Page 1

[KV0971GB]

KV-5000/3000 Tutorial for

Beginners

(Basic Ladder Circuit)

This tutorial is for people who are using a programmable logic controller

for the first time. It extracts frequently used commands from the User's

Manual and describes them accordingly.

In addition, it is possible to input commands to the KV-5000/3000

and do programming based on the explanations in this book.

However, if you want to try it without connecting to the

KV-5000/3000, please replace the R000 to R005 with MR000 to

MR005, etc. and perform the contacts' ON/OFF operation using

the ladder diagram software. (When operation is based on a

simulator, it can also be performed without changing the R000 to

R005.)

Please read this tutorial in combination with the actual KV-5000/3000.

KEYENCE Corporation

Control System Division

Page 2

Content

Chapter 1 What is KV-5000/3000?

What is the KV-5000/3000? ...........................P2

Control in FA ................................................P3

What is Sequential Program Control? ............P4

Functions of the KV-5000/3000......................P5

Chapter 2 Programming of the KV-5000/3000

What is a Ladder Program? ...........................P6

Programs of the KV-5000/3000......................P7

Structure of Devices of the KV-5000/3000 ......P8

Startup of the KV STUDIO ...........................P9

New Programming Method with Ladder Diagram

and Initial Setting of the Units .......................P10

Writing Ladder Programs (① LD OUT) ...........P12

Transfer and Monitoring of Ladder Programs..P14

Writing Ladder Programs (② LDB OUT) ...............P16

Writing Ladder Programs (③ AND circuit) ......P18

Writing Ladder Programs (④ OR circuit) ........P19

Writing Ladder Programs (Self⑤ -hold circuit) P20

Relationship between Control and Time .........P21

Control Based Upon an ON Delay Timer...............P22

Application of the an ON Delay Timer ...................P23

Control Based Upon an OFF Delay Timer....... P24

Control Based Upon a One-Shot Timer .......... P25

Summary of Control Based Timers................. P26

Flexible Use of Counters ...............................P27

Control of Counters .....................................P28

Ideas About Scan Time/Dual Coil................... P30

Principle of A Dual Coil .................................P31

Questions Sum-up ........................................ P32

Answers to Questions ................................... P33

Convenient Commands ...............................P35

Simulator Function ......................................P37

- 1 -

Page 3

Chapter 1 What is the KV-5000/3000?

[What is KV-5000/3000?]

KV-5000/3000 is a programmable logic controller with a built-in CPU and memory.

It is a device that can conveniently and freely control external output devices (such as

indicator lights or cylinder shape coils) through the operation of various external input

devices (push buttons, limit switches, etc.) equipped on the control panel and

equipment.

From a PC with the dedicated ladder support software (KV STUDIO) installed,

programs can be written into the internal memory of the KV-5000/3000.

Various external input devices

Push button

Switchover switch

Memory

Output circuit

Limit switch

Relay contact

Photoelectric

sensor

Proximity sensor

Various sensors

Other

Control section

Micro

Computer

KV-5000/3000

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

To use the KV-5000/3000, computer knowledge is not

necessary. Simply imagine the KV-5000/3000 as a box

which contains a large number of relays, timers, and

counters.

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

Indicator light

Digital indicator

Cylinder shape

coil

Solenoid valve

Electromagnetic

clutch

Contactor

Motor

Other

Various external output devices

- 2 -

Page 4

[Control in FA]

Control in FA is briefly described below.

What is "FA"? = Factory Automation

To make manufacturing systems automatic, labor saving, and

unattended.

What is "Control"? = The operation that is performed to make the

machinery/devices keep their target status.

Why should we strive for automation?

The following are some advantages of automation:

・ Reduction in production costs

・ Increase in production output

・ Extended running time

・ Decrease in the rate of defects.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

"Control" mentioned in FA industry refers to:

"Sequential Program Control"

Sequence Control

(Continuous) (To realize desired operationtate)

Control is performed according to a sequence determined in

advance.

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

- 3 -

Page 5

[What is Sequential Program Control?]

The flow of sequential program control will be explained by using a real-life example of

a piece of equipment.

Example

■ When playing a claw machine ■ When using a fully automatic

game in an arcade. washing machine.

① Determine the object ① Inject water

② Align the horizontal position ② Wash

③ Align the back and forth position ③ Drain water

Grab the presents ④ ④ Inject water

⑤ Wash

⑥ Drain water

⑦ Dry

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

The PLC will verify the condition changes under the above-mentioned

sequential program control, and is responsible for performing control

tasks until the next process. It is referred to as a “programmable

controller".

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

[What is a PLC?]

"PLC" is short for "Programmable Logic Controller".

It means "a logic controller device that can be programmed". To put it simply, it is a

computer that is used in a factory.

- 4 -

Page 6

L

-net

g

[Functions of the KV-5000/3000]

The KV-5000/3000 Series are PLCs with high performance and high expansibility.

In this tutorial, we will only discuss the basic aspects of the controller. However, it can

also be used in the following controls, in order to deepen the understanding of the

KV-5000/3000 PLCs.

■ An example of the functions/expansibility of the KV-5000/3000 Series

CPU functions

●Ethernet function

Communication with PC/external

equipment communication used for

production management or operation

management etc., possible to realize

the communication between the field

PLC and PC.

Also possible to realize a high speed

connection to multiple touch panels and

image sensors.

●FL-net function

It is possible to realize a high speed/high

volume data connection to PLCs of various

manufacturers using the CPU unit.

● Logging/tracking function

Through the built-in memory card slot in

the main unit, it is possible to write data

onto a memory card.

Ethernet

F

Other PLCsOther PLCs

Functions that can be realized

throu

● Analog control

Through super high conversion speed of

25 μ s/ch and analog control with a

resolution of 1/20000, the measurement

data of the displacement sensor can be

loaded into the PLC in real time.

Flowmeter

● Positioning control

It is possible to control the motor used for

positioning. Possible to perform correct

positioning control of the XY table etc.

(CPU unit also has a built-in positioning

function.)

h special units

Displacement

sensor

Pressure

sensor

- 5 -

Page 7

Chapter 2 Programming of the KV-5000/3000

To make the PLC perform controller operation, a program is required.

This program is called a “ladder program”.

In Chapter 2, we will describe the steps for actual programming.

[What is a Ladder Program?]

A ladder program is a program in which the wiring diagram has been simplified.

What steps need to be taken to complete a ladder program?

Please look at the following diagram.

Wiring diagram of units Sequential program diagram Ladder program

First, verify the wiring diagram of units. This is the wiring diagram for a battery

and a switch that we have tested in previous physical experiments.

Actually, this switch may be a sensor or a limit switch, and the light may be a solenoid

valve, a motor, etc. In such a case, the actual unit wiring is relatively hard to view.

We can then put the "+" and "-" end of the battery on the left and right side

respectively, and represent the switch (PB) and the light (PL) using symbols,

then a easy-to-view sequential program diagram is completed. A sequential

program diagram is composed of graphs and symbols developed in order to

simplify the wiring diagram when performing relay sequential program control.

However, it is necessary to further simplify it when performing control through a PLC.

The reason is that the actual inputs and outputs are not limited to PB (push buttons) or

PL (indicator lights), a variety of other equipment may also be included. No matter what

equipment is connected, they all can be represented only by the connected terminal

numbers.

The R000 or R500 shown in the diagram is the number for the PLC.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

The shape of the completed program is like a ladder, so it is called

"ladder program".

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

PB1

+ -

PL1

R000

R500

END

ENDH

- 6 -

Page 8

[Programs of the KV-5000/3000]

A program of KV-5000/3000 is written using many commands.

These commands are composed of an instruction (symbol) and a device number

(element number), and are divided into basic commands, application commands,

arithmetic commands, etc.

Generally, basic commands can be used to write a program, and application

commands can be used to simplify a program or to perform more complicated control.

A device number (element number) refers to the number of an input relay, an

output relay, a timer, a counter, or an internal auxiliary relay, etc. It can freely

use any number within the number range in the KV-5000/3000 PLC.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

For the range of device numbers that can be used, please refer to the

list of devices in section "1-3 Devices and Constants" in the

"KV-5000/3000/1000 Instruction Reference Manual".

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

R000 R500

Device no.

Instruction

(symbol)

- 7 -

Page 9

[Structure of Devices of the KV-5000/3000]

The main devices of the KV-5000/3000 are divided into the following types.

Please verify according to each device.

◆Bit device◆

【Input relay】 R

The device used to load ON/OFF information from external equipment.

【Output relay】 R

The device used to output ON/OFF information from external equipment.

【Internal auxiliary relay】 MR

The device that can only be used inside a CPU

※ When a relay circuit is used and the same relay contact is used many

times in the circuit, sometimes multiple relays with the corresponding

number of times of use have to be used. Since the internal auxiliary relay

functions only on the program level, it completely eliminates the

complexity of the relay circuit, making circuit design easier.

【Control relay】 CR

The device used to control functions of the PLC or get its states.

※ The control relay has been assigned with special functions in advance

according to the device number.

【Timer】 T

1ms/10ms/100ms down timer and 10ms up/down timer

※ It is possible to assign settings respectively according to different devices.

The number of counts that can be used is 4000.

【Counter】 C

Up counter/up and down counter

※ It is possible to assign settings respectively according to different devices.

In addition, there are also latching relay (LR), link relay (B), etc.

The number of counts that can be used is 4000.

◆Word device◆

【Data memory】 DM

The device used to store digital data in the PLC. Data will be processed in

16-bit unit.

※ For example, it is used when performing arithmetic operation in the PLC.

The data stored in the data memory will be kept even if the PLC is turned

off.

【Control memory】 CM

The device used to control functions of the PLC or get its states.

※ The control memory has been assigned with special functions in advance according to

In addition, there also expansion data memory (EM), file register (FM), link register (W)

and index register (Z), etc.

the device number.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

Bit Only processes ON/OFF

Word Processes numerical value 1 word = 16 bit (to process

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

16

2

=65535)

- 8 -

Page 10

[Startup of the Ladder Support Software "KV STUDIO"]

A ladder program is written through the dedicated ladder support software.

The ladder support software installed on the KV-5000/3000 Series PLCs is "KV

STUDIO".

Here, we will actually start the KV STUDIO support software.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

For the installation procedure of the software, please refer to Chapter

1 of the "KV STUDIO User's Manual".

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

After installation, let’s start the software!

① Double click the KV STUDIO icon on the desktop to start the KV STUDIO.

The title screen of KV STUDIO

② After the title screen appears, the edit screen will be displayed.

Let’s try to write an actual ladder diagram.

The edit screen after startup

- 9 -

Page 11

[New Programming Method with Ladder Diagram and Initial Setting of the Units]

Before writing a ladder program with KV STUDIO, set up the unit first.

Follow the instructions below.

① Click the "New project" icon.

② Enter the project name.

The project name is the name that

corresponds to the file name of the ladder

program.

Please enter suitable names for

equipment/objects.

③ A "Setup initial unit configuration?" message

will appear. Select "Yes(Y)".

・ If you select "Yes", the Unit Editor will be started, and you can perform initial setup for

the units in it.

・ If you select "No", the edit screen will be displayed. You can also start the Unit

Editor while editing the ladder program.

・ If you select "Read unit configuration", the unit configuration information will

be read from the KV-5000/3000. At this point, the PC (with KV STUDIO) should

be connected to the KV-5000/3000.

- 10 -

Page 12

④ Start the Unit Editor.

Here, you can perform unit setup of the KV-5000/3000 Series PLC.

What is unit setup? To specify the units that need to be added to the

KV-5000/3000 and perform basic settings for the units

(the range and functions of the device number used).

The operation of unit addition is done by dragging/dropping

and connecting the CPU unit from the "Unit selection(1)" tag

on the right of the Unit Editor screen, and the added units

can be set up through the "Unit setting(2)" tag.

⑤ To perform assignment setting of relays/DMs,

click the icon below.

Here, you can perform unit setup of the

KV-5000/3000 Series PLC.

What is the assignment setting of relays/DMs? To setup the leading device

number of each unit.

For the CPU, it is fixed within R000-R015

(input)/R500-R507 (output); For the added units,

it can be set up freely in the range of R1000

(10ch)-R99900 (999ch) for both inputs and

outputs.

※ The initial value uses R30000 (300ch)-。

⑤ The initial setup is now complete. Click "Close" icon to exit

the Unit Editor.

- 11 -

Page 13

[Writing a Ladder Program ①(LD OUT)]

After the initial setting of the units is completed, an actual ladder program will be

written as follows.

■ Example 1:a program for LD+OUT

We will write a basic program first.

・ When R000 is ON, the light R500 will be ON (light up).

For the convenience of operation, program input can be done without many input

methods. The method used in this example is the "direct input method" in which

instructions are input directly using the keyboard.

In this case, move the green cursor on the KV STUDIO screen to the position where an

instruction is to be input (a cell), and input directly using the keyboard.

By pushing - , enter a connection

line.

Draw the connection line up to the

right end with the Alt + Enter key.

END and ENDH commands represent the end of the ladder program.

They have to be entered at the very end of the ladder program.

※ When writing a new module, the END/ENDH commands will be added

automatically at the end of the program.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

"A_0" is the short form for "LD_0". "LD" stands for "LOAD", and has the

same meaning as a-contact (normally open contact).

In addition, the OUT (output) command can also be abbreviated into "O_500".

Since they are commonly used commands, please memorize them through

unique input forms.

For the short input forms for other commands, please refer to the

"KV-5000/3000/1000 Command Reference Manual".

Attention

!

_ refers to a space. It is actually blank.

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

Input A (blank) 0 Enter .

(Processed as "LD_0'" in the program, so the result is the same as that of

entering LD (blank) 0 Enter. )

(Processed as "OUT_500" in the program.

"O" is the short input form of "OUT".

- 12 -

Page 14

What is the Relay Number (Device Number) of the Built-In

I/O of the KV-5000/3000?

A relay number (device number) refers to the number used to distinguish between the

input equipment (sensors or switches) and output equipment (lights or motors) that are

connected to the KV-5000/3000 or the expansion units.

Up to 16 input devices can be connected to KV-5000/3000 (R000-R015), and up

to 8 output devices can be connected (R500-R507).

Input/output connector

R000 R500

Terminal No. of the connector

- 13 -

Page 15

[Transfer and Monitoring of Ladder Programs]

After writing a program, please transfer it and verify its operation.

Transfer the completed ladder program to the KV-5000/3000 series PLC, and verify the

actual operation.

① Connect the KV-5000/3000 to a PC (with KV STUDIO ).

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

When the operating system is Windows XP/2000, it is necessary to

install the driver for KV-5000/3000 only when connecting the

KV-5000/3000 to the PC for the first time.

For more information on how to install the USB driver, please refer to

the "KV STUDIO User's Manual".

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

② Click the "PLC transfer"→”Monitor mode" icon.

(Cable length: 3m)

USB connector

PC

- 14 -

Page 16

③ The dialog box for confirming project

transfer appears. Click the "Execute"

button.

④ The program transfer starts.

⑤ The dialog box for confirming the operationtate

of PLC appears. Click the "Yes" button.

After "Yes" is clicked, it will say "RUN" state.

⑥ After the monitor is displayed, verify that it is in the "RUN" state.

If "PROG" is displayed in the lower part

of the screen instead of "RUN", it

indicates that the program has been

started.

Monitor

Current operation mode of KV

STUDIO is displayed.

PLC not running.

(PROG mode)

PLC running.

(RUN mode)

- 15 -

Page 17

⑥ When the R000 of KV-5000/3000 is ON, the input R000 on the ladder diagram will

light up green, and the R500 will be ON (light up green).

[Writing Ladder Programs (② LDB OUT)]

LD (LOAD) represents N.O.(normally open) = a-contact (normally open contact)

LDB (LOAD BAR) represents N.C. (normally closed) = b-contact (normally closed

contact).

Please write a ladder program and verify its operation.

The ladder diagram will add records to the program of "LD OUT" just entered.

When adding the logging program, it is necessary to leave space (a blank line) after the

END command.

Additional lines can be done as shown below.

Method for inserting and deleting a line.

R000

R000

R500

■ Inserting a line

Move the cursor to the place

for inserting a line, and press

the "Shift+Enter" buttons to

insert a line.

R500

■ Deleting a line

Move the cursor to the place

for deleting a line, and press

the "Shift+Delete" buttons to

delete a line.

- 16 -

Page 18

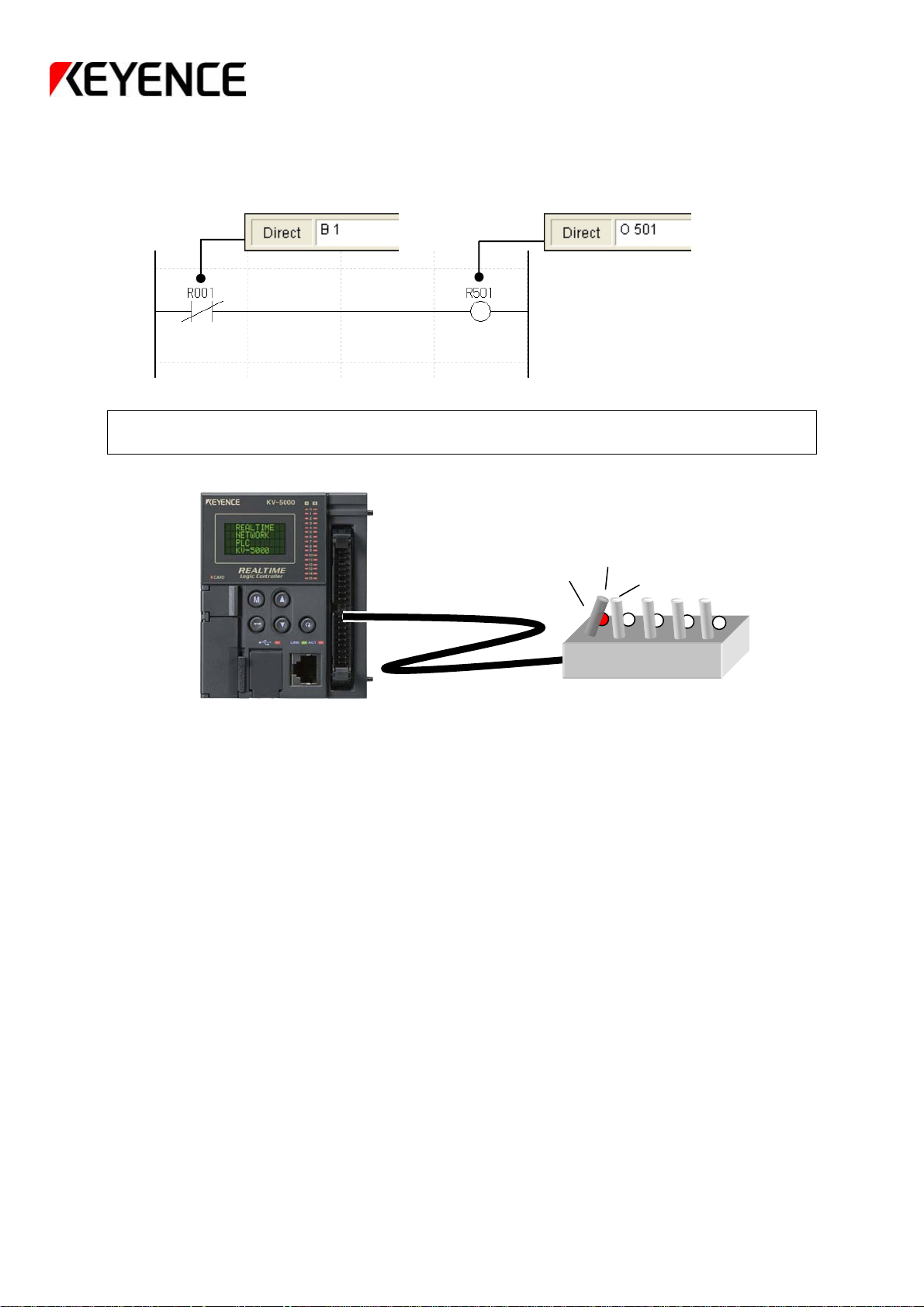

■ Example 2: a program for LDB OUT

When the switch R001 is OFF, R501 will be ON.

After the program is entered,

please transfer the program and verify its operation.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

"B_0" is the short form for "LDB_0". "LDB" stands for "LOAD

BAR", and has the same meaning as b-contact (normally closed

contact).

Attention

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

!

_ refers to a space. It is actually blank.

- 17 -

Page 19

[Writing Ladder Programs (③ AND circuit)]

If a circuit is ON when both contacts are ON, then it is called an "AND" circuit.

Please write a ladder program and verify its operation.

Add a ladder program after operation of line insertion has been performed.

■ Example 3: a program of an AND circuit (AND command)

When both the switch R002 and R003 are ON, the light R502 will be ON.

■ Example 4: a program of an AND circuit (ANB command)

When the switch R004 is ON and the switch R005 is OFF, the light R503 will be ON.

After the program is entered,

please transfer the program and verify its operation.

Processed as "AND_3" in the program.

The same result will appear even if you

have input "AND_3" or "LD_3".

Processed as "ANB_5" in the program.

The same result will appear even if you

have input "ANB_5" or "LDB_5".

- 18 -

Page 20

[Writing Ladder Programs (④ OR circuit)]

If a circuit will be ON when one of the two contacts is ON, it is called an "OR" circuit.

Please write a ladder program and verify its operation.

After deleting the program that has been written up to now through the line

deletion operation, rewrite the ladder program.

■ Example 5: a program of an OR circuit (OR command)

When either switch R000 or switch R001 is ON, the light R500 will be ON.

Processed as "OR_1" in the program.

After "OR_1" is input, the vertical line will be drawn at

the same time.

・The vertical connection line is input

through the F8 key.

・ The vertical connection line is

deleted through the Shift + F8

key.

■ Example 6: a program of an OR circuit (ORB command)

When the switch R002 is ON or the switch R003 is OFF, the light R501 will be ON.

・The vertical connection line is input

through the F8 key.

・ The vertical connection line is

deleted through the Shift + F8

key.

Processed as "ORB_1" in the program.

After "ORB_1" is input, the vertical line will be drawn at the

same time.

After the program is entered,

please transfer the program and verify its operation.

- 19 -

Page 21

[Writing Ladder Programs (Self⑤ -hold circuit)]

If the output of a circuit will be ON continuously once the contact is ON, this circuit is

called a self-hold circuit.

Please write a ladder program and verify its operation.

After deleting the program that has been written up to now through the line

deletion operation, rewrite the ladder program.

■ Example 7: a program of a self-hold circuit

When the switch R000 is ON, the light R500 will be ON.

Even if the switch R000 is OFF, the light R500 will remain ON.

When the switch R001 is ON, the light R500 will be OFF.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

Such a circuit as the above one is called a self-hold circuit.

The program flow: at the moment when the input R000 is ON, the

output R500 will be ON, and the second contact R500 will also be ON.

Since the R500 itself is ON, so it will keep its own output at the ON

state (hold), even if the input R000 is OFF.

This is a basic circuit that is effective for control when input time is

short (single pulse).

Attention

!

The self-hold circuit must contain a reset input.

(In this example, input R001 is the reset input.)

POINT The commands that have the same functions include KEEP

and SET/RES commands, etc.

Please verify them in the KV-5000/3000 Command Manual.

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

The coil and contact

are ON at the same

time

- 20 -

Page 22

[Relationship between Control and Time]

Often, time has to be considered when performing controlling devices.

The function of adjusting time through control is called "Timer" function.

Example

① Verify a signal input error, and make buzzer sound after 1 second.

② Verify that a work-piece has arrived, and set the cylinder to ON after 1

second.

③ After the conveyor belt has verified passing of the workpiece, it will still

move for a certain time.

[Timers of the KV-5000/3000]

The processing of timers is an important element of control. Of course, PLCs

represented by the KV-5000/3000 are also equipped with timers. It is possible to

realize time control only with the KV-5000/3000.

The timer commands of the KV-5000/3000 are divided into the following 3 types.

Command Symbol Mnemonics Function

#dddd

#dddd

XXX

#dddd

XXX

TMR

TMH

TMS

Timer

High speed

timer

High speed 1ms

timer

Timer number and settings

XXX : Number of timers. PLCs represented by the KV-5000/3000 equipped with

many timers.

To distinguish between various timers, we add a number to each timer in order

to facilitate management.

The number of timers that can be used depends upon the PLC model.

KV-5000/3000 may use 4000 counts between T0000-T3999.

ddddd : The time before the timer becomes ON (setting).

The setting range of this value of the KV-5000/3000 is #0-#4294967295.

Possible timing range:

Timer (TMR): 0-429496729.5 s (4971 days)

High speed timer (TMH): 0-42949672.95 s (497 days)

High speed 1ms timer (TMS): 0-4294967.295 s (49 days)

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

In addition, KV-5000/3000 also has a built-in calendar timer.

Through this calendar timer, it is possible to realize control based on

"Year/Month/Day/Hour/Minute/Second/Week" system.

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

Decrement delay in 0.1 s

unit

ON timer

Decrement delay in 0.01

s unit

ON timer

Decrement delay in

0.001 s unit

ON timer

- 21 -

Page 23

[Control Based Upon ON Delay Timer]

In the following section, we will describe the controls in which timers are used.

On Delay Timer

To perform ON delay

Example: to analyze an output error.

× Without a timer ◎ Wi th a timer

Buzzer sounds instantly

When there is no timer, or the error signal vibrates, the buzzer will sound for a short period.

When there is a timer, the buzzer will sound only after an error signal is actually detected to

prevent mis-operation.

Please write a ladder program and verify its operation.

After deleting the program that has been written up to now through the line

deletion operation, rewrite the ladder program.

■ Example 8: a program of an ON delay timer

When the switch R000 is ON, the light R500 will be ON after 3 seconds.

When the switch R000 is OFF, the light R500 will be OFF immediately.

please transfer the program and verify its operation.

・・・・The timer that makes the next operation (action) delay to ON.

Error signal ON

Error signal ON

Error lasts 1 s

Buzzer sounds

After the program is entered,

- 22 -

Page 24

[Application of the ON Delay Timer]

In this section, we will discuss the controls in which the timer functions of

KV-5000/3000 are flexibly used.

First, let us consider a control combined with an ON delay timer and a self-hold

function.

For example, let's try to analyze the operation of a conveyor belt.

Please write a ladder program and verify its operation.

After deleting the program that has been written up to now through the line deletion

operation, rewrite the ladder program.

■ Example 9: a program combined with an ON delay timer and a self-hold circuit

Start switch

On delay timer

Conveyor belt starts moving

Stop switch

Conveyor belt stops moving

① After the start switch R000 is ON

Wait 3 seconds (ON delay)

②

When the timer is ON, the output R500 of

③

KV-5000/3000 will be ON and self hold.

④ After the stop switch R001 is ON

The output R500 of KV-5000/3000 is OFF

⑤

After the program is entered,

please transfer the program and verify its operation.

- 23 -

Page 25

[Control Based Upon OFF Delay Timer]

Off Delay Timer

For example, let's try to analyze the operation of a conveyor belt.

Photoelectric switch ON

Conveyor belt starts moving

Photoelectric switch OFF

Timer OFF delay

Please write a ladder program and verify its operation.

After deleting the program that has been written up to now through the line deletion

operation, rewrite the ladder program.

■ Example 10: a program of an OFF delay timer

please transfer the program and verify its operation.

a timer that enables a signal in ON state to perform OFF delay.

① After the photoelectric switch detects a workpiece

② Output of the KV-5000/3000 is ON

The conveyor belt will continue to move for some

③

time even if the work-piece has passed the sensor

completely

④ 3 seconds after the detection signal is OFF

Stop moving

Output of the KV-5000/3000 is OFF

⑤

After the program is entered,

- 24 -

Page 26

[Control Based Upon a One-Shot Timer]

One-Shot Timer

For example, let's try to analyze the operation of a buzzer.

Push button ON

■ Example 11: a program of a one-shot timer

After the program is entered, please transfer the program and verify its

A timer that generates a signal that will be ON for a certain time.

① Operator sets the push button switch R000 to

After 1 second, the output will be OFF

Buzzer sounds

Single shot timer

Buzzer stops

ON state

② Output R500 of KV-5000/3000 turns ON

immediately

③ The buzzer will sound continuously for 1

second even if the switch is OFF

④

operation.

- 25 -

Page 27

[Summary of Control Based Timers]

Do you understand control based timers?

The program charts of timers used as control centers are summed up below, so

be sure to remember them. They can help reduce the time required to write

programs.

In addition, an operation timing sequence is listed on the right of the ladder for easy

understanding. Please verify the actual operation according to the timing sequence.

ON delay timer

When switch R000 is ON, light

R500 will be ON after 3 seconds.

Output R500 will not be ON within 3

seconds after input R000 is ON.

ON

R000

OFF

ON

R500

OFF

OFF delay timer

Single-shot

When input R000 is ON, output R500

will be ON.

After R000 is OFF, R500 will be

OFF after 3 seconds.

ON

R000

OFF

ON

R500

OFF

After R000 is ON, output R500 will

be ON, and will be OFF after 3

seconds.

ON

R000

OFF

ON

R500

OFF

3 s 0.5 s

3 s

3 s 3 s

- 26 -

Page 28

[Flexible Use of Counters]

The KV-5000/3000 PLCs can perform counting.

The device that is used to count during control is called a counter.

Let’s analyze the controls in which a counter is used.

Example

① Counting of production quantity

② Counting of the quantity of defective products

[Counters of the KV-5000/3000]

Counters play an important role in control. Of course, PLCs represented by the

KV-5000/3000 are also equipped with counters. It is possible to realize counting

control only with the KV-5000/3000.

The counting commands of the KV-5000/3000 are shown as follows.

Command Symbol Mnemonics Function

#dddd

Counter

XXX

C

nnnnn

#dddd

OUT Counter

XXX

OUTC

Counter number and settings

XXX : Number of the counter. PLCs represented by the KV-5000/3000 equipped with

many counters.

To distinguish between various counters, we add a number to each counter to

facilitate management.

The number of counters that can be used depends upon the PLC model.

KV-5000/3000 may use 4000 counts between C0-C3999.

ddddd : The value until the counter is ON (setting).

The setting range of this value of the KV-5000/3000 is #0-#4294967295.

nnnnn : The number of the contact used to perform counting input.

Specifies the input relay for which the value of connected switch is to be

counted.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

Whereas timer command is always decrement operation, counter

command is always increment operation.

The reason is that a counter needs to realize overflow counting (i.e., it

will continue to count even if the setting value is reached).

☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆

Up counter

※

Counts according to

nnnnn, and resets when

the execution condition

is OFF.

Up counter

※

Counts according to the

execution condition, and

resets through the RES

command.

- 27 -

Page 29

[Control of Counters]

Let’s write a control program that uses a counter.

For example, let's try to analyze the management of production quantity.

The finished products will be checked using a photoelectric sensor and will be counted

using a counter of the KV-5000/3000.

A light will light up when the number of products reaches 10, notifying the operator that

production is finished.

After verifying, the operator will press the push button switch to turn off the light, and

reset the counter of the KV-5000/3000 (return to 0).

■ Timing sequence

R000

(Count)

R001

(Reset)

Setting 10

C0

(Current value)

C0

(Contact)

R500

(Output)

KV-5000/3000

(Reset)

(Output)

- 28 -

Page 30

Please write a ladder program and verify its operation.

After deleting the program that has been written up to now through the line deletion

operation, rewrite the ladder program.

■ Example 12: a program of counter

The contact is ON, the counter will reset.

Setting value of

the counter

After the current value of

the counter changes to

10, contact C0 will be

ON.

Counting input

After the program is entered,

please transfer the program and verify its operation.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

Write input conditions through the B-contact before the counter

command.

(It is LDB_1 in the above ladder)

Since B-contact is used, the power of the counter will always be

ON. (When the input R0 is ON, counting will be performed all the

time)

When this contact is disconnected, the current value of the counter

will be reset (the power of the counter is turned off).

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

- 29 -

Page 31

The concepts of scan time and dual coil that are familiar to us will be described

here.

[Concept of scan time]

The KV-5000/3000 PLCs can complete operations of the entered program through

repeatedly performing a sequence of operation called "scan execution".

As shown below, scan execution is composed of three elements: input processing,

program execution processing and output processing, and the time required for "scan

execution" is called "scan time".

Input

processing

The ON/OFF state of the input will be loaded during input processing; during output

processing, the results of the program execution will be output collectively.

★☆★ The PLC with shorter scan time can write a program for a device that can

perform tasks faster ★☆★

Program execution processing

Scan time

Output

processing

[Concept of a dual coil]

Here, we describe the "dual coil" concept that has to be considered when writing a ladder

program.

The way in which the KV-5000/3000 executes a program is line by line from top to bottom

(from left to right).

PLC-specific rules apply for the steps of executing a program.

Please write a ladder program and verify its operation.

After deleting the program that has been written up to now through the line deletion

operation, rewrite the ladder program.

■ Example 13: a program of a dual coil

After the above ladder program is executed, the output R500 will not be ON even if the

contact R000 or R001 is ON. Only when R002 is ON, will R500 be ON.

After the program is entered,

please transfer the program and verify its operation.

Output R500 is used

many times.

- 30 -

Page 32

[Principle of a Dual Coil]

Here we describe the reason why execution of the verified program will cause the

operations shown in Example 13.

A ladder program will not output a result after each command execution.

★ Incorrect

・・・・①

・・・・②

・・・・③

・・・・④

R500:ON R500:ON R500:OFF

☆ Correct (refresh method)

R500:ON R500:ON R500:OFF

As described above, the PLC will not output a result after each

command execution, instead it will output total results at the end of

the scan time. Obviously, to easier for a PLC with shorter scan time

to realize high speed control.

① ②

output output output

①

② ③

③

output

④

- 31 -

Page 33

[Questions Summary]

Please consider the following issues after you have learned about circuits from this

tutorial.

Normal controls as shown below can be realized by combining the basic circuits

together.

■ Question

You are a responsible person for Production Technique in a food processing company.

In order to produce and sell new products for Christmas, it is necessary to rebuild the

production equipment.

Please try to write a program for realizing the following operation.

Example ①: Whether the produced chocolate products are good or defective needs

to be decided. After being detected by the decision sensor (R000), defective

products are to be pushed out using a 3-second push lever (R500).

Example ②:Good chocolate products are transferred on the conveyor belt.

After 12 products are detected by the sensor (R001), the buzzer (R501) will

sound for 5 seconds.

(The counter will be reset automatically after counting is finished.)

Example ③: 12 chocolates are put in one box.

The number of boxes is counted through a sensor (R002); the job

completion light will turn ON when 10 boxes are reached.

The job completion light will remain in an ON state, until operator A presses

the confirmation switch (R004).

- 32 -

Page 34

t

[Answers to Questions]

Example ①

☆ The key point is to use a single-shot timer.

Example ②

NG signal inpu

Push lever

☆ The key point is to perform a counter reset when the buzzer begins to sound

Reset signal

Counter

Self-hold circuit

Will be ON when setting of the counter is reached

It also seems possible to perform a counter reset through the buzzer

output R501; however, if the buzzer output R501 is used, the subsequent

workpieces cannot be counted, since the reset operation will be

performed all the time while the buzzer is sounding (5 seconds).

Therefore, the correct answer is that you should perform counter reset

through the signal that is output when the counter reaches its setting

value (C0).

3-second timer

5-second timer

Push lever

3-second timer

Setting

Sensor input

Counter

Self-hold circuit

5-second timer

- 33 -

Page 35

Example ③

☆ The key point is to build a self-hold circuit through the signal of the counter.

Counter

Job completion

indicator light

Self-hold circuit

Will be ON when setting of Self-hold circuit reset

the counter is reached

Counter reset is done still by the signal of C1.

When composing a self-hold circuit, don't forget the reset signal!

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

The commands that have the same functions as in the self-hold circuit

include KEEP and SET/RES commands, etc.

Please verify using the following reference ladder diagrams.

Please refer to Chapter 2 "Basic Commands" in the

KV-5000/3000/1000 Command Manual.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

※SET/RES command ※KEEP command

Setting

Sensor input

- 34 -

Page 36

[Convenient Commands]

In order to make composing ladder diagrams easier, the KV-5000/3000 Series

PLCs are equipped with many convenient commands. Here we will describe

some of the commands.

Be sure to use them flexibly in subsequent programming.

The circuits described in this tutorial are frequently used circuits when building any control

schemes.

The KV-5000/3000 PLCs have added the most frequently used common circuits that

can be used for the ON delay or OFF delay ladder programs as new commands.

A circuit with multiple lines is changed into one command through new commands

(convenient commands), which reduces the time required for programming and

realizes efficient program operation.

Example ① The ON delay timer circuit

The ON delay timer circuit we discussed on the last page is shown as follows.

The two-line program can be realized using one line in a convenient command.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

A convenient command also has advantages/disadvantages.

The advantages are: the program is simplified, time for

programming is reduced, and scan time is shorter. In addition, it

can be used without limit, since no timer number is required.

The disadvantages are: the timer unit is only 0.01 s, and the current value

cannot be displayed during monitoring, etc. (The normal timer can monitor

the decrement state.)

Please use normal commands and convenient commands flexibly

according to different conditions.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

NOTE The unit of the timer is 0.01s.

Therefore, a setting value of 3 s should be

entered by #300.

- 35 -

Page 37

Example ② The OFF delay timer circuit

The ON delay timer circuit we discussed on last page is shown below.

The two-line program can be realized through one line in a convenient command.

The following convenient commands are included in the KV-5000/3000.

・ SET command ・ RESET command

・ ON delay command ・ OFF delay command

・ Blinking command

・ Single-shot command ・ Alternating command

★ Be sure to try to using them in the program and verify their operation!

- 36 -

Page 38

[Simulator Function]

Until now, switches and other devices have been used to verify operation after a

program is transferred to the KV-5000/3000 unit. However, when configuring a

device, the PLC unit is often connected to the device. Even if you want to

perform a program test (debugging), sometimes it is not possible to verify before

the device installation is finished.

In order to avoid this kind of debugging problem, the KV-5000/3000 is equipped with a

"simulator function" in the ladder support software "KV STUDIO", through which it is

possible to debug a program without transferring the ladder program to the unit.

Here, we will describe how to use the simulator.

■ The method used until now

■ The simulator function of the KV STUDIO

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

The following page will describe how to start the simulator.

After confirmation, please practice the programs you have learned

until now (self-hold or timer/counter) by using the simulator.

In addition to having the simple timer/counter function, this simulator

function is very useful for operation programs used in the future.

Be sure to understand it.

★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★☆★

The ladder diagram is

transferred to the PLC,

and operations of the

program are verified.

It is possible to verify

operation of the program by

only using a PC.

- 37 -

Page 39

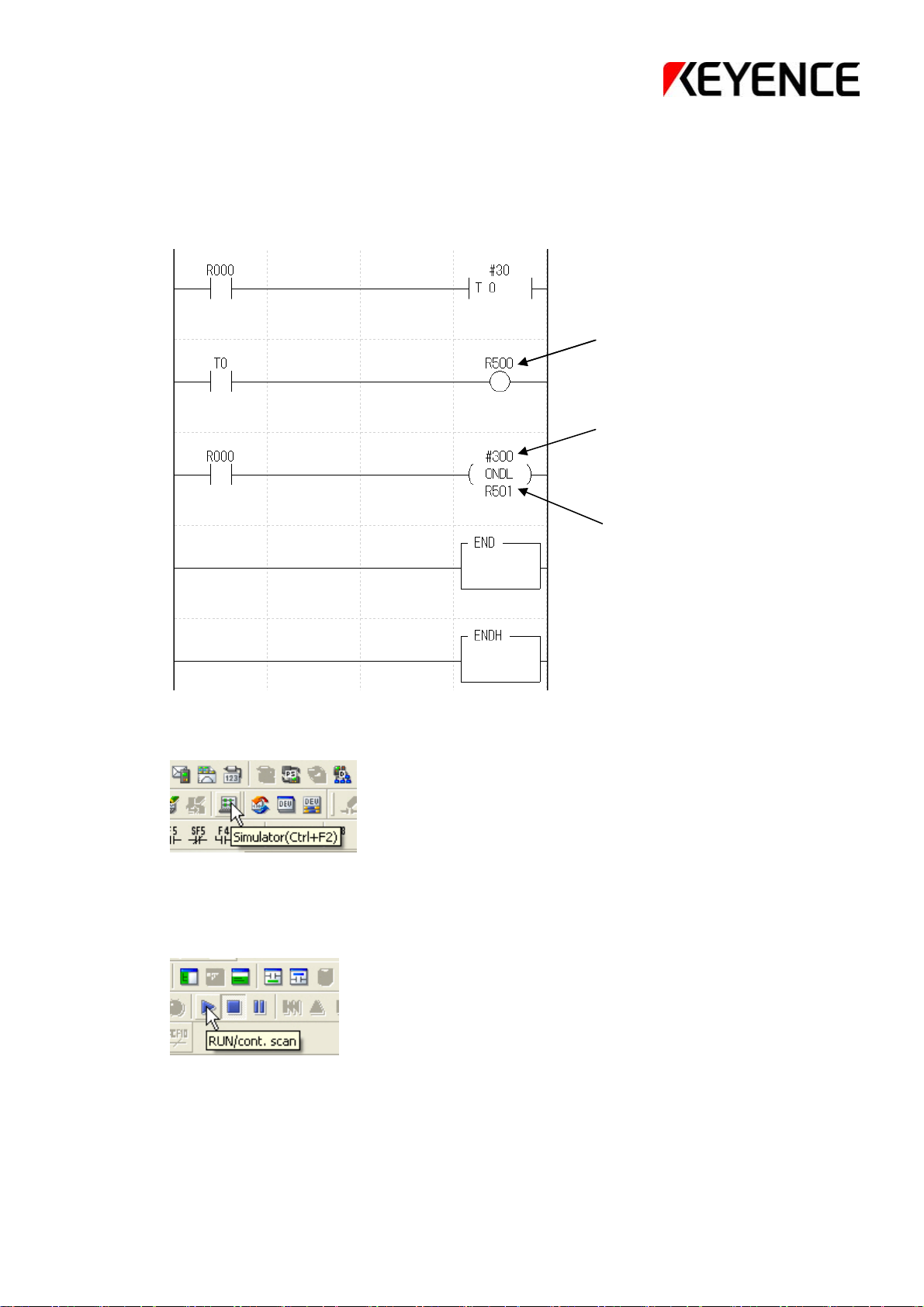

① First, write the program as shown below.

This is the program written by using the ON delay timer through a common method,

in which convenient commands are used.

After the input R000 is ON, it is possible to verify that the normal command and the

convenient command have set output R500 and R501 to ON simultaneously.

Output R500

Pay attention to the unit!

Output R501

② Click the "Simulator" icon to run the simulator.

③ Change to the simulator screen, and click the "Execute continuous scan" icon.

The ladder program will run on the PC.

- 38 -

Page 40

④ On the simulator screen, double click a contact on the ladder program to switch

the input ON/OFF。

Try to double click the input R000. The input will be ON, and the timer will

begin to operate.

Double click the cell

for the contact R000

⑤ After 3 seconds, both inputs will be ON.

⑥ On the simulator screen, double click

the contact on the ladder program again.

The input R000 will turn OFF, and the timer will reset.

- 39 -

Page 41

MEMO

- 40 -

Page 42

[End]

Were you able to understand and grasp the content in this tutorial?

If you have any questions about the content in this tutorial, please contact our

company's business office.

The personnel of each business office are ready to help you.

You are also welcome to purchase any of our products in the future.

※All of the content in this tutorial is copyrighted.

Reprinting or reproduction is not allowed without permission.

Model ※ number, specifications, and other information are subject to change without notice

- 41 -

1094-1 600F63

Loading...

Loading...