Liebherr R944C User Manual

Machine for Industrial Applications R 944 C

litronic`

Operating Weight: 46,900 – 53,300 kg

Engine Output: 190 kW / 258 HP

Technical Data

Engine

Engine

Rating per ISO 9249 _____________ 190 kW (258 HP) at 1800 RPM Model ______________________________ Liebherr D 936 L

Type ________________________________ 6 cylinder in-line Bore/Stroke__________________ 122/150 mm Displacement________________ 10,5 l

Engine operation _________________ 4-stroke diesel unit pump system

turbo-charged and after-cooled reduced emissions

Cooling _____________________________ water-cooled and integrated motor oil cooler

Air cleaner _________________________ dry-type air cleaner with pre-cleaner, primary and safety elements, automatic dust discharge

Fuel tank ___________________________ 660 l

Standard ___________________________ sensor controlled engine idling Electrical system

Voltage _______________________ 24 V

Batteries______________________ 2 x 170 Ah/12 V Starter ________________________ 24 V/6,6 kW

Alternator_____________________ three phase current 28 V/80 A

Hydraulic System

Hydraulic System

Hydraulic pump

for attachment and

travel drive ___________________ two Liebherr variable flow, swash plate pumps Max. flow_____________________ 2 x 303 l/min.

Max. pressure _______________ 350 bar

Pump regulation __________________ electro-hydraulic with electronic engine speed sensing regulation, pressure compensation, flow compensation, automatic oil flow optimizer

______________ reversible, variable flow, swash plate pump, closed-loop circuit

Max. flow_____________________ 205 l/min. Max. pressure _______________ 400 bar

Hydraulic tank ____________________ 460 l Hydraulic system _________________ 710 l

Hydraulic oil filter _________________ 2 full flow filters in return line with integrated fine filter area (5 µm)

Hydraulic oil cooler_______________ cooler unit, consisting of radiator for engine coolant with after-cooler core, for hydraulic fluid with hydrostatically controlled fan drive

MODE selection __________________ adjustment of machine performance and the hydraulics via a mode selector to match application

ECO ___________________________ for especially economical and environmentally friendly operation

POWER_______________________ for maximum digging power and heavy duty jobs LIFT ___________________________ for lifting

FINE __________________________ for precision work and lifting through very sensitive movements

RPM adjustment _________________ stepless adjustment of engine output via the rpm at each selected mode

Liebherr Tool Control ____________ ten preadjustable pump flows and pressures for add on tools (option)

Hydraulic Controls

Hydraulic Controls

Power distribution________________ via monoblock control valve with integrated safety valves

Flow summation ____________ to boom and stick Closed-loop circuit _________ for uppercarriage swing drive

Servo circuit

Attachment and swing_____ – proportional via joystick levers

Travel _________________________ – proportional via foot pedals or removable hand levers

– speed pre-selection

Additional functions______________ via foot pedals or joystick toggle switch

Swing Drive

Swing Drive

Drive by ____________________________ Liebherr swash plate motor

Transmission ______________________ Liebherr compact planetary reduction gear Swing ring _________________________ Liebherr, sealed single race ball bearing swing

ring, internal teeth Swing speed ______________________ 0 – 8 RPM stepless Swing torque ______________________ 125 kNm

Holding brake _____________________ wet multi-disc (spring applied, pressure released) Option ______________________________ pedal controlled positioning brake

Operator’s Cab

Operator’s Cab

Cab _________________________________ built from deep drawn components, resiliently mounted, sound insulated, tinted windows, front window stores overhead, door with sliding window

Operator’s seat ___________________ shock absorbing suspension, adjustable to operator’s weight, 6-way adjustable seat

Joysticks___________________________ integrated into adjustable seat consoles Monitoring _________________________ menu driven query of current operating condi-

tions via the LCD display. Automatic monitoring, display, warning (acoustical and optical signal) and saving machine malfunction data, for example, engine overheating, low engine oil pressure or low hydraulic oil level

Heating system ___________________ standard air conditioning, combined cooler/ heater, additional dust filter in fresh air/recirculated

Noise emission

ISO 6396___________________________ LpA (inside cab) = 75 dB(A) 2000/14/EC________________________ LWA (surround noise) = 105 dB(A)

Undercarriage

Undercarriage

Versions

EW_____________________________ special duty, extra wide gauge S-EW__________________________ special duty, extra wide gauge, reinforced track

components

Drive ________________________________ Liebherr swash plate motors with integrated brake valves on both sides

Transmission ______________________ Liebherr planetary reduction gears

Travel speed ______________________ EW: |

low range – 3,2 km/h |

|

high range – 5,0 km/h |

S-EW: low range – 2,8 km/h |

|

|

high range – 4,1 km/h |

Drawbar pull max.________________ EW: |

336 kN |

S-EW: 429 kN |

|

Track components _______________ EW: |

D 7, maintenance-free |

S-EW: D 7 G, maintenance-free |

|

Track rollers/Carrier rollers _____ EW: |

9/2 |

S-EW: 10/2

Tracks ______________________________ sealed and greased Track pads ________________________ triple grouser

Digging locks _____________________ wet multi-discs (spring applied, pressure released)

Brake valves ______________________ integrated into travel motor

Attachment |

Type ________________________________ high-strength steel plates at highlystressed points for the toughest requirements. Complex and stable mountings of attachment and cylinders. Unrivalled strength, even at high loads

Hydraulic cylinders_______________ Liebherr cylinders with special seal system. Shock absorption

Pivots_______________________________ sealed, low maintenance

Lubrication ________________________ Liebherr semi-automatic central lubrication system

2 R 944 C Litronic Machine for Industrial Applications

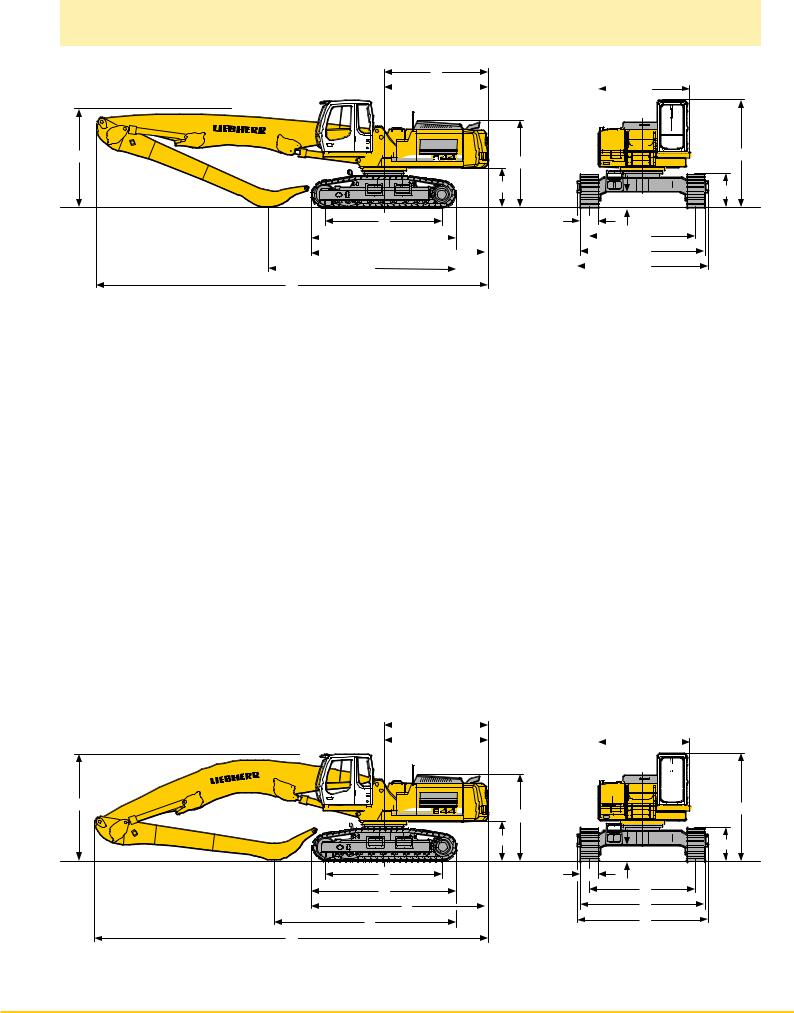

Dimensions

E

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

||||||||||

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W |

H |

C |

|

|

|

K |

P |

|

|

|

|

|

Q |

L |

|

N |

|

|

|

U |

|

|

|

|

|

|

|

|

|

|

S |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Z |

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||||||||

|

|

V |

|

|

|

|

|

|

|

|

G |

|||||

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|||||||||||||

X

|

EW |

|

mm |

S-EW |

|

mm |

A |

|

|

3070 |

|

|

3070 |

C |

|

|

3630 |

|

|

3630 |

D |

|

|

3605 |

|

|

3605 |

E |

|

|

3605 |

|

|

3605 |

H |

|

|

2905 |

|

|

2905 |

K |

|

|

1320 |

|

|

1320 |

L |

|

|

4000 |

|

|

4400 |

P |

|

|

1120 |

|

|

1170 |

Q |

|

|

532 |

|

|

532 |

S |

|

|

3600 |

|

|

3800 |

U |

|

|

4915 |

|

|

5360 |

N |

500 600 750 |

500 600 750 |

||||

B |

4200 |

4200 |

4350 |

4412 |

4412 |

4550 |

G |

4410 |

4410 |

4410 |

4620 |

4620 |

4620 |

Z |

|

|

5980 |

|

|

6300 |

E = Tail radius

Industrial-Type Straight Boom 7,50 m |

|

|

||

and Industrial Stick |

m |

|

5,80 |

|

with Undercarriage |

|

|

EW |

|

V |

|

mm |

|

6000 |

W |

|

mm |

|

3200 |

X |

|

mm |

|

11600 |

|

|

|

|

|

Industrial-Type Straight Boom 8,50 m |

|

|

||

and Industrial Stick |

m |

7,30 |

||

with Undercarriage |

|

EW |

S-EW |

|

V |

|

mm |

5500 |

5700 |

W |

|

mm |

3250 |

3250 |

X |

|

mm |

12600 |

12600 |

|

|

|

|

|

Industrial-Type Straight Boom 9,50 m |

|

|

||

and Industrial Stick |

m |

7,30 |

8,80 |

|

with Undercarriage |

|

S-EW S-EW |

||

V |

|

mm |

6700 |

5650 |

W |

|

mm |

3350 |

4650 |

X |

|

mm |

13600 |

13400 |

|

|

|

|

|

Industrial-Type Gooseneck Boom 9,50 m |

|

|

||

and Industrial Stick |

m |

7,30 |

8,80 |

|

with Undercarriage |

|

S-EW |

S-EW |

|

|

|

|

V |

|

|

|

|

|

|

|

|

|

mm |

6400 |

5360 |

|||

|

|

|

W |

|

|

|

|

|

|

|

|

|

mm |

3600 |

4300 |

|||

|

|

|

X |

|

|

|

|

|

|

|

|

|

mm |

13500 |

13550 |

|||

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

D |

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W |

|

|

C |

|

|

H |

|

|

|

|

|

|

K |

|

P |

|

|

|

|

|

|

|

Q |

L |

|

|

N |

U |

|

|

S |

Z |

|

|

B |

V |

|

|

G |

X |

|

|

|

These dimensions are stated with cab carrier. This assembly is only valid for transportation.

R 944 C Litronic Machine for Industrial Applications 3

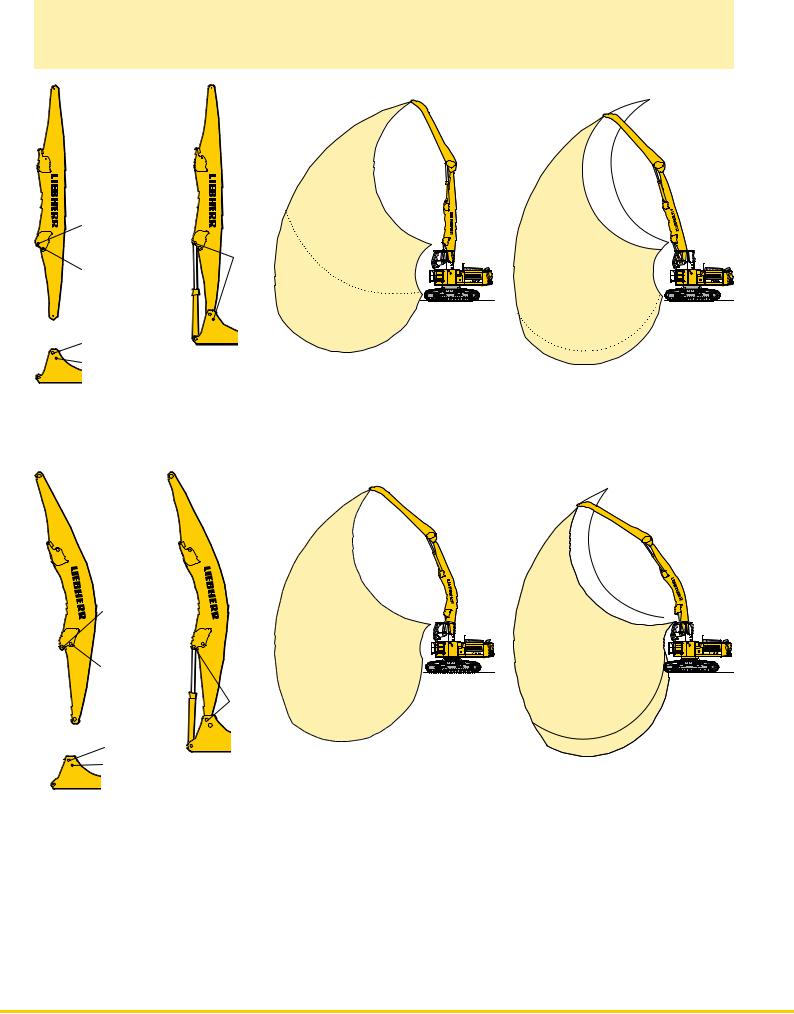

VarioLiftPlus

Variable Boom Mounting Positions for Optimized Lift Capacities

Hole A

Hole B

Hole 3

Hole 2

Hole D

Hole C

Hole 3

Hole 2

with the same working range |

with a different working range |

2A

2A

|

3B |

3B |

|

Version 2A |

3A |

Kinematic variant 2A: |

Kinematic variant 3A: |

Increased lift capacities above ground level |

Altered range curve with additional reach |

Kinematic variant 3B: |

depth, e.g. for unloading from ships |

Increased lift capacities below ground level |

|

and when working at large outreach |

|

|

with a different working range |

3D

3D

|

|

3C |

Version 3D |

Kinematic variant 3D: |

Kinematic variant 3C: |

|

Increased lift capacities below ground level |

Altered range curve with additional reach |

|

and when working at large outreach |

depth, e.g. for unloading from ships |

4 R 944 C Litronic Machine for Industrial Applications

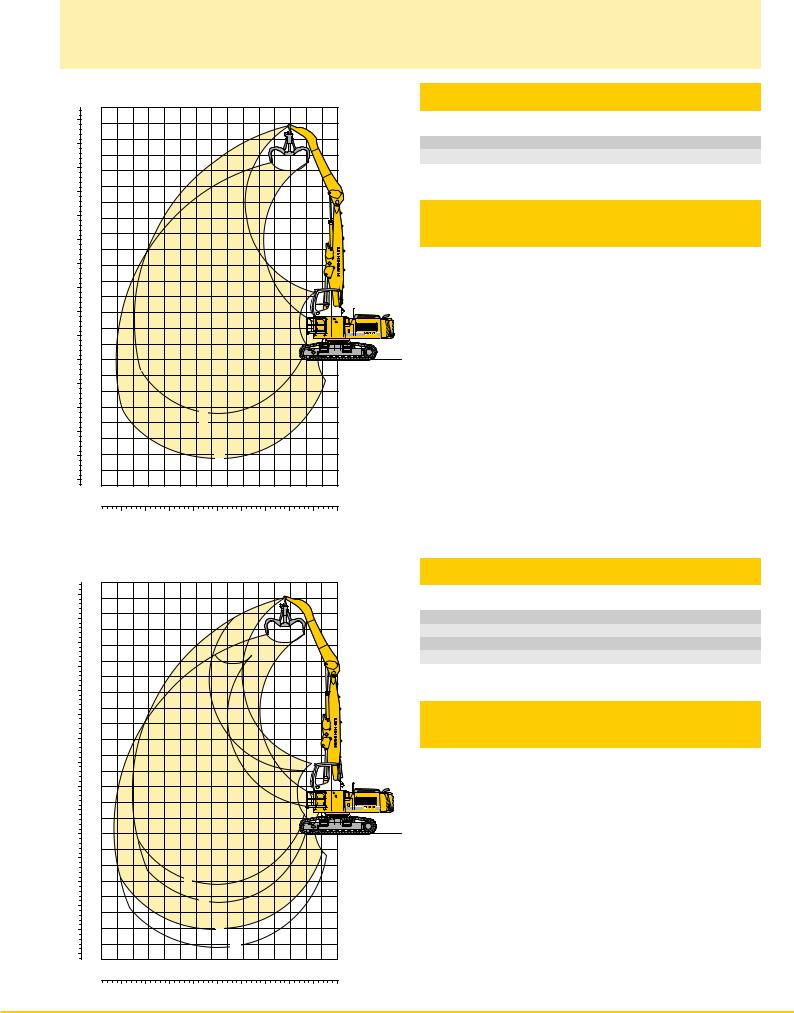

Industrial Attachment

with Industrial-Type Straight Boom 7,50 m

ft |

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

45 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

35 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-5 |

-1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-10 |

-3 |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

-4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-20 |

-6 |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

-25 |

-7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

14 |

13 |

12 |

11 |

10 |

9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

0 |

m |

|

|

45 |

|

40 |

35 |

|

30 |

25 |

|

20 |

15 |

|

10 |

|

5 |

0 |

ft |

ft |

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

45 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

35 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-5 |

-1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-10 |

-3 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

-15 |

-4 |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

-5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-20 |

-6 |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

-25 |

-7 |

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

-8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m |

|

|

15 |

14 |

13 |

12 |

11 |

10 |

9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

0 |

|

|

|

45 |

|

40 |

35 |

|

30 |

25 |

|

20 |

15 |

|

10 |

|

5 |

0 |

ft |

Attachment Envelope

Kinematic variant 2A

1 with industrial stick 5,80 m

2 with industrial stick 5,80 m and grapple model 70 C

Operating Weight

and Ground Pressure

Operating weight includes basic machine with rigid cab elevation 1,20 m, counterweight 11,0 t, industrial-type straight boom 7,50 m, industrial stick 5,80 m and grapple model 70 C with 5 semi-closed tines 1,10 m3.

Undercarriage |

|

EW |

|

|

|

|

|

Pad width |

mm |

600 |

750 |

Weight |

kg |

46900 |

47500 |

Ground pressure |

kg/cm2 |

0,98 |

0,79 |

Attachment Envelope

Kinematic variants 3A/3B

1 with industrial stick 5,80 m (3B)

2 with industrial stick 5,80 m and grapple model 70 C (3B) 3 with industrial stick 5,80 m (3A)

4 with industrial stick 5,80 m and grapple model 70 C (3A)

Operating Weight

and Ground Pressure

Operating weight includes basic machine with rigid cab elevation 1,20 m, counterweight 11,0 t, industrial-type straight boom 7,50 m, industrial stick 5,80 m and grapple model 70 C with 5 semi-closed tines 1,10 m3.

Undercarriage |

|

EW |

|

|

|

|

|

Pad width |

mm |

600 |

750 |

Weight |

kg |

46900 |

47500 |

Ground pressure |

kg/cm2 |

0,98 |

0,79 |

R 944 C Litronic Machine for Industrial Applications 5

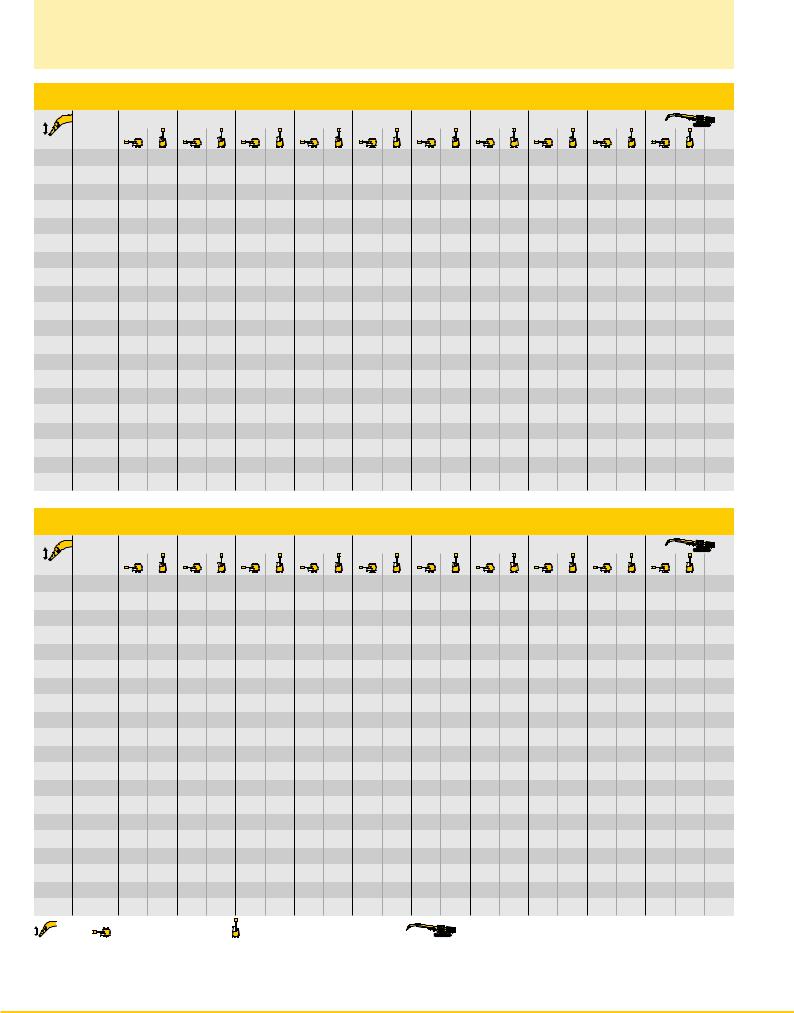

Lift Capacities

with Industrial-Type Straight Boom 7,50 m

Industrial Stick 5,80 m (Variant 2A)

|

|

4,5 m |

6,0 m |

7,5 m |

9,0 m |

10,5 m |

12,0 m 13,5 m 15,0 m |

16,5 m |

|

|

||||||

|

Under- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m |

carriage |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m |

19,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13,5 |

EW |

|

|

13,1* |

13,1* |

|

|

|

|

|

|

|

|

11,6* |

11,6* |

6,48 |

12,0 |

EW |

|

|

15,2* |

15,2* |

13,1* |

13,1* |

|

|

|

|

|

|

9,8* |

9,8* |

8,57 |

10,5 |

EW |

|

|

14,7* |

14,7* |

12,9* |

12,9* |

11,0 |

11,5* |

|

|

|

|

9,0* |

9,0* |

10,02 |

9,0 |

EW |

|

|

14,7* |

14,7* |

12,9* |

12,9* |

11,0 |

11,4* |

8,4 |

8,9 |

|

|

7,6 |

8,0 |

11,07 |

7,5 |

EW |

|

|

15,2* |

15,2* |

13,1* |

13,1* |

10,9 |

11,4 |

8,4 |

8,8 |

|

|

6,8 |

7,1 |

11,85 |

6,0 |

EW |

18,6* |

18,6* |

16,1* |

16,1* |

13,5* |

13,5* |

10,6 |

11,2 |

8,3 |

8,7 |

6,6 |

6,9 |

6,2 |

6,6 |

12,39 |

4,5 |

EW |

22,1* |

22,1* |

17,2* |

17,2* |

13,7 |

14,1* |

10,3 |

10,8 |

8,1 |

8,5 |

6,5 |

6,9 |

5,9 |

6,2 |

12,73 |

3,0 |

EW |

24,3* |

24,3* |

18,2* |

18,2* |

13,1 |

13,8 |

9,9 |

10,5 |

7,8 |

8,3 |

6,4 |

6,7 |

5,7 |

6,0 |

12,89 |

1,5 |

EW |

25,0* |

25,0* |

17,4 |

18,5 |

12,5 |

13,2 |

9,5 |

10,1 |

7,6 |

8,0 |

6,3 |

6,6 |

5,7 |

6,0 |

12,88 |

0 |

EW |

16,1* |

16,1* |

16,6 |

17,7 |

12,0 |

12,7 |

9,3 |

9,8 |

7,5 |

7,9 |

6,2 |

6,5 |

5,8 |

5,9* |

12,68 |

– 1,5 |

EW |

15,7* |

15,7* |

15,8* |

15,8* |

11,7 |

12,4 |

9,1 |

9,6 |

7,3 |

7,8 |

|

|

5,8* |

5,8* |

11,89 |

– 3,0 |

EW |

|

|

12,7* |

12,7* |

10,4* |

10,4* |

8,3* |

8,3* |

|

|

|

|

7,3* |

7,3* |

9,72 |

– 4,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 6,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 7,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 9,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Industrial Stick 5,80 m (Variant 3A)

|

|

4,5 m |

6,0 m |

7,5 m |

9,0 m |

10,5 m |

12,0 m 13,5 m 15,0 m 16,5 m |

|

|

|||||||

|

Under- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m |

carriage |

|

|

|

|

|

|

|

|

|

|

|

|

|

m |

|

19,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

11,2* |

11,2* |

6,97 |

12,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

9,7* |

9,7* |

8,94 |

10,5 |

EW |

|

|

|

|

|

|

10,8* |

10,8* |

|

|

|

|

8,5 |

8,9* |

10,32 |

9,0 |

EW |

|

|

|

|

|

|

10,7* |

10,7* |

8,4 |

8,8 |

|

|

7,3 |

7,7 |

11,34 |

7,5 |

EW |

|

|

|

|

|

|

10,8 |

10,9* |

8,3 |

8,8 |

6,6 |

6,9 |

6,5 |

6,9 |

12,07 |

6,0 |

EW |

|

|

|

|

12,8* |

12,8* |

10,5 |

11,1 |

8,2 |

8,6 |

6,5 |

6,9 |

6,0 |

6,3 |

12,59 |

4,5 |

EW |

|

|

16,5* |

16,5* |

13,5 |

13,8* |

10,2 |

10,7 |

8,0 |

8,4 |

6,4 |

6,8 |

5,7 |

6,0 |

12,91 |

3,0 |

EW |

24,7* |

24,7* |

18,1 |

18,3* |

12,9 |

13,6 |

9,8 |

10,3 |

7,8 |

8,2 |

6,3 |

6,7 |

5,6 |

5,9 |

13,04 |

1,5 |

EW |

19,9* |

19,9* |

17,0 |

18,1 |

12,3 |

13,0 |

9,4 |

9,9 |

7,5 |

7,9 |

6,2 |

6,5 |

5,5 |

5,8 |

13,00 |

0 |

EW |

14,4* |

14,4* |

16,3 |

17,4 |

11,8 |

12,5 |

9,1 |

9,7 |

7,4 |

7,8 |

6,1 |

6,5 |

5,6 |

5,9 |

12,78 |

– 1,5 |

EW |

14,8* |

14,8* |

15,9 |

17,0 |

11,5 |

12,2 |

8,9 |

9,5 |

7,3 |

7,7 |

6,1 |

6,4 |

5,9 |

6,2 |

12,37 |

– 3,0 |

EW |

16,7* |

16,7* |

15,9 |

16,9 |

11,4 |

12,1 |

8,9 |

9,4 |

7,3 |

7,7 |

|

|

6,6 |

6,9 |

11,37 |

– 4,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 6,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 7,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 9,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height |

Can be slewed through 360° |

In longitudinal position of undercarriage |

|

Max. reach |

* Limited by hydr. capacity |

|

|

|||||||||

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load diagram and automatic check valves on the hoist cylinders, when they are used for lifting operations which require the use of lifting accessories.

6 R 944 C Litronic Machine for Industrial Applications

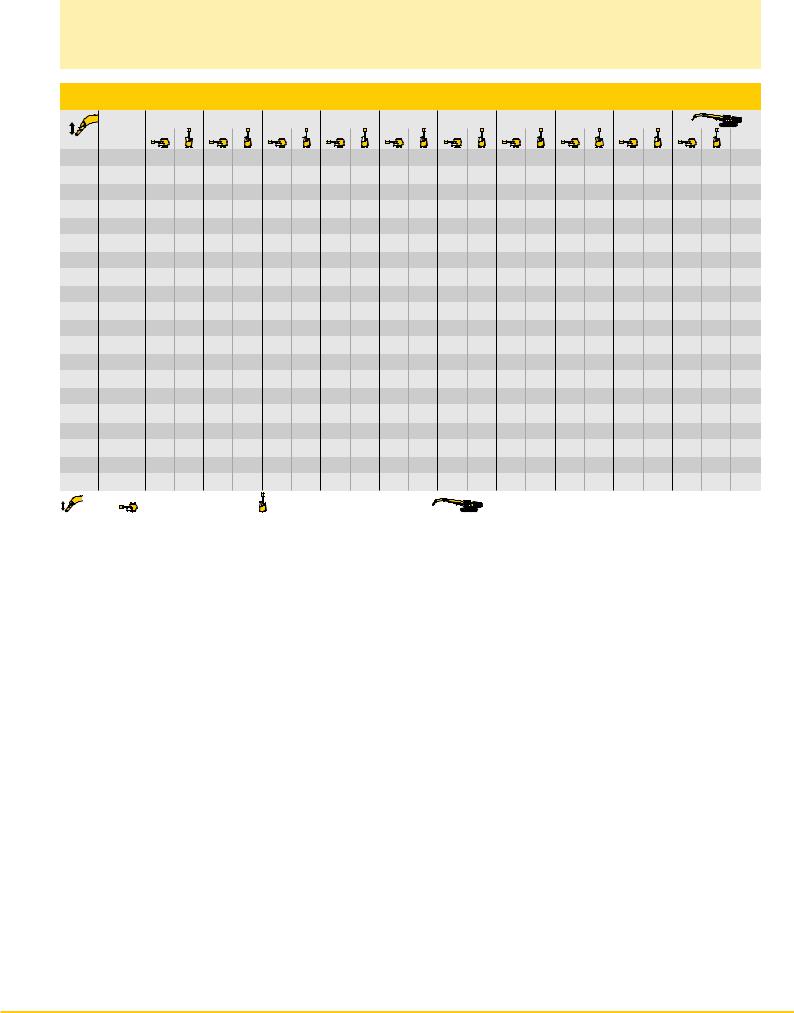

Lift Capacities

with Industrial-Type Straight Boom 7,50 m

Industrial Stick 5,80 m (Variant 3B)

|

|

4,5 m |

6,0 m |

7,5 m |

9,0 m |

10,5 m |

12,0 m 13,5 m 15,0 m 16,5 m |

|

|

|||||||

|

Under- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m |

carriage |

|

|

|

|

|

|

|

|

|

|

|

|

|

m |

|

19,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

16,3* |

16,3* |

3,46 |

13,5 |

EW |

|

|

13,2* |

13,2* |

|

|

|

|

|

|

|

|

11,2* |

11,2* |

6,97 |

12,0 |

EW |

|

|

11,9* |

11,9* |

11,1* |

11,1* |

|

|

|

|

|

|

9,7* |

9,7* |

8,94 |

10,5 |

EW |

|

|

|

|

10,7* |

10,7* |

10,1* |

10,1* |

|

|

|

|

8,6 |

8,9* |

10,32 |

9,0 |

EW |

|

|

11,5* |

11,5* |

10,7* |

10,7* |

10,1* |

10,1* |

8,4 |

8,8 |

|

|

7,3 |

7,7 |

11,34 |

7,5 |

EW |

|

|

12,2* |

12,2* |

11,1* |

11,1* |

10,3* |

10,3* |

8,4 |

8,8 |

6,6 |

6,9 |

6,5 |

6,9 |

12,07 |

6,0 |

EW |

15,9* |

15,9* |

13,6* |

13,6* |

11,9* |

11,9* |

10,5 |

10,7* |

8,2 |

8,6 |

6,6 |

6,9 |

6,0 |

6,4 |

12,59 |

4,5 |

EW |

19,5* |

19,5* |

15,4* |

15,4* |

13,0* |

13,0* |

10,2 |

10,7 |

8,0 |

8,4 |

6,5 |

6,8 |

5,7 |

6,0 |

12,91 |

3,0 |

EW |

23,4* |

23,4* |

17,4* |

17,4* |

12,9 |

13,6 |

9,8 |

10,3 |

7,8 |

8,2 |

6,3 |

6,7 |

5,6 |

5,9 |

13,04 |

1,5 |

EW |

19,9* |

19,9* |

17,1 |

18,2 |

12,3 |

13,0 |

9,4 |

10,0 |

7,5 |

8,0 |

6,2 |

6,6 |

5,5 |

5,8 |

13,00 |

0 |

EW |

14,4* |

14,4* |

16,3 |

17,4 |

11,8 |

12,5 |

9,1 |

9,7 |

7,4 |

7,8 |

6,1 |

6,5 |

5,6 |

5,9 |

12,78 |

– 1,5 |

EW |

14,8* |

14,8* |

15,9 |

17,0 |

11,5 |

12,2 |

9,0 |

9,5 |

7,3 |

7,7 |

|

|

6,2 |

6,6 |

11,83 |

– 3,0 |

EW |

|

|

|

|

11,4 |

12,2 |

8,9 |

9,4 |

|

|

|

|

8,6 |

9,1 |

9,22 |

– 4,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 6,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 7,5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 9,0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height |

Can be slewed through 360° |

In longitudinal position of undercarriage |

|

Max. reach |

* Limited by hydr. capacity |

|

|

|||||||||

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load diagram and automatic check valves on the hoist cylinders, when they are used for lifting operations which require the use of lifting accessories.

R 944 C Litronic Machine for Industrial Applications 7

Loading...

Loading...