Page 1

Technical Guide

AJ-V8 Engine

and

5HP24 Transmission

Introduction

Page 2

Published by Service Communications, Jaguar Cars Limited

Publication Part No JJM 18 15 15/70, August 1996

Page 3

Page 4

Published by Service Communications, Jaguar Cars Limited

Publication Part No JJM 18 15 15/70, August 1996

Technical Guide

AJ-V8 Engine

and

5HP24 Transmission

Introduction

Page 5

PrefaceAJ-V8/5HP24

This Technical Guide introduces the new AJ V8 engine and 5HP24 transmission installed in the XK8

Sports car. It is intended to give Jaguar Dealer workshop personnel an overview of their construction

and operation, and is for information purposes only. The contents of this Technical Guide must not be

used as a reference source for servicing procedures; all servicing procedures must be in accordance

with the appropriate Service Manual.

This Technical Guide will not be updated. While every effort is made to ensure accuracy, changes may

occur between going to press and the equipment being introduced to the market. Once the equipment

is in service, details of changes can be obtained from Service Bulletins and revisions to the Service

Manuals.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form, electronic, mechanical, photocopying, recording or other means without prior

written permission from the Service Division of Jaguar Cars Limited.

Page 6

Contents AJ-V8/5HP24

1

Subject Page

Glossary

Abbreviations 2

Introduction 3

Engine

Basic Engine 5

Engine Cooling 17

Engine Lubrication 20

Variable Valve Timing 24

Air Intake System 27

Fuel System 33

Ignition System 35

Crankcase Ventilation 35

EGR System 37

Engine Accessories 38

Accessory Drive 39

Engine Harness 41

Engine Covers 42

Engine Specifications 43

Engine Management

ECM 45

Electronic Throttle 53

Fuel Pump 58

Fuel Injection 58

Ignition 59

EVAP System 60

Variable Valve Timing 61

EGR System 61

Engine Starting 61

HO2S Heaters 62

Instrument Cluster 62

A/C Compressor Clutch 62

Windshield and Backlight Heaters 62

Radiator Cooling Fans 62

Diagnostics 63

Transmission

Introduction 65

Technical Data 66

Gearshifting 66

Mechanical Description 66

Electrical Description 67

Transmission Management

Transmission Management 68

Service Tools

New Tools 72

Page 7

GlossaryAJ-V8/5HP24

2

The following abbreviations are used in this document:

Abbreviation Description

ABS anti-lock braking system

A/C air conditioning

A/CCM air conditioning control module

BPM body processor module

BHP brake horse power

˚C degree Celsius

CAN controller area network

CDI cubic inch displacement

DIN Deutsche Institut für Normung

dc direct current

DTC diagnostic trouble code

ECM engine control module

ECT engine coolant temperature

EGR exhaust gas recirculation

EMS engine management system

EVAP evaporative emission

˚F degree Fahrenheit

ft foot

HO2S heated oxygen sensor

in inch

JDS Jaguar diagnostic system

lb pound

lbf.ft pound force feet

kg kilogram

km/h kilometer per hour

kW kilowatt

m meter

MAFS mass air flow sensor

MIL malfunction indicator lamp

mph miles per hour

mm millimeter

ms millisecond

Nm Newton meter

NOx nitrous oxide

OBD on-board diagnostics

O2S oxygen sensor

PAS power assisted steering

PDU portable diagnostic unit

psi pounds per square inch

PTFE polytetrafluoroethane

rpm revolutions per minute

SAE Society of Automotive Engineers (USA)

SCP standard corporate protocol

TCM transmission control module

USA United States of America

V volt

VSV vacuum solenoid valve

Page 8

Introduction AJ-V8/5HP24

3

The AJ-V8 4.0 litre, engine is the first of a new family of Jaguar engines. Designed to give excellent

performance, refinement, economy and low vibration levels it also conforms to the strictest emission

legislation. Weighing only 200 kilograms (441 lb), the engine is shorter by 12 inches (300 mm) than the

current AJ16 4.0 litre engine. Compression ratio is 10.75:1, with four valves per cylinder. The cylinder

heads, block and bedplate are all cast aluminum. Cylinders have electro-plated bores which reduce

piston friction, improve warm-up and oil retention. A variable valve timing system has been introduced

to give improved low and high-speed engine performance and excellent idle quality. The valve gear is

chain driven for durability. Low valve overlap improves engine idle speed and low residual fuel levels

which improves combustion and reduces hydrocarbon emissions. The inlet manifold is a one-piece,

composite moulding with integral fuel rails connecting to the eight side feed fuel injectors. Air flow into

the engine is via an electronic throttle assembly. Movement of the throttle is controlled by sensors in

the throttle assembly through the ECM. The engine has a low volume, high velocity, cooling system

which achieves a very fast warm-up with reduced and even metal temperatures in the combustion

chamber and increased bore temperatures.

The generator, A/C pump, and PAS pump are mounted to the cylinder block on rigid cradle supports.

Accessory drive is from a single, 7-ribbed vee belt. Hydraulic engine mounts minimise noise and

vibration.

A new engine management system adjusts fuel and ignition settings, monitors and controls exhaust

emissions and provides an on-board diagnostic capability.

The transmission is a new ZF 5-speed, automatic, electronically controlled unit.

The unit is oil filled for life so does not have an oil gauge (dipstick). Two driver selected modes are

available, sport or normal. The TCM is programmed with cruise, traction, gradient, warm-up and hot

mode features. It also provides an on-board diagnostic capability.

The engine and transmission meet OBDII USA environmental regulations.

Default limp home modes for both engine and transmission are provided.

Page 9

4

Page 10

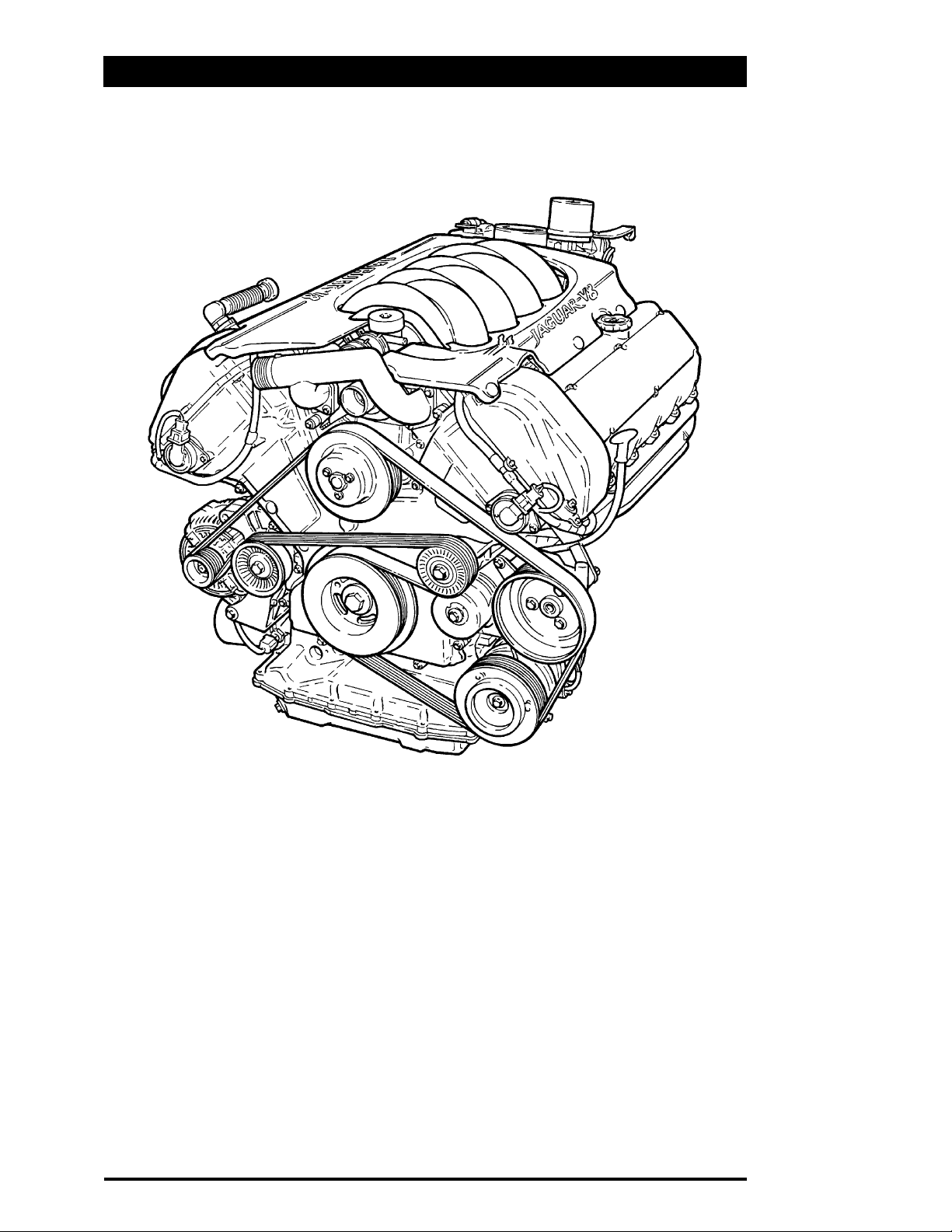

Engine AJ-V8/5HP24

5

Basic Engine

The AJ-V8 is an all new 90° V8 liquid cooled engine that gives refined and effortless performance.

Constructed in aluminum alloy, the AJ-V8 introduces several innovative design features new to Jaguar

engines, the most notable of these being:

• a bedplate

• nikasil coated cylinder bores

• fracture split connecting rods

• variable valve timing

• aluminum alloy valve lifters

• electronic throttle control.

303-056

Page 11

EngineAJ-V8/5HP24

6

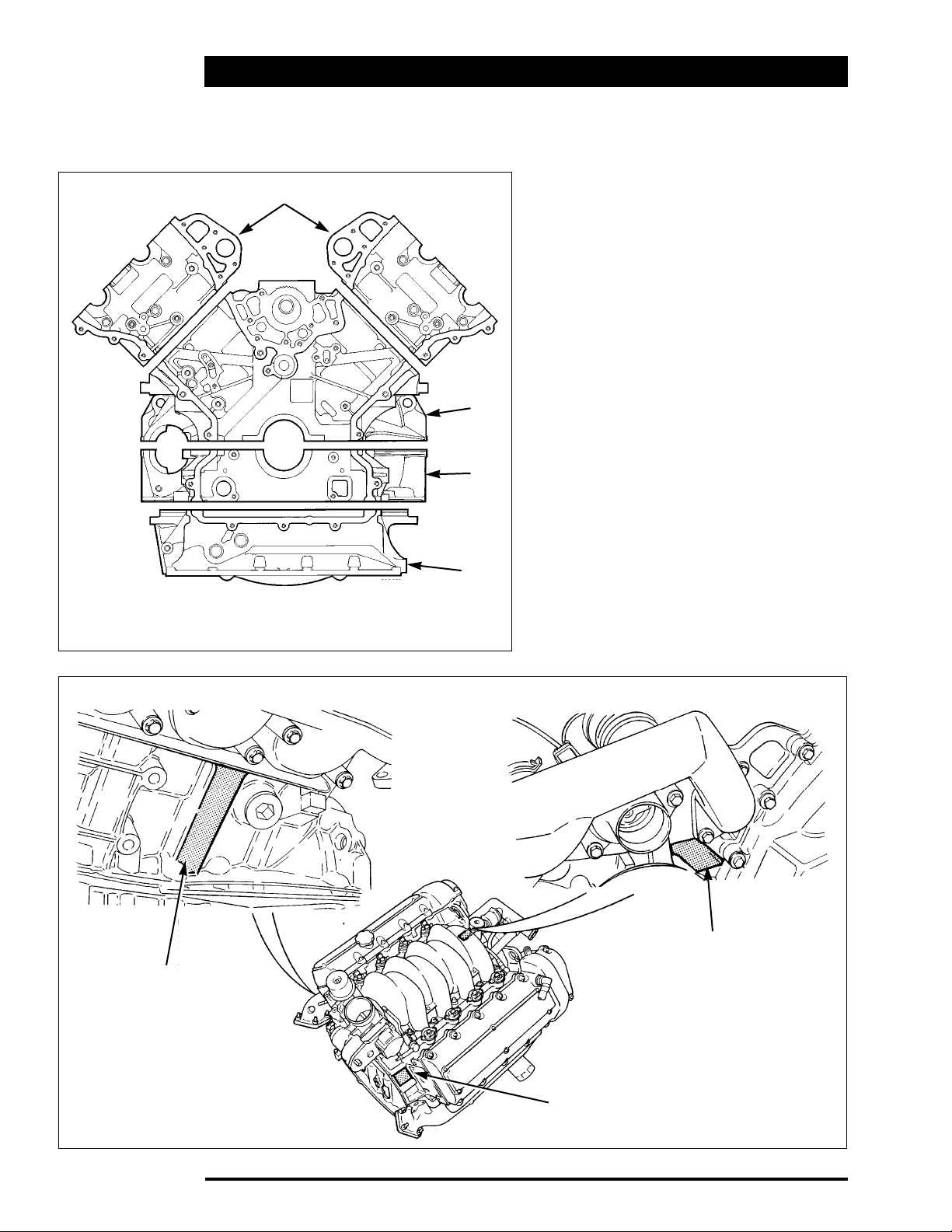

ENGINE STRUCTURE

ENGINE DATA LOCATIONS

303-052

303-001

Cylinder Block

The cylinder block is an "enclosed V" design,

which provides an inherently rigid structure with

good vibration levels. Nikasil (a composition of

nickel and silicon) coated cylinder bores provide

good friction, heat transfer and piston noise

levels. A low volume coolant jacket improves

warm-up times and piston noise levels; the

longitudinal flow design of the jacket, with a

single cylinder head coolant transfer port in each

bank, improves rigidity and head gasket sealing.

The right hand cylinder bank is designated as "A"

bank, and the left hand as "B" bank. The cylinder

bores of each bank are numbered from 1 to 4,

starting from the front.

Engine data is marked at three locations on the

cylinder block. Component diameters are

represented by alphabetical and numerical codes;

keys to the codes are in the Service Manual.

1

2

3

4

1. Cylinder Head

2. Cylinder Block

3. Bed Plate

4. Structural Sump

Emissions Code

Serial Number

* Main Bearing Crankshaft

Diameters * Connecting

Rod Bearing Crankshaft

Diameters * Cylinder Bore

Diameters * Main Bearing

Bore Diameters *

Page 12

Engine AJ-V8/5HP24

7

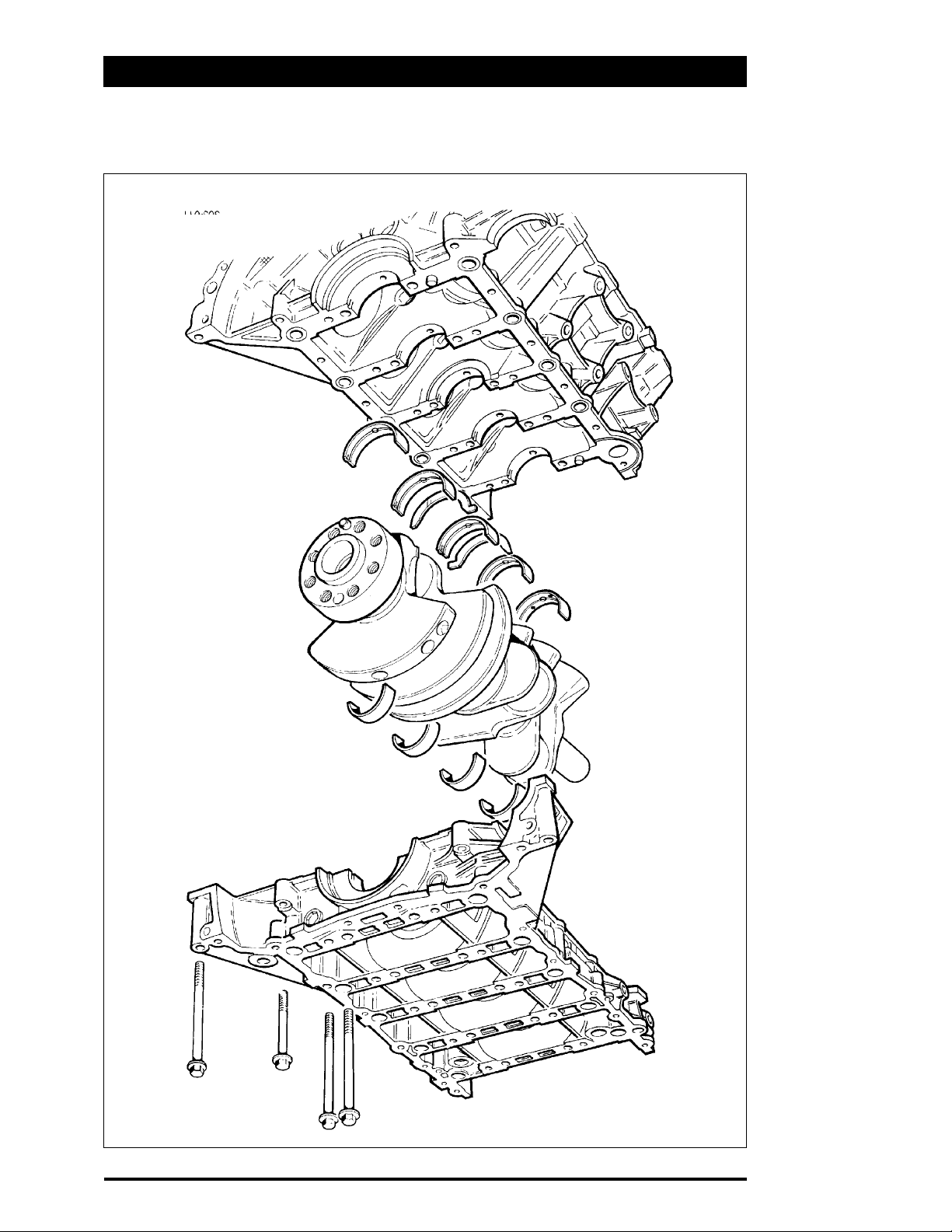

CYLINDER BLOCK, CRANKSHAFT AND BEDPLATE

303-011

Page 13

EngineAJ-V8/5HP24

8

Bedplate

The bedplate is a structural casting bolted to the

bottom of the cylinder block to retain the

crankshaft. The use of a bedplate further

improves rigidity. Iron inserts, cast into the main

bearing supports of the bedplate, minimise main

bearing clearance changes due to heat

expansion.

Two hollow dowels align the bedplate with the

cylinder block.

Beads of sealant seal the joint between the

bedplate and the cylinder block.

Crankshaft

Six counter-balance weights ensure good

vibration levels from the four throw, five bearing

crankshaft. Manufactured in cast iron, the

crankshaft also has undercut and rolled fillets for

improved strength.

The main bearings are aluminum/tin split plain

bearings. An oil groove in the top half of each

bearing transfers oil into the crankshaft for

lubrication of the connecting rod bearings. A

lead/bronze thrust washer is installed each side of

the top half of the center main bearing.

The crankshaft rear oil seal (a lip seal similar to

that used on the AJ16 engine) is a press fit in the

bedplate to cylinder block interface.

SEALANT TRACK ON BEDPLATE

303-012

CRANKSHAFT REAR OIL SEAL

303-013

Page 14

Engine AJ-V8/5HP24

9

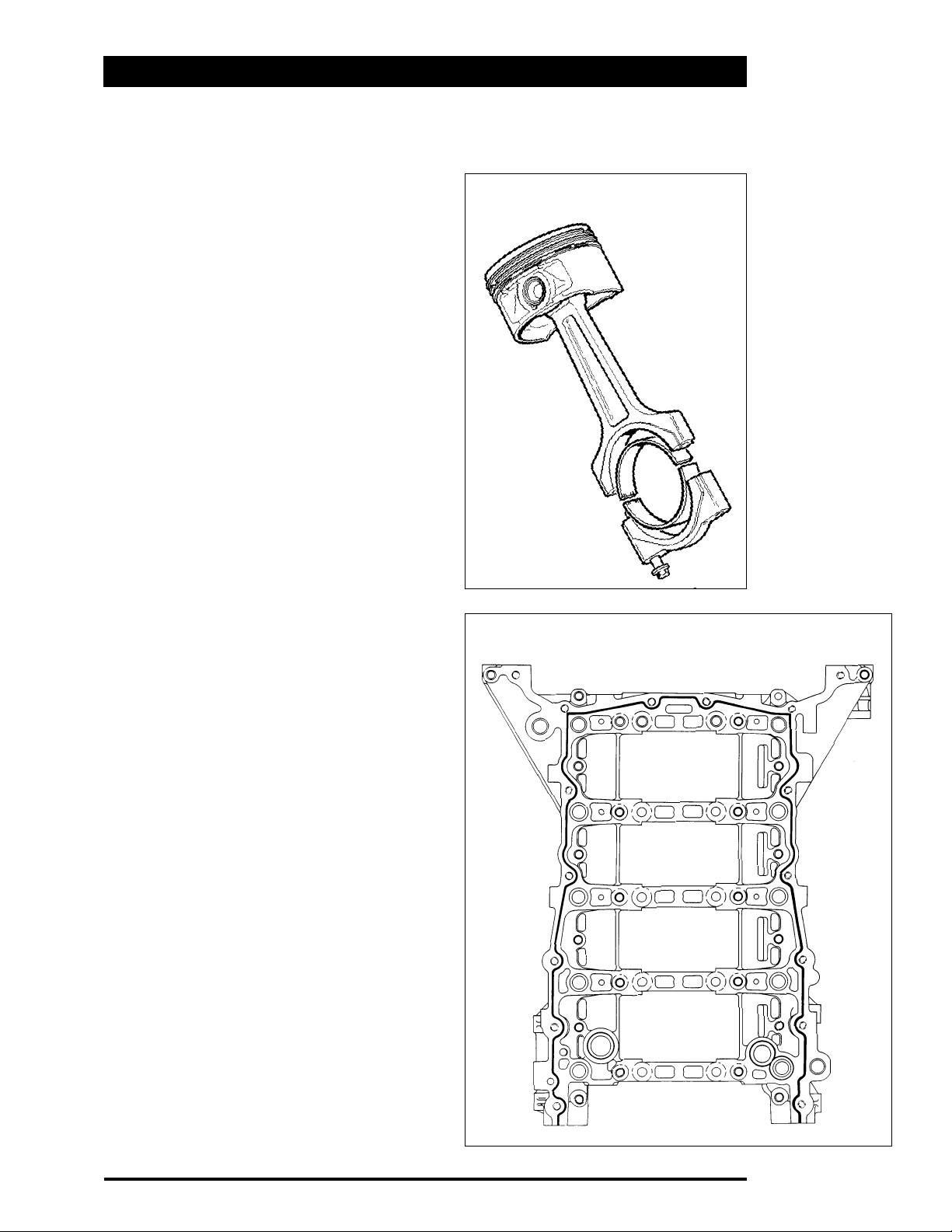

Connecting Rods and Pistons

The connecting rods are manufactured in sinter

forged steel. The bearing caps are produced by

fracturing the opposing sides of the connecting rod at

the bearing horizontal center-line. As well as being

easier to manufacture, when re-assembled the

fractured surfaces interlock to form a strong

seamless joint. The cylinder position is etched on

adjoining sides of the joint to identify matching

connecting rods and bearing caps. The connecting

rod bearings are lead/bronze split plain bearings.

The pistons are of the open ended skirt design with

flat upper surfaces to reduce heat absorbtion. Three

piston rings, two compression and one oil control, are

installed on each piston. Each piston is installed on a

wrist pin located in a lead/bronze bushing in the

connecting rod.

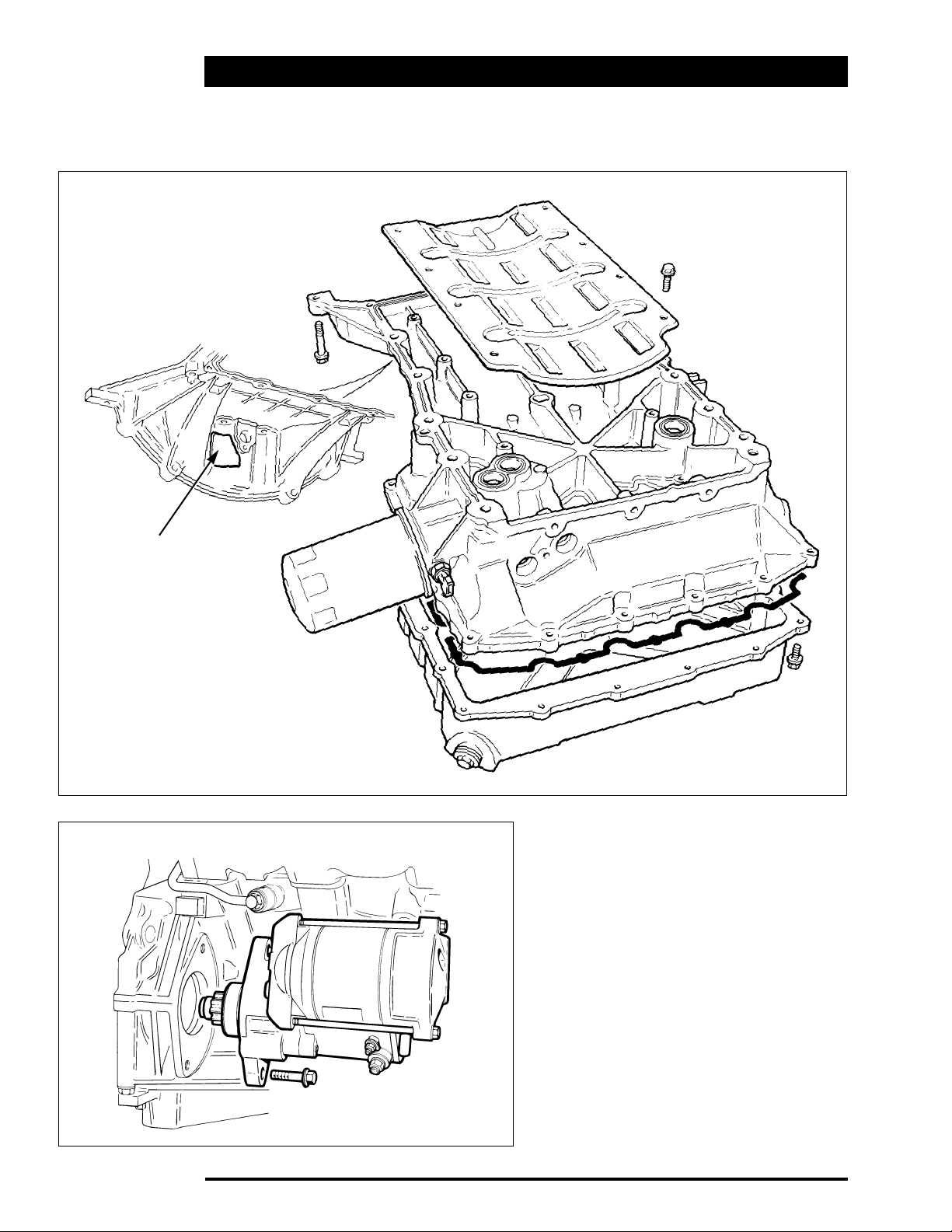

Sump

The sump consists of an aluminum alloy structural

sump bolted to the bedplate, and a pressed steel oil

pan bolted to the structural sump. A windage tray

attached to the top of the structural sump isolates

the oil pan from the disturbed air produced by the

rotation of the crankshaft, to prevent oil aeration and

improve oil drainage. A rubber plug at the rear of the

structural sump seals the port that provides access to

the torque converter securing bolts. The engine oil

drain plug is located at the front right corner of the oil

pan.

A silicon rubber in-groove gasket seals the joint

between the oil pan and the structural sump; a bead

of sealant seals the joint between the structural

sump and the bedplate.

CONNECTING ROD AND PISTON

303-014

SEALANT TRACK ON STRUCTURAL SUMP

303-021

Page 15

EngineAJ-V8/5HP24

10

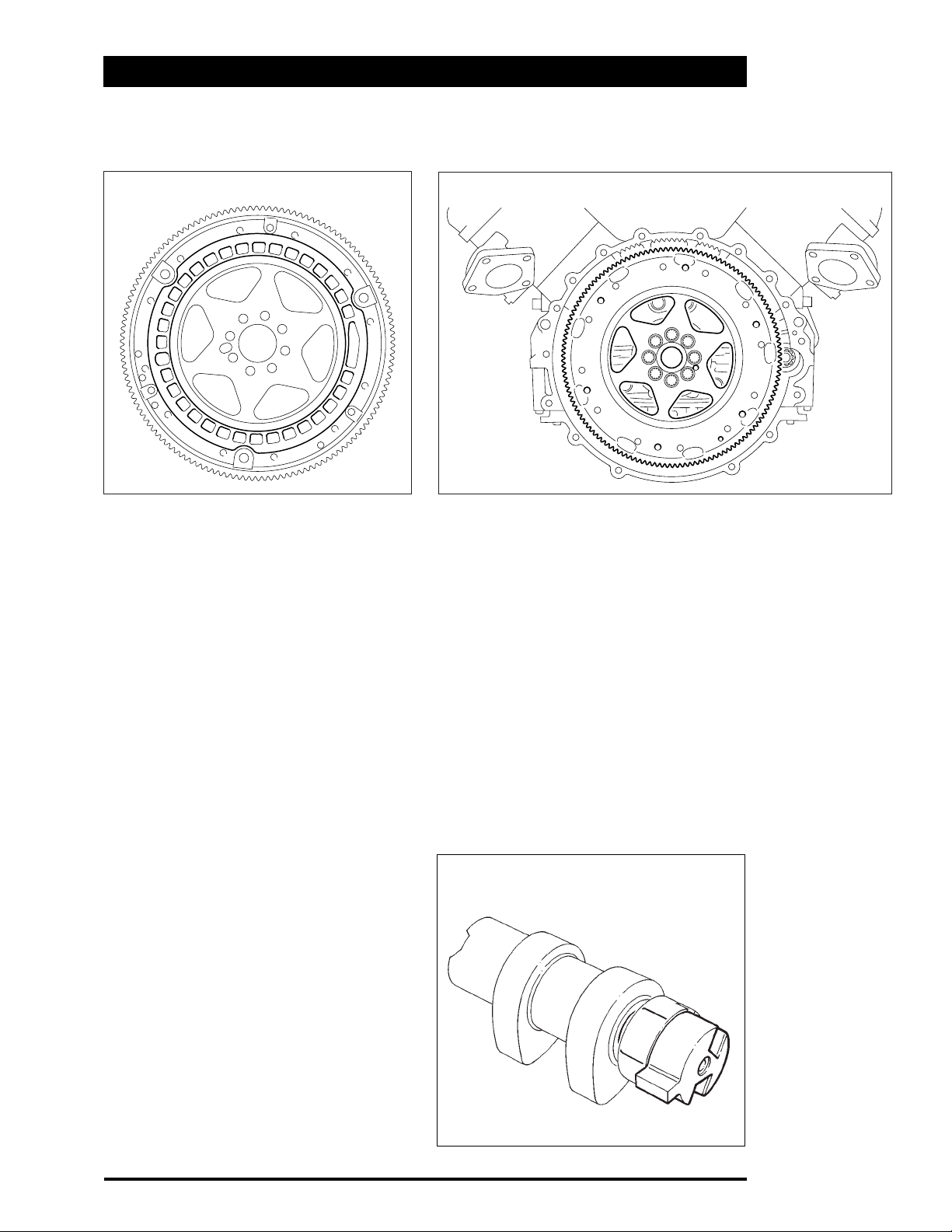

Starter and Drive Plate

The engine starter motor is installed at the rear

right side of the engine, at the cylinder block to

bedplate split line (for further details of the

starter motor see Technical Guide, XK8

Introduction).

The starter drive plate is attached to the rear of

the crankshaft. A timing disc, for the engine

speed sensor, is spot welded to the front face of

the drive plate.

STRUCTURAL SUMP AND OIL PAN

STARTER MOTOR

303-062

Torque

Converter

Access

303-010

Page 16

Engine AJ-V8/5HP24

11

Cylinder Heads

The cylinder heads are unique to each cylinder

bank. Deep seated bolts, to reduce distortion,

secure the cylinder heads to the cylinder block.

Two hollow dowels align each cylinder head with

the cylinder block.

The cylinder head gaskets consist of a silicon

beaded composite gasket with metal eyelets for

the cylinder bores, similar to that on the AJ16

engine.

Each cylinder head incorporates dual overhead

camshafts operating four valves per cylinder via

solid aluminum alloy valve lifters. Steel shims in

the top of the valve lifters enable adjustment of

valve clearances.

The lightweight valve gear provides good

economy and noise levels. Valve head diameters

are 31mm (1.220 in) for the exhaust and 35mm

(1.378 in) for the intake. All valves have 5mm

(0.197 in) diameter stems supported in sintered

metal seats and guide inserts. Collets, valve

collars and spring seats locate single valve

springs on both intake and exhaust valves. Valve

stem seals are integrated into the spring seats.

The camshafts are manufactured in chilled cast

iron. Five aluminum alloy caps retain each

camshaft. Location numbers, 0 to 4 for the intake

camshaft and 5 to 9 for the exhaust camshaft,

are marked on the outer faces of the caps. The

rear of B bank intake camshaft has a timing ring

for the camshaft position sensor. A flat,

machined near the front of each camshaft,

enables the camshafts to be locked during the

valve timing procedure.

CAMSHAFT POSITION SENSOR

TIMING RING

303-054

The 14 mm spark plugs, one per cylinder, locate

in recesses down the center-line of each cylinder

head.

An engine lifting eye is cast into the front of each

cylinder head (the rear lifting eyes, one on each

cylinder head, are bolt-on tools).

TIMING DISC

STARTER DRIVE PLATE

303-035

303-034

Page 17

EngineAJ-V8/5HP24

12

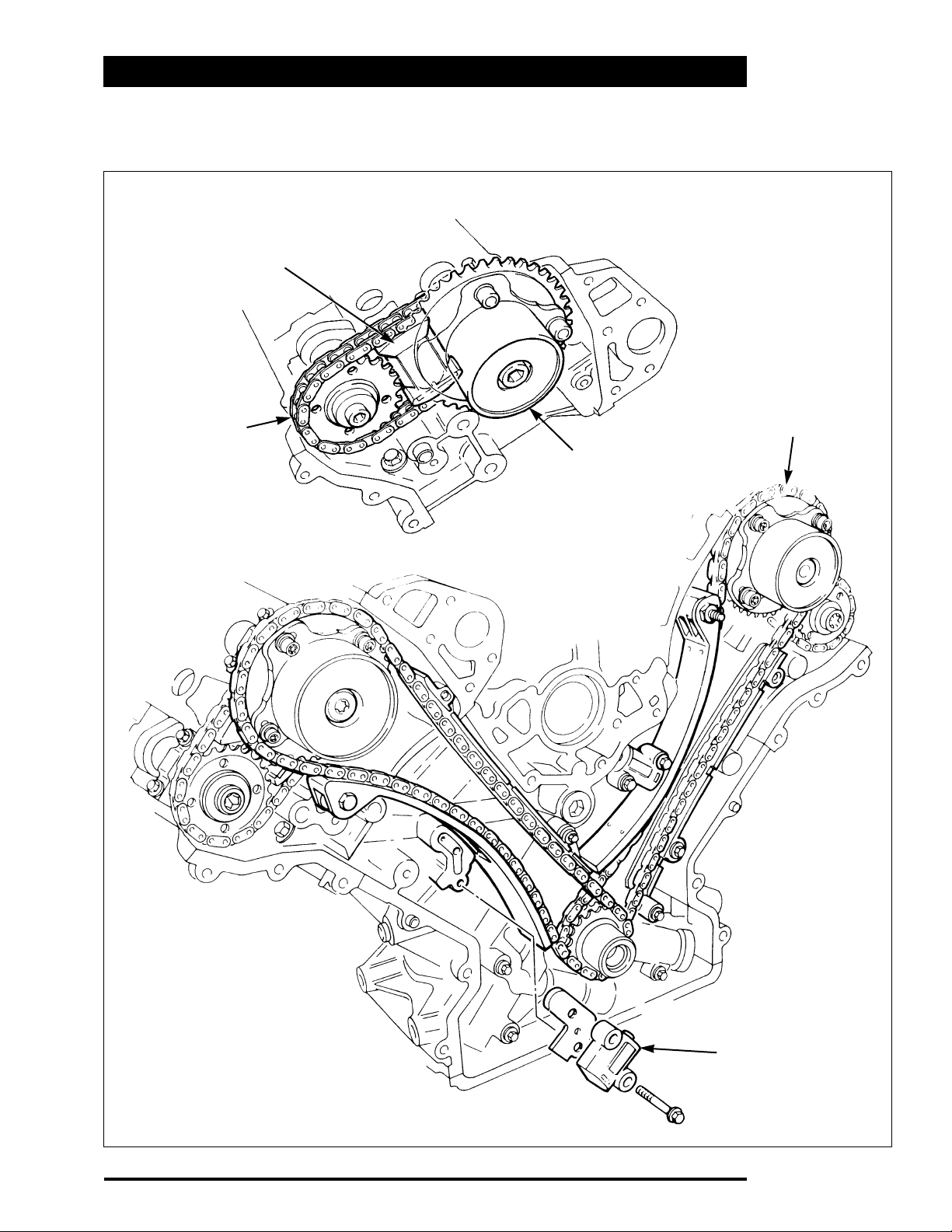

Timing Gear

Single row primary and secondary chains drive

the camshafts of each cylinder bank. The primary

chains transmit the drive from two sprockets on

the crankshaft to variable valve timing units on

the intake camshafts. The secondary chains

transmit the drive from the variable valve timing

units to sprockets on the exhaust camshafts.

A BANK CYLINDER HEAD

303-047

Lifting

Eye

Intake Camshaft

Exhaust Camshaft

(Continued on Page 14)

Page 18

Engine AJ-V8/5HP24

13

303-016 / 017

Primary Chain

Tensioner

Secondary Chain

Tensioner

Secondary

Chain

Variable Valve

Timing Unit

Primary Chain

TIMING GEAR

Page 19

EngineAJ-V8/5HP24

14

A key locates the two drive sprockets on the

crankshaft. The crankshaft's torsional vibration

damper retains the sprockets in position.

The variable valve timing units and the exhaust

camshaft sprockets are non-interference, nonkeyed fits on their respective camshafts; the

drive being transmitted by the face to face

friction load produced by the valve timing

unit/sprocket securing bolt.

Each chain has an hydraulic tensioner operated

by engine oil. A jet of oil from the end of each

tensioner lubricates the chains. The primary chain

tensioners act on pivoting flexible tensioner

blades. The secondary chain tensioners act

directly on the chains. Guide rails are installed on

the drive side of the primary chains.

Timing Cover

The aluminum alloy timing cover accommodates

the crankshaft front oil seal (a PTFE lip seal) and

the two variable valve timing solenoids. Silicon

rubber in-groove gaskets seal the joint between

the timing cover and the front face of the engine.

TIMING COVER

Crankshaft

Front Oil

Seal

303-015

Timing Gear (Continued)

Variable Valve

Timing Solenoid

Page 20

Engine AJ-V8/5HP24

15

Camshaft Covers

The camshaft covers are manufactured from vinyl

ester composite. The A bank camshaft cover

incorporates an outlet for the full load engine

breather. The B bank camshaft cover incorporates

the engine oil filler cap and an outlet for the part

load engine breather. Identical oil separators are

incorporated below the breather outlet in each

cover (see Crankcase Ventilation, page 35).

Silicon rubber in-groove gaskets seal the joints

between the camshaft covers and the cylinder

heads. Together with spacers and seals on the

camshaft cover fasteners, they also isolate the

covers from direct contact with the cylinder

heads, to reduce noise.

B BANK CAMSHAFT COVER

303-042

Page 21

EngineAJ-V8/5HP24

16

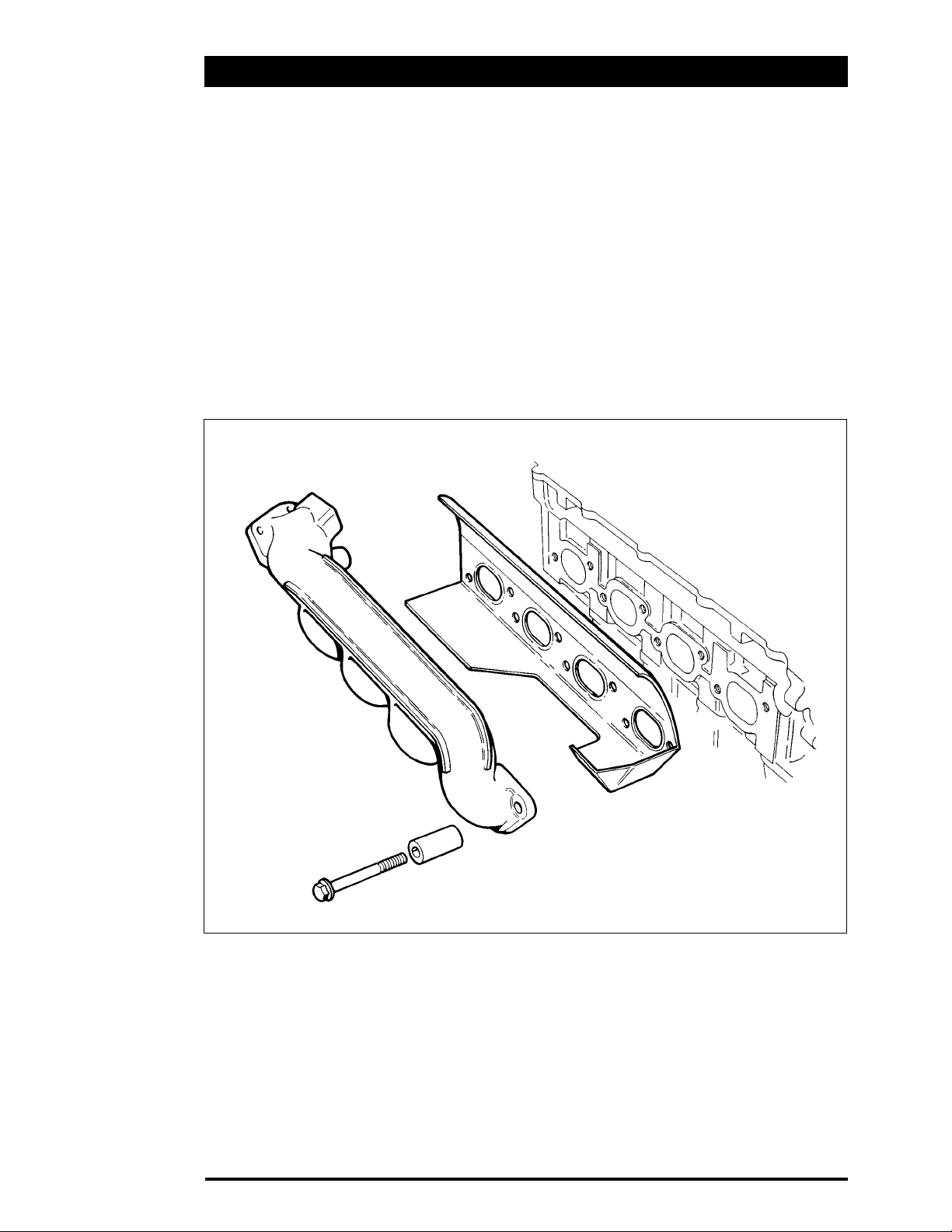

Exhaust Manifold

The thin-wall cast iron manifolds are unique for

each cylinder bank. On engines with EGR, the A

bank manifold has a connection for the transfer

pipe.

Spacers on the securing bolts allow the

manifolds to expand and retract with changes of

temperature while maintaining the clamping

loads.

Heat shields are integrated into the exhaust

manifold gaskets.

EXHAUST MANIFOLD

303-023

Page 22

Engine AJ-V8/5HP24

17

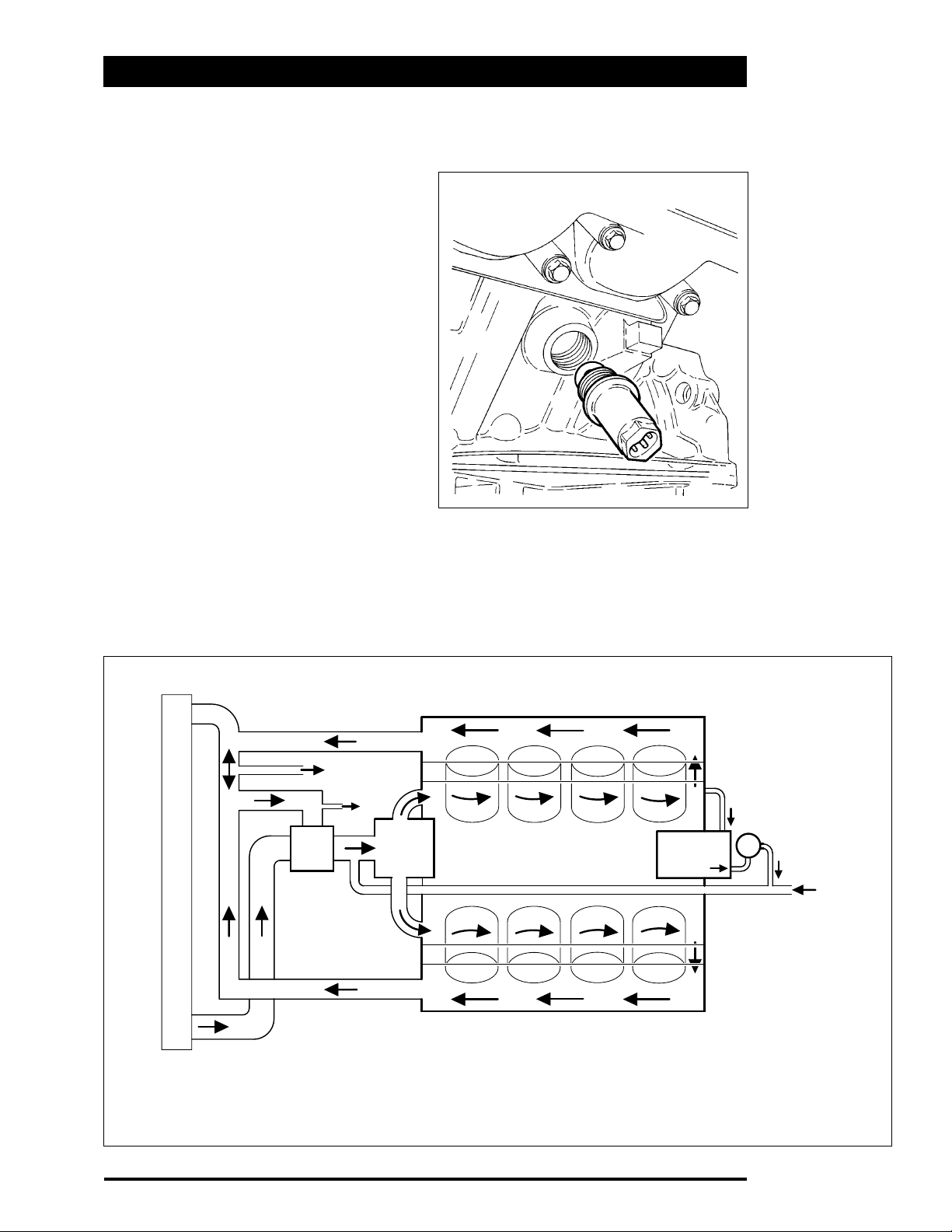

Engine Cooling

The cooling system is a low volume, high velocity

system with good warm-up and temperature

profile characteristics.

From the pump, the coolant flows into each bank

of the cylinder block. In each bank, 50% of the

coolant cools the cylinder bores and 50% is

diverted through a bypass gallery. At the rear of

the banks the two flows mix and enter the

cylinder heads. The coolant then flows forwards

to the outlet ports. When the thermostat is

closed, the coolant returns directly to the pump

through the bypass on the thermostat housing.

When the thermostat is open, the coolant returns

to the pump via the vehicle's radiator.

A coolant drain plug is installed on the rear left

side of the cylinder block. On vehicles with the

cold climate package, the cylinder block heater

replaces the drain plug.

Note: Coolant is drained from the right bank of

the cylinder block by removing the

coolant pipe behind the starter motor.

CYLINDER BLOCK DRAIN/HEATER

COOLING SYSTEM DIAGRAM

1. Electronic Throttle

2. EGR Valve

3. A/C Heater Return

4. Coolant Pump

5. Thermostat Housing

6. Vehicle Radiator (Reference)

7. A/C Heater Supply

8. Bleed Outlet

8

1

2

3

4

7

6

5

303-O63

303-028

Page 23

EngineAJ-V8/5HP24

18

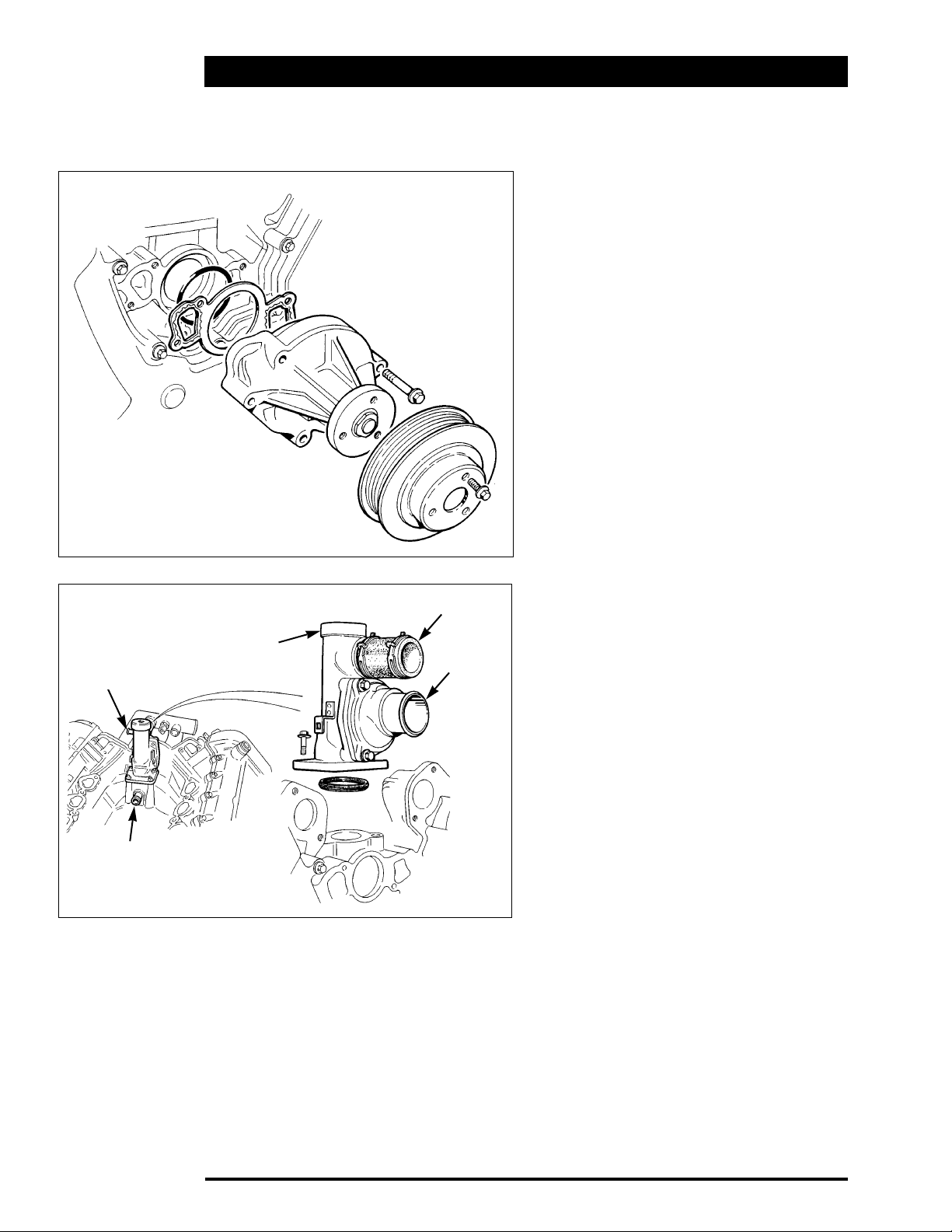

Coolant Pump

The coolant pump is installed between the two

cylinder banks, on the front face of the cylinder

block. The pumping element is a shrouded

composite impeller. Coolant escapes from seal

breather holes in the housing if the pump's

bearing seal fails.

An O-ring and an edge bonded rubber/aluminum

alloy gasket seal the pump to cylinder block

interface. The O-ring seals the inlet port from the

thermostat. The gasket seals the outlet ports into

the cylinder banks.

Thermostat Housing

The composite thermostat housing is installed

between the two cylinder banks, immediately

above the coolant pump. The thermostat controls

the flow of coolant through the radiator. It starts

to open at 80 to 84°C (176 to 183˚F) and is fully

open at 96°C (205˚F).

A duct in the cylinder block connects the

thermostat housing outlet to the pump inlet. A

stub pipe connects the duct to the air conditioning

heater matrix return line.

An in-groove gasket seals the joint between the

thermostat housing and the cylinder block.

In addition to containing the thermostat, the

composite thermostat housing incorporates

connections for the bleed, bypass and radiator

bottom hoses. The bleed outlet vents any air in

the system into the vehicle's coolant reservoir.

The cap of the thermostat housing is removable,

to allow air out of the system when filling from

empty.

CAUTION: Use the correct torque (marked on

the cap) when re-installing the

cap, or the cap/thermostat

housing could be damaged.

COOLANT PUMP

303-030

THERMOSTAT HOUSING

Coolant Hoses

Supply and return hoses for the air conditioning

heater matrix are installed between the cylinder

banks.

A connection at the rear of A bank provides the

coolant supply for the electronic throttle and the

EGR valve. The outlet from the EGR valve

connects to the return hose of the air conditioning

heater matrix.

By-pass

From

Radiator

A/C Heater

Return

Cap

Bleed

303-029

Page 24

Engine AJ-V8/5HP24

19

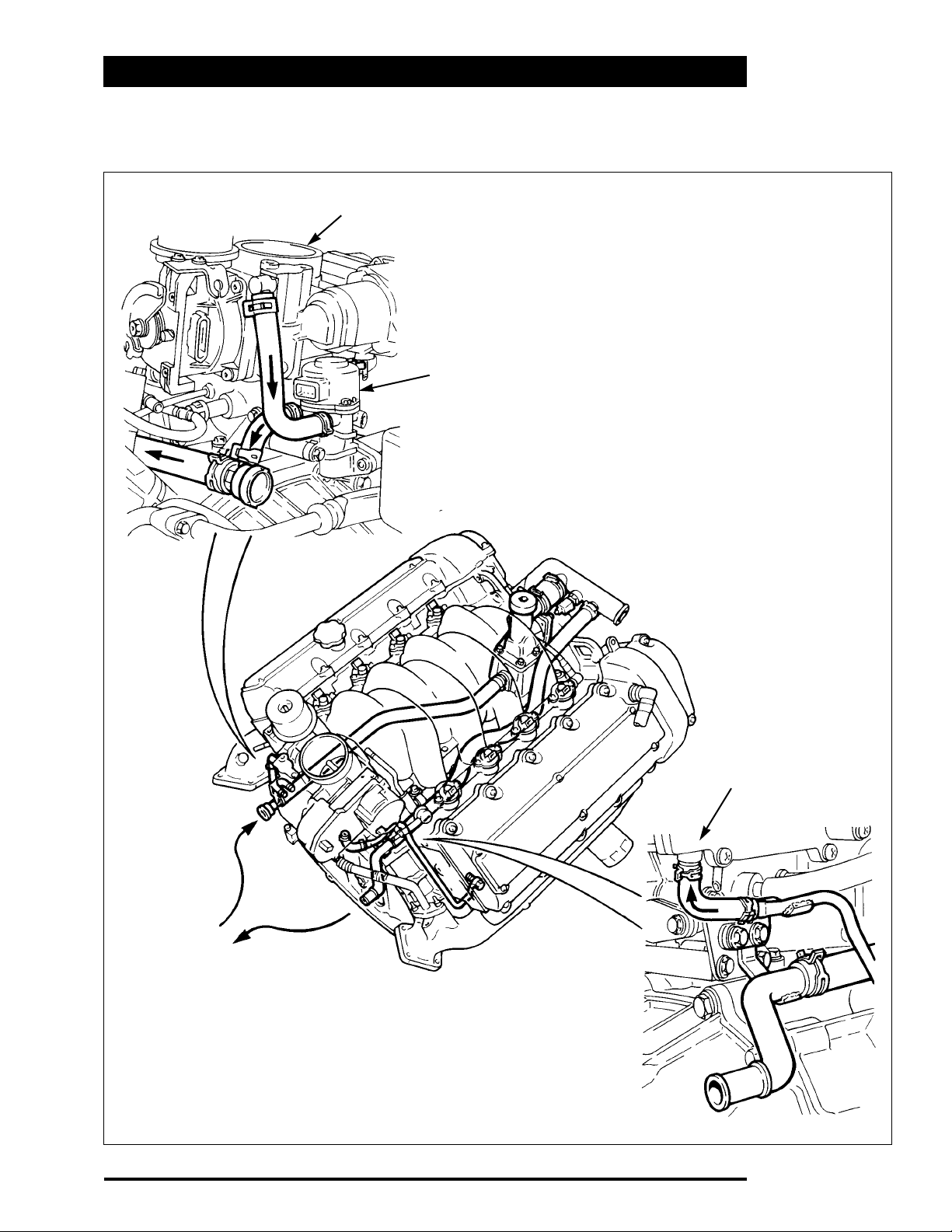

COOLANT HOSES

A/C Heater Matrix

303-032

Electronic Throttle

EGR Valve

Electronic Throttle

Page 25

EngineAJ-V8/5HP24

20

Engine Lubrication

Oil is drawn from the reservoir in the oil pan and

pressurised by the oil pump. The output from the

oil pump is then filtered and distributed through

internal oil passages.

All moving parts are lubricated by pressure or

splash oil. Pressurised oil is also provided for

operation of the variable valve timing units and

the timing gear chain tensioners.

The oil returns to the oil pan under gravity. Large

drain holes through the cylinder heads and

cylinder block ensure the quick return of the oil,

reducing the volume of oil required and enabling

an accurate check of the contents soon after the

engine stops.

System replenishment is through the oil filler cap

on the B bank camshaft cover.

With the exception of the pump and level gauge,

all oil system components are installed on the

structural sump.

Coolant Outlet Duct

The composite coolant outlet duct connects to

the outlet port of each cylinder head to provide a

common connection point for the radiator top

hose. It also incorporates connections for the

coolant temperature sensor, the supply to the air

conditioning heater matrix, and the bypass flow

to the thermostat housing.

An in-groove gasket seals each of the joints

between the outlet duct and the cylinder heads.

COOLANT OUTLET DUCT

ECT Sensor

A/C Heater

Supply

By-pass

To Radiator

303-066

Page 26

Engine AJ-V8/5HP24

21

LUBRICATION SYSTEM

8

7

6

5

1. Valve Lifter Supply

2. Main Bearing Supply

3. Connecting Rod Bearing Supply

4. Bedplate/Cylinder Block Interface

5. Oil Pick-up

6. Pressure Relief Valve

7. Oil Pressure Switch

8. Oil Filter

9. Structural Sump/Bedplate Interface

10. Bedplate/Cylinder Block Interface

11. Oil Pump

12. Primary Chain Tensioner Supply

13. Cylinder Block/Cylinder Head Interface

14. Variable Valve Timing Supply

15. Camshaft Bearing Supply

16. Secondary Chain Tensioner Supply

303-007

12

14

15

2

11

3

1

13

16

10

9

4

Page 27

EngineAJ-V8/5HP24

22

Oil Pump

The oil pump is installed on the crankshaft at the

front of the engine. The pump inlet and outlet

ports align with oil passages in the bedplate. A

rubber coated metal gasket seals the pump to

bedplate interface.

The pumping element is an eccentric rotor, which

is directly driven by flats on the crankshaft. An

integral pressure relief valve regulates pump

outlet pressure at 4.5 bar (65.25 psi).

Oil Filter

The oil filter is a replaceable cartridge installed on

an adapter. An internal bypass facility permits full

flow bypass if the filter is blocked.

Oil Pressure Switch

The oil pressure switch connects a ground input

to the instrument cluster when oil pressure is

present. The switch operates at a pressure of

0.15 to 0.41 bar (2.2 to 5.9 psi).

Oil Level Gauge

The oil level gauge locates midway along the left

side of the oil pan, supported in a tube installed in

the bedplate. Two holes in the end of the gauge

indicate the minimum and maximum oil levels.

There is a difference of approximately 1 liter

(1 US quart) between the two levels.

OIL LEVEL GAUGE

303-022

OIL PUMP

303-009

Oil Pick-up

The moulded composite oil pick-up is immersed

in the oil reservoir to provide a supply to the oil

pump during all normal vehicle attitudes. The

castellated inlet allows the supply to be

maintained even if the sump pan is deformed (eg.

by “grounding”). A mesh screen in the inlet

prevents debris from entering the oil system.

Page 28

Engine AJ-V8/5HP24

OIL SYSTEM COMPONENTS ON STRUCTURAL SUMP

Pressure Switch

Pick-up

Filter

303-185

Page 29

EngineAJ-V8/5HP24

24

Variable Valve Timing

The variable valve timing system improves low

and high speed engine performance, engine idle

quality and exhaust emission. It is a two position

system that operates on the intake camshafts

only. There are 30° of crankshaft movement

between the retarded and advanced positions.

Engine oil pressure operates the system under

the control of the ECM.

For each intake camshaft there is a valve timing

unit, a bush carrier assembly and a valve timing

solenoid.

Valve Timing Unit

The valve timing unit turns the intake camshaft in

relation to the primary chain to advance and

retard the timing.

The unit consists of a body and sprocket

assembly separated from an inner sleeve by a

ring piston and two ring gears. A bolt secures the

inner sleeve to the camshaft. The ring gears

engage in opposing helical splines on the body

and sprocket assembly and on the inner sleeve.

The ring gears transmit the drive from the body

and sprocket assembly to the inner sleeve and,

when moved axially, turn the inner sleeve in

relation to the body and sprocket assembly.

Engine oil pressure (controlled by the valve timing

solenoid) moves the ring gears and piston to turn

the inner sleeve in the advanced timing direction.

A return spring moves the ring gears and piston

to turn the inner sleeve in the retarded timing

direction.

Additional springs absorb backlash to reduce

noise and wear. The springs between the ring

gears absorb rotational backlash. The spring

between the inner sleeve and the end of the

body and sprocket assembly absorbs axial

backlash.

Retarded Advanced

TDC

Intake

Exhaust

BDC

Exhaust

TDC

Intake

BDC

35°

5°

10°

10°

25°

5°

VALVE TIMING DIAGRAMS

65°

50°

35°

50°

303-068

Page 30

Engine AJ-V8/5HP24

25

Bush Carrier

The bush carrier contains oil passages that link

the engine oil supply to the valve timing unit. A

lug on the bush carrier locates in the central bore

of the valve timing unit. Two hollow dowels at

the bush carrier to cylinder block interface ensure

the lug is accurately located. A scarf- jointed fibre

ring seals the joint between the lug and the valve

timing unit. An integral shuttle valve, biased by a

coil spring, controls the flow of oil through the oil

passages.

VALVE TIMING UNIT

BUSH CARRIERS

Inner

Sleeve

Return

Spring

Piston

Ring Gears

Body and Sprocket

Assembly

303-002

303-003

Page 31

EngineAJ-V8/5HP24

26

Valve Timing Solenoid

The valve timing solenoid controls the position of

the shuttle valve in the bush carrier. A plunger on

the solenoid extends when the solenoid is

energised and retracts when the solenoid is deenergised.

Operation

When the valve timing solenoids are deenergised, the coil springs in the bush carriers

position the shuttle valves to connect the valve

timing units to drain. In the valve timing units, the

return springs hold the ring pistons and gears in

the retarded position.

When the valve timing solenoids are energised

by the ECM, the solenoid plungers position the

shuttle valves to direct engine oil to the valve

timing units. In the valve timing units, the oil

pressure overcomes the force of the return

springs and moves the gears and ring pistons to

the advanced position.

System response times are 1.0 second maximum

for advancing and 0.7 second maximum for

retarding.

While the valve timing is in the retarded mode,

the ECM produces a periodic lubrication pulse.

VALVE TIMING SOLENOID

VARIABLE VALVE TIMING OPERATION

Retarded

Advanced

Engine Oil Pressure

303-004

Engine Oil Pressure

303-005

Page 32

Engine AJ-V8/5HP24

27

This momentarily energises the valve timing

solenoids to allow a spurt of oil into the valve

timing units. The lubrication pulse occurs once

every 5 minutes.

Note: With the vehicle stationary and the hood

open, operation of the valve timing

solenoids may be audible when the

lubrication pulse occurs at engine idle

speed.

Air Intake System

Filtered air from the vehicle's intake ducting is

metered by the electronic throttle then directed

through the induction elbow into the intake

manifold.

AIR INTAKE SYSTEM

Intake

Manifold

Electronic

Throttle

Induction

Elbow

303-050

Page 33

EngineAJ-V8/5HP24

28

Electronic Throttle

The electronic throttle enables the ECM to

control the flow of air into the engine. It includes:

• an input shaft that receives driver inputs from

the accelerator pedal via a conventional

throttle cable

• a mechanical guard, to prevent throttle valve

position exceeding driver demand and to

operate the throttle valve mechanically if the

electronic system fails

• a vacuum actuator, to operate the mechanical

guard in the cruise control mode of operation

• a throttle valve, to regulate the air flow

• a thermostatic air valve, to control a bypass

flow around the throttle valve

• a dc motor, to operate the throttle valve in

response to inputs from the ECM

• three position sensors, to supply the ECM

with the position's of the input shaft (ie.

accelerator pedal), the mechanical guard and

the throttle valve

• springs connected to the input shaft, the

mechanical guard, the throttle valve and the

drive gear of the dc motor.

Vacuum Actuator

On vehicles with cruise control, the vacuum

actuator is connected to manifold vacuum and

controlled by the ECM. On vehicles without

cruise control, the vacuum actuator is open to

atmosphere and the actuator is inoperative.

Thermostatic Air Valve

The thermostatic air valve is a wax capsule

operated valve that enables engine starting at

low engine temperatures (with the accelerator

pedal in the idle position, the degree of throttle

valve movement available between fully closed

and the mechanical guard is insufficient to start

the engine at low temperatures). The

thermostatic air valve is fully open at a coolant

temperature of approximately -30°C (-22˚F) and

progressively closes until it is fully closed at

+40 °C (+104˚F). A flow of engine coolant

through the throttle body provides the

temperature source to operate the thermostatic

air valve.

SIMPLIFIED VIEW OF ELECTRONIC THROTTLE

Throttle Valve

Position Sensor

Mechanical Guard

Mechanical Guard

Position Sensor

Accelerator Pedal

Position Sensor

Input

Shaft

303-080

Spring Force

Page 34

Engine AJ-V8/5HP24

29

Springs

The input shaft spring and the mechanical guard

spring oppose movement in the throttle open

direction, and provide the "feel" of the accelerator

pedal. The throttle valve spring and the drive gear

spring oppose movement in the throttle closed

direction.

Operation

The design of the input shaft and the mechanical

guard, and the bias of their respective springs,

means that, except in cruise control, they always

rotate together. The throttle cable turns them in

the open direction; the springs keep their

adjacent levers locked together and turn them in

the closed direction.

The ECM monitors the position of the input shaft

and mechanical guard using the inputs from the

accelerator pedal and mechanical guard position

sensors. During normal operation, when the ECM

detects any movement it signals the dc motor to

turn the throttle valve and follow the input shaft

and mechanical guard, maintaining a constant

gap between the adjacent levers of the throttle

valve and mechanical guard. The dc motor drive

gears turn the throttle valve in the closed

direction; the throttle valve spring turns the

throttle valve in the open direction and keeps the

throttle valve in contact with the drive gear.

Inputs from the throttle valve position sensor

enable the ECM to exercise closed loop control.

The arrangement of the throttle valve drive

prevents the ECM from exceeding driver

demand, since if the motor is driven fully open

the throttle valve engages the mechanical guard

and disengages from the dc motor drive gears.

The arrangement of the mechanical guard to

throttle valve interface allows the ECM to reduce

throttle opening to less than driver demand, eg.

during stability/traction control or engine power

limiting.

ELECTRONIC THROTTLE

Coolant

Inlet

Thermostatic

Air Valve

dc Motor

Coolant

Outlet

Vent

Vacuum Actuator

303-067

Page 35

EngineAJ-V8/5HP24

30

Operating Modes (Refer to the figure, page 31)

Normal

1. Throttle cable inputs driver demand

2. Input shaft turns mechanical guard

3. Sensors supply ECM with inputs of driver demand

4. ECM operates dc motor

5. Sensor supplies ECM with inputs of throttle valve position

6. Gap maintained between throttle valve and mechanical guard

Cruise Control

1. Vacuum actuator turns mechanical guard

2. Sensor supplies ECM with mechanical guard position

3. ECM operates dc motor

4. Sensor supplies ECM with inputs of throttle valve position

5. Gap maintained between throttle valve and mechanical guard

6. Input shaft at idle position, disengaged from mechanical guard

Mechanical Guard

1. Throttle cable inputs driver demand

2. Input shaft turns mechanical guard

3. Mechanical guard turns throttle valve

4. dc motor drive disengaged from throttle valve

At idle, the ECM controls engine speed using the

restricted throttle valve movement available

between the mechanical guard (open limit) and a

factory set stop on the dc motor drive gear

(closed limit).

When cruise control is engaged, the ECM

calculates the required throttle valve opening and

operates the vacuum system connected to the

vacuum actuator. The vacuum actuator then turns

the mechanical guard to a position that allows the

required throttle valve opening. The inputs from

their respective position sensors allow the ECM

to monitor and adjust the mechanical guard and

the throttle valve to maintain the set speed. As

the driver releases the accelerator pedal, the

input shaft disengages from the mechanical

guard. Note that during cruise control, when

accelerating above the set speed, the accelerator

pedal has a lighter "feel" until the input shaft

engages with the mechanical guard again.

Mechanical operation of the throttle valve occurs

if the ECM selects the mechanical guard mode of

operation after detecting a fault. The ECM deenergizes the dc motor and the throttle valve

spring turns the throttle valve in the open

direction until it engages the mechanical guard.

The input shaft, mechanical guard and throttle

valve are then effectively locked together by their

springs, so that the throttle cable is in direct

control of the throttle valve. When the throttle

valve opens, it turns the dc motor drive gears. On

subsequent closing of the throttle valve the drive

gears remain in the open position, disengaged

from the throttle valve.

Page 36

Engine AJ-V8/5HP24

31

ELECTRONIC THROTTLE OPERATING MODES

Normal

Mechanical Guard

Cruise Crontrol

Spring Force

303-080,/081/082

6

2

5

6

3

2

1

4

5

3

2

4

1

1

3

4

Page 37

EngineAJ-V8/5HP24

32

Induction Elbow

The induction elbow provides the interface

between the electronic throttle and the intake

manifold. Connections on the induction elbow

provide vacuum take-offs for various services. A

boss on the rear of the elbow accommodates the

EGR valve.

Intake Manifold

The intake manifold is manufactured in

composite, with integrated composite fuel rails

and metal thread inserts. Individual ducts lead off

a central chamber to the inlet ports of each

cylinder.

Silicon rubber gaskets, located in channels in the

intake manifold, seal the joints between the ducts

and the cylinder heads.

Fuel Tank Vacuum

and Pressure Relief

Valve Connection

Part Load Breather/

EVAP Valve Vacuum

Connection

Brake Booster

Vacuum Connection

Fuel Pressure

Regulator/

Cruise Control

Vacuum

Connection

303-033

INDUCTION ELBOW

SECTION THROUGH INTAKE MANIFOLD

303-051

Page 38

Engine AJ-V8/5HP24

33

Fuel System

Fuel injectors, controlled by the ECM, are

installed in the fuel rails on each side of the

intake manifold. A cross-over pipe connects the

two fuel rails together at the front of the

manifold. A test valve in the cross-over pipe

allows the fuel rail to be pressurised and

depressurised during servicing and

troubleshooting.

A pressure regulator on the rear of the right fuel

rail controls the pressure in the fuel rails.

A return line directs excess fuel from the

pressure regulator back to the fuel tank.

FUEL SYSTEM

Test Valve

Fuel Injector

Fuel Return

Intake Manifold Pressure

Fuel Pressure Regulator

303-024/059/078/155

Page 39

EngineAJ-V8/5HP24

34

Fuel Injectors

Eight, side fed, dual straight jet, fuel injectors are

installed in the fuel rails. The injectors are

electromagnetic solenoid valves controlled by the

ECM. Two O-rings seal each injector to manifold

interface. The fuel jets from the injectors are

directed onto the back of the intake valves.

Pressure Regulator

The pressure regulator is a diaphragm operated

valve that regulates fuel rail pressure at 2.9 bar

(42.05 psi) above intake manifold pressure.

FUEL INJECTOR

303-025

Page 40

Engine AJ-V8/5HP24

35

Ignition System

The ignition system consists of two ECM

controlled ignition amplifier modules, which each

supply four spark plug mounted ignition coils.

The 14 mm spark plugs, one per cylinder, locate

in recesses down the center-line of each cylinder

head.

The on-plug ignition coils are secured to the

camshaft covers. The engine harness connects

the on-plug ignition coils to the ignition amplifiers

located on the vehicle body. A composite cover

fits over the on-plug coils.

Crankcase Ventilation

The engine is ventilated through a part load and a

full load breather.

The part load breather is a flexible composite

hose connected between the oil separator in B

bank camshaft cover and the induction elbow. A

restrictor in the outlet from the oil separator

prevents reverse flow.

The full load breather is a flexible composite hose

connected between the oil separator in A bank

camshaft cover and the air intake duct.

The ends of the breather hoses incorporate quick

release connectors (see figure, page 36).

The oil separators consist of wire gauze packed

into an open ended enclosure below the breather

outlet.

IGNITION COIL AND SPARK PLUG

303-049

OIL SEPARATOR

303-046

Page 41

EngineAJ-V8/5HP24

36

CRANKCASE VENTILATION SYSTEM

Part Load Breather Hose Connector

Full Load Breather Hose Connector

303-065/077/079

Page 42

Engine AJ-V8/5HP24

37

EGR System

The EGR system is controlled by the ECM and

consists of an EGR valve and a transfer pipe.

The EGR valve is a 4 pole stepper motor installed

on the rear of the induction elbow. The valve is

cooled by the coolant return from the electronic

throttle.

The transfer pipe connects the right exhaust

manifold to the EGR valve.

EGR VALVE AND TRANSFER PIPE

303-048

Page 43

EngineAJ-V8/5HP24

38

Engine Accessories

All engine accessories are rigidly mounted to

improve refinement, ie. there are no shock

mounts.

Accessory mounting brackets on the left and

right sides of the engine support the A/C

compressor/ PAS pump and the generator

respectively. Dowels between the accessory

mounting brackets and the engine ensure the

accessory pulleys are accurately aligned with the

accessory drive belt (for further details of the

accessories see Technical Guide, XK8

Introduction).

ACCESSORY MOUNTING BRACKETS

303-019

Page 44

Engine AJ-V8/5HP24

39

Replace Belt

New Belt Maximum Length

New Belt Minimum Length

Belt Wear

Indicator

AUTOMATIC TENSIONER

Accessory Drive

A single seven ribbed belt drives all the engine

mounted accessories. The torsional vibration

damper on the front of the crankshaft drives the

belt. An automatic tensioner, located on the left

accessory mounting bracket, keeps the belt at

the correct tension. An idler pulley on the right

accessory mounting bracket increases the wrap

angle around the generator pulley.

The torsional vibration damper incorporates

compressed rubber between its inner and outer

diameters to absorb vibration and shock loads.

The automatic tensioner consists of an idler

pulley on the end of a spring loaded pivot arm.

The pivot arm can be turned counter-clockwise

(viewed from the front of the engine) for removal

and installation of the belt. A belt wear indicator

is incorporated on the rear of the pivot arm.

PAS Pump

A/C

Compressor

Generator

303-018

ENGINE ACCESSORIES AND DRIVE BELT

303-020

Page 45

EngineAJ-V8/5HP24

40

3

4

5

2

6

1

20

19

18

7

8

9

10

11

12

13

14

15

16

17

Connectors

1. PI032, B Bank VVT solenoid

2. PI027, B Bank Knock Sensor

3. PI004, Engine Coolant Temperature Sensor

4. PI026, A Bank Knock Sensor

5. PI031, A Bank Valve Timing Solenoid

6. PI035, MAFS (On vehicle)

7. PI050, Generator

8. PI040, Oil Pressure Switch

9. PI018-PI021, A Bank Ignition Coils 1-4

PI022-PI025, B Bank Ignition Coils 1-4

10. PI006, Throttle Position Sensor

ENGINE HARNESS

11. PI002, Engine Management Harness (On vehicle)

12. PI001, Engine Management Harness (On vehicle)

13. PI033, Throttle Valve Motor

14. PI034, EGR Valve

15. PI015, Camshaft Position Sensor

16. PI042, Accelerator Pedal and Mechanical Guard

Position Sensors

17. PI007-PI010, A Bank Injectors 1-4

PI011-PI014, B Bank Injectors 1-4

18. PI037, A/C Compressor Lock Sensor

19. PI036, A/C Compressor Clutch

20. PI017, Engine Speed Sensor

303-057

Page 46

Engine AJ-V8/5HP24

41

Engine Harness

The engine harness links engine mounted

electrical components to the vehicle's engine

management harness. The connectors that

interface with the engine management harness

are attached to a bracket on the transmission

housing. Integral nylon fasteners attach the

harness to the engine. Connectors on component

flying leads are attached to engine mounted

brackets.

CONNECTORS ON TRANSMISSION

HOUSING BRACKET

303-061

HARNESS FASTENER

303-064

FLYING LEAD CONNECTOR BRACKET

303-058

Page 47

EngineAJ-V8/5HP24

42

Engine Covers

Engine covers are installed over the fuel injectors.

The covers are a push fit, held in position by

mating studs and grommets on the covers and

the engine. The rubber grommets isolate the

covers from the engine to prevent noise. A sleeve

connects the covers together at the rear.

ENGINE COVERS

MOUNTING POINTS ON ENGINE COVER

MOUNTING POINTS ON ENGINE

303-055

303-040

303-039

Page 48

Engine AJ-V8/5HP24

43

Engine Specifications

Configuration 90° V8

Cylinder Head Dual overhead camshafts, 4 valves per cylinder

Valve Clearances (Cold):

Intake 0.18 to 0.22 mm (0.007 to 0.009 in)

Exhaust 0.23 to 0.27 mm (0.009 to 0.011 in)

Spark Plug Type: NGK PFR5011E (platinum tipped center electrode)

Spark Plug Gap: 1.0 mm (0.040 in)

Firing Order 1A, 1B, 4A, 2A, 2B, 3A, 3B, 4B

Bore 86 mm (3.386 in)

Stroke 86 mm (3.386 in)

Displacement 3.996 liters (244 CDI)

Compression Ratio 10.75 : 1

Maximum Power (DIN) 216 kW (290 BHP) at 6100 rpm

Maximum Torque (DIN) 393 Nm (290 lbf. ft) at 4250 rpm

Maximum Speed (Limited) 7100 rpm

Coolant Type Water and Jaguar anti-freeze to specification ESD-M97B49-A

(see Service Manual for mixture ratio)

Coolant Volume:

Engine Only 3.7 liters (0.98 US gallon)

Complete System 10 liters (2.65 US gallons)

Oil Specification: SAE 5W30 - API SH/ILSAC GF-2

Oil Volume: 6.5 liters (6.88 US quarts)

Weight (With Accessories) Approximately 200 kg (441 lb)

Page 49

Engine ManagementAJ-V8/5HP24

44

ECM

The engine management system is controlled by

the ECM, which is installed in the control module

enclosure in the engine compartment. The ECM

provides optimum control of the engine under all

operating conditions. It also incorporates a

comprehensive monitoring and diagnostic

capability. Software variations ensure that the

system complies with the latest diagnostic and

emissions legislation of the destination market.

The ECM receives inputs from engine related

sensors and various vehicle systems, and

provides outputs for the following:

• electronic throttle

• fuel pump

• fuel injection

• ignition

• EVAP system

• variable valve timing

• EGR system

• engine starting

• HO2S heaters

• instrument cluster

• A/C compressor clutch

• windshield and backlight heaters

• radiator cooling fans

• diagnostics.

ECM

303-118

Page 50

Engine Management AJ-V8/5HP24

45

Inputs and Outputs

Inputs and outputs are directed to and from the ECM through hard-wired connections and the CAN and

ISO 9141/2 (Serial Communication) data buses contained in the engine management harness (for

further information on the data buses, refer to the Technical Guide, XK8 1997 Model Year Introduction).

ECM Pin Connections

Connector/

Pin Circuit Pin Circuit Pin Circuit

EM010

001 Ignition supply

002 Load inhibit

003 Windshield/Backlight heater

request

004 A/C clutch request

005 Ignition supply

006 OK to fuel (where

incorporated)

007 Not used

008 Not used

009 Battery supply

010 Brake switch (foot brake on)

011 Brake switch (cancel cruise

control)

012 ISO 9141/2

(Serial Communication) in (L)

013 ISO 9141/2

(Serial Communication) out (K)

014 Parking brake switch

015 Park/Neutral switch

016 EMS control relay

017 Security acknowledged

018 Not used

019 Not used

020 Sensor ground (ECT, air intake

temperature, accelerator pedal

position, mechanical guard

position and throttle position)

021 Sensor 5 V supply (accelerator

pedal position, mechanical

guard position and throttle

position)

022 EGR ground

023 Signal ground 1

024 Not used

025 CAN in (-)

026 CAN in (+)

027 CAN out (-)

028 CAN out (+)

EM011

001 Cruise control set +/set -

(acceleration/deceleration)

002 Not used

003 ECM programming

004 Cruise control on/off

005 Cruise control resume/cancel

006 Engine crank

007 Not used

008 Sensor 5 V supply (accelerator

pedal position, mechanical

guard position and throttle

position)

009 ECT sensor

010 Throttle position sensor 2

011 Throttle position sensor 1

012 Sensor ground (ECT, air intake

temperature, accelerator pedal

position, mechanical guard

position and throttle position)

013 Mechanical guard position

sensor

014 Shield ground (accelerator

pedal position, mechanical

guard position and throttle

position sensors)

015 Accelerator pedal position

sensor 2

016 Accelerator pedal position

sensor 1

EM012

001 EGR valve 1

002 EGR valve 2

003 EGR valve 3

004 EGR valve 4

005 A/C high pressure switch

006 A/C low pressure switch

007 Not used

008 Ignition failure amplifier 2

009 Ignition failure amplifier 1

010 A/C clutch relay

011 Not used

012 Air intake temperature sensor

013 MAFS

014 HO2S B

015 HO2S A

016 O2S B (where fitted)

017 O2S A (where fitted)

018 MAFS ground

019 MAFS ground

020 Not used

021 Not used

022 Shield ground (HO2S and O2S)

Page 51

AJ-V8/5HP24

46

Engine Management

16

22

14

9

1

28

21

13

8

12

8

5

1

11

4

18

12

7

1

22

17

11

6

27

17

11

1

10

26

34

12

6

7

1

22

11

1

12

16

7

ECM PIN CONNECTIONS

Connector/

Pin Circuit Pin Circuit Pin Circuit

EM013

001 Fuel pump control

002 EMS programming

003 Cruise control switch LED

004 )

005 )

006 )

007 ) Not used

008 )

009 )

010 )

011 VSV 3

012 VSV 1

013 VSV 2

014 Throttle motor relay

015 Radiator cooling fans, slow

016 Radiator cooling fans, fast

017 Knock sensor B

018 Knock sensor A

019 Engine speed sensor

020 Camshaft position sensor

021 Not used

022 Ignition coil relay

023 Ignition amplifier 4A

024 Ignition amplifier 3A

025 Ignition amplifier 2A

026 Ignition amplifier 1A

027 Shield ground (knock, engine

speed and camshaft sensors)

028 Engine speed sensor ground

029 Camshaft sensor ground

030 Not used

031 Ignition amplifier 4B

032 Ignition amplifier 3B

033 Ignition amplifier 2B

034 Ignition amplifier 1B

EM014

001 Throttle motor power

002 Throttle motor power

003 Ignition supply

004 Signal ground 2

005 Throttle motor (+)

006 Throttle motor (+)

007 Throttle motor ground 2

008 Throttle motor ground 1

009 Valve timing ground

010 Power ground (miscellaneous)

011 Throttle motor (-)

012 Throttle motor (-)

EM015

001 HO2S B heater

002 HO2S A heater

003 EVAP valve

004 Injector 3B

005 Injector 2B

006 Injector 4A

007 Injector 1A

008 Valve timing solenoid B

009 Valve timing solenoid A

010 Not used

011 Injector ground (1A, 2B, 3B, 4A)

012 HO2S heaters ground

013 Not used

014 Not used

015 Injector 4B

016 Injector 3A

017 Injector 2A

018 Injector 1B

019)

020) Not used

021)

022 Injector ground (1B, 2A, 3A, 4B)

EM014 EM015 EM013 EM012 EM011 EM010

303-129

Page 52

AJ-V8/5HP24

47

Engine Management

Engine Harness to Engine Management Harness Pin Connections

Connector/

Pin Circuit Pin Circuit Pin Circuit

PI001

001 Throttle position sensor 2

002 A/C compressor lock sensor

ground

003 Throttle position sensor 1

004 Shield ground (throttle

position sensor)

005 ECT sensor

006 Sensor ground (ECT,

accelerator pedal position,

mechanical guard position and

throttle position)

007 EGR valve 4

008 EGR valve 1

009 EGR valve 2

010 EGR valve 3

011 Generator regulator charge

warning

012 Mechanical guard position

sensor

013 A/C clutch

014 Sensor 5 V supply (accelerator

pedal position, mechanical

guard position and throttle

position)

015 Not used

016 Valve timing solenoid A

017 Knock sensor A

018 Screen ground (knock sensor A)

019 Knock sensor B

020 Shield ground (knock sensor B)

021 Engine speed sensor ground

022 Engine speed sensor

023 Screen ground (engine speed

sensor)

024 Camshaft position sensor ground

025 Camshaft position sensor

026 Shield ground (camshaft

sensor)

027 Valve timing solenoid B

028 Valve timing solenoids and

MAFS/intake air temperature

sensor supply

029 Not used

030 Injector 1A

031 Intake air temperature sensor

ground

032 Injector 2A

033 Injector 3A

034 Injector 4A

035 Injector 1B

036 Injector 2B

037 Injector 3B

038 Injector 4B

039 Ignition coil 4A

040 Ignition coil 1A

041 Ignition coil 3B

042 Ignition coil 2B

043 Ignition coil 4B

044 Ignition coil 3A

045 Ignition coil 2A

046 Ignition coil 1B

047 EGR valve supply

048 Engine oil pressure sensor

049 Shield ground (accelerator

pedal position and mechanical

guard position sensors)

050 Accelerator pedal position 1

051 Accelerator pedal position 2

052 MAFS

053 Ignition supply

054 MAFS ground

055 A/C compressor lock sensor

056 MAFS ground

057 Intake air temperature sensor

ENGINE HARNESS PIN CONNECTIONS

4

10

16

22

26

28

34

40

30

46

52

57

1

5

11

17

23

27

31

35

29

41

47

53

5

9

13

1

6

10

PI001

PI002

PI001

PI002

303-061/136/137

Page 53

AJ-V8/5HP24

48

Engine Management

Connector/

Pin Circuit Pin Circuit Pin Circuit

PI002

001 )

002 ) Not used

003 )

004 )

005 Injector supply

006 Throttle motor (-)

007 Throttle motor (+)

008 )

009 ) Not used

010 )

011 Not used

012 Generator regulator supply

013 Not used

CAN Messages

Messages on the CAN data bus used or output by the ECM are detailed below:

Note: This list does not include network monitoring or diagnostic related messages.

Message Used by ECM Source/Used by Message Produced by ECM

ABS MALFUNCTION Brake control module BRAKE PEDAL PRESSED

FAST TORQUE REDUCTION CYLINDER ENGINE MALFUNCTION

FAST TORQUE REDUCTION IGNITION ENGINE SPEED

FRONT LEFT WHEEL SPEED ESTIMATED ENGINE TORQUE

FRONT RIGHT WHEEL SPEED PEDAL POSITION

REAR LEFT WHEEL SPEED THROTTLE POSITION

REAR RIGHT WHEEL SPEED TRACTION ACKNOWLEDGE

TORQUE REDUCTION THROTTLE

TRACTION STATUS

VEHICLE REFERENCE SPEED

FUEL LEVEL Instrument cluster BRAKE PEDAL PRESSED

HEADLAMP HIGH BEAM STATUS ENGINE COOLANT TEMPERATURE

HEADLAMP LOW BEAM STATUS ENGINE MALFUNCTION

SIDE LAMP STATUS ENGINE SPEED

FUEL USED

PARK BRAKE STATUS

THROTTLE MALFUNCTION AMBER

THROTTLE MALFUNCTION RED

GEAR POSITION ACTUAL TCM CRUISE CONTROL STATUS

GEAR POSITION SELECTED ENGINE SPEED

GEAR SELECTION FAULT ESTIMATED ENGINE TORQUE

KICKDOWN STATUS PEDAL POSITION

TORQUE CONVERTER SLIP THROTTLE POSITION

TORQUE CONVERTER STATUS TORQUE REDUCTION ACKNOWLEDGE

TORQUE REDUCTION REQUEST

TRANSMISSION INPUT SPEED

TRANSMISSION MALFUNCTION

TRANSMISSION OIL TEMPERATURE

TRANSMISSION OUTPUT SPEED

TRANSMISSION OVERLOAD

Page 54

AJ-V8/5HP24

49

Engine Management

Sensors

Engine management sensors that input to the

ECM are detailed below:

Barometric Pressure Sensor

The barometric pressure sensor is installed in the

ECM. It senses ambient pressure in the engine

management enclosure of the engine

compartment.

HO2S

A HO2S is installed in the intake end of each

catalytic converter. They provide inputs

proportional to the oxygen content of the exhaust

gases leaving the engine. The heater elements

improve the response time of the sensors during

engine warm-up.

O2S

An O2S is installed in the outlet end of each

catalytic converter. They provide inputs

proportional to the oxygen content of the exhaust

gases leaving the catalytic converter.

Intake Air Temperature Sensor

The intake air temperature sensor is a thermistor

integrated into the same housing as the MAFS, in

the intake duct immediately downstream of the

intake air cleaner. It provides an input inversely

proportional to the temperature of the air in the

duct.

MAFS

The MAFS is a hot wire sensor that provides an

input which is (approximately) proportional to

mass air flow into the engine.

OXYGEN SENSORS

303-119

MAFS/INTAKE AIR TEMPERATURE SENSOR

303-128

H02S

02S

Page 55

AJ-V8/5HP24

50

Engine Management

Camshaft Position Sensor

The camshaft position sensor is installed in B

bank cylinder head at the rear of the intake

camshaft. It is a variable reluctance sensor that

provides an input of intake camshaft position.

ECT Sensor

The ECT sensor is installed in the coolant outlet

duct. It provides an input of coolant temperature

at the cylinder head outlets.

Engine Speed Sensor

The engine speed sensor is installed at the rear

of the bed plate. It is a variable reluctance sensor

that provides an input of engine crankshaft speed

and position.

Knock Sensors

The knock sensors are installed in the cylinder

block on the inboard side of each cylinder bank.

They are piezo-electric sensors that provide

inputs to detect and locate detonation during

combustion.

ELECTRONIC THROTTLE SENSORS

Accelerator Pedal Position Sensor

The accelerator pedal position sensor is

connected to the input shaft in the electronic

throttle. It is a dual track potentiometer that

provides inputs of driver demand at the

accelerator pedal.

Mechanical Guard Position Sensor

The mechanical guard position sensor is a single

track potentiometer connected to the mechanical

guard in the electronic throttle. It provides an

input of the position of the mechanical guard.

Throttle Position Sensor

The throttle position sensor is a dual Hall effect

sensor in the motor end of the electronic throttle.

It provides inputs of the position of the throttle

valve.

Accelerator Pedal Position

and Mechanical Guard

Position Sensors

Throttle Position

Sensor

303-090

Page 56

AJ-V8/5HP24

51

Engine Management

ENGINE SENSORS

Knock Sensors

ECT Sensor

Camshaft Position Sensor

Engine Speed Sensor

303-127

Page 57

AJ-V8/5HP24

52

Engine Management

M

ECM Inputs and Outputs

1. Intake Air Temperature Sensor

2. MAFS

3. Throttle Position Sensor

4. (Throttle) dc Motor

5. EGR Valve

6. Fuel Injector

7. Camshaft Position Sensor

8. On-plug Ignition Coil

9. H02S

10. 02S

11. Engine Speed Sensor

12. Accelerator Pedal Position

Sensor

13. Mechanical Guard Position

Sensor

14. ECT Sensor

15. Knock Sensors

ENGINE MANAGEMENT SCHEMATIC

1

3

2

4

5

12

13

6

8

14

15

6

7

9

11

10

8

9

10

303-130

Page 58

AJ-V8/5HP24

53

Engine Management

Electronic Throttle

The electronic throttle enables the ECM to

perform the following functions:

• engine air flow (ie. power) control

• engine idle speed control

• vehicle cruise control

• stability/traction control (in response to

ABS commands)

• engine power limiting

• vehicle speed limiting

• reverse gear torque reduction

Engine Air Flow Control

During normal operation, when the accelerator

pedal is above idle, the ECM positions the

throttle valve in response to the inputs from the

accelerator pedal position sensor. The throttle

valve follows or leads at a minimum distance the

mechanical guard as the guard is moved by the

accelerator pedal. Thus engine power output is

directly related to driver demand. With the

engine running, the time for the throttle to travel

from idle to fully open is approximately 120 ms

maximum, and from fully open to idle

approximately 140 ms maximum.

Idle Speed Control

During engine idle speed control, the ECM

operates in a closed speed control loop to

maintain a given target idle speed. The ECM

uses gear selection, intake air temperature and

battery voltage to determine the required target

idle speed.

Gear selection is derived from the input of the

Park/Neutral switch in the transmission rotary

switch.

Battery voltage is monitored and, if low voltage is

detected (11.8 V and below), target idle speeds

are increased by up to 50 rpm to increase the

output from the generator.

When the ECM selects a change of target idle

speed, overshoot is kept to 50 rpm maximum.

Certain vehicle services/functions cause a

significant change in engine load as they are

selected on and off. To minimize the effect on

idle speed, the ECM anticipates the change in

load rather than correct the subsequent change in

rpm. The services/functions the ECM anticipates

load changes for are:

• A/C compressor clutch

• gear shifts between Park/Neutral and

Reverse/Drive

• headlamps and side lamps

• windshield and backlight heaters

• radiator cooling fans.

The ECM detects gear shifts, headlamp status

and side lamp status from their related status

messages on the CAN data bus. The ECM

directly controls the A/C compressor clutch and

the radiator cooling fans. The windshield and

backlight heaters are controlled by the ACCM

upon consent of the ECM via the heater

request/load inhibit circuits.

If a fault develops in the idle control function, the

ECM goes to open loop control. During open loop

control, rpm is within +100 and -0 rpm of the

target speed for a warm engine (ie. when the

coolant temperature is >30 ˚C (86˚F).

Idle Target Speeds

Intake Air Temperature, ˚C (˚F) Engine Speed, (rpm)

Drive/Reverse Park/Neutral

>-10 (14) 600 ± 25 650 ± 25

-10 to >-20 (14 to >-4) 625 ± 25 675 ± 25

-20 to >-30 (-4 to >-22) 650 ± 25 700 ± 25

≤-30 (≤-22) 675 ± 25 725 ± 25

Page 59

AJ-V8/5HP24

54

Engine Management

Vehicle Cruise Control

The ECM operates the vehicle cruise control

system, in all forward gears, in response to driver

inputs through the master, SET+, SET-, CANCEL

and RES switches.

When the master switch is pressed, two 12 V

ignition supplies are connected to the ECM, one

direct and one via the brake switch. The LED in

the switch comes on to indicate the system is

armed.

With the system armed, a momentary press of

either the SET+ or the SET- switch engages

cruise control, provided the vehicle speed is

28 km/h (17.5 mph) or above. The ECM

memorizes the current road speed as the `set’

speed and signals the vacuum system to operate

the mechanical guard. The inputs from the

position sensors in the electronic throttle allow

the ECM to monitor and adjust the mechanical

guard and the throttle valve to maintain the set

speed.

The vacuum components are installed in a line

connected between the induction elbow and the

vacuum actuator on the electronic throttle. In the

vacuum system:

• the check valve isolates the system from

the induction elbow at wide open throttle

when there is little or no vacuum available

• the reservoirs extend the time (to

approximately 20 minutes) that, at wide open

throttle, sufficient vacuum can be maintained

in the system to operate the vacuum

actuator

• VSV 1 regulates the vacuum applied to the

vacuum actuator to control the position of

the mechanical guard

• VSV 2 connects the vacuum actuator to

atmosphere to release the mechanical guard

when cruise control is disengaged

• VSV 3 is a back-up for VSV 2 (because cruise

control disengagement is safety critical)

• filters on the atmospheric ports of VSV 2 and

VSV 3 prevent moisture ingress.

CRUISE CONTROL STEERING WHEEL

SWITCHES

CRUISE CONTROL MASTER SWITCH

303-131

303-132

Page 60

AJ-V8/5HP24

55

Engine Management

M

CRUISE CONTROL SCHEMATIC

B+ Ignition

Driver’s Facia Fuse Box

To Dimmer Switch

Master Switch

Ignition Switched

Ground

Brake

Switch

Steering Wheel

Switches

Parking

Brake

Switch

Engine

Speed

Sensor

-VEHICLE SPEED

-TRACTION STATUS

-GEAR POSITION SELECTED

CAN

ECM

VSV 2

VSV 3

VSV 1

Reservoirs

Check Valve

Throttle Valve

Position Sensor

Accelerator Pedal

Position and

Mechanical Guard

Position Sensors

Vacuum

Actuator

dc Motor

RES

CANCEL

SET-

SET+

F14

303-133

Brake

Cancel

Switch

Page 61

AJ-V8/5HP24

56

Engine Management

Once cruise control is engaged, a further

momentary press of the SET+ or SET- switch

increments or decrements the set speed by

1.6 km/h (1.0 mph). The ECM then accelerates or

decelerates the vehicle to the new set speed.

The ECM stores a maximum of five incremental

or decremental commands at any one time. Once

the ECM has actioned the first stored command,

a further command can be added. On momentary

operation of the opposite sense switch, the ECM

deletes the last command from memory.

Pressing and holding the SET+ or SET- switch

causes the ECM to increase or decrease the set

speed, and smoothly accelerate or decelerate the

vehicle, until the switch is released. To protect

against switch failure in the closed position, if

either switch is held for longer than 10 minutes,

the ECM disables cruise control until the next

ignition cycle.

The throttle pedal can be used to accelerate the

vehicle beyond the set speed, without

disengaging cruise control (since the diaphragm

actuator is holding the mechanical guard, there is

a noticeable reduction in accelerator pedal load

up to the point at which the input shaft in the

electronic throttle begins to turn the mechanical

guard). When the pedal is released the ECM

returns the vehicle to the set speed in a

controlled manner. Alternatively, a momentary

press of the SET+ or SET- switch causes the

increased vehicle speed to be adopted as the

new set speed.

On receipt of an input from the CANCEL switch,

the ECM disengages cruise control and clears the

set speed from memory. Disengagement is in a

controlled manner to provide a smooth return of

throttle control to the driver.

The ECM disengages cruise control, clears the

set speed from memory and immediately

returns

control of the throttle to the driver if any of the

following occur:

• the master switch is pressed, to switch the

system off

• a fault is detected in the electronic throttle

system, the brake switch or the cruise

control switches

• the parking brake is applied

• the engine overspeeds.

The ECM disengages cruise control, immediately

returns control of the throttle to the driver and

r

etains the set speed in memory, if any of the

following occur:

• the brake pedal is pressed

• the vehicle decelerates too fast (ie. as

under heavy braking, to guard against

sticking contacts in the brake switch)

• the gear selector moves to neutral, park

or reverse

• after resuming cruise control the vehicle

accelerates to only 50% of the set speed

(eg. due to a steep hill)

• the stability/traction control system

operates

• vehicle speed decreases below 26 km/h

(16 mph).

On receipt of an input from the RES switch, if a

set speed is stored in the ECM memory, the

cruise control function is re-engaged and the

vehicle accelerated or decelerated to resume the

set speed in a controlled manner.

The ECM continuously monitors the cruise

control switches. If a switch fails closed, on the

initial failure the input is treated as a driver

command and the system responds accordingly.

However, after subsequent disengagement then

re-engagement of the system, the input from the

failed switch is diagnosed as a fault. On detection

of a switch fault, operation of cruise control is

inhibited until the fault is corrected.

The ECM also conducts internal checking

procedures to ensure that only permitted outputs

are generated for given input conditions.

Page 62

AJ-V8/5HP24

57

Engine Management

CRUISE CONTROL VACUUM SYSTEM

Reservoirs

Check Valve

VSV 1

303-121

Stability/Traction Control

If the CAN- TORQUE REDUCTION THROTTLE

message from the brake control module requests

torque reduction, the ECM reduces the throttle

valve opening. It also changes the CANTRACTION ACKNOWLEDGE message to confirm

that torque reduction is in progress.

Engine Power Limiting

If the TCM detects a fault in the transmission, it

changes the CAN- TRANSMISSION OVERLOAD

message to request an engine torque limit. The

ECM then limits throttle valve opening to 18˚

maximum in all forward gears.

Vehicle Speed Limiting

The ECM uses throttle control to limit the

vehicle's maximum speed to 248 km/h (155

mph).

Reverse Gear Torque Reduction

When reverse gear is selected the CANTRANSMISSION OVERLOAD message from the

TCM requests an engine torque limit. The ECM

then limits throttle valve opening to 18˚

maximum.

VSV 2

VSV 3

Page 63

AJ-V8/5HP24

58

Engine Management

Fuel Injection

The ECM operates eight injectors to provide the

engine with fuel. The amount of fuel required is

determined from a base air:fuel ratio which is

then adjusted for specific operating conditions.

The ECM varies the number and duration of

injector pulses per engine cycle to regulate the

fuel flow. Injector timing is synchronised with

engine rotation, except during starting and

acceleration.

Feedback signals from the two HO2S in the

vehicle's exhaust system enable the ECM to

exercise closed loop fueling control and adaptive

fueling. Separate channels in the ECM control

each bank of injectors.

Adaptive fueling accommodates engine efficiency

variations, system tolerances and engine ageing.

Adaptations are produced at idle speed and four

other points through the RPM/load range, on a

fully warm engine, when the adaptive fueling

function centralizes the feedback range. The ECM

retains the adaptations in memory, for use in

subsequent driving cycles. If the difference

between the new and previous adaptations is

excessive, a DTC is logged in the ECM memory.

If the battery supply to the ECM is disrupted (eg.

battery disconnection), the adaptations are lost

from memory. On restoration of the battery

supply, engine operation may be uneven until the

adaptations are restored, especially at idle speed.

An output from the ECM controls the relay that

operates the fuel pump. At ignition on, the pump

will operate for 2 seconds without the ignition

switch being set to crank, after which time the

pump will be de-energized. Similarly, if the engine

stops with the ignition on, the pump will be deenergized after 2 seconds. The pump operates

continuously while the ignition switch is set to

crank, or to on with the engine running.

FUEL PUMP CONTROL

B+ Battery

B+ Ignition

Fuel Pump

Relay

Trunk

Fuse Box

ECM

Fuel Pump

F7

303-134

Fuel Pump

The two O2S in the vehicle's exhaust system

provide inputs which enable the ECM to monitor

the efficiency of the downpipe catalytic

converters. These inputs also enable the ECM to

modify the HO2S inputs, to optimise the life of

the catalytic converters.

Base Fuel Map

The ECM contains a base fuel map that corrects

the base air:fuel ratio to the optimum mixture for

a nominal engine throughout the engine speed

and load ranges.

Battery Voltage Correction

Fuel flow through the injectors changes with

voltage, so the ECM monitors their supply

voltage and compensates for any variation from

the nominal.

Page 64

AJ-V8/5HP24

59

Engine Management

Starting

The fueling start strategy operates independent

of accelerator pedal position or movement, with

the exception of a wide open throttle. The ECM

produces steady state running at the target idle