Page 1

Ultra High-speed Sheath Sensing Ionizer

SJ-H(A)(V)(C) Series

SJ-H036*/060*/084*/108*/132*/156*/180*/204*/228*/252*/300*

Instruction Manual

Read this instruction manual b efore using the product in order to achieve ma ximum performance.

Keep this instruction manua l in a safe place aft er reading it so that it c an be used at any time.

Danger

Warning

Caution

Important

NOTE

Reference

Danger

Danger

Caution

Caution

Caution

Caution

Caution

96M00282

Symbols

The following symbols alert you to important messages. Be sure to read these messages carefully.

Warning

• To avoid the risk of electric shock and ensure proper static elimination, be sure to completely ground the SJ-H* Series' 10-pin I/O cable.

• To avoid the risk of electric shock or product malfunctions, prevent water, oil, or flammable

solvent from splashing onto the SJ-H* Series.

• To avoid the risk of electric shock or product malfunctions, keep fingers and metallic

objects such as tools or wires away from the SJ-H* Series during operation.

• When the SJ-H* Series is used in an enclosed space, the generated ozone may become

harmful.

Make sure that there is adequate ventilation when using the SJ-H* Series in an enclosed

space.

• Do not use the SJ-H* Series in a location in which the temperature changes suddenly, or

where condensation occurs. This may lead to an accident or product breakdown.

• To avoid the risk of electric shock, do not operate the SJ-H* Series with wet hands.

• To avoid the risk of electric shock or product malfunctions, be sure to turn the power off

during maintenance of the SJ-H* Series.

• To avoid the risk of injury, do not touch the electrode probes directly with your hands or fingers during maintenance.

• If any abnormality is observed in the SJ-H* Series, immediately turn off the power and

contact the nearest KEYENCE office. Do not try to repair the SJ-H* Series by yourself.

This may cause electric shock or product malfunctions.

• Do not touch the SJ-H* Series' electrode probes with hard objects such as tools. If the

electrode probes are damaged, the SJ-H* Series does not operate properly, resulting in

product malfunctions.

• Operate the control panel of the SJ-H* Series with the flat-blade screwdriver provided with

the product.

• When mounting the SJ-H* Series, use the provided End units (L/R) and Auxiliary Support

Part, otherwise product malfunctions may result.

• When the SJ-H* Series is used over a long time, dust accumulates on the electrode

probes. Clean the electrode probes when the alarm indicator flashes. If you continue to

use the SJ-H* Series with dust accumulating on the electrode probes, the SJ-H* Series

will not operate properly, resulting in product malfunctions. Regular cleaning (about every

2 weeks) is recommended.

Do not drop the SJ-H* Series or subject it to a strong impact. This may cause product mal-

•

functions.

• Do not use the SJ-H* Series for any purpose other than eliminating static electricity.

• When the SJ-H* Series is used in combination with other instruments, functions and

performance maybe degraded, depending on operating conditions and the surrounding

environment.

Failure to follow instructions may lead to death or serious injury.

Failure to follow instructions may lead to injury.

Failure to follow instructions may lead to product damage (product malfunctions, etc.).

Provides important precautions and restrictions on proper operation.

Provides additional information on proper operation.

Provides useful information on proper operation.

Provides reference pages.

Indicates that the operation is done on the SJ-H01 Remote Control Console for the SJ-H*

Series.

Safety Precautions

General precautions

• You must verify that the SJ-H* Series are operating correctly in terms of functionality and

performance before the start and the operation of the SJ-H* series.

Warnings and cautions specific to the SJ-H* Series

The SJ-H* Series is a high-voltage device that is not designed to be explosion proof. Before using the

SJ-H* Series, be sure to read the following warnings and precautions carefully.

• We recommend that you take substantial safety measures to avoid any damage in the

event of a problem occurring.

• KEYENCE never warrant the function or performance of the SJ-H* Series if it is used in a

manner that differs from the SJ-H* Series specifications contained in this instruction manual or if the SJ-H* Series are modified by yourself.

• Do not use the SJ-H* Series for the purpose of protecting the human body.

• Filling a closed space with nitrogen will reduce the oxygen levels in the air to dangerous

levels.

Make sure that there is adequate ventilation when using the SJ-H* Series in an enclosed

space.

• Do not use the SJ-H* Series in the presence of flammable or explosive gases or elements.

Precautions for power supply

• Use a DC power supply at a rated supply voltage of 24 to 36 V.

• Noise conveyed through the power supply line may cause the SJ-H* Series to malfunction.

Be sure to use a stabilized DC power supply with an insulated transformer.

• When using a commercially available switching regulator, be sure to completely ground

switching regulator's frame ground terminal.

• Do not connect a number of power supplies to a single SJ-H* unit or more than one SJ-H*

unit connected together, otherwise the power supplies will be short-circuited and product

malfunctions may result.

Precautions for grounding

The 10-pin I/O cable for the SJ-H* Series is provided with a ground wire.

• For proper static elimination, be sure to completely ground the SJ-H* Series' grounding

cable.

• The grounding cable must be grounded at a resistance not exceeding 100 Ω.

Warning labels on SJ-H* Series

For safety reasons, the warning labels are attached to the SJ-H* Series. Read each label carefully

and follow the instructions on the labels.

Locations

To prevent product malfunctions, avoid installing the SJ-H* Series in the following locations.

• Locations in which the SJ-H* Series may be directly subjected to vibration or impact.

• Locations in which the ambient temperature drops below 0°C or exceeds + 40°C.

• Locations in which the relative humidity drops below 35% or exceeds 85%, or where

condensation occurs.

• Locations in which the temperature changes suddenly.

• Locations in which the SJ-H* Series is exposed to a direct breeze from an air conditioner.

• Locations in which there are volatile, flammable substances or corrosive gas.

• Locations exposed to dust, salt, metal particles, or greasy fumes.

• Locations in which water, oil or chemicals may splash onto the SJ-H* Series.

• Locations in which a strong magnetic or electric field is generated.

• Locations where the altitude exceeds 2000 m.

• Outdoors

Other precautions

• Follow the warning instructions and cautions specified in this instruction manual.

• The SJ-H* Series uses an EEPROM. Do not turn off the unit while settings are made in

the SJ-H* Series.

1

Page 2

Precautions for CSA Certificate

Auxiliary Support Part

SJ-H036* : 0

SJ-H060* : 0

SJ-H084* : 0

SJ-H108* : 0

SJ-H132* : 1

SJ-H156* : 1

SJ-H180* : 1

SJ-H204* : 1

SJ-H228* : 2

SJ-H252* : 2

SJ-H300* : 2

0 1 2 3

4 5 6 7

8 9 10 11

12 13 14 15

SJ-H060*/084*/108*/132*/156*/180*/204*/228*/252*/3 00* Controller-built-in Static Eliminato r

SJ-H036* Static Elimination Bar

SJ-H036* Controller

Electrode probe

replacement kit

End Units (L/R)

End Unit Securing Screws: 2

Instruction Manual Flat-blade screwdriver

The CAUTION/WARNING labels in

Japanese, German, French, Italian,

and Chinese

*1

ID number seal

*1

NOTE

* The figure is for the SJ-H084*/108*/132*/156*/180*/204*/228*/252*/300*.

The position of Ion monitor of SJ-H060* is different from other models.

The position of it is located to the right side of Remote control infrared receiver.

SJ-H036* does not have 1 through 3 and 5.

8

3

5

14

76 2

312

546

High-speed

Low-speed

10 mm

min.

10 mm

min.

10 mm

min.

20 mm min.

10 mm

min.

10 mm

min.

10 mm min.

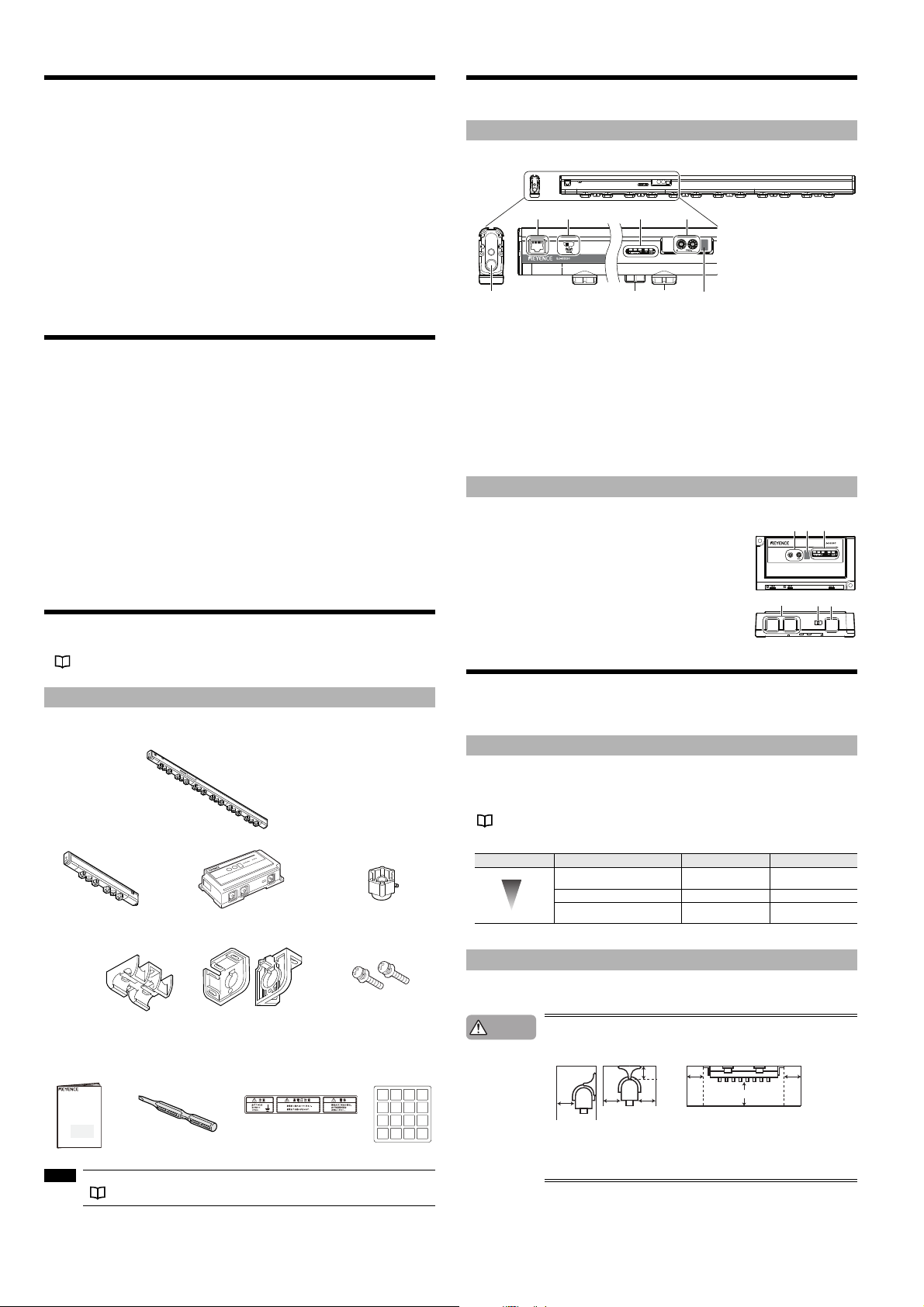

Part Names

The SJ-H* Series complies with the following CSA and UL standards, and has been certified by CSA.

CAN/CSA-C22.2 No.61010-1

Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use

UL61010-1

Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use

<Precautions>

• When selecting a power supply for use with the SJ-H* Series, always use a CSA/UL-listed power

supply that either provides Class 2 output as defined in the Canadian Electrical Code/National

Electrical Code, or that has been evaluated as a Limited Power Source as defined in CAN/

CSA-C22.2 No. 60950-1/UL60950-1.

• Always establish a proper ground connections when installing the SJ-H* Series.

se only the cables provided by KEYENCE (po wer cables and connector cables) to connect SJ-H*

•U

Series units to one another or to their power suppli es.

• Install the SJ-H* Series in accordance with the installation and wiring instructions described in this

instruction manual. Never operate the SJ-H* Series with the ratings that does not conform to the

specifications described in this instruction manual.

* Seven units can be connected only when the 36 V power supply is used.

Please contact the nearest KEYENCE office when the 24 V power supply is used.

Precautions for CE Marking

The SJ-H* Series complies with the following EU Directives and EN standards.

<Precautions>

• Be sure to completely ground the SJ-H* Series' ground terminal when installing the SJ-H* Series.

• Overvoltage Category (Installation Category): I

• Pollution Degree: 2

• When selecting a power supply for use with the SJ-H* Series, always use a power supply that has

been certified by a EU Notified Body (as a Limited Power Source as defined in EN60950).

• Use only the cables provided by KEYENCE (power cabl es and connector cables) to connect SJ-H *

Series units to one another or to their power suppli es.

• Install the SJ-H* Series in accordance with the installation and wiring instructions described in this

instruction manual.Never operate the SJ-H* Series with the ratings that does not conform to the

specifications described in this instruction manual.

* Seven units can be connected only when the 36 V power supply is used.

EU Directives

• EMC Directives (2004/108/EC)

• Low-voltage Directive (2006/95/EC)

EN Standards

• EN61326-1 Class A

• EN61010-1

Please contact the nearest KEYENCE office when the 24 V power supply is used.

Checking the Package Contents

This section lists the part names of the SJ-H* Series. For details about the operation keys and indicators

on the controller's front panel, see "Names and functions of operation keys, switches, and indicators".

Static elimination bar (Control panel)

1. Setting block (Not provided on SJ-H036*) (The ID switch is not provided on the SJ-HA Series)

2. Remote control infrared receiver (Not provided on the SJ-HA Series or SJ-H036*)

3. Indicator block (Not provided on SJ-H036*)

4. Cable connector (two on the SJ-H/HV/HC Series (except for SJ-H036*), and one on the SJ-HA

Series and SJ-H036*)

5. Terminator switch (Not provided on the SJ-HA Series or SJ-H036*)

6. Electrode probe

7. Accelerating electrode probe (Not provided on the SJ-HA/HV/HC Series)

8. Air supply opening (Two on SJ-H036*/060*/084*/108*/132*/156*/180*/204*, and three on

SJ-H228*/252*/300*)

Control panel (SJ-H036*)

Setting block (The ID switch is not provided on the SJ-H036A)

1.

2.

Remote control infrared receiver (Not provided on the SJ-H036A)

3. Indicator block

4. I/O Cable connector (Only one on the SJ-H036A)

5. Cable connector

6. Terminator switch (Not provided on the SJ-H036A)

The package of SJ-H* Series includes the following items. Ensure that these items are included in

your package before using the Unit. Extension cables and electrode probes for replacement are

available as options.

See "List of Optional Accessories" (page 9).

Contents

Installation and Connection

This section explains how to set up and install the SJ-H* Series.

Before installation, carefully consider the operating condit ions such as the distance between the static

elimination bar and the target, or the time required for the elimination of the target's static charge.

Static elimination ability

Static elimination speed and operating distance

The SJ-H* Series offers a variety of frequency settings to enable flexible static elimination

according to the location and application.

See "Frequency setting" (page 4).

Static elmination speed

Precautions for installation

Installation location

Caution

Refer to the following illustration to install the SJ-H* Series.

• Provide enough space between the static elimination bar and surrounding walls as shown

in the figures below.

Location Operating distance (mm)

Production lines of films or sheets

(Short distance)

Clean bench (Middle distance) 300-1000 10, 8, 5

On ceiling of clean room (Long distance)

50-300 68, 47, 33, 22

1000-2000 3, 1

Recommended frequency (Hz)

Ultra High-speed Sheath Sensing Ionizer

SJ-H(A)(V)(C) Series

SJ-H036*/060*/084*/108*/132*/156*/180*/204*/228*/252*/300*

Instruction Manual

*1 Use these language warning labels and ID number seals as needed.

The cables are sold separately.

See "Cables" (page 3).

• When mounting the SJ-H* Series, use the provided end unit and auxiliary suppor t part,

otherwise an accident or malfunction may result.

• Be sure that the cable stays more than 10 mm away from the SJ-H* Series, otherwise an

accident or malfunction may result.

2

Page 3

Interference

200 mm

min.

200 mm

min.

150 mm min.

150 mm

min.

150 mm

min.

400 mm

min.

100 mm

min.

Side-to -side installation

Face-to-face installation

Caution

Caution

• Mounting from the side

•

Mounting from the top

NOTE

Caution

[Pink (Static Elimination Interrupt Input)]

Apply NPN open collector input to the INPUT

and 0 V terminals from non-voltage contacts

(such as relays).

INPUT (Pink)

0V (Blue)

2.7 kΩ

2.4 kΩ

VCC (Power supply)

Photo Relay Output

[Black (Ion Level Alarm Output),

White (Condition Alarm Output)]

Photo Relay Output

[Gray (Alarm Output)]

OUT

DC40 V

100 mA

ALM_B

ALM_A

Output GND

Output GND

Output GND

The SJ-H* Series may not operate properly if there is any conductive object close to the SJ-H* Series

or if another SJ-H* unit is installed closely together. Refer to the following illustration and isolate the

SJ-H* Series from the conductive object.

2 Attach the end unit to each end of the static elimi-

nation bar.

If two SJ-H* units are used, refer to the following illustration and separate the static elimination bars

properly.

Auxiliary support part (SJ-H132*/156*/180*/204*/228*/252*/300*)

Install the SJ-H132*/156*/180*/204*/228*/252*/300* with auxiliary support part. Auxiliary support par t

prevents the static elimination bar from bending. Do not install the SJ-H132*/156*/180*/204*/228*/

252*/300* without using auxiliary support part.

Type

SJ-H036*/060*/084*/108* 0

SJ-H132*/156*/180*/20 4*

SJ-H

228*/

252*/300* 2

No. of auxiliary support parts necessary

for installation

1

Cables

The cables, including power cables and connector cables, required for the SJ-H* Series are not

included in the package. Confirm the installation location before installing and make sure to buy the

proper lengths of cables (10 pin I/O cable, 10-to-10-pin cable and 10-to-10-pin for SJ-H036* cables).

Item Type Appearance Description

10-pin I/O cable

10-to-10-pin cable

10-to-10-pin cable

for SJ-H036*

Relay box

for SJ-H*

SJ-C2U

SJ-C5U

SJ-C10U

OP-42210

OP-42211

OP-42212

SJ-C2H

SJ-C5H

SJ-C10H

OP-84296

Power cable for the SJ-H*

Series. Three types (2-, 5-,

10-m cables) are available.

(Cable color :Gray)

Cable for connecting the

SJ-H* Series units. Three

types (2-, 5-, 10-m cables)

are available. This cable

connects to the Relay Box as

well. (Cable color :Gra y)

The cable that connects the

SJ-H036* controller to the

bar. Three types (2-, 5-, 10-m

cables) are available. 10-pin

I/O cable is necessary for

supplying power.

(cable color :Black)

This is required if the cables

will extend more than 10

meters. (For use with the

10-to-10-pin cable)

3 Secure the SJ-H* Series with M4 screws at the

desired installation position.

When installing the SJ-H132*/156*/180*/204*/

228*/252*/300*, secure the auxiliary support part

with M4 screws as well.

When removing the auxiliary support part, be sure to

remove it from the side along the guide rails.

Wiring diagram (SJ-C2U/C5U/C10U 10-pin I/O cable)

Cord color Description

Brown

Brown/White

Blue

Blue/White

Pink

Orange Output signal GND

Black Ion level alarm output

White Condition alar m output

Gray Alarm output

Shield wire (thick black wire) Ground (Ground at a resistance not exceeding 100Ω.)

* The blue wire and orange wire are insulated from each other.

* Be sure install both of the brown and brown/white wires and

blue and blue/white wires.

Do not short-circuit the output signal wire and output signal GND wire together without any

load, otherwise the internal circuit will be damaged, which may result in product

malfunctions, because the SJ-H* Series does not have any overcurrent protection circuit.

DC power supply (rated voltage of DC 24 to 36 V ±10 %)

[The ends are soldered together before shipping]

Power supply GND

[The ends are soldered together before shipping]

Static elimination interrupt input

Input circuit

Installing SJ-H* Series

Installing SJ-H* Series

Install the SJ-H* Series in places where a static problem occurs or may occur.

1

Mount the auxiliary suppor t parts on top of the static elimination bar or along the guide rails.

The SJ-H132*/156*/180*/204* requires a single auxiliary support part, the SJ-H228*/252*/300*

requires two auxiliary support parts. Mount them at approximately equal intervals.

• When installing the SJ-H132*/156*/180*/204*/228*/252*/300*, mount and secure the auxiliary support parts with screws for the prevention of the static elimination bar from bending, otherwise the static elimination bar may be broken.

See "Precautions for installation" (page 2).

• Keep a space of at least 10 mm around the static elimination bar after installation, otherwise the static elimination bar may malfunction or receive damage.

Confirm that the hooks on the auxiliary support part grasp the guide rails on the static

elimination bar when installing.

Output circuit

A

B

A

B

3

Page 4

Connection of power supply

Caution

When connecting the SJ-H/HV/HC Series, set the terminator switch according to the cable connector to be used.

If the terminator switch is not set correctly, alarm output

will not output correctly.

See "Terminator switch setting" (page 6).

NOTE

Caution

Caution

When connecting the SJ-H/HV/HC Series, set the terminator switch according to the cable connector to be used.

If the terminator switch is not set correctly, alarm output

will not output correctly.

See "Terminator switch setting" (page 6).

NOTE

Caution

NOTE

12

3

4

5

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

Static Elimination Setting

Connecting SJ-H060*/084*/108*/132*/156*/180*/204*/228*/252*/300* to power

supply

A 10-pin I/O cable (sold separately) is required to connect the SJ-H060*/084*/108*/132*/156*/180*/

204*/228*/252*/300* to power supply.

See "Terminator switch setting" (page 6).

1 See "Wiring diagram" (page 3) and connect each wire of the 10-pin I/O cable.

• For proper static elimination, the ground wire must be grounded at a resistance not

exceeding 100Ω.

• Use a DC power supply with a marginal output (at least 500 mA) at a rated voltage of 24 to

36 V.

• Do not connect a number of power supplies to a single SJ-H* unit or more than one SJ-H*

unit connected together, otherwise the power supplies will be short-circuited an accident

or malfunction may result.

2 Connect the modular connector of the 10-pin I/O cable to

the SJ-H060*/084*/108*/132*/156*/180*/204*/228*/252*/300*.

A 10-pin cable connector each is provided to the front and

back of the SJ-H060*/084*/108*/132*/156*/180*/204*/228*/

252*/300*. (for the SJ-HA Series, it is provided only to the front)

The connector will snap when it is connected correctly.

• Press the tab of the modular connector to disconnect the cable. Do not pull the cable without pressing the tab, otherwise the cable may be damaged.

• Keep a space of at least 10 mm around the static elimination bar after installation, otherwise the static elimination bar may malfunction or receive damage.

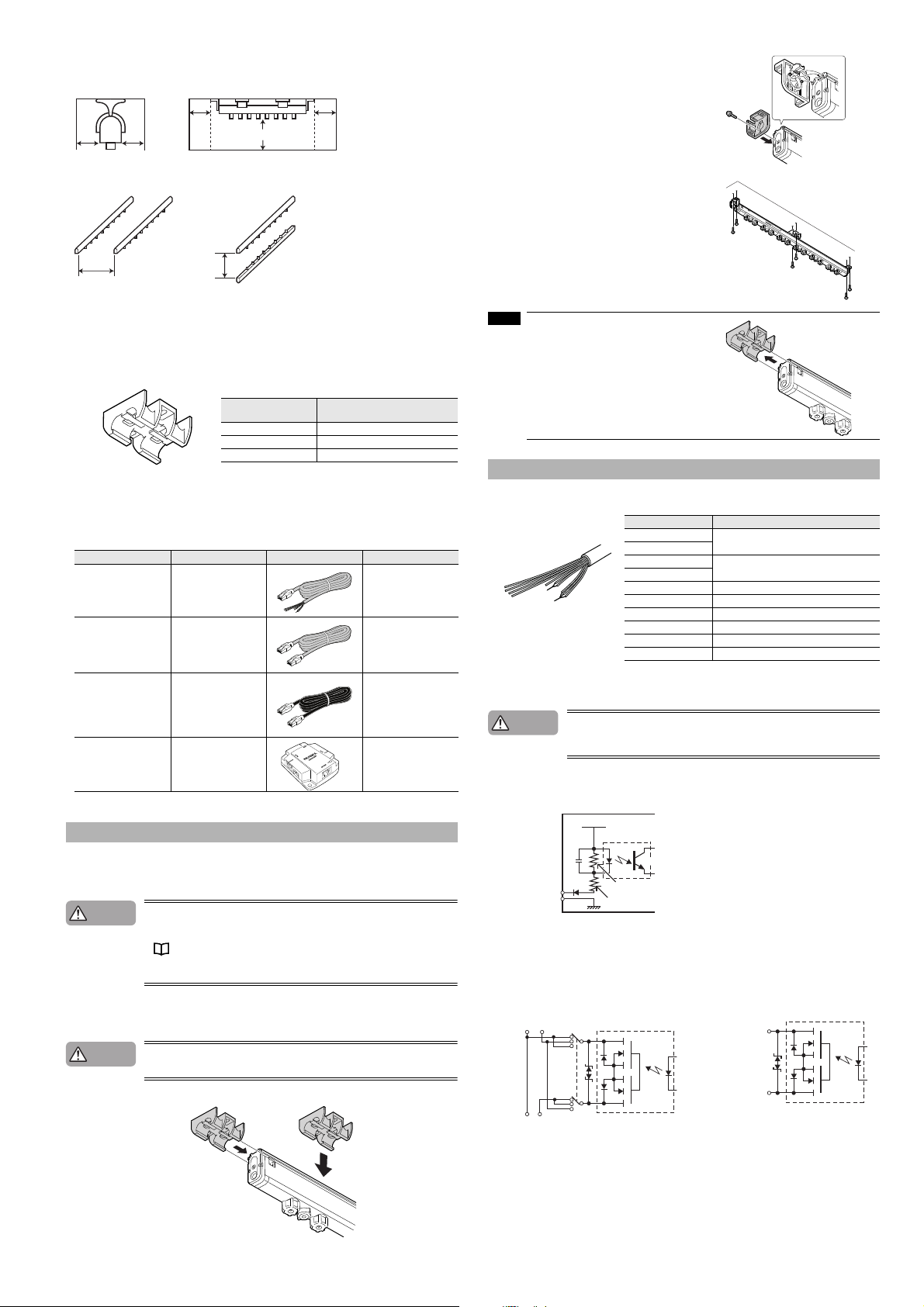

This section provides the name and functions of operation keys, switches, and indicators on the controller’s front panel. It also describes the operation procedure for the static elimination setting.

Names and functions of operation keys, switches, and indicators

The control panel of the SJ-H084*/108*/132*/156*/180*/204*/228*/252*/300* has the same layout.

The control panel of the SJ-H060* and SJ-H036* has the setting switch and LED positions swapped.

1. ID switch............. Sets the ID number if the SJ-H* unit is used with another SJ-H* unit. (The SJ-HA

2. FREQ switch....... Sets the frequency

3. ION MONITOR ... Displays the strength of the electric charge of the object. If the SJ-H01 is used,

4. RC Control/Setting Indicator

........................... This flashes when the SJ-H* Series is being controlled via remote control, during

5. Alarm Indicator... This flashes once per second if static elimination power is affected by situations

Series does not have this switch)

the quantity of ion generation will be displayed.

Dual I.C.C. confirmation and when the L.P.C. function is in use. (This cannot be

used on the SJ-HA Series)

such as an absorption of ions by surrounding metals, which can cause instability of the setting environment (temperature, humidity, surrounding metals).

(Condition alarm) This will blink twice per second if the ion generation capability

falls below the set value due to wear or dirt on the electrode probe.

(Ion level alarm) Flashes if the quantity of ion generation is low due to the deterioration of the electrode probes or the dirt on the electrode probes. Then static

elimination will be forcibly turned OFF. (Alarm)

Connecting SJ-H036* to power supply

A 10-pin I/O cable and a 10-to-10-pin cable (both sold separately) are required to connect the

SJ-H036* to power supply.

See "Terminator switch setting" (page 6).

1 See "Wiring diagram" (page 3) and connect each wire of the 10-pin I/O cable.

• For proper static elimination, the ground wire must be grounded at a resistance not

exceeding 100 Ω.

• Use a DC power supply with a marginal output (at least 500 mA) at a rated voltage of 24 to

36 V.

• Do not connect a number of power supplies to a single SJ-H* unit or more than one SJ-H*

unit connected together, otherwise the power supplies will be short-circuited an accident

or malfunction may result.

2 Connect the modular connector of the

10-pin I/O cable to the SJ-H036* controller.

The SJ-H036* controller has two 10-pin cable connectors

indicated GRAY (the SJ-H036A only has one), either one of

which can be used.

The connector will snap when it is connected correctly.

3 Connect the SJ-H036* controller and the static elimina-

tion bar over the 10-to-10-pin cable.

Connect the cable to the connector marked by the word

"BLACK." Then connect the cable to the static elimination bar

of the SJ-H036*.

The connector will snap when it is connected correctly.

• Press the tab of the modular connector to disconnect the cable. Do not pull the cable without pressing the tab, otherwise the cable may be damaged.

• Keep a space of at least 10 mm around the static elimination bar after installation, otherwise the static elimination bar may malfunction or receive damage.

The SJ-H036* static elimination bar and controller should bear the same serial number. Check that they

bear the same serial number when connecting them.

Frequency setting

A frequency is set with the FREQ switch in the SJ-H* Series.

When the frequency setting is made, the indicator for the present frequency on the ION MONITOR

will flash for approximately five seconds. Then the indicator will be turned OFF.

Frequency FREQ. switch ION MONITOR

68Hz 0

47Hz 1

33Hz 2

22Hz 3

10Hz 4

8Hz 5

5Hz 6

3Hz 7

1Hz 8

For remote control console

* This cannot be used on the SJ-HA Series.

For frequency settings in detail, see "Static elimination ability" (page 2).

*

OFF OFF Green

OFF OFF Yel lo w

OFF OFF Red

OFF Green OFF

OFF Yel lo w OFF

OFF Red OFF

Green OFF OFF

Yel lo w OFF OFF

Red OFF OFF

9

4

Page 5

Other Functions

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

Positively charged object

Negatively charged object

High

Middle

Low

Low

Middle

High

Large quantity of ion

Small quantity of ion

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

Danger

Caution

Caution

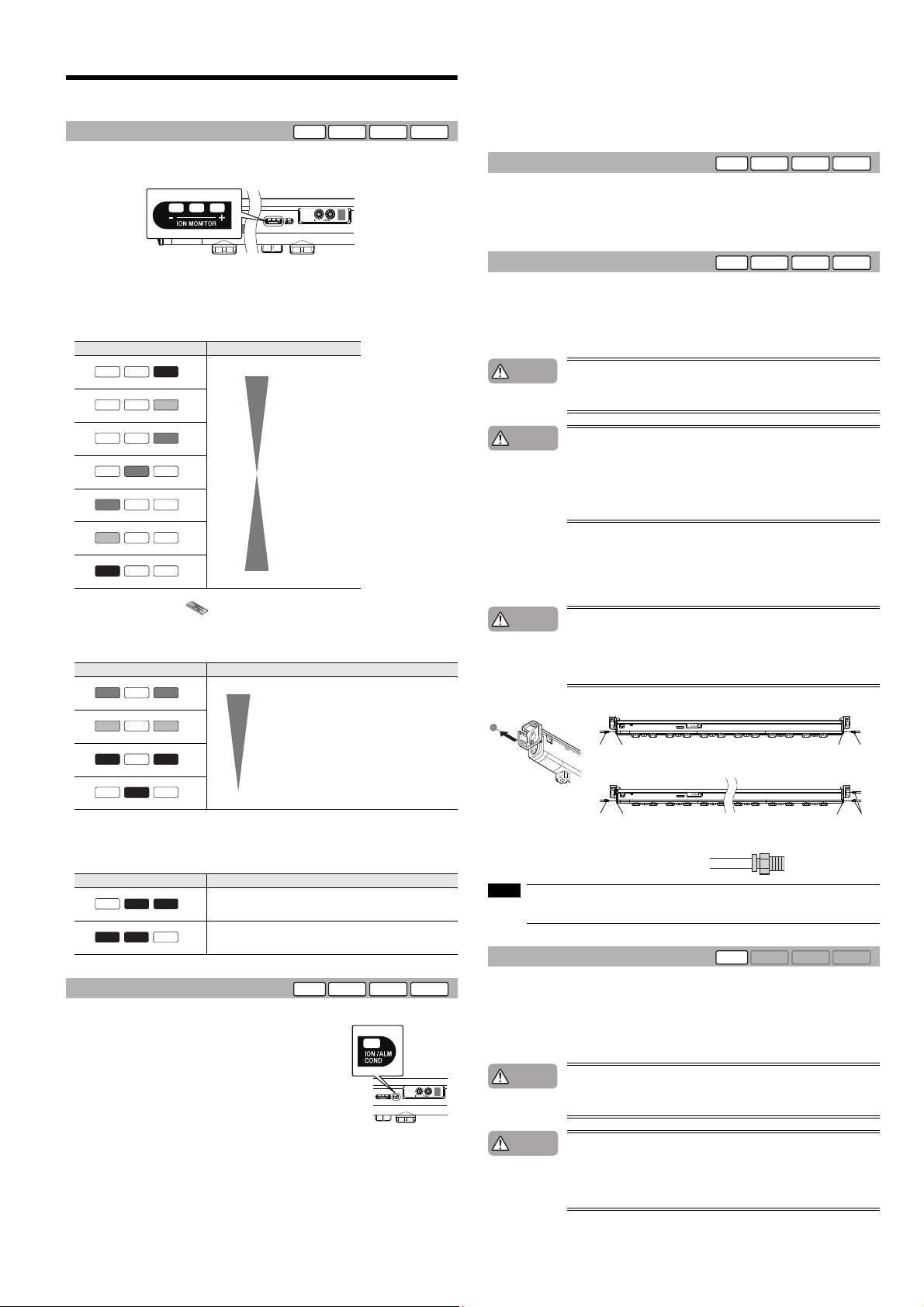

SJ-H036*/060*/084*/108*/132*/156*/180*/204*

SJ-H228*/252*/300*

R1/8

Rc1/8

Rc1/8

Rc1/8

Rc1/8

R1/8

R1/8

R1/8

Tube diameter φ 8 mm : PC8-01

NOTE

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

Caution

This section describes other functions such as the display function, alarm output function, and air purge function.

Indicators

The target's static charge and the quantity of ions generated from the static elimination bar are displayed on the ION MONITOR.

Electric charge indicator

The ION MONITOR works as an electric charge indicator that displays the target's static charge,

polarity of the static charge, and condition of static elimination.

The plus and minus side LEDs will illuminate in response to the current charge level.

When static elimination is finished, the indicator in the middle will be illuminated. Therefore, the user

will know the process of static elimination.

ION MONITOR Condition

OFF OFF Red

OFF OFF Yellow

OFF OFF Green

OFF Green OFF

Green OFF OFF

Yel lo w OFF OF F

Red OFF OFF

Ion quantity indicator

The ION MONITOR works as an ion quantity indicator as well, and continuously monitors the q uantity of ions generated

from the static elimination bar and displays the measurement in the colors of the LED.

When leftmost and rightmost indicators are illuminated green, it means that on the SJ-H* Series is fully generating ions.

* This cannot be used on the SJ-HA Series.

ION MONITOR Condition

Condition alarm function (COND)

The ION/ALM/COND indicator will flash once per second and an alarm signal (N.O. control signal)

will be output if the installation environmental conditions (e.g., the temperature, humidity, and ambient metal) are

unstable and likely to affect the perfor mance of static elimination adversely (e.g., the absorption of ions) caused

by ambient metal objects. Static elimination will not be interrupted in this case. By using the SJ-H01 Remote Control Console, the warning output can be adjusted in four levels according to the installation environment.

warning output cannot be adjusted on the SJ-HA Series)

Elimination interruption function

For the purpose of energy saving, by short-circuiting the blue (DC GND wire) and pink (static elimination interruption input signal wire) wire terminals of the 10-pin I/O cable, only the static elimination

function will be turned OFF without turning off the SJ-H* Series.

Air-purge function

Supplying clean air through the air duct on both ends of the static elimination bar will prevent the dust

accumulation on the electrode probes. The air purge widens the static elimination area and increases

the speed of static elimination as well.

* The air pressure indicates the pneumatic value at the route of the joint.

Please contact the nearest KEYENCE office when using the air-purge function with intermittent air supply.

*

Filling a closed space with nitrogen will reduce the oxygen levels in the air to dangerous

levels.

Make sure that there is adequate ventilation when using the SJ-H* Series in an enclosed

space.

• Check that the air pressure does not exceed 0.5 MPa, otherwise an accident or malfunction may result.

• Please contact the nearest KEYENCE office when opening and closing the air duct.

• Be sure to provide clean, dry air to the static elimination bar. If the air contains water or oil,

air leaks or electrical discharges may occur in the static elimination bar, thus resulting in

accidents or malfunctions.

• Be sure to supply air from both sides (2 locations) of the SJ-H036*/060*/084*/108*/132*/

156*/180*/204*.

• Be sure to supply air from both sides (3 locations) of the SJ-H228*/252*/300*.

Provide clean, dry air free of organic matter at a condensation point of -25 °C and approximately 0.01

μm in mesh size.

Air supply method

As shown in the illustration below, remove the screw that block the air duct on either end of the static

elimination bar, connect a joint to the air duct, and provide air.

• Be sure to limit the tightening torque to 1.2 N•m (12 kg•cm2) or less. Otherwise, an accident or product breakdown may occur.

• Be sure to supply only clean, dry air. The use of improper air may cause an accident or

product malfunctions.

• Be sure to supply air from both sides (2 locations) of the SJ-H036*/060*/084*/108*/132*/

156*/180*/204*.

• Be sure to supply air from both sides (3 locations) of the SJ-H228*/252*/300*.

(The

Alarm function (ALM)

Ion level alarm function (ION)

Green OFF Green

Yel lo w OFF Yellow

Red OFF Red

OFF Red OFF

When the SJ-H01 Remote Control Console is used to set continuous generation of positive (or negative) ions, only two indicators on the positive (or negative) side will be illuminated.

The ION MONITOR does not display the target's static charge or condition of static elimination.

* This cannot be used on the SJ-HA Series.

ION MONITOR Condition

OFF Red Red

Red Red OFF

Alarm output function

The ION/ALM/COND indicator will flash red three times per second and

an alarm signal (N.C. control signal) will be output if the internal circuit is

damaged or an abnormal electrical di scharge occurs.

Then the SJ-H* Series will stop generating i ons.

Alarm output will activate rega rdless of whether or not static elimination

is being interrupted manually or forcibly.

The ION/ALM/COND indicator will flash twice per second and an alarm

signal (N.O. control signal) will be output if the quantity of ion generation is low due to the deterioration

of the electrode probes or the dirt on the electrode probes. Static elimination will not be interrupted in

this case. By using the SJ-H01 Remote Control Console, the warning output can be adjusted in four levels according to the quantity of ions generated. (The warning output cannot be adjusted on the SJ-HA

Series).

The ion level warning can be a notice for the maintenance of the electromagnetic probes. Static elimination continues, so make sure to turn off the power when you perform maintenance on the electromagnetic probes.

Continuous positive ion generation

Continuous negative ion generation

Recommended joint

The recommended joint is the Tube Fitting (tube diameter : φ 8 mm) manufactured by Pisco Co.

• Use a joint having a tube diameter of 8 mm on the SJ-H* Series.

• When providing air to more than one SJ-H* unit, check that each static elimination bar is provided with

air. If the air supply source is one, each static elimination bar may not be provided with enough air.

Air booster

An optional air booster can be mounted to the SJ-H Series.

By using the air booster, the static elimination speed can be improved and the static elimination

range can be expanded.

For more details, see the air booster Instruction Manual.

* The air booster cannot be used with SJ-HA/SJ-HV/SJ-HC Series.

Please contact the nearest KEYENCE office when using the air-purge function with intermittent air supply.

*

Danger

Provide clean, dry air at a condensation point of -25 °C and approximately 0.01 μm in mesh size.

Filling a closed space with nitrogen will reduce the oxygen levels in the air to dangerous

levels.

Make sure that there is adequate ventilation when using the SJ-H* Series in an enclosed

space.

• Check that the air pressure does not exceed 0.5 MPa, otherwise an accident or malfunction may result.

• Please contact the nearest KEYENCE office when opening and closing the air duct.

• Be sure to provide clean, dry air to the static elimination bar. If the air contains water or oil,

air leaks or electrical discharges may occur in the static elimination bar, thus resulting in

accidents or malfunctions.

• Be sure to supply air from both sides (2 locations) of the air booster.

5

Page 6

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

Caution

NOTE

DC power supply at a rated

voltage of 24 to 36 V.

10-to-10 pin

cable

10-pin I/O cable

DC power supply at a rated

voltage of 24 to 36 V.

Relay box

10-to-10-pin cable

10-to-10-pin cable for

SJ-H036*

10-pin I/O cable

Terminator switch

NOTE

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

NOTE

Laminar flow assisting part

The optional laminar flow assisting part can be installed to the SJ-HV Series.

The laminar flow assisting part shows its maximum power when eliminating static electricity under the

downflow in a clean room without disturbing the laminar flow.

For details, see the Instruction Manual of the laminar flow assisting part.

* The SJ-H/HA/HC Series cannot use the laminar flow assisting part.

Abnormal discharge detection function

The SJ-H* Series detects abnormal electric discharge caused by the condensation on the tips of

the electrode probes or conductive objects that may come close to the electrode probes, thus

interrupting the generation of ions and prevent the occurrence of trouble.

L.P.C. function

Connecting in parallel

Up to seven SJ-H* units can be connected in parallel over the optional 10-to-10-pin serial cable

through the optional OP-84296 relay box.

This function is used to reduce the amount of foreign matter adhering to the electrode probes when

the air purge function is not used. It controls the supply of high voltage so that application of high

voltage to the electrode probes is interrupted for a fixed cycle. In this way, the adhesion of foreign

matter to the electrode probes is prevented.

Settings for SJ-H* Units in Coupled Operation

This section explains how to make settings for SJ-H* units used in coupled operation.

* The SJ-HA Series can be coupled in parallel by using the relay box.

Frequency setting

When using SJ-H* units in coupled operation, set a unique frequency for each SJ-H* unit individually.

ID number setting

When using SJ-H/SJ-HV/SJ-HC units in coupled operation, it is convenient to set a unique ID number for each unit individually. The ID

number of the SJ-H/SJ-HV/SJ-HC Series is set to 0 before shipping.

The ID number can be set in hexadecimal between 0 and F (i.e., 16

in total). Turn the ID Switch with the provided flat-blade screwdriver

to set the ID number.

SJ-H* Series ID number switch 0-9 A B C D E F

Remote control ID number key

and ID number seal

By setting the ID number for each SJ-H* unit, it will be easy to control

each static elimination bar through the SJ-H01 Remote Control Console.

See "Settings for SJ-H* Series Used with Remote Control Console" (page 7).

0-9101112131415

Connecting SJ-H* Series units in coupled operation

It is possible to connect seven SJ-H* units in coupled operation, provided that the total length

between the power supply and the farthest static elimination bar is within 30 m.

Seven units can be connected only when a 36 V power supply is used. Contact KEYENCE when a

*

power supply is used.

24 V

Terminator switch setting

If the SJ-H/SJ-HV/SJ-HC Series is installed in serial, set the terminator switch to meet the connection

state.

* The SJ-HA Series does not have the terminator switch.

• If the modular plug is connected to port A:

Set the terminator switch to "A."

• If the modular plug is connected to port B:

Set the terminator switch to "B."

• If the modular plug is connected to both ports A and B:

Set the terminator switch to the center.

• Only move the terminator switch when the power to the SJ-H/SJ-HV/SJ-HC is OFF.

• If the terminal switch is not set correctly, alarm outputs on the SJ-H/SJ-HV/SJ-HC Series will not be

output correctly.

OP-84296 relay box

Using the OP-84296 relay box allows the SJ-H* Series to be connected in parallel.

Use the relay box when the connection between SJ-H* Series is

greater than 10 m.

* If no relay box is used, the SJ-H* Series can only be connected

in serial.

• Set the terminator switch to "2" if the SJ-H* Series is connected to

the OUT port of the relay box.

• Set the terminator switch of the OUT port that is not connected to the SJ-H* Series to "1".

*

Connecting in series

Up to seven SJ-H/SJ-HV/SJ-HC units can be connected in series over the optional 10-to-10-pin serial

cable.

* The SJ-HA Series cannot be connected in series.

Do not connect a number of power supplies to a single SJ-H* unit or more than one SJ-H*

unit connected together, otherwise the power supplies will be short-circuited an accident or

malfunction may result.

• A coupled installation of the SJ-H* units is possible under the following restrictive conditions.

• Up to seven SJ-H* units can be connected.

(Seven units can be connected only when a 36 V power supply is used. Contact KEYENCE when a

24 V power supply is used.)

• The total extension length between the power supply an d the farthest static eliminatio n bar is within

30 m.

• When providing air to more than one SJ-H* unit, check that each static elimination bar is provided with

air. If the air supply source is one, each static elimination bar may not be provided with enough air.

Caution

Do not connect a number of power supplies to a single SJ-H* unit or more than one SJ-H*

unit connected together, otherwise the power supplies will be short-circuited an accident or

malfunction may result.

• A coupled installation of the SJ-H* units is possible under the following restrictive conditions.

• Up to seven SJ-H* units can be connected.

(Seven units can be connected only when a 36 V power supply is used. Contact KEYENCE when a

24 V power supply is used.)

• The total extension length between the power supply and the farthest static eliminat ion bar is within

30 m.

• When providing air to more than one SJ-H* unit, check that each static elimination bar is provided with

air. If the air supply source is one, each static elimination bar may not be provided with enough air.

• If the terminal switch is not set correctly when using a relay box, alarm outputs on SJ-H* units in the

series will not be output correctly.

6

Page 7

Settings when Remote Control Console is Used

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H* Series ID number switch

0-9

ABCDEF

Remote control ID number key

and ID number seal

0-9

10 11 12 13 14 15

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

SJ-H

Series

SJ-HA

Series

SJ-HV

Series

SJ-HC

Series

Warning

NOTE

Device markings

Electrode probe markings

O-ring

NOTE

Attachment mark

<Accelerating electrode probe: Not fixed>

<Accelerating electrode probe: Fixed>

Attachment mark

This section explains setting items when the optional Remote Control Console is used.

* The SJ-HA Series does not have the remote control function.

Frequency setting

Cleaning the electrode probes : OP-84299 Electrode probe cleaning kit for

Soak the filter of the cleaning kit with alcohol, and place the cleaning kit on the electrode probe and

rotate it gently two or three times.

The filter on the cleaning kit will remove any dirt from the electrode probes. Replacement filters

(OP-42218) are also available.

the SJ-H* Series

It is necessary to set the FREQ switch of the SJ-H/SJ-HV/SJ-HC Series to 9 before using the SJ-H01

Remote Control Console (SJ-H01) to control the SJ-H/SJ-HV/SJ-HC Series.

For details, see the Instruction Manual of the SJ-H01 Remote Control Console.

ID number setting

If the SJ-H01 Remote Control Console is used to

control more than one SJ-H/SJ-HV/SJ-HC units, it is

convenient to set a unique ID number for each unit

individually.

The ID number can be set in hexa decimal between

0 and F (i.e., 16 in total). Turn the ID Switch with the

provided flat-blade screwdriver to set th e ID number.

Dual I.C.C. (Ion Current Control) setting

By using the SJ-H01 Remote Control Console the Dual I.C.C. (Ion Current Control) function can be

turned OFF. When the Dual I.C.C. function is turned OFF, it will be possible to use the ion balance

adjustment function to generate positive and negative ions at a fixed ratio.

For details, see the Instruction Manual of the SJ-H01 Remote Control Console.

Ion balance adjustment function

It is possible to fine-tune the zero point of ion balance by using the SJ-H01 Remote Control Console.

This adjustment cannot be made by the static elimination bar by itself.

The zero point of the ion balance is adjusted before shipping. The zero point may shift according to

the environment of installation. The ion balance adjustment made by the SJ-H01 makes it possible to

maintain proper static elimination.

For details, see the Instruction Manual of the SJ-H01 Remote Control Console.

L.P.C. function

* For the information on how to remove the filter, refer to the Instruction Manual of the Electrode

Probe Cleaning Kit for the SJ-H Series.

Clean the electrode probe : Cotton bud

Clean the electrode probe with a cotton bud moistened with alcohol.

Changing the electrode probes

Place an OP-84363 electrode probe replacement kit over the electrode probe and press it towards

the device while rotating it counter-clockwise to remove the electrode probe.

To attach an electrode probe, place the new probe in the electrode probe replacement kit, line it up

with the grooves and insert it. Press the kit towards the device and turn clockwise to secure the electrode probe.

•

When attaching an electrode probe, line up the mar kings on the device and the markings on the electrode

probe.

The L.P.C. (Long-cycle Pulse Control) function can be turned on when using the SJ-H01 Remote Control Console.

See "Other Functions" (page 5) for more information on the L.P.C. function.

Clearing an alarm state

Alarm states can be cleared when using the SJ-H01 Remote Control Console.

For details, see the Instruction Manual of the SJ-H01 Remote Control Console.

Alarm output control function

Any type of warning (Ion level warning, Condition warning or alarm) can be raised at any time when

using the SJ-H01 Remote Control Console.

For details, see the Instruction Manual of the SJ-H01 Remote Control Console.

Quick ion check function

The quantity of generated ions can be checked faster than usual using the SJ-H01 Remote Control Console.

For details, see the Instruction Manual of the SJ-H01 Remote Control Console.

Maintenance of Electrode Probes

When the SJ-H* Series is used for a long period, the electrode probes become dirty due to the accumulation of dust.

If you continue to use the SJ-H* Series with dust accumulating on the electrode probes, the static

elimination ability may deteriorate, resulting in an accident or product breakdown. Therefore, be sure

to clean the electrode probes periodically.

Maintenance of electrode probes

Use an OP-84299 electrode probe cleaning kit for the SJ-H* Series or a cotton swab when performing

maintenance on the electrical probes.

• When attaching an electrode probe, check that the O-ring is at the designated position.

Changing the accelerating electrode probes

Place an OP-84363 electrode probe replacement kit over the accelerating electrode probe and press

it towards the device while rotating it counter-clockwise to remove the accelerating electrode probe.

To attach an accelerating electrode probe, place the new electrode probe in the replacement kit, line

it up with the grooves and insert it. Press the kit towards the device and turn clockwise to secure the

electrode probe.

When attaching the accelerating electrode probe, be sure to align the attachment marks on the SJ-H*

Series and the protrusions of the accelerating electrode probe.

The accelerating electrode probe can not be attached to the SJ-HA/SJ-HV/SJ-HC Series.

• Turn off the SJ-H* Series before the maintenance of the electrode probes.

• Do not touch the electrode probes directly with your hand or fingers, as this may cause

injury. Be extremely careful when cleaning them.

7

Page 8

Timing Charts

Normally ONNormally

OFF

Normally ONForced

OFF

Normally ONNormally

OFF

ForcedONNormally ONNormally

OFF

Normally ONForced

OFF

Normally

OFF

Normally

ON

Static elimination

interruption input

(SJ-H* Series)

ON

OFF

Static elimination

ON/OFF Key

(Remote control)

ON

OFF

Ion generation

condition

SJ-H* indicator

Yes

No

Alarm output

ON

OFF

Normal operation

Static charge or ion quantity

Normal static elimination OFF

Flashing red

Forced static elimination ON

Flashing green

Forced static elimination OFF

Flashing red

50 ms max.

ON

OFF

Yes

No

Static elimination

interruption input

(SJ-H* Series)

High voltage

output

(

)

Power supply

ON

OFF

Static elimination

interruption input

ON

OFF

ION/ALM/COND

indicator

Flashing

OFF

Alarm output

(N.C.)

ON

OFF

Ion generation

Yes

No

After an alarm is once displayed,

the SJ-H* Series will not return to

the previous state unless any of

the following items is performed.

1. The SJ-H* Series is turned off

and on.

2. The alarm is cleared through

remote control.

Troubleshooting

This section explains the timing charts of the SJ-H* Series.

Control of Ion generation

z Static elimination ON/OFF Indicator

Input response

Ion level alarm output timing chart

ON

Power supply

OFF

ON

Static elimination

interruption input

OFF

Yes

Ion generation

No

ON

Alarm output

(N.C.)

OFF

Flashing

ION/ALM/COND

indicator

OFF

ION LEVEL

ON

alarm output

OFF

N.O.

Condition alarm output timing chart

ON

Power supply

OFF

ON

Static elimination

interruption input

OFF

Yes

Ion generation

No

ON

Alarm output

(N.C.)

OFF

Flashing

ION/ALM/COND

indicator

OFF

ON

Condition alarm

output (N.O.)

OFF

Alarm output timing chart

After the ION LEVEL alarm is once

displayed, the SJ-H* Series will not

return to the previous state unless any

of the following items is performed.

1. Static elimination is interrupted.

2. Setting changes are made.

3.

The SJ-H* Series is turned off and on.

When the cause of the condition

alarm output is remedied after the

condition alarm is displayed once, the

SJ-H* Series will return to normal

mode.

Refer to the following list for troubleshooting and remedies before sending out the unit for repairs.

Problem Inspection Remedy

No ION MONITOR indicators are

working.

No static elimination is performed.

Static elimination is not performed

properly.

Ion level (ION LEVEL) alarm is

illuminated and output freq uently.

The condition (COND) alarm is

illuminated and output freq uently.

The alarm (ALM) indicator is

illuminated.

Control output is not output correctly.

Static elimination interrupt input is not

input properly.

Cannot understand the meaning of the

indicators

It is not accepting remote controller

operation

A distance extension of 10 m or mo re

is required.

Check that the power supply cable is

connected correctly.

Check that the power supply is within

the rated range.

Check that the electrode p robes are

not worn out or dirty.

Check that static elimination is not

interrupted.

Check if the abnormal discharge

detection function is working. (Check if

the alarm is output)

Check that the ground is connected.

Check that the correct frequency

setting is selected.

Check that there is no condu ctive

object or another Static Eliminator Unit

close to the SJ-H* Series.

Check that the ground is connected.

Check that the electrode p robes are

not worn out or dirty.

Check that there is no condu ctive

object or another Static Eliminator Unit

close to the SJ-H* Series.

Check that there is no condu ctive

object within 10 mm of the SJ-H*

Series.

Check that the SJ-C*H is connected.

Check that the cable is wired correctly.

Check if no sensitivity setting is made.

Check that the terminator switch is set

properly.

Check that the cable is wired correctly.

-

-

-

Connect the power supply cable

correctly.

Use power supply within the rated

range.

Carry out maintenance work on the

electrode probes or replace them.

Cancel the static elimination

interruption input of the SJ-H* Series

and the static elimination interruption

setting in the Remote Control Console.

Eliminate conductive objects within 20

mm of the electrode probe and turn on

the SJ-H* Series again.

Confirm that the ground is properly

connected.

Select the optimal frequency setting

according to the operating distance.

Keep the SJ-H* Series away from the

conductive object or the Static

Eliminator Unit.

Confirm that the ground is properly

connected.

Carry out maintenance work on the

electrode probes or replace them.

Keep the SJ-H* Series away from the

conductive object or the Static

Eliminator Unit.

Eliminate the conductive object within

10 mm of the SJ-H* Series and turn the

SJ-H* Series OFF and ON. The

abnormal discharge detection function

may have been turned ON.

The modular jack may not be inserted

properly or the cable may be

disconnected. Connect the modular

jack correctly and turn the SJ-H* Series

OFF and ON.

Check the output circuit and make sure

that the wiring is correct.

Make a sensitivity setting so that the

alarms will be output.

Confirm the connection method and

make the correct settings.

Check the input circuit and make sure

that the wiring is correct.

See "Indicator specifications" (page 9).

Refer to the SJ-H Remote Control

Console SJ-H01 Instructi on Manual.

Purchase the Extension Cable and

Relay Connector.

Warnings and Remedies

This section explains each type of warning, as well as the most common causes and best remedies

for each issue.

Alarm

Ion level warning

Condition warning

Warnin g Major ca uses Remedy

Irregular discharge from the end of a

probe

Ground not connected

Internal circuit damage Contact your nearest sales office.

Dirt on the electrode probes

Electrode probe wear

Ground not connected

Influence from a grounding con ductor

near the static eliminati on device

Ground not connected

Turn the power off and remove any

conductive objects from the area

around the static elimination bar.

Confirm that the ground is properly

connected.

Turn the power OFF and clean the

electrode probe. If the ion leve l

warning persists after cleaning,

confirm the surroundings of the

electrode probe.

Turn the power OFF and replace the

electrode probe

Confirm that the ground is properly

connected.

The warning may f lash when a

grounding conductor such as a metal

object is close enough to interfere with

the static elimination device. Remove

any grounding conductors near the

static elimination device.

See "Interference" (page 3).

Confirm that the ground is properly

connected.

8

Page 9

Indicator Specifications

Indicator specifications during setting change, checking, and while in operation

Indicator Lighting specifications Description

One of the "ION MONITOR" lights is illuminated

The rightmost two ION MONITOR indicators are

illuminated red.

The leftmost two ION MONITOR indicators are

illuminated red.

A single ION MONITOR indicator on the

positive side is illumina ted along with a single

ION MONITOR on the negative side.

ION MONITOR

One of the "ION MONITOR" lights flashes.

The ION MONITOR indicator in the middle

flashes red.

The ION MONITOR indicators on the left and

right flash red.

The ION MONITOR indicators on the left and

right flash green.

The ION/ALM/COND flashes once per second

ION/ALM/COND

The ION/ALM/COND indicator flashes twice per

second.

The ION/ALM/COND indicator and the all ION

ION/ALM/COND, ION

MONITOR

MONITOR indicator fl ash red.

The RC indicator illuminates or flashes

RC

The RC indicator flashes once per second

The RC indicator flashes twice per second

The RC indicator flashes three times per

second

Charge level display

Displays the target's static charge. When the

leftmost (or rightmost) indicator is illuminated, it

means that the target's negative (or positive)

static charge is very high. The indicator

illuminated changes according to the quantity

of the target's static charge.

See "Indicators" (page 5).

Continuous positive ion generation

Positive ions are generated continuously

Continuous negative ion generation

Negative ions are generated continuously

Ion quantity indicator

Displays the quantity of ions generated by the

SJ-H/SJ-HV/SJ-HC Series.

See "Indicators" (page 5).

Frequency setting

When the frequency is set, the indicator

corresponding to the set freq uency will flashes

for approximately five seconds.

See "Frequency Settin gs" (page 4).

Normal static elimination interruption

The indicator will flash red when static

elimination is interrupted by short-circuiting the

blue and pink wires of the 10-pin I/O cable.

Forced static elimination interruption

The indicator will flash red when static

elimination is interr upted by the remote control,

regardless of the static elimination setting of the

10-pin I/O cable.

Forced static elimination

The indicator will flash green when static

elimination is started by the remote control,

regardless of the static elimination setting of the

10-pin I/O cable.

Condition warning

The indicator flashes if the ion balance is bad

due to the influence of the installation

environment.

Flashes Green :Sensitivity low

Flashes Yellow:Sensitivity medium

Flashes Red :Sensitivity high

OFF :No sensitivity setting

When the alarm level is changed to another

level, the corresponding color will flash slowly

for approximately five seconds.

When the condition warning and the ion level

warning occur at the same time, the "ION/ALM/

COND" indicator flashes first for the ion level

warning.

Ion level warning

The indicator flashes when the quantity of ion

generation drops below the set value.

Flashes Green :Sensitivity low

Flashes Yellow:Sensitivity medium

Flashes Red :Sensitivity high

OFF :No sensitivity setting

When the alarm level is changed to another

level, the corresponding color will flash slowly

for approximately five seconds.

When the condition warning and the ion level

warning occur at the same time, the "ION/ALM/

COND" indicator flashes first for the ion level

warning.

Alarm

When an abnormal electric discharge occurs or

the internal circuit is damaged, the ION/ALM/

COND indicator will flash three times per

second and the ION MONITOR indicators will

flash red slowly.

Remote control

The indicator is illumina ted for flashes when the

SJ-H* Series is under remote control.

Illuminates Yellow

Flashes Yellow :The ID number of the static

Quickly Flashes Yellow

OFF : Remote control is not locked.

Dual I.C.C. setting/confirmation

The indicator flashes after Dual I.C.C. setting or

confirmation.

Flashes Green : Dual I.C.C. ON

Flashes Red : Dual I.C.C. OFF

Ion balance adjustment confirmation

The indicator flashes after confirmation of

whether the ion balance is being adjusted.

Flashes Green : Ion balance adjustment OFF

Flashes Red : Ion balance adjustment ON

L.P.C. setting/confirmation

The indicator flashes after L.P.C. setting or

confirmation.

Flashes Green : L.P.C. OFF

Flashes Red : L.P.C. ON

: Remote control is locked.

elimination bar from the

remote control is selected or

the remote control lock is

unlocked

:The ID number is selected

during lock or the remote

control lock is set.

List of Optional Accessories

Item Typ e Appearance Description

10-pin I/O cable

10 pin-10 pin cable

10-to-10-pin cable for SJ-H036

Tungsten electrode probes (four)

for SJ-H

Tungsten accelerating

electrode probes (two) f or SJ-H

Tungsten electrode probes

(four) for SJ-HA

Tungsten electrode probes

(four) for SJ-HV

Silicon electrode probes (four)

for SJ-HC

SJ-C2U

SJ-C5U

SJ-C10U

OP-42210

OP-42211

OP-42212

SJ-C2H

SJ-C5H

SJ-C10H

OP-84292

OP-84293

OP-84294

OP-84295

Relay Box for SJ-H* Series OP-84296

End unit for SJ-H* Series OP-84301 Used for installing the SJ-H* Series.

Auxiliary support

for SJ-H* Series

Electrode probe cleaning kit

for SJ-H* Series

Replacement filters for the

electrode cleaning kit

(10 pieces)

Electrode probe cleaning kit 2

for the SJ-H* Series

Replacement filter for the

electrode probe cleaning kit 2

(10 pieces)

SJ-GL/G/V/R exchange

side supports

SJ-GL/G/V/R exchange

central supports

Electrode probe replacement kit

for SJ-H* Series

OP-84300

OP-84299

OP-42218 Cotton filters for the cleaning kit.

OP-84454

OP-84455

OP-84297

OP-84298

OP-84363

Straight air booster starter unit SJ-HS01

Wide angle booster starter unit SJ-HW01

Extension unit for straight air

booster

Extension unit for wide angle

booster

Sealing extension unit for air

booster

SJ-HS02

SJ-HW02

SJ-HM01

End unit for air booster OP-84386

Auxiliary support for air booster OP-84385

Laminar flow assisting p art

starter unit

Extension unit for laminar flow

assisting part

Electrode probe replacement kit

for laminar flow assisting part

OP-84380 Supports the laminar downflow.

OP-84381

OP-84382

Power cable for the SJ-H* Series.

Three types (2-, 5-, 10-m cable s)

are available.

(Cable color: Gray)

Cable for connecting the SJ-H*

Series units. Three types (2-, 5-, 10m cables) are available. Thi s cable

connects to the Relay Box as well.

(Cable color: Gray)

The cable that connects the

SJ-H036 controller to the bar. Three

types (2-, 5-, 10-m cables) are

available.

(Cable color: Black)

Tungsten-made electrode probes and

accelarating electrode probes (Made

for SJ-H)

Tungsten-made electrode probes

(Made for SJ-HA)

Tungsten-made electrode probes

(Made for SJ-HV)

Silicon-made electrode probes

(Made for SJ-HC)

Used for connecting SJ-H* units

together.

Used to for installing

SJ-H* Series.

Used for maintaining the electrode

probes on the SJ-H* Series .

* This cannot be used when the

laminar flow assisting part is a

attached.

Used to perform maintenance on

the inside wall of the electrode

probe cap.

Replacement filters for the cleaning

kit 2.

Used to match the installation

dimensions of the SJ-GL/ G/V/R

Series. Also used for rotation.

Used to match the installation

dimensions of the SJ-GL/ G/V/R

Series. Also used for rotation.

Used for changing the electrode

probes on the SJ-H* Series .

Used to increase the static

elimination speed.

Used to widen the static elimination

range.

Used to extend the auxiliary air

straight unit.

Used to extend the auxiliary air

diffusion unit.

Used over areas where auxiliary air

should not be used.

Used to mount the SJ-H* Series

wearing an air booster.

Used to mount the SJ-H* Series

wearing an air booster.

Used to extend the laminar flow

assisting part.

Used to replace the electrode

probes when the laminar flow

assisting part is attached.

mote Control Console

Re

for SJ-H* Series

SJ-H01

Remote Control Console to operate

the SJ-H* Series

9

Page 10

Dimensions

71

130

33

(14.5)

(20)

*

(43) (35)

48.2

(R24)

120

2-φ5

59

* SJ-H036A has no modular socket.

39.5

23

11

21

38*

2

12.5 70

*1

25

A

C

D

E

12.5

23

48.5

10.5

10

9.2

B

SJ-H type has a nozzle.

SJ-H036* has no modular socket

SJ-HA type has no modular socket.

(Except for the SJ-H036A)

Mount one auxiliary support bracket per meter.

(67.7)

22.5

SJ-H036*

*1 90mm

*2 21mm

39.5

45

45

22.5

(28)

(R24)

*2

(R24)

*1

48

Rc1/8

*1 SJ-H036* only has the left socket.

*2 SJ-HA type only has the right socket.

(Except for the SJ-H036A)

Common for the left side of the bar Common for the right side of the bar

(SJ-H228* and longer models)

(119)

61.3

9.2

29 18

A

B

C

48.5

21

38

*2

70

*1

30

23

SJ-H036* has no modular socket

SJ-HA type has no modular socket.

(Except for the SJ-H036A)

When a rotating mounting bracket is attached

SJ-H036*

*1 90mm

*2 21mm

27.5

45

45

(79.5)

(R24)

*1

(R24)

*2

Rc1/8

99.5

*1 SJ-H036* only has the left socket.

*2 SJ-HA type only has the right socket.

(Except for the SJ-H036A)

Common for the left side of the bar

Common for the right side of the bar

(SJ-H228* and longer models)

(

)

91 86

4

27.5

68.6

29

5.2

18

16 30

8

4-Ellipse hole(*)

(*)Ellipse hole

(When rotated by 90

o

)

(40)

63.5

70

56

48

47

58

48

48

48

2-φ5

(9)

(5.5)

25.5

4.5

(R24)

(14)

(9)

(14)

Controller unit (SJ-H036* only)

99.5 27.5

*

Rc1/8

73.5

Main body

Type

SJ-H036* 4 380 340 365 P60×3=180 P120×1=120

SJ-H060* 8 600 560 585 P60×7=420 P120×3=360

SJ-H084* 12 840 800 825 P60×11=660 P120×5=600

SJ-H108* 16 1080 1040 1065 P60×15=900 P120×7=840

SJ-H132* 20 1320 1280 1305 P60×19=1 140 P120×9=1080

SJ-H156* 24 1560 1520 1545 P60×23=1 380 P120×11=1320

SJ-H180* 28 1800 1760 1785 P60×27=1 620 P120×13=1560

SJ-H204* 32 2040 2000 2025 P60×31=1 860 P120×15=1800

SJ-H228* 36 2280 2240 2265 P60×35=2 100 P120×17=2040

SJ-H252* 40 2520 2480 2505 P60×39=2 340 P120×19=2280

SJ-H300* 48 3000 2960 2985 P60×47=2 820 P120×23=2760

Electrode probes A B C D E

* Not provided for the SJ-H204* or shorter models.

End unit L ■End unit R

12.5

12.5

20

10.5

23

4-Ellipse hole(*)

23

11

39.5 35

5

(*)Ellipse hole

4.4

39.5

22.5

5

6

10.5

4-Ellipse hole(*)

20

12.5

23

12.5

23

11

Auxiliary support

(Rear)

5

2-Ellipse hole(*2)

28

(Thickness: 5 mm)

34

45

2-Ellipse hole(*1)

Thickness: 5 mm

5

22.5

(*1)Ellipse hole (*2)Ellipse hole

2.6

1.4

4.4

4.4

5

Support part for converting to SJ-GL/G/V/R (side)

Rc1/8

39.5

22.5

5

5

(*)Ellipse hole

4.4

39.535

6

39.5

22.5

*

Rc1/8

Rc1/8

Type

* Not provided for the SJ-H204* or shorter models.

A B C

SJ-H036* 451 432 400

SJ-H060* 671 652 620

SJ-H084* 911 892 860

SJ-H108* 1151 1132 1100

SJ-H132* 1391 1372 1340

SJ-H156* 1631 1612 1580

SJ-H180* 1871 1852 1820

SJ-H204* 2111 2092 2060

SJ-H228* 2351 2332 2300

SJ-H252* 2591 2572 2540

SJ-H300* 3071 3052 3020

22

48

Support part for converting to SJ-GL/G/V/R (intermediate)

3

2-Ellipse hole(*)

(40)

40

(When rotated by 90o)

27.5

(*)Ellipse hole

4

27.5

64.7

5.4

78 62

Relay box (OP-84296)

10

Page 11

Static Elimination Function List

150300450

300

600

900mm

150 300 450mm

5sec

15sec

10sec

30sec

m

150300450

300

600

1500mm

600 150 300 450 600mm

900

1200

1sec

2sec

0.5sec

3sec

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ± 100 V is measured.

The 150

×150mm plate monitor (20 pF) is used.

SJ-H108 is used.

No downflow

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ±100 V is measured.

The 150

×150 mm plate monitor (20 pF) is used.

SJ-H108 is used.

Under the downward air flow of 0.3 m/sec.

Measurement conditions:

The time required to eliminate the static charge of

the target ±1000 V to ±100 V is measured.

The 150

×150 mm plate monitor (20 pF) is used.

SJ-H108 is used.

Under the downward air flow of 0.3 m/sec.

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ± 100 V is measured.

The 150

×150mm plate monitor (20 pF) is used.

SJ-H108 is used.

No downflow

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ±100 V is measured.

The 150

×150mm plate monitor (20 pF) is used.

SJ-H108A is used.

No downflow

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ±100 V is measured.

The 150

×150 mm plate monitor (20 pF) is used.

SJ-H108A is used.

Under the downward air flow of 0.3 m/sec.

Measurement conditions:

The time required to eliminate the static charge of

the target ±1000 V to ±100 V is measured.

The 150

×150 mm plate monitor (20 pF) is used.

SJ-H108A is used.

Under the downward air flow of 0.3 m/sec.

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ±100 V is measured.

The 150

×150mm plate monitor (20 pF) is used.

SJ-H108A is used.

No downflow

m

150300450

300

600

900mm

150 300 450mm

5sec

15sec

10sec

30sec

150300450

300

600

1500mm

600 150 300 450 600mm

900

1200

1sec

2sec

0.5sec

3sec

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ±100 V is measured.

The 150

×150mm plate monitor (20 pF) is used.

SJ-H108V is used.

Air supply 16 /min, no downflow

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ±100 V is measured.

The 150

×150 mm plate monitor (20 pF) is used.

SJ-H108V is used.

Air supply 16 /min.

Under the downward air flow of 0.3 m/sec.

Measurement conditions:

The time required to eliminate the static charge of

the target ±1000 V to ±100 V is measured.

The 150

×150 mm plate monitor (20 pF) is used.

SJ-H108V is used.

Air supply 16 /min.

Under the downward air flow of 0.3 m/sec.

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ± 100 V is measured.

The 150

×150mm plate monitor (20 pF) is used.

SJ-H108V is used.

No downflow

m

150300450

300

600

900mm

150 300 450mm

5sec

30sec

10sec

15sec

150300450

300

600

1500mm

600 150 300 450 600mm

900

1200

3sec

150300450

300

600

1500mm

600 150 300 450 600mm

900

1200

1sec

2sec

0.5sec

m

150300450

300

600

900mm

150 300 450mm

5sec

30sec

10sec

15sec

150300450

300

600

1500mm

600 150 300 450 600mm

900

1200

10sec

20sec

4sec

30sec

6sec

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ± 100 V is measured.

The 150

×150mm plate monitor (20 pF) is used.

SJ-H108C is used.

No downflow

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ±100 V is measured.

The 150

×150 mm plate monitor (20 pF) is used.

SJ-H108C is used.

Under the downward air flow of 0.3 m/sec.

Measurement conditions:

The time required to eliminate the static charge of

the target ±1000 V to ±100 V is measured.

The 150

×150 mm plate monitor (20 pF) is used.

SJ-H108C is used.

Under the downward air flow of 0.3 m/sec.

Measurement conditions:

The time required to eliminate the static charge of

the target from ±1000 V to ± 100 V is measured.

The 150

×150mm plate monitor (20 pF) is used.

SJ-H108C is used.

No downflow

Operating area and operation time

This section shows typical examples of the time necessary for static elimination, and the relationship of the installation distance between the target and the static elimination bar.

zSJ-H Series

Operating area and time (33 Hz) Operating area and time (10 Hz) Operating area and time (1 Hz) Operating area and time (at air MAX)

150300450

50100150 50 100 150mm

600 150 300 450 600mm