Page 1

WARNINGWARNING

CAUTION

Note

WARNINGWARNING

WARNINGWARNING

96M11149

CCD

Thrubeam Type Laser Sensor

IG Series

Instruction manual

Read this instruction manual carefully prior to operating the IG Series CCD Thrubeam

Laser Sensor.

After reading, keep this manual in a safe place so that you can refer to it at any time.

• For details of each function, refer to “CCD Thrubeam Laser Sensor IG Series User’s

Manual”.

• You can download “CCD Thrubeam Laser Sensor IG Series User’s Manual” from

KEYENCE homepage (http://www.keyence.co.jp/).

Abnormal conditions

If the following conditions occur, turn off the power immediately. Continuing

to use this product under abnormal conditions may cause product failure.

• When water or foreign matter enters the IG Series

WARNINGWARNING

• When the IG Series is dropped or the case is damaged

• When the IG Series pr oduces smoke or an unpleasant smell

Precautions on use

• Use with the specified power source and voltage. Otherwise, fire, electric

shock or product failure may result.

WARNINGWARNING

•

Never disassemble or modify this product. Fire or electric shock may result.

• Before disconnecting the cables, make sure to turn off the main unit and

devices connected to the main unit. Otherwise, the unit could be

damaged.

CAUTION

• Do not turn off the power to the unit while it is being programmed. Some

or all of the set data may be lost.

Failure to follow these instructions may lead to injury.

Failure to follow these instructions may lead to product damage (product

malfunction, etc.).

This provides additional helpful information to ensure your understanding of

the unit's functions.

This references information that will aid your understanding of the text

Reference

.

descriptions.

Safety Information for IG series

General precautions

• At startup and during operation, be sure to monitor the functions and performance of this

product and confirm normal operation.

• We recommend that you take substantial safety measures to avoid any damage in the

event that a problem occurs.

• If the product is modified or used in any way other than described in the specifications, its

functions and performance cannot be guaranteed.

• Do not use this product for the purpose of protecting the human body.

• Do not subject this device to rapid temperature changes, otherwise product failure may

occur.

• The IG Series is intended for measuring objects. Do not use this product

for the purpose of protecti ng the human body.

• This product is not made with an explosion proof construction. Do not use

it in a location where any flammable gases, liquid, or powder exist.

Safety Precautions on Laser Product

• This product employs a semiconductor laser for its light source.

• Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

• Follow the instructions mentioned in this manual. Otherwise, injur y to the

human body (eyes and skin) may result.

Precautions on class 1 laser products

• Do not disassemble this product. Laser emission from this product is not

automatically stopped when it is disassembled.

• Do not stare into the beam.

Sensor head IG-010/028

Wavelength 660 nm

Output 62 μW

Pulse width 48 μs

FDA(CDRH)Part1040.10* Class 1 Laser Product

IEC60825-1 Class 1 Laser Product

* The classification is based on IEC60825-1 standard following the Laser Notice No. 50 from

FDA (CDRH).

Laser emission stop input

When the laser emission stop input is activated, the laser emission stops by setting the

external input to ON (for 2 ms or more). The laser emission continues to stop while the

external input is ON. When the external input is set to OFF, the laser is emitted within 2 ms.

For details of the discrete outputs or analog output conditions during the laser emission

stop input, refer to the User’s Manual “11. External input”.

Installation environment

To ensure that it is being safely used, do not install this product in the following locations.

• High-humidity, dusty and poorly-ventilated locations.

• High-temperature locations where the unit is exposed to direct sunlight.

• Locations where there is corrosive gas or combustible gas.

• Locations where the unit may be directly subjected to vibration or impact.

• Locations where water, oil, or chemicals may splash onto the unit.

• Locations where the static electricity tend to be generated.

Influence of dirt

• Measurement errors may occur due to dust, water, oil, etc.

• Remove such dirt stuck to transmitter and receiver with either an air purge or wipe with a

soft cloth moistened with alcohol for heavy dirt. If the transmitter and receiver get

scratched, measurement errors may occur.

• Remove dirt attached to the target with either an air purge or it off.

• If dirt is floating within the measurement range, take adequate measures, such as

installing a dust protection cover or air purging.

Anti-noise prevention

When the unit is installed near a noisy source such as a power generator or high-voltage

line, operational errors or product failure may occur. Take adequate measures such as

using a noise filter, arranging cords appropriately, or insulating the amplifier and sensor

head.

Warm up

Wait approximately 10 minutes after power up before using the IG series so as to allow

forthe display value to stabilize upon warm up.

Other Precautions

Power source

• Operation errors may occur due to noise superimposed upon the power source. Make

certain to use the direct current stabilized power source which uses an insulation

transformer.

• When using a commercially available switching regulator, make sure to properly ground

the frame.

Precautions on UL Certificate

The IG series complies with the following UL and CSA standards. The IG series has

obtained UL and C-UL certificate.

• Applicable standardUL508 Industrial Control Equipment

CAN/CSA C22.2 No.14-M05 Industrial Control Equipment

• UL File No.E301717

• UL category: NRKH, NRKH7

Precautions

• The IG series must have its power supplied from a Class 2 power source according to

NFPA70 (NEC: National Electrical Code).

• The UL certificate for the IG series is for the sensor head and amplifier used in

combination. The IG series sensor head must be used together with the IG series sensor

amplifier unit exclusively.

• Power supply/Control input/Control output shall be connected to a single Class2 source

only.

• Use with over current protection device which is rated 30V or more and not more than 1A.

1

Page 2

Checking the Package Contents

Before using the unit, confirm that the parts and equipment listed below are included in the

package of the model you purchased.

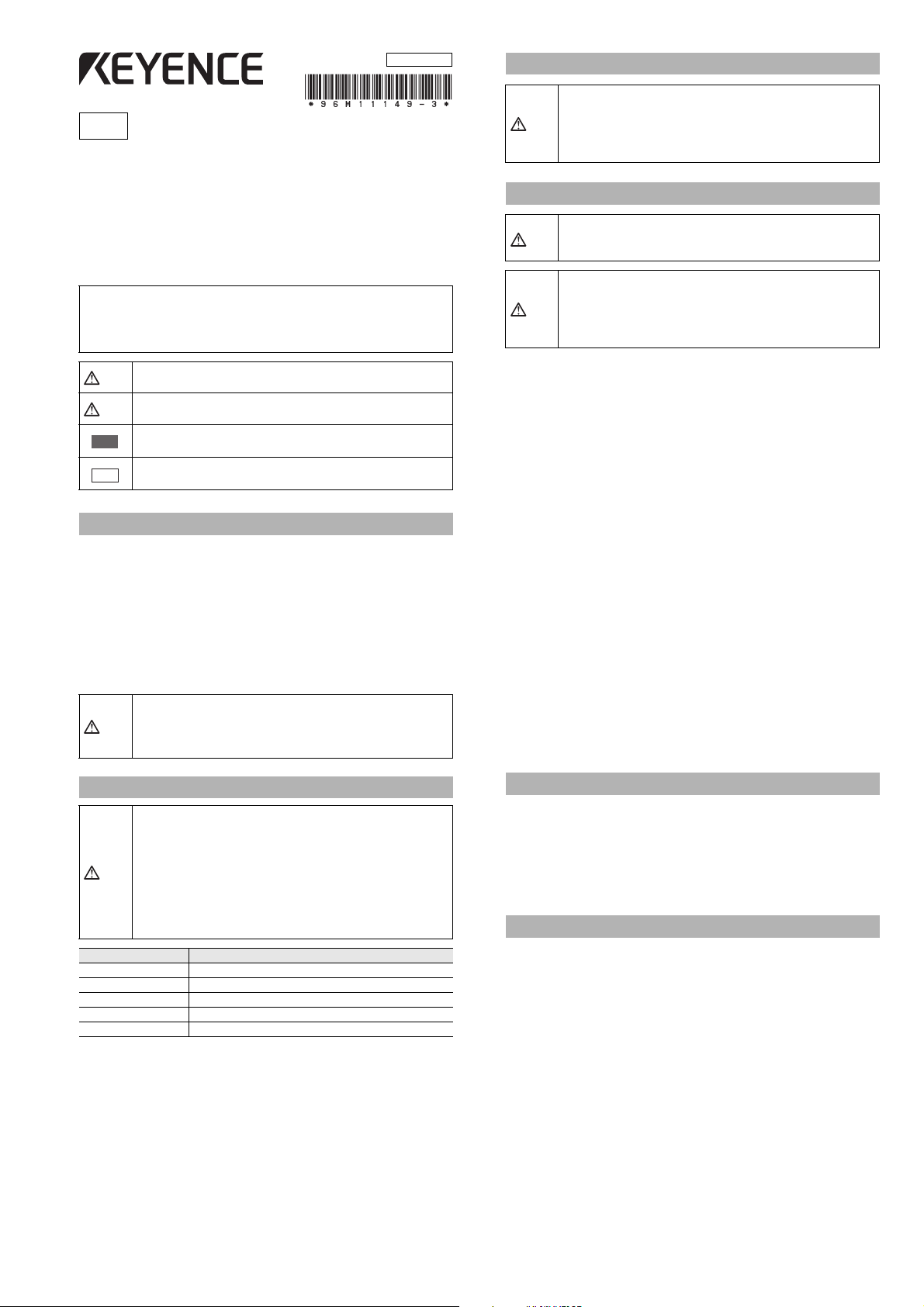

Sensor amplifier

z DIN rail mount type

IG-1000 (main unit)

Amplifier x 1 Instruction manual x 1

Part names

Sensor amplifier

z DIN rail mount type (IG-1000/IG-1050)

(1)

(2)

(3)

(4)

(5)

(16) (15) (14)

(13)

IG-1050 (expansion unit)

z Panel mount type

IG-1500 (main unit)

Instruction manual x 1

IG-1550 (expansion unit)

Sensor head

IG-010 (10 mm width)

Amplifier x 1

Amplifier x 1

Front protection

cover

x 1

Amplifier x 1

Front protection

cover

×1

Input-output cable

(2 m) x 1

(Number of cable

cores: 8)

Panel mounting

tool

x 1

Power/Inputoutput cable (2 m)

x 1

(Number of cable

cores: 12)

Panel mounting

tool

×1

Expansion cable

(50 mm) x 1

(7) (8) (9)

(11) (12)(10)(6)

z Panel mount type (IG-1500/IG-1550)

(1)

(16) (15) (14)

(2)

(3)

(4)

(5)

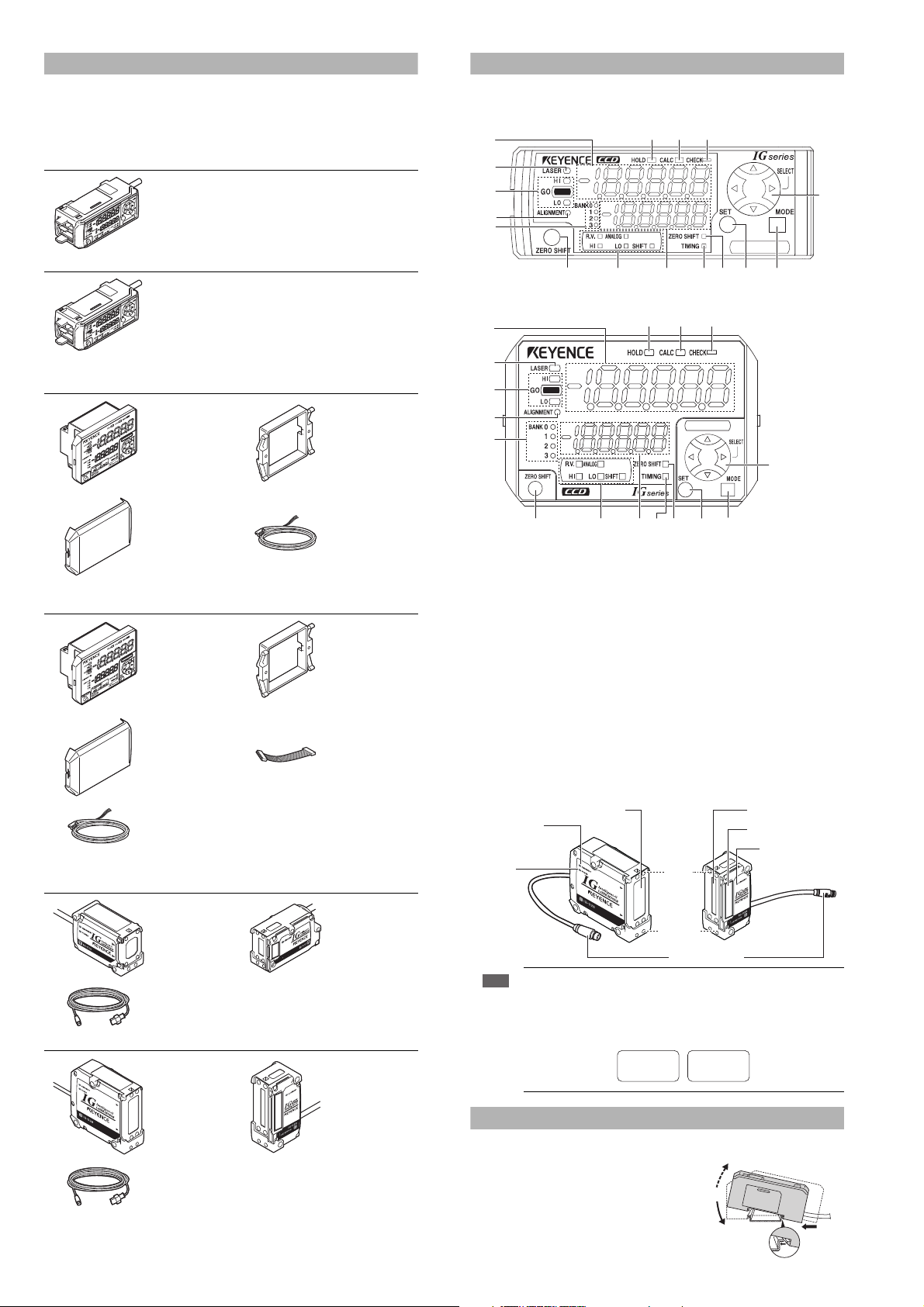

(1) Main display

(2) Laser emission indicator [LASER]

(3) Judgment indicator [HI / GO / LO]

(4) Optical axis alignment indicator [ALIGNMENT]

(5) Bank indicator [BANK 0 to 3]

(6) Zero shift button [ZERO SHIFT]

(7) Sub display identification indicator [R.V. / ANALOG / HI / LO / SHIFT]

(8) Sub display

(9) Timing input indicator [TIMING]

(10)Zero shift indicator [ZERO SHIFT]

(11)SET button [SET]

(12)MODE button [MODE]

(13) Arrow buttons

(14) Check indicator [CHECK]

(15) Calculation indicator [CALC]

(16)Hold indicator [HOLD]

(7) (8) (9)

(11) (12)(10)(6)

Sensor head

Transmitter Receiver

Optical axis

alignment

indicator

Power

indicator

Laser transmitter

Top

Laser Receiver

Position monitor

(13)

Optical axis

alignment

indicator

Transmitter (T) x 1 Receiver (R) x 1

Sensor head

connection cable

(2 m)

IG-028 (28 mm width)

Transmitter (T) x 1 Receiver (R) x 1

Sensor head

connection cable

(2 m)

We have thoroughly inspected the package contents before shipmen t. However, in the event

of defective or broken items, please contact your nearest KEYENCE office.

x 2

x 2

Use the transmitter and receiver in combination with the same serial

Note

number. If they are used in combination with different ser ial numbers, the

operation and accuracy are not guaranteed. The serial number is located on

top of the transmitter and receiver.

Transmitter

SERIAL No.

12345678

Mounting the Amplifier

DIN rail mount type, main unit (IG-1000)

Align the claw at the bottom of the main body with the

DIN rail. While pushing the main body in the direction

of the arrow (1), tilt the amplifier in the direction of the

arrow (2).

To remove the amplifier, raise the main body in the

direction of the arrow (3) while pushing it in the

direction of the arrow (1).

2

Bottom

Connector

Receiver

No.

12345678

(3)

(2)

(1)

Page 3

DIN rail mount type, expansion unit (IG-1050)

CAUTION

Note

Connector cover

Main unit

Connecter

Expansion unit

Main unit

· Thickness of the panel mounting part 1 to 6 mm

· X = 48 × (Number of amplifier) - 3

+ 0.6

- 0

45 mm

+ 0.6

- 0

45 mm

+ 0.6

- 0

45 mm

X mm

Minimum 85 mm

When arranging

lengthwise to attach

When arranging widthwise

to attach

Panel mounting tool

Panel

Sensor amplifier

Front protection cover

Up to 3 expansion units can be connected to one main unit.

•

When connecting multiple amplifiers (expansion units), first check to make sure

that the power is turned off to all of the main and expansion units. Connecting

the units with the power turned on could damage them.

•

Push the amplifiers (expansion units) as far as possible into the main unit. If they

are connected at an angle or not inserted securely, the units could get damaged.

Panel mount type, expansion unit (IG-1550)

Up to 3 expansion units can be connected to one main unit.

• When connecting the expansion cable, make sure to turn off the power

beforehand. Inserting or removing the cable with the power turned on may

cause damage to the units.

CAUTION

• Push the expansion cable connector securely all the way. If it is connected

at an angle or not inserted securely, the units could get damaged.

• When connecting the expansion units, make sure to initialize the

Note

expansion units and set the output polarity.

(1) When turning on the amplifier for the first ti me after connecting the sensor head

please reference

“Operation When the Power is Turned on for the First Time” (page 6)

(2) When initializing the unit please reference

“Initial Reset (Initialize)” (page 7)

•

Expansion units with different setting of output polarity (such as an NPN output

expansion unit to a PNP output main unit) cannot be connected together.

• Expansion units using DIN rail mount cannot be connected to a panel

mount style main unit.

1 Remove the expansion protective cover from the IG-1000 (main unit).

2 Install the amplifiers (main and expansion units) onto the DIN rail.

3

Push the expansion unit into the main unit connector until a clicking sound can be heard.

4 Install the end units (OP-26751: 2 units per set) (sold separately) on both sides of the

amplifiers (main or expansion units). Secure the end units in place with screws on top

(2 on each end unit).

The end units are mounted in the same way as the amplifiers.

Mount the amplifiers securely using the end units (OP-26751: 2 units

per set) (sold separately) or a commercially available DIN rail mounting

tool to prevent the amplifiers from slipping and coming off from the DIN

rail due to machine vibration.

Panel mount type, main unit (IG-1500)

1 Make a hole on the panel to attach according to the measurement below.

• When connecting the expansion units, make sure to initialize the

Note

1

2 Install the amplifiers (expansion units) on the panel.

3

connected expansion units and set the output polarity.

(1)

When turning on the amplifier for the first time after connecting the sensor head

please reference

“Operation When the Power is Turned on for the First Time” (page 6)

(2) When initializing the unit please reference

“Initial Reset (Initialize)” (page 7)

•

Expansion units with different setting of output polarity (such as an NPN output

expansion unit to a PNP output main unit) cannot be connected together.

• Expansion units using panel mount cannot be connected to a DIN rail

mounted main unit.

Make the appropriate number of hole in the panel according to the number of

amplifiers required (main and connected expansion units).

For the panel cutting measurement, refer to the “Panel mount type, main unit”.

For the amplifier mounting method, refer to the “Panel mount type, main unit”.

Connect the

supplied with the expansion unit.

amplifiers (

main

and expansion units)

Expansion

cable

using the expansion cable (50 mm

When arranging the

amplifiers as depicted in

the pictorial on the left, the

Reference

300 mm expansion cable

(OP-35361) is required.

Mounting the Sensor Head

If the mounting distance between the transmitter and receiver is as follows, the optical axis

alignment is not required when mounting within the “parallel acceptable range” and “tilt

acceptable range”.

• IG-010 : 3 to 500 mm

• IG-028 : 50 to 500mm

However if the distance is out of the above range(s), adjust the optical axis after mounting.

“Optical axis alignment” (page 6)

The minimum detectable object, linearity and temperature characteristics

Note

found in the specifications are valid only if the sensor head is mounted within

the “parallel acceptable range” and “tilt acceptable range”.

“Specifications” (page 10)

z Parallel acceptable range

)

2 Insert the back side of amplifier to the hole of the panel.

3 Arrange the panel mounting tool in the direction below, mount to the amplifier from the

back and attach the front protection cover to the amplifier.

To remove the panel mounting tool, widen the

claws at both ends of the panel mounting tool using

a slotted screwdriver, as demonstrated in the

pictorial on the right.

Transmitter Receiver

Transmitter Receiver

within ± 0.5 mm

within ± 0.5 mm

z Tilt acceptable range

Tilt of transmitter Tilt of receiver

Transmitter Receiver

Mounting distance

Transmitter Receiver

Mounting

distance

500 mm or less within ±0.05° within ±0.05° within ±1° within ±2°

100 mm or less within ±0.2° within ±0.2° within ±1° within ±2°

3

AC

B

A B C D

Transmitter Receiver

Mounting distance

Transmitter Receiver

D

Page 4

z When mounting the sensor head from the lateral side

Note

DIN rail mount type

(IG-1000/IG-1050)

Panel mount type

(IG-1500/IG-1550)

Lock lever

DIN rail mount type

(IG-1000/IG-1050)

Panel mount type

(IG-1500/IG-1550)

Mounting from the sensor side

Mount using the commercially available screws (IG-010: M3, IG-028: M4)

Tightening torque: 1.6 N·m or less

IG-010 IG-028

Connection and Wiring

Connecting the sensor head and amplifier

1 Attach the sensor head connection cables to the transmitter and receiver cables

respectively.

(1)

Align the arrow position of the connector to insert.

(2) Rotate the connector screw to tighten.

Mounting from the jig side

Mount using the commercially available screws (IG-010: M4, IG-028: M5, length: board

thickness + 5 mm or less).

Tightening torque: 1.6 N·m or less

IG-010 IG-028

z When mounting from the bottom side

Mount using the commercially available screws (M3, length(IG-010): board thickness + 4

mm or less, length(IG-028): board thickness + 5 mm or less).

Tightening torque: 1.6 N·m or less

IG-010 IG-028

The red O-ring is attached to the transmission

cable and the blue O-ring to the receiver cable.

Connect the sensor head connection cable with

red O-ring attached to the transmitter and

connect the sensor head connection cable with

the blue O-ring attached to the receiver.

Tighten the connectors securely by hand.

If they are loose, the environment resistance IP67 cannot be guaranteed.

2 Attach the sensor head connection cable on the receiver side to the [R] connector of

amplifier.

Remove th e lock cover of the

connector and insert it into the

connectors (R) of amplifier until a

clicking sound can be heard.

Right:

R side

Click

Blue O-ring

Lock cover

Unlocked

Down: R side

z When the mounting bracket (IG-TB01/IG-TB02: optional) is used

1 Attach the mounting bracket to the sensor head.

Press the sensor head to the mounting bracket firmly and

mount with the hexagon socket head bolt (M3, length: 5

mm).

Tightening torque: 1.6 N·m or less

IG-010 IG-028

2 Mount the mounting bracket.

Use the commercially available hexagon socket head bolt (M4) to mount the mounting

bracket through its holes.

IG-010 IG-028

3 Attach the lock cover to the connector to secure the cable.

Lock cover

Locked

When removing the sensor head connection cable, push the lock lever

Note

and pull it out.

4 Attach the sensor head connection cable on the transmitter side to the [T] connector

of amplifier.

Left:

T side

Up: T side

Red O-ring

The connection procedure is the same as that for the receiver side.

4

Page 5

Attaching the sensor head cable connector

Note

Note

Brown

Blue

Black

White

Gray

Light blue

Orange

Shield

Pink

Yellow

Pink/Purple

Purple

Green

DC10-30 V

0 V

HIGH judgment output

LOW judgment output

GO judgment output

Analog output +

Analog output GND

External input 1

(Zero shift input)

External input 2 (Reset input)

External input 3 (Timing input)

External input 4 (Not Used)

Edge check output

*1

*1

*1

*2

*2

*3

*3

*3

*3

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

[HOLD] lights up.

GO

HOLD CALC

CHECK

(OP-84338: optional)

Cut the sensor head cable to the required length and attach the new connector to use the

sensor. The method for attaching the connector is the same for both the transmitter and the

receiver.

1 Cut the cable to the required length and strip approx. 15 mm of insulation from the end

of it.

z Power/Input-output cable

The following information shows the details of power/Input-output cable. For information

about the input-output circuit, see page 9 of this Instruction Manual.

Do not strip the core wire insulation.

2 Insert each color coded cable into the same colored marked points on the connector.

Insert further

Black

Blue

Brown

White

3 Confirm that all the cables are inserted properly into the connector and crimp them

using a pair of pliers or similar tool.

Once the connector has been installed, make sure to connect it to the

amplifier and confirm that the sensor operates normally.

Once the connector is crimped, it cannot be reused.

Amplifier wiring

z Connecting power/Input-output cable (IG-1500/IG-1550 panel mount

type)

Connect the power/Input-output cable to the panel mount type main unit and Input-output

cable to the expansion units.

To attach To remove

Power/Input-output cable

• The number of core wires for the power/Input-output cable for the main

Note

unit is 12, and the number of core wires for the Input-output cable for the

expansion units is 8.

• Power for the expansion units is supplied from the main unit.

• If the input-output cable is not used for the expansion units, cut the cable

at the connector base, or terminate them separately for future use.

than here.

*1 IG-1050/IG-1550 (expansion unit) do not have brown, blue, or light blue wires.

Power is supplied to the expansion units through IG-1000/IG-1500 (main unit).

*2 The Analog output can be set for the following: “Not used (OFF), 0 - 5 V, ±5 V, 1 - 5 V

and 4 - 20 mA”.

Please reference, “Operation When the Power is Turned on for the First Time” (page 6)

and “Initial Reset (Initialize)” (page 7)

*3 In addition to the selections noted on the pictorial above, the External inputs can also

be selected to perform the following: Bank A, Bank B, Laser emission stop input and

Not used (OFF). The Gain input can be selected only for the external input 4.

For details, refer to the User’s Manual.

Amplifier functions and displays

Setting method

Basic display

HOLD CALC

0

1

2

3

ANALOG

R.V.

LO

HI SHIFT

CHECK

Press [MODE] and [SET] for 2 seconds.

ZERO SHIFT

TIMING

Press [MODE] for 2 seconds.

While pressing [MODE]

Press [SET] for 5 times.

and

Press for 2 seconds.

[MODE] and

Press for 2 seconds.

While pressing [MODE]

or

[MODE] and

Press for 2 seconds.

[MODE] and , or [MODE] and

Press for 2 seconds.

“Registering the standard waveform” (page 6)

“Basic setting” (page 8)

“Initial Reset (Initialize)” (page 7)

"Setting the measurement sensitivity",

refer to the User's Manual

"Calculation function", refer to the User's

Manual

"Bank switching function", refer to the

User's Manual

"Calibration function", refer to the User's

Manual

"Key lock function", refer to the User's

Manual

LASER

HI

GO

LO

BANK

ALIGNMENT

Basic display

z

R.V. (internal measurement value) and P.V. (judgment value)

R.V. (internal measurement value) means the value displayed when the desired object to be

measured is inserted into the measurement range.

* R.V. = Raw Value

P.V. (judgment value) is the value associated with the output state (ON or OFF) depending

on the tolerance setting value. Also, the analog output is based on the P.V. value.

* P.V. = Present Value

“Setting the Tolerance Setting Value” (page 6)

The P.V. (judgment value) and R.V. (internal measurement value) are basically the same,

however, those values differ when the hold function and calculation function are used.

z Main display

P.V. (judgment value) is displayed on the main display.

HOLD CALC

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

ANALOG

HI SHIFT

LO

5

[CALC] lights up.

HOLD CALC

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

ANALOG

R.V.

LO

HI SHIFT

Normal

CHECK

The same value as the R.V. (internal measurement value) is

displayed and the output will send its signal based on the value.

ZERO SHIFT

TIMING

When the hold function is being used

The held value is displayed and the output will send its signal

depending on the value.

For details, refer to the User’s Manual.

When the calculation function is used

Main unit : The calculation result with expansion units is

CHECK

Expansion units : The P.V. (judgment value) on the expansion unit

ZERO SHIFT

TIMING

displayed and the output will send its signal

depending on the value.

alone is displayed and the output will send its

signal depending on the value.

Page 6

z Sub display

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

GO

R.V. value

[R.V.]

lights up.

Tolerance tuning setting width

Measurement upper limit value

Measurement lower limit value

LOW tolerance value (lower limit)

Master workpiece P.V. (judgment value)

HIGH tolerance value (upper limit)

The sub display switches each time the W/X button is pressed. According to the type of

displayed value selected, the sub display identification indicator will show one of the

following: [R.V. / ANALOG / HI / LO / SHIFT]

HOLD CALC

0

1

2

3

ANALOG

R.V.

HI SHIFT

LO

HOLD CALC

0

1

2

X

3

ANALOG

R.V.

HI SHIFT

LO

HOLD CALC

0

1

2

3

ANALOG

R.V.

LO

HI SHIFT

HOLD CALC

0

1

2

3

ANALOG

R.V.

HI SHIFT

LO

HOLD CALC

0

1

2

3

R.V.

ANALOG

LO

HI

SHIFT

ZERO SHIFT

ZERO SHIFT

ZERO SHIFT

ZERO SHIFT

ZERO SHIFT

CHECK

TIMING

CHECK

TIMING

CHECK

TIMING

CHECK

TIMING

CHECK

TIMING

LASER

GO

ALIGNMENT

LASER

GO

ALIGNMENT

LASER

GO

ALIGNMENT

LASER

GO

ALIGNMENT

LASER

GO

ALIGNMENT

HI

LO

BANK

HI

LO

BANK

HI

LO

BANK

HI

LO

BANK

HI

LO

BANK

Operation When the Power is Turned on for the First Time

When the amplifier is turned on for the first time after the sensor head is connected, the initial setting

display appears. Make the initial setting acc ording to the following procedure as this is necessary for

both the main unit an d the expansion units when units are added.

1 Press the S/T button to select the polarity of the signal

output and the edge check output and press the [MODE]

button.

Setting value

NPN output

PRP

PNP output

RPR

2 Press the S/T button to select the analog output method and

press the [MODE] button.

Setting value

Not output

QHH

Analog output after the judgment value is converted to the range from 0 to 5 V.

W

Analog output after the judgment value is converted to the range of ±5 V.

W

Analog output after the judgment value is converted to the range from 1 to 5 V.

W

Analog output after the judgment value is converted to the range from 4 to 20 mA.

CORT

After the setting is complete, [

The initial setting display appears only when the power is turned on for the

Note

first time. It will not appear when the power is turned on the second time or

thereafter. To change the initial setting, perform the initial reset.

3

Perform “Optical Axis Alignment” and “Standard Light-Receiving Amount Registry” (page 6).

Make other settings as necessary.

Optical Axis Alignment

If the optical axis alignment indicators [ALIGNMENT] of transmitter, receiver and amplifier do not both

light up upon power up, align the optical axis of the sensor head.

Adjust the angle of the transmitter and receiver while a target object is not present within

the measuring range. Then fix mount the transmitter and receiver once the alignment

indicators [ALIGNMENT] light up.

R.V. (internal measurement value)

The actual measurement value for the object is displayed.

This displayed value is not held.

•

With the pin size judging mode or pin interval judging mode,

the R.V. (internal measurement value) for each pin size and

each pin interval can be displayed.

“1. Measurement mode” (page 8)

The analog output will only be displayed for the main unit and

only when it is enabled.

The voltage value (unit: V) or current value (unit: mA) of the

analog output is displayed.

“Operation When the Power is Turned on for the First Time” (page 6)

“Initial Reset (Initialize)” (page 7)

HIGH side setting value

The upper limit of the acceptable range (tolerance setting value) for

the object that is being measured is displayed. Also, the setting

value can be changed. If the P.V. (judgment value) exceeds the

value set here, the HIGH output signal will be sent.

“Setting the Tolerance Setting Value” (page 6)

LOW side setting value

The lower limit of the acceptable range (tolerance setting value)

for the object that is being measured is displayed. Also, the

setting value can be changed. If the P.V. (judgment value) falls

below the value set here, the LOW output signal will be sent.

“Setting the Tolerance Setting Value” (page 6)

Shift target value

When the zero shift button is pressed or the zero shift input is

set to ON, the R.V. (internal measurement value) will be

matched to the value set here.

“Zero shift function” (page 7)

LASER

HI

GO

LO

ALIGNMENT

Description

LASER

HI

GO

LO

Description

GPF

] blinks several times on the sub display and changes to the basic display.

ALIGNMENT

“Initial Reset (Initialize) page 7”

Optical axis alignment indicator [ALIGNMENT]

Transmitter

HOLD CALC

QWV

BANK

0

1

2

PRP

3

ZERO SHIFT

ANALOG

R.V.

HI SHIFT

LO

Output polarity

HOLD CALC

#P.)

BANK

0

1

2

QHH

3

ZERO SHIFT

ANALOG

R.V.

HI SHIFT

LO

Analog output

Receiver

Registering the standard waveform (Gain adjustment)

The measurments will be stabilized once the standard waveform has been registered. (Gain adjustment)

The total light received will be registered as 100%.

Register the standard waveform when the unit is used for the first time, when the setting

environment is changed, or when the measurement sensitivity is changed. For details, refer to

the User’s Manual.

1 Confirm that the optical axis alignment indicators [ALIGNMENT] of the transmitter,

receiver and amplifier are lit up.

If the optical axis adjustment indicators are off, align the optical axis.

2 Press the [MODE] and [SET] buttons at the same time for approx. 2 seconds on the

basic display.

[CNKIP] is displayed on the main display (upper level) and the standard waveform will

be registered. The basic display will be restored when the registry is complete.

If attempting to register the standard waveform while the optical axis

Note

alignment indicators [ALIGNMENT] are off, an error message will be

displayed and the standard waveform cannot be registered.

“Error message and countermeasures” (page 8)

The standard waveform can be registered by the external input as well.

Reference

Select the "Gain input" for the external input 4 (purple wire).

Setting the Tolerance Setting Value (Threshold)

There are two types of tolerance setting values: HIGH (upper limit) and LOW (lower limit) The

value displayed will output its signal as one of the following 3 levels: When the value exceeds the

upper limit (HIGH); when the value is within the tolerance range (GO); and when the value falls

below the lower limit (LOW)

"4. Output format" (page 8)

Automatic setting (Tolerance tuning)

When the object to be measured is present, and the measurement value for the master

workpiece is set, the HIGH (upper limit) and LOW (lower limit) will be automatically set with

the master workpiece measurement value centered.

1 Press the W/X buttons several times on the basic display.

Then display the R.V. (internal measurement value) on the

sub display (lower level).

2 Measure the master workpiece and press the [SET] button.

The P.V. (judgment value) will be set as a standard value for

the tolerance settings.

[UGV] and the tolerance setting width are displayed alternately on the sub display

(lower level).

3

Press the

S/T

CHECK

buttons to set the tolerance width and press the [SET] button.

Setting range Default value

0.000 to 99.999 0.100

TIMING

After [UGV] blinks several times, the display returns to the R.V.

(internal measurement value).

The tolerance tuning is complete.

CHECK

TIMING

The tolerance tuning cannot be performed when the P.V. (judgment

Note

value) is displayed as [].

When the tuning result exceeds the setting range (-99.999 to 99.999), the

Reference

limit values of the setting range become the High and Low tolerances.

Automatic setting (2-point tuning)

The following will explain how to set up a mean tolerance level that distinguishes between

acceptable vs. defective targets.

1 Press the W/X buttons several times until the HIGH tolerance

value on the sub display (lower level) is shown.

2 Place the acceptable target within the measuring range and

press the [SET] button.

The R.V. (internal measurement value) will be registered and

[JKUGV] will be shown on the main display (upper level).

3 Now place the defective target within the measuring range and press the [SET] button.

The R.V. (internal measurement value) will be registered and after [UGV] blinks on the

main display (upper level), the P.V. (judgment value) will be shown.

On the sub display (lower level), the medium value between the acceptable target

value registered in step 2 and the HIGH side defective target value will now be

displayed.

The HIGH tolerance value (upper limit) is now setup.

4 Press the X button once and display the LOW tolerance value

on the sub display (lower level).

5 Measure the acceptable target again and press the [SET]

button.

The R.V. (internal measurement value) is now registered.

[NQUGV] will be shown and on the main display (upper level).

6

Master work P.V.

LASER

HI

GO

LO

BANK

ALIGNMENT

Tolerance setting width

LASER

HIGH tolerance value

HI

GO

LO

BANK

ALIGNMENT

[HI]

lights up.

LASER

LOW tolerance value

HI

GO

LO

BANK

ALIGNMENT

[LO]

lights up.

HOLD CALC

0

1

2

3

ANALOG

R.V.

HI SHIFT

LO

HOLD CALC

0

1

2

3

ANALOG

R.V.

HI SHIFT

LO

HOLD CALC

0

1

2

3

ANALOG

R.V.

HI SHIFT

LO

ZERO SHIFT

ZERO SHIFT

ZERO SHIFT

CHECK

TIMING

CHECK

TIMING

CHECK

TIMING

Page 7

6 Measure the LOW side defective target and press the [SET] button.

Setting value for the HIGH side defective target

Setting value for the LOW side defective target

Setting value for the acceptable target

Measurement upper limit value

Measurement lower limit value

LOW tolerance value (lower limit)

HIGH tolerance value (upper limit)

GO

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

LOW tolerance value

[LO]

lights up.

GO

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

Shift target value

[SHIFT]

lights up.

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

2TQ

GO

HOLD CALC

CHECK

The R.V. (internal measurement value) is now registered.

After [UGV] blinks on the main display (upper level), the P.V. (judgment value) will be

shown.

On the sub display (lower level), the medium value between the acceptable target

value registered on step 5 and the LOW side defective target value will be displayed.

The LOW side setting value (lower limit) is complete.

The 2-point tuning is complete.

Manual setting

Set the HIGH tolerance value (upper limit) and LOW tolerance value (lower limit) to an

arbitrary value.

1 Press the W/X buttons several times on the basic display.

Then display the HIGH side setting value on the sub display

(lower level).

2 Press S/T buttons to set the HIGH tolerance value.

3 Press the X button once and display the LOW tolerance value

on the sub display (lower level).

4 Press the S/T buttons to set the LOW side setting value.

The tolerance settings are complete.

Note

Zero Shift Function

When the [ZERO SHIFT] button is pressed or the external zero shift input (pink wire) has

been activated, the R.V. (internal measurement value) now becomes the newly shifted

target value.

Setting the shift target value

1 Use the W/X buttons on the basic display to navigate your

way to the shift target value on the sub display (lower level).

2 Press the S/T buttons to change the shift target value.

The shift target value has now been set.

Activating the zero shift

Press the [ZERO SHIFT] button or short the external pink wire to 0V or 24VDC (based on

the NPN or PNP setup).

The zero shift indicator [ZERO SHIFT] will light up for approx. 0.5 second and the current

R.V. (internal measurement value) will now become the shifted target value.

Note

Cancelling the zero shift

Press the zero shift button [ZERO SHIFT] for 2 seconds or more.

[TGUGV] is displayed on the sub display and the zero shift is cancelled.

Initial Reset (Initialize)

The initial reset initializes all settings except for the calibration setting and standard

waveform registry (Gain adjustment).

When using initial reset, the output polarity (NPN / PNP) edge check output, and the analog

output settings can be changed.

1 While holding down the [MODE] button on the basic display, press the [SET] button 5

times.

[TGUGV] will be displayed on the main display.

2 Press S/T button to select [[GU] and press the [MODE]

button.

When [MODE] and [ZERO SHIFT] buttons are pressed at the

same time for approx. 2 seconds, the display units (inch / mm)

can be accessed. [OO] and [KPEJ], represent “mm” and "inch"

respectively.

Press the [MODE] button.

LASER

GO

ALIGNMENT

[HI]

lights up.

Setting range Default value

-99.999 to 99.999 8.000

Setting range Default value

-99.999 to 99.999 2.000

When setting the tolerance value manually or with the 2-point tuning,

make sure to set “HIGH tolerance value then the LOW tolerance value”

Setting range Default value

-99.999 to 99.999 0.000

• When using the external zero shift function, any newly shifted states

will be lost when the unit is powered down unless the memory

function is utilized.

For details, refer to the User's Manual.

• When the R.V. (internal measurement value) is [], the zero shift

function cannot be used.

LASER

GO

ALIGNMENT

Performing the initial reset

HOLD CALC

0

1

2

3

ANALOG

R.V.

HI SHIFT

LO

HOLD CALC

T'5'V

0

1

2

3

ANALOG

R.V.

HI SHIFT

LO

ZERO SHIFT

TIMING

;GU

ZERO SHIFT

TIMING

CHECK

CHECK

HIGH tolerance value

HI

LO

BANK

HI

LO

BANK

3 Press S/T button to select the output polarity and press the

[MODE] button.

Setting value

PRP

RPR

NPN output

PNP output

Description

4 Press the S/T buttons to select the analog output and press

[MODE] button.

Setting value

Not using the analog output

QHH

Analog output range is from 0 to 5 V.

W

Analog output range is from ±5 V.

W

Analog output range is from 1 to 5 V.

W

Analog output range is from 4 to 20 mA.

CORT

After the initialization is complete, [GPF] blinks several times on the sub display and the

basic display is restored.

Setting Method

z Calling the setting display

Hold the [MODE] button for approx. 2 seconds on the basic display.

The setting display appears.

Basic operations on the setting display

To change the setting, press the S/T button

To move the next item, press the [MODE] button or X button

To return to the previous item, press the W button

To skip the rest of the settings and finish: Press and hold the [MODE] button for approx. 2

seconds.

Setting procedures (Basic)

HOLD CALC

CHECK

Basic display

ZERO SHIFT

TIMING

CHECK

“1. Measurement mode”

ZERO SHIFT

TIMING

CHECK

“2. Measurement direction”

VQR

ZERO SHIFT

TIMING

CHECK

“3. Averaging”

ZERO SHIFT

TIMING

CHECK

“4. Output state” Use S/T to select.

PQ

ZERO SHIFT

TIMING

CHECK

“Basic setting complete”

'PF

ZERO SHIFT

TIMING

“Advanced settings” See User’s Manual

7

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

ANALOG

R.V.

HI SHIFT

LO

Press the [MODE] button for 2 seconds.

HOLD CALC

LASER

HI

GO

(PE

LO

BANK

0

1

ALIGNMENT

2

#'&)

3

R.V.

ANALOG

HI SHIFT

LO

Press the [MODE] or X button.

HOLD CALC

LASER

HI

GO

FKT

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

ANALOG

HI SHIFT

LO

Press the [MODE] or X button.

HOLD CALC

LASER

HI

GO

#W'

LO

BANK

0

1

ALIGNMENT

2

3

ANALOG

R.V.

HI SHIFT

LO

Press the [MODE] or X button.

HOLD CALC

LASER

HI

GO

QWV

LO

BANK

0

1

ALIGNMENT

2

3

ANALOG

R.V.

HI SHIFT

LO

Press the [MODE] or X button.

HOLD CALC

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

ANALOG

R.V.

HI SHIFT

LO

Press the T or S button.

Press the [MODE] or X button.

Advanced setting

Description

Use S/T to select.

Setting the edge control/positioning, outer

diameter/width, inner diameter/opening,

glass edge,

pin position (See User's Manual),

pin interval (See User's Manual),

pin diameter (See User's Manual),

specified edges interval (See User's

Manual)

Use S/T to select.

Setting the top and bottom

Use S/T to select.

Setting the averaging

Setting N.O. (Normally Open) and N.C.

(Normally Closed)

Press the [MODE] button or the X button

to return to the basic display.

Press the W button to return to the basic

display.

When the advanced setting is selected, the

following items can be set. For details, see

the User’s Manual.

“5. Hold function” “6. Timing input” “7.

Delay timer” “8. Hysteresis” “9. Edge check

function” “10. Analog output scaling” “11.

External input” “12. Standard waveform

memory function” “13. Zero shift value

memory function” “14. Interference prevention function” “15. Number of digit displayed” “16. Power saving function” “17.

Position monitor” “18. Display color”

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

Output polarity

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

Analog output

HOLD CALC

QWV

ANALOG

LO

HOLD CALC

#P.)

ANALOG

LO

PRP

ZERO SHIFT

TIMING

QHH

ZERO SHIFT

TIMING

CHECK

CHECK

Page 8

Basic functions

Reference

Reference

Normally open [PQ]

judgment

judgment output

HIGH GO LOW

HIGH ON OFF OFF

GO OFF ON OFF

LOW OFF OFF ON

[] OFF OFF OFF

Error ON OFF ON

Normally closed [PE]

judgment

judgment output

HIGH GO LOW

HIGH OFF ON ON

GO ON OFF ON

LOW ON ON OFF

[] ONONON

Error OFF ON OFF

4''2

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD CALC

CHECK

#.K)P

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD CALC

CHECK

1. Measurement mode

Setting the position to measure.

At the point when the selection is switched on the setting display, it is

Note

reflected to the R.V. (internal measurement value).

4. Output method

Setting the judgment output method

Setting

value

Output is normally open c

PQ

Output is normally closed

PE

Description

Default

value

Edge control/Positioning mode, c

C.GFI

Outer diameter/Width measurement mode

D.FKC

Inner diameter/Opening measurement mode

E.KPU

Glass edge mode

F.INU

Pin position measurement mode, Pin interval judgment mode,

G.RQU

Pin diameter judgment mode, Specified edge interval measurement

to

mode

J.WUT

z Edge control/Positioning mode

Measurement mode

When the measurement direction [

measurement range to bottom side of the measured target is the R.V. (internal measurement

value). When [

DVO

] (bottom) is selected, the distance from the bottom edge of the measurement

range to the top side of the measured target is the R.V. (internal measurement value).

If there is no measurement target, R.V. (internal measurement value) will display [].

When the measurement direction is [

Top

Bottom

VQR

] (top) is selected, the distance from the top edge of the

6Q2

]

When the measurement direction is [

Top

Top

R.V.

Measurement

range

Bottom

Bottom

z Outer diameter/Width measurement mode

The distance from the to p edge of the target closest to the top of the measuring range to the

bottom edge of the target closest to the bottom of the measuring range will be calculated as

the R.V. (internal measurement value). If there is no target present, the R.V. (internal

measurement value) will display [].

Top

Top

Top

R.V.

Bottom

Bottom

Bottom

z Inner diameter/Opening measurement mode

The distance from the bottom edge of the target closest to the top of the measuring range to

the top edge of the next target near the bottom of the measuring range will be calculated as

the R.V. (internal measurement value).

If there is no target present, the R.V. (internal measurement value) will display [].

Top

Top

Top

R.V.

Bottom

Bottom

Bottom

z Glass edge mode

This operation is the same as that for the Edge control/Positioning mode, however the

measurement sensitivity is increased.

For details of other measurement modes, see the User’s Manual.

2. Measurement direction

Setting the measurement direction of the master workpiece to the sensor head.

Setting

value

Measures the distance from the top side of sensor head to the specified edge.

VQR

Measures the distance from the bottom side of sensor head to the specified edge.

DVO

Description

3. Averaging (Response time)

The response time is the time from whe n the sensor head star ts the measuring operation to the point where

the output signal is sent. When the average number of times is increased, the response time becomes

longer, but the R.V. (internal measurement value) and P.V. (judgment value) will be more stable.

Setting range

JUR / / / / / / / / / / / /

• The response time for [JR] (High speed) is 1.96 ms.

Reference

•

1 indicated in [] means the average number. The response time can be calculated

256 times or less: Response time = Number of times for averaging x 0.98 + 2.94 ms

512 times or more: Response time = Number of times for averaging ÷ 256 x 257 x 0.98 + 1.96 ms

• When “Pin interval judgment mode” or “Pin diameter judgment mode” is

selected in “1. Measurement mode”, the setting range and the response

time will differ.

Top

Bottom

Top

Bottom

Top

Bottom

Default value

$6/

R.V.

R.V.

R.V.

Default

value

c

Default

value

Error Displays and Corrective Actions

"4. Output format" (page 8)

Reference

• The edge check output operates regardless of the error.

• When [GTE] is displayed, all the outputs will turn OFF.

• When an error is displayed, the analog voltage output will be 5.5 V and

analog current output will be 3.0 mA.

]

Error indication Error Actions

The transmitter and r eceiver are not connect ed.

CHECK

HOLD CALC

LASER

HI

GO

'T*

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

Displayed

R.V.

HI SHIFT

alternately.

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

LASER

HI

GO

LO

BANK

0

1

ALIGNMENT

2

3

R.V.

HI SHIFT

ANALOG

LO

HOLD CALC

ANALOG

LO

HOLD CALC

ANALOG

LO

HOLD CALC

ANALOG

LO

HOLD CALC

.#5'4

ANALOG

LO

HOLD CALC

T#P)G

ANALOG

LO

HOLD CALC

ANALOG

LO

HOLD CALC

ANALOG

LO

HOLD CALC

'TEQ/

ANALOG

LO

HOLD CALC

#.K)P

'TTQ

ANALOG

LO

HOLD CALC

#.K)P

'TTF

ANALOG

LO

HOLD CALC

#.K)P

'TT5

ANALOG

LO

The transmitter and receiver are broken.

VT

The sensor head cable of the transmitter

ZERO SHIFT

TIMING

and receiver is disconnected.

CHECK

The transmitter and receiver are

reversely connected to the amplifier.

'T*

TV

ZERO SHIFT

TIMING

The receiver is not connected. Connect the receiver.

CHECK

'T*

The receiver is broken. Replace the transmitter

T

ZERO SHIFT

TIMING

The sensor head cable of the receiver is disconnect ed

The transmitter is not connected. Connect the transmitter.

CHECK

'T*

The transmitter is broken.

V

The sensor head cable of the

ZERO SHIFT

TIMING

transmitter is disconnected.

The laser of the transmitter has been

CHECK

damaged.

'T*

ZERO SHIFT

TIMING

Reading/writing the nonvolatile memory

(EEPROM) storage data failed.

Data has been written in the nonvolatile

memory (EEPROM) over 500 thousands

times and malfunction occurred.

The transmitter and receiver type

CHECK

(Measurement range) do not match.

'T*

ZERO SHIFT

TIMING

The standard waveform was not

registered properly.

Overcurrent was detected on the

CHECK

output.

'T%

ZERO SHIFT

TIMING

Reading/writing the nonvolatile memory

CHECK

(EEPROM) storage data failed.

'T'

Data has been written in the nonvolatile

ZERO SHIFT

memory (EEPROM) over 1 million times

TIMING

and malfunction occurred.

Communication is not possible

CHECK

between the amplifiers.

ZERO SHIFT

TIMING

The light-receiving amount is too large

CHECK

to register the standard waveform.

ZERO SHIFT

TIMING

The light-receiving amount is too small

CHECK

to register the standard waveform.

ZERO SHIFT

TIMING

The standard waveform cannot be

CHECK

registered because the receiver is

receiving the laser light of the

transmitter from another amplifier.

ZERO SHIFT

TIMING

8

Connect the transmitter and receiver.

Replace the transmitter and receiver.

Replace the sensor head

cable.

Connect the transmitter

and receiver correctly.

and receiver.

Replace the sensor head cable.

Replace the transmitt er and receiver.

Replace the sensor head

cable.

Replace the transmitter and

receiver.

Turn the power on again.

Replace the transmitter

and receiver.

Replace with the same type

(measurement range) of the

transmitter and receiver.

Do not turn off the sensor head

or disconnect it fr om the sensor

amplifier while register ing the

standard waveform.

Register the standard waveform

again.

Check the load and

•

reduce the current to

within the rated range.

•

Check that the output

wire does not touch

another wire or a frame.

Turn the power on again and

perform the initial reset.

Replace the amplifier unit if

data writing is necessary.

Turn the power on and check

the connection status

between amplifiers.

Check whether too much

ambient light or light from

another sensor enters the

receiver or not.

•

Align the optical axis so

the optical axis alignment

indicator lights up.

•

Clean the sensor head's

transmitter and receiver.

Use the transmitter and

receiver associated with

their designated amplifier.

Page 9

Circuit Diagram

Main circuit

Overcurrent protection circuit

10 to 30 VDC

Brown

0 V

Blue

*

Load

* Black (HIGH output)/White (LOW output)/

Gray (GO output)/Green (edge check output)

10 to 30 VDC

0 V

* Black (HIGH output)/White (LOW output)/

Gray (GO output)/Green (edge check output)

Main circuit

Overcurrent protection circuit

Brown

Blue

*

Load

Main circuit

Analog current output circuit

Analog voltage output circuit

(Switching number)

Shield

Orange

Analog output GND

Analog voltage/

current output

0 to 5 V, 1 to 5 V,

-

5 to 5 V, 4 to 20 mA

10 to 30 VDC

0 V

*

Brown

Blue

Main circuit

* Pink (External input 1)/Yellow (External input 2)/

Pink·Purple(External input 3)/

Purple (External input 4)

(Short-circuit current 2 mA or less)

+5V

10 to 30 VDC

0 V

*

* Pink (External input 1)/Yellow (External input 2)/

Pink·Purple(External input 3)/

Purple (External input 4)

(Short-circuit current 2 mA or less)

Brown

Blue

Main circuit

44.7

15.3

4

9.5

1.5

35

20.2

2.3

7.6

73.6

48

19.1

19.1

10.310.3

17.6

27.2

44.7

Cable diameter φ4.8

Cable diameter φ4.7

Cable length 2 m

Dimensions

Sensor head

z Output circuit

When NPN output is selected

When PNP output is selected

z Analog output circuit

Sensor amplifier

z IG-1000/IG-1050

28.3

18.5

8.9

Cable diameter φ4.8

3

37.4

42.4

20 21.6

17.4

z IG-1500/IG-1550

Cable diameter φ4.7 Cable length 2 m

18.5

Max. 135°

17.6

35.4

76.3

When the cover is open: Max. 109.2

z Input circuit

When NPN output is selected

When PNP output is selected

Sensor head

z IG-010

Transmitter

2-φ3.4 (Mounting hole)

(26)

9

φ

4.8 Cable length 170

φ

Edge M8 connector

3-M3 Valid screw depth 4

Receiver

31.8

18.8±1

11.2

* Light-receiving area

(5x14 rectangle)

10.4

1.6

Measurement center

23

17

Base

level

23.5 28.5

Transmission spot center

39.8

54.7

50.5

10.6

32.7

2-φ3.4 (Mounting hole)

51.5

55

25.4

6.7

3.2

* Transmission spot

(reference value)

3.7

6.7

4.8

2-M4

Valid screw depth

12.6

4.8 Cable length 170

φ

Edge M8 connector

16.2

3-M3 Valid screw depth 4

(26)

31.8

18.8

11.2

23

12

15

5.2

9

φ

3

Base level

49.4

13.5

4.3

2-M4 Valid screw depth 5.2

9

Page 10

10.4

* Light-receiving area

(3.6 x 31.2 rectangle)

Measurement center

56.2

33.1±0.3

11.4

23

48.2

4.1

2-φ4.5 (Mounting hole)

φ

4.8 Cable length 170

Edge M8 connector

29.3

7

17.1

11.4

30.2

Base level

15.5

4.3

2.5

18.5

16.6

0.8

3-M3 Valid screw depth 5.5

Base level

2-M5 Valid screw depth 5.2

(26)

φ

9

Voltage output Current output

Output range

±5 V

(full scale 10 V)

4-20 mA

(full scale 16 mA)

Output resistance

100 : -

Maximum load resistan ce

- 350 :

Repetition acc uracy

±1 mV ±1.5 μA

Display accuracy

±0.05 %ofF.S. ±0.25 %ofF.S.

Temperature characteristic s

±0.005 %ofF.S./°C 0.01%ofF.S./°C

Update cycle Same as sensor head sampling cycle

Response time

Same as Response time (judgment output)

Time constant *310 μs (90 % response) 30 μs (90 % response)

1.8

47.6

Base level

Transmission spot center

16.6

6.4

18.8 25.4

3-φ4.5 (Mounting hole)

11.5

66.2

63.8

6.5

43.8

47.5

4.2

4.8

Base level

56.2

33.1

11.4

23

* Transmission spot

(reference value)

10.4

33

12

3-M5 Valid screw depth 5.2

z IG-028

Transmitter

4.8 Cable length 170

φ

Edge M8 connector

(26)

9

φ

4-M3 Valid screw depth 5.5

Receiver

Specifications

Sensor amplifier

Model IG-1000 IG-1050 IG-1500 IG-1550

Amplifier type DIN rail mount Panel mount

Main unit/Expansion unit Main unit

Analog output Yes No Yes No

Power supply voltage DC10-30 V , Ripple (P-P): 10% included, Class2

Powe r

consumption

(including analog

current output)

Normal

Power saving function (HALF)

Power saving function (ALL)

Digital display method

Display range

Display resolution 1 μm, 10 μm, 100 μm, 1000 μm (selectable)

Operation status indicator

Judgment output

(selectable between

NPN and PNP)

Response time

(judgment output)

Edge check output

(selectable between

NPN and PNP)

2700 mW or less

(at 30 V: 90 mA or less)

2300 mW (at 30 V: 77 mA or less)

2200 mW (at 30 V: 74 mA or less)

Dual 7-seg display

Upper level: Red, 5 digits

Lower level: Green, 5 digits

-99.999 to 99.999, -99.99 to 99.99,

-99.9 to 99.9, -99 to 99 (switchable)

Judgment indicator: Red/Green 2 colors (HI, LO, GO)

Bank indicator: Green LED x 4

Laser emission indicator: Green LED

Others: Green LED x 8, Red LED x 3

NPN (PNP) open collector x3ch, DC 30 V (Power supply voltage) or

less, residual voltage1 V (2 V) or less, NO/NC selectable

Max. 50 mA/ch

1.96 to 4031.72 ms*

NPN (PNP) open collector x1ch, DC 30 V (Power supply voltage) or

less, residual voltage 1 V (2 V) or less, NO/NC selectable

Max. 50 mA *1, response time 20 ms

Output

Expansion unit

*1

2

Main unit

2880 mW or less

(at 30 V: 96 mA or less)

Dual 7-seg display

Upper level: Red/Gr een, 2 color s, 5 digits

Lower level: Green, 5 digits

Expansion unit

Sensor head

Model IG-010 IG-028

Operation principle CCD detector

Light

source

Mounting distance 0 to 1000 mm 0 to 1500 mm

Measurement range 10 mm 28 mm

Sampling cycle 980μs (when averaging is set to [hsp]: 490μs)

Laser class Class1(IEC60825-1,FDA CDRH Part1040.10

Smallest detectable object

Repeatability

Linearity

Temperature characteristics *5±0.03 %ofF.S./°C (±3 μm/°C) ±0.01 %ofF.S./°C (±3 μm/°C)

Operation

indicator

Environment

resistance

Material

Weight (including supplied items)

*1

*2

*3 When the light quantity from the transmitter is cut by half at the center position of the setting

*4 When the setting distance is 100 mm, and light from the transmitter is blocked by an object at 50

*5

*6 Excluding when the average number of times is set to [JUR]

*3

*4

Tra n s mi t t er

Receiver

Protection structure

Ambient temperature

Ambient humidity 35 to 85%RH (No condensation)

Ambient light

Vibration resistance 10 to 55 Hz Double amplitude 1.5 mm XYZeach axis: 2 hours

Pollution degree 2

Case

Lens cover Glass

Cable PVC

The classification is based on IEC60825-1 standard following the Laser Notice No.50 from FDA (CDRH).

When the measurement target object is measured at the center positi on of the setting distance.

When the sensitivity setting is set to the high sensi tivity mode:

When the measurement mode is set to the glass edge mode, a glass edge of C 0.1 mm or more can be detecte d (Setting

distance: 500 mm).

distance.

Vibration width when the averaging is set to 16 and sampling is performed for 30 seconds

(When the analog output is used, the margin of error of analog output is added.)

mm from the receiver.

Margin of error to the ideal line.

When the setting distance is 100 mm, and light is shielde d by half at 50 mm position from the receiver.

Visible light semiconductor laser (Wavelength:660 nm)

I0.2 mm (Setting distance: 40

*2

mm or less), I0.5 mm (Setting

distance: 500 mm)

5 μm (Setting distance: 100 mm)

10 μm (Setting distance: 500 mm)

80 μm (Setting distance: 1000 mm)

±0.28 %ofF.S. (±28 μm) ±0.1 %ofF.S. (±28 μm)

Optical axis alignment indicator: Green LED

Power indicator: Green LED

Optical axis alignment indicator: Green LED

Position monitor: Dual bar LED (Red, Green)

IP67

-10 to +45°C (No freezing)

*6

Incandescent lamp: 5000 lx Sunlight: 5000 lx

Zinc die-cast (Lower case), PBT (Upper case),

Poly Arylate (PAR) (Display part), SUS304 (Metallic part)

I0.2 mm (Setting distance: 50

mm or less), I0.5 mm (Setting

distance: 500 mm)

5 μm (Setting distance: 100 mm)

10 μm (Setting distance: 500 mm)

80 μm (Setting distance: 1000 mm)

140 μm (Setting distance: 1500 mm)

Approx. 380 g Approx. 500 g

I

0.1mm (Setting distance: 100 mm)

*1

)

Warranty

KEYENCE products are strictly factory-inspected. However, in the event of a failure, contact

your nearest KEYENCE office with details of the failure.

1. WARRANTY PERIOD

The warranty period shall be for one year from the date that the product was delivered to the

location specified by the purchaser.

2. WARRANTY SCOPE

(1)

If a failure attri butable to KEYENCE occurs within t he above mentioned warranty period, we will repair the

product, free of ch arge. However, the following cases shall be excluded from the warranty scope.

•

Any failure resulting from improper conditions, improper environments, improper handling,

or improper usage other than described in the instruction manual, the user’s manual, or the

specifications specifically arranged between the purchaser and KEYENCE.

• Any failure resulting from factors other than a defect of our product, such as the

purchaser’s equipment or the design of the purchaser’s software.

•

Any failure resulting from modifications or repairs carried out by any person other than KEYENCE staff.

• Any failure that can cer tainly be prevented when the expendable part(s) is maintained

or replaced correctly as described in the instruction manual, the user’s manual, etc.

• Any failure caused by a factor that cannot be foreseen at a scientific/technical level at

the time when the product was shipped from KEYENCE.

• Any disaster such as fire, ear thquake, and flood, or any other external factor, such as

abnormal voltage, for which we are not liable.

(2)

The warranty scope is limited to the extent set forth in item (1), and KEYENCE assumes no

liability for any purchaser’s secondary damage (damage of equipment, loss of opportunities,

loss of profits, etc.) or any other damage resulting from a failure of our product.

3. PRODUCT APPLICABILITY

KEYENCE products are designed and manufactured as general -purpose produ cts for general industr ies.

Therefore, our products are not intended for th e applications below and are not applicable to them. If, however,

the purchaser consults with us in advance regarding the employment of our product, understands the

specifications, rat ings, and performance of the product on their own responsibility, and takes necessary safety

measures, the product may be applied. In this case, the warranty scope shall be the same as above.

•

Facilities where the product may greatly affect human life or property, such as nuclear

power plants, aviation, railroads, ships, motor vehicles, or medical equipment

• Public utilities such as electricity, gas, or water services

• Usage outdoors, under similar conditions or in similar environments

Analog output

(selectable among

±5 V, 1 -5 V, 0 -5 V, 4- 20

mA)

Gain input

Reset input Input time: 20 ms or more, Response delay time: 20 ms or less

Input

Environmen

t resistance

Material

Weight (including supplied items)

*1 When expansion units are added: Max. 20 mA/ch

*2 “3. Average number of times” (page 8)

*3 Delay time that occurs from the analog output circuit after the judgment is output.

*4 For detailed time chart, refer to the User’s Manual.

Timing input Input time: 2 ms or more, Response delay time: 2 ms or less

Zero shift input

Bank A input/

Bank B input

Laser emission stop input

Ambient temperature

Ambient humidity 35 - 85%RH (No condensation)

Vibration resistance 10 - 55 Hz Double amplitude1.5 mm XYZeach axis: 2 hours

Pollution degree 2

Input time: 20 ms or more

Response delay time: 120 ms or less (Nonvolatile memory

(EEPROM) 1.5 s)

Input time: 20 ms or more, Response delay time: 20 ms or less

Input time: 20 ms or more, Response delay time: 20 ms or less*

Input time: 2 ms or more, Response delay time: 2 ms or less

-10 - +50°C (No freezing)

Main unit case/Front sheet: Polycarbonate

Key top: Polyacetal

Cable: PVC

Approx. 150 g

Approx. 140 g Approx. 170 g Approx. 165 g

4

Copyright (c) 2010 KEYENCE CORPORATION. All rights reserved.

11149E 1070-3 96M11149 Printed in Japan

10

Loading...

Loading...