Page 1

CH-9101 Herisau/Switzerland

E-Mail

www.metrohm.com

info@metrohm.ch

789 Robotic Sample Processor XL

778 Sample Processor

Program version 5.789.0020+

and 5.778.0020+

Instructions for Use

8.789.1063 03.2007 / dm

Page 2

Teachware

Metrohm AG

Oberdorfstr. 68

CH-9100 Herisau

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great

care, errors cannot be entirely excluded. Should you notice any mistakes please inform the author at the address given above.

© Metrohm AG 2007

Printed in Switzerland

II Metrohm Sample Processor

Page 3

Table of Contents

1 Introduction 1

1.1 Instrument description ....................................................................1

1.1.1 Field of application of the Metrohm Sample Processors........................1

1.1.2 Instrument versions..................................................................................3

1.2 Sample Processors as part of a system ........................................5

1.3 Information about these Instructions for Use................................6

1.3.1 Please note ..............................................................................................6

1.3.2 Additional documents..............................................................................6

1.3.3 Notation and pictograms.........................................................................6

1.4 Parts and controls ...........................................................................7

1.4.1 Overall view..............................................................................................7

1.4.2 Rear view..................................................................................................8

1.5 Connections.....................................................................................9

1.5.1 Sensors of the Sample Processor...........................................................9

1.6 Accessories .................................................................................. 11

1.7 The keypad.................................................................................... 13

1.7.1 The display.............................................................................................14

1.7.2 The keys.................................................................................................15

1.8 Safety information ........................................................................ 23

1.8.1 General: .................................................................................................23

1.8.2 Electrical safety ......................................................................................23

1.8.3 Personal protection................................................................................24

2 Installation 25

2.1 Installation flow chart................................................................... 25

2.2 Instrument setup........................................................................... 26

2.2.1 Setup......................................................................................................26

2.2.2 Mains connection...................................................................................26

2.2.3 Connecting the keypad .........................................................................27

2.2.4 Mounting a 786 Swing Head .................................................................27

2.2.5 Mounting the robotic arm ......................................................................28

2.2.6 Connecting pumps ................................................................................29

2.2.7 Connecting dosing devices and stirrers................................................30

2.3 Data transmission connections ................................................... 31

2.3.1 Remote connections..............................................................................31

2.3.2 Serial connections (RS232) ...................................................................37

2.3.3 Connecting a printer ..............................................................................38

2.4 Connecting up accessories ......................................................... 40

Metrohm Sample Processor III

Page 4

2.4.1 Connecting rinsing and aspiration equipment......................................40

2.4.2 Attaching the tubing ..............................................................................41

2.4.3 Installing the titration accessories .........................................................42

2.4.4 Assembling pipetting accessories ........................................................44

2.4.5 Installing a double-hollow needle..........................................................45

2.4.6 Spray nozzles ........................................................................................45

2.4.7 Magnetic stirrer......................................................................................46

2.4.8 Mounting the stand support ..................................................................46

2.4.9 Installing the collection trough...............................................................47

2.4.10 Sample racks.........................................................................................47

2.4.11 Mounting the safety shield ....................................................................48

2.5 Start-up.......................................................................................... 49

3 Operation 51

3.1 Operating principles..................................................................... 51

3.1.1 Display ...................................................................................................51

3.1.2 Instrument dialog...................................................................................52

3.1.3 Data input ..............................................................................................54

3.1.4 Text input ...............................................................................................55

3.2 Configuration ................................................................................ 57

3.2.1 Miscellaneous........................................................................................57

3.2.2 Tower settings .......................................................................................59

3.2.3 Rack definitions .....................................................................................61

3.2.4 Dosing units...........................................................................................64

3.2.5 RS232 settings.......................................................................................65

3.3 Composition of a method............................................................. 66

3.3.1 Run sequences and method parameters .............................................66

3.3.2 Sample Processor settings ...................................................................68

3.3.3 Stirrer settings........................................................................................69

3.3.4 Dosing device settings ..........................................................................70

3.3.5 Behavior during timeout ........................................................................71

3.3.6 Manual stop settings .............................................................................72

3.4 Commands.................................................................................... 74

3.4.1 Sample Processor commands..............................................................74

3.4.2 Switching components..........................................................................77

3.4.3 Dosing device control............................................................................78

3.4.4 Communication commands..................................................................80

3.4.5 Auxiliary commands ..............................................................................84

3.5 Managing methods....................................................................... 87

3.5.1 User-defined methods...........................................................................87

3.5.2 POWERUP method................................................................................88

3.6 Run control ................................................................................... 89

3.7 Sample racks ................................................................................ 90

IV Metrohm Sample Processor

Page 5

3.7.1 Metrohm standard sample racks ..........................................................90

3.7.2 Magnet codes........................................................................................91

3.7.3 Rack data...............................................................................................92

3.8 Dosing and liquid handling.......................................................... 95

3.8.1 Dosimats and Dosinos ..........................................................................95

3.8.2 Liquid handling functions ................................................................... 100

3.8.3 The DOS command............................................................................ 101

3.8.4 Pictograms.......................................................................................... 101

3.8.5 Liquid handling functions in detail...................................................... 102

3.8.6 Pipetting equipment............................................................................ 105

3.8.7 Pipetting procedure ............................................................................ 105

3.8.8 Preparing the Dosing unit................................................................... 106

3.8.9 Pipetting .............................................................................................. 106

3.9 The Remote interface ................................................................. 109

3.9.1 Output lines......................................................................................... 109

3.9.2 Input lines............................................................................................ 109

3.9.3 SCN command ................................................................................... 110

3.9.4 CTL command .................................................................................... 110

3.9.5 Manual stop options ........................................................................... 111

3.10 LEARN mode............................................................................... 112

3.10.1 Setting lift and robotic arm positions.................................................. 112

3.10.2 Rack adjustment................................................................................. 113

3.10.3 Parametrizing sequence commands ................................................. 113

3.11 TRACE function .......................................................................... 114

3.12 Disabling keypad functions ....................................................... 114

3.12.1 Disable whole keypad......................................................................... 114

3.12.2 Disable configuration.......................................................................... 115

3.12.3 Disable parameter .............................................................................. 115

3.12.4 Disable method storage functions ..................................................... 115

3.12.5 Disable display.................................................................................... 115

3.13 786 Swing Head settings ........................................................... 116

4 Service, maintenance, errors 119

4.1 Service......................................................................................... 119

4.1.1 Running time meter............................................................................. 119

4.2 Care and maintenance ............................................................... 119

4.3 Error messages .......................................................................... 120

5 GLP validation – diagnosis 122

5.1 Validation / GLP .......................................................................... 122

5.2 Initializing the working memory ................................................ 123

Metrohm Sample Processor V

Page 6

6 Annex 125

6.1 Technical data............................................................................. 125

6.1.1 Keypad.................................................................................................125

6.1.2 Interfaces ............................................................................................. 125

6.1.3 MSB connections ................................................................................125

6.1.4 Pumps and pump connections...........................................................125

6.1.5 Swing Head connection ......................................................................126

6.1.6 Lift ........................................................................................................126

6.1.7 Turntable..............................................................................................126

6.1.8 Stirrer connection (DIN socket) ...........................................................126

6.1.9 Mains connection ................................................................................126

6.1.10 Safety specifications............................................................................126

6.1.11 Electromagnetic compatibility (EMC)..................................................126

6.1.12 Ambient temperature...........................................................................127

6.1.13 Dimensions and materials...................................................................127

6.2 Standard methods ...................................................................... 128

6.2.1 Titrino ...................................................................................................129

6.2.2 PIP ext ..................................................................................................130

6.2.3 KF_ext. .................................................................................................132

6.2.4 pH_cal..................................................................................................134

6.2.5 Std_add ...............................................................................................135

6.3 Standard equipment ................................................................... 137

6.3.1 Metrohm Sample Processor:...............................................................137

6.3.2 Sample racks and sample beakers ....................................................149

6.3.3 786 Swing Head ..................................................................................153

6.3.4 Connection cables...............................................................................157

6.3.5 Optional accessories and additional devices .....................................158

6.3.6 Electrodes for automation ...................................................................161

6.4 Warranty and conformity.......................................................... 1621

6.4.1 Warranty.............................................................................................1621

6.4.2 Declaration of Conformity (778 Sample Processor) .........................1632

6.4.3 Declaration of Conformity (789 Robotic Sample Processor XL) ......1643

6.4.4 Quality Management Principles ........................................................1654

7 Index 1665

VI Metrohm Sample Processor

Page 7

List of Illustrations

Fig. 1 System components ........................................................................................................5

Fig. 2 Overall view......................................................................................................................7

Fig. 3 Rear view .........................................................................................................................8

Fig. 4 Connection strip...............................................................................................................9

Fig. 5 Magnet sensor for rack code...........................................................................................9

Fig. 6 Beaker sensor on the tower ...........................................................................................10

Fig. 7 Sensor on a robotic arm ................................................................................................10

Fig. 8 Accessories ...................................................................................................................11

Fig. 9 Keypad...........................................................................................................................13

Fig. 10 Safety Shield (example shown: 6.2751.0xx for transfer robotic arm) ...........................24

Fig. 11 Mounting the Swing Head .............................................................................................27

Fig. 12 Robotic arm with limiting screw .....................................................................................28

Fig. 13 Mounting the robotic arm ..............................................................................................29

Fig. 13 MSB connections...........................................................................................................30

Fig. 14 Remote cable.................................................................................................................31

Fig. 15 RS232 connections........................................................................................................37

Fig. 16 Distributor piece.............................................................................................................40

Fig. 17 Attaching the tubing.......................................................................................................41

Fig. 18 Macro titration head.......................................................................................................42

Fig. 19 Micro titration head ........................................................................................................42

Fig. 20 Robotic arm with titration accessories ...........................................................................43

Fig. 22 Transfer robotic arm with pipetting accessories............................................................44

Fig. 23 Transfe r robotic arm with double-hollow needle...........................................................45

Fig. 24 Spray nozzles.................................................................................................................45

Fig. 25 741 Magnetic stirrer .......................................................................................................46

Fig. 24 Stand support ................................................................................................................46

Fig. 25 Collection trough............................................................................................................47

Fig. 26 Attaching a sample rack ................................................................................................47

Fig. 27 Sample rack for XL models............................................................................................48

Fig. 28 Mounting the safety shield.............................................................................................48

Fig. 29 Safety shield for Swing Heads.......................................................................................48

Fig. 30 Dialog arrangement .......................................................................................................53

Fig. 31 Text input .......................................................................................................................56

Fig. 32 800 Dosino with Dosing units ........................................................................................95

Fig. 33 Dosing unit from below..................................................................................................96

Fig. 34 Dosing unit - ports .......................................................................................................100

Fig. 35 Remote interface..........................................................................................................125

Tables

Table 1 Model versions (1 tower) .................................................................................................3

Table 2 Model versions (2 towers)................................................................................................4

Metrohm Sample Processor VII

Page 8

VIII Metrohm Sample Processor

Page 9

1.1 Instrument description

1 Introduction

This section offers you a first overview of the Metrohm Sample Processors. All the information applies to both the 789 Robotic Sample Processor XL and the 778 Sample Processor. You are informed about how you

can use these versatile instruments and are introduced to the most important parts and controls.

1.1 Instrument description

1.1.1 Field of application of the Metrohm Sample Processors

The Metrohm Sample Processors are very versatile instruments intended exclusively for use in factories and laboratories, where they

cover a wide range of applications. In this way they provide an indispensable service wherever large series of samples have to be processed, no matter whether in the titration, measurement or liquid

handling sectors.

As a result of the extensive communication possibilities you can work

via the parallel Remote and serial RS232 interface not just with the wide

range of Metrohm titrators, measuring instruments and dosing devices,

but you can also work with any other instruments that have a suitable

communications interface; these can be controlled by or control the

Sample Processor. These abilities mean that they are predestined for all

imaginable automation tasks in a modern laboratory, even within highly

integrated laboratory data systems.

Despite their comprehensive range of commands and the numerous

possible configurations, the Metrohm Sample Processors offer an uncomplicated type of operation that is also suitable for routine work as a

result of the possibility of managing user-defined methods.

The standard methods supplied with the instruments can be used for

routine tasks without any further fuss. After a short familiarization period

the user can alter them to meet any particular requirements and store

them in the instrument. This means that, apart from routine work,

Metrohm Sample Processors can also be used for demanding special

applications.

The run sequences for processing the individual samples are freely definable within wide limits. The same applies to the start sequence and

Metrohm Sample Processor, Introduction 1

Page 10

1.1 Instrument description

final sequence, which have to be carried out once before the start of a

sample series or once after it has been completed. This offers many

advantages, particularly for titrations. The electrode can be conditioned

before the first titration or subjected to a special rinsing process.

A learn mode is available for creating run sequences and, with its help,

command parameters can be set in manual operation.

Exchangeable standard sample racks are available for many sizes of

beakers and test tubes. Freely selectable "special beaker" positions can

be defined for each rack. These are then used for including rinsing or

conditioning beakers, which can be addressed in any part sequence,

on the rack.

By extending the system with a 786 Swing Head the number of samples

to be processed on a rack can be considerably increased. The robotic

arm of the 786 Swing Head allows any point on a sample rack to be

addressed. This means that the number (max. 999 rack positions) and

arrangement of the samples is virtually unlimited. On request we can

supply customer-specific special racks for individual requirements.

Freely definable position tables can be loaded via the RS232 interface

and suitable PC software for the configuration of special racks.

2 Metrohm Sample Processor, Introduction

Page 11

1.1 Instrument description

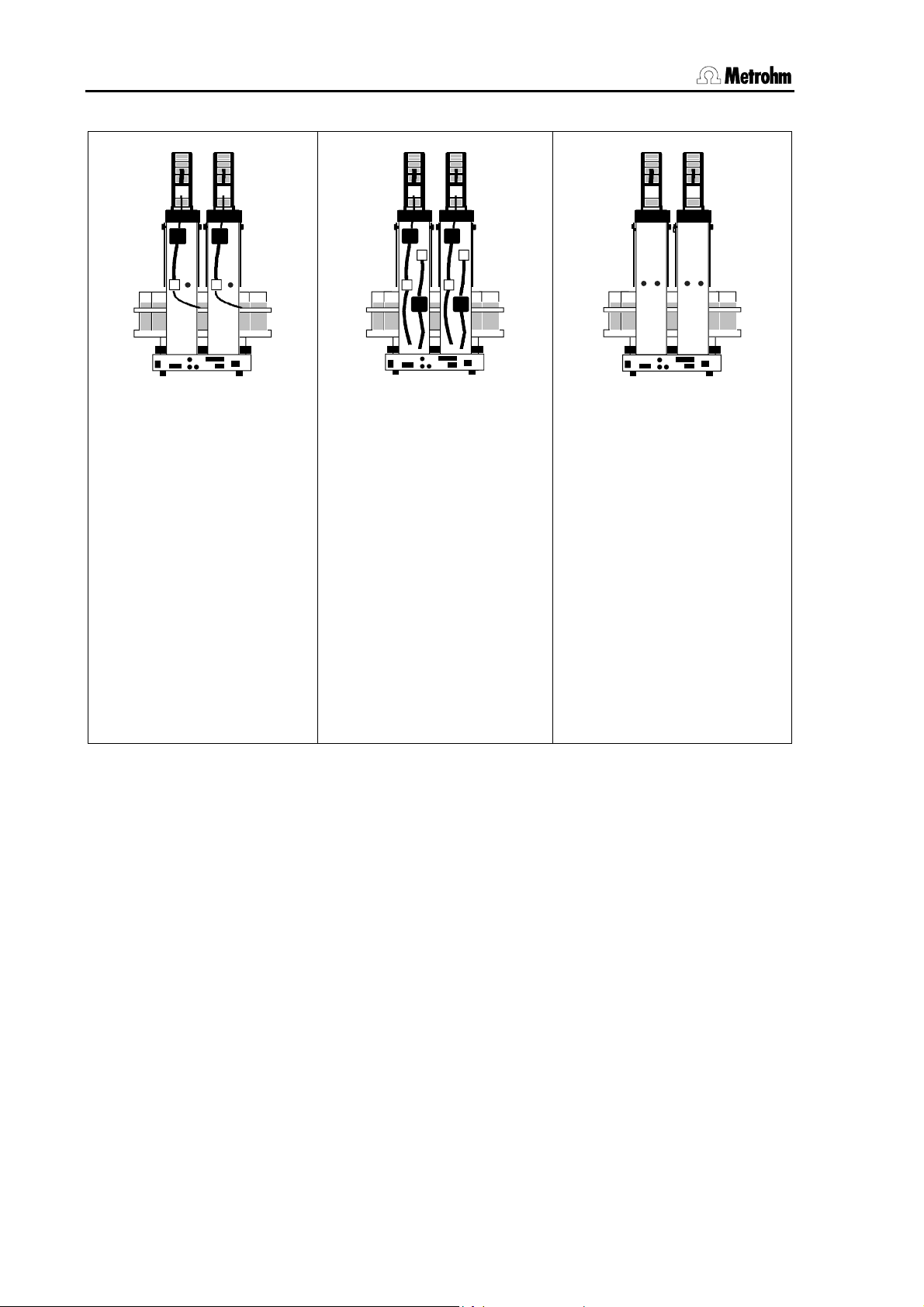

1.1.2 Instrument versions

Variously equipped Metrohm Sample Processors models are available:

• All versions of the 789 Robotic Sample Processor XL are suitable

for sample racks of up to 48 cm diameter.

• All versions of the 778 Sample Processor are suitable for sample

racks of up to 42 cm diameter.

Model 2.789.0010

Model 2.778.0010

1 tower with 1 pump

+ 1 ext. pump connection

+ 1 stirrer connection

+ 1 Swing Head connection

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Model 2.789.0020

Model 2.778.0020

1 tower with 2 pumps

+ 1 stirrer connection

+ 1 Swing Head connection

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Model 2.789.0030

Model 2.778.0030

1 tower without pumps

+ 2 ext. pump connections

+ 1 stirrer connection

+ 1 Swing Head connection

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Table 1 Model versions (1 tower)

Metrohm Sample Processor, Introduction 3

Page 12

1.1 Instrument description

Model 2.789.0110

Model 2.778.0110

2 towers with 2 pumps

+ 2 ext. pump connections

+ 2 stirrer connections

+ 2 Swing Head connections

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Table 2 Model versions (2 towers)

Model 2.789.0120

Model 2.778.0120

2 towers with 4 pumps

+ 2 stirrer connections

+ 2 Swing Head connections

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Model 2.789.0130

Model 2.778.0130

2 towers without pumps

+ 4 ext. pump connections

+ 2 stirrer connections

+ 2 Swing Head connections

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

4 Metrohm Sample Processor, Introduction

Page 13

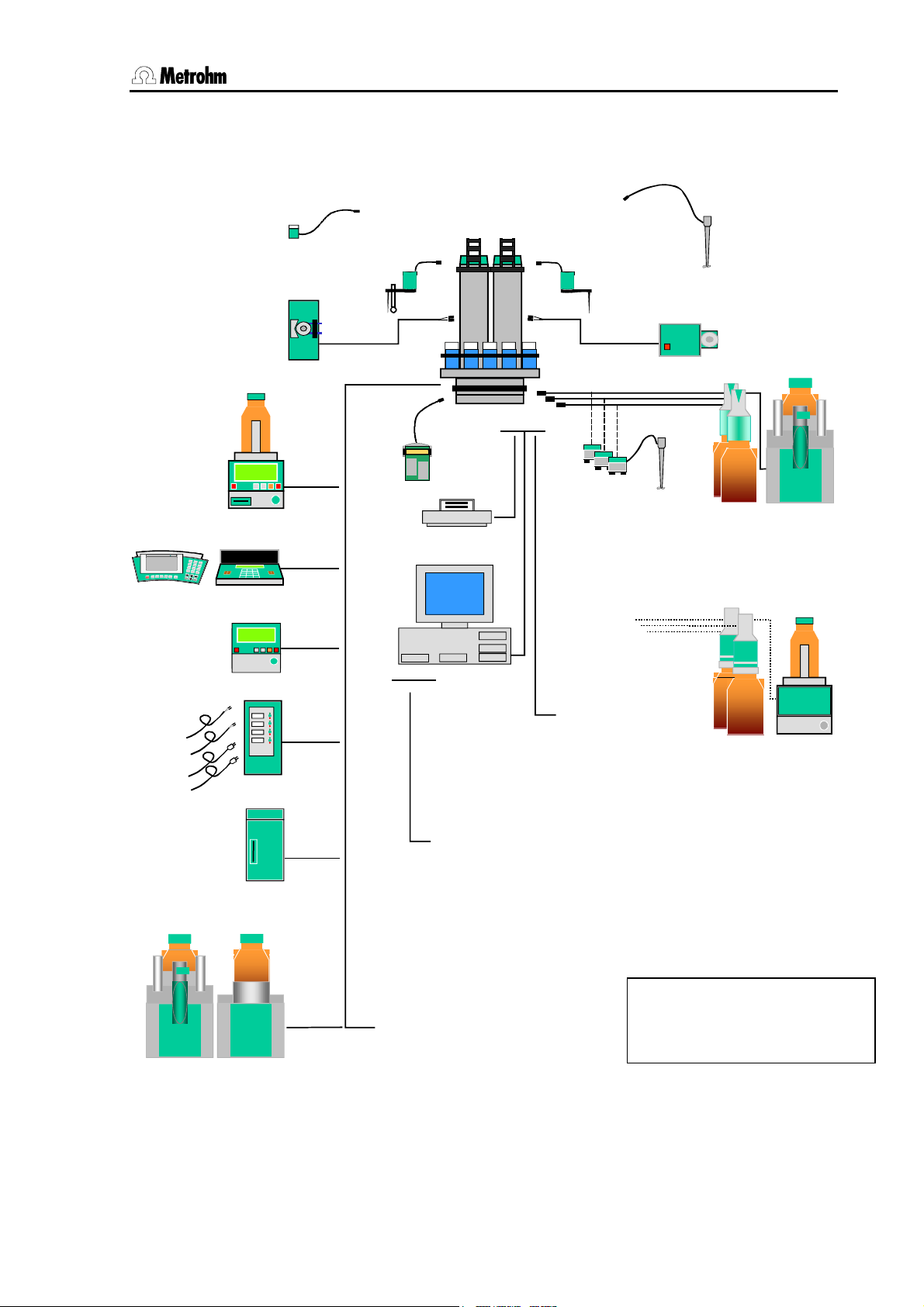

1.2 Sample Processors as part of a system

1.2 Sample Processors as part of a system

741 Magnetic

Stirrer

772 Pump Unit

Titrinos

781 pH/Ion Meter Metrohm781 pH/Ion Meter Metrohm

pH Meter / Ion Meter

756/831

756 KF

Coulometer

DC

731

AC

Relay Box

731 Relay Box

711 Liquino

711 Liquino

786 Swing Head*

772 Pump

Remote

Keypad

PC

COM 1

RS 232

786 Swing Head**

MSB

RS 232

801 Stirrer

804 Titation Stand

Printer

TiNet

PC

2.x

USB

COMx

COM 2

LPT 1

COM 2

Personal

Computer

• Titrinos

• pH Meter

• Coulometer

• other

Metrohm instruments

• other manu-

• Titrinos

• pH Meter

facturers instruments

• Coulometer

• other Metrohm instruments

• balance

• instruments from

other manufacturers

MSB

802 Rod Stirrer

823823

800

800

800

800

Dosino

Dosino

Dosino

Dosino

800 Dosino

805 Dosimat

700

700

Dosino

Dosino

Dosino

Dosino

700 Dosino

685 Dosimat

823 Membrane

Pump Unit

805 Dosimat805 Dosimat

700

700

685 Dosimat

786 Swing Head

809 Titrando809 Titrando808 Titrando808 Titrando

• other Metrohm

instruments

* with titration-robotic arm

** with transfer-robotic arm

Fig. 1 System components

Titrandos

(6.2148.010 Remote Box

required)

Metrohm Sample Processor, Introduction 5

Page 14

1.3 Information about these Instructions for Use

1.3 Information about these Instructions for Use

1.3.1 Please note

Please read through these Instructions for Use carefully before you

start to use the Sample Processor. The instructions contain information

and warnings that must be observed by the user in order to guarantee

the safe use of the instrument.

1.3.2 Additional documents

• Quick Reference 8.789.1013 for the Metrohm Sample Processors

• Operating Tutorial 8.789.1023 for the Metrohm Sample Processors

• Technical Reference 8.789.1033 for the Metrohm Sample Proces-

sors

1.3.3 Notation and pictograms

The following notation and pictograms are used in these Instructions for

Use:

Location Menu item, parameter or input value

<OK> button, key

Danger

This symbol indicates a possible risk of death or injury to

the user if the instructions are not followed correctly.

Warning

This symbol indicates a possible risk of damage to the instruments or their components if the instructions are not followed correctly.

Attention

This symbol indicates important information. Read the information provided before you continue.

Remarks

This symbol indicates additional information and tips.

6 Metrohm Sample Processor, Introduction

Page 15

1.4 Parts and controls

1.4 Parts and controls

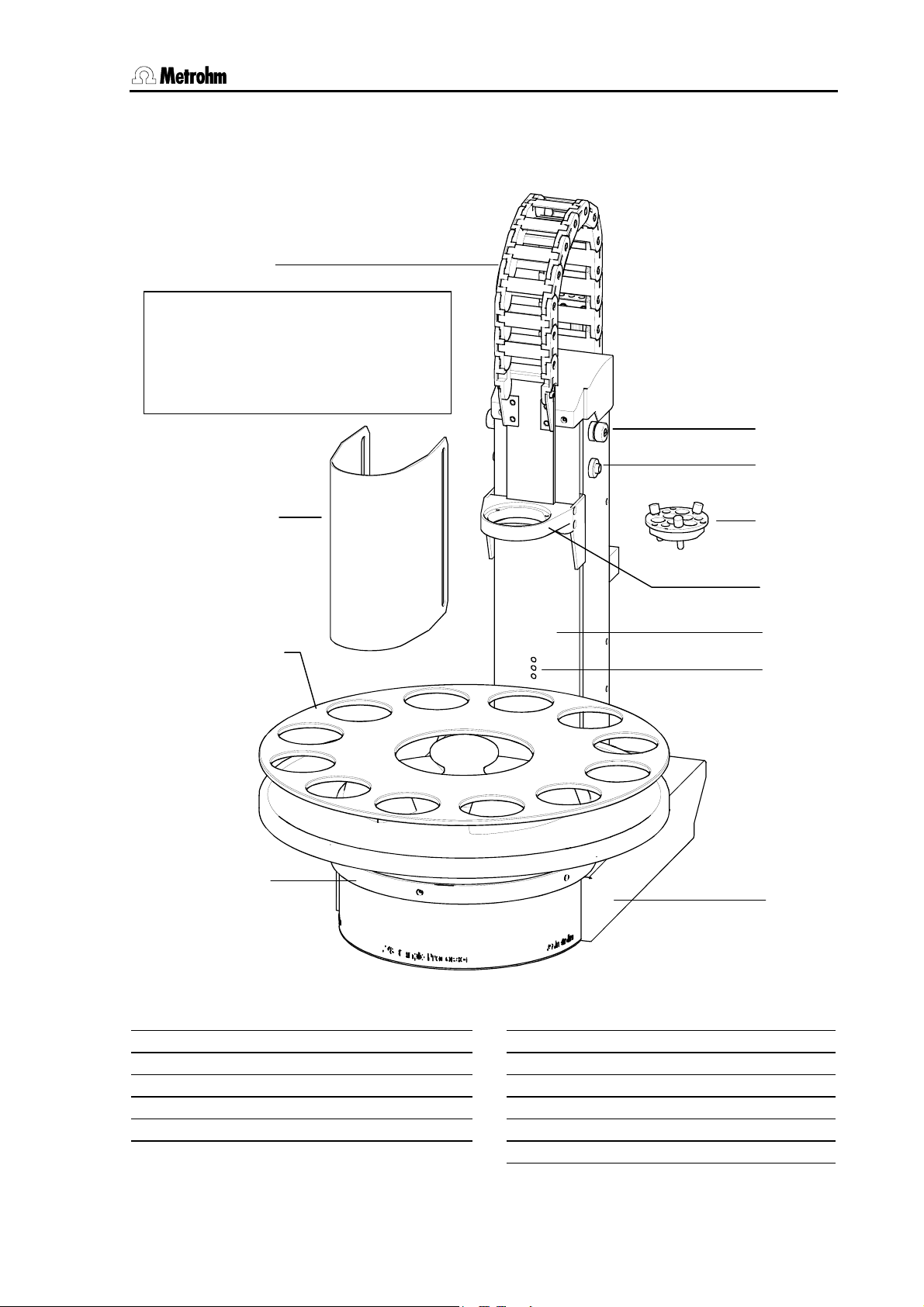

1.4.1 Overall view

1

Safety information

Safety shield 2 must always be in position before the Metrohm Sample

Processor is used.

5

6

2

3

4

Fig. 2 Overall view

7

8

9

10

11

Guide chain

1

Safety shield/Splash protection

2

Sample rack

3

Stirrer rail

4

Splash protection fixing

5

Metrohm Sample Processor, Introduction 7

6

7

8

9

10

11

Splash protection guide

Titration head

Lift

Tower

Beaker sensor

Chassis

Page 16

1.4 Parts and controls

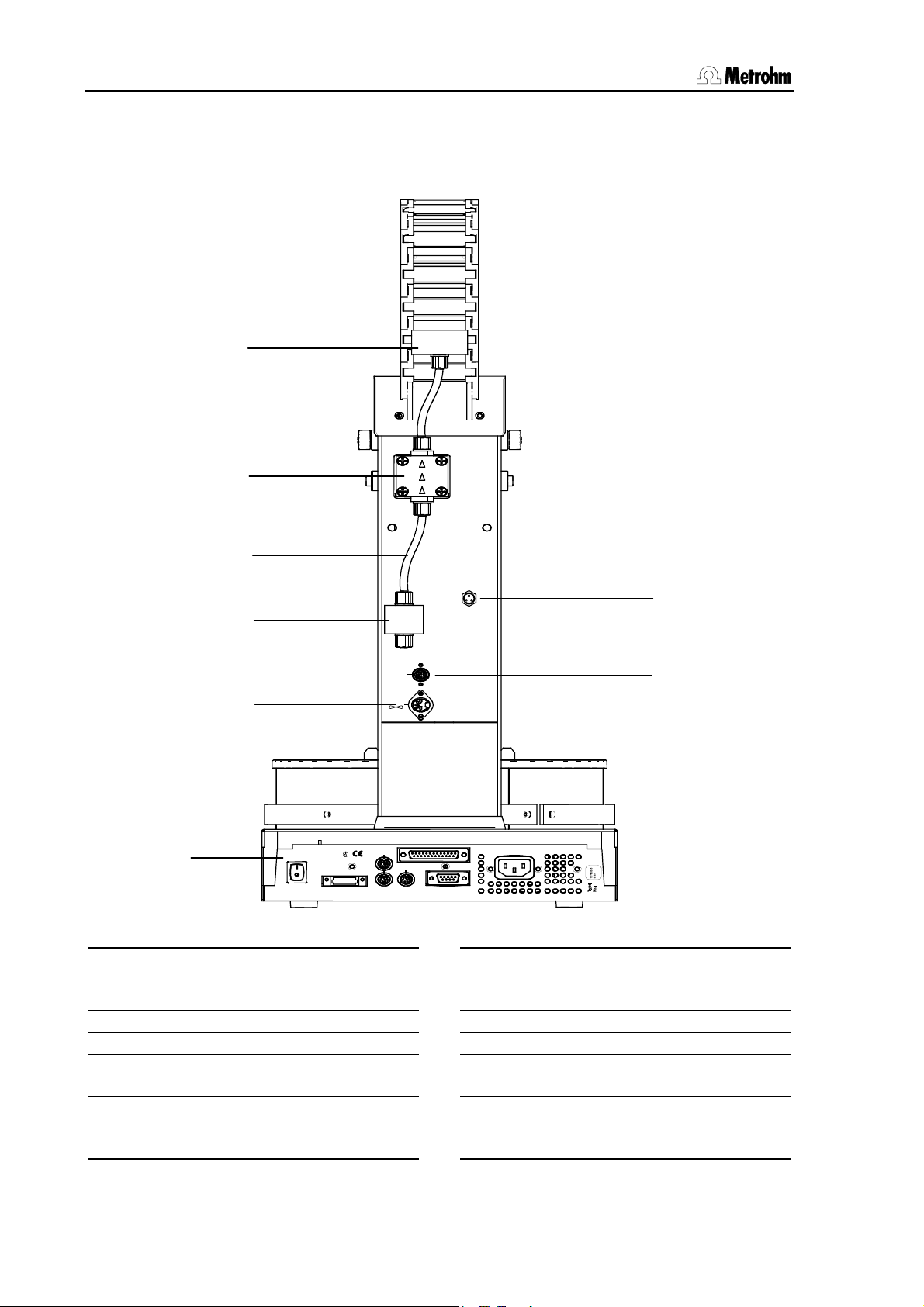

1.4.2 Rear view

This illustration shows the rear view of the standard model 2.778.0010 with

one tower, one membrane pump and one connection for an external pump.

12

13

Pump 1

17

Distributor block

12

Membrane pump

13

PTFE tubing

14

Solenoid valve

15

Warning: Biohazard

a

See Section

14

15

Swing

16

W

R

A

N

I

N

G

-

e

i

r

F

H

a

z

-

a

d

o

u

c

i

n

r

o

t

n

i

e

h

s

a

t

t

h

t

t

e

p

i

o

o

d

c

r

e

e

l

r

p

n

e

e

y

d

p

a

m

t

n

g

i

n

a

t

r

Made by Metrohm

Herisau Switzerland

r

a

l

y

c

e

n

o

s

f

e

u

f

o

Keyboard

MSB1

MSB2

F

w

Power

Fig. 3 Rear view

1.8.3 Personal protection

Head

Remote

RS 232

MSB3

16

17

18

19

b

Ext.

Pump 2

18

19

S: 115 VA

U: 100 - 240 V f: 50 - 60 Hz

Stirrer connection (Tower 1)

For 802 Rod Stirrer or

741 Magnetic Stirrer

Connection strip

Pump connection M8 (external)

Connection socket for the

786 Swing Head

Warning: Resistance to chemicals

See section

2.4.1 Connecting rinsing

and aspiration equipment

8 Metrohm Sample Processor, Introduction

Page 17

1.5 Connections

1.5 Connections

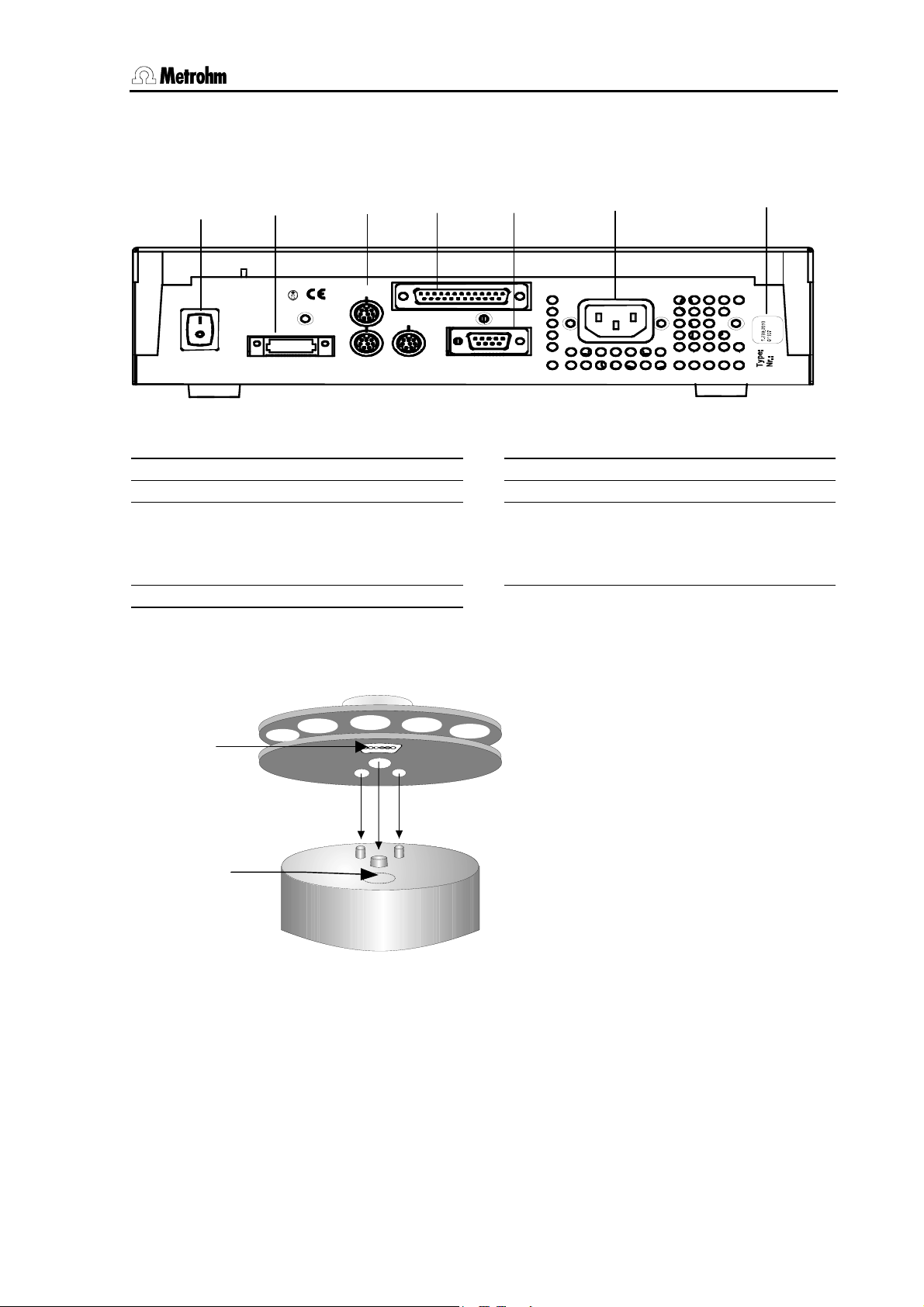

The electrical connections are the same for all models of the Metrohm

778/789 Sample Processor series.

21

W

R

A

N

-

I

G

N

F

e

i

r

H

a

z

-

a

d

t

e

c

a

t

n

i

o

n

a

r

d

e

r

l

a

p

c

e

o

f

o

g

i

n

t

f

u

r

l

y

n

s

e

Keyboard

MSB1

MSB2

c

o

r

o

F

n

w

i

t

t

h

e

h

Power

p

u

d

r

i

n

e

t

o

s

a

e

y

e

m

p

t

Made by M etrohm

Heris au Switzerland

Mains switch

20

Keyboard connection

21

MSB connections MSB1 … MSB3

22

Metrohm Serial Bus

Connection of dosing devices and stirrers

Remote connection (25-pin)

23

22

23 24

Remote

MSB3

RS 232

Fig. 4 Connection strip

24

25

26

25

S: 115 VA U : 100 - 240 V f: 50 - 60 Hz

26

Serial RS232 connection (9-pin)

Mains connection

Type plate

1.5.1 Sensors of the Sample Processor

Magnet holder

Magnet

sensor

Fig. 5 Magnet sensor for rack code

Rack sensor

The magnet sensor for recognizing

the individual rack code is located beneath the turntable of the Sample

Processor. The magnet code of a

rack can only be read in when the

rack is in the initial position. The magnet holder must be positioned directly

above the sensor.

For this reason the Sample Processor

should be initialized each time that a

rack is changed with the <RACK>

key.

Metrohm Sample Processor, Introduction 9

Page 18

1.5 Connections

/

k

Optical beaker sensor

Each tower of a Metrohm Sample

Splash protection

Safety shield

Beaker sensor

Sample rac

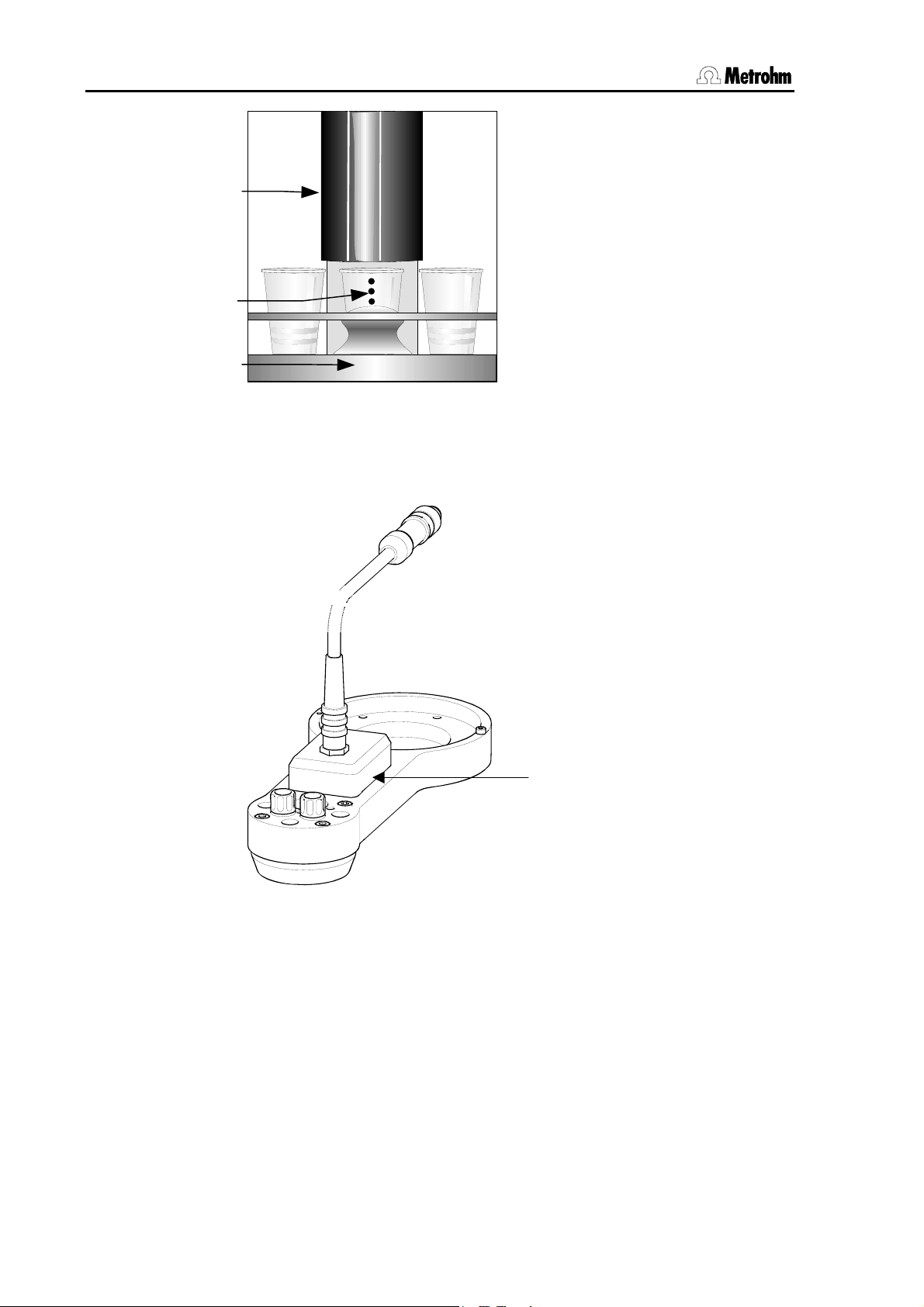

Fig. 6 Beaker sensor on the

tower

Processor is equipped with a beaker

sensor that detects the presence of

a beaker in front of the tower. With

this infrared sensor beakers made

from different materials can be detected, provided that they are located in the correct position in front

of the tower and the beaker sensor

'Tower' has been selected in the

rack definition. This "Beaker test" is

carried out after each MOVE command (i.e. each rotation of the rack).

The beaker sensor on the tower can

only be used with single-row sample

racks.

Tactile robotic arm sensor

Robotic arms with piezo sensors

may be used with multi-row racks.

The sensor is activated, when the lift

is run to work position and makes

physical contact with a sample

beaker.

Piezo sensor

Fig. 7 Sensor on a robotic arm

10 Metrohm Sample Processor, Introduction

Page 19

1.6 Accessories

k

1.6 Accessories

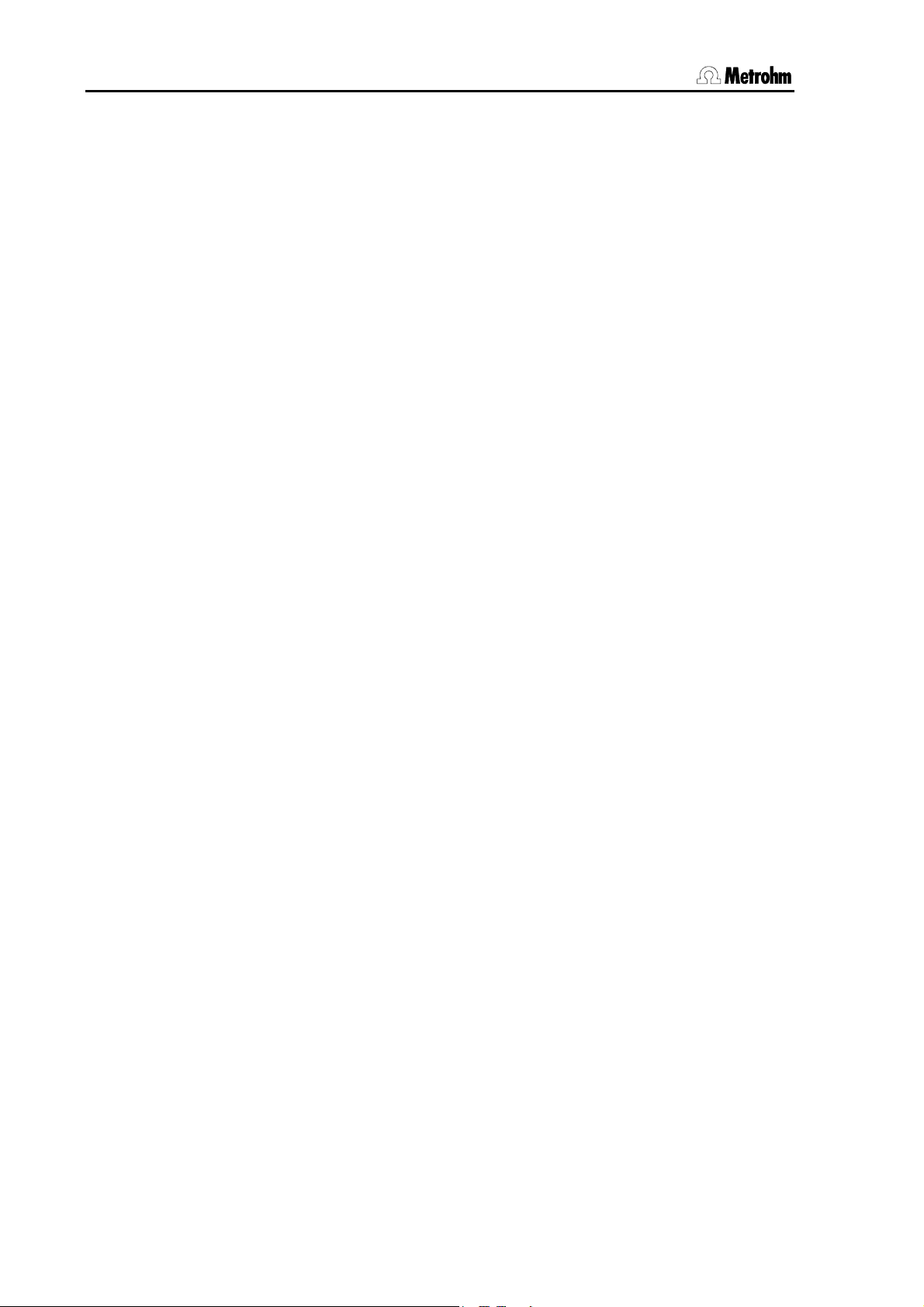

Robotic arm with

titration head

786 Swing Heads

Stand support

Sample rac

Robotic arm for

sample transfer

Fig. 8 Accessories

With suitable accessories a Sample Processor can be extended to form

a comprehensive automated system. Depending on the tasks to be

carried out, various standard components or even custom-made special parts can be used. Please consult the list of accessories on page

137ff.

Sample racks

Custom-made racks for various vessel sizes with any arrangement of

rack positions can also be supplied in addition to the standard racks.

786 Swing Head with robotic arm

The use of multi-row sample racks or external titration cells requires the

use of a 786 Swing Head. This motor drive, which is mounted on the lift

of one of the Sample Processor towers, can move different types of robotic arm. Various types of standard robotic arms with accessories for

titrating on the sample rack or for sample transfer to an external titration

cell are available.

Stand support

If an external titration cell is to be used then we recommend the use of

a stand support. The stand support can accommodate a magnetic stirrer (e.g. model 801) and, with a support rod, enables you to attach a titration cell or other accessories.

Metrohm Sample Processor, Introduction 11

Page 20

1.6 Accessories

Swing head with tactile piezo sensor

When using a multi-row rack and a 786 Swing Head, a robotic arm with

a touch-sensitive piezo sensor may be used. With that kind of sensor

the presence of a sample beaker can be detected reliably.

Robotic arm for removing covers

Whenever covered sample containers are required (e. g. with volatile

samples) the lids can be removed by a special robotic arm (so called

Dis-Cover) with magnetic contact before the sample treatment. Special

lids are available for this purpose.

Accessory set for sample transfer

For pipetting samples into external titration cells an accessory set

(6.5619.000) is available, comprising all necessary parts.

12 Metrohm Sample Processor, Introduction

Page 21

1.7 The keypad

1.7 The keypad

Controller

********

PUMP---- STIR----

TOW ER 1 TOW ER 2 LEAR N

CONFIG PARAM

HOME END

NEXT

TOWER

counter

USER

METHOD

PREV

RESET

1/12

ready

-

SAMPLE MOVE LIFT

PUMP STI R DO S

SCAN CTRL WA IT

Met r ohm

INSERT

DELETE

6.2142.040

SELECT

QUIT ENTER

CLEAR

DEF

LEARN

HOLD

PRI NT

+

STOP

<

RACK

-

START

>

Fig. 9 Keypad

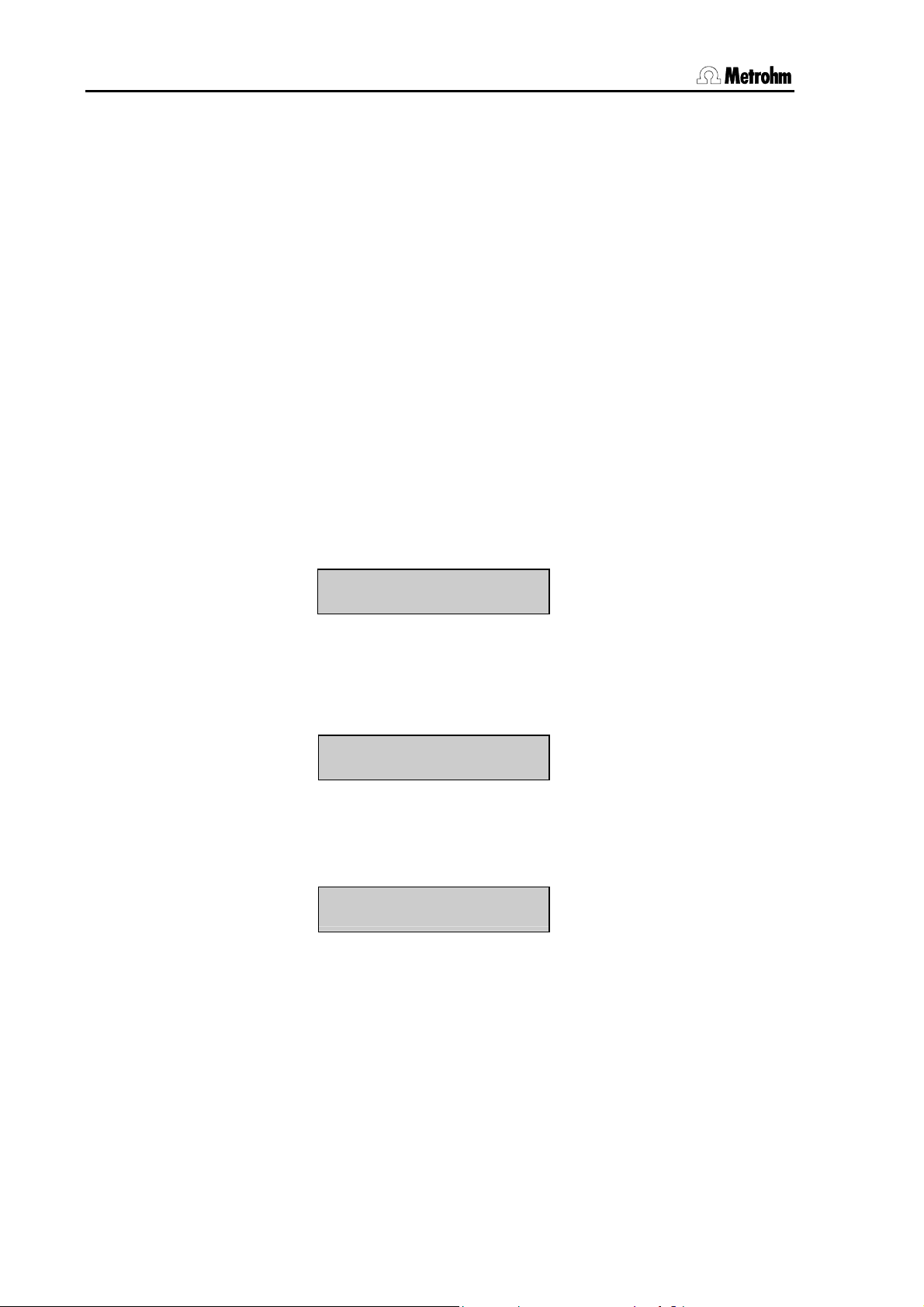

Below the 2-line display there are three LEDs. The two LEDs 'TOWER 1'

and 'TOWER 2' indicate the tower that is currently active. The LED

'LEARN' lights up when the learn mode is activated.

Most keys have two functions, depending on whether the Sample Processor is in the normal operating mode or in the editing mode.

Selection menus can be accessed with the upper row of keys (<CON-

FIG>, <PARAM>, <USER METHOD>). The other keys on the left-

Metrohm Sample Processor, Introduction 13

Page 22

1.7 The keypad

hand side of the keypad are used for navigation in the menus or for altering parameters. For entering parameters the numerical block on the

right-hand side of the keypad is also available.

The lowest row of keys (<HOLD>, <STOP>, <START>) are used

for the direct control of a method sequence.

1.7.1 The display

The display consists of two lines each with 24 characters.

The first line is used as the title line, in which the current method and

the sample counter count are shown. In the editing mode the menu title

appears here.

The second line is used as the status line, which shows specific activities depending on the operating status. In the editing mode it is used as

the input line.

Normal condition

Method name

Pump status

Sample counter

******** counter 1/12

PUMP--++STIR+---- ready

Stirrer status

Method sequence

Running sequence

******** counter 2/12

START 03 WAIT 11 s

Current command with line number

Editing mode

Menu line or command

Menu title

>Sample sequence

1 MOVE 1 : Sample

st

1

parameter

If the Sample Processor is included in a computer-controlled automation system and is completely controlled via the RS232 interface then it

may be advisable to switch off the display. This can be done in the

setup menu of the Sample Processor, see p.

Instrument status

Parameter

nd

2

parameter

114.

14 Metrohm Sample Processor, Introduction

Page 23

1.7 The keypad

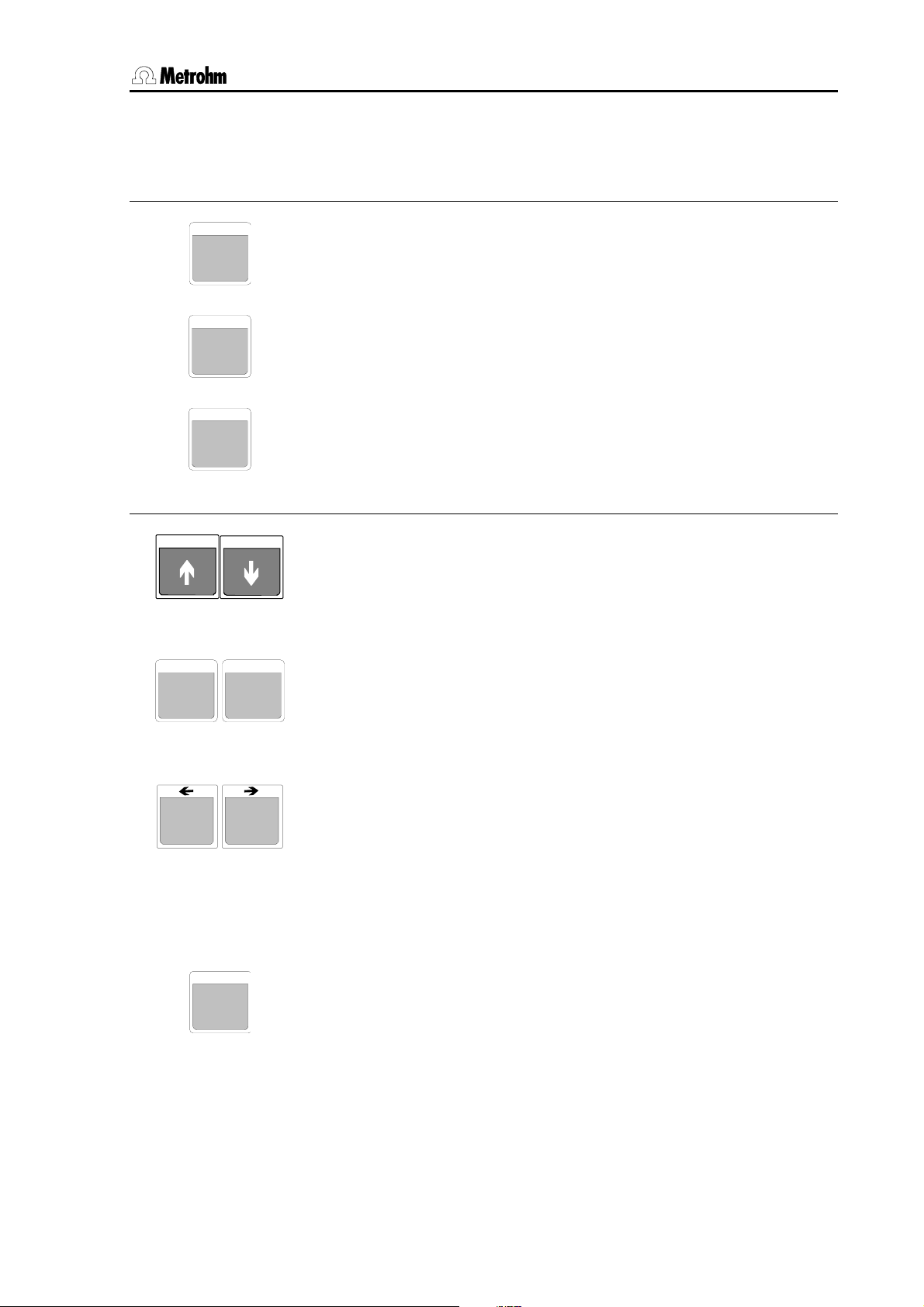

1.7.2 The keys

The menu keys

The <Config> key opens the selection menu for the configuration of

CONFIG

the Sample Processor.

The <PARAM> key opens the selection menu for editing the run se-

PARAM

quences and method parameters.

The <User Method> key opens the selection menu for opening, sav-

USER

METHOD

ing and deleting default or user-defined methods.

Lift operation and sample positioning keys

With the <> and <> keys the lift of the currently active tower can

be moved up and down respectively. The lowest possible lift position

is defined by the configuration parameter 'max. stroke path'.

In the editing mode the arrow keys <> and <> are used

for navigation in the particular menu or submenu.

HOME

NEXT

TOWER

SELECT

END

PREV

With the <HOME> key the lift of the currently active tower is returned

to the rest position (0 mm), i.e. to the uppermost stop.

<END> moves the lift to the predefined working position (see p.

In the editing mode the <HOME> and <END> keys move to

the first and last line of the menu or submenu respectively.

With the < NEXT> and < PREV> keys the sample rack can be

rotated forward or backward by one position. The beaker positions

depend on the active lift. If necessary, the lift (or both lifts) are automatically raised to the shifting position. When the rack position has

been reached a robotic arm which may be mounted will automatically

be directed to the corresponding rack position.

In the editing mode the arrow keys <> and <> are

used for navigation in a menu line.

Most functions for manual operation apply specifically to a single

tower. With the 2-tower models the <SELECT/TOWER> key can be

used to switch between the towers. The currently active tower is indicated by the TOWER 1 or TOWER 2 LED. The following commands

or keys refer to the active tower: MOVE, <>, <> , LIFT, <>,

<>, <HOME>, <END> and <PUMP>.

During data input the <SELECT> key is used to select a pre-

defined entry from a selection list.

61).

Metrohm Sample Processor, Introduction 15

Page 24

1.7 The keypad

Editing and sequence control

When editing a method sequence the <INSERT> and <DELETE>

INSERT DELETE

keys are used to insert or delete a command line.

RESET

CLEAR

QUIT

ENTE R

Command keys

SAMPLE

7

MOVE

8

The <CLEAR/RESET> key is used to initialize the Sample Processor

and dosing devices. This corresponds to the switching-on process.

During data input the <CLEAR/RESET> key is used to de-

lete an entry or to reset the default value. In text entry mode

the last character is deleted.

During a method sequence the <QUIT> key can be used to terminate the command which is currently being carried out. The following

command is executed.

During data input the <QUIT> key is used to terminate an en-

try. During navigation in a menu the <QUIT> key is used to

exit the active (sub)menu and select the next highest menu

level.

During data input the <ENTER> key is used to accept the entry.

The <SAMPLE> key is used to set the current sample position. This

has to be done before a sample series is run.

At the start of a method this position is assumed to be the first sample

in a series. If no sample position has been set then the Sample Processor will select rack position 1.

With <MOVE> a vessel or a particular rack position can be moved to

the active tower or a robotic arm can be swung to an external position.

The <SELECT> key is used to select the tower.

As well as the actual sample beaker a maximum of 16 possible special beakers can also be defined. A particular rack position can be

moved to directly by entering the position number (with the numerical

keys).

The direction and speed of rotation can be altered in the parameter

menu or with the <DEF> key.

Important:

For safety reasons it is only possible to rotate the sample rack when

the lift or both lifts are located in the shifting position or above it. During a rack rotation the lift (or both lifts) are automatically first raised to

the predefined shift height.

16 Metrohm Sample Processor, Introduction

Page 25

1.7 The keypad

LIFT

Raises or lowers the lift of the active tower. The predefined lift positions (working position, rest position, rinsing position, shifting position,

9

special position) can be selected with the <SELECT> key. They can

be entered and saved separately for each rack in the configuration

menu.

As well as the predefined lift positions it is also possible to enter absolute lift positions in mm via the numerical keys.

In the 2-tower models the tower can be selected with <SE-

LECT/TOWER>.

PUMP

The <PUMP> key is used for switching the pumps 1 or 2 of the active tower on and off. By entering the pump number (1 or 2) the condi-

4

tion of the corresponding pump will be switched, i.e. if the pump is

switched off it will be switched on and vice versa. With Sample Processor models that have no pump or only one built-in membrane pump

the selected pump connection will be switched on or off.

The status of all pumps is shown in the display (e.g.

PUMP–+–+; +

means switched on, - means switched off).

Example:

PUMP on/off No. ? <2> Display: PUMP -+--

PUMP on/off No. ? <2> Display: PUMP ----

In this case pump 2 is switched on and off.

Under <PARAM>,

>manual stop you can define whether the pumps

should be switched off with the <STOP> key or not.

STIR

The <STIR> key is used for controlling the stirrers. A stirrer can be

switched on permanently or switched on for a given period and then

5

switched off again. The <SELECT> key is used to select both the

stirrer and the function. The current status of the stirrer is shown directly in the display.

Example:

STIR: T1 : ON s Display: STIR +- (+=on -=off)

STIR: MSB2 : 10 s Display: STIR 10 s

In this case in the first line the stirrer at tower 1 is switched on. The stirrer is selected with the <SELECT> key. As can be seen in the sec-

ond line, the duration of the stirring process can also be entered.

The stirring rate can be set for each stirrer in the parameter menu or

with the <DEF> key.

Under <PARAM>,

>manual stop you can define which stirrers can

be switched off with the <STOP> key.

DOS

The <DOS> key is used to control the connected dosing devices.

Both positive and negative volumes can be dosed. Negative volumes

6

are used for aspirating liquids, e.g. during pipetting.

As well as entering the volume to be dosed (with the numerical keys),

Metrohm Sample Processor, Introduction 17

Page 26

1.7 The keypad

<SELECT> can also be used to select additional functions:

- Filling the dosing or exchange unit (fill)

- Initializing the escange of a Dosing unit (release)

- Preparing the tubing systems and cylinder (prep.)

- Emptying the tubing system and the dosing cylinder (empty)

- Ejecting the cylinder contents (Eject)

- Driving the piston to the max. volume

- Compensating for the play between piston and spindle (compen.)

- Valve switching (port)

The first parameter of the DOS command stands for the number of the

dosing instrument (1…3, * = all) and the Dosino port (e. g. 1.1 stands

for Dosino 1, port 1), the second parameter for the function or the volume to be dosed.

Example:

DOS: 2.1 <ENTER> 4.51 ml <ENTER>

DOS: 2.* <ENTER> <SELECT> ... fill <ENTER>

The dosing and filling rates can be set in the parameter menu or with

the <DEF> key.

SCAN

Shows the incoming signals or data from the Remote or the serial

RS232 interfaces.

1

This function is used for checking the data communication with connected devices.

The first parameter shows the selected interface. The second parameter shows the signals or data that are received directly.

If the parallel Remote interface (Rm) is selected then the signal states

of the incoming Remote lines are shown in binary form (1=line active,

0=line inactive).

If the serial RS232 interface (RS) is selected then the data string received via this interface will be shown (14 characters per line).

Example (Remote interface):

SCN:Rm :00000001

In this case the Ready line (Remote line input 0) of a connected Titrino is set.

CTRL

Controls external devices via the Remote or RS232 interface.

The first parameter sets the interface (<SELECT>). The second pa-

2

rameter defines the status of the lines (Remote lines) or data (RS232

interface) to be outputted via the selected interface.

2nd parameter, for Remote interface

Binary pattern with 14 digits (0, 1 or ∗) for the 14 output lines or prede-

18 Metrohm Sample Processor, Introduction

Page 27

1.7 The keypad

WAIT

3

DEF

0

DEF settings

DEF

0

DOSRATE

fined binary pattern (<SELECT> selection), e.g.

INIT etc.

START device 1,

2nd parameter, for RS232 interface

Data string with up to 14 alphanumeric characters (any).

The default value "&M;$G" (for starting Metrohm instruments) can be

set with <CLEAR>.

The <WAIT> key has no function in the normal operating condition. It

is used to insert the WAIT command in a run sequence.

The <DEF> key is used to edit various settings for manual operation. Repeated pressing of the <DEF> key is used to select the various settings. In order to change the entry you must first press

<ENTER> and then enter the new value.

Alterations made in this way only apply to manual operation.

Change dosing rate

• The dosing rate in mL/min can be set separately for each dosing

device, see p.

• Syntax:

DOSRATE [dosing device] [dosing rate]

70.

COCKMOVE

DEF

0

FILLRATE

DEF

0

DEF

0

LIFTRATE

Change filling rate

• The filling rate in mL/min can be set separately for each dosing

device, see p.

• Syntax:

FILLRATE [dosing device] [filling rate]

70.

Direction of stopcock rotation

• For each connected Dosino the direction of rotation of the stopcock switching can be defined separately, see p.

• Syntax:

COCKMOVE [Dosing device] [Direction of rotation]

70.

Change lift rate

• The lift speed in mm/s can be set separately for each tower (for 2tower models), see p.

• Syntax:

LIFTRATE [Tower] [Lift rate]

68.

Metrohm Sample Processor, Introduction 19

Page 28

1.7 The keypad

SHIFTRATE

SWINGRATE

STIRRATE

DEF

0

DEF

0

DEF

0

Change rack rate and direction of rotation

• As well as the speed of rotation of the sample rack in degrees/second the direction of rotation can also be defined.

• Direction of rotation "+" means that the rack always rotates coun-

terclockwise, i.e. in increasing rack position sequence, Direction

of rotation "–" means clockwise, i.e. decreasing sequence.

• Direction of rotation

shortest possible path for a rack rotation, see p.

• Syntax:

SHIFTRATE [Direction of rotation] [Rotation rate]

auto: the Sample Processor itself selects the

68.

Change swing rate

• The swing rate in degrees/s of a robotic arm can be set separately for each connected 786 Swing Head, see p.

• Syntax:

SWINGRATE [Tower] [Swing rate]

68.

Change stirring rate

• The stirring speed can be controlled separately for each stirrer

(rod or magnetic stirrer), see p.

• Syntax:

STIRRATE [Stirrer] [Stirrer rate]

69.

20 Metrohm Sample Processor, Introduction

Page 29

1.7 The keypad

Auxiliary commands

PRINT

<

.

RACK

>

-

*

The <PRINT> key is used to print out a report. The following can be

selected: parameter report (method), configuration report, list of

stored methods, all reports.

The type of report can be selected with <SELECT>.

e. g.

Print: config

The selection of the printer type and the settings of the RS232 interface must be made in the configuration menu under

tings, see p. 37.

>RS232 Set-

With the <RACK> key the sample rack can be initialized. The connected peripheral devices (e.g. Dosimats, Dosinos) are not affected

by this.

The sample rack and lift (both lifts in 2-tower versions) are moved to

the zero position and automatic rack recognition is carried out.

Metrohm Sample Processor, Introduction 21

Page 30

1.7 The keypad

Sequence control

The <START> key starts a method. A start is only possible when the

START

Sample Processor is in the normal operating condition, i.e. when the

display shows

ready.

If <START> is activated after an interruption (<HOLD>, see below),

then the sequence continues with the next command.

The <START> can also be used to carry out a single command line

in a run sequence (TRACE function), see p.

114.

The <STOP> key ends a method.

STOP

If a sample series is stopped manually with <STOP> then the final

sequence of a method will not be carried out. When the <STOP> key

is pressed the functions listed in the parameter menu under

stop will be carried out.

>manual

LEARN

HOLD

The <HOLD> key interrupts a method sequence.

Connected peripheral devices (Titrinos, etc.) will not be stopped

automatically. Only the method sequence will be interrupted. In the

HOLD condition a method can be completely terminated with

<STOP> or continued with <START>.

After an error message in the method sequence the Sample Processor switches automatically to the HOLD condition after <QUIT>.

22 Metrohm Sample Processor, Introduction

Page 31

1.8 Safety information

1.8 Safety information

Warning!

This instrument should only be used in accordance with the information

given in these Instructions for Use.

1.8.1 General:

This instrument left our works in perfect condition from the point of view

of its operational safety (see Technical data, safety specifications). To

keep it in this condition and to continue to operate safely the following

information must be carefully observed.

1.8.2 Electrical safety

Please observe the following guidelines:

• Only qualified Metrohm personnel should carry out service work on

electronic components.

• Do not open the instrument housing as this could damage the instrument. The housing contains no components which could be

serviced or exchanged by the user.

Electrical safety when handling the instrument is guaranteed within the

scope of Standard IEC 61010-1.

• Protection against electrostatic charges

Warning!

Electronic components are sensitive to electrostatic charges and can

be destroyed by a discharge. Before touching any electronic components of the Sample Processor one should ground himself and his tools

by grasping a grounded object (e.g. the instrument housing or a radiator) in order to eliminate any electrostatic charges that may be present.

• Mains connection

This instrument must only be operated at the specified mains voltages

(see rear panel of instrument).

• Opening a Sample Processor

When the Sample Processor is connected to the mains supply the instrument must not be opened, nor should any of its components be

dismantled as otherwise one could come into contact with currentcarrying components. Before opening the instrument it must be separated from all current sources. The mains cable has to be removed

from the mains connection socket!

Metrohm Sample Processor, Introduction 23

Page 32

1.8 Safety information

1.8.3 Personal protection

The different drives of the Sample Processor and the 786 Swing Head

possess considerable force in order that they can freely move even under heavy loads. They are fitted with electronic overload limiters that are

triggered if the mechanical resistance is too high.

When the instrument is running do not intrude in the working range

of the Sample Processor.

For the user there is a considerable risk of injury from manual in-

terference with the automatic processes of the instrument.

LEARN

HOLD

Running methods and individual commands can be interrupted with

the <HOLD> key and then continued with <START>.

Emergency stop

STOP

The <STOP> key always terminates all running processes immedi-

ately (exception: initialization during switch-on).

Important!

Before you use the instrument for the first time you must install the

included 6.2751.0xx Safety Shield, see p.

The Sample Processor must not be operated without the Safety

48.

Shield in position!

Fig. 10 Safety Shield

(example shown: 6.2751.0xx for transfer robotic arm)

Biohazard

The Sample Processor does not provide sufficient protection when

processing potentially infectious samples or reagents.

In this case install the necessary safety devices.

24 Metrohm Sample Processor, Introduction

Page 33

2.1 Installation flow chart

2 Installation

This section described the installation of all the components of a Sample

Processor and shows how it is connected to other instruments. Please

read through the following sections carefully and follow the instructions

in detail.

2.1 Installation flow chart

The following flow chart provides an overview of all the necessary installation work. Detailed information can be found in the given sections.

Setup Section

2.2

Connecting the mains cable Section 2.2.2

Connecting the keypad Section 2.2.3

* Mounting a 786 Swing Head Section 2.2.4

* Mounting a robotic arm Section 2.2.5

* Connecting the pumps Section 2.2.6

* Connecting a dosing device Section 2.2.7

Connecting the connection cables Section 2.3

Setting up the titration accessories Section 2.4.3

* Mounting the stand support Section 2.4.8

Mounting the safety shield Section 2.4.11

* optional

Metrohm Sample Processor, Installation 25

Page 34

2.2 Instrument setup

2.2 Instrument setup

2.2.1 Setup

Packaging

A Metrohm Sample Processor and its specially packed accessories are

supplied in very protective special packaging consisting of shockabsorbing plastic foam. Please store this packaging in a safe place; it is

the only way in which the safe transport of the instrument can be guaranteed.

Checks

Please check that the delivery is complete and undamaged immediately on receipt (compare with delivery note and list of accessories

given in Section

fer to the information given in Section

Location

6.3, p. 137). If transport damage is evident please re-

6.4.1 "Warranty", p. 162.

The Sample Processor is a robust instrument and can therefore be

used even in rough surroundings in laboratories and factories.

However, please ensure that it is not exposed to a corrosive atmosphere. The instrument should be serviced at regular intervals, particularly when operated under rough conditions.

2.2.2 Mains connection

This instrument must only be operated at the specified mains voltages

(see rear panel of instrument).

Protect the connection sockets against moisture.

Mains connection 25

S: 115 VA U: 100 - 240 V f: 50 - 60 Hz

26 Metrohm Sample Processor, Installation

Page 35

2.2 Instrument setup

A

2.2.3 Connecting the keypad

778

789

2.2.4 Mounting a 786 Swing Head

The procedure for the installation of the 786 Swing Head is described

below. This is normally carried out by the service technician.

The keypad is attached to the keyboard socket provided for it on the

rear panel of the instrument. To remove the plug press both sides together.

ttachment plate

Fig. 11 Mounting the Swing Head

For Sample Processors with 2 towers Tower 1 is moved to a central lift

position and Tower 2 to the parking position.

Switch off the instrument at the mains switch.

• Loosen the titration head holder fitted as standard from the lift

guide by removing the four side-mounted screws.

• Loosen the attachment plate from the titration

head holder and remove the holder.

• Screw the Swing Head onto the attachment

plate with the 2 delivered mounting screws.

• Mount the Swing Head on the lift guide.

786 Swing Head

Lift guide

Titration head holder

Metrohm Sample Processor, Installation 27

Page 36

2.2 Instrument setup

Swing

Head

Connecting to the Swing Head connection socket

Lead the connection cable of the 786 Swing Head through the guide

chain of the tower and connect the mini-DIN plug of the Swing Head

connection cable to the Swing Head socket on the rear panel of the

tower.

Configuring the Swing Head and robotic arm

As each type of robotic arm has its own dimensions, it is essential to

adapt the Swing Head setup settings to suit the particular type of robotic arm.

The necessary alterations are made in the setup dialog, see Section

3.13. The individual settings affect:

• Swing offset (default: 0°)

• Max. swing angle (default: 84°)

• Swing radius (=length of robotic arm, default: 110 mm)

• Swing direction (default Tower1: –, default Tower 2: +)

The setup dialog of the Sample Processor is opened by pressing the

<CONFIG> key as the instrument is switched on. A short explanation

is given in Section

3.13. Details about the individual settings and types

of robotic arm can be found in the Instructions for Use of the 786 Swing

Head.

2.2.5 Mounting the robotic arm

Certain robotic arms can, depending on the model, be mounted so that

they swing to the right or the left. During the mounting process the location of the limiting screw of the robotic arm must be taken into account.

Limiting screw

(for swing-right mounting)

Limiting screw

(for swing-left mounting)

Fig. 12 Robotic arm with limiting screw

Swing-right mounting means: The robotic arm can swing from the

zero-axis (center of the rack) to the right, as seen from the front. The

swing direction has to be set to '–'.

28 Metrohm Sample Processor, Installation

Page 37

2.2 Instrument setup

Robotic arms that can be mounted in two different ways (e. g.

6.1462.050) can have the limiting screw positioned according to the required swing direction (see above).

Mounting procedure

The 786 Swing Head must already be in position and configured before

the robotic arm can be mounted.

• Switch the instrument off and then on again. Wait

until the Swing Head drive has finished the initialization movements.

• Carefully push the robotic arm over guide cam 10

from below (see drawing). Hold the robotic arm in

such a way that limiting screw 9 points toward the

tower of the Sample Processor while the robotic

arm assumes the maximum swing angle.

10

9

Fig. 13 Mounting the robotic arm

Details about the individual robotic arm types can be found in the Instructions for Use of the 786 Swing Head.

2.2.6 Connecting pumps

On the Sample Processor models with one built-in membrane pump

one external pump per tower can be connected and controlled. The

models with no pumps even have two connections for external pumps.

Ext.

Pump 2

The pump connections (for 3-pin M8 connectors) on the rear panel of

the Sample Processor tower supply a feed voltage of 16 V for a max.

load of 600 mA.

Suitable pump models are:

• Use the three enclosed screws to attach the robotic

arm from below.

• Switch the instrument off and on again.

• Metrohm 823 Membrane Pump Unit (membrane pump, suitable for

aqueous media without particles)

• Metrohm 772 Pump Unit (peristaltic pump, suitable for organic solvents and aqueous solutions containing particles)

Metrohm Sample Processor, Installation 29

Page 38

2.2 Instrument setup

2.2.7 Connecting dosing devices and stirrers

Metrohm Sample Processors have various connections to which dosing

devices and stirrers can be connected.

Stirrers

The 722/802 Rod Stirrers and 741 Magnetic Stirrer have a DIN

connector and are connected to the rear panel of a tower (Tower stirrer

T1 and T2).

As with other Metrohm instruments, e. g. Titrandos, the three MSB

connectors (MSB = Metrohm Serial Bus) are very versatile. You can

connect an 801 Stirrer or an 804 Ti Stand to them.

Dosing devices

Up to three 700/800 Dosino or 685/805 Dosimat type dosing drives

can be operated by connecting them directly to the MSB sockets of a

Sample Processor. One 800 Dosino or 805 Dosimat can also be connected to the MSB output connector of another instrument connected

to the MSB socket, such as the 801 Stirrer, in a so-called 'daisy chain'.

Please note that only one instrument of a particular type may be present in such a daisy chain, e. g. a 801 Stirrer and a 805 Dosimat.

A 700 Dosino or a 685 Dosimat must be connected directly to the

MSB socket of the Sample Processor.

Dosing device and

stirrer connections

MSB1…3

The instrument will only recognize automatically a connected dosing

device when it is switched on or after RESET.

MSB1

Remote

MSB2

MSB3

Fig. 14 MSB connections

RS 232

30 Metrohm Sample Processor, Installation

Page 39

2.3 Data transmission connections

2.3 Data transmission connections

Connection cables

Only Metrohm cables should be used to connect a Metrohm Sample

Processor to other instruments. Only these will guarantee interferencefree data transmission.

Note:

The Remote cables for Metrohm Sample Processors and Sample

Processors have markings at each end of the cable to indicate the instrument that the particular connector is intended to be used with and

the connection into which it is to be plugged.

Example:

Titrino B

692 / 712 / 713

Fig. 15 Remote cable

The Sample Processor must be switched off before peripheral devices

are connected, as otherwise the instruments could be damaged.

2.3.1 Remote connections

In order to connect Remote cables to Titrandos and the 780/781

pH/Ion Meter an 8.2148.010 Remote Box is required as an additional

adapter; this is connected to one of the MSB sockets (MSB1…4), see

above.

Sample Processor — Titrino / Titrando

with standard cable (and 6.2148.010 Remote Box)

B

A

778

789

Titrino

C

D

778

789

6.2148.010

MSB

Titrando

Cable 6.2141.020

Metrohm Sample Processor, Installation 31

Cable 6.2141.020

Page 40

2.3 Data transmission connections

Titrinos and Titrandos can be connected to a Sample Processor in the

same way and can also be controlled.

Control commands:

CTL:Rm : START Device1 starts Titrino/Titrando

CTL:Rm : *************1 "

Final scan:

SCN:Rm : End1 waits for end of titration (EOD-impulse)

SCN:Rm : ****1*** "

SCN:Rm : Ready1 waits until Titrino/Titrando is ready

SCN:Rm : *******1 "

Sample Processor — pH / Ion Meter / Conductometer (692/712/713)

778

789

692

712

713

Control commands:

CTL:Rm : START device1 starts instrument

CTL:Rm : *************1 "

CTL:Rm : METER Mode pH switches to pH measurement

CTL:Rm : *********0001* " (not for 712)

CTL:Rm : METER Mode T switches to temp. measurement

CTL:Rm : *********0010* " (not for 712)

CTL:Rm : METER Mode U switches to mV measurement

CTL:Rm : *********0011* " (not for 712)

CTL:Rm : METER Mode I switches to Ipol (mV measurement)

CTL:Rm : *********0100* " (not for 712)

CTL:Rm : METER Mode C switches to Conc measurement

CTL:Rm : *********1000* " (for 692/781 only)

CTL:Rm : METER Cal pH switches to pH calibration

CTL:Rm : *********0101* " (not for 712)

CTL:Rm : METER Cal C switches to Conc calibration

CTL:Rm : *********1001 " (for 692/781 only)

Cable 6.2141.020

32 Metrohm Sample Processor, Installation

Page 41

2.3 Data transmission connections

CTL:Rm : METER enter simulates <ENTER> key

CTL:Rm : *********1111* " (not for 712)

Final scan:

SCN:Rm : End1 waits for end of measurement

SCN:Rm : ****1*** "

Sample Processor — 780/781 pH / Ion Meter

778

789

6.2148.010

MSB

Cable 6.2141.020

Control commands: see above (692/712/713 pH/Ion meter/ Conductometer).

Sample Processor — 781 Ion Meter — 665 Dosimat

For ion measurements with calibration and standard addition.

778

789

6.2148.010

A

765

D

B

C

MSB

Cable 6.2141.070

The 781 Ion Meter automatically controls Stirrer T1 of the Sample Processor.

Metrohm Sample Processor, Installation 33

Page 42

2.3 Data transmission connections

Start commands:

In principle these are the same commands as those given in the previ-

ous section.

Final scan:

In principle these are the same commands as those given in the previous section, with the addition of:

SCN:Rm : EndMeter waits for end impulse from 781

SCN:Rm : ***11*** "

Sample Processor— 2 x Titrino/Titrandos

778

789

Device 1

B

A

Titrino

C

D

Device 2

B

A

Titrino

C

D

Cable 6.2141.030

Control commands:

CTL:Rm : START Device1 starts Titrino/Titrando 1

CTL:Rm : *************1 "

CTL:Rm : START Device2 starts Titrino/Titrando 2

CTL:Rm : ********1***** "

CTL:Rm : START Device* starts both Titrino/Titrandos

CTL:Rm : ********1****1 "

Final scan:

SCN:Rm : End1 waits for end of titration Titrino/Titrando 1

SCN:Rm : ****1*** "

SCN:Rm : End2 waits for end of titration Titrino/Titrando 2

SCN:Rm : *1****** "

SCN:Rm : Ready1 waits until Titrino/Titrando 1 is ready

SCN:Rm : *******1 "

SCN:Rm : Ready2 waits until Titrino/Titrando 2 is ready

SCN:Rm : **1***** "

SCN:Rm : Ready* waits until both Titrino/Titrandos are ready

SCN:Rm : **1****1 "

The combined operation of the Titrino/Titrando/pH meter can also be

carried out without any problems by the same means.

34 Metrohm Sample Processor, Installation

Page 43

2.3 Data transmission connections

Sample Processor — Titrino/Titrando/pH Meter — 665/725 Dosimat

B

778

789

A

Titrino

C

D

A

765

D

B

C

Cable 6.2141.040

Control commands:

CTL:Rm : START Device1 starts Titrino

CTL:Rm : *************1 "

CTL:Rm : START Dos1 starts Dosimat 1

CTL:Rm : *******1****** "

Final scan:

SCN:Rm : End1 waits for end of titration (impulse)

SCN:Rm : ****1*** "

SCN:Rm : Ready1 waits until Titrino is ready

SCN:Rm : *******1 "

Sample Processor — Titrino/Titrando/pH Meter — 2x 665/725 Dosimat

B

778

789

A

C

D

Tit rino

A

D

B

C

A

765

765

D

B

C

Cable 6.2141.050

Control commands:

CTL:Rm : START Device1 starts Titrino

CTL:Rm : *************1 "

CTL:Rm : START Dos1 starts Dosimat 1

Metrohm Sample Processor, Installation 35

Page 44

2.3 Data transmission connections

CTL:Rm : *******1****** "

CTL:Rm : START Dos2 starts Dosimat 2

CTL:Rm : *****1******** "

CTL:Rm : START Dos* starts Dosimat 1 and 2

CTL:Rm : *****1*1****** "

Final scan:

SCN:Rm : End1 waits for end of titration (impulse)

SCN:Rm : ****1*** "

SCN:Rm : Ready1 waits until Titrino is ready

SCN:Rm : *******1 "

36 Metrohm Sample Processor, Installation

Page 45

2.3 Data transmission connections

2.3.2 Serial connections (RS232)

Many different connection to the RS232 interface are possible. As well

as all Metrohm instruments which understand the Metrohm Remote

language (see 'Technical Reference 8.789.1033'), a printer (requirement: serial interface or parallel/serial converter) or a personal computer can be connected. Instruments from other manufacturers that

have a serial RS232 interface can also be connected.

BA

Titrino

C

D

Cable 6.2143.040

Printer cable, see next page but one

Fig. 16 RS232 connections

A precondition for correct data transmission is that the transmission parameters are set correctly, these must correspond to the interface settings of the connected instrument (see next page).

The following section provides information about the settings and cables required for the connection of a printer.

Metrohm Sample Processor, Installation 37

Page 46

2.3 Data transmission connections

2.3.3 Connecting a printer

A printer with a serial or parallel interface can be connected to the

RS232 interface for printing out reports (e. g. parameter report).

Printers with the following printer emulation can be connected:

IBM IBM Proprinter and printers with IBM emulation

Epson EPSON printers and printers with EPSON emulation

Seiko Seiko printer DPU-411

Citizen Citizen printer IDP560 RS

HP HP printers and printers with HP PCL3 emulation

If you wish to connect a different printer then you must ensure that it

can emulate one of the printer modes supported by the Sample Processor.

Printers with a parallel interface require a serial/parallel converter (e.g.

2.145.0300) and the 6.2125.020 Cable.

The Sample Processor must be switched off before a printer is connected to the RS232 interface!

The interface parameters are entered in the configuration menu under

>RS232 settings".

"

The following table provided information about connecting some selected printers.

38 Metrohm Sample Processor, Installation

Page 47

2.3 Data transmission connections

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

Printer Cable 789/789 settings Printer settings

Custom

DP40-S4N

Seiko

DPU-414

Citizen

iDP562 RS

Epson LX300+

HP Desk Jet

with serial interface

HP Desk Jet

with parallel

interface

6.2134.110 Send to: Citizen

Baud rate: 9600

Data bit: 8

Stop bit: 1

Parity: none