Page 1

96M11353

Instruction

Manual

Laser Displacement Sensors

LB-1000(W) Series

Page 2

CONTENTS

SAFETY INFORMATION ON LB-1000 SERIES

Safety Information for LB-1000 Series .................................................... 2

Safety Precautions on Laser Product ..................................................... 3

Precautions on Regulations and Standards ............................................ 6

Part Names ............................................................................................. 7

Connections ............................................................................................ 8

Installation ............................................................................................... 9

Setting ................................................................................................... 10

Auto Zero/Output Adjustment ............................................................... 10

Measuring Range vs. Analog Output .................................................... 11

Setting Dip Switch 1 (FUZZY logic control) ........................................... 12

Setting Dip Switch 2 (Interference suppression function) ..................... 13

Setting Dip Switch 3 (Laser power control) ........................................... 14

Setting Dip Switch 4 (AUTO ZERO) ..................................................... 14

Troubleshooting .................................................................................... 15

Hints on Correct Use ............................................................................. 16

Characteristics ...................................................................................... 17

Specifications ........................................................................................ 19

Dimensions ........................................................................................... 21

Warranty ............................................................................................... 23

This manual describes how to install the LB-1000 Series as well as its

operating procedures and precautions. Read this manual carefully for

your safety.

Symbols

The following symbols alert you to important messages. Be sure to read

these messages carefully.

WARNING

CAUTION

Note

Failure to follow instructions may lead to injury.

(electric shock, burn, etc.)

Failure to follow instructions may lead to product

damage.

Provides additional information on proper operation.

General precautions

• At startup and during operation, be sure to monitor the functions and

performance of the LB-1000 series.

• We recommend that you take substantial safety measures to avoid

any damage in the event a problem occurs.

• Do not open or modify the LB-1000 series or use it in any way other

than described in the specifications.

• When the LB-1000 series is used in combination with other instruments, functions and performance may be degraded, depending on

operating conditions and the surrounding environment.

• Do not use this product for the purpose to protect a human body or a

part of human body.

• This product is not intended for use as explosion-proof product. Do

not use this product in hazardous location and/or potentially explosive

atmosphere.

2

Page 3

SAFETY PRECAUTIONS ON LASER PRODUCT

1. Classification

LB-041/ LB-081/ LB-301/

LB-1001(W) LB-1101(W) LB-1201(W)

FDA (CDRH) 21CFR Part 1040.10 Class IIIa IIIb

IEC/EN 60825-1 Class 2M Class 3R Class 3B

2. Labels

FDA (CDRH) Class IIIa FDA (CDRH) Class IIIb

[LB-041/1001(W) [LB-301/1201(W)]

LB-081/1101(W)]

AVOID EXPOSURE

VISIBLE LASER RADIATION IS

EMITTED FROM THIS APERTURE

DANGER

VISIBLE LASER RADIATION AVOID

DIRECT EXPOSURE TO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 3mW

PULSE DURATION 35µSEC

CLASS IIIa LASER PRODUCT

DANGER - Visible laser radiation when open

AVOID DIRECT EXPOSURE TO BEAM

IEC Class 2M [LB-41] IEC Class 3R [LB-81]

IEC Class 3B [LB-301]

AVOID EXPOSURE

INVISIBLE LASER RADIATION IS

EMITTED FROM THIS APERTURE

DANGER

INVISIBLE LASER RADIATION AVOID

DIRECT EXPOSURE TO BEAM

SEMICONDUCTOR LASER 780nm

MAXIMUM OUTPUT 20mW

PULSE DURATION 35µSEC

CLASS IIIb LASER PRODUCT

DANGER - Invisible laser radiation when open

AVOID DIRECT EXPOSURE TO BEAM

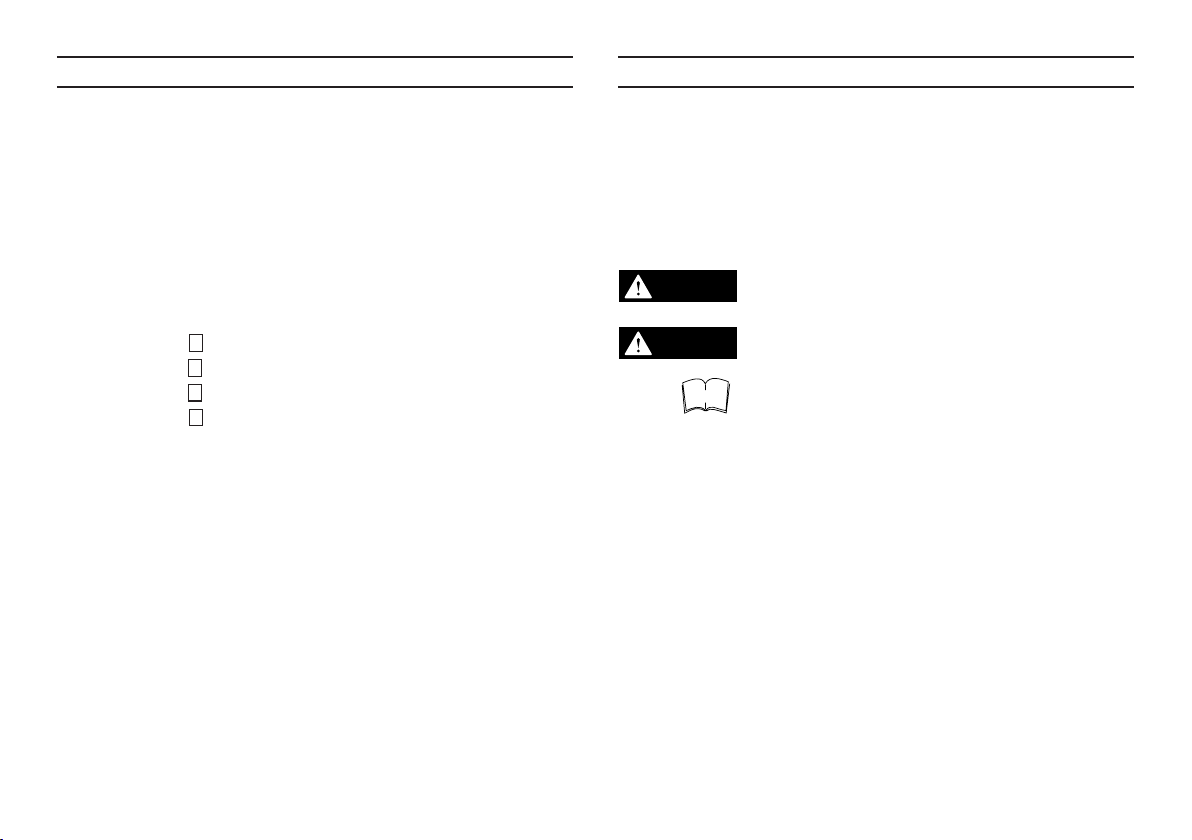

3. Labels location

FDA Warning labels are attached to the sensor head as shown below.

When using this product in the countries and/or regions other than

U.S.A., use the IEC warning/explanatory label in the package of this

product. In this case, it can be affixed on the FDA (CDRH) warning label,

which has already been affixed to this product.

FDA (CDRH)

LB-041 LB-081

AVOID EXPOSURE

VISIBLE LASER RADIATION IS

EMITTED FROM THIS APERTURE

DANGER

VISIBLE LASER RADIATION AVOID

DIRECT EXPOSURE TO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 3mW

PULSE DURATION 35µSEC

CLASS IIIa LASER PRODUCT

LB-301

AVOID EXPOSURE

LB-041

DANGER

AVOID EXPOSURE

VISIBLE LASER RADIATION IS

EMITTED FROM THIS APERTURE

DANGER

VISIBLE LASER RADIATION AVOID

DIRECT EXPOSURE TO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 3mW

PULSE DURATION 35µSEC

CLASS IIIa LASER PRODUCT

DANGER - Visible laser radiation when open

AVOID DIRECT EXPOSURE TO BEAM

AVOID EXPOSURE

DANGER

AVOID EXPOSURE

VISIBLE LASER RADIATION IS

EMITTED FROM THIS APERTURE

DANGER

VISIBLE LASER RADIATION AVOID

DIRECT EXPOSURE TO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 3mW

PULSE DURATION 35µSEC

CLASS IIIa LASER PRODUCT

LB-081

AVOID EXPOSURE

VISIBLE LASER RADIATION IS

EMITTED FROM THIS APERTURE

DANGER

VISIBLE LASER RADIATION AVOID

DIRECT EXPOSURE TO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 3mW

PULSE DURATION 35µSEC

CLASS IIIa LASER PRODUCT

DANGER - Visible laser radiation when open

AVOID DIRECT EXPOSURE TO BEAM

3

Page 4

SAFETY PRECAUTIONS ON LASER PRODUCT

4. Safety consideration

CAUTION

Use of controls or adjustments or the performance of procedures other

than those specified herein may result in hazardous radiation exposure.

1) Class IIIb/3B laser products

WARNING

Follow the instructions mentioned in this manual. Otherwise, injury to the

human body (eyes and skin) may result.

• Do not directly look at or touch the laser beam and its reflection

from a mirror-like surface.

• Do not direct the beam at other people or into areas where other

people unconnected with the laser work might be present.

• Be careful of the path of the laser beam. Make the laser path as

short as possible and be sure to terminate the laser path with a

diffusion reflector or diffusion absorber with proper reflectance

and thermal characteristics so that the laser beam does not

diffuse. (It is recommended that you install a protective enclosure.)

• Install the laser product carefully so that the laser beam is not

unintentionally directed at mirror-like surfaces.

• Install the products so that the path of the laser beam is not as

the same height as that of human eye.

• Wear protective eye goggles appropriate for the laser beam

wavelength.

• Do not disassemble this product. Laser emission from this

product is not automatically stopped when it is disassembled.

• Clean the aperture regularly. In addition, stop the emission of the

laser beam when cleaning.

• MPE (Maximum Permissible Exposure): 1.66mW/cm

• NOHD (Nominal Ocular Hazard Distance): 17.2 m (LB-301) from

the aperture.

2

(LB-301)

2) Class IIIa/3R laser products

WARNING

Follow the instructions mentioned in this manual. Otherwise, injury to the

human body (eyes and skin) may result.

• Do not directly look at or touch the laser beam and its reflection

from a mirror-like surface.

• Do not direct the beam at other people or into areas where other

people unconnected with the laser work might be present.

• Be careful of the path of the laser beam. Make the laser path as

short as possible and be sure to terminate the laser path with a

diffusion reflector or diffusion absorber with proper reflectance

and thermal characteristics so that the laser beam does not

diffuse. (It is recommended that you install a protective enclosure.)

• Install the laser product carefully so that the laser beam is not

unintentionally directed at mirror-like surfaces.

• Install the products so that the path of the laser beam is not as

the same height as that of human eye.

• Do not disassemble this product. Laser emission from this

product is not automatically stopped when it is disassembled.

4

Page 5

SAFETY PRECAUTIONS ON LASER PRODUCT

3) Class 2M laser products

WARNING

Viewing the laser output with certain optical instruments designed for

use at a distance (for example, telescopes and binoculars) may pose an

eye hazard.

Follow the instructions mentioned in this manual. Otherwise, injury to the

human body (eyes and skin) may result.

• Do not stare into the beam.

• Do not direct the beam at other people or into areas where other

people unconnected with the laser work might be present.

• Be careful of the path of the laser beam.

If there is a danger that the operator may be exposed to the laser

beam reflected by specular or diffuse reflection, block the beam by

installing an enclosure with the appropriate reflectance.

• Install the products so that the path of the laser beam is not as

the same height as that of human eye.

• Do not disassemble this product. Laser emission from this

product is not automatically stopped when it is disassembled.

5. Safety features provided with the LB-1000

series

The LB-1000 series is provided with the following safety features. Make

sure these features function correctly before operating.

1. Laser radiation emission warning

A visible LED informs you that the laser beam is being emitted, or is

about to be emitted, at least 3 second after power is provided to the

controller and the sensor head.

2. Laser emission delay

Laser emission only starts after the LED has been ON for at least 3

seconds, thus decreasing the possibility of laser exposure.

3. Laser emission stop input terminals

Terminals for controlling laser emission are provided on the controller.

You can remotely control laser emission using these terminals.

4. Key-operated switch

Set to the ON position to supply power. You can lock the power switch

using the supplied key; the key can be removed only when the switch

is set to the OFF position.

5. Beam attenuator

A laser beam shield is supplied. This cover is to be attached to the

laser-beam-emitting portion of the sensor head. If an operator must

work in front of the sensor head and there is risk to the eyes from the

laser beam, be sure to attach this cover.

5

Page 6

SAFETY PRECAUTIONS ON LASER PRODUCT

For use with shield:

Attach the shield to the front surface of the sensor head.

LB-041/LB-081 LB-301

For use without shield:

Place the shield as shown below, and screw in place.

LB-041/LB-081 LB-301

PRECAUTIONS ON REGULATIONS AND STANDARDS

CE Marking

Applicable Models: LB-041/LB-1001W, LB-081/LB-1101W and

Keyence Corporation has confirmed that these products comply with the

essential requirements of the applicable EC Directives, based on the

following specifications. Be sure to consider the following specifications

when using these products in the Member State of European Union.

■ EMC Directive (2004/108/EC)

• Applicable Standard EMI: EN61326-1, Class A

•

The length of the cable connected to the Sensor head or the Controller must be less than or equal to 30 m.

Remarks:

These specifications do not give any guarantee that the end-product with

these products incorporated complies with the essential requirements of

EMC Directive. The manufacturer of the end-product is solely responsible

for the compliance on the end-product itself according to EMC Directive.

LB-301/ LB-1201W

EMS: EN61326-1

6

Page 7

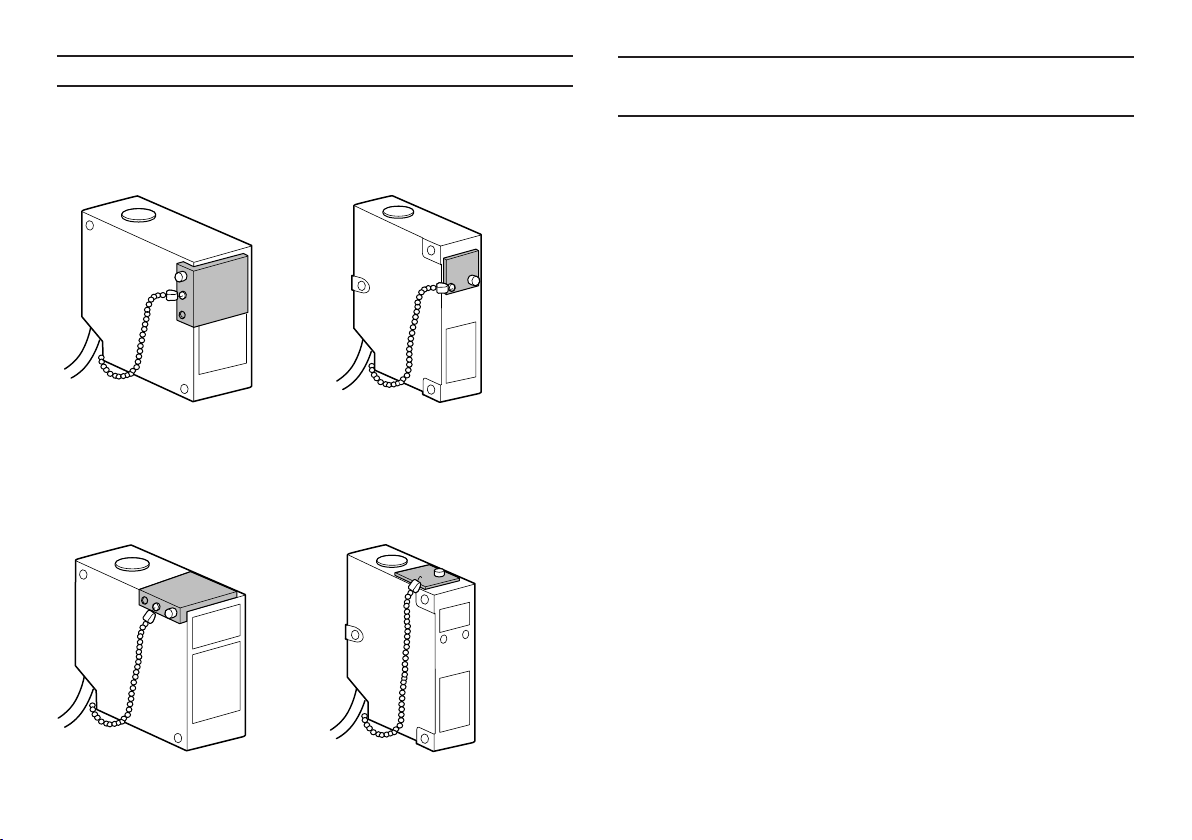

PART NAMES

Controller

5

4

Beam attenuator

LASER ON alarm LED

Sensor head

1

Key-operated

power switch

2

6

7

3

1 Indicators

TIM: Timing indicator

STB: Stability indicator (3-color indicator)

BRIGHT: Excessive light quantity indicator

DARK: Insufficient light quantity indicator

LASER ON: Laser radiation emission warning

2 RESPONSE speed selector switch

Used to select response speed (0.4 ms, 10 ms, or 40 ms)

3 SENS (sensitivity) selector switch

Used to select WHITE, BLACK, or AUTO mode.

4 DIP switches (see p.11)

Used to switch to FUZZY logic control, alternating oscillation circuit,

etc.

5 Output adjustment trimmers

SPAN: Span adjustment

For adjusting output voltage level relative to target displacement.

SHIFT: Zero point adjustment

For shifting output voltage reading to zero.

6 AUTO ZERO key

For resetting the analog output to 0 V (12 mA for current output).

7 Receptacle for sensor head cable

7

Page 8

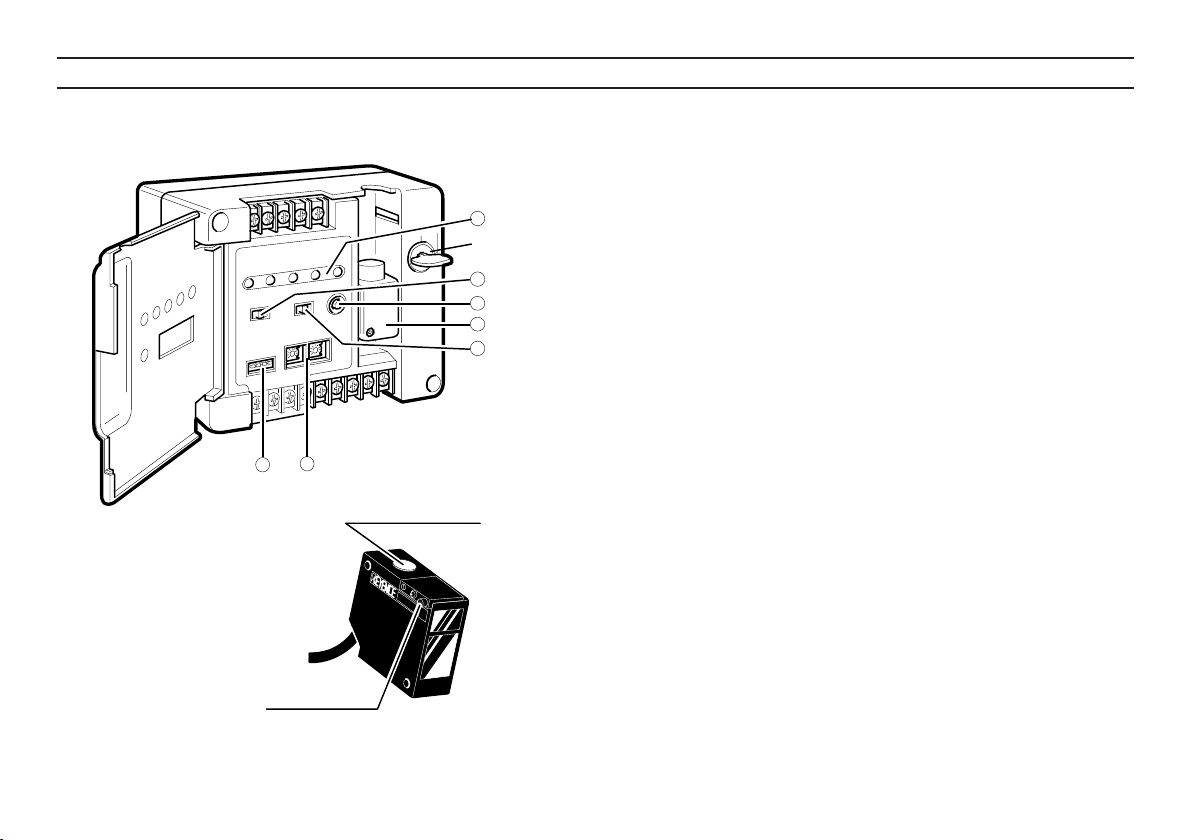

CONNECTIONS

LB-1001/1101/1201

CAUTION

Be sure to confirm

the model number.

* GND terminals

4, 0, and B

are connected

internally.

■ Description of terminals

3 Earth ground terminal

5 Alarm output (NPN open-collector)

Outputs if light quantity is insufficient or excessive, or when no target

is present in the operating range.

6 AUTO ZERO input

Connecting this terminal to a GND terminal (4, 0, or B) resets the

analog voltage output to 0 V (12 mA for current output).

9 Analog current output

Current of 4 to 20 mA relative to full measuring range is output.

CAUTION

LB-1001W/1101W/1201W

CAUTION

8

CAUTION

Be sure to confirm

the model number.

* GND terminals

4, 0, and B

are connected

internally.

A Laser emission stop input

Disconnecting this terminal from a GND terminal (4, 0, or B) stops

laser emission. Use this terminal in an emergency to stop laser

emission. (Output will be retained at 12 V.)

C Synchronous (timing) input

Connecting this terminal to a GND terminal (4, 0, or B) permits

timing input. Laser emission will stop, and the analog output value just

prior to timing input will be retained. (DIP switch 2 of the controller

must be set to MAIN.)

D Synchronous (timing) output

When using 2 sensors (for thickness measurement, etc.), use this

terminal to prevent mutual interference. It allows 2 sensors to

alternately emit a laser beam at oscillation output of 30 Hz. (Set DIP

switch 2 of one controller to MAIN, and the other to SUB.)

Page 9

CONNECTIONS

INSTALLATION

■ Description of DIP switches

RESPONSE

MANUAL

1 2 3 4

DIP

FUZZY SUB AUTO LOCK

MAIN

1 RESPONSE speed mode selector switch

To use the FUZZY logic control circuit, set the switch to FUZZY.

2 Interference suppression function selector switch

To have 2 sensors emit laser beams alternately, set the switch of one

controller to MAIN and the other to SUB.

3 Laser power control selector switch

MAX: Laser emission power is set to maximum.

AUTO: Laser emission power is controlled according to changes in

received light quantity. (Selecting AUTO mode prevents

fluctuations in received light quantity caused by surface

unevenness from affecting target measurement.

4 AUTO ZERO setting lock

LASER

POWER

MAX

ZERO

FREE

Controller

The controller can be mounted to a DIN

rail. When mounting or removing the

controller, pull the claw (bottom center) in

the direction of the arrow. The controller

can also be screw-mounted using the

mounting holes provided.

Sensor head

1. First, tilt the receptacle of the controller

forward, as shown.

2. To attach the connector, gently press

the plug into the receptacle, turn the

plug left or right to locate the engaging

position, then press until you hear a

click.

(Also follow this procedure to connect an

extension cable or sensor head cable to the

receptacle.)

To remove the connector, hold the

connecting sleeve as shown, and pull it

out in the direction of the arrow.

Mounting the sensor head

The sensor head has mounting holes, as

shown in the figure on the right.

Secure the sensor head using M4

screws.

(LB-301 has three mounting holes.)

9

Page 10

SETTING

AUTO ZERO/OUTPUT ADJUSTMENT

1. Adjust the distance between the sensor head and target and confirm

the position with the LASER ON alarm LED. Set the sensor head so

that the laser emitting surface is parallel to the measuring surface of

the target, then secure it in place. (See figure below.)

Distance between sensor head and target

Out of

measuring

range

(Operating range)

Red Yellow Green Yellow Red

Measuring range

Center

Out of

measuring

range

(Operating range)

LASER ON

alarm LED

When the LED lights green, the target is in the center area of the

measuring range.

LB-041: approx. 40 mm

LB-081: approx. 80 mm

LB-301: approx. 300 mm

2. Adjust orientation of the sensor head (for a moving target).

Be sure to mount the sensor head as shown in the right-hand figure

below to ensure stable measurement.

Example: Step detection

Incorrect

Correct

Example: Eccentricity measurement

Press the AUTO ZERO key to reset the output voltage to zero at the

mounting position.

Example: LB-041

The LED light green.

ZERO Panel meter

Approx.

40 mm

*12 mA for

current output.

V

AUTO ZERO setting is possible from external terminals (connecting the

6 terminal to a GND terminal).

* The AUTO ZERO function can be used when the DIP switch No. 3 of

the controller is set to FREE (top setting).

Output adjustment

If the output voltage value is not in proportion with the target displacement, adjust the output voltage using the SPAN adjustment trimmer.

Example: LB-041

40 mm

V V

Change by 2 mm

(To change

-2.010 to -2.000.)

38 mm

Span adjustment

adjustment +0.010.

SPN-ADJ

V

10

Incorrect

Correct

When a sensor is positioned on both sides of a

Note

target for measurement, be sure to adjust the span

of each sensor separately.

Page 11

MEASURING RANGE VS. ANALOG OUTPUT

OFF

LB-041/LB-1001(W)

LB-081/LB-1101(W)

Spot size (mm)

Alarm output (N.C.)

Spot size (mm)

Alarm output (N.C.)

LB-041

1.1

2.2

35 mm

35 37.5 40 42.5 45

ON

OFF

1.2

2.3

65 mm 30 mm

ON

OFF

1.0

0.9

2.0

10 mm

Measuring range

12

7

6

(20 mA)

5

Analog output voltage (V)

4

3

2

1

(12 mA)

0

-1

Measuring distance (mm)

-2

-3

-4

(4 mA)

-5

-6

-7

1.0

0.9

2.0

Measuring range

12

7

6

(20 m A)

5

Analog output voltage (V)

4

3

2

1

(12 mA)

0

72.5 80 87. 5 9565

-1

Measuring distance (mm)

-2

-3

-4

(4 mA)

-5

-6

-7

LB-301/LB-1201(W)

1.8

Spot size (mm)

Alarm output (N.C.)

200 mm

ON

1.4

3.0

1.2

2.5

200 mm

Measuring range

12

7

6

(20 mA)

5

4

Analog output voltage (V)

3

2

1

0

250 300200 350 400

Measuring distance (mm)

-1

-2

-3

-4

(4 mA)

-5

-6

-7

1.0

(12 mA)

2.2

If the target is out of the measuring range:

1.7

Less than 200 mm from the sensor: Analog output is retained at 12 V

when the target is approximately 195 mm away from the sensor.

More than 400 mm from the sensor: Analog output is retained at 12 V

when the target is approximately 405 mm away from the sensor.

11

Page 12

SETTING DIP SWITCH 1 (FUZZY LOGIC CONTROL)

To use the FUZZY logic control circuit, set DIP switch 1 to FUZZY

(bottom setting).

(The switch is factory-set to MANUAL)

1234

DIP

The FUZZY logic control circuit is used to obtain both stability and high

response speed when measuring a target traveling on a production line.

FUZZY mode is selected using the RESPONSE speed selector switch.

RESPONSE

LO HIGH MID

FUZZY mode settings

• RESPONSE speed selector switch MID

Select for normal measurement. The optimal response speed is given

according to absolute light quantity and changes in distance and light

quantity received.

* The switch should normally be set to MID. Set to HIGH or LO only

when you cannot perform accurate measurement with MID.

• RESPONSE speed selector switch HIGH

Response speed is determined based mainly on changes in distance.

Set to HIGH when positioning for stepped target detection, or

detection of target recesses or projections.

• RESPONSE speed selector switch LO

Response speed is determined based mainly on changes in received

light quantity. When detecting hairline finishes or targets of mottled

material, setting the switch to LO will stabilize the output.

12

Page 13

SETTING DIP SWITCH 2 (INTERFERENCE SUPPRESSION FUNCTION)

When using 2 sensor heads in close proximity, set the DIP switch of one

controller to MAIN, and that of the other to SUB to suppress interference.

(This can also be used for synchronized measurement.)

DIP 1 2 3 4

Wire as follows. (Upper terminals of controller)

10 11 12 13 14 10 11 12 1413

Set DIP switch 2 to MAIN Set DIP switch 2 to SUB

Example: Step measurement using 2 sensors.

Alternating oscillation frequency and ON/OFF ratio (all models)

Frequency ON/OFF ratio

30Hz 1 : 1

Synchronous

(timing) pulse

AB

ON

OFF

Note

• Controller set to MAIN: Monitor output is retained when the synchro-

nous (timing) pulse is OFF.

Controller set to SUB: Monitor output is retained when the synchro-

nous (timing) pulse is ON.

• Controller set to MAIN: The laser beam is emitted at the rising edge

of the synchronous (timing) pulse, but the

signal is not read for 8 to 10 ms. Effective

measurement occurs only during the last half

of the synchronous (timing) pulse (6 to 8 ms).

Controller set to SUB: The laser beam is emitted at the falling edge

of the synchronous (timing) pulse, but the

signal is not read for 8 to 10 ms. Effective

measurement occurs only during the last half

of the synchronous (timing) pulse (6 to 8 ms).

Synchronous

(timing) pulse (TIM OUT)

Controller set to MAIN

Laser emission

Controller set to MAIN

Data reading

Controller set to SUB

Laser emission

Approx.

6 to 8 ms

Controller set to SUB

Data reading

Approx. 6 to 8 ms

13

Page 14

SETTING DIP SWITCH 3

(LASER POWER CONTROL)

SETTING DIP SWITCH 4

(AUTO ZERO)

Laser power control

DIP

1234

When the DIP switch is set to AUTO (bottom setting), emitted laser beam

quantity is automatically controlled according to the reflectivity of the

target. The switch is factory-set to MAX.

The AUTO mode is especially effective for measuring metal targets or

targets of a mottled material.

AUTO ZERO setting lock

DIP

1234

DIP switch 4 is factory-set to FREE. In this mode, AUTO ZERO can be

performed by either using the key on the controller panel or short

circuiting the terminals.

To prevent the output voltage from being mistakenly reset to zero, disable

AUTO ZERO by setting the switch to LOCK (bottom setting).

Note:

• The SHIFT adjustment trimmer on the controller panel functions only

when the switch is set to LOCK.

• When AUTO ZERO is used with the DIP switch set to FREE and then

the switch is switched to LOCK, the AUTO ZERO setting becomes

invalid and the AUTO ZERO function is disabled.

Caution:

After DIP switch 4 has been switched between FREE and LOCK, be

sure to turn the power supply OFF once and then ON again.

14

Page 15

TROUBLESHOOTING

If a problem occurs, first apply the remedy given in the troubleshooting

guide below.

If this does not solve the problem, please contact your nearest distributor

or Keyence office.

Problem Cause Remedy

Analog voltage

does not change.

(Measured value is

not indicated.)

Analog voltage

output fluctuates.

Sensor head is

incorrectly mounted.

Connector of sensor head is

not firmly inserted.

BRIGHT or DARK indicator

is lit.

Filter glass of sensor head

is dirty

Noise is affecting sensor

operation.

There is vibration in feeder

line.

Secure sensor head in range

where LASER ON alarm LED

lights yellow or green.

Fully insert connector to make

proper contact.

Adjust position and orientation of

the sensor head to increase or

decrease the light quantity

received.

Set DIP switch 3 to AUTO

(bottom setting) to control laser

power.

Switch sensitivity selector switch.

Clean using a soft cloth.

Isolate power cable and

connecting cable(s) of sensor

from high-tension lines or power

lines.

Minimize vibration near

measuring position.

Problem Cause Remedy

Resolution

fluctuates greatly.

Measurement is

inaccurate.

When 2 sensors

are used for

thickness

measurement, etc.,

analog output

voltage fluctuates

greatly.

Output voltage value is not

in proportion with target

displacement.

RESPONSE speed selector

switch is set to HIGH

(0.4 ms).

Target is moving.

Extraneous light is affecting

sensor operation.

SPAN adjustment has been

performed for only one

sensor.

Calibrate output voltage using

SPAN adjustment trimmer.

If high response speed is not

required, select lowest possible

response speed.

Set DIP switch 1 to FUZZY and

use FUZZY logic control.

Make sure that extraneous light

does not fall on the light emitting/

receiving lenses of the sensor

head.

Perform SPAN adjustment for

each sensor separately.

15

Page 16

HINTS ON CORRECT USE

Compatibility

The controller and sensor head of the LB-1000 series have been factorycalibrated in pairs. Therefore, in order to satisfy specifications, be sure to

use a sensor head and controller having the same serial number.

Interference prevention

• Isolate the power cable and connecting cable(s) of the sensor from

high-tension lines or power lines; otherwise the sensor may malfunction or the laser diode may deteriorate or be broken due to noise

interference.

• The sensor head is case-grounded. If noise occurs at the mounting

position of the sensor head, install insulation between the mounting

position and sensor head.

• To prevent radiation noise interference, cover the sensor head with a

metal casing. (Be sure that noise does not enter at the mounting

position of the casing.)

• To prevent radiation noise and inductive noise interference, shield the

cables with metal or use independent metal conduits.

• To avoid a malfunction due to excessive noise interference, be sure to

correctly ground the earth ground terminal.

Operating environment

• Always keep the sensor head free from light-refracting substances

such as water or oil.

• Make sure that extraneous light does not fall on the lenses of the

sensor head.

• When extremely high measurement accuracy is required, install a

cover over the sensor head to prevent light from entering.

• When no target is present, the effect of extraneous light on the sensor

can be ignored by using timing input.

16

CAUTION

CAUTION

CAUTION

AUTO ZERO function lock (DIP switch 4 )

• When DIP switch 4 is set to LOCK (bottom setting), the AUTO ZERO

key on the front panel does not function. Note that when the switch is

set to FREE, the AUTO ZERO function operates but the SHIFT

adjustment trimmers cannot be used to adjust output.

• When AUTO ZERO is used with the DIP switch set to FREE and then

the switch is switched to LOCK, the AUTO ZERO setting becomes

invalid, and the AUTO ZERO function is disabled.

• After switching between FREE and LOCK, turn the power supply OFF

once and then ON again to ensure that the monitor voltage will be

normally output.

Sensor head orientation

When a target consists of differently colored portions or different

materials separated by a border, measurement error may result

depending on the orientation of the sensor head. To minimize measurement deviation, install the sensor head parallel to the border line as

shown in the illustration below.

Incorrect Correct

Operating illumination

Although the operating illumination is specified to 2,500 lux max., (LB301: 4000 lux max.) if possible avoid using the sensor near lighting

equipment that emits light in recurring pulses. If the sensor must be

positioned near such equipment, minimize the effect by using a light

shielding plate.

Note

Note

Page 17

CHARACTERISTICS (TYPICAL)

■ LB-041/LB-1001(W): 40 mm ± 5 mm

Shift-point adjustment range Span adjustment range

Changes in detection span when target is tilted Changes in detection span when target is tilted

■ LB-081/LB-1101(W): 80 mm ± 15 mm

Shift-point adjustment range Span adjustment range

The shift-point adjustment range shows the range where the output voltage reading can be shifted to zero using the SHIFT adjustment trimmer (operates when DIP switch 4 is set to LOCK). The AUTO ZERO function (operates when DIP switch 4 is set to FREE), allows 0.V resetting at any position

within the measuring range.

17

Page 18

CHARACTERISTICS (TYPICAL)

■ LB-301/LB-1201(W): 300 mm ± 100 mm

Shift-point adjustment range Span adjustment range

Changes in detection span when target is tilted

The shift-point adjustment range shows the range where the output

voltage reading can be shifted to zero using the SHIFT adjustment

trimmer (operates when DIP switch 4 is set to LOCK). The AUTO

ZERO function (operates when DIP switch 4 is set to FREE), allows 0.V

resetting at any position within the measuring range.

18

■ Frequency characteristic

Common to LB-1001(W), LB-1101(W), and LB-1201(W)

RESPONSE speed selector switch set to HIGH

Analog output

voltage (dB)

0

-10

-20

-30

915 Hz (-3dB)

100 1 K

Frequency (Hz)

RESPONSE speed selector switch set to MID

Analog output

voltage (dB)

0

-10

-20

-30

36 Hz (-3dB)

10 100

Frequency (Hz)

RESPONSE speed selector switch set to LO

■ Interference range*

a

XY

b

XY

LB-041 40 mm 20 mm 40 mm

LB-081 50 mm 30 mm 80 mm

LB-301 200 mm 180 mm 290 mm

* Use of the interference suppression function enables close mounting

of 2 sensors. Since sensors “X” and “Y” alternately emit a laser beam

at 30 Hz, interference does not occur. (Target: white paper)

c

XY

Page 19

SPECIFICATIONS

Type High resolution Standard Long range

Model Sensor head LB-041 LB-081 LB-301

Reference distance 40 mm 80 mm 300 mm

Measuring range ±5 mm ±15 mm ±100 mm

Light source Visible red semiconductor laser

Output 3.0 mW (FDA), 2.0 mW (IEC) 3.0 mW (FDA), 2.5 mW (IEC) 20 mW (FDA), 15 mW (IEC)

Pulse duration 35 µs

Wavelength 670 nm 785 nm

Laser FDA (CDRH) 21CFR Part 1040.10 Class IIIa Class IIIb

Class IEC/EN 60825-1 Class 2M Class 3R Class 3B

Spot diameter (with white paper) 1 x 2 mm (at reference distance)

Linearity 0.25% of F.S. 0.4% of F.S.

Resolution (at LO mode) 2 µm 8 µm 50 µm

Output Analog voltage ±5 V (1 mm/V) ±5 V (3 mm/V) ±5 V (20 mm/V)

Adjustment range Zero-point ±0.35 V max.

Response frequency (-3 dB) 915 Hz (HIGH), 36 Hz (MID), 9 Hz (LO)

Sensitivity WHITE, BLACK and AUTO (switch selectable)

Other functions AUTO ZERO, Response speed selectable, Fuzzy logic control, Interference suppression

Temperature Sensor head 0.02% of F.S./°C

fluctuation Controller 0.02% of F.S./°C

Ambient light

Ambient Sensor head 0 to +45°C (32 to 113°F)

temperature Controller 0 to +50°C (32 to 122°F), No condensation

Relative humidity 35 to 85%, No condensation

Power supply 100 to 240 VAC ±10% 50/60 Hz

Power consumption Approx. 15 VA

Vibration resistance 10 to 55 Hz, 1.5 mm double amplitude in X, Y, and Z directions, 2 hours respectively

Material Sensor head Aluminum die-cast

Weight Sensor head Approx. 170 g Approx. 250 g

1. Every measuring point within measuring range can be shifted to zero with the AUTO ZERO

function.

2. Incandescent/fluorescent lamps

The LB-1000 series controller and sensor head are calibrated as a pair. Therefore, to satisfy

specifications, combine units having the same serial number.

Controller LB-1001 LB-1101 LB-1201

Invisible infrared semiconductor laser

1.2 x 2.5 mm (at reference distance)

Impedance 100 Ω

Analog current 4 to 20 mA (350 Ω max.)

Alarm NPN open-collector: 100 mA (40 V) max. (N.C.) Residual voltage: 1 V max.

Span ±4% max.

2.

Controller Polycarbonate

Controller Approx. 530 g

2,500 lux max. 4,000 lux max.

1.

Option

Extension cable

The sensor head cable can be extended up to 40 m.

Model Cable length

LB-C2 2 m

LB-C3 3 m

LB-C8 8 m

19

Page 20

SPECIFICATIONS

Type High resolution Standard Long range

Model Sensor head LB-041 LB-081 LB-301

Reference distance 40 mm 80 mm 300 mm

Measuring range ±5 mm ±15 mm ±100 mm

Light source Visible red semiconductor laser

Output 3.0 mW (FDA), 2.0 mW (IEC) 3.0 mW (FDA), 2.5 mW (IEC) 20 mW (FDA), 15 mW (IEC)

Pulse duration 35 µs

Wavelength 670 nm 785 nm

Laser FDA (CDRH) 21CFR Part 1040.10 Class IIIa Class IIIb

Class IEC/EN 60825-1 Class 2M Class 3R Class 3B

Spot diameter (with white paper) 1 x 2 mm (at reference distance)

Linearity 0.25% of F.S. 0.4% of F.S.

Resolution (at LO mode) 2 µm 8 µm 50 µm

Output Analog voltage ±5 V (1 mm/V) ±5 V (3 mm/V) ±5 V (20 mm/V)

Adjustment range Zero-point ±0.35 V max.

Response frequency (-3 dB) 915 Hz (HIGH), 36 Hz (MID), 9 Hz (LO)

Sensitivity WHITE, BLACK and AUTO (switch selectable)

Other functions AUTO ZERO, Response speed selectable, Fuzzy logic control, Interference suppression

Temperature Sensor head 0.02% of F.S./°C

fluctuation Controller 0.02% of F.S./°C

Ambient light

Ambient Sensor head 0 to +45°C (32 to 113°F)

temperature Controller 0 to +50°C (32 to 122°F), No condensation

Relative humidity 35 to 85%, No condensation

Power supply 24 VDC ± 10%, Ripple (P-P): 10% max.

Current consumption (Max.) Approx. 320 mA Approx. 350 mA

Vibration resistance 10 to 55 Hz, 1.5 mm double amplitude in X, Y, and Z directions, 2 hours respectively

Material Sensor head Aluminum die-cast

Weight Sensor head Approx. 170 g Approx. 250 g

1. Every measuring point within measuring range can be shifted to zero with the AUTO ZERO

function.

2. Incandescent/fluorescent lamps

The LB-1000 series controller and sensor head are calibrated as a pair. Therefore, to satisfy

specifications, combine units having the same serial number.

Controller LB-1001W LB-1101W LB-1201W

Invisible infrared semiconductor laser

1.2 x 2.5 mm (at reference distance)

Impedance 100 Ω

Analog current 4 to 20 mA (350 Ω max.)

Alarm NPN open-collector: 100 mA (40 V) max. (N.C.) Residual voltage: 1 V max.

Span ±4% max.

2.

Controller Polycarbonate

Controller Approx. 500 g

2,500 lux max. 4,000 lux max.

1.

Option

Extension cable

The sensor head cable can be extended up to 40 m.

Model Cable length

LB-C2 2 m

LB-C3 3 m

LB-C8 8 m

20

Page 21

DIMENSIONS

Unit: mm

Sensor head

LB-041/LB-081

Data in ( ) applies to LB-081.

All other dimension are the

same for both models.

62

4

2 x φ 4.5

mounting hole

LASER ON

alarm LED

(65 to 95)

35 to 45

54

56

28° (18°)

Reference position

13

52 60

Controller

LB-301

φ 7

52 60

4

3 x φ 4.5

mounting hole

φ 15

43

190

28

14

φ

15

43

φ 7

4

190

25

LASER ON

alarm LED

56

200 to 400

12.5

85

77

4

38.5

9°

15.5

LB-1001(W)/LB-1101(W)/

LB-1201(W)

21

Page 22

22

Page 23

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and workmanship for a period of one (1) year from the date of shipment. If any models

or samples were shown to Buyer, such models or samples were used merely to illustrate the general type and quality of the Products and not to

represent that the Products would necessarily conform to said models or samples. Any Products found to be defective must be shipped to KEYENCE

with all shipping costs paid by Buyer or offered to KEYENCE for inspection and examination. Upon examination by KEYENCE, KEYENCE, at its sole

option, will refund the purchase price of, or repair or replace at no charge any Products found to be defective. This warranty does not apply to any defects

resulting from any action of Buyer, including but not limited to improper installation, improper interfacing, improper repair, unauthorized modification,

misapplication and mishandling, such as exposure to excessive current, heat, coldness, moisture, vibration or outdoors air. Components which wear are

not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products. They are only suggestions, and it is Buyer's responsibility to ascertain the

fitness of the Products for Buyer’s intended use. KEYENCE will not be responsible for any damages that may result from the use of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are not to be used internally in humans, for human transportation, as safety

devices or fail-safe systems, unless their written specifications state otherwise. Should any Products/Samples be used in such a manner or misused in

any way, KEYENCE assumes no responsibility, and additionally Buyer will indemnify KEYENCE and hold KEYENCE harmless from any liability or

damage whatsoever arising out of any misuse of the Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL

EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED. IN NO

EVENT SHALL KEYENCE AND ITS A FFILIATED ENTITIES BE LIABLE TO ANY PERSON OR ENTITY FOR ANY DIRECT, INDIRECT,

INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM

LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF PROFITS, LOSS OF

SAVINGS, THE COST OF PROCUREMENT OF SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR ANY MATTER ARISING OUT

OF OR IN CONNECTION WITH THE USE OR INABILITY TO USE THE PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS AFFILIATED ENTITIES

WAS ADVISED OF A POSSIBLE THIRD PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST BUYER. In some jurisdictions, some

of the foregoing warranty disclaimers or damage limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered to a third party, Buyer must provide such third party with a copy of this

document, all specifications, manuals, catalogs, leaflets and written information provided to Buyer pertaining to the Products/Samples.

E 1110-2

23

Page 24

Copyright (c) 2010 KEYENCE CORPORATION. All rights reserved. 1422E 1110-2a 96M11353 Printed in Japan

Loading...

Loading...