JLG E300 Parts Manual

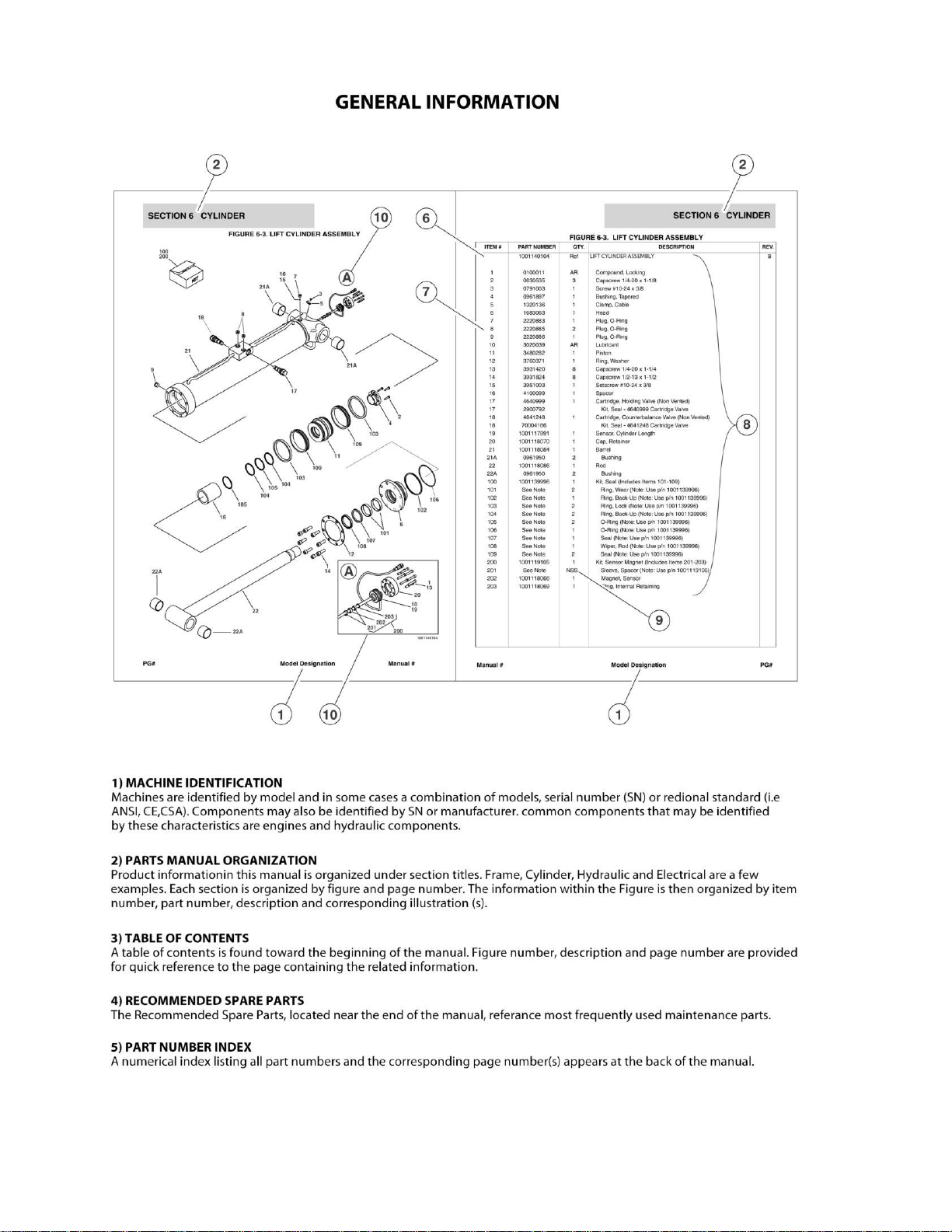

3121254 E300AJ/E300AJP 3

4 E300AJ/E300AJP 3121254

3121254 E300AJ/E300AJP 5

TABLE OF CONTENTS

SECTION 1 - FRAME ........................................................................................................................................................................... 9

FIGURE 1-1. STEER INSTALLATION ............................................................................................................................................ 10

FIGURE 1-2. TIRE AND WHEEL DRIVE INSTALLATION ............................................................................................................. 12

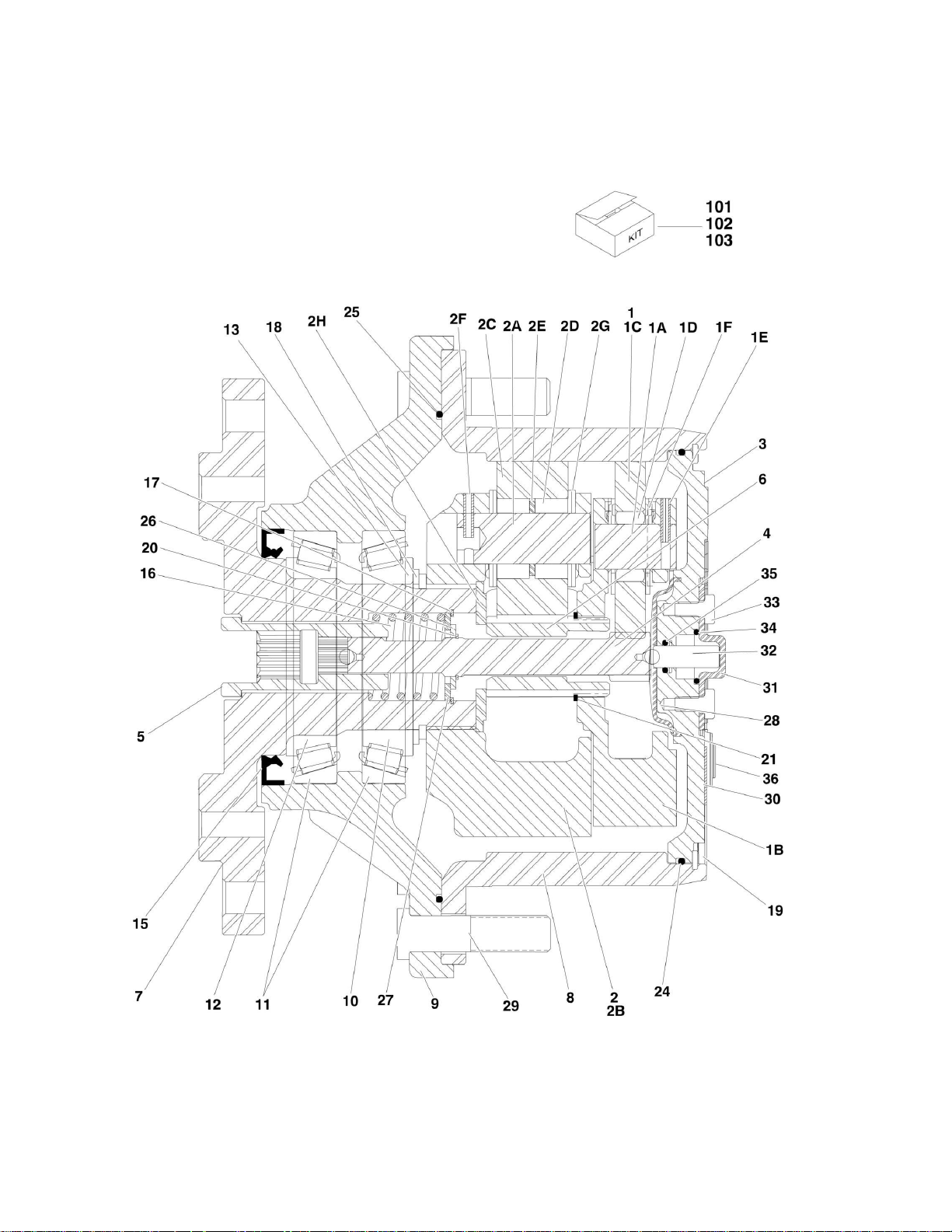

FIGURE 1-3. DRIVE HUB ASSEMBLY .......................................................................................................................................... 14

FIGURE 1-4. DRIVE MOTOR ASSEMBLY .................................................................................................................................... 18

FIGURE 1-5. ELECTRICAL COMPONENTS INSTALLATION (FRAME MOUNTED) .................................................................... 20

FIGURE 1-6. BATTERY BOX INSTALLATION .............................................................................................................................. 24

FIGURE 1-7. FRAME COVERS INSTALLATION ........................................................................................................................... 26

FIGURE 1-8. INVERTER INSTALLATION (OPTIONAL) ................................................................................................................ 28

SECTION 2 - TURNTABLE ................................................................................................................................................................ 31

FIGURE 2-1. CONTROL VALVES AND TANK/MOTOR INSTALLATIONS ................................................................................... 32

FIGURE 2-2. MAIN CONTROL VALVE ASSEMBLY ...................................................................................................................... 36

FIGURE 2-3. BOOM FUNCTION VALVE ASSEMBLY ................................................................................................................... 38

FIGURE 2-4. TURNTABLE AND SWING DRIVE INSTALLATION ................................................................................................. 40

FIGURE 2-5. TURNTABLE BEARING ASSEMBLY ....................................................................................................................... 42

FIGURE 2-6. SWING MOTOR ASSEMBLY ................................................................................................................................... 44

FIGURE 2-7. GROUND CONTROL BOX ASSEMBLY ................................................................................................................... 46

FIGURE 2-8. ELECTRICAL COMPONENTS INSTALLATIONS .................................................................................................... 50

FIGURE 2-9. HOODS INSTALLATION (Prior to SN 0300194887) ................................................................................................. 54

FIGURE 2-10. HOOD INSTALLATION (SN 0300194887 to Present) ............................................................................................ 56

SECTION 3 - BOOM .......................................................................................................................................................................... 59

FIGURE 3-1. BOOM AND CYLINDERS INSTALLATION ............................................................................................................... 60

FIGURE 3-2. TOWER BOOM ASSEMBLY .................................................................................................................................... 64

FIGURE 3-3. MAIN BOOM ASSEMBLY ......................................................................................................................................... 66

FIGURE 3-4. JIB ASSEMBLY AND PLATFORM SUPPORT INSTALLATION ............................................................................... 70

FIGURE 3-5. PLATFORM ROTATOR ASSEMBLY ........................................................................................................................ 74

FIGURE 3-6. JIB SWING ROTATOR ASSEMBLY (E300AJP ONLY) ............................................................................................ 76

FIGURE 3-7. CABLE, CLAMPS AND LIMIT SWITCHES INSTALLATION ..................................................................................... 78

SECTION 4 - PLATFORM .................................................................................................................................................................. 81

FIGURE 4-1. PLATFORM ASSEMBLY .......................................................................................................................................... 82

FIGURE 4-2. PLATFORM CONSOLE ASSEMBLY ........................................................................................................................ 86

FIGURE 4-3. CONTROLLER ASSEMBLY (DRIVE AND STEER) (Prior to SN 0300194240) ........................................................ 90

FIGURE 4-4. CONTROLLER ASSEMBLY (DRIVE AND STEER) (SN 0300194240 to Present) ................................................... 94

FIGURE 4-5. CONTROLLER ASSEMBLY (SWING AND LIFT) (Prior to SN 0300194240) ........................................................... 96

FIGURE 4-6. CONTROLLER ASSEMBLY (SWING AND LIFT) (SN 0300194240 to Present) .................................................... 100

SECTION 5 - CYLINDER ................................................................................................................................................................. 103

FIGURE 5-1. LEVEL (PLATFORM SLAVE) CYLINDER ASSEMBLY .......................................................................................... 104

FIGURE 5-2. LIFT (JIB) CYLINDER ASSEMBLY ......................................................................................................................... 106

FIGURE 5-3. LIFT (MAIN BOOM) CYLINDER ASSEMBLY ......................................................................................................... 108

FIGURE 5-4. LIFT (TOWER BOOM) CYLINDER ASSEMBLY ..................................................................................................... 110

FIGURE 5-5. MASTER CYLINDER ASSEMBLY .......................................................................................................................... 112

FIGURE 5-6. STEER CYLINDER ASSEMBLY ............................................................................................................................. 114

FIGURE 5-7. TELESCOPE CYLINDER ASSEMBLY ................................................................................................................... 116

SECTION 6 - HYDRAULIC .............................................................................................................................................................. 119

FIGURE 6-1. HYDRAULIC DIAGRAM - E300AJ .......................................................................................................................... 120

FIGURE 6-2. DRIVE HYDRAULIC DIAGRAM - E300AJP ............................................................................................................ 122

FIGURE 6-3. HYDRAULIC DIAGRAM LIST ................................................................................................................................. 124

SECTION 7 - ELECTRICAL ............................................................................................................................................................. 125

FIGURE 7-1. ELECTRICAL DIAGRAM LIST ................................................................................................................................ 126

FIGURE 7-2. HARNESS COMPONENTS INSTALLATION .......................................................................................................... 128

SECTION 8 - DECALS ..................................................................................................................................................................... 141

3121254 E300AJ/E300AJP 7

TABLE OF CONTENTS

FIGURE 8-1. DECAL INSTALLATION (ANSI SPEC) .................................................................................................................... 142

FIGURE 8-2. DECAL INSTALLATION (COUNTRY SPECS) ........................................................................................................ 146

FIGURE 8-3. DECAL INSTALLATION (AUSTRALIAN/CE SPECS) ............................................................................................. 152

SECTION 9 - RECOMMENDED SERVICE PARTS STOCK ............................................................................................................ 157

FIGURE 9-1. MODELS E300AJ AND E300AJP STANDARD PARTS .......................................................................................... 158

FIGURE 9-2. MODELS E300AJ AND E300AJP VARIABLE PARTS ............................................................................................ 160

SECTION 10 - SPECIAL OPTION .................................................................................................................................................... 161

FIGURE 10-1. SPECIAL OPTIONS .............................................................................................................................................. 162

PART NUMBER INDEX .................................................................................................................................................................... 165

8 E300AJ/E300AJP 3121254

SECTION 1 - FRAME

SECTION 1 - FRAME

3121254 E300AJ/E300AJP 9

SECTION 1 - FRAME

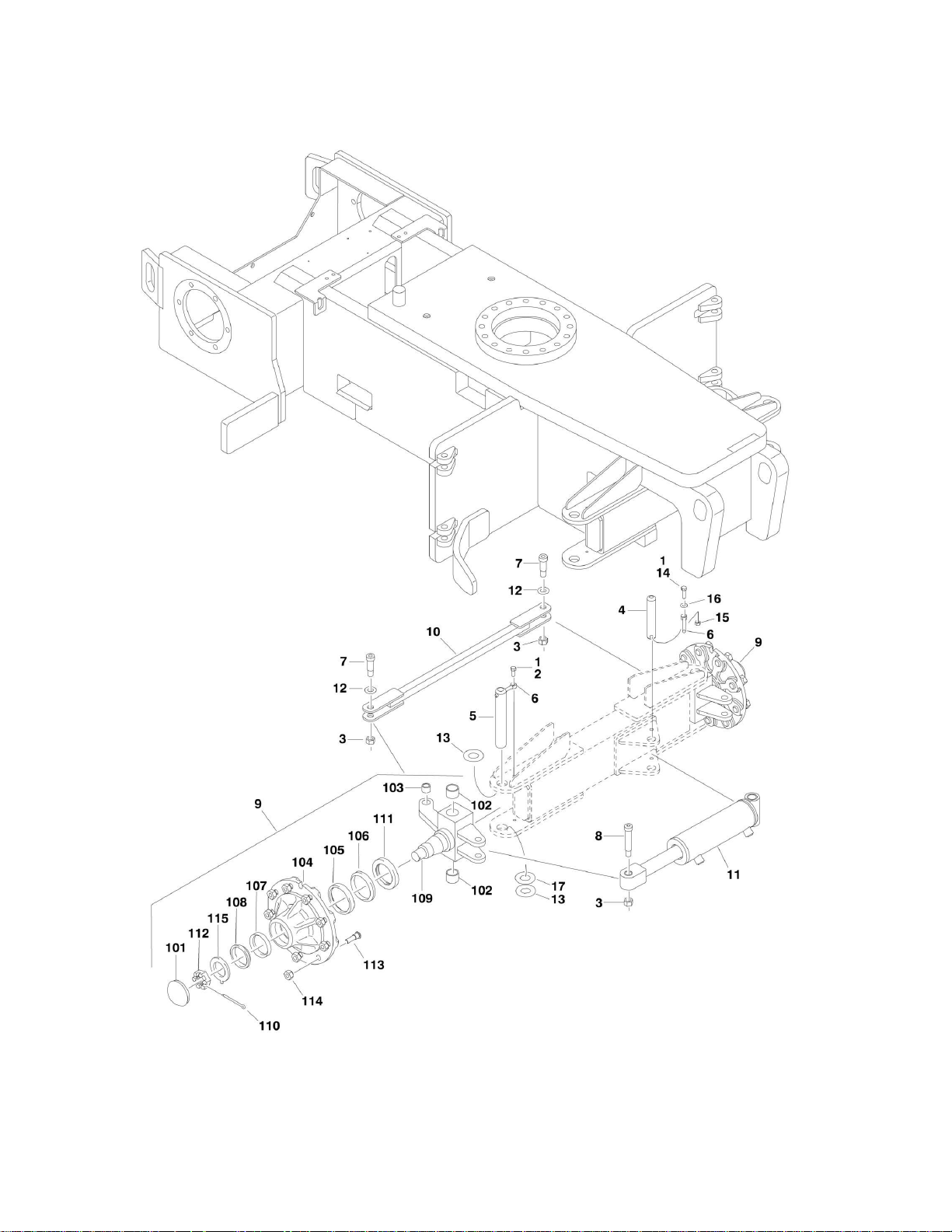

FIGURE 1-1. STEER INSTALLATION

10 E300AJ/E300AJP 3121254

FIGURE 1-1. STEER INSTALLATION

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

1001108599

Ref

STEER INSTALLATION

C 1 0100011

AR

Compound, Locking

2 0641607

2

Bolt 3/8in-16NC x 7/8in

3 3312005

3

Locknut 5/8in-11NC

4 3422181

1

Pin 5

3422562

2

Pin 6

3841143

3

Keeper, Pin

7 3900118

2

Screw, Shoulder

8 3900255

1

Capscrew, Shoulder 3/4in x 3in

9 1001107712

2

Hub/Spindle Assembly (See Items 101-115 for Breakdown)

10

1001107727

1

Tie-Rod

11

1001108310

1

Steer Cylinder Assembly (See CYLINDER SECTION for

Breakdown)

12

4740086

2

Thrustwasher

13

0440162

4

Thrustwasher

14

0641610

1

Bolt 3/8in-16NC x 1-1/4in

15

3311605

1

Locknut 3/8in-16NC

16

4711600

1

Flatwasher 3/8in Thin

17

1001151428

AR

Plate, Shim (SN 0300176716 to Present)

1001107712

Ref

HUB/SPINDLE ASSEMBLY

A

Ref

Note: Qty shown is for 1 Hub Assembly. Machine requires 2

assemblies.

101

7020137

1

Cap, Dust

102

0961951

2

Bushing, Garmax

103

0962140

1

Bearing, Garmax

104

70002434

1

Hub 105

7020036

1

Cup, Bearing (Inner) (Part of Item 104)

106

7020037

1

Cone, Bearing (Inner)

107

7020038

1

Cup, Bearing (Outer) (Part of Item 104)

108

7020039

1

Cone, Bearing (Outer)

109

70002435

1

Spindle

110

7020140

1

Pin, Cotter

111

7020040

1

Seal 112

7020054

1

Nut, Castle 1-1/4in-12

113

7020041

9

Stud 5/8in-18NF

114

7020042

9

Lugnut 5/8in-18NF

115

7020055

1

Washer, Tanged 1-1/4in

SECTION 1 - FRAME

3121254 E300AJ/E300AJP 11

SECTION 1 - FRAME

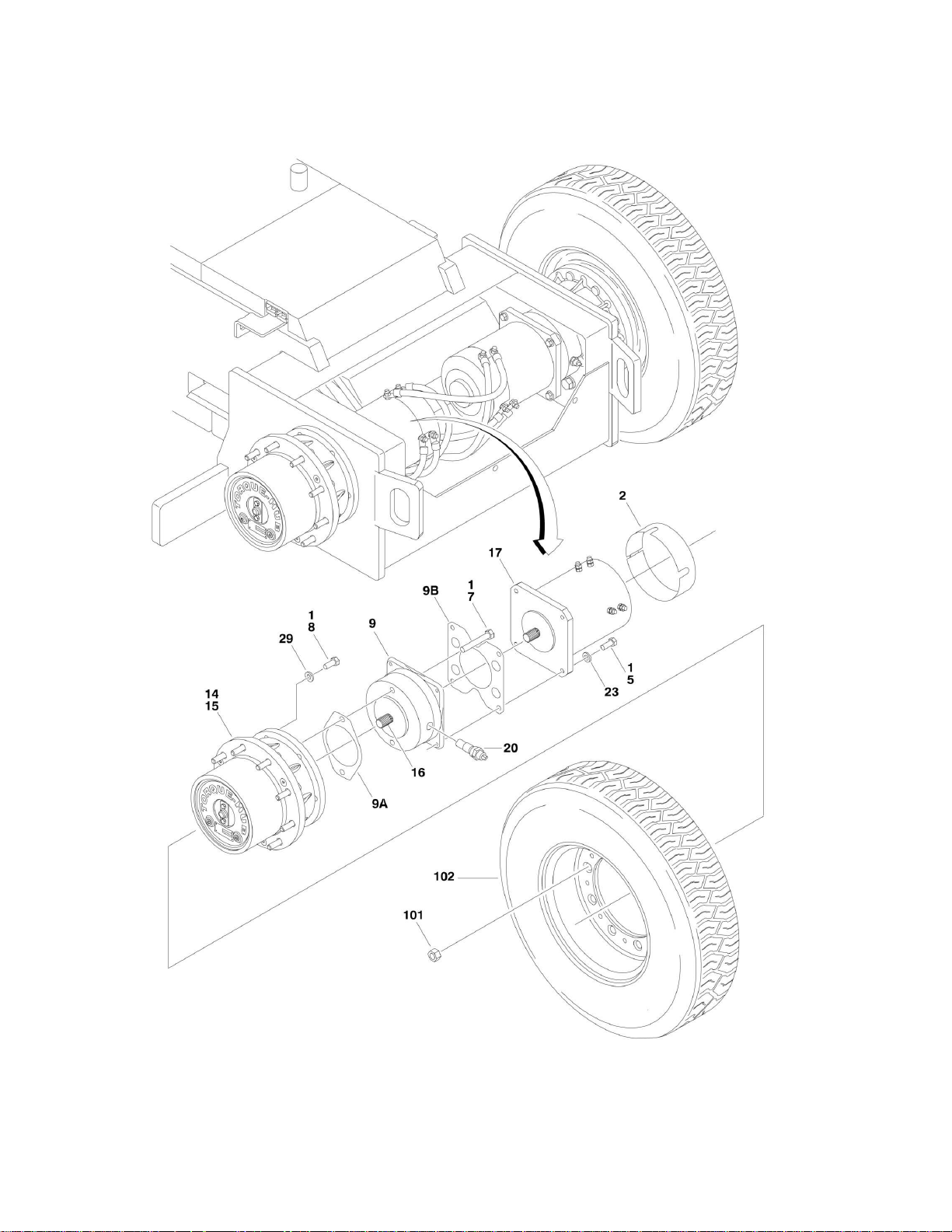

FIGURE 1-2. TIRE AND WHEEL DRIVE INSTALLATION

12 E300AJ/E300AJP 3121254

SECTION 1 - FRAME

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

WHEEL DRIVE INSTALLATION OPTIONS:

1001109430

Ref

Standard Spec

F 1001109431

Ref

UL Spec

H 1 0100019

AR

Compound, Locking

2 0340047

2

Band, Motor (UL Spec Only)

5 0641609

8

Bolt 3/8in-16NC x 1-1/8in

7 0641826

4

Bolt 1/2in-13NC x 3-1/2in

8

0682012

12

Bolt 5/8in-11NC x 1-1/2in (SN 0300113683 through

0300138358)

9

0920113

2

Drive Brake Assembly

9

0920113

2

Ring, Sensor (1 Per Assembly) (was p/n 7027275 which is no

longer available. Replace Complete Brake.)

9

7007977

2

Ring, Bearing Retaining (Large) (1 per Assembly)

9 7011716

2

Ring, Bearing Retaining (Small) (1 per Assembly)

9 7007913

4

Bolt

9

7011757

2

Complete Repair Kit (Includes Case and Oil Seals, O-Rings,

Back-Up Rings, Stator and Rotor Discs, Return Plate, Springs,

Bearing and Brake To Hub Gasket) (1 Per Assembly)

9

2900768

2

Bearing Kit (1 per Assembly)

9 7007900

2

Seal, Oil - Front (1 per Assembly)

9A

7007933

2

Gasket (1 Per Assembly)

9B

70002408

2

Gasket, Brake to Motor (1 Per Assembly) (Not Included in

Repair Kit)

14

2780282

2

Drive Hub Assembly (See DRIVE HUB ASSEMBLY for

Breakdown)

15

3020008

AR

Lubricant, Mobilube HD 80W-90

16

3020037

AR

Lube, Coupling Grease

17

3160237

2

Drive Motor Assembly (See DRIVE MOTOR ASSEMBLY for

Breakdown)

20

3990105

2

Speed Sensor Assembly

23

4711600

8

Flatwasher 3/8in Thin

29

4892000

12

Flatwasher 5/8in Hardened

0258986

Ref

TIRE AND WHEEL INSTALLATION

C

101

3300106

18

Lugnut 102

1001110772

4

Tire and Wheel Assembly

FIGURE 1-2. TIRE AND WHEEL DRIVE INSTALLATION

3121254 E300AJ/E300AJP 13

SECTION 1 - FRAME

FIGURE 1-3. DRIVE HUB ASSEMBLY

14 E300AJ/E300AJP 3121254

FIGURE 1-3. DRIVE HUB ASSEMBLY

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

2780282

Ref

DRIVE HUB ASSEMBLY

B 1 70001366

1

Carrier, Sub Assembly (Purchase p/n 70001366 for items 1A-1F)

1A

70001366

3

Shaft, Planet

1B

70001366

1

Carrier

1C

70001366

3

Gear, Planet

1D

70001366

42

Bearing, Needle

1E

70001366

3

Pin, Roll

1F

70001366

6

Thrustwasher

2 70001367

1

Carrier, Input (Purchase p/n 70001367 for items 2A-2H)

2A

70001367

3

Shaft, Planet

2B

70001367

1

Carrier

2C

70001367

3

Gear, Planet

2D

70001367

84

Bearing, Needle

2E

70001367

3

Spacer, Thrust

2F

70001367

3

Pin, Roll

2G

70001367

12

Thrustwasher

2H

70001367

1

Thrustwasher

3 70001368

1

Cover 4

70001369

1

Shaft, Input

5 70001370

1

Coupling

6 70001371

1

Shaft, Sun Gear

7 70001372

1

Spindle 8

70001373

1

Gear, Ring

9 2780282

1

Housing

10

7017007

1

Bearing, Tapered-Cone

11

7017007

2

Bearing, Tapered-Cup

12

7017007

1

Bearing, Tapered-Cone

13

7017009

1

Thrustwasher

15

70001380

1

Seal, Lip

16

70001374

1

Spring 17

70001375

1

Ring, Retaining (Internal)

18

70001380

1

Ring, Retaining (External)

19

7024738

1

Ring, Retaining (Internal)

20

70001376

1

Ring, Retaining (External)

21

70001377

1

Ring, Retaining (External)

22

7000281

4

Screw (Not Shown - ID plate screws)

23

7017022

3

Bolt, Flathead (Not Shown - Located on front of hub)

24

70001380

1

O-Ring 25

70001380

1

O-Ring 26

70001378

1

Spacer, Thrust

27

70001379

1

Thrustwasher

28

7024741

1

Spacer, Thrust

29

7007640

9

Stud, Wheel

30

70001368

1

Flange, Plate

31

70001368

1

Cap, Disengage

32

70001368

1

Pin, Dowel

33

70001368

2

Bolt 34

70001368

1

O-Ring 35

70001368

1

O-Ring 36

70001368

1

Plug

SECTION 1 - FRAME

3121254 E300AJ/E300AJP 15

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

Kit Options

101

7017007

1

Planet Gear Bearing Kit (Includes Items 10-12)

102

70001380

1

Planet Gear Seal Kit (Includes Items 15, 18, 24 & 25)

103

70001368

1

Cap/Disengage Kit (Includes Items 30-36)

SECTION 1 - FRAME

16 E300AJ/E300AJP 3121254

SECTION 1 - FRAME

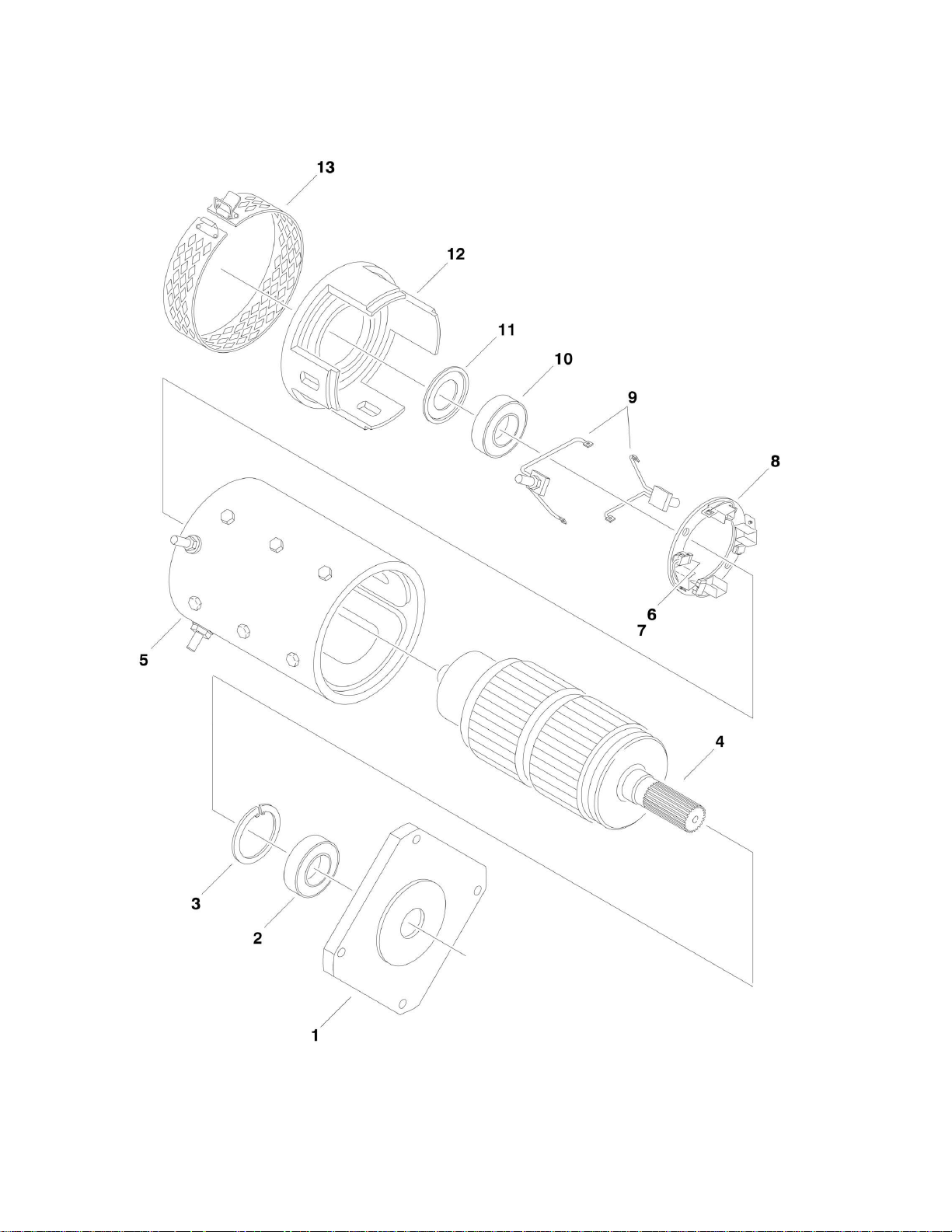

FIGURE 1-4. DRIVE MOTOR ASSEMBLY

18 E300AJ/E300AJP 3121254

FIGURE 1-4. DRIVE MOTOR ASSEMBLY

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

3160237

Ref

DRIVE MOTOR ASSEMBLY

E 1 7020184

1

Plate, Drive End

2 7012545

1

Bearing 3

7020185

1

Ring, Retaining

4 3160237

1

Armature

5 3160237

1

Frame and Field Assembly

6 7012548

4

Spring, Brush

7 7020149

4

Brush 8

7020150

1

Holder, Brush

9 7020151

2

Brush Lead Assembly Kit

10

7012545

1

Bearing

11

7012549

1

Washer, Wavy

12

7020189

1

End, Commutator

13

7019609

1

Headband Assembly

SECTION 1 - FRAME

3121254 E300AJ/E300AJP 19

SECTION 1 - FRAME

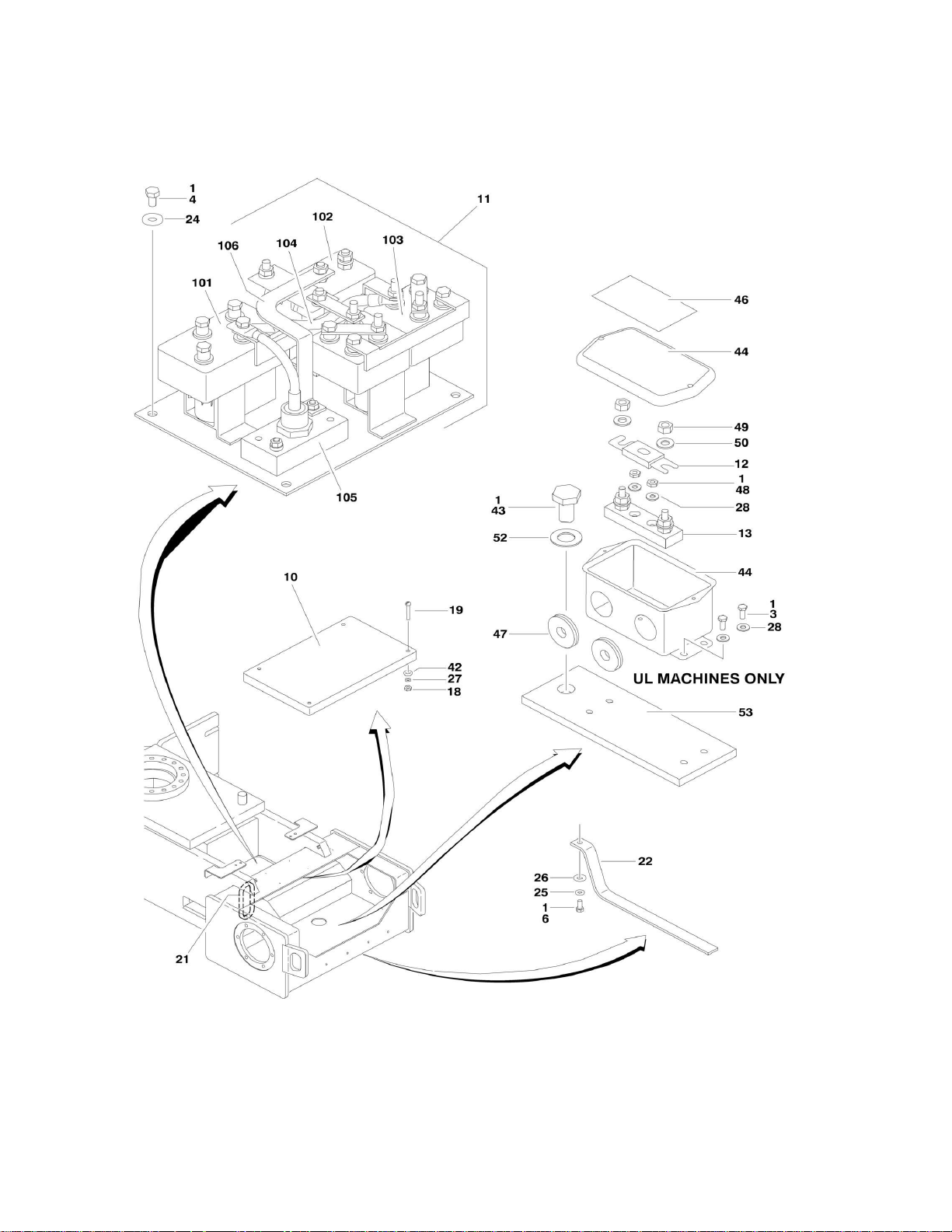

FIGURE 1-5. ELECTRICAL COMPONENTS INSTALLATION (FRAME MOUNTED)

20 E300AJ/E300AJP 3121254

SECTION 1 - FRAME

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

ELECTRICAL COMPONENTS INSTALLATION

1001109430

Ref

Standard Spec

F 1001109431

Ref

UL Spec

H 1 0100019

AR

Compound, Locking

3 0721003

2

Screw #10-24NC x 3/8in (UL Spec Only)

4 0641504

4

Bolt 5/16in-18NC x 3/4in

6 0641610

1

Bolt 3/8in-16NC x 1-1/4in

10

1600293

1

Module (Note: Calibration is required when replaced)

11 Ref

Contactor Plate Assembly Options (See Items 101 to 106 for

Breakdown):

11

1600294

1

Standard Spec

11

1600300

1

UL Spec

12

2400062

1

Fuse, 300 Amp (UL Spec Only)

13

2400044

1

Holder, Fuse (UL Spec Only)

18

3310601

4

Nut #6-32NC

19

3910628

4

Screw #6-32NC x 1-3/4in

21

4060807

14

in/36cm

Shield, Flex Trim

22

4240084

1

Strap, Anti-Static

24

4751500

4

Flatwasher 5/16in Regular

25

4751600

1

Flatwasher 3/8in Regular

26

4752200

1

Flatwasher 3/4in Regular

27

4760600

4

Lockwasher #6

28

4751000

2

Flatwasher #10 Regular

41 Ref

Drive Cable System Cables Options (Not Shown - See

ELECTRICAL SECTION for Breakdown):

41

2901818

1

Standard Spec

41

2901864

1

UL Spec

42

4750600

4

Flatwasher #6 Regular

43

0642208

1

Bolt 3/4in-10NC x 1in

44

0861375

1

Box 46

1704712

1

Decal - 300 Amp Fuse

47

2540037

2

Grommet

48

3311001

2

Nut #10-24NC

49

3311501

2

Nut 5/16in-18NC

50

4711500

4

Flatwasher 5/16in Thin

52

4712200

1

Flatwasher 3/4in Thin

53

1001116273

1

Bracket

Ref

CONTACTOR PLATE ASSEMBLY

1600294

Ref

Standard Spec

1600300

Ref

UL Spec

Ref

Harness, Contactor Options (Not Shown) (See ELECTRICAL

SECTION for Breakdown):

7022003

1

Standard Spec

7022008

1

UL Spec

7022004

1

Harness, Posi-Track Contactor (Not Shown) (See ELECTRICAL

SECTION for Breakdown)

7022005

1

Harness, Shunt (Not Shown) (See ELECTRICAL SECTION for

Breakdown)

101

Ref

Contactor, FWD / REV Options:

101

7022002

1

Standard Spec

FIGURE 1-5. ELECTRICAL COMPONENTS INSTALLATION (FRAME MOUNTED)

3121254 E300AJ/E300AJP 21

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

101

7022007

1

UL Spec

102

Ref

Contactor, Main Options:

102

7022001

1

Standard Spec

102

7022009

1

UL Spec

103

Ref

Contactor, Posi-Track Options:

103

7022000

1

Standard Spec

103

7022010

2

UL Spec

104

7022012

1

Cable, Power

105

7022011

1

Diode, Power

106

70001052

1

Shunt/Bus Bar With Harness Assembly

SECTION 1 - FRAME

22 E300AJ/E300AJP 3121254

SECTION 1 - FRAME

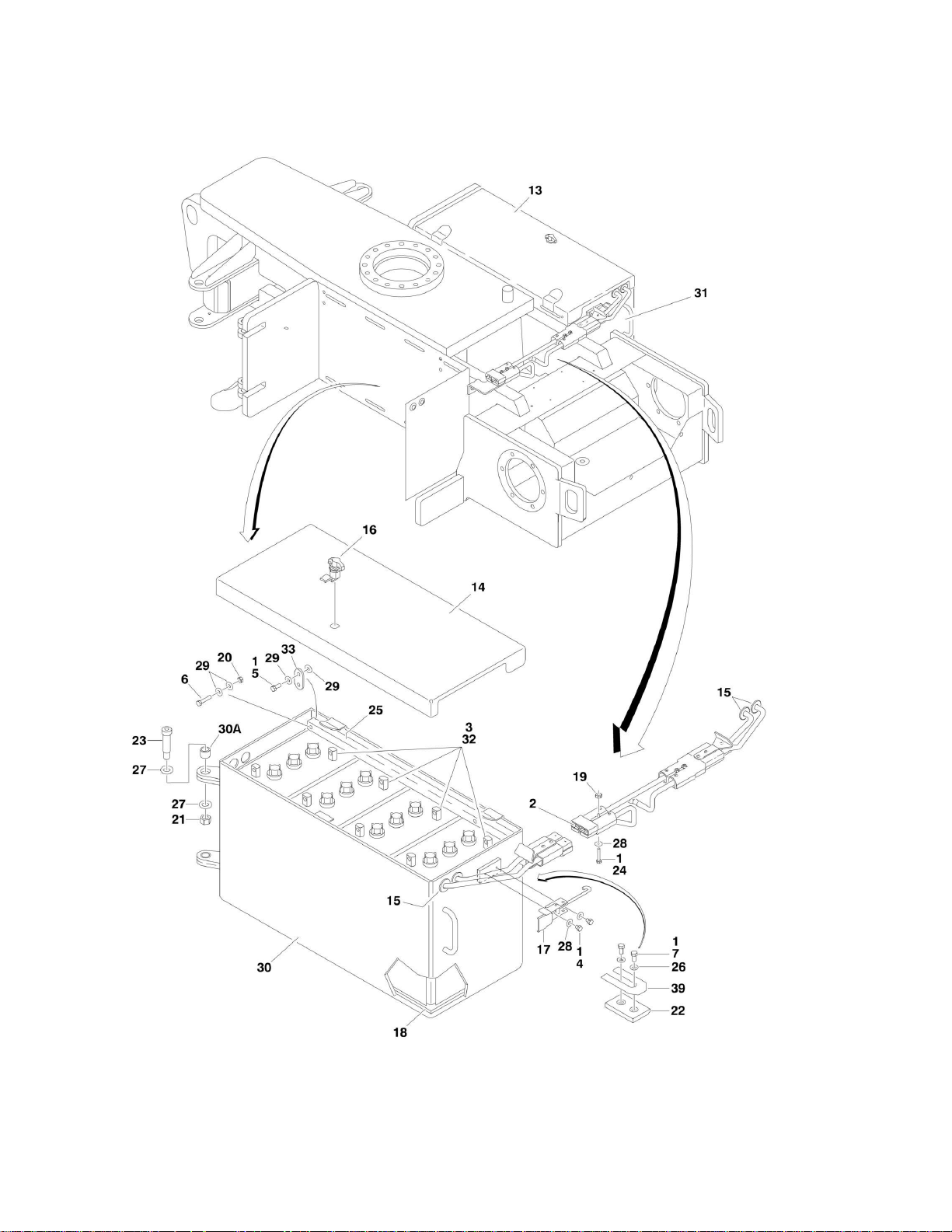

FIGURE 1-6. BATTERY BOX INSTALLATION

24 E300AJ/E300AJP 3121254

FIGURE 1-6. BATTERY BOX INSTALLATION

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

BATTERIES INSTALLATION

1001108560

Ref

Machines with 305AH Batteries

B 1001115997

Ref

Machines with 305AH AGM Batteries

A 0259042

Ref

Machines with 375AH Batteries

J 1 0100011

AR

Compound, Locking

2 0100048

AR

Grease, Dialectric

3 0100051

AR

Grease, Battery Terminal

4 0641403

4

Bolt 1/4in-20NC x 3/8in

5 0641505

4

Bolt 5/16in-18NC x 5/8in (Machines with AGM Batteries Only)

6 Ref

Bolt 5/16in-18NC Options:

6 0641512

4

Bolt 5/16in-18NC x 1-1/2in

6 0641514

4

Bolt 5/16in-18NC x 1-3/4in

7 0641606

4

Bolt 3/8in-16NC x 3/4in

13

1670878

1

Cover, (Right)

14

1670890

1

Cover, (Left)

15

2540020

4

Grommet

16

2940073

2

Latch 17

2940114

2

Latch 18

3000003

2

Liner 19

3311401

4

Nut 1/4in-20NC

20

3311505

4

Locknut 5/16in-18NC (Machines with 305AH Batteries Only)

21

3312005

4

Locknut 5/8in-11NC

22

3340852

2

Pad 23

3900266

4

Screw, Shoulder

24

3931430

4

Bolt 1/4in-20NC x 1-7/8in

25

4567739

2

Tube

26

4711600

4

Flatwasher 3/8in Thin

27

4740086

8

Thrustwasher

28

4751400

8

Flatwasher 1/4in Regular

29

4751500

AR

Flatwasher 5/16in Regular

30

4845923

1

Box, Battery (Left)

30A

0962233

2

Bushing

31

4845924

1

Box, Battery (Right)

31A

0962233

2

Bushing (Not Shown)

32 Ref

Battery Options:

32

1001105091

8

Wet Battery (6V-305-S)

32

1001114782

8

Wet Battery (6V-305A-A AGM)

32

0400055

8

Wet Battery (6V-370-S)

32

See Note

8

Dry Battery (6V-305-S) (Note: Not Available for Purchase)

32

See Note

8

Dry Battery (6V-305A-A AGM) (Note: Not available for

purchase)

32

0400107

8

Dry Battery (6V-370-S)

33

1001116006

4

Bracket (Machines with AGM Batteries Only)

39

4070904

2

Shim

SECTION 1 - FRAME

3121254 E300AJ/E300AJP 25

SECTION 1 - FRAME

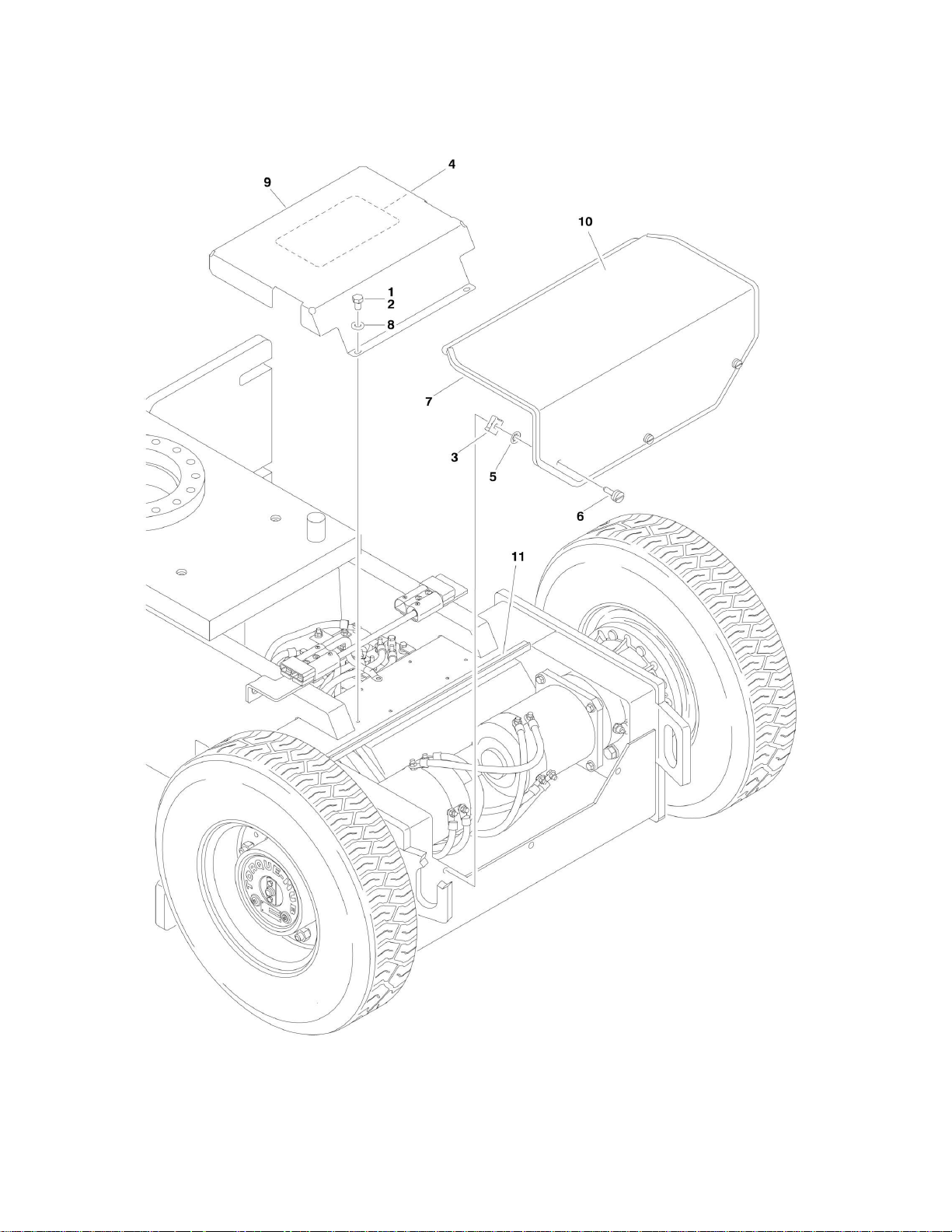

FIGURE 1-7. FRAME COVERS INSTALLATION

26 E300AJ/E300AJP 3121254

FIGURE 1-7. FRAME COVERS INSTALLATION

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

1001109383

Ref

FRAME COVERS INSTALLATION

C 1 0100011

AR

Compound, Locking

2 0641504

2

Bolt 5/16in-18NC x 1/2in

3 1380138

3

Nut, Clip

4 1704246

1

Decal - Cable Routing

5 3760308

3

Retainer

6 1001112496

3

Thumbscrew

7 3960447

63 in/1.6m

Seal 8

4711500

2

Flatwasher 5/16in Thin

9 1001107751

1

Cover, Contactor

10

1001108251

1

Cover, Rear Axle

11

3960389

2 ft/.6m

Seal

SECTION 1 - FRAME

3121254 E300AJ/E300AJP 27

SECTION 1 - FRAME

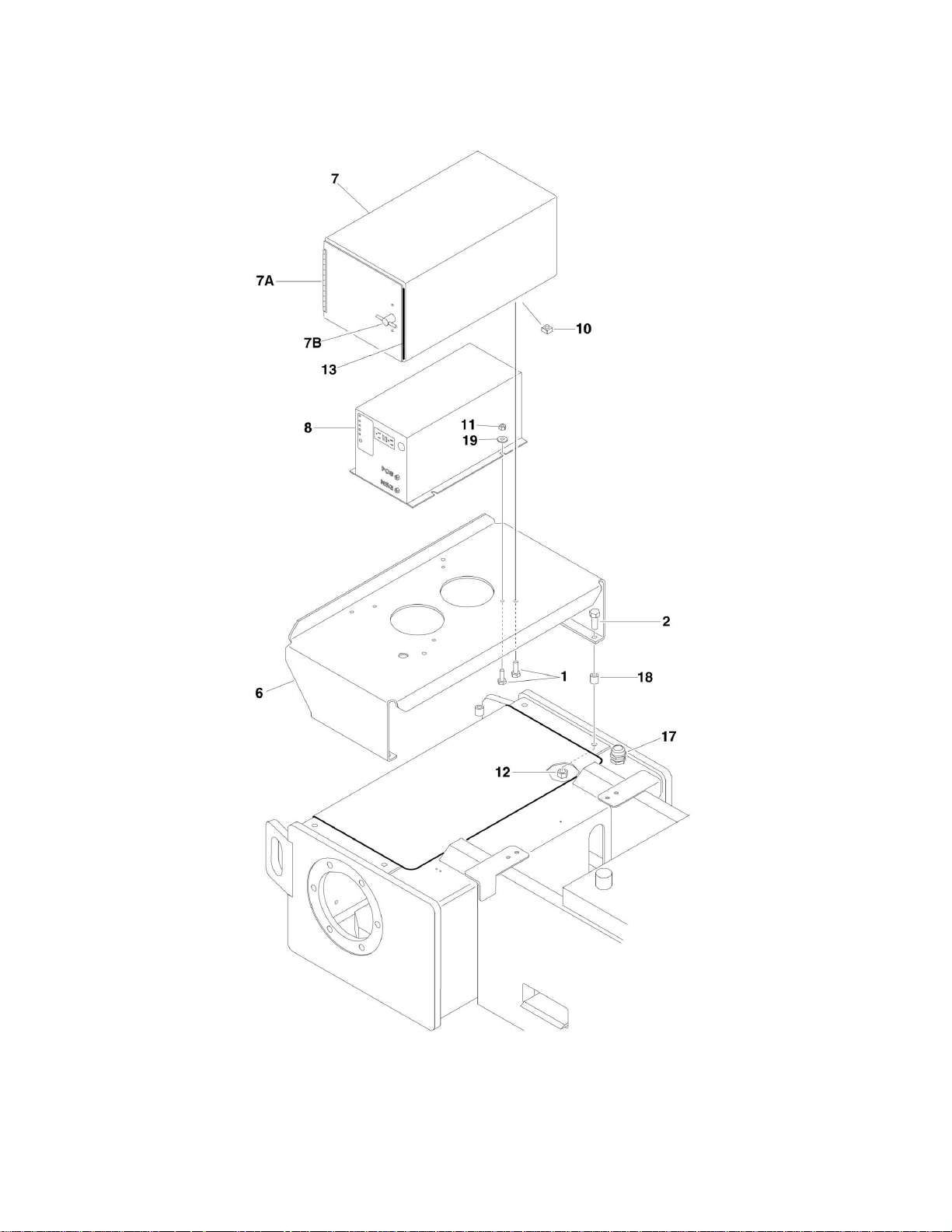

FIGURE 1-8. INVERTER INSTALLATION (OPTIONAL)

28 E300AJ/E300AJP 3121254

SECTION 1 - FRAME

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

1001110271

Ref

INVERTER INSTALLATION

B 1 0641406

8

Bolt 1/4in-20NC x 3/4in

2 0641618

4

Bolt 3/8in-16NC x 2-1/4in

6 1271463

1

Channel, Mounting

7 1670953

1

Cover 7A

2600103

1

Hinge (Welded on Part)

7B

2940048

1

Latch 8

2460037

1

Inverter/Generator Assembly

10

3300353

4

Nut, Tinnerman

11

3311405

4

Locknut 1/4in-20NC

12

3311605

4

Locknut 3/8in-16NC

13

4060803

8.5

in/21cm

Flex-Trim

17

4460426

1

Connector, Strain Relief

18

4568165

4

Spacer, Tube

19

4751400

4

Flatwasher 1/4in Regular

FIGURE 1-8. INVERTER INSTALLATION (OPTIONAL)

3121254 E300AJ/E300AJP 29

Loading...

Loading...