KEYENCE KV Series User Manual

96M11802

*96M11802-1*

Super-small Programmable Logic

Controller with Built-in Display

KV Series

Expansion Unit Instruction Manual

CONTENTS

Safety Precautions ....................................................................................... 1

Precautions on Regulations and Standards ........................................................

Inspection and Maintenance ........................................................................ 3

Specifications ............................................................................................... 4

KV-E4X/E8X/E16X (Expansion input unit) ................................................... 5

KV-E4R/E4T/E8R/E8T(P)/E16R/E16T(P) (Expansion output unit) .............. 8

KV-E4XR/E4XT(P) (Expansion I/O unit) .................................................... 13

Installation environment ............................................................................. 16

Installation position ..................................................................................... 16

Installation procedure ................................................................................. 17

Cautions on wiring for each unit ................................................................. 18

Contact protection ..................................................................................... 19

Connecting KV Series Expansion Units ..................................................... 20

Dimensions ................................................................................................ 22

Metal fixture for screw tightening ............................................................... 23

WARRANTIES AND DISCLAIMERS .......................................................... 24

2

SAFETY PRECAUTIONS

This instruction manual describes the operation and function of the KV.

Read this manual carefully to ensure safe use and maximum performance

from your KV.

Symbols

The following symbols alert you to important messages. Be sure to read

these messages carefully.

WARNING

CAUTION

Note:

General Precautions

• Do not use this product for the purpose to protect a human body or a part

of human body.

• This product is not intended for use as explosion-proof product. Do not

use this product in a hazardous location and/or potentially explosive

atmosphere.

• At startup and during operation of the Ladder Builder for KV, be sure to

monitor the functions and performance of the KV Sereis basic unit and the

KV CPU.

• We recommend that you take substantial safety measures to avoid any

damage in the event a problem occurs.

• Do not open or modify the KV or use it in any way other than described in

the specifications.

• When the KV is used in combination with other instruments, functions and

performance may be degraded, depending on operating conditions and

the surrounding environment.

Failure to follow instruction may lead to injury. (electric shock,

burn, etc.)

Failure to follow instructions may lead to product damage.

Provides additional information on proper operation.

96M11802

1

PRECAUTIONS ON REGULATIONS AND STANDARDS

■ CE Marking

Keyence Corporation has confirmed that this product complies with the

essential requirements of the applicable EC Directive, based on the following

specifications. Be sure to consider the following specifications when using

this product in the Member State of European Union.

●EMC Directive (2004/108/EC)

• Applicable Standard EMI: EN61131-2, Class A

When using a relay output type unit (whose model name ends with "R"),

connect spark killers having the appropriate withstand voltage against the

load to the output terminals in parallel to contacts (because the unit

discharges when a relay contact becomes open and noise is generated). In

our experiments, we use the following models of spark killers.

XEB0101 0.1 µF-10 Ω manufactured by OKAYA DENKI SANGYO

The following 1-turn ferrite core is added to the AC power input circuit of the

KV-40AR/T, the KV-24AR/T and to the DC power input circuit of the KV40DR/T.

ZCAT3035-1330 manufactured by TDK

Remarks: These specifications do not give any guarantee that the endproduct with this product incorporated complies with the essential requirements of EMC Directive. The manufacturer of the end-product is solely

responsible for the compliance on the end-product itself according to EMC

Directive.

●Low-Voltage Directive (2006/95/EC)

The Low-voltage Directive is applied to Relay output type only.

• Applicable standard EN61131-2

• Over voltage category II

• Use insulated type crimp-style terminals.

• For wiring materials, use lead wires whose sheath is 0.4 mm or more.

• The KV Series is allowed to be installed in a front installation only.

(Spacers for expansion units are not available.)

• When installing this product, it must be installed in an enclosure (Industrial

control panel) with IP 54 or higher.

• For wiring to the Power input terminal, Input terminal block and Output

Terminal block, use stranded copper wire having a gage of AWG#16 to

#24. The tightening torque is 0.5 N•m.

EMS: EN61131-2

2

INSPECTION AND MAINTENANCE

Inspection

While basic units and other units have been used for a long period of time,

the connector connection area may become loose, the battery may wear out,

or another nonconformity may occur in operation.

To avoid any nonconformities, inspect the basic units, other units, and the

wiring periodically. The major inspection items are as follows.

• Check to ensure that the connector is not disconnected or loose.

• Check to ensure that terminals on terminal plates are not loose.

• Check to ensure that the wiring cables among units and each equipment

are not damaged.

Maintenance

While basic units and other units have been used for a long period of time,

dirt will adhered. Wipe off any collected dirt with a clean, dry cloth.

Wipe off any dust and dirt that has collected on small and narrow portions

with cotton swabs.

Be sure to turn off the power before starting any inspection or maintenance.

3

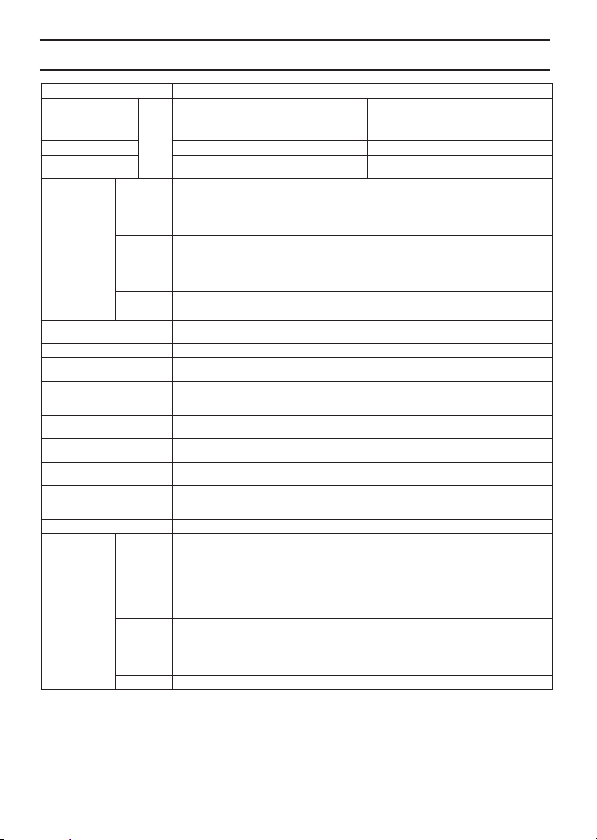

SPECIFICATIONS

metIsnoitacificepS

epytylppusrewoP

cisaB

stinu

egatlovylppustupnI (CAV042ot001 ± )%01)%02-,%01+(CDV42

elbawollA

emitsuoenatnatsni

stinucisaB

tnerruclanretnI

noitpmusnoc

otnidetrevnoc(

noisnapxE

)eulavCDV42

stinu

srehtO

erutarepmetriagnidnuorruS

ytidimuhevitaleR noitasnednocoN,%58ot53

egarotstneibmA

erutarepmet

egatlovdnatshtiW

ecnatsiseresioN

ecnatsisertcapmI

ecnatsisernoitarbiV

ecnatsisernoitalusnI

erehpsomtagnitarepO .dewollasesagevisorrocrotsudevissecxeoN

stinucisaB

thgieW

noisnapxE

stinu

srehtO :)10(E3P-VKg032.xorppA

epytrewopCAepytrewopCD

)P(TA/RA01-VK)P(TA/RA61-VK)P(TD/RD01-VK)P(TD/RD61-VK

)P(TA/RA42-VK)P(TA/RA04-VK)P(TD/RD42-VK)P(TD/RD04-VK

sm04nahtsseLsm2nahtsseL

sselroAm001:RD/RA01-VKsselroAm08:TD/TA01-VKsselroAm58:PTD/PTA01-VK

sselroAm021:RD/RA61-VKsselroAm09:TD/TA61-VKsselroAm001:PTD/PTA61-VK

sselroAm041:RD/RA42-VKsselroAm001:TD/TA42-VKsselroAm501:PTD/PTA42-VK

sselroAm081:RD/RA04-VKsselroAm021:TD/TA04-VKsselroAm031:PTD/PTA04-VK

sselroAm02:X4E-VKsselroAm52:X8E-VKsselroAm53:X61E-VK

sselroAm52:T4E-VKsselroAm04:)P(T8E-VKsselroAm06:T61E-VK

sselroAm04:R4E-VKsselroAm07:R8E-VKsselroAm07:PT61E-VK

sselroAm03:)P(TX4E-VKsselroAm54:RX4E-VKsselroAm011:R61E-VK

05+ot0 ° 221ot23(C ° gnizeerfoN,)F

54+ot0 ° 311ot23(C ° gnizeerfoN,])10(E3P-VK[)F

07+ot02- ° 851ot0.4-(C ° gnizeerfoN,)F

1:htdiweslup,eromrop-pV005,1 µ )rotalumisesionyb(sn05,s

2

s/m051,1400CSIJotecnamrofnocnI

M05 Ω eromro

g052.xorppA:RA01-VKg051.xorppA:RD01-VKg003.xorppA:RA61-VK

g091.xorppA:RD61-VKg053.xorppA:RA42-VKg042.xorppA:RD42-VK

g054.xorppA:RA04-VKg033.xorppA:RD04-VKg042.xorppA:)P(TA01-VK

g041.xorppA:)P(TD01-VKg082.xorppA:)P(TA61-VKg081.xorppA:)P(TD61-VK

g033.xorppA:)P(TA42-VKg012.xorppA:)P(TD42-VKg014.xorppA:)P(TA04-VK

g082.xorppA:)P(TD04-VK

g08.xorppA:X4E-VKg001.xorppA:X8E-VKg031.xorppA:X61E-VK

g08.xorppA:T4E-VKg001.xorppA:)P(T8E-VKg031.xorppA:)P(T61E-VK

g001.xorppA:R4E-VKg031.xorppA:R8E-VKg091.xorppA:R61E-VK

g001.xorppA:)P(TX4E-VKg021.xorppA:RX4E-VK

sselroAm06:lenapecafretnirotarepO02D-VK

sselroAm56:remmargorpdlehdnaH)10(E3P-VK

etunim1rofCAV005,1

slanimretO/IdnalanimretrewopneewteB(

snoitceridsixaZdnaY,Xfohcaenieciwt

sallewsaslanimretO/IdnalanimretrewopneewteB(

)esacdnaslanimretlanretxeeritneneewtebsallewsa

)6-/4-/3-/2-4-00016NE(dradnatsNEhtiwecnamrofnocnI

,sm11:emitgnikrow,)G051(

dnaY,Xfohcaenisruoh2,sselromm5.1:edutilpmaelbuod,zH55ot01

)liarNIDotdehcattanehwsselroG1(snoitceridsixaZ

)retemmhogemCDV005ybesacdnaslanimretlanretxeeritneneewteb

4

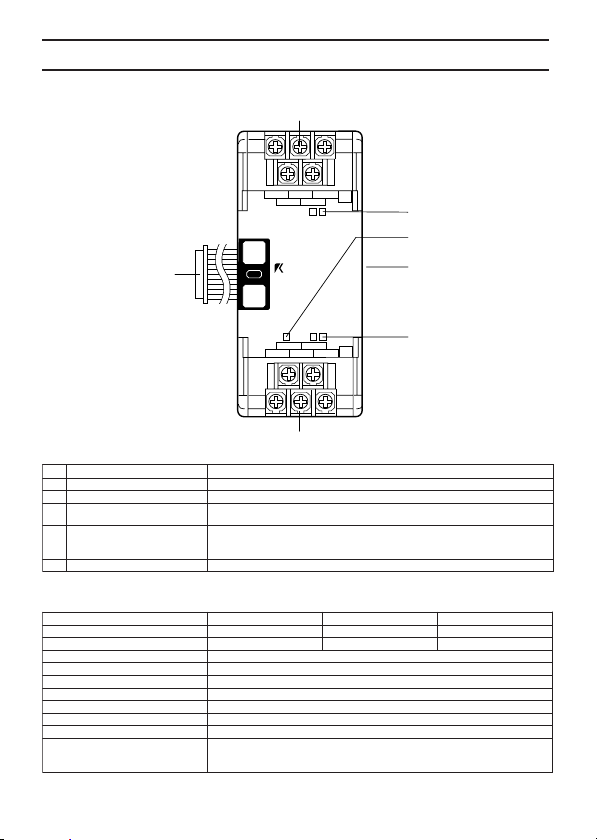

KV-E4X/E8X/E16X (EXPANSION INPUT UNIT)

Part names and functions

1. Input terminal block

C1

3

1

IN

02

01

4. Expansion cable

ch

EYENCE

KV-E4X

READY

2

/ERROR

V4V2

V1 V3 V5

3

1. Input terminal block

.oNemaNnoitcnuF

1etalplanimrettupnI etalplanimrettupniCDV42

2spmalrotacidnitupnI .NOtapusthgilpmalhcaE.sutatstupnietacidnI

3pmalrotacidniRORRE/YDAER

4elbacnoisnapxE

5rotcennoC .tinunoisnapxenatcennocotdesU

IN

2. Input indicator lamps

3. READY/ERROR indicator lamp

5. Connector (provided on side)

2. Input indicator lamps

.tinutupninoisnapxefosutatsnoitareposetacidnI

.tinunoisnapxerehtonaro,tinucisabatcennocotdesU

detcennoctonrewoP:tiltoNrorrenoitacinummoC:gnihsalFnoitarepolamroN:tiL

.dedivorpsihtgnelnimm06yletamixorppaelbacnoisnapxedradnatsA

.)16353-PO(elbacnoisnapxemm003lanoitpoehtesu,snoisnetxeroF

Input specifications

➮

For more about the general specifications, refer to "Specifications" on page 4.

ledoMX4E-VKXE8-VKX61E-VK

epyttinUtupnitniop-4tupnitniop-8tupnitniop-61

stupniforebmuN 48 61

dohtemnoitcennoclanretxE etalplanimreT

gnitartupnimumixaM CDV4.62

egatlovtupnI Am3.5,CDV42

egatlovNOmuminiM V91

tnerrucFFOmumixaM Am2

ecnadepmitupnI k3.4 Ω

dohtemnommoC nommoc/stniop4

tnatsnocemittupnI

laicepsybspetsowtnidegnahC(

)2162ot9062syalerytilitu

FFO(gnisirhtobroF ➞ NO(gnillafdna)NO ➞ ,snoitarepo)FFO

sm01:sm01 ± 01,%02 µ 01:s µs ± %02

5

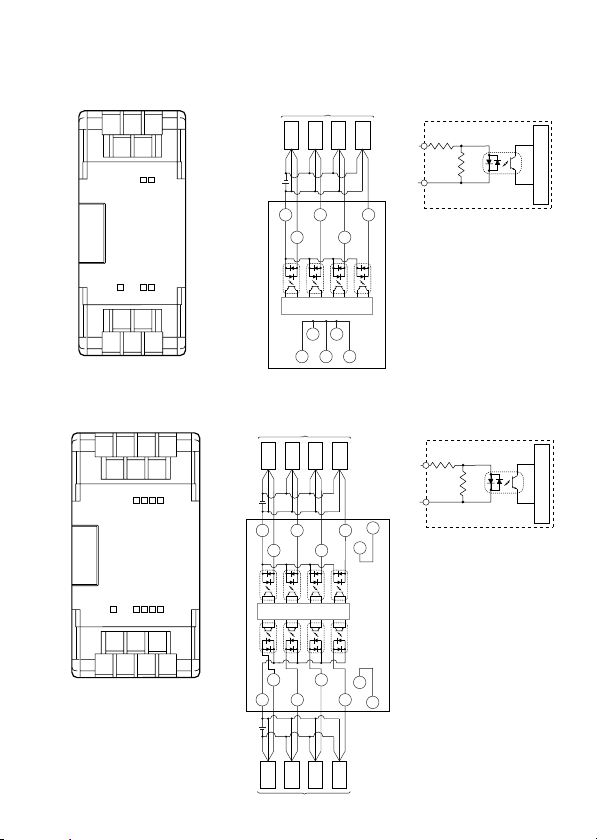

Terminal layout drawings and input circuit diagrams

KV-E4X (4-point expansion input unit)

■ Terminal layout drawing ■ Input circuit diagram

C1 1 3

02

Three-wire

Blue

C1

Sensor

tipe

tipe

tipe

tipe

Three-wire

Three-wire

Three-wire

Blue

Blue

Blue

Black

Black

Black

Brown

Brown

Brown

Brown

1

3

2

0

0 to 3

Black

C1

4.3 KΩ

510 Ω

• V1 to V5 are shortcircuited inside

(so they can be used as

a relay terminal block).

Photocoupler

insulation

Internal circuit

V2 V4

V1 V3 V5

Internal Circuit

V2

V4

V5V3V1

KV-E8X (8-point expansion input unit)

■ Terminal layout drawing ■ Input circuit diagram

C1 1 3 V2

02V1

46V3

C2 5 7 V4

tipe

Three-wire

Blue

Black

Brown

C1

0

Internal Circuit

4

C2 5

Brown

Blue

Black

tipe

Three-wire

Sensor

tipe

Three-wire

Blue

Brown

1

Brown

Blue

tipe

Three-wire

Sensor

Black

Black

tipe

Three-wire

Blue

Brown

2

6

Brown

Blue

tipe

Three-wire

Black

Black

tipe

Three-wire

Blue

Brown

3

7

Brown

Blue

tipe

Three-wire

Black

Black

0 to 3

4 to 7

C1

C2

V2

• C1 and C2 are each

V1

V3

independent.

• V1 to V2 and V3 to V4 are

short-circuited inside

respectively (so they can

be used as relay terminal

plates).

V4

4.3 KΩ

510 Ω

6

Photocoupler

insulation

Internal circuit

Loading...

Loading...