Page 1

User's Manual

Visual KV Series

1

Installation

96M0364

How this manual is organized:

The Visual KV Series User’s Manual is composed of 3 separate

manuals; 1-Installation, 2-Support Software, 3-Programming.

Please read each manual relevant to your purpose.

Page 2

Safety Precautions

This instruction manual describes the operation and function of the KV Series PLC.

Read this manual carefully to ensure safe use and maximum performance from your

KV Series PLC.

Symbols

The following symbols alert you to important messages. Be sure to read these

messages carefully.

Note:

Conventions

This manual describes the operation/function of all Keyence KV Series PLC.

Note following conventions when you use.

Visual KV (Series) KV-10AR/AT/DR/DT KV-16AR/AT/DR/DT

KV-10xx, 16xx, 24xx, 40xx KV-24AR/AT/DR/DT KV-40AR/AT/DR/DT

Conventional KV (Series) KV-10R(W)/T(W) KV-16R(W)/T(W)

KV-300 (Series) KV-24R(W)/T(W) KV-40R(W)/T(W)

KV-10/80 (Series) KV-80R(W)/T(W)

General Precautions

• At startup and during operation, be sure to monitor the functions and performance of the KV Sereis PLC.

WARNING

CAUTION

Failure to follow instructions may lead to injury. (electric

shock, burn, etc.)

Failure to follow instructions may lead to product damage.

Provides additional information on proper operation.

KV-300

• We recommend that you take substantial safety measures to avoid any damage

in the event a problem occurs.

• Do not open or modify the KV Series PLC or use it in any way other than described in the specifications.

• When the KV Series PLC is used in combination with other instruments, functions and performance may be degraded, depending on operating conditions and

the surrounding environment.

• Do not use the KV Series PLC for the purpose of protecting the human body.

Note: The built-in display may show the error message "Error 40" blinking the very

first time you turn on the power supply to the Visual KV Series. Press any key

around the display to cancel this message.

The Visual KV Series shows this message when no program is loaded.

(1)

Page 3

Note to User

When using the Visual KV Series in the following conditions or environments, be

sure to use the Visual KV Series with sufficient margin regarding the rating and

functions, take appropriate safety precautions such as fail-safe, and contact our

sales personnel if any questions arise.

• Use in conditions or environments not described in this manual

• Use for nuclear power control, railway facilities, air service facilities, vehicles,

combustion devices, medical equipment, amusement machines, safety equipment, etc.

• Use for applications where large effects are predicted to be given on human lives

and properties and safety is especially requested.

Restriction on Acquiring the CE Marking

■ Restriction to be compatible with EMC directives

• When using a relay output type unit (whose model name ends with "R"), connect

spark killers having the appropriate withstand voltage against the load to the

output terminals in parallel to contacts (because the unit discharges when a relay

contact becomes open and noise is generated). In our experiments, we use the

following models of spark killers.

XEB0101 0.1 µF-10 Ω manufactured by OKAYA DENKI SANGYO

The following 1-turn ferrite core is added to the AC power input circuit of the KV-

40AR/T, the KV-24AR/T and to the DC power input circuit of the KV-40DR/T.

ZCAT3035-1330 manufactured by TDK

Note: The contents above do not by themselves ensure that the entire machine

manufactured in accordance with the above contents is compatible with EMC

directives.

You must judge by yourself whether or not the entire machine is compatible with

EMC directives because compatibility may change depending on the component

configuration, wiring and location inside of the machine.

■ Restriction on compatibility with low-voltage directives (IEC-1010-1)

• Use insulated type crimp-style terminals.

• For wiring materials, use lead wires whose sheath is 0.4 mm or more.

• The Visual KV Series is allowed to be installed in a vertical position only.

(Spacers for expansion units are not available.)

• Be sure to use the Visual KV Series inside the control panel.

(2)

Page 4

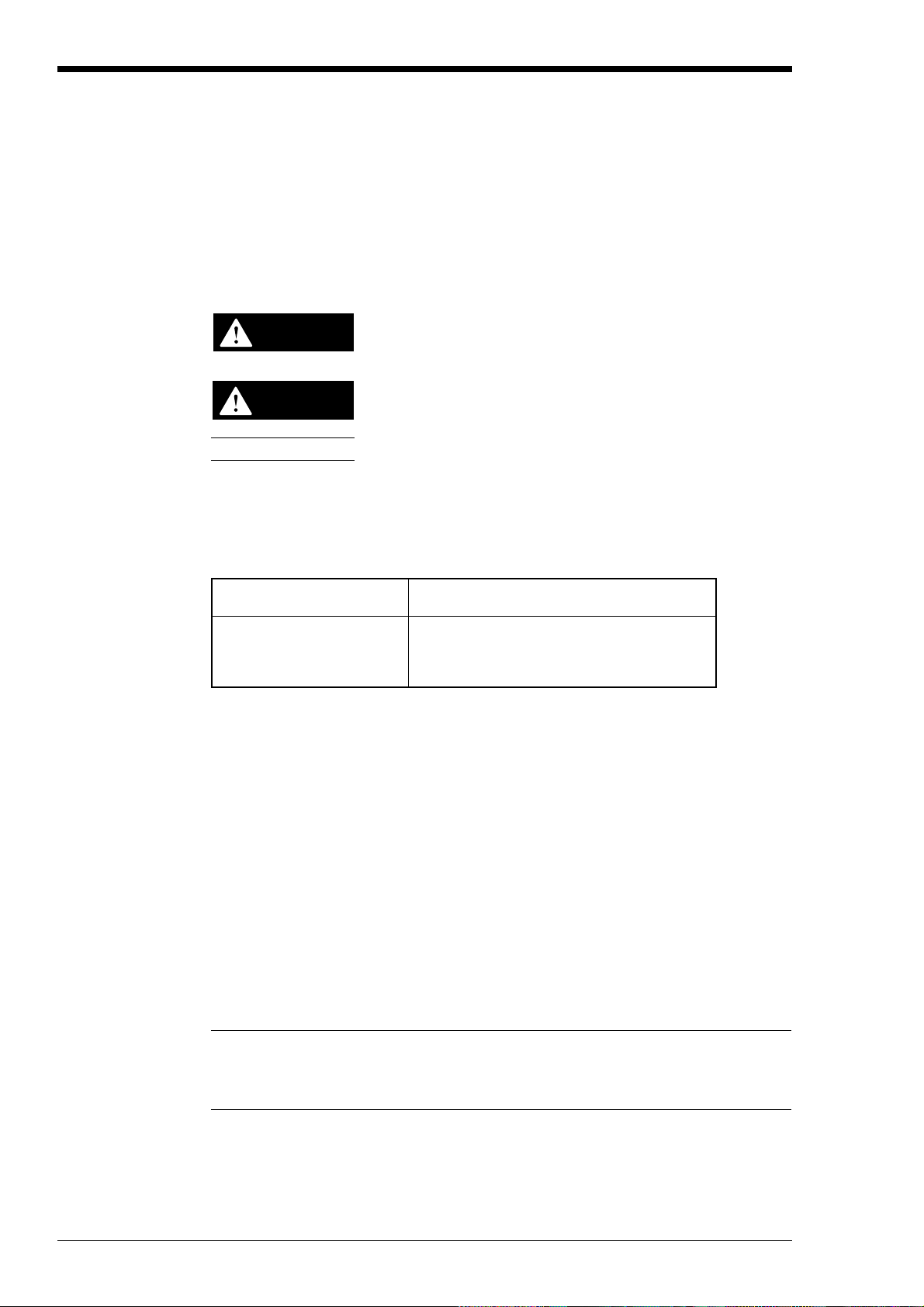

Features of the Visual KV Series

● Extremely small

The Visual KV Series is the smallest in the world among AC type PLCs equipped

with screw terminal blocks, and saves installation space.

● Extremely fast

The minimum scan time is 140 µs and minimum instruction execution time is 0.7

µs, which is the fastest control in its class.

● AC power built-in type newly added

AC power built-in type units are newly added. This type can be used in small

spaces where a switching power supply unit cannot be installed.

● Excellent Access Window

An Access Window with two-color backlight is adopted in all models to facilitate

changing and monitoring of device data. Changing between RUN mode and

PROGRAM mode, checking the error code when an error has occurred, etc. can

be performed in a Visual KV Series unit without the need for any handheld

programmer.

The analog trimmer, which has been popular in the conventional KV Series, is

digitized to enable more detail settings. [Digital trimmers]

● User message setting function

In the Access Window, 256 different user messages can be displayed. This

function can be used to give instructions on works on the production line, indicate

abnormalities in the units, etc.

● Program write in RUN mode

Ladder programs can be changed even while the system is running.

● Equipped with two serial ports

Visual KV Series basic units are equipped with two serial ports to connect peripheral units, improving the debug environment.

(The KV-10xx is equipped with only one serial port.)

● Easy Ramp-up/down control function

The one-axis motor control function is offered separately from high-speed

counters so that feedback control is enabled.

● Equipped with two 24-bit high-speed 30 kHz, two-phase counters

The Visual KV Series is equipped with two high-speed counters each with a twopoint comparator output function that enables high-speed encoder input.

● Specified frequency pulse output function

High-speed counters can function as pulse oscillators of 50 kHz maximum with

easy setting, without creating a complicated ladder program.

● Frequency counter function

High-speed counters can function as frequency counters with easy setting,

without creating complicated ladder programs.

(3)

● Cam switch function

High-speed counters can function as cam switches with easy setting, without

creating complicated ladder programs.

Page 5

● Interrupt function

The Visual KV Series is equipped with four high-speed interrupt inputs of

10 µs maximum.

● Input time constant change function

The time constant can be set in 7 steps from 10 µs to 10 ms.

● Double memory backup functions

In addition to a conventional SRAM battery backup function, the Visual KV Series

is also equipped with an EEPROM backup function.

Compatibility with Conventional KV Series Peripheral Units

The Visual KV Series functions as a high-end compatible model of the conventional

KV Series. Peripheral units of the conventional KV Series such as the ladder support

software "KV IncrediWare (DOS)" and "LADDER BUILDER for KV" and the

handheld programmer KV-P3E(01) can be used since they are part of the Visual KV

Series.

However, it should be noted that the contents have changed as follows.

• The internal clock cycle of high-speed counters consists of three types: 1 µs, 10

µs, and 100 µs.

• The time constant for an input relay specified by the HSP instruction is 10 µs.

• The analog trimmer function is set with the Access Window built into the basic

unit.

• The available device setting range of the TMIN instruction is from 0 to 65535.

[Handheld programmer KV-P3E(01) can display 0 to 9999 .]

• The RUN/PROGRAM LED is displayed in the Access Window provided on the

front face of the basic unit.

• Transistor output is not independent, but is common.

• With the transistor type, the output terminal layout is different.

• The specifications for output current of transistor outputs Nos. 500 to 502 is 100

mA.

• Conventional KV Series expansion units are not available as expansion units for

the Visual KV Series.

• The channel setting switch is not provided for expansion units. Channels are

determined in connection order.

• Scans in expansion I/O units are not synchronous with the scan time in Visual KV

Series basic units.

• Assignment of special utility relays has partially changed.

• Data memory device Nos. DM1000 to DM1999 are assigned as special data

memories.

(4)

Page 6

Cautions when using the previous version of ladder support software

Pay strict attention to the following items when using the ladder support software.

• When using the ladder support software "KV IncrediWare (DOS)" or "LADDER

BUILDER for KV Ver. 1.0x", set the model to "KV-300".

• DM0 to DM1999 are only available.

CAUTION

When the ladder support software "LADDER BUILDER for KV Ver. 1.0x" is

used, do not use the monitor’s Change All function. If the Change All function

is used, the basic unit may be damaged. Never use the Change All function.

Peripheral units and other units incompatible with the Visual KV Series

Peripheral units in the conventional KV Series and other units shown below are not

compatible with the Visual KV Series.

• Expansion I/O units for the conventional KV Series: KV-8ER/8ET/8EX/16EX/

8EYR/8EYT/16EYR/16EYT

• Analog I/O units for the conventional KV Series: KV-AD4/DA4

Cautions when Using the Serial Port

The KV-16xx/24xx/40xx units are equipped with two RJ-11 modular connectors for

serial communication.

When using them, pay strict attention to the following contents:

• Programs can be transferred and monitored using either communication port A or

B. However, never connect the ladder software and a handheld programmer to

the two ports at the same time.

• The KV-D20 operator interface panel can be connected to either communication

port A or B. However, only one KV-D20 unit can be connected to a single basic

unit.

• Never leave both the KV-D20 operator interface panel and KV-P3E(01) handheld

programmer on simultaneously for a long period of time.

(5)

Page 7

(6)

Page 8

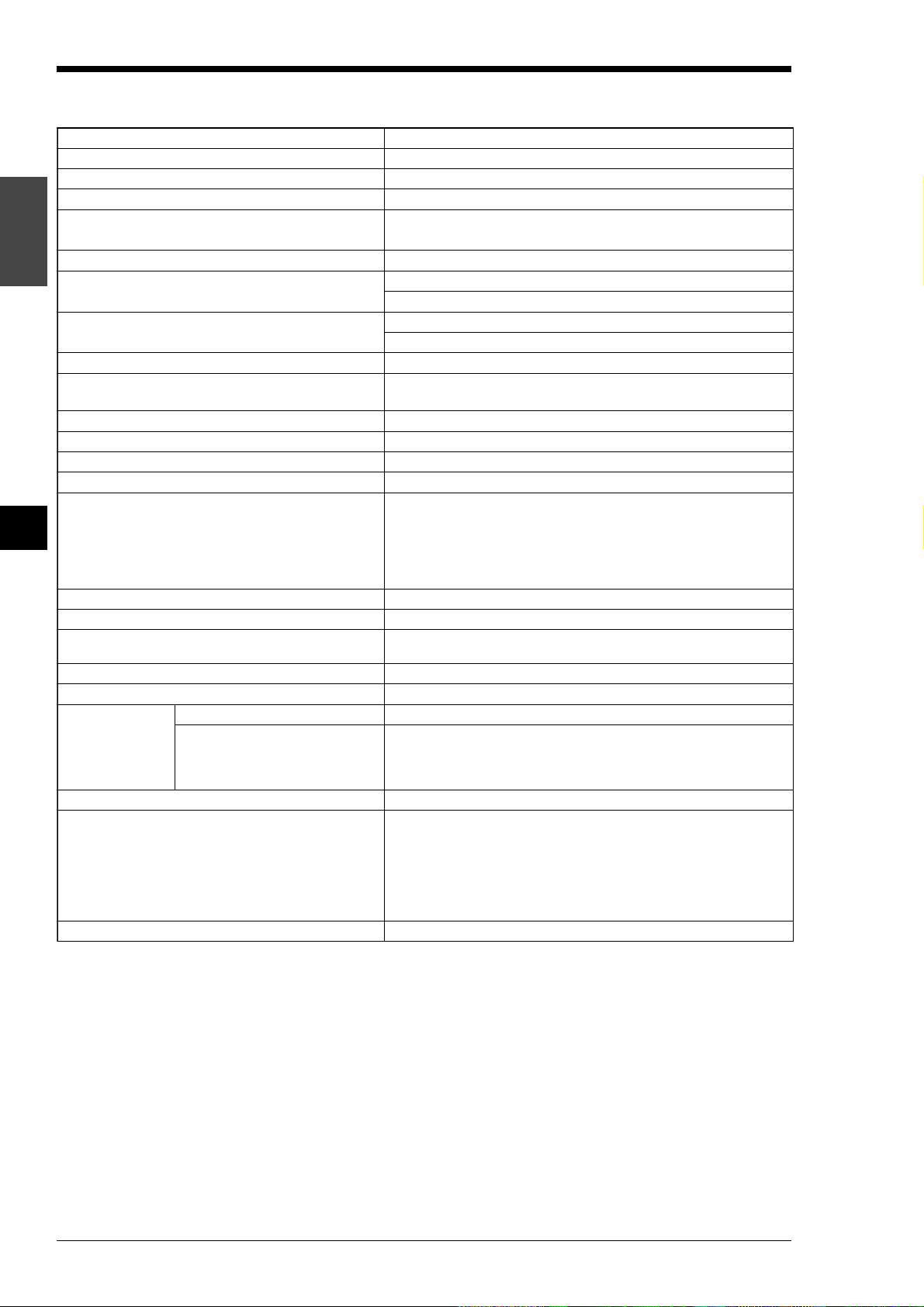

How this manual is organized

The Visual KV Series User’s Manual is composed of 3 separate manuals;

1-Installation, 2-Support Software, 3-Programming. Please read each manual

relevant to your purpose.

1

Installation

Chapter 1 Configuration and Specifications [Visual KV Series Only]

Describes the system configuration of the Visual KV Series, the names and functions of

each part, and the specifications.

Chapter 2 System Installation [Visual KV Series Only]

Describes the installation and connection of each Visual KV Series unit as well as

system maintenance.

Chapter 3 Access Window [Visual KV Series Only]

Describes the Access Window used for changing and monitoring data.

Chapter 4 KV-D20 Operator Interface Panel [Visual KV Series Only]

Describes the KV-D20 Operator Interface Panel used for changing, monitoring, and

displaying the status of inside relays, timers, counters and data memories.

Chapter 5 KV-300, KV-10/80 Hardware [KV-300, KV-10/80 Series Only]

Describes the hardware specifications and wirings for KV-300 and KV-10/80 Series.

Chapter 6 Handheld Programmer

Describes how to use the handheld programmer and memory card.

Chapter 7 KV-L2 Serial Interface Module [KV-300 Series Only]

Describes the serial interface modules for KV-300 Series.

Chapter 8 KV-AN6 Analog I/O Module [KV-300 Series Only]

Describes the optional Analog I/O module for KV-300 Series

Chapter 9 KV-AD4/DA4 Analog I/O Unit [KV-10/80 Series Only]

Describes the optional Analog I/O unit for KV-10/80 Series.

Chapter 10 Troubleshooting

This chapter describes the error code list, countermeasures against problems, and error

indications for each unit.

2

Support Software

Chapter 1 Introduction

(7)

Appendices

The appendix includes a list of ladder program applications and the index.

Describes the items included in the package, the product outline, the method to connect

a personal computer, the installation method, etc.

Page 9

Chapter 2 Editor

Chapter 3 Simulator

Chapter 4 Monitor

3

Programming

Chapter 1 Programming

Chapter 2 Instructions

Describes the operating procedures in Editor mode.

Describes the operating procedures in Simulator mode.

Describes the operating procedures in Monitor mode.

Appendices

Includes instructions list, devices list, sample program list and quick reference for key

operation and shortcuts.

Describes basic knowledge including program creation procedures, device configuration,

relay assignments, special functions to set and confirm Visual KV Series operations, as

well as the extended ladder diagrams. Understand the contents described here completely at first before creating programs.

Describes the concrete usage of instructions in the KV Series.

Refer to "Chapter 3 Interrupts" on page 3-183 for details of interrupt instructions.

Refer to "Chapter 4 High-speed counters" on page 3-195 for details of the high-speed

counters used in the application instruction.

Chapter 3 Interrupts [Visual KV Series Only]

The interrupt processing function executes an interrupt program when an external input

or request from the high-speed counter comparator (interrupt factor) is encountered

during KV operation.

This chapter describes the types of interrupt factors as well as inputs and outputs

encountered during interrupt processing.

Chapter 4 High-speed Counters [Visual KV Series Only]

Describes high-speed counters and high-speed counter comparators, which allow highspeed pulse measurement and pulse output, independent of the scan time.

Chapter 5 Positioning Control [Visual KV Series Only]

Describes ramp-up/down control of stepping motors and servo motors.

Chapter 6

Interrupts, High-speed Counters, Positioning Control [KV-300, KV-10/80 Series Only]

Describes ramp-up/down control of stepping motors and servo motors.

Chapter 7 Serial Communication

The KV Series can be connected to an external device with an RS-232C interface to

establish communication.

This chapter describes communications specifications, how to connect the KV Series to

external devices, and how to perform communication.

Chapter 8 Programming Examples

Describes the typical programming examples for KV-10/80 Series. These programs can

be used for Visual KV Series. However, pay attention to the I/O addressing compatibility

before use.

(8)

Page 10

Contents

1

Installation

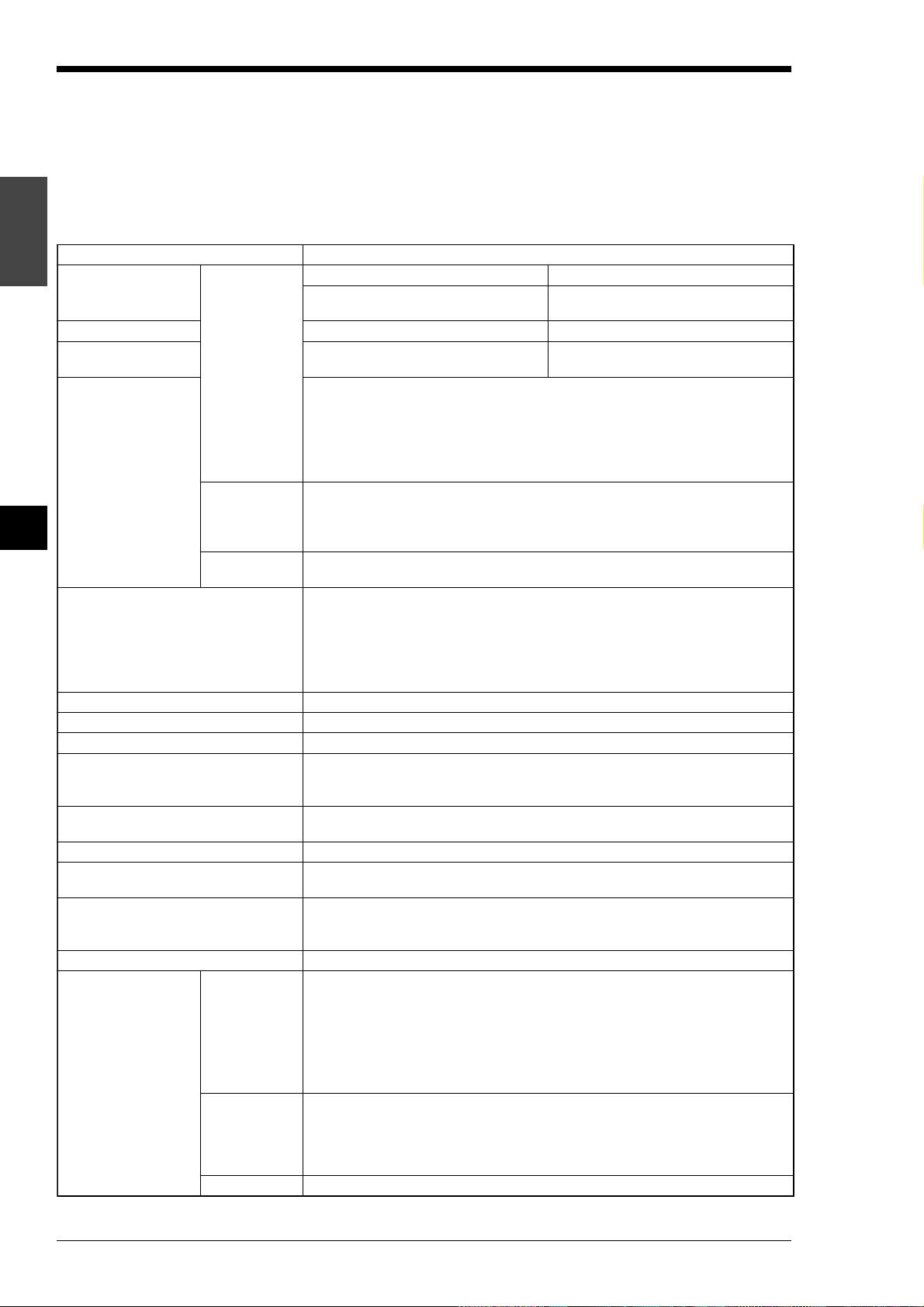

Chapter 1 Configuration and Specifications Visual KV

1.1 System Configuration ......................................................................................1-2

1.1.1 System Configuration .........................................................................................1-2

1.2 Specifications ...................................................................................................1-4

1.2.1 General Specifications........................................................................................1-4

1.2.2 AC Power Specifications ....................................................................................1-5

Visual KV Series operation at power interruption ........................................1-5

1.2.3 Performance Specifications ................................................................................1-6

Data backup function against instantaneous power interruption .................1-7

1.3 Common I/O Specifications of Basic Units ...................................................1-8

1.3.1 Model of a Basic Unit..........................................................................................1-8

1.3.2 Common I/O Specifications ................................................................................1-8

1.4 KV-10AR/AT(P)/DR/DT(P) (10-I/O Basic Unit) .............................................1-10

1.4.1 Part Names and Functions ...............................................................................1-10

1.4.2 Terminal Layout Drawings and I/O Circuit Diagrams........................................1-11

KV-10AR/DR (Relay output type) ..............................................................1-11

KV-10AT(P)/DT(P) (Transistor output type)...............................................1-13

1.4.3 AC Power Input (KV-10AR/AT(P))....................................................................1-14

Relationship between Continuous Simultaneous ON Ratio and Ambient Temperature

1.4.4

1.4.5 Dimensions .......................................................................................................1-16

1.5 KV-16AR/AT(P)/DR/DT(P) (16-I/O Basic Unit) .............................................1-17

1.5.1 Part Names and Functions ...............................................................................1-17

1.5.2 Terminal Layout Drawings and I/O Circuit Diagrams........................................1-18

KV-16AR/DR (Relay output type) ..............................................................1-18

KV-16AT(P)/DT(P) (Transistor output type)...............................................1-20

1.5.3 AC Power Input (KV-16AR/AT(P))....................................................................1-21

Relationship between Continuous Simultaneous ON Ratio and Ambient Temperature

1.5.4

1.5.5 Dimensions .......................................................................................................1-23

1.6 KV-24AR/AT(P)/DR/DT(P) (24-I/O Basic Unit) .............................................1-24

1.6.1 Part Names and Functions ...............................................................................1-24

1.6.2 Terminal Layout Drawings and I/O Circuit Diagrams........................................1-25

KV-24AR/DR (Relay output type) ..............................................................1-25

KV-24AT(P)/DT(P) (Transistor output type)...............................................1-27

1.6.3 AC Power Input (KV-24AR/AT(P))....................................................................1-28

1.6.4

Relationship between Continuous Simultaneous ON Ratio and Ambient Temperature

1.6.5 Dimensions .......................................................................................................1-30

1.7 KV-40AR/AT(P)/DR/DT(P) (40-I/O Basic Unit) ..............................................1-31

1.7.1 Part Names and Functions ...............................................................................1-31

1.7.2 Terminal Layout Drawings and I/O Circuit Diagrams........................................1-32

KV-40AR/DR (Relay output type) ..............................................................1-32

KV-40AT(P)/DT(P) (Transistor output type)...............................................1-34

1.7.3 AC Power Input (KV-40AR/AT(P))....................................................................1-35

Relationship between Continuous Simultaneous ON Ratio and Ambient Temperature

1.7.4

1.7.5 Dimensions .......................................................................................................1-37

1.8 KV-E4X/E8X/E16X (Expansion Input Unit) ..................................................1-38

1.8.1 Part Names and Functions ...............................................................................1-38

1.8.2 Input Specifications...........................................................................................1-38

1.8.3 Terminal Layout Drawings and Input Circuit Diagrams ....................................1-39

KV-E4X (4-I/O expansion input unit)..........................................................1-39

KV-E8X (8-I/O expansion input unit)..........................................................1-40

KV-E16X (16-I/O expansion input unit)......................................................1-41

1.8.4 Dimensions .......................................................................................................1-42

1.9 KV-E4R/E4T/E8R/E8T(P)/E16R/E16T(P) (Expansion Output Unit) .............1-43

1.9.1 Part Names and Functions ...............................................................................1-43

1.9.2 Output Specifications........................................................................................1-43

KV-E4R/E8R/E16R (Relay output type).....................................................1-44

KV-E4T/E8T(P)/E16T(P) [Transistor output type (NPN/PNP)] ..................1-44

1.9.3 Terminal Layout Drawings and Input Circuit Diagrams ....................................1-45

KV-E4R [4-I/O expansion output unit (relay output type)]..........................1-45

1-15

1-22

1-29

1-36

(9)

Page 11

KV-E4T [4-I/O expansion output unit transistor output type)] ....................1-46

KV-E8R [8-I/O expansion output unit (relay output type)]..........................1-47

KV-E8T(P) [8-I/O expansion output unit (transistor output type)] ..............1-48

KV-E16R [16-I/O expansion output unit (relay output type)]......................1-49

KV-E16T(P) [16-I/O expansion input unit (transistor output)] ....................1-50

1.9.4 Dimensions .......................................................................................................1-51

1.10 KV-E4XR/E4XT(P) (Expansion I/O Unit) .......................................................1-52

1.10.1 Part Names and Functions ...............................................................................1-52

1.10.2 Input Specifications...........................................................................................1-53

1.10.3 Output Specifications........................................................................................1-53

KV-E4XR (Relay output type) ....................................................................1-53

KV-E4XT(P) (Transistor output type) .........................................................1-53

1.10.4 Terminal Layout Drawings and Input Circuit Diagrams ....................................1-54

KV-E4XR (Relay output type) ....................................................................1-54

KV-E4XT(P) (Transistor output type) .........................................................1-56

1.10.5 Dimensions .......................................................................................................1-58

1.11 KV-D20 (Operator Interface Panel) ...............................................................1-59

1.11.1 Part Names and Functions ...............................................................................1-59

1.11.2 General Specifications ......................................................................................1-60

1.11.3 Functional Specifications ..................................................................................1-60

1.11.4 Dimensions .......................................................................................................1-61

Chapter 2 System Installation Visual KV

2.1 Installation Environment ...............................................................................1-64

2.1.1 Installation Environment ...................................................................................1-64

2.1.2 Installation Position...........................................................................................1-65

2.1.3 Installation Procedure .......................................................................................1-66

Expansion unit spacer................................................................................1-66

2.1.4 Cautions on Wiring for Each Unit......................................................................1-67

Wiring procedures for basic units...............................................................1-67

Cautions on wiring for I/O units..................................................................1-68

Terminal .....................................................................................................1-68

Cautions on grounding...............................................................................1-69

2.1.5 Contact Protection ............................................................................................1-69

2.2 Connecting Visual KV Series Expansion Units ..........................................1-70

2.2.1 Visual KV Series Expansion Units ....................................................................1-70

2.2.2 Connecting Visual KV Series Expansion Units.................................................1-71

Connection methods ..................................................................................1-72

Number of connectable units .....................................................................1-73

2.2.3 Confirming the Connection Settings of Expansion Units ..................................1-74

Expansion unit relay list .............................................................................1-74

Connection information for expansion units...............................................1-75

Input time constant for expansion units .....................................................1-76

Clearing the input value when disconnecting.............................................1-76

2.2.4 Transferring I/O Information between Expansion Units and the Basic Unit......1-77

When inputting ...........................................................................................1-77

In the case of output ..................................................................................1-77

2.3 Inspection and Maintenance .........................................................................1-78

2.3.1 Inspection .........................................................................................................1-78

2.3.2 Maintenance .....................................................................................................1-78

Chapter 3 Access Window Visual KV

3.1 Overview of the Access Window ..................................................................1-80

3.1.1 What is the Access Window .............................................................................1-80

3.1.2 Access Window Use Examples ........................................................................1-80

3.2 Basic Operating Procedures .........................................................................1-81

3.2.1 Operation Mode ................................................................................................1-81

3.2.2 Access Window Modes.....................................................................................1-81

3.2.3 Part Names and Functions of the Access Window...........................................1-82

3.2.4 Selecting Modes and Setting/Resetting Key Lock ............................................1-82

3.2.5 Turbo Function..................................................................................................1-83

3.3 Digital Trimmer Mode ....................................................................................1-84

3.3.1 Function and Operating Procedure...................................................................1-84

(10)

Page 12

Key operation and screen display..............................................................1-84

Function and operating procedure .............................................................1-84

3.4 Device Mode ...................................................................................................1-87

3.4.1 Function and Operating Procedure...................................................................1-87

Devices that can be displayed and changed .............................................1-87

Key operation and screen display..............................................................1-87

Selecting the device and displaying the current value/set value................1-88

Changing a numeric value .........................................................................1-89

Holding the setting .....................................................................................1-91

3.4.2 Screen Display for Each Device Type ..............................................................1-91

Data memory (DM) ....................................................................................1-91

Temporary data memory (TM) ...................................................................1-91

Timer/counter (T/C)....................................................................................1-92

High-speed counter comparator (CTC)......................................................1-92

Trimmer (TRM) ..........................................................................................1-93

Relay (RLY) ...............................................................................................1-93

3.5 System Mode ..................................................................................................1-94

3.5.1 Function and Operating Procedure...................................................................1-94

Key operation and screen display..............................................................1-94

LOAD mode and SAVE mode....................................................................1-96

Display in LOAD/SAVE mode ....................................................................1-96

3.6 Message Display ............................................................................................1-97

3.6.1 Error Messages and Error Status .....................................................................1-97

3.6.2 User Messages.................................................................................................1-97

How to use the user messages..................................................................1-98

Chapter 4 KV-D20 Operator Interface Panel Visual KV

4.1 Before Operation ..........................................................................................1-100

4.1.1 Checking Package Contents ..........................................................................1-100

4.1.2 Part Names and Functions .............................................................................1-101

4.1.3 Details about the KV-D20 ...............................................................................1-102

General specifications..............................................................................1-102

Functional specifications..........................................................................1-102

Dimensions ..............................................................................................1-103

4.1.4 Installation and Environment ..........................................................................1-104

Use environment......................................................................................1-104

Panel mounting ........................................................................................1-105

4.1.5 Inspection and Maintenance...........................................................................1-106

Inspection.................................................................................................1-106

Maintenance ............................................................................................1-106

4.2 Overview and Operation ..............................................................................1-107

4.2.1 Use Examples for the KV-D20........................................................................1-107

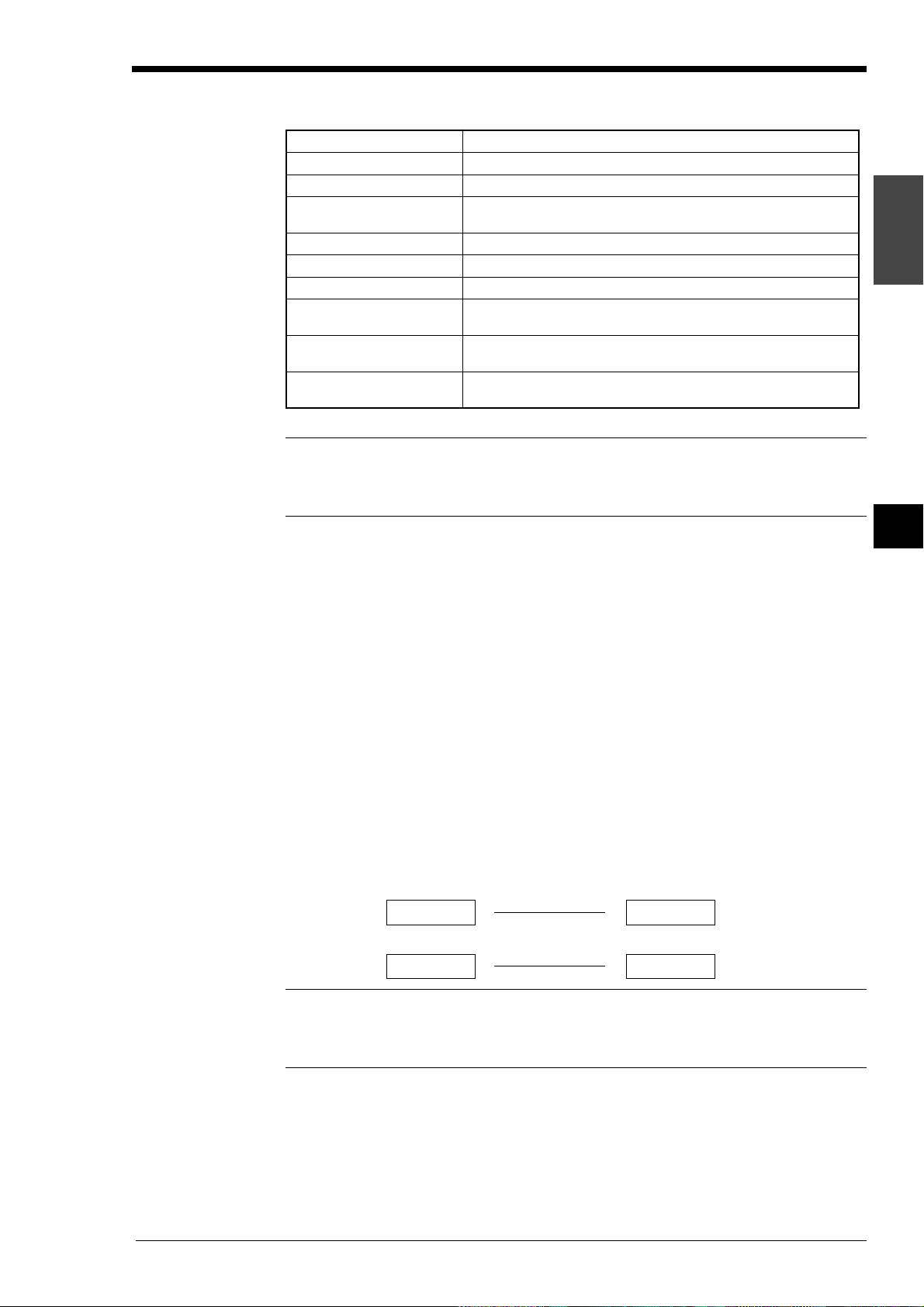

4.2.2 Connection with the KV Series .......................................................................1-108

Connection...............................................................................................1-108

Precautions ..............................................................................................1-108

4.2.3 Overview of the KV-D20 .................................................................................1-109

Switching the display mode .....................................................................1-109

Overview of each display mode ...............................................................1-110

Assignment of relays/DM .........................................................................1-111

Other functions.........................................................................................1-112

Precautions about screen change function..............................................1-115

4.2.4 Operator Mode................................................................................................1-117

Screen selection in operator mode ..........................................................1-117

Operator screen .......................................................................................1-118

Direct access screen................................................................................1-126

KV-I/O monitor screen .............................................................................1-127

Switch comment screen...........................................................................1-128

Lamp comment screen ............................................................................1-128

Screen change permission in operator mode ..........................................1-129

4.2.5 Device Mode...................................................................................................1-130

Device mode ............................................................................................1-130

Operation example for device mode ........................................................1-132

4.2.6 System Mode..................................................................................................1-134

System mode ...........................................................................................1-134

4.3 Examples of Ladder Programs ...................................................................1-135

(11)

Page 13

4.3.1 Basic Ladder Programs ..................................................................................1-135

Before creating ladder programs .............................................................1-135

Basic ladder programs .............................................................................1-136

4.3.2 Examples of Ladder Programs .......................................................................1-143

Example of displaying user messages.....................................................1-143

Example of displaying messages with titles.............................................1-145

Example of position control......................................................................1-146

Example of frequency counter .................................................................1-149

Example of 24-bit high-speed counter .....................................................1-152

Example of cam switch function...............................................................1-154

4.4 Appendix .......................................................................................................1-158

4.4.1 Troubleshooting ..............................................................................................1-158

4.4.2 Available Character List..................................................................................1-162

4.4.3 Comment Draft Sheet .....................................................................................1-163

Chapter 5 KV-300, KV-10/80 Hardware KV-300, KV-10/80

5.1 System Configuration ..................................................................................1-166

5.1.1 KV-300............................................................................................................1-166

5.1.2 KV-10/80.........................................................................................................1-167

5.2 Module/Unit Specifications .........................................................................1-168

5.2.1 Wiring: KV-U4 Power Supply Module .............................................................1-168

Parts and functions ..................................................................................1-168

5.2.2 Wiring: KV-U5 DC Power Distribution Module................................................1-169

Parts and functions ..................................................................................1-169

5.2.3 Wiring: KV-300 CPU .......................................................................................1-170

Parts and functions ..................................................................................1-170

5.2.4 Wiring: KV-C16X/C32X Connector Input Module ...........................................1-171

Parts and functions ..................................................................................1-171

5.2.5 Wiring: KV-C32T/B16R/B16S Connector Output Module...............................1-172

Parts and functions ..................................................................................1-172

5.2.6 Wiring: KV-R1A I/O Distribution Module .........................................................1-173

Parts and functions ..................................................................................1-173

5.2.7 Wiring: KV-R8X/R16X/R8R/R16R/R8T/R16T I/O Terminal Modules .............1-174

Parts and functions ..................................................................................1-174

5.2.8 Module Names and Functions ........................................................................1-175

5.2.9 Peripheral Equipment Names and Functions .................................................1-176

5.3 Module/Unit Connections ............................................................................1-178

5.3.1 Environmental Requirements .........................................................................1-178

5.3.2 Installation Guidelines.....................................................................................1-178

5.3.3 Assembling the System ..................................................................................1-179

Connecting modules ................................................................................1-179

5.3.4 Mounting to the DIN Rail.................................................................................1-180

5.3.5 Removing the Terminal Block.........................................................................1-181

Connecting the AC Power Supply Module and DC Power Distribution Module....

5.3.6

KV-U4 AC Power Supply Module ............................................................1-182

KV-U5 DC Power Distribution Module .....................................................1-182

5.3.7 I/O Connectors................................................................................................1-183

KV-300 CPU ............................................................................................1-183

KV-C16X/C32X ........................................................................................1-184

KV-C32T/B16R/B16S ..............................................................................1-185

KV-R8X/R16X/R8R/R16R/R8T/R16T ......................................................1-186

5.3.8 I/O Terminal Modules: Communication Cables and Power Distribution .........1-187

Transmission distance by cable type .......................................................1-187

Connection patterns.................................................................................1-187

Incorrect wiring patterns...........................................................................1-188

Power distribution ....................................................................................1-188

5.3.9 Connector Assembly Instructions ...................................................................1-189

5.3.10 KV-300 CPU I/O Indicators .............................................................................1-191

5.3.11 KV-10/80 Expansion Units..............................................................................1-192

5.3.12 Mounting Environment ....................................................................................1-194

1-182

Chapter 6 Handheld Programmer

6.1 Using the Handheld Programmer ...............................................................1-196

6.1.1 Outline of the Handheld Programmer .............................................................1-196

(12)

Page 14

6.1.2 Precautions.....................................................................................................1-198

6.2 Basic Operations .........................................................................................1-200

6.2.1 Basic Programming Operation........................................................................1-200

6.3 Functions ......................................................................................................1-216

Function Nos. list .....................................................................................1-216

ALL CLEAR..............................................................................................1-217

HANDHELD PROGRAMMER CLEAR.....................................................1-217

COUNTER CLEAR ..................................................................................1-218

HIGH-SPEED COUNTER CLEAR...........................................................1-218

ALL DATA MEMORY CLEAR..................................................................1-219

ALL LATCHING RELAYS RESET ...........................................................1-219

PROGRAM SENT OR RECEIVED ..........................................................1-220

OFFLINE EDITOR START ......................................................................1-221

OFFLINE EDITOR STOP ........................................................................1-221

TIMER/COUNTER CURRENT VALUE CHANGE ...................................1-222

TIMER/COUNTER SETTING CHANGE ..................................................1-224

RELAY ON/OFF.......................................................................................1-226

WRITE INTO DATA MEMORY ................................................................1-227

READ TRIMMER SETTING.....................................................................1-228

SYNTAX CHECK .....................................................................................1-228

PROGRAM CAPACITY CHECK..............................................................1-229

6.4 Memory Card ................................................................................................1-230

6.4.1 Functions [used with KV-P3E(01)]..................................................................1-230

6.4.2 Storage Capacity ............................................................................................1-230

CLEAR .....................................................................................................1-232

NEW.........................................................................................................1-233

ACCS .......................................................................................................1-234

ACCS: SAVE ...........................................................................................1-235

ACCS: LOAD ...........................................................................................1-236

ACCS: VERIFY ........................................................................................1-236

ACCS: DELETE .......................................................................................1-237

Chapter 7 KV-L2 Serial Interface Module KV-300

7.1 Outline .........................................................................................................1-240

7.1.1 Features..........................................................................................................1-240

7.2 Configuration ...............................................................................................1-241

7.2.1 Parts and Functions........................................................................................1-241

7.2.2 System Configuration .....................................................................................1-242

7.2.3 Outline of Operation Modes............................................................................1-244

7.3 Installation ....................................................................................................1-245

7.3.1 Setting the Operation Mode............................................................................1-245

7.3.2 Communications Protocols .............................................................................1-247

7.3.3 Connector Wiring ............................................................................................1-248

7.3.4 Connecting to External Units ..........................................................................1-249

Connecting to An External Display ..........................................................1-249

Connecting to an IBM PC-AT Computer..................................................1-249

Connecting to the KV-10/16/24/40/80......................................................1-250

Connecting KV-L2s ..................................................................................1-250

7.4 Software Setup .............................................................................................1-252

7.4.1 Using KV Software [KV IncrediWare (DOS)] ..................................................1-252

Starting KV IncrediWare (DOS) from the KV-L2 ........................................................1-252

7.5 KV Mode Programming ...............................................................................1-253

7.5.1 Operating in KV Mode ....................................................................................1-253

Communications protocol ........................................................................1-253

7.5.2 Serial Communications Procedure .................................................................1-255

Command transmission procedure ..........................................................1-255

Command/response format .....................................................................1-256

Communications commands and responses ...........................................1-256

Communications commands....................................................................1-257

7.5.3 Transmission and Reception of Text Data......................................................1-262

Assigning relay nos. and data memory address nos. ..............................1-262

Transmitting Text Data.............................................................................1-264

Receiving text data ..................................................................................1-265

ASCII code/binary conversion function ....................................................1-266

(13)

Page 15

Example program.....................................................................................1-269

7.6 Display Interface Mode Programming .......................................................1-270

7.6.1 Operating in Display Interface Mode ..............................................................1-270

Communications protocols.......................................................................1-270

Communications control procedure .........................................................1-271

7.6.2 Command and Response Format...................................................................1-273

7.6.3 Commands and Responses ...........................................................................1-275

List of commands and responses ............................................................1-275

Description of commands and responses................................................1-277

End codes ................................................................................................1-291

7.7 Non-procedure Mode Programming ..........................................................1-292

7.7.1 Operating in Non-procedure Mode .................................................................1-292

Communications protocol ........................................................................1-292

Connecting to the KV-L2..........................................................................1-293

7.7.2 Assignment of Relay Nos. and Data Memory Address Nos. ..........................1-294

Assigning relay nos. and data memory address nos. ..............................1-294

7.7.3 Transmitting Text Data ...................................................................................1-297

Data transmission and internal data memory addresses.........................1-297

7.7.4 Receiving Text Data .......................................................................................1-298

Format of received data and data memory addresses ............................1-298

7.7.5 ASCII code/Binary Conversion Function ........................................................1-300

7.8 Troubleshooting Guide ...............................................................................1-304

7.8.1 Troubleshooting ..............................................................................................1-304

7.8.2 Precautions.....................................................................................................1-305

7.9 Specifications ...............................................................................................1-306

7.9.1 Specifications..................................................................................................1-306

General specifications..............................................................................1-306

Communications protocol ........................................................................1-306

RS-232C connector specifications...........................................................1-306

RS-422A terminal block specifications.....................................................1-306

7.9.2 Dimensions .....................................................................................................1-307

7.10 Command List ..............................................................................................1-308

7.10.1 List of Commands and Responses.................................................................1-308

7.10.2 List of Commands and Responses in Display Interface mode .......................1-309

Chapter 8 KV-AN6 Analog I/O Module KV-300

8.1 Outline .........................................................................................................1-312

Features...................................................................................................1-312

8.2 Configuration ...............................................................................................1-313

8.2.1 Parts and Functions........................................................................................1-313

8.2.2 System Configuration .....................................................................................1-314

8.3 Installation ....................................................................................................1-315

8.3.1 Terminal Nos. .................................................................................................1-315

8.3.2 Removing the Terminal Block.........................................................................1-316

8.3.3 Example of Voltage I/O Wiring........................................................................1-317

8.3.4 Example of Current I/O Wiring........................................................................1-318

8.3.5 Setting I/O Ranges .........................................................................................1-319

8.4 Programming ................................................................................................1-320

8.4.1 Input Characteristics (A/D)..............................................................................1-320

8.4.2 Calculating Input Data (A/D) ...........................................................................1-321

8.4.3 Output Characteristics (D/A)...........................................................................1-322

8.4.4 Calculating Output Data (D/A) ........................................................................1-323

8.4.5 Assigning Data Memory (DM) Addresses.......................................................1-324

8.4.6 Reading Analog Input .....................................................................................1-325

8.4.7 Measuring Analog Input Average ...................................................................1-326

8.4.8 Writing Analog Output.....................................................................................1-327

8.4.9 Converting Analog Input to Analog Output .....................................................1-328

8.5 KV-AN6 Appendices ....................................................................................1-329

8.5.1 Troubleshooting ..............................................................................................1-329

8.5.2 Precautions.....................................................................................................1-330

8.5.3 Specifications..................................................................................................1-331

Environmental specifications ...................................................................1-331

System specifications ..............................................................................1-331

(14)

Page 16

8.5.4 Dimensions .....................................................................................................1-332

Chapter 9 KV-AD4/DA4 Analog I/O Unit KV-10/80

9.1 Outline .........................................................................................................1-334

Features...................................................................................................1-334

9.2 Configuration ...............................................................................................1-335

9.2.1 Part Names and Functions .............................................................................1-335

KV-AD4 ....................................................................................................1-335

KV-DA4 ....................................................................................................1-336

9.2.2 Specifications..................................................................................................1-337

KV-AD4 ....................................................................................................1-337

KV-DA4 ....................................................................................................1-339

9.2.3 System Configuration .....................................................................................1-341

9.3 Installation ....................................................................................................1-342

9.3.1 Installation Procedure .....................................................................................1-342

9.3.2 Checking the Installation Environment ...........................................................1-343

9.3.3 Setting the KV-AD4 Input Mode......................................................................1-344

Setting the input mode .............................................................................1-344

9.3.4 Connecting External Instruments....................................................................1-345

Wiring.......................................................................................................1-345

Wiring diagrams .......................................................................................1-346

9.3.5 Connecting to the KV-10 to 80........................................................................1-348

9.3.6 Maintenance ...................................................................................................1-349

Inspection and Cleaning ..........................................................................1-349

9.4 Programming ................................................................................................1-350

9.4.1 Programming the KV-AD4 ..............................................................................1-350

A/D Conversion Mechanism ....................................................................1-350

About Digital Data after A/D Conversion..................................................1-351

Calculating Voltage and Current Values from Digital Data ......................1-352

9.4.2 Programming the KV-DA4 ..............................................................................1-353

D/A Conversion Mechanism ....................................................................1-353

Converting Digital Data to Voltage or Current Values to be Output.........1-354

Writing Digital Data to Data Memory for D/A Conversion ........................1-356

9.4.3 A/D and D/A Conversion Tables.....................................................................1-357

Voltage Conversion Table........................................................................1-357

Current Conversion Table........................................................................1-358

9.5 Programming Examples ..............................................................................1-359

Calculating Analog Data Values from Digital Data...................................1-359

Writing Data to be Analog-output.............................................................1-361

Outputting Analog Trimmer Values..........................................................1-364

Outputting Analog Input Data...................................................................1-365

Outputting Analog Input from a Pressure Sensor to an Air Valve............1-366

Setting the Minimum and Maximum Voltage Limits and Measuring the

Average Voltage ......................................................................................1-367

9.6 Troubleshooting ...........................................................................................1-370

Chapter 10 Troubleshooting

10.1 Error List .......................................................................................................1-372

10.1.1 List of Error Codes in Basic Units ...................................................................1-372

10.1.2 Error indication in Expansion Units .................................................................1-374

10.1.3 Program Errors ...............................................................................................1-375

10.1.4 Memory Card Errors and Other Errors ...........................................................1-376

10.2 Replacing Relays .........................................................................................1-377

Replacement procedure...........................................................................1-377

10.3 Troubleshooting ...........................................................................................1-378

10.3.1 Troubleshooting List .......................................................................................1-378

10.4 Error Messages ............................................................................................1-380

Appendices

Appendix A. Specifications and Dimensions [Visual KV Series] ....................1-382

A.1 System Specifications [Visual KV Series].......................................................1-382

(15)

Page 17

Hardware .................................................................................................1-382

Software and Programming .....................................................................1-383

AC power supply unit ...............................................................................1-384

A.2 Common I/O Specifications of Basic Units .....................................................1-384

Input specifications ..................................................................................1-384

Output specifications (relay output): KV-10AR/DR, KV-16AR/DR,

KV-24AR/DR, and KV-40AR/DR..............................................................1-385

Output specifications (transistor output): KV-10AT(P)/DT(P),

KV-16AT(P)/DT(P), KV-24AT(P)/DT(P), and KV-40AT(P)/DT(P) ............1-385

A.3 Expansion Unit Specifications ........................................................................1-385

A.4 Dimensions .....................................................................................................1-389

Appendix B. Specifications and Dimensions [KV-300 Series] .........................1-392

B.1 System Specifications [KV-300 Series] ..........................................................1-392

Hardware .................................................................................................1-392

Software and Programming .....................................................................1-393

AC Power supply module/DC power distribution module ........................1-394

B.2 Module Specifications.....................................................................................1-398

KV-300 CPU ............................................................................................1-398

KV-C16X/C32X Input Modules ................................................................1-399

KV-C32T/B16R/B16S Output Modules ...................................................1-400

KV-R8X/R16X I/O Terminal Modules.......................................................1-401

KV-R8T/R16T/R8R/R16R I/O Terminal Modules.....................................1-402

KV-R8T/R16T/R8R/R16R I/O Terminal Modules (RUN Output)..............1-403

KV-R1A I/O Distribution Module ..............................................................1-403

B.3 Dimensions .....................................................................................................1-404

Appendix C. Ladder Program List ......................................................................1-406

Appendix D. A/D and D/A Conversion Tables [KV-AN6] .....................................1-408

Voltage conversion table..........................................................................1-408

Current conversion table..........................................................................1-409

WARRANTIES AND DISCLAIMERS 1-419

2 Support software

Chapter 1 Introduction

1.1 Items Included in the Package ........................................................................2-2

1.2 Outline of the Ladder Builder for KV ..............................................................2-3

1.2.1 Operating environment and system configuration ..............................................2-3

1.2.2 Features and functions of the Ladder Builder for KV..........................................2-4

Features of the Ladder Builder for KV .........................................................2-4

Functions of the Ladder Builder for KV ........................................................2-6

1.3 Before Programming .......................................................................................2-7

Machines to be prepared .............................................................................2-7

1.3.1 Differences from the KV IncrediWare (DOS) ......................................................2-8

1.3.2 Differences from the Ladder Builder for KV Ver 1.0 ...........................................2-8

1.4 Installing the Software .....................................................................................2-9

1.4.1 Preparation for installation ..................................................................................2-9

1.4.2 Installation Procedure .......................................................................................2-10

Installation in Windows 95 .........................................................................2-10

Installation in Windows 3.1 ........................................................................2-12

1.5 Cautions for Use ............................................................................................2-13

1.6 Basic Operations ...........................................................................................2-14

1.6.1 Program creation flow and available modes.....................................................2-14

1.6.2 Starting up and exiting from the software .........................................................2-16

1.6.3 Screen ..............................................................................................................2-18

1.6.4 Mouse operation and keyboard operation ........................................................2-21

1.6.5 Online Help .......................................................................................................2-23

Chapter 2 Editor KV-300

2.1 Outline of the Editor Functions ....................................................................2-26

2.1.1 Cautions for editing ladder programs................................................................2-26

2.2 Edit Screen .....................................................................................................2-27

(16)

Page 18

2.2.1 Name and function of each part of the screen..................................................2-27

2.2.2 Ladder program window screen .......................................................................2-28

2.3 File Management ............................................................................................2-29

2.3.1 Creating a new file ............................................................................................2-29

2.3.2 Setting the automatic file read function.............................................................2-30

2.3.3 Setting automatic file save for the file ...............................................................2-31

2.3.4 Saving and reading files ...................................................................................2-32

2.3.5 Reading and saving a file in another format .....................................................2-33

2.3.6 Saving a ladder diagram in text format .............................................................2-36

2.3.7 Verifying files ....................................................................................................2-36

2.4 Entering/Deleting Symbols and Connection Lines ....................................2-37

2.4.1 Entering symbols ..............................................................................................2-37

2.4.2 Deleting symbols ..............................................................................................2-42

2.4.3 Entering contacts/coils directly .........................................................................2-42

2.4.4 Changing the device at the current cursor position ..........................................2-43

2.4.5 Entering/Deleting connection lines ...................................................................2-44

2.4.6 Canceling edit operations .................................................................................2-45

2.5 Entering Comments/Labels .........................................................................2-46

2.5.1 Editing comments/labels...................................................................................2-46

2.5.2 Editing line comments.......................................................................................2-50

2.5.3 Changing ladder lines into comments...............................................................2-51

2.6 Edit and Arrangement ..................................................................................2-52

2.6.1 Copy, move, and delete....................................................................................2-52

2.6.2 Inserting and deleting lines ...............................................................................2-57

2.7 Jump, Search, and Replace .........................................................................2-58

2.7.1 Jump .................................................................................................................2-58

2.7.2 Searching for instruction words/operands ........................................................2-62

2.7.3 Searching for the device at the cursor position.................................................2-63

2.7.4 Replacing operands..........................................................................................2-64

2.7.5 Converting a/b contacts ....................................................................................2-65

2.8 Editing the Mnemonic List ...........................................................................2-67

2.8.1 Displaying and terminating a mnemonic list .....................................................2-67

2.8.2 Copy, move, and delete....................................................................................2-69

2.9 Displaying the Use Status .............................................................................2-70

2.9.1 Displaying a use status list ...............................................................................2-70

2.10 Setting the System .........................................................................................2-71

2.10.1 Setting the system ............................................................................................2-71

2.11 Entering and Developing Macros ................................................................2-72

2.11.1 Creating a macro file.........................................................................................2-72

2.11.2 Entering and developing macros ......................................................................2-74

2.12 Compilation ....................................................................................................2-75

2.12.1 Executing compilation .......................................................................................2-75

2.12.2 Error display......................................................................................................2-76

2.12.3 Double coil check..............................................................................................2-76

2.13 Printing Functions .........................................................................................2-77

2.13.1 Printing..............................................................................................................2-77

2.13.2 Preview display .................................................................................................2-81

2.14 Changing the Display Color on the Screen .................................................2-82

2.14.1 Changing display colors on the screen.............................................................2-82

Chapter 3 Simulator

3.1 Outline of the Simulator Functions ..............................................................2-84

3.1.1 Outline of the functions .....................................................................................2-84

3.1.2 Restrictions in the simulator..............................................................................2-84

3.2 Starting up and Exiting from the Simulator .................................................2-86

3.2.1 Operating procedure for startup and exit ..........................................................2-86

3.2.2 Name and function of each part of the screen..................................................2-88

3.3 Ladder Monitor ...............................................................................................2-89

3.3.1 Outline of the ladder monitor ............................................................................2-89

3.3.2 Executing scans................................................................................................2-89

3.3.3 Executing steps ..............................................................................................2-101

(17)

Page 19

3.3.4 Jump and search ............................................................................................2-105

3.3.5 Stop/reset and device all clear........................................................................2-108

3.4 Monitor All ....................................................................................................2-109

3.4.1 Outline of monitor all.......................................................................................2-109

3.4.2 Displaying, saving, and reading the monitor all window .................................2-109

3.4.3 Monitor all window ..........................................................................................2-113

3.4.4 Registering devices ........................................................................................2-113

3.4.5 Selecting and changing devices .....................................................................2-116

3.5 Registration Monitor ....................................................................................2-119

3.5.1 Outline of the registration monitor...................................................................2-119

3.5.2 Displaying, saving, and reading the registration monitor ................................2-119

3.5.3 Registration monitor window...........................................................................2-122

3.5.4 Registering devices ........................................................................................2-122

3.5.5 Selecting and changing devices .....................................................................2-123

3.5.6 Manipulating timing charts ..............................................................................2-128

3.5.7 Printing out the registration monitor................................................................2-131

Chapter 4 Monitor

4.1 Outline of the Monitor Functions ...............................................................2-134

4.1.1 Outline of the functions ...................................................................................2-134

4.1.2 Restrictions in the monitor ..............................................................................2-134

4.1.3 Precautions for communication ......................................................................2-135

4.2 Communicating with the PLC .....................................................................2-136

4.2.1 Setting the PLC communication parameters ..................................................2-136