Page 1

CAD

all ceramic

all you need

For dental use only.

Rx ONLY

IPS e.max® CAD bridge

Manufacturer:

Ivoclar Vivadent AG, 9494 Schaan, Liechtenstein

www.ivoclarvivadent.com

Date information prepared:

2013-04-11, Rev. 0

662640/en

Page 2

IPS e.max® CAD

CAD

in s t r u c t i o n s

fo r

us e

CAD

labs ide

all ceramic

all you need

emax CAD-VA labside 2010-e_635991 1

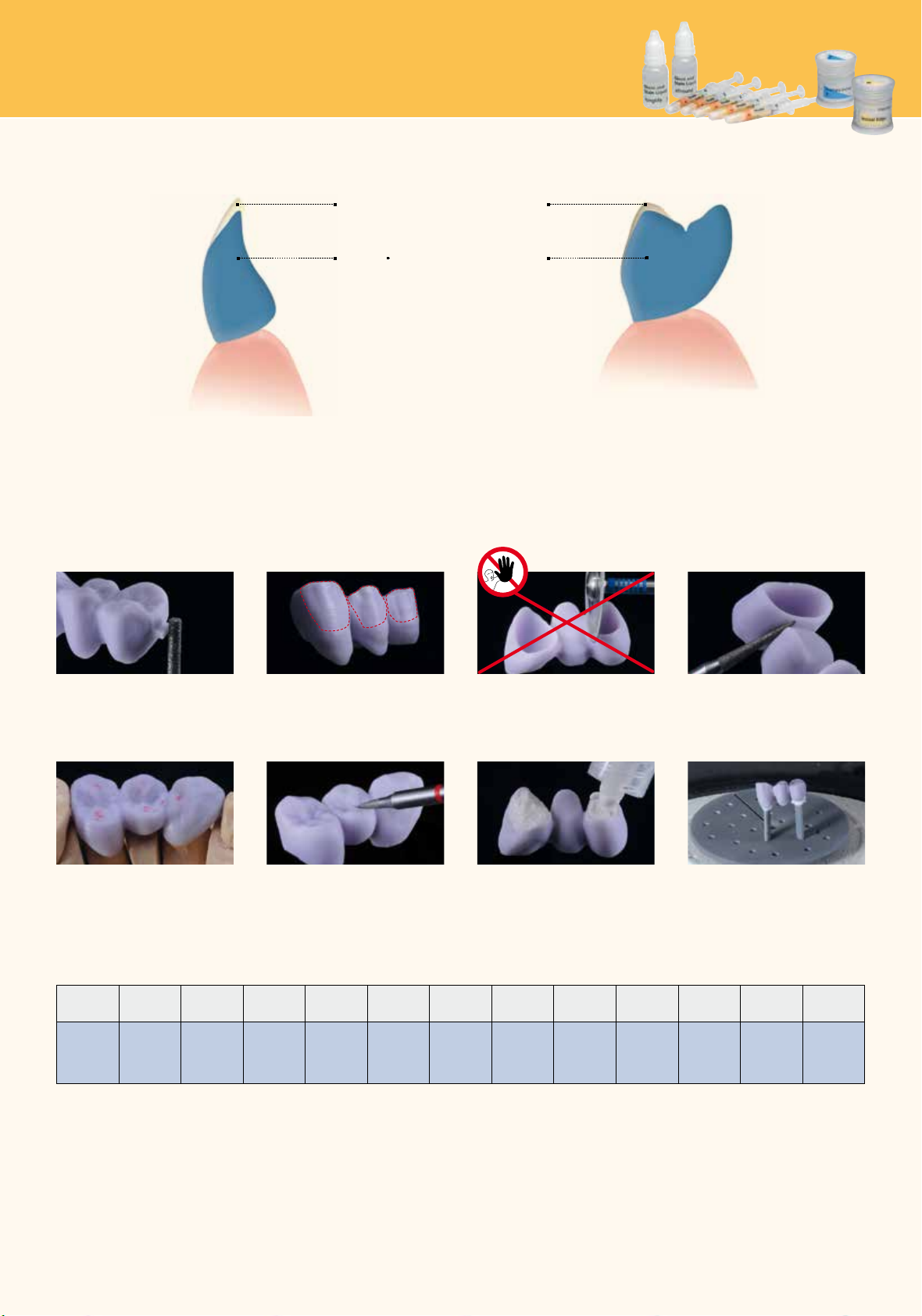

1.0

1.0

1.5

1.2 1.2

1.0

1.5

1.5

1.0

1.0

1.5

1.5

1.5

6°

6°

1.0

1.0

100-120°

1.0

1.0

1.5

1.2 1.2

1.0

Product information

These Instructions for Use contain additional information on the fabrication of 3-unit bridges using

IPS e.max CAD LT. For the basic working steps on the processing of IPS e.max CAD LT please refer to the

”IPS e.max CAD chairside“ and ”IPS e.max CAD labside“ Instructions for Use.

In the fabrication of bridges, you may choose between the staining technique and the cut-back technique.

Please observe the directions related to each individual technique.

Indications

Up to three-unit bridges up to the second premolar as the abutment tooth

Contraindications

– Inlay bridges

– Parafunction (e.g. bruxism)

– Cantilever bridges

– Maryland bridges

– Pontic width > 11 mm in the anterior region

– Pontic width > 9 mm in the premolar region

– Any other use not listed as an indication for IPS e.max CAD

Important processing restrictions

Please observe the information in the "IPS e.max CAD chairside" and "IPS e.max CAD labside" Instructions for Use.

all ceramic

all you need

in s t r u c t i o n s f o r us e

chai rsid e

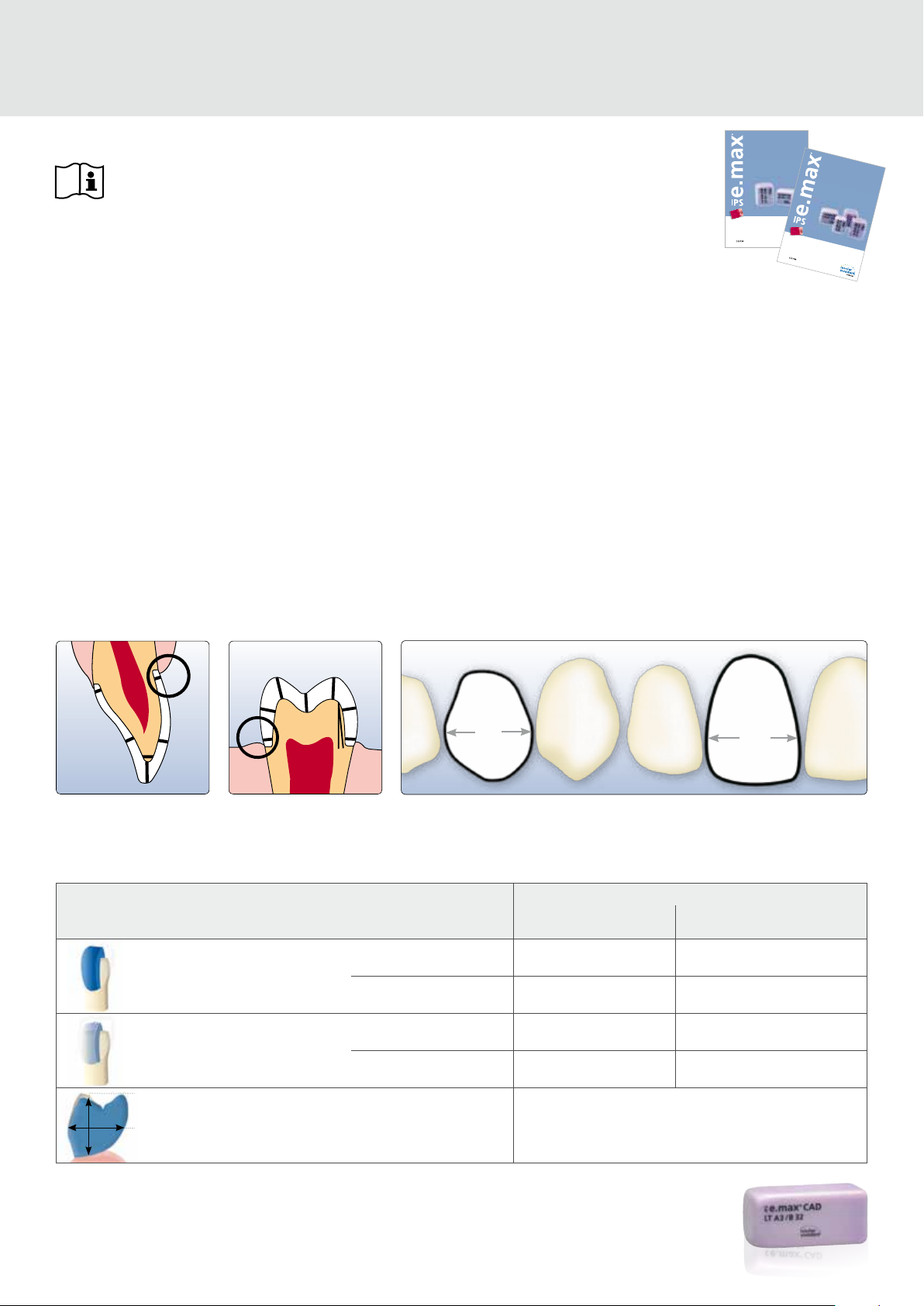

Preparation guidelines

Abutment in the

anterior region

Minimum thickness

Abutment in the

premolar region

Staining technique

Maximum pontic width in the anterior and premolar region

9 mm

Premolar region

to canine

11 mm

Anterior region

Bridges

Anterior region

mm

circular 1.2 1.5

incisal/occlusal 1.5 1.5

Premolar region

mm

Cut-back technique*

incisal/occlusal 0.8 1.0

Height ≥ Width

Width

*For maximum layer thickness of the IPS e.max Ceram veneer see IPS e.max CAD labside Instructions for Use.

IPS e.max CAD is processed by means of CAD/CAM systems from authorized partners,

the details of which can be found at www.ivoclarvivadent.com

Connector dimensions

circular 1.2 1.5

16 mm2

Basically, the following applies: Height ≥ Width

Page 3

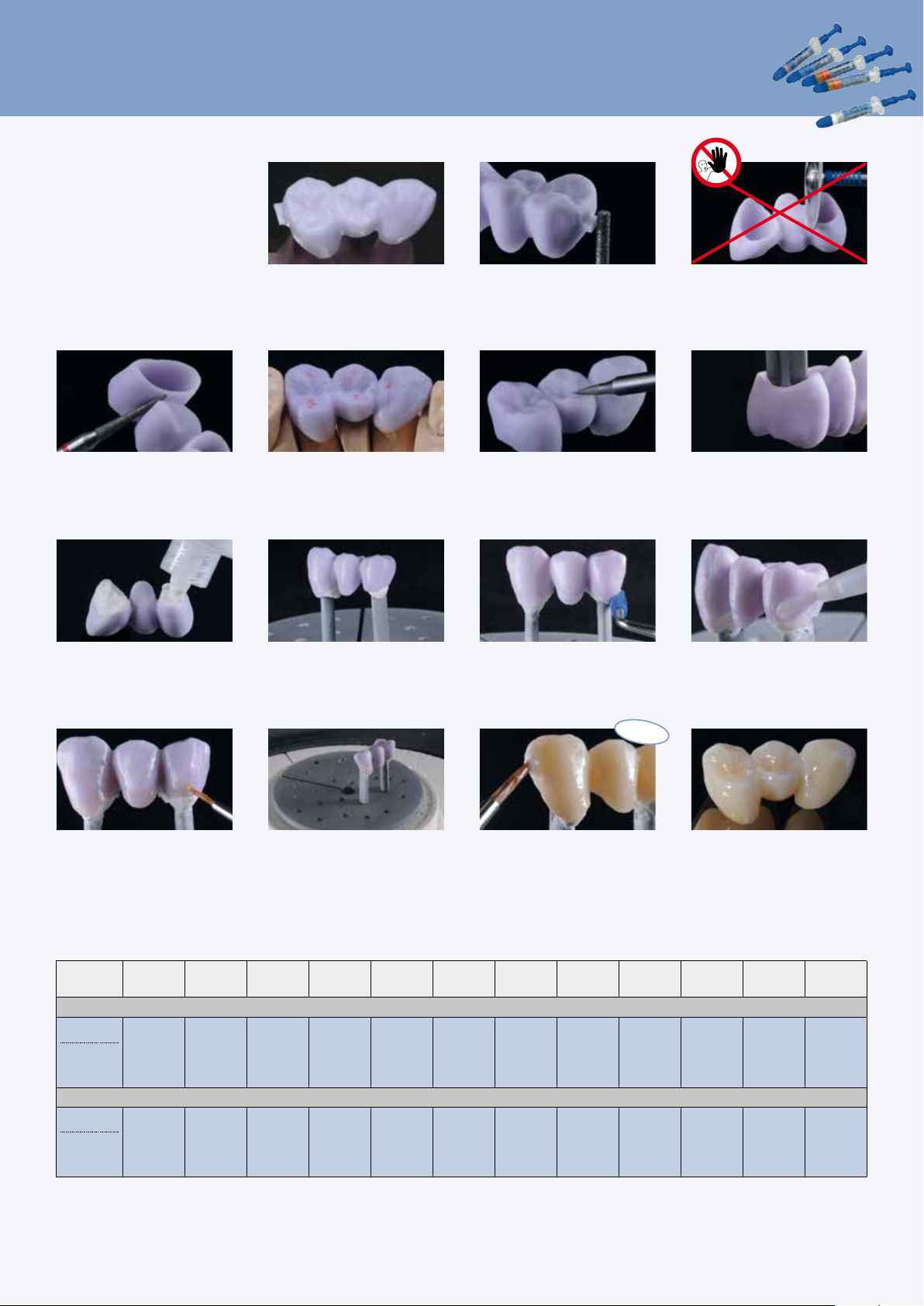

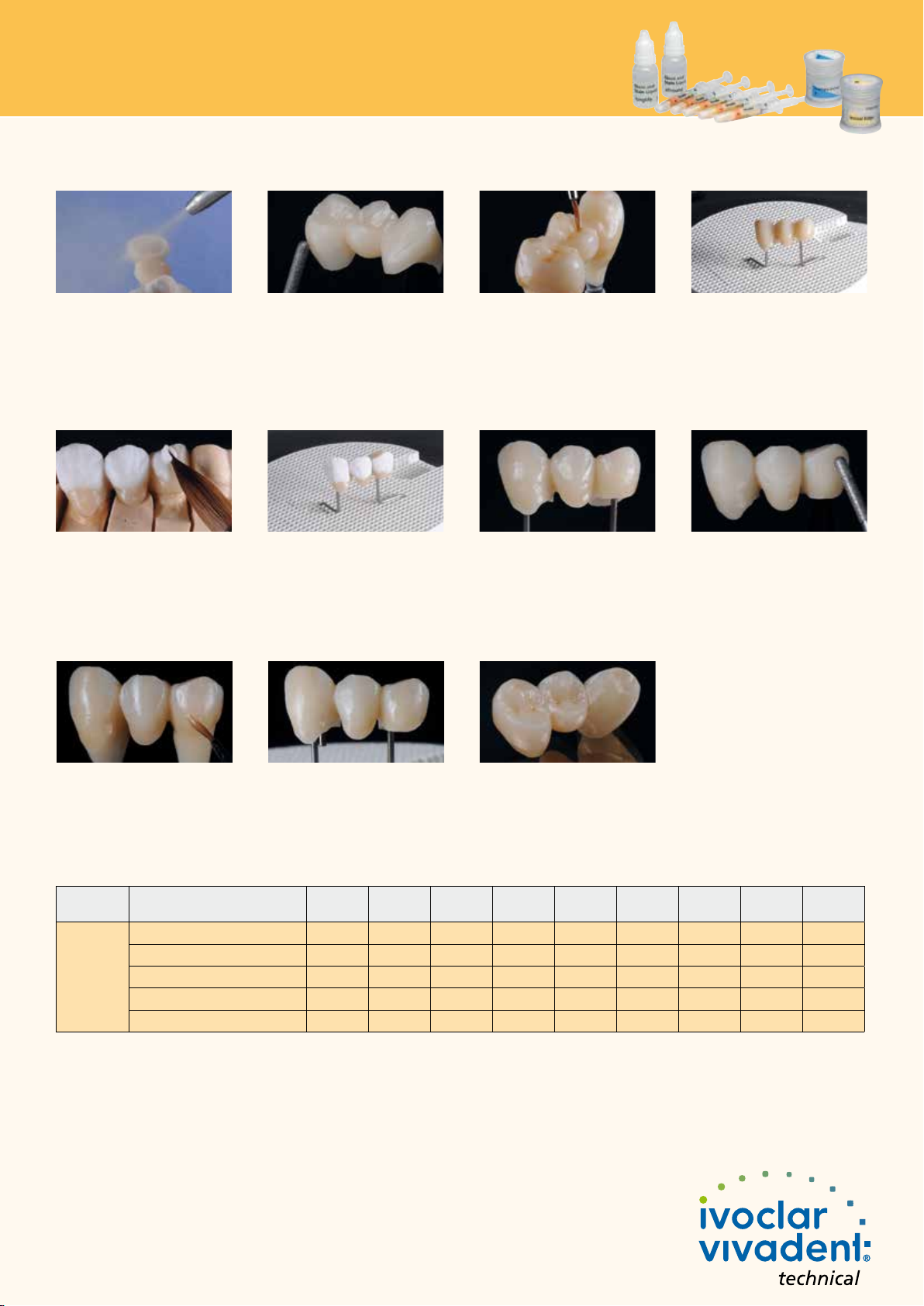

Staining technique using

IPS e.max CAD Crystall./Shades, Stains, Glaze

When using the staining technique,

apply individual characterizations and

glaze prior to combination firing

(crystallization and glaze firing). As a

result of the combined firing, this

technique is very efficient and leads

to a highly esthetic result quickly and

easily.

Bridge after CAD/CAM processing

Smooth out the attachment point and take

proximal contacts into account. Do not

inhale ceramic dust during finishing – use

exhaust air discharge and wear face mask.

Do not use diamond discs for finishing,

since this may result in predetermined

breaking points.

Finish interdental areas with fine-grit

diamonds (grit size 40–50 μm). Make sure

to observe the connector dimensions.

Fill the inside of the crowns of the previously

cleaned bridge with IPS Object Fix Putty

or Flow and press the appropriate

IPS e.max CAD Crystallization Pin

deeply into the IPS Object Fix material.

Apply IPS e.max CAD Crystall./Glaze

paste evenly to the blue restoration. Apply

the mixed IPS e.max CAD Crystall./

Shades and Stains into the unfired

IPS e.max CAD Crystall./Glaze paste.

Check occlusion, articulation and proximal

contacts.

Place the bridge on the IPS e.max CAD

Crystallization Tray immediately.

Place the IPS e.max CAD Crystallization Tray

with the glazed and stained restoration in

the furnace and conduct the combination

firing.

Surface-grind the outer surface, par-

ticularly the functional areas of the restoration, with a fine diamond to smooth out

the surface structure created by the

CAD/CAM process.

Smooth out displaced IPS Object Fix

Putty or Flow with a plastic spatula from

the margin towards the support pin so that

the pin is secured in the paste and the

crown wall is precisely supported.

Optional

If adjustments are required (shade, glaze,

contact points), conduct a separate

corrective firing cycle on the IPS e.max

CAD Crystallization Tray.

Use the largest possible IPS e.max CAD

Crystallization Pin for crystallization.

Clean off any possible residue adhering to

the outer surface of the restoration with a

brush moistened with water and then

dry.

Completed IPS e.max CAD LT bridge. To

remove any residue, immerse the restoration

in an ultrasonic cleaning bath or use a

steam cleaner.

Firing parameters

Furnaces

Stand-by

temperature

B [°C/°F]

Combination firing (crystallization/glaze firing)

Programat CS

(Program 1)

Programat

P300

P500

P700

403/757 6:00 90/162 820/1508 0:10 30/54 840/1544 7:00

Corrective firing

Programat CS

(Program 1)

Programat

P300

P500

P700

403/757 6:00 90/162 820/1508 0:10 30/54 840/1544 3:00

Note

Cooling after firing:

– Remove IPS e.max CAD objects from the furnace after completion of the firing cycle (wait for the acoustic signal of the furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

– Do not blast or quench the objects.

Closing time

S [min]

Heating rate

t

[°C/°F/min]

1

Firing

temperature

T

[°C/°F]

1

Holding time

H

[min]

1

Heating rate

t

[°C/°F/min]

2

Firing

temperature

T

[min]

2

Holding time

H

[min]

2

Vacuum 1

1

[°C/°F]

1

1

[°C/°F]

2

550/820

1022/1508

550/820

1022/1508

Vacuum 2

2

[°C/°F]

1

2

[°C/°F]

2

820/840

1508/1540

820/840

1508/1540

Long-term

cooling

L [°C/°F]

Cooling rate

t

[°C/°F/min]

l

700/1292 0

700/1292 0

Page 4

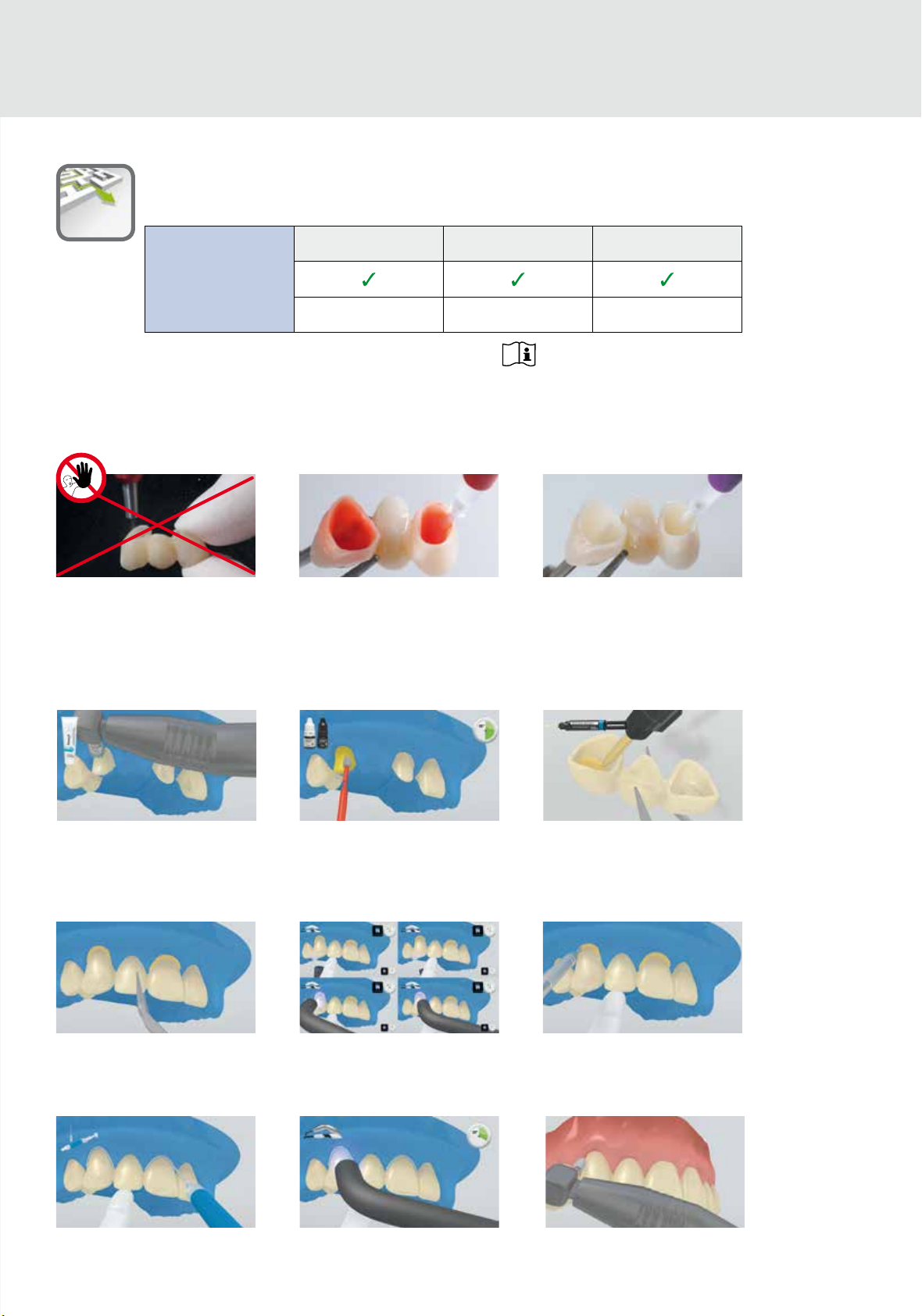

Cementation

The Cementation Navigation System, a new multimedia application from Ivoclar Vivadent, offers dentists prac-

tical orientation and guidance in the selection of the best luting material for each case.

www.cementation-navigation.com

CNS

Adhesive

cementation

Self-adhesive

cementation

Conventional

cementation

IPS e.max® CAD

Variolink® II,

SpeedCEM

®

Vivaglass® CEM

Multilink® Automix

Please observe the respective Instructions for Use.

Conditioning of the restoration

IPS® Ceramic Etching Gel contains hydrofluoric acid. Contact with skin, eyes and clothing must be prevented at all costs, since

the material is extremely toxic and corrosive. The etching gel is intended for extraoral use only and must not be applied

intraorally (inside the mouth).

®

Do not blast the restorations with Al

polishing beads.

2O3

or glass

Etch with 5% hydrofluoric acid (e.g. IPS

Etching Gel) for 20 seconds and rinse the acid off with

water.

Ceramic

Allow Monobond Plus to react for 60 s and then blow

dry with the air syringe. Silanization is not required for

conventional cementation procedures.

Cementation with e.g. Multilink Automix

Adhesive cementation

Ensure reliable isolation of the operating field,

preferably by placing a rubber dam (e.g. OptraDam

Clean preparation, rinse with water spray.

Subsequently, blow dry with oil- and moisture-free air.

Avoid overdrying.

Seat the restoration in place and fix/hold while

maintaining stable pressure.

Like all composite resins, Multilink Automix is subject

to oxygen inhibition. To avoid this, cover the restoration margins with glycerine gel/air block (e.g. Liquid

Strip) immediately after the removal of excess.

®

Apply the mixed Multilink Primer A/B with a micro-

).

brush to the entire bonding surface, starting with the

enamel, and scrub for 30 s. Take up fresh primer with

the micro-brush for each abutment. Disperse excess

amounts of Multilink Primer with a strong stream of

air until the mobile liquid film has disappeared.

Light-activate cement excess with a curing light (e.g.

®

) at a distance of max. 10 mm per quarter

Bluephase

surface (mesio-oral, disto-oral, mesio-buccal, distobuccal). Observe the indicated light intensity.

Subsequently, light-cure all cement lines again for

20 s (e.g. Bluephase, HIGH mode, approx.

1,200 mW/cm

the rubber dam.

2

). Rinse off glycerine gel and remove

Apply Multilink Automix directly into the conditioned

restoration.

The excess material has a gel-like consistency and

can be easily removed with a scaler.

Use finishing and polishing strips in the proximal

regions. Check occlusion and functional movements

and make adjustments if necessary. Polish restoration

margins with polishers (Astropol

®

) or discs.

Page 5

Cut-back technique using

IPS e.max Ceram

Design guidelines

IPS e.max Ceram veneer

Extension of IPS e.max CAD

Anterior region

Premolar region

When using the cut-back technique, IPS e.max Ceram Impulse and Incisal materials are applied in the incisal and/or occlusal area of the milled, reduced IPS e.max CAD pattern.

Make sure to observe the minimum dimensions during the cut-back process and refrain from designing extreme morphologies with undercuts for mamelons.

proximal contacts into account. Do not

Bridge after cut-back Smooth out the attachment point and take

inhale ceramic dust during finishing – use

exhaust air discharge and wear face mask.

Do not use diamond discs for finishing

as this may result in predetermined

breaking points.

Finish the interdental areas with fine-grit

diamonds (grit size 40–50 μm), making sure

to observe the connector dimensions

Check occlusion, articulation and proximal

contacts.

Surface-grind the outer surface,

particularly the functional areas of the

restoration with a fine diamond to smooth

out the surface structure created by the

CAD/CAM process.

Fill the inside of the crowns of the previously

cleaned bridge with IPS Object Fix Putty

or Flow and press the selected IPS e.max

CAD Crystallization Pin deeply into the

Object Fix material. Place the restoration on

Place the firing tray in the furnace and

conduct the crystallization firing cycle

with the respective parameters.

the IPS e.max CAD Crystallization Tray

Firing parameters

immediately.

Crystallization/Glaze

Furnace

Programat

P300

P500

P700

Stand-by

temperature

B [°C/°F]

403/757 6:00 90/162 820/1508 0:10 30/54 840/1544 7:00

Closing time

S [min]

Heating rate

t

[°C/°F/min]

1

Firing

temperature

T

[°C/°F]

1

Holding time

H

[min]

1

Heating rate

t

[°C/°F/min]

2

Firing

temperature

T

[°C/°F]

2

Holding time

H

[min]

2

Vacuum 1

1

[°C/°F]

1

1

[°C/°F]

2

550/820

1022/1508

Vacuum 2

2

[°C/°F]

1

2

[°C/°F]

2

820/840

1508/1540

Note

Cooling after firing

– Remove IPS e.max CAD objects from the furnace after completion of the firing cycle (wait for the acoustic signal of the furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

– Do not blast or quench the objects.

Long-term

cooling

L [°C/°F]

Cooling rate

t

[°C/°F/min]

l

700/1292 0

Page 6

Cut-back technique using

IPS e.max Ceram

Wash firing (foundation)

Remove adhering IPS Object Fix residue by

immersing the restoration in an ultrasonic

cleaning bath or using a steam

cleaner. Do not blast the restoration with

or glass polishing beads.

Al

2O3

Incisal firing

Complete the anatomical shape using

IPS e.max Ceram Incisal und Transpa

materials. Do not veneer or separate

the connectors.

Stain and glaze firing

Finish the full-contour portion of the

IPS e.max CAD bridge using diamond

grinders and create a natural shape and

surface texture. (For details on the fabrication

of dies using IPS Natural Die Material see

"IPS e.max CAD labside").

Place the firing tray in the furnace and

conduct the incisal firing cycle with the

respective parameters.

Apply IPS e.max Ceram Glaze to the

entire bridge and apply individual characterizations using IPS e.max Ceram Shades

and Essences.

Bridge after incisal firing

The wash (foundation) must be fired before

the actual layering procedure is started.

Place the honey-combed firing tray in the

furnace and conduct the wash (founda-

tion) firing cycle with the respective

parameters.

Finish the veneered areas using diamond

grinders and create a natural shape and

surface texture.

Apply IPS e.max Ceram Glaze to the

entire bridge. If desired, apply individual

characterizations using IPS e.max Ceram

Shades and Essences.

Place the firing tray in the furnace and start

the stain/glaze firing cycle with the

respective parameters.

Completed IPS e.max CAD LT bridge

Remove any residue by immersing the

restoration in an ultrasonic cleaning bath or

using a steam cleaner.

Firing parameters

Furnaces IPS e.max Ceram on IPS e.max CAD

Programat

P300

P500

P700

Cut-back technique

Wash firing (foundation)

Incisal firing

Stain/glaze firing

Add-On with glaze firing

Add-On after glaze firing

Stand-by

temperature

B [°C/°F]

403/757 4:00 50/90 750/1382 1:00 450/842 749/1380 0 0

403/757 4:00 50/90 750/1382 1:00 450/842 749/1380 0 0

403/757 6:00 60/108 725/1337 1:00 450/842 724/1335 0 0

403/757 6:00 60/108 725/1337 1:00 450/842 724/1335 0 0

403/757 6:00 50/90 700/1292 1:00 450/842 699/1290 0 0

Note

Cooling after firing

– Remove IPS e.max CAD objects from the furnace after completion of the firing cycle (wait for the acoustic signal of the furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

– Do not blast or quench the objects.

Closing time

S [min]

Heating rate

t

[°C/°F/min]

1

Firing

temperature

T

[°C/°F]

1

Holding time

H

[min]

1

Vacuum 1

1

[°C/°F]

1

Vacuum 2

2

[°C/°F]

1

Long-term

cooling

L [°C/°F]

Cooling rate

t

[°C/°F/min]

l

Loading...

Loading...