Page 1

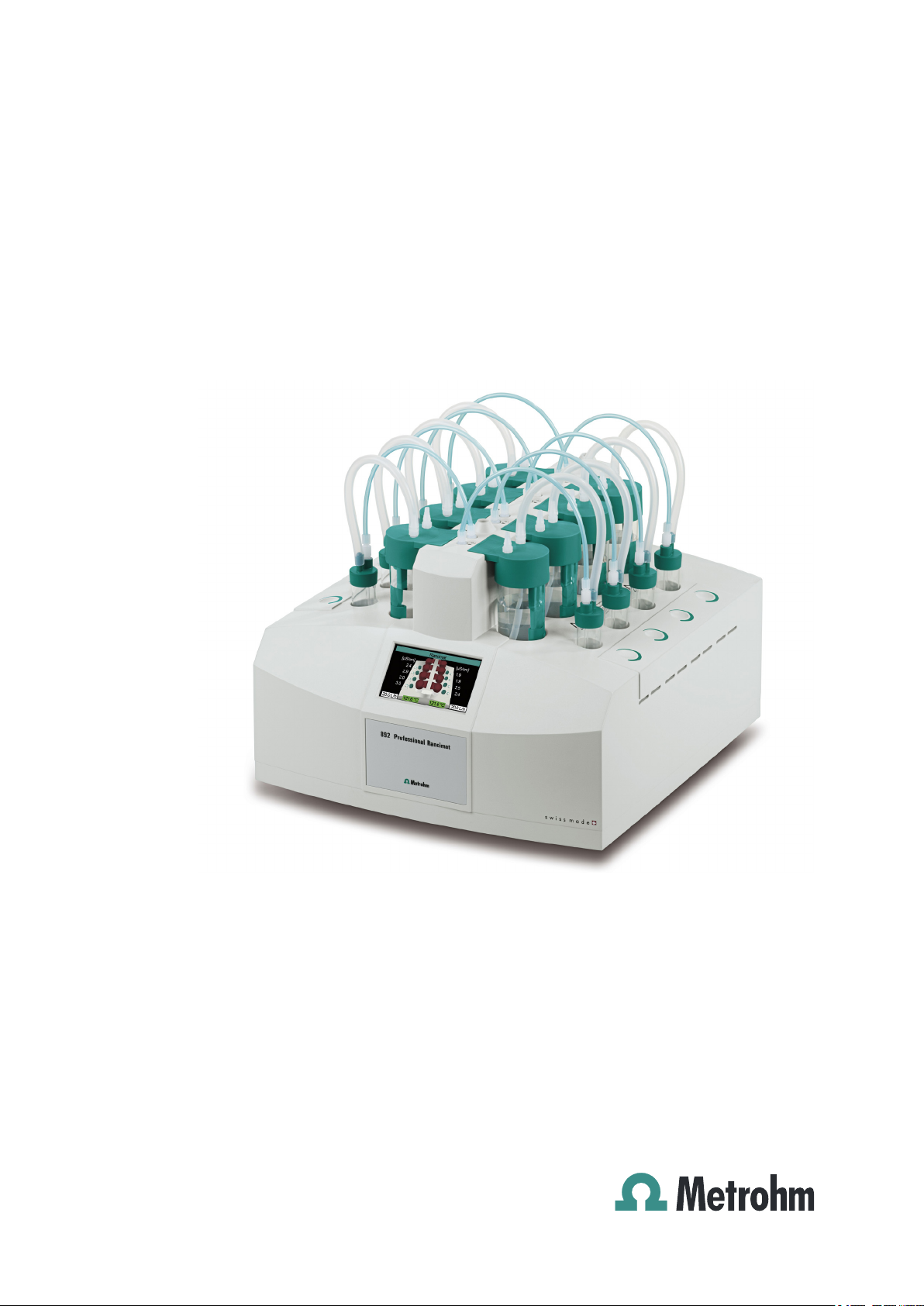

892 Professional Rancimat

Manual

8.892.8001EN / 2014-05-09

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

892 Professional Rancimat

8.892.8001EN / 2014-05-09

Manual

fpe

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.2 About the documentation ................................................... 2

1.2.1 Symbols and conventions ........................................................ 2

1.3 Safety instructions ................................................................ 3

1.3.1 General notes on safety ........................................................... 3

1.3.2 Electrical safety ........................................................................ 3

1.3.3 Flammable solvents and chemicals ........................................... 5

1.3.4 Recycling and disposal ............................................................. 5

2 Overview of the instrument 6

2.1 Front of the instrument ........................................................ 6

2.2 Rear of the instrument ......................................................... 7

Table of contents

2.3 Instrument display ................................................................ 8

3 Installation 10

3.1 Setting up the instrument .................................................. 10

3.1.1 Packaging .............................................................................. 10

3.1.2 Checks .................................................................................. 10

3.1.3 Location ................................................................................ 10

3.2 Mounting accessories ......................................................... 11

3.2.1 Mounting the internal air supply ............................................ 11

3.2.2 Mounting the external air supply ........................................... 13

3.2.3 Assembling the reaction and measuring vessels ..................... 14

3.2.4 Inserting vessels / Establishing tubing connections ................. 17

3.2.5 Mounting the exhaust air collection tube ............................... 18

3.2.6 Mounting the oil separator .................................................... 19

3.3 Power socket ...................................................................... 21

3.3.1 Replacing fuses ...................................................................... 21

3.3.2 Power supply cable and power socket ................................... 22

3.3.3 Switching the instrument on and off ...................................... 22

3.4 Connecting a computer ...................................................... 23

3.4.1 Connecting the 892 Professional Rancimat and the com-

puter ..................................................................................... 23

4 Operation 25

892 Professional Rancimat

4.1 Rancimat method ............................................................... 25

4.2 Calibration functions .......................................................... 26

4.2.1 Determining the cell constant ................................................ 26

4.2.2 Determining the temperature correction ................................ 27

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.3 Determinations ................................................................... 30

4.3.1 Preparing a sample ................................................................ 30

4.3.2 Preparing the instrument and the accessories ......................... 34

4.3.3 Preparing the determination .................................................. 35

4.3.4 Cleaning the accessories ........................................................ 37

4.3.5 Cleaning the oil separator ...................................................... 38

5 Operation and maintenance 40

5.1 General notes ...................................................................... 40

5.1.1 Care ...................................................................................... 40

5.1.2 Maintenance by Metrohm Service .......................................... 40

5.2 Replacing the dust filter .................................................... 41

5.3 Regenerating or replacing the molecular sieve ............... 41

5.4 Quality management and qualification with Metrohm .. 42

6 Troubleshooting 43

6.1 Problems ............................................................................. 43

7 Technical specifications 48

7.1 General data ....................................................................... 48

7.2 Temperature control and measurement .......................... 48

7.3 External temperature sensor ............................................. 49

7.4 Conductivity measurement ................................................ 49

7.5 Gas flow regulation ............................................................ 50

7.6 USB interface ...................................................................... 50

7.7 Power socket ...................................................................... 50

7.8 Safety specifications ........................................................... 50

7.9 Electromagnetic compatibility (EMC) ................................ 51

7.10 Ambient temperature ......................................................... 51

7.11 Dimensions/Material .......................................................... 51

8 Conformity and warranty 52

8.1 Quality Management Principles ........................................ 52

8.2 Warranty (guarantee) ......................................................... 53

■■■■■■■■

IV

9 Accessories 55

Index 57

892 Professional Rancimat

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 Front 892 Professional Rancimat ........................................................ 6

Figure 2 Rear 892 Professional Rancimat ......................................................... 7

Figure 3 Instrument display ............................................................................. 8

Figure 4 Mounting accessories for the air supply ........................................... 11

Figure 5 Drying flask - Individual parts ........................................................... 12

Figure 6 Drying flask mounted in place ......................................................... 13

Figure 7 Equipping the reaction and measuring vessels ................................. 15

Figure 8 Mounting the air tube: correct - incorrect ........................................ 17

Figure 9 Mounting the foam barrier .............................................................. 17

Figure 10 Mounting the oil separator .............................................................. 20

Figure 11 Instrument display with instrument name ........................................ 22

Figure 12 Instrument display with "no connection" symbol ............................. 22

Figure 13 Instrument display without instrument name and symbol ................ 23

Figure 14 Instrument display with serial number ............................................. 23

Figure 15 Measuring arrangement (schematic representation) ......................... 26

Figure 16 Assembling the reaction vessel for determining the temperature correc-

tion ................................................................................................. 28

Figure 17 Oil separator (6.2753.200), disassembled ........................................ 38

Figure 18 Dust filter - conditions ..................................................................... 41

Table of figures

892 Professional Rancimat

■■■■■■■■

V

Page 8

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 892 Professional Rancimat is a computer-controlled measuring device

for determining the oxidation stability of samples containing oil and fat.

It is equipped with two heating blocks each with 4 measuring positions.

Each block can be heated individually, i.e., 4 samples can each be measured at two different temperatures or 8 samples at the same temperature. The measurements at the individual measuring positions can be

started individually for this.

The 892 Professional Rancimat is controlled by means of the StabNet

computer software and a computer that is connected via the USB interface. Up to 4 instruments can be controlled and monitored by each computer, hence allowing a maximum of 32 samples to be analyzed at the

same time. The evaluation algorithm of the computer software determines

the break point of the Rancimat curve and thus the induction time fully

automatically. Besides the induction time, the so-called stability time,

i.e., the time until a defined conductivity change has been achieved, can

also be determined. In the case of conductivity changes (stages) which do

not have anything to do with the autoxidation, the evaluation can be suspended for definite time intervals. The results determined can be further

processed mathematically. In particular, the induction times can be converted to the standard temperatures defined in the respective standards.

1 Introduction

Each Rancimat curve can also be evaluated manually. A computer-supported tangential method is available for this, in which you can position

the tangents anywhere on your curves. This makes evaluations possible in

extreme cases as well.

The results of the determinations are saved in a database together with all

method and determination data. Determinations can be searched for,

sorted, filtered, exported and printed in the Database program part.

Apart from graphically displaying individual and multiple curves, the software is also capable of conducting recalculations with changed parameters and extrapolating the results to a certain temperature.

892 Professional Rancimat

■■■■■■■■

1

Page 10

1.2 About the documentation

1.2 About the documentation

CAUTION

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.2.1 Symbols and conventions

The following symbols and formatting may appear in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

■■■■■■■■■■■■■■■■■■■■■■

Instruction step

Carry out these steps in the sequence shown.

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

WARNING

This symbol draws attention to a possible life-threatening hazard or risk of injury.

WARNING

This symbol draws attention to a possible hazard due

to electrical current.

WARNING

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

WARNING

This symbol draws attention to a possible biological

hazard.

■■■■■■■■

2

CAUTION

This symbol draws attention to possible damage to

instruments or instrument parts.

892 Professional Rancimat

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1.3 Safety instructions

1.3.1 General notes on safety

WARNING

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

Hot reaction vessels

1 Introduction

NOTE

This symbol highlights additional information and

tips.

The reaction vessels can become very hot.

Avoid any contact with the hot reaction vessels. Place these in the vessel holders provided for cooling down.

Flammable substances

The heating block of the 892 Professional Rancimat can be heated to

229.9 °C.

Flammable substances may ignite at such temperatures.

Adjust the oven's maximum heating temperature to the sample that is

to be analyzed.

1.3.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

WARNING

WARNING

892 Professional Rancimat

■■■■■■■■

3

Page 12

1.3 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

WARNING

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

WARNING

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

WARNING

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Protection against electrostatic charges

WARNING

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Do not fail to pull the mains cable out of the mains connection socket

before you set up or disconnect electrical plug connections at the rear

of the instrument.

■■■■■■■■

4

892 Professional Rancimat

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1.3.3 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. fume cup-

board).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.3.4 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

1 Introduction

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

892 Professional Rancimat

■■■■■■■■

5

Page 14

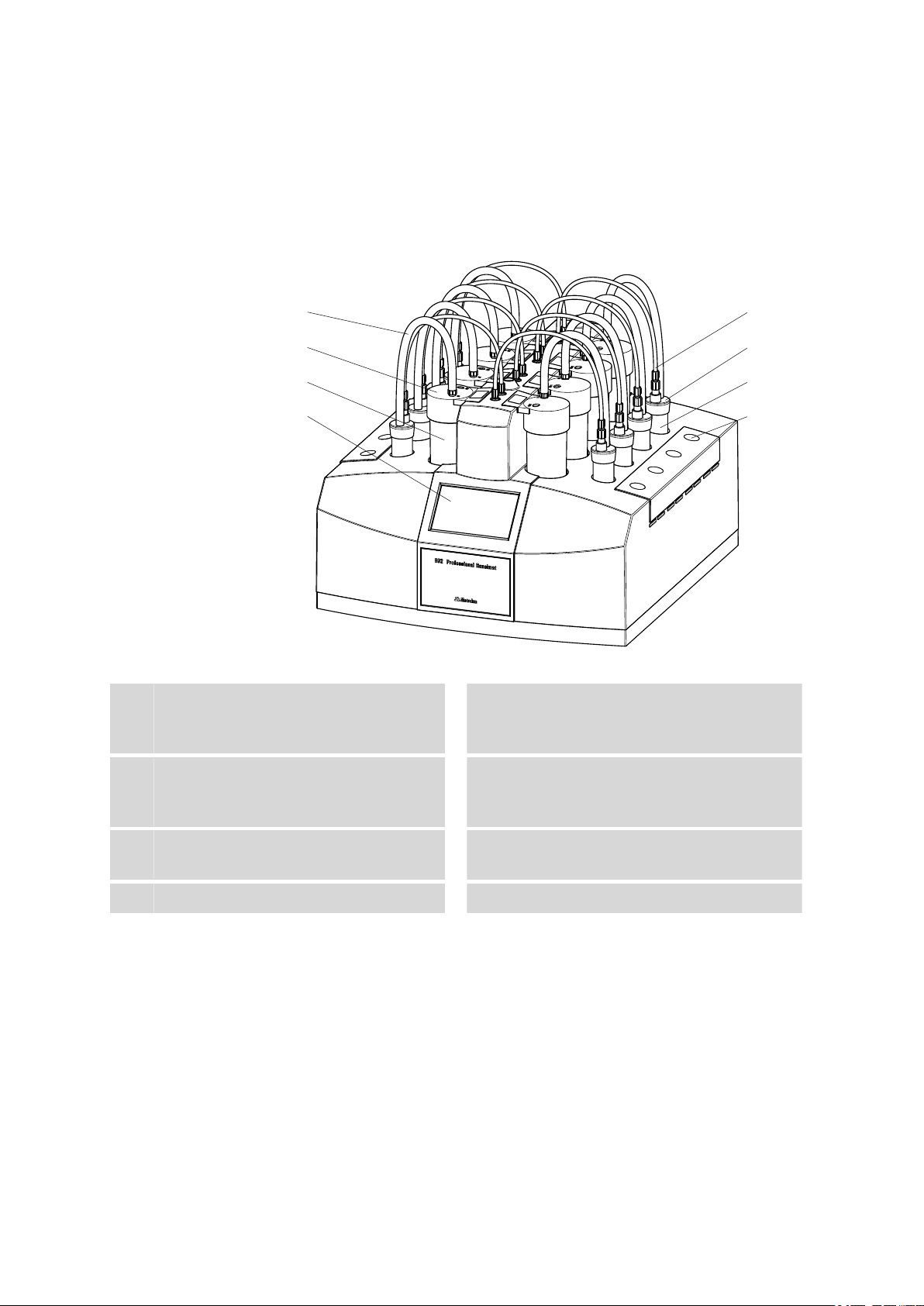

2.1 Front of the instrument

1

2

3

4

5

6

7

8

2 Overview of the instrument

2.1 Front of the instrument

■■■■■■■■■■■■■■■■■■■■■■

Figure 1 Front 892 Professional Rancimat

Silicone tubing (6.1816.010)

1

For connecting the reaction vessel to the

measuring vessel.

Measuring vessel (6.1428.107)

3

FEP tubing 250 mm (6.1805.080)

5

For supplying air into the reaction vessel.

Reaction vessels (6.1429.040)

7

Measuring vessel cover (6.0913.130)

2

Contains an integrated conductivity measuring cell.

Instrument display

4

Displays the status of the instrument and the

individual measuring positions.

Reaction vessel cover (6.2753.107)

6

Start buttons

8

■■■■■■■■

6

892 Professional Rancimat

Page 15

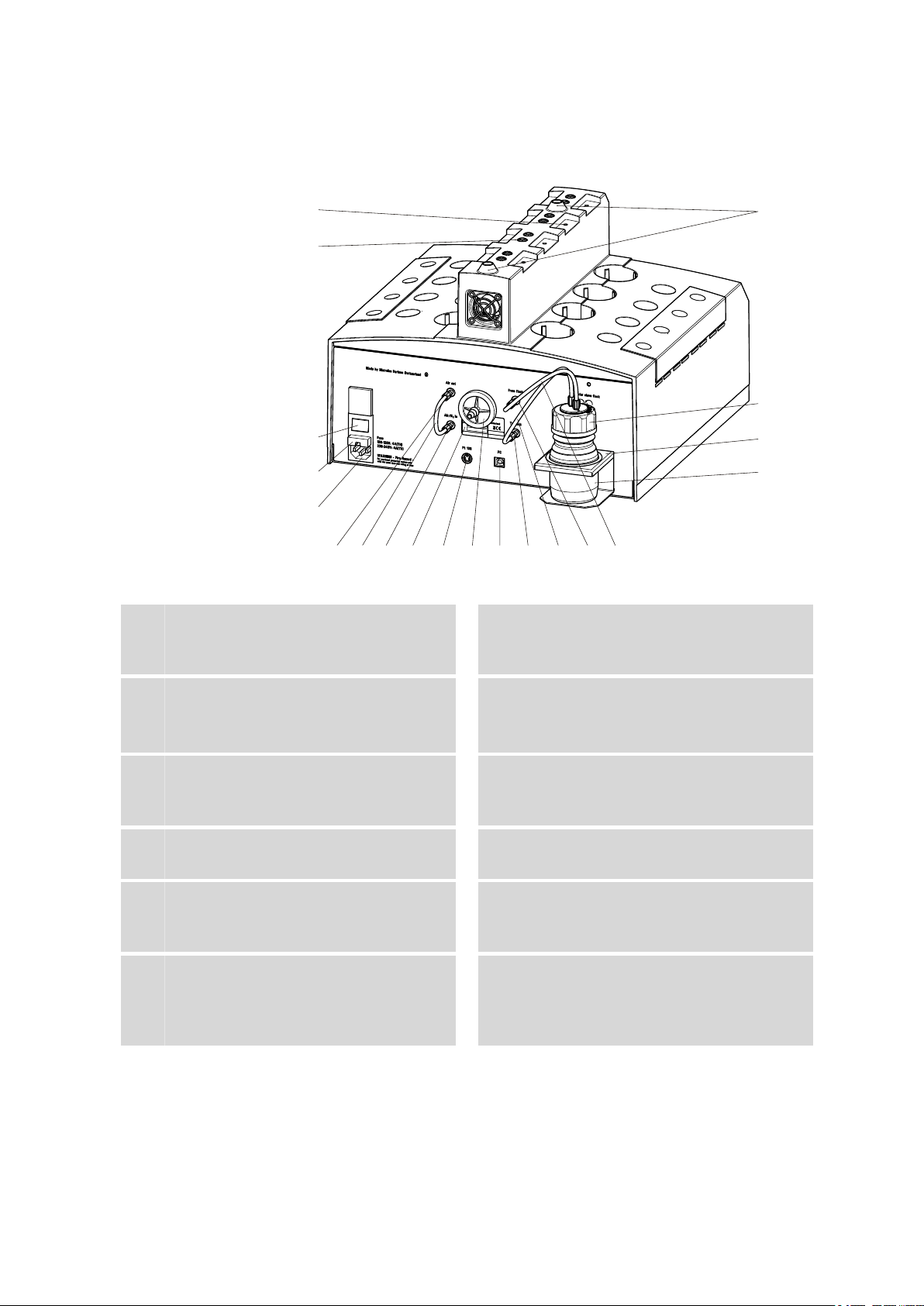

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15 16 17 18 19 20

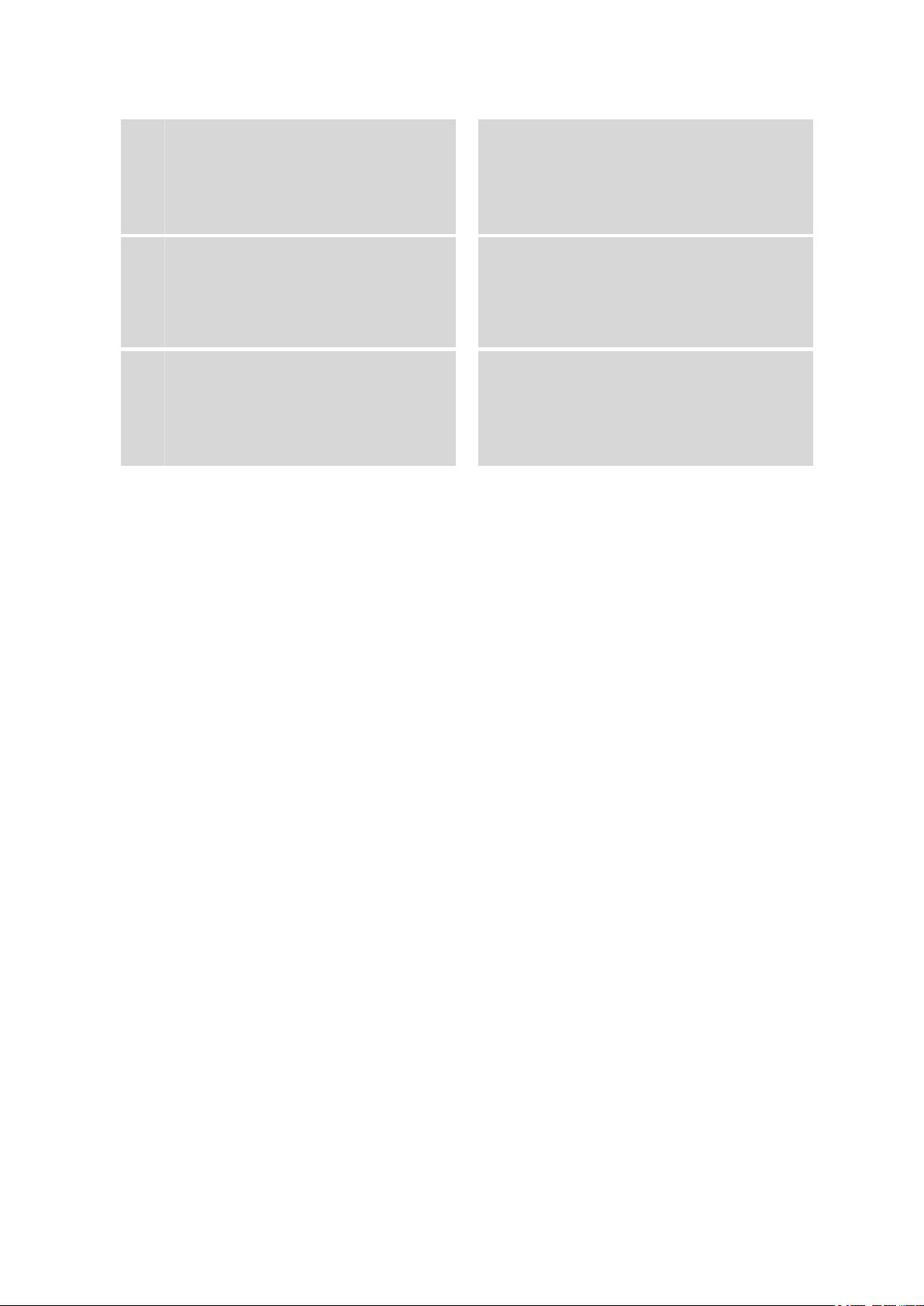

2.2 Rear of the instrument

2 Overview of the instrument

Figure 2 Rear 892 Professional Rancimat

Electrode connector

1

For connecting the conductivity measuring

cell integrated in the measuring vessel cover.

Power switch

3

For switching the instrument on and off.

I = ON / 0 = OFF.

Power socket

5

For important information on the power

connection, see Chapter 3.3.

Drying flask cap (6.1602.145)

7

Cap for the drying flask.

Drying flask (6.1608.050)

9

Drying flask filled with molecular sieve

(6.2811.000).

FEP tubing 130 mm (6.1805.010)

11

For connecting the Air out connector to the

Air/N2 in connector during normal opera-

tion with the internal air pump.

Air supply connector

2

For connecting the FEP tubing 250 mm.

Fuse holder

4

For replacing fuses (see Chapter 3.3.1, page

21).

Collection tube holder

6

For fastening the optional exhaust air collection tube (6.2757.000).

Bottle holder

8

For fastening the drying flask.

"Air out" connector

10

"Air/N2 in" connector

12

892 Professional Rancimat

■■■■■■■■

7

Page 16

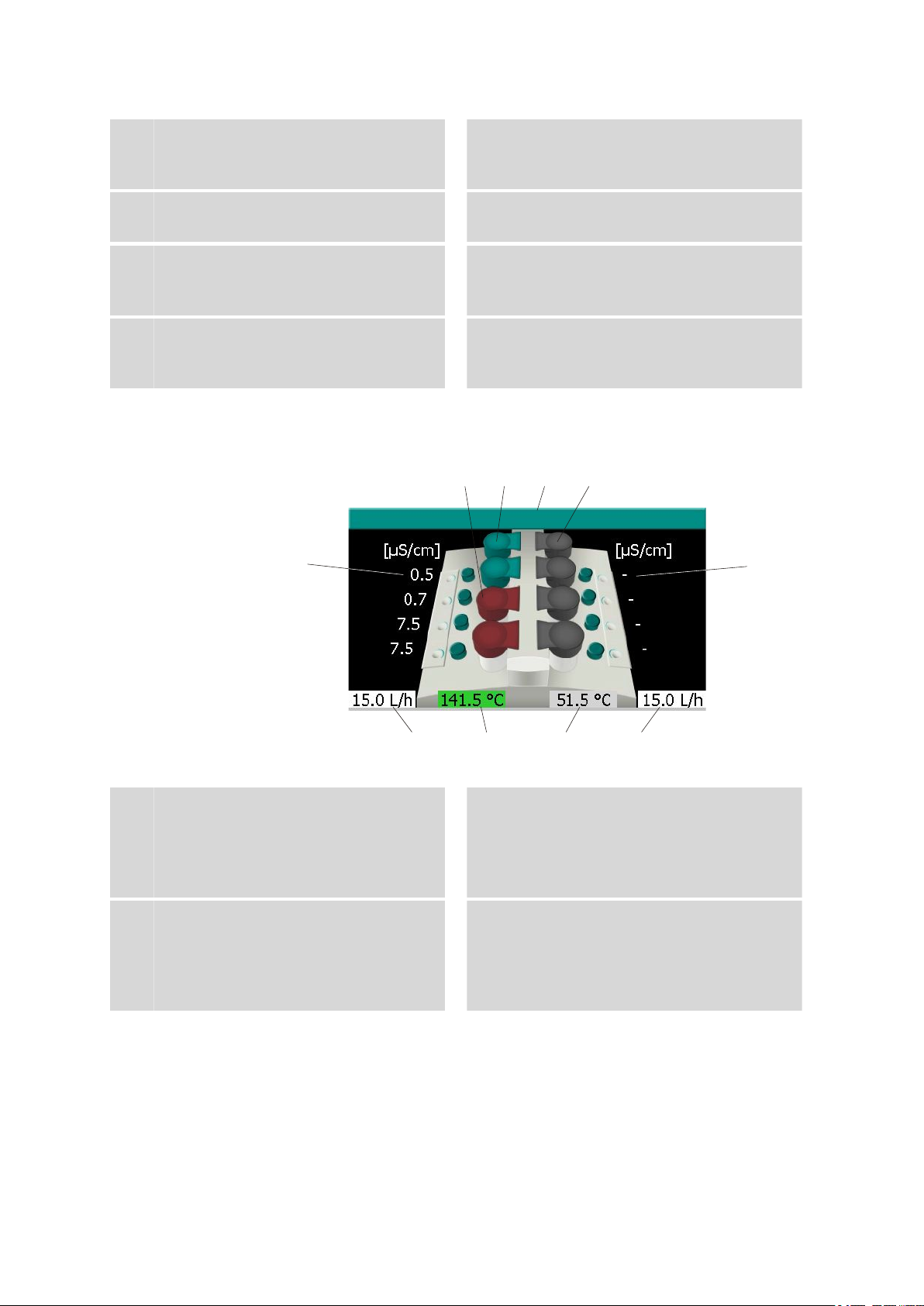

2.3 Instrument display

892_1

1 2 3 4

9 8 7 6

10

5

■■■■■■■■■■■■■■■■■■■■■■

Type plate

13

Contains specifications concerning supply

voltage and serial number.

Dust filter (6.2724.010)

15

"To flask" connector

17

"From flask" connector

19

2.3 Instrument display

Pt100 connector

14

For connecting an external temperature sensor.

USB connector

16

For connecting the computer.

FEP tubing 250 mm (6.1805.080)

18

For supplying the air from the internal pump

to the drying flask.

FEP tubing 250 mm (6.1805.080)

20

For supplying the air from the drying flask to

the reaction vessels.

1

3

■■■■■■■■

8

Figure 3

Measuring vessel cover red

This measuring position is not available for a

determination (determination is running or

multiple determination has not yet been

completed).

Instrument name

The instrument name display corresponds to

the configuration in StabNet.

Instrument display

Measuring vessel cover green

2

A determination can be started on this measuring position.

Measuring vessel cover gray

4

This measuring position is not available for

starting a determination (instrument not

connected to computer or no method loaded).

892 Professional Rancimat

Page 17

■■■■■■■■■■■■■■■■■■■■■■

2 Overview of the instrument

Conductivity display block B

5

Shows the measured conductivity.

Dash (-) is displayed = Conductivity cannot

be displayed (no sensor connected or no

valid measuring signal).

Temperature display block B

7

Shows the temperature measured on block

B (gray background: heater switched off; red

background: temperature not stable; green

background: temperature stable).

Gas flow display block A

9

Shows the gas flow measured on block A

(gray background: gas flow switched off;

white background: gas flow switched on).

Gas flow display block B

6

Shows the gas flow measured on block B

(gray background: gas flow switched off;

white background: gas flow switched on).

Temperature display block A

8

Shows the temperature measured on block

A (gray background: heater switched off;

red background: temperature not stable;

green background: temperature stable).

Conductivity display block A

10

Shows the measured conductivity.

Dash (-) is displayed = Conductivity cannot

be displayed (no sensor connected or no

valid measuring signal).

892 Professional Rancimat

■■■■■■■■

9

Page 18

3.1 Setting up the instrument

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

■■■■■■■■■■■■■■■■■■■■■■

Place the instrument in a location of the laboratory which is suitable for

operation and free of vibrations and which provides protection against

corrosive atmosphere and contamination by chemicals to the extent possible.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

NOTE

In order to improve accessibility of the measuring positions, the instrument can also be placed on the optionally available turning ring

(6.2059.000).

■■■■■■■■

10

892 Professional Rancimat

Page 19

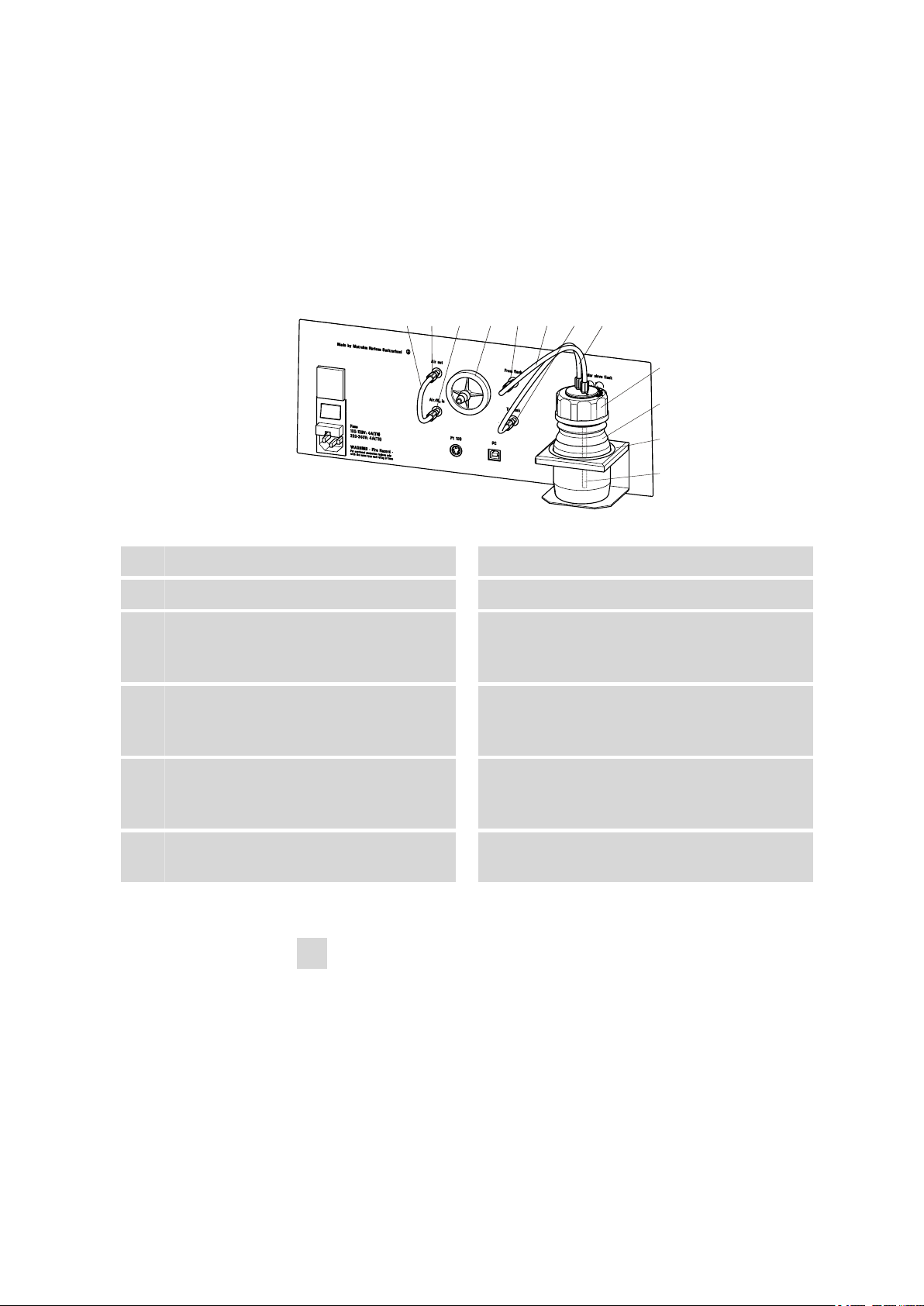

■■■■■■■■■■■■■■■■■■■■■■

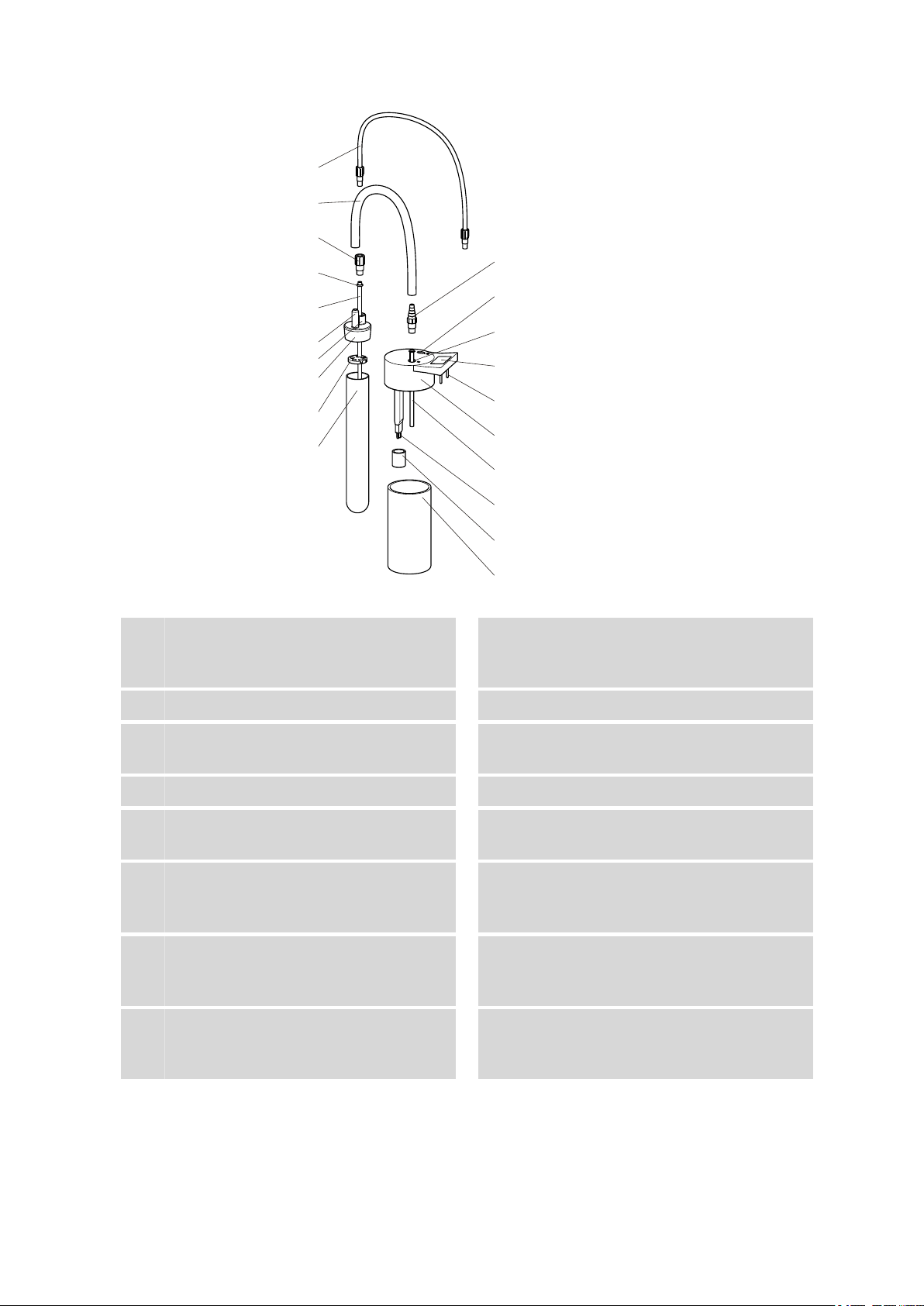

1 2 3 4 5 6 7 8

9

10

11

12

3.2 Mounting accessories

3.2.1 Mounting the internal air supply

The gas in the 892 Professional Rancimat is normally supplied using the

internal air pump, which aspirates laboratory air. For air supply and

air purification, the following accessories must be mounted on the rear of

the 892 Professional Rancimat:

3 Installation

Figure 4 Mounting accessories for the air supply

FEP tubing 130 mm (6.1805.010)

1

"Air/N2 in" connector

3

"From flask" connector

5

"To flask" connector

7

Drying flask cap (6.1602.145)

9

Cap for the drying flask.

Bottle holder

11

For fastening the drying flask.

Mount the accessories for the air supply as follows:

"Air out" connector

2

Dust filter (6.2724.010)

4

FEP tubing 250 mm (6.1805.080)

6

For supplying the air from the drying flask to

the reaction vessel.

FEP tubing 250 mm (6.1805.080)

8

For supplying the air from the internal pump

to the drying flask.

Drying flask (6.1608.050)

10

Drying flask filled with molecular sieve

(6.2811.000).

Filter tube (6.1821.040)

12

1

Mounting the dust filter

■ Insert the dust filter on the connector marked with Filter on the

rear of the 892 Professional Rancimat.

■ If the laboratory air is heavily contaminated, a tubing for supply-

ing fresh air can be connected to the dust filter.

892 Professional Rancimat

■■■■■■■■

11

Page 20

3.2 Mounting accessories

■■■■■■■■■■■■■■■■■■■■■■

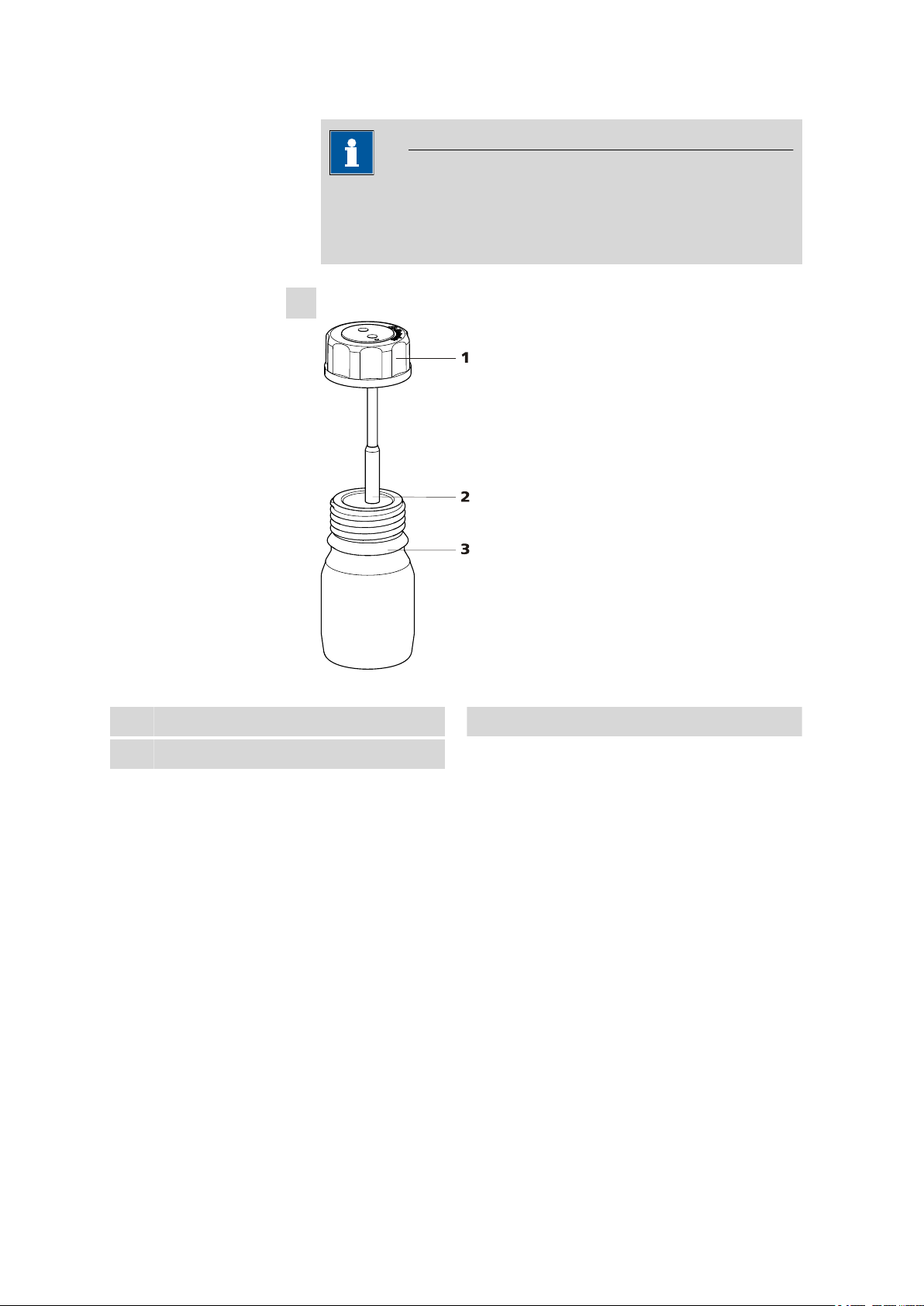

NOTE

The dust filter serves for filtering the air aspirated through the air

pump and must be replaced at periodic intervals (see Chapter 5.2,

page 41).

2

Mounting the drying flask

Drying flask cap (6.1602.145)

1

Bottle (6.1608.050)

3

Figure 5 Drying flask - Individual parts

Filter tube (6.1821.040)

2

■ Fill the molecular sieve into the drying flask.

■ Screw the filter tube on the bottom side of the drying flask cap

into the opening marked with a dot (on the upper side).

■ Screw the drying flask cap with mounted filter tube onto the dry-

ing flask and insert it in the flask holder on the rear of the 892

Professional Rancimat.

■ Screw one end of the FEP tubing 250 mm to the opening on the

drying flask cap marked with a dot.

■ Screw the other end of the FEP tubing to the From flask connec-

tor on the rear of the 892 Professional Rancimat.

■ Screw one end of the second FEP tubing 250 mm to the second

opening on the drying flask cap.

■ Screw the other end of the second FEP tubing to the To flask

connector.

■■■■■■■■

12

892 Professional Rancimat

Page 21

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

Figure 6 Drying flask mounted in place

NOTE

The molecular sieve serves to adsorb interfering oxidizing gases as

well as water from the aspirated air.

You can regenerate it in the drying oven at +140 - +180 °C for 24

to 48 h (see Chapter 5.3, page 41).

3

Mount the FEP tubing for the air supply

■ Screw one end of the FEP tubing 130 mm to the Air out connec-

tor.

■ Screw the other end of the FEP tubing to the Air/N

tor.

3.2.2 Mounting the external air supply

If the laboratory air is heavily contaminated, an external gas supply with

synthetic air can be provided.

For this, the corresponding accessories must be mounted on the rear of

the 892 Professional Rancimat.

NOTE

If air is supplied externally, the gas flow cannot be regulated in the

computer program.

in connec-

2

892 Professional Rancimat

The gas flow must be set manually using the reducing valve and the gas

flow display.

■■■■■■■■

13

Page 22

3.2 Mounting accessories

Mount the accessories for the external air supply as follows:

1

Mounting the FEP tubing

■ Screw one end of the FEP tubing 130 mm to the Air/N

nector (2-12) on the rear of the 892 Professional Rancimat.

■ Screw the tubing adapter M6/olive (6.1808.020) onto the other

end of the FEP tubing.

2

Connecting the gas supply

■ Mount the compressed air bottle on the M6/olive tubing adapter

(6.1808.020).

■ Adjust the air flow by means of the reducing valve at the com-

pressed air bottle.

3.2.3 Assembling the reaction and measuring vessels

The following figure shows in detail how the accessory parts for measuring the oxidation stability have to be mounted and connected to one

another.

■■■■■■■■■■■■■■■■■■■■■■

in con-

2

■■■■■■■■

14

892 Professional Rancimat

Page 23

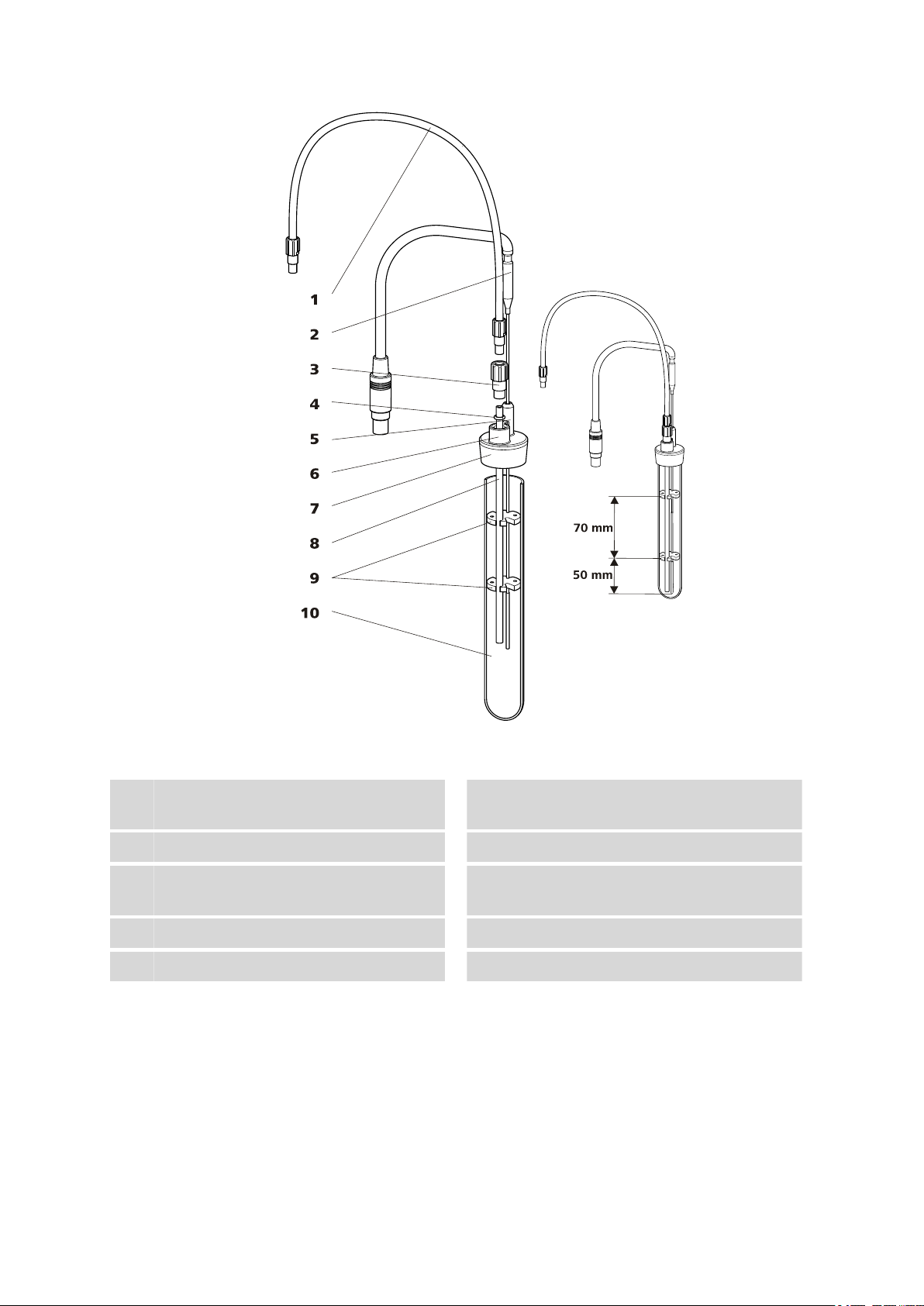

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

3 Installation

Figure 7 Equipping the reaction and measuring vessels

FEP tubing 250 mm (6.1805.080)

1

For supplying air into the reaction vessel.

Thread adapter M8/M6 (6.1808.090)

3

Air tube (6.2418.100)

5

Thread adapter M8/M6 connector

7

Foam barrier (6.1451.010)

9

Optional foam barrier.

Tubing adapter M8/olive (6.1808.050)

11

For connecting the silicone tubing to the In

opening.

Opening "In"

13

For supplying the air to the measuring vessel.

Connector plug

15

892 Professional Rancimat

Silicone tubing (6.1816.010)

2

For connecting the reaction vessel to the

measuring vessel.

O-ring (6.1454.040)

4

Tubing connector

6

For connecting the silicone tubing.

Reaction vessel cover (6.2753.107)

8

Reaction vessel (6.1429.040)

10

Opening "Out"

12

For removing the air from the measuring

vessel.

Label field

14

For attaching labels (e.g. 6.2250.000 laminated labels).

Measuring vessel cover (6.0913.130)

16

Contains an integrated conductivity measuring cell.

■■■■■■■■

15

Page 24

3.2 Mounting accessories

■■■■■■■■■■■■■■■■■■■■■■

PTFE cannula (6.1819.080)

17

For supplying the air to the measuring solution.

Protection ring

19

Proceed as follows to mount the measuring vessel and the reaction vessel:

1

Mounting the measuring vessel cover

■ Screw the PTFE cannula from above into the In opening of the

■ Screw the M8/olive tubing adapter into the In opening of the

■ Pour 50 - 80 mL of deionized water into the measuring vessel (the

■ Place the measuring vessel cover onto the measuring vessel.

2

Mounting the reaction vessel cover

■ Place the O-ring (6.1454.040) over the upper end of the air tube.

■ Feed the air tube (6.2418.xx0) into the connector of the reaction

■ Gently screw the M8/M6 thread adapter into the connector while

■ Optional: If determinations are being carried out with highly

■ Blow out the reaction vessel with nitrogen to free it from foreign

■ Before putting the cover in place, briefly rotate the upper part of

■ Place the reaction vessel cover on the reaction vessel.

Electrode

18

Measuring vessel (6.1428.107)

20

measuring vessel cover.

measuring vessel cover.

exact quantity depends on the application).

vessel cover (6.2753.107) from above.

pressing the air tube against the thread adapter from below. Then

fix the air tube onto the reaction vessel cover by firmly tightening

the thread adapter.

foaming samples, clamp the foam barrier (6.1451.010) onto the

air tube.

substances (e.g. dust or cardboard shreds).

the reaction vessel in your hand. This slightly lubricates the glass

and facilitates removal of the covers after the measurement.

■■■■■■■■

16

NOTE

When mounted without foam barrier, the air tube must be in a vertical

position in the reaction vessel.

892 Professional Rancimat

Page 25

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

Figure 8 Mounting the air tube: correct - incorrect

WARNING

The foam barrier can melt if it projects too deeply into the heating

block.

Ensure that the foam barrier is at least 7 cm above the base of the

reaction vessel.

Figure 9

Mounting the foam barrier

3.2.4 Inserting vessels / Establishing tubing connections

After you have assembled the reaction and measuring vessels, insert them

in the 892 Professional Rancimat and establish the tubing connections

(see Chapter 2.1, page 6) as follows:

1

Inserting the measuring vessel

■ Fill distilled water into the measuring vessel.

■ Place the measuring vessel cover onto the measuring vessel.

■ Insert the measuring vessel into the openings provided on the 892

Professional Rancimat. While doing so, carefully guide the connector plug into the electrode connector.

■ Connect the white silicone tubing to the M8/olive tubing adapter

of the measuring vessel cover.

892 Professional Rancimat

■■■■■■■■

17

Page 26

3.2 Mounting accessories

■■■■■■■■■■■■■■■■■■■■■■

2

Mounting the tubing for the air supply

■ Screw the FEP tubing 250 mm to the air supply connections of

the 892 Professional Rancimat.

3

Inserting the reaction vessel

■ Fill the reaction vessel with the sample.

■ After the required reaction temperature has been reached, insert

the reaction vessel with the mounted reaction vessel cover in the

openings provided on the 892 Professional Rancimat.

4

Establishing the tubing connections

■ Connect the white silicone tubing that is connected to the mea-

suring vessel cover to the tubing connector of the reaction vessel

cover.

■ Screw the FEP tubing 250 mm which is connected to the M8/olive

tubing adapter of the 892 Professional Rancimat to the M8/M6

thread adapter of the reaction vessel cover.

NOTE

The optional clear glass measuring vessels (6.1428.030) [Link target not

found in publication context!] may also be used in place of the polystyr-

ene measuring vessel (6.1428.107).

In contrast to the polystyrene vessel, the measuring vessel (6.1428.030)

can also be cleaned with acetone.

3.2.5 Mounting the exhaust air collection tube

The optional exhaust air collection tube (6.2757.000) [Link target not

found in publication context!] can be mounted on the 892 Professional

Rancimat for targeted removal of the exhaust air.

NOTE

A total of 8 pieces of silicone tubing (6.1816.010) (220 mm) are

required in addition to the exhaust air collection tube.

■■■■■■■■

18

892 Professional Rancimat

Page 27

■■■■■■■■■■■■■■■■■■■■■■

Proceed as follows to mount the collection tube:

1

Mounting the exhaust air collection tube

■ Insert the exhaust air collection tube with both support pins into

the collection tube holders on the 892 Professional Rancimat in

such a way that the connector to the exhaust air removal is

located to the rear.

2

Connecting the measuring vessels

■ Screw the M8/olive tubing adapter into the Out opening of the

measuring vessel cover.

■ Connect one end of the silicone tubing to the M8/olive tubing

adapter.

■ Insert the other end of the silicone tubing into the corresponding

opening on the collection tube.

■ Seal the unused openings on the collection tube with the

enclosed stoppers.

3

Connecting the exhaust air collection tube

■ Connect a suitable tubing to the connector of the exhaust air col-

lection tube and connect it to an active suction device (e.g. water

jet pump).

3 Installation

3.2.6 Mounting the oil separator

If samples with a high content of highly volatile compounds are used,

there is a risk that the sample is transferred to the measuring vessel in the

vapor phase. This can compromise the conductivity measurement. The

amount of oil contained in the vapor phase can be reduced by means of

the oil separator (6.2753.200). The use of the oil separator is recommended if the conductivity measurement is compromised by the presence of

the sample in the measuring vessel [Link target not found in publication

context!].

NOTE

An additional 8 pieces of silicone tubing (6.1816.010) are required if 8

oil separators are used.

NOTE

The oil separators must be cleaned after each measurement (see Chapter 4.3.5, page 38).

892 Professional Rancimat

■■■■■■■■

19

Page 28

3.2 Mounting accessories

1

2

3

4 5

■■■■■■■■■■■■■■■■■■■■■■

Figure 10 Mounting the oil separator

Oil separator (6.2753.200)

1

Oil separator with sealing cover (bottom).

Measuring vessel

3

Silicone tubing to the measuring vessel

5

Proceed as follows to mount the oil separator:

1

Clamping the oil separator in place

■ Clamp an oil separator in place on the side of each reaction vessel

2

Attaching the silicone tubing to the oil separator

■ Attach one end of the silicone tubing to the tubing connector of

■ Attach the other end of the silicone tubing to the inlet opening IN

3

Attaching the silicone tubing to the measuring vessel

■ Attach one end of the silicone tubing to the outlet opening OUT

■ Attach the other end of the silicone tubing to the tubing connec-

Reaction vessel

2

Silicone tubing to the oil separator

4

(sealing cover on the bottom).

the reaction vessel.

of the oil separator.

of the oil separator.

tor of the measuring vessel.

■■■■■■■■

20

892 Professional Rancimat

Page 29

■■■■■■■■■■■■■■■■■■■■■■

3.3 Power socket

There is a risk of fire if the instrument is operated with an incorrect

mains fuse!

Follow the regulations below for the mains connection.

3.3.1 Replacing fuses

The fuse holder of the 892 Professional Rancimat contains two fuses:

■ Two slow-acting 4 A fuses

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is a risk of fire!

3 Installation

WARNING

WARNING

Proceed as follows to replace defective fuses:

1

Pulling out the power supply cable

■ Pull the power supply cable out of the power socket of the 892

Professional Rancimat.

2

Removing the fuse holder

■ Release the fuse holder located on the rear of the instrument

above the power socket by pressing the catch spring and pull out

the holder completely.

3

Replacing the fuses

■ Carefully remove the defective fuses from the fuse holder and

replace them with two new slow-acting 4 A fuses:

4

Inserting the fuse holder

■ Push the fuse holder back into the instrument until it latches into

place.

892 Professional Rancimat

■■■■■■■■

21

Page 30

3.3 Power socket

3.3.2 Power supply cable and power socket

Power supply cable

The instrument is supplied with a three-core power supply cable and a

plug with protective grounding. If another plug has to be mounted, then

the yellow/green conductor (IEC standard) must be connected to the protective ground (protection class 1).

WARNING

Any interruption to the grounding within or outside the instrument can

make it dangerous!

Power socket

Plug the power supply cable into the power socket (2-5) of the 892 Professional Rancimat.

3.3.3 Switching the instrument on and off

The 892 Professional Rancimat is switched on and off using the power

switch (2-3). The instrument display is switched on when the instrument is

switched on.

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

22

Figure 11

Instrument display with instrument name

The instrument 892 Professional Rancimat has been recognized by the

StabNet computer program and the instrument name entered has been

transmitted.

Figure 12

Instrument display with "no connection" symbol

The USB connection between the instrument 892 Professional Rancimat

and the computer has been interrupted and the corresponding symbol is

displayed.

892 Professional Rancimat

Page 31

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

Figure 13 Instrument display without instrument name and symbol

The instrument 892 Professional Rancimat is connected to the computer

but the StabNet computer program has been closed.

Figure 14

Instrument display with serial number

The instrument 892 Professional Rancimat has been started, but the StabNet computer program was not previously started.

3.4 Connecting a computer

3.4.1 Connecting the 892 Professional Rancimat and the computer

NOTE

The StabNet computer program has to be installed before you can

connect the instrument to the computer.

The StabNet computer program allows you to control up to 4 instruments.

Connect and set up the 892 Professional Rancimat as follows:

Establish a connection between the USB interface (2-16) of the 892

1

Professional Rancimat and the required USB interface on the computer using the USB cable (6.2151.130).

Start the StabNet computer program.

2

Switch on the 892 Professional Rancimat using the power switch.

3

892 Professional Rancimat

■■■■■■■■

23

Page 32

3.4 Connecting a computer

■■■■■■■■■■■■■■■■■■■■■■

Wait for the instrument 892 Professional Rancimat to be detected

4

and installed.

Enter the instrument information into the dialog fields of the 892

5

Professional Rancimat configuration.

NOTE

You will find detailed information regarding the StabNet computer program in the Tutorial.

The instrument name entered in the configuration must appear on

the instrument display (3-3).

■■■■■■■■

24

892 Professional Rancimat

Page 33

■■■■■■■■■■■■■■■■■■■■■■

4 Operation

4.1 Rancimat method

The decay of vegetable and animal fats, which can be perceived in the initial stage through a deterioration of odor and taste (rancidity), is to a

great extent the result of chemical modifications caused by the effect of

atmospheric oxygen. These oxidation processes, which progress slowly at

ambient temperatures, are referred to as autoxidation. They start with

radical reactions on unsaturated fatty acids and undergo a process involving multiple stages resulting in diverse decomposition products, in particular peroxides as primary oxidation products and alcohols, aldehydes and

carboxylic acids as secondary oxidation products.

In the Rancimat method, the sample is exposed to an air flow at a constant temperature between 100 - 140 °C. Highly volatile, secondary oxidation products (for the most part formic acid and acetic acid) are transferred into the measuring vessel with the air flow, where they are absorbed

in the measuring solution (distilled water). Here the conductivity is continuously registered. The organic acids can thus be detected by an increase

in the conductivity. The time until these secondary reaction products occur

is referred to as the induction time or induction period, which is a good

characteristic for the oxidation stability.

4 Operation

The Rancimat method has been developed as an automated variant of the

extremely complex AOM (active oxygen method) for determining the

induction time of fats and oils. This method has become established

over the course of time and has been incorporated in various national and

international standards, e.g. AOCS Cd 12b-92 and ISO 6886.

892 Professional Rancimat

■■■■■■■■

25

Page 34

4.2 Calibration functions

■■■■■■■■■■■■■■■■■■■■■■

Figure 15 Measuring arrangement (schematic representation)

Reaction vessel

1

Heating block

3

Conductivity measuring cell

5

4.2 Calibration functions

4.2.1 Determining the cell constant

The cell constant of the conductivity sensor (6.0913.130) is normally at

1.1 ± 0.1 cm-1. This accuracy is sufficient for an induction time determination since only the shape of the curve is evaluated. For the determination of the stability time, however, the conductivity change is measured

in absolute terms. As a rule, the time until an increase in conductivity of

50 µS/cm is determined. The cell constant for the conductivity electrode

being used has to be calibrated in order to be able to measure the conductivity correctly.

Sample

2

Measuring vessel

4

Measuring solution

6

■■■■■■■■

26

892 Professional Rancimat

Page 35

■■■■■■■■■■■■■■■■■■■■■■

The cell constants can be either entered manually or determined automatically by means of a defined standard solution, e.g. the conductivity standard 100 µS/cm (6.2324.010).

NOTE

You will find detailed information regarding the StabNet computer

program in the Tutorial.

4.2.2 Determining the temperature correction

Temperature correction indicates the deviation of the current sample

temperature from the temperature of the heating block and forms part of

the method as a parameter.

It can be determined automatically with the calibrated, external temperature sensor.

4 Operation

892 Professional Rancimat

■■■■■■■■

27

Page 36

4.2 Calibration functions

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

28

Figure 16 Assembling the reaction vessel for determining the tempera-

FEP tubing 250 mm (6.1805.080)

1

For supplying air into the reaction vessel.

Thread adapter M8/M6 (6.1808.090)

3

Temperature sensor opening

5

For inserting the temperature sensor.

Reaction vessel cover (6.2753.107)

7

Spacer (6.2042.040)

9

ture correction

Pt100 temperature sensor

2

(6.1111.010)

O-ring (6.1454.040)

4

Connector

6

For connecting the thread adapter M8/M6.

Air tube (6.2418.100)

8

Reaction vessel (6.1429.040)

10

892 Professional Rancimat

Page 37

■■■■■■■■■■■■■■■■■■■■■■

4 Operation

Preparing the determination of the temperature correction

The figure shows in detail how the accessory parts are to be assembled

for the determination of the temperature correction. Proceed as follows:

1

Preparing the reaction vessel cover

■ Mount the air tube on the reaction vessel cover.

■ Clamp the first spacer at a distance of approx. 12 cm from the

lower end onto the air tube.

■ Clamp the second spacer at a distance of approx. 5 cm from the

lower end onto the air tube.

■ Insert the temperature sensor from above into the temperature

sensor opening and fasten it in the corresponding openings of the

spacers.

2

Preparing the reaction vessel

■ Fill the reaction vessel with 6 g silicone oil (6.2326.000).

■ Place the reaction vessel cover with the temperature sensor on

the reaction vessel.

■ Push the temperature sensor all the way down (the sensor must

touch the vessel base).

3

Inserting and connecting the reaction vessel

■ Insert the reaction vessel with the mounted reaction vessel cover

in the measuring position 2 or 3 of the required heating block.

■ Screw one end of the FEP tubing 250 mm to the M8/M6 thread

adapter of the reaction vessel cover.

■ Screw the other end of the FEP tubing to the corresponding con-

nector of the 892 Professional Rancimat.

■ Connect the temperature sensor to the Pt100 connector (2-14)

on the rear of the 892 Professional Rancimat.

892 Professional Rancimat

NOTE

You will find detailed information regarding the StabNet computer

program in the Tutorial.

■■■■■■■■

29

Page 38

4.3 Determinations

4.3 Determinations

4.3.1 Preparing a sample

Use new reaction vessels and air tubes for each measurement.

Blow out the reaction vessels with nitrogen before use.

This chapter contains information on how to prepare the following samples:

■ Pure, clear oils (see page 30)

■ Non-liquid, pure fats (see page 30)

■ Samples containing oil and fat (see page 31)

■ Emulsion fats (see page 33)

■ Solid samples (e.g. PVC) (see page 34)

■■■■■■■■■■■■■■■■■■■■■■

NOTE

Preparing pure, clear oils

Prepare oil that is completely pure and clear as follows:

1

Weighing in the sample

■ Place the reaction vessel on a scale using a 6.2628.000 holder.

■ Weigh the sample material directly in the reaction vessel.

Normally, 3 g of sample material are used for vegetable oils.

2

Checking the filling level

■ Make sure that the quantity of sample material in the reaction

vessel is sufficient so that the air tube is immersed deeply enough.

If this is not the case, add more sample material.

Preparing non-liquid, pure fats

Prepare non-liquid, pure fat as follows:

1

Weighing in the sample

either

■■■■■■■■

30

■ Completely liquefy the fat in a water bath or in a drying oven at

a temperature exceeding its melting point by 10 °C.

■ Place the reaction vessel on a scale using a 6.2628.000 holder.

892 Professional Rancimat

Page 39

■■■■■■■■■■■■■■■■■■■■■■

4 Operation

■ Then transfer 3 g sample material to the reaction vessel using

preheated pipettes.

or

■ Place the reaction vessel on a scale using a 6.2628.000 holder.

■ Weigh in the fat as solid.

For this, weigh in 3 g sample material directly in the reaction

vessel and insert it briefly in the heated block of the 892 Professional Rancimat, so that the fat melts.

2

Checking the filling level

■ Make sure that the quantity of melted sample material in the

reaction vessel is sufficient so that the air tube is immersed deeply

enough. If this is not the case, add more sample material.

Preparing samples containing oil and fat

Oils and fats made from products containing oil and fat must be extracted

with petroleum ether (low-boiling) while being protected from light as follows:

1

Crushing the samples

■ Finely and homogeneously grind oilseed fruit, cocoa beans as well

as other solids in coarse form in a knife mill or another suitable

crushing apparatus (if possible, metal-free).

NOTE

Oil/fat extraction through pressing has not proven effective in

practice.

2

Extraction

■ Prepare a 300 mL Erlenmeyer flask with standard ground-joint.

■ Weigh in between 50 and 100 g (depending on the oil/fat con-

tent) of the sample in powder form (e.g. milk powder, cocoa

powder, hazelnut powder) or the finely ground material.

■ Cover the sample material with a layer of approx. 1 cm of petro-

leum ether (low-boiling).

■ Extract the oil or fat while continuously stirring for around 12 h

and keeping it protected from light.

892 Professional Rancimat

■■■■■■■■

31

Page 40

4.3 Determinations

■■■■■■■■■■■■■■■■■■■■■■

NOTE

In order to carry out at least one double determination on the 892

Professional Rancimat, you have to extract approx. 10 g pure oil or

fat, allowing for a certain transfer loss (for more than two determinations, an accordingly higher amount is necessary).

■ Prepare a clean 250 mL round-bottom flask with standard

ground-joint and a folded filter.

■ Filtrate, if possible protected from light. Rewash the residue with

a little petroleum ether.

NOTE

If the folded filter becomes blocked (e.g. due to the consistency of

the sample material), a Soxhlet apparatus should be used for solid/

liquid separation. You can use up to 40 g of sample material per

batch.

3

Distillation and filtration

■ Distill the petroleum ether from the clear, perhaps slightly yellow

extract.

NOTE

It is safest and easiest if you do this in a rotary evaporator; in a

slight vacuum, protected from direct light (cover the water bath

e.g. with aluminum foil) and at a temperature of +30 - 35 °C the

petroleum ether can gently and efficiently be removed.

■ Dry the oil/fat sample after the distillation has been completed for

approx. 30 min at a pressure of < 1,330 Pa (13.3 mbar).

■ Filtrate the oil/fat sample now present together with water-free

Na2SO4 with a folded filter. If necessary, work in the drying oven

at a temperature exceeding the melting point of this fat by 10 °C.

4

Further sample preparation

■ Treat the isolated oil/fat samples afterwards just as pure oils and

fats.

■■■■■■■■

32

892 Professional Rancimat

Page 41

■■■■■■■■■■■■■■■■■■■■■■

4 Operation

NOTE

If the isolated oil/fat samples are not immediately analyzed, you

have to store the samples in a cool place and protected from

light; for storing the samples, you should cover them in their vessels with a nitrogen layer. This type of storage does not provide

complete protection against unintended and uncontrolled changes

in the oxidation stability, but it represents a useful preservation in

many cases.

You can find further information on the treatment of oil and fat samples

in Rancidity in Foods, Allen J.C., Hamilton R.J., Applied Science Publish-

ers, London and New York, 1983.

Preparing emulsion fats

You can use emulsion fats like pure substances and prepare them as follows:

1

Weighing in the sample

■ Weigh in the sample.

NOTE

As the water evaporates right at the beginning of the analysis and

is carried away by the air blown through, you have to use correspondingly more sample material.

2

Mounting the foam barrier

■ Mount the foam barrier (see figure 9, page 17), as the samples

can foam heavily.

NOTE

If the emulsion fat samples are not immediately analyzed, you

need to store the samples in a cool place and protected from

light; for storing the samples, you should cover them in their vessels with a nitrogen layer. This type of storage does not provide

complete protection against unintended and uncontrolled changes

in the oxidation stability, but it provides useful preservation in

many cases.

892 Professional Rancimat

■■■■■■■■

33

Page 42

4.3 Determinations

Solid samples (e.g. nuts)

Prepare the sample as follows:

Place the reaction vessel on a scale using a 6.2628.000 holder.

1

If necessary, pulverize the sample material and weigh it directly in the

2

reaction vessel. Normally, 0.5 g of sample material is used.

Alternatively you can melt the emulsion fats (e.g. butter, margarine) at a

temperature exceeding the melting point of these fats by 10 °C (i.e. at

approx. +50 °C) centrifuge them and pipette off the resultant oil phase.

4.3.2 Preparing the instrument and the accessories

The cleanliness of instrument and accessory parts is an indispensable prerequisite for reliable, reproducible and correct analysis results. Even

the slightest contamination could catalytically accelerate the oxidative

decomposition and lead to completely incorrect results. Therefore, always

observe the instructions for use of measuring and reaction vessels in this

chapter.

■■■■■■■■■■■■■■■■■■■■■■

Check and prepare the instruments and vessels as follows:

1

Checking the positions for reaction vessels

■ Check whether the positions in the heating block are clean and

empty.

Blow out contamination and dust in the positions with nitrogen.

If the instrument is not used, always seal the corresponding positions with the stoppers.

2

Filling the measuring vessels

NOTE

Only use measuring vessels and accessories which are absolutely clean and in a flawless condition.

■ Fill the cleaned measuring vessels with 60 mL distilled water

each.

For analysis times of more than 24 h approx. 7 mL more distilled

water must be added per day to compensate for the evaporation

loss, so that the electrodes remain safely immersed.

■■■■■■■■

34

892 Professional Rancimat

Page 43

■■■■■■■■■■■■■■■■■■■■■■

3

Inserting the measuring vessels

■ Place the clean measuring vessel covers equipped with a PTFE

cannula on the measuring vessels.

■ Insert the measuring vessels with the measuring vessel covers into

the openings provided for this on the 892 Professional Rancimat

while carefully guiding the connector plugs of the cover into the

electrode connectors.

4

Weighing in samples

NOTE

Use new reaction vessels and air tubes for each measurement. Blow out the reaction vessels with nitrogen before use so

that any adhering particles are removed.

■ Weigh in 3 g of the samples in each reaction vessel (see Chap-

ter 4.3.1, page 30).

5

Mounting the accessories

■ Hold the upper edge of the reaction vessel in your hand (e.g. in

the recess between your thumb and index finger) and rotate the

glass once.

This serves to cover the degreased glasses with a light fat film so

that the vessel covers can be removed more easily after the determination.

■ Insert an air tube into the connector of the reaction vessel cover,

fix it with the O-ring and fasten it by screwing in the M8/M6

thread adapter.

■ Place the reaction vessel cover on the reaction vessel. Turn the

cover in such a way that the air tube is as close as possible to the

vessel wall.

■ Connect the white silicone tubing to the tubing connector of the

reaction vessel cover.

■ Place the prepared reaction vessel in the vessel holder.

4 Operation

4.3.3 Preparing the determination

1

Selecting the method (StabNet)

■ In the Workplace program part, click on the symbol within the

block A area and select a Method for block A.

■ If required, also select a method for block B.

892 Professional Rancimat

■■■■■■■■

35

Page 44

4.3 Determinations

■■■■■■■■■■■■■■■■■■■■■■

NOTE

Different methods with different temperatures can be selected for

block A and block B.

The gas flow for the two blocks A and B cannot be switched on

and off individually for each block but only collectively. If methods

with different gas flows are loaded on the two blocks, then the

value from the block in which the gas flow is switched on is used.

2

Starting the heater (StabNet)

■ In the Workplace program part, click on the [Start] button for

Heater within the block A area.

■ If required, also switch on the heater for Block B.

The color of the temperature display on the 892 Professional Rancimat changes to red during the heating phase.

The color of the temperature display on the 892 Professional Rancimat changes to green once the setpoint temperature has been

reached.

Heating period to 120 °C: approx. 45 min.

Heating period to 200 °C: approx. 60 min.

NOTE

If you wish to switch off the heating, click on the [Stop] button.

3

Enter sample identification (StabNet)

■ Enter the sample identifications Ident and Info 1 - 3 for all sam-

ple positions used.

The entries for Ident and Info 1 - 3 can be selected from the Text

templates.

NOTE

■■■■■■■■

36

The Info 2 and Info 3 info fields can be activated in the subwindow Properties - Sample data in the Method program

part.

892 Professional Rancimat

Page 45

■■■■■■■■■■■■■■■■■■■■■■

4

Connecting and inserting reaction vessels

NOTE

The temperature defined in the method has to be reached before

you insert the reaction vessels, i.e., the temperature display has to

be green.

■ Seal the unused positions with stoppers or empty reaction vessels

for protection against impurities.

■ Connect the white silicone tubing which is connected to the reac-

tion vessel covers to the M8/olive tubing adapter of the measuring vessel covers.

■ Screw the pieces of FEP tubing 250 mm to the M8/M6 thread

adapters of the reaction vessel covers and the air supply connectors of the 892 Professional Rancimat.

■ Insert the prepared reaction vessels into the recesses of the heat-

ing block.

■ Press the start button to start the data recording immediately

after inserting each single reaction vessel.

4 Operation

4.3.4 Cleaning the accessories

1

Cleaning the measuring vessels and accessories

■ Clean used measuring vessels after pouring off the measuring

solution with ethanol or 2-propanol (do not use acetone!) or in

the dishwasher.

Pre-clean with dishwashing detergent in the case of severe contamination.

■ Pre-clean with dishwashing detergent in the case of severe con-

tamination.

■ Thoroughly rinse with distilled water.

■ Clean the measuring vessel covers, the PTFE cannula and the

electrodes with acetone or 2-propanol or in the dishwasher and

thoroughly rinse with distilled water.

Pre-clean with dishwashing detergent in the case of severe contamination.

Remove the protective ring to facilitate cleaning of the electrodes.

2

Cleaning the reaction vessels and accessories

■ Dispose of used reaction vessels and air tubes and use new

reaction vessels and air tubes for the next measurement.

892 Professional Rancimat

■■■■■■■■

37

Page 46

4.3 Determinations

■■■■■■■■■■■■■■■■■■■■■■

■ Clean the reaction vessel covers with acetone or 2-propanol or

in the dishwasher and rinse with distilled water.

Pre-clean with dishwashing detergent in the case of severe contamination.

■ Then heat the reaction vessel covers in the drying oven for 2

hours at 80 °C.

NOTE

Replace the reaction vessel covers if they no longer sit tightly on

the reaction vessel or the material is brittle.

3

Cleaning the tubing

■ Clean the silicone tubing with acetone or 2-propanol or in the

dishwasher and rinse with distilled water.

Pre-clean with dishwashing detergent in the case of severe contamination.

■ Then heat the silicone tubing in the drying oven for 2 hours at

80 °C.

4.3.5 Cleaning the oil separator

Figure 17

Body

1

Body with the IN and OUT connectors.

1

Disassembling the oil separator

■ Remove the base.

Oil separator (6.2753.200), disassembled

Base

2

Base with O-ring (6.1454.050) used for sealing the oil separator.

■■■■■■■■

38

892 Professional Rancimat

Page 47

■■■■■■■■■■■■■■■■■■■■■■

NOTE

Remove the base carefully.

Do not use sharp or pointed tools.

2

Cleaning the oil separator bodies

■ Clean the oil separator bodies with acetone or 2-propanol or in

the dishwasher and rinse with distilled water.

Pre-clean with dishwashing detergent in the case of severe contamination.

■ Then heat the oil separator bodies in the drying oven for 2

hours at 80 °C.

3

Cleaning the oil separator bases

■ Clean the oil separator bases with 2-propanol or in the dish-

washer and rinse with distilled water.

Pre-clean with dishwashing detergent in the case of severe contamination.

■ Then heat the oil separator bases in the drying oven for 2

hours at 80 °C.

■ Mount new O-rings where necessary.

4 Operation

NOTE

Do not allow the oil separator bases to come into contact with

acetone for extended periods of time.

NOTE

Replace the O-rings if they no longer sit tightly on the body or if

the material is brittle.

4

Assembling the oil separator

■ Press the base onto the body by hand until it sits flush.

892 Professional Rancimat

■■■■■■■■

39

Page 48

5.1 General notes

5 Operation and maintenance

5.1 General notes

5.1.1 Care

The 892 Professional Rancimat requires appropriate care. Excess contamination of the instrument may result in functional disruptions and a reduction in the service life of the otherwise sturdy mechanics and electronics.

Spilled chemicals and solvents should be removed immediately. Above all,

the plug connections on the rear of the instrument (in particular the

power socket) should be protected from contamination.

CAUTION

Although this is largely prevented by design measures, the power plug

should be unplugged immediately if aggressive media have found their

way into the interior of the instrument to prevent serious damage to

the instrument electronics. In such cases, Metrohm Service must be

informed.

■■■■■■■■■■■■■■■■■■■■■■

5.1.2 Maintenance by Metrohm Service

Maintenance of the 892 Professional Rancimat is best carried out as part

of annual service, which is performed by specialist personnel from

Metrohm. If you are frequently working with caustic and corrosive chemicals, we recommend a shorter maintenance interval.

Metrohm Service offers every form of technical advice for maintenance

and service of all Metrohm instruments.

■■■■■■■■

40

892 Professional Rancimat

Page 49

■■■■■■■■■■■■■■■■■■■■■■

5.2 Replacing the dust filter

The dust filter (2-15) is mounted on the opening marked with Filter on

the rear of the instrument and serves for filtration of the air aspirated

through the air pump. It must be checked at periodic intervals and

replaced in the case of more intense contamination (6.2724.010).

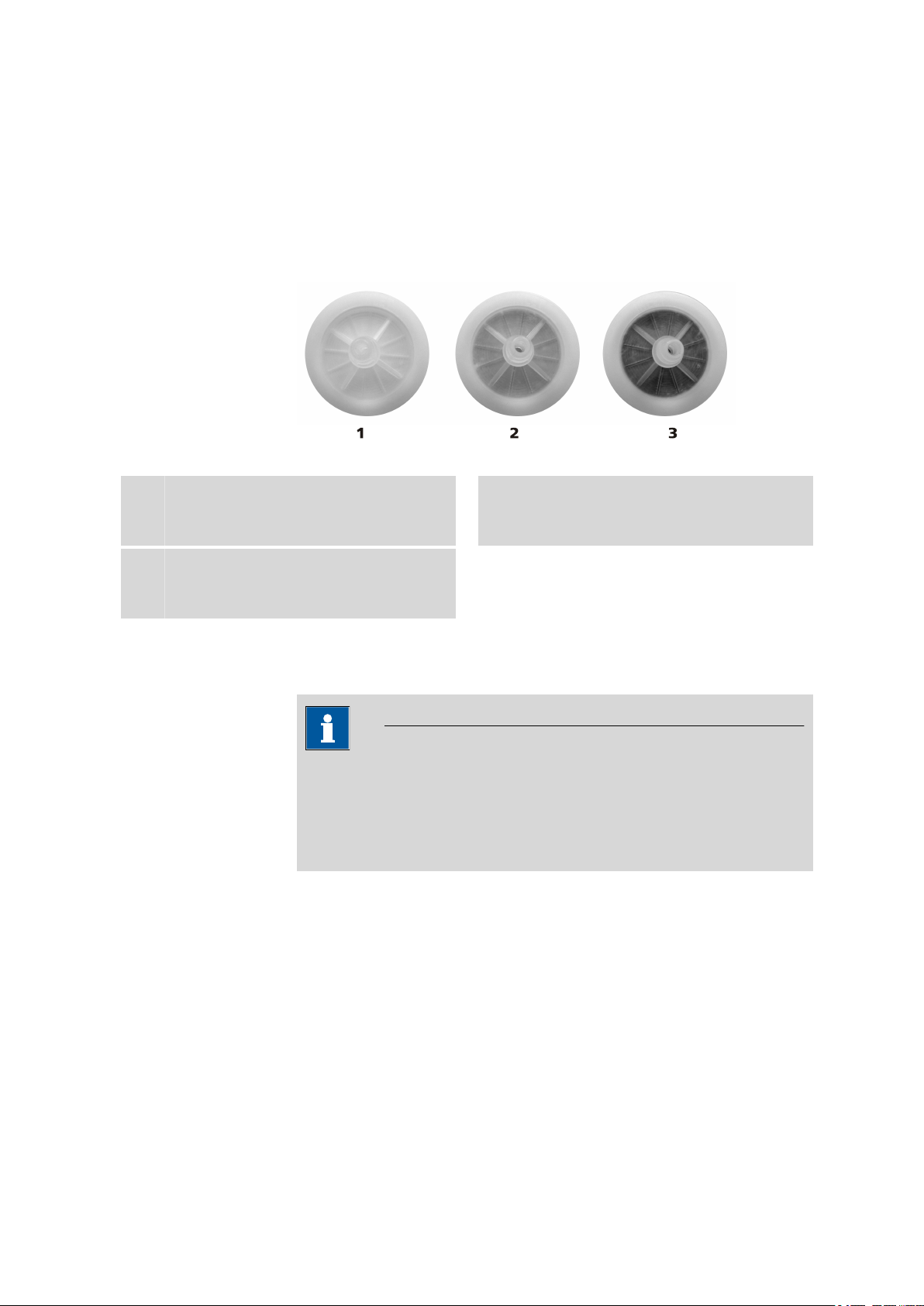

Figure 18 Dust filter - conditions

5 Operation and maintenance

Dust filter new

1

New dust filters are white on the intake side.

Dust filter full

3

Full dust filters have a dark to black color on

the intake side and must be exchanged.

Dust filter used

2

Used dust filters are discolored on the intake

side.

5.3 Regenerating or replacing the molecular sieve

NOTE

Regenerate the molecular sieve regularly.

The intervals at which you have to regenerate the molecular sieve

depends on the humidity in the laboratory and also on the frequency

of use of the instrument.

The molecular sieve filled in the drying flask (2-9) serves to adsorb disruptive oxidizing gases as well as of the water from the aspirated air.

892 Professional Rancimat

You can regenerate the molecular sieve in the drying oven at

approx. +140 - +180 °C for 24 to 48 h. You can order a new molecular

sieve under the order number 6.2811.000.

■■■■■■■■

41

Page 50

5.4 Quality management and qualification with Metrohm

CAUTION

Do not fill the hot molecular sieve directly into the drying flask after

regeneration, as otherwise the plastic filter on the filter tube will melt.

Wait until the molecular sieve has cooled down before filling.

■■■■■■■■■■■■■■■■■■■■■■

5.4 Quality management and qualification with

Metrohm

Quality management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software.

Qualification

Please contact your local Metrohm representative for support in qualification of instruments and software. The Installation Qualification (IQ)

and Operational Qualification (OQ) are offered by Metrohm representatives as a service. They are carried out by trained employees using standardized qualification documents and in accordance with the currently

applicable requirements of the regulated industry.

Maintenance

The electronic and mechanical functional groups of Metrohm instruments

can and should be checked by specialist personnel from Metrohm as part

of a regular preventive maintenance schedule. Please ask your local

Metrohm representative regarding the precise terms and conditions

involved in concluding a corresponding maintenance agreement.

For detailed information on this topic, please visit www.metrohm.com.

■■■■■■■■

42

892 Professional Rancimat

Page 51

■■■■■■■■■■■■■■■■■■■■■■

6 Troubleshooting

6.1 Problems

Problem Cause Remedy

6 Troubleshooting

The pump is louder

than normal.

No air flow can be

detected in the reaction vessel (it does

not bubble),

although the pump

is running.

The air flow is blocked

somewhere before or after

the pump.

■ Check dust filter and replace it if necessary.

■ Check filter tube on the drying flask cap for

blockages and, if necessary, gently tap on

it to remove them.

Extra air is aspirated from

elsewhere other than the

dust filter. There is a leak

somewhere in the system

■ Check the FEP tubing for cracks, kinks, etc.

and fasten it tightly. Replace it if necessary.

■ Place the drying flask cap correctly on the

drying flask and screw tight.

before the pump.

The air supply is blocked. ■ Remove the FEP tubing from the thread

adapter. Here, a slight air flow must be

perceptible. If this is not the case, please

contact Metrohm Service.

■ Check FEP tubing for blockages. If neces-

sary, clean or replace.

■ Check the thread adapter and the air tube

on the reaction vessel cover for blockages.

If necessary, clean or replace.

The FEP tubing for the air

supply is defective.

Check the FEP tubing for cracks, kinks etc. If

necessary, replace.

No air flow can be

detected in the measuring vessel (it does

not bubble),

although an air flow

can be discerned in

the reaction vessel.

892 Professional Rancimat

The FEP tubing for the air

Tighten the FEP tubing on both sides.

supply is not connected

correctly.

The air tube does not

immerse in the sample.

■ Press the reaction vessel cover all the way

down.

■ Use more sample.

The connection is blocked. ■ Check the tubing connector on the reac-

tion vessel cover for blockage and, if necessary, clean.

■ Check the silicone tubing for blockage and,

if necessary, clean.

■ Check the tubing adapter and the PTFE

cannula on the measuring vessel cover for

blockage and, if necessary, clean.

■■■■■■■■

43

Page 52

6.1 Problems

Problem Cause Remedy

The connection is leaking. Check the silicone tubing for leakages and, if

necessary, replace.

■■■■■■■■■■■■■■■■■■■■■■

The induction times

are not reproducible

for multiple determinations.

The reaction vessel cover

does not sit correctly or

tightly enough.

The connection is wrongly

connected.

The reaction vessels used

are not clean.

■ If the reaction vessel cover is oblique or not

completely mounted, press it all the way

down.

■ If the reaction vessel cover is loose on the

reaction vessel despite correct assembly,

the cover has to be replaced.

■ Make sure that the PTFE cannula for air

supply is connected to the In opening of

the measuring vessel cover.

■ Make sure that the silicone tubing is con-

nected to the tubing adapter that is mounted on the In opening.

■ Make sure that the reaction vessel is con-

nected to the measuring vessel that

belongs to the corresponding measuring

position.

■ Clean the reaction vessels of particles (dust,

cardboard, etc.) with nitrogen before

weighing in the sample.

■ Only use new, unused reaction vessels.

The reaction vessels used

are scratched on the

inside.

The reaction vessel cover

does not sit correctly or

tightly enough.

The connection to the

measuring vessel is not

mounted correctly.

Only use new, unused reaction vessels.

■ If the reaction vessel cover is oblique or not

completely mounted, press it all the way

down.

■ If the reaction vessel cover is loose on the

reaction vessel despite correct assembly,

the cover has to be replaced.

Ensure that no air can escape through leaks

when transferring from the reaction vessel to

the measuring vessel.

■■■■■■■■

44

892 Professional Rancimat

Page 53

■■■■■■■■■■■■■■■■■■■■■■

Problem Cause Remedy

6 Troubleshooting

The stability times

are not reproducible

for multiple determinations.

The temperature in different positions of a heating

block differs, as sample has

burnt on at one or more

places in the recess of the

heating block.

The sample is not homogenous.

The cell constant was not

determined or does not

correspond to the value

entered.

The conductivity measuring

cell is contaminated.

See also: The induction

times are not reproducible

for multiple determinations.

If necessary, carefully remove contamination

from the cold heating block.

Homogenize the sample.

■ Determine the cell constant.

■ Make sure that the assignment of the con-

ductivity sensors is correct, so that the

determined cell constant actually corresponds to the measuring cell used.

■ Make sure that the measuring cell is not

contaminated. Clean if necessary.

Check the measuring cell and, if necessary,

clean.

The induction time

is longer/shorter

than expected.

The stability time is

longer/shorter than

expected.

The temperature is not

selected correctly.

See also: The induction

times are not reproducible

for multiple determinations.

The conductivity change is

not correctly defined.

See also: The stability times

are not reproducible for

multiple determinations.

See also: The induction

time is longer/shorter than

expected.

■ Make sure that the correct method for the

determination has been selected.

■ Check whether the Sample temperature

and the Temperature correction are

indicated correctly in the method.

Make sure that the value defined for the conductivity change in the method is correct.

892 Professional Rancimat

■■■■■■■■

45

Page 54

6.1 Problems

Problem Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

The measurement

curves are extremely

noisy.

The air supply for the measuring solution is directed

to the conductivity measuring cell.

Gas bubbles adhere to the

conductivity measuring cell

during measurement.

During the measurement,

sample evaporates in the

reaction vessel and condenses in the measuring

vessel. This results in contamination of the conductivity measuring cell, which

in turn promotes adherence of gas bubbles.

Loosen the tubing adapter on the measuring

vessel cover and turn the PTFE cannula such

that the air is no longer directed to the electrode and fix it in this position.

■ Make sure that the measuring cell is clean

and free of fat. If necessary, clean thoroughly.

■ In some cases, ultrapure water contains a

large proportion of dissolved air. In this

case, degas the ultrapure water before the

measurement for 5 to 10 min in a vacuum.

■ Keep the measuring time as short as possi-

ble, by about 4 to 6 h. The induction time

can be reduced by about half by increasing

the temperature by 10 °C.

■ Reduce the temperature to such an extent

that sample evaporation is minimized or

eliminated. However, this can substantially

extend the measuring time. The induction

time approximately doubles by reducing

the temperature by 10 °C.

■ Use an oil separator (6.2753.200).

The curve shows a

step which means

that the induction

time is no longer

determined correctly.

Side reactions occur at the

start or during the measurement. These reactions

cause the conductivity in

the measuring cell to rise.

■ Use the Evaluation suppression in the

method.

■ In addition to Endpoint(s) activate also

Conductivity (e.g. 200 µS/cm) as stop cri-

terion in the method and select the Stop

once all the criteria have been fulfilled

option. The evaluation parameters can be

optimized on the basis of this curve, or the

curve can be evaluated manually.

■ Increase the Evaluation sensitivity

method parameter.

■■■■■■■■

46

892 Professional Rancimat

Page 55

■■■■■■■■■■■■■■■■■■■■■■

Problem Cause Remedy

6 Troubleshooting

The curve shows a

step at the start of

the measurement,

which has not occurred in previous

measurements.

The induction time

is not evaluated

automatically,

although a significant break point can

be noticed in the

curve.

The reaction vessel cover

and/or the tubing still contain residues from previous

measurements. These residues are then transferred

to the measuring vessel

with the flow of warm air

during a new measurement.

The Evaluate induction

time option is deactivated

in the method.

The Evaluation suppres-

sion option preventing the

evaluation of the curve in

the corresponding time

period is defined in the

method.

Automatic detection of the

induction time is not yet

possible.

■ Thoroughly clean the reaction vessel cover

and the silicone tubing.

■ Replace the reaction vessel cover and the

silicone tubing from time to time.

■ If an oil separator has been used, thor-

oughly clean it.

Activate the evaluation of the induction time in

the method.

Deactivate the corresponding option in the

method.

Keep the determination running until the

induction time is automatically found.

The measurement

aborts without an

endpoint being