JLG 120HX Service Manual

Service and Maintenance Manual

Model

120HX

P/N - 3120686

April 6, 2009

INTRODUCTION

SECTION A. INTRODUCTION - MAINTENANCE SAFETY

PRECAUTIONS

A GENERAL

This section contains the general safety precautions which

must be observed during maintenance of the aerial platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions

to avoid possible injury to themselves or others, or damage to the equipment. A maintenance program must be

followed to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED, IS A SAFETY VIOLATION.

The specific precautions to be observed during maintenance are inserted at the appropriate point in the manual.

These precautions are, for the most part, those that apply

when servicing hydraulic and larger machine component

parts.

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support is

provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE,

SAFETY IN THIS AREA RESPONSIBILITY OF THE OWNER/OPERATOR.

B HYDRAULIC SYSTEM SAFETY

It should be noted that the machines hydraulic systems

operate at extremely high potentially dangerous pressures.

Every effort should be made to relieve any system pressure prior to disconnecting or removing any portion of the

system.

feed lines to system components can then be disconnected

with minimal fluid loss.

C MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION MAY RESULT IN MACHINE DAMAGE, PERSONNEL

INJURY OR DEATH AND IS A SAFETY VIOLATION.

• NO SMOKING IS MANDATORY. NEVER REFUEL DURING ELECTRICAL STORMS. ENSURE THAT FUEL

CAP IS CLOSED AND SECURE AT ALL OTHER

TIMES.

• REMOVE ALL RINGS, WATCHES AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE-FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL WARNINGS AND CAUTIONS ON MACHINE AND IN SERVICEMANUAL.

• KEEP OIL, GREASE, WATER, ETC. WIPED FROM

STANDING SURFACES AND HAND HOLDS.

• USE CAUTION WHEN CHECKING A HOT, PRESSURIZED COOLANT SYSTEM.

• NEVER WORK UNDER AN ELEVATED BOOM UNTIL

BOOM HAS BEEN SAFELY RESTRAINED FROM ANY

MOVEMENT BY BLOCKING OR OVERHEAD SLING,

OR BOOM SAFETY PROP HAS BEEN ENGAGED.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

• BATTERY SHOULD ALWAYS BE DISCONNECTEDDURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

Relieve system pressure by cycling the applicable control

several times with the engine stopped and ignition on, to

direct any line pressure back into the reservoir. Pressure

3120686 – JLG Lift – A-1

INTRODUCTION

REVISON LOG

July 1, 1992 - Original Issue

June 1, 1995 - Revised

January, 1999 - Revised

August 9, 2001 - Revised

May 15, 2002 - Revised

April 6, 2009 - Revised

A-2 – JLG Lift – 3120686

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

B Hydraulic System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

SECTION 1 - SPECIFICATIONS

1.1 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hydraulic Oil Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hydraulic System (Including Tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Engine Crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Component Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Diesel Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Drive/Steer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Swing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Function Hydraulic Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Drive Hydraulic Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Auxiliary Power Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hydraulic Filter - Inline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Travel Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Gradeability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Turning Radius (4 Wheel Steer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Platform Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Boom Elevation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Machine Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Maximum Tire Load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Machine Height (Stowed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Machine Length (Stowed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Machine Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Function Speeds (Machines Built Prior to S/N 38697) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Telescope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Lift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Extend-A-Reach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Swing Speed 360° . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Platform Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Ground to 120’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

From 120’ to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Ground to 120’ to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 Function Speeds (Machines Built After S/N 38697) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Telescope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Lift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Extend-A-Reach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Swing Speed 360° . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Platform Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Ground to 120’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

From 120’ to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Ground to 120’ to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.7 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Engine (Crankcase) Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3120686 – JLG Lift – i

TABLE OF CONTENTS (Continued)

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH PAGE NO.

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.8 Pressure Settings - PSI (Bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Main Control Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Frame Mounted Control Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.9 Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.10 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.11 Boom Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Standard Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

w/Boom Wipers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.12 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.13 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

SECTION 2 - PROCEDURES

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Servicing and Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety and Workmanship . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Cleanliness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Components Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Component Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pressure-Fit Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Bolt Usage and Torque Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Hydraulic Lines and Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Lubrication and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Lubrication Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Changing Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Cylinders - Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.5 Valves - Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Solenoid Control Valves (Bang-Bang) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Manual Hydraulic Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Relief Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Crossover Relief Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.6 Boom Chains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Adjusting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Inspection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7 Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.8 Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Telescope Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Lift Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.9 Cylinder Checking Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Cylinder w/o Counterbalance Valves - Steer Cylinders, Master Level Cylinder,

Frame Jack Cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Cylinders w/Single Counterbalance Valves - Lift Cylinder, Telescope Cylinder,

Extend-A-Reach Cylinder. 2-10

Cylinders w/Dual Counterbalance Valve - Axle Extension Cylinders,

Telescope Cylinder, Platform Slave Level Cylinder 2-10

ii – JLG Lift – 3120686

TABLE OF CONTENTS

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH PAGE NO.

2.10 Cylinder Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Telescope Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Telescope Cylinder Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Lift Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Lift Cylinder Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Master Level Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Master Level Cylinder Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.11 Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.12 Boom Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.13 Tilt Alarm Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Manual Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Voltmeter Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.14 Limit Switch Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Boom Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Horizontal Cut-Out Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.15 Throttle Checks and Adjustments - Deutz Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

2.16 Pressure Setting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Main Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Frame Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.17 Swing Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Turntable Bearing Mounting Bolt Condition Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Wear Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Swing Bearing Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.18 Drive Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

2.19 Swing Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

2.20 swing brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

2.21 Drive Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

2.22 Free Wheeling Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

To Disengage Drive Motors and Brakes (Free Wheel) for Towing, etc. . . . . . . . . . . . . . . . . 2-47

To Engage Drive Motors and Brakes (Normal Operation) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

2.23 PQ Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

TRIM Adjustment (Prior to S/N 38697) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

TRIM Adjustment (S/N 38697 to Present) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

RAMP Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

3120686 – JLG Lift – iii

TABLE OF CONTENTS (Continued)

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH PAGE NO.

2.24 Boom Marking Tape Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52

2.25 Boom Length/Angle Sensor Adjusting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52

Length Indicator Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Boom Angle Sensor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Radius Adjust and Display Lights Setting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Operational Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

Lift Down Speed Limit Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

2.26 Load Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

Platform Position Indication System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

Overmoment Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

Overmoment Control Monitoring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

Load Management System Daily Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

2.27 Load Management System Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

2.28 Turntable Springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-58

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

2.29 Drive Motor Adjustment Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-58

2.30 Preventive Maintenance and Inspection Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-59

SECTION 3 - TROUBLESHOOTING

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 Hydraulic Circuit Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

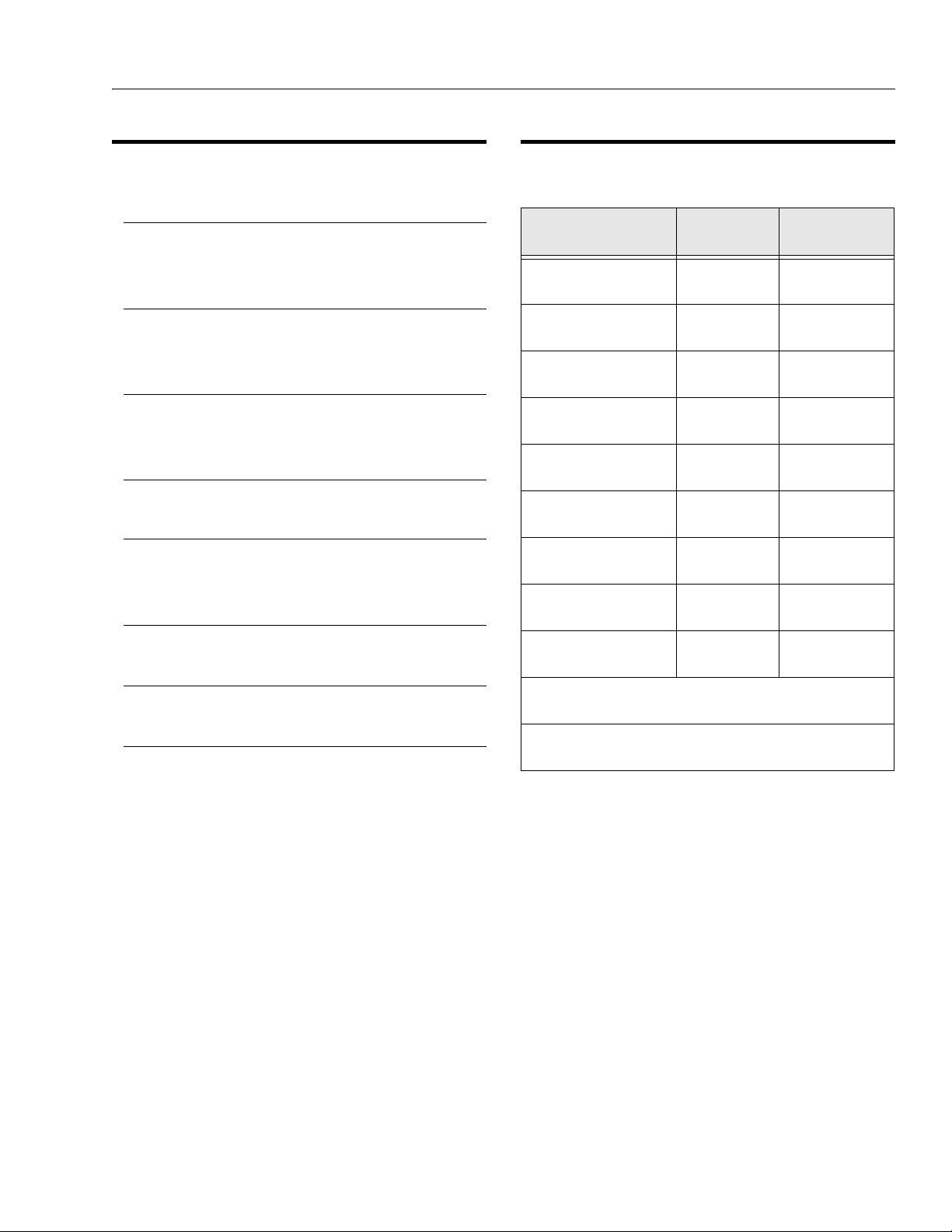

1-1. Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

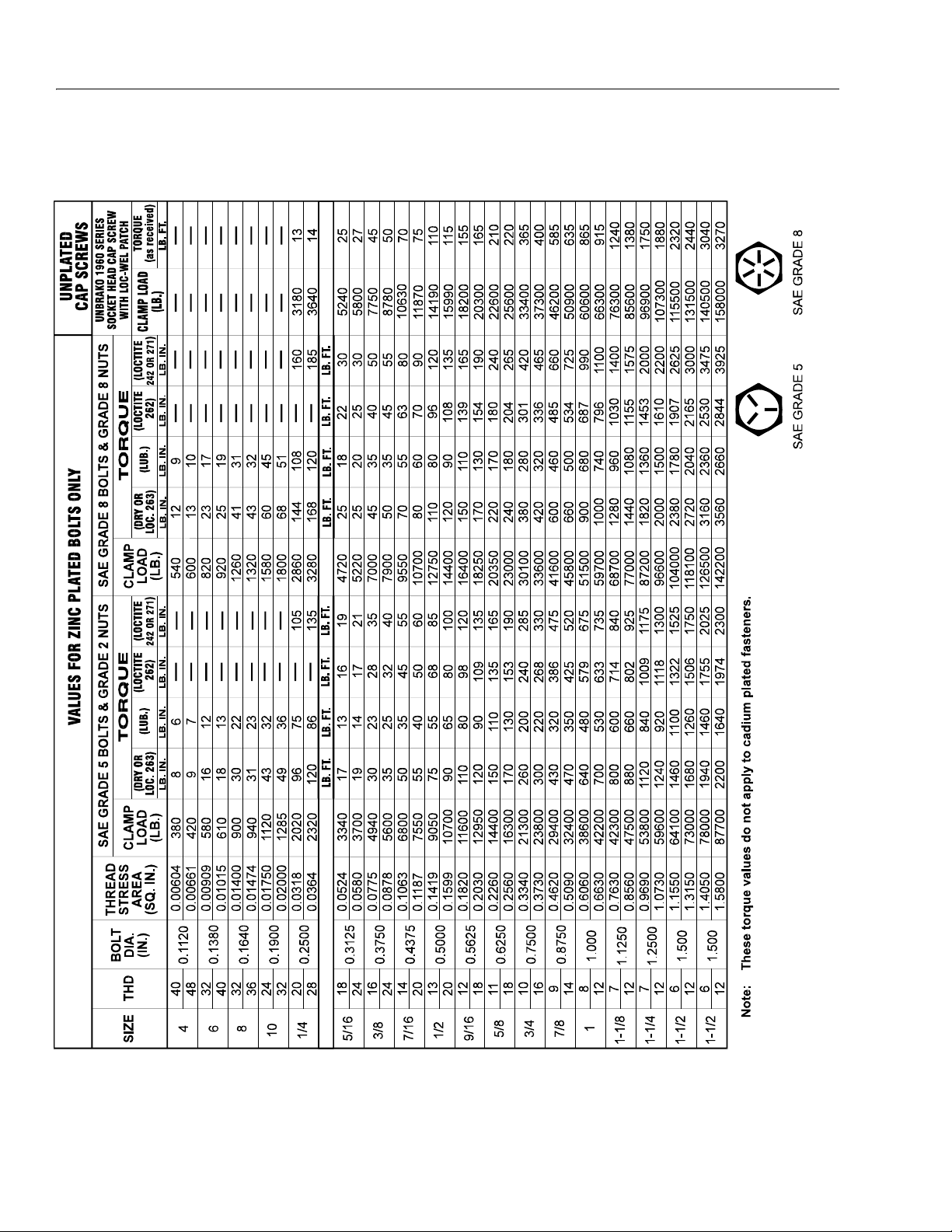

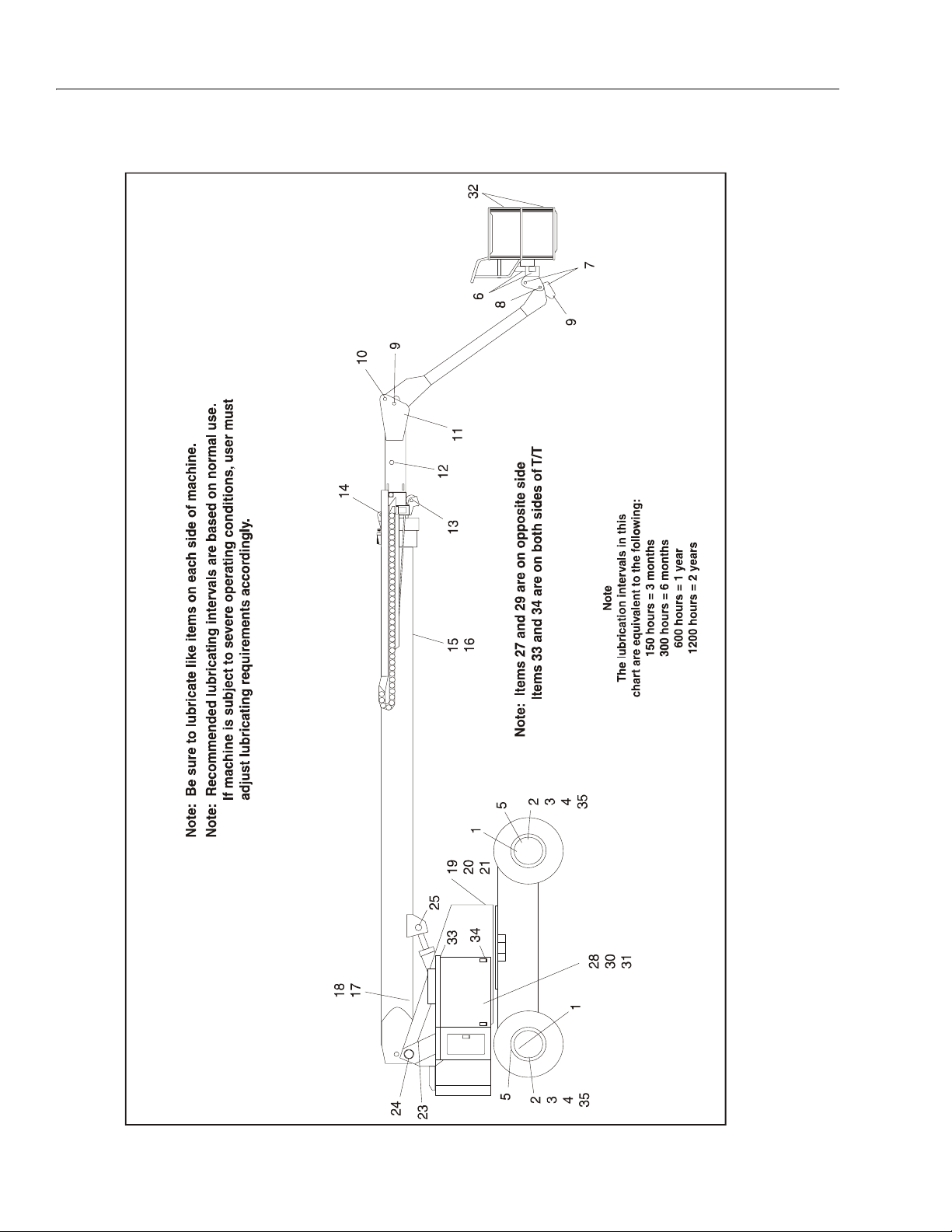

1-2. Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-3. Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2-1. Boom Chain Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-2. Typical Boom Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-3. Cylinder Barrel Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2-4. Cylinder Rod Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2-5. Poly-Pak Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2-6. Boom Assembly - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

2-7. Boom Assembly - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2-8. Tilt Switch Adjustment - Voltmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2-9. Tilt Switch Adjustment - Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2-10. Throttle Checks and Adjustments - Deutz Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2-11. Pressure Setting Adjustments - Main Valve - Machines Built Before S/N 38697 . . . . . . . . . . . . . .2-28

2-12. Pressure Setting Adjustments - Frame Valve - Machines Built Before S/N 38697. . . . . . . . . . . . .2-29

2-13. Pressure Setting Adjustments - Main Valve - Machines Built After S/N 38697 . . . . . . . . . . . . . . .2-30

2-14. Pressure Setting Adjustments - Frame Valve - Machines Built After S/N 38697 . . . . . . . . . . . . . .2-31

2-15. Swing Bearing Bolt Feeler Gauge Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2-16. Swing Bearing Tolerance Boom Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

2-17. Swing Bearing Tolerance Measuring Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

2-18. Swing Bearing Bolt Torquing Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

2-19. Drive Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2-20. Swing Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

2-21. Swing Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

2-22. Drive Brake, Mico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

2-23. Spring Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

iv – JLG Lift – 3120686

TABLE OF CONTENTS

LIST OF FIGURES (continued)

FIGURE NO. TITLE PAGE NO.

2-24. Boom Marking Tape Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52

2-25. Control Box Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-54

2-27. Boom Length/Angle Sensor Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

2-28. Load Radius Circuit Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

2-26. Load Moment Limiting System Monitoring Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-57

2-29. Drive Motor Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-59

3-1. Electrical Diagram - Boom Length Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3-2. Electrical Schematic - Sheet 1 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3-3. Electrical Schematic - Sheet 2 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3-4. Electrical Schematic - Sheet 3 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3-5. Electrical Schematic - Sheet 4 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

3-6. Hydraulic Schematic - (Sheet 1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3-7. Hydraulic Schematic - (Sheet 2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-2 Single Viscosity Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-3 Multi Viscosity Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-4 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-5 Lubrication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-6 Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1-7 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1-8 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1-9 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2-1 Chain Stretch Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-2 Cylinder Piston Nut Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2-3 Holding Valve Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2-4 Function Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

2-5 Platform Controller Settings (Prior to S/N 38697). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

2-6 Platform Controller Settings (S/N 38697 to Present) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

2-7 Preventive Maintenance and Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-60

3-1 Platform Assembly - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2 Boom Assembly - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-3 Turntable Assembly - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-4 Chassis Assembly - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3-5 Hydraulic System - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3-6 Electrical System - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3120686 – JLG Lift – v

TABLE OF CONTENTS (Continued)

This page left blank intentionally.

vi – JLG Lift – 3120686

SECTION 1 - SPECIFICATIONS

SECTION 1. SPECIFICATIONS

1.1 CAPACITIES

Fuel Tank

26 gallons (98 liters).

Hydraulic Oil Tank

50 gallons (189 liters).

Hydraulic System (Including Tank)

Approximately 60 gallons (227 liters).

Tor q u e H u b

Drive - 2.9 quarts (2.7 liters).

Swing - 1.4 quarts (1.3 liters).

NOTE: Torque hubs should be one half full of lubricant.

Engine Crankcase

10.0 quarts (9.5 liters) w/o filter.

1.2 COMPONENT DATA

Swing System

Swing Motor Displacement - 2.0 in.[3]/rev. (32.8 cm[3]/

rev).

Swing Brake - Automatic spring applied, hydraulically

released. Release pressure 150 psi (10.5 kg/cm[2]) initial,

170 psi (12.0 kg/cm[2]) full.

Function Hydraulic Pump

Vendor - John Barnes.

Single section gear pump - 97 in.[3] (1589 cm[3]) displacement.

Output - 7.5 gpm (28.4 lpm) @ 1800 rpm; 10.5 gpm (39.7

lpm) @ 2500 rpm.

Drive Hydraulic Pump

Vendor - Sunstrand.

Overcenter piston pump - 2.8 in.[3] (45.9 cm[3]) displacement.

Output - 30 gpm (113.5 lpm) @ 2500 rpm.

Auxiliary Power Pump

Vendor - John Barnes.

Diesel Engine

Manufacturer/Model - Deutz F4L912.

Oil Capacity - 10.0 quarts (9.5 liters) w/o filter.

Low RPM - 1800.

High RPM - 2500.

Alternator - 60 Amp, belt drive.

Battery - 85 Amphour, 550 Cold Cranking Amps, 12 VDC.

Horsepower - 76 @ 2500 RPM, no load.

Drive/Steer System

Tires - 445/65R22.5, foam filled.

Drive Hub - 93.7:1 ratio.

Drive Brake - Spring applied, hydraulically released,

release pressure 140 psi (9.7 bar).

Drive Motor - 2 speed, 0.4 in.[3]/rev. (6.4 cm[3]/rev.) low

speed, 0.2 in.[3]/rev. (2.5 cm[3]/rev.) high speed.

Single section gear pump.

Displacement - 0.2 in.[3] (2.1 cm[3])/rev.

Output - 4.8 gpm (18 lpm).

Hydraulic Filter - Inline

Return - Bypass Type.

25 Microns Nominal.

1.3 PERFORMANCE DATA

Travel Speed

2WD - 3.2 mph (5.1 km/hr).

4WD - 2.7 mph (4.3 km/hr).

Gradeability

2WD - 25%.

4WD - 40%.

3120686 – JLG Lift – 1-1

SECTION 1 - SPECIFICATIONS

Turning Radius (4 Wheel Steer)

Outside.

19 ft. 3 in. (5.86 m) w/axles extended.

18 ft. 0 in. (5.48 m) w/axles retracted.

Inside.

8 ft. 6 in. (2.59 m) w/axles extended.

9 ft. 2 in. (2.79 m) w/axles retracted.

Platform Capacity

Standard - 500 lb. (230 kg).

Boom Elevation

Main boom - -14° to +75°.

Extend-A-Reach - +15° to -80°.

Machine Weight

Approximately 44,000 lb. (19,958 kg).

1.4 FUNCTION SPEEDS (MACHINES BUILT PRIOR TO S/N 38697)

Te le sc op e

Extend - 132-170 seconds.

Retract - 140-175 seconds.

Lift

Up - 125-160 seconds.

Down - 108-132 seconds.

Extend-A-Reach

Up - 15-25 seconds.

Down - 15-25 seconds.

Swing Speed 360°

143-243 seconds.

Maximum Tire Load

26,090 lb. (11,834 kg) @ 149 psi (10 bar).

Machine Height (Stowed)

10 ft. 3-27/32 in. (3.1 m).

Machine Length (Stowed)

Boom erected for use - 52 ft. 4 in. (15.9 m).

Boom stowed for shipping - 35 ft. 10-5/8 in. (10.9 m).

Machine Width

8 ft. 6 in. (2.6 m) w/axles retracted.

10 ft. 10 in. (3.3 m) w/ axles extended.

Wheelbase

11 ft. 4-1/2 in. (3.5 m).

Platform Rotation

Left - 20-30 seconds.

Right - 20-30 seconds.

Ground to 120’

257-330 seconds.

From 120’ to Ground

248 to 307 seconds.

Ground to 120’ to Ground

505 to 637 seconds.

1-2 – JLG Lift – 3120686

SECTION 1 - SPECIFICATIONS

1.5 FUNCTION SPEEDS (MACHINES BUILT AFTER S/N 38697)

Te le sc op e

Extend - 80-100 seconds.

Retract - 85-100 seconds.

Lift

Up - 85-100 seconds.

Down - 75-100 seconds.

Extend-A-Reach

Up - 15-25 seconds.

Down - 15-25 seconds.

Swing Speed 360°

143-243 seconds.

Platform Rotation

Left - 7-20 seconds.

Right - 7-20 seconds.

Ground to 120’

165 to 200 seconds.

From 120’ to Ground

150 to 200 Seconds

1.6 TORQUE REQUIREMENTS

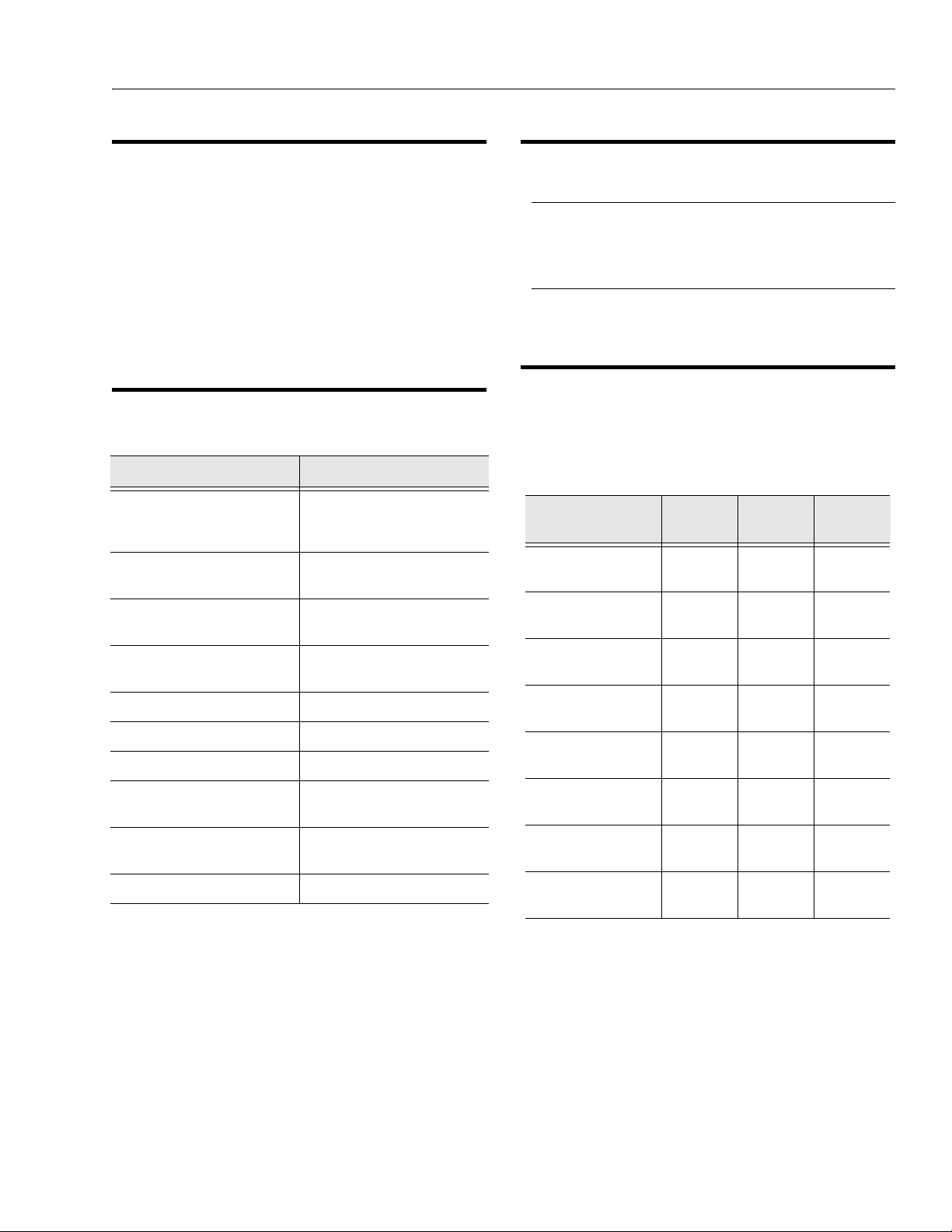

Ta b l e 1 - 1 . To r q u e R e q u i r e m e n t s

Description

Bearing To Chassis 220 FT LB

Bearing To Turntable

Wheel Lugs

Drive Torque Hub to

Spindle

Boom Chains

Swing Motor to Swing

Brake

Swing Brake to

To r qu e H u b

Torque Hub to Mounting Plate

Frame Valve Bolts

* Retorque swing bearing bolts after first 200 hours of operation and every 500 hours thereafter.

Torque Va lue

(Dry)

(298 NM)

220 FT LB

(298 NM)

300 FT LB

(407 NM)

260 FT LB

(353 NM)

59 FT LB (80

NM)

75 FT LB (102

NM)

110 FT LB

(149 NM)

260 FT LB

(353 NM)

80 IN LB (9

NM)

Interval Hours

200/500*

200/500*

50

500

200

500

500

500

See Note

Below**

Ground to 120’ to Ground

315 to 400 Seconds

**Re-torque frame valve bolts after checking or adjusting

steer pressure.

NOTE: See Section 2 for tightening sequence of turntable

bearing bolts.

NOTE: When maintenance becomes necessary or a fas-

tener has loosened, refer to the Torque Chart Figure

1-1 to determine proper torque value.

3120686 – JLG Lift – 1-3

SECTION 1 - SPECIFICATIONS

Figure 1-1. Torque Chart

1-4 – JLG Lift – 3120686

SECTION 1 - SPECIFICATIONS

1.7 LUBRICATION

Engine (Crankcase) Oil

NOTE: Crankcase oil must be a high quality detergent type

meeting one of the following API service classifications: CC/SE, CC/SF, CD/SE, CD/SF, CE/SF or CE/

SG.l

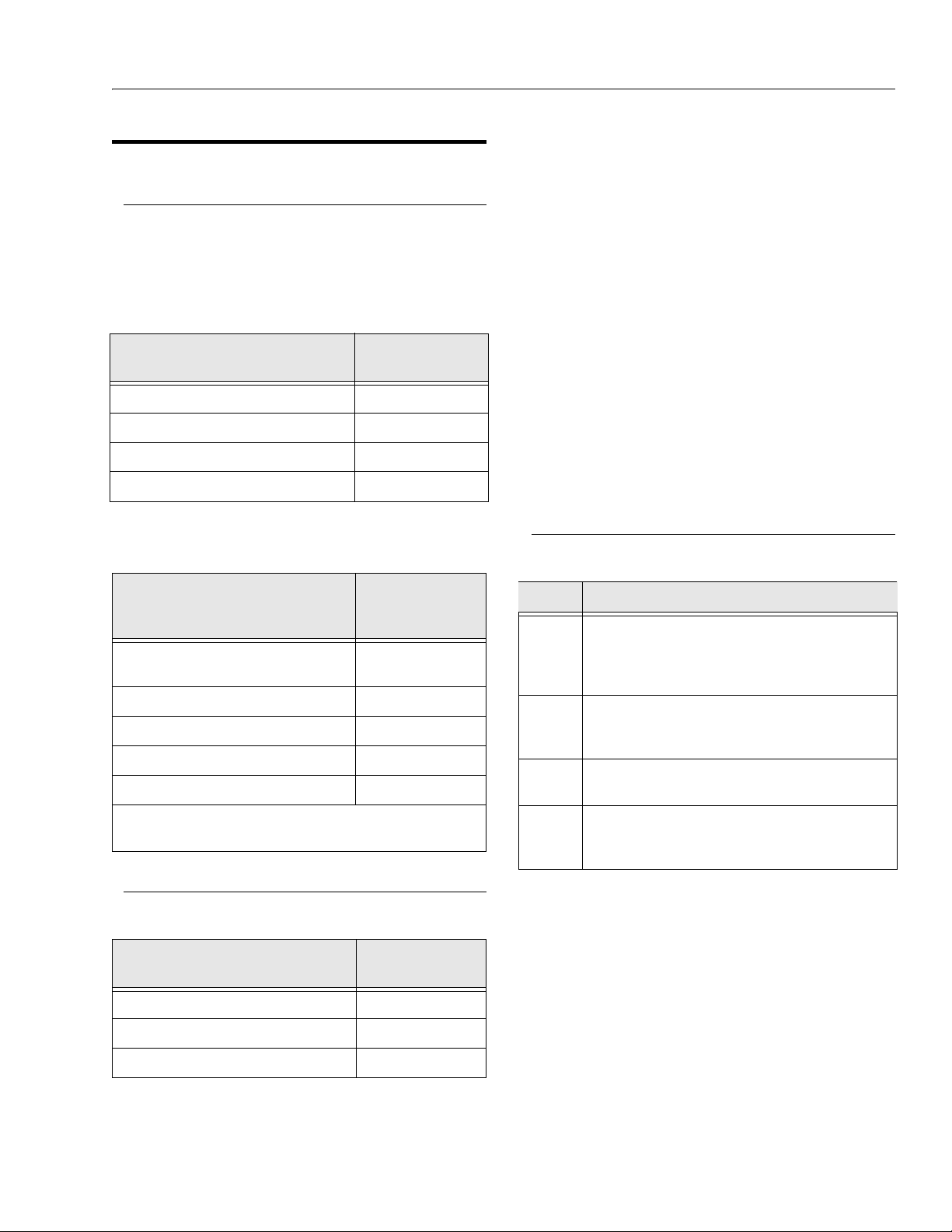

Ta b l e 1 - 2 . S i n g l e V i s c o s i t y O i l

When Outside Temperature is

Consistently

-20° F to +25° F (-29° C to -4° C) *10W

+15° F to +50° F (-10° C to +10° C) 20W-20

+40° F to ++85° F (+4° C to +30° C) 30

Above +75° F (Above +24° C) 40

Table 1-3. Multi Viscosity Oil

When Outside Temperature is

Consistently

-40° F to +75° F (-40° C to +24° C) *5W-20

-5° F to +70° F (-21° C to +21° C) 10W-30

-5° F to +85° F (-21° C to +30° C) 10W-40

+15° F to +75° F (-10° C to +24° C) 15W-30

Above +15° F (-10° C and above) 15W-40

Use SAE Viscosity

Number

Use SAE

Viscosity

Number

(synthetic)

chemical stability for mobile hydraulic system service. JLG Industries recommends Kendall Hyken

052 hydraulic oil, which has an SAE viscosity of

10W-20 and a viscosity index of 152, or Mobilfluid

424, which has an SAE viscosity of 10W-30 and a

viscosity index of 152. Kendall Hyken 052 and Mobilfluid 424 are fully compatible and can be mixed as

necessary.

NOTE: Aside from JLG recommendations, it is not advisable

to mix oils of different brands or types, as they may

not contain the same required additives or be of

comparable viscosities. If use of hydraulic oil other

than Kendall Hyken 052 or Mobilfluid 424 is desired,

contact JLG Industries for proper recommendations.

Kendall Hyken 052 and Mobilfluid 424 are fully compatible and can be mixed as necessary.

NOTE: When temperatures remain consistentlybelow 20

degrees F. (-7 degrees C), JLG Industries recommends the use of Mobil DTE11.

Lubrication Specifications

Table 1-5. Lubrication Specifications

KEY SPECIFICATIONS

MPG

EPGL Extreme Pressure Gear Lube (oil) meeting API

HO Hyd raulic Oil. API service classification GL-3, e.g.

Multipurpose Grease having a minimum dripping

point of 350° F. Excellent water resistance and

adhesive qualities, and being of extreme pressure type. (Timken OK 40 pounds minimum.)

service classification GL-5 or MIL-Spec MI L-L-

2105.

Kendall Hyken 052 or Mobilfluid 424.

* This viscosity can be used at colder temperatures only

with engine oil preheating.

EO Engine (crankcase) Oil. Gas - API SG/SH class,

MIL-L-2104. Diesel - API CC/CD/CE class, MIL-L2104B/MIL-L-2104C.

Hydraulic Oil

NOTE: Refer to Figure 1-2 for specific lubrication proce-

Ta b l e 1 - 4 . H y d r a u l i c O i l

HYDRAULIC SYSTEM OPERATING

TEMPERATURE RANGE

0° F to +23° F (-18° C to -5° C)

0° F to +210° F (-18° C to +99° C) 10W-20, 10W30

+50° F to +210° F (+10° C to +99° C) 20W-20

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

SAE VISCOSITY

GRADE

10W

3120686 – JLG Lift – 1-5

dures.

SECTION 1 - SPECIFICATIONS

Figure 1-2. Lubrication Diagram

1-6 – JLG Lift – 3120686

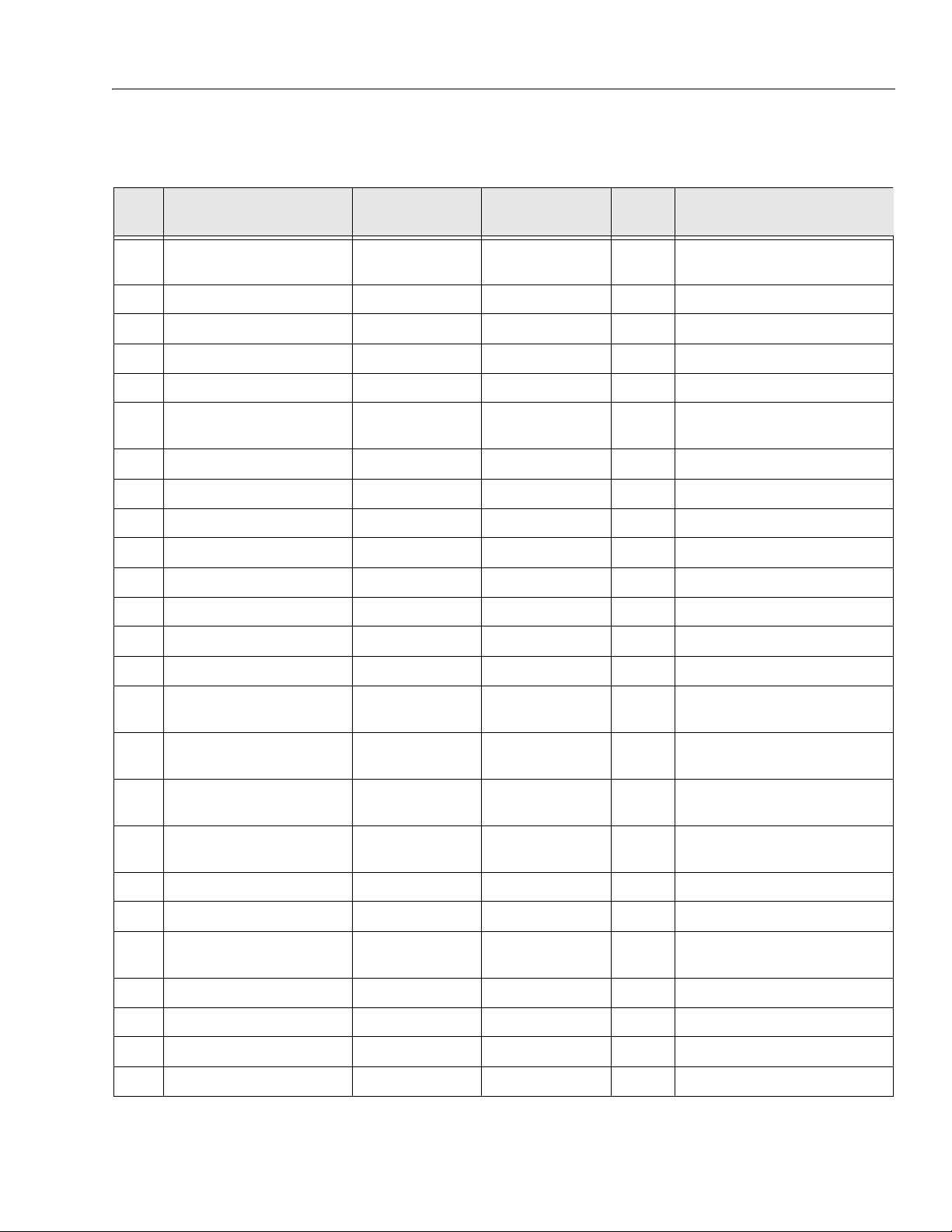

Table 1-6. Lubrication Chart

SECTION 1 - SPECIFICATIONS

Index

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Component

Wheel Drive Hubs

Steer Cylinders - Rod End

Steer Cylinders - Barrel End

King Pins

Tie Rods

Rotary Platform Stand

Rotary Worm Gear

Platform Level cylinder

Platform Pivot Pin

Link Level P in

E-A-R Pivot Pin

E-A-R Lift Cylinder - Rod End

E-A-R Lift Cylinder - Barrel End

Sheave Pin - Fly Extend

Number/Type

Lube Points

Lube &

Method

Interval

Hours

Fill/Drain Plugs EPGL (SAE 90) 150/

1200

2 Grease Fitting MPG - Pressure Gun 150

2 Grease Fittings MPG - Pressu re Gun 150

4 Grease Fittings MPG - Pressu re Gun 150

4 Grease Fitting MPG - Pressure Gun 150

2 Grease Fittings

N/A

MPG - Pressure Gun

MPG - Brush

150

150

3 Grease Fittings MPG - Pressu re Gun 150

1 Grease Fitting MPG - Pressure Gun 150

2 Grease Fittings MPG - Pressu re Gun 150

1 Grease Fitting MPG - Pressure Gun 150

1 Grease Fitting MPG - Pressure Gun 150

1 Grease Fitting MPG - Pressure Gun 150

1 Grease Fitting MPG - Pressure Gun 150

Comments

Check Every 150 Hours/Change Every

1200 Hours

Remove Cover to Grea se

Sheave Pin - Upper Aux.

14

Tele Cyl. She ave Pin

15

Boom Chains

16

Sheave Pin - Fly Retract

17

Sheave P in - Outer-Mid Retra ct

18

Lift Cylinder - Barrel End

19

Master Cylinder - Barrel End

20

Swing Bearing

21

Swing Bearing Gear

22

Master Cylinder - Rod End

23

Boom Pivot Bearings

24

Lift Cylin der - Rod End

25

1 Grease Fitting MPG - Pressure Gun 150

1 Grease Fitting MPG - Pressure Gun 150 Extend boom until grease fitting is acces-

sible thru hole in f ly sec.

N/A Chain Lube/Hot Oil

1200 Extend and Re tract Chains

Dip

2 Grease Fittings MPG - Pressu re Gun 150 Extend boom until fitt ing is accessible

thru hole in fl y

2 Grease Fittings MPG - Pressu re Gun 150 Extend boom until fitt ing is accessible

thru hole in fl y

1 Grease Fitting MPG - Pressure Gun 150 Remote Access

1 Grease Fitting MPG - Pressure Gun 150 Remote Access

1 Grease Fitting MPG - Pressure Gun 150 Rem ote Access. Lube, rotate 180°, lub e

again.

N/A MPG - Brush 150

1 Grease Fitting MPG - Pressure Gun 150

2 Grease Fittings MPG - Pressu re Gun 150

1 Grease Fitting MPG - Pressure Gun 150

3120686 – JLG Lift – 1-7

SECTION 1 - SPECIFICATIONS

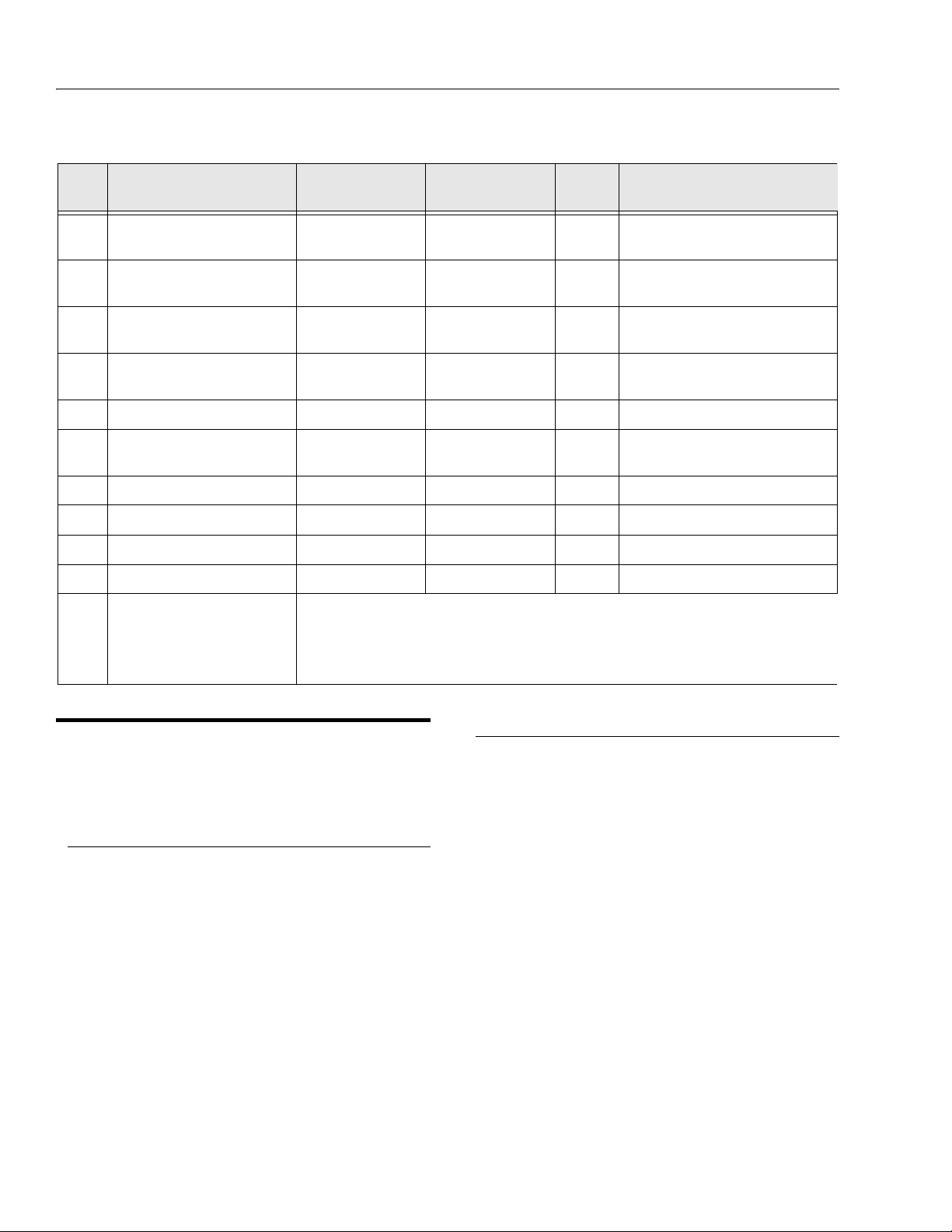

Table 1-6. Lubrication Chart

Index

No.

26

27

28

29

30

31

32

33

34

35

Component

Load Moment Pivot Pins

Hydraulic Filter - Function

Pump

Hydraulic Filter - Drive Pump

Hydraulic Fluid

Engine Crankcase

Engine Oil Filter

Platform Door Hinges

Access Door Hinges

Access Door Latches

Axle Beams

Key to Lubricants:

Number/Type

Lube Points

Lube &

Method

Interval

Hours

Comments

1 Grease Fitting MPG - Pressure Gun 150 Position boom over side for access

under turntable

N/A N/A 50/300 Replace after first 50 hrs. of operation,

then every 300 hrs. the reafter

N/A N/A 50/300 Replace after first 50 hrs. of operation,

then every 300 hrs. the reafter

Fill Cap HO 10/1200 Check oil daily/Ch ange oil every 1200

hrs

Fill Cap/Drain Plug EO - SAE30 10/300 Check oil daily/Change oil every 300 hrs.

N/A Replaceable Car-

300

tridge

2 Grease Fittings MPG - Pressu re Gun 150

N/A SAE10 - Oil Can 150 As Ne eded

N/A SAE10 - Oil Can 150 As Ne eded

N/A MPG - Brush 600 As Ne eded

MPG - Multipurpose Grease

EPGL - Extrem e Pressure Gear Lubricant

HO - Hydraulic Fluid

EO - Engine Oil

1.8 PRESSURE SETTINGS - PSI (BAR)

Frame Mounted Control Valve

Front Steer Relief - 2000 (138)

NOTE: All pressures are given in pounds per square inch

(psi), with the metric equivalent, bar, given in parentheses.

Main Control Valve

Main Relief - 3450 (238)

Lift Down Relief - 1200 (83)

Rear Steer Relief - 2000 (138)

Front Axle Extend Relief - 2000 (138)

Front Axle Retract Relief - 2200 (152)

Rear Axle Extend Relief - 2000 (138)

Rear Axle Retract Relief - 2200 (152)

Swing Relief - 1200 (83)

Level Up Relief - 2500 (172)

Level Down Relief - 2000 (138)

Rotate Relief - 2500 (172)

Extend-A-Reach Up Relief - 3000 (207)

Extend-A-Reach Down Relief - 1400 (97)

Sequence (Load Sense) - 160 (11)*

* Sequence pressure is pre-set and not normally

adjusted.

1-8 – JLG Lift – 3120686

SECTION 1 - SPECIFICATIONS

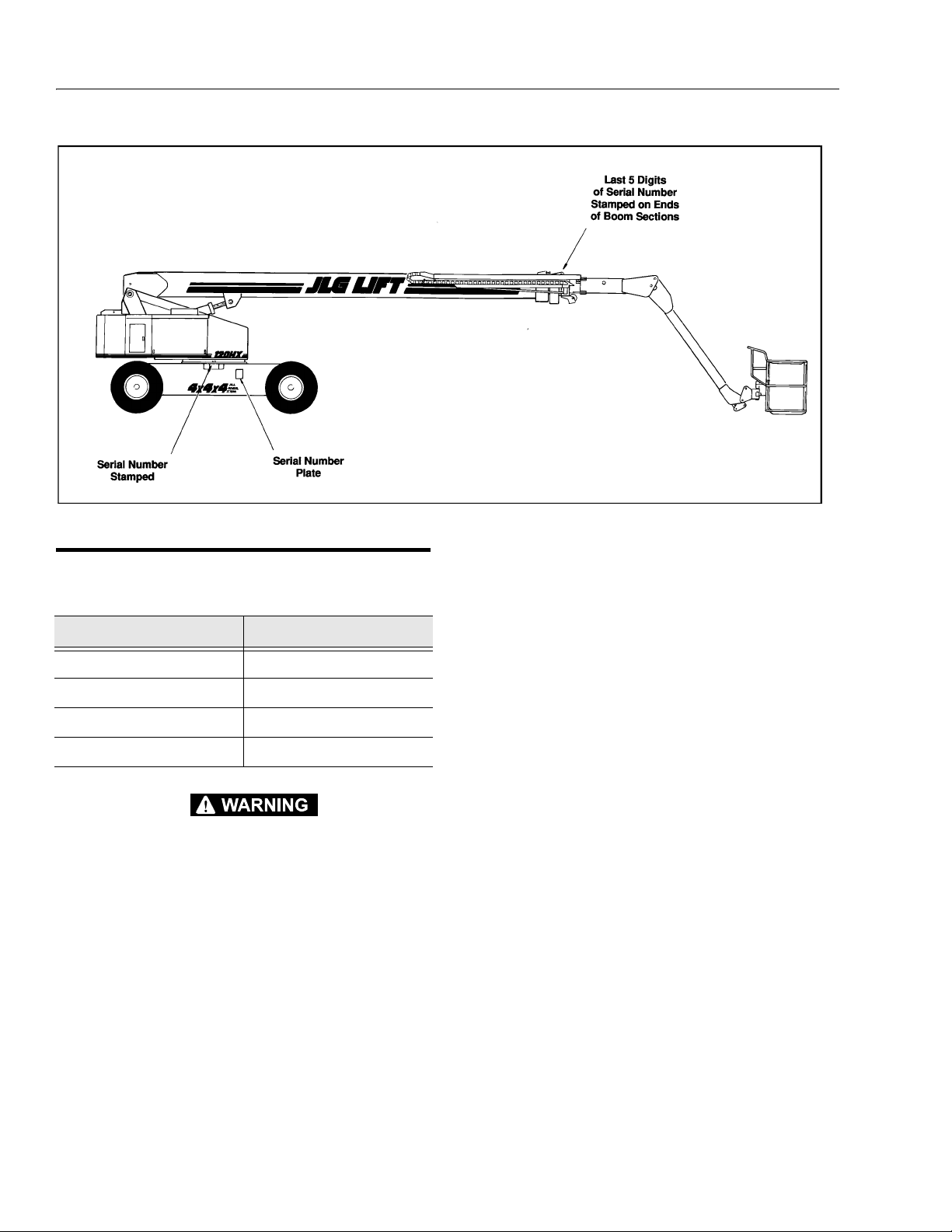

1.9 SERIAL NUMBER LOCATIONS

For machine identification, a serial number plate is affixed

to the machine. The plate is located on the left side of the

frame, between the bearing area and the left rear wheel. If

the serial number plate is damaged or missing, the

machine serial number is stamped on the left side of the

frame, at the center top, below the turntable bearing; the

serial number is also stamped on the left side of the turntable, at center, along the left turntable upright close to the

bearing area. In addition, the last five digits of the serial

number are stamped on the top left of the fly end of each

boom section.

1.10 MAJOR COMPONENT WEIGHTS

Table 1-7. Major Component Weights

COMPONENT LB (KG)

Platform - 36 x 72 in. (0.9 x

1.8 m) w/Control Box Support and Rotator.

Boom (Less Extend-AReach Jib and Platform)

Jib, Extend-A-Reach and

Pivot Attach

Turntable Complete (Less

Counterweight)

Counterweight

Lift Cylinder

Level Cylinder

243(110)

9,502 (4310)

789(358)

9,101 (4,128)

9,050 (4,105)

809 (367)

60 (27)

1.11 BOOM TAPE

Standard Boom

Red Tape - 56-1/2 in. (143.5 cm).

White Tape - 91-5/8 in. (232.7 cm)

w/Boom Wipers

Red Tape - 54-1/2 in. (138.4 cm).

White Tape - 89-5/8 in. (227.6 cm).

1.12 CYLINDER SPECIFICATIONS

NOTE: All dimensions are given in inches (in.), with the met-

ric equivalent, centimeters (cm), given in parentheses.

Table 1-8. Cylinder Specifications

DESCRIPTION BORE STROKE

Lift Cylinder 9.0

(22.9)

Master Cylinder 2.5

(6.4)

Slave Cylinder 3.5

(8.9)

Extend-A-Reach

Cyl.

Telescope Cylinder 5.0

3.5

(8.9)

(12.7)

48.5

(123.2)

15.1

(38.4)

(18.5)

18.3

(46.5)

266.0

(675.6)

7.3

ROD

DIA.

4.0

(10.2)

1.3

(3.2)

1.8

(4.4)

2.5

(6.4)

3.5

(8.9)

Frame Complete (Includes

Tires and Wheels)

Wheel and Tire Assembly

(Each)

Complete Machine - 4WD

14,400 (6,532)

933 (423)

44,004 (19,960)

Frame Jack Cyl . (2) 5.0

(12.7)

Axle Extend Cyl. (2) 3.0

(7.6)

Steer Cylinder (2) 3.0

(7.6)

17.6

(44.8)

29.0

(73.7)

9.8

(24.9)

3.0

(7.6)

2.0

(5.1)

1.5

(3.8)

3120686 – JLG Lift – 1-9

SECTION 1 - SPECIFICATIONS

Figure 1-3. Serial Number Locations

1.13 CRITICAL STABILITY WEIGHTS

Table 1-9. Critical Stability Weights

COMPONENT WEIGHT

Counterweight

Foam-Filled Tires (each) 932 lb. (423 kg)

Deutz Engine 837 lb. (380 kg)

Platform 243 lb. (110 kg)

DO NOT REPLACE ITEMS CRITICAL TO STABILITY, SUCH AS THE

COUNTERWEIGHT OR FOAM-FILLED TIRES, WITH ITEMS OF DIFFERENT WEIGHT OR SPECIFICATION. DO NOT MODIFY UNIT IN

ANY WAY TO AFFECT STABILITY.

9, 050 lb. (4,105 kg)

1-10 – JLG Lift – 3120686

SECTION 2. PROCEDURES

SECTION 2 - PROCEDURES

2.1 GENERAL

This section provides information necessary to perform

maintenance on the aerial platform. Descriptions, techniques and specific procedures are designed to provide

the safest and most efficient maintenance for use by personnel responsible for ensuring the correct installation

and operation of machine components and systems.

WHEN AN ABNORMAL CONDITION IS NOTED AND PROCEDURES

CONTAINED HEREIN DO NOT SPECIFICALLY RELATE TO THE

NOTED IRREGULARITY, WORK SHOULD BE STOPPED AND

TECHNICALLY QUALIFIED GUIDANCE OBTAINED BEFORE WORK

IS RESUMED.

The maintenance procedures included consist of servicing and component removal and installation, disassembly

and assembly, inspection, lubrication and cleaning. Information on any special tools or test equipment is also provided where applicable.

2.2 SERVICING AND MAINTENANCE GUIDELINES

General

The following information is provided to assist you in the

use and application of servicing and maintenance procedures contained in this chapter.

Safety and Workmanship

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

Cleanliness

1. The most important single item in preserving the

long service life of a machine is to keep dirt and foreign materials out of the vital components. Precautions have been taken to safeguard against this.

Shields, covers, seals, and filters are provided to

keep air, fuel, and oil supplies clean; however, these

items must be maintained on a scheduled basis in

order to function properly.

2. At any time when air, fuel, or oil lines are disconnected, clear adjacent areas as well as the openings

and fittings themselves. As soon as a line or component is disconnected, cap or cover all openings to

prevent entry of foreign matter.

3. Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings

are unobstructed. Cover all parts to keep them

clean. Be sure all parts are clean before they are

installed. New parts should remain in their containers until they are ready to be used.

Components Removal and Installation

1. Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as

near perpendicular as possible to top of part being

lifted.

2. Should it be necessary to remove a component on

an angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as the angle between

the supporting structure and the component

becomes less than 90 degrees.

3. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc., have been

removed and that no adjacent parts are interfering.

Component Disassembly and Reassembly

When disassembling or reassembling a component, complete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure-Fit Parts

When assembling pressure-fit parts, use an “anti-seize” or

molybdenum disulfide base compound to lubricate the

mating surface.

Bearings

1. When a bearing is removed, cover it to keep out dirt

and abrasives. Clean bearings in nonflammable

cleaning solvent and allow to drip dry. Compressed

air can be used but do not spin the bearing.

2. Discard bearings if the races and balls (or rollers)

are pitted, scored, or burned.

3120686 – JLG Lift – 2-1

SECTION 2 - PROCEDURES

3. If bearing is found to be serviceable, apply a light

coat of oil and wrap it in clean (waxed) paper. Do not

unwrap reusable or new bearings until they are

ready to install.

4. Lubricate new or used serviceable bearings before

installation. When pressing a bearing into a retainer

or bore, apply pressure to the outer race. If the bearing is to be installed on a shaft, apply pressure to the

inner race.

Gaskets

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand-fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location, as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application

1. Use bolts of proper length. A bolt which is too long

will bottom before the head is tight against its related

part. If a bolt is too short, there will not be enough

thread area to engage and hold the part properly.

When replacing bolts, use only those having the

same specifications of the original, or one which is

equivalent.

2. Unless specific torque requirements are given within

the text, standard torque values should be used on

heat-treated bolts, studs, and steel nuts, in accordance with recommended shop practices. (See Figure 1-1.)

Hydraulic Lines and Electrical Wiring

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System

1. Keep the system clean. If evidence of metal or rubber particles are found in the hydraulic system, drain

and flush the entire system.

2. Disassemble and reassemble parts on clean work

surface. Clean all metal parts with non-flammable

cleaning solvent. Lubricate components, as

required, to aid assembly.

Lubrication

Service applicable components with the amount, type,

and grade of lubricant recommended in this manual, at

the specified intervals. When recommended lubricants are

not available, consult your local supplier for an equivalent

that meets or exceeds the specifications listed.

Battery

Clean battery, using a non-metallic brush and a solution of

baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry battery and coat terminals with

an anti-corrosion compound.

Lubrication and Servicing

Components and assemblies requiring lubrication and

servicing are shown in Figure 1-2.

2.3 LUBRICATION INFORMATION

Hydraulic System

1. The primary enemy of a hydraulic system is contamination. Contaminants enter the system by various

means, e.g., using inadequate hydraulic oil, allowing

moisture, grease, filings, sealing components, sand,

etc., to enter when performing maintenance, or by

permitting the pump to cavitate due to insufficient

system warm-up or leaks in the pump supply (suction) lines.

2. The design and manufacturing tolerances of the

component working parts are very close, therefore,

even the smallest amount of dirt or foreign matter

entering a system can cause wear or damage to the

components and generally results in faulty operation. Every precaution must be taken to keep

hydraulic oil clean, including reserve oil in storage.

Hydraulic system filters should be checked,

cleaned, and/or replaced as necessary, at the specified intervals required in Figure 1-2. Always examine

filters for evidence of metal particles.

3. Cloudy oils indicate a high moisture content which

permits organic growth, resulting in oxidation or corrosion. If this condition occurs, the system must be

drained, flushed, and refilled with clean oil.

4. It is not advisable to mix oils of different brands or

types, as they may not contain the same required

additives or be of comparable viscosities. Good

grade mineral oils, with viscosities suited to the

ambient temperatures in which the machine is operating, are recommended for use.

NOTE: Metal particles may appear in the oil or filters of new

machines due to the wear-in of meshing components.

2-2 – JLG Lift – 3120686

SECTION 2 - PROCEDURES

Hydraulic Oil

1. Refer to Table 1-1 for recommendations for viscosity

ranges.

2. JLG recommends Kendall Hyken 052 hydraulic oil,

which has an SAE viscosity of 10W-20 and a viscosity index of 152 or Mobilfluid 424 hydraulic oil, which

has an SAE viscosity of 10W-30 and a viscosity

index of 152. Kendall Hyken 052 and Mobilfluid 424

are fully compatible, and can be mixed as necessary.

NOTE: Start-up of hydraulic system with oil temperatures

below -15 degrees F (-26 degrees C). is not recommended. If it is necessary to start the system in a

sub-zero environment, it will be necessary to heat

the oil with a low density, 100VAC heater to a minimum temperature of -15 degrees F (-26 degrees C).

3. The only exception to the above is to drain and fill

the system with Mobil DTE 11 oil or its equivalent.

This will allow start up at temperatures down to -20

degrees F (-29 degrees C). However, use of this oil

will give poor performance at temperatures above

120 degrees F (49 degrees C). Systems using DTE

11 oil should not be operated at temperatures above

200 degrees F (94 degrees C) under any condition.

Changing Hydraulic Oil

1. Use of any of the recommended crankcase or

hydraulic oils eliminates the need for changing the

oil on a regular basis. However, filter elements must

be changed after the first 40 hours of operation and

every 250 hours thereafter. If it is necessary to

change the oil, use only those oils meeting or

exceeding the specifications appearing in this manual. If unable to obtain the same type of oil supplied

with the machine, consult local supplier for assistance in selecting the proper equivalent. Avoid mixing petroleum and synthetic base oils. JLG

Industries recommends changing the hydraulic oil

annually.

2. Use every precaution to keep the hydraulic oil clean.

If the oil must be poured from the original container

into another, be sure to clean all possible contaminants from the service container. Always clean the

mesh element of the filter and replace the cartridge

any time the system oil is changed.

3. While the unit is shut down, a good preventive maintenance measure is to make a thorough inspection

of all hydraulic components, lines, fittings, etc., as

well as a functional check of each system, before

placing the machine back in service.

Lubrication Specifications

Specified lubricants, as recommended by the component

manufacturers, are always the best choice, however,

multi-purpose greases usually have the qualities which

meet a variety of single purpose grease requirements.

Should any question arise regarding the use of greases in

maintenance stock, consult your local supplier for evaluation. Refer to Table 1-2 for an explanation of the lubricant

key designations appearing in the Lubrication Chart.

2.4 CYLINDERS - THEORY OF OPERATION

Cylinders are of the double acting type. Systems incorporating double acting cylinders are as follows: Lift, Telescope, Steer, Master Level, Slave Level, Frame Lift, Axle

Extend and Extend-A-Reach. A double acting cylinder is

one that requires oil flow to operate the cylinder rod in

both directions. Directing oil (by actuating the corresponding control valve to the piston side of the cylinder)

forces the piston to travel toward the rod end of the barrel,

extending the cylinder rod (piston attached to rod). When

the oil flow is stopped, movement of the rod will stop. By

directing oil to the rod side of the cylinder, the piston will

be forced in the opposite direction and the cylinder rod

will retract.

Holding valves are used in the Lift, Platform Level, Telescope, and Extend-A-Reach circuits to prevent retraction

of the cylinder rod should a hydraulic line rupture or a leak

develop between the cylinder and its related control valve.

2.5 VALVES - THEORY OF OPERATION

Solenoid Control Valves (Bang-Bang)

Control valves used are four-way three-position solenoid

valves of the sliding spool design. When a circuit is activated and the control valve solenoid energizes, the spool

is shifted and the corresponding work port opens to permit oil flow to the component in the selected circuit, with

the opposite work port opening to reservoir. Once the circuit is deactivated (control returned to neutral), the valve

spool returns to neutral (center) and oil flow is then

directed through the valve body and returns to reservoir. A

typical control valve consists of the valve body, sliding

spool, and two solenoid assemblies. The spool is

machine fitted in the bore of the valve body. Lands on the

spool divide the bore into various chambers, which, when

the spool is shifted, align with corresponding ports in the

valve body open to common flow. At the same time other

ports would be blocked to flow. The spool is springloaded to center position, therefore when the control is

released, the spool automatically returns to neutral, prohibiting any flow through the circuit.

3120686 – JLG Lift – 2-3

SECTION 2 - PROCEDURES

Manual Hydraulic Control Valves

The manual hydraulic control valves consist of four-way,

multi-position valve sections, each section incorporating a

sliding spool, spring-loaded to neutral or off. Each spool is

attached to a control lever which provides for proportional

control of the selected system function. This proportional

control enables metering of oil flow in accordance with

spool position, affording variable and smooth speed control capability. Spool movement causes work ports within

the valve to align in a predetermined way, permitting flow

to the selected function, with the opposing work ports

positioned to allow return flow to the hydraulic reservoir.

Relief Valves

Main relief valves are installed at various points with the

hydraulic system to protect associated systems and components against excessive pressure. Excessive pressure

can be developed when a cylinder reaches its limit of

travel and the flow of pressurized fluid continues from the

system control. The relief valve provides an alternate path

for the continuing flow from the pump, thus preventing

rupture of the cylinder, hydraulic line or fitting. Complete

failure of the system pump is also avoided by relieving circuit pressure. The relief valve is installed in the circuit

between the pump outlet (pressure line) and the cylinder

of the circuit, generally as an integral part of the system

valve bank. Relief pressures are set slightly higher than

the load requirement, with the valve diverting excess

pump delivery back to the reservoir when operating pressure of the component is reached.

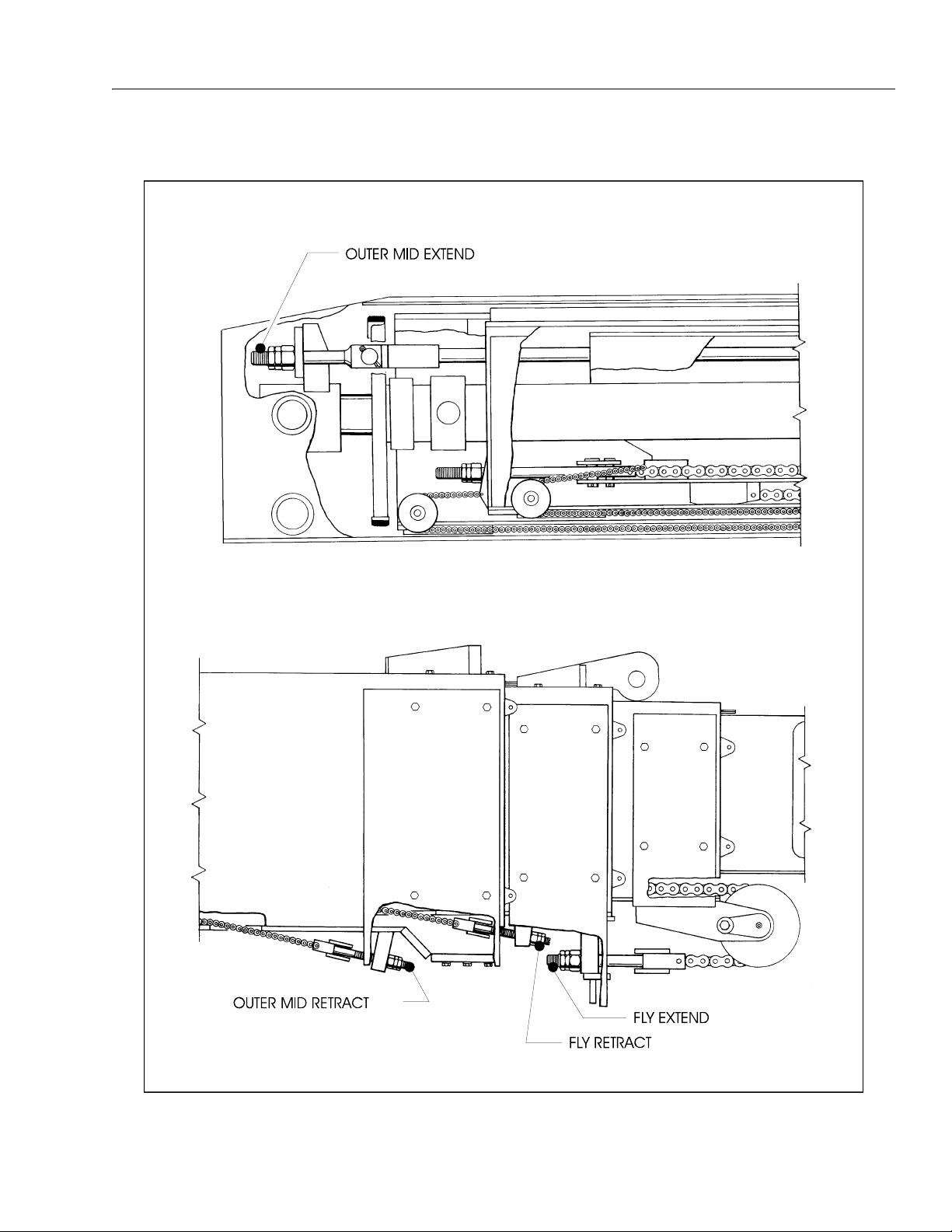

2.6 BOOM CHAINS

Adjusting Procedures

ENSURE MACHINE IS ON A FIRM AND LEVEL SURFACE.

1. Position boom fully retracted at +5 degrees horizontal, no load in platform.

2. Torque outer mid section extend chain adjuster to 59

ft. lb. (80 Nm).

3. Torque outer mid section retract chain adjuster to 59

ft. lb. (80 Nm).

4. Torque fly section extend chain adjuster to 59 ft. lb.

(80 Nm).

5. Torque fly section retract chain adjuster to 59 ft. lb.

(80 Nm).

6. Cycle boom (extend at least 6 feet (2 meters), then

retract fully).

7. Recheck outer mid section extend chain.

8. Recheck outer mid section retract chain.

9. Recheck fly section extend chain.

10. Recheck fly section retract chain.

11. Repeat steps (2) thru (10) if necessary.

Crossover Relief Valves

Crossover relief valves are used in circuits where the actuator requires an operating pressure lower than that supplied to the system. When the circuit is activated and the

required pressure at the actuator is developed, the crossover relief diverts excess pump flow to the reservoir. Individual, integral reliefs are provided for each side of the

circuit.

12. Check for proper operation of boom.

JLG Industries, Inc. requires a complete boom disassembly, per the instructions outlined in paragraph 2-11, Boom

Maintenance, every two years. All boom chains and

related components (i.e., sheaves, pins, sprockets, wear

pads, etc.) must also be inspected and replaced, as necessary, during this disassembly.

2-4 – JLG Lift – 3120686

SECTION 2 - PROCEDURES

Figure 2-1. Boom Chain Adjustments

3120686 – JLG Lift – 2-5

SECTION 2 - PROCEDURES

Figure 2-2. Typical Boom Assembly

An immediate disassembly of the boom assembly and

inspection of the boom chains and related components is

required if any of the following conditions occur:

1. After machine is exposed to hostile environments or

conditions (i.e., extreme cold, dust, sand, blasting

grit, salt, chemicals, etc.) which could adversely

affect boom operation.

2. Erratic boom operation or unusual noise exists.

Refer to troubleshooting tables in Section 3.

3. Chain adjustment is required more often than specified in this Section or links need to be removed

(chain shortened) to make adjustment.

4. Machine is idle for an extended period (6 months or

longer).

5. Boom is overloaded or has sustained a shock load.

FAILURE TO DISASSEMBLE THE BOOM ASSEMBLY AND PROPERLY INSPECT AND/OR REPLACE THE BOOM CHAINS AND

RELATED COMPONENTS (I.E., SHEAVES, PINS, SPROCKETS,

WEAR PADS, ETC.) COULD RESULT IN THE DAMAGE AND/OR

BREAKAGE OF THE BOOM CHAINS AND/OR RELATED COMPONENTS. DAMAGE AND/OR BREAKAGE OF THESE ITEMS COULD

RESULT IN UNCONTROLLED EXTENSION OR RETRACTION OF

THE BOOM ASSEMBLY AND COULD CAUSE SERIOUS INJURY OR

DEATH TO PERSONNEL OPERATING THE JLG BOOM LIFT.

Inspection Procedure

BOOM CHAINS TO BE INSPECTED AT TIME OF NEXT BOOM

OVERHAUL AND WHEN DEEMED NECESSARY BY MACHINE

OWNER, BUT NOT TO EXCEED 2 YEARS OF MACHINE OPERATION.

1. Inspect boom chains for the following conditions:

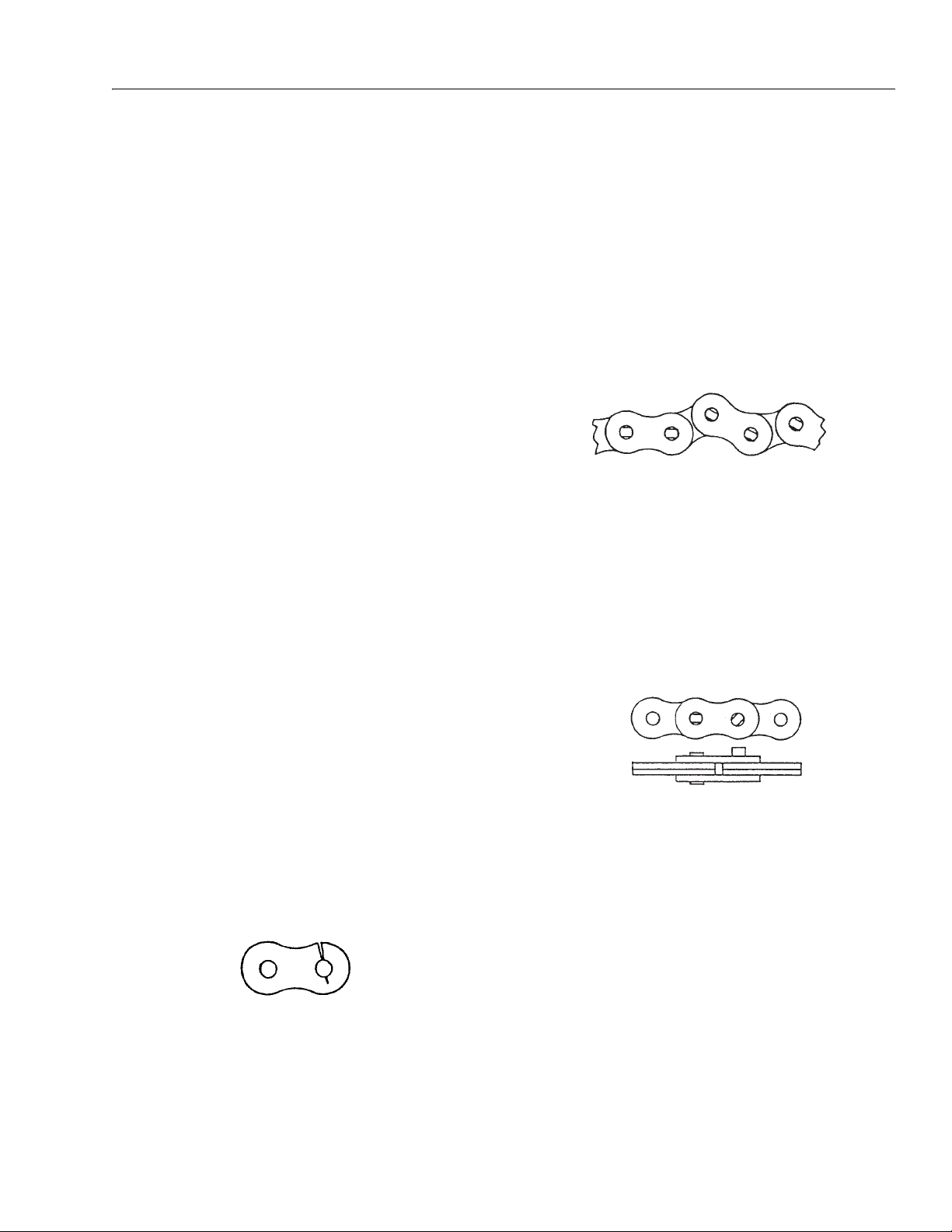

a. Wear: Always inspect that segment of chain that

operates over a sheave. As the chain flexes over

the extend/retract sheaves, joints and plate

edges very gradually wear. Chain “stretch” can

be measured using a manufacturers wear scale

or steel tape. When chains have elongated 3%

they must be removed and replaced. Refer to

Table 2-1 for proper chain specifications and

allowable stretch tolerances. Peening and wear

of chain plate edges are caused by sliding over

a chain worn contact face of a sheave, or unusually heavy loads. All of the above require

replacement of the chain and correction of the

cause. Chain side wear, noticeable when pin

heads and outside plates show a definite wear

pattern, is caused by misalignment of the

sheave/chain anchors and must be corrected

promptly. Do not repair chains; if a section of

chain is damaged, replace the entire chain set.

2-6 – JLG Lift – 3120686

SECTION 2 - PROCEDURES

b. Lubrication: One of the most important but often

overlooked factors is adequate lubrication. In

addition to reducing internal friction, maintaining

a film of oil on all chain surfaces will inhibit rusting and corrosion. This is important as corrosion

of highly stressed, hardened steel chain components can cause a major reduction in the load

capacity of leaf chain and result in link plate

cracking.

NOTE: The need for lubrication can be determined by the

presence of rust on the exposed portions of chain.

c. Rust and Corrosion: Rust and corrosion will

cause a major reduction in the load carrying

capacity of the chain, because these are primary

reasons for side plate cracking. The initial lubrication at the factory is applied in a hot dip tank

to assure full penetration into the joint. Do not

steam clean or degrease this lubricant of chains.

At time of chain installation, factory lube must be

supplemented by a maintenance program to

provide a film of oil on the chains at all times. A

grade of SAE 30 or 40 weight, non-detergent

motor oil should be used as a supplemental

lubricant and a film of this oil should be constantly maintained on the surfaces and internal

joints. If chains are corroded, they must be

inspected, especially the outside plates, for

cracks in-line with the pins. If cracks are found,

replace the chain; if no cracks are discovered,

lubricate the chains by dipping in heated oil, and

reinstall on the machine. Keep chains lubricated.

d. Fatigue Cracks: Fatigue is a phenomenon that

affects most metals, and is the most common

cause of chain plate failures. Fatigue cracks are

found through the link holes, perpendicular (90

degrees) from the pin in-line position. Inspect

chains carefully after long time use and heavy

loading for this type of crack. If any cracks are

discovered, replace all chains, as seemingly

sound plates are on the verge of cracking.

Fatigue and ultimate strength failures on JLG

Lifts are incurred as a result of severe abuse as

design specs are well within the rated lifting

capacity of these chains.

e. Tight Joints: All joints in the roller chain should

flex freely. On roller chain, tight joints are usually

caused by rust/corrosion, or the inside plates

“walking” off the bushing. Limber up rusty/corroded chains (after inspecting carefully) with a

heavy application of oil (preferably a hot oil dip).

Tap inside “walking” plates inward; if “walking”

persists, replace the chain. This type of problem

is accelerated by poor lubrication maintenance

practice, and most tight joint chains have been

operated with little or no lubrication. Tight joints