Page 1

IL Series

User’s Manual

Read this manual before using in order to achieve

maximum performance.

After reading, keep this manual in a safe place so that

you can refer to it at any time.

CMOS Multi-Function

Analog Laser Sensor

236GB

Page 2

Introduction

This manual describes the basic operations and information for the IL Series.

Read this manual carefully to ensure performance and function of the IL Series for safe use.

Keep this manual in a safe place for future reference.

Make sure this manual is provided to the end user of this device.

Symbols

The following symbols alert you to important messages. Be sure to read these messages

carefully.

DANGER

WARNING

CAUTION

NOTICE

Important

Point

Reference

It indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

It indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

It indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

It indicates a situation which, if not avoided, could result in product

damage as well as property damage.

It indicates cautions and limitations that must be followed during

operation.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

Provides reference pages.

Page 3

Safety Precautions

WARNING

General Precautions

• At startup and during operation, be sure to monitor the functions and performance of this

product and confirm normal operation.

• We recommend that you take substantial safety measures to avoid any damage in the

event that a problem occurs.

• If the product is modified or used in any way other than those described in the

specifications, its functions and performance cannot be guaranteed.

• When this product is used in combination with other devices, the functions and

performance may be weaken, depending on the operating conditions, surrounding

environment, etc.

• Do not use this product for the purpose of protecting the human body.

• Do not subject each device including peripheral devices to rapid temperature change.

Product failure may occur due to condensation.

Safety Information for the IL series

• This product is just intended to detect the object(s). Do not use

this product for the purpose to protect a human body or a part of

human body.

• This product is not intended for use as explosion-proof product.

Do not use this product in hazardous location and/or potentially

explosive atmosphere.

Safety Precautions on Laser Products

• Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

• Follow the instructions mentioned in this manual. Otherwise, injury to the human body

(eyes and skin) may result.

• Do not disassemble this product. Laser emission from this product is not automatically

stopped when it is disassembled.

• Precautions on class 2 laser products

- Do not stare into the beam.

- Do not direct the beam at other people or into areas where other people unconnected

with the laser work might be present.

- Be careful of the path of the laser beam.

When the laser beam is reflected or diffused from a mirror surface, and this reflection

may cause danger, block this reflection using a surrounding enclosure.

- Install the products so that the path of the laser beam is not as the same height as that

of human eye.

IL-E

236GB

1

Page 4

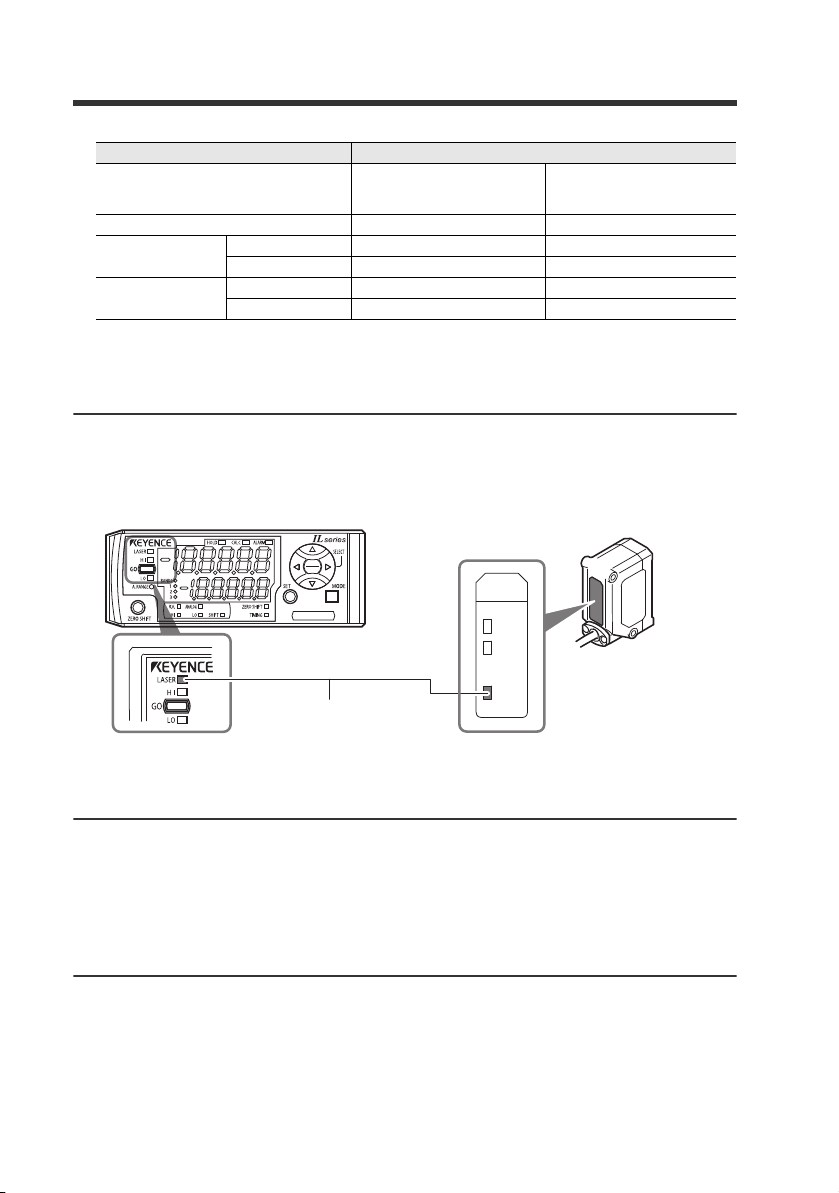

Laser radiation

emission indicator

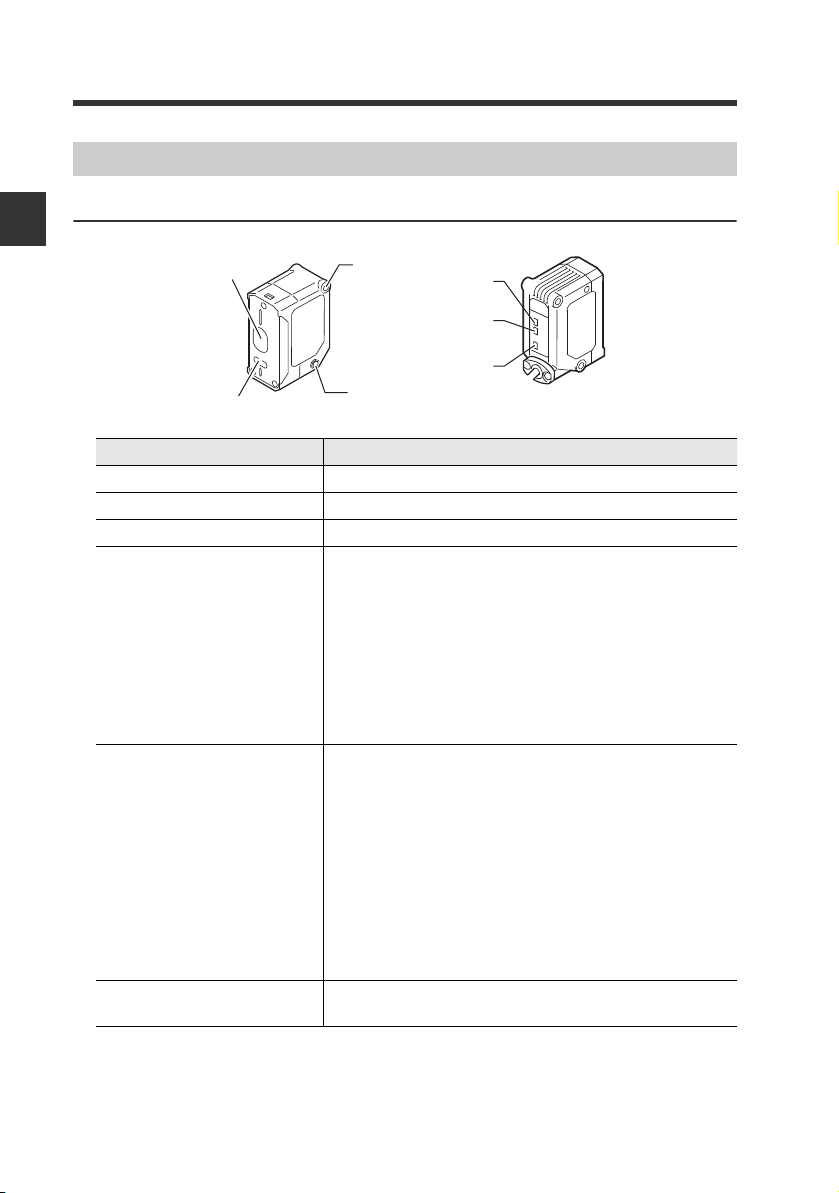

<Sensor amplifier>

<Sensor head>

Item Description

Model IL-030

Wavelength 655 nm 655 nm

FDA (CDRH)

Part1040.10

IEC 60825-1

Laser Class Class 1 Laser Product* Class 2 Laser Product*

Output 220 μW560 μW

Laser Class Class 1 Laser Product Class 2 Laser Product

Output 220 μW560 μW

IL-S025/IL-S065/IL-065/

IL-100/IL-300/IL-600/

IL-2000

* The classification is implemented based on IEC60825-1 following the requirement of

Laser Notice No.50 of FDA (CDRH).

Safety measures for the laser

Laser radiation emission indicator

The laser radiation emission indicator is lit during laser emission. It flashes when laser

emission is stopped.

IL-030

CENTER

A. RANGE

LASER

The position of the indicator of the IL-S025/IL-S065/IL-2000 will differ from above.

Laser emission stop input

When laser emission stop input is set as an external input, laser emission can be stopped

by turning on the external input (input response time 20 ms). Laser emission remains

stopped while the external input is on. The laser is emitted within 20 ms being external

input of the turned off. For the conditions of detection outputs and analog outputs during

laser emission stop input, refer to

Warming up

Leave the IL Series about 30 minutes after turning on the power.

The circuit is not stable immediately after the power turns on, so the display value may

gradually fluctuate.

2

"11. External Input" (page 4-30) of the User's Manual.

IL-E

Page 5

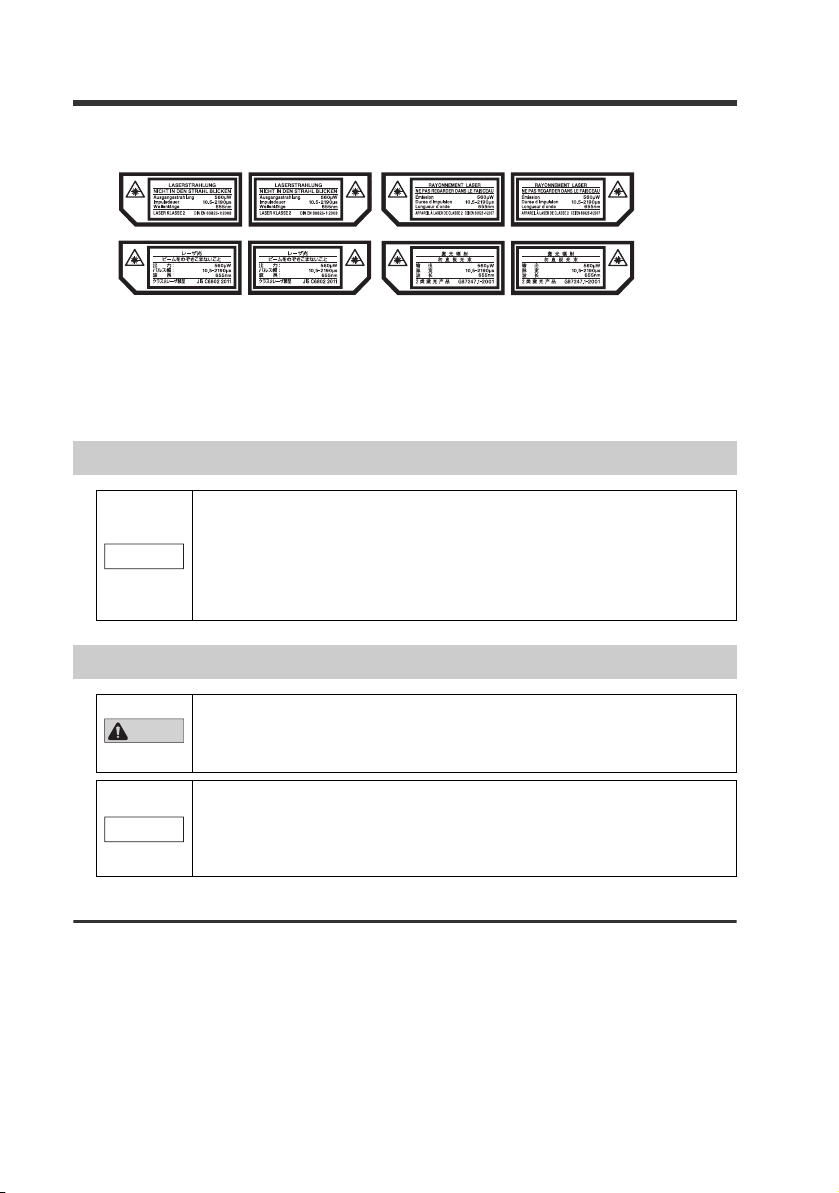

Laser warning labels

Aperture

label

Aperture

label

Laser

transmitter

IEC warning label (Class 2)

Aperture

label

Aperture

label

Laser transmitter

IEC warning/explanatory

label (Class 2)

The following diagrams show the type and position of laser warning labels on to the IL Series.

IL-S025/IL-S065/IL-065/IL-100/IL-300/IL-600

Aperture label

IEC warning/explanatory label (CLASS 2)

IL-E

IL-2000

Aperture label

3

Page 6

CAU

IEC warning/explanatory label (CLASS 2)

The IEC warning/explanatory labels are only affixed to Class 2 laser products.

Use the suitable IEC warning/explanatory label included in the package of this product

according to the countries and/or regions where this product is used.

In this case, it can be affixed on the IEC warning/explanatory label, which has already been

affixed to this product.

Abnormal Conditions

If the following conditions occur, turn OFF the power immediately.

Continuing to use this product under abnormal conditions may

NOTICE

cause product failure.

• When water or foreign matter enters the IL Series

• When the IL Series is dropped or the case is damaged

• If smoke or unpleasant odor is present.

Precautions on Use

• Use with the correct power source and voltage. Otherwise, fire,

CAUTION

NOTICE

electric shock or product failure may result.

• Do not attempt to open or modify the IL Series. Doing so may

cause fire or electric shock.

• Before disconnecting the cables, make sure to turn off the main

unit and devices connected to the main unit. Otherwise, the unit

may be damaged.

• Do not turn off the power while modifying settings. Some or all of

the setting data may be lost.

Installation environment

To use this product normally and safely, do not install this product in the following locations.

Product failure may occur.

• High-humidity, dusty and poorly-ventilated locations

• High-temperature locations where the unit is exposed to direct sunlight

• Locations where there is corrosive or combustible gas

• Locations where the unit may be directly subjected to vibration or impact

• Locations where water, oil or chemicals may splash onto the unit

• Locations where static electricity tends to be generated

4

IL-E

Page 7

Influence of dirt

Measurement errors may occur due to dust, water, oil, etc.

• Blow away dirt on the transmitter and the receiver with clean air. Wipe with a soft cloth

moistened with alcohol for heavy dirt.

• Blow away the dirt attached to the object with clean air or wipe it off.

• If dirt is floating in the measurement range, take adequate measures, such as installing a

protective cover or air purge.

Anti-noise prevention

When the unit is installed near electric noise source such as a power source or high-voltage

line, operational errors or product failure may occur. Take adequate measures such as using a

noise filter, arranging cables separately or insulating the sensor amplifier and the sensor head.

Power ON Reset

After the power is turned ON, it will take approx. two seconds for the measurement to start.

The judgment results will be output after the sampling period has elapsed.

Other Precautions

Power source

• Noise superimposed on the power supply may cause malfunction. Use a direct current

stabilized power source which uses an insulation transformer.

• When using a commercially available switching regulator, make sure to ground the frame

ground terminal.

Precautions on Regulations and Standards

CE Marking

Keyence corporation has confirmed that this product complies with the essential

requirements of the applicable EC Directives, based on the following specifications.

Be sure to consider the following specifications when using this product in the Member

States of European Union.

EMC Directive

• Applicable standards EMI : EN61326-1,ClassA

EMS : EN61326-1

• The length of the sensor head cable and all I/O cables must be less than 30m.

Remarks

These specifications do not give any guarantee that the end-product with this product

incorporated complies with the essential requirements of EMC Directive.

The manufacturer of the end-product is solely responsible for the compliance on the

end-product itself according to EMC Directive.

IL-E

5

Page 8

CSA Certificate

IL series complies with the following CSA and UL standards and has been certified by CSA

(Class 2252 05 / Class 2252 85).

• Applicable standard: CAN/CSA C22.2 No.61010-1

• Use the following power supply.

CSA/UL-listed power supply that provides Class 2 output as defined in the CEC

(Canadian Electrical Code) and NEC (National Electrical Code), or CSA/UL-listed power

supply that has been evaluated as a Limited Power Source as defined in CAN/

CSA-C22.2 No. 60950-1/UL60950-1

• Use this product at the altitude of 2000 m or less.

• Indoor use only.

• The sensor head cable and the sensor head connection cable must be installed in such a

way as to avoid mechanical damage (e.g.: crushing).

• The power/input-output cable for amplifier unit is for internal wiring only.

• The following cables are rated 30 V.

- sensor head cable

- sensor head connection cable

- power/input-output cable for amplifier unit

Install these cables where it is separated from the circuit over 30 V.

UL61010-1

6

IL-E

Page 9

IL-E

7

Page 10

Table of Contents

Introduction

Safety Precautions.................................................................................... 1

General Precautions ................................................................................ 1

Safety Information for the IL series .......................................................... 1

Safety Precautions on Laser Products..................................................... 1

Abnormal Conditions................................................................................ 4

Precautions on Use.................................................................................. 4

Other Precautions .................................................................................... 5

Precautions on Regulations and Standards............................................. 5

Chapter 1 Before Use

1-1 Checking the Package Contents ................................................... 1-2

Sensor Amplifier.................................................................................... 1-2

Sensor Head ......................................................................................... 1-3

List of Optional Parts............................................................................. 1-3

1-2 Part Names and Functions............................................................1-5

Sensor Amplifier Unit ............................................................................ 1-5

Sensor Head Unit.................................................................................. 1-8

Chapter 2 Installation and Connection

2-1 Mounting and Wiring the Sensor Amplifier .................................... 2-2

Mounting the Sensor Amplifier.............................................................. 2-2

Sensor Amplifier Wiring ........................................................................ 2-6

2-2 Connecting and Mounting the Sensor Head .................................2-8

Mounting the Sensor Head ................................................................... 2-8

Connection and Wiring.......................................................................... 2-9

Chapter 3 Basic Operations

3-1 Operation When the Power is Turned on for the First Time.......... 3-2

3-2 Operations on the Main Screens................................................... 3-3

R.V. (Internal Measurement Value) and P.V. (Judgment Value) .......... 3-3

Main Display (Upper Level)................................................................... 3-3

Sub Display (Lower Level) .................................................................... 3-4

Setting Operations ................................................................................ 3-6

8

IL-E

Page 11

3-3 Initial Reset (Initialize)................................................................... 3-8

Operation for Changing the Model of Connected Head........................ 3-9

3-4 Setting the Tolerance Setting Value ........................................... 3-10

Manual Setting .................................................................................... 3-11

Automatic Setting (When other than step count filter) ........................ 3-12

Automatic Setting (When step count filter).......................................... 3-16

3-5 Zero Shift Function (Shifting the Internal Measurement Value (R.V.)) .3-18

Setting the Shift Target Value ............................................................. 3-18

Enabling the Zero Shift ....................................................................... 3-19

Canceling the Zero Shift (Reset)......................................................... 3-19

3-6 Bank Function (Registering Multiple Tolerance Setting Values). 3-20

Settings Registered with the Bank ...................................................... 3-20

How to Switch the Bank ...................................................................... 3-20

3-7 Key Lock Function ...................................................................... 3-21

Starting the Key Lock .......................................................................... 3-21

Canceling the Key Lock (Unlock) ........................................................ 3-21

Chapter 4 Setting Various Functions

4-1 Setting Operations ........................................................................ 4-2

Setting Operations ................................................................................ 4-2

4-2 Basic Settings and Advanced Settings ......................................... 4-4

List of Setting Items .............................................................................. 4-4

Setting Screen ...................................................................................... 4-6

1. Measurement Direction ..................................................................... 4-8

2. Sampling Rate .................................................................................. 4-8

3. Averaging rate, Step count filter, High-pass filter.............................. 4-9

4. Alarm Setting .................................................................................. 4-13

5. Output State.................................................................................... 4-14

6. Hold Function.................................................................................. 4-15

7. Timing Input .................................................................................... 4-23

8. Delay Timer..................................................................................... 4-23

9. Hysteresis ....................................................................................... 4-26

10. Analog Output Scaling .................................................................. 4-27

Analog Output Accuracy ..................................................................... 4-29

11. External Input ................................................................................ 4-30

12. Bank Switching Method ................................................................ 4-35

13. Zero Shift Value Memory Function ............................................... 4-38

14. Interference Prevention Function (Only for IL-1000/1500)............ 4-38

IL-E

9

Page 12

15. Display Digit .................................................................................. 4-39

16. Power Saving Function ................................................................. 4-40

17. Head Display Mode....................................................................... 4-40

18. Display Color................................................................................. 4-41

4-3 Calculation Function.................................................................... 4-42

Calculation Value (CALC value) ......................................................... 4-42

Addition Mode ..................................................................................... 4-43

Subtraction Mode................................................................................ 4-43

Setting Method (Only Main Unit)......................................................... 4-44

4-4 Calibration Function ....................................................................4-45

Setting method (Calibrating R.V.) ....................................................... 4-45

Setting method (Two-point calibration of calculated value (CALC value)) ....4-48

Setting method (Three-point calibration of calculated value (CALC value)).. 4-50

Chapter 5 Specifications

5-1 Specifications ................................................................................ 5-2

Sensor Head ......................................................................................... 5-2

Sensor Amplifier.................................................................................... 5-4

5-2 Circuit Diagram.............................................................................. 5-5

Output Circuit Diagram ......................................................................... 5-5

Analog Output Circuit............................................................................ 5-5

Input Circuit Diagram ............................................................................ 5-6

5-3 Dimensions.................................................................................... 5-7

Mutual-interference ............................................................................. 5-13

Spot Diameter ..................................................................................... 5-16

5-4 Response Time ........................................................................... 5-18

Appendix

Troubleshooting .................................................................................... A-2

Frequently Asked Questions.................................................................A-2

Error Displays and Corrective Actions .................................................. A-4

Non-Error Displays and Corrective Actions .......................................... A-5

Display Screen and Output................................................................... A-8

Factory Setting (Default Value) List ...................................................... A-9

Index ................................................................................................... A-10

10

IL-E

Page 13

Before Use1

This chapter describes the overview of the IL Series and the name

and function of each part.

1-1 Checking the Package Contents.......................... 1-2

1-2 Part Names and Functions ................................... 1-5

1

IL-E

1-1

Page 14

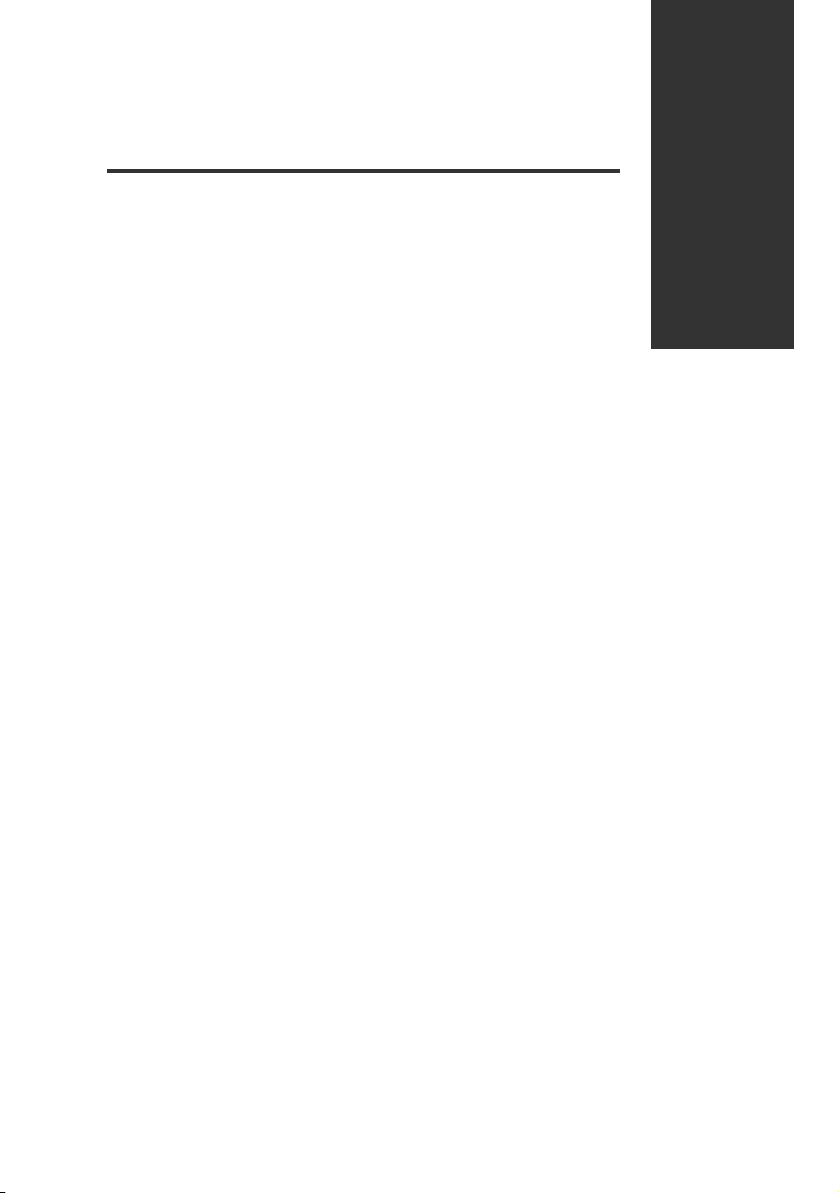

1

Sensor amplifier x 1

Instruction manual x 1

Sensor amplifier x 1

IL-1000 (main unit)

IL-1050 (expansion unit)

IL-1500 (main unit)

Sensor amplifier x 1 Panel mounting

bracket x 1

Front protection

cover x 1

Power/Input-output cable (2 m) x 1

(12 cores)

Instruction manual x 1

IL-1550 (expansion unit)

Sensor amplifier x 1 Panel mounting

bracket x 1

Front protection

cover x 1

Input-output cable (2 m) x 1

(8 cores)

Expansion cable

(50 mm) x 1

Before Use

1-1 Checking the Package Contents

The following equipment and accessories are included in the package. Before using the

unit, make sure that all items are included.

We have thoroughly inspected the package contents before shipment. However, in the

event of defective or broken items, contact your nearest KEYENCE office.

Sensor Amplifier

DIN rail mount type

Panel mount type

1-2

IL-E

Page 15

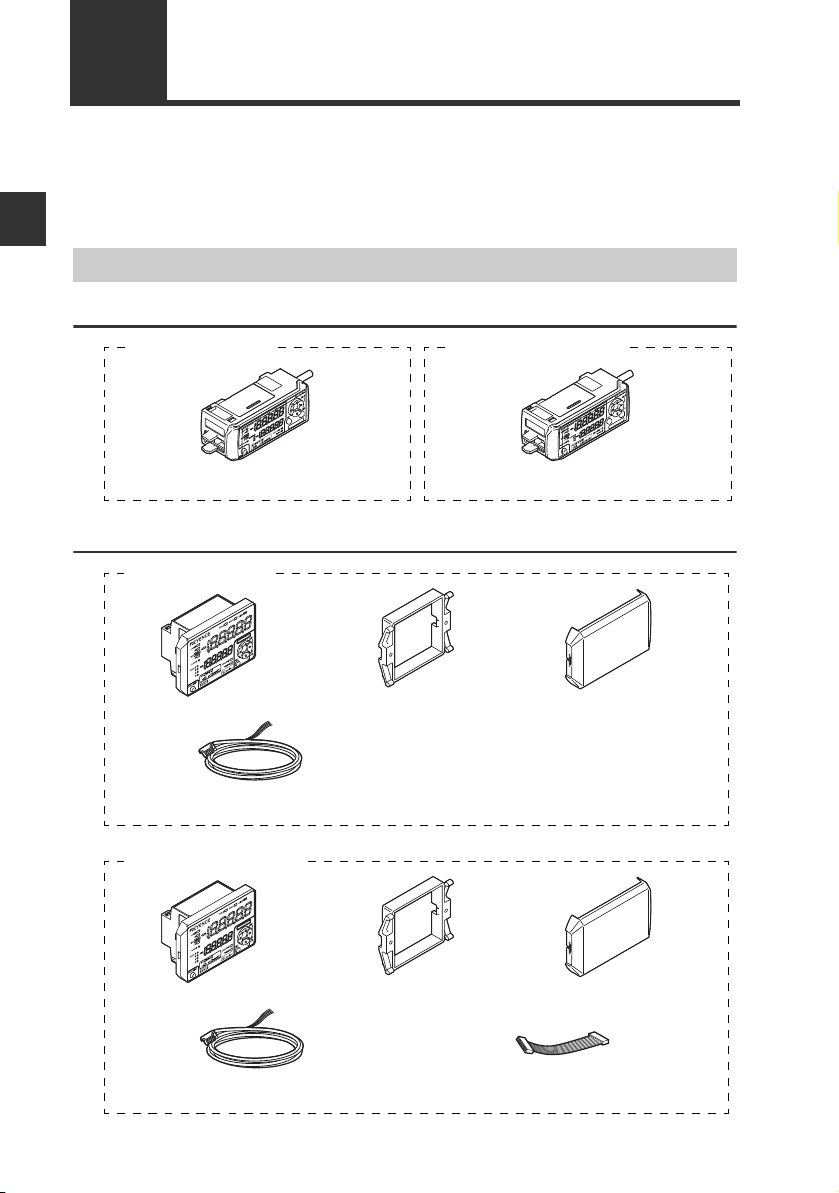

Sensor Head

Sensor head x 1

Mounting bracket x 1

Insulating sheet x 1

Flat nut x 1

M3 x L30 screw x 2

Sensor head x 1

Mounting bracket x 1

Insulating sheet x 1

Flat nut x 1

M3 x L30 screw x 2

Laser warning sticker x 1

IL-030 (30 mm type) IL-S025 (25 mm type)

IL-S065 (65 mm type)

IL-065 (65 mm type)

IL-100 (100 mm type)

Sensor head x 1

Mounting bracket x 1

Insulating sheet x 1

Flat nut x 1

M4 x L35 screw x 2

Laser warning sticker x 1

IL-300 (300 mm type)

IL-600 (600 mm type)

IL-2000 (2000 mm type)

Sensor head x 1

M5 x L60 screw x 2

Laser warning sticker x 1

End unit

x 2

Expansion cable

(300 mm) x 1

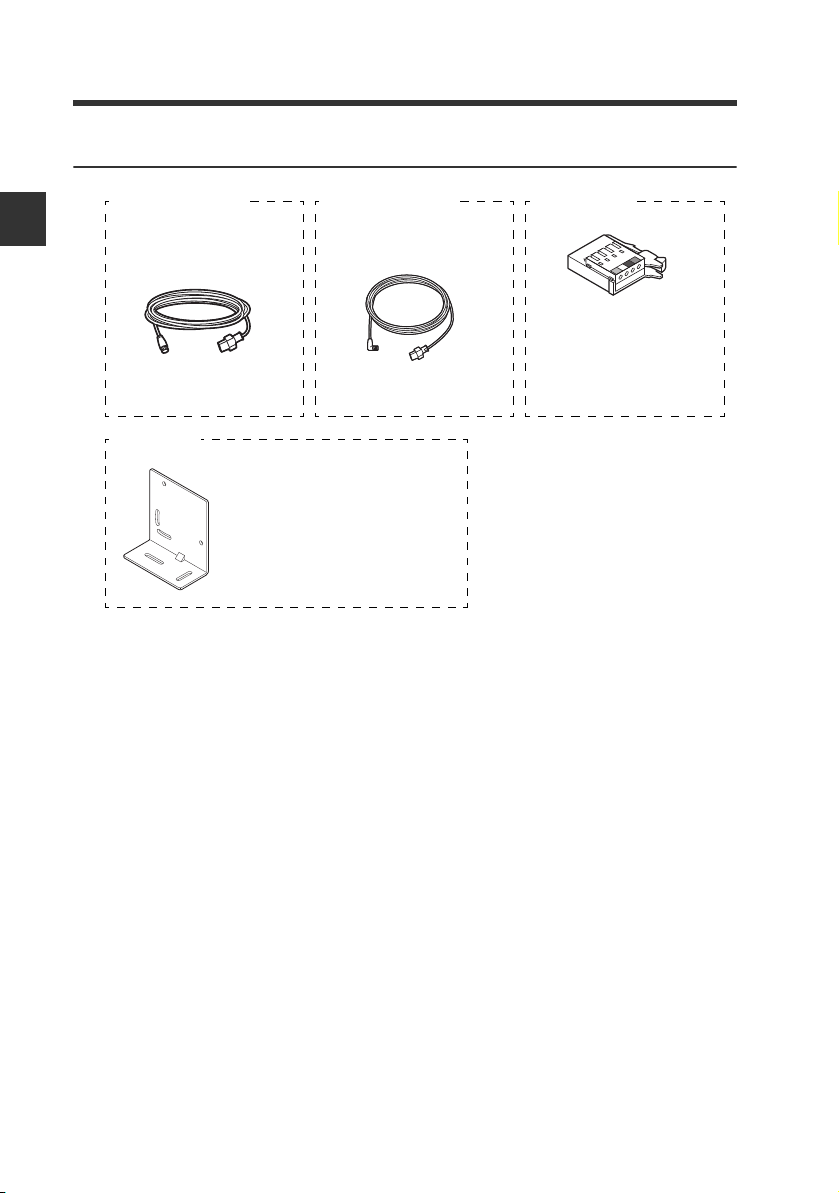

OP-26751 (For IL-1000/IL-1050) OP-35361 (For IL-1550)

Panel mounting

bracket x 1

Front protection

cover x 1

OP-4122 (For IL-1500/IL-1550) OP-87076 (For IL-1500/IL-1550)

1-1 Checking the Package Contents

1

Before Use

List of Optional Parts

For sensor amplifier

IL-E

1-3

Page 16

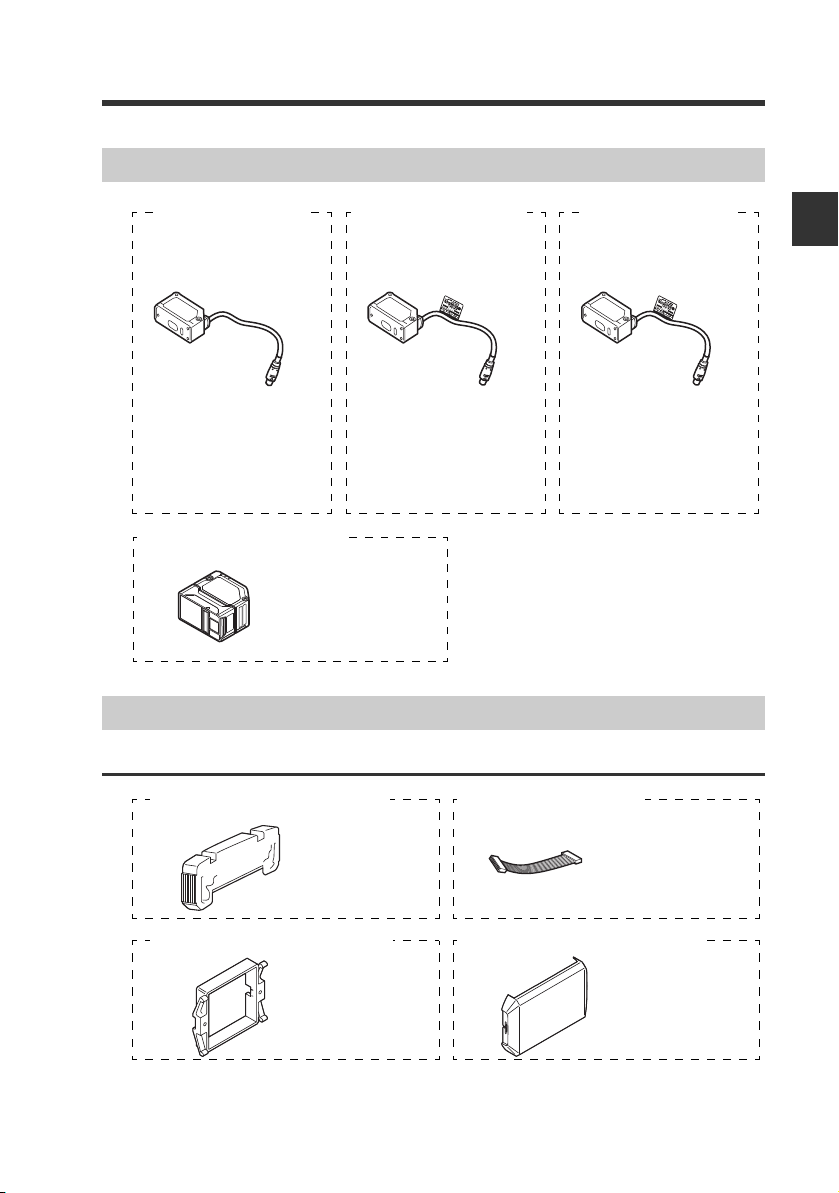

1-1 Checking the Package Contents

Sensor head connection cable

(M8 straight connector) x 1

Sensor head

cable connector x 2

OP-87056 (2 m)

OP-87057 (5 m)

OP-87058 (10 m)

OP-87059 (20 m)

OP-84338

Sensor head connection cable

(M8 L-shaped connector) x 1

OP-87660 (2 m)

OP-87661 (5 m)

OP-87662 (10 m)

OP-87663 (20 m)

IL-2000 head mounting bracket x 1

Flat nut x 1

M5 x L60 screw x 2

OP-87606

For sensor head

1

Before Use

1-4

IL-E

Page 17

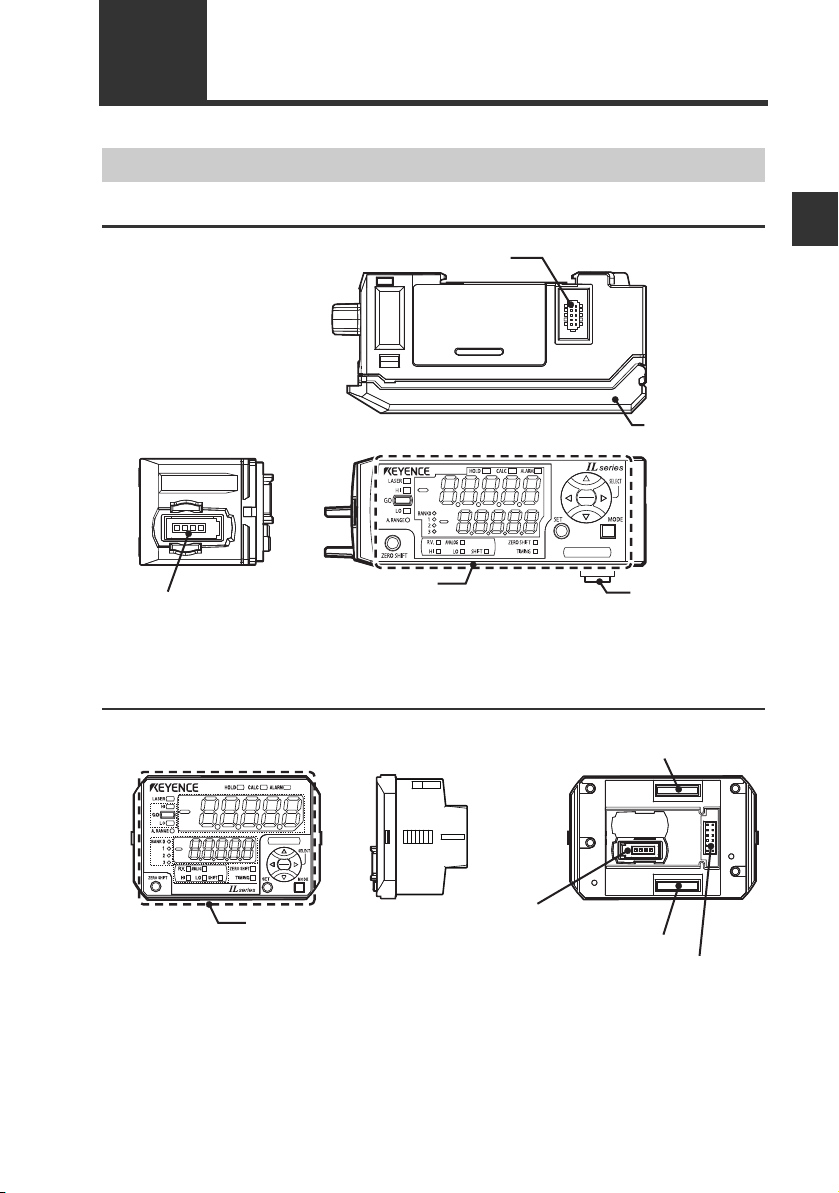

1-2 Part Names and Functions

Expansion unit connector*

1

Amplifier control

unit cover

Amplifier control unit

Sensor head connector

Expansion unit

connector*

2

Sensor Amplifier Unit

DIN rail mount type (IL-1000/IL-1050)

*1 When shipped from the factory, a protective cover is installed over the expansion slots.

*2 It is not installed on the main unit (IL-1000).

Panel mount type (IL-1500/IL-1550)

Expansion unit connector

1

(upper)*

1

Before Use

*1 It is not installed on the main unit (IL-1500).

*2 When shipped from the factory, a protective seal is attached.

IL-E

Amplifier control unit

Sensor head connector

Expansion unit connector (lower)*

2

Power/Input-output

cable connector

1-5

Page 18

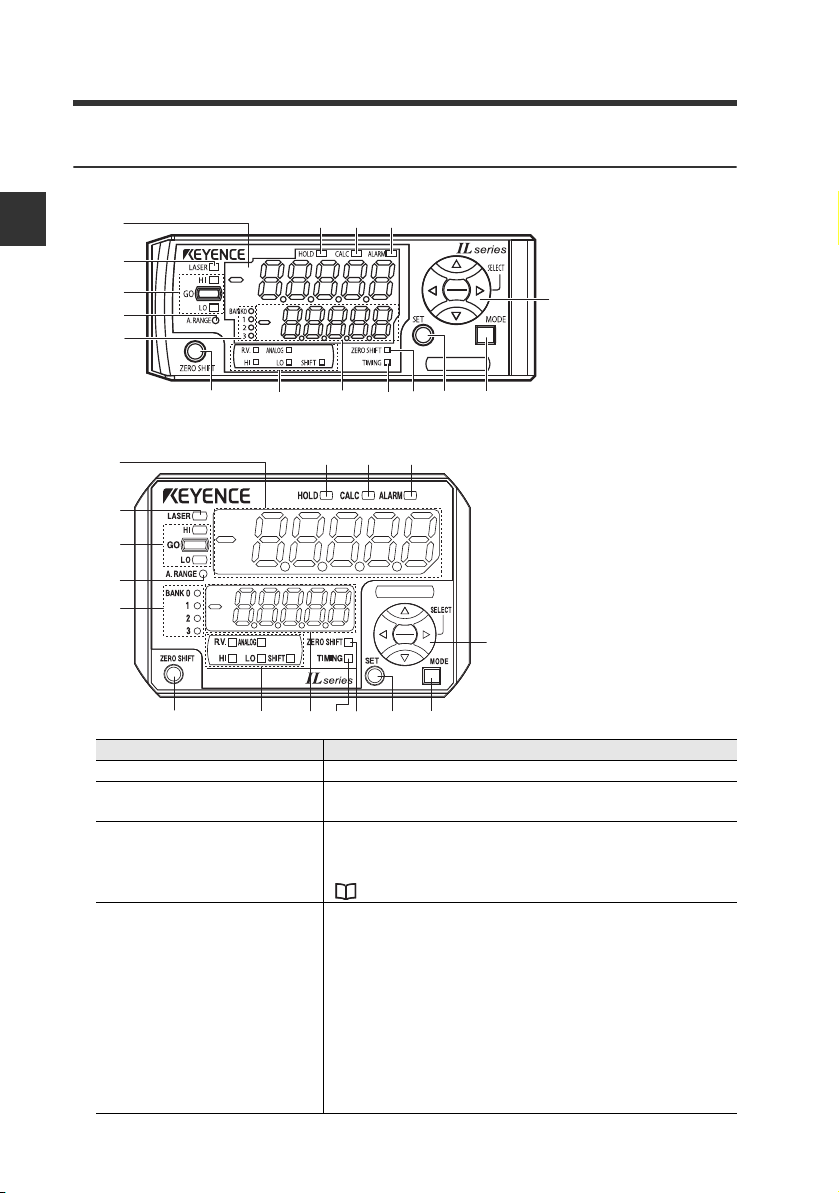

1-2 Part Names and Functions

(11) (12)(10)(6)

(16) (15) (14)

(1)

(2)

(3)

(4)

(7) (8) (9)

(13)

(5)

(11) (12)(10)(6)

(16) (15) (14)

(1)

(2)

(3)

(4)

(5)

(7) (8) (9)

(13)

Amplifier control unit

DIN rail mount type (IL-1000/IL-1050)

1

Before Use

Panel mount type (IL-1500/IL-1550)

Item Description

(1) Main display Displays the judgment value (P.V.) and each setting item.

(2) Laser warning emission

indicator

(3) Judgment indicator

(4) Analog range indicator

Lights up while the laser beam is being emitted.

Blinks while the laser beam emission is stopped.

Displays whether the judgment value (P.V.) is HIGH (over the

upper limit), GO (within the acceptable range) or LOW (below

the lower limit) against the tolerance setting value.

"3-4 Setting the Tolerance Setting Value" (page 3-10)

Lights up when the P.V. (judgment value) is within the analog

output range. If the analog output setting is OFF, or when

using the expansion unit, the indicator lights within the

following detection range.

• IL-S025: 25 ± 5 mm

• IL-030: 30 ± 5 mm

• IL-S065/IL-065: 65 ± 10 mm

• IL-100: 100 ± 20 mm

• IL-300: 300 ± 140 mm

• IL-600: 600 ± 400 mm

• IL-2000: 2000 ± 1000mm

1-6

IL-E

Page 19

1-2 Part Names and Functions

Item Description

Displays a bank in use.

(5) Bank indicator

(6) Zero shift button

(7) Sub display indicator

(8) Sub display

(9) Timing input indicator

(10) Zero shift indicator

(11) SET button

(12) MODE button

(13) Arrow button

(14) Alarm indicator Lights up in the alarm state or error state.

(15) Calculation indicator

(16) Hold indicator

"3-6 Bank Function (Registering Multiple Tolerance

Setting Values)" (page 3-20)

Press this button to match the internal measurement value

(R.V.) to the shift target value.

"3-5 Zero Shift Function (Shifting the Internal

Measurement Value (R.V.))" (page 3-18)

Lights up according to the type of values displayed on the

sub display.

Displays the internal measurement value (R.V.), analog

output value and each setting (selection) item.

Lights up while the timing input is ON when the timing input

(external input) is set to Level. Lights on approx. 0.5 sec.

when the timing input is set to Edge and the timing input is

turned ON.

The zero shift indicator will light up for approx. 0.5 second

when the zero shift function is used.

Used to automatically adjust the setting values when setting

each item.

Used when setting each item, starting/ending the setting or

moving items.

Used when selecting settings, changing display contents on

the sub display, etc.

Lights up when calculation is in process using the calculation

function.

"4-3 Calculation Function" (page 4-42)

Lights up when the Judgment Value (P.V.) is held and when

the step count filter is used.

"6. Hold Function" (page 4-15)

1

Before Use

IL-E

1-7

Page 20

1-2 Part Names and Functions

(1)

(2)

(3)

(3)

(4)

(5)

(6)

Sensor Head Unit

IL-S025/IL-030/IL-S065/IL-065/IL-100/IL-300/IL-600/IL-2000

1

Before Use

Item Description

(1) Laser receiver Laser receiver port. The surface is covered with glass.

(2) Laser transmitter Laser emission port. The surface is covered with glass.

(3) Mounting section Screwed onto dedicated bracket, etc.

(4) Reference distance

indicator

(5) Analog range indicator

(6) Laser warning emission

indicator

IL-030

CENTER

A. RANGE

LASER

By default (normal display mode), and "17. Head Display

Mode" (page 4-40), the reference distance indicator lights

within the following detection range.

• IL-S025: 25 mm ± 0.25 mm

• IL-030: 30 mm ± 0.25 mm

• IL-S065/IL-065: 65 mm ± 0.5 mm

• IL-100: 100 mm ± 1 mm

• IL-300: 300 mm ± 7 mm

• IL-600: 600 mm ± 20 mm

• IL-2000: 2000 mm ± 50 mm

By default (normal display mode), the analog range indicator

lights when the P.V. (judgment value) is within analog output

range. The indicator lights within the following detection

range, when the analog output setting is OFF and with the

expansion units.

• IL-S025: 25 mm ± 5 mm

• IL-030: 30 mm ± 5 mm

• IL-S065/IL-065: 65 mm ± 10 mm

• IL-100: 100 mm ± 20 mm

• IL-300: 300 mm ± 140 mm

• IL-600: 600 mm ± 400 mm

• IL-2000: 2000 ± 1000 mm

Lights up while the laser beam is being emitted.

Blinks while the laser beam emission is stopped.

1-8

IL-E

Page 21

Installation and Connection2

This chapter describes precautions when installing and

connecting the IL Series.

2-1 Mounting and Wiring the Sensor Amplifier ........ 2-2

2-2 Connecting and Mounting the Sensor Head....... 2-8

2

IL-E

2-1

Page 22

2

(1)

(2)

(3)

CAU

Point

Installation and Connection

2-1

Mounting and Wiring the Sensor Amplifier

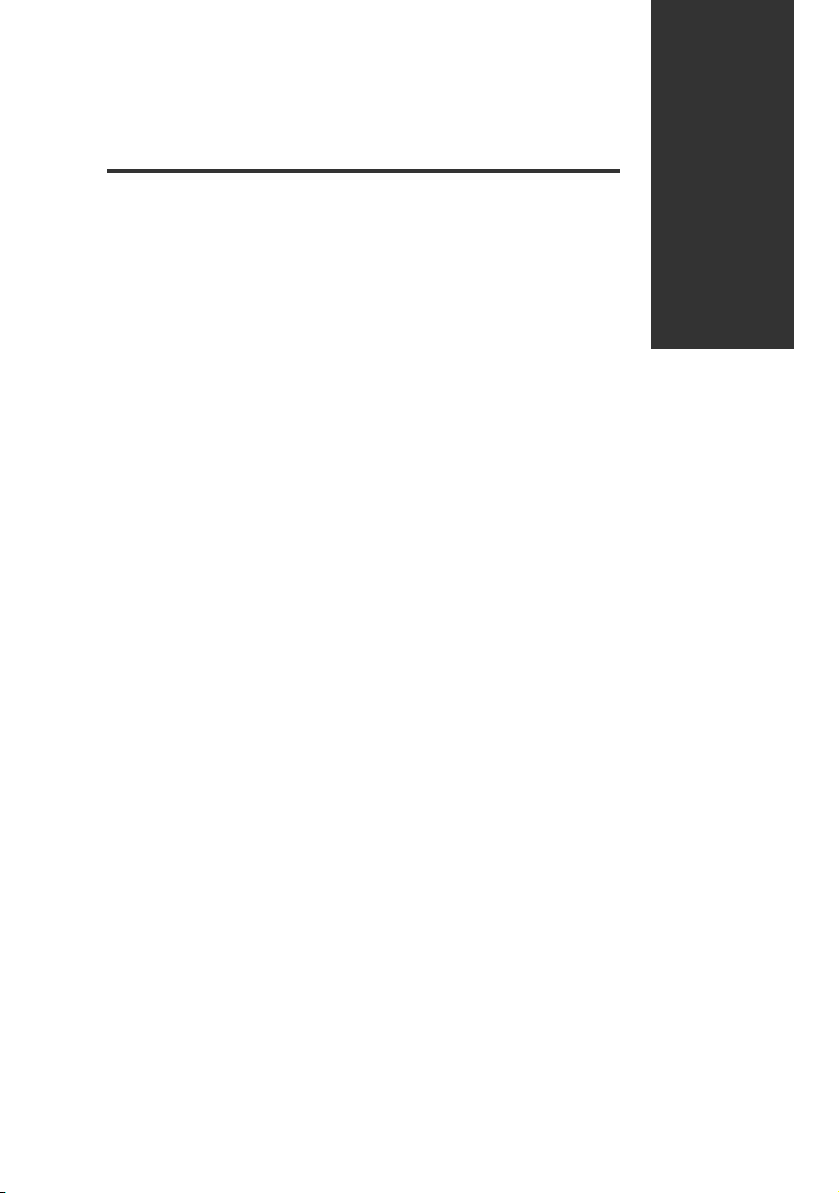

Mounting the Sensor Amplifier

DIN rail mount type, main unit (IL-1000)

Align the claw at the bottom of the main body with the DIN rail. While

1

pushing the main body in the direction of the arrow (1), slant it in the

direction of the arrow (2).

To dismount the sensor, raise the main body in the direction of the arrow

2

(3) while pushing the main body in the direction of the arrow (1).

DIN rail mount type, expansion unit (IL-1050)

Up to 7 expansion units can be connected to one main unit.

• Always mount expansion units onto a DIN rail.

• When connecting multiple amplifiers (expansion units), first check

CAUTION

2-2

to make sure that the power is turned OFF to all of the main and

expansion units. Connecting the units with the power turned ON

may cause damage to the units.

• Push the amplifiers (expansion units) as close as possible the

main unit. Improper connections may damage the equipment.

• When connecting the expansion units, make sure to initialize the

connected expansion units and set the output polarity.

(1) When turning on the amplifier for the first time after connecting

the sensor head

"3-1 Operation When the Power is Turned on for the First Time" (page 3-2)

(2) When performing the initial reset

"3-3 Initial Reset (Initialize)" (page 3-8)

• Expansion units with different setting of output polarity (such as

an NPN output expansion unit to a PNP output main unit) cannot

be connected together.

• Expansion units of DIN rail mount type cannot be connected to the

main unit of panel mount type.

IL-E

Page 23

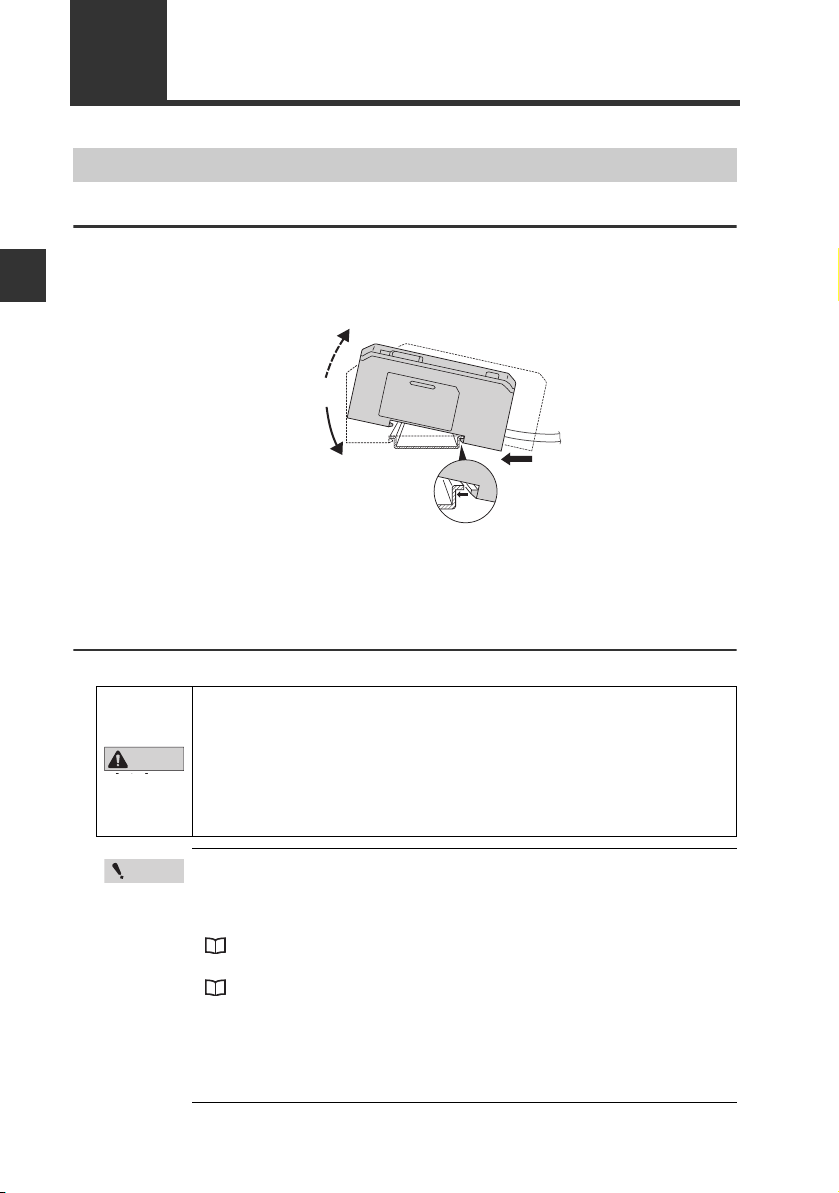

2-1 Mounting and Wiring the Sensor Amplifier

Point

Connector cover

Main unit

End unit

End unit

Remove the expansion protective cover from the IL-1000 (main unit).

1

Install the amplifiers (expansion units) on the DIN rail.

2

Refer to "DIN rail mount type, main unit (IL-1000)" (page 2-2) for details about how to

mount.

Push the expansion unit into the main unit connector until a clicking

3

sound can be heard.

The expansion unit installed next to the main unit is referred to as expansion unit 1.

Subsequent expansion units are referred to as expansion unit 2, expansion unit 3,

etc.

Main unit

Expansion unit 1

Connecter

2

Installation and Connection

IL-E

Install the end units (OP-26751: 2 units in a set) (optional accessory) on

4

both sides of the amplifiers (main and expansion units). Secure the end

units in place with screws on top (2 on each end unit).

The end units are mounted in the same way as the amplifiers.

Fix the amplifiers securely using the end units (OP-26751: 2

units in a set) (optional accessory) or commercially available

DIN rail fixing tool to prevent the amplifiers from slipping the

DIN rail or coming off from the DIN rail due to machine

vibration.

2-3

Page 24

2-1 Mounting and Wiring the Sensor Amplifier

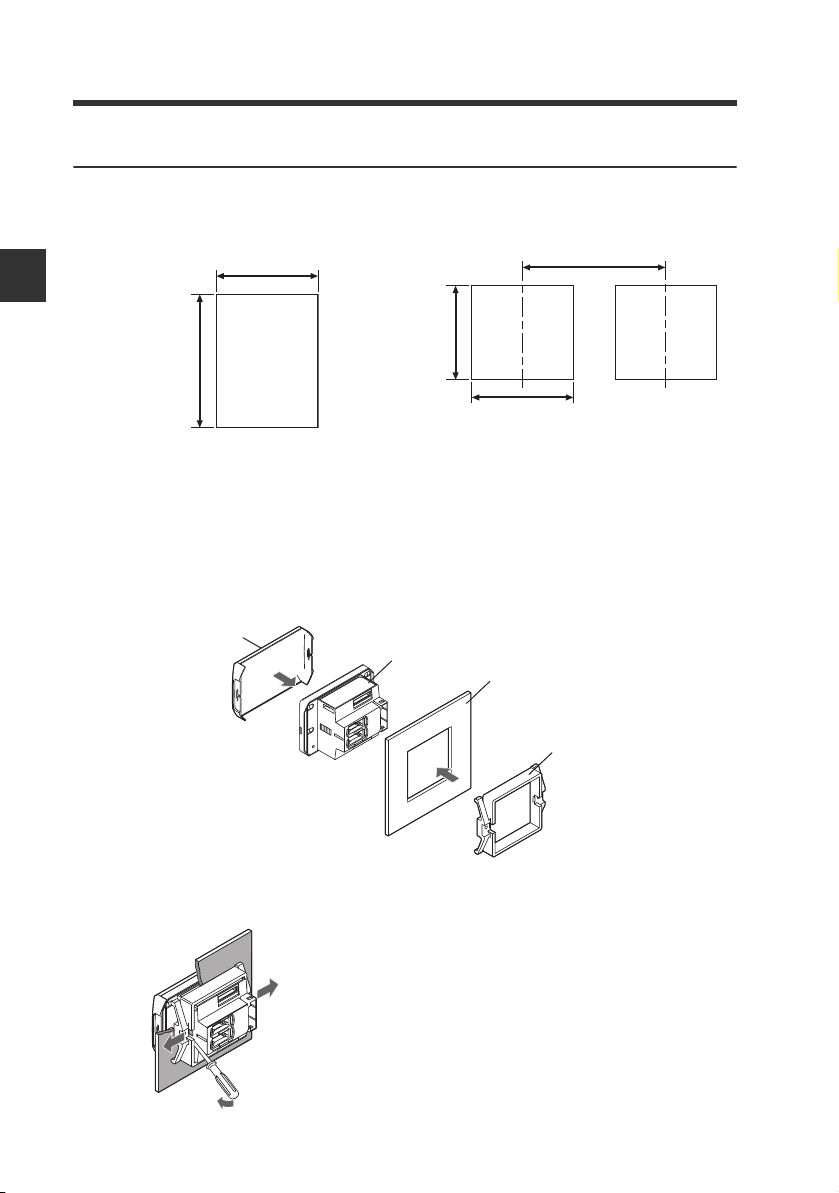

45 mm

X mm

+ 0.6

− 0

Panel mount type, main unit (IL-1500)

Make a hole on the panel as shown in the diagrams below.

1

When stacking the units vertically. When stacking the units horizontally.

2

Installation and Connection

• Panel thickness 1 to 6 mm

• X=48 x (number of amplifiers) -3

Insert the amplifier into the panel.

2

Arrange the panel mounting bracket as shown below, attach the bracket

3

to the amplifier from the back and attach the front protection cover to the

amplifier.

Front protection cover

45 mm

+ 0.6

− 0

Sensor amplifier

45 mm

Panel

Min. 85 mm

+ 0.6

− 0

2-4

Panel mounting bracket

To remove the panel mounting bracket, widen the claws at both ends of the panel

mounting bracket using a screwdriver, etc. and remove alternately.

IL-E

Page 25

2-1 Mounting and Wiring the Sensor Amplifier

CAU

CAUTION

Point

Reference

Expansion cable

Panel mount type, expansion unit (IL-1550)

Up to 7 expansion units can be connected to one main unit.

• Turn OFF the power before connecting the expansion cable.

Inserting or removing the cable with the power turned on may

cause damage to the units.

• Be sure to completely connect the expansion cable. Improper

connections may damage the equipment.

• When connecting the expansion units, make sure to initialize the

connected expansion units and set the output polarity.

When turning on the amplifier for the first time after connecting the sensor head

(1)

"3-1 Operation When the Power is Turned on for the First Time" (page 3-2)

(2) When performing the initial reset

"3-3 Initial Reset (Initialize)" (page 3-8)

•

Expansion units with different setting of output polarity (such as an NPN output

expansion unit to a PNP output main unit) cannot be connected together.

• Expansion units of panel mount type cannot be connected to the

main unit of DIN rail mount type.

Make holes on the panel to attach according to the number of amplifiers

1

(connected expansion units).

For the panel cutout dimensions, refer to the "Panel mount type, main unit (IL-1500)" (page 2-4).

Install the amplifiers (expansion units) on the panel.

2

For the amplifier mounting method, refer to the "Panel mount type, main unit

(IL-1500)" (page 2-4).

2

Installation and Connection

3

IL-E

Connect the amplifier (main unit) and amplifier (expansion unit) using the

expansion cable (50 mm) supplied with the expansion unit.

The expansion unit installed next to the main unit is referred to as expansion unit 1.

Subsequent expansion units are referred to as expansion unit 2, expansion unit 3, etc.

When arranging the amplifiers side by side, the expansion cable of 300 mm

(OP-35361) is necessary.

2-5

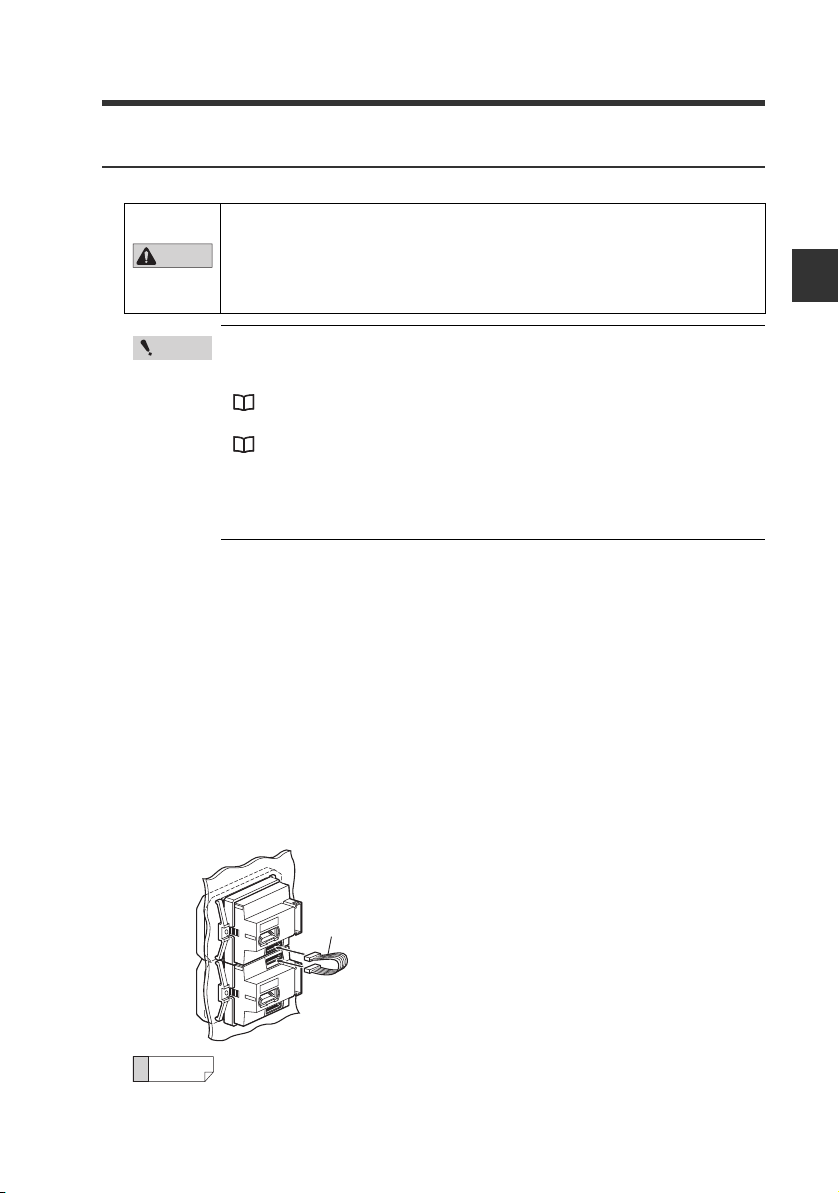

Page 26

2-1 Mounting and Wiring the Sensor Amplifier

Power/Input-output cable

To attach To remove

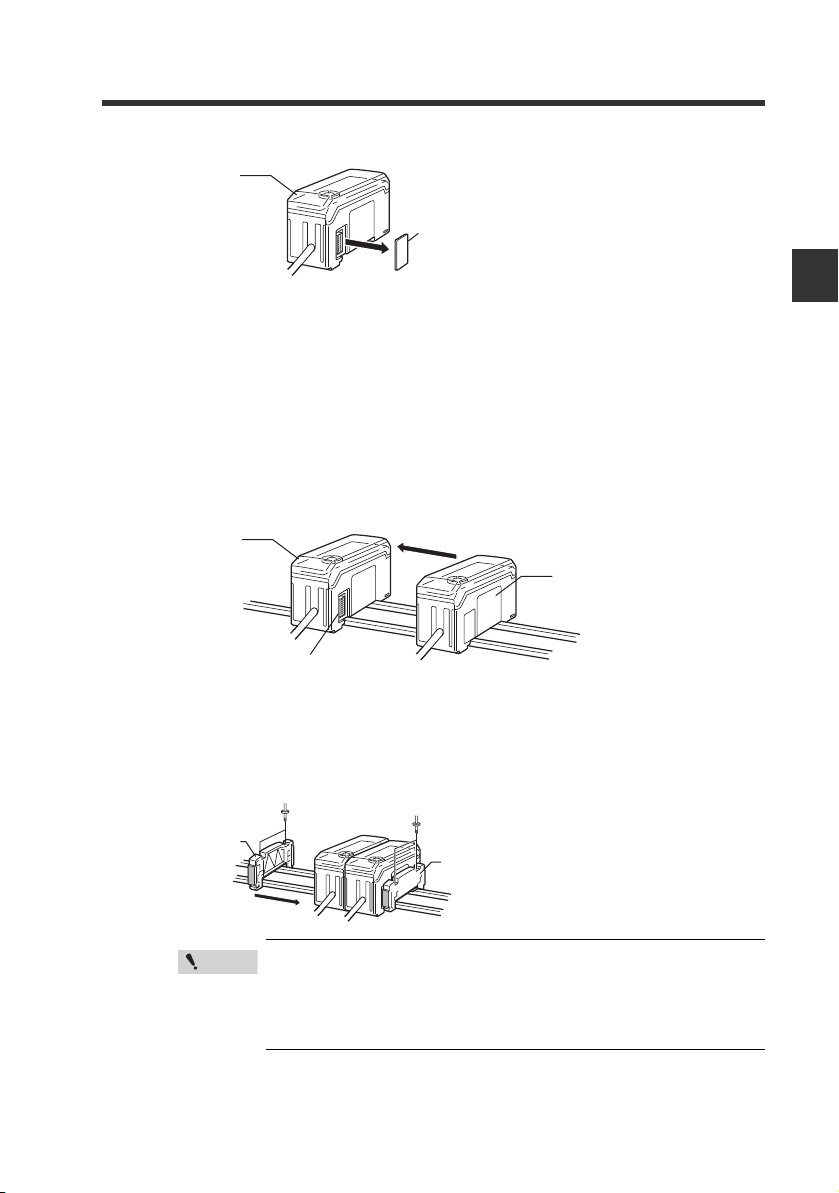

Sensor Amplifier Wiring

Connecting power/Input-output cable (only for panel mount type)

Connect the power/input-output cable to the panel mount type main unit and connect the

input-output cable to the expansion units.

2

Installation and Connection

Point

• The power/input-output cable for the main unit has 12 core wires,

and the Input-output cable for the expansion units has 8.

• Power for the expansion units is supplied from the main unit.

• If the input-output is not used for the expansion units, cut the

cable at the connector base or terminate the wires properly for

future use.

2-6

IL-E

Page 27

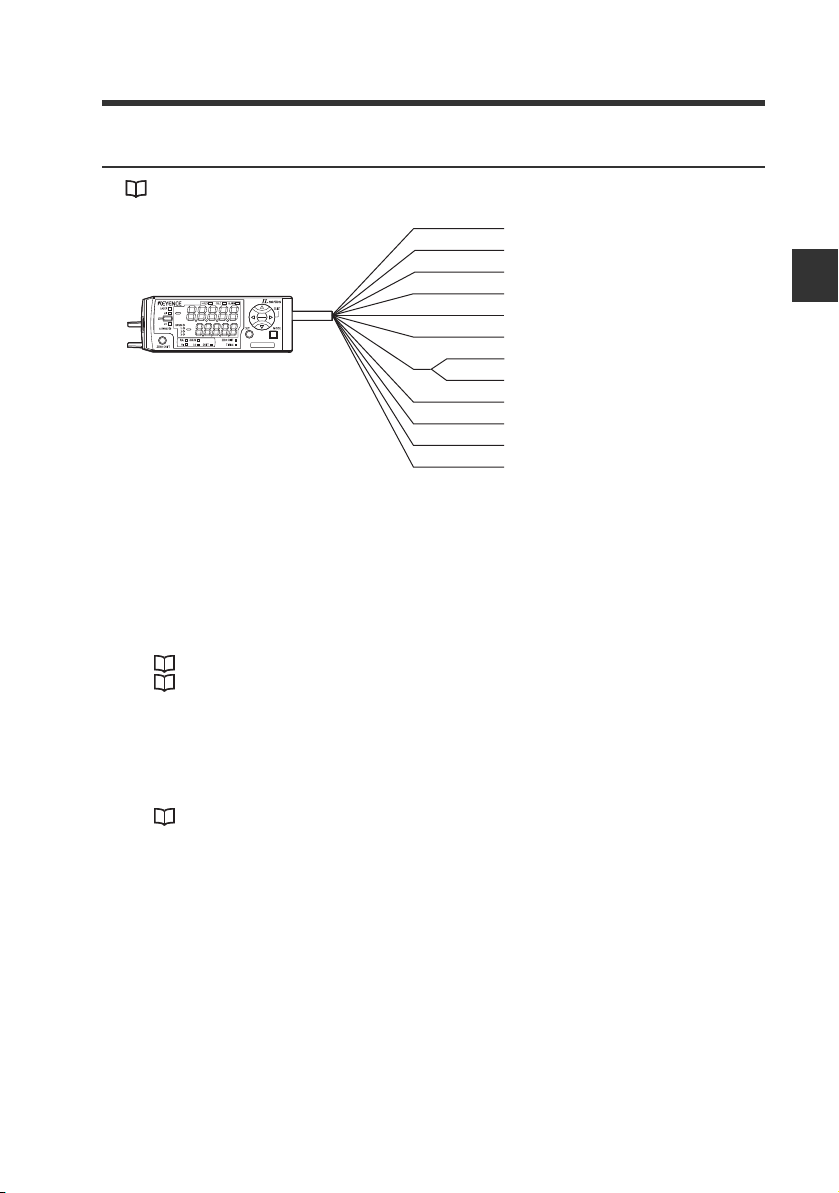

2-1 Mounting and Wiring the Sensor Amplifier

Brown

Blue

Black

White

Gray

Light blue

Orange

Shield

Pink

Yellow

Pink/Purple

Purple

Green

10 to 30 VDC

0 V

HIGH judgment output

LOW judgment output

GO judgment output

Analog output +

Analog output GND

External input 1 (Zero shift input)

External input 2 (Reset input)

External input 3 (Timing input)

External Input 4 (Not in use)

Alarm output

*1

*1

*1

*2

*2

*3

*3

*3

*3

Power/Input-output cable

"Output Circuit Diagram" (page 5-5)

*1 IL-1050/IL-1550 (expansion units) do not have brown, blue or light blue wires.

Power is supplied to the expansion units through IL-1000/IL-1500 (main unit).

*2 The analog output can be set to any of the following options either "When the power is

turned on for the first time" or "When performing the initial reset".

• Not used (OFF)

• 0 to 5 V

• -5 to 5 V

• 1 to 5 V

• 4 to 20 mA

"3-1 Operation When the Power is Turned on for the First Time" (page 3-2)

"3-3 Initial Reset (Initialize)" (page 3-8)

*3 The external input can be selected among the following in addition to the above.

• Bank A input

• Bank B input

• Laser emission stop input

• Not used (OFF)

Gain input only be selected for external input 4.

"11. External Input" (page 4-30)

*4 When expanding to six or more units, use a power supply that provides 20 to 30 V.

2

Installation and Connection

IL-E

2-7

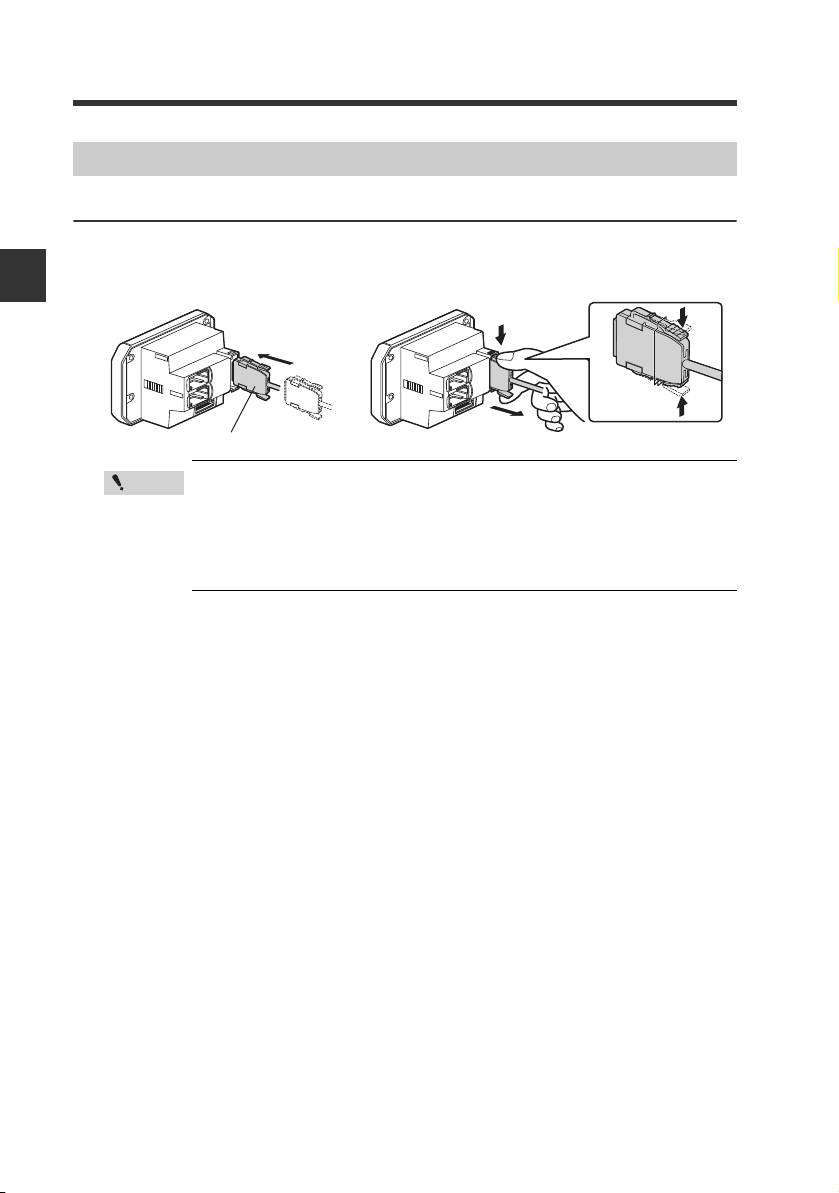

Page 28

2

Insulating sheet

Sensor head

Screws included

with the head

Intelligent-L

AVOID EXPOSURE

LASER RADIATION IS EMITTED

FROM THIS APERTURE

IL

-

030

Tightening torque:

1.2 Nm (12kgf•cm) or less

(IL-S025/IL-030/IL-S065/IL-065/

IL-100)

2.7 Nm (27kgf•cm) or less

(IL-300/IL-600)

3.0 Nm (30kgf•cm) or less

(IL-2000)

• The stray

reflections

from the wall

have little

effect.

• Variations in

the detection

value are

possible due

to stray laser

light.

• The target

cannot be

detected when

the transmitter or

receiver is

blocked.

• Stable

detection

even on

uneven

areas.

• Incorrect values

can be detected

on uneven

areas.

Installation and Connection

2-2

Connecting and Mounting the Sensor Head

Mounting the Sensor Head

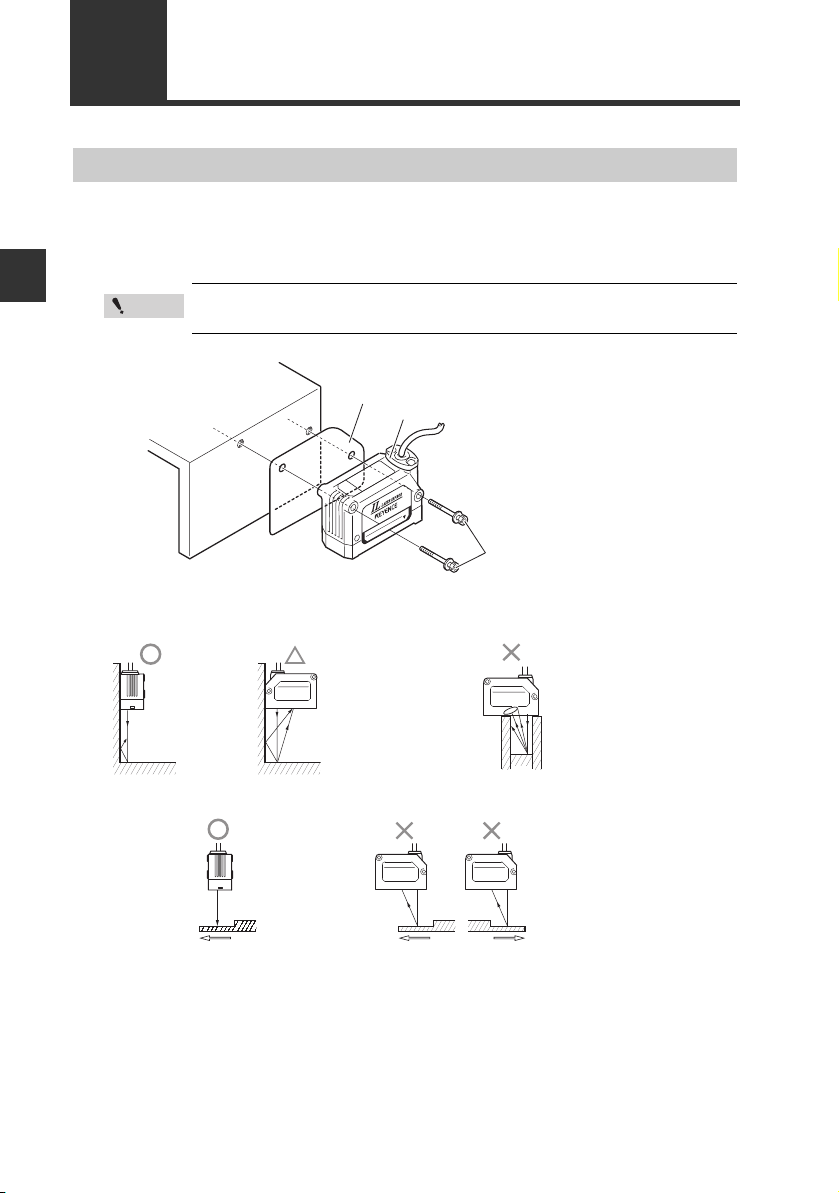

Attach the sensor head using the dedicated mounting bracket.

When the dedicated bracket is not used, place the included insulation sheet between the

mounting surface and the sensor head as indicated in the diagram. (When the dedicated

bracket is used, or when the IL-2000 is used, the insulation sheet is unnecessary.)

Point

The optical axis may vary by approximately ±1.5° (IL-S025/IL-S065/

±

IL-2000), or

2.0° (IL-030/IL-065/IL-100/IL-300/IL-600).

z Mounting when detecting targets

close to a wall

z When detecting uneven workpieces

2-8

z Mounting when detecting targets in

a hole

IL-E

Page 29

2-2 Connecting and Mounting the Sensor Head

Point

(1) Align the arrow position of the connector to insert.

(2) Rotate the connector screw to tighten.

* For the IL-2000, the direct connector will come out

directly from the sensor head, so there is no arrow.

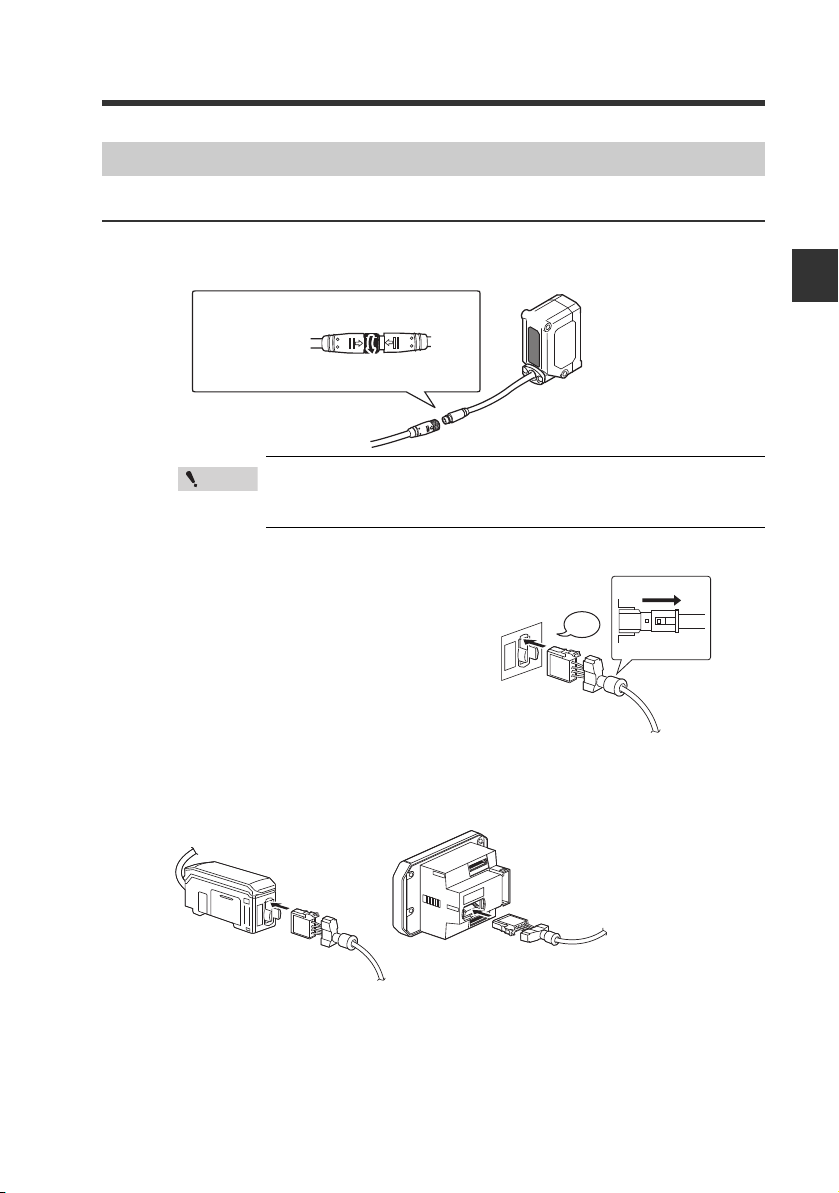

Connection and Wiring

Connecting the sensor head and amplifier

Attach the sensor head connection cables to the sensor head cable

1

Tighten the connectors securely by hand.

If they are loose, the IP67 environmental resistance rating

cannot be guaranteed.

Attach the sensor head connection cable to the amplifier connector.

2

Remove the lock cover of the connector and

insert it into the connectors of amplifier until a

clicking sound is heard.

Click

2

Installation and Connection

Lock cover

Unlocked

DIN rail mount type

(IL-1000/IL-1050)

IL-E

Panel mount type

(IL-1500/IL-1550)

2-9

Page 30

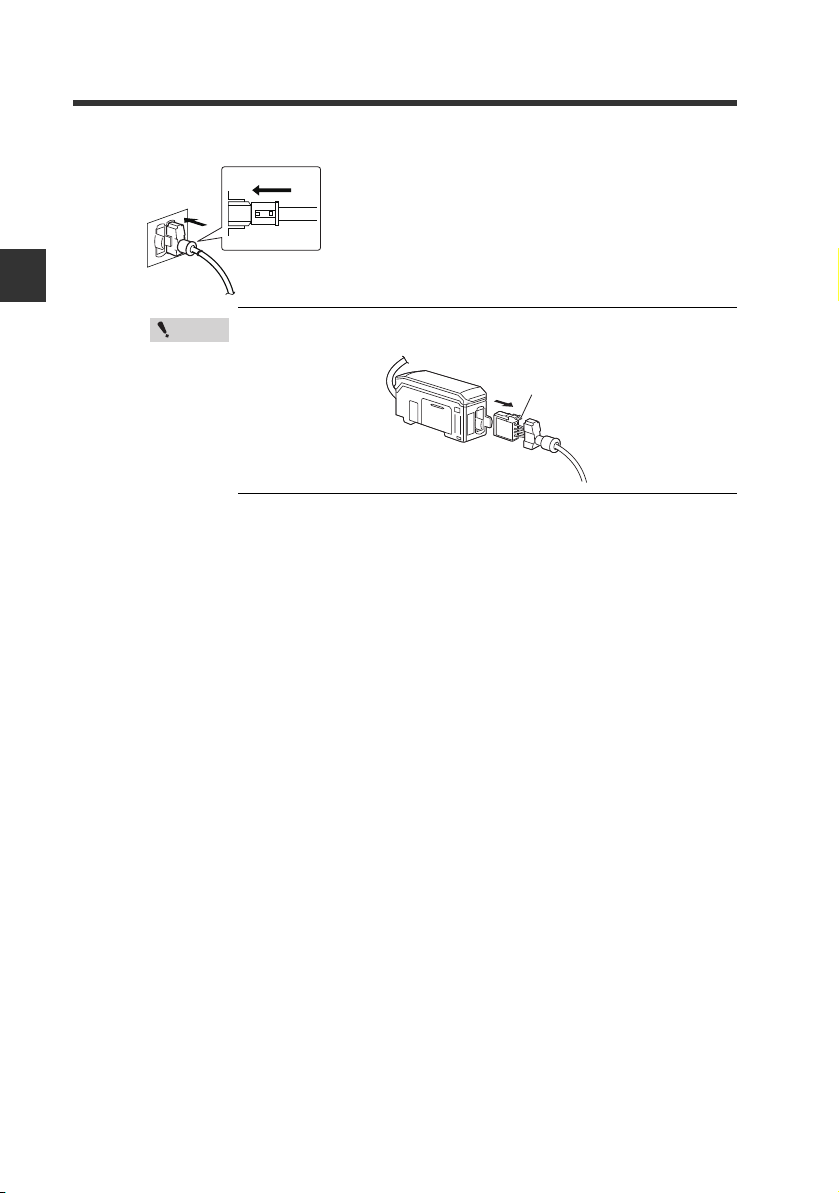

2-2 Connecting and Mounting the Sensor Head

Lock lever

Attach the lock cover to the connector to secure the cable.

3

Lock cover

Locked

2

Installation and Connection

Point

When removing the sensor head connection cable, push the

lock lever and pull it out.

2-10

IL-E

Page 31

2-2 Connecting and Mounting the Sensor Head

Point

Point

Blue

White

Black

Brown

Insert further

than here.

Attaching the sensor head cable connector (OP-84338: optional accessory)

Cut the sensor head connection cable to the required length and attach the new connector

to use the sensor. The attaching method is the same for both transmitter and receiver.

Cut the cable to the required length and strip approx. 15 mm of insulation

1

from the end of the cable.

Do not strip the core wire insulation.

Insert each cable to the end matching to the same color marks on the

2

connector.

The cables should be inserted to the end and held in place.

2

Installation and Connection

IL-E

Confirm that all cables are inserted to the specified position and crimp

3

them using pliers or a similar tool.

If the connector is changed, make sure to connect it to the

amplifier and confirm the normal operation.

If it does not operate normally, crimp the connector again with

pliers.

Once the connector is crimped, it cannot be reused.

2-11

Page 32

2-2 Connecting and Mounting the Sensor Head

2

Installation and Connection

MEMO

2-12

IL-E

Page 33

Basic Operations3

This chapter describes basic operations and settings for the IL

Series.

Operation When the Power is Turned on for the First Time

3-1

3-2 Operations on the Main Screens ......................... 3-3

3-3 Initial Reset (Initialize) .......................................... 3-8

3-4 Setting the Tolerance Setting Value .................. 3-10

3-5

Zero Shift Function (Shifting the Internal Measurement Value (R.V.))

3-6

Bank Function (Registering Multiple Tolerance Setting Values)

3-7 Key Lock Function .............................................. 3-21

....... 3-2

.... 3-18

.... 3-20

3

IL-E

3-1

Page 34

3

Point

Powe r ON

Setting value

Description

npn

NPN output

pnp

PNP output

Setting value

Description

off

Not output

0-5 u

Analog output after the judgment value (P.V.) is converted to

the range from 0 to 5 V.

-5-5 u

Analog output after the judgment value (P.V.) is converted to

the range from -5 to 5 V.

1-5 u

Analog output after the judgment value (P.V.) is converted to

the range from 1 to 5 V.

ampr

Analog output after the judgment value (P.V.) is converted to

the range from 4 to 20 mA.

Basic Operations

3-1

Operation When the Power is Turned on for the First Time

When the amplifier is turned on for the first time after the sensor head is connected, the

initial setting screen appears after a few seconds. Make the initial settings according to the

following procedure.

The initial setting is necessary for both the main unit and the expansion units when units

are added.

Once the initial setting is completed, the initial setting display will

not appear when the power is turned on the second time or the after.

To change these settings, perform an initial reset.

"3-3 Initial Reset (Initialize)" (page 3-8)

LASER

GO

ALIGNMENT

HI

LO

BANK

R.V.

HOLD CALC

QWV

0

1

2

PRP

3

ZERO SHIFT

ANALOG

HI SHIFT

LO

TIMING

Output polarity

Press S/T button to select the polarity of judgment

1

output and edge check output, and then press [MODE]

button.

CHECK

[MODE] button

CHECK

LASER

GO

ALIGNMENT

HI

LO

BANK

0

1

2

3

R.V.

HI SHIFT

HOLD CALC

#P.)

QHH

ZERO SHIFT

ANALOG

LO

TIMING

Analog output

Press S/T button to select the type of analog output

2

and press [MODE] button. (for IL-1000 / IL-1500 only)

[MODE] button

"10. Analog Output Scaling" (page 4-27)

CHECK

HOLD CALC

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

'PF

3

ZERO SHIFT

ANALOG

R.V.

HI SHIFT

LO

TIMING

Make other settings as necessary.

4

After the setting is complete, [end] blinks several

3

times on the sub display and the main screen

appears.

3-2

IL-E

Page 35

3-2 Operations on the Main Screens

LASER

BANK

0

1

2

3

HI

GO

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

[HOLD] ON

GO

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

GO

[CALC] ON

R.V. (Internal Measurement Value) and P.V. (Judgment Value)

This section describes R.V. (Internal Measurement Value) displayed on the sub display

(lower level) and P.V. (Judgment Value) displayed on the main display (upper level).

R.V. (Internal Measurement Value)

R.V. (Internal Measurement Value) is the value displayed when a target is inserted into the

measurement range.

* R.V. = Raw Value

P.V. ( Jud g me n t Va lu e )

P.V. (Judgment Value) is the value to set the judgment output to ON/OFF according to the

tolerance setting value. Also, the analog output is output based on the P.V..

* P.V. = Present Value

"3-4 Setting the Tolerance Setting Value" (page 3-10)

The Judgment value (P.V.) and the Internal Measurement Value (R.V.) are in general the

same value. However, when the hold function or step-count filter is used, or when only the

calculation function is used, they will become different values.

"6. Hold Function" (page 4-15)

"4-3 Calculation Function" (page 4-42) (page 4-39)

Main Display (Upper Level)

The judgment value (P.V.) is displayed on the main display.

The display varies as below according to each function to be used such as Normal, Hold

function, Calculation function.

Normal

The same value as the internal measurement value (R.V.) is displayed

as a judgment value (P.V.).

When the hold function is used, when the step count filter is used

The judgment value (P.V.) is held according to the hold function settings.

The Judgment Value (P.V.) is held according to the step count filter

settings if they are stepped and acknowledged.

"6. Hold Function" (page 4-15)

"3. Averaging rate, Step count filter, High-pass filter" (page 4-9)

When the calculation function is used

Main unit:

Expansion unit: The same display as for Normal

"4-3 Calculation Function" (page 4-42) (page 4-39)

Displays the calculated result (calculation value) with the

calculation function as a judgment value (P.V.).

3

Basic Operations

Reference

When using both the hold function and calculation function with the main

unit, the hold indicator [HOLD] and calculation indicator [CALC] will light.

The judgment value (P.V.) on the main display will follow the hold function

settings. The calculated value (CALC value) will be held and displayed as

the judgment value (P.V.)

IL-E

3-3

Page 36

3-2 Operations on the Main Screens

(1) R.V. display screen

(6) Calculated value display screen

* Displayed only for the main

unit and when the calculation

function is used.

* Displayed only for the

main unit and when the

analog output is used.

(2) Analog output screen

(5) Shift target value setting screen

(3) HIGH side setting value screen

(4) LOW side setting value screen

*1 (6) [CALc] displayed for

approx. 2 seconds when

calculated value display

screen appears.

Sub Display (Lower Level)

The sub display can be switched with the arrow button W/X.

According to the type of displayed value, the sub display indicator [R.V. / ANALOG / HI / LO

/ SHIFT] lights up.

3

Basic Operations

LASER

HI

GO

[R.V.]

LO

ALIGNMENT

BANK

ON

HOLD CALC

R.V.

0

1

2

3

ZERO SHIFT

R.V.

ANALOG

HI SHIFT

LO

CHECK

TIMING

LASER

HI

GO

All

LO

BANK

0

1

ALIGNMENT

OFF

2

3

R.V.

ANALOG

HI SHIFT

LO

LASER

Shift target value

HI

GO

LO

BANK

0

1

ALIGNMENT

2

[SHIFT]

3

ANALOG

R.V.

ON

HI SHIFT

LO

HOLD CALC

CHECK

CALC value

ZERO SHIFT

TIMING

CHECK

HOLD CALC

ZERO SHIFT

TIMING

*1

LASER

GO

ALIGNMENT

[ANALOG]

LASER

HIGH side setting value

GO

ALIGNMENT

[HI]

ON

LASER

LOW side setting value

HI

GO

LO

BANK

0

1

ALIGNMENT

2

[LO]

3

R.V.

ON

HI SHIFT

CHECK

HOLD CALC

ZERO SHIFT

ANALOG

LO

TIMING

HOLD CALC

Analog output

HI

LO

BANK

0

1

2

W

3

ANALOG

R.V.

ON

HI SHIFT

LO

HOLD CALC

HI

LO

BANK

0

1

2

3

R.V.

ANALOG

LO

HI SHIFT

CHECK

ZERO SHIFT

TIMING

CHECK

ZERO SHIFT

TIMING

3-4

IL-E

Page 37

3-2 Operations on the Main Screens

(1) R.V. display screen

The internal measurement value (R.V.) is displayed. The displayed value is not held.

(2) Analog output screen (Displayed when using main unit's analog output)

The voltage value (unit: V) or current value (unit: mA) of the analog output is displayed.

"3-1 Operation When the Power is Turned on for the First Time" (page 3-2)

"3-3 Initial Reset (Initialize)" (page 3-8)

(3) HIGH side setting value screen

The upper limit of the acceptable range (tolerance setting value) for the object is

displayed. Also, the setting value can be changed. If the judgment value (P.V.) exceeds

the value set here, the HIGH judgment output turns on.

"3-4 Setting the Tolerance Setting Value" (page 3-10)

(4) LOW side setting value screen

The lower limit of the acceptable range (tolerance setting value) for the object is

displayed. Also, the setting value can be changed. If the judgment value (P.V.) falls

below the value set here, the LOW judgment output turns on.

"3-4 Setting the Tolerance Setting Value" (page 3-10)

(5) Shift target value screen

When the zero shift button is pressed or the zero shift input is set to ON, the internal

measurement value (R.V.) is adjusted to the value set here.

"3-5 Zero Shift Function (Shifting the Internal Measurement Value (R.V.))" (page 3-18)

(page 3-18)

3

Basic Operations

(6) Calculation value screen (Displayed when using main unit's calculation function)

The calculated value (CALC value) is displayed. The displayed value is not held.

"4-3 Calculation Function" (page 4-42) (page 4-39)

IL-E

3-5

Page 38

3-2 Operations on the Main Screens

LASER

BANK

0

1

2

3

HI

GO

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

Setting Operations

This section explains functions operable on the main screen and functions operable after

the display changes to each setting screen.

Functions Operable on the Main Screen

DIN rail mount type (IL-1000/IL-1050) Panel mount type (IL-1500/IL-1550)

3

Basic Operations

Main screen

Buttons used

Press W or X button.

Switching display on the sub display (lower level) (page 3-4)

Any of the internal measurement value (R.V.), analog output

value, HIGH side setting value, LOW side setting value or shift

target value are displayed and the settings can be changed.

3-4 Setting the Tolerance Setting Value (page 3-10)

HIGH side setting value and LOW side setting value are set. The judgment is

made among HIGH/GO/LOW, and the value is displayed and output.

3-5 Zero Shift Function (Shifting the Internal Measurement

Value (R.V.)) (page 3-18)

The internal measurement value (R.V.) can be shifted (offset)

to an arbitrary shift target value.

While pressing down [MODE], press S or T button.

3-6 Bank Function (Registering Multiple Tolerance Setting Values) (page 3-20)

HIGH side setting value, LOW side setting value, shift target

value, and analog output scaling upper / lower limit value can

be saved at up to four banks and switched.

Press [MODE] and S buttons for approx. 2 seconds.

or

Press [MODE] and T buttons for approx. 2 seconds.

3-7 Key Lock Function (page 3-21)

This function prevents unwanted button operations during measurement.

3-6

IL-E

Page 39

Available Functions from the Main Screen

LASER

BANK

0

1

2

3

HI

GO

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

Main screen

Press [MODE] button for approx. 2 seconds.

4-2 Basic Settings and Advanced Settings (page 4-4)

Basic settings

Basic settings such as measurement mode, response time

are made.

Advanced settings

More advanced settings such as hold function, delay timer

enable the unit to be used in wider applications.

Press [MODE] and W buttons for approx. 2 seconds.

4-3 Calculation Function (page 4-42)

The internal measurement value (R.V.) of two sets of the

sensor amplifier can be calculated (addition or subtraction).

Press [MODE] and X buttons for approx. 2 seconds.

4-4 Calibration Function (page 4-45)

When there is a difference between the internal

measurement value (R.V.) or calculated value (CALC value)

and the actual dimension of the object, the value can be

calibrated.

While pressing the [MODE] button, press the [SET] button 5

times.

3-3 Initial Reset (Initialize) (page 3-8)

All settings, excluding the calibration function, are initialized.

3-2 Operations on the Main Screens

3

Basic Operations

IL-E

3-7

Page 40

3

Reference

Setting value

Description

npn

NPN output

pnp

PNP output

Setting value

Description

off

Not output

0-5 u

Analog output after the judgment value is converted to the range from 0 to 5 V.

-5-5 u

Analog output after the judgment value is converted to the range from -5 to 5 V.

1-5 u

Analog output after the judgment value is converted to the range from 1 to 5 V.

aMpr

Analog output after the judgment value is converted to the range from 4 to 20 mA.

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

.QE

GO

HOLD CALC

CHECK

Basic Operations

3-3 Initial Reset (Initialize)

When initial reset is performed, all settings, excluding the calibration function, are initialized.

The judgment output's polarity and analog output setting can be changed with the same operation.

Main screen

HOLD CALC

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

ANALOG

R.V.

HI SHIFT

LO

While pressing the

[MODE] button,

press the [SET]

button 5 times.

HOLD CALC

LASER

HI

GO

T'5'V

LO

BANK

0

1

ALIGNMENT

2

3

ANALOG

R.V.

HI SHIFT

LO

Performing the initial reset

[MODE] button

HOLD CALC

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

ANALOG

R.V.

HI SHIFT

LO

Output polarity

[MODE] button

HOLD CALC

LASER

HI

GO

#P.)

LO

BANK

0

1

ALIGNMENT

2

3

ANALOG

R.V.

HI SHIFT

LO

Analog output

ZERO SHIFT

TIMING

;GU

ZERO SHIFT

TIMING

QWV

PRP

ZERO SHIFT

TIMING

QHH

ZERO SHIFT

TIMING

CHECK

CHECK

CHECK

CHECK

While pressing the [MODE] button on the main screen,

1

press the [SET] button 5 times.

[reset] is displayed on the main display (upper level).

Press S/T button to select [yes] and press the

2

[MODE] button.

If [no] is selected at this point, only the output polarity and analog

output settings can be changed without performing the initial reset.

Press S/T button to select the output polarity and

3

press the [MODE] button.

Press S/T button to select the analog output and

4

press the [MODE] button. (only for IL-1000 / IL-1500

only)

[MODE] button

LASER

GO

ALIGNMENT

HI

LO

BANK

HOLD CALC

T'5'V

0

1

2

3

ANALOG

R.V.

HI SHIFT

LO

Point

CHECK

'PF

ZERO SHIFT

TIMING

If the calculation function is used, perform the initial reset for the

main unit first.

After the initialization is complete, [

5

times on the sub display and the main screen is restored.

• When buttons other than the S/T button and [MODE] button are pressed

during the initial reset procedure, the initial reset is canceled and the

screen in step 2 is restored.

• When you attempt to initialize the unit while the key

lock function is set, the screen shown on the right

appears and the initialization fails.

3-8

Cancel the key lock before attempting to initialize the unit.

"3-7 Key Lock Function" (page 3-21)

"10. Analog Output Scaling" (page 4-27)

end

] blinks several

IL-E

Page 41

3-3 Initial Reset (Initialize)

GO

;QTP

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

T'5'V

HOLD CALC

CHECK

Operation for Changing the Model of Connected Head

If the model of the connected head has been changed, the zero shift function and

calibration function must be initialized.

The following display will appear when the connected head's model is changed.

Connect the head of different model into the amplifier.

1

[rESET] will appear on the main display, and [Y.or.n] will appear on the sub display.

Press S/T button to select [yes] and press the [MODE] button.

2

When [yes] is selected, all functions including the calibration function will be

initialized. After the initialization is complete, [End] blinks several times on the sub

display and the main screen is restored. When [no] is selected, the main screen is

restored. The zero shift function and calibration function will not be initialized.

3

Basic Operations

IL-E

3-9

Page 42

3

Basic Operations

3-4

The tolerance setting value consists of the upper limit value (HIGH side setting value) and

the lower limit value (LOW side setting value). By setting these values, judgments are made

in three levels: when the judgment value (P.V.) goes beyond the upper limit (HIGH

judgment), when the judgment goes beyond the lower limit (LOW judgment) and when the

judgment is within the acceptable range (GO judgment). Then, the judgment indicator and

judgment output are turned ON/OFF.

judgment

HIGH ON OFF OFF Red OFF OFF

GO OFF ON OFF OFF Green OFF

LOW OFF OFF ON OFF OFF Red

Error

*1 When the output state of judgment output is Normally Open (default value) ON/OFF is

reversed for Normal Close.

*2 The judgment indicator ON/OFF condition can be changed.

*3 "Error Displays and Corrective Actions" (page A-4)

DIN rail mount type (IL-1000/IL-1050) Panel mount type (IL-1500/IL-1550)

Setting the Tolerance Setting Value

judgment output

HIGH GO LOW HI GO LO

*3

ON OFF ON Red OFF Red

"5. Output State" (page 4-14)

"18. Display Color" (page 4-41)

*1

judgment indicator

*2

Judgment indicator

The tolerance setting value can be set either manually or automatically.

Item Setting Method

Manual setting

Automatic

setting

(When other

than step count

filter)

Automatic

setting

(When step

count filter)

Point

Tolerance tuning Detect the master workpiece and set the tolerance.

2 point tuning

2 point tuning Detect the step, set the tolerance.

1 point tuning

When setting the tolerance setting value manually using the two-point

tuning, make sure to set "HIGH side setting value

Directly enter the tolerance setting value (HIGH side

setting value, LOW side setting value).

Detect the good target and defective target and set the

tolerance.

Detect the present P.V. (Judgment Value), set the

tolerance.

3-10

>

LOW side setting value".

IL-E

Page 43

3-4 Setting the Tolerance Setting Value

Reference

GO

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

[HI]

ON

HIGH side setting value

When setting "HIGH side setting value < LOW side setting value", the

judgment output is as follows.

GO judgment output is not output regardless of the judgment value (P.V.).

•

(When setting HIGH side setting value = LOW side setting value = judgment value

(P.V.) and setting the hysteresis to 0.000, GO judgment output is turned on.)

• When the judgment value (P.V.) goes beyond the HIGH side setting value

and falls below the LOW side setting value, the HIGH judgment output

and LOW judgment output are output at the same time.

Manual Setting

This is the method to directly enter the tolerance setting value (HIGH side setting value,

LOW side setting value).

Press the W / X button several times on the main screen. Then display the

1

HIGH side setting value on the sub display (lower level).

"Sub Display (Lower Level)" (page 3-4)

Press S / T button to set the HIGH side setting value.

2

IL-S025/IL-030/IL-S065/IL-065/IL-100

Item Setting range

HIGH side setting value -99.999 to 99.999 5.000

IL-300/IL-600

Item Setting range

HIGH side setting value -999.99 to 999.99 50.00

IL-2000

Item Setting range

HIGH side setting value -9999.9 to 9999.9 500.0

Press the X

3

display (lower level).

button once and display the LOW side setting value on the sub

Default value

Default value

Default value

3

Basic Operations

IL-E

LOW side setting value

[LO]

ON

3-11

Page 44

3-4 Setting the Tolerance Setting Value

Reference

Reference

Press S / T button to set the LOW side setting value.

4

IL-S025/IL-030/IL-S065/IL-065/IL-100

Item Setting range

LOW side setting value -99.999 to 99.999 -5.000

IL-300/IL-600

Item Setting range

LOW side setting value -999.99 to 999.99 -50.00

3

IL-2000

Item Setting range

Basic Operations

LOW side setting value -9999.9 to 9999.9 -500.0

After setting, press W / X button to return the sub display to the original display as

necessary.

As soon as the HIGH side setting value and the LOW side setting value are

entered, the judgment and output begin with the new setting value.

Automatic Setting (When other than step count filter)

Tolerance tuning

When the target (master workpiece) as a reference is present, the HIGH side setting value

(upper limit) and LOW side setting value (lower limit) can automatically be set with the

master workpiece measurement value as the center value.

When the tuning result exceeds the setting range, the limit value of the

setting range is considered as the setting value.

Default value

Default value

Default value

3-12

Point

The tolerance tuning cannot be performed when the judgment value

(P.V.) is displayed as [-----].

If attempting to perform, [no.uaL] blinks several times on the main

display.

Press the W / X button several times on the main screen. Then display the

1

R.V. display screen on the sub display (lower level).

"Sub Display (Lower Level)" (page 3-4)

HOLD CALC

LASER

HI

GO

[R.V.]

LO

BANK

0

1

ALIGNMENT

ON

2

3

R.V.

HI SHIFT

Measure the master workpiece and press the [SET] button.

2

CHECK

R.V.

ZERO SHIFT

ANALOG

LO

TIMING

The judgment value (P.V.) as a reference value for the tolerance setting is imported.

[

set

] and the tolerance setting width are displayed alternately on the sub display (lower level).

IL-E

Page 45

3-4 Setting the Tolerance Setting Value

Setting width

Measurement upper limit value

Measurement lower limit value

LOW side setting value (lower limit)

HIGH side setting value (upper limit)

Master target P.V. (reference value)

IL-S025/IL-030/IL-S065/IL-065/IL-100

IL-300/IL-600

IL-2000

Item Setting range

Default value

Setting width 0.000 to 99.999 0.200

Item Setting range

Default value

Setting width 0.00 to 999.99 2.00

Item Setting range

Default value

Setting width 0.0 to 9999.9 20.0

Press S / T button to set the tolerance setting width.

3

Master workpiece P.V.

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

Tolerance setting width

Press the [SET] button to complete the tolerance tuning.

4

[set]

blinks on the main display (upper level), and the HIGH side setting value and LOW

ANALOG

LO

HOLD CALC

CHECK

ZERO SHIFT

TIMING

side setting value are determined. Then, the display returns to the R.V. screen automatically.

3

Basic Operations

IL-E

3-13

Page 46

3-4 Setting the Tolerance Setting Value

Reference

2 point tuning

With this method, the median value of the good target and defective target is set as the

tolerance setting value when there are good target and HIGH/LOW defective target.

When the tuning result exceeds the setting range, the limit value of the

setting range becomes the setting value.

Point

Two-point tuning is not performed if the internal measurement value

(R.V.) is [-----].

If performed, [no.uaL] will blink several times on the main display.

3

Press the W / X button several times on the main screen. Then display the

Basic Operations

1

HIGH side setting value on the sub display (lower level).

"Sub Display (Lower Level)" (page 3-4)

HOLD CALC

LASER

HIGH side setting value

HI

GO

LO

BANK

0

1

ALIGNMENT

2

[HI]

3

R.V.

ON

HI SHIFT

Measure the good target and press the [SET] button. (HIGH side 1st point

2

confirmation operation)

CHECK

ZERO SHIFT

ANALOG

LO

TIMING

The internal measurement value (R.V.) is imported as a good target measurement value.

[Hiset] is displayed on the main display (upper level).

3-14

Measure the HIGH side defective target and press the [SET] button. (HIGH

3

side 2nd point confirmation operation)

The internal measurement value (R.V.) is imported as a measurement value for

HIGH side defective target.

After [set] blinks on the main display (upper level), the judgment value (P.V.) is

displayed.

On the sub display (lower level), the median value of the good target value (1st point)

imported on step 5 and HIGH defective target value (2nd point) is displayed.

Setting the HIGH side setting value (upper limit) is complete.

Press the X

4

display (lower level).

button once and display the LOW side setting value on the sub

LOW side setting value

[LO]

ON

IL-E

Page 47

3-4 Setting the Tolerance Setting Value

Setting value for the HIGH side defective target

Setting value for the LOW side defective target

Setting value for the good target

Measurement upper limit value

Measurement lower limit value

LOW side setting value (lower limit)

HIGH side setting value (upper limit)

Measure the good target again and press the [SET] button. (LOW side 1st

5

point confirmation operation)

The internal measurement value (R.V.) is imported as a good target measurement

value.

[Loset] is displayed on the main display (upper level).

Measure the LOW side defective target and press the [SET] button. (LOW

6

side 2nd point confirmation operation)

The internal measurement value (R.V.) is imported as a measurement value for LOW

side defective target.

After [set] blinks on the main display (upper level), the judgment value (P.V.) is

displayed.

On the sub display (lower level), the median value of the good target value (1st point)

imported on step 5 and LOW defective target value (2nd point) is displayed.

Setting the LOW side setting value (lower limit) is complete.

The two-point tuning is complete.

3

Basic Operations

IL-E

3-15

Page 48

3-4 Setting the Tolerance Setting Value

R.V (Internal Measurement Value)

P.V (Judgment Value)

*.5'V

Displays the difference with the absolute value of

the first taken R.V. (Internal Measurement Value).

Automatic Setting (When step count filter)

2 point tuning

When there is a standard step, 2 times the value of the step will be set as HIGH (upper limit

value) and half of the value of the step will be set as LOW (lower limit value) automatically.

If the step of the measured value of the upper part is A, and the measured part of the lower

part of the step is B, it will be set as HIGH= |(A-B) x 2|, LOW = |(A-B) ÷ 2|

If the tuning result exceeds the setting range, the setting range limit will become the setting value.

3

Basic Operations

Point

From the main screen press the W / X button multiple times, from the sub-

1

display (bottom step) the R.V. (Internal Measurement Value) display

screen will appear.

When the R.V. (Internal Measurement Value) is [-----], the 2 point

tuning cannot occur. If it does occur, [no.vAL] will be displayed on the

main screen, and the number of points will decrease. The setting

value cannot be changed.

"Sub Display (Lower Level)" (page 3-4)

Press the [SET] button at the top of the step.

2

The following screen is displayed after operation.

Change the position of the work piece, press the (SET) button at the

3

bottom of the step.

The following screen is displayed after operation.

5'V

The HIGH side setting value (upper limit value) will be set as a value

4

double of the step, and the LOW side setting value (lower limit value) will

be set as a value of half of the step.

(Example) The case below is when the upper part of the step is 5.000, the lower part

of the step is 2.000.

HIGH side setting value: |(5.000-2.000) x 2| = 6.000

LOW setting side value: |(5.000-2.000) ÷ 2| = 1.500

*1 The upper and lower parts of 2 and 3 can be switched.

3-16

*1

Quickly blinking

Displays the difference between the first taken R.V.

(Internal Measurement Value) and the second absolute.

*1

IL-E

Page 49

3-4 Setting the Tolerance Setting Value

Point

1 point tuning

When there is a measurement object (herein masterwork) that can be understood from the

standard step, based on the step value (P.V.) of the masterwork, 2 times the Judgment

Value HIGH side setting value (upper limit) and 1/2 of the Judgment Value LOW side setting

value (lower limit) can be set automatically.

If the P.V. (Judgment Value) is A, HIGH = |(A) x 2|, and LOW = |(A) ÷ 2| will be the settings.

If the tuning result surpasses the setting range, the setting value will be the setting range

limit value.

When the P.V. (Judgment Value) is [-----], the 1 point tuning cannot

occur. If it does occur, [no.vAL] will be displayed on the main screen,

and the number of points will decrease. The setting value cannot be

changed.

From the main screen press the W / X button multiple times, from the sub-

1

display (bottom step) the R.V. (Internal Measurement Value) display

screen will appear.

"Sub Display (Lower Level)" (page 3-4)

After the step measurement by the masterwork (after P.V. is fixed), press

2

and hold the [SET] button.

The HIGH side setting value (upper limit value) will be set a 2 times the

3

value of the P.V. (Judgment Value), and the LOW side setting value (lower

limit value) will be set as 1/2 of the setting value.

(Example) When the P.V. (Judgment Value) is 4000, it will be as follows.

HIGH side setting value: |(4.000) x 2| = 8.000

LOW setting side value: |(4.000) ÷ 2| = 2.000

P.V (Judgment Value)

R.V (Internal Measurement Value)

3

Basic Operations

IL-E

3-17

Page 50

3

Basic Operations

3-5