Page 1

DANGER

WARNING

CAUTION

NOTICE

Important

Point

Reference

WARNING

CAUTION

NOTICE

KV-10AR

Output type: R = relay output, T(P) = transistor output (PNP)

Power supply type: A = AC power type, D = DC power type

Number of I/O points:

10 = 10 points, 16 = 16 points, 24 = 24 points, 40 = 40 points

metI snoitacificepS

epytylppusrewoP

cisaB

stinu

epytrewopCAepytrewopCD

)P(TA/RA01-VK)P(TA/RA61-VK)P(TD/RD01-VK)P(TD/RD61-VK

)P(TA/RA42-VK)P(TA/RA04-VK)P(TD/RD42-VK)P(TD/RD04-VK

egatlovylppustupnI (CAV042ot001±)%

01)%02-,%01+(CDV42

elbawollA

emitsuoenatnatsni

sm04nahtsseLsm2nahtsseL

tnerruclanretnI

noitpmusnoc

otnidetrevnoc(

)eulavCDV42

stinucisaB

sselroAm001:RD/RA01-VKsselroAm08:TD/TA01-VKsselroAm58:PTD/PTA01-VK

sselroAm021:RD/RA61-VKsselroAm09:TD/TA61-VKsselroAm001:PTD/PTA61-VK

sselroAm041:RD/RA42-VKsselroAm001:TD/TA42-VKsselroAm501:PTD/PTA42-VK

sselroAm081:RD/RA04-VKsselroAm021:TD/TA04-VKsselroAm031:PTD/PTA04-VK

noisnapxE

stinu

sselroAm02:X4E-VKsselroAm52:X8E-VKsselroAm53:X61E-VK

sselroAm52:T4E-VKsselroAm04:)P(T8E-VKsselroAm06:T61E-VK

sselroAm04:R4E-VKsselroAm07:R8E-VKsselroAm07:PT61E-VK

sselroAm03:)P(TX4E-VKsselroAm54:RX4E-VKsselroAm011:R61E-VK

srehtO

sselroAm06:lenapecafretnirotarepO02D-VK

sselroAm56:remmargorpdlehdnaH)10(E3P-VK

Sur

r

ounding air temperature 05+ot0° 221ot23(C° 54+ot0:)10(E3P-VK,)F°31

1ot23(C° gnizeerfoN,)F

ytidimuhevitaleR noitasnednocoN,%58ot53

erutarepmetegarotstneibmA 07+ot02-° 85

1ot4-(C° gnizeerfoN,)F

egatlovdnatshtiW

etunim1rofCAV005,1

slanimretO/IdnalanimretrewopneewteB(

)esacdnaslanimretlanretxeeritneneewtebsallewsa

ecnatsiseresioN

1:htdiweslup,eromrop-pV005,1µ)r

otalumisesionyb(sn05,s

)6-/4-/3-/2-4-00016CEI(dradnatsCEIhtiwecnamrofnocnI

ecnatsisertcapmI

otsmrofnoC

dna2053BSIJ

2-13116CEI

tneserpsinoitarbivtnettimretninehWspeewsfoycneuqerF

ycneuqerFnoitareleccAedutilpmA

)setunim08(semit01

ZdnaY,Xfohcaeni

snoitceridsixa

zH75ot01–

mm

570.0

zH051ot75s/m8.9

2

–

tneserpsinoitarbivsuounitnocnehW

ycneuqerFnoitareleccAedutilpmA

zH75ot01–mm530.0

zH051ot75s/m9.4

2

–

ecnatsisernoitarbiV

s/m741,2-13116CEIdna2053BSIJotsmrofnoC

2

,

snoitceridsixaZdnaY,Xfohcaenisemit3,sm11:emitgnikrow

ecnatsisernoitalusnI

M05 Ω eromro

sallewsaslanimretO/IdnalanimretrewopneewteB(

)retemmhogemCDV005ybesacdnaslanimretlanretxeeritneneewteb

erehpsomtagnitarepO .dewollasesagevisorrocrotsudevissecxeoN

thgieW

stinucisaB

g052.xorppA:RA01-VKg051.xorppA:RD01-VKg003.xorppA:RA61-VK

g091.xorppA:RD61-VKg053.xorppA:RA42-VKg042.xorppA:RD42-VK

g054.xorppA:RA04-VKg033.xorppA:RD04-VKg042.xorppA:)P(TA01-VK

g041.xorppA:)P(TD01-VKg082.xorppA:)P(TA61-VKg081.xorppA:)P(TD61-VK

g033.xorppA:)P(TA42-VKg012.xorppA:)P(TD42-VKg014.xorppA:)P(TA04-VK

g082.xorppA:)P(TD04-VK

noisnapxE

stinu

g08.xorppA:X4E-VKg001.xorppA:X8E-VKg031.xorppA:X61E-VK

g08.xorppA:T4E-VKg001.xorppA:)P(T8E-VKg031.xorppA:)P(T61E-VK

g001.xorppA:R4E-VKg031.xorppA:R8E-VKg091.xorppA:R61E-VK

g001.xorppA:)P(TX4E-VKg021.xorppA:RX4E-VK

srehtO :)10(E3P-VKg032.xorppA

sselroAm014:lenapecafretnirotarepO03D-VK

metIedomV42

edomV5

ebnac700ot000stupnI(

).tupniV5otdegnahc

gnitartupnimumixaM CDV4.62

egatlovtupnI Am3.5,CDV42mA0.1,CDV5

egatlovNOmuminiM V915 V.

4

)egatlov(tnerrucFFOmuminiM Am25 V.2

dohtemnommoC .edisniderahssiMOC

tnatsnocemittupnI

01,lacipytsm01

µ

spets7nielbairaV,desusinoitcurtsniPSHnehws

01morfµ

)0

491MDybteS(NOsi3182yalerytilitulaicepselihwsm01ots

esnopsertupnitpurretnI 01

µ

)evitatneserper(s

esnopsertupniretnuocdeeps-hgiH V42(zHk03

±

)%05:ytud()%01

5 V mode response frequency characteristic chart (representative example)

Input voltage (V)

Response frequency

(kHz)

96M11767

Super-small Programmable Logic Controller

with Built-in Display

KV Series Basic Unit

Instruction Manual

Read this manual before using the product in order to achieve maximum performance.

Keep this manual in a safe place after reading it so that it can be used at any time.

Symbols

The following symbols alert you to important messages. Be sure to read these messages

carefully.

It indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

It indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

It indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

It indicates a situation which, if not avoided, could result in product

damage as well as property damage.

It indicates cautions and limitations that must be followed during operation.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

Low-Voltage Directive (2006/95/EC)

The Low-voltage Directive is applied to AC power type and/or Relay output type.

• Applicable standard EN61131-2

• Over voltage c ateg ory II

• Use this product under pollution degree 2.

• The AC power type models are designed as Class I equipment. Be sure to connect the

protective earthing terminal located on the power supply terminal to the protective

earthing conductor in the building installation.

• This product has the temperature derating curve depends on the Continuous

Simultaneous ON Ratio. Install the product within the tempeature derating curve.

• Use insulated type crimp-style terminals.

• For wiring materials, use lead wires whose sheath is 0.4 mm or more.

• The KV Series is allowed to be installed in a front installation only. (Spacers for

expansion units are not available.)

• This product is an open type device. Therefore, it must be installed in an enclosure with

IP54 or higher. (e.g. Industrial control panel)

• For wiring to the Power input terminal, Input terminal block and Output Terminal block,

use stranded copper wire having a gage of AWG#16 to #24. The tightening torque is 0.5

N·m.

Model of a Basic Unit

Basic unit model designation

The model of a KV Series basic unit is indicated as follows:

When the ladder support software "KV-IncrediWare (DOS)" or

"LADDER BUILDER for KV Ver. 1.0x" is used, the change all function

NOTICE

on the monitor is not available. Using the change all function may

damage the basic unit. Never use the change all function.

Specifications

Safety Information for KV Series

General Precautions

• Do not use this product for the purpose to protect a human body or

a part of human body.

• This product is not intended for use as explosion-proof product. Do

not use this product in a hazardous location and/or potentially

explosive atmosphere.

• At startup and during operation of the Ladder Builder for KV, be

sure to monitor the functions and performance of the KV Series

basic unit and the KV CPU.

• We recommend that you take substantial safety measures to avoid

any damage in the event a problem occurs.

• Do not open or modify the KV or use it in any way other than

described in the specifications.

• When the KV is used in combination with other instruments,

Precautions on Regulations and Standards

CE Marking

Keyence Corporation has confirmed that this product complies with the essential requirements of

the applicable EC Directive, based on the following specifications. Be sure to consider the

following specifications when using this product in the Member State of European Union.

EMC Directive(2004/108/EC)

• Applicable standard EMI : EN61131-2, Class A

• Any of the following specifications must be considered if the DC power type (the letter

"D" is assigned in models) is installed for use.

- The length of cable connected to the power supply connector must be less than

or equal to 30 m.

-

Mount the following silicon surge protector to the power input terminal of the unit.

Okaya Electric Industries Co., Ltd.: RSP-DC24Q-4 (However, shorten the cable

length of the silicon surge protector to 100 mm or less)

• When you use the relay output type unit (A model type with R on the end), connect the

pressure resistance spark killer which has an appropriate load capacity to the output

terminal in tandem with the contact. (As the equipment discharges when the relay

contact opens and a noise occurs)KEYENCE use the following spark killer for the test.

Okaya Electric Industries Co., Ltd.: XEB0101 0.1μF-10

• As for KV-24AR/T(P) and KV-40AR/T(P), insert the following ferrite core once to the AC

power input terminal, and for KV-40DR/T(P) to the DC power input terminal.

TDK Corporation: ZCAT3035-1330

Remarks:

These specifications do not give any guarantee that the end-product with this product

incorporated complies with the essential requirements of EMC Directive. The manufacturer

of the end-product is solely responsible for the compli ance on the end-product itself

according to EMC Directive.

functions and performance may be degraded, depending on

operating conditions and the surrounding environment.

EMS : EN61131-2

Common I/O specifications

Input specifications

*

For 5 V ±10%, refer to the 5 V mode response frequency characteristic chart (representative example).

1

40

35

30

25

20

15

10

5

0

5.55.45.35.25.154.94.84.74.6

KV Series Basic Unit-IM_E

Page 2

Output specifications

Point

Instantaneous power interruption: Less than 40 ms

Instantaneous power interruption: 40 ms or more

Rated voltage

Rated voltage

Rated voltage

Rated voltage

Point

NOTICE

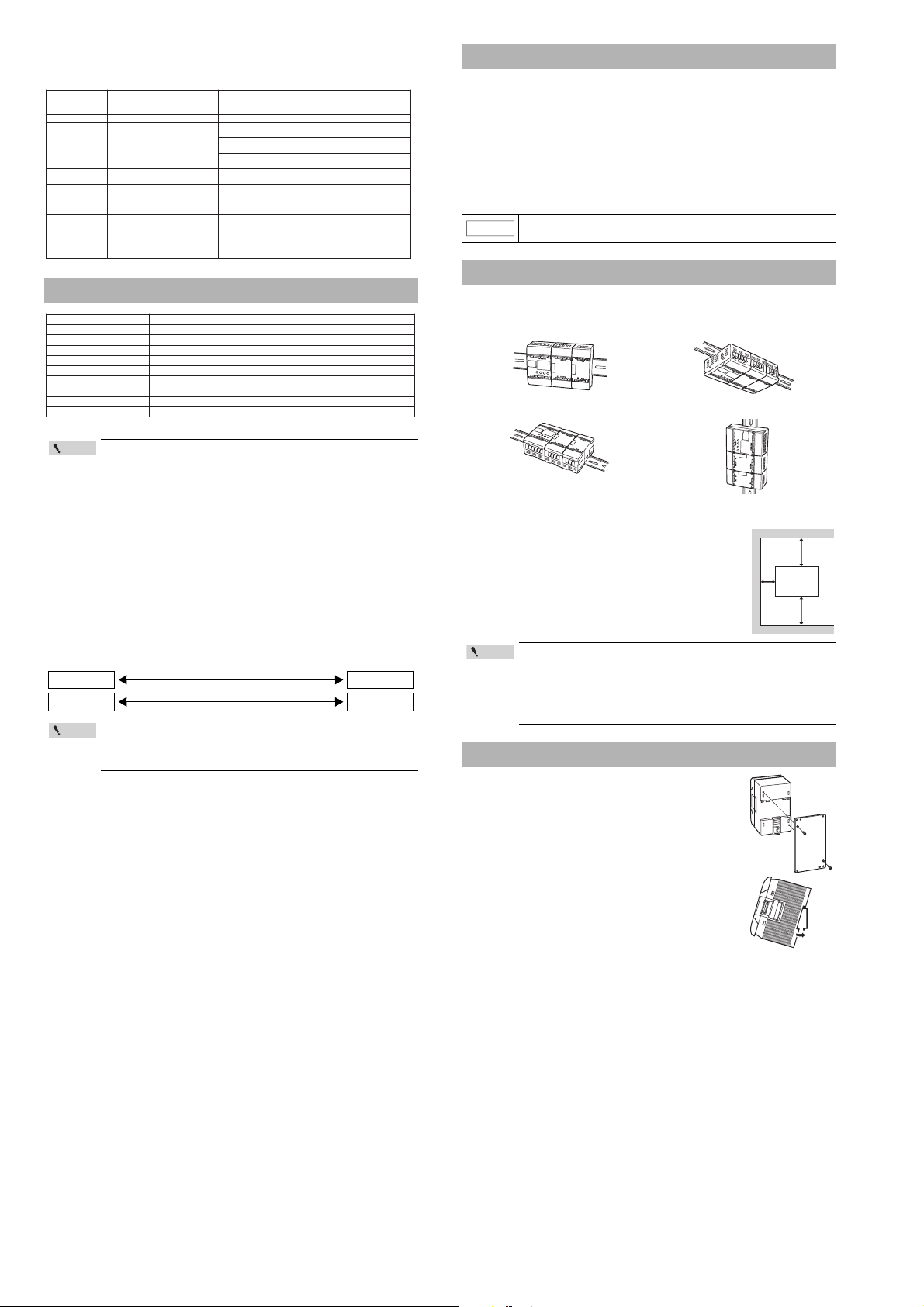

Front installation

Correct Incorrect

* See page 3.

Installation on ceiling

Upward installation Vertical installation

Correct

Incorrect

20 mm

20 mm

10 mm

Point

(relay output): KV-10AR/DR, KV-16AR/DR, KV-24AR/DR, and KV-40AR/DR

(transistor output): KV-10AT(P)/DT(P), KV-16AT(P)/DT(P), KV-24AT(P)/DT(P),

Item Specifications (relay output): Specifications (transistor output):

Rated load

Peak load current

ON resistance

Rising operating

time (OFF → ON)

Falling operating

time (ON → OFF)

Common method

Relay service life

Relay

replacement

and KV-40AT(P)/DT(P)

250 V AC/30 V DC, 2 A (inductive load),

4 A (resistive load)

5A 0.2 A (500 to 502), 1 A (others)

50 mΩ or less

10 ms or less

10 ms or less

Each common terminal is

independent.

Electrical service life: 100,000 times

or more (20 times/min)

Mechanical service life: 20,000,000

times or more

Not allowed

30 V DC, 0.1 A (500 to 502), 0.3 A (others)

Maximum

voltage at OFF

Leak current in

OFF status

Residual voltage

in ON status

10 µs or less (500 to 502) (at 5 to 100 mA),

20 µs or less (others) (at 10 to 300 mA)

10 µs or less (500 to 502) (at 5 to 100 mA),

100 µs or less (others) (at 10 to 300 mA)

1 common

Output

frequency

Built-in serial

resistance

1.6 kΩ 1/2 W (R500 to R502)

30VDC

100 µA or less

0.8Vorless

50 kHz (500 to 502)

AC Power Specifications

metInsoitacificepS

dohteM dohtemgnihctiwS

esionelppiR sselrop-pVm042

egatlovtuptuO CDV42

yticapactuptuO A7.0:xA04-VKA6.0:xA42-VKA6.0:xA61-VKA4.0:xA01-VK

esufdesU epytgnitlem-tsaF:scitsiretcarahC,A51.3:tnerrucdetar,CAV042:egatlovdetaR

* Includes the internal current consumption and current consumption of expansion units.

KV Series operation at power interruption

Drop in supply voltage

• When the supply voltage drops, the KV Series stops operating and the output turns off.

Detection of instantaneous power interruption

• An AC type basic unit continues operating against instantaneous power interruption of

less than 40 ms. A DC type basic unit continues operating against instantaneous power

interruption of less than 2 ms.

• An AC type basic unit may or may not accept instantaneous power interruption of 40 ms

or more. A DC type basic unit may or may not accept instantaneous power interruption

of 2 ms or more.

• When accepting instantaneous power interruption, a basic unit stops operating and the

output turns off.

Automatic recovery

• Once the supply voltage recovers, the KV Series restarts operation automatically.

noitpmusnoctnerrucrewopCA A7.0:xA04-VKA4.0:xA42-VKA5.0:xA61-VKA4.0:xA01-VK

egatlovtupnirewopCA (CAV042ot001

rotcafrewopCA %06

noitpmusnocrewoP W42:xA04-VKW12:xA42-VKW12:xA61-VKW41:xA01-VK

The maximum output capacity available with the AC type service

power output is the output capacity of each basic unit subtracted by

the internal current consumption of the basic unit, connected

expansion units, and connected peripheral units.

If the supply voltage increases gradually or drops, the KV Series may repeat

operation and then stop. If problems continue to occur with equipment and

other operations from repetitive starts and stops, provide a protection circuit

so that the output shuts down until the voltage reaches the rated value.

)%01

±

%01

±

Installation Environment

Installation environment

• Locations exposed to direct sunlight

• Locations whose ambient temperature is outside the allowable range of 0 to +50°C (32

to 122°F) (No freezing)

• Locations whose ambient humidity is outside the allowable range of 35 to 85% RH (No

condensation)

• Locations subject to drastic temperature change where condensation may occur

• Locations with corrosive or flammable gases

• Locations with excessive dust, salt, iron powder, or soot

• Locations subject to direct vibrations and impacts

• Locations subject to splashes of water, oil, chemicals, etc.

• Locations where a strong magnetic or electrical field is generated

Units are made of synthetic resin. If the unit surf ace touches a solvent with a strong

dissolving force, it could melt. Keep such solvents away from the units.

.

Installation Position

Installation direction

When attaching a unit inside a panel, install the unit so that the front face (equipped with the

access window, communication ports, etc.) faces front or upward.

Distance between adjacent panels/equipment

When installing a unit, keep the distances shown on the right

between the panel or equipment so that the power suppl y can

release heat.

• If the temperature inside the panel exceeds 50°C (122°F), which is

specified as the maximum ambient operating temperature, then

install heat exchangers, etc. to reduce the temperature.

• Ensure sufficient ventilation space so that the power supply can

release heat.

• Never install a unit just above any equipment which generates a lot

of heat.

Installation Procedure

This section describes how to attach a connected unit directly to a

panel, to a DIN rail, or to a DIN rail with an expansion unit spacer.

Attaching a unit directly to a panel

Attach a metal fixture for screw tightening to a KV Series basic unit

with set screws. Then, attach the basic unit with a metal fixture

directly to the panel.

Attaching a unit to a DIN rail

Hang an upper claw of a KV Series basic unit to the upper side of

the DIN rail, and press the basic unit onto the DIN rain until a click

sound is heard.

Removing a unit from a DIN rail

Pull a lower claw of a KV Series basic unit downward from the

front direction using a screwdriver, and then remove the basic unit

from the DIN rail.

KV Series Basic Unit-IM_E

2

Page 3

Cautions on Wiring for Each Unit

NOTICE

24 V DC service

power supply

(supplied from

outside)

Grounding

The power input

terminals at the lower

side of the unit

Insulating transformer,

noise filter, etc.

Breaker

AC100 to

240 V

±10%

KV-10AR

Point

24 V DC external power supply

Breaker

Point

RL

24 V DC

KV

Sensor

Ground

Shielded cable

Input

Output

M3

6.0 maximum

Completely grounding

012345

0123456789

5ch

0ch

C1 001 003 005 007 009

008006004002

500

KV-16AR

C324V-OUT-OV C4 503 505

501 502 504

000

IN

OUT

EYENCE

24V

5V

INPUT

VOLT

AC100V-240V

0.5A 50/60Hz

L

~

N

.oNemaNnoitcnuF

1etalplanimrettupnI .)tupniV5otdegnahcebnac700ot000(etalplanimrettupniCDV42

2etalplanimrettuptuO

Output terminal plate. Pulse output function is built in 500 to 502 (in transistor output type only).

k6.1A Ω .)revirdrotomatcennocot(205Rnitliubsirotsisergnitimiltnerruc

3

lanimrettupnirewoP

))P(TD/RD-VK(

.CDV42seilppuS

lanimrettuptuorewoP

))P(TA/RA-VK(

tinuehtfoedisrewolehtnoslanimrettupnirewopehtotCAV042ot001seilppuS

.lanimretCDV42ehtmorfnekatebotrewopecivresswolladna

4spmalrotacidnitupnI .NOtapusthgilpmalhcaE.sutatstupnietacidnI

5spmalrotacidnituptuO .NOtapusthgilpmalhcaE.sutatstuptuoetacidnI

6)edisnodedivorp(rotcennoC .tinunoisnapxenatcennocotdesU

7wodniwsseccA

sasretnuocdnasremitfoseulavtesdnatnerrucehtegnahcdnaotreferotdesU

.seiromematadfostnetnocehtsallew

.sutatsnoitarepoehtsetacidnirolocthgilkcabehT

sutatsrorrE:dergnihsalFedomMARGORP:dernitiLedomNUR:neergnitiL

8syekgnitteS .wodniwsseccaehtotgnirreferelihw.cte,seulavtnerrucegnahcdnaotreferotdesU

9hctiwsrotcelesegatlovtupnI

.tinucisabehtfoegatlovtupniehtsegnahC

tupniV5:tupniV42:

01AtropnoitacinummoC

Modular connector for connecting a personal computer, handheld programmer, or operator panel.

11BtropnoitacinummoC

Modular connector for connecting a personal computer, handheld programmer, or operator panel.

6.

Connector (provided on side)

2. Output terminal block

3. Power input terminal

10.Communication

port A

9. Input voltage selector

switch

Provided on side

1. Input terminal block

4. Input indicator lamps

5. Output indicator lamps

7. Access window

11. Communication

port B

(Power input terminals for

AC power types are provided

on the lower

side of the

unit.)

8. Setting keys

503

502C4501

C35000V24V

• C3 and C4 are each independent.

Internal circuit

Internal circuit

C4

501

C3 503 505

500 502 504

0V

24V

C1 001 003 005 007 009

000 002 004 006 008

24V 0V C3 C4 503 505

500 501 502 504

• C3 and C4 are each independent.

Internal circuit

Internal circuit

C1 001 003 005 007 009 011 013 015

000 002 004 006 008 010 012 014

24V 0V C3 C4 C5 C6 505 507

500 501 502 503 504 506

C6

503

C5 505 507

502 504 506

C4C3

501500

0V

24V

500

501

502 to 503

504 to 507

C3

C4

C5

C6

• C3 to C6 are each independent.

Internal circuit

Internal circuit

This section describes cautions to keep in mind when wiring is performed for I/O units. Be

sure to read this section before starting wiring.

Wiring procedures for basic units

The wiring procedures for basic units are described below.

• Turn off the power before starting wiring.

• For the installation position, select a location whose ambient

temperature is 0 to +50°C (32 to 122°F) (No freezing), whose

ambient humidity is 35 to 85% RH (No condensation), and one

which is not subject to drastic temperature changes.

• If the 24 V DC + output terminal and the 24 V DC - output terminal

are switched, the power supply unit and connected units may be

damaged. Never switch them.

• Be sure that the sum of the current consumption of all connected

units does not exceed the output capacity of the service power

supply. If the system is operating in an overload status, the internal

circuits may generate heat or be damaged. To recover from an

overload status, disconnect some of the connected units.

• Never connect the DC output of any other power supply, either in

serial or parallel, to the 24 V DC output terminals. If the DC output is

connected, the power supply unit may be damaged.

Wiring for an AC type basic unit

For an AC type basic unit, perform the wiring as shown in the figure below.

• Connect an insulating transformer (1:1) or noise filter to reduce line noise.

• Use twisted cables to reduce induction effects.

• When using a basic unit in a location with a lot of noise, the noise

may be reduced by using completely grounding the basic unit.

Wiring for a DC type basic unit

For a DC type basic unit, perform the wiring as shown in the figure below.

.

001 002 003 004 005

000

EYENCE

KV-10AR

C1

000

EYENCE

C2

0ch

012345

0123

5ch

50024V-OUT-OV C3 C4 503

KV-10DR

001 002 003 004 005

C2

C1

0ch

012345

IN

501 502

OUT

IN

Contact Protection

If inductive loads such as clutches, motors, and solenoids are used, a rush current may flow

when the load power supply is turned on, or a counter electromotive voltage may be

generated when the load power supply is shut down. The rush current and the counter

electromotive voltage can contribute considerably to shortening the service life of the

contacts. To prevent this from happening, provide a contact protection circuit.

Part Names and Functions

• Connect the power supply to the power supply input terminals with

24 VDC output, which offers a sufficient margin of power capacity.

Usually, the sum of the current consumption of all connected units

multiplied by 1.5 or more is required for the power capacity.

• To reduce line noise, insert a ferrite core.

Cautions on wiring for I/O units

When performing wiring for an I/O unit, pay strict attention to the following contents.

• Separate input lines from output lines in wiring.

• If the wiring for power is located near I/O signal lines, a malfunction may occur caused

by the effects of a high voltage and large current.

• Keep I/O signal lines away from the power wiring by at least 100 mm.

• Separate 24VDC I/O lines from 100 VAC and 200 VAC lines.

• When using pipes for wiring, make sure that the pipes are securely grounded.

When I/O signal lines cannot be separated from the wiring for power

In such a case, perform grounding on the KV side using batch-shielded cables. (In some

environments, grounding should be performed on the reverse side of the KV.)

Term inal

The terminal screws used are M3. When performing wiring with crimp-style terminals, use

the following ones.

Cautions on grounding

Because the KV Series is constructed to be sufficiently resistant to noise, it can usually be

used without being grounded. However, when the KV Series is used in an environment with

a lot of noise, grounding is required. In such a case, pay strict attention to the following

contents.

• Perform completely grounding for each individual unit. In this case, the ground

resistance should be 100 ¾ or less.

• If individual grounding is not possible, perform common grounding. In this case, the

length of each grounding cable should be equal.

KV KV

A

A = B A > B

0123

KV-10DR

5ch

50024V-IN-OV C3 C4 503

B

KV

A

501 502

A < B

OUT

Terminal layout drawings and I/O circuit diagrams

KV-10AR/DR (Relay output type)

Terminal layout drawing Output circuit diagram

000 001 002 003 004 005

C1 C2

500

501 to 503

501 502

24V 0V 500 C3 C4 503

C3

C4

KV-16AR/DR (Relay output type)

Terminal layout drawing Output circuit diagram

500 to 501

502 to 505

C3

C4

KV-24AR/DR (Relay output type)

Terminal layout drawing Output circuit diagram

B

3

KV Series Basic Unit-IM_E

Page 4

Terminal layout drawings and I/O circuit diagrams

C1 001 003 005 007 009 011 013 015 101 103 105 107

24V 0V C3 C4 C5 C6 505 507 509 511 C8 513 515

000 002 004 006 008 010 012 014 100 102 104 106

500 501 502 503 504 506 508 510 C7 512 514

C6

503

C5 505 507 509 511 C8 513 515

502 504 506 508 510 C7 512 514

C4C3

501500

0V

24V

• C3 to C8 are each

independent.

Internal circuit

Internal circuit

005

004 002 000

C1001003

*

C1 is shared

in common.

Three wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Blue

Three-wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Black

Blue

Circuit

000 to 007

C1

4.3 KΩ

Circuit configuration of inputs 000 to 007

Circuit configuration of inputs 008 to 107

Internal circuit

Internal circuit

Photocoupler

insulation

Photocoupler

insulation

24 V/5 V

selector

circuit

000 001 002 003 004 005

24V 0V 500 C3 C4 503

C1 C2

501 502

503

500

502

R502

501

C3

*

0V24V

Insultating

power

supply

Internal circuit

500 to 503

C3

R502

1.6 kΩ W

1

2

•A 1.6 k current limiting resistor is built in R502

(to connect a motor driver).

Internal circuit

NPN

* For KV-10ATP/KV-10DTP

PNP

Insultating

power

supply

Internal circuit

500 to 505

C3

R502

1.6 kΩ W

1

2

C1 001 003 005 007 009

000 002 004 006 008

24V 0V C3

R502

503 505

24V 500 501 502 504

500 to 505

C3

R502

1.6 kΩ

W

1

2

Insultating

power

supply

Internal

circuit

•A 1.6 k current limiting resistor is built in

R502 (to connect a motor driver).

Internal circuit

NPN

* For KV-16ATP/

KV-16DTP

PNP

Insultating

power

supply

Internal circuit

R500 to R502

C3

500 to 507

1.6 kΩ W

1

2

•A 1.6 k current limiting resistor is built in each

of R500 to R502 (to connect a motor driver).

• V1 to V3 are short-circuited inside (so they

can be used as a relay terminal block).

Internal circuit

NPN

* For KV-24ATP/KV-24DTP

PNP

C1 001 003 005 007 009 011 013 015 101 103 105 107

24V 0V C3

R500 R501 R502

V3 505 507 509 511 513 515

000 002 004 006 008 010 012 014 100 102 104 106

V1 V2 500 501 502 503 504 506 508 510 512 514

V2

R5O1

501

R502

502V3503

505

504

507

506

R500

500

V1

C30V*24V 509

508

511

510

513

512

515

514

500 to 515

C3

R500 to R502

1.6 kΩ W

1

2

Insultating

power

supply

Internal

circuit

•A 1.6 k current limiting resistor is built in each of R500 to R502 (to connect a motor driver).

• V1 to V3 are short-circuited inside (so they can be used as a relay terminal block).

Internal circuit

NPN

* For KV-40ATP/KV-40DTP

PNP

000 to 007

C1

4.3 kΩ

008 to 107

C1

4.3 KΩ

510 Ω

005

004 002 000

C1001003

*

C1 is shared

in common.

Three wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Blue

Three-wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Black

Blue

Three-wire

tipe

Brown

Black

Blue

Circuit

Circuit configuration of inputs 000 to 007

Circuit configuration of inputs 008 to 107

Internal circuit

Internal circuit

Photocoupler

insulation

Photocoupler

insulation

24 V/5 V

selector

circuit

KV-40AR/DR (Relay output type)

Terminal layout drawing

KV-24AT(P)/DT(P) (Transistor output type)

Terminal layout drawing Output circuit diagram

C1 001 003 005 007 009 011 013 015

000 002 004 006 008 010 012 014

V1

V2

501

502V3503

500

R500

C30V24V

*

504

R5O1

R502

506

505

507

Output circuit diagram

Input circuit diagram (KV-AR/KV-DR)

*The number of input points varies with the model.

008 to 107

C1

4.3 KΩ

510 Ω

500

501

502 to 503

504 to 507

508 to 511

512 to 515

C3

C4

C5

C6

C7

C8

V1 V2 500 501 502 503 504 506

24V 0V C3

R500 R501 R502

V3 505 507

Internal

circuit

Insultating

power

supply

KV-40AT(P)/DT(P) (Transistor output type)

Terminal layout drawing

Output circuit diagram

1

1.6 k

2

Ω W

R500 to R502

500 to 507

C3

C3

KV-10AT(P)/DT(P) (Transmitter output type)

Terminal layout drawing Output circuit diagram

1.6 kΩ W

1

2

R502

500 to 503

C3

Internal

circuit

Insultating

power

supply

KV-16AT(P)/DT(P) (Transistor output type)

Terminal layout drawing Output circuit diagram

KV Series Basic Unit-IM_E

24V

500 502

501

C3

*

503

R502

504

5050V24V

Input circuit diagram (KV-AT( P) /K V-DT(P))

*The number of input points varies with the model.

4

Internal circuit

Insultating

power

supply

1.6 kΩ W

1

2

500 to 515

R500 to R502

Page 5

Relationship between Continuous Simultaneous

NOTICE

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

45°C

58%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

48°C

80%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

36°C 37°C

41°C

40°C

39°C

50%

38%

18%

13%

44%

49

L=0

L=1/2Max.

L=1/2Max.

L=Max.

L=Max.

L=0

35°C

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

43°C 47°C

50%

75%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

44°C 49°C

58%

93%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

32°C 33°C

29°C

11%

6%

L=0

L=1/2Max.

L=1/2Max.

L=Max.

L=Max.

L=0

31°C

34°C

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

37°C

36°C

29°C 31°C

19%

38%

45%

6%

L=0

L=1/2Max.

L=1/2Max.

L=Max.

L=Max.

L=0

35°C

38°C

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

43°C 44°C

63%

72%

88%

50%

L=0, 1/2Max.

L=Max.

L=0, 1/2Max.

L=Max.

48°C

40°C

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

37°C 43°C

67%

44%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

47°C

91%

79%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

43°C

41%

50%

90%

83%

75%

L=1/2Max.

L=Max.

L=0

L=1/2Max.

L=Max.

L=0

48°C46°C

41°C

44°C

45°C

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

ON Ratio and Ambient Temperature

If the number of I/O points which turn ON at the same time exceeds the

specifications range, the unit may be damaged.

The graphs below show the relationship between the ambient temperature and the

continuous simultaneous ON ratio.

Load current L:

(AC power output

capacity at 400 mA)

KV-10AR/AT (P)/DR/DT (P)

Derating when KV-10AR is mounted upward Derating when KV-10AR is mounted in front

110

100

90

80

70

60

50

40

30

20

10

0

Continuous simultaneous ON ratio (%)

Derating when KV-10AT(P) is mounted upward Derating when KV-10AT(P) is mounted in front

110

100

90

80

70

60

50

40

30

20

10

0

Continuous simultaneous ON ratio (%)

Derating when KV-10DR is mounted upward Derating when KV-10DR is mounted in front

(Individual current

-

consumption when KV-D20

is connected)

41°C

44°C

42°C

39°C

L=0

L=1/2Max.

L=Max.

L=0

L=1/2Max.

41°C 43°C 46°C 47°C

L=0

L=1/2Max.

L=Max.

L=Max.

L=0

Individual unit

With expansion unit

30 35 40 45 50

Ambient temperature (°C)

Individual unit

With expansion unit

30 35 40 45 50

Ambient temperature (°C)

(Service power

=

output current)

110

46°C

49

100

90

80

70

63%

60

50

40

38%

30

25%

20

10

0

Continuous simultaneous ON ratio (%)

86%

68%

60%

30%

(Expansion unit current

+

consumption)

47°C 48°C

45°C

L=Max.

L=0,1/2Max.

L=Max.

Individual unit

With expansion unit

30 35 40 45 50

Ambient temperature (°C)

86%

79%

64%

Derating when KV-16DT(P)is mounted upward Derating when KV-16DT(P) is mounted in front

110

100

90

80

70

60

50

40

30

20

Individual unit

10

With expansion unit

0

Continuous simultaneous ON ratio (%)

30 35 40 45 50

Ambient temperature (°C)

KV-24AR/AT (P)/DR/DT (P)

Load current L:

(AC power output

capacity at 600 mA)

43°C 47°C

(Individual current

-

consumption when KV-D20

is connected)

75%

50%

110

100

90

80

70

60

50

40

30

20

10

0

Continuous simultaneous ON ratio (%)

(Service power

=

output current)

44°C 49°C

Individual unit

With expansion unit

30 35 40 45 50

Ambient temperature (°C)

(Expansion unit current

+

consumption)

93%

58%

Derating when KV-24AR is mounted upward Derating when KV-24AR is mounted in front

110

100

90

80

70

60

50

40

30

20

10

0

Continuous simultaneous ON ratio (%)

Derating when KV-24AT(P) is mounted upward Derating when KV-24AT(P) is mounted in front

37°C 40°C

L=0 to Max.

L=0 to Max.

Individual unit

With expansion unit

30 35 40 45 50

Ambient temperature (°C)

56%

44%

Derating when KV-10DT(P) is mounted upward Derating when KV-10DT(P) is mounted in front

110

100

90

80

70

60

50

40

30

20

Individual unit

10

With expansion unit

0

Continuous simultaneous ON ratio (%)

30 35 40 45 50

Ambient temperature (°C)

KV-16AR/AT (P)/DR/DT (P)

Load current L:

(AC power output

capacity at 600 mA)

Derating when KV-16AR is mounted upward Derating when KV-16AR is mounted in front

110

100

90

80

70

60

50

40

30

20

10

0

Continuous simultaneous ON ratio (%)

Derating when KV-16AT(P) is mounted upward Derating when KV-16AT(P) is mounted in front

(Individual current

-

consumption when KV-D20

is connected)

36°C 37°C

35°C

39°C

L=1/2Max.

L=Max.

L=0

L=1/2Max.

Individual unit

With expansion unit

30 35 40 45 50

L=Max.

Ambient temperature (°C)

40°C

49°C

88%

(Service power

=

output current)

110

41°C

L=0

49

100

90

80

70

60

50

50%

44%

40

38%

30

20

18%

13%

10

0

Continuous simultaneous ON ratio (%)

110

100

90

80

70

60

50

40

30

20

10

0

Continuous simultaneous ON ratio (%)

(Expansion unit current

+

consumption)

47°C

44°C

46°C

L=0, 1/2Max.

L=0, 1/2Max.

L=Max.

L=Max.

Individual unit

With expansion unit

30 35 40 45 50

Ambient temperature (°C)

47°C

44°C

46°C

L=0, 1/2Max.

L=0, 1/2Max.

L=Max.

L=Max.

Individual unit

With expansion unit

30 35 40 45 50

Ambient temperature (°C)

49°C

91%

75%

66%

50%

49°C

91%

75%

66%

50%

Derating when KV-16DR is mounted upward Derating when KV-16DR is mounted in front

Derating when KV-24DR is mounted upward Derating when KV-24DR is mounted in front

110

30°C 35°C

100

90

80

70

60

50

40

30

20

Individual unit

10

With expansion unit

0

Continuous simultaneous ON ratio (%)

30 35 40 45 50

Derating when KV-24DT(P)is mounted upward Derating when KV-24DT(P) is mounted in front

KV-40AR/AT (P)/DR/DT (P)

Load current L:

(AC power output

capacity at 700 mA)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

Individual unit

10

With expansion unit

0

Continuous simultaneous ON ratio (%)

30 35 40 45 50

Ambient temperature (°C)

37°C 42°C

(Individual current

-

consumption when KV-D20

is connected)

42%

16%

67%

39%

(Service power

=

output current)

(Expansion unit current

+

consumption)

Derating when KV-40AR is mounted upward Derating when KV-40AR is mounted in front

110

33°C

100

90

80

70

60

50

40

30

20

10

0

Continuous simultaneous ON ratio (%)

Derating when KV-40AT(P) is mounted upward Derating when KV-40AT(P) is mounted in front

110

100

90

80

70

60

50

40

30

20

10

0

Continuous simultaneous ON ratio (%)

34°C

35°C

32°C

Individual unit

With expansion unit

30 35 40 45

Ambient temperature (°C)

27°C

33°C 34°C

31°C

Individual unit

With expansion unit

30 35 40 45 50

Ambient temperature (°C)

L=0

L=1/2Max.

L=0

L=1/2Max.

L=1/2Max. Max

L=Max.

35°C

L=Max.

L=0

L=1/2Max.

L=Max.

L=0

49

48

49

110

100

90

80

70

60

50

40

33%

30

27%

20

Individual unit

10

Continuous simultaneous ON ratio (%)

0

With expansion unit

6%

38%

27%

39°C

44°C 45°C

40°C

41°C

37°C

L=1/2Max.

L=Max.

L=1/2Max.

30 35 40 45 50

Ambient temperature (°C)

L=0

L=0

L=Max.

75%

70%

55%

16%

8%

5

KV Series Basic Unit-IM_E

Page 6

Derating when KV-40DR is mounted upward Derating when KV-40DR is mounted in front

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

33°C 36°C

53%

34%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

42°C 46°C

80%

60%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

40°C36°C

54%

30%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

110

100

90

80

70

60

50

40

30

20

10

0

30 35 40 45 50

48°C44°C

87%

62.5%

Individual unit

With expansion unit

Continuous simultaneous ON ratio (%)

Ambient temperature (°C)

111

99

50

(66)

64

(79)

6-ø5.0

(Mounting hole)

Main unit

mounting hole*

(2 positions)

t=2

31

(48)

* Two M3.5 countersunk-head screws are

included for mounting the main unit.

KV-40AR/AT(P)/DR/DT(P)

(40-I/O basic unit)

OP-35348

Copyright (c) 2011 KEYENCE CORPORATION. All rights reserved.

11767E 1081-1 96M11767 Printed in Japan

Derating when KV-40DT(P)is mounted upward Derating when KV-40DT(P) is mounted in front

Dimensions

24.5

9.9

17

35.4 90

35.4 90

17.5

4.1

3.8

A

22

70

4

22

KV-10AR/AT(P)/DR/DT(P) (10-I/O basic unit)

KV-16AR/AT(P)/DR/DT(P) (16-I/O basic unit)

KV-24AR/AT(P)/DR/DT(P) (24-I/O basic unit)

KV-40AR/AT(P)/DR/DT(P) (40-I/O basic unit)

3.8

4

43

20.5

A

55

65

80

110

Metal Fixture for Screw Tightening

KV-10AR/AT(P)/DR/DT(P) KV-16 (24) AR/AT(P)/DR/DT(P)

(10-I/O basic unit) (16 (24) -I/O basic unit)

OP-35345 OP-35346 (OP-35347)

Main unit

mounting hole*

(2 positions)

* Two M3.5 countersunk-head screws are

included for mounting the main unit.

4-ø5.0

(Mounting hole)

40

54

11199

t=2

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any

models or samples were shown to Buyer, such models or samples were

used merely to illustrate the general type and quality of the Products and

not to represent that the Products would necessarily conform to said

models or samples. Any Products found to be defective must be shipped to

KEYENCE with all shipping costs paid by Buyer or offered to KEYENCE for

inspection and examination. Upon examination by KEYENCE, KEYENCE,

at its sole option, will refund the purchase price of, or repair or replace at no

charge any Products found to be defective. This warranty does not apply to

any defects resulting from any action of Buyer, including but not limited to

improper installation, improper interfacing, improper repair, unauthorized

modification, misapplication and mishandling, such as exposure to

excessive current, heat, coldness, moisture, vibration or outdoors air.

Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various

Products. They are only suggestions, and it is Buyer's responsibility to

ascertain the fitness of the Products for Buyer’s intended use. KEYENCE

will not be responsible for any damages that may result from the use of the

Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are

not to be used internally in humans, for human transportation, as safety

devices or fail-safe systems, unless their written specifications state

otherwise. Should any Products/Samples be used in such a manner or

misused in any way, KEYENCE assumes no responsibility, and additionally

Buyer will indemnify KEYENCE and hold KEYENCE harmless from any

liability or damage whatsoever arising out of any misuse of the Products/

Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE

PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL

EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING,

WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT

OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS A FFILIATED ENTITIES BE

LIABLE TO ANY PERSON OR ENTITY FOR ANY DIRECT, INDIRECT,

INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES

(INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING

FROM LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF

INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF

PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF

SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR

ANY MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE

OR INABILITY TO USE THE PRODUCTS, EVEN IF KEYENCE OR ONE

OF ITS AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD

PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST

BUYER. In some jurisdictions, some of the foregoing warranty disclaimers

or damage limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered

to a third party, Buyer must provide such third party with a copy of this

document, all specifications, manuals, catalogs, leaflets and written

information provided to Buyer pertaining to the Products/Samples.

E 1110-2

* Two M3.5 countersunk-head screws are

included for mounting the main unit.

KV Series Basic Unit-IM_E

Main unit

mounting hole*

(2 positions)

78

109

4-ø5.0

(Mounting hole)

11199

t=2

6

Loading...

Loading...