NSERIES

F4G TIER 3

Agricultural applications (Hyundai)

F4GE9484F*J608

F4GE9454J*J604

Technical and Repair manual

This publication contains data, features, instructions and

methods for performing repair interventions on the assembly

and its components.

This publication is addressed to qualified, specialised personnel.

Check that you have the publication related to the assembly

on which you are about to work available before you start.

Make sure that you have all the necessary safety apparatuses,

suchas,forexample,protectiveeyewear,helmet,gloves,footwear, etc. Check that the working, lifting and transport equipment etc. is available and in working order. Make sure that the

group is prepared and secured.

Proceed by carefully observing the instructions contained

herein and use the indicated specific tools to ensure correct

repair procedures, observance of time schedules and safety of

operators.

All repair interventions are aimed at restoring the conditions

of operation, efficiency and safety contemplated by FPT.

All on-group interventions, aimed at implementing changes,

alterations or other not authorised by FPT will relieve FPT

from responsibility. Specifically, the warranty (where applicable) will be immediately cancelled.

FPT cannot be held responsible for repair interventions.

FPT is available to provide any additional information needed

for performing the inventions and indications in the cases and

situations not contemplated in this publication.

The data contained in this publication may not be up-to-date

if changes are made by the manufacturer at any time for technical or commercial reasons or if required to meet legal requirements of countries worldwide.

Contact a FPT dealership before proceedingin the event of differences between the contents of this publication and the

actual assembly.

Reproduction, even partial, of this text and the illustrations

contained herein is prohibited.

Publication edited by

FIAT Powertrain Technologies

Mkt. Advertising & Promotion

Viale dell’Industria, 15/17

20010 Pregnana Milanese

Milano (Italy)

Print P2D32N010 E -1

st

Ed. 02.2009

Produced by:

B.U. TECHNICAL PUBLISHING

Iveco Technical Publications

Lungo Stura Lazio, 15/19

10156 Turin - Italy

F4GE N SERIES

1

F4GE N SERIES

F4GE N Series Part 1

-

2

F4GE N SERIES

-

F4GE N SERIES

INTRODUCTION 1

Introduction

Page

PREFACE TO USER’S GUIDELINE MANUAL 3....

SYMBOLS 5...............................

- Warnings 3.............................

- Service operations 3......................

GENERAL WARNINGS 5.....................

GENERAL WARNINGS

ON THE ELECTRIC SYSTEM 7...............

- Bonding and screening 8...................

CONVERSIONS BETWEEN THE MAIN UNITS

OF MEASUREMENT OF THE INTERNATIONAL

SYSTEM AND MOST USED DERIVED

QUANTITIES 9...........................

KEY OF LECTURE OF THE HEADINGS

AND FOOTNOTES 10.....................

-

2

INTRODUCTION

F4GE N SERIES

-

F4GE N SERIES

INTRODUCTION 3

PREFACE TO USER’S GUIDELINE MANUAL

Manuals for repairs are split into Parts and Sections, each one of which is marked by a numeral; the contents of these sections are

indicated in the general table of contents.

The sections dealing with things mechanic introduce the specifications, tightening torque values, tool lists, assembly

detaching/reattaching operations, bench overhauling operations, diagnosis procedures and maintenance schedules.

The sections (or parts) of the electric/electronic system include the descriptions of the electric network and the assembly’s

electronic systems, wiring diagrams, electric features of components, component coding and the diagnosis procedures for the

control units peculiar to the electric system.

Section 1 describes the engine illustrating its features and working in general.

Section 2 describes the type of fuel feed.

Section 3 relates to the specific duty and is divided in four separate parts:

1. Mechanical part, related to the engine overhaul, limited to those components with different characteristics based on the relating

specific duty.

2. Electrical part, concerning wiring harness, electrical and electronic equipment with different characteristics based on the relating

specific duty.

3. Maintenance planning and specific overhaul.

4. Troubleshooting part dedicated to the operators who, being entitled to provide technical assistance, shall have simple and direct

instructions to identify the cause of the major inconveniences.

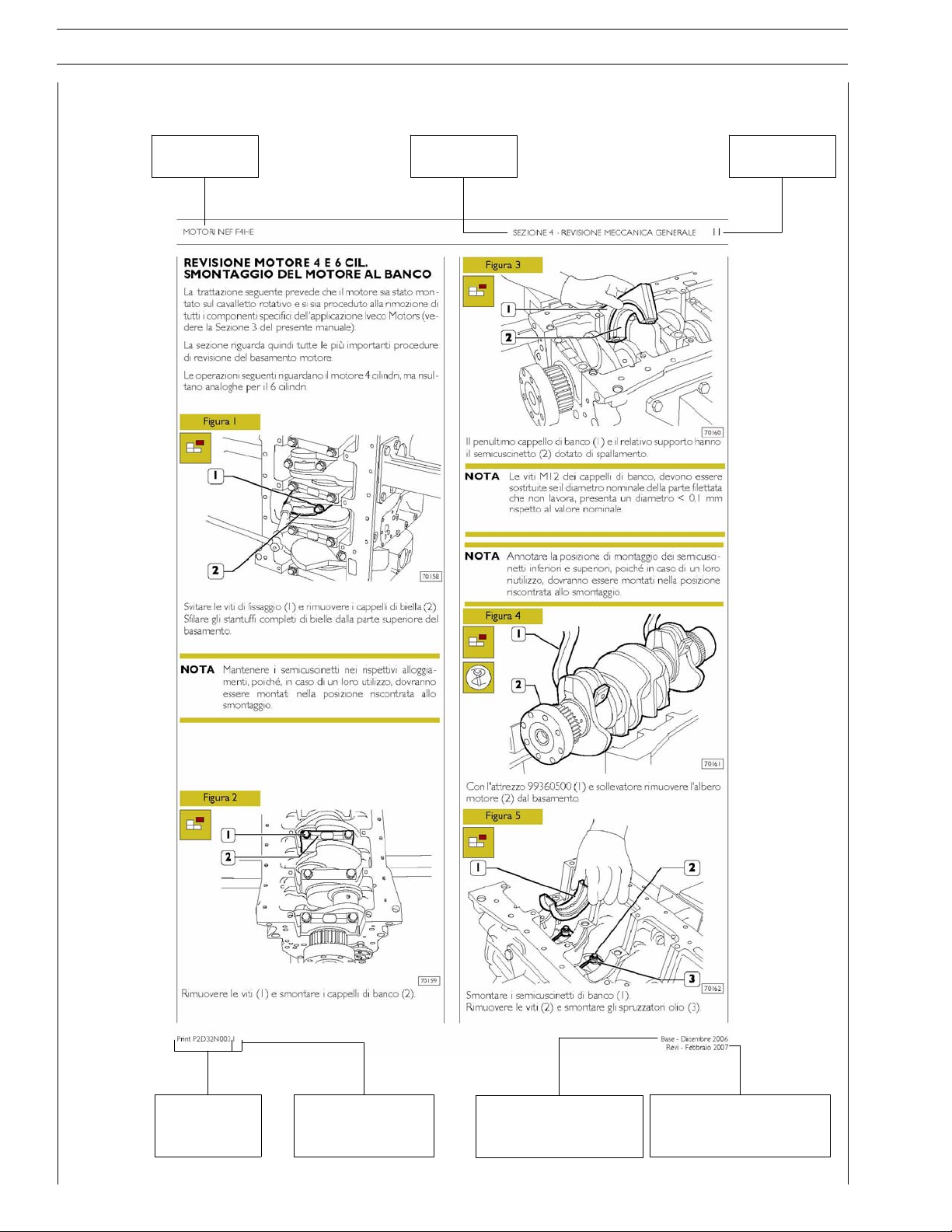

Sections 4 and 5 illustrate the overhaul operations of the engine overhaul on stand and the necessary equipment to execute such

operations.

The appendix contains a list of the general safety regulations to be respected by all installation and maintenance engineers in order

to prevent serious accidents taking place.

The manual uses proper symbols in its descriptions; the purpose of these symbols is to classify contained information. In particular,

there have been defined a set of symbols to classify warnings and a set for assistance operations.

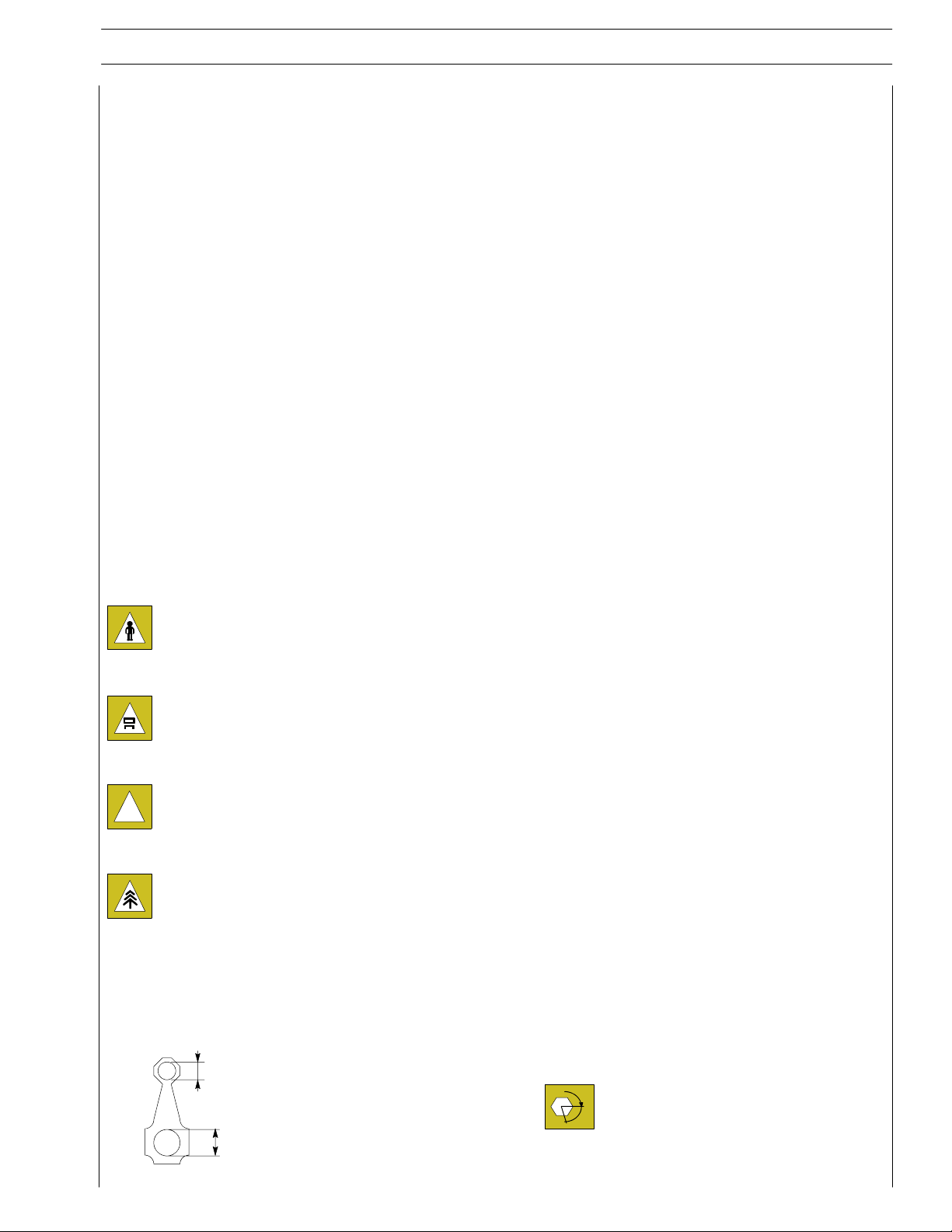

SYMBOLS - Warnings

Danger for persons

Missing or incomplete observance of these prescriptions can cause serious danger for persons’ safety.

Danger of serious damage for the assembly

Failure to comply, both fully or in part, with such prescriptions will involve serious damage to the assembly and may

sometimes cause the warranty to become null and void.

General danger

!

It includes the dangers of above described signals.

Environment protection

Moreover, it describes the correct actions to be taken to ensure that the assembly is used in such a way so as to protect

the environment as much as possible.

NOTE

It indicates an additional explanation for a piece of information.

Service operations

Example

∅

Ø 1 = housing for connecting rod small end bush

1

Ø 2 = housing for connecting rod bearings

∅

2

Tighten to torque

Tighten to torque + angular value

α

-

4

INTRODUCTION

F4GE N SERIES

Removal

Disconnection

Refitting

Connection

Removal

Disassembly

Fitting in place

Assembly

Tighten to torque

ρ

Intake

Exhaust

Operation

Compression ratio

Tolerance

Weight difference

Tighten to torque + angle value Rolling torque

α

Press or caulk Rotation

Regulation

Adjustment

Angle

Angular value

Visual inspection

Fitting position check

Preload

Measurement

Value to find

Number of revolutions

Check

Equipment Temperature

Surface for machining

Machine finish

Interference

Strained assembly

Thickness

Clearance

Lubrication

Damp

Grease

Sealant

Adhesive

bar

Pressure

Oversized

Higher than….

Maximum, peak

Undersized

Less than….

Minimum

Selection

Classes

Oversizing

Temperature < 0 °C

Cold

Winter

Temperature > 0 °C

Air bleeding

Hot

Summer

-

F4GE N SERIES

GENERAL WARNINGS

Warnings shown cannot be representative of all danger situationspossibly occurring. Therefore, it is suggested to contact

immediate superiors where a danger situation occurs which is not described.

!

Use both specific and general-purpose toolings according to the prescriptions contained in respective use and

maintenance handbooks. Check use state and suitability of tools not subjected to regular check.

The manual handling of loads must be assessed in advance because it also depends, besides weight, on its size and on

the path.

Handling by mechanical means must be with hoisters proper as for weight as well as for shape and volume. Hoisters,

ropes and hooks used must contain clear indications on maximum carrying capacity acceptable. The use of said means

is compulsorily permitted to authorised personnel only. Stay duly clear of the load, and, anyhow, never under it.

In disassembling operations, always observe provided prescriptions; prevent mechanical parts being taken out from

accidentally striking workshop personnel.

Workshop jobs performed in pairs must always be performed in maximum safety; avoid operations which could be

dangerous for the co-operator because of lack of visibility or of his/her not correct position.

Keep personnel not authorised to operations clear of working area.

You shall get familiar with the operating and safety instructions for the assembly prior to operating on the latter. Strictly

follow all the safety indications found on the assembly.

INTRODUCTION 5

Do not leave the running assembly unattended when making repairs.

When carrying out work on the assembly lifted off the ground, verify that the assembly is firmly placed on its supporting

stands, and that the manual/automatic safety devices have been actuated in the event that the assembly is to be lifted

by means of a hoist.

When you have to operate on assemblies powered by natural gas, follow the instructions contained in the document,

as well as all the specific safety standards provided for.

Only remove radiator cap when the engine is cold by cautiously unscrewing it in order to let system residual pressure

out.

Inflammable fuel and all inflammable fluids and liquids must be handled with care, according to what contained on harmful

materials 12-point c ards. Refuelling must be performed outdoors with the engine off, avoiding lit cigarettes, free flames

or sparks in order to prevent sudden fires/bursts. Adequately store inflammable, corrosive and polluting fluids and liquids

according to what provided by regulations in force. Compulsorily avoid to use food containers to store harmful liquids.

Avoid to drill or bore pressurised containers, and throw cloths impregnated with inflammable substances into suitable

containers.

Worn out, damaged or consumable parts must be replaced by original spares.

During workshopactivity, always keep the work place clean; timely clear or clean floors from accidental liquid or oil spots.

Electric sockets and electric equipment necessary to perform r epair interventions must meet safety rules.

-

6

INTRODUCTION

F4GE N SERIES

Put on, where required by the intervention, garments and protections provided in accident prevention rules; contact

with moving parts can cause serious injuries. Use suitable, preferably tight-fitted garments, and avoid to use jewels,

scarves, etc.

Do not leave the engine in motion at workshop locations not provided with a pipe to scavenge exhaust gas outside.

Avoid to breathe fumes coming from heating or from paint welding because they can cause damages to health; operate

outdoors or in suitably ventilated areas. Put on proper inspirator if paint powder is present.

Avoid contact with hot water or steam coming from the engine, radiator and pipings because they could cause serious

burns. Avoid direct c ontact with liquids and fluids present in vehicle systems; where an accidental contact has occurred,

refer to 12-point cards for provisions to make.

Clean the assemblies and carefully verify that they are intact prior to overhauling. Tidy up detached or disassembled

parts with their securing elements (screws, nuts, etc.) into special containers.

Check for the integrity of the parts which prevent screws from being unscrewed: broken washers, dowels, clips, etc.

Self-locking nuts with an insert made of nylon must always be replaced.

Avoid contact of rubber parts with diesel oil, petrol or other not compatible substances.

Before washing under pressure mechanical parts, protect electric connectors, and central units, if present.

Tightening screws and nuts must always be according to prescriptions; FPT commercial and assistance network is

available to give all clarifications necessary to perform repair interventions not provided in this document.

Before welding:

- Disconnect all electronic central units, take power cable off battery positive terminal (connect it to chassis bonding)

and detach connectors.

- Remove paint by using proper solvents or paint removers and clean relevant surfices with soap and water.

- Await about 15 minutes before welding.

- Equip with suitable fire resistant protections to protect hoses or other components where fluids or other materials

flow which may catch fire easily on welding.

Should the vehicle be subjected to temperatures exceeding 80°C (dryer ovens), disassemble drive electronic central

units.

The disposal of all liquids and fluids must be performed with full observance of specific rules in force.

-

F4GE N SERIES

GENERALWARNINGS O N THE ELECTRIC SYSTEM

If an intervention has to be made on the electric/electronic system, disconnect batteries from the system; in this case,

!

always disconnect, as a first one, the chassis bonding cable from batteries negative terminal.

Before connecting the batteries to the system, make sure that the system is well isolated.

Disconnect the external recharging apparatus from the public utility network before taking apparatus pins off battery

terminals.

Do not cause sparks to be generated in checking if the circuit is energised.

Do not use a test lamp in checking circuit continuity, but only use proper control apparatuses.

Make sure that the electronic devices wiring harnesses (length, lead type, location, strapping, connection to screening

braiding, bonding, etc.) comply with FPT system and are carefully recovered after repair or maintenance interventions.

Measurements in drive electronic central units, plugged connections and electric connections to components can only

be made on proper testing lines with special plugs and plug bushes. Never use improper means like wires, screwdrivers,

clips and the like in order to avoid the danger of causing a short circuit, as well as of damaging plugged connections, which

would later cause contact problems.

INTRODUCTION 7

To start up the engine, do not use fast chargers. Start up must only be performed with either separate batteries or special

truck.

A wrong polarisation of supply voltage in drive electronic central units (for instance, a wrong polarisation of batteries)

can cause them to be destroyed.

Disconnect the batteries from the system during their recharging with an external apparatus.

On connecting, only screw up connector (temperature sensors, pressure sensors etc.) nuts at prescribed tightening

torque.

Before disconnecting the junction connector from an electronic central unit, isolate the system.

Do not directly supply electronic central units servo components at nominal vehicle voltage.

Cables must be arranged such as to result to be parallel to reference plane, i.e. as close as possible to chassis/body

structure.

Once the intervention on the electric system has been completed, recover connectors and wiring harnesses according

to original arrangement.

NOTE

Connectors present must be seen from cable side. Connectors views contained in the manual are representative of cable

side.

-

8

INTRODUCTION

F4GE N SERIES

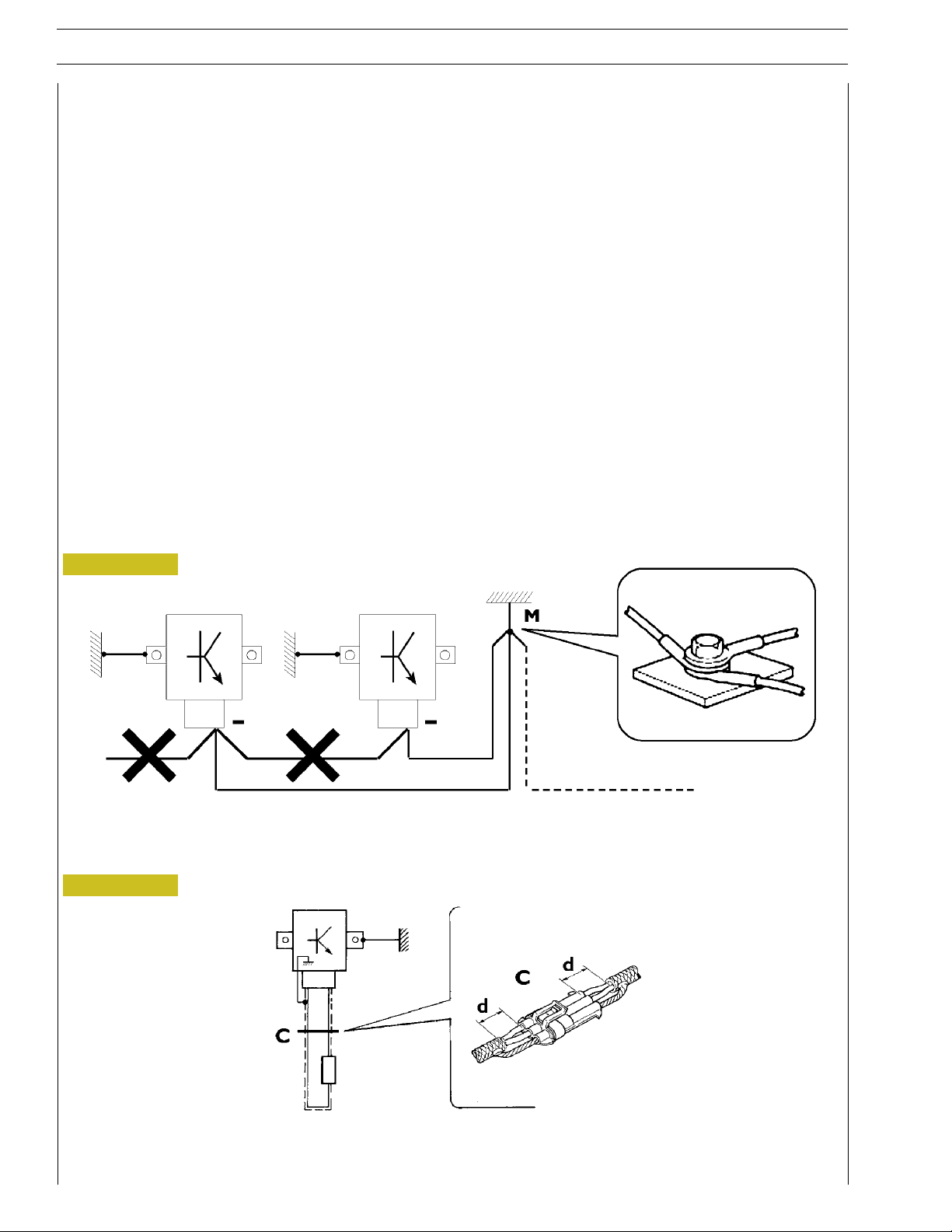

Bonding and screening

Negative leads connected to a system bonded point must be both as short and possible and “star“-connected to each other, trying

then to have their centering tidily and properly made (Figure 1, re. M).

Further, following warnings are to be compulsorily observed for electronic components:

- Electronic central units must be connected to system bonding when they are provided with a metallic shell.

- Electronic central units negative cables must be connected both to a system bonding point such as the dashboard opening

bonding (avoiding “serial“ or “chain“ connections), and to battery negative terminal.

- Analog bonding (sensors), although not connected to battery negative system/terminal bonding, must have optimal isolation.

Consequently, particularly considered must be parasitic resistances in lugs: oxidising, clinching defects, etc.

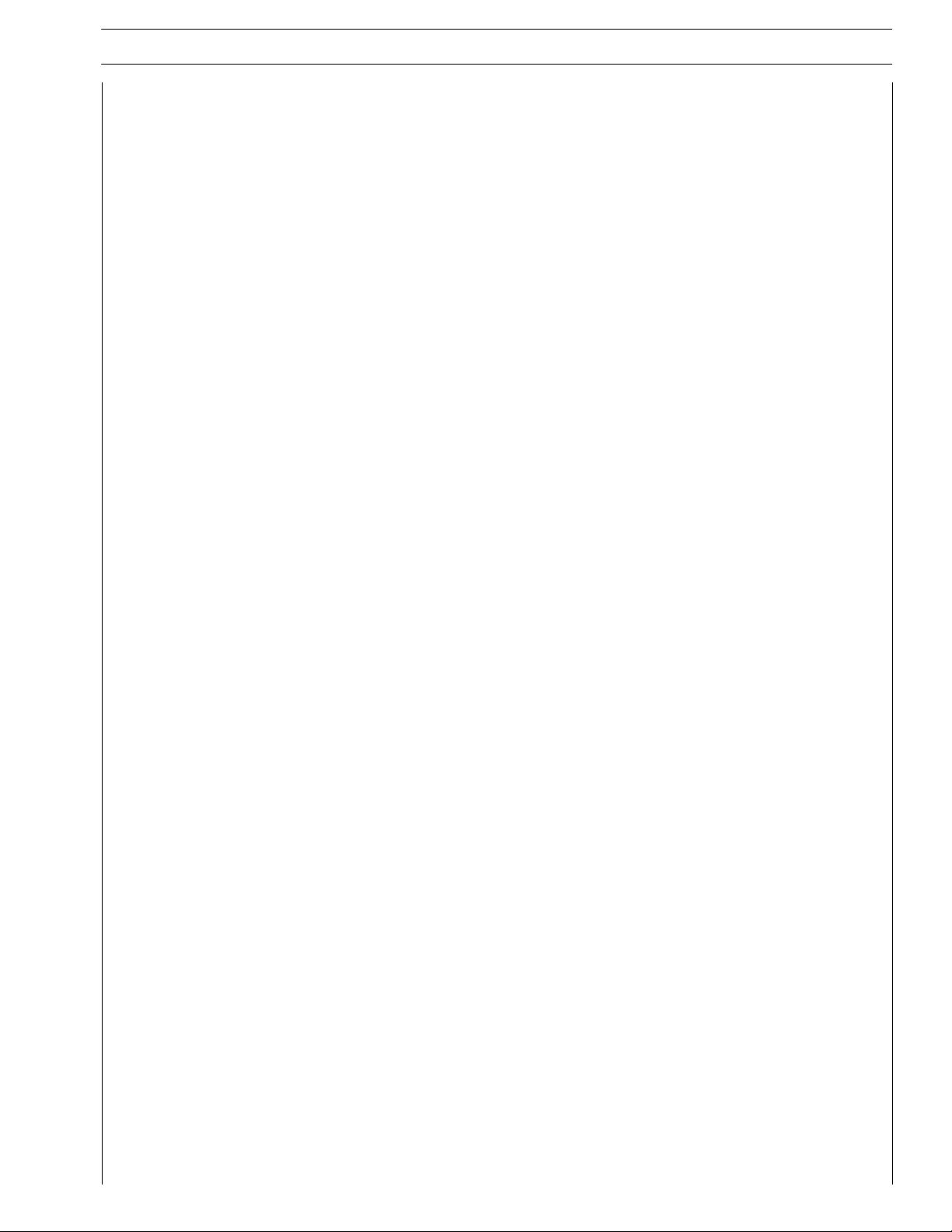

- Screened circuits braiding must only electrically contact the end towards the central unit entered by the signal (Figure 2).

- If junction connectors are present, unscreened section d, near them, must be as short as possible (Figure 2).

- Cables must be arranged such as to result to be parallel to reference plane, i.e. as close as possible to chassis/body structure.

Figure 1

1. NEGATIVE CABLES “STAR“ CONNECTION TO SYSTEM BONDING M

Figure 2

2. SCREENING THROUGH METALLIC BRAIDING OF A CABLE TO AN ELECTRONIC COMPONENT — C. CONNECTOR

d. DISTANCE ! 0

-

88039

F4GE N SERIES

INTRODUCTION 9

CONVERSIONS BETWEEN THE MAIN UNITS OF MEASUREMENT OF THE

INTERNATIONAL SYSTEM AND MOST USED DERIVED QUANTITIES

Power

1 kW = 1.36 metric HP

1 kW = 1.34 HP

1 metric HP = 0.736 kW

1 metric HP = 0.986 HP

1 HP = 0.746 kW

1 HP = 1.014 metric HP

Torque

1 Nm = 0.1019 kgm

1 kgm = 9.81 Nm

Revolutions per time unit

1 rad/s = 1 rpm x 0.1046

1 rpm = 1 rad/s x 9.5602

Pressure

Pa

2

2

according to ratio 1:1

1 bar = 1.02 kg/cm

1 kg/cm

1bar = 10

2

= 0.981 bar

5

Where accuracy is not particularly needed:

- Nm unit is for the sake of simplicity converted into kgm according to ratio 10:1

1 kgm = 10 Nm;

- bar unit is for the sake of simplicity converted into kg/cm

2

1 kg/cm

=1bar.

Temperature

0° C=32° F

1° C = (1 x 1.8 + 32) ° F

-

10

INTRODUCTION

KEY OF LECTURE OF THE HEADINGS AND FOOTNOTES

F4GE N SERIES

Type of

vehicle

Section

title

Page

number

Printout

number

-

Language

Publication

Basic edition referred to

month - year editorial

phase closing

When month - year update

is present (revi) to the

basic edition

F4GE N SERIES

1

Part 1

F4GE N SERIES

Section

General specifications

Fuel 2

Agricultural applications 3

Overhaul and technical specifications 4

Tools 5

Safety prescriptions Appendix

1

-

2

F4GE N SERIES

-

F4GE N SERIES

UPDATING

Section Description Page Date of revision

3

-

4

F4GE N SERIES

-

F4GE N SERIES

SECTION 1 - GENERAL SPECIFICATIONS 1

SECTION 1

General Specifications

Page

LUBRICATION 3............................

OIL VAPOUR RECIRCULATING SYSTEM 4.......

COOLING SYSTEM 5........................

AIR INDUCTION BOOST DIAGRAM 6..........

- Boosting version engines 6.................

- Description 6...........................

- Inter-cooled engine version 7...............

- Description 7...........................

EXHAUST GAS RE-CIRCULATION SYSTEM (EGR) 8

-

2

SECTION 1 - GENERAL SPECIFICATIONS

F4GE N SERIES

-

F4GE N SERIES

SECTION 1 - GENERAL SPECIFICATIONS 3

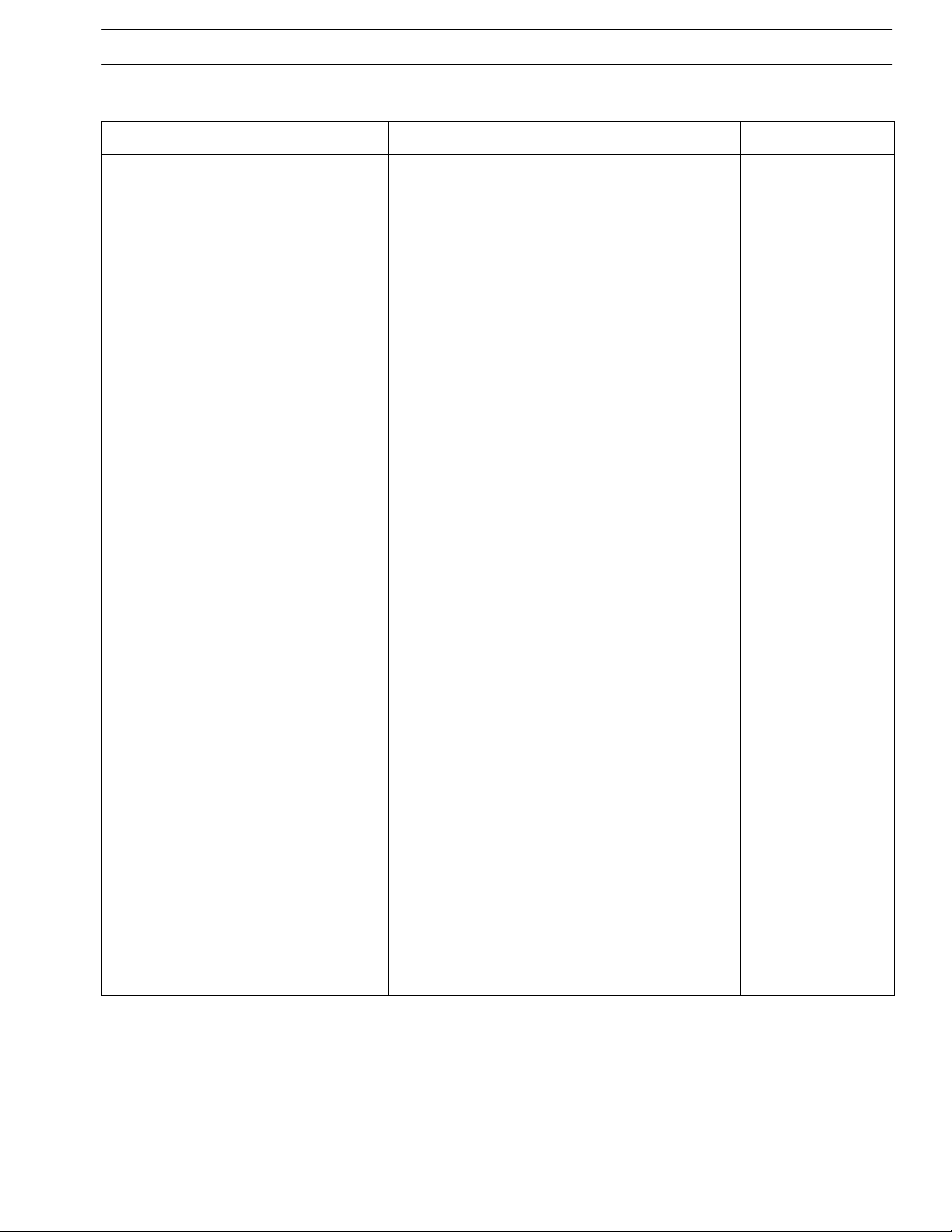

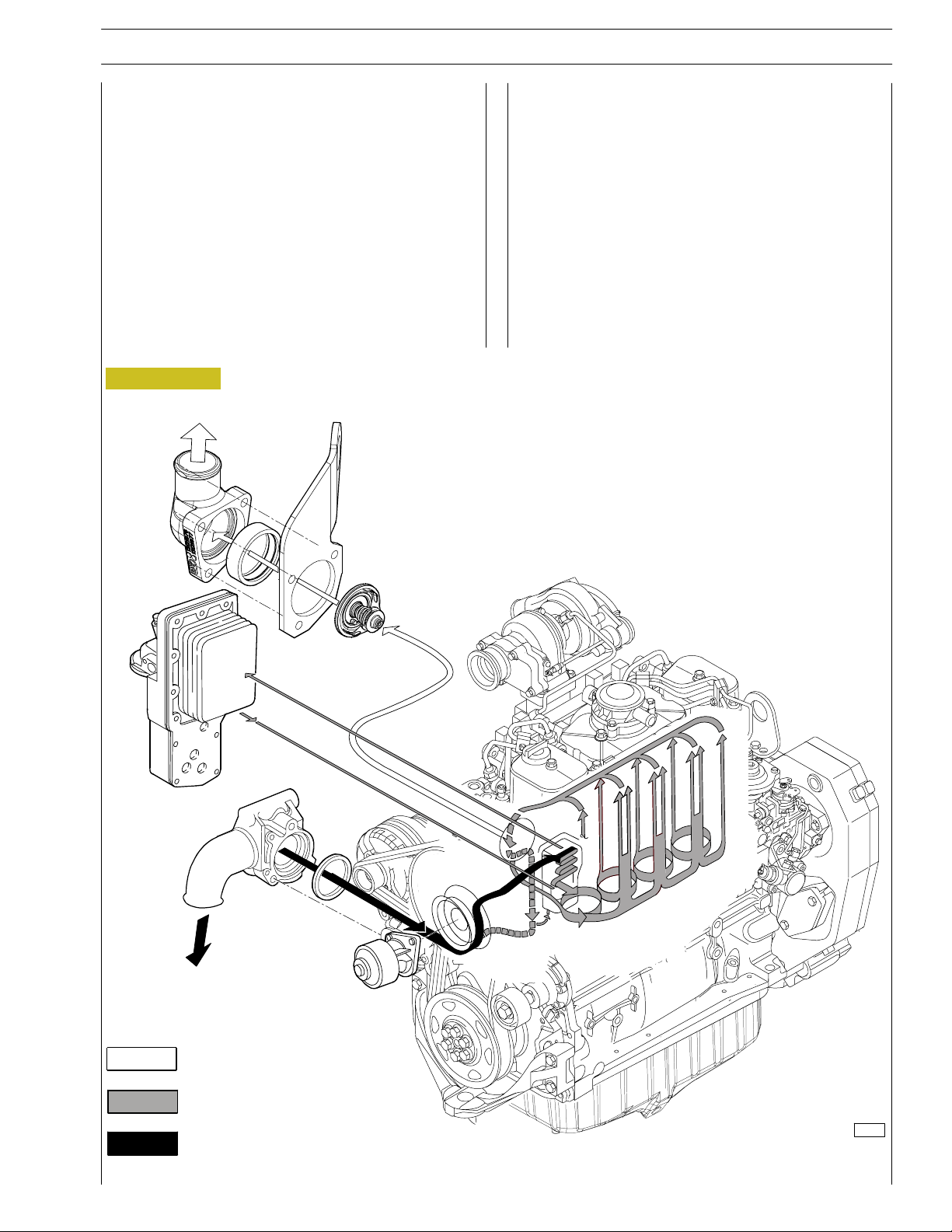

LUBRICATION

Lubrication by forced circulation is achieved through oil rotary

expansion pump, placed in the front part of the basement,

driven by the straight-tooth gear splined to the shaft’s bar hold.

From the pan, the lubrication oil flows to the driving shaft, to

the camshaft and to the valve drive.

Figure 1

Lubrication involves the heat exchanger and the turboblower.

All these components may often vary according to the specific

duty.

Routing of oil under

pressure

Routing of oil return

by gravity to sump

Introduction of oil

LUBRICATION SYSTEM LAYOUT

1. Lubrication oil pipe to supercharger - 2. Heat exchanger body - 3. Oil rotary expansion pump - 4. Oil filter.

132102

-

4

SECTION 1 - GENERAL SPECIFICATIONS

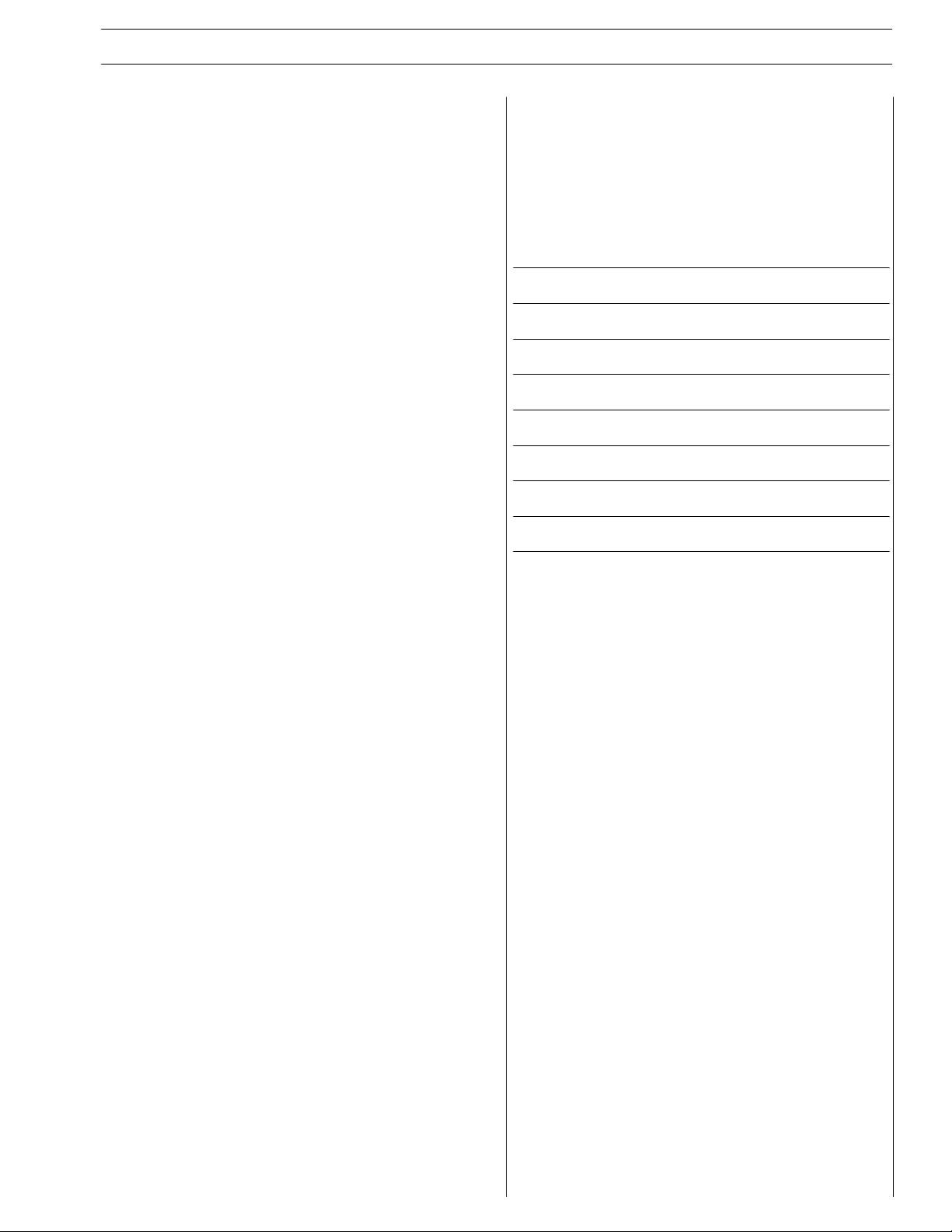

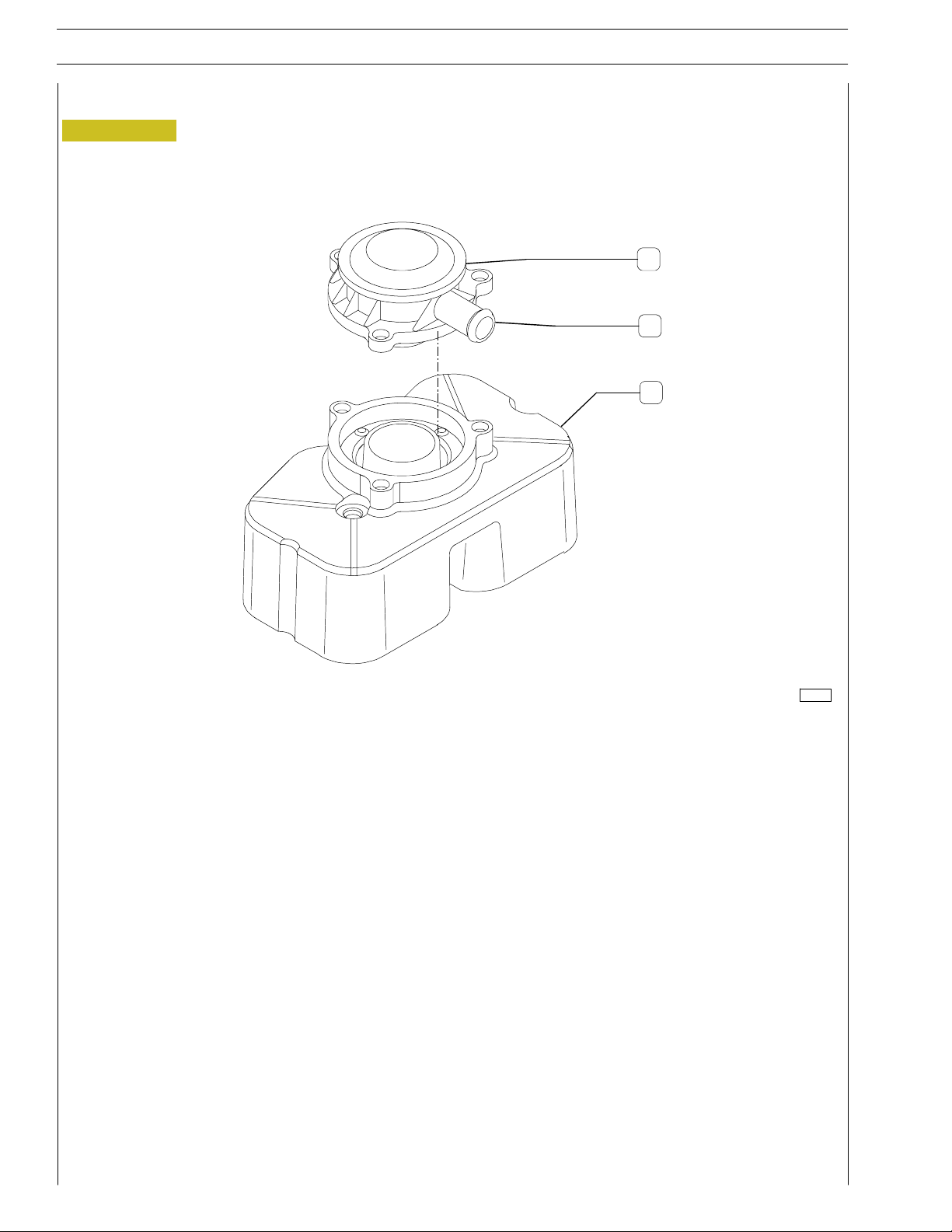

OIL VAPOUR RECIRCULATING SYSTEM

Figure 2

F4GE N SERIES

1

2

3

3240t

1. Valve - 2. Breather pipe - 3. Tappet Cap

On the tappet cap (3) there is a valve (1) whose duty is to condense oil vapour inducing these to fall down because of gravity,

to the Tappet cap underneath.

The remaining non-condensed vapours shall be properly conveyed through the breather pipe (2), by suction as an example (connection towards these vapours shall be designed by the Engineer).

-

F4GE N SERIES

SECTION 1 - GENERAL SPECIFICATIONS 5

COOLING SYSTEM

The engine cooling system, closed circuit forced circulation

type, generally incorporates the following components:

- Expansion tank; placement, shape and dimensions are

subject to change according to the engine’s equipment.

- Radiator, which has the duty to dissipate the heat

subtracted to the engine by the cooling liquid. Also this

component will have specific peculiarities based on the

equipment developed, both for what concerns the

placement and the dimensions.

- Visc pusher fan, having the duty to increase the heat

dissipating power of the radiator. This component as well

will be specifically equipped based on the engine’s

development.

Figure 3

TO RADIATOR

- Heat exchanger to cool the lubrication oil: even this

component is part of the engine’s specific equipment.

- Centrifugal water pump, placed in the front part of the

engine block.

- Thermostat regulating the circulation of the cooling liquid.

FROM RADIATOR

Water coming out from thermostat

Water recirculating in engine

Water coming into pump

127129

COOLING SYSTEM LAYOUT

-

6

SECTION 1 - GENERAL SPECIFICATIONS

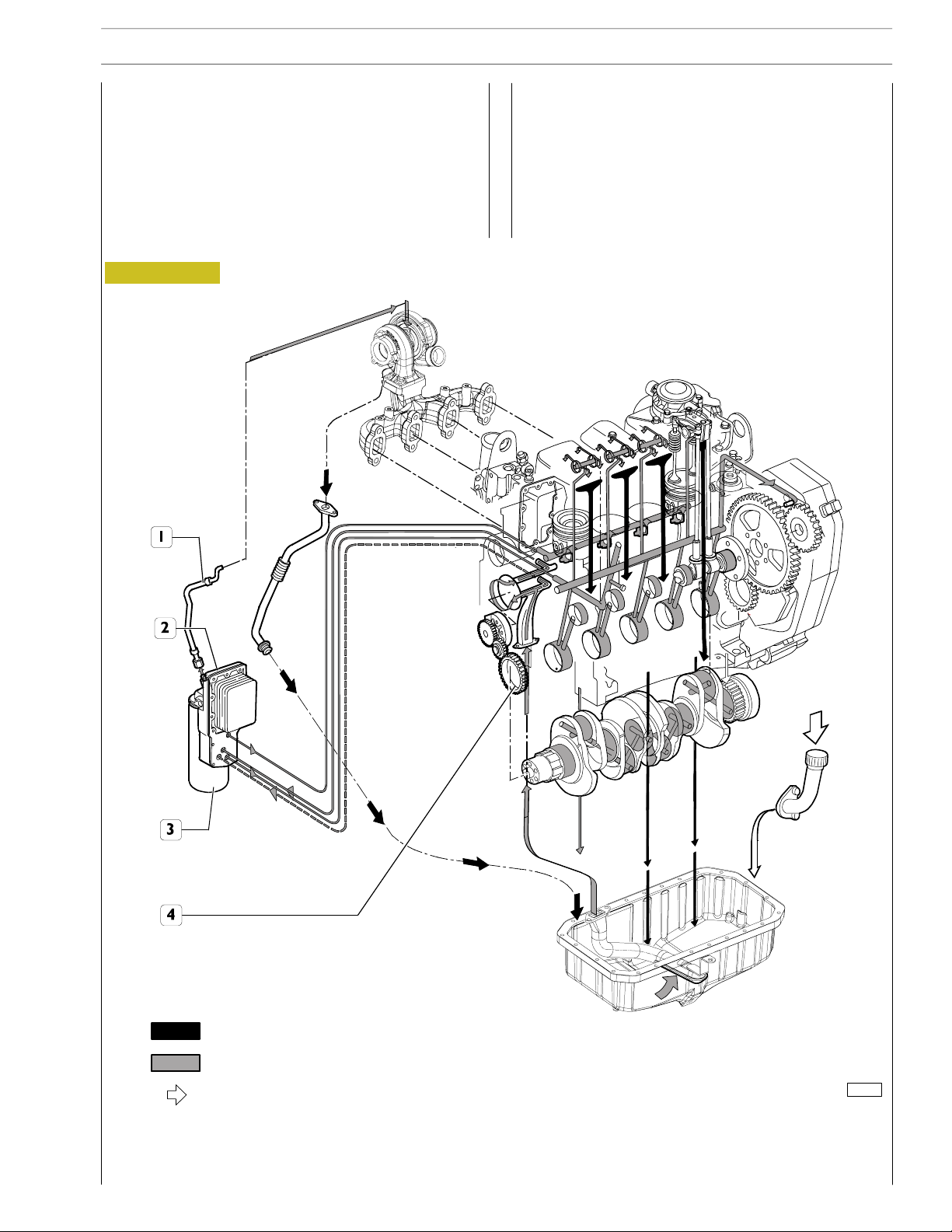

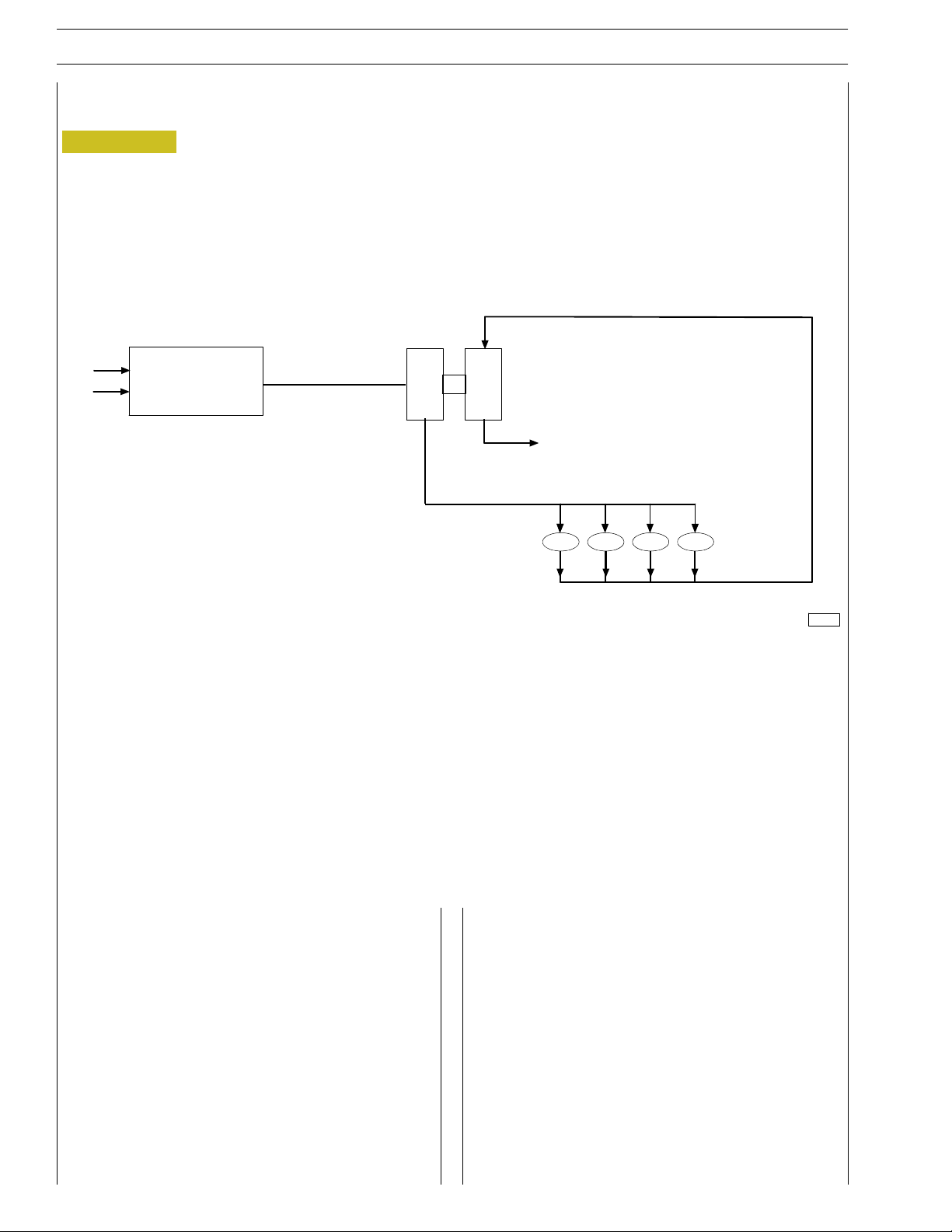

AIRINDUCTION BOOST DIAGRAM

Boosting version engines

Figure 4

F4GE N SERIES

AIR FILTER

TURBOCHARGER

EXHAUST

88208

Description

The turbocharger is composed by the following main parts:

one turbine, one transforming valve to regulate the boost

feeding pressure , one main body and one compressor.

During engine working process, the exhaust emission flow

through the body of the turbine, provoking the turbine disk

wheel’s rotation.

The compressor rotor, being connected by shaft to the

turbine disk wheel, rotates as long as this last one rotates,

compressing the sucked air through the air filter.

The air coming out of the compressor is sent via the intake

manifold directly to the pistons.

-

The turbocharger is equipped with a transforming valve to

regulate the pressure , that is l ocated on the exhaust collector

before the turbine and connected by piping to the induction

collector.

It’s duty is to choke the exhaust of the emissions , releasing part

of them directly to the exhau st tube when the boost feeding

pressure, over the compressor, reaches the prescribed bar

value.

The cooling process and the lubrication of the turbocharger

and of the bearings is made by the oil of the engine.

F4GE N SERIES

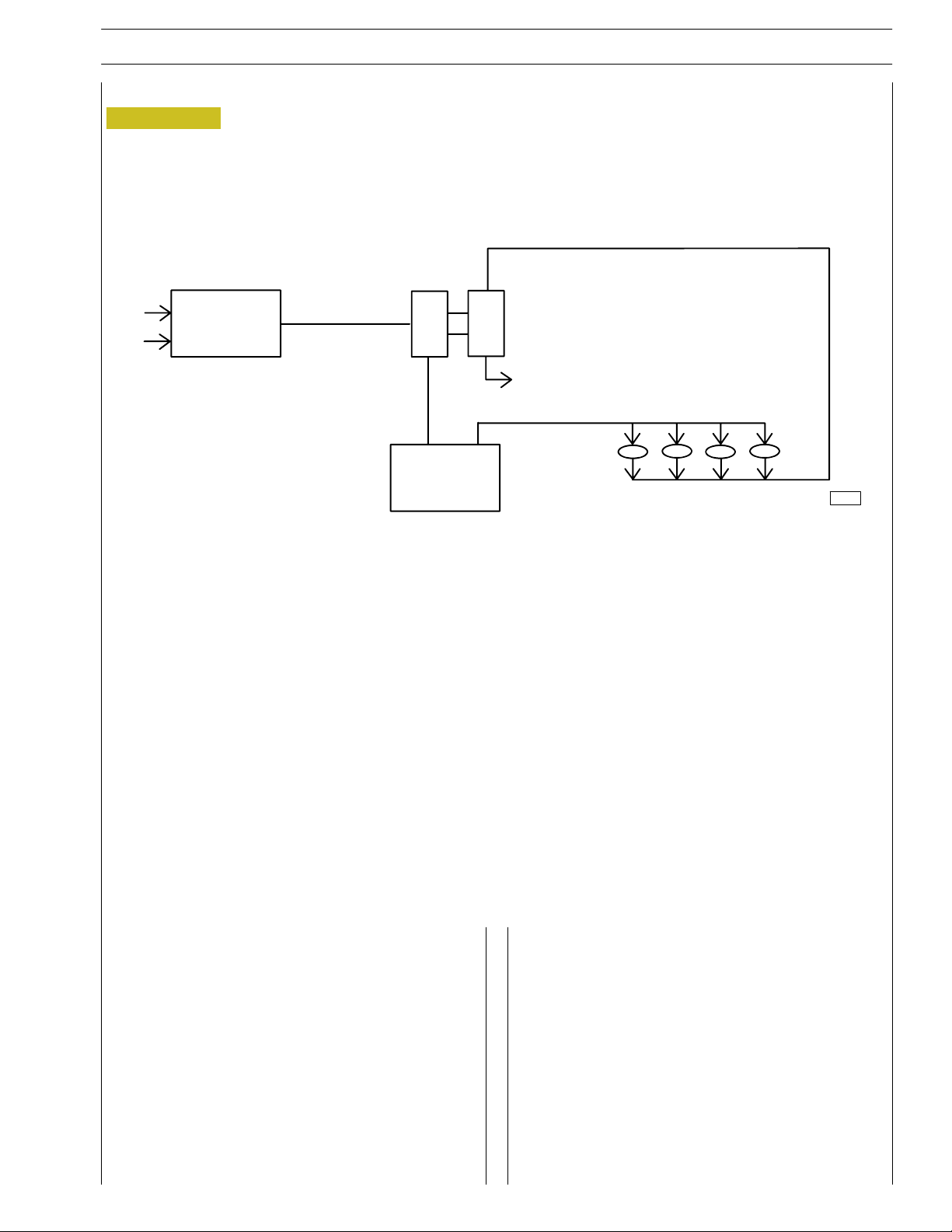

Inter-cooled engine version

Figure 5

SECTION 1 - GENERAL SPECIFICATIONS 7

AIR FILTER

TURBOCHARGER

EXHAUST

RADIATOR

74195

4 cylinders version

Description

The turbocharger is composed by the following main parts:

one turbine, one transforming valve to regulate the boost

feeding pressure , one main body and one compressor.

During engine working process, the exhaust emission flow

through the body of the turbine, provoking the turbine disk

wheel’s rotation.

The compressor rotor, being connected by shaft to the

turbine disk wheel, rotates as long as this last one rotates,

compressing the sucked air through the air filter.

The above mentioned air is then cooled by the radiator and

flown through the piston induction collector.

The turbocharger is equipped with a transforming valve to

regulate the pressure , that is l ocated on the exhaust collector

before the turbine and connected by piping to the induction

collector.

It’s duty is to choke the exhaust of the emissions , releasing part

of them directly to the exhau st tube when the boost feeding

pressure, over the compressor, reaches the prescribed bar

value.

The cooling process and the lubrication of the turbocharger

and of the bearings is made by the oil of the engine.

-

8

SECTION 1 - GENERAL SPECIFICATIONS

F4GE N SERIES

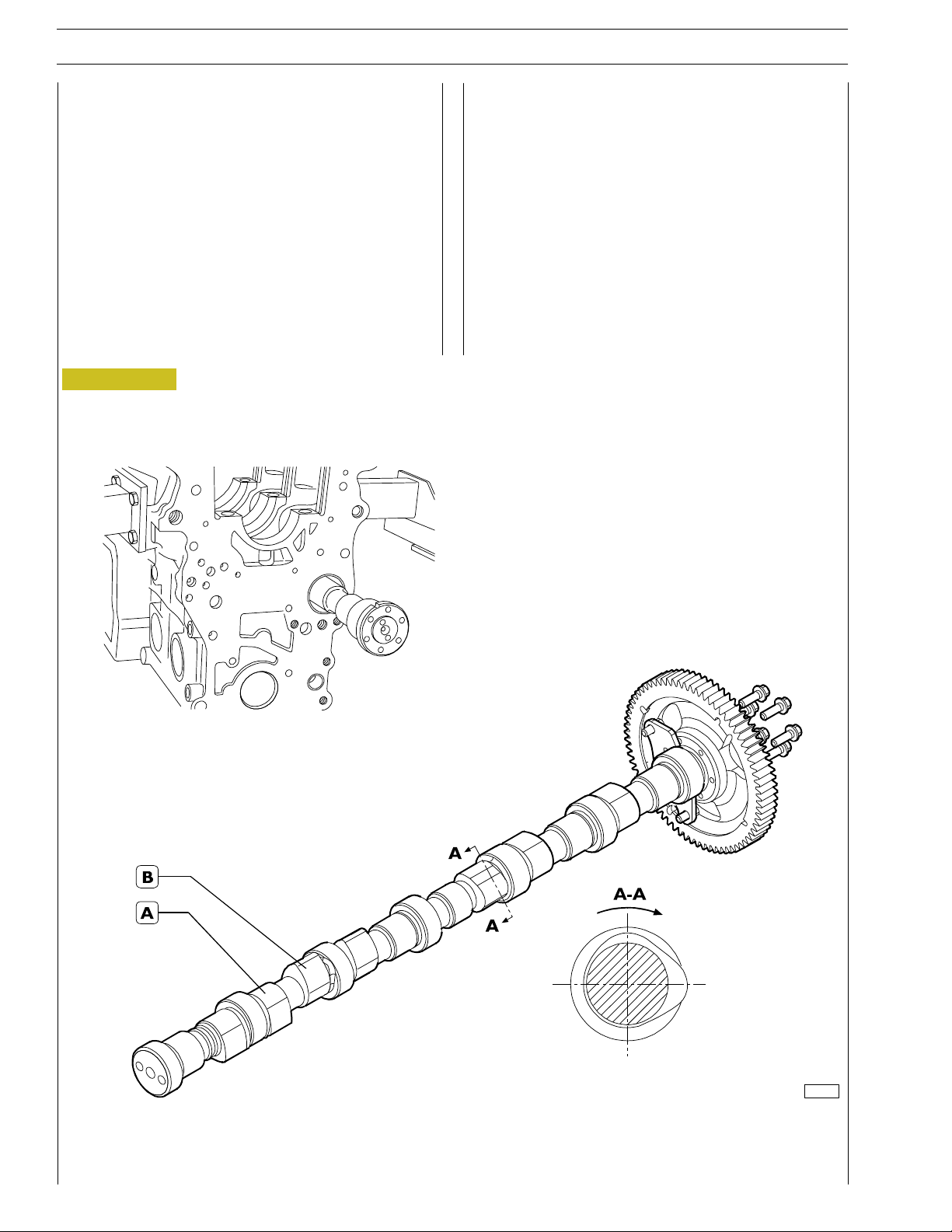

EXHAUST GAS RE-CIRCULATION SYSTEM

(EGR)

In the TIER 3 version, the profile of the exhaust cam has been

modified in order to allow the partial opening of the relative

valve during the aspiration phase (re-circulation of EGR

exhaust gas) with the subsequent re-introduction of part of

the exhaust gas into the engine cylinders.

The exhaust gases can partially be re-directed into the

cylinders so as to reduce the maximum combustion

temperature values responsible for the production of nitric

acid (NO

The exhaust gas re-circulation system (EGR), reducing the

combustion temperature by means of the diminishing of the

concentration of oxygen in the combustion chamber,

represents therefore an efficient control system of the

emission of NO

).

x

Figure 6

.

x

The internal EGR system is not equipped with any

electronically controlled elements: the system is always active.

Its configuration does not need additional elements

i.e.checking valves, piping or heat exchangers.

The exhaust cam (B) has another lobe apart from the major

lobe (see Section. A-A fig.) with respects to the configur ation

without EGR.

The additional lobe, during the aspiration phase in the cylinder

in question, allows a brief opening of the exhaust valve

generating re-circulation due to the intake of the exhaust gases

caused by depression which is created in the aspiration phase

inside the cylinder.

114789

A. Aspiration valve control - B. Exhaust valve control.

-

F4GE N SERIES

SECTION 2 - FUEL 1

SECTION 2

Fuel

Page

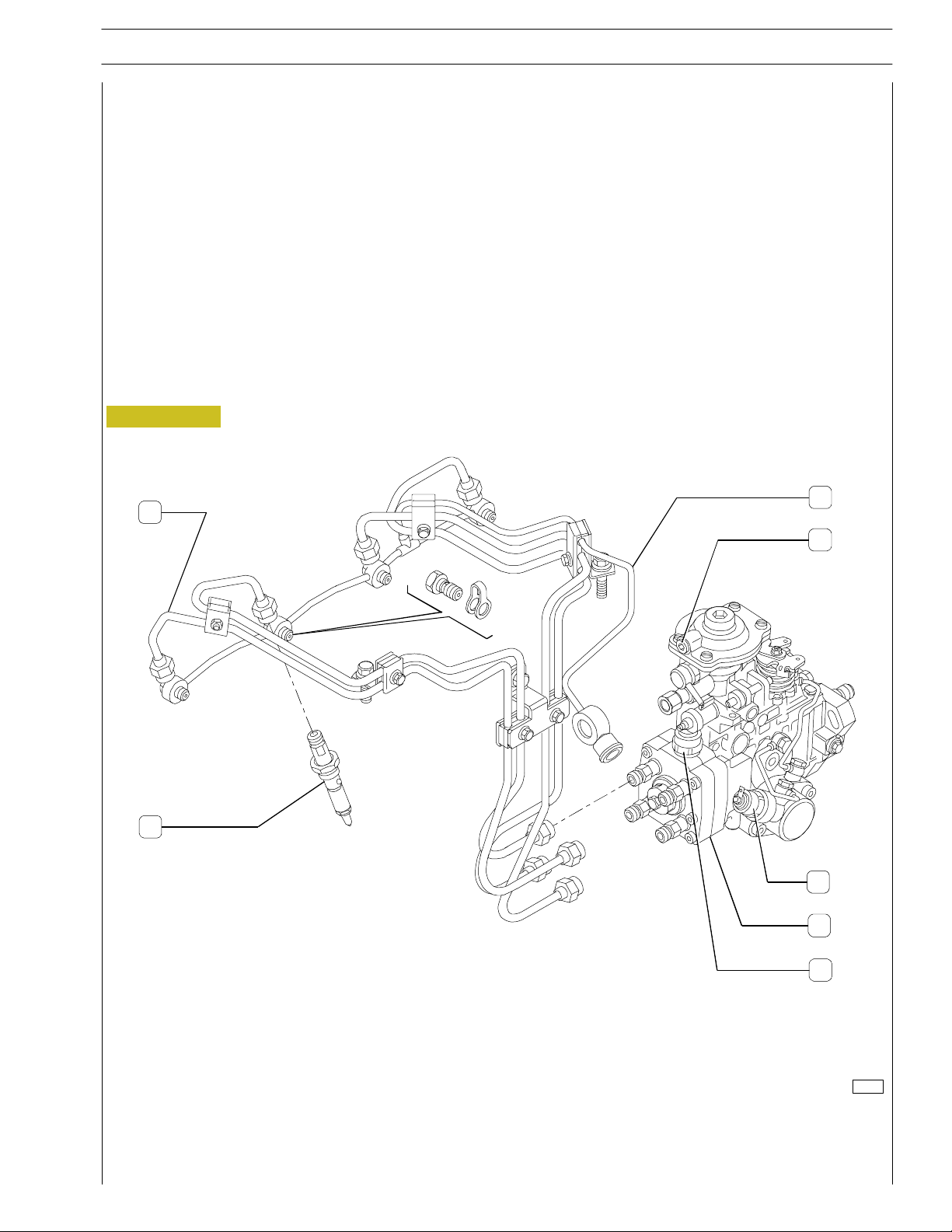

4-CYLINDER ENGINES WITH BOSCH VE 4/12 F

ROTARY MECHANICAL PUMP 3............

- General information 3.....................

- Description of working principles 4...........

FEED PUMP 5..............................

- Example of identification 5.................

PRIMING PUMP 6...........................

FUEL FILTER 7..............................

-

2

SECTION 2 - FUEL

F4GE N SERIES

-

F4GE N SERIES

ase-February2009

SECTION 2 - FUEL

4-CYLINDER ENGINES WITH BOSCH VE 4/12 F ROTARY MECHANICAL PUMP

General information

Fuel feed system is composed by:

- Fuel tank (placed on the machine)

- Fuel delivery and back-flow to tank

- Fuel pre-filter (if available, it is usually placed close to the engine on the machine frame)

- Priming pump, assembled to the engine and driven by the camshaft

- Fuel filter (assembled to the engine in different positions ac cording to equipment application and duty)

- Fuel feed rotary pump

- Injec t or feed pipeline (from fuel feed pump to injectors)

- Injectors

Figure 1

3

2

1

4

7

5

3

6

74168

1. Injector feed pipes - 2. Fuel exhaust pipes from injectors - 3. Fuel feed rotary pump - 4. Connector for LDA pressure

gauge pipe within suction c ollector - 5. KSB thermal bulb - 6. Electro-valve - 7. Injector.

PrintP2D32N010E B

4

ase-February2009Print

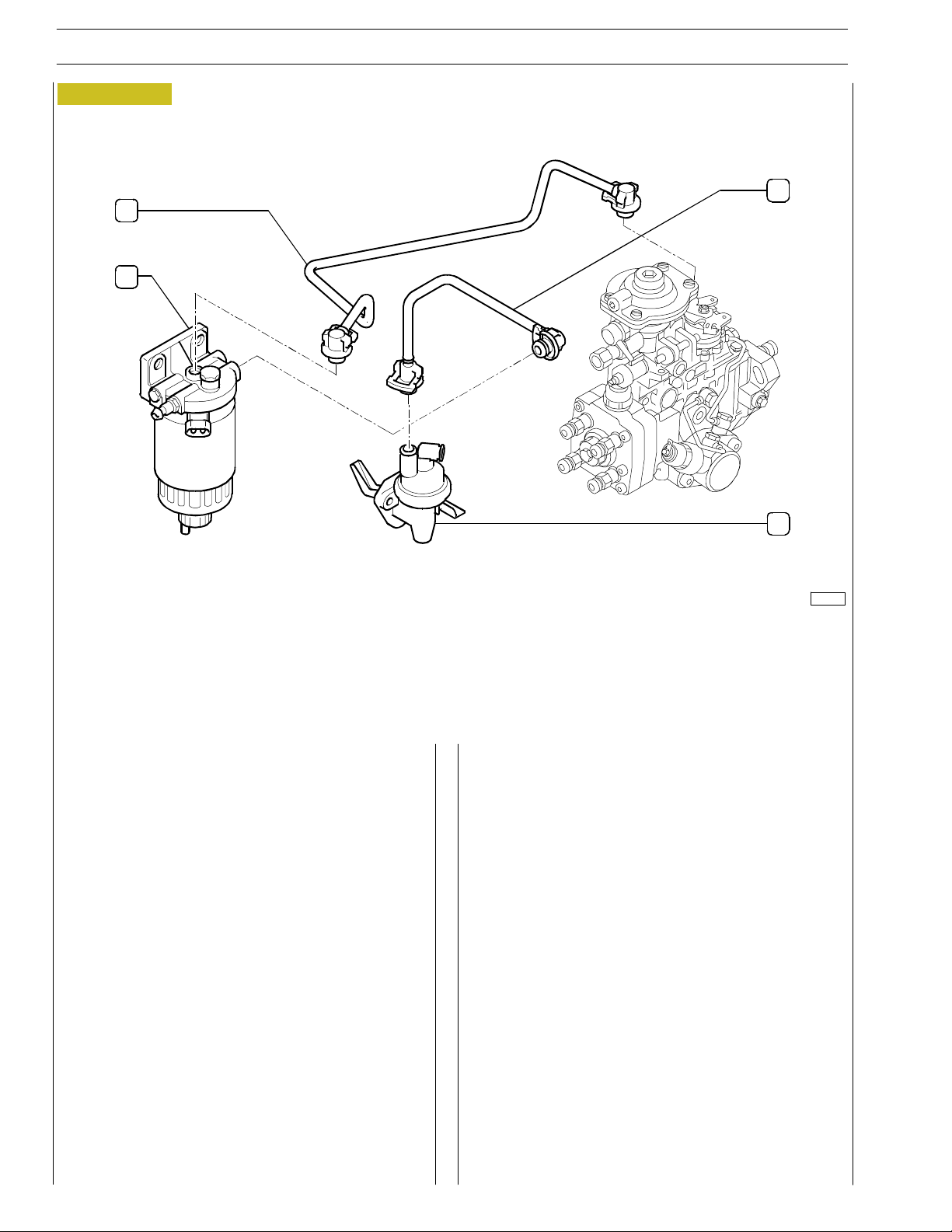

Figure 2

SECTION 2 - FUEL

2

1

F4GE N SERIES

3

1. Fuel filter - 2. Feed pipeline from filter to fuel pump - 3. Feed pipeline from priming pump to filter - 4. Priming pump.

Description of working principles

Fuel is sucked from the fuel tank by the priming pump. This

last one is placed on the engine basement and is driven by

the camshaft.

Throughout the filter, the fuel is piped to the union fitting

vacuum c hamber of the transfer pump. (For applications to

be equipped in cold climate areas, the fuel filter is provided

with heater).

Transfer pump is placed inside the feed pump, and is bladed

type; its duty is to increase fuel pressure in c orrespondence

with the increase of the number of revolutions.

The fuel arrives therefore to the valve gauging the pressure

inside feed pump.

The distribution plunger further increases this pressure and

delivers fuel throughout the delivery pipe fitting to the

injectors.

The fuel drawing from the injectors is recovered and delivered

to the tank again.

4

75807

B

P2D32N010E

Loading...

Loading...