Page 1

CAD

all ceramic

all you need

I N S T R U C T I O N S F O R U S E

L A B S I D E

Page 2

Table of Contents

3 IPS e.max System – one system for every indication

CAD

PR OD UC T

IN FO RM ATI ON

4 Product Information

Material

Usage

Composition

Scientific Data

Block Concept

CAD/CAM Partners

9 Clinical steps, model preparation, CAD/CAM process

Overview of the Clinical Working Steps, Fabrication Process

Shade Determination — Tooth Shade, Shade of the Prepared Tooth

Preparation Guidelines

Model and Tooth Preparation

Layer Thicknesses

Design Guidelines for the Restoration

CAD/CAM Processing

18 Staining Technique

Finishing

Crystallization and Stain/Glaze Firing

– Option A: Crystallization and Stain/Glaze Firing in One Step with Glaze Paste

– Option B: Crystallization and Stain/Glaze Firing in One Step with Glaze Spray

– Option C: Crystallization and Separate Stain/Glaze Firing

35 Cut-Back Technique

Finishing and Preparation for Crystallization

Crystallization

Veneering with IPS e.max Ceram

PR AC TI CA L NO TE S ON P RO CE SS IN G

-

IN FO R

MAT IO N

CAD

45 Layering Technique

Finishing and Preparation for Crystallization

Crystallization

Veneering with IPS e.max Ceram

53 Seating and Follow-Up Care

Possibilities for Cementation

Preparing for Cementation

Care notes

56 General Information

Frequently Asked Questions

Table on Block Selection

Crystallization and Firing Parameters

2

Page 3

®

e.max

IPS

System –

all you need

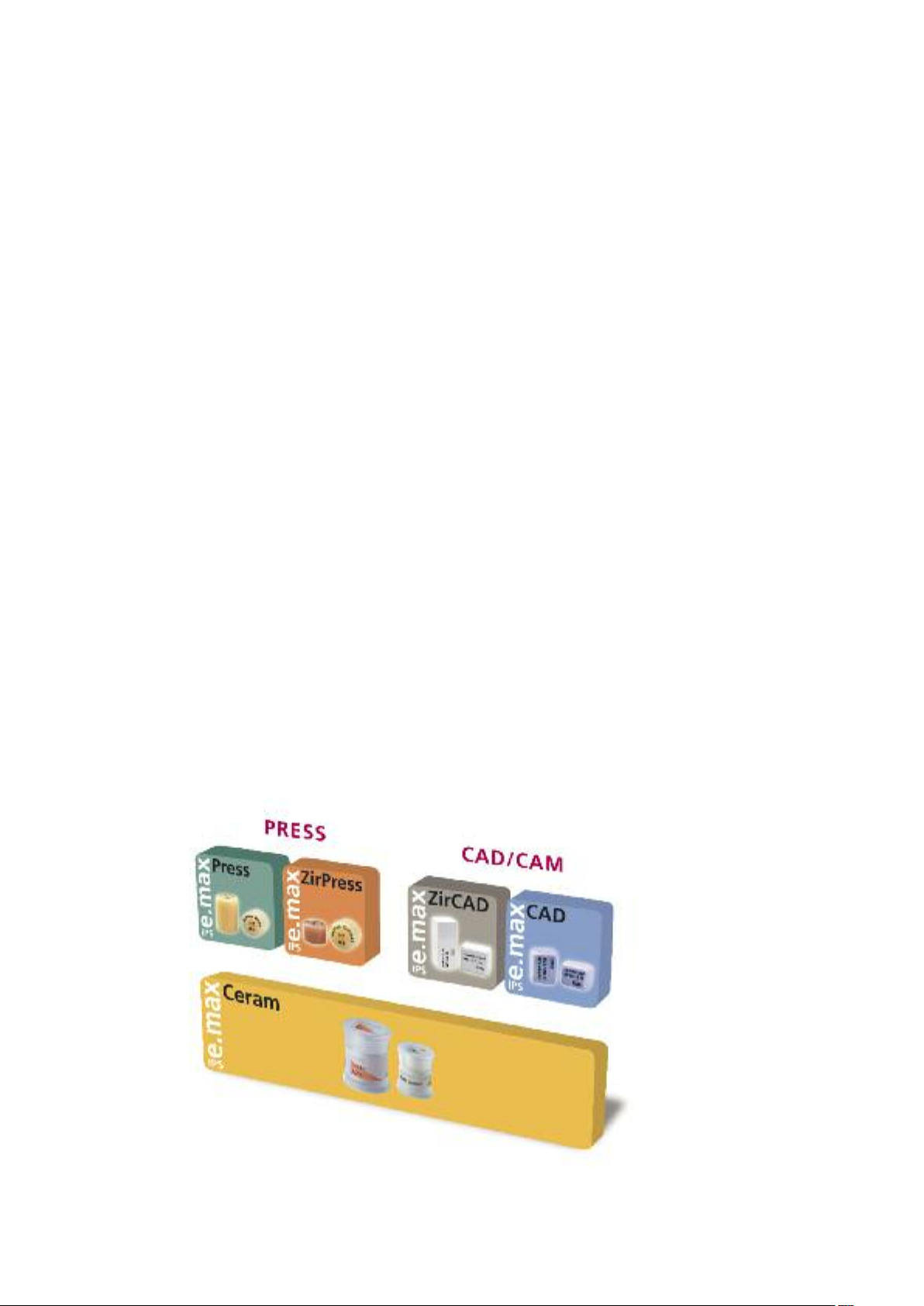

IPS e.max is an innovative all-ceramic system which covers the entire all-ceramic indication range – from

thin veneers to 10-unit bridges.

IPS e.max delivers high-strength and highly esthetic materials for the Press and the CAD/CAM

technologies. The system consists of innovative lithium disilicate glass-ceramics used mainly for singletooth restorations and high-strength zirconium oxide for large-span bridges.

Every patient situation presents its own requirements and objectives. IPS e.max meets these

requirements. Due to the system components you obtain exactly what you need.

– The components of the Press technology include the highly esthetic IPS e.max Press lithium disilicate

glass-ceramic ingots and the IPS e.max ZirPress fluorapatite glass-ceramic ingots for the fast and

efficient press-on-zirconia technique.

– Depending on the case requirements, two types of materials are available for CAD/CAM techniques:

the innovative IPS e.max CAD lithium disilicate blocks and the high-strength zirconium oxide IPS e.max

ZirCAD.

– The nano-fluorapatite layering ceramic IPS e.max Ceram, which is used to characterize/veneer all

IPS e.max components – glass or oxide ceramics – completes the IPS e.max System.

IPS e.max CAD

The shades and translucency levels of the IPS e.max CAD blocks are based on the overarching IPS e.max

shade system. The system has a flexible design and can be used in conjunction with the A-D,

Chromascop as well as Bleach BL shade guides.

The shades of the Press ingots and CAD/CAM blocks offered in the IPS e.max System are all coordinated

with each other. They are available in different degrees of opacity and/or translucency. The selection of

the translucency level is based on the clinical requirements (shade of the prepared tooth, desired tooth

shade) presented by the patient, as well as the desired processing technique (layering, cut-back, staining

technique).

The more opaque HO (only IPS e.max Press) and MO blocks are predominantly suitable for the layering

technique, while the more translucent LT and HT blocks are used for the cut-back and also the staining

technique.

3

Page 4

®

e.max

IPS

CAD

Product Information

Material

IPS e.max CAD is a lithium disilicate glass-ceramic block for the

CAD/CAM technique. It is fabricated using an innovative process

which provides an impressive homogeneity of the material. The

block can be processed very easily in a CAD/CAM unit in this

crystalline intermediate stage. The typical and striking colour of

IPS e.max CAD ranges from whitish to blue and bluish-grey. This

shade is a result of the composition and the microstructure of the

glass-ceramic. The strength of the material in this processable intermediate phase is 130-150 MPa. After the IPS e.max CAD blocks are

milled, the restoration is crystallized in an Ivoclar Vivadent ceramic

furnace (e.g. Programat®P300, P500, P700). Unlike with some

other CAD/CAM ceramics, the approximately 20-31-minute, easyto-conduct crystallization process neither causes any major

shrinkage, nor are any complicated infiltration processes required.

The crystallization process at 840-850°C (1544-1562°F) results in a

transformation of the microstructure, during which lithium disilicate

crystals grow in a controlled manner. The densification of 0.2% is

accounted for in the CAD software and taken into account upon

milling.

The final physical properties, such as the strength of 360 MPa and

the corresponding optical properties, are achieved through the

transformation of the microstructure.

CTE (100-400°C) [10-6/K] 10.2

CTE (100-500°C) [10-6/K] 10.5

Flexural strength (biaxial) [MPa]* 360

Fracture toughness [MPa m

Modulus of elasticity [GPa] 95

Vickers hardness [MPa] 5800

Chem. solubility [µg/cm2]* 40

Crystallization temperature [°C/°F] 840–850/1544-1562

*according to ISO 6872

4

0.5

] 2.25

Page 5

Usage

Composition

Indications

– Veneers

– Inlays

– Onlays

– Partial crowns

– Crowns in the anterior and posterior region

– Implant superstructures for single-tooth restorations (anterior and

posterior region)

– Primary telescope crowns

Contraindications

– Full veneers on molar crowns

– Very deep sub gingival preparations

– Patients with substantially reduced residual dentition

– Bruxism

– Any other use not listed in the indications

Important processing restrictions

Failure to observe the following restrictions may compromise the

results achieved with IPS e.max CAD:

– The frameworks must not fall below the required minimum

thickness.

– Do not mill the blocks with non-compatible CAD/CAM systems.

– Crystallization must not be conducted in a ceramic furnace that

has not been approved and/or recommended.

– Crystallization must not be conducted in a ceramic furnace that

has no vacuum function.

– Crystallization must not be conducted in a ceramic furnace that

has not been calibrated.

– Crystallization must not be conducted in a high-temperature

furnace (e.g. Sintramat).

– Do not mix IPS e.max CAD Crystall./Glaze, Shades and Stains with

other dental ceramics (e.g. IPS e.max Ceram Glaze, Stains and

Essence).

– Do not layer with a veneering ceramic other than IPS e.max

Ceram.

– IPS e.max CAD Blocks

Components: SiO

Additional contents: Li2O, K2O, MgO, Al2O3, P2O5and other

oxides.

– IPS e.max CAD Crystall./Glaze, Shades and Stains

Components: oxides, glycols

– IPS e.max CAD Crystall./Glaze Spray

Components: oxides, propanol, propellant: isobutane

– IPS e.max CAD Crystall./Glaze Liquid

Components: butandiol

– IPS e.max CAD Crystall./Add-On

Components: oxides

– IPS e.max CAD Crystall./Add-On Liquid

components: water, propylene glycol, butandiol and chloride

– IPS Object Fix Putty / Flow

Components: oxides, water, thickening agent

– IPS Contrast Spray Labside

Components: pigment suspension in ethanol;

propellant: propane/butane mixture

– IPS Natural Die Material

Components: polymethacrylate, paraffin oil, SiO2and copolymer

– IPS Natural Die Material Separator

Components: wax dissolved in hexane

– IPS Ceramic Etching Gel

Components: hydrofluoric acid (approx. 5%)

2

Side effects

If the patient is known to be allergic to any of the components

of IPS e.max CAD, the material must not be used to fabricate

restorations.

Warning

– Hexane is highly flammable and detrimental to health. Avoid con-

tact of the material with skin and eyes. Do not inhale vapours and

keep away from sources of ignition.

– Do not inhale ceramic dust during finishing – use exhaust air

discharge and mouth protection.

– IPS Ceramic Etching Gel contains hydrofluoric acid. Contact with

skin, eyes and clothing must be prevented at all costs, since the

material is extremely toxic and corrosive. The etching gel is

intended for professional use only and must not be applied intraorally (inside the mouth).

– IPS Contrast Spray Labside must not be used intra-orally.

5

Page 6

Scientific Data

Further scientific data (e.g. strength, wear, biocompatibility) are contained in the “Scientific

Documentation IPS e.max CAD”. The Documentation also provides a set of studies that describe the

clinical performance of IPS e.max CAD.

This Scientific Documentation can be obtained from Ivoclar Vivadent.

For further information about all-ceramics and IPS e.max in general, please refer to the Ivoclar Vivadent

Reports No. 16 and No. 17.

Scien

n

tatio

en

m

cu

c Do

tifi

6

Page 7

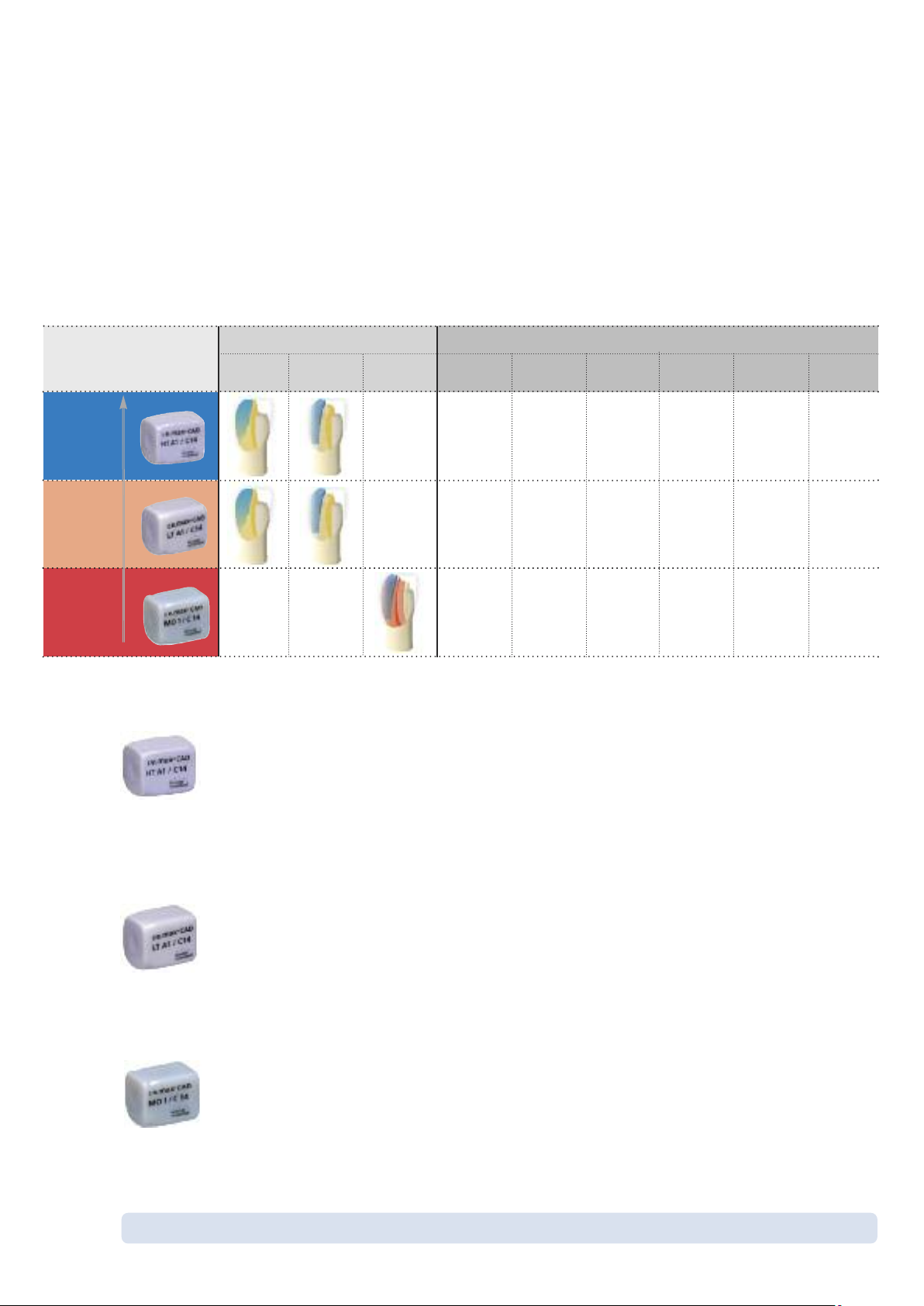

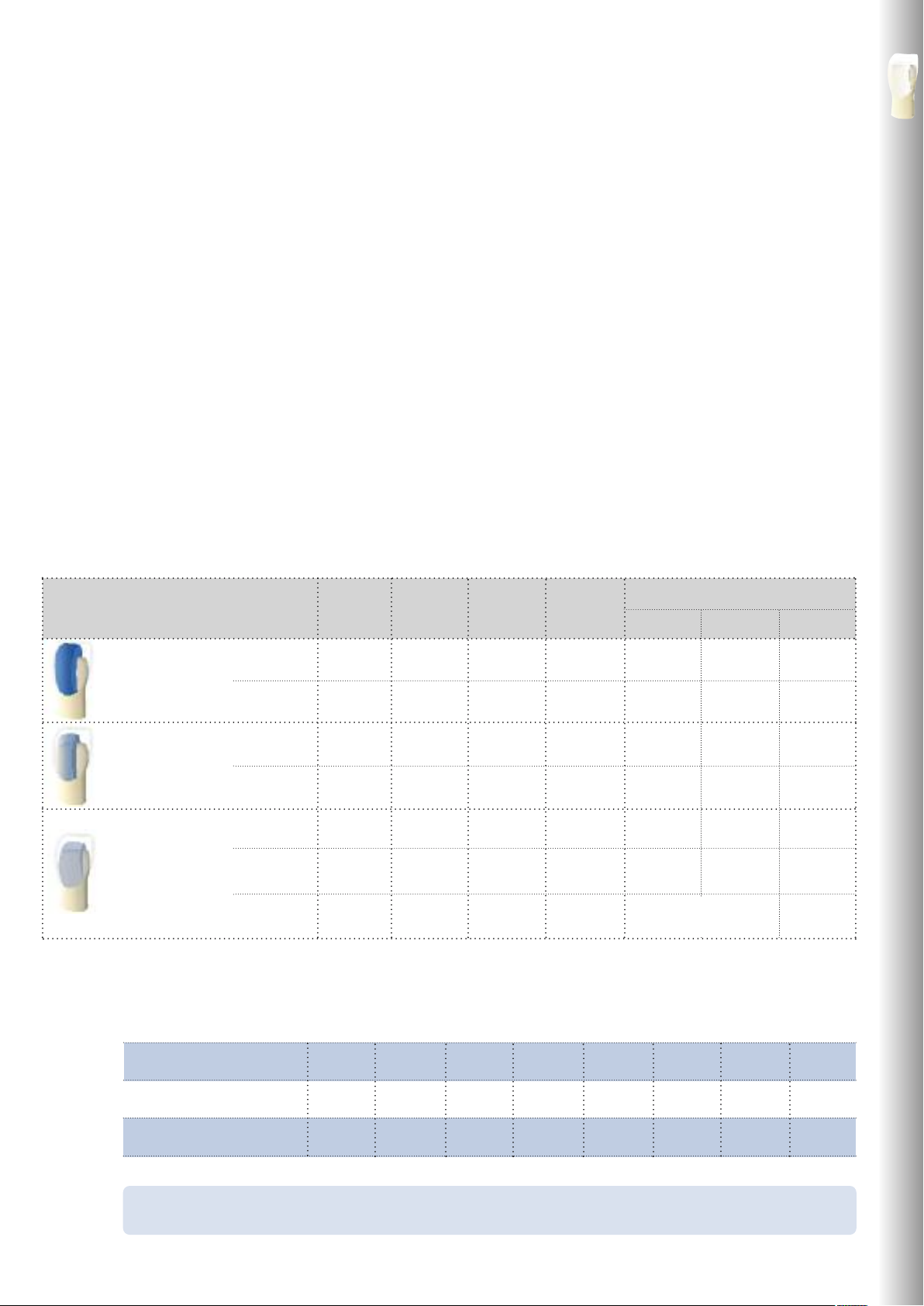

Block Concept

IPS e.max CAD is available in three levels of translucency (HT, LT, MO) and two sizes (I12, C14).

From a processing point of view, basically all restorations can be fabricated from any block.

For reasons of esthetics, however, the following processing techniques and indications are recommended

for the individual blocks (translucency levels):

Translucency Level

High

Translucency

Low

Translucency

Medium

Opacity

CR %

Processing Technique

Staining

echnique

T

Cut-Back

echnique

T

Layering

echnique

T

Inlays Onlays Veneers Partial

Indications

rowns

C

Anterior

C

IPS e.max CAD HT (High Translucency)

The HT Blocks are available in 16 A-D and 4 Bleach BL shades and 2 sizes (I 12, C 14). Given their

translucency, they are ideally suitable for the fabrication of small restorations (e.g. inlays, onlays) by

means of the staining technique, but they can also be used for the cut-back technique. Restorations

made of HT blocks exhibit a true-to-nature chameleon effect and exceptional adaption to the remaining

tooth structure. The stain and characterization firing, as well as glaze firing may be conducted with

either IPS e.max CAD Crystall./Shades and Stains, Glaze, or IPS e.max Ceram Shades, Essences and

Glaze.

rowns

Posterior

rowns

C

* up to the second premolar

*

IPS e.max CAD LT (Low Translucency)

The LT Blocks are available in 16 A-D and 4 Bleach BL shades and 2 sizes (I 12, C 14). Given their

translucency, they are suitable for the cut-back and also the staining technique. Restorations made of LT

blocks exhibit lifelike brightness value and chroma. This prevents the incorporated restorations from

graying. The cut-back is supplemented with IPS e.max Ceram Incisal and/or Impulse and characterized

using IPS e.max Ceram Essence and Shade.

IPS e.max CAD MO (Medium Opacity)

The MO Blocks are available in 5 group shades (MO 0 - MO 4) in one size (C 14). Given their opacity,

they are ideally suitable for the fabrication of frameworks on vital or slightly discoloured preparations.

The anatomical shape is individually layered using ISP e.max Ceram. Finally, the Stain/Glaze

firing with IPS e.max Ceram is conducted.

The entire IPS e.max delivery program can be found at www.ivoclarvivadent.com!

7

Page 8

CAD/CAM Partners

IPS e.max CAD can be processed with a system of the CAD/CAM partners. For questions regarding

the different systems, please contact the respective cooperation partners.

Information is available from:

Sirona Dental Systems GmbH

Fabrikstrasse 31

64625 Bensheim

Germany

E-mail: contact@sirona.de

www.sirona.com

inLab®is a registered trademark of Sirona Dental

ystems GmbH

S

Information is available from:

Institut Straumann AG

Peter Merian-Weg 12

4052 Basel

Switzerland

E-mail:info@straumann.com

www.straumann.com

Information is available from:

KaVo Dental GmbH

Bismarckring 39

88400 Biberach

Germany

E-mail:info@kavo.com

www.kavo-everest.com

®

verest

s a registered trademark of

E

i

KaVo Dental GmbH

8

Page 9

®

e.max

IPS

CAD

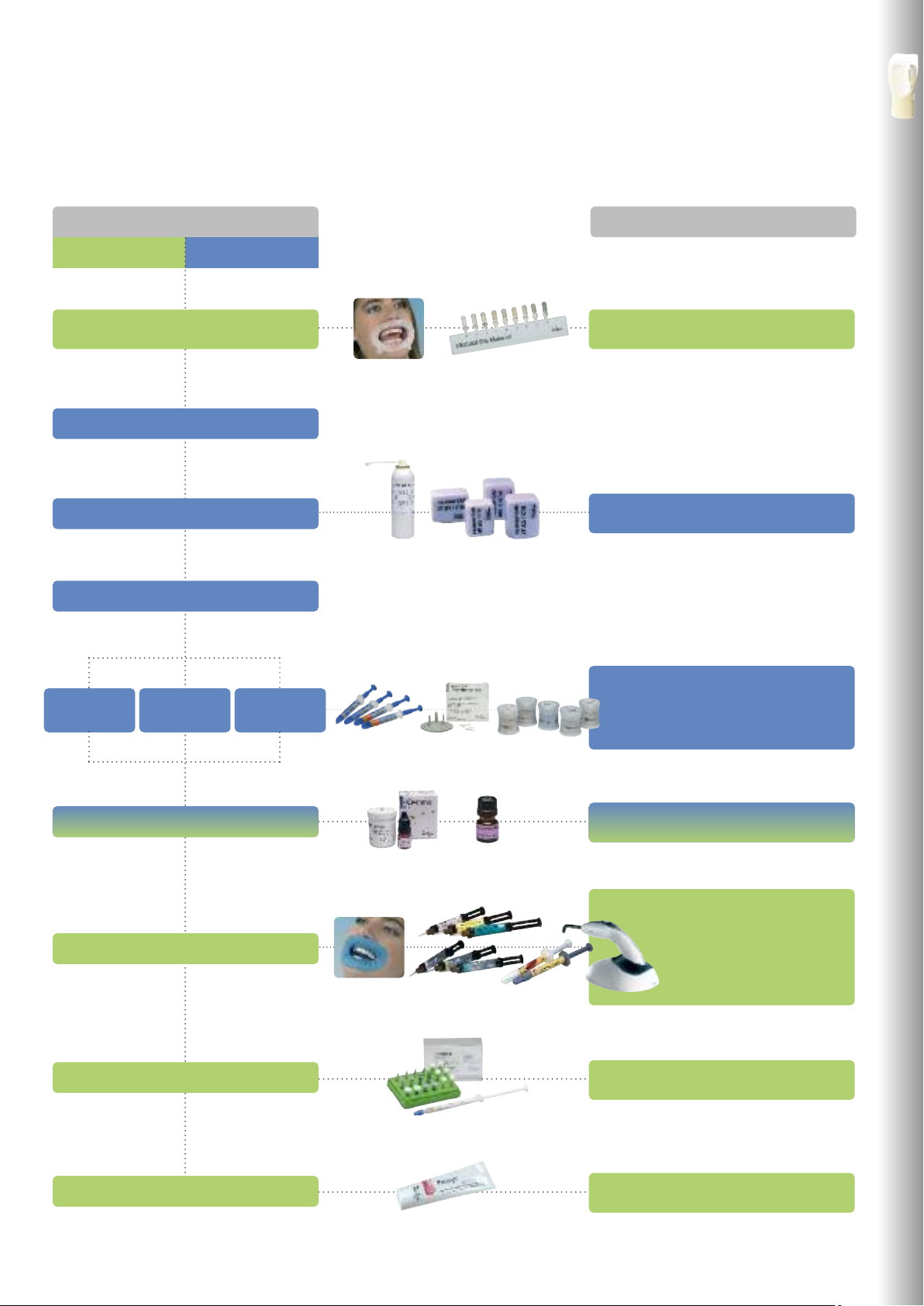

Clinical Working Steps, Fabrication Process

Working Step

Practice

Preparation, Shade Determination

Impression Taking

Model Fabrication

CAD/CAM Process

Finishing, Check on Model

Laboratory

Ivoclar Vivadent Products

OptraGate,

IPS Natural Die Material

Overview of the Clinical Working Steps, Fabrication Process

IPS Contrast Spray Labside

IPS e.max CAD

Staining

Technique

Preparation for Cementation

Check of Articulation/Occlusion

Cut-Back

Technique

Cementation

Layering

Technique

IPS e.max CAD Crystall./Shades, Stains

IPS e.max CAD Crystall./Glaze

IPS CAD Crystallization Tray and Pins

IPS e.max Ceram Layering Materials

IPS e.max Ceram Shades, Essences, Glaze

IPS Ceramic Etching Gel

Monobond Plus

OptraGate

OptraDam

Variolink II, Variolink Veneer

Multilink Automix

SpeedCEM

Vivaglass CEM

bluephase

OptraFine

Recall

Proxyt

The range of products on offer may vary from country to country

9

Page 10

Shade Determination — Tooth Shade, Shade of the Prepared

Tooth

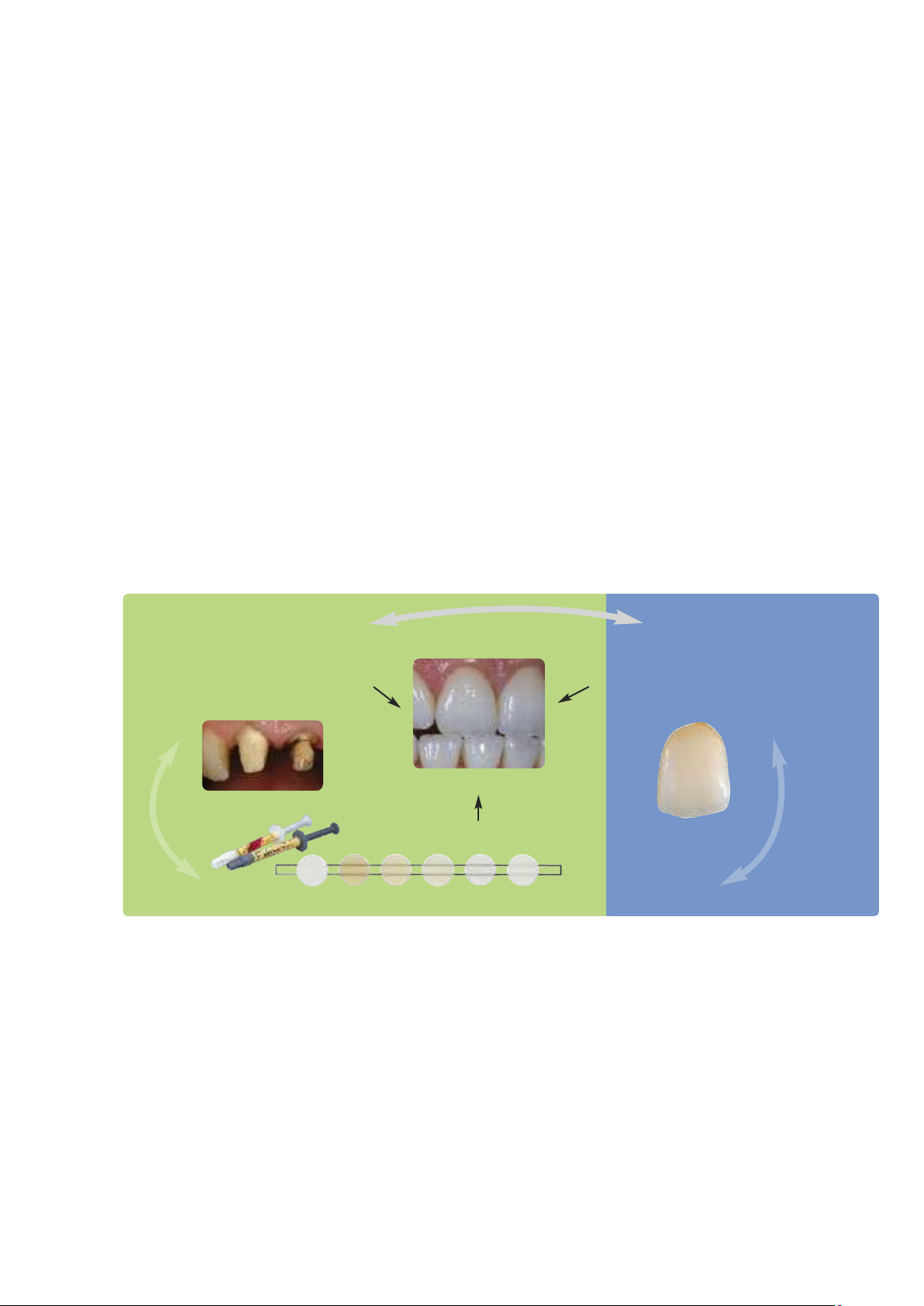

Optimum integration in the oral cavity of the patient is the prerequisite for a true-to-nature all-ceramic

restoration. To achieve this, the following guidelines and notes must be observed by both the dentist

and the laboratory.

The overall esthetic result of an all-ceramic restoration is influenced by the following factors:

• Shade of the preparation (natural preparation, core build-up, abutment, implant)

• Shade of the restoration (framework shade, veneer, characterization)

• Shade of the cementation material

The optical effect of the preparation shade must not be underestimated during the fabrication of highly

esthetic restorations. For that reason, the shade of the preparation should be determined together with

the desired tooth shade in order to select the suitable block. Especially with severely discoloured preparations or non-tooth-shaded build-ups, this is of utmost importance. Only if the dentist determines the

shade of the preparation and its subsequent transmission to the laboratory may the desired esthetic

result be achieved.

Preparation Shade

– Prepared natural tooth

– Core build-up

– Implant, abutment

Desired Tooth Shade

Cementation Material

Responsibility of the Dental Office Responsibility of the Laboratory

Restoration Shade

Framework

–

– Veneer

– Characterization

10

Page 11

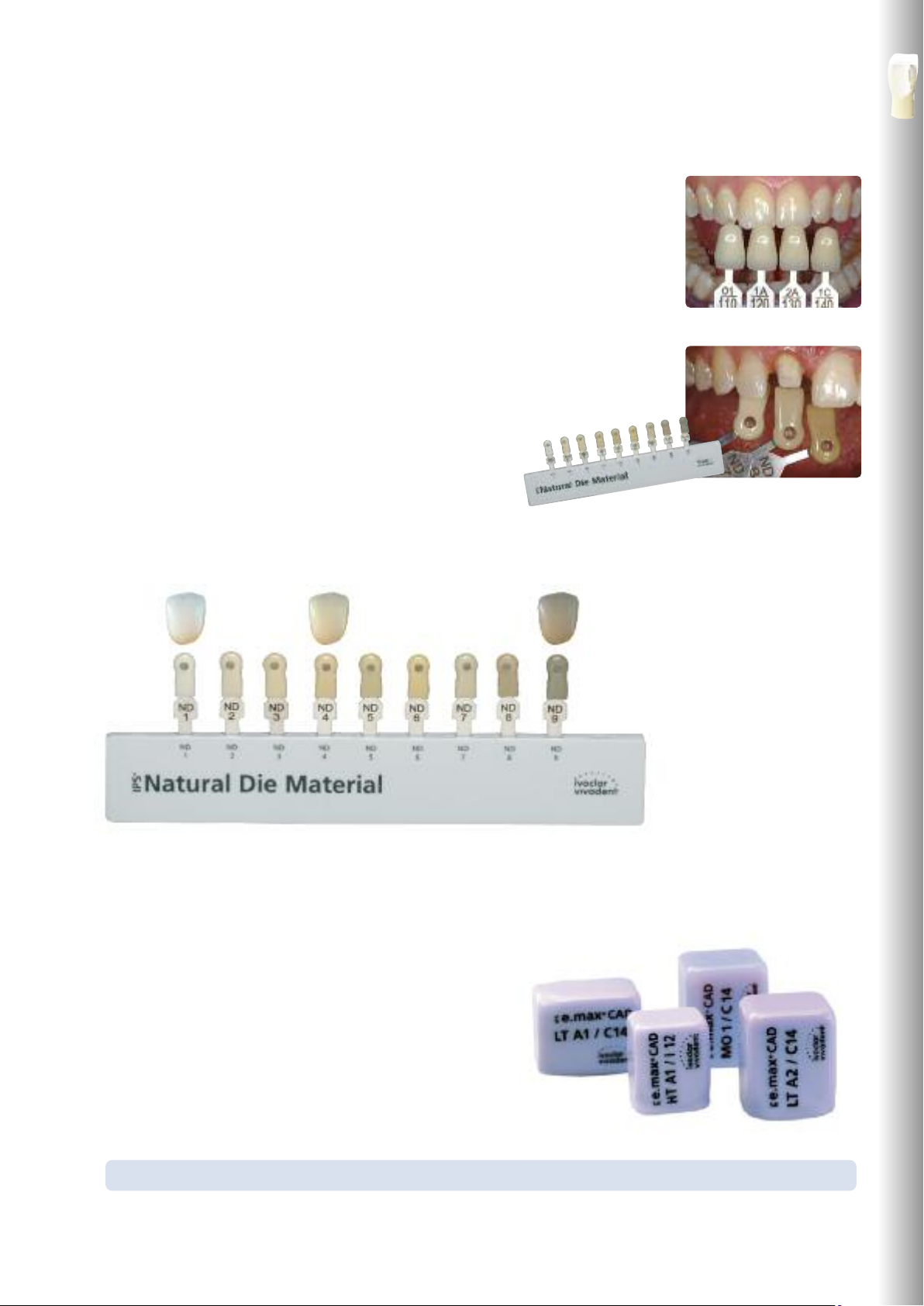

Shade determination of the natural tooth

After tooth cleaning, the tooth shade of the non-prepared tooth and/or the adjacent teeth is determined

with the help of a shade guide. Individual characteristics have to be considered when determining the

tooth shade. If a crown preparation is planned, for example, the cervical shade should also be determined. In order to achieve the best possible true-to-nature results, shade determination should be

carried out in daylight. Furthermore, the patient should not wear clothes of intense colours and/or

lipstick.

Die shade selection

In order to facilitate the reproduction of the desired tooth shade, the shade of the preparation is

determined with the help of the IPS Natural Die Material shade guide. This enables the technician to

fabricate a model die similar to the preparation of the patient, on the basis of which

the correct shade and brightness values of the all-ceramic restorations may be

selected.

Example of the preparation shade effect

Crown made of IPS e.max CAD HT B1 on different preparation shades.

Overview of the Clinical Working Steps, Fabrication Process

Which block should be used?

The suitable block is selected on the basis of the following criteria:

1. Desired tooth shade

2. Preparation shade or abutment shade

3. Type of restoration

4. Restoration thickness and/or preparation depth

5. Processing technique (staining, cut-back or layering technique)

6. Cementation material

Please refer to the table on page 62 for block selection

11

Page 12

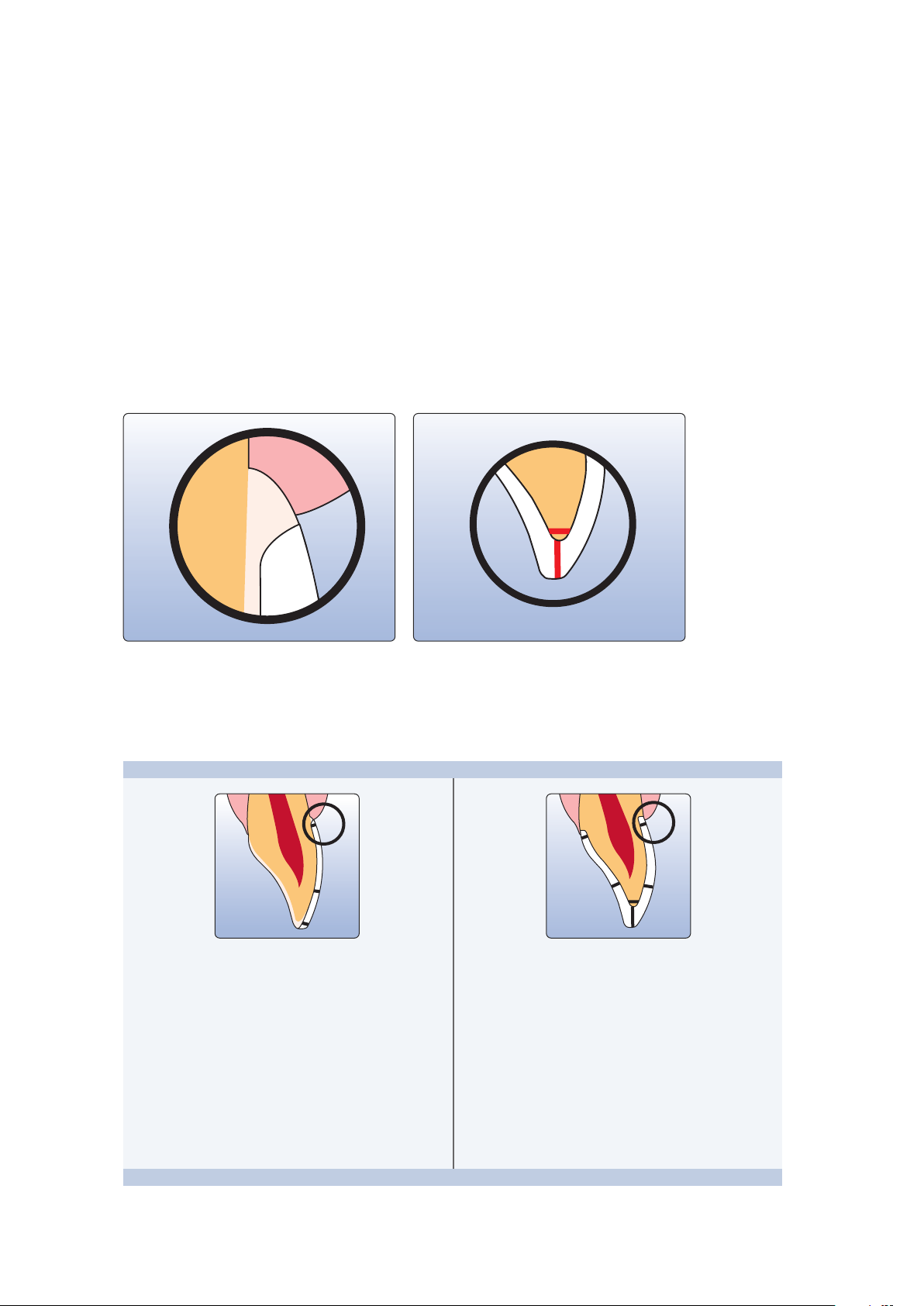

Preparation guidelines

1.0

1.5

0.6

0.6

0.7

1.0

1.0

1.5

1.2 1.2

1.0

Successful results can only be achieved with IPS e.max CAD if the guidelines and framework thicknesses are strictly

observed.

Basic preparation guidelines for all-ceramic restorations

– no angles or sharp edges

– shoulder preparation with rounded inner edges and/or chamfer preparation

– the indicated dimensions reflect the minimum thickness for IPS e.max CAD restorations

– the incisal edge of the preparation, particularly for anterior teeth, should be at least 1.0 mm (milling tool geometry) in

order to permit optimum milling during CAD/CAM processing.

Veneer Anterior crown

– If possible, the preparation should be located in the

enamel.

– The incisal preparation margins should not be located

in the area of static or dynamic enamel contact.

– Reduction in the cervical and/or labial area by 0.6 mm,

and the incisal edge by 0.7 mm.

– Reduce the anatomical shape and observe the

stipulated minimum thickness. Prepare a shoulder with

rounded inner edges or a deep chamfer. Width of the

shoulder/chamfer at least 1.0 mm.

– Reduce the edge by approx. 1.5 mm.

– Reduce the labial and lingual area by approx. 1.2 mm.

– For conventional and/or self-adhesive cementation,

the preparation must demonstrate retentive surfaces

12

Page 13

1.5

1.0

1.5

1.5

1.5

1.5

1.5

1.0

1.0

1.5

1.5

1.5

6°

1.0

1.0

6°

1

00-120°

6°

1.0

1.0

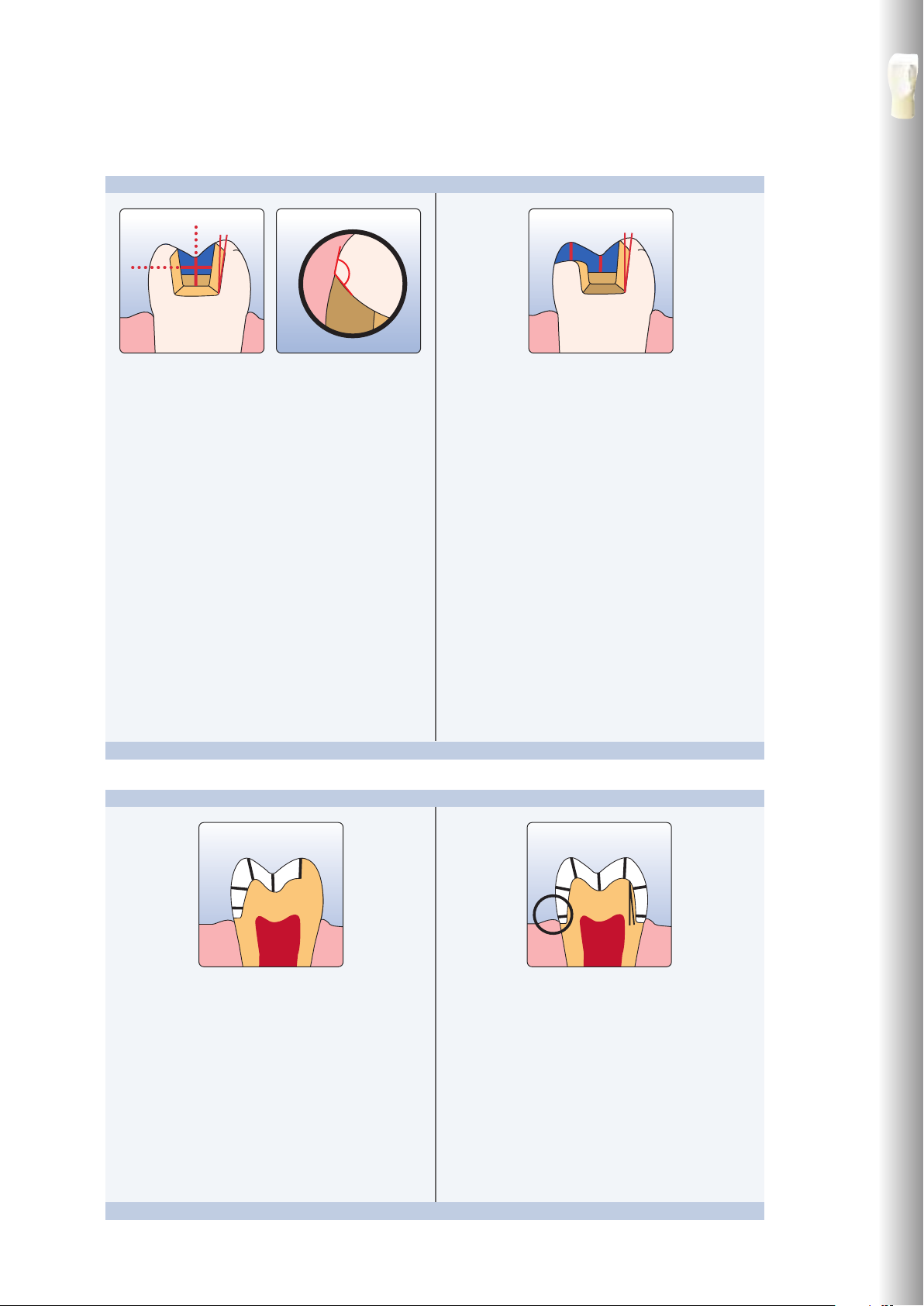

Inlay Onlay

– Static and dynamic antagonist contacts must be taken

into consideration.

– The preparation margins must not be located on

centric antagonist contacts.

– A preparation depth of at least 1.0 mm and an

isthmus width of at least 1.0 mm must be observed in

the fissure area.

– Prepare the proximal box with slightly diverging walls

and observe an angle of 100°-120° between the

proximal cavity walls and the prospective proximal

inlay surfaces. For inlays with pronounced convex

cavity walls without adequate support by the proximal

shoulder, marginal ridge contacts should be avoided.

– Round out internal edges in order to prevent stress

concentration within the ceramic material.

– Do not prepare slice-cuts or feather edges.

Partial crown Posterior crown

– Static and dynamic antagonist contacts must be taken

into consideration.

– The preparation margins must not be located on

centric antagonist contacts.

– A preparation depth of at least 1.0 mm and an

isthmus width of at least 1.0 mm must be observed

in the fissure area.

– Prepare the proximal box with slightly diverging walls

and observe an angle of 100°-120° between the

proximal cavity walls and the prospective proximal

onlay surfaces. For onlays with pronounced convex

cavity walls without adequate support by the proximal

shoulder, marginal ridge contacts should be avoided.

– Round out internal edges in order to prevent stress

concentration within the ceramic material.

– Do not prepare slice-cuts or feather edges.

– Provide at least 1.0 mm of reduction in the cusp areas.

Overview of the Clinical Working Steps, Fabrication Process

– Static and dynamic antagonist contacts must be taken

into consideration.

– The preparation margins must not be located on

centric antagonist contacts.

– Provide at least 1.5 mm of reduction in the cusp

areas.

– Prepare a circular shoulder with rounded inner edges

or a deep chamfer. Width of the shoulder/chamfer

should be at least 1.0 mm.

– Reduce the anatomical shape and observe the

stipulated minimum thickness. Prepare a circular

shoulder with rounded inner edges or a deep

chamfer. Width of the shoulder/chamfer at least

1.0 mm.

– Reduce the incisal crown third by approx. 1.5 mm.

– Reduce the buccal or lingual area by approx. 1.5 mm.

– For conventional and/or self-adhesive cementation,

the preparation must demonstrate retentive surfaces

13

Page 14

Model and Tooth Preparation

Fabricate a working model with removable segments as usual. The directions of the manufacturers of the

different CAD/CAM systems regarding the plaster to be used must be observed.

Important for die preparation:

– Check the radius of the incisal/occlusal edge on the prepared die (maxilla and mandible).

– The prepared incisal edge should be at least as thick as the diameter of the bur used in the cavity

during the CAD/CAM process.

– If the incisal edge of the prepared die is thinner than the diameter of the bur, the incisal edge has to

be blocked out accordingly.

– Also observe the information provided by the manufacturer of the CAD/CAM system regarding the die

geometry.

Inlay/onlay Veneer and anterior crown

Posterior crown

Anterior crown on a ZrO2abutment

(Straumann®Anatomic IPS e.max®Abutment)

14

Page 15

Layer thicknesses

The restoration design is key to the success of durable all-ceramic restorations. The more attention is given to the design,

the better the final results and the clinical success will turn out to be. The following basic guidelines have to be observed:

– IPS e.max CAD is the high-strength component of your restoration and must, therefore, always make up at

least 50% of the total layer thickness of the restoration.

– In large preparations and for veneered or partially veneered restorations, the excess available space must be

compensated by the corresponding dimensions of the high-strength IPS e.max CAD component and not by

the IPS e.max Ceram layering material.

– The design of the restoration generated by the software has to be individually adjusted, if necessary, in accordance with

the clinical situation using the design tools.

– The areas that support and reinforce the shape and cusps of the restoration are constructed with the integrated design

tools of the different types of software used.

– In partially veneered restorations, the transition between the layering material and IPS e.max CAD must not be located

in the area of the functional contact points.

The following minimum thicknesses have to be observed to match the tooth shade of the shade guide and to

fulfil the requirements given from the preparation guidelines:

Overview of the Clinical Working Steps, Fabrication Process

Veneer Inlay Onlay Partial

crown

Anterior Premolar Molar

Minimum thickness

IPS e.max CAD

Staining technique

Minimum thickness

IPS e.max CAD

circular

incisal/occlusal

circular

0.6

0.7

0.6

1.0

isthmus width

1.0

isthmus width

–

1.0

1.0

1.5

1.5

–

1.5

1.2

1.5

1.2

Cut-back technique

(after reduction)

labial/occlusal

circular

0.4

–

–

–

–

–

1.3

0.4

–

0.8

Minimum thickness

IPS e.max CAD

incisal/occlusal

–

–

–

–

0.8

Layering technique

design type

–

–

–

–

supporting the tooth shape

For the cut-back and layering techniques the relationship of the layer thickness between IPS e.max CAD (framework)

and IPS e.max Ceram (veneer) must also be observed:

Crowns

1.5

1.5

1.5

1.0

0.8

1.0

1.5

1.5

1.5

1.3

–

–

–

dimensions in mm

Total layer thickness of the

restoration in mm

Minimum layer thickness of the

framework ceramic mm

Maximum layer thickness of the

veneer with IPS e.max Ceram in mm

0.8

0.4

0.4

1.0

0.5

0.5

1.2

0.6

0.6

1.5

0.8

0.7

1.8

1.0

0.8

2.0

1.1

0.9

2.5

1.3

1.2

3.0

1.6

1.4

Failure to observe the stipulated framework design criteria and minimum thicknesses may result in clinical failures, such as

cracks, delamination, and fracture of the restoration.

15

Page 16

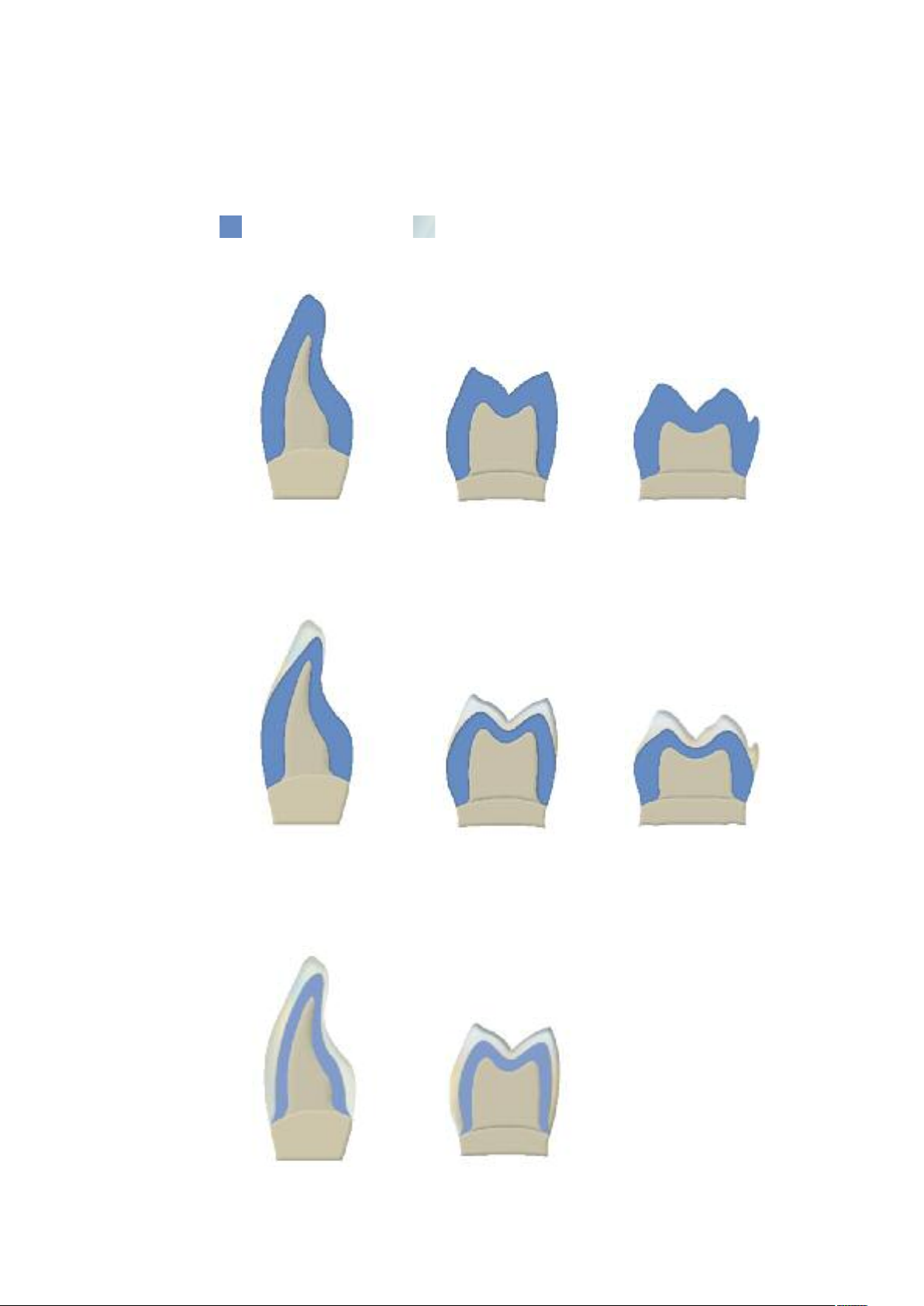

Design guidelines for the restoration

IPS e.max CAD Veneering with IPS e.max Ceram

Staining Technique

– fully anatomical design

nterior tooth Premolar

A

Cut-back Technique

– partially reduced, cusp-supporting design

Anterior tooth Premolar

Layering Technique

– cusp-supporting design

olar

M

Molar

Anterior tooth Premolar

16

Page 17

CAD/CAM processing

As densification of about 0.2% takes place in IPS e.max CAD during the crystallization process. This factor has been taken

into account in the software. Consequently, the milled IPS e.max CAD restorations demonstrate precision of fit after

crystallization. The fabrication steps are described in the directions for use and user manuals of the different CAD/CAM

systems. The instructions of the manufacturers must be followed:

Information is available from:

Sirona Dental Systems GmbH

Fabrikstrasse 31

64625 Bensheim

Germany

E-mail: contact@sirona.de

www.sirona.com

inLab®is a registered trademark of Sirona Dental

ystems GmbH

S

Information is available from:

Institut Straumann AG

Peter Merian-Weg 12

4052 Basel

Switzerland

E-mail:info@straumann.com

www.straumann.com

Information is available from:

KaVo Dental GmbH

Bismarckring 39

88400 Biberach

Germany

E-mail:info@kavo.com

www.kavo-everest.com

®

verest

s a registered trademark of

E

i

KaVo Dental GmbH

Overview of the Clinical Working Steps, Fabrication Process

17

Page 18

®

e.max

IPS

CAD –

Staining technique

In the staining technique, the milled full-contour restorations are completed by applying stains and glaze materials.

Individualized characterizations and glaze can be applied either before or after Crystallization firing. Coordinated materials

are available for the different procedures.

In this way, the use of translucent IPS e.max CAD blocks permit the fabrication of very esthetic restorations on only

slightly or non-discoloured preparations with minimum effort.

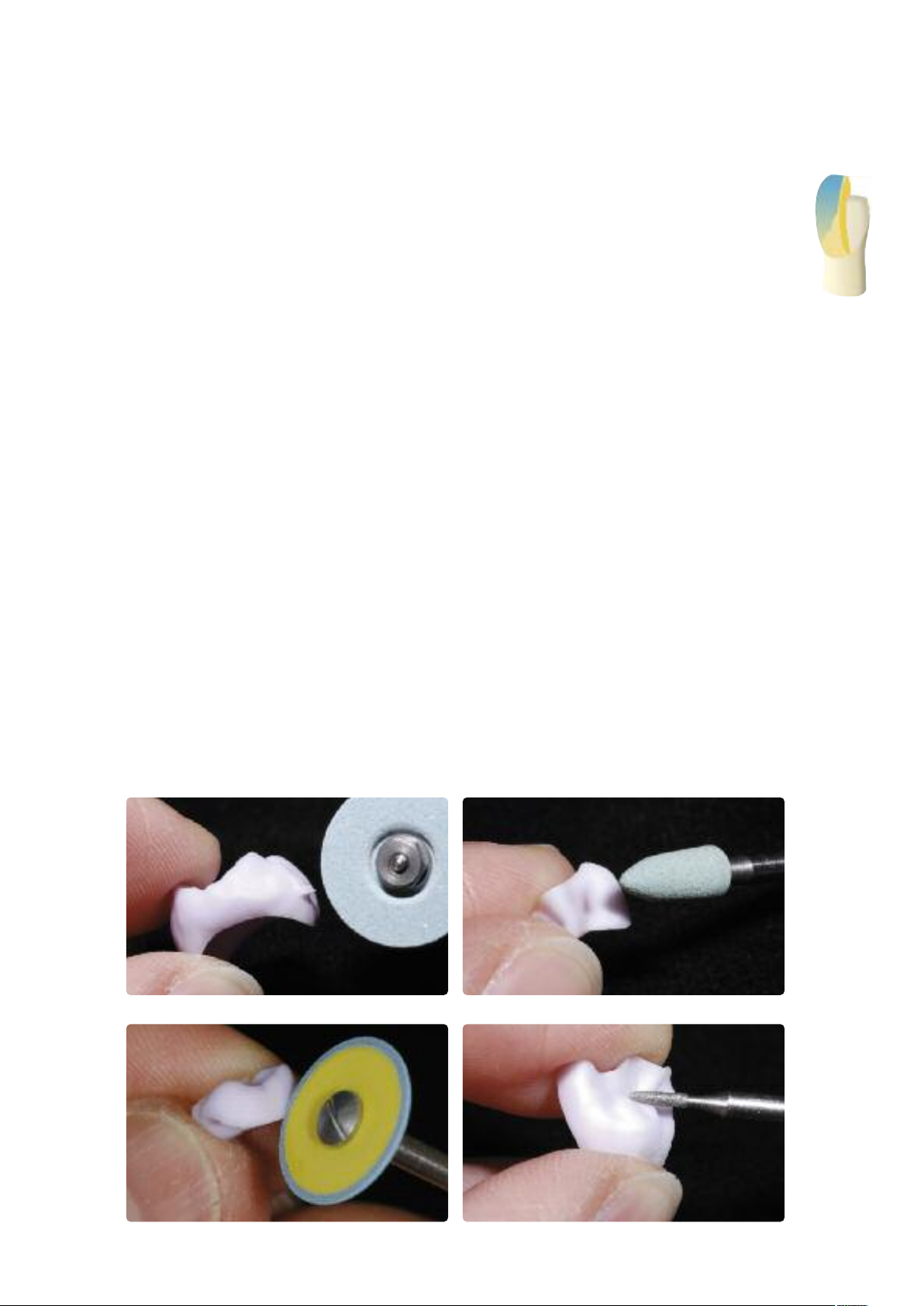

Finishing

It is of critical importance to use the correct grinding instruments for finishing and adjusting IPS e.max CAD. If unsuitable

grinding instruments are used, chipping of the edges and local overheating may occur (please observe the Ivoclar Vivadent

Flow Chart ”Recommended grinding tools for PS e.max glass-ceramics”.

Observe the following procedure for finishing IPS e.max CAD restorations:

– Carry out adjustments by grinding of IPS e.max CAD restorations while they are still in their pre-crystallized (blue) state,

if possible.

– Only use suitable grinding instruments, low rpms and light pressure to prevent delamination and chipping at the edges

in particular.

– Overheating of the glass-ceramic must be avoided.

– The restorations are tried in on the dies and carefully finished.

– Check proximal and occlusal contact points.

– Surface-grind the entire occlusal surface with a fine diamond to smooth out the surface structure created by the

CAD/CAM procedure.

– Make sure that the minimum thicknesses are maintained even after the minor adjustments.

– Design surface textures.

– Always clean the restoration with ultrasound in a water bath or blast with the steam jet before crystallization.

– Make sure to thoroughly clean the restoration before further processing and to remove any residue of the milling

additive of the CAD/CAM milling unit. Residue of the milling additive remaining on the surface may result in bonding

problems and discolouration.

– Do not blast the restorations with Al2O3or glass polishing beads.

Finish margins with suitable polishers

Finish the restoration surface with suitable grinding instruments

Surface-grind the outer surface, particularly functional areas of the restoration with a fine

diamond to smooth out the surface structure created by the CAD/CAM process

18

Page 19

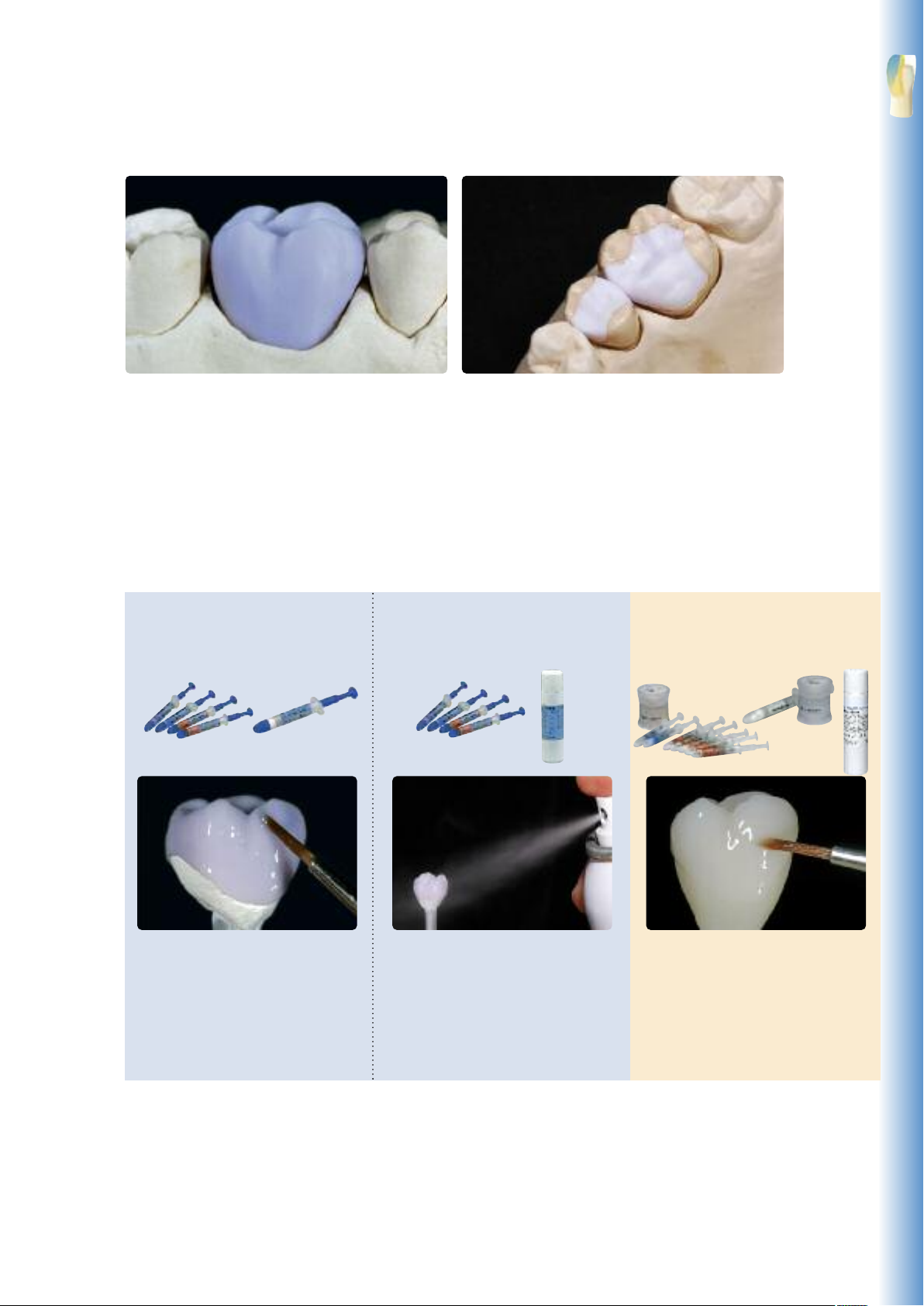

IPS e.max CAD LT crown on the model IPS e.max CAD HT inlay/onlay on the model.

Crystallization and Stain/Glaze Firing

Basically, fully anatomically milled restorations made of IPS e.max CAD can be completed in three different ways.

Staining Technique

Option A:

Crystallization and Glaze firing with

IPS e.max CAD Crystall./Glaze paste

Characterization of the non-crystallized,

blue restoration permits quick comple-

tion of the restoration with the

subsequent combination firing

(Crystallization/Glaze HT/LT).

Option B:

Crystallization and Stain/Glaze firing

with IPS e.max CAD Crystall./Glaze spray

Characterization of the non-crystallized,

blue restoration permits quick comple-

tion of the restoration with the

subsequent combination firing

(Crystallization/Glaze HT/LT).

Option C:

Crystallization and separate Stain/Glaze

firing with IPS e.max Ceram Shades,

Essences and Glaze

Characterization of the tooth-coloured

restoration after crystallization.

19

Page 20

Option A:

Crystallization and Glaze firing in one step with IPS e.max CAD Crystall./Glaze paste

In this processing technique, crystallization and Glaze firing are performed in one step.

Characterizations are applied using IPS e.max CAD Crystall./Shades and Stains.

Preparation for Crystallization and Glaze firing

Depending on the type of restoration, they have to be placed on an IPS e.max CAD Crystallization Pin

before the Stains and Glaze are applied. Smaller restorations (veneers, inlays, onlays) do not need to

be entirely supported.

Either IPS Object Fix Putty or Flow are recommended to secure the restoration on the pin. The

Putty demonstrates a denser consistency and thus higher stability. Given its lower viscosity, Flow is

suitable for smaller restorations.

with

IPS e.max CAD Crystallization Pin

Partial Crown, Anterior Crown,

Posterior Crown

Use either IPS Object Fix Putty or Flow to

secure the restoration on the pin.

without

IPS e.max CAD Crystallization Pin

Veneer,

Inlay, Onlay

To apply Glaze, Shades and Stains, secure the

restoration

– with an OptraStick,

– with diamond tweezers, or

– directly on the die

Note: the restoration must be placed on a

Crystallization pin with IPS Object Fix Putty or

Flow before firing.

Observe the following procedure for partial crowns and crowns:

– Select the largest possible IPS e.max CAD Crystallization Pin (S, M, L) that best “fills” the inside of the

restoration, but does not come into contact with the circular crown walls.

– Fill the inside of the restoration with IPS Object Fix Putty or Flow up to the restoration margin.

Immediately reseal the IPS Object Fix Putty/Flow syringe after extruding the material. Once

removed from the aluminium bag, the syringe is ideally stored in a resealable plastic bag or a

container with a humid atmosphere.

– Press the selected IPS e.max CAD Crystallization Pin deeply into the IPS Object Fix Putty or Flow

material so that it is adequately secured.

– Smooth out displaced auxiliary firing paste using a plastic spatula so that the pin is securely in place

and the restoration margins are optimally supported.

– Prevent contamination of the outer restoration surface. Clean off contamination with a brush

dampened with water and dry.

20

Page 21

Staining Technique

Select the largest possible IPS e.max CAD Crystallization PinIPS Object Fix Flow and IPS Object Fix Putty

ill the inside of the crown with IPS Object Fix Putty or Flow.

F

Smooth out displaced IPS Object Fix Putty or Flow with a plastic spatula from the margin

towards the spport pin so that the pin is secured in the paste and the crown wall is exactly

supported

Press the selected IPS e.max CAD Crystallization Pin deeply into the IPS Object Fix Putty or

Clean off any possible residue adhering to the outer surface of the crown with a brush

dampened with water and dry

low material

F

21

Page 22

Combination firing (Crystallization and Stain/Glaze firing in one step)

Before crystallization, IPS e.max CAD Crystall./Glaze, Shades and Stains are applied.

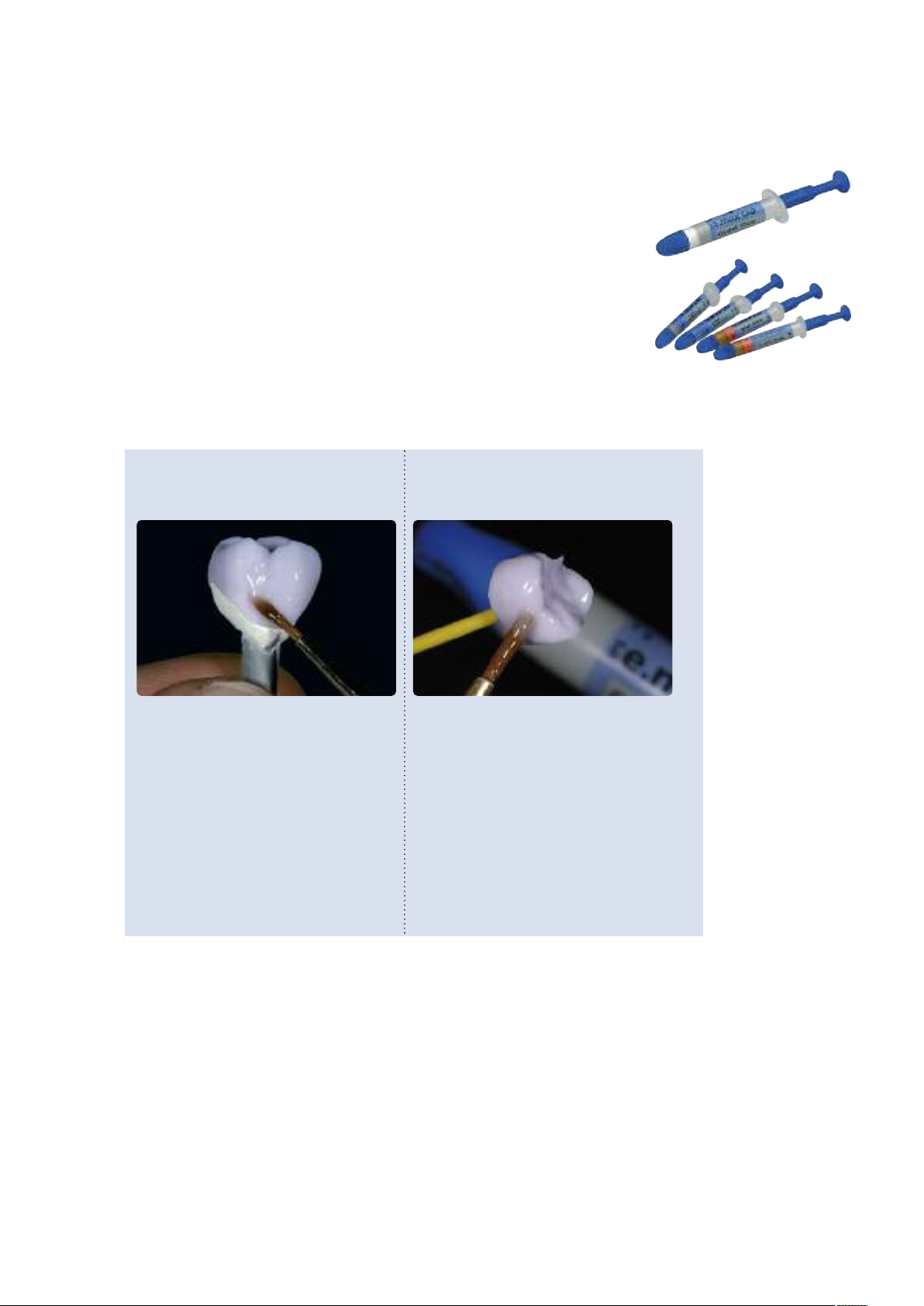

– IPS e.max CAD Crystall./Shades are ready-to-use “Dentin and Incisal” stains in syringes

– IPS e.max CAD Crystall./Stains are ready-to-use intensive stains in syringes

– IPS e.max CAD Crystall./Glaze Paste is a ready-to-use glazing paste

Shade

Shade

Incisal 2

Incisal 1

IPS e.max CAD Crystall./Shades IPS e.max CAD Crystall./Stains

Shade 0 Shade 1 Shade 2 Shade 3 Shade 4

cream sunset copper olive khaki mahogany

hite

w

Please observe the following procedure:

– Hold the restoration by the firing pin and apply IPS e.max CAD Crystall./Glaze Paste evenly on the entire restoration

using a brush.

– Hold inlays, onlays or veneers with an OptraStick or diamond tweezers when applying IPS e.max CAD Crystall./Glaze

Paste, or directly apply paste while the restoration is seated on the die.

– If a slight thinning is desired, the glaze may also be mixed with a little IPS e.max CAD Crystall./Glaze Liquid.

– Avoid applying too thick a glaze layer. Avoid pooling, especially on the occlusal surface.

– Too thin a glaze layer may lead to an unsatisfactory gloss.

– If characterizations are desired, the restoration can be individualized using IPS e.max CAD Crystall./Shades and Stains

before Crystallization firing.

– Extrude Shades and Stains from the syringe and mix thoroughly.

– The Shades and Stains may be slightly thinned using IPS e.max CAD Crystall./Glaze Liquid. However, the consistency

should still remain pasty.

– Apply mixed Shades and Stains directly into the unfired glaze layer using a fine brush.

Procedure for partial crowns,

Procedure for veneers, inlays, onlays

anterior crowns, posterior crowns

Hold the restoration by the firing pin and apply IPS e.max CAD

Crystall./Glaze Paste evenly on the blue restoration

Apply the mixed IPS e.max CAD Crystall./Shades and Stains directly into the

unfired IPS e.max CAD Crystall./Glaze Paste

Secure inlays, onlays on an OptraStick for the application of

IPS e.max CAD Crystall./Glaze Paste, Shades and Stains

22

Page 23

Example: Individualized characterizations are applied using IPS e.max CAD Crystall./Shades and Stains on the

blue restoration; shade A2

Buccal view

Slight characterizations on the buccal surfaces using IPS e.max CAD Crystall./Shades and

Stains

Occlusal characterizations using IPS e.max CAD Crystall./Shades and Stains

•••• Cusp inclinations: Shade Incisal I1

•••• Fissures: Stains mahogany

•••• Cusps, marginal ridges: Stains white/cream

•••• Reinforcing the chroma: Stains sunset/copper

Example of IPS e.max CAD Crystall./Shades and Stains applied too thickly

Occlusal view

Staining Technique

23

Too thick a layer of IPS e.max CAD Crystall./Shades Too thick a layer or IPS e.max CAD Crystall./Shades and Stains

Place the restoration in the center of the IPS e.max CAD Crystallization Tray and fire using

the stipulated parameters

23

Page 24

After glazing and staining, the Combination firing (crystallization/glaze) is conducted in a compatible ceramic furnace

(e.g. Programat®P700). When placing the objects into the furnace and setting the firing parameters, observe the following

points:

– Place the restoration including the pin into the center of the IPS e.max CAD Crystallization Tray.

– Place veneers, inlays and onlays directly on the IPS e.max CAD Crystallization Pin with a small amount of IPS Object Fix

Flow.

– A maximum of 6 restorations can be positioned on the firing tray and crystallized using the Combination firing with

IPS e.max CAD Crystall./Glaze Paste.

– Conduct the Combination firing (Speed Crystallization/Glaze LT/HT) using the stipulated parameters.

Firing parameters Crystallization/Glaze LT/HT

Furnace

300

P

P500

P700

Stand-by

emperature

t

B [°C/°F]

403/757

Closing time

S [min]

6:00

Heating rate

1

t

[°C/°F/min]

90/162

Firing

emperature

t

1

T

[°C/°F]

820/1508

Holding time

1

H

[min]

0:10

Heating rate

2

t

[°C/°F/min]

30/54

Firing

emperature

t

2

T

[°C/°F]

840/1544

Holding time

2

H

[min]

7:00

Vacuum 1

1

°C/°F]

1

[

2

1

[°C/°F]

550/820

022/1508

1

Vacuum 2

1

°C/°F]

2

[

2

2

[°C/°F]

820/840

508/1540

1

Please note:

– Crystallization/Glaze HT/LT can only be used for IPS e.max CAD HT and LT.

– IPS e.max Ceram materials (Essences, Shades etc.) must not be used in combination with IPS e.max CAD

Crystall./Glaze, Shades and Stains.

Long-term

ooling

c

L [°C/°F]

700/1292

Cooling rate

t [°C/°F/min]

0

Note

Cooling after firing

– Remove IPS e.max CAD objects from the furnace after completion of the firing cycle (wait for the acoustic

signal of the furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

– Do not blast or quench the objects.

If additional characterizations or adjustments are required after crystallization, a corrective firing using

IPS e.max CAD Crystall./Shades, Stains and Glaze can be conducted. Conduct the corrective firing also on the

IPS e.max CAD Crystallization Tray.

For minor shape adjustments (e.g. proximal or occlusal contact points), IPS e.max CAD Crystall./Add-On is

available . The adjustments may be made with both Crystallization/Glaze and Corrective firing.

The detailed procedure is described on page 30.

Firing parameters for the Corrective firing

Furnace

P300

P500

P700

Stand-by

temperature

B [°C/°F]

403/757

Closing time

S [min]

6:00

Heating rate

t1 [°C/°F/min]

90/162

Firing

temperature

T1 [°C/°F]

820/1508

Holding time

H1 [min]

0:10

Heating rate

t2 [°C/°F/min]

30/54

Firing

temperature

T2 [°C/°F]

840/1544

Holding time

H2 [min]

3:00

Vacuum 1

11 [°C/°F]

12 [°C/°F]

550/820

1022/1508

Vacuum 2

21 [°C/°F]

22 [°C/°F]

820/840

1508/1540

Long-term

cooling

L [°C/°F]

700/1292

Cooling rate

t [°C/°F/min]

0

24

Page 25

Option B:

Crystallization and Stain/Glaze firing in one step with IPS e.max CAD Crystall./Glaze Spray

IPS e.max CAD Crystall./Glaze Spray is used instead of IPS e.max CAD Crystall./Glaze Paste. The spray

should only be used if IPS Object Fix auxiliary firing paste is adapted up to the margins.

Preparation for Crystallization and Glaze firing

If IPS e.max CAD Crystall./Glaze Spray is used, all the restorations, irrespective of their geometry, have to

be placed on the IPS e.max CAD Crystallization Pin with the help of IPS Object Fix Putty or Flow.

Staining Technique

with

IPS e.max CAD Crystallization Pin

IPS e.max CAD Crystallization Pin

without

Veneers, inlays, onlays,

partial crowns, anterior crowns,

posterior crowns

Exactly adapt IPS Object Fix Putty or Flow to the

restoration margin so that the Glaze Spray is

prevented from reaching the inner aspects.

Procedure:

– Secure the restoration on a suitable IPS e.max CAD Crystallization Pin as described in Option A.

– Make sure that the auxiliary firing paste (IPS Object Fix Putty or Flow) is flush with the restoration

margin. If veneers, inlays, and onlays are glazed with Glaze Spray, they also have to be enclosed in

firing paste exactly to the restoration margin.

Combination firing (Crystallization and Stain/Glaze firing in one step)

– Before starting the characterization and glazing procedure, make sure the outside of the restoration is

free of auxiliary firing paste.

– If characterizations are desired, the restoration can be individualized using IPS e.max CAD

Crystall./Shades and IPS e.max CAD Crystall./Stains before Crystallization firing.

– Extrude ready-to-use Shades and Stains from the syringe and mix thoroughly.

– The Shades and Stains may be slightly thinned using IPS e.max CAD Crystall./Glaze Liquid. However,

the consistency should still remain pasty.

– Apply mixed Shades and Stains directly on the blue restoration using a brush.

Extrude IPS e.max CAD Crystall./Shades and Stains from the syringe and mix thoroughly. If

required, thin with IPS e.max CAD Crystall./Glaze Liquid

Apply mixed Shades and Stains directly on the blue restoration

25

Page 26

Please observe the following procedure for the application of the IPS e.max CAD Crystall./Glaze Spray:

– Hold the restoration by the IPS e.max CAD Crystallization Pin. Do not spray the restoration while it is placed on the

IPS e.max CAD Crystallization Tray, as it would also be coated with glaze.

– Shake the spray can well immediately before use until the mixing ball in the container is moving freely

(approximately 20 seconds). If the spray is not sufficiently shaken, mainly the propellant is discharged

with a spraying burst. This, in turn, results in insufficient application of the glazing powder.

– Observe a distance of approx. 10 cm between the nozzle and the surface to be sprayed.

– Hold the spray can as upright as possible during spraying.

– Spray the restoration from all sides with short bursts while simultaneously rotating the restoration so that

an even, covering layer is created. Shake the spray can again between individual bursts.

– Spray the restoration a second time from all sides with short bursts while simultaneously rotating the

restoration so that an even, covering layer is created. Shake the spray can again between individual

bursts.

– Wait briefly until the glaze layer is dry and has assumed a whitish colour.

– Areas that do not show an even layer have to be sprayed again.

– Place the restoration in the center of the IPS e.max CAD Crystallization Tray.

– Conduct the Combination firing (Crystallization/Glaze LT/HT) using the stipulated parameters.

Hold the restoration by the IPS e.max CAD Crystallization Pin. Spray the IPS e.max CAD Crystall./Glaze Spray directly on the unfired

Shake the spray can again between individual bursts. Spray an even layer onto the restoration.

IPS e.max CAD Crystall./Shades and Stains. Spray the restoration from all sides

while simultaneously rotating it.

26

Page 27

Staining Technique

Allow the IPS e.max CAD Crystall./Glaze Spray to dry briefly until a whitish layer has formed.

If required, spray the restoration again to achieve an even Glaze Spray layer on the IPS e.max

AD restoration.

C

Place the restoration in the center of the IPS e.max CAD Crystallization Tray and fire using the

stipulated parameters.

Firing parameters Crystallization / Glaze LT/HT

Furnace

300

P

P500

P700

Stand-by

temperature

B [°C/°F]

403/757

Closing time

S [min]

6:00

Heating rate

1

t

[°C/°F/min]

90/162

Firing

temperature

1

T

[°C/°F]

820/1508

Holding time

1

H

[min]

0:10

Heating rate

2

t

[°C/°F/min]

30/54

Firing

temperature

2

T

[°C/°F]

840/1544

Holding time

2

H

[min]

7:00

Vacuum 1

1

1

[°C/°F]

2

1

[°C/°F]

550/820

022/1508

1

Vacuum 2

1

2

[°C/°F]

2

2

[°C/°F]

820/840

508/1540

1

Please note:

– Crystallization/Glaze HT/LT can only be used for IPS e.max CAD HT and LT.

– If only max. two restorations are crystallized at the same time, the closing time S can be reduced to

1:30 min. This reduced time is only for Glaze Spray. Glaze Paste may not be used.

– IPS e.max Ceram materials (Essences, Shades etc.) must not be used in combination with IPS e.max CAD

Crystall./Glaze, Shades, Stains.

Note

Cooling after firing

– Remove IPS e.max CAD objects from the furnace after completion of the firing cycle (wait for the acoustic

signal of the furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

– Do not blast or quench the objects.

Long-term

cooling

L [°C/°F]

700/1292

Cooling rate

t [°C/°F/min]

0

If additional characterizations or adjustments are required after crystallization, a corrective firing using

IPS e.max CAD Crystall./Shades and Stains and Glaze can be conducted. Conduct the corrective firing also on the

IPS e.max CAD Crystallization Tray.

For minor shape adjustments (e.g. proximal or occlusal contact points), IPS e.max CAD Crystall./Add-On is

available. The adjustments may be made with both Crystallization/Glaze and Corrective firing.

The detailed procedure is described on page 30.

Firing parameters for the Stain and Correction firing

Furnace

P300

P500

P700

Stand-by

temperature

B [°C/°F]

403/757

Closing time

S [min]

6:00

Heating rate

t1 [°C/°F/min]

90/162

Firing

temperature

T1 [°C/°F]

820/1508

Holding time

H1 [min]

0:10

Heating rate

t2 [°C/°F/min]

30/54

27

Firing

temperature

T2 [°C/°F]

840/1544

Holding time

H2 [min]

3:00

Vacuum 1

11 [°C/°F]

12 [°C/°F]

550/820

1022/1508

1508/1540

Vacuum 2

21 [°C/°F]

22 [°C/°F]

820/840

Long-term

cooling

L [°C/°F]

700/1292

Cooling rate

t [°C/°F/min]

0

Page 28

Example of incorrect Glaze Spray application

Problem/Cause Before Firing

Problem:

Not enough Glaze Spray on the

restoration

Possible cause:

– Distance between the spray can and

the restoration too far

– Spraying too short

– Spray can not shaken sufficiently

– Spray can held not upright during

spraying

Problem:

Too much Glaze Spray on the

restoration

Possible cause:

– Distance between the spray can and

the restoration too close

– Too much Glaze Spray applied

Application of the Glaze Spray

Insufficient application of IPS e.max CAD Crystall./Glaze Spray

After Firing

Detailed view of the surface

Insufficient gloss or imcomplete glossy layer

oo much IPS e.max CAD Crystall./Glaze Spray applied

T

oss of texture and too glossy surface

L

28

Page 29

Once the IPS e.max CAD restoration has cooled to room temperature, proceed with the following steps:

– Remove the restoration from the hardened IPS Object Fix Putty or Flow..

– Remove any residue with ultrasound in a water bath and/or with steam.

– Do not blast the framework with Al2O3or glass polishing beads.

– Place the restoration on the model, check fit and make slight adjustments, if necessary.

– If adjustments by grinding of the restoration are required, make sure that no overheating of the ceramic occurs.

– If the restoration is ground, manually polish the corresponding areas to a high gloss after grinding.

Remove the cool restoration from the hardened IPS Object Fix Putty or Flow. Remove residue with ultrasound in a water bath…

Staining Technique

… or with steam Do not blast the restoration with Al2O

IPS e.max CAD LT crown on the model after Combination firing Onlay and inlay made of IPS e.max CAD HT after Combination firing

29

3

Page 30

Optional

Adjustments with IPS e.max CAD Crystall./Add-On

For minor shape adjustments (e.g. proximal or occlusal contact points), IPS e.max CAD Crystall./Add-On is

available . The adjustments may be made with both Crystallization/Glaze and Corrective firing.

Processing:

– Mix IPS e.max CAD Crystall/Add-On with IPS e.max CAD Crystall/Add-On Liquid to an easy-to-contour

consistency.

– Ensure even mixing of the add-on material and the liquid in order to achieve an optimum firing result.

– Apply the mixed add-on material directly on the unfired Glaze Paste and/or Shades and Stains in the areas to be

adjusted and fire.

– If the Glaze Spray is used, apply the Shades and Stains first. Subsequently, supplement the missing areas using Add-On.

Apply the Glaze Spray immediately after the application of the Add-On and fire.

– Conduct the Combination firing (crystallization/glaze HT/LT) after the application of Add-On on the ”blue”, non-

crystallized restoration.

– Conduct the Corrective firing if Add-On is applied on an already crystallized restoration.

Mix IPS e.max CAD Crystall/Add-On with IPS e.max CAD

Crystall/Add-On Liquid to an easy-to-contour consistency

Application of the mixed Add-On on the blue restoration

before crystallization

Firing parameters Crystallization / Glaze HT/LT

Furnace

P300

P500

P700

Stand-by

temperature

B [°C/°F]

403/757

Closing time

S [min]

6:00

Heating rate

t1

[°C/°F/min]

90/162

Firing

temperature

T1 [°C/°F]

820/1508

Firing parameters for the Corrective firing

Furnace

P300

P500

P700

Stand-by

temperature

B [°C/°F]

403/757

Closing time

S [min]

6:00

Heating rate

t1

[°C/°F/min]

90/162

Firing

temperature

T1 [°C/°F]

820/1508

Holding

time

H1 [min]

0:10

Holding

time

H1 [min]

0:10

Heating rate

t2

[°C/°Fmin]

30/54

Heating rate

t2

[°C/°Fmin]

30/54

Firing

temperature

T2 [°C]

840/1544

Firing

temperature

T2 [°C]

840/1544

Holding

time

H2 [min]

7:00

Holding

time

H2 [min]

3:00

Application of the mixed Add-On on the crystallized

Vacuum 1

11 [°C/°F]

12 [°C/°F]

550/820

1022/1508

Vacuum 1

11 [°C/°F]

12 [°C/°F]

550/820

1022/1508

Vacuum 2

21 [°C/°F]

22 [°C/°F]

820/840

1508/1544

Vacuum 2

21 [°C/°F]

22 [°C/°F]

820/840

1508/1544

Long-term

cooling

L [°C/°F]

700/1292

Long-term

cooling

L [°C/°F]

700/1292

restoration

Cooling rate

tl

[°C/°F/min]

0

Cooling rate

tl

[°C/°F/min]

0

30

Page 31

Option C:

Crystallization and separate Stain/Glaze firing

In this processing technique, the IPS e.max CAD restorations are crystallized in a first step without applying any Stains and

Glaze materials. Subsequently, the Stain and Glaze firing of the tooth-coloured restoration is conducted.

For this technique, the IPS e.max Ceram Shades, Essences and Glaze materials are required.

IPS e.max CAD Crystall./ Shades, Stains, Glaze and IPS e.max Ceram Shades, Essence, Glaze must not be mixed

with one another!

Crystallization

Observe the following procedure for the crystallization of IPS e.max CAD restorations:

– Always clean the restoration with ultrasound in a water bath or blast with the steam jet before crystallization.

– Do not blast the restoration with Al

– Use only IPS Object Fix Putty or Flow as an auxiliary firing paste to ideally place the restoration on the firing tray.

– Slightly overfill the restoration with the auxiliary firing paste so that there is a reservoir.

– Place the restoration in the center of the IPS e.max CAD Crystallization Tray and fire using the stipulated parameters.

– Use only the IPS e.max CAD Crystallization Tray from Ivoclar Vivadent, since it stores the heat necessary for slow and

above all tension-free cooling of the restoration.

or glass polishing beads.

2O3

Staining Technique

Fill the entire cavity with IPS Object Fix Putty or Flow and place the restoration on the IPS

e.max CAD CrystallizationTray

Remove the crystallization tray from the furnace once the crystallization program has been

completed. and allow it to cool

Firing parameters Crystallization / Glaze HT/LT

Furnace

P300

P500

P700

Stand-by

temperature

B [°C/°F]

403/757

Closing time

S [min]

6:00

Heating rate

t1 [°C/°F/min]

90/162

Firing

temperature

T1 [°C/°F]

820/1508

Holding time

H1 [min]

0:10

Heating rate

t2 [°C/°F/min]

30/54

Firing

temperature

T2 [°C/°F]

840/1544

Holding time

H2 [min]

7:00

Vacuum 1

11 [°C/°F]

12 [°C/°F]

550/820

1022/1508

Vacuum 2

21 [°C/°F]

22 [°C/°F]

820/840

1508/1540

Please note:

– Crystallization/Glaze HT/LT can only be used for IPS e.max CAD HT and LT.

– If only max. two restorations are crystallized at the same time, the closing time S can be reduced to 1:30 min.

31

Long-term

cooling

L [°C/°F]

700/1292

Cooling rate

t [°C/°F/min]

0

Page 32

Once the IPS e.max CAD restoration has cooled to room temperature, proceed with the following steps:

– Remove the restoration from the hardened IPS Object Fix Putty or Flow.

– Remove any residue with ultrasound in a water bath and/or with steam.

– Do not blast the framework with Al2O3or glass polishing beads.

– Place the restoration on the model, check fit and make slight adjustments, if necessary.

– If adjustments by grinding of the restoration are required, make sure that no overheating of the ceramic occurs.

Remove residue with ultrasound in a water bath… … or with steam.

Do not blast the restoration withAl2O3or glass polishing beads

32

Page 33

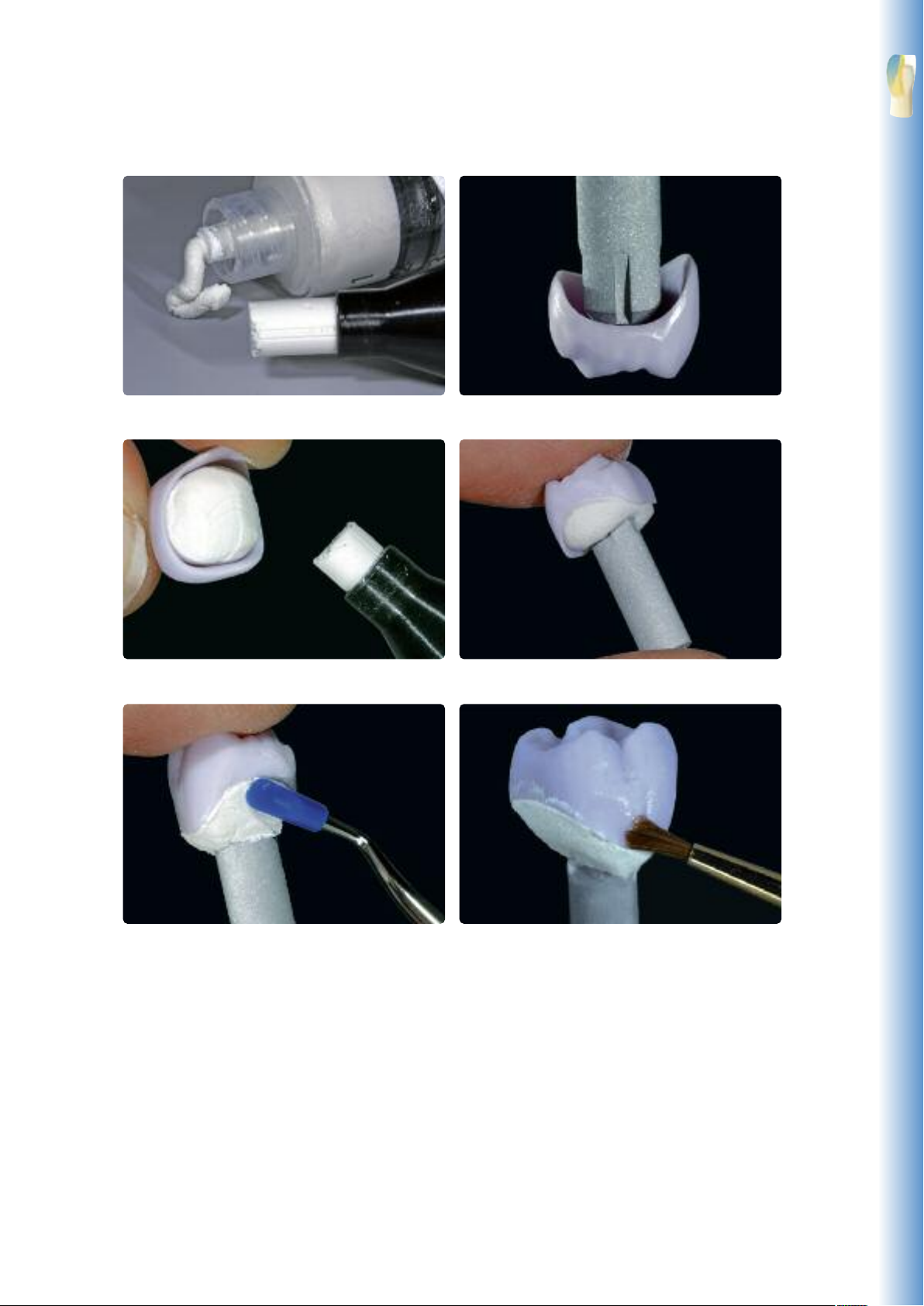

Die fabrication with IPS Natural Die Material

The light-curing IPS Natural Die Material simulates the shade of the preparation. Fabricate a die according to the shade

information supplied by the dentist (shade selection), which serves as the optimum basis for a true-to-nature shade

reproduction of the given oral situation. Please observe the following procedure:

– Coat the inner surfaces of the ceramic restoration with IPS Natural Die Material Separator and allow it to react for a

short time.

– Apply the selected IPS Natural Die Material on the inner aspects of the restoration using the IPS Condenser. Make sure

that the entire inner aspect is covered and filled.

– Insert the IPS Die Holder into the material and adapt excess around the die holder. Make sure that there is no gap at the

restoration margins.

– Cure the IPS Natural Die Material die in a customary light polymerization device for 60 seconds.

– If necessary, the die can be further finished and smoothed after polymerization.

Staining Technique

oat the inner surfaces of the ceramic restoration with IPS Natural Die Material Separator

C

and allow it to react for a short time.

Cure in a customary light polymerization device.

pply IPS Natural Die Material in the restoration and place the die holder.

A

33

Page 34

Stain and Glaze firing

After the restoration has been cleaned, the Stain and Glaze firing is conducted. Use IPS e.max Ceram Shades, Essences and

Glaze for these firing procedure.

– IPS e.max Shades are ready-to-use stains in syringes.

– IPS e.max Ceram Essences are intensively shaded powdered stains, which are mixed with IPS e.max

Ceram Glaze and Stain Liquid.

– IPS e.max Ceram Glaze Paste is a ready-to-use glaze paste supplied in a syringe.

– IPS e.max Ceram Glaze Spray is a ready-to-use glaze spray.

Please observe the following procedure:

– Depending on the situation, the Stain and Glaze firing may be conducted together or separately one after

the other. A separate Stain firing permits exact shade match with the given clinical situation.

– If more pronounced characterizations are required, a separate Stain and Characterization firing is

recommended, rather than the application of a thicker stains layer. Conduct it as a second firing after Glaze firing.

firing.

Application of IPS e.max Ceram Glaze before Glaze firing.Application of IPS e.max Ceram Essences and Shades before the Stain and Characterization

Firing parameters for the Stain and Characterization firing, Glaze firing

IPS e.max Ceram on IPS e.max CAD B StÀ T H V1 V2

Staining Technique

Stain and Characterization firing 403/757 6:00 60/108 770/1418 1:00-2:00 450/842 769/1416

Glaze firing 403/757 6:00 60/108 770/1418 1:00 - 2:00 450/842 769/1416

[°C/°F] [min] [°C/°F/min] [°C/°F] [min] [°C/°F] [°C/°F]

Completed IPS e.max CAD LT crown after Glaze firing

34

Page 35

®

e.max

IPS

CAD

Cut-Back Technique

In the cut-back technique, IPS e.max Ceram Impulse and Incisal materials are applied in the incisal and/or

occlusal area of the milled, reduced IPS e.max CAD. Subsequently, the Stain and Glaze firing is conducted.

The limited application of layering material permits achieving highly esthetic restoration in an efficient manner.

Finishing and Preparation for Crystallization

It is of critical importance to use the correct grinding instruments for finishing IPS e.max CAD. If unsuitable grinding

instruments are used, chipping of the edges and local overheating may occur (please observe the Ivoclar Vivadent Flow

Chart ”Recommended grinding tools for PS e.max glass-ceramics”.

Observe the following procedure for finishing IPS e.max CAD restorations:

– Carry out adjustments by grinding of IPS e.max CAD restorations while they are still in their pre-crystallized (blue) state,

whenever possible.

– Only use suitable grinding instruments, low rpms and light pressure to prevent delamination and chipping at the edges

in particular.

– Overheating of the glass-ceramic must be avoided.

– The restorations are tried in on the dies and carefully finished.

– Depending on the type of reduction, check contact points and occlusion and adjust by grinding in accordance with the

given clinical situation.

– Make sure that the minimum thicknesses are maintained even after the minor adjustments.

– Refrain from designing extreme morphologies with undercuts for mamelons.

– Always clean the restoration with ultrasound in a water bath or blast with the steam jet before crystallization.

– Do not blast the framework with Al2O3or glass polishing beads.

Cut-back Technique

Try in the milled restoration on the model.

Tooth 11: anterior crown with cut-back

Tooth 21: fully anatomical veneer

Finish the restoration surface with suitable grinding instruments Refrain from designing extreme morphologies with undercuts for mamelons

Make sure that the minimum layer thickness of the restoration is maintained during finishing

35

Page 36

Veneer and anterior crown on dies Anterior crown on ZrO2abutment (Straumann®Anatomic IPS e.max®Abutment)

Crystallization

The following points should be observed for the crystallization:

– Crystallization should be carried out in an Ivoclar Vivadent furnace (e.g. Programat P300, P500 or

P700).

– Use only IPS Object Fix Putty or Flow as an auxiliary firing paste to ideally place the restoration on the

firing tray.

– Slightly overfill the restoration with the auxiliary firing paste so that there is a reservoir.

– Use only the IPS e.max CAD Crystallization Tray, since it stores the heat necessary for slow and above all tension-free

cooling of the restoration.

Do not place the IPS e.max CAD restoration on metal pins and do not use a honey-combed

firing tray

Place the restoration on the IPS e.max CAD Crystallization Tray Place the firing tray in the furnace and start the crystallization with the respective parameters

36

Slightly overfill the restoration cavity with IPS Object Fix Putty or Flow

Page 37

Firing parameters Crystallization/Glaze HT/LT

Furnace

P300

P500

P700

Stand-by

temperature

B [°C/°F]

403/757

Closing time

S [min]

6:00

Heating rate

t1 [°C/°F/min]

90/162

Firing

temperature

T1 [°C/°F]

820/1508

Holding time

H1 [min]

0:10

Heating rate

t2 [°C/°F/min]

30/54

Firing

temperature

T2 [°C/°F]

840/1544

Holding time

H2 [min]

7:00

Vacuum 1

11 [°C/°F]

12 [°C/°F]

550/820

022/1508

1

Vacuum 2

21 [°C/°F]

22 [°C/°F]

820/840

508/1540

1

Long-term

cooling

L [°C/°F]

700/1292

Please note:

– Crystallization/Glaze HT/LT can only be used for IPS e.max CAD HT and LT.

– If only max. two

restorations are crystallized at the same time, the closing time S can be reduced to 1:30 min.

Note

Cooling after firing

– Remove IPS e.max CAD objects from the furnace after completion of the firing cycle (wait for the acoustic signal of the

furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

– Do not blast or quench the objects.

Cooling rate

t [°C/°F/min]

Cut-Back Technique

0

37

Page 38

Preparing for veneering

Once the IPS e.max CAD restoration has cooled to room temperature, proceed with the following steps:

– Remove the restoration from IPS Object Fix Putty or Flow.

– Remove any residue with ultrasound in a water bath and/or with steam.

– Do not blast the framework with Al2O3or glass polishing beads.

– Place the restoration on the model, check fit and make slight adjustments, if necessary.

– Check margins and finish with rubber wheels, if required.

– Make sure that the minimum thicknesses are maintained even after the minor adjustments.

– Before veneering, clean the framework with the steam jet.

– Do not blast the restoration with Al2O3or glass polishing beads.

Remove the crystallization tray from the furnace once the crystallization program has been

ompleted and allow it to cool to room temperature

c

Do not blast the restoration with Al2O

3

Remove the restoration from the hardened auxiliary firing paste

Remove residue with ultrasound in a water bath…

… or with steam Reduced IPS e.max CAD framework prepared for veneering

38

Page 39

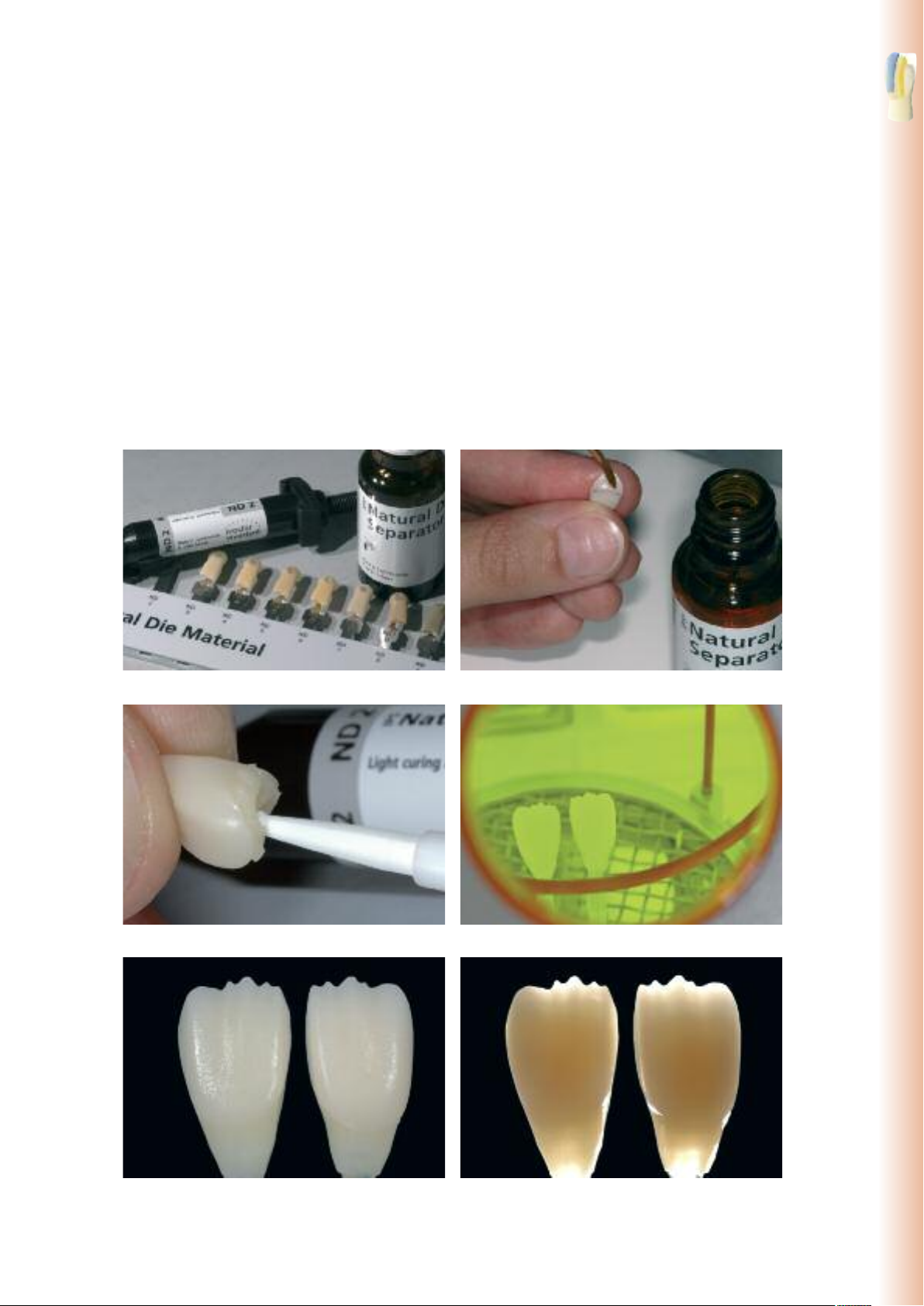

Die fabrication with IPS Natural Die Material

The light-curing IPS Natural Die Material simulates the shade of the preparation. Fabricate a die according to the shade

information supplied by the dentist (shade selection), which serves as the optimum basis for a true-to-nature shade reproduction of the given oral situation. Please observe the following procedure:

– Coat the inner surfaces of the ceramic restoration with IPS Natural Die Material Separator and allow it to react for a

short time.

– Apply the selected IPS Natural Die Material on the inner aspects of the restoration using the IPS Condenser. Make sure

that the entire inner aspect is covered and filled.

– Insert the IPS Die Holder into the material and adapt excess around the die holder. Make sure that there is no gap at the

restoration margins.

– Cure the IPS Natural Die Material die in a customary light-polymerization device for 60 seconds.

– If necessary, the die can be further finished and smoothed after polymerization.

Cut-Back Technique

oat the inner surfaces of the ceramic restoration with IPS Natural Die Material Separator and allow it to react for a short time

C

Completely fill the restoration, insert the IPS Die Holder into the material, adapt excess around the die holder, and cure in a customary light polymerization device

A die made of IPS Natural Die Material provides the optimum basis for true-to-nature all-ceramic restorations

39

Page 40

Before veneering, clean the framework with running water or the steam jet Do not blast the framework with Al2O3or glass polishing beads.

Veneering with IPS e.max Ceram

The following paragraphs will explain the most important veneering steps. For further

information on the nano-fluorapatite layering ceramic and its processing, please refer to

the IPS e.max Ceram Instructions for Use.

Firing tray and pins

Use a honey-combed firing tray (e.g. IPS

®

UniTray) and the corresponding support pins to fire the

restorations (do not use IPS e.max CAD Crystallization Tray or IPS e.max CAD Crystallization Pins). Round

the top edges of the support pin to prevent the restoration from sticking to the pin. Another method of

reducing this risk is to cover the pins with platinum foil or a small amount of IPS Object Fix Putty or

Flow. Regularly clean the support pins. Do not use contaminated pins.

40

Page 41

Wash firing (foundation)

The restoration must be free of dirt and grease before the wash firing is done. Any contamination after cleaning must be

prevented. Wash firing is carried out with IPS e.max Ceram Incisal and Impulse materials or Shades and Essences.

Cut-Back Technique

Option A: Powder

Conduct the wash firing with the required IPS e.max

Ceram Incisal and/or Impulse materials. Use the IPS e.max

Ceram Build-Up Liquids allround or soft to mix the

materials. If a more plastic consistency is desired, IPS e.max

Ceram Glaze and Stain Liquid allround or longlife can be

used. Apply the wash in a thin coat on the entire framework.

Apply the wash using Incisal and/or Impulse

materials…

Option B: Glaze, Shades and Essence

To enhance the in-depth chroma effect or for individualized

internal characterizations, the wash firing can be

conducted with Glaze, Shades and Essence. Mix the paste

or powder with the IPS e.max Ceram Glaze and Stain

Liquids allround or longlife to the desired consistency.

Apply the wash in a thin coat on the entire framework.

Apply the wash using Glaze, Shades, and

Essence…

…and fire using the indicated

firing parameters

…and fire using the indicated

firing parameters

Firing parameters for the Wash firing (foundation firing)

IPS e.max Ceram on IPS e.max CAD B StÀ T H V

Cut-Back Technique [°C/°F] [min] [°C/°F/min] [°C/°F] [min] [°C/°F] [°C/°F]

Wash firing (foundation) 403/757 4:00 50/90 750/1382 1:00 450/842 749/1380

1

V

Layering materials must not be applied on unfired wash layers (powders and pastes), since this will result in

a delamination of the layering ceramic. The wash (foundation) must be fired before the actual layering

procedure is started.

41

2

Page 42

Incisal firing

With the Incisal firing, the anatomical shape is completed and the individual esthetic appearance achieved.

The layering procedure is conducted with IPS e.max Ceram Transpa and Impulse materials. To achieve the

desired consistency, the IPS e.max Ceram Build-Up Liquid allround and soft can be used.

If a different consistency is desired, the liquids can also be mixed in any ratio.

esign the incisal edge using Impulse and Transpa materials Complete the layering procedure with Incisal andTranspa materials

D

Fire with the firing parameters for Incisal firing

Firing parameters for the Incisal firing

IPS e.max Ceram on IPS e.max CAD B StÀ T H V

Cut-Back Technique [°C/°F] [min] [°C/°F/min] [°C/°F] [min] [°C/°F] [°C/°F]

Incisal firing 403/757 4:00 50/90 750/1382 1:00 450/842 749/1380

1

2

V

Due to the thin material layer and the thus resulting limited shape change during firing, the cut-back technique also allows

to complete the restoration with one firing cycle. If a second Incisal firing is required, however, it can be conducted using

the same firing parameters.

Finishing and preparing for the Stain and Glaze firing

Before the Stain and Glaze firing, the restoration has to be finished as follows:

– Finish the restoration using diamonds and give it a true-to-nature shape and

surface structure, such as growth lines and convex/concave areas.

– If gold and/or silver dust was used to visualize the surface texture, the

restoration has to be thoroughly cleaned with steam. Make sure to remove

all gold or silver dust in order to avoid any discolouration.

Finish the restoration with diamonds and give it a true-to-nature shape and surface structure

42

Page 43

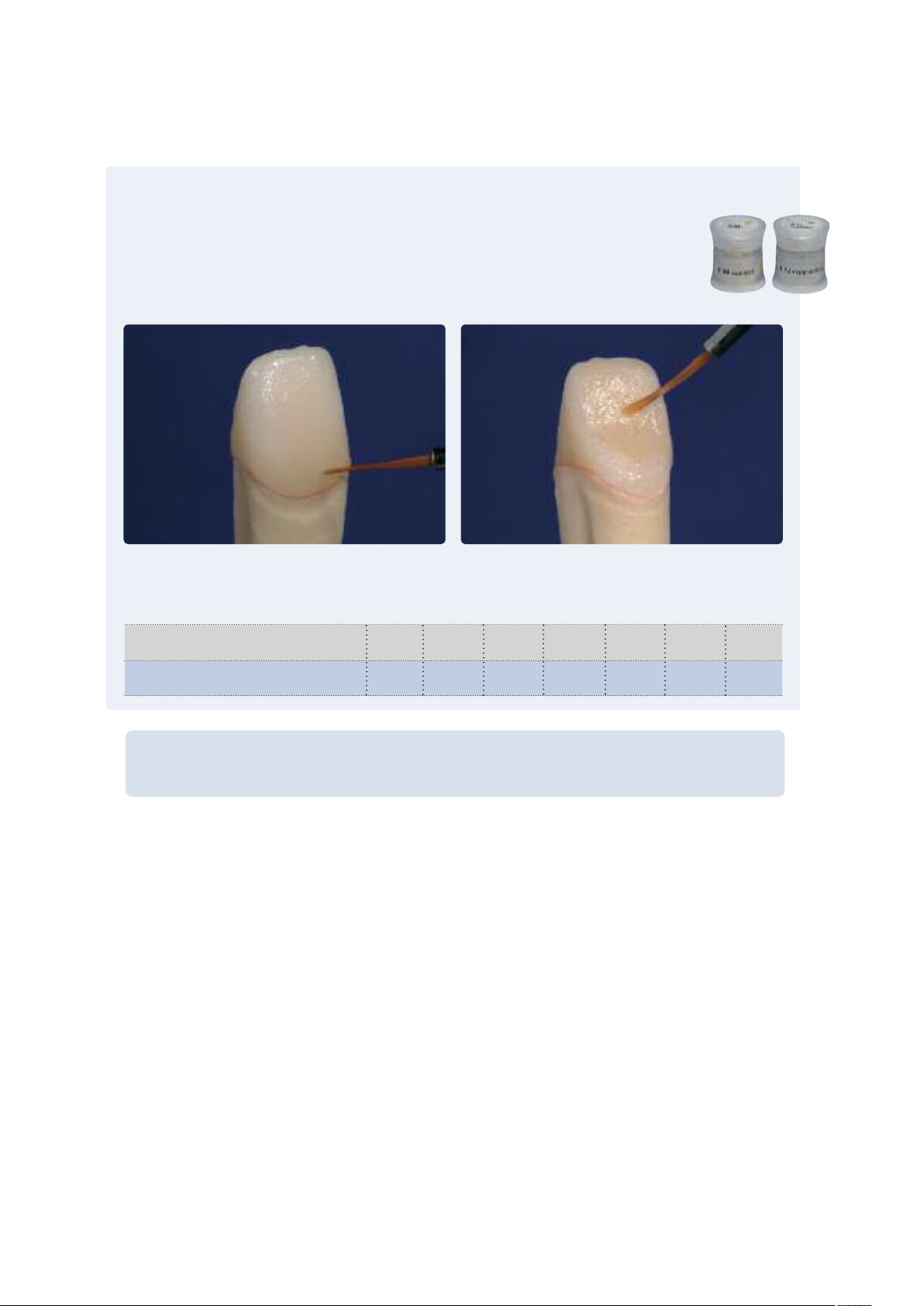

Stain and Glaze firing

Stain firing is conducted with IPS e.max Ceram Essence and IPS e.max Ceram Shades, while Glaze firing is carried out with

IPS e.max Ceram Glaze powder or paste. Depending on the situation, the Stain and Glaze firings may be conducted

together or separately one after the other. The firing parameters are identical.

In order to achieve an even gloss during Glaze firing of cut-back restorations veneered with IPS e.max Ceram, two

different procedures are possible:

Cut-Back Technique

Standard

(high-gloss appearance)

– Prepolish unlayered areas (IPS e.max CAD) using rubber

wheels.

– Rub the surface with moist ceramic (layering material) in

order to improve the wetting properties of the surface.

– Clean the restoration with steam.

– Apply IPS e.max Ceram Glaze on the entire restoration.

Option

(true-to-nature appearance)

– Prepolish unlayered areas (IPS e.max CAD) using rubber

wheels.

– Rub the surface with moist ceramic (layering material) in

order to improve the wetting properties of the surface.

– Clean the restoration with steam.

– Use Self-Glaze for veneered areas.

– Apply IPS e.max Ceram Glaze only on unlayered areas

(IPS e.max CAD LT).

– Subsequently, adjust the level of gloss by manually

polishing the restoration.

Apply IPS e.max Ceram Glaze on

the entire restoration

Apply IPS e.max Ceram Glaze only

on unlayered areas

Firing parameters for the Stain and Glaze firing

IPS e.max Ceram on IPS e.max CAD B StÀ T H V1 V2

Cut-Back Technique [°C/°F] [min] [°C/°F/min] [°C/°F] [min] [°C/°F] [°C/°F]

Stain firing 403/757 6:00 60/108 725/1337 1:00 450/842 724/1335

Glaze firing 403/757 6:00 60/108 725/1337 1:00 450/842 724/1335

43

Page 44

Completed IPS e.max CADLT veneer and anterior crown after Glaze firing

IPS e.max CAD LT anterior crown on a Straumann®Anatomic IPS e.max®Abutment

44

Page 45

®

e.max

IPS

CAD –

Layering Technique

In the layering technique, the IPS e.max Ceram layering materials are fired onto the framework made of

IPS e.max CAD MO. This enables very individualized design possibilities. The opacity of IPS e.max CAD MO

permits the design of highly esthetic restorations even on discoloured dies as well as metal core build-ups or

Ti abutments.

Finishing and Preparation for Crystallization

It is of critical importance to use the correct grinding instruments for finishing and adjusting IPS e.max CAD. If unsuitable

grinding instruments are used, chipping of the edges and local overheating may occur (please observe the corresponding

Ivoclar Vivadent Flow Chart ”Recommended grinding tools for IPS e.max glass-ceramics”.

Observe the following procedure for finishing IPS e.max CAD restorations:

– Carry out adjustments by grinding of milled IPS e.max CAD restorations while they are still in their pre-crystallized (blue)

state whenever possible.

– Only use suitable grinding instruments, low rpms and light pressure to prevent delamination and chipping at the edges

in particular.

– Overheating of the glass-ceramic must be avoided.

– The frameworks are tried in on the dies and carefully finished.

– Make sure that the minimum thicknesses are maintained even after the minor adjustments.

– Always clean the framework with ultrasound in a water bath or blast with the steam jet before crystallization.

– Do not blast the framework with Al2O3or glass polishing beads.

Layering Technique

Try in the milled framework on the model and check fit Finish the framework with suitable grinding instruments

Make sure that the minimum thicknesses are maintained even after finishing Finish the margins with suitable grinding instruments

45

Page 46

Crystallization

The following points should be observed for the crystallization:

– Crystallization should be carried out in an Ivoclar Vivadent ceramic furnace (e.g. Programat

P300, P500 or P700).

– Use only IPS Object Fix Putty or Flow as an auxiliary firing paste to ideally place the restoration

on the firing tray.

– The cavity of the restoration must be entirely filled with IPS Object Putty or Flow and extended so that

there is a reservoir.

– IPS e.max CAD restorations must neither be placed on metal firing pins nor a honey-combed tray for

crystallization.

– Use only the IPS e.max CAD Crystallization Tray, since it stores the heat necessary for slow and above all tension-free

cooling of the restoration.

– Always allow the restoration to cool to room temperature after crystallization before further processing.

Do not place the IPS e.max CAD restoration on metal pins and do not use a honey-combed