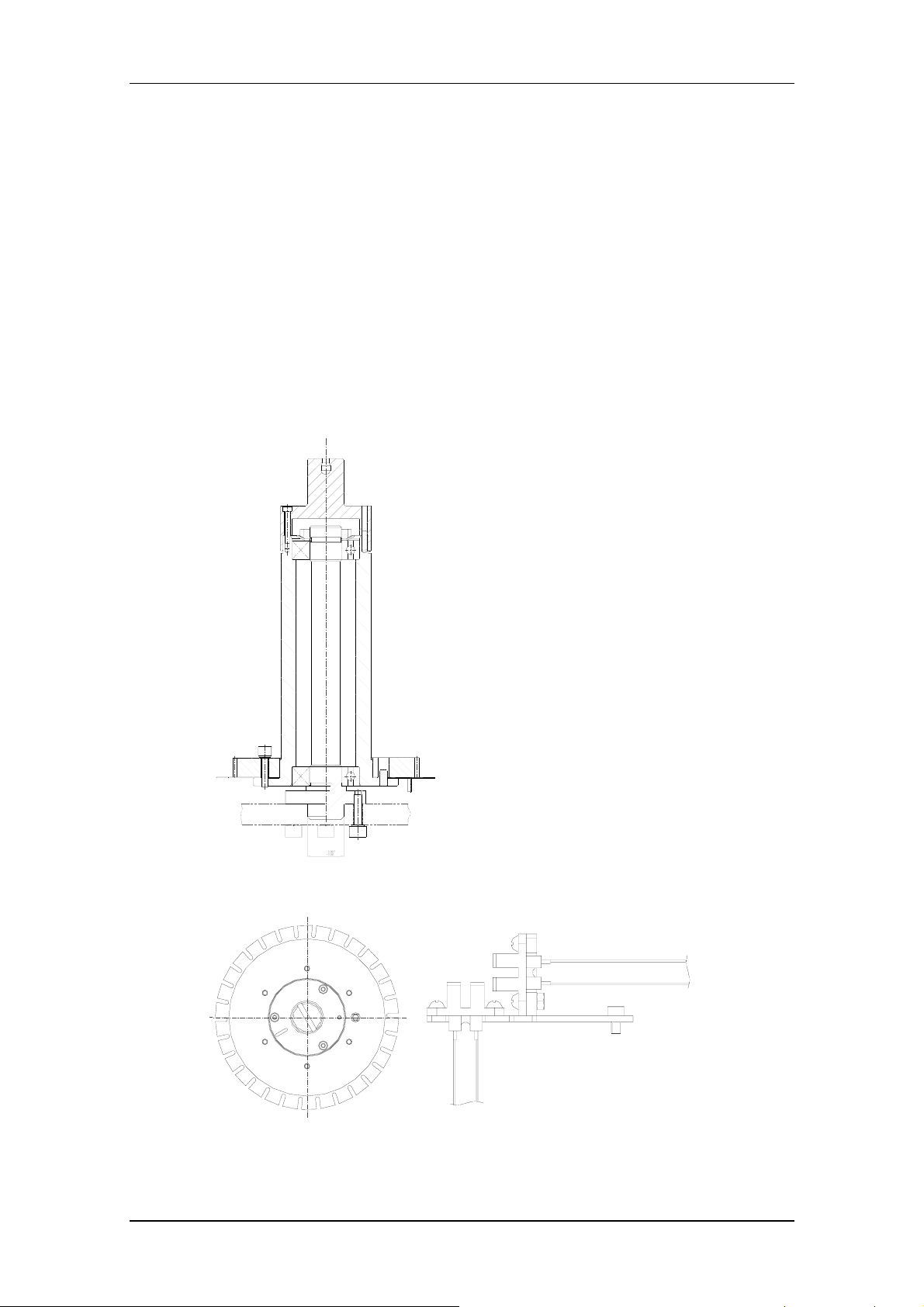

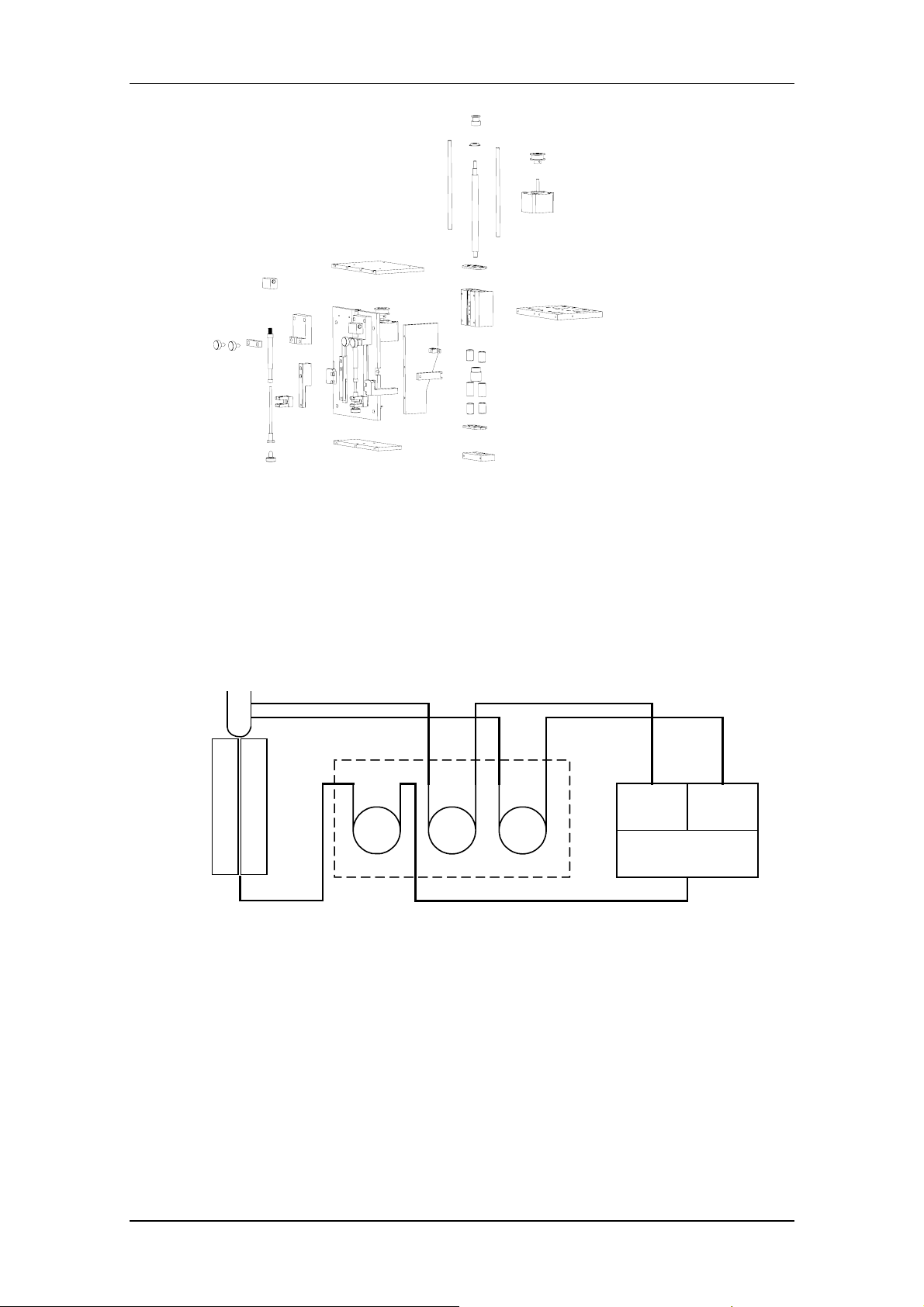

3.3.1 Temperature control assembly

The temperature control assembly of the reaction disk consists of the

temperature-controlled pot, heat-insulating sheath/plate, top heater, bottom heater,

reaction disk/cuvettes, photoelectric seat, temperature transducer, fan and control

circuit.

3-5

Page 20

System Descriptions

1: Temperature transducer and the support

2: Fan

3: photoelectric seat

4: Heat-insulating sheath

5: top heater

6: Cover

7: temperature-controlled pot

8: bottom heater

Upper heater: square in shape, 220/110VAC, 125W

Lower heater: ring in shape, 220/110VAC, 350W

Total power: 475W.

The function of heaters is to compensate the heat for incubating the reagent and for

maintaining the temperature of the temperature-controlled chamber .

Fans are used in series in the temperature-controlled chamber. It makes the air

circulating in the chamber, and enhances the convective heat exchange. There are

four fans in the chamber. All have the alarm function.

The temperature transducer feeds back the air temperature at the position several

millimeters from the bottom of the reaction cuvette.

The overheat protection switch is to switch off the power when the temperature

controller does work and the temperature-controlled chamber reaches 55℃, so as to

avoid overheat or fire. When the temperature-controlled chamber becomes 35℃,

this switch will automatically be reset.

3.3.2 Reagent preheating

The preheating assembly consists of two aluminum plates, a Te flon tube having nine

loop sections, heating components, transducer, temperature protection switch,

thermal conductive colloid, a section of tube and the reagent probe.

The temperature of the thermal source of the preheater is controlled at 45℃. The

initial temperature of the reagent is 4 ~ 10℃ when it is taken out of the refrigeration

3-6

Page 21

System Descriptions

chamber. When the reagent passes the heater, its temperature increases to 35℃.

Then the reagent is added into the reaction cuvette and the preheating process is

finished.

Reagent preheating assembly

3.3.3 Reagent refrigeration

The refrigeration module consists of refrigeration cabin, PU heat-insulating sheath,

reagent disk, reagent bottle, temperature transducer, refrigeration flakes, heat

sinking component, fan and control circuit. The refrigeration module is shown in the

following figure.

The refrigeration assembly consists of fan, hot-end radiator, POM connector,

cold-end heat-conductive aluminum block, and PELTIER refrigeration flake. Each

analyzer has two such refrigeration assemblies, as shown in the figure below. The

cold-side of the refrigeration flake clings to the refrigeration compartment, and the

hot-side clings to the radiator (The side having letters should cling to the refrigeration

aluminum block).

3-7

Page 22

System Descriptions

Each refrigeration flake corresponds to a heat-sinking block and a cooling fan. It

should be installed with the cold side upward.

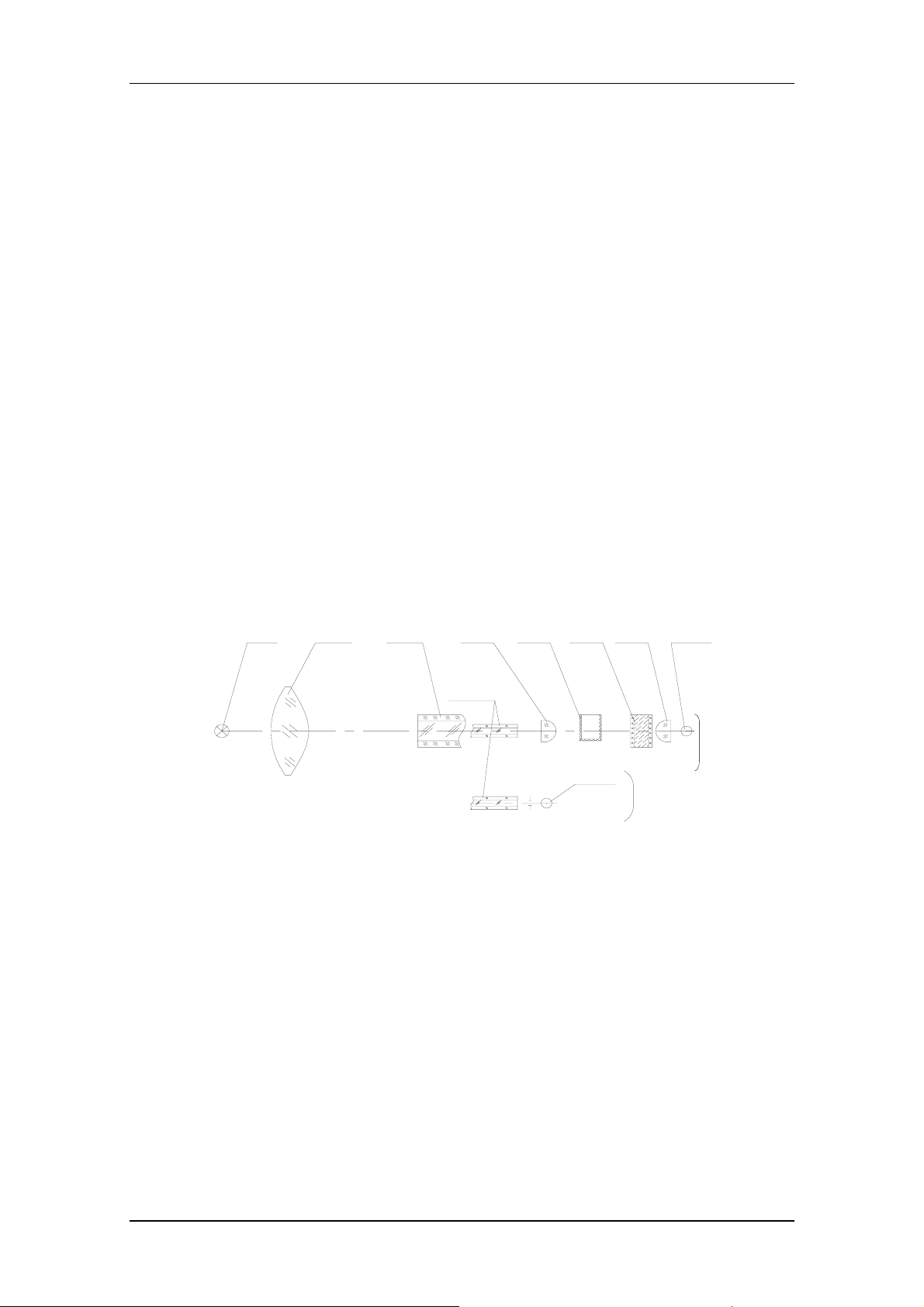

3.4 Photometric System

The photometric system consists of a measurement photometric system and a

reference photometric system. The measurement photometric system provides 9

monochromatic lights to measure the absorbance of the reacting liquid in the rotating

reaction cuvettes. The reference photometric system compensates the

measurement photometric system to make the measurement more accurate.

Tungsten-halogen

lamp

卤钨灯 聚光镜

Biconvex lens

3.5 Fluid System

The fluid system is shown in the following figure.

Main fiber

传光束

Plano

小透镜 反应杯 滤光片 小透镜 光电管

convex lens

Fibers

传光束小端

Cuvette Filter

Photodiode

convex lens

共路

光电管

Plano

参考光路

Reference light

Photodiode

测量光路

Measurement

.

.

.

lights

3-8

Page 23

Sample syringe

System Descriptions

Reagent syringe

Mixing bar

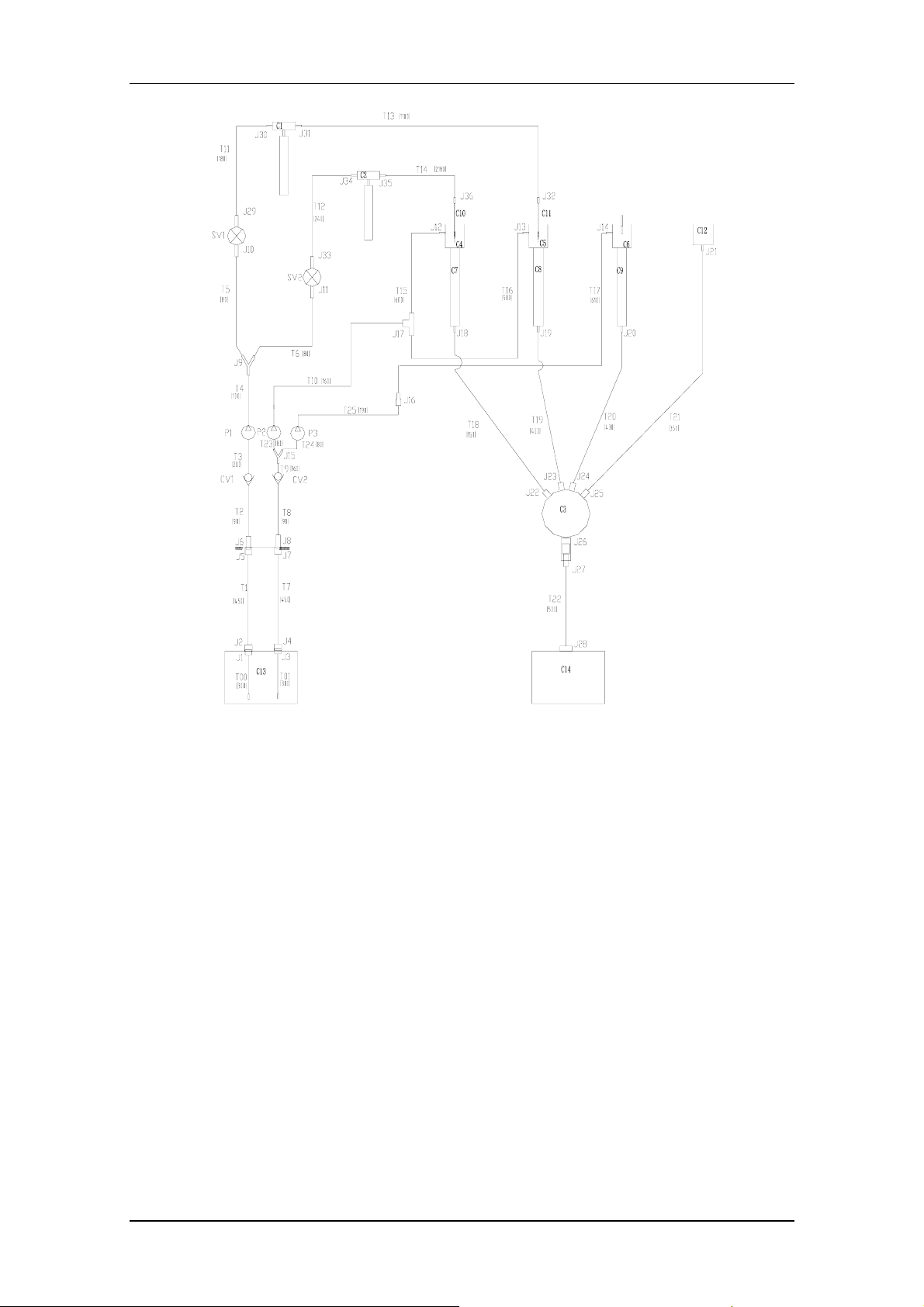

As shown in the figure above, the fluid system consists of interior washing and

exterior washing.

The syringe assembly controls the aspiration volume by controlling the travel of the

sample/reagent syringe. It is the core part of the fluid system.

3-9

Page 24

System Descriptions

3.6 ISE Module (optional)

The ISE module that is used to measure the concentration of K+, Na+, Cl- and Li+ in

serum, plasma and urine consists of ion-selective electrodes, peristaltic pumps and

calibrants.

ISE

Pump W

Calibrant B

Pump BPump A

Calibrant A

Waste

3-10

Page 25

System Descriptions

3-11

Page 26

Page 27

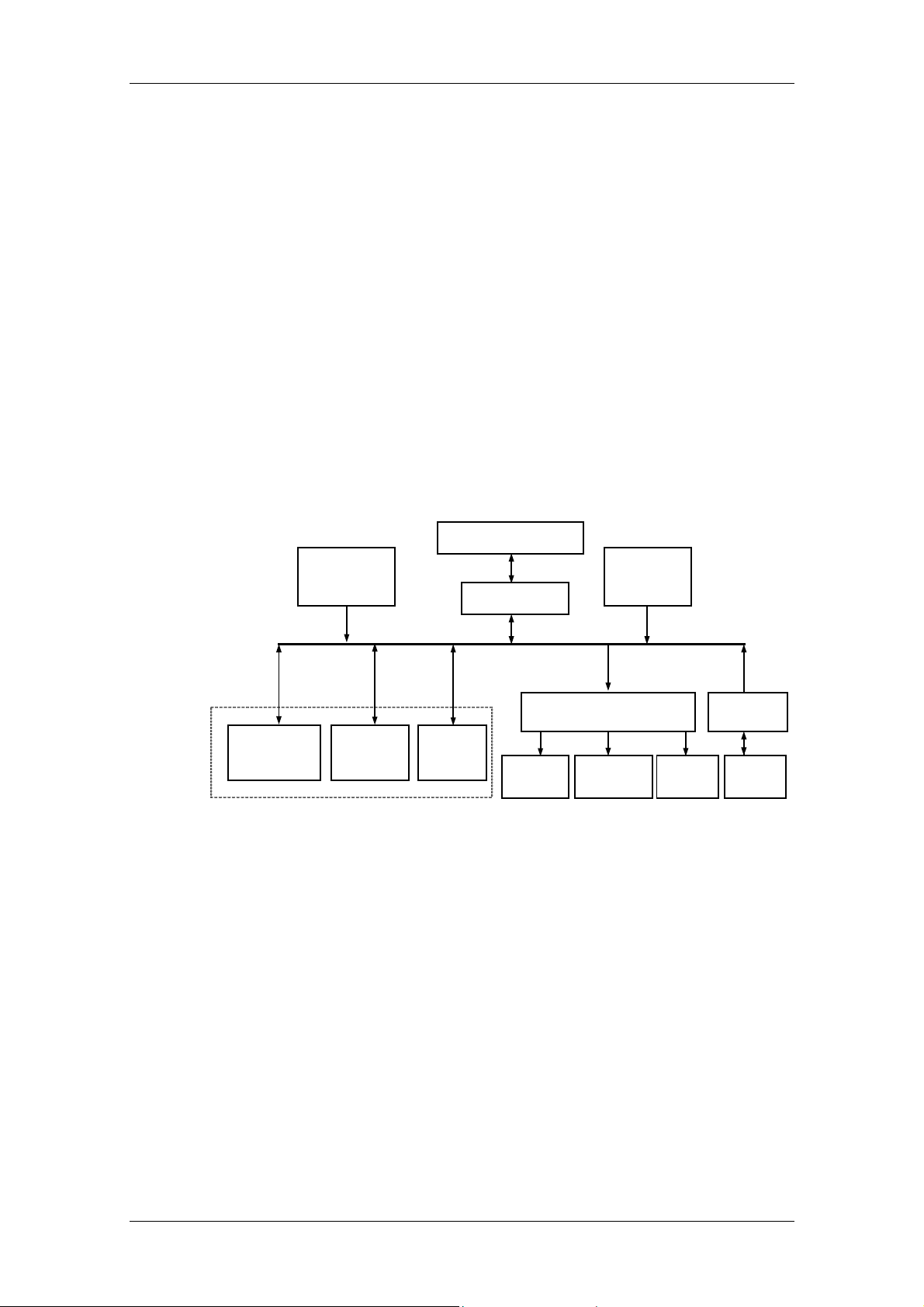

4 Functions of Boards

The analyzer is integrated with the following boards:

Main control board

Power drive board

Sample level detection board

Reagent level detection board

A/D conversion board

Ten photoelectric conversion boards (340nm, 405nm, 450nm, 510nm, 546nm,

578nm, 630nm, 670nm, 700nm and reference light)

Reagent refrigeration board

Power supply assembly

Manipulator connection board

Feeder connection board

Probes connection board

Functions of Boards

Power supply assembly

PFC board

12V&5V board

24V board

ISE power supply board

A/D conversion board

10 photoelectric

conversion boards

Build-in sample bar

code scanner

4.1 Main Control Board

The main control board is the control center of the whole hardware system. It

consists of the control circuits of 6 functional units (including main control unit,

photoelectric unit, reagent unit, sample unit, loading/mixing unit, temperature control

unit). Each functional unit has an MCU. They communicate in the multi-unit mode

and thus compose the whole control system.

ISE module

PC

Main control board

Step motors

DC motors

Pumps, valves

Level detection boards

Transducers

Power drive board

Heaters of reaction

disk

Reagent pre-heater

Lamp

Reagent

refrigeration board

Peltiers

transducers

The functions of the main control board are:

communicating with the PC through the RS232, receiving and analyzing

instructions from the PC and sending data to the PC.

controlling photoelectric conversion through the interface with the A/D conversion

board, reading and saving data from the A/D conversion board.

outputting control signals of each unit through the interface with the power drive

board.

4-1

Page 28

Functions of Boards

receiving signals of fluid level detection and bump collision through the interface

with the level detection boards.

detecting signals from temperature transducers and controlling temperature of the

reaction disk and reagent preheating.

receiving signals from position transducers, deionized water transducer and waste

transducer and controlling the transducers.

controlling the built-in sample bar code scanner, reading the data and sending it to

the PC.

controlling the ISE module, reading the results and sending them to the PC.

4.2 Power Drive Board

The main functions of the power drive board are to receive the control signals from

the main control board and control drive components. The block diagram of the

power drive board is shown in the figure below.

Control signals from

Main Control Board

to 13 step motors to 2 DC motors

to 2 solenoid valves to 3 pumps

to 2 heaters of

reaction disk

4.3 A/D Conversion Board

The 10 photoelectric conversion circuits convert the intensity signals of the lights

transmitting through the reaction cuvettes to electric signals, and then transmit them

to the A/D conversion board through a 5-core shielded cable. Photoelectric

conversion boards for different wavelengths have different gains and cannot be

replaced by each other.

The A/D conversion board filters and amplifies the 10 channels of electric signals

output from the photoelectric conversion boards, transmits them through the

multi-way gating switch to the A/D converter and then sends them to the main control

board for further processing.

to lamp power

to 2 magnets

to reagent

preheating

4.4 Reagent Refrigeration Board

The circuits of the reagent refrigeration board include the refrigeration circuit and the

fan circuit.

The refrigeration circuit is needed to work continuously, so it is powered separately.

The control objects of the reagent refrigeration board include:

Reagent refrigeration: 2 PELTIER components, 4 fans.

4-2

Page 29

Heat sink system for the whole device: 3 lamp-cooling fans, 4 temperature control

fans of the reaction disk.

4.5 Level Detection Boards

The level detection boards that include sample level detection board and reagent

level detection board are used to detect the fluid level of sample and reagent

separately. When the analyzer aspirates reagents/samples, the probes dip into the

liquid to a specific depth, so as to avoid carryovers that have impacts on test results,

and to avoid air aspiration when the reagent/sample is insufficient.

4.6 Feeder Connection Board

The feeder connection board transfers the signals between the feeder transducer

and the main control board, and connects the power drive board and the loading

motor (DC).

Functions of Boards

Connections:

Connector Connected with

J91 Front transducer

J92 Back transducer

J93 Intermediate transducer

J94 No-cuvette transducer

J95 Pressure transducer

J96 Motor control wire (connected with the power drive board)

J97 Motor control wire (connected the motors)

J98 Cuvette-loading button

J99 Connection wire of the main control board

4.7 Manipulator Connection Board

The manipulator connection board transfers the signals between the manipulator

transducer and the main control board, and connects the power drive board and the

electromagnet.

Connections:

Connector Connected with

J101 Horizontal loading position transducer

J102 Vertical loading position transducer

J103 Electromagnet-closing transducer of the lower hand

4-3

Page 30

Functions of Boards

Connector Connected with

J108 Electromagnet-closing transducer of the upper hand

J104 Drive wire of the electromagnet of the upper hand

J105 Drive wire of the electromagnet of the lower hand

J106 Drive wire of the electromagnet (connected with the power drive

board)

J107 Connection wire of the main control board

J109 Safeguard transducer (reserved)

J110 Safeguard transducer (reserved)

4.8 Probes Connection Board

The probes connection board transfers the signals between the sample/reagent level

detection board and the main control board, inputs the temperature signals, outputs

the reagent preheating signals, and transfers the signals between the power drive

board and the mixing motor (DC).

Connector Connected with

J200 Interface of the sample level detection board

J201 Interface of the reagent level detection board

J202 Interface of the mixing motor (DC)

J203 Sample detection signal interface of the main control board

J204 Reagent detection signal interface of the main control board

J205 Temperature control signal interface of the reaction disk

J206 Reagent preheating signal interface

J207 Interface of the power drive board

4.9 Power Supply Assembly

The power supply assembly consists of three boards: PFC board, 24V board,

12V&5V board and ISE (optional) power supply board.

The functions of the PFC board include:

AC/DC conversion;

Supplying the +390V and VDD voltage to the 24V board and the 12V&5V board;

Supplying stable 12V voltage for the lamp;

Supplying control signals of the analyzing unit switch to control the C12V, 5V and

24V outputs.

The 24V board converts the 390VDC current transmitted from the PFC board to the

separated 24VDC outputs through the forward converter.

4-4

Page 31

Functions of Boards

The 12V&5V board converts the 390VDC voltage from the PFC board to B12V,

C12V and 5V voltages through the forward converter .

The ISE power supply board converts the 12V of the reagent refrigeration board to

24V that provides power supply for the ISE unit (optional).

4-5

Page 32

Page 33

5 Maintenance and Service

WARNING:

Before disassembling or assembling the analyzing unit, ensure the

POWER is placed to OFF.

The probe tip is sharp and can cause puncture wounds. To prevent

injury, exercise caution when working around the probe.

BIOHAZARD:

Wear gloves and lab coat and, if necessary, goggles.

Dispose of the waste in accordance with your local or national

guidelines for biohazard waste disposal.

CAUTION:

Please use Mindray-recommended consumables. Other consumables

may decrease the system performance.

Maintenance and Service

Refer to the BS-300 Chemistry Analyzer Operation Manual for details about

unclogging the sample probe

unclogging the reagent probe

replacing the sample probe

replacing the reagent probe

replacing the mixing bar

replacing the plunger assembly of syringe

replacing the lamp

5.1 Replacing Light Filter Assembly

The light filter and optical assembly are fixed in the supporting sleeve. The back end

is compacted and enclosed with the photoelectric amplification board and the screen

gland. Generally, the supporting sleeve is replaced together with the filter and optical

assembly.

5-1

Page 34

Maintenance and Service

Figure 5-1 Light filter assembly

Gasket

Supporting Sleeve

Filter

Flat Spring

Lens

Lens Seat

Gasket

Screw

Photoelectric

Conversion Board

Shield Box

WARNING:

Before operating, ensure to place the POWER (main switch) to OFF.

1 Unscrew (counter clockwise) the two cap screws on the screen gland

whose wavelength is to be replaced.

2 Open the cover of the A/D conversion board, and unplug the plug

corresponding to certain wavelength.

5-2

Page 35

Maintenance and Service

3 Take out the photoelectric conversion board and the supporting sleeve.

4 Keep the photoelectric conversion board upward, and loosen the two

retaining screws on it.

5 Keep the photoelectric conversion board upward, and pull the photoelectric

amplification board out of the supporting sleeve.

6 Unpack the new supporting sleeve containing the optical assembly. Be sure

to keep the top side (where to assemble the photoelectric amplification

board) of the supporting sleeve upward.

7 Install the original photoelectric conversion board onto the new supporting

sleeve, and then fasten the two retaining screws.

8 Install the screen gland, and fasten the retaining screws.

5-3

Page 36

Maintenance and Service

9 Connect the photoelectric conversion board to the A/D conversion board,

and assemble the cover.

WARNING:

When replacing the light filter assembly, do not touch the optical

assembly in the supporting sleeve and the photoelectric receiving tube

of the photoelectric conversion board by hand.

The light filters and the photoelectric conversion boards are in

one-to-one relationship. Do not disarrange them.

5.2 Replacing Optical Fiber

WARNING:

Before operating, ensure to place the POWER (main switch) to OFF.

1 Unscrew the four screws on the supporting pillars of the cuvette feeder, and

remove the cuvette feeder.

5-4

Page 37

Maintenance and Service

2 Unscrew the four screws on the reaction disk cover, and open the reaction

disk cover.

Attention should be paid to the power cable of the upper heater when the

reaction disk cover is being opened.

Power cable of

upper heater

3 Take out two cuvette segments in a diagonal with the needle-nose pliers to

make two spaces for disassemble the colorimetric disk.

4 Unscrew three M3 cap screws, and then disassemble the colorimetric disk.

5-5

Page 38

Maintenance and Service

5 Use an M3 cap screwdriver to loosen the retaining screws of the optical

fibers on the colorimetric clamp and the reference light support.

6 T ake out the optical fibers one by one, and fix the optical component s in the

colorimetric clamp by fastening the screws slightly.

Screw of the reference light

7 Draw out all the nine optical fibers from the reaction compartment.

8 Loosen the M3 cap screw (used for retaining optical fibers) on the lamp

housing, and then draw out the optical fibers.

9 Put nine of the ten branches of the new optical fiber into the reaction disk

from its bottom one by one, loosen the retaining screw, insert the optical

fiber to the end, and then fasten the retaining screw.

10 Fix the reference light optical fiber.

5-6

Page 39

Maintenance and Service

11 Fix the optical fiber of the lamp housing.

12 Put the colorimetric disk back and fix it.

13 Put the reaction disk cover back and fix it.

14 Install the cuvette feeder and fix it.

CAUTION:

When replacing the optical fiber, ensure that its bending radius is no

less than 20cm. Otherwise, the optical fiber will be damaged.

5.3 Adjusting Reaction Disk, Manipulator and Feeder

NOTE:

Debug the lower arm first (The relation between the lower arm position

and the reaction cuvette position is very important.), and then the upper

arm. When debugging the lower arm, move the cuvette compartment

aside.

1 Disassemble the cuvette feeder, and adjust the circular position of the

reaction disk (through the initial position transducer of the reaction disk) to

the standard position (The finger of the lower arm point s to the cen ter of the

slot between reaction cuvette segments).

2 Horizontally adjust the manipulator to the standard position (The finger of

the lower arm can work on reaction cuvettes well, and it should be 0.2mm

away from the nearest point of the reaction cuvette).

5-7

Page 40

Maintenance and Service

3 Vertically adjust the manipulator the standard position (The finger of the

lower arm can work on reaction cuvette well, and the finger support of the

lower arm should be 0.15mm above the reaction cuvette.).

4 Run the manipulator to the position for taking new cuvettes, and

horizontally adjust the reaction cuvettes in the feeder. When catching a

cuvette, ensure a clearance of 0.4mm ~ 0.6mm between the finger of the

upper arm and the cuvette, and center them.

5.4 Adjusting Probes and Disks

NOTE:

Adjust the positions of the three probes and reaction cuvettes, and then

others.

Adjust the working position of the reagent probe (To minimize the

1

cumulative error, ensure that the reagent probe return to the initial position

before each adjustment.) as follows:

A For the reagent discharging position, ensure the reagent probe is in

the center of the reaction cuvette and the probe tin is 2 ~ 3mm away

from the bottom of the reaction cuvette.

B Adjust the position of the initial-position transducer of the reagent

disk. Ensure the mouths of reagent cuvettes in the inner and outer

circles fit the reagent disk cover well.

C Adjust the washing position of the reagent probe. Ensure the reagent

probe is in the center of the wash well and the probe pin is 5mm

away from the bottom of the wash well. If necessary, adjust the

position of the wash well.

D Adjust the reagent probe’s position on the outer circle of the reagent

disk. Ensure the reagent probe is in the center of the hole of the outer

circle.

5-8

Page 41

Maintenance and Service

E Adjust the reagent probe’s position on the inner circle of the reagent

disk. Ensure the reagent probe is in the center of the hole of the inner

circle.

Adjust the working position of the sample probe (To minimize the

2

cumulative error, ensure that the sample probe return to the initial position

before each adjustment.) as follows:

A For the sample discharging position, ensure the sample probe is in

the center of the reaction cuvette and the probe tin is 2 ~ 3mm away

from the bottom of the reaction cuvette.

B Adjust the position of the initial-position transducer of the sample

disk. Ensure the mouths of sample cuvettes in the inner and outer

circles fit the reagent disk cover well.

C Adjust the washing position of the sample probe. Ensure the sample

probe is in the center of the wash well and the probe pin is 5mm

away from the bottom of the wash well. If necessary, adjust the

position of the wash well.

D Adjust the sample probe’s position on the outer circle of the sample

disk. Ensure the sample probe is in the center of the hole of the outer

circle.

E Adjust the sample probe’s position on the inner circle of the sample

disk. Ensure the sample probe is in the center of the hole of the inner

circle.

Adjust the working position of the mixing bar.

3

A Switch off the analyzing unit first, and then rotate the mixing arm to

see if its rotation radius is proper. If the mixing bar cannot reach the

center of the reaction cuvette, adjust the position of the mixing bar on

the mixing arm properly.

B Disassemble the mixing arm, and then switch on the analyzing unit to

run the reaction disk and stop it at any cuvette. Hold the mixing arm

by hand, and fix it at the center of the reaction cuvette.

C Vertically adjust the mixing bar’s position in the reaction cuvette.

Ensure the mixing bar tip is 1 ~ 2mm away from the bottom of the

reaction cuvette.

D Adjust the washing position of the mixing bar. Ensure the mixing bar

is in the center of the wash well and about 5mm away from the

bottom of the wash well. If necessary, adjust the position of the wash

well.

4 In the engineering adjustment software, select the Debug instruction

menu, and rotate the reaction disk for one lap. Dive probes and mix the

reactant at every position or every several positions to see if the three

probes interfere with any reaction cuvette (Command 61). If the mixing bar

knocks the side or the bottom of any cuvette, repeat Step 3.

5-9

Page 42

Maintenance and Service

5.5 Replacing Components of ISE Unit (optional)

5.5.1 Replacing Tubing

NOTE:

(1) Fluidic tubing can be divided into the following six types.

W1 with two adapters connects the ISE module and the pump W.

Pump module

ISE module

Reagent module to be

placed here

Pump B Pump A

Pump tubing adapter

Pump tubing

Pump head

Pump W

Fluidic tubing adapter

W2 connects the reagent module and the pump W.

A1 (B1) with one adapter connects the sample entry port and the pump

A (pump B).

A2 (B2) with two adapters connects reagent module and the pump A

(pump B).

They are different in length and W1, A2 and B2 are not directional

when they are installed.

Usually the adapter has not been mounted to the fluidic tubing, so you

have to do it by hand. The tubing should be mounted to a short metallic

tube on the adapter. For convenience, the connectin g end of the tubing

can be dipped into hot water for several seconds.

(2) Pump tubing is used around a pump head. It has one adapter on

each end that makes connection with the fluidic tubing easy.

5-10

Page 43

5.5.1.1 Replacing Fluidic Tubing W1 and W2

1 Place the POWER to OFF.

2 Open the ISE unit door.

3 If you want to replace the W1, unscrew the screw of the ISE module and

take off the cover.

4 Put out the fluidic tubing W2 and insert it into a container such as a cup that

is used to contain the waste solution flowing from the W2.

5 Start the analyzing unit and the system software.

6 Enter the ISE Maintenance screen of the system software.

7 Click the Maintenance button several times until there is no solution

flowing out from the W2.

8 Place the POWER to OFF.

9 If you want to replace W1, pull out its two adapters directly from the waste

pump tubing adapter and the right angle adapter that is fixed to the

compression plate.

Maintenance and Service

Right angle adapter

The side matches

the adapter of

fluid tubing W1

The side with a recess

matches the compressio n

plate of the ISE module.

Note that when pulling out the fluidic tubing adapter, in order not to release

the right angle adapter, you can hold the right angle adapter with a finger.

After that, install a new W1. For W2 exchange, it just needs to replace the

W2 with a new one.

10 If you want to replace the W2, replace it with a new one. Otherwise, insert

the W2 back to the reagent module.

11 Place the POWER to ON.

12 Enter the System Maintenance screen of the system software.

13 Select the Others tab and click the Download Settings button.

14 Enter the ISE Maintenance screen.

15 Click the A purge button to observe if there is solution leaking out. If there

is solution leaking out, repeat from the step 4 to install the tubing again.

16 Install the cover of the ISE module if it has been taken off.

17 Close the ISE unit door.

5-11

Page 44

Maintenance and Service

5.5.1.2 Replacing Fluidic Tubing A1, A2, B1 and B2

1 Place the POWER to OFF.

2 T ake off the panel under the sample disk and you can see the shiel ding box

and the peristaltic pumps.

3 Open the ISE unit door.

4 Take out the reagent module.

5 Put the fluidic tubing W2 in a container such as a cup that is used to contain

the fluid flowing out from the W2.

6 Start the analyzing unit and the system software.

7 Enter the ISE Maintenance screen of the system software.

8 If you want to replace A1 or A2, click the A purge button. If you want to

replace B1 or B2, click the B purge button.

Repeat this step for several times until the received data indicates that the

Calibrant A or Calibrant B has air bubble in it.

9 Place the POWER to OFF.

10 Replace the tubing with a new one.

Note that before installing the A1 or B1 to the sample entry port, you can

dip the connecting end of the A1 or B1 into hot water for several minutes to

make the following procedures easily performed.

11 Start the analyzing unit.

12 If the system software is not running, start it. Otherwise, enter the System

Maintenance screen of the system software, select the Others tab and

click the Download Settings button.

13 Enter the ISE Maintenance screen of the system software.

14 If you have replaced A1 or A2, click the A purge button. If you have

replaced B1 or B2, click the B purge button.

Repeat this step for several times until the received data indicates that the

Calibrant A or Calibrant B has no air bubble in it.

5.5.1.3 Replacing Pump Tubing

1 Place the POWER to OFF.

2 Open the ISE unit door.

3 Pinch one adapter of the pump tubing and take it out from the tubing shelf.

Then take off the whole tubing.

Tubing shelf

5-12

Page 45

4 Put one adapter of the new pump tubing onto the tubing shelf and make the

tubing around the pump ahead, then put the other adapter onto the shelf

with a little strength.

5 Start the analyzing unit and the system software.

6 Enter the ISE Maintenance screen.

7 Click the Pumps button to see if the calibration of pump is correct. If not,

repeat the upper steps.

5.5.2 Replacing Pumps

1 Place the POWER to OFF.

2 Take off the pump tubing around the pump head.

3 Disconnect the cable and the pump motor.

Maintenance and Service

4 Unscrew the four screws around the pump head.

5 Pull out the pump directly.

6 Put a new pump on the pump shelf, tighten the screws, connect the calbe

and pump motor, and then put the pump tubing around the pump head.

7 Start the analyzing unit and the system software.

8 Enter the ISE Maintenance screen.

9 Click the Pumps button to see if the calibration of pump is correct. If not,

repeat the upper steps.

5.5.3 Replacing ISE Module

Some times there is something wrong with the components in the ISE module such

as sample entry port, bubble detector, PCB and so on. In these cases, the ISE

module should be replaced according to the following procedure.

Cable

Pump motor

1 Place the POWER to OFF.

2 T ake off the panel under the sample disk and you can see the shiel ding box

and the pumps easily.

3 Open the ISE unit door.

4 Start the analyzing unit and the system software.

5 Enter the ISE Maintenance screen.

5-13

Page 46

Maintenance and Service

6 Click the Maintenance button.

7 Place the POWER to OFF.

8 Unscrew the screw of the ISE module and take off the cover.

9 Take off all electrodes from above to below.

10 Disconnect the right angle adapter and the compression plate.

11 Disconnect the cable.

12 Unscrew the four screws that fix the ISE module to the shielding box. Then

take out the module from the shielding box.

13 Put a new ISE module to the shielding box. Then connect the cable and

install the electrodes sequentially. At last mount the right angle adapter to

the compression plate.

14 Install the electrodes sequentially.

15 Enter the System Maintenance screen of the system software.

16 Select the Others tab and click the Download Settings button.

17 Enter the ISE Maintenance screen.

18 Click the A pur ge button to see if there is solution leaking out. If there is,

take off the electrodes and install them again.

19 Check if the new ISE module can work normally.

5-14

Page 47

6 Software Introduction

The software of BS-300 analyzer is composed of the system sof tware an d the control

software.

6.1 System Software

The system software can, according to the requirements and inputs of users,

generate a work schedule (instruction sequence), control the units of analyzing unit in

the sequence of instructions in the work schedule, receive photoelectric data,

response messages or execution results from the analyzing unit, output them to the

PC screen or the printer. With these outputs, users can obtain correct test results.

According to different functions, the entire PC softwa re system can be divided into the

following parts:

System Initialization

This part includes the initialization of the PC operating system, the initialization of the

communication between the PC and analyzing unit, and the controls of analyzing unit

reset.

Software Introduction

Control system

This part includes the formation of the work schedule, instruction data sending and

receiving.

GUI

This part includes the requests for tests (routine tests, emergency tests, calibration

tests and QC tests), the observation of test statu s (status of the reaction disk, sample

disk and reagent disk), test management, calibration management, QC manage ment,

result query, alarm management and the help system.

Shutdown Processing

This part includes the resets of sub-units.

6.1.1 System initialization

To initialize the PC operating system,

Check the PC operating system. The system software must run under Windows

2000 or Windows XP. Otherwise, the system will prompt that the system software

cannot run under other operating system, and then the system software system

exits automatically.

Check the current screen resolution for the operating system. The system software

must run under the resolution of 1024 × 768. Otherwise, the system prompts to

reset the resolution before restarting the system software and exit the system

software.

Disable the screen protection program. The system software must keep displayed

while running. To prevent the screen protection program from disturbing users in

the operating and observing processes, disable it.

Lock the keyboard. When running, the system software will lock some key

combinations to prevent users from starting any other program and condu cting any

6-1

Page 48

Software Introduction

other operation. In this case, users cannot switch over to any other program or

print the current screen.

Check whether there is any username and password of the

maintenance/debugging personnel in the registry. The system software has the

debugging function. Only the authorized maintenance/debugging personnel can

enter the debugging window and maintain or debug the system and the host. For

the confidentiality, the username and password are saved in the registry. If they

are unavailable in the registry, the system will re-write the default username and

password into the registry.

To initialize the communication and the units auto-check,

Set serial ports and initialize them, including such parameters as the baud rate,

data bit, start bit, stop bit, parity bit, transmitting/receiving buffer, control protocol

and so on. In addition, start the serial port receiving thread.

Handshake for communication. Send a handshake instruction to the analyzing unit.

If the analyzing unit responds to this instruction (namely, send back a handshake

instruction to the PC), it indicates the PC handshakes with the host successfully. If

the host fails to respond to handshake instruction, it will re-send the handshake

instruction back in a specific period. If it fails for continuously three times, the

system will prompt to exit the system software. If you ignore that and continue to

enter the system software, all tests cannot be conducted under the system.

Check whether the printer is connected. If not, the system will prompt to connect it.

Send an instruction for querying the auto-check results of the units, check the

auto-check result of each unit. (The units are auto-checked when the analyzing

unit is started, and the auto-check results are stored in the main unit.) In case of

any fault data in the auto-check result of any unit, the system will prompt to switch

off the analyzing unit and check the faulty unit.

6.1.2 Shutdown processing

In the BS-300 Chemistry Analyzer Control System window, click the Exit button.

The Confirm dialog box appears. If you click OK, the system will

Switch off the lamp;

Unload all reaction cuvettes;

Wash the fluid tubing;

Reset all units;

Unlock the keyboard;

Prompt to exit the operating system and shut down the PC.

6.2 Control Software

The analyzing unit can be functionally divided into the following units: photoelectric

unit, reaction disk unit, reagent disk unit, sample disk unit, reagent probe syringe unit,

sample probe syringe unit, mixing bar unit, loading and manipulator unit, temperature

control unit, fluid tubing unit and reagent refrigeration unit. The functions of those

units are listed in the following table.

6-2

Page 49

Software Introduction

Unit Function

Main unit Receives macroinstructions from the PC, decomposes them

into a series of action instructions, and then delivers the

action instructions to destination sub-units (in specific order)

at a certain interval.

Monitors the status of other units, and transmits data

collected by the photoelectric unit to the PC.

Photoelectric

unit

Reaction disk

unit

Reagent disk

unit

Sample disk

unit

Reagent probe

syringe unit

Photoelectrically detects, amplifies and converts the solution

in reaction cuvettes, and stores A/D converted data at the

twin port FIFO for the main unit to read and transmit them to

the PC.

Contains 80 cuvette No.

Runs the reaction cuvette with the specified No., following

the instruction of the main unit, to the reagent dispensing

position, sample dispensing position, mixing position, and

photoelectric detection position at all wavelengths.

Contains 50 bottle positions.

Carries reagents, and runs the reagent bottles with specified

No., following the instruction of the main unit, to the reagent

aspirating position.

Contains 60 tube positions in the inner and outer circles.

Carries samples, and runs the sample tubes with specified

No., following the instruction of the main unit, to the sample

aspirating position.

Receives instructions from the PC, and controls the reagent

probe in aspirating a specific volume of reagent from the

reagent bottle and dispensing it to the specified reaction

cuvette.

Sample probe

syringe unit

Mixing bar unit Receives instructions from the PC, and controls the mixing

Loading and

manipulator

unit

Receives instructions from the PC, and controls the sample

probe in aspirating a specific volume of sample from the

sample tube and dispensing it to the specified cuvette.

bar in mixing the solution in the cuvette that has been run to

the mixing position.

Runs the mixing bar to the wash well, and wash it after each

mixing process to avoid carryover.

Controls the cuvette feeder and manipulator.

The feeder assembly is responsible for detecting whether

there are enough reaction cuvettes in the cuvettes

compartment and pushing reaction cuvettes to the position

for the manipulator to take cuvettes.

The manipulator is responsible for taking reaction cuvettes

from the reaction disk, placing them into the used cuvette

bucket, taking new reaction cuvettes from the cuvette

compartment, and putting them on the reaction disk.

6-3

Page 50

Software Introduction

Unit Function

Temperature

control unit

Fluid tubing unit Controls the fluid tubing in washing the reagent probe,

Controls the reaction disk temperature, reagent probe

preheating temperature and fluid tubing.

Note: The reaction disk temperature should be kept at 37 , ℃

the heating cavity of the reagent probe should be preheated

to 45 ℃.

sample probe and mixing bar.

Reagent

refrigeration

unit

Refrigerates the reagent chamber and controls its

temperature between 4 ~ 10 .℃

6-4

Page 51

Service Flow

7 Service Flow

WARNING:

Before disassembling or assembling the analyzing unit, ensure the

POWER is placed to OFF.

The probe tip is sharp and can cause puncture wounds. To prevent

injury, exercise caution when working around the probe.

When you disassemble or replace any board, ensure to wear antistatic

gloves.

BIOHAZARD:

Wear gloves and lab coat and, if necessary, goggles.

7.1 Fluid Level Detection Failure of Reagent Probe

Surface

detection

failure of

reagent

probe(Th

e reagent

probe

does not

detect

the

surface

on the

reaction

disk.)

The

reagent

probe

cannot

detect

the

surface

on the

reagent

disk

Surface detection signal transmission error: The surface detection

board does not have the working voltage, or when the probe touches

the surface, the indicator of the surface detection board is normal, but

there is always a host alarm indicating surface detection failure.

Possible cause: The patch cord for the reagent surface detection is

disconnected, or the connector is not well connected.

Surface detection signal processing error: When the probe touches

the surface, the indicator of the surface detection board is normal, the

connection between the main control board and the surface detection

board is normal, and no surface detection signal reaches the main

control board, but there is always a host alarm indicating surface

detection failure.

The surface

detection

signal fails

to be

generated

by

capacitance

change.

Possible cause: Main control board.

Power failure: The working voltage of the surface

detection board is 12V. In case of no power supply, the

surface detection signal cannot be generated.

Possible cause: Disconnection; the connector is not well

connected; there is no 12V out put from t he main cont rol

board.

Probe failure: The detection terminal has a changeable

capacitance. Loose exterior or interior of the probe, the

sealing-off of the probe connecting wire and the probe

breakage will result in unsteady voltage or obvious

voltage changes. In this case, the capacitance signal

will be unavailable or exceed the range of the surface

detection board.

Possible cause: Reagent probe assembly, connector.

Surface detection board failure: When there is no probe

failure, but the indicator is always on, or the indicator is

not on when the probe touches the surface, there must

be a surface detection board failure.

Troubleshooting: Replace the surface detection board.

The

reagent

probe mis-

detected

the surface

When this failure occurs, the sample probe cannot detect

the surface at the reaction disk, but there is no alarm at

the reagent unit. For details, see Surface Detection

Failure: Sample Probe.

7-1

Page 52

Service Flow

7.2 Fluid Level Detection Failure of Sample Probe

No reagent in the reaction disk: The reagent probe misdetects the surface, aspirates air and dispenses into the

reaction cuvette. Therefore, the reagent unit CPU fails to

make any judgment. In this case, the sample probe cannot

detect the surface when dispensing the sample into this

The sample

probe cannot

detect the

surface at the

reaction disk.

reaction cuvette.

Possible cause: Surface detection failure of the reagent probe

insufficient reagent: The reagent probe aspirates less reagent

than the set volume. As a result, the sample probe cannot

detect the surface at the preset height.

Possible cause: The reagent is prepared in the bottle, the

reagent syringe is not fixed, leakage occurs in the tubing of

the reagent probe, or there are bubbles in the reagent.

Position correction parameter error of the sample probe: In

case of such an error, the sample probe cannot reach the

surface in the steps.

Troubleshooting: Re-correct the sample probe position.

Surface

detection

failure of

the

sample

probe

The sample

probe cannot

detect the

surface at the

reaction disk.

The sample

probe misdetects the

surface (In

this case,

there will be

no alarm, but

test results

will become

abnormal. On

the reaction

curve, you

can see that

no sample is

added.)

Surface detection signal transmission failure: When the probe

touches the surface and stops, the indicator of the surface

detection board is on for about 2 seconds. The output signal

of the surface detection board switche s normally, but there is

always a host alarm indicating that no surface is dete cted.

Possible cause: The patch cord for detecting the sample

surface is disconnected, or the connector is not well

connected.

Signal processing failure of the main control board: When the

probe touches the surface, the indicator works normally. But

there is always a host alarm indicating that no surface is

detected. Ensure that the sample surface detection signal is

transmitted to the relevant connector of the main control

board.

Possible cause: Main control board failure

Surface detection signal failure: The indicator of the surface

detection board is not on or always on when the sample

probe touches the surface.

Surface mis-detection at the sample d isk: In this case, there

will be no alarm, but the sample probe fails to aspirate the

sample, and the test result and reaction curve become

abnormal.

Possible cause: Sample probe, surface detection board,

surface detection patch cord.

Surface mis-detection at the reaction disk: In this case, there

will be no alarm, but there is residual sample on the sample

probe tip, and drops on the table when the probe leaves the

reaction disk.

Possible cause: The sub-unit software is later than V1.7, or

the sample probe is not in the center of the reaction cuvette.

7-2

Page 53

7.3 Liquid Dropping From Probes

Drips drop from the sample probe

due to fluid tubing leakage. In this

case, there will be liquid dropping

onto the table widely, and there may

be liquid dropping even when the

sample probe is static.

Troubleshootin

g for the liquid

dropping from

the reagent

probe and

sample probe.

Drips drop from the sample probe

due to surface detection failures. In

this case, most liquid drop on the

area between the reaction disk and

the wash well.

Service Flow

Tubing leakage due to the abraded syringe

piston

Troubleshooting: Replace the syringe or the

syringe piston

The reagent probe takes liquid from the

reaction disk.

The reagent probe did not detect the surface at

the reaction disk, and dispenses the reagent at

the corresponding height. If the reagent probe

cannot touch the surface at the position for

dispensing reagent, the last reagent drop will

be taken out by the reagent probe.

Possible cause: The probe arm is installed at a

too high position; the position of the sample

probe has not been corrected; the syringe is

loose; there are bubbles in the reagent bottle.

The sample probe takes liquid from the reaction

disk.

The sample probe detects the surface and

stops immediately. Then it dispenses the

sample at 1mm under the surface. If the

reagent probe mis-detects the surface, the

dispensed sample will fail to be added into the

reagent, but taken at the probe tip and drops

when the probe is moving. As a result, some

test results become abnormal.

Possible cause: There are bubbles in the

reaction cuvette; the sample probe is not in the

center of the reaction cuvette, and its position

has not been corrected.

Other failures

Drips taken from the reagent disk or sample

disk and dropping from probes

Such failures are usually followed by alarms

indicating that no surface is detected at the

reagent/sample disk. The reagent/sample

probe does not aspirate reagent/sample, but

the reagent/sample probe will stretch out to the

bottom of the reagent bottle/sample tube due to

surface detection failures. As a result, reagent/

sample liquid will be taken on the exterior of

the probe and drop while the probe is moving.

Probe being bent

Troubleshooting: Replace the probe.

Smudges on the sample probe absorb some

liquid and drop it while the probe is moving.

Troubleshooting: Cleaning the sample probe.

Probe driving assemblies are not assembled

well, resulting in probe jittering and liquid

dropping in the vertical movements.

Troubleshooting: Adjust or replace the probe

driving assemblies.

7-3

Page 54

Service Flow

7.4 Failing to Detect Level of Water for Washing Exteriors

Surface detection signal failure:

See relevant resolutions for the

surface detection failure.

No water in the wash water tank: Users

can see this failure in the alarm

information detergen t em pty. In case of

no alarm information, check whether

Failing to

Detect the

Surface of

the Water

for

Washing

Exteriors

there is any problem in the detergent tank

Pump damaged: In this case, there will

be no water in the three wash wells.

Troubleshooting: Replace the pump.

No water in the

wash well

Tubing blocked: In this case, there will be

insufficient water for washing exteriors,

the three water flows are no t the same, or