Page 1

96M00217

Using the Air Booster

For SJ-H Series Air Booster

SJ-HS01/02 (Straight air booster)

SJ-HW01/02 (Wide angle booster)

SJ-HM01 (Air Booster Sealing unit)

Instruction Manual

Read this manual before using the system in order to achieve

maximum performance.

Keep this manual in a safe place for future reference.

Safety Precautions

■ General Cautions

Danger

■ Precautions for handling the air booster

Danger

• We recommend that you take substantial safety measures to avoid any damage

in the event of a problem occurring.

•

Do not modify the product or use it in any way other than described in the specifications.

• Do not use the air booster for the purpose of protecting the human body.

When supplying nitrogen-rich air to a sealed location, the oxygen levels become

low, which can cause injury.

Always use ventilation when using in a sealed location.

Danger

Caution

When supplying nitrogen-rich air to a sealed location, the oxygen levels become

low, which can cause injury.

Always use ventilation when using in a sealed location.

When setting on SJ-H060/084/108/132/156/180/204/228/252/300, secure the

intermediate support with a screw to prevent twisting. Otherwise, product damage

will result.

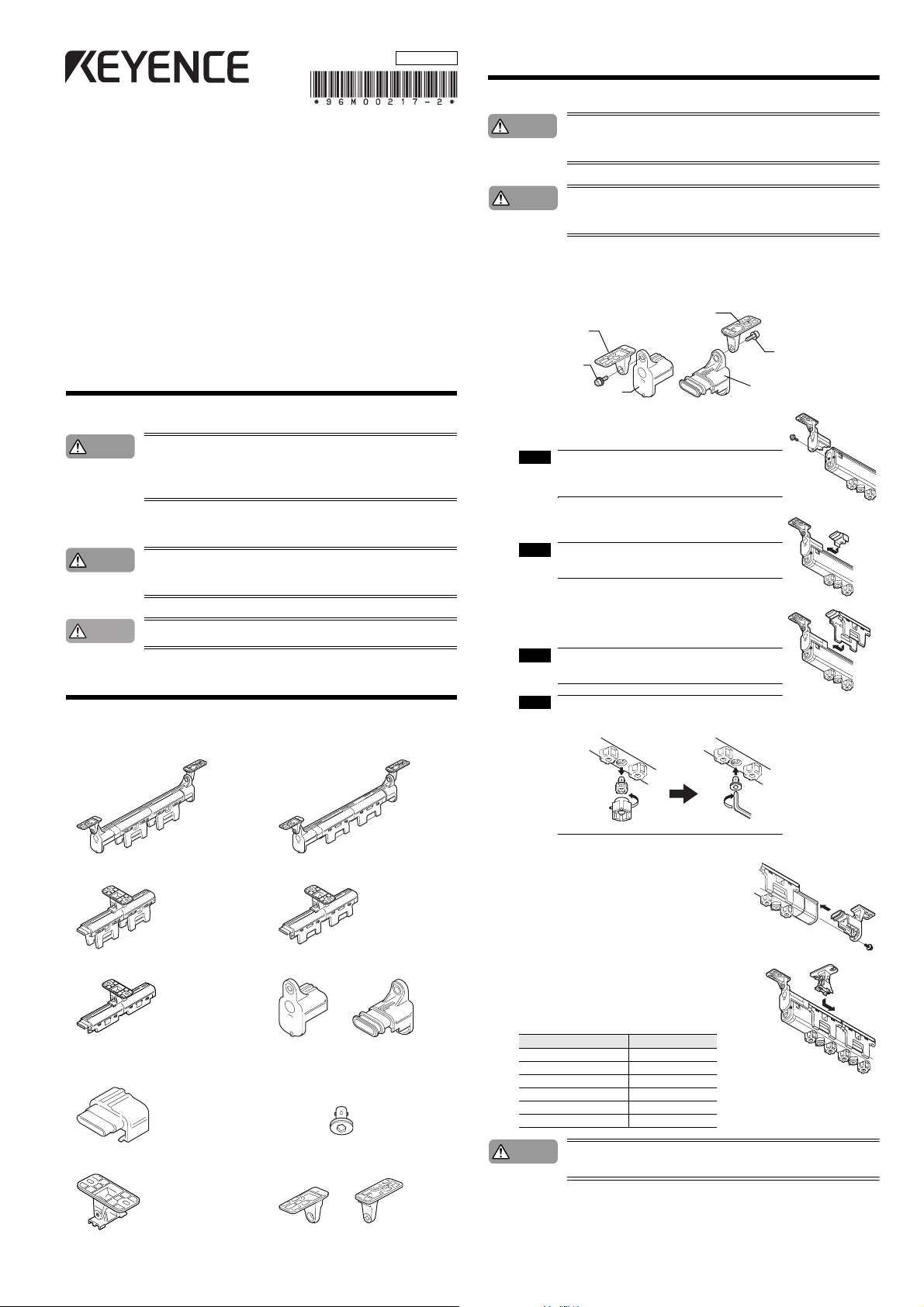

■ Mounting the air booster

1 Combine the air booster side support with the air booster end unit.

Put together one set (for the left and for the right).

Air booster end unit

M6 x 12 hexagon

socket head bolt

Air booster side support A

2 Mount the air booster side support A and end unit that were

combined in Step 1 to the cable connection side of the static

elimination bar.

Note

Always mount the air booster side support A to the modular side.

Also, mount air booster side support A first, and then

mount air booster side support B last.

3 Mount the air booster 036 conversion part to the static

elimination bar.

Note

When using a static elimination bar model other than SJ-H036,

the "Air booster 036 conversion part" is not needed.

Air booster end unit

Air booster side support B

M6 x 12 hexagon

socket head bolt

Warning

Use earplugs or similar protective devices during use to protect against high noise.

System Configuration

This section describes the name of air booster parts.

Straight air booster starter unit Wide angle booster starter unit

(SJ-HS01) (SJ-HW01)

Straight air booster expansion unit Wide angle booster expansion unit

(SJ-HS02) (SJ-HW02)

Air booster sealing extension unit Air booster side support A/B

(SJ-HM01) (Included with starter unit)

Air booster

side support A

Air booster 036 conversion part Air booster sealing cap

(Included with starter unit) (supplied with the wide angle booster starter

unit and the wide angle booster expansion unit)

Air booster

side support B

4 Mount the straight air booster (or wide angle booster) unit to the

static elimination bar.

A click can be heard when the part is mounted correctly.

Note

For models other than SJ-H036, the optional straight air

booster (or wide angle booster) extension unit is required.

Important

When mounting with the wide angle booster, remove the

acceleration electrode probe and attach the air booster

sealing cap.

5 Mount the air booster side support B and end unit that

were combined in Step 1.

6 Mount the air booster intermediate support to the

static elimination bar.

Mount air booster intermediate supports to all static

elimination bars except for the SJ-H036 model.

The required number of air booster intermediate supports is

different depending on the model of the static elimination bar

being used.

Model

SJ-H036 0

SJ-H060/SJ-H084/SJ-H108 1

SJ-H132/SJ-H156 2

SJ-H180/SJ-H204 3

SJ-H228/SJ-H252 4

SJ-H300 5

No. of parts to mount

Air booster intermediate support (OP-84385) Air booster end unit (OP-84386)

(Included with extension unit) (Included with starter unit)

Caution

Be sure to mount the specified number of the air booster intermediate support to

SJ-H060/084/108/132/156/180/204/228/252/300.

1

Page 2

7 Use M5 screws to secure the SJ-H Series in the

8

]

installation location.

Note

Be sure to secure the end unit with four M5 screws.

■ Removing the air booster

1 Remove the air booster side support B.

2 Remove the straight air booster (wide angle booster)

through the groove on the static elimination bar guide rail.

The straight air booster (wide angle booster) can

Reference

be removed as a single unit by using a narrow,

slotted screwdriver or similar small tool to unlock

the lock.

3 Remove the air booster side support A.

■ Supplying air

As shown in the diagram below, install the joint to the air supply opening in order to supply air.

Caution

Recommended joint

We recommend using the tube fitting (tube diameter φ10 mm) joint manufactured by Nihon Pisco.

Note

• Be sure to use a joint tightening torque of 1.2 N•m (12 kgf•cm) or less. Otherwise

an accident or malfunction may result.

• Be sure to supply air from both sides (2 locations).

•

Please contact the nearest KEYENCE office when opening and closing the air duct.

R3/8

Rc3/8

R3/8

Rc3/8

Tube diameter φ10mm: PC10-03

• Use a joint with a tube diameter of φ10 mm for the air booster.

• When supplying air to multiple units at the same time, supply air to each air booster. If an attempt is

made to supply air to multiple SJ-H Series unit from one air supply source, sufficient air supply may not

be obtained.

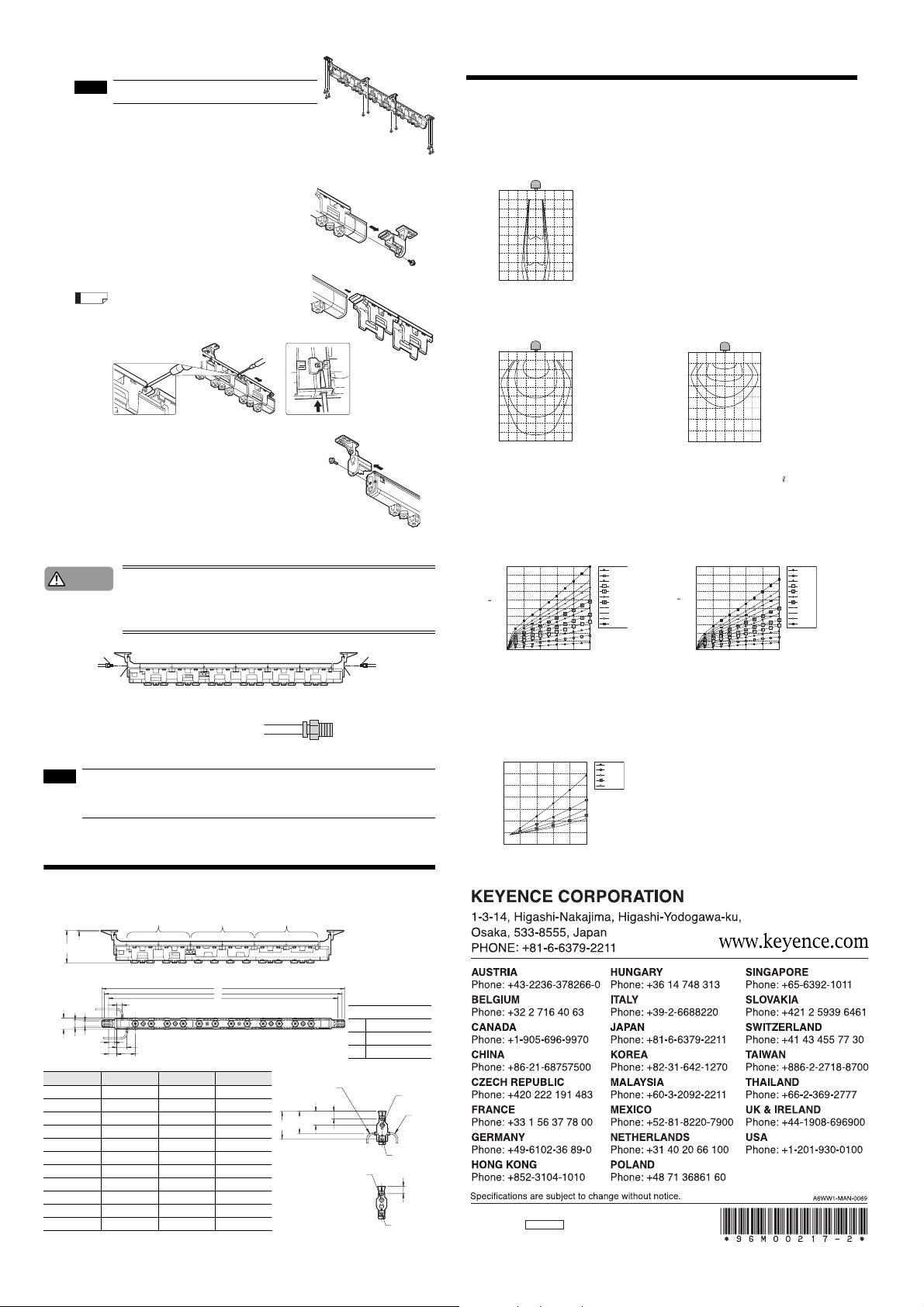

Dimensions

Static Elimination Ability Chart

■ Static elimination area and static elimination time

The following examples show the relationship between the time required for static elimination on the

target and the operating distance from the target to the static elimination bar.

● Straight air booster

Operating area and time

(33Hz)

150300450

600 150 300 450 600mm

300

600

0.4sec

900

0.6sec

1200

0.8sec

1.0sec

1500

mm

Measurement conditions:

Elimination time from ±1000 V to ±100 V

The 150 × 150 mm plate monitor (20 pF) is used.

SJ-H060 + Straight air booster is used. No downflow.

Air supply / SJ-H060: 0.5 MPa, Straight air booster: 0.5 MPa

● Wide angle booster

Operating area and time

(33Hz)

150300450

600 150 300 450 600mm

300

0.5sec

600

1.0sec

900

2.0sec

1200

3.0sec

1500

mm

Measurement conditions:

Elimination time from ±1000 V to ±100 V

The 150 × 150 mm plate monitor (20 pF) is used.

SJ-H060 + Wide angle booster is used. No downflow.

Air supply / SJ-H060: 0.1 MPa, Wide angle booster: 0.5 MPa

■

Relationship between air pressure and flow according to static elimination bar length

The relationship between the supplied air flow and the air pressure changes depending on the static elimination bar length.

Refer to the typical examples and select an air supply device (compressor) that will provide sufficient air flow.

● Straight air booster ● Wide angle booster

5000

4500

4000

3500

3000

2500

2000

1500

Supplied flow[N /min]

1000

500

0

0 0.1 0.2 0.3 0.4 0.5

Air pressure[MPa]

■ Relationship between static elimination speed and operating distance depend-

ing on air pressure

The relationship between the static elimination speed and the static elimination bar operating distance is different depending on the air pressure.

Refer to the typical examples and adjust the air pressure.

● Straight air booster

3.5

3.0

2.5

2.0

1.5

1.0

Static elimination time[sec]

0.5

0

0 300 600 900 1200 1500

Operating distance[mm

Measurement conditions:

Elimination time from ±1000 V to ±100 V

The 150 × 150 mm plate monitor (20 pF) is used.

SJ-H060+ Straight air booster is used. No downflow.

0.1MPa

0.2MPa

0.3MPa

0.4MPa

0.5MPa

SJ-H036

SJ-H060

SJ-H084

SJ-H108

SJ-H132

SJ-H156

SJ-H180

SJ-H204

SJ-H228

SJ-H252

SJ-H300

Operating area and time

(10Hz)

150300450

600 150 300 450 600mm

0.5sec

300

1.0sec

2.0sec

600

3.0sec

900

1200

mm

Measurement conditions:

Elimination time from ±1000 V to ±100 V

The 150 × 150 mm plate monitor (20 pF) is used.

SJ-H060 + Wide angle booster is used. No downflow.

Air supply / Main body: none,

Wide angle booster: 0.25 MPa (50 /min per electrode)

5000

4500

4000

3500

3000

2500

2000

Supplied flow[N /min]

1500

1000

500

0

0 0.1 0.2 0.3 0.4 0.5

Air pressure[MPa]

SJ-H036

SJ-H060

SJ-H084

SJ-H108

SJ-H132

SJ-H156

SJ-H180

SJ-H204

SJ-H228

SJ-H252

SJ-H300

■ With SJ-H Series attached

4

122

Straight air booster*Wide angle booster*Sealing unit

* The straight air booster and the wide angle booster can not be mounted at the same time.

A

B

*3

18

29

21

C

42

23

30

SJ-H036 451 432 400

SJ-H060 671 652 620

SJ-H084 911 892 860

SJ-H108 1151 1132 1100

SJ-H132 1391 1372 1340

SJ-H156 1631 1612 1580

SJ-H180 1871 1852 1820

SJ-H204 2111 2092 2060

SJ-H228 2351 2332 2300

SJ-H252 2591 2572 2540

SJ-H300 3071 3052 3020

38

70

Total length A

*2

*1

Mounting pitch B Mounting pitch C

Bar (left)

(82)

102

Bar (Right)

(R24)

51

SJ-H036*

*1 90mm

*2 21mm

*3 No modular socket

27.5

Rc3/8

Rc3/8

Rc1/8

27.5

Rc1/

(R24)

Copyright (c) 2008 KEYENCE CORPORATION. All rights reserved.

00217E 0099-2 96M00217 Printed in Japan

2

Loading...

Loading...