Page 1

788 IC Filtration Sample Processor

METROHM AG

CH-9101 Herisau

Switzerland

DES FUSIBLES DE 250V

USE ONLY WITH 250V

100-120V

UNIQUEMENT AVEC

FUSES/EMPLOYER

Metrohm

Metrohm

MetrohmMetrohm

220-240V

Instructions for Use

8.788.1003

Page 2

CH-9101 Herisau/Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

E-Mail info@metrohm.com

Internet www.metrohm.com

788 IC Filtration Sample Processor

Instructions for Use

8.788.1003 03.2001 / up, dö

Page 3

Table of contents

Table of contents

1 Introduction

1.1 Instrument description ................................................................... 1

1.2 Parts and controls........................................................................... 2

1.3 Information about the Instructions for Use................................. 5

1.3.1 Organization........................................................................... 5

1.3.2 Notation and pictograms ....................................................... 6

1.4 Support dokumentation.................................................................. 7

1.4.1 Application Bulletins............................................................... 7

1.4.2 Application Notes................................................................... 7

1.5 Safety Notes ..................................................................................... 7

1.5.1 Electrical Safety...................................................................... 7

1.5.2 General safety rules ............................................................... 8

2 Installation

2.1 Setting up the instrument ..............................................................9

2.1.1 Packaging ..............................................................................9

2.1.2 Check ..................................................................................... 9

2.1.3 Location.................................................................................. 9

2.1.4 Arrangement of the instruments............................................. 9

.....................................................................................

........................................................................................

1

9

2.2 Mains connection ..........................................................................10

2.2.1 Setting the mains voltage..................................................... 10

2.2.2 Fuses.................................................................................... 11

2.2.3 Mains cable and mains connection ..................................... 11

2.2.4 Switching the instrument on/off............................................ 11

2.3 Attaching the accessories ...........................................................12

2.3.1 Connecting the swing head .................................................12

2.3.2 Connecting the keyboard..................................................... 12

2.3.3 Installing the plug cover ....................................................... 12

2.3.4 Installing the splash protection ............................................ 13

2.3.5 Installing the needle or tubing.............................................. 13

2.3.6 Placing the sample rack....................................................... 14

2.3.7 Adjusting the sample rack.................................................... 14

2.3.8 Assembling the ultra-filtration cell ........................................ 16

2.3.9 Tubing connections.............................................................. 19

2.3.10 Tubing connections 788 – 754 Dialysis Unit ...................... 22

2.3.11 Fixing tubing and cables.................................................... 22

788 IC Filtration Sample Processor

I

Page 4

Table of contents

2.4 Installation for full control with «IC Net»................................... 23

2.4.1 Connection options.............................................................. 23

2.4.2 General information on interface connections..................... 24

2.4.3 Metrohm IC Systems ........................................................... 25

2.4.4 MIC 1 – Modular anion or cation system

with electronic suppression.................................. 26

2.4.5 MIC 2 Modular anion system

with chemical suppression ................................... 27

2.4.6 MIC 3 Modular anion and cation system

with chemical suppression .................................. 28

2.4.7 MIC 7 Modular anion system

with chemical suppression and dialysis .............. 30

2.5 Installation with compact IC systems........................................ 34

2.5.1 Connection to 761 Compact IC or 790 Personal IC ............ 34

2.6 Installation for simple remote control of the IC system.......... 37

2.6.1 IC system without suppression............................................ 38

2.6.2 IC system with suppression with 788 as "Master"................ 38

2.6.3 IC system with suppression with PC as "Master"................. 39

2.6.4 IC system for simultaneous anion/cation determination...... 39

2.6.5 IC system with sample dialysis............................................ 40

2.7 Connection of devices to the RS232 interface ......................... 41

2.7.1 General information on RS232 interface.............................. 41

2.7.2 Connecting a printer ............................................................ 42

3 Operating tutorial

3.1 Prerequisites / Preparations........................................................ 45

3.2 Configuration................................................................................. 46

3.3 Rack configuration........................................................................ 47

3.4 Methods .......................................................................................... 49

3.5 "Tracing" ......................................................................................... 49

....................................................................

45

II

788 IC Filtration Sample Processor

Page 5

Table of contents

4 Operation

4.1 Fundamentals of operation..........................................................53

4.1.1 Display.................................................................................. 53

4.1.2 Keyboard.............................................................................. 54

4.1.3 Overview of key functions .................................................... 55

4.1.4 Instrument dialog ................................................................. 64

4.1.5 Data entry............................................................................. 66

4.1.6 Text entry.............................................................................. 67

4.2 Basic settings ................................................................................69

4.2.1 Configuration – <CONFIG> key .........................................69

4.2.2 Locking keyboard functions ................................................. 73

4.3 Methoden ........................................................................................ 75

4.3.1 Structure of a method .......................................................... 75

4.3.2 Method parameters – <PARAM> key................................. 76

4.3.3 Programming of sequences................................................. 78

4.3.4 LEARN mode........................................................................ 79

4.3.5 TRACE funktion .................................................................... 79

4.3.6 Commands for sequences................................................... 80

4.3.7 Process control .................................................................... 85

4.3.8 User defined methods.......................................................... 86

4.3.9 POWERUP method .............................................................. 87

.........................................................................................

53

4.4 Manual operation...........................................................................88

4.4.1 Turning the sample rack / Positioning the samples............. 88

4.4.2 Moving the lift ....................................................................... 88

4.4.3 Setting the sample position.................................................. 89

4.4.4 Pump control........................................................................ 89

4.4.5 Display interface signals ......................................................89

4.4.6 Interface control ................................................................... 90

4.4.7 Print out reports.................................................................... 91

4.5 Sample racks.................................................................................. 93

4.5.1 Standard rack (6.2041.430).................................................. 93

4.5.2 Magnetic code ..................................................................... 93

4.5.3 Rack data ............................................................................. 94

4.5.4 Special beakers.................................................................... 96

4.6 Standard methods......................................................................... 97

4.6.1 Method "PC" and "PC Seg"................................................... 99

4.6.2 Method "SP" and "SP Seg".................................................. 100

4.6.3 Method "761" and "761 Seg"............................................... 101

4.6.4 Method "An Cat" and "AnCatSeg"....................................... 102

4.6.5 Method "Preconc"............................................................... 104

4.6.6 Method "Dialysis"................................................................ 106

4.7 Filtration........................................................................................108

4.6.1 Selecting suitable sample types ........................................ 108

4.6.2 Filtration membrane life...................................................... 108

4.6.3 Selecting a suitable filtration membrane............................ 109

788 IC Filtration Sample Processor

III

Page 6

Table of contents

5 Interfaces

5.1 Remote interface ......................................................................... 111

5.1.1 Pin assignment of the remote socket .................................111

5.1.2 Functional characteristics ...................................................112

5.2 RS232 interface ........................................................................... 115

5.2.1 General rules for remote control .........................................115

5.2.2 Call-up of objects................................................................116

5.2.3 Trigger.................................................................................117

5.2.4 Status messages ................................................................118

5.2.5 Error messages...................................................................119

5.2.6 Remote control commands ................................................120

5.2.7 Data transmission protocol.................................................127

5.2.8 Handshake..........................................................................128

5.2.9 Pin assignment ...................................................................131

5.2.10 RS232 error rectification....................................................132

6 Appendix

6.1 Error messages ........................................................................... 133

....................................................................................

.......................................................................................

111

133

6.2 Technical data ............................................................................. 135

6.3 Maintenance and servicing........................................................ 137

6.3.1 Maintenance by Metrohm service.......................................137

6.3.2 Care of the unit ...................................................................137

6.3.3 Replacing the pump tubing ................................................138

6.3.4 Replacing the filtration membrane......................................139

6.4 Diagnosis...................................................................................... 141

6.4.1 General Information ............................................................141

6.4.2 Preparing the instrument ....................................................142

6.4.3 Working memory (RAM)......................................................143

6.4.4 Display ................................................................................143

6.4.5 Keyboard ............................................................................144

6.4.6 Remote interface.................................................................145

6.4.7 RS232 interface...................................................................146

6.4.8 External Bus interface .........................................................146

6.4.9 Beeper ................................................................................147

6.4.10 Rack code recognition......................................................147

6.5 Initialize data memory ................................................................ 148

6.6 Validierung / GLP ........................................................................ 150

IV

6.7 Warranty and conformity ........................................................... 151

6.7.1 Warranty..............................................................................151

6.7.2 EU Declaration of conformity..............................................152

6.7.3 Certificate of conformity and system validation..................153

6.8 Standard equipment ................................................................... 154

6.9 Optional accessories.................................................................. 157

6.10 Index............................................................................................ 159

788 IC Filtration Sample Processor

Page 7

Table of contents

List of figures

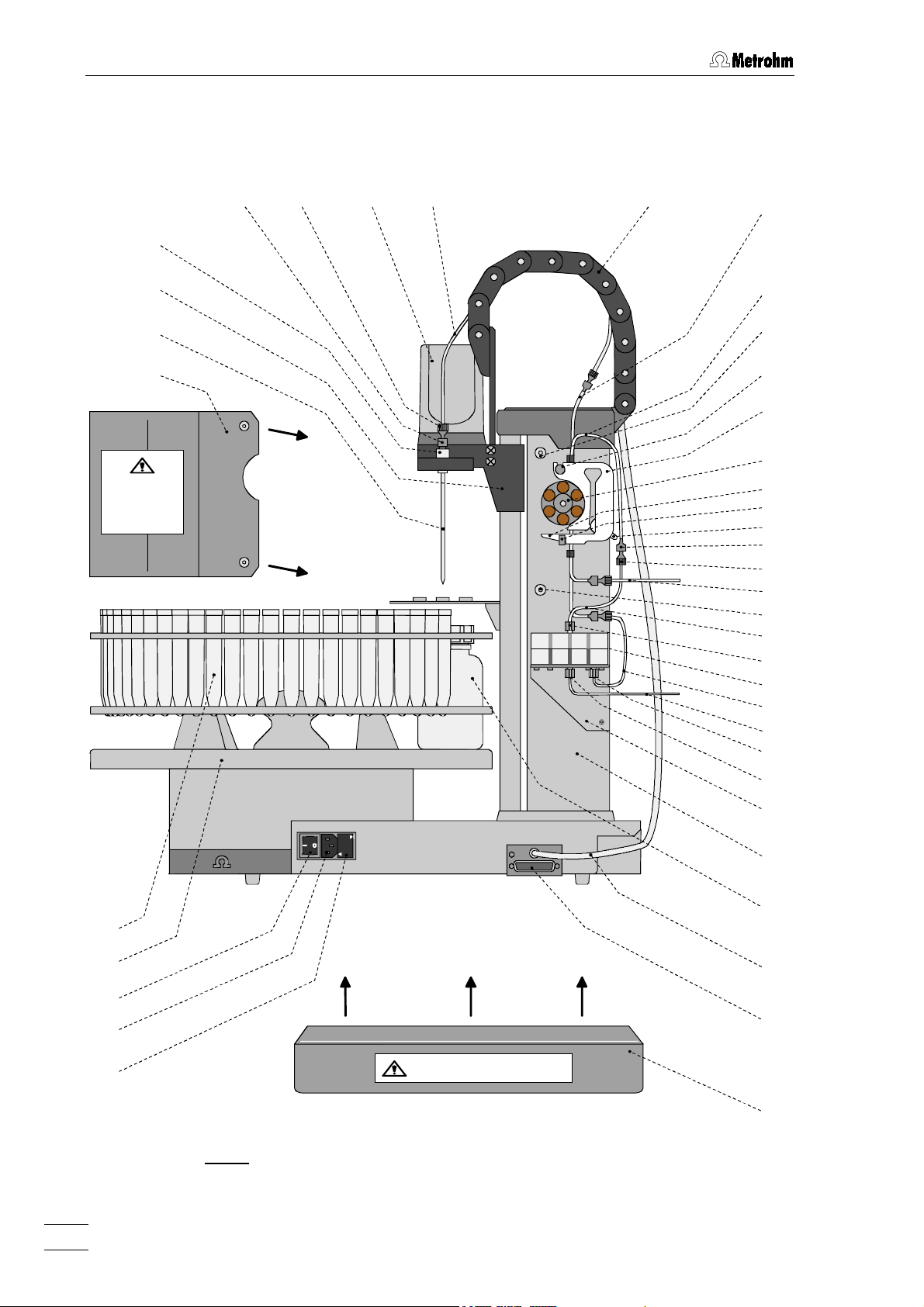

Fig. 1

: Side view of the 788 IC Filtration Sample Processor ........................................2

Fig. 2

: Rear of the 788 IC Filtration Sample Processor ................................................4

: Setting the mains voltage ................................................................................ 10

Fig. 3

Fig. 4

: Keyboard connection ......................................................................................12

Fig. 5

: Installing the splash protection........................................................................13

: Needle installation ...........................................................................................14

Fig. 6

Fig. 7

: Sample rack placing........................................................................................14

Fig. 8

: Adjusting the sample rack .............................................................................15

Fig. 9

: Assembling the ultra-filtration cell....................................................................16

Fig. 10

: Installing the pump tubing ...............................................................................19

Fig. 11

: Mount ultra-filtration cell...................................................................................20

Fig. 12

: Opening chain links .........................................................................................22

Fig. 13

: Interconnection with anion or cation IC system

with electronic suppression (MIC 1) ................................................................26

Fig. 14

: Interconnection with anion IC system

with chemical suppression (MIC 2) ................................................................. 27

Fig. 15

: Interconnection with the combined anion and cation IC system

with chemical suppression (MIC 3) ................................................................. 28

Fig. 16

: Interconnection with anion IC system

with chemical suppression and dialysis (MIC 7).............................................30

Fig. 17

: Interconnection of with compact IC systems ..................................................34

Fig. 18

:

Interconnection with IC system without suppression..........................

Fig. 19:

Fig. 20

Fig. 21

Fig. 22

Fig. 23

Fig. 24

Fig. 25

Interconnection with IC system with suppression with 788 as "Master"

: Interconnection with IC system with suppression with PC as "Master"

:

Interconnection for anion/cation system.............................................

:

Interconnection with IC system with dialysis.......................................

: Connection possibilities for the RS232 interface ............................................41

: Schematic representation of the instrument dialog .......................................65

: Installation of the preconcentration column ..................................................104

.......

........

38

38

39

39

40

788 IC Filtration Sample Processor

V

Page 8

Table of contents

VI

788 IC Filtration Sample Processor

Page 9

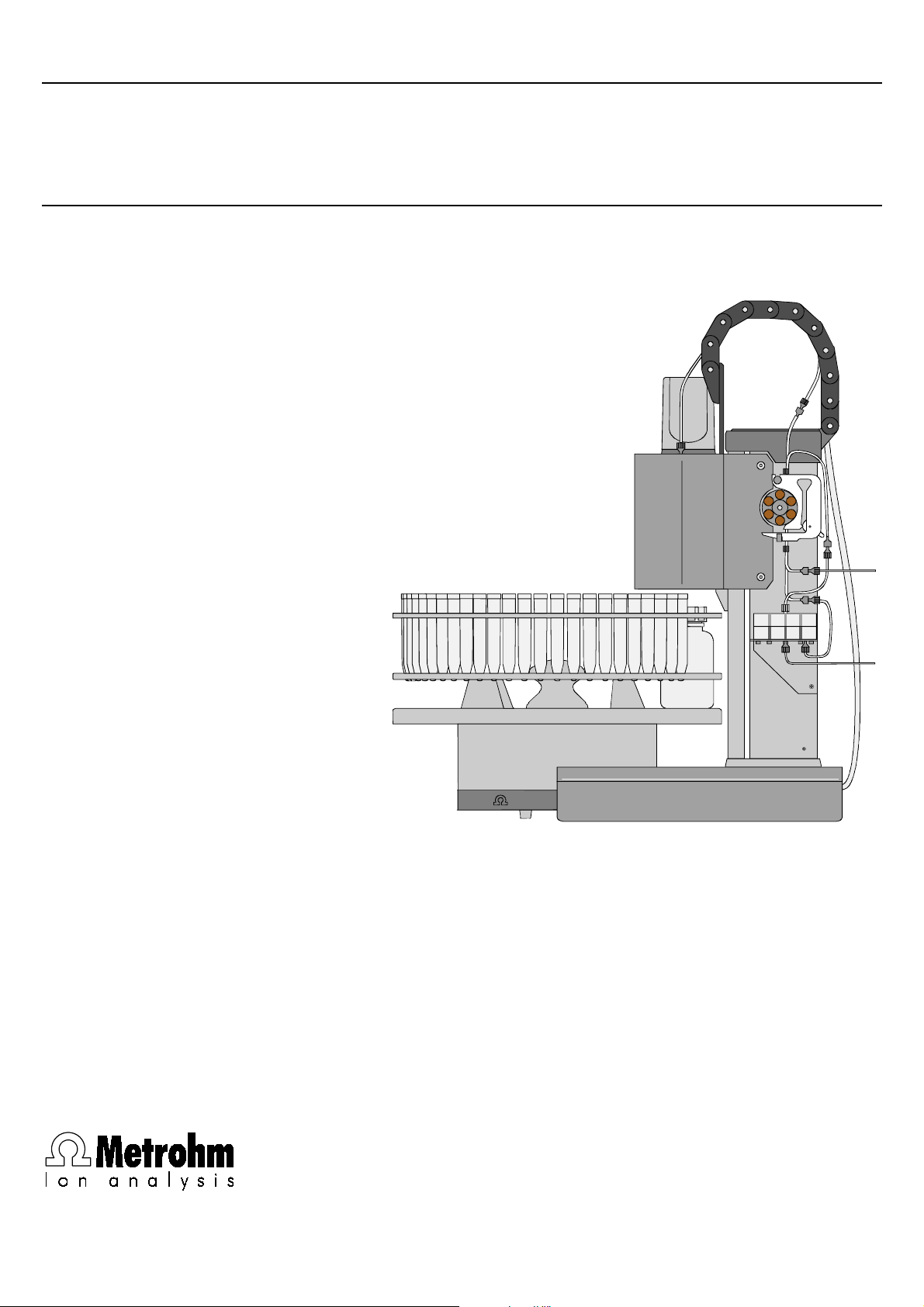

1.1 Instrument description

1 Introduction

1.1 Instrument description

788 IC Filtration Sample Processor

The

ion chromatographic determinations including in-line filtration, especially in combination with Metrohm IC system instruments. It is possible

to apply and automate existing procedures for sample preparation using the ultra-filtration of the 788 IC Filtration Sample Processor.

The 127 sample tubes with a volume of 11 mL are arranged on the

sample rack in three rows, which guarantees easy access and unrestricted programming. Two additional rinsing positions allow sample introduction free from cross-contamination even with widely varying sample matrices. Sample tubes made of polypropylene are standard. To

protect the samples from external contamination, the tubes can be

hermetically sealed.

can be used for automating

Sample filtration and introduction to the injector is achieved by means

of its integrated double-channel peristaltic pump. The sample is conveyed by one channel of the pump through the ultra-filtration cell passing the membrane. At the same time the filtrate is aspirated off from the

rear of this membrane and transferred to the sample loop by the second channel of the pump. A PEEK needle for sealed or a PEEK tube for

open sample tubes can be used alternatively.

The sequences for the processing of each sample are freely definable

within broad boundaries. The same is true for the start and final sequences that are executed once either before or at the end of a sample

series. With the help of the LEARN mode, which is provided for creating

process methods, methods can be created easily and stored as user

methods.

Preprogrammed standard methods for the most common modes of

operation allow to use the 788 IC Filtration Sample Processor directly,

with only little programming effort. The time frame can be given by the

788 IC Filtration Sample Processor; alternatively, the whole sequence

can be managed by the «IC Net» remote control software via the

«

Queue» (sample table). The RS232 interface built in as standard allows remote control of the 788 IC Filtration Sample Processor from a

PC.

788 IC Filtration Sample Processor

1

Page 10

1 Introduction

1.2 Parts and controls

4444

3333

2222

1111

Always install splash

protection!

55556

67

66

78

77

89

88

9

99

10

10

1010

11

11

1111

12

12

1212

13

13

1313

14

14

1414

15

15

1515

16

16

1616

17

17

1717

18

18

1818

19

19

1919

6666

20

20

2020

12

12

1212

21

21

2121

22

22

2222

23

23

2323

24

24

2424

25

25

2525

22

22

2222

36

36

3636

35

35

3535

34

34

3434

33

33

3333

32

32

3232

DES FU SI B LE S D E 25 0V

100-120V

USE ONLY WITH 250V

UNIQUEMENT AVEC

FUSES/EMPLOYER

Metrohm

Metrohm

MetrohmMetrohm

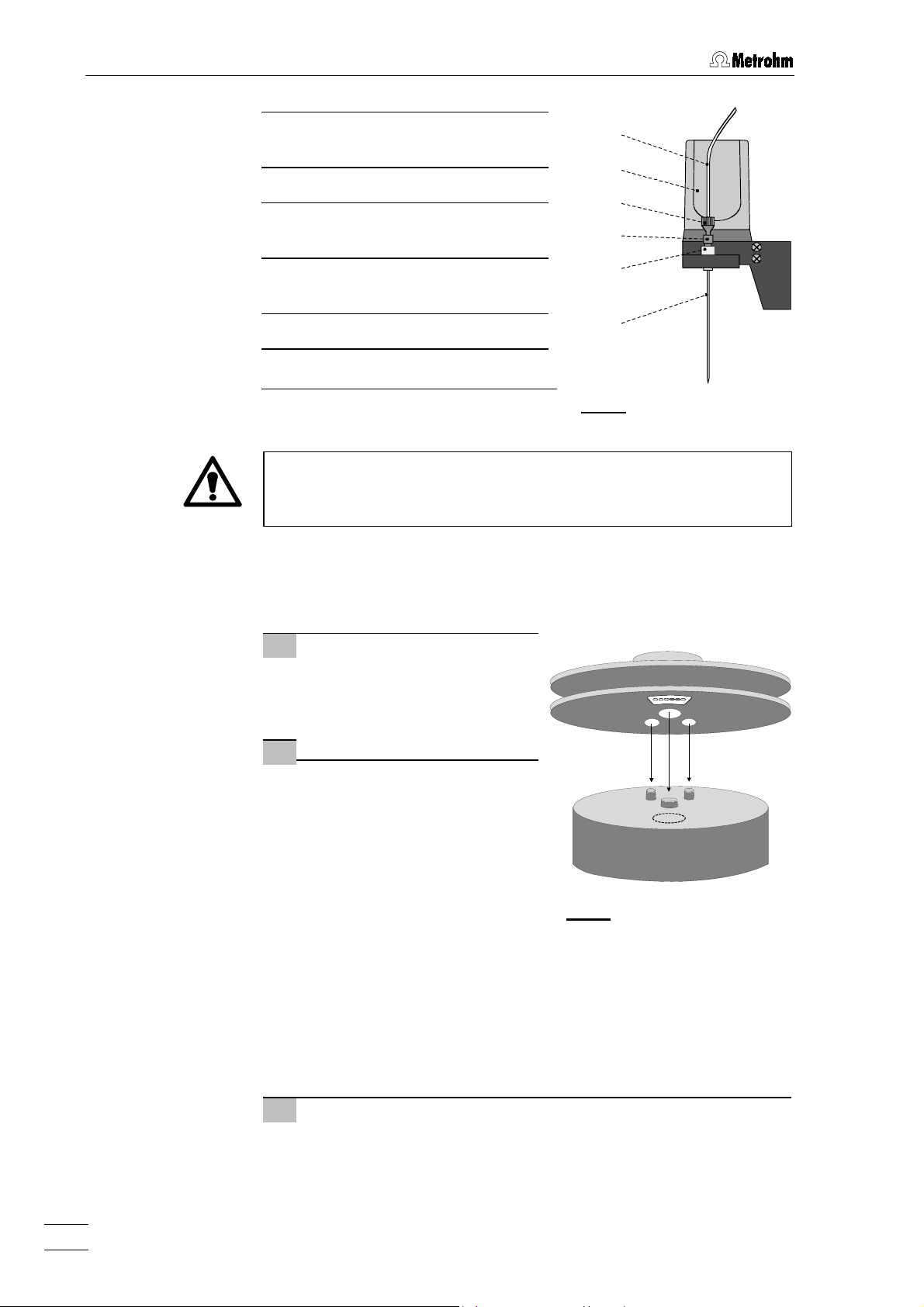

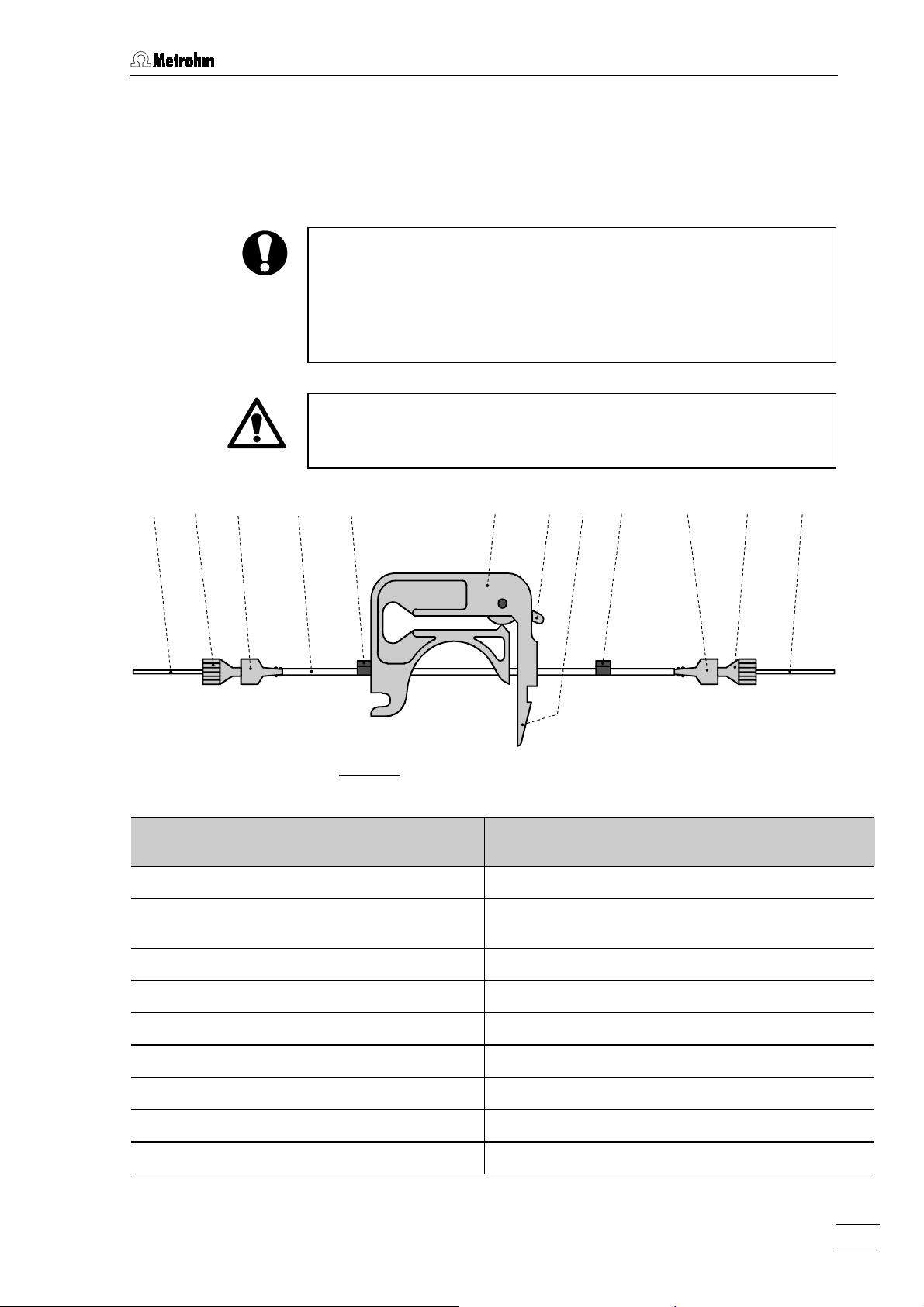

Fig. 1

: Side view of the 788 IC Filtration Sample Processor

220-240V

Always install plug cover!

22

22

2222

26

26

2626

27

27

2727

28

28

2828

29

29

2929

30

30

3030

31

31

3131

788 IC Filtration Sample Processor

2

Page 11

1.2 Parts and controls

Splash protection (6.2751.040)

1111

Must be installed always in operation!

Needle

2222

PEEK needle (6.1835.010) or

PEEK tubing (6.1835.020)

Lift

3333

4444

5555 PEEK compression fitting

6666

7777

8888

With swing head attached

Needle guide (4.766.4330)

Attached (part of needle holder

(6.2833.000))

(4.766.4320)

PEEK compression fitting

(6.2744.010)

PTFE capillaries 1/16 "

Swing head

Attached

PTFE capillary (6.1803.070)

(0.97 mm / 0.40 m) Connection

needle – pump tubing

For PEEK needle or tubing

For connection of PEEK or

19

19 PEEK coupling (6.2744.030)

1919

Connecting compression fitting and

pump tubing

20

20 PEEK capillary (6.1831.060)

2020

For conveying the filtrate into the

sample loop

21

21 PTFE capillary (6.1803.050)

2121

(0.5 mm / 0.2 m) Connecting ultrafiltration cell and filtrate pump tubing

22

22 PVDF compression fitting

2222

(6.2744.000)

ies (6.1803.0X0) to ultra-filtration cell

23

23 Ultra-filtration cell (6.2729.110)

2323

(Plexiglass)

24

24 PTFE capillary (6.1803.060)

2424

(0.97 mm / 0.2 m) Connecting sample

pump tubing and ultra-filtration cell

25

25 PTFE capillary (6.1803.080)

2525

(0.97 mm / 1 m) Connecting ultrafiltration cell and waste

26

26 Cell holder

2626

For ultra-filtration cell

Connecting PTFE capillar-

(Olive)

(1 m)

Guide chain

9999

For fixing tubings and cables

10

10 Pump tubing (6.1826.070)

1010

(yellow/yellow) Conveying the sample

to the ultra-filtration cell

11

11 Pump tubing (6.1826.030)

1111

(orange/yellow) Conveying the filtrate

to the sample loop

Screw thread for splash protection 30

12

12

1212

Mounting pin

13

13

1313

For attaching the tubing cartridges

Tubing cartridge (6.2755.000)

14

14

1414

For pump tubing (6.1826.0X0)

Pump drive

15

15

1515

Roller head with contact rollers

Snap-action lever

16

16

1616

For releasing the tubing cartridge

Holding clamp

17

17

1717

For locking the tubing cartridge into

place

27

27 Tower

2727

28

28 PE bottle (6.1608.080)

2828

Connection cable for swing head

29

29

2929

Attached, incl. branch plug for remote

connection

30 Remote connection

3030

For additional Metrohm instruments

31

31 Plug cover (6.2752.010)

3131

32

32 Fuse holder

3232

Changing the fuses, see

33

33 Mains connection plug

3333

Mains connection, see

34

34 Mains switch

3434

For switching the instrument on/off:

I = ON 0 = OFF

Sample rack (6.2041.430)

35

35

3535

(300 mL)

section 2.2.2

section 2.2.3

18

18 Contact pressure lever

1818

For adjusting the contact pressure

788 IC Filtration Sample Processor

PP sample tube (6.2743.050) (11 mL)

36

36

3636

Can be sealed with 6.2743.070 PP caps

3

Page 12

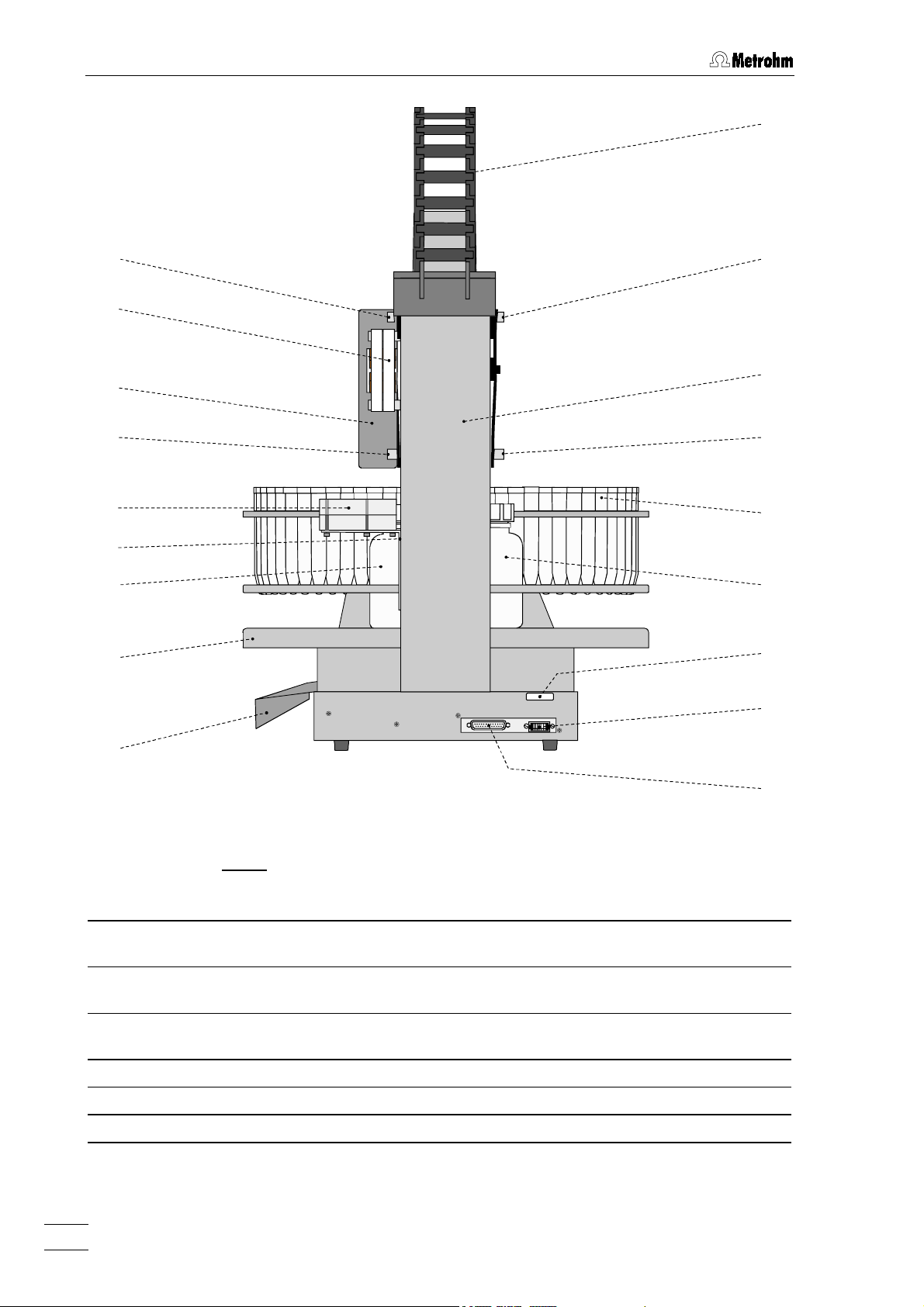

1 Introduction

9999

37

37

3737

14

14

1414

37

37

3737

27

27

2727

1111

37

37

37

37

3737

23

23

2323

3737

36

36

3636

26

26

2626

28

28

2828

35

35

3535

31

31

3131

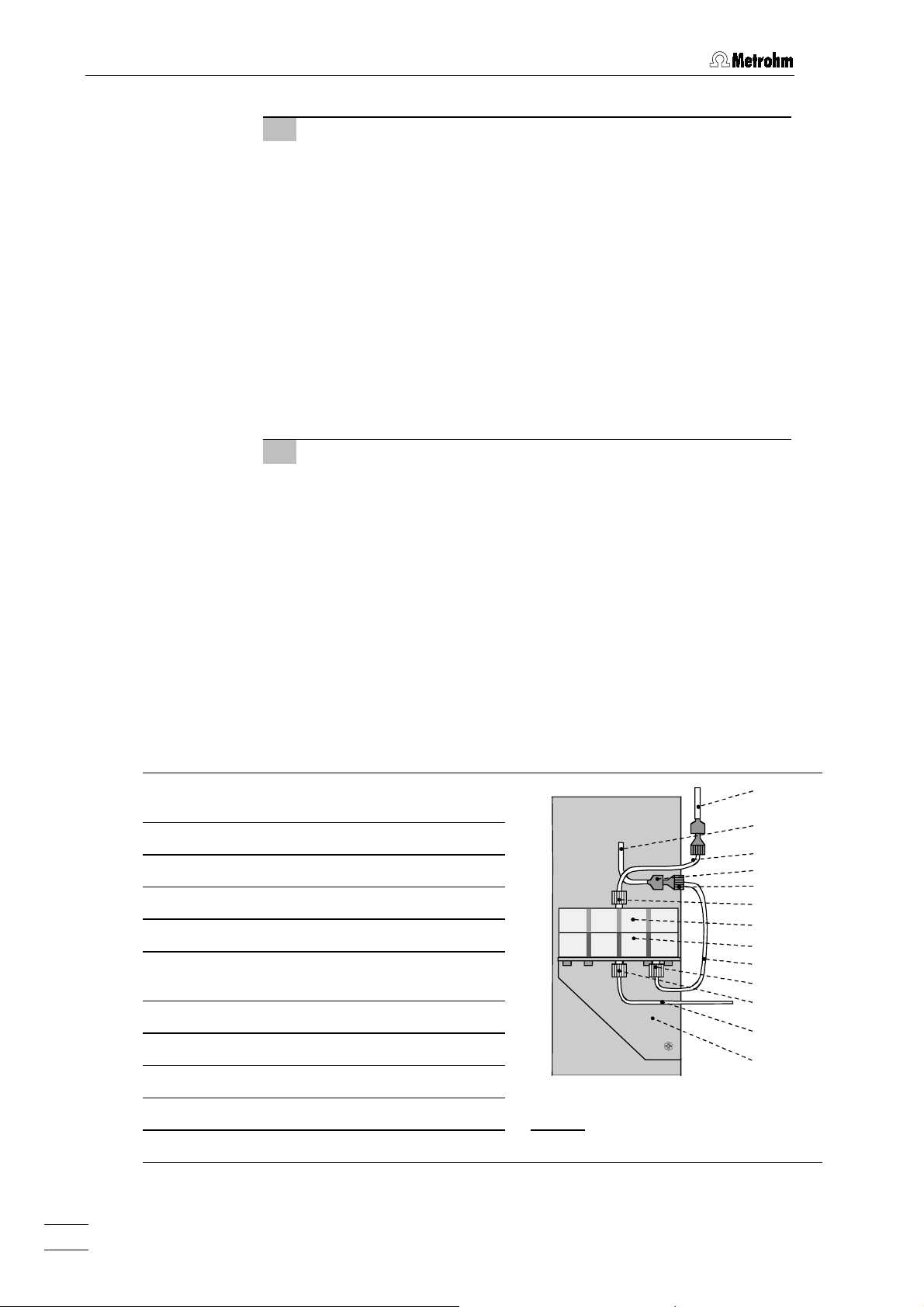

: Rear of the 788 IC Filtration Sample Processor

Fig. 2

Splash protection (6.2751.040)

1111

Must be installed always in operation!

Guide chain

9999

For fixing tubings and cables

Type 1.788.

RS 232 Keyboard

Made by Metro hm Herisau Swi tzerland

35

35 Sample rack 6.2041.430

3535

36

36 PP sample tube (6.2743.050) (11 mL)

3636

Can be sealed with 6.2743.070 PP caps

28

28

2828

38

38

3838

39

39

3939

40

40

4040

Tubing cartridges (6.2755.000)

14

14

1414

For 6.1826.0X0 pump tubing

Tower

27

27

2727

PE bottle (6.1608.080)

28

28

2828

Plug cover (6.2752.010)

31

31

3131

788 IC Filtration Sample Processor

4

(300 mL)

37

37 Mounting screws for splash protec-

3737

tion

38

38 Serial number

3838

39

39 Keyboard connection

3939

40

40 RS232 connection

4040

Page 13

1.3 Information about the Instructions for Use

1.3 Information about the Instructions for Use

Please read through these Instructions for Use carefully before

operating the 788 IC Filtration Sample Processor. The Instructions for

Use contain information and warnings to which the user must pay

attention in order to assure safe operation of the instrument..

1.3.1 Organization

These

ple Processor provide a comprehensive overview of the installation,

startup procedure, operation, fault rectification and technical specifications of this instrument. The Instructions for Use are organized as follows:

8.788.1003 Instructions for Use

Section 1 Introduction

Description of the instrument, parts and controls,

safety notes

Section 2 Installation

Mains connection, attachment of accessories,

connection to IC systems

Section 3 Operating tutorial

Introduction to the operation

Section 4 Operation

Detailed description of display, keyboard, methods,

manual operation, sample racks, standard methods,

and filtration

Section 5 Interfaces

Remote interface, RS232 interface and

remote control language

for the 788 IC Filtration Sam-

788 IC Filtration Sample Processor

Section 6 Appendix

Error messages, technical data, maintenance

and servicing, diagnosis, warranty, declaration

of conformity, standard equipment, optional

accessories, index

To find the information you require about the instruments please use either the

Quick Reference Guide

daily use as it explains the most important parameters and key functions.

Table of contents

is suitable for use as a reference work for

or the

Index

at the back. The

8.788.1013

5

Page 14

1 Introduction

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these

Instructions for Use:

<PUMP>

15

15

1515

89

89

8989

26

26

2626

'Bereich'

******** counter 0/127

PUMP- ready

Switch or key

Part or control of 788

Part or control of 732/733

Part or control of 754

Parameter or entry value

at 788 IC Filtration Sample

Processor

Display

Text in keyboard display of 788

IC Filtration Sample Processor

Hazard

This symbol draws attention to

a possible danger to life or

injury if the associated

directions are not followed

correctly.

Warning

This symbol draws attention to

possible damage to instruments or instrument parts if the

associated directions are not

followed correctly.

Caution

This symbol marks important

information. Read these directions before continuing.

Comment

This symbol marks additional

information and tips.

788 IC Filtration Sample Processor

6

Page 15

1.4 Support documentation

1.4 Support documentation

1.4.1 Application Bulletins

The «Application Bulletin» is a collection of analytical methods, application examples and literature references. All these Application Bulletins

are available on request free of charge from your Metrohm supplier.

You will find an updated list of the Application Bulletins at any time under «http://www.metrohm.com».

1.4.2 Application Notes

The «Application Notes» present application information in concentrated form, i.e. on maximum 2 pages. You can order these free of

charge from your Metrohm supplier or view them in the Internet under

«

http://www.metrohm.com» and copy them from there.

1.5 Safety notes

1.5.1 Electrical safety

While electrical safety in the handling of the 788 IC Filtration Sample

Processor is assured in the context of the specifications IEC 1010-1

(protection class I), the following points should be noted:

x

Mains connection

Set the mains voltage and check the mains fuse and mains

connection in accordance with the instructions in section 2.2.

x

Opening the 788 IC Filtration Sample Processor

To avoid all danger of coming into contact with live components do

not open the instrument or remove any parts when the 788 IC Filtration

Sample Processor is connected to the power supply. Always disconnect the instrument from all voltage sources before you open it and

ensure that the mains cable is disconnected from mains con-

nection 33

33 !

3333

x

788 IC Filtration Sample Processor

Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 788 IC Filtration Sample Processor, you should earth

yourself and any tools you are using by touching an earthed object

(e.g. housing of the instrument or a radiator) to eliminate any static

charges which exist.

7

Page 16

1 Introduction

1.5.2 General safety rules

x

Install splash protection

To avoid any danger of injury by the needle, the splash protection

must always be installed when operating the 788 IC Filtration Sample

Processor!

x

Install plug cover

To prevent any contamination of the mains and remote connection by

spilled solvents or chemicals, the plug cover must always be installed

when operating the 788 IC Filtration Sample Processor!

x

Do not use caps together with the PEEK tube

If you are using the 6.1835.020 PEEK tube, the sample tubes may not

be sealed with caps because they cannot be pierced by the PEEK

tubing and the tubing may be damaged thereby.

x

Handling of solvents

Check the pump tubing and all input and output leads periodically for

possible leaks. Follow the relevant instructions regarding the handling

of flammable and/or toxic solvents and their disposal.

x

Regular exchange of pump tubings

Pump tubings constitute consumable material and must be replaced

from time to time (see section 6.3.3). Suitable measures must be

taken so that any leak which might occur in the pump tubing or

connections during unattended operation will cause no damage

(collection device for any liquid which may leak out).

788 IC Filtration Sample Processor

8

Page 17

2.1 Setting up the instrument

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 788 IC Filtration Sample Processor is supplied together with the

separately packed accessories in special packaging containing shockabsorbing foam linings designed to provide excellent protection. The

actual instrument is packed in an evacuated polyethylene bag to

prevent the ingress of dust. Please store all these special packagings

as only they can assure damage-free transport of the instrument.

2.1.2 Check

After receipt, immediately check whether the shipment is complete and

undamaged (compare with delivery note and list of accessories in

section 6.8

section 6.7.1

). In the case of transport damage, see instructions in

"Warranty".

2.1.3 Location

Position the instrument in the laboratory at a location convenient for

operation, free from vibrations and protected against a corrosive

atmosphere and contamination by chemicals.

Do not operate the 788 IC Filtration Sample Processor without splash

protection 1111 and plug cover 31

31 being installed!

3131

2.1.4 Arrangement of the instruments

788 IC Filtration Sample Processor

To make the connection for conveying the sample filtrate to the injection

valve at the 733 IC Separation Center (or 761 Compact IC or 790

20

Personal IC) with the peek capillary

the 788 IC Filtration Sample Processor immediately on the left side of

the IC system.

Take precautions to ensure that any leaks from pump tubings or

connections cannot cause more damage.

20

(length 1 m) supplied, position

2020

9

Page 18

2 Installation

2.2 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with the mains voltage set wrongly and/or

wrong mains fuse there is a danger of fire!

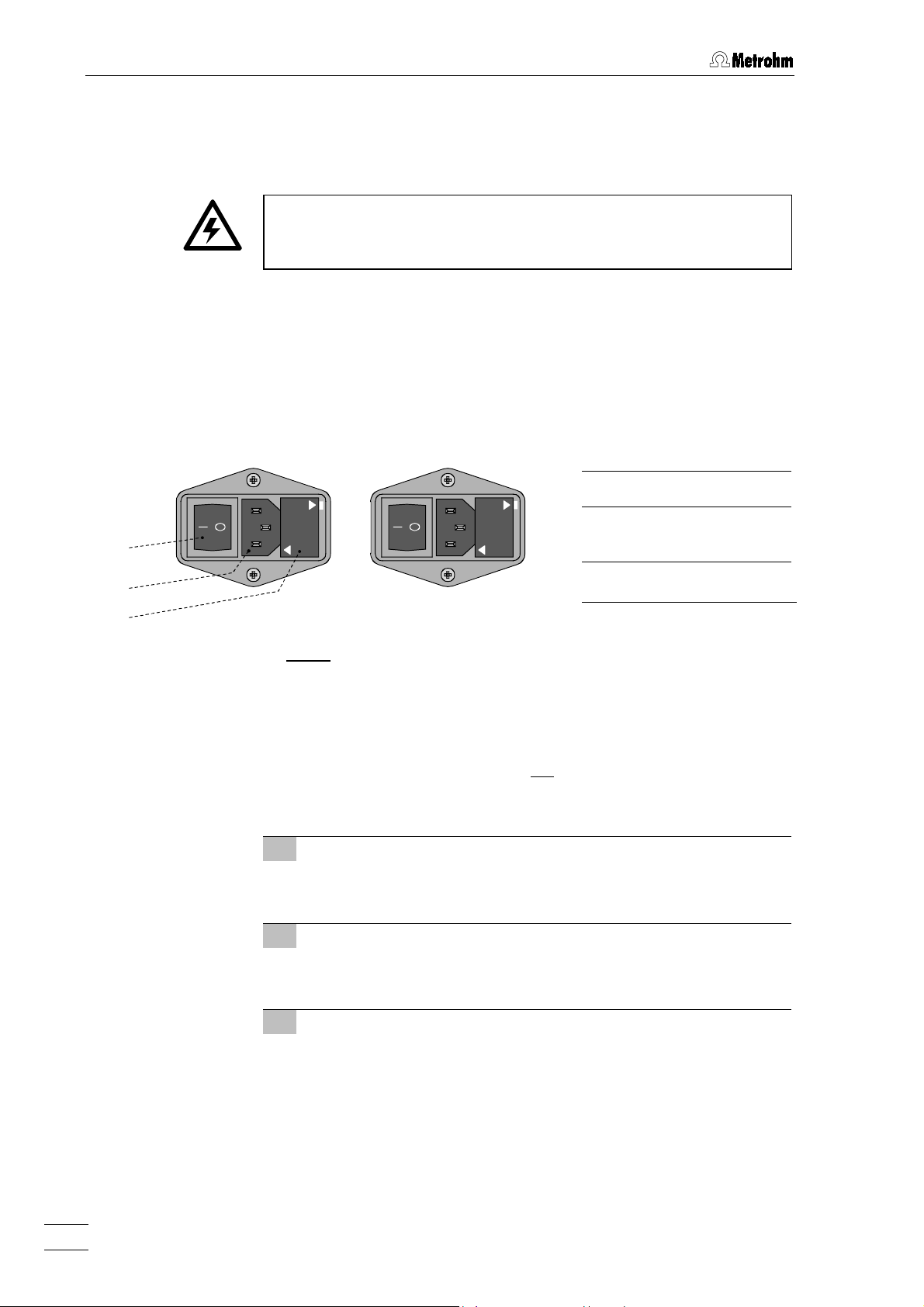

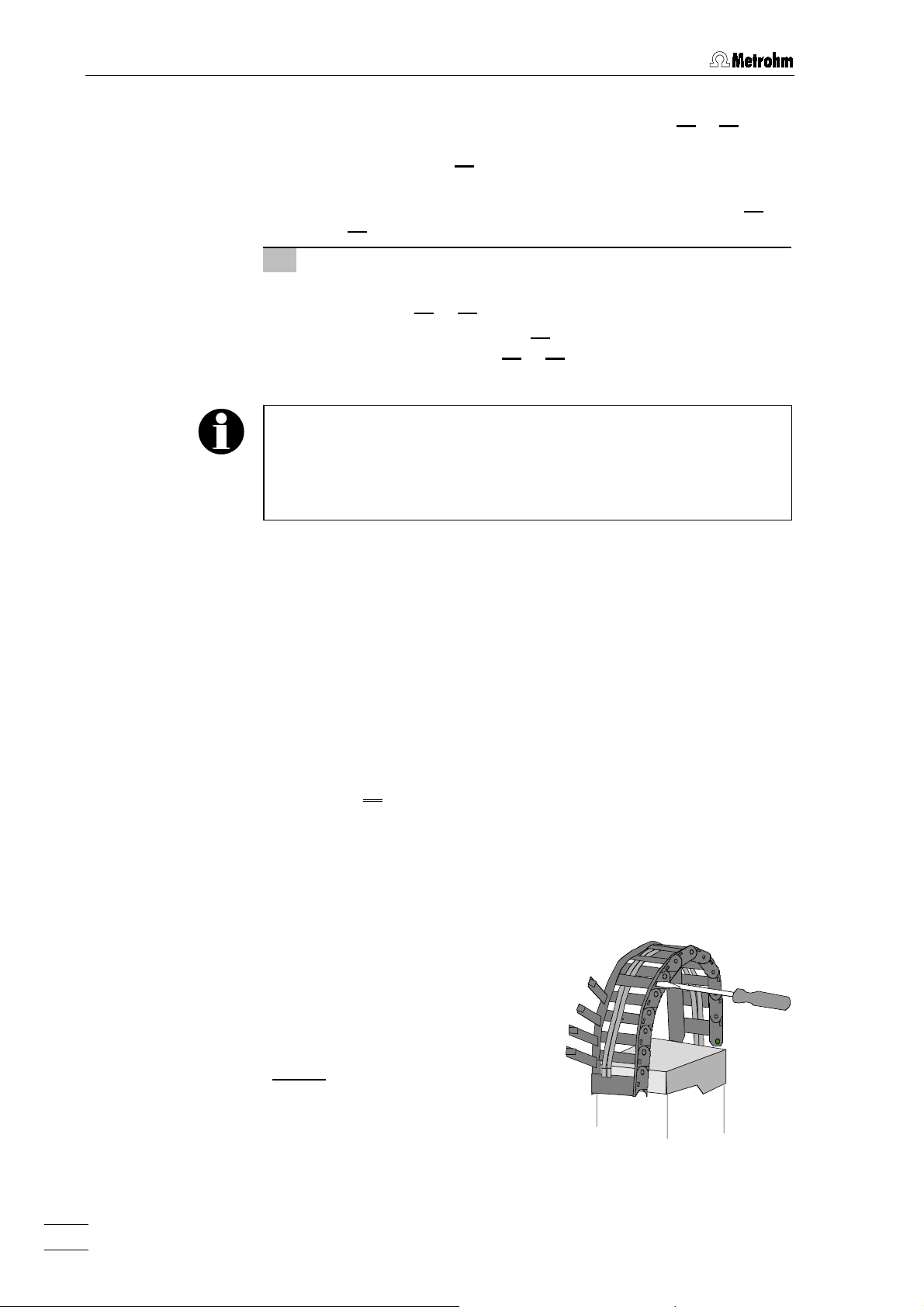

2.2.1 Setting the mains voltage

34

34

3434

33

33

3333

32

32

3232

100 – 120 V

Before switching on the 788 IC Filtration Sample Processor for the first

time, check that the mains voltage set on the instrument (see

matches the local mains voltage. If not

instrument as follows:

1 Disconnect mains cable

220 -

--

- 240 V

--

- 120 V

100 -

220 – 240 V

32

Fuse holder

100 -

--

- 120 V

--

- 240 V

220 -

323232

33

33 Mains connection

3333

plug

34

34 Mains switch

3434

: Setting the mains voltage

Fig. 3

, reset the mains voltage on the

Disconnect mains cable from mains connection plug

788 IC Filtration Sample Processor.

33

33

of the

3333

Fig. 3

)

2 Remove fuse holder

32

Using a screwdriver, loosen fuse holder

32

beside the mains

3232

connection and take out completely.

3 Check fuse

Carefully take the fuse installed for the desired mains voltage out

of fuse holder and check its specifications (the position of the

fuse in the fuse holder is marked by the white arrow imprinted

next to the mains voltage range):

100}}}}120 V 0.5 A (slow-blow)

220}}}}240 V 0.25 A (slow-blow)

788 IC Filtration Sample Processor

10

Metrohm-Nr. U.600.0013

Metrohm-Nr. U.600.0010

Page 19

2.2 Mains connection

4 Insert fuse

32

Change fuse if necessary and reinsert in fuse holder

32

3232

.

5 Install fuse holder

32

Depending on the desired mains voltage, insert fuse holder

32

3232

in

the 788 IC Filtration Sample Processor so that the corresponding

mains voltage range can be read normally and the adjacent

white arrow points to the white bar imprinted on the right side of

the fuse holder (see

Fig. 3

).

2.2.2 Fuses

One of the two fuses 0.5 A/slow-blow for 100}120 V or 0.25 A/slow-

32

blow for 220}240 V is installed in fuse holder

Sample Processor as standard.

32

of the 788 IC Filtration

3232

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

For checking or changing fuses, proceed as described in

2.2.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

x

6.2122.020 with plug SEV 12 (Switzerland, })

x

6.2122.040 with plug CEE(7), VII (Germany, })

x

6.2133.070 with plug NEMA 5-15 (USA, })

which are three-cored and fitted with a plug with an earthing pin. If a

different plug has to be fitted, the yellow/green lead (IEC standard)

must be connected to protective earth (protection class I).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug

Filtration Sample Processor (see

Fig. 3

).

section 2.2.1

33

33

of the 788 IC

3333

.

2.2.4 Switching the instrument on/off

The 788 IC Filtration Sample Processor is switched on and off using

34

mains switch

788 IC Filtration Sample Processor

34

3434

.

11

Page 20

2 Installation

2.3 Attaching the accessories

For attaching the accessories at the 788 IC Filtration Sample

Processor, proceed in the order described below.

2.3.1 Connecting the swing head

29

Plug in the branch plug of the connection cable

attached to the swing head into the remote connection socket at the

788 IC Filtration Sample Processor and screw it onto this connection

using a screw-driver (see

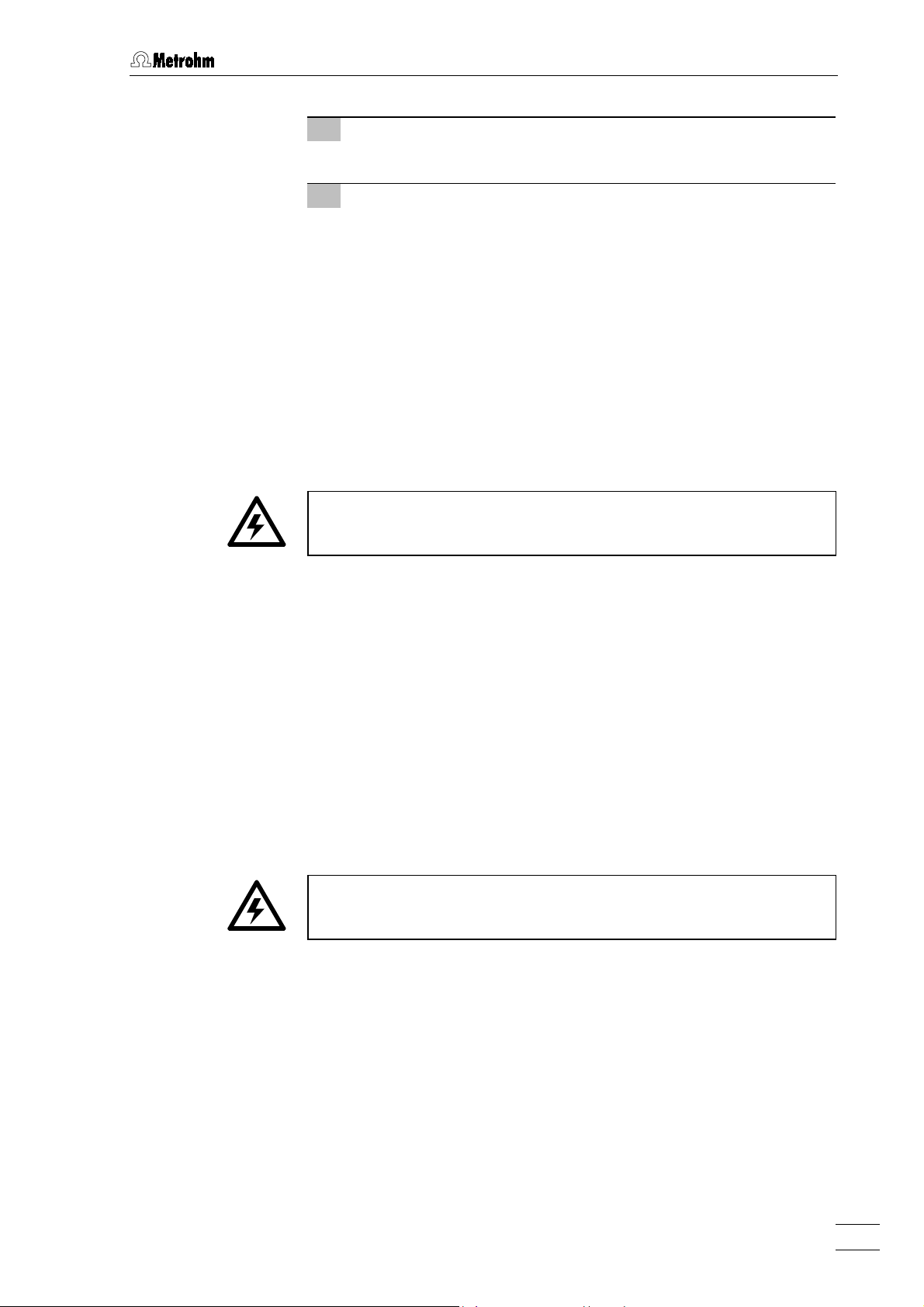

2.3.2 Connecting the keyboard

Fig. 1

).

29

permanently

29 29

1

Connecting the keyboard

Connect the 6.2142.010 keyboard

to the keyboard connection

"Keyboard". For disconnection,

press the plug together slightly on

both sides.

2

Switch on instrument

Switch on the 788 IC Filtration

Sample Processor with mains

34

switch

lights up. The instrument is

initialized and the lift is raised

completely.

34

. The keyboard display

3434

2.3.3 Installing the plug cover

39

39

3939

Fig. 4

: Keyboard connection

To prevent any contamination of the mains and remote connection by

spilled solvents or chemicals, the 6.2752.010 plug cover must always

be installed when operating the 788 IC Filtration Sample Processor!

31

Install the plug cover

mains connection plug

Fig. 2

).

788 IC Filtration Sample Processor

12

31

in the corresponding guide groove above

3131

33

33

and remote connection

3333

30

30

3030

(see

Fig. 1

and

Page 21

2.3 Attaching the accessories

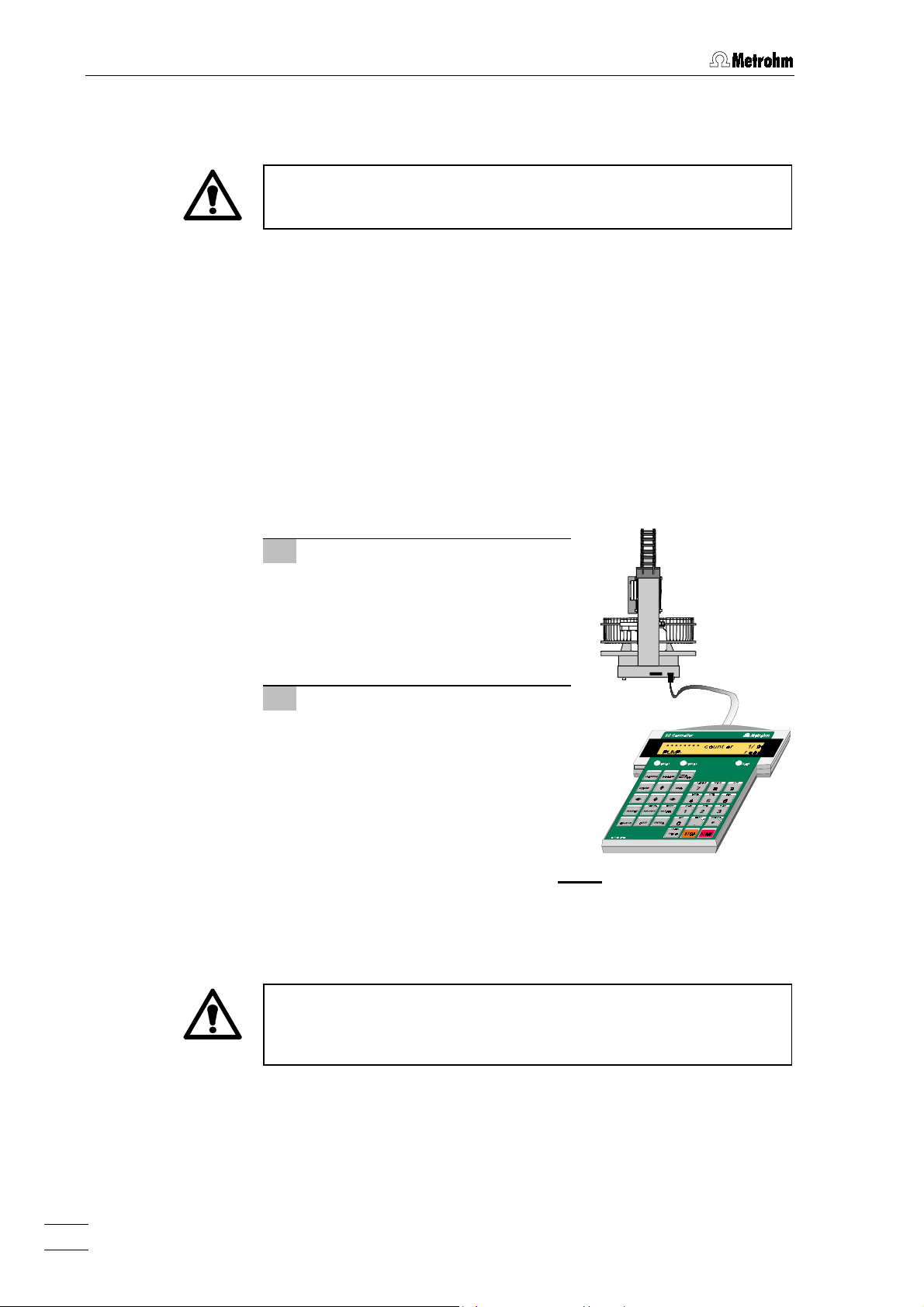

2.3.4 Installing the splash protection

To avoid any danger of injury by the needle, the 6.2751.040 splash

protection must always be installed when operating the 788 IC

Filtration Sample Processor!

1 Remove holding screws

37

Remove the holding screws

12

screw threads

2 Remove protective film from splash protection

Remove the plastic film glued on both sides of the splash

protection

3 Install splash protection

Attach splash protection onto the screw threads at the tower and

fix it with the holding screws and the washer using the

6.2621.100 Allen key.

12

at tower

1212

1111

.

37

and the washer mounted on the

3737

27

27

using the 6.2621.100 Allen key.

2727

1111 Splash protection

(6.2751.040)

37

Holding screws

373737

2.3.5 Installing the needle or tubing

1 Remove PEEK compression fitting 5

Remove PEEK compression fitting

holder

2 Insert needle

Insert needle

tubing) completely into the opening of the needle holder

4444

.

2222

(6.1835.010) PEEK needle or 6.1835.020 PEEK

: Installing the splash protection

Fig. 5

5555

screwed onto the needle

37

37

3737

1111

37

37

3737

4444

.

788 IC Filtration Sample Processor

3 Fix needle or tubing

Tighten compression fitting

use tools!).

(never

5555

in needle holder

4444

by hand

13

Page 22

2 Installation

2222 PEEK needle (6.1835.010) or

PEEK tubing (6.1835.020)

4444 Needle holder

5555 PEEK compression fitting

(4.766.4320)

6666 PEEK compression fitting

(6.2744.010)

7777 Swing head

8888 PTFE capillary (6.1803.070)

If you are using the 6.1835.020 PEEK tubing, the sample tubes may

not be sealed with caps because they cannot be pierced by the PEEK

tubing and the needle may be damaged thereby.

2.3.6 Placing the sample rack

8888

7777

6666

5555

4444

2222

Fig. 6

: Needle installation

1

Place sample rack

Place sample rack

turntable of the 788 IC Filtration

Sample Processor according

Fig. 7

to

2

Read magnetic code

Press <RESET> to move

the rack to the home position,

in which the magnetic code

can be read (details see

section 4.5

.

).

2.3.7 Adjusting the sample rack

If a new sample rack is placed on the 788 IC Filtration Sample

Processor for the first time, it must be adjusted on a rack position in the

middle row (example: position 37) as follows:

35

35

on the

3535

Fig. 7

: Sample rack placing

1 Place sample rack

Place empty sample rack on the 788 IC Filtration Sample

Processor and press <RESET> (see

788 IC Filtration Sample Processor

14

section 2.3.6

).

Page 23

2.3 Attaching the accessories

2222 PEEK needle (6.1835.010) or

2222

PEEK tubing (6.1835.020)

41

41

35

Sample rack (6.2041.430)

353535

41

Adjusting position 37

414141

42

Adjusting screw

424242

: Adjusting the sample rack

Fig. 8

2 Move to adjusting position

Press <MOVE>, enter number '37' and confirm with <ENTER>.

Sample rack and swing head are turned until needle is above

the adjusting position 37 (first opening of the middle row).

3 Check needle position

x

Press <

of the sample rack.

x

Check needle position: If the needle cannot be lowered

unhindered through the upper hole of the adjusting position,

continue directly with point 4.

x

Continue lowering the needle by pressing <

needle is ca. 1 cm above the lower level of the sample rack.

x

Check needle position: If the needle cannot be lowered

unhindered through the lower hole of the adjusting position,

continue directly with point 4.

x

Lower needle completely by pressing <

x

Check needle position: If the needle is in the middle of the

lower hole, the sample rack must not be adjusted (continue in

this case with point 5).

Ð

> until the needle is ca. 1 cm above the upper level

Ð

> until the

Ð

>.

4141

42

42

4242

35

35

3535

788 IC Filtration Sample Processor

4 Adjust sample rack

42

41

41

4141

42

on the lower level of the

4242

.

x

Loosen the three adjusting screws

sample rack using the 6.2621.100 Allen key.

x

Carefully turn the two upper levels of the sample rack by hand

until the lowered needle is exactly in the middle of the lower

hole at the adjusting position

x

Tighten the adjusting screws.

5 Move to rest position

Press <RESET> to move the sample rack to the rest position.

15

Page 24

2 Installation

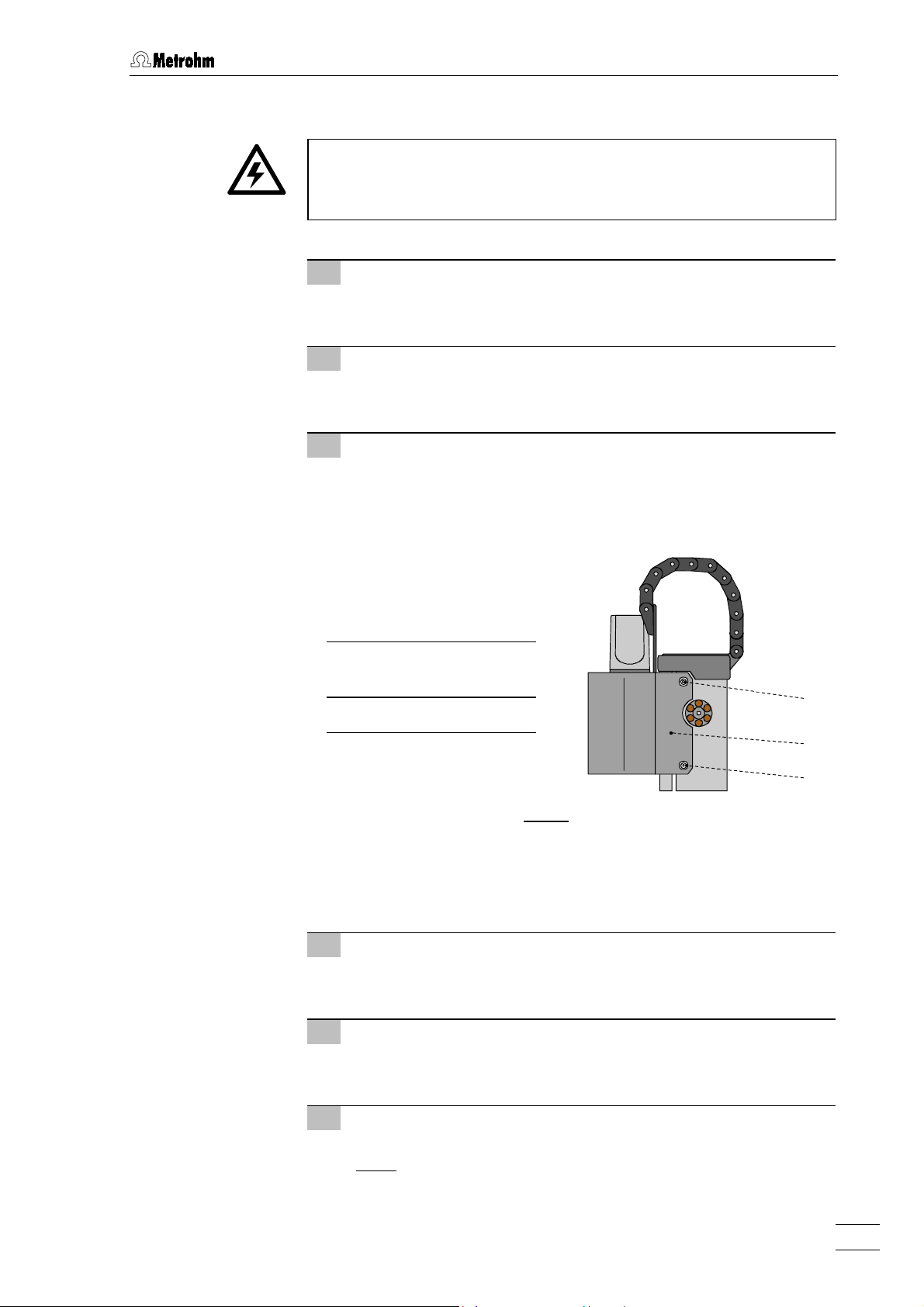

2.3.8 Assembling the ultra-filtration cell

In this section, the assembling of the ultra-filtration cell including the

filtration membrane is described. Please consider section 4.7 for

evaluating the membrane type and time of exchange. The exchange of

filtration membranes is also described in section 6.3.4.

23

23 43

2323

43 44

4343

44

4444

45

45 46

4545

46

4646

47

47

4747

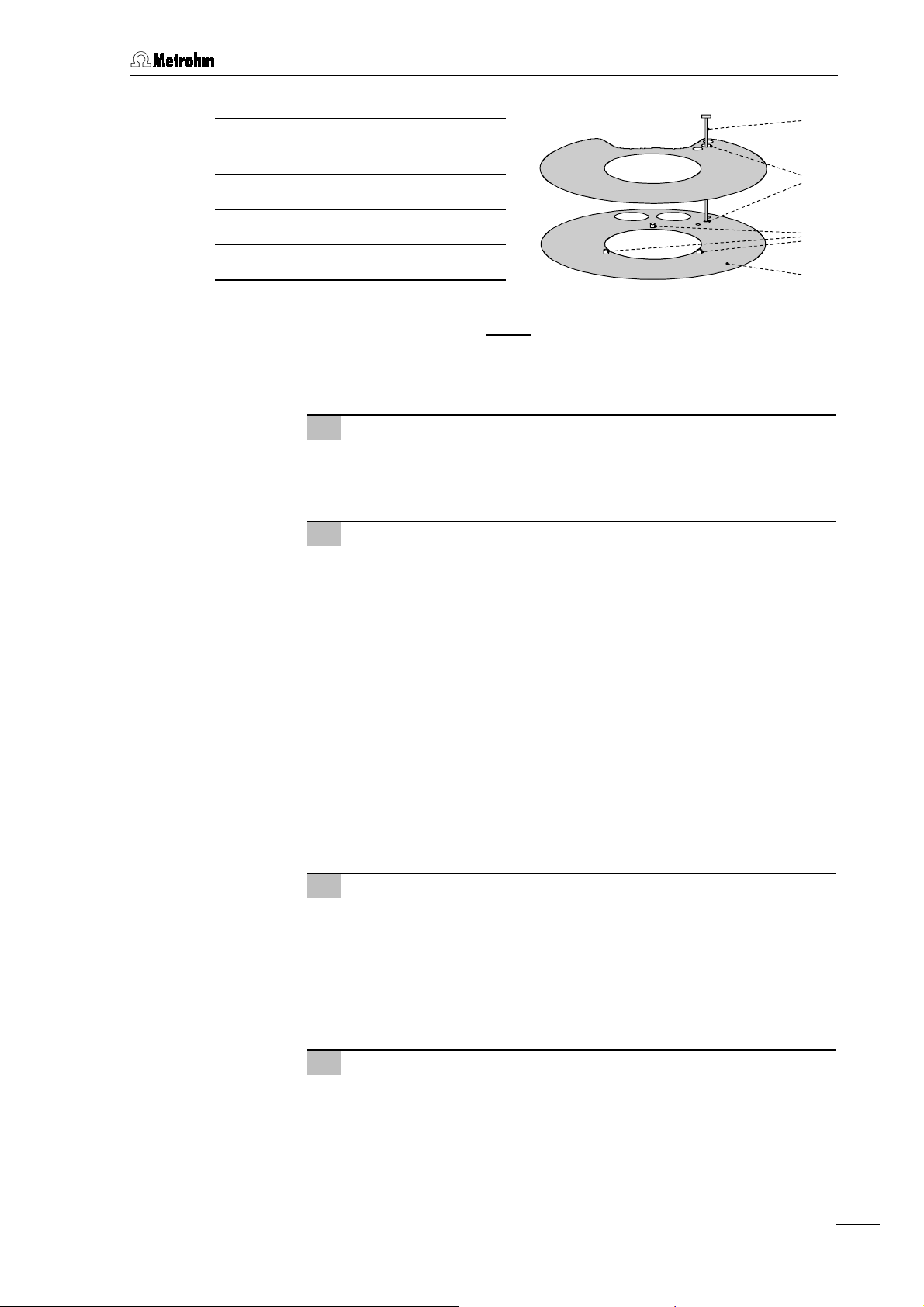

Fig. 9

Ultra-filtration cell (6.2729.110)

23

23

2323

Top part of the ultra-filtration cell 47

43

43

4343

44

44 Sealing ring (E.301.0111) 48

4444

Bottom part of the ultra-

45

45

4545

filtration cell

Filtration membrane (6.2714.020)

50

50

5050

1 Prepare ultra-filtration cell

x

Extract ultra-filtration cell

the four dummy stoppers.

x

Using the 6.2621.070 Allen key, completely loosen the 5

screws

remove sealing ring

x

Thoroughly rinse the sealing ring, bottom part and top part of

the dialysis cell with ultrapure water.

: Assembling the ultra-filtration cell

46

46

, separate top part

4646

50

5050

46

46 Screws V.022.6030 incl.

4646

47 Outlet for sample filtrate

4747

Inlet for sample solution

48

4848

49

49 Outlet for sample solution

4949

44

44

4444

34

34

3434

.

48

48 49

4848

washer 4.754.4090

from its packaging and remove

43

43

from bottom part

4343

4950

4949

45

45

4545

and

788 IC Filtration Sample Processor

16

Page 25

2.3 Attaching the accessories

Use only ultrapure water or ethanol to clean the dialysis cell;

organic solvents (e.g. acetone) will cause damage to the plexiglas

cell!

2 Prepare filtration membrane

x

Use the 6.2831.010 tweezers to extract a new filtration

50

membrane

50

(6.2714.020) from its packaging and immerse

5050

in a Petri dish containing ultra pure water for approx. 2 min

until the membrane is completely saturated with water.

Because the filtration membrane it is stretched out thereby, it has to

be watered before inserting into the ultra-filtration cell. Otherwise, the

membrane could be crumbled in the cell, which leads to blocking.

3 Insert filtration membrane

43

x

Lay top part

43

on a paper wipe with its inside facing

4343

upwards.

44

x

Insert sealing ring

x

Using the tweezers, place the wet dialysis membrane inside

44

in the appropriate recess in the top part.

4444

the sealing ring on the top part of the filtration cell.

Do not connect the dialysis cell with anything other than the

6.2744.000 PVDF compression fittings supplied. If 6.2744.010

PEEK compression fittings are used, stress cracks may appear in the

ultra-filtration cell !

4 Close ultra-filtration cell

43

46

46

46 46

43

.

4343

right

x

Insert sealing ring in the appropriate recess in top part

45

x

Place top part on bottom part

x

Using the 6.2621.070 Allen key, screw the 5 screws

45

so that both parts lie flush.

4545

in and tighten up.

5 Attach ultra-filtration cell

26

x

Insert the assembled ultra-filtration cell in the cell holder

26

26 26

according to Fig. 1 or Fig. 11. The heads of the five screws

46

46

fit to the small holes of the cell holder.

46 46

788 IC Filtration Sample Processor

17

Page 26

2 Installation

6 Rinse ultra-filtration cell

x

Before rinsing the cell, please finish all tubing connections as

described in the following sections.

x

Every time the filtration membrane is changed, the remaining

air in the cell and tubings has to be removed. This can be

done by rinsing with ultrapure water.

x

A completely installed 788 IC Filtration Sample Processor with

ultra-filtration cell is required for processing the following

steps. The rinsing solution (e.g. ultrapure water) is stored in a

300 mL PE bottle on the special beaker position 1. The 788 IC

Filtration Sample Processor is online and in normal state. The

').

PUMP–'

) and the 788 is ready

pump is switched of (display: '

for use (display: '

x

Turn the sample rack to position the beaker with the rinsing

ready

solution under the needle by pressing <MOVE> followed by

choosing 's

pec.1

' with <SELECT>.

x

Lower the lift into rinse position with <LIFT> and <SELECT>

rinse

'

x

Turn on the pump by pressing <PUMP>. All connected

'

tubings and the ultra-filtration cell will be rinsed.

x

After adequate time (e.g. 5 min.), switch off the Pump

(<PUMP>) and raise the lift to its rest position by pressing

<HOME>.

788 IC Filtration Sample Processor

18

Page 27

2.3 Attaching the accessories

2.3.9 Tubing connections

The tubing connections on the 788 IC Filtration Sample Processor and

the connection to the injection valve of the 733 IC Separation Center

must be made as follows:

Pump tubings are consumable material with a lifetime which depends

on the contact pressure (see chapter 6.3.3). This is why the tubing

cartridges should be raised completely by loosening snap-action lever

on the right-hand side if the pump is to remain switched off for a

16

16

1616

considerable length of time (the set contact pressure remains

unchanged).

The 6.1826.0X0 pump tubing is made of PVC and must not be used

for rinsing with solutions which contain acetone. In such cases, rinse

with different pump tubing or a different pump.

19

8/21

8/21

8/218/21

19 10/11

1919

10/11 43

10/1110/11

43 14

4343

14 18

1414

18 43

1818

43 19

16

16 66666666

4343

1616

19

1919

24/20

24/20

24/2024/20

Abb. 10

Line 1: Conveying the sample

to the ultra-filtration cell

8888 PTFE capillary (6.1803.070)

6666 PEEK compression fitting

(6.2744.010)

PEEK coupling (6.2744.030)

19

19

1919

10

10 Pump tubing (6.1826.070)

1010

43

43 Stopper (yellow/yellow)

4343

Tubing cartridge (6.2755.000)

14

14

1414

Contact pressure lever

18

18

1818

16

16 Snap-action lever

1616

PTFE capillary (6.1803.060)

24

24

2424

: Installing the pump tubing

Line 2: Conveying the filtrate

to the injection loop

21

21 PTFE capillary (6.1803.050)

2121

6666 PEEK compression fitting (6.2744.010)

19

19 PEEK coupling (6.2744.030)

1919

11

11 Pump tubing 6.1826.030

1111

43

43 Stopper (orange/yellow)

4343

14

14 Tubing cartridge (6.2755.000)

1414

18

18 Contact pressure lever

1818

16

16 Snap-action lever

1616

20

20 PEEK capillary (6.1831.060)

2020

788 IC Filtration Sample Processor

19

Page 28

2 Installation

1 Install pump tubing

14

x

Release tubing cartridge

sing down snap-action lever

13

13

pin

on the 788 IC Filtration Sample Processor (see

1313

x

Press contact pressure lever

as far as it will go.

x

Insert pump tubings

shown in

the corresponding holder on the left-hand side of each tubing

cartridge.

x

Place both tubing cartridges on mounting pin

down on the right-hand side until snap-action lever

into position on holding clamp

formed in the pump tubing.

2 Connection needle – pump tubing 10

x

Mount a PEEK compression fitting

PTFE capillary

x

Screw the PTFE capillary

on to the PEEK compression fitting

needle holder

x

Insert PTFE capillary into the guide chain

section 2.3.10

x

Screw a coupling

the other end of the PTFE capillary.

x

Push coupling on to the inlet end of the pump tubing

(yellow/yellow, see

Fig. 10

4444

).

. The black-black stopper

8888

.

(see

19

19

1919

14

from holding clamp

1414

16

16

and remove from mounting

1616

18

18

on the tubing cartridge down

1818

10

10

1010

Fig. 6

on to the PEEK compression fitting

Fig. 10

11

11

and

in the tubing cartridges

1111

17

17

. Take care that no kinks are

1717

6666

on both ends of the

8888

with the PEEK compression fitting

5555

already mounted on

).

9999

).

17

17

by pres-

1717

43

43

must click into

4343

13

13

and press

1313

16

16

1616

Fig. 1

(see

10

10

1010

Fig. 1

13

13

1313

click

and

6666

).

as

at

6666 PEEK compression fitting

(6.2744.010)

10

10 Pump tubing (6.1826.070)

1010

Pump tubing 6.1826.030

11

11

1111

19

19 PEEK coupling (6.2744.030)

1919

21

21 PTFE capillary (6.1803.050)

2121

PVDF compression fitting

22

22

2222

(6.2744.000)

24

24 PTFE capillary (6.1803.060)

2424

PTFE capillary (6.1803.080)

25

25

2525

Cell holder

26

26

2626

Top part of the ultra-filtration cell

43

43

4343

45

45 Bottom part of the ultra-filtration cell

4545

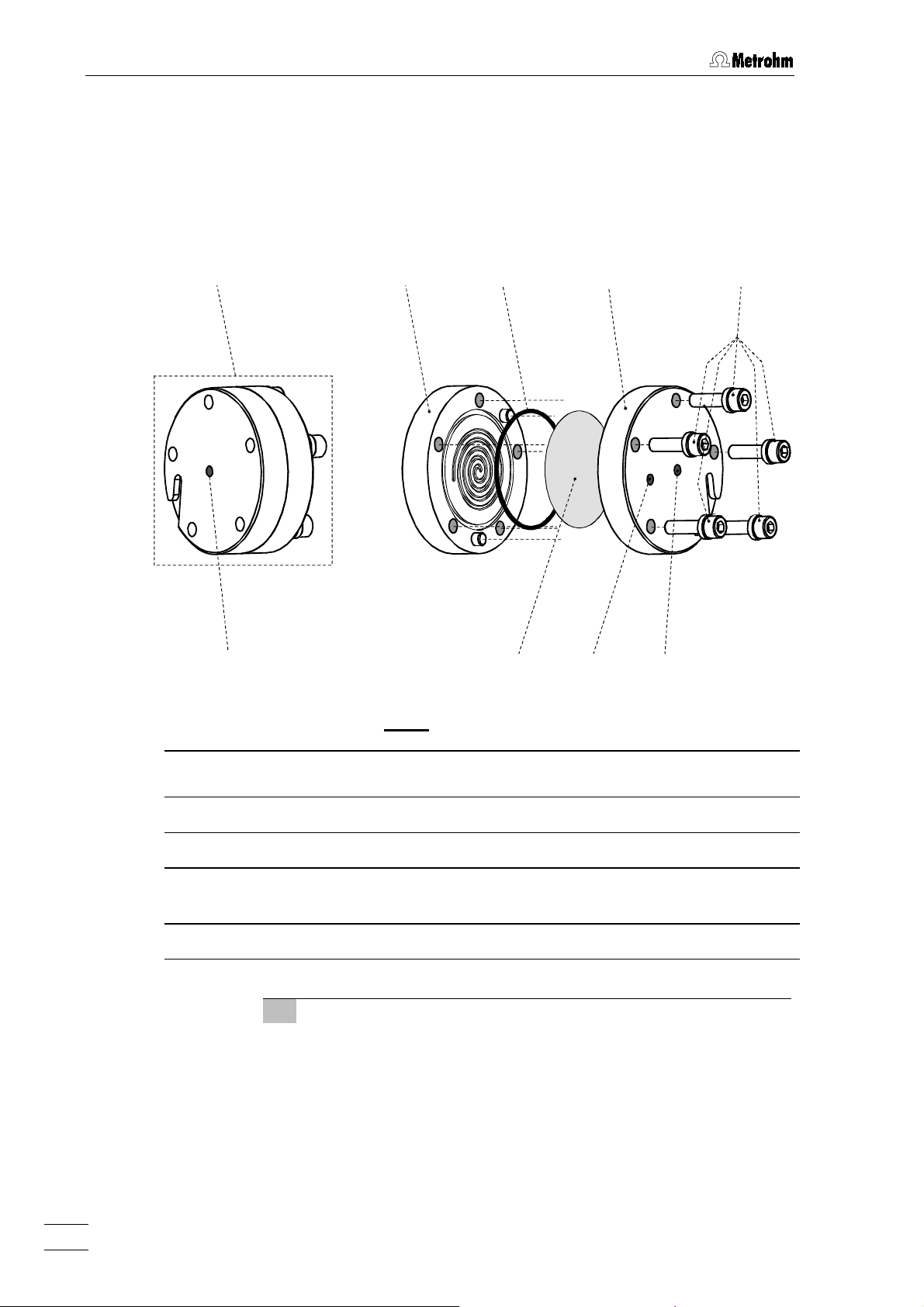

Fig. 11

11

11

1111

10

10

1010

21

21

2121

19

19

1919

6666

22

22

2222

43

43

4343

45

45

4545

24

24

2424

22

22

2222

22

22

2222

25

25

2525

26

26

2626

: Mount ultra-filtration cell

788 IC Filtration Sample Processor

20

Page 29

2.3 Attaching the accessories

Do not connect the dialysis cell with anything other than the

6.2744.000 PVDF compression fittings supplied. If 6.2744.010

PEEK compression fittings are used, stress cracks may appear in the

ultra-filtration cell !

3 Connection pump tubing 10 – ultra-filtration cell

x

Mount a PEEK compression fitting

24

capillary

x

Mount a PVDF compression fitting

PTFE capillary

x

Screw this PEEK capillary with the PVDF compression fitting

to inlet opening

x

Push coupling

(yellow/yellow) (see

24

and screw it on to coupling

24 24

24

24

.

2424

48

48

of the bottom part of the cell (see

4848

19

19

on to the outlet end of the pump tubing

1919

Fig. 10

).

6666

on the end of the PTFE

19

19

.

1919

22

22

on the other end of the

2222

Fig. 9

).

10

10

1010

4 Connection ultra-filtration cell – waste

22

x

Mount a PVDF compression fitting

25

capillary

x

Screw this end of the PTFE capillary with the PVDF

25

2525

.

compression fitting to outlet opening

the cell (see

x

Mount the other end of the PTFE capillary to a waste bottle

Fig. 9

).

22

on the end of the PTFE

2222

49

49

of the bottom part of

4949

(e.g. optional: 6.1608.070 bottle with 6.1602.150 siphon

GL45).

5 Connection ultra-filtration cell – pump tubing 11

x

Mount a PEEK compression fitting

21

capillary

x

Mount a PVDF compression fitting

PTFE capillary

x

Screw this PTFE capillary with the PVDF compression fitting

21

and screw it on to coupling

2121

21

21

.

2121

to outlet opening for the filtrate

Fig. 9

(see

x

Push coupling

(orange/yellow) (see

).

19

19

on to the inlet end of the pump tubing

1919

Fig. 10

).

6666

on the end of the PTFE

19

19

.

1919

22

22

on the other end of the

2222

47

47

of the top part of the cell

4747

11

11

1111

6 Connection pump tubing 11 – injection valve

(Underlined numbers are parts or controls from the Instructions

for Use for the 733 IC Separation Center)

(see

6666

on the end of the PEEK

19

19

.

1919

22

22

28

28

or

2828

.

of the

Fig. 14

2222

and

Fig. 15

x

Mount a PEEK compression fitting

20

capillary

x

Push coupling

(orange/yellow) (see

x

At the 733 IC Separation Center, loosen the rotary nipple

20

and screw it on to coupling

2020

19

19

on to the outlet end of the pump tubing

1919

Fig. 10

).

screwed onto the interior side of connection

84

x

Take PTFE suction tubing

84

8484

732/733 Instructions for Use) completely out of connection

66

28

28

and unscrew from connection "1" of injection valve

or

2828

66

6666

11

11

1111

22

22

2222

.

788 IC Filtration Sample Processor

21

Page 30

2 Installation

20

x

Pull the PEEK capillary

the 733 IC Separation Center and screw onto connection "1"

of injection valve

6666

fitting

x

Retighten rotary nipple on the interior side of connection

or

7 Tubing connection injection valve – waste

x

Insert 6.2744.020 coupling (from 733 accessories) into

connection

x

Screw PTFE suction tubing

attached to connection

container.

In the case of the 733.0020 IC Separation Center with two injection

valves, it is possible to fill both sample loops from the same 788 IC

Filtration Sample Processor. For this, connection "1" of valve A (outlet

of the sample loop) must be connected to connection "2" of valve B

(inlet of the sample loop) using a 6.1803.040 PEEK capillary (15 cm).

.

28

28

to fix the capillary

2828

21

21

or

2121

20

through the opening

2020

66

66

using a 6.2744.010 PEEK compression

6666

20

20

.

2020

27

27

of the 733 IC Separation Center.

2727

84

84

onto the 6.2744.020 coupling

8484

27

27

21

21

or

and lead it into the waste

2727

2121

22

22

2222

or

28

28

2828

of

22

22

2222

2.3.10 Tubing connections 788 – 754 Dialysis Unit

If the 788 IC Filtration Sample Processor is used for an IC system with

sample dialysis (see

at the 754 Dialysis Unit is used for sample conveying instead of the

pump at the 788 IC Filtration Sample Processor. Additionally, the ultrafiltration cell is bridged. The tubing connections between the 754

Dialysis Unit and the 733 IC Separation Center have to be made as

shown in

the inlet of the sample, which is installed as follows:

Install a PEEK compression fitting 6.2744.010 on the inlet end of the

PTFE tubing

connected to the 754 Dialysis Unit and screw it on the PEEK

compression fitting

Fig. 8

26

26

2626

section 2.4.7 or section 2.5.8

of the

754 Instruction for Use

(6.1803.030, see

5555

(see

Fig. 6

).

Fig. 8 of the 754 Instruction for Use

. The only change concerns

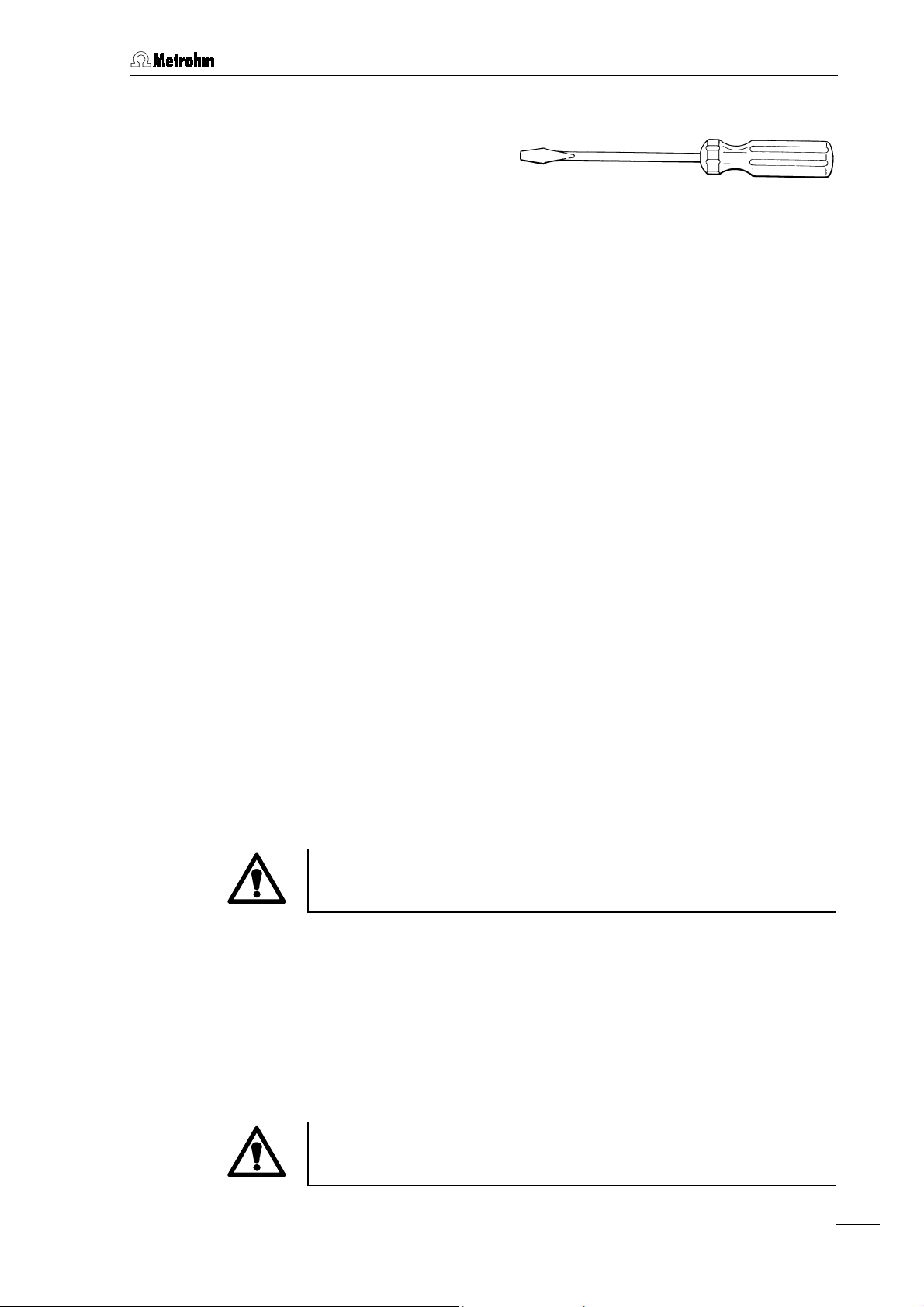

2.3.11 Fixing tubing and cables

In order to fix tubing or cables in the

guide chain

opened with a screw driver or another

appropriate tool..

9999

any chain link may be

), the peristaltic pump

)

Fig. 12

788 IC Filtration Sample Processor

22

: Opening chain links

Page 31

2.4 Installation for full control with «IC Net»

2.4 Installation for full control with «IC Net»

2.4.1 Connection options

The 788 IC Filtration Sample Processor can be connected to Metrohm

IC Systems according to the following techniques:

1. The IC System is totally controlled by the PC software

Data acquisition and direct control of the IC components is done by the

PC software «IC Net 2.1» in combination with the 762 IC Interface. The

788 IC Filtration Sample Processor is connected to the IC system both

by the RS232 Interface and by the remote interface. Due to direct

control of all procedures by the PC software, internal methods of the

788 IC Filtration Sample Processor are not used. This section describes

several example combinations of the 788 IC Filtration Sample

Processor with Metrohm IC systems based on this technique.

2. Compact IC Systems are remote controlled by PC software

Compact designed IC-Systems 761 Compact IC and 790 Personal IC

are also controlled by the PC. The 788 IC Filtration Sample Processor is

connected to these IC Systems by remote connection only. Therefore,

internal methods of the sample processor are used. Please find a

description of the connection of the 788 IC Filtration Sample Processor

to the IC Systems 761 Compact IC and 790 Personal IC in

The required 788 standard method is given in section 4.6.3.

3. The IC System is connected to PC for simple control

Instead of using the 762 IC Interface, modular Metrohm IC Systems can

be simply controlled via the 714 PC Board or 771 IC Compact Interface.

These devices just convert the analog signals from the 732 IC Detector

to digital data for the PC. For simple control of the IC system, the 732 IC

detector has to be connected to the PC additionally via its RS232 port.

«IC Net» and the prior software «IC Metrodata» use this serial

connection for a simple control of the IC system. As described for

compact IC systems the 788 IC Filtration Sample Processor is

connected to these IC Systems by remote connection. Also, internal

methods of the Sample Processor are used. Please find a description

of the connection of the 788 IC Filtration Sample Processor to such IC

Systems in

methods is given in

section 2.6

section 4.6

. The use of the corresponding 788 standard

.

section 2.5

.

788 IC Filtration Sample Processor

23

Page 32

2 Installation

2.4.2 General information on interface connections

Before an external device is connected to remote connection 30

RS232 interface 40

always be switched off using mains switch 34

40, the 788 IC Filtration Sample Processor must

4040

34!

3434

30 or

3030

Remote connection

29

The branch plug of cable

plugged into the 25 pin remote interface (see

29

leading from the swing head (see

2929

section 2.3.1

external devices can be connected to remote connection

Fig. 1

). Any

30

30

of this

3030

branch plug. The 788 IC Filtration Sample Processor can be remote

controlled via the 8 input lines, the 14 output lines can be used to

control external devices.

The pin assignment of the remote interface, its functions, the electrical

requirements and conditions are described in

RS232 interface

section 5.1

.

Many different instruments may be connected via the serial RS232

40

interface

that support the Metrohm remote control language (see

40

. In addition to Metrohm instruments (e.g. 762 IC Interface)

4040

section 5.2

any printer with serial interface (or parallel interface and parallel/serial

converter) or a personal computer (PC) may be connected (see

section 2.7

). Other measuring instrument may be controlled via RS232

interface, as long as it supports serial data transmission.

) is

)

In order to guarantee safe data transmission, it is important to set the

same RS232 interface parameters correctly for both instruments

connected (see

section 4.2.1

).

Connection cables

Connecting peripheral instruments to the 788 IC Filtration Sample

Processor requires Metrohm cables. Otherwise a safe data

transmission may not be guaranteed.

Metrohm cables are labeled with the type of the instrument, which

they may be connected with and optionally with the particular socket.

Mind the cable ends.

Example

:

732/1 Remote

cable 6.2125.060

788 IC Filtration Sample Processor

24

Page 33

2.4 Installation for full control with «IC Net»

2.4.3 Metrohm IC systems

Metrohm IC systems can be classified into modular IC systems ("

and compact IC systems (e.g.

761 Compact IC

790 Personal IC

or

MIC

The following table gives a review over pre-configured Metrohm IC

systems:

Name Application

MIC 1 Anion or cation system with electronic suppression

MIC 2 Anion system with chemical suppression

MIC 3 Anion and cation system with chemical suppression

MIC 4 Anion or cation system with electronic suppression and preconcentration

MIC 5 Anion system with chemical suppression and preconcentration

MIC 6 Anion system with chemical suppression, preconcentration and matrix elimination

MIC 7 Anion system with chemical suppression and dialysis

The following sections describe the electronic connection of some of

these systems with the 788 IC Filtration Sample Processor on the base

of full control by «

4 and MIC 2 / MIC 5, only the common used systems

are described. Additionally, the anion and cation system

as the dialysis system

IC Net 2.1

MIC 7

». Due to similar compilation of MIC 1 / MIC

MIC 1

MIC 3

und

MIC 2

as well

are included. Please note that with the MIC

7 system the 788 IC Filtration Sample Processor can be used for

dialysis in combination with the 754 Dialysis Unit. For this purpose, the

ultra-filtration cell of the 788 IC Filtration Sample Processor should be

bridged (see

section 2.3.10

).

")

).

For connecting the 788 IC Filtration Sample Processor to

IC

and

790 Personal IC

, the remote connection is used only.

761 Compact

Therefore, internal methods of the sample processor are used. Please

find the corresponding descriptions in

section 4.6.3

(methods).

section 2.5

(connection) and

788 IC Filtration Sample Processor

25

Page 34

2 Installation

2.4.4 MIC 1

Modular anion or cation system

with electronic suppression

The 788 IC Filtration Sample Processor is connected to an IC system

with electronic suppression consisting of 732 IC Detector, 733 IC

Separation Center, 709 IC Pump and 762 IC Interface as shown in

Fig. 13

6.2134.080 RS232 cable.

6.2128.130

using the 6.2141.110 remote connection cable and the

732

733

6.2115.070

PC

6.2134.100

709762

6.2125.090

6.2141.110

788

6.2134.090

Fig. 13

: Interconnection with anion or cation IC system

6.2134.080

with electronic suppression (MIC 1)

Settings in the «IC Net 2.1» program

Creation of a time program for the 788 IC Filtration Sample Processor:

001 Ctrl INIT 732

002 Move sample

003 Lift work

004 Ctrl ZERO 1

005 Ctrl FILL A 1

006 Pump 240 s

007 Ctrl INJECT A 1

Initialize remote interface at 732

Move needle to sample

Place lift with needle to working position

Trigger autozero at 732

Switch injection valve A at 733 to "Fill"

Fill sample loop with sample during 240 s

Switch injection valve A at 733 to "Inject"

788 IC Filtration Sample Processor

26

Page 35

2.4 Installation for full control with «IC Net»

2.4.5 MIC 2

Modular anion system with chemical suppression

The 788 IC Filtration Sample Processor is connected to an anion IC

system with chemical suppression consisting of 732 IC Detector, 733 IC

Separation Center, 709 IC Pump, 752 IC Pump Unit, and 762 IC

Interface as shown in

cable and the 6.2134.080 RS232 cable.

6.2128.130

6.2134.090

6.2115.070

Fig. 14

732

733

using the 6.2141.110 remote connection

6.2125.090

6.2141.110

709

PC

6.2134.100

762

752

788

6.2128.180

6.2134.080

Fig. 14: Interconnection with anion IC system with chemical

suppression (MIC 2)

Settings in the «IC Net 2.1» program

Creation of a time program for the 788 IC Filtration Sample Processor:

001 Ctrl INIT 732

002 Move sample

003 Lift work

004 Ctrl ZERO 1

005 Ctrl FILL A 1

006 Pump 240 s

007 Ctrl INJECT A 1

Initialize remote interface at 732

Move needle to sample

Place lift with needle to working position

Trigger autozero at 732

Switch injection valve A at 733 to "Fill"

Fill sample loop with sample during 240 s

Switch injection valve A at 733 to "Inject"

788 IC Filtration Sample Processor

27

Page 36

2 Installation

2.4.6 MIC 3

Modular anion and cation system

with chemical suppression

6.2128.130

732

PC

6.2134.100

762

709

The modular anion and cation system can be operated with chemical or

electronic suppression. The 788 IC Filtration Sample Processor is

connected to the MIC 3 system consisting of two 732 IC Detectors, 733

IC Separation Center (two injectors), two 709 IC Pumps, 753 IC

Suppressor Module (if suppression is used), and the 762 IC Interface as

shown in

Fig. 15

using the 6.2125.120 remote adapter, the 6.2125.090

remote connection cable and the 6.2134.080 RS232 cable.

6.2125.120

6.2125.090

733

6.2125.090

6.2115.070

732

709

753

6.2143.210

6.2141.110

788

6.2134.090

6.2128.180

6.2134.080

Fig. 15: Interconnection with the combined anion and cation IC

system with chemical suppression (MIC 3)

788 IC Filtration Sample Processor

28

Page 37

2.4 Installation for full control with «IC Net»

Settings in the «IC Net 2.1» program

1. Definition of new program parameters for the 788 IC Filtration

Sample Processor under

INJECT A 2 = ---***1*000***

ZERO 2 = ---***0*011***

FILL A 2 = ---***0*010***

2. Program for the 788 IC Filtration Sample Processor:

001 Ctrl INIT

002 Move sample

003 Lift work

004 Ctrl ZERO 1

005 Ctrl FILL A 1

006 Ctrl STEP MSM 753

007 Pump 240 s

008 Ctrl INJECT A 1

009 Move sample+1

010 Lift work

011 Ctrl ZERO 2

012 Ctrl Init 732

013 Scan Wait1

014 Ctrl FILL A 2

015 Ctrl Init 732

016 Pump 240 s

017 Ctrl INJECT A 2

018 Ctrl Init 732

Configuration/Control

:

Initialize remote interface

Move needle to sample position

Place lift with needle to working position

Trigger autozero at 732/1 IC Detector

Switch injection valve A at 733 to "Fill"

Switch 753 suppressor module to next position

Fill sample loop A with sample during 240 s

Switch injection valve A at 733 to "Inject"

Move needle to sample position (+1)

Place lift with needle to working position

Trigger autozero at 732/2 IC Detector

Initialize remote lines at 732/1 and 732/2

Wait until 732/1 IC Det. sends signal on remote line 3

Switch injection valve B at 733 to "Fill"

Initialize remote lines at 732/1 and 732/2

Fill sample loop B with sample during 240 s

Switch injection valve B at 733 to "Inject"

Initialize remote lines at 732/1 and 732/2

3. Definition of new program parameters for the 723/1 IC Detector

Programm/Remote Configuration

under

Start_788 = **1*****

Reset_Start_788 = **0*****

:

4. To synchronize the second injection to the start of the second

chromatogram, a time program is started for the 732/1 IC Detector

directly with the first injection:

1.1 Reset_Start_788

1.2 Flag end

1.0 Start_788

Both detectors 732/1 and 732/2 are registered in the system window

Setup/Start mode

under

in the field

'Start with inject

' .

4. By this procedure, with a delay of one minute, the 788 IC Filtration

Sample Processor receives a signal for processing the second

sample. The total resulting delay (5 min.) is now independent from

the time the sampler needs for rotating to the next sample.

Therefore, the method for the second sample injection (e.g. method

cation

'

') gets a start delay under

Start delay: 5.0 min

Method Setup/Measure

:

788 IC Filtration Sample Processor

29

Page 38

2 Installation

2.4.7 MIC-7

6.2128.130

Modular anion system with chemical suppression

and dialysis

It is possible to operate the 788 IC Filtration Sample Processor in

combination with an anion IC system with dialysis. For this purpose, the