Page 1

F32TIER3

SERIES

Industrial application

F32 MNS

F32 MNT

Technical and Repair manual

Page 2

This publication provides unit and relevant component repair

data, specifications, instructions and methodologies.

This publication has been drawn up for qualified and

specialised personnel.

Before performing any operation check that the part relevant

to the unit on which you must work is available along with all

safety devices for accident-prevention, such as, goggles,

helmet, gloves, shoes, etc. and hoisting and transporting

equipment.

Operationsaretobeperformedbyfollowingtheindications

included here, using the special equipment indicated and

assuring proper repair, compliance with schedule and

operator's safety requirements.

Each repair must aim to restore operating efficiency and safety

in compliance with the FPT provisions.

FPT cannot be held liable for modifications, alterations or other

interventions non authorised by FPT on the vehicle and if the

unit is warranted the above mentioned interventions will cause

its expiration.

FPT is not liable for repairing interventions.

FPT will provide further details required to carry out the

interventions and all the instructions that are not included on

this publication.

Data included in this publication may not be up-to-date

therefore subject to Manufacturer's modifications that can be

added at any time for technical or commercial purposes and

also to meet new law regulations in other Countries.

If issues on this publication differ from what is actually noticed

on the unit, please get in touch with the FPT network before

starting any intervention”.

It is forbidden to copy this text or any of its parts and all

illustrations included.

Publication edited by:

FPT - Fiat Powertrain Technologies

www.fptpowertrain.com

Print P2D32F005 E -2

nd

Ed. 04.2009

Revi 04.2012

Page 3

F32 SERIES

p

r

1

F32 SERIES

F32 Series Part 1

PrintP2D32F005 E Base - A

il 2009

Page 4

2

p

r

F32 SERIES

il 2009

PrintP2D32F005 EBase - A

Page 5

F32 SERIES

p

r

INTRODUCTION 1

Introduction

Page

PREFACE 3...............................

SYMBOLS 3.............................

- Warnings 3.............................

- Service operations 3......................

GENERAL WARNINGS 5...................

GENERAL WARNINGS

ON THE ELECTRIC SYSTEM 7.............

- Bonding and screening 8...................

CONVERSIONS BETWEEN THE MAIN UNITS

OF MEASUREMENT OF THE INTERNATIONAL

SYSTEM AND MOST USED DERIVED

QUANTITIES 9.........................

KEY OF LECTURE OF THE HEADINGS

AND FOOTNOTES 10...................

PrintP2D32F005 E Base - A

il 2009

Page 6

2

p

r

INTRODUCTION

F32 SERIES

Base - A

il 2009 PrintP2D32F005 E

Page 7

F32 SERIES

p

r

INTRODUCTION 3

PREFACE

Manuals for repairs are split into Parts and Sections, each one of which is marked by a numeral; the contents of these sections are

indicated in the general table of contents.

The sections dealing with things mechanic introduce the specifications, tightening torque values, tool lists, assembly

detaching/reattaching operations, bench overhauling operations, diagnosis procedures and maintenance schedules.

The sections (or parts) of the electric/electronic system include the descriptions of the electric network and the assembly’s

electronic systems, wiring diagrams, electric features of components, component coding and the diagnosis procedures for the

control units peculiar to the electric system.

Section 1 describes the engines illustrating its features and working in general.

Section 2 describes the type of fuel feed.

Section 3 relates to the specific duty and is divided in four separate parts:

1. Mechanical part, related to the engine overhaul, limited to those components with different characteristics based on the relating

specific duty.

2. Electrical part, concerning wiring harness, electrical and electronic equipment with different characteristics based on the relating

specific duty.

3. Maintenance planning and specific overhaul.

4. Troubleshooting part dedicated to the operators who, being entitled to provide technical assistance, shall have simple and direct

instructions to identify the cause of the major inconveniences.

Sections 4 and 5 illustrate the overhaul operations of the engine overhaul on stand and the necessary equipment to execute such

operations.

The appendix contains a list of the general safety regulations to be respected by all installation and maintenance engineers in order

to prevent serious accidents taking place.

The manual uses proper symbols in its descriptions; the purpose of these symbols is to classify contained i nformation. In particular,

there have been defined a set of symbols to classify warnings and a set for assistance operations.

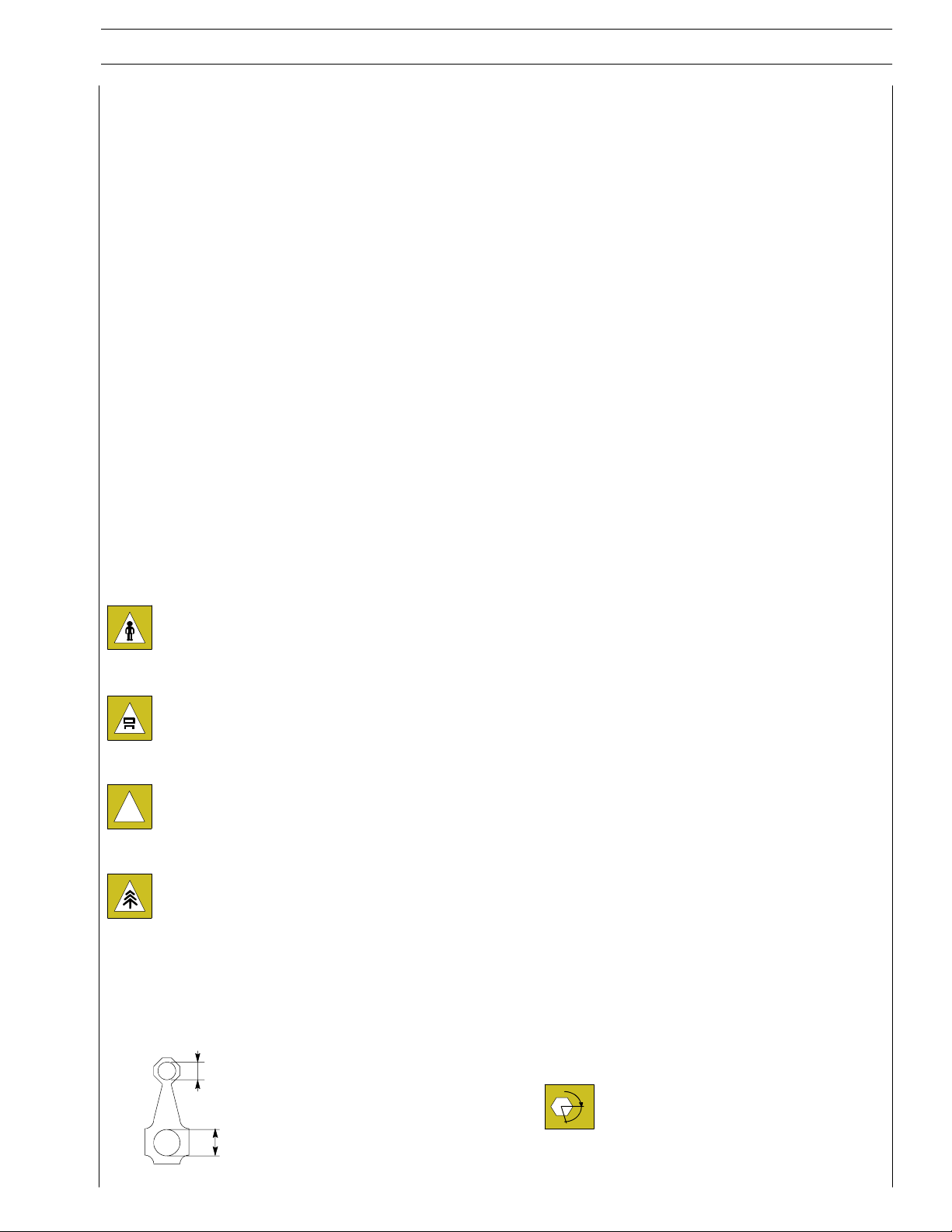

SYMBOLS - Warnings

Danger for persons

Missing or incomplete observance of these prescriptions can cause serious danger for persons’ safety.

Danger of serious damage for the assembly

Failure to comply, both fully or in part, with such prescriptions will involve serious damage to the assembly and may

sometimes cause the warranty to become null and void.

General danger

!

It includes the dangers of above described signals.

Environment protection

Moreover, it describes the correct actions to be taken to ensure that the assembly is used in such a way so as to protect

the environment as much as possible.

NOTE

It indicates an additional explanation for a piece of information.

Service operations

Example

∅

Ø 1 = Seat of small end bush

1

Close applying the required torque

Closeapplyingtherequiredtorque+angular

Ø 2 = Seat of connecting rod bearings.

∅

2

PrintP2D32F005 E Base - A

α

value

il 2009

Page 8

4

p

r

INTRODUCTION

F32 SERIES

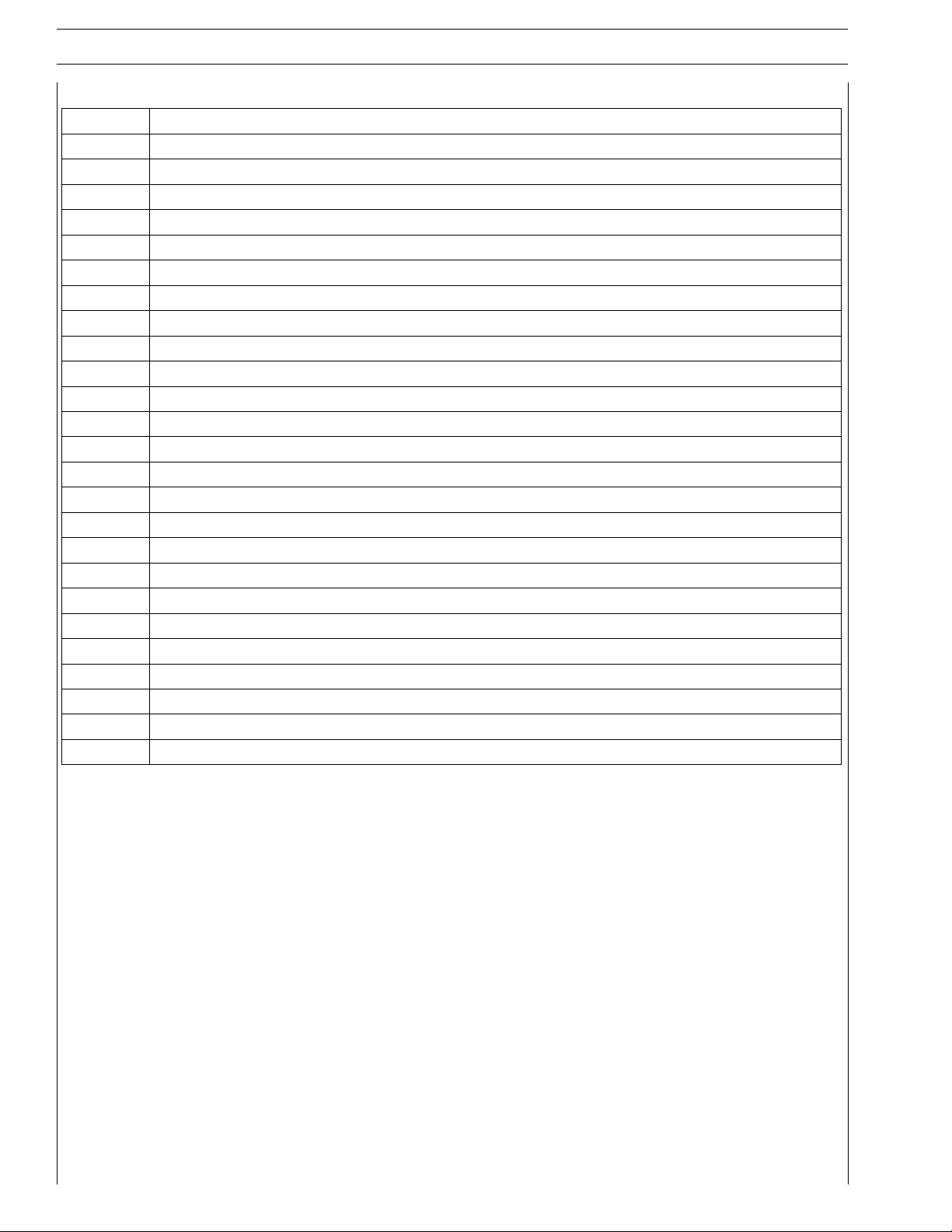

Removal

Disconnection

Refitting

Connection

Removal

Disassembly

Fitting in place

Assembly

ρ

Exhaust

Operation

Compression ratio

Tolerance

Weight difference

Tighten to torque Rolling torque

Tighten to torque + angle value Rotation

α

Press or caulk

Regulation

Adjustment

Angle

Angular value

Preload

Visual inspection

Fitting position check

Measurement

Value to find

Check

Equipment

Surface for machining

Machine finish

Interference

Strained assembly

Thickness

Clearance

Lubrication

Damp

Grease

Sealant

Adhesive

bar

Number of revolutions

Temperature

Pressure

Oversized

Higher than….

Maximum, peak

Undersized

Less than….

Minimum

Selection

Classes

Oversizing

Temperature < 0 °C

Cold

Winter

Temperature > 0 °C

Hot

Summer

Air bleeding

Intake

Base - A

il 2009 PrintP2D32F005 E

Page 9

F32 SERIES

p

r

GENERAL WARNINGS

Warnings shown cannot be representative of all danger situations possibly occurring. Therefore, it is suggested to contact

immediate superiors where a danger situation occurs which is not described.

!

Use both specific and general-purpose toolings according to the prescriptions contained in respective use and

maintenance handbooks. Check use state and suitability of tools not subjected to regular check.

Manual handling of loads must be appraised beforehand, because this not only depends on the weight but also on the

size and path.

Handling with mechanical means must be done with lifters that are suitable for weight, shape and volume. Hoisters, ropes

and hooks used must contain clear indications on maximum carrying capacity acceptable. The use of said means is

compulsorily permitted to authorised personnel only. Stay duly clear of the load, and, anyhow, never under it.

In disassembling operations, always observe provided prescriptions; prevent mechanical parts being taken out from

accidentally striking workshop personnel.

Workshop jobs performed in pairs must always be performed in maximum safety; avoid operations which could be

dangerous for the c o-operator because of lack of visibility or of his/her not correct position.

Keep personnel not authorised to operations clear of working area.

You shall get familiar with the operating and safety instructions for the assembly prior to operating on the latter. Strictly

follow all the safety indications found on the assembly.

INTRODUCTION 5

Do not leave the running assembly unattended when making repairs.

When carrying out work on the assembly lifted off the ground, verify that the assembly is firmly placed on its supporting

stands, and that the manual/automatic safety devices have been actuated in the event that the assembly is to be lifted

by means of a hoist.

When you have to operate on assemblies powered by natural gas, follow the instructions contained in the document,

as well as all the specific safety standards provided for.

Only remove radiator cap when the engine is cold by cautiously unscrewing it in order to let system residual pressure

out.

Inflammable fuel and all inflammable fluids and liquids must be handled with care, according to what contained on harmful

materials 16-point cards. Refuelling must be performed outdoors with the engine off, avoiding lit cigarettes, free flames

or sparks in order to prevent sudden fires/bursts. Adequately store inflammable, corrosive and polluting fluids and liquids

according to what provided by regulations in force. Compulsorily avoid to use food containers to store harmful liquids.

Avoid to drill or bore pressurised containers, and throw cloths impregnated with inflammable substances into suitable

containers.

Worn out, damaged or consumable parts must be replaced by original spares.

During workshop activity, always keep the work place clean; timely clear or clean floors from accidental liquid or oil spots.

Electric sockets and electric equipment necessary to perform repair interventions must meet safety rules.

PrintP2D32F005 E Base - A

il 2009

Page 10

6

p

r

INTRODUCTION

F32 SERIES

Put on, where required by the intervention, garments and protections provided in accident prevention rules; contact

with moving parts can cause serious injuries. Use suitable, preferably tight-fitted garments, and avoid to use jewels,

scarves, etc.

Do not leave the engine in motion at workshop locations not provided with a pipe to scavenge exhaust gas outside.

Avoid to breathe fumes coming from heating or from paint welding because they can cause damages to health; operate

outdoors or in suitably ventilated areas. Put on proper inspirator if paint powder is present.

Avoid contact with hot water or steam coming from the engine, radiator and pipings because they could cause serious

burns. Avoid direct contact with liquids and fluids present in vehicle systems; where an accidental contact has occurred,

refer to 16-point cards for provisions to make.

Clean the assemblies and carefully verify that they are intact prior to overhauling. Tidy up detached or disassembled

parts with their securing elements (screws, nuts, etc.) into special containers.

Check for the integrity of the parts which prevent screws from being unscrewed: broken washers, dowels, clips, etc.

Self-locking nuts with an insert made of nylon must always be replaced.

Avoid contact of rubber parts with diesel oil, petrol or other not compatible substances.

Before washing under pressure mechanical parts, protect electric connectors, and central units, if present.

Tightening screws and nuts must always be according to prescriptions; FPT commercial and assistance network is

available to give all clarifications necessary to perform repair interventions not provided in this document.

Before welding:

- Disconnect all electronic central units, take power cable off battery positive terminal (connect it to chassis bonding)

and detach connectors.

- Remove paint by using proper solvents or paint removers and clean relevant surfices with soap and water.

- Await about 15 minutes before welding.

- Equip with suitable fire resistant protections to protect hoses or other components where fluids or other materials

flow which may catch fire easily on welding.

Should the vehicle be subjected to temperatures exceeding 80°C (dryer ovens), disassemble drive electronic central

units.

The disposal of all liquids and fluids must be performed with full observance of specific rules in force.

Base - A

il 2009 PrintP2D32F005 E

Page 11

F32 SERIES

p

r

GENERALWARNINGS ON THE ELECTRIC SYSTEM

If an intervention has to be made on the electric/electronic system, disconnect batteries from the system; in this case,

!

always disconnect, as a first one, the chassis bonding cable from batteries negative terminal.

Before connecting the batteries to the system, make sure that the system is well isolated.

Disconnect the external recharging apparatus from the public utility network before taking apparatus pins off battery

terminals.

Do not cause sparks to be generated in checking if the circuit is energised.

Do not use a test lamp in checking circuit continuity, but only use proper control apparatuses.

Make sure that the electronic devices wiring harnesses (length, lead type, location, strapping, connection to screening

braiding, bonding, etc.) comply with FPT system and are carefully recovered after repair or maintenance interventions.

Measurements in drive electronic central units, plugged connections and electric connections to components can only

be made on proper testing lines with special plugs and plug bushes. Never use improper means like wires, screwdrivers,

clips and the like in order to avoid the danger of causing a short circuit, as well as of damaging plugged connections, which

would later cause contact problems.

INTRODUCTION 7

To start up the engine, do not use fast chargers. Start up must only be performed with either separate batteries or special

truck.

A wrong polarisation of supply voltage in drive electronic central units (for instance, a wrong polarisation of batteries)

can cause them to be destroyed.

Disconnect the batteries from the system during their recharging with an external apparatus.

On connecting, only screw up connector (temperature sensors, pressure sensors etc.) nuts at prescribed tightening

torque.

Before disconnecting the junction connector from an electronic central unit, isolate the system.

Do not directly supply electronic central units servo components at nominal vehicle voltage.

Cables must be arranged such as to result to be parallel to reference plane, i.e. as close as possible to chassis/body

structure.

Once the intervention on the electric system has been completed, recover connectors and wiring harnesses according

to original arrangement.

NOTE

Connectors present must be seen from cable side. Connectors views contained i n the manual are representative of cable

side.

PrintP2D32F005 E Base - A

il 2009

Page 12

8

p

r

INTRODUCTION

F32 SERIES

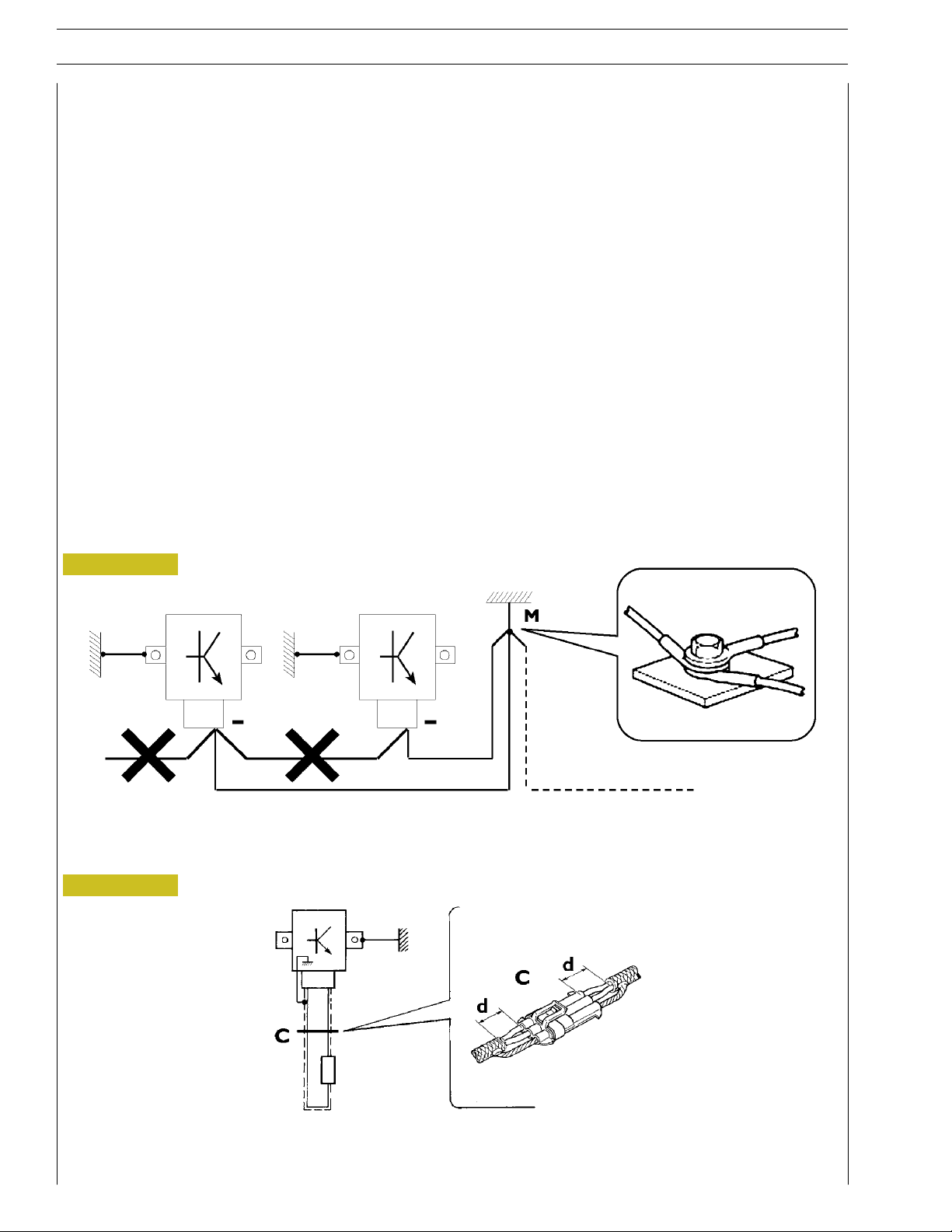

Bonding and screening

Negative leads connected to a system bonded point must be both as short and possible and “star“-connected to each other, trying

then to have their centering tidily and properly made (Figure 1, re. M).

Further, following warnings are to be compulsorily observed for electronic components:

- Electronic central units must be connected to system bonding when they are provided with a metallic shell.

- Electronic central units negative cables must be connected both to a system bonding point such as the dashboard opening

bonding (avoiding “serial“ or “chain“ connections), and to battery negative terminal.

- Analog bonding (sensors), although not connected to battery negative system/terminal bonding, must have optimal isolation.

Consequently, particularly considered must be parasitic resistances in lugs: oxidising, clinching defects, etc.

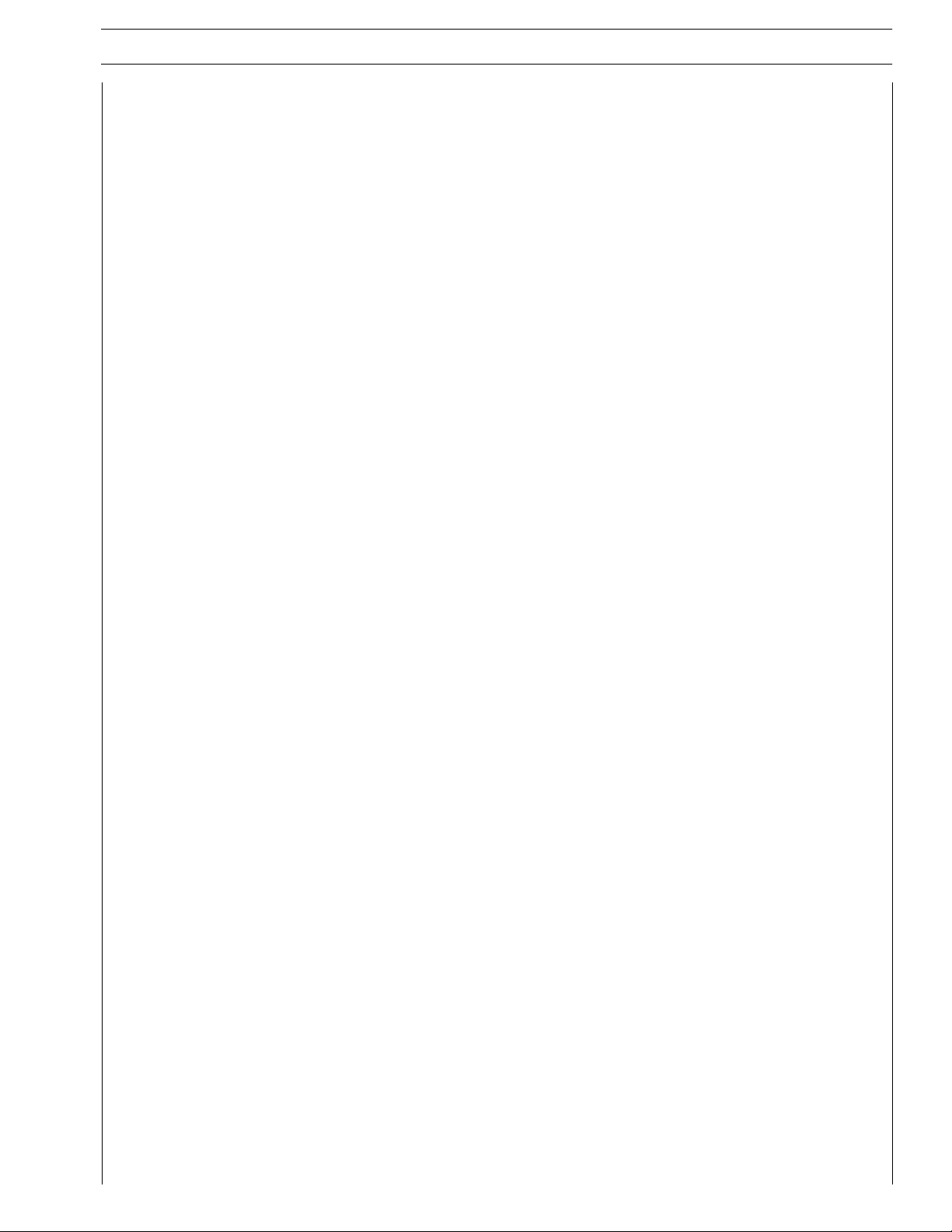

- Screened circuits braiding must only electrically contact the end towards the central unit entered by the signal (Figure 2).

- If junction connectors are present, unscreened section d, near them, must be as short as possible (Figure 2).

- Cables must be arranged such as to result to be parallel to reference plane, i.e. as close as possible to chassis/body structure.

Figure 1

1. NEGATIVE CABLES “STAR“ CONNECTION TO SYSTEM BONDING M

Figure 2

88039

2. SCREENING THROUGH METALLIC BRAIDING OF A CABLE TO AN ELECTRONIC COMPONENT — C. CONNECTOR

d. DISTANCE ! 0

Base - A

il 2009 PrintP2D32F005 E

Page 13

F32 SERIES

p

r

INTRODUCTION 9

CONVERSIONS BETWEEN THE MAIN UNITS OF MEASUREMENT OF THE INTERNATIONAL SYSTEM AND MOST USED DERIVED QUANTITIES

Power

1 kW = 1.36 metric HP

1 kW = 1.34 HP

1 metric HP = 0.736 kW

1 metric HP = 0.986 HP

1 HP = 0.746 kW

1 HP = 1.014 metric HP

Torque

1 Nm = 0.1019 kgm

1 kgm = 9.81 Nm

Revolutions per time unit

1 rad/s = 1 rpm x 0.1046

1 rpm = 1 rad/s x 9.5602

Pressure

Pa

2

2

according to ratio 1:1

1 bar = 1.02 kg/cm

1 kg/cm

1bar = 10

2

= 0.981 bar

5

Where accuracy is not particularly needed:

- Nm unit is for the sake of simplicity converted into kgm according to ratio 10:1

1 kgm = 10 Nm;

- bar unit is for the sake of simplicity converted into kg/cm

2

1 kg/cm

=1bar.

Temperature

0° C=32° F

1° C = (1 x 1.8 + 32) ° F

PrintP2D32F005 E Base - A

il 2009

Page 14

10

p

r

INTRODUCTION

KEY OF LECTURE OF THE HEADINGS AND FOOTNOTES

F32 SERIES

Type of

vehicle

Section

title

Page

number

Printout

number

Base - A

il 2009 PrintP2D32F005 E

Language

Publication

Basic edition referred to

month - year editorial

phase closing

When month - year update

is present (revi) to the basic

edition

Page 15

F32 SERIES

p

r

1

Part 1

F32 SERIES

Section

General specifications

Fuel 2

Industrial application 3

Overhaul and technical specifications 4

Tools 5

Safety prescriptions Appendix

1

PrintP2D32F005 E Base - A

il 2009

Page 16

2

p

r

F32 SERIES

Base - A

il 2009 PrintP2D32F005 E

Page 17

F32 SERIES

UPDATING

Section Description Page Date of revision

3

3

4

Industrial application

Mechanical overhaul

21, 64

30, 31, 32, 33

January 2010

April 2012

Print P2D32F005 E Base - April 2009

Revi 04.2012

Page 18

4

p

r

F32 SERIES

Base - A

il 2009 PrintP2D32F005 E

Page 19

F32 SERIES

p

r

SECTION 1 - GENERAL SPECIFICATIONS 1

SECTION 1

General specifications

Page

CORRESPONDENCY BETWEEN TECHNICAL

CODING AND COMMERCIAL CODING 3....

ENGINE VIEWS

(for F5CE9454E*A005, F5CE9484D*A002 engines) 4..

ENGINE VIEWS

(for F5CE5454B*A004 engines) 5.............

ENGINE LUBRICATION SYSTEM 6.............

- Oil pump 7.............................

- Engine oil filter 8.........................

ENGINE OIL VAPOUR RECIRCULATION 9......

ENGINE COOLING SYSTEM 10.................

- For engines without external EGR 10..........

- For engines with external EGR 11............

WATER PUMP 12............................

THERMOSTAT 12............................

- Working system 12........................

HEAT EXCHANGER 13.......................

EGR EXHAUST GAS RECYCLE SYSTEM 14........

- Internal EGR operating on the intake valves

(for F5CE9454, F5CE9484 engines) 14.........

- Intake cam profile 14......................

- External E.G.R. system

(for F5CE5454 engines) 15..................

- Working system 15........................

BOOSTING 16..............................

- For engines without external EGR 16..........

- For engines with external EGR 17............

PrintP2D32F005 E Base - A

il 2009

Page 20

2

p

r

SECTION 1 - GENERAL SPECIFICATIONS

F32 SERIES

Base - A

il 2009 PrintP2D32F005 E

Page 21

F32 SERIES

p

r

F32MN

S.X

SECTION 1 - GENERAL SPECIFICATIONS 3

CORRESPONDENCY BETWEEN TECHNICAL CODING AND COMMERCIAL CODING

Technical Code Commercial Code

F5CE5454B*A004

F5CE9454E*A005

F5CE9484D*A002 F32 MNT.X

PrintP2D32F005 E Base - A

il 2009

Page 22

4

p

r

SECTION 1 - GENERAL SPECIFICATIONS

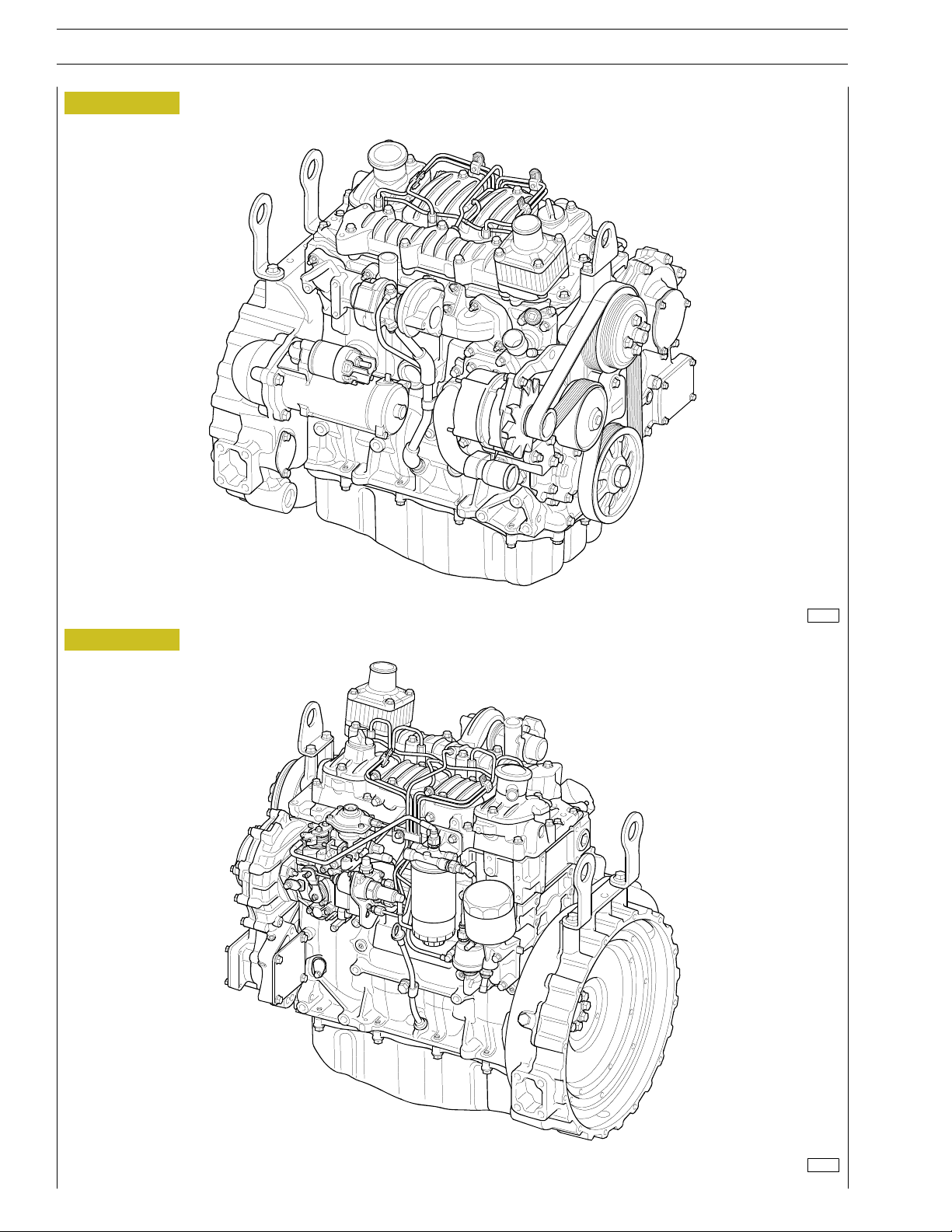

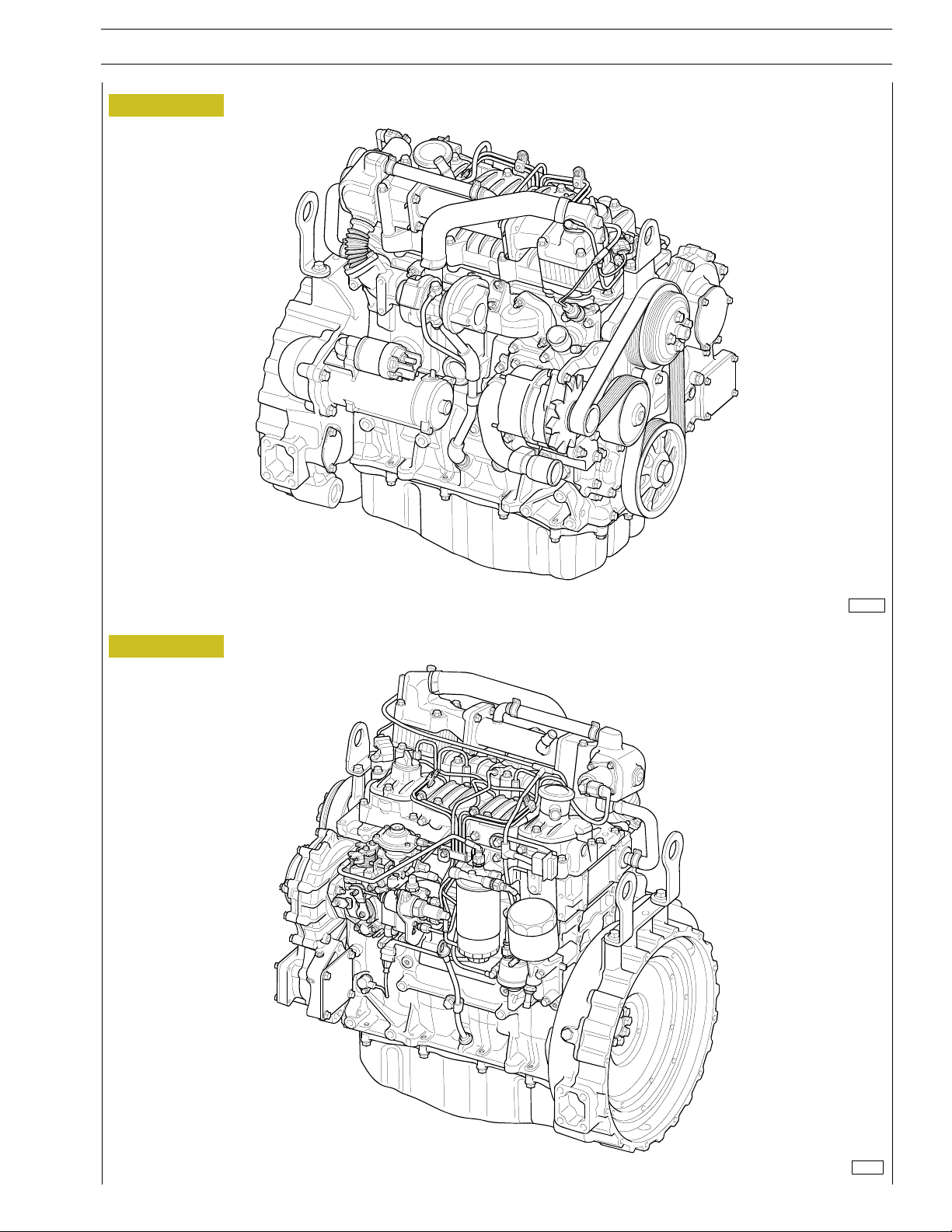

ENGINE VIEWS (for F5CE9454E*A005, F5CE9484D*A002 engines)

Figure 1

F32 SERIES

Figure 2

128134

128135

Base - A

il 2009 PrintP2D32F005 E

Page 23

F32 SERIES

p

r

ENGINE VIEWS (for F5CE5454B*A004 engines)

Figure 3

SECTION 1 - GENERAL SPECIFICATIONS 5

Figure 4

128136

128137

PrintP2D32F005 E Base - A

il 2009

Page 24

6

p

r

SECTION 1 - GENERAL SPECIFICATIONS

F32 SERIES

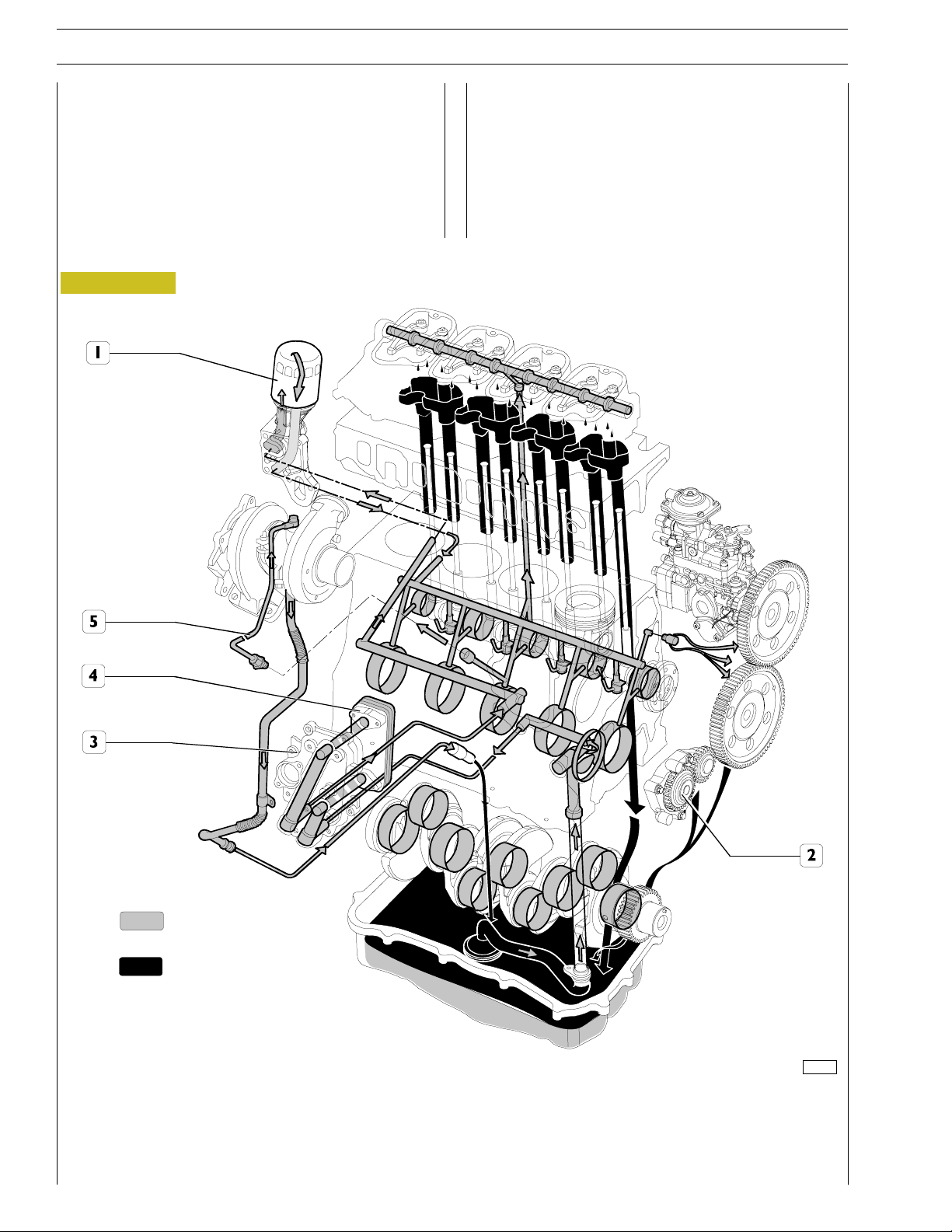

ENGINE LUBRICATION SYSTEM

Forced circulation lubrication is controlled by the rotor oil

pump housed in the front part of the engine basement and

driven by the toothed gear splined on the shank of the engine

drive shaft.

From the oil pan, the lubrication oil is distributed to the engine

drive shaft, the camshaft and the valve control.

Figure 5

The lubrication system also comprises the heat exchanger, he

centrifugal blower for the versions with turbosupercharger

and eventually the compressor if the compressed air system

is also fitted.

All the above mentioned components vary depending on their

use and therefore will be illustrated in the specific section.

Pressurized oil

Dropping oil

127695

LUBRICATION SYSTEM DIAGRAM

1. Oil filter - 2. Oil pump - 3. Heat exchanging unit - 4. Heat exchanger -

5. Turbosupercharger lubrication feed pipe

Base - A

il 2009 PrintP2D32F005 E

Page 25

F32 SERIES

p

r

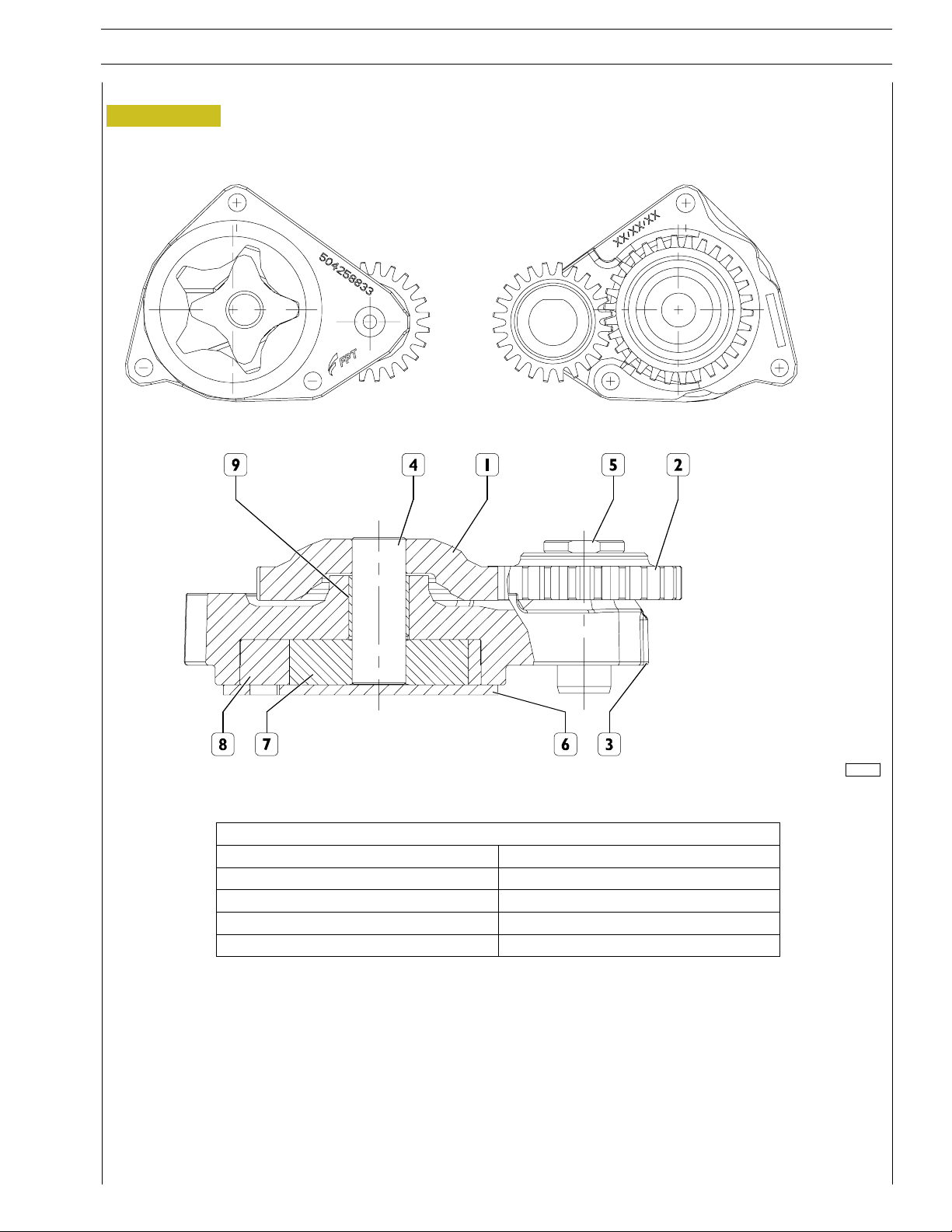

Oil pump

Figure 6

SECTION 1 - GENERAL SPECIFICATIONS 7

119405

PUMP SPECIFICATIONS

Rotating speed 750 rpm - 4200 rpm

Feed pressure 2Bar-4Bar

Rated flow 12.2 l/min - 75.9 l/min

Oil type SAE 20/30

Max. oil temperature 80 °C

1. Main gear - 2. Secondary gear - 3. Pump unit - 4. Drive shaft - 5. Secondary shaft

6. Cover - 7. Internal rotor - 8. External rotor - 9. Bush.

PrintP2D32F005 E Base - A

il 2009

Page 26

8

p

r

SECTION 1 - GENERAL SPECIFICATIONS

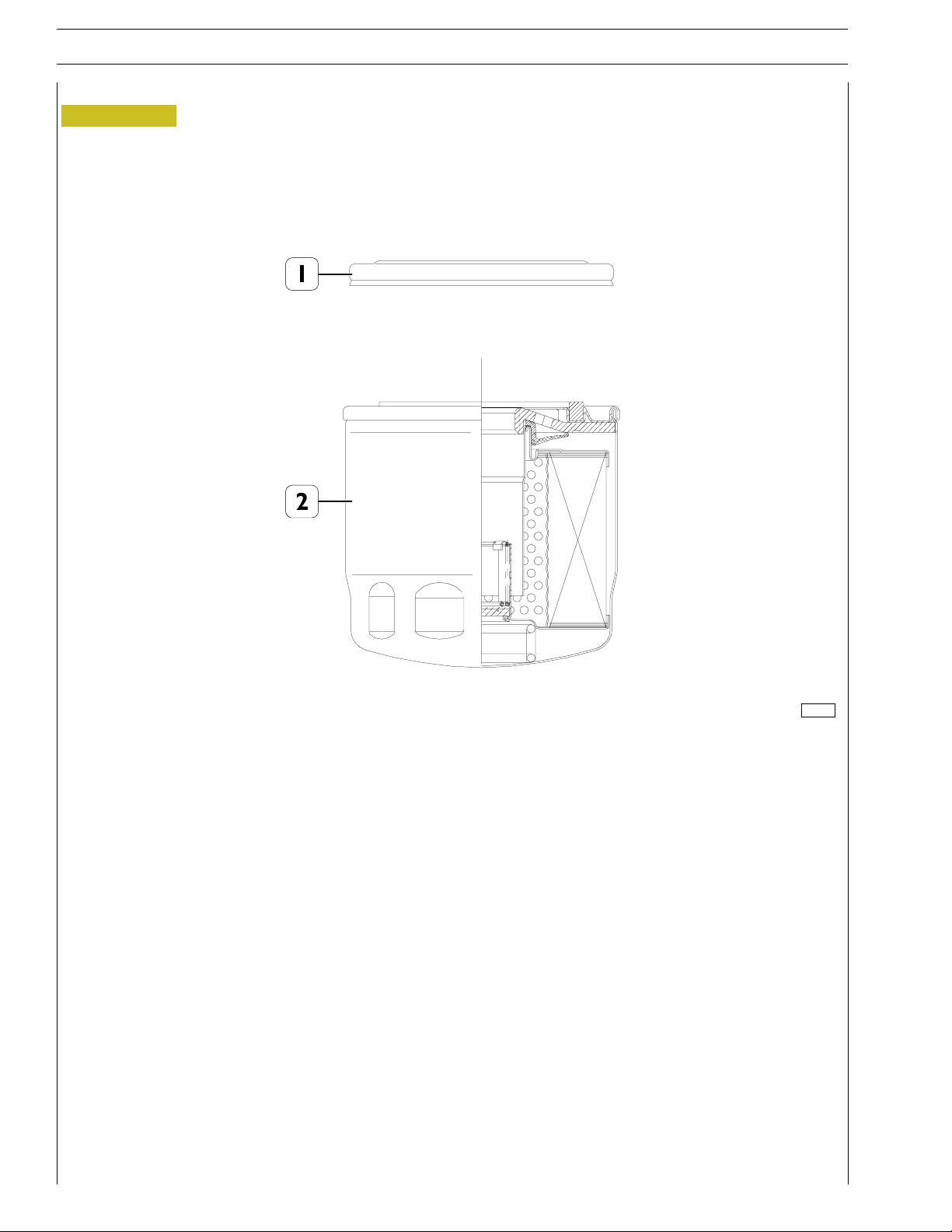

Engine oil filter

Figure 7

F32 SERIES

1. Protective cover - 2. Cartridge

Booster pressure: 20 bar (ISO 4548/3)

Dynamic pressure: 0-15 bar (1Hz) > 50,000 cycles (ISO 4548/5)

Operating temperature: -40 / + 140 ˚C

Torque wrench setting: 32.5 ± 2.5 Nm

Maximum flow: 50 l/min.

Load loss at the end of life cycle: 2.5 bar

Accumulation: > 15 gr with 2.5 bar load loss (ISO 16889)

119406

Base - A

il 2009 PrintP2D32F005 E

Page 27

F32 SERIES

p

r

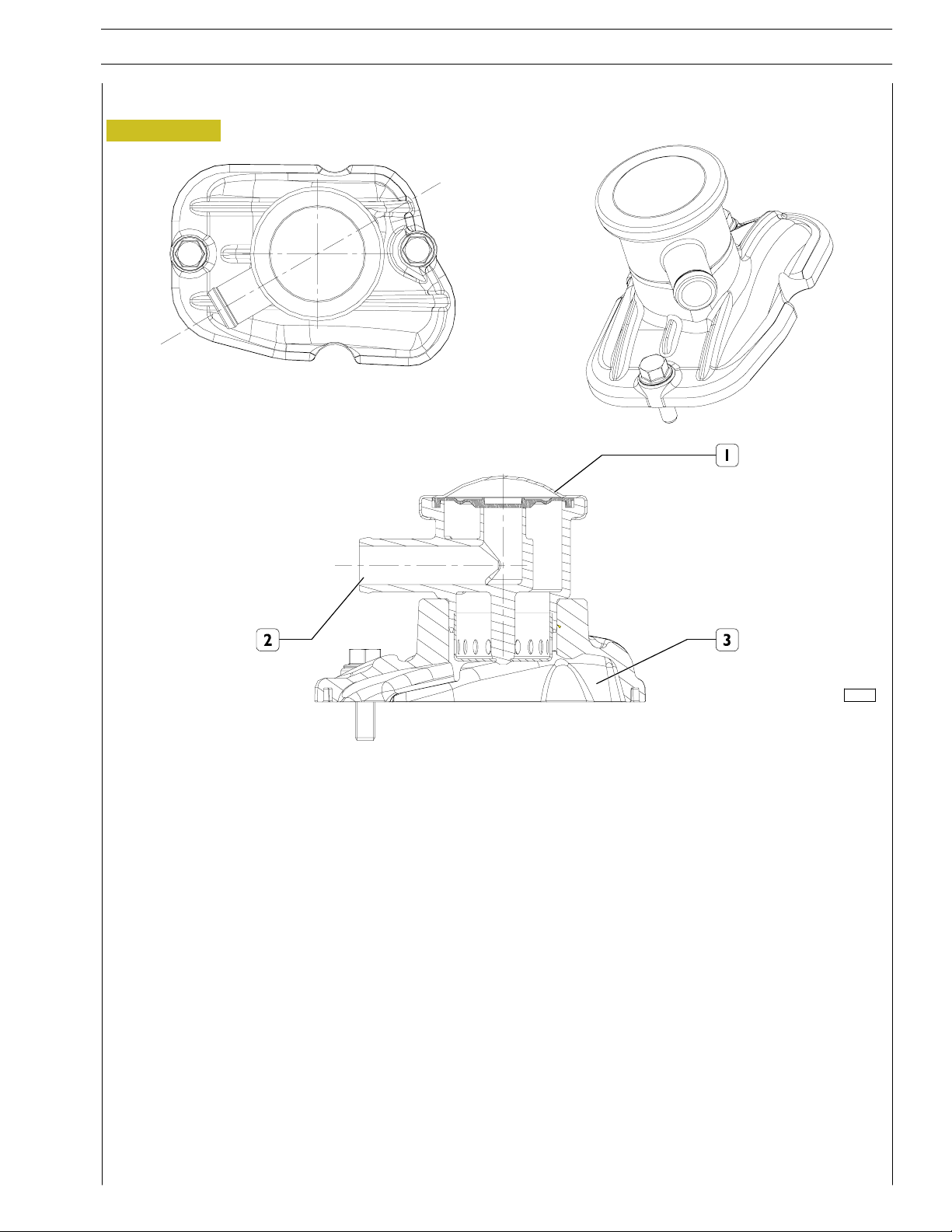

ENGINE OIL VAPOUR RECIRCULATION

Figure 8

SECTION 1 - GENERAL SPECIFICATIONS 9

119407

1. Valve - 2. Breather - 3. Tappet cover

On the tappet cover (3) there is a valve (1) having the duty to cause condensation of oil vapours making them drop by gravity

on the underlying tappet cover (3).

The remaining non condensed vapours will be duly conveyed through the breather (2), for instance by suction (appropriate

connection must be provided by the outfitter).

PrintP2D32F005 E Base - A

il 2009

Page 28

10

p

r

SECTION 1 - GENERAL SPECIFICATIONS

F32 SERIES

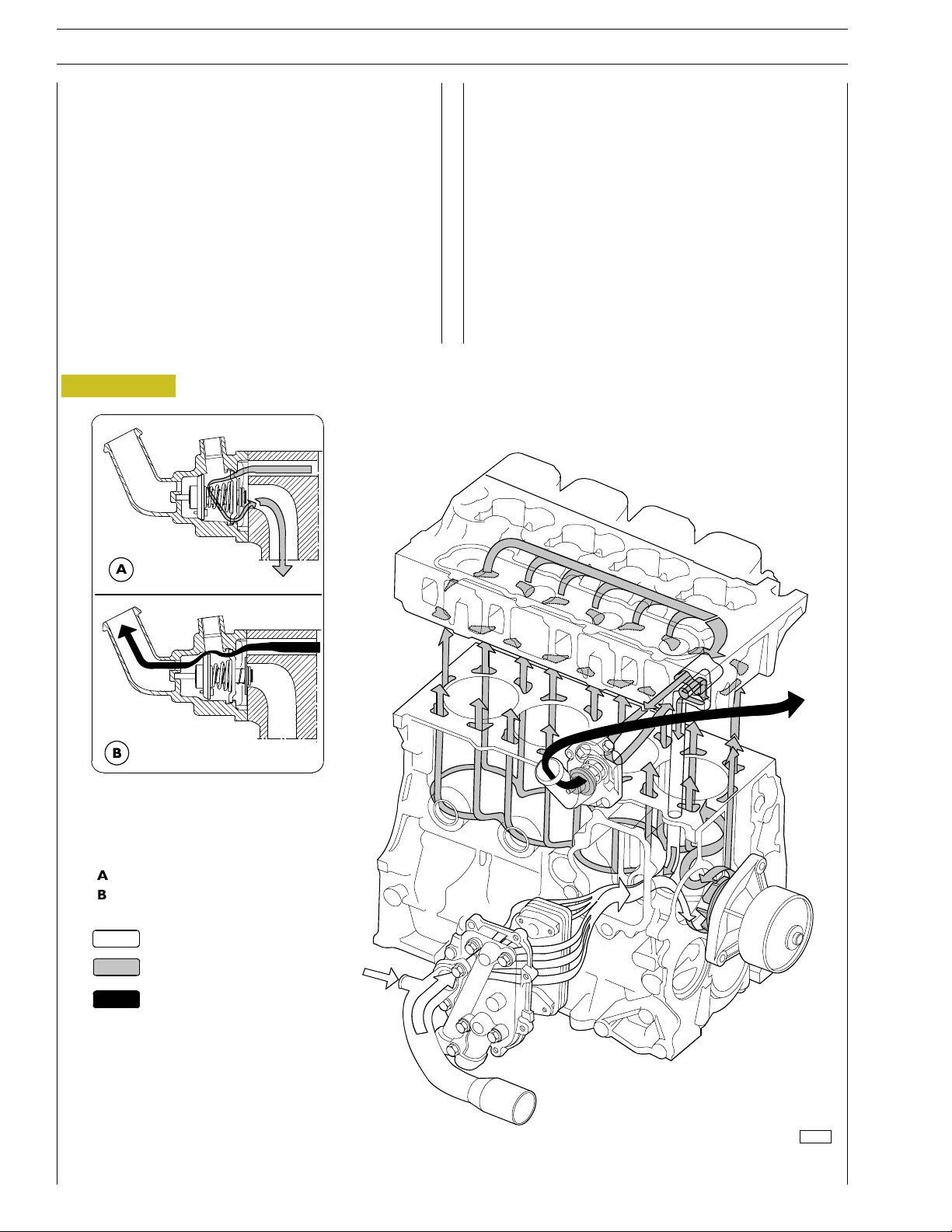

ENGINE COOLING SYSTEM

For engines without external EGR

The closed circuit forced circulation engine cooling system is

composed of the following parts:

- expansion tank: position, form and dimensions may vary

depending on the engine fitting;

- radiator dissipating the heat absorbed by the engine

cooling liquid. This component’s position and dimensions

may vary depending on the outfit;

- fan increasing the radiator’s cooling power. This

component may vary depending on the specific engine

fitting;

Figure 9

- heat exchanger coolingthe lubricant oil. This component

may vary depending on the specific engine fitting;

- centrifugal water pump positioned in the front part of the

engine basement;

- thermostat controlling cooling liquid circulation.

Closed thermostat

Open thermostat

Water inflow

Engine cooling water

Water outflow from thermostat

120018

ENGINE COOLING SYSTEM DIAGRAM

Base - A

il 2009 PrintP2D32F005 E

Page 29

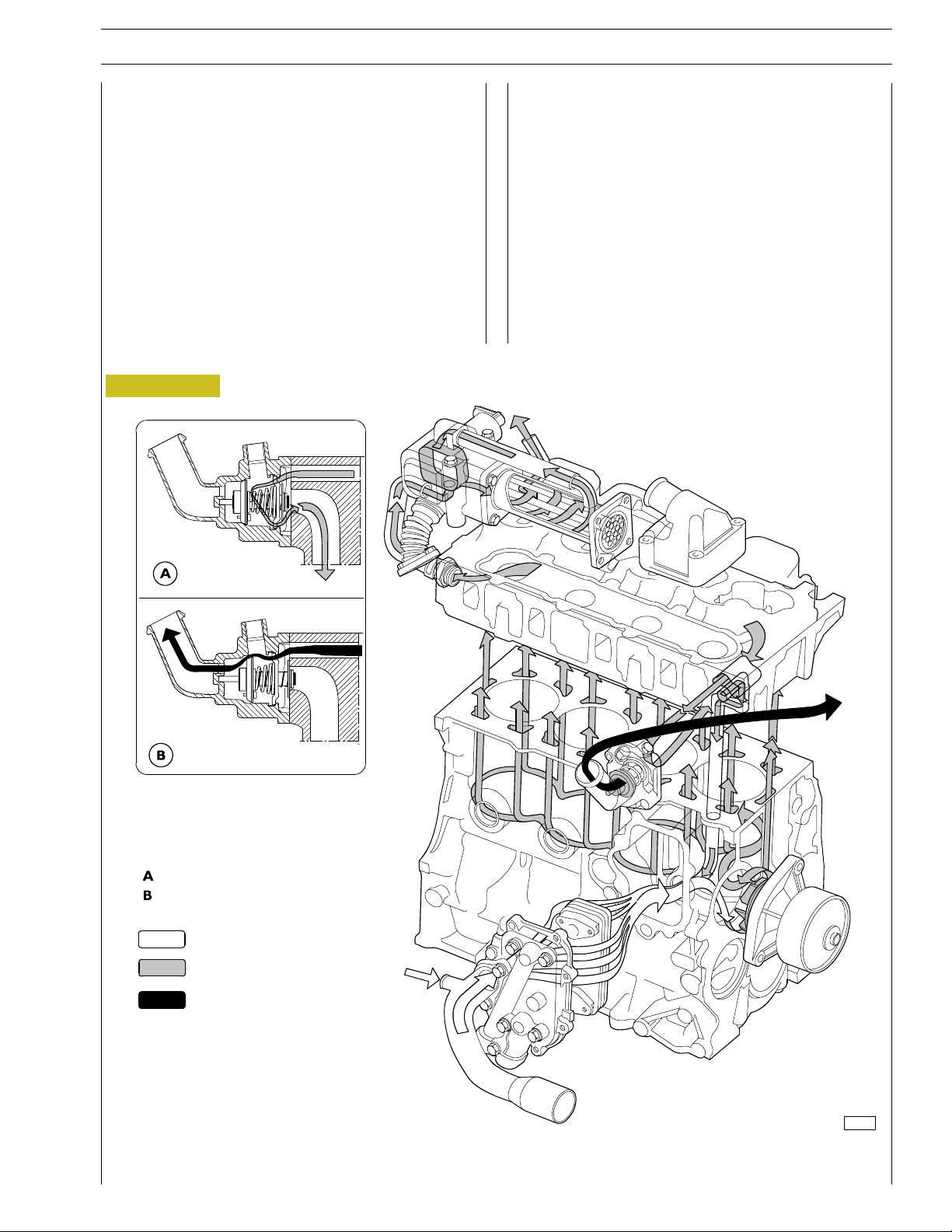

F32 SERIES

p

r

SECTION 1 - GENERAL SPECIFICATIONS 11

For engines with external EGR

The closed circuit forced circulation engine cooling system is

composed of the following parts:

- expansion tank: position, form and dimensions may vary

depending on the engine fitting;

- radiator dissipating the heat absorbed by the engine

cooling liquid. This component’s position and dimensions

may vary depending on the outfit;

- fan increasing the radiator’s cooling power. This

component may vary depending on the specific engine

fitting;

Figure 10

- heat exchanger coolingthe lubricant oil. This component

may vary depending on the specific engine fitting;

- centrifugal water pump positioned in the front part of the

engine basement;

- thermostat controlling cooling liquid circulation.

Closed thermostat

Open thermostat

Water inflow

Engine cooling water

Water outflow from thermostat

118983

ENGINE COOLING SYSTEM DIAGRAM

PrintP2D32F005 E Base - A

il 2009

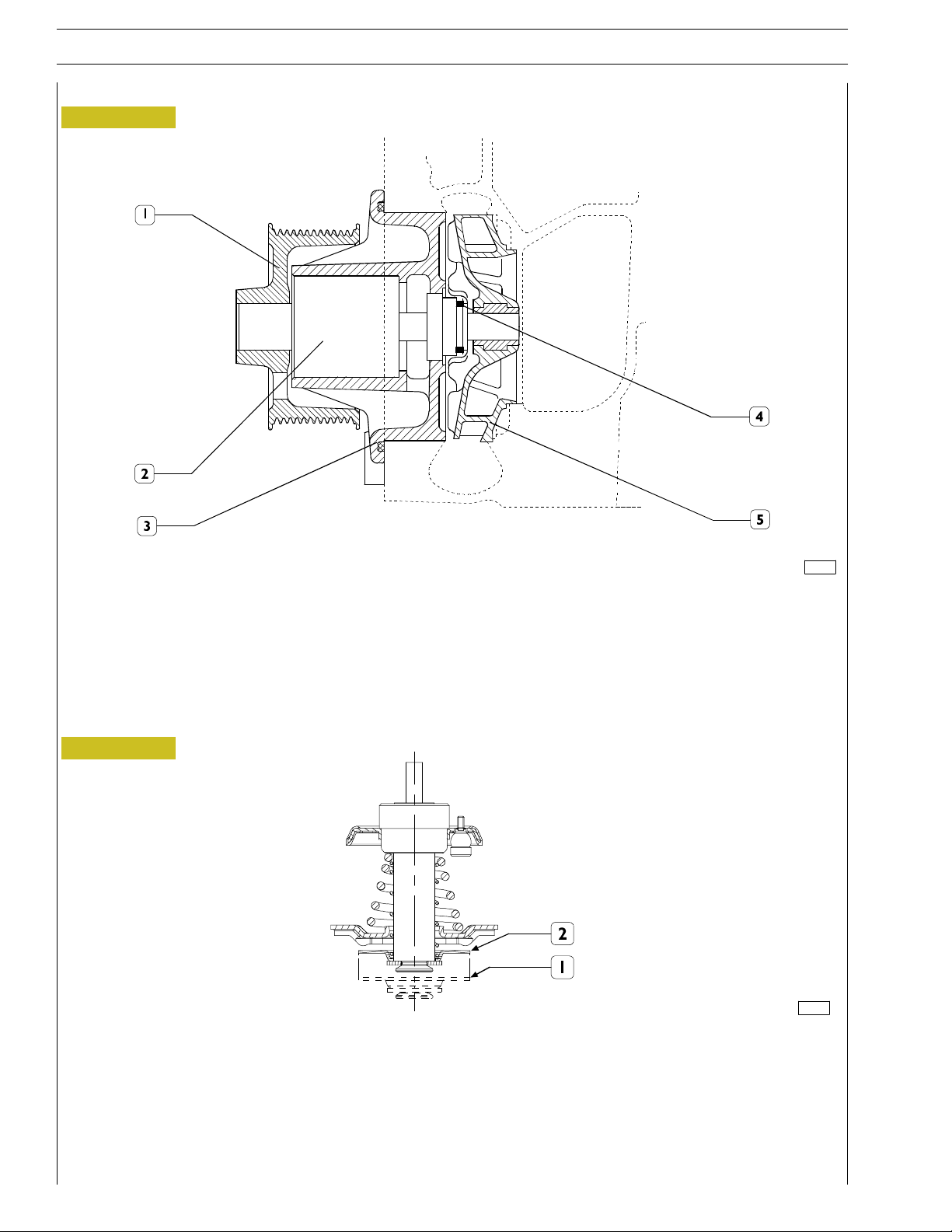

Page 30

W

12

p

r

SECTION 1 - GENERAL SPECIFICATIONS

ATERPUMP

Figure 11

F32 SERIES

120047

WATER PUMP SECTION

1. Hub - 2. Shaft with bearing - 3. Pump unit - 4. Sheath - 5 . Impeller.

The water pump is a centrifugal blade turbine type pump. The pump’s bearing (2) is connected to the impeller’s shaft as a whole.

Water tight between the pump unit (3) and the shaft (2) is ensured by the sheath (4).

THERMOSTAT

Figure 12

119412

THERMOSTAT DIAGRAM

Working system

When the engine is cool, water output from the front part of the cylinder head flows into an inlet containing the thermostat, which

cuts out water circulation to the radiator. This way, water circulation will only be possible in the pump-enginecircuit, insofar allowing

engine heat-up quickly. The thermostat valve starts opening at nearly 80 ˚C, allowing water circulation into the radiator and also

obstructing direct return towards the engine. Check the thermostat efficiency and replace it in case of doubtful functioning.

1. Stroke starts at 79˚ ±2˚C

2. 7 mm stroke at 94˚±2˚C

Base - A

il 2009 PrintP2D32F005 E

Page 31

R

F32 SERIES

p

r

HEAT EXCHANGE

Figure 13

SECTION 1 - GENERAL SPECIFICATIONS 13

SECTION A-A

SECTION B-B

119408

The heat exchanger within the engine cooling system has the duty to control the engine oil temperature, reducing it by absorbing

heat throughout the engine cooling liquid.

PrintP2D32F005 E Base - A

il 2009

Page 32

14

p

r

SECTION 1 - GENERAL SPECIFICATIONS

F32 SERIES

EGR EXHAUST GAS RECYCLE SYSTEM

The exhaust gas can be partially recycled to cylinders to reduce maximum temperature values of combustion that produce nitrogen

oxides (NOx).

The exhaust gas recycle system (EGR) reduces combustion temperature and therefore is an efficient NOx emission control system.

Internal EGR operating on the intake valves (for F5CE9454, F5CE9484 engines)

The specific design of suction cams of the internal EGR system allows part of exhaust gas to be recycled to engine cylinders.

This type of EGR, called internal EGR, is not equipped with any electronic control, the system is always active. Its configuration

requires no additional parts such as control valves, pipelines or heat exchangers therefore engine profile remains unchanged

Besides main lobe, suction cam has an additional lobe as to configuration without EGR. During concerned cylinder exhaust phase,

this lobe allows a shaft advanced opening of intake valve (*). In this way, part of the exhaust gas is trapped in the suction duct and

later, during cylinder suction phase, this gas is recycled to cylinder inlet for combustion phase..

Intake cam profile

Figure 14

*

122430

X. Cam rotation angle (degrees) - Y. Cam lift mm

Base - A

il 2009 PrintP2D32F005 E

Page 33

(

f

)

F32 SERIES

p

r

SECTION 1 - GENERAL SPECIFICATIONS 15

External E.G.R.system

Figure 15

or F5CE5454 engines

119409

1. Valve unit - 2. Heat exchanger - 3. Water pipe - 4. Exhaust gas pipe - 5. Intake manifold

6. Exhaust manifold - 7. Engine head.

Working system

The EGR system fitted in between the exhaust manifold and the intake manifold allows partial exhaust gas recovery into the engine

cylinders after having been cooled throughout a heat exchanger. This way the combustion temperature maximum values,

responsible of the formation of Nitrogen oxides (NOx) can be reduced. Hence, reducing the aforesaid temperatures by decreasing

the concentration of oxygen in the combustion chamber, the EGR system efficiently controls NOx emissions.

As shown in the figure, throughout pipe (4) the exhaust gas will be conveyed through the exhaust manifold to the valve unit (1).

If the control unit enables the valve, the exhaust gas will be conveyed to the heat exchanger (2) where it will be cooled throughout

the engine cooling liquid system which controls the cooling liquid recirculation through the water pipe (3) and the valve unit (1)

(cooling the valve as well) from the engine head to the heat exchanger. The cooled exhaust gas will be further conveyed from the

heat exchanger to the intake manifold.

PrintP2D32F005 E Base - A

il 2009

Page 34

16

p

r

SECTION 1 - GENERAL SPECIFICATIONS

BOOSTING

For engines without external EGR

The boosting system is composed of the following parts:

- Air filter;

- Turbosupercharger.

- An ”intercooler” radiator (if fitted)

Figure 16

F32 SERIES

124466

Sucked air

Heated compressed air

Engine exhaust gas

Base - A

il 2009 PrintP2D32F005 E

Page 35

F32 SERIES

p

r

For engines with external EGR

The boosting system is composed of the following parts:

- Air filter;

- Turbosupercharger.

Figure 17

SECTION 1 - GENERAL SPECIFICATIONS 17

EGR closed valve

EGR open valve

Sucked air

Heated compressed air

Engine exhaust gas

Exhaust gas recirculation

127696

PrintP2D32F005 E Base - A

il 2009

Page 36

18

p

r

SECTION 1 - GENERAL SPECIFICATIONS

F32 SERIES

Base - A

il 2009 PrintP2D32F005 E

Page 37

F32 SERIES

p

r

SECTION 2 - SUPPLY 1

SECTION 2

Supply

Page

SUPPLY 3.................................

PIPE LAYOUT 4............................

- Working System Description 5.............

SUPPLY PUMP 6............................

- Identification coding example 6.............

WORKING SYSTEM DESCRIPTION 7...........

- Supply Phase 7..........................

- Delivery Phase 7.........................

- End of Delivery Phase 8...................

- Engine Stop 8...........................

- L.D.A. Load Delivery Adjustment device 9.....

- Working System 9.......................

PRIMING PUMP 10...........................

FUEL FILTER 11.............................

PrintP2D32F005 E Base - A

il 2009

Page 38

2

p

r

SECTION 2 - SUPPLY

F32 SERIES

Base - A

il 2009 PrintP2D32F005 E

Page 39

F32 SERIES

p

r

SUPPLY

The engine supply system consists of the following components:

- Fuel tank (aboard the vehicle)

- Fuel delivery and return pipes

- Fuel pre-filter (if fitted, it is placed nearby the engine on the vehicle’s chassis)

- Priming pump, fitted on the engine and driver by the engine camshaft

- Fuel filter (its position on the engine may vary depending on the outfit and use)

- Supplyrotarypump

- Injector feed pipe (from the fuel supply pump to the fuel injectors)

- Injectors

Figure 1

SECTION 2 - SUPPLY

3

119420

SUPPLY SYSTEM DIAGRAM

1. Injectors - 2. Fuel filter - 3. Tank - 4. Supply rotary pump - 5. Ignition pump.

PrintP2D32F005 E Base - A

il 2009

Page 40

4

p

r

SECTION 2 - SUPPLY

PIPE LAYOUT

Figure 2

F32 SERIES

118976

1. Injector feed pipe - 2. Fuel exhaust pipe from injectors - 3. Supply rotary pump - 4. Union for pressure gauge pipe within

LDA intake manifold - 5. KSB thermal bulb - 6. Solenoid valve - 7. Injector.

Base - A

il 2009 PrintP2D32F005 E

Page 41

F32 SERIES

p

r

Figure 3

SECTION 2 - SUPPLY

5

Working system description

The fuel (5) is primed from the fuel tank from the priming

pump (6). The latter is fitted on the engine basement and is

driven by the engine camshaft.

Throughout the filter (4), fuel is conveyed to the transfer

pump, which is placed inside the supply rotary pump (2),

which is a turbine blade pump type. The supply rotary pump

duty is to increase the fuel pressure based on the increase of

engine revolutions’ number.

119961

Then, the fuel reach es the valve con trolling fuel pressure with in

the supply pump.

The distributor piston further inc reases such pressure and

delivers the fuel to the injectors (1) throughout the delivery

pipe fitting.

The fuel leak (3) from the injectors is recovered and sent back

to the fuel tank.

PrintP2D32F005 E Base - A

il 2009

Page 42

6

p

r

SECTION 2 - SUPPLY

SUPPLY PUMP

The rotary type supply pump is driven by a gear which is coupled to the en gine camshaft gear.

Identification coding example

V = rotary distributor piston pump

E = pump dimensions

4 = four cylinder engines

12 = distributor piston size in mm

1150 = no. of pump rev./min.

RV = right direction rotation

Figure 4

F32 SERIES

1

15

2

14

3

4

5

13

12

6

7

8

9

11

10

30454

Ignition pump longitudinal section

1. Membrane - 2. Setting ring - 3. Feeler pin - 4. Drive lever - 5. Speed regulator - 6. Transfer pump - 7. Drive shaft -

8. Cam disk - 9. Spark lead adjuster - 10. Distributor piston - 11. Feed pipe fitting - 12. Hydraulic head - 13. Control plate -

14. Adjusting pin - 15. Counter spring.

Base - A

il 2009 PrintP2D32F005 E

Page 43

F32 SERIES

p

r

WORKING SYSTEM DESCRIPTION

Supply phase

Figure 5

SECTION 2 - SUPPLY

7

119415

1. Fuel supply pipe - 2. Solenoid valve - 3. Axial groove - 4. Compression chamber - 5. Fuel delivery pipe from pump to

injectors - 6. Distributor piston - 7. End of delivery port - 8. Cursor - 9. Injector.

The distributor piston (6) is at B.D.C. and the cursor (8) closes the delivery port (7). The fuel is delivered to the compression

chamber (4) through the feed pipe (1) which is kept open by the solenoid valve (2).

Delivery phase

Figure 6

119416

1. Fuel feed pipe - 2. Compression chamber - 3. Distributor piston inner pipe

4. Fuel delivery pipe from pump to injec tor - 5. Distributor piston - 6. Injector.

The distributor piston (5) driven by the cam disk, goes up to the T.D.C. and simultaneously rotates on its own axle. The

combination of the two motions determines the closure of the fuel feed pipe (1) as well as the fuel compression within the

chamber (2). The distributor piston inner pipe (5) is connected to the feed pipe (4) thus enabling fuel delivery to the injectors

(6).

PrintP2D32F005 E Base - A

il 2009

Page 44

8

p

r

SECTION 2 - SUPPLY

End of delivery phase

Figure 7

F32 SERIES

119417

1. Fuel feed pipe - 2. Compression chamber - 3. Fuel delivery pipe - 4. End of delivery pipe -

5. Cursor - 6. Distributor piston.

The distributor piston (6) moving towards the T.D.C. connects the high pressure inner chamber to the pipe (1), thereby

establishing pressure balance between the distributor piston inner chamber, the injectors’ delivery pipe and the pump interior.

Since such pressure is lower than the one required to start the injector, end of delivery will be determined.

Engine stop

Figure 8

119418

1. Fuel feed pipe - 2. Mobile cap - 3. Spring - 4. Solenoid valve - 5. Compression chamber.

Engine stop is provoked cutting out the starter contact.

The electric flux to the solenoid valve (4) is c ut out. The solenoid valve, throughout its spring (3), drives the mobile cap to the

end of stroke (2) and the mobile cap obstructs the fuel feed pipe (1).

Base - A

il 2009 PrintP2D32F005 E

Page 45

F32 SERIES

p

r

L.D.A. Load Delivery Adjustment device

Figure 9

SECTION 2 - SUPPLY

9

119419

Working system

The duty of the L.D.A. device is to adjust the fuel delivery depending on the air pressure within the intake manifold.

Air pressure acts on the membrane (1), which is tied up to the setting pin (4). In the lower part of the setting pin (4) there is

a conical hou sing (5) in which the feeling pin runs (6).

The setting pin (4) axial motion drives the feeling pin (6) shift and the latter acts on th e stop lever (7). The stop lever rotates

on its own axle (8) and acts on the control plate in order to adjust the fuel delivery depending on the air quantity within the

cylinders.

PrintP2D32F005 E Base - A

il 2009

Page 46

10

p

r

SECTION 2 - SUPPLY

F32 SERIES

PRIMING PUMP

The primingpump duty is to prime the fuel from the tank and convey it to the fuel supply pump. It is fitted on the engine basement

and driven by the engine camsh aft.

Figure 10

1. Pump - 2. Control lever - 3. Camshaft.

88209

Base - A

il 2009 PrintP2D32F005 E

Page 47

F32 SERIES

p

r

SECTION 2 - SUPPLY

FUEL FILTER

The filter is placed nearby the supply pump and the priming pump. Its duty is to retain impurities and separate water from the

fuel in which it is contained.

At th e bottom of th e filtering cartridge there may be a water drainage device (3).

Figure 11

11

119411

1. Fuel filter support - 2. Cartridge filter- 3. Water drainage device

PrintP2D32F005 E Base - A

il 2009

Page 48

12

p

r

SECTION 2 - SUPPLY

F32 SERIES

Base - A

il 2009 PrintP2D32F005 E

Page 49

F32 SERIES

p

r

SECTION 3 - INDUSTRIAL APPLICATION

SECTION 3

Industrial application

MAIN SPECIFICATIONS 3..................

PART ONE -

MECHANICAL COMPONENTS 5.........

ENGINE DISASSEMBLY ON BENCH 7........

- Cylinder 1 T.D.C. search 8.................

- BOSCH VE 4/12F Pump 9.................

- Timing gearcase 12........................

- Rear side co mponent assembly 14...........

- Flywheel assembly 14......................

1

Page

- Front side component installation 15..........

- Timing 16...............................

- Piston projection measurement 17...........

- Checks and inspections 25..................

- Rocker cover blow-by removal and refitting 26..

- Rotary feed pump disassembly and assembly

procedure 30............................

- Injection pump static advance control on engine at

cylinder 1 TDC 33........................

- Power takeoff 33.........................

PART TWO - ELECTRICAL EQUIPMENT 35...

ENGINE CABLE FOR EXTERNAL EGR SYSTEM

(FOR F5CE5454 ENGINES) 37..............

EXTERNAL EGR E.C.U. ELECTRICAL LAYOUT

(FOR F5CE5454 ENGINES) 38..............

- External EGR E.C.U.

(for F5CE5454 engines) 39.................

- Pin out EGR E.C.U. 40.....................

KSB - BOSCH PUMP CONNECTION CABLE 41.

PrintP2D32F005 E Base - A

il 2009

Page 50

2

p

r

SECTION 3 - INDUSTRIAL APPLICATION

Page

- E n gine cooling liquid temperature sensor

(for F5CE5454 engines) 42.................

- O il pressure switch 43.....................

- Cooling liquid temperature sensor for KSB 44...

- Air pressure temperature sensor

(for F5CE5454 engines) 45.................

- Engine drive shaft sensor (for F5CE5454 engines) 46

- EGR Solenoid valve (for F5CE5454 engines) 47.

- Delivery specifications 47...................

- Starter 48...............................

- BOSCH 14V Alternator 49.................

PART THREE - TROUBLESHOOTING 51.......

DIAGNOSIS BY FAILURE 53..................

F32 SERIES

PART FOUR - MAINTENANCE PLANNING 59..

SCHEDULED MAINTENANCE 61.............

- Servicing Plan 61.........................

- Overhaul and/or basic maintenance 61........

- Checks not included in maintenance planning-daily

checks 62...............................

MAINTENANCE PROCEDURES 62............

- Chec ks and controls 62....................

Base - A

il 2009 PrintP2D32F005 E

Page 51

F32 SERIES

p

r

MAIN SPECIFICATIONS

Type F5CE9454E*A005 F5CE5454B*A004 F5CE9484D*A002

Cycle Diesel 4 strokes

Feeding Turbocharged

Injection Direct

N. of cylinders 4 on-line

∅

Diameter mm 99

Stroke mm 104

SECTION 3 - INDUSTRIAL APPLICATION 3

Turbocharged

Turbocharged -

intercooler

+++..=

ρ

Total displacement cm

Compression ratio

Max. power kW

Max. power Nm

Loadless engine

idling rpm

Loadless engine

peak rpm

EGR Internal External Internal

COOLING

Water pump contr ol

Thermostat

- start of opening ºC

3

3200

17 ± 0.5 : 1

(HP)

55

(75)

61

(83)

rpm 2500 2500 2300

(kgm)

281

(29)

310

(32)

rpm 1250 1250 1400

750 750 750

3000 3000 3000

Liquid

Through belt

79 ± 2

65

(88)

340

(35)

OIL SUPPLY

NOTE

Total quantity l

st

1

SAE 15W40 T2

URANIA LD7

filling (kg)

MIN level l

(engine off) (kg)

MAX level l

(engine off) (kg)

Data, features and performances are valid only if the setter fully complies with all the installation prescriptions provided

10.5

(9.2)

7.5

(6.6)

9.5

(8.4)

by FPT.

Furthermore, the users assembled by the setter shall always be in conformance to couple, power and number of turns

based on which the engine has been designed.

PrintP2D32F005 E Base - A

il 2009

Page 52

4

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Base - A

il 2009 PrintP2D32F005 E

Page 53

F32 SERIES

p

r

DIAGNOSI

SECTION 3 - INDUSTRIAL APPLICATION 5

PART ONE - MECHANICAL COMPONENTS

PrintP2D32F005 E Base - A

il 2009

Page 54

6

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Base - A

il 2009 PrintP2D32F005 E

Page 55

F32 SERIES

p

r

zl

SECTION 3 - INDUSTRIAL APPLICATION

7

ENGINE DISASSEMBLY ON BENCH

NOTE

NOTE

NOTE

- Drain the engine oil from the oil pan collecting it in a

Engine disassembly operations to remove the

engine from the vehicle are described in the specific

section. Engine disassembly operations, as w ell as

engine overhaul, must be executed by qualified

engineers only, duly provided with the specific

tools required.

Depending on the appliance, some units may have

different position on the engine.

Before fitting the engine on the rotary stand

99322205, disassemble the parts which may

interfere with the bracket 99361043 assembly.

Depending on the appliance, it may be necessary

to remove the starter and the oil filter.

suitable contain er.

Warning! Avoid skin contac t with the engine oil: in

case of contact wash your skin with running water.

For F5CE5454 engines

Figure 2

119904

- Remove the water delivery pipe (1) from the exchanger.

- Loose the clip and disconnect the pipe (2); remove oil

delivery pipe connected to the t urbocharger (3) and t

the oil return pipe (4).

- Remove the turbocharger unit (5)

The engine oil is highly polluting: waste disposal must

be executed complying with the laws and regulations

in force.

- Remove the electric wiring from the injection pump.

For F5CE9454, F5CE9484 engines

Figure 1

124496

- Remove oil delivery pipe connected t o the turbocharger

(3) and t the oil return pipe (1).

- Remove the turbocharger unit (2).

- Duly hold the starter (5), unscrew the fastening screws

and remove the starter.

- Remove the water h ose (4).

Figure 3

6

4

3

2

1

7

- Using pincers, remove the clips (1) and the water

delivery pipe c onnected to the valve su pport and the

exchanger (2). Loosen the clip (3) and detach the pipe

(4), from the EGR valve housing. Unscrew the EGR

fastening screws on the front side (5), and those on the

valve support side (6), then remove the EGR unit.

- Duly hold the starter (7), unscrew the fastening screws

and remove the starter.

5

119104

PrintP2D32F005 E Base - A

il 2009

Page 56

8

p

r

SECTION 3 - INDUSTRIAL APPLICATION

zl

F32 SERIES

For all engines

Figure 4

119720

- Remove the L.D.A. pipe. Remove the fast clu tch fuel

pipes from the priming pump to the filter (1) and from

the filter to the ignition pump (2), then fit the specially

provided caps to the pipes, the pumps and the filter.

Unscrew the screws (3), fastening the fuel ignition pipes

and remove them.

Cylinder 1 T.D.C. search

Figure 6

124497

- Fit tool (1) 99360330 to flywheel housing to rotate the

flywheel (must be used with a suitable wrench).

Figure 7

Figure 5

119106

- Unscrew the pump fastening screws on the rear part of

the gear cover. To disassemble the pump, fit tool

99340025 to the pump wheel and fix it with the three

screws (1).

Using the specially provided wrenc h , slowly tighten the

screw (2) holding the rear part of the pump removing

the pump completely.

NOTE

Before pump disassembly, use the

speciallyprovided tool (99360612), lock the engine

into theposition corresponding to T.D.C. for

cylinder 1. Now block with the specific sy stem the

pump shaft; this way the pump should be timed, so

that when refitting (if no maintenance intervention

is required on it) no adjustment is necessary.

132006

- Loosen the screws of the plate in which tool 99360612

(1) is to be fitted.

Figure 8

133189

Position the engine drive shaft at T.D.C. of cylinder 1 rotating

the flywheel until achieving the following conditions:

- the notch (1) is visible from the inspection hole;

- tool 99360612 should be fitt ed through the carter into

the port on the flywheel.

Remove tools and tighten the previously loosened plate

screws.

Base - A

il 2009 PrintP2D32F005 E

Page 57

F32 SERIES

p

r

BOSCH VE 4/12F Pump

Figure 9

SECTION 3 - INDUSTRIAL APPLICATION

9

118976

1. Fuel delivery pipes - 2. Fuel recovery pipes - 3. Mechanical pump - 4. LDA - 5. Wax KSB - 6. Injectors.

PrintP2D32F005 E Base - A

il 2009

Page 58

10

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Figure 10

119721

- Place a container under the diesel fuel filter and unscrew

the condense drainage faucet under said filter;

completely drain the diesel fuel container therein.

- Disassemble the diesel fuel filter (1), the filter support

(2), t he priming pump (3), the oil filter (4), the oil filter

support (5), and the KSB water sensor (6).

Warning! The oil filter contains a certain quantity of

engine oil.

Collect the engine oil and dispose it complying with

the applicable laws and regulations in force.

Figure 12

127697

- Loosen the screw (4) and the relevant screw nut on the

belt tensioning bracket (3).

- Loos en the screws (1, 2, 5) and the screw nut (6) in

order to withdraw the belt (2).

- Remove the belt tensioning bracket (3).

- Disassemble the pulleys and the guide rollers.

Figure 13

1

2

Figure 11

122435

- Unscrew the injector support fastening screws (1), disas-

semble the injector supports and remove the injectors (2).

- Loosen the screws (3) and remove the tappet covers.

- Remove the intake manifold (6).

- Remove the thermostat unit (4) and the exhaust

manifold (5).

NOTE

On the central cover there is a lubrication oil

vapour blow-by valve.

All the gaskets must always be replaced in phase of

assembly.

75686

- Duly hold the alternator (1) and detach it from its

support loosening the screw (2): recover nut and

washer.

Figure 14

119109

- Place a container under the heat exchanger (2) to collect

the cooling liquid contained therein.

- Loosen the screws (1) and disassemble the heat

exchanger unit (2).

Base - A

il 2009 PrintP2D32F005 E

Page 59

F32 SERIES

p

r

SECTION 3 - INDUSTRIAL APPLICATION

11

Figure 15

125127

- Remove the electromagnetic joint support (1) and the

water pump (2).

- Loosen the screw (5) and remove the pulley (4), using

a pin (3).

Figure 16

Figure 17

124497

- Fit tool (1) 99360330 to the flywheel box and, using a

wrench, lock the flywheel rotation.

- Loosen the screws fastening the flywheel to the engine

drive shaft.

Figure 18

119113

- Screw two medium length screws in the ports (4), in

order to secure the flywheel with a sling.

- By means of two guide pins (2) previously screwed in the

engine drive shaft ports (3), guide the flywheel

withdrawal throughout a hoist.

- Withdraw the flywheel casing grommet.

- Withdraw the grommet of the timing gearcase.

119111

- Loosen the fastening screws (1), remove the overhead

holding the whole rocker arm unit (2) and recover the

two gaskets (3).

PrintP2D32F005 E Base - A

il 2009

Page 60

12

p

r

SECTION 3 - INDUSTRIAL APPLICATION

Timing gearcase

Figure 19

F32 SERIES

1

- Remove t he rear part (1), of the timing gearcase cover.

127698

Figure 20

119115

- Remove the tappet rods (1).

- Disassemble the cylinder head;

loosen the cylinder head (3) fastening screws (2);

hook the brackets with metal ropes and, throughout a

hoister, detach the cylinder h ead w ith valves from the

basement.

- Remove the cylinder head gasket.

Base - A

il 2009 PrintP2D32F005 E

Page 61

F32 SERIES

p

r

SECTION 3 - INDUSTRIAL APPLICATION

13

Figure 21

119130

- Turntheengineupsidedown.

- Loosen th e screws (2), disassemble the plate (3) and

remove the oil pan (1).

NOTE

The shape and dimensions of the oil pan and the

suction rose may vary depending on th e engine

appliance. Hence, the figures provide a general

indication of the operation to be executed. Yet, the

herein description of th e procedures is exhaustive

and applicable.

Figure 23

119117

- Loosen the screws (1) and remove the oil pump (2).

Figure 24

Figure 22

119116

- Loosen the su ction rose support fastening screws (1).

- Loosen the suction rose (3) fastening screws (3) and

then remove the suction rose.

119118

- Loosen the rocker arm fastening screw (1) from the

disassembled rocker arm holding unit and then remove

the rocker arm.

Figure 25

119119

- Withdraw the rocker arm (1) from one side recovering

the equalizers (2) from the other.

PrintP2D32F005 E Base - A

il 2009

Page 62

14

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Rear side component assembly

Figure 26

133190

SCHEME FOR THE APPLIANCE OF LOCTITE 5999

SEALER ON THE TIMING GEARCASE

- Accurately clean the timing gearcase (1) and the engine

basement.

Figure 27

119121

- Fit the specific tool 99346259 (5) to the rear shank (6)

oftheenginedriveshaft,fixitwiththescrews(4)and

spline the new grommet (3) thereon.

- Position part (1) on part (5), tighten th e screw nut (2)

until the grommet has been fitted (3) into the flywheel

casing (7).

It is absolutely necessary to clean the surface to be

sealed in order to obtain perfect tightness.

!

Apply LOCTITE 5999 sealer on the gearcase in

order to form a sealing bead of a few mm.

The sealing bead must be homogeneous (no lumps),

free of air bubbles, thinner areas and gaps.

Any imperfection must be corrected as soon as

possible.

Avoid the excess of sealer: too much sealing material

would leak and pour out on both sides of the joint

parts and, as a consequence, obstruct the passage of

the lubricant.

After having applied the sealer, the parts must be

joined within 10 minutes.

Flywheel assembly

Figure 28

119113

- Screwtwohooksoreyeboltsontheflywheel(1)

through the ports (4).

- By means of a hoister, draw the flywheel up to its housing

inside the casing.

NOTE

The flywheel has a reference dowel that couples

with the relevant seat on the box.

- Screw two pins (2) of appropriate length into the shaft’s

ports (3) and, using them as a guide, duly fit the engine

flywheel (1) into its casing.

- Tighten the screws fastening the engine flywheel to the

engine drive shaft. Fit the tool 99360330 to the flywheel

casing in order to lock the engine flywheel rotation.

Base - A

il 2009 PrintP2D32F005 E

Page 63

F32 SERIES

p

r

SECTION 3 - INDUSTRIAL APPLICATION

15

Figure 29

α

119463

Tighten the engine flywheel (2) fastening screws (1) in two

steps:

- Step 1: 30 ± 1.5 Nm torque setting ;

- Step 2: 90º ± 4.5º angular fastening.

NOTE

Angular fastening must be executed using tool

99395216.

Before assembly, always ch eck th at the port

threads and th e screws show no trace of wear and

dirt.

Front side component installation

Figure 30

Figure 31

SCHEME FOR THE APPLIANCE OF LOCTITE 5999

SEALER

NOTE

It is absolutely necessary to clean the surface to be

sealed in order to obtain perfect tightness.

Apply LOCTITE 5999 sealer on the gearcase in

order to form a sealing bead of a few mm.

The sealing bead must be homogeneous (no

lumps), free of air bubbles, thinner areas and gaps.

Any imperfection must be corrected as soon as

possible.

Avoid the excess of sealer: too much sealing

material would leak and pour out on both sides of

the joint parts and, as a consequence, obstruct the

passage of the lubricant.

After having applied the sealer, the parts must be

joined within 10 minutes.

119733

- Assemble the front case (1) and tighten the fastening

screws to the prescribed torque wrench.

119117

- Assemble the oil pump (2).

- Tighten the fastening screws (1) to the prescribed

torque wrench.

PrintP2D32F005 E Base - A

il 2009

Page 64

16

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Timing

Figure 32

124497

- Fit tool (1) 99360330 to flywheel housing to rotate the

flywheel (must be used with a suitable wrench).

Figure 33

Figure 35

132006

- Loosen the screws of the plate in which tool 99360612

(1) is to be fitted.

Figure 34

133189

Position the engine drive shaft at T.D.C. of cylinder 1 rotating

the flywheel until achieving the following conditions:

- the notch (1) is visible from the inspection hole;

- tool 99360612 should be fitt ed through the carter into

the port on the flywheel.

Remove tools and tighten the previously loosened plate

screws.

119125

- Seize the 45˚ bevel tooth (1) of t he engine drive shaft

gear wit h th e timing gear t ooth marked with t wo

notches (2), as shown in the figure.

- Rotate the camshaft keeping the timing gear fix until the

camshaft’s pin fits into the relevant housing within the

timing gear.

- Screw the screws of the transmission gear w i thout fully

tightening them.

- With magnetic base c omparator, chec k the clearance

among the engine shaft gear and the cam shaft gear: it

must be 0.068 ÷ 0.168 mm.

- Screw the fastening screws (1) of the transmission gear.

Base - A

il 2009 PrintP2D32F005 E

Page 65

F32 SERIES

p

r

(mm)

SECTION 3 - INDUSTRIAL APPLICATION

17

Figure 36

119735

- Fit the ignition pump cogwheel (1) into its housing.

- Fit the pre-set ignition pump into its housing on the

engine, inserting the shaft into the gear hole.

- Tighten the three screw nuts on the rear part of the

timing gearcase and the front cover fixing the shaft to the

gear.

- Unblock the pump with magnetic base comparator,

check the clearance among the engine shaft gear and the

oil pump gear: it must be 0.068 ÷ 0.168 mm.

- Fit the new gasket using the centring pins (2) on the

casing for its correct positioning.

- Fit the casing’s cover using the centring pins (2) to

correctly position it and then tighten the fastening

screws to the prescribed torque wrench.

- Unlock the fly-wheel

Figure 38

70221

- Fit a new grommet (2) to the water pump (1).

- Assemble the water pump (1).

- Tighten the fastening screws to the prescribed torque

wrench.

Piston projection measurement

Figure 39

NOTE

To carry out the correct ignition pump assembly,

proceed as shown in the specific section.

Figure 37

119461

- Fit the inner part of tool 99346258 to the front shank of

the engine drive shaft. Make sure that th e engin e drive

shaft pin is correctly fitted into the tool spline in order

to avoid damaging it. Fix it with the screw (1) and spline

the new grommet thereon.

- Place the outer section of the tool on the previously

fitted one, tighten the screw nut (2) until completely

fitting the grommet (3) into the casing.

119462

Piston projection from

basement A

Engine gasket thickness

B

Thickness (mm)

From 0.07 to 0.07 0.80

From 0.08 to 0.22 0.70

- Measure the piston projection and refer to the table

above to select the appropriate thickness of the sheath.

PrintP2D32F005 E Base - A

il 2009

Page 66

18

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Figure 40

119573

- Fit the gasket (1) on the basement centring it taking the

pins (2) as a reference. The gasket’s thickness must be

selected based on t h e piston projection in respect to the

upper plan of the basement.

NOTE

Check that the block’s laying plan is clean.

Do not grease the gasket. It is recommended to

keep the gasket inside its wrapping until it has to be

fitted.

The fitting direction is univocal and defined by the

centring pins on the basement, which must match

with the ports on the gasket.

Figure 41

119115

Always use new screws for assembly.NOTE

- Lubricate the head fastening screws (2) and tighten them

to the prescribed torque wrench.

- Place the head (3) on the block taking the c entring pins

as a reference.

NOTE

The head screws should be tightened in a precise

order.

Therefollowsthelockingsequenceandthe

torques to be applied for each type of screw.

Base - A

il 2009 PrintP2D32F005 E

Page 67

F32 SERIES

p

r

SECTION 3 - INDUSTRIAL APPLICATION

19

Figure 42

α

7

8

Screws 1,2,3,4,5,6: M15x1,5 6g x193

Screws 7,8,9,10: M12 x1,5 6g x165

- Lubricate the screws;

- Tighten the sc rews with a torque wrench following the

locking order described above:

• M15 Screws: torque 130±6,5Nm;

• M12 Screws: torque 65±3,25Nm;

- Tighten the screws further with a torque wrench

following the locking order described above:

• M15 Screws: torque 90±4,5Nm;

• M12 Screws: torque 90±4,5Nm;

- Wait a few minutes for settling;

- Then apply the final angular closing following the locking

order described above:

• M15 Screws: 80˚±4˚;

• M12 Screws: 60˚±3˚.

426

234

3

HEAD SCREW LOCKING ORDER

1

1

5

10

9

133184

Figure 43

125128

- Reassemble the electromagnetic joint support (1).

- Reassemble the pulley (2).

- Reassemble the pulley (3), tighten the fastening screw

(4) to the prescribed torque setting.

- Reassemble the heat exchanger reminding to replace the

old gasket with a new one; tighten the fastening screws

to the prescribed torque setting.

Figure 44

1

2

75686

- Put the alternator back in place (1).

- Screw up without tightening (2).

PrintP2D32F005 E Base - A

il 2009

Page 68

20

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Figure 45

127697

- Fit th e drive belt (7) on the pulley and the guide rollers.

- Tension drive belt (7) tightening screw (5) until screw (2)

reaches the end of the channel in which bracket (3) is

seated. Tighten nut (6) and screw (1).

- Tighten the screw (4) and the screw nut (1) fasteningthe

alternator to the support.

Figure 47

122587

Before reassembly, check that the rocker arm rods must not

be deformed; there must be no trace of wear or seizure on

the spherical h o usings of the rocker arm adjusting screws as

well as on the tappets (pointers); otherwise these parts must

be replaced. The suction valve rods are identical and

therefore interchangeable.

- Fit the control rods in their housing.

Figure 46

122432

Figure 48

119119

- Fit the rocker arm positioning the equalizer couples: the

suction equalizer first (short rod) and then the exhaust

- Fit the exhaust collector (3) with a new gasket (2) and

tighten the fastening screws (1) to the prescribed torque

setting.

Base - A

il 2009 PrintP2D32F005 E

equalizer (long rod) (2).

- Tight en th e fastening screw (1).

Page 69

F32 SERIES

005

ase-Ap

r

009

SECTION 3 - INDUSTRIAL APPLICATION

21

Figure 49

Each cylinder must be checked by taking it to the T.D.C. (top

dead centre) at the end of compression and adjusting the

clearance of both valves on the cylinder in question.

Position the crankshaft at TDC of cylinder 1.

Rotate crankshaft as required (see table) and check that

intake and exhaust valves are both closed and not in a

balanced position.

For cylinder 4 it is possible to check the correct position of

the crankshaft with tool 99360612.

Adjust the clearance between the rockers and valves using

a pair of pliers (2), a wrench (3) and a feeler gauge (1).

Clearance shall be as follows:

- i ntake valves 0.5 ± 0.1 mm

- exhaust valves 0.50 ± 0.1 mm.

FIRINGSEQUENCE1-3-4-

Starting and

crankshaft

rotation

Balance

valves of

cylinder no.

2

Adjust

clearance of

intake and

exhaust valves of

cylinder no.

1toTDC 1 1

180° 3 3

180° 4 4

180° 2 2

119111

- Replace the gaskets (3), reassemble the rocker arm

holding case (2) and tighten the fastening screws to the

prescribed torque setting.

- After having completed the assembly, check that the

rocker arms are correctly positioned on the valves and

the tappet control rods.

Figure 50

128138

For F5CE5454 engines

NOTE

In order carry out a quicker adjustment of the

working slack between rocker arms and valves,

proceed as following:

Rotate th e engine drive shaft, balance the valves of

cylinder 1 and adjust the valves identified by star

symbol, as indicated in the following table:

Cylinder n°

Suction

Exhaust

Rotate the engine drive shaft., balance the valves of

cylinder 4 and adjust the valves identified by star

symbol, as indicated in the following table:

Cylinder n°

Suction

Exhaust

1

-

234

-

*

-*-

1

*

*

234

*

--

-*

*

*

-

On TIER 3 engines with internal EGR (F5CE9454,

F5CE9484) it is not possible to use the valve clearance

adjustment procedure in which all the valve clearances can

be checked using just 2 different crankshaft positions.

PrintP2D32F

E B

Revi - January 2010

il 2

Page 70

22

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Figure 51

120020

- Reassemble the injectors (2) replacing the grommets.

Tighten the fastening screws(1) to the prescribedtorque

setting.

Figure 53

119721

- Reassemble the KSB water temperature sensor (6), the

oil filter support (5), the priming pump (3), the diesel fuel

filter support (2), t he fuel filter (1) and the oil filt er (4).

Figure 52

119128

- Make the holes (1) for fuel exhaust all face the same

direction.

Base - A

il 2009 PrintP2D32F005 E

Figure 54

119905

- Fit the head covers (1) replacing the gaskets (2).

Page 71

F32 SERIES

p

r

SECTION 3 - INDUSTRIAL APPLICATION

23

Figure 55

- Reassemble the fuel exhaust pipes (1).

Figure 56

122571

Figure 57

119105

- Reassemble the pipe from the pump to the injector and

tighten the brackets’ fastening screws (3).

- Reassemble th e pipe from the pump to the fuel filter (2)

and from the fuel filter to the priming pump (1).

- Reassemble the L.D.A. pipe

Figure 58

119116

- Reassemble the suction rose tightening the support

fastening screws (1) and the screw fixing the suction rose

(2) to the prescribed torque setting.

119124

Figure 59

- Reassemble the whole intake manifold (1) replacing the

gasket (2) and (3).

119123

- Fit the new gasket (1) to the oil pan (2).

PrintP2D32F005 E Base - A

il 2009

Page 72

24

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Figure 60

119130

- Assemble the oil pan (1) and fit the plate thereon (3).

Tighten the fastening screws (2) to the prescribed

torque setting.

NOTE

Before assembly, check that the port threads and

the gaskets show no trace of wear or dirt.

For F5CE5454 engines

Figure 62

6

4

3

2

1

7

- Place the whole E.G.R. on the intake manifold, tighten

the front side (5) and valve support (6) fastening screws

to the prescribed torque pair.

- Connect the pipe (4) to the E.G.R. valve housing and

then tighten the clip (3).

- Reassemble the pipe (2) and, using pincers, fit the

relevant clip (1).

- Fit the starter (7) and tighten the fastening screws to the

prescribed torque setting.

5

119104

For F5CE9454, F5CE9484 engines

Figure 61

124496

- Reassemble the turbocharger (2) unit.

- Reassemble the pipe (4) and fit the clip in the correct

housing.

- Reassemble the oil delivery pipe (3) and the return pipe

(1).

- Refit the starter (5) and tighten the fastening screws to

the prescribed torque setting.

For all engines

Figure 63

119904

- Reassemble the turbocharger (5) unit.

- Reassemble the pipe (2) and fit the clip in the correct

housing.

- Reassemble the oil delivery pipe (3) and the return pipe

(4).

Base - A

il 2009 PrintP2D32F005 E

Page 73

F32 SERIES

p

r

SECTION 3 - INDUSTRIAL APPLICATION

25

Figure 64

124486

- Disconnect the fuel filter pipe (1) and act on the priming

pump (2) drainage lever.

- Continue drainage until fuel discharge is completed.

- Connect the pipe (1) to the filter.

Checks and inspections

The following checks must be executed after the

engine fitting on vehicle.

!

Check t h at t he liquid refuelling or top up has been

provided to the correct levels prescribed.

Start the engine, keep it running at a number of

rev./min. slightly over idling and wait until the cooling

liquid temperature reaches the value prescribed for

thermostat valve opening and then provide checking

the following:

- check there is no water leak from the manifolds

connecting the engine cooling circuit pipes and the cabin

interior heating pipes, eventually further tightening th e

O-rings.

- Carefully check the fuel filter pipe fittings.

- Check there is no oil leakage from cylinder head and

cover, oil pan and basement, heat exchanger oil filter and

relevant h ousings in between the various lubrication

circuit pipes.

- Check there is n o fuel leakage from the fuel pipes.

- Check there is no air leak from the pneumatic pipes (if

fitted).

- Check that the warning lights on the instrument panel

and equipment disconnected upon engine

disconnection efficiently work.

- Check and c arefully bleed the engine cooling system

throughout reiterated drainage.

PrintP2D32F005 E Base - A

il 2009

Page 74

26

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Rocker cover blow-by removal and refitting

Figure 65

133191

- Unscrew the screws (2) from th e tappets cover (1) with

theblow-byfilterandremovetheplateguard(3).

Figure 67

133193

- Secure the rocker cover (1) in a vice.

Figure 66

- Remove the gasket (1) from th e rocker cover (2).

133192

Figure 68

133199

- Mark the relative position (as pointed out by the arrows)

among the blow by (1) and the rocker cover (2).

NOTE

In case of replacement of the blow-by unit (1) it is

important to mark the cover (2) for the correct

positioning of the blow-by pipe (1).

Base - A

il 2009 PrintP2D32F005 E

Page 75

F32 SERIES

p

r

SECTION 3 - INDUSTRIAL APPLICATION

27

Figure 69

133194

To remove the blow-by (1) from t he rocker cover (2) it is

necessary to free the elements from the hold of the sealant.

- With special hot air device (3) heat the concerned area

between blow-by and cover.

Figure 71

133196

Remove the blow-by (1) from the rocker cover (2).

Handle with suitable protections; hot parts.

Figure 70

133195

Inserting a screwdriver in the blow-by pipe (1) try to rotate

the blow-by alternatively in both clockwise and

counterclockwise directions (1) up to when it makes free

from the hold of the sealant.

Figure 72

133197

Clean the blow-by seat on the rocker cover (1) from possible

traces of sealant.

PrintP2D32F005 E Base - A

il 2009

Page 76

28

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Figure 73

133198

- Apply a regular layer of LOCTITE 510 all arou nd the

blow-by body (1).

Figure 75

133200

- Lean the complete c over assembly on a stiff surface.

- By means of a plastic hammer make sure that the

blow-by (2) goes completely inside its seat on the rocker

cover (1).

Figure 74

133199

- Fit the blow-by (1) on the rocker cover (2) having care

to position the exit h ole (1) in the c orrect direction.

NOTE

The position of the blow-by exit hole can vary

according to the specific applications of the engine.

A wrong positioning of the blow-by body (1) on

the cover (2) may, therefore, result in difficult while

refitting the engine aboard specific applications.

Figure 76

134376

- Position a new gasket (1) in its seat on the rocker cover.

The position of the gasket in the seat is univocal.NOTE

Base - A

il 2009 PrintP2D32F005 E

Page 77

F32 SERIES

p

r

Figure 77

133191

- Refit the plate (3) on the tappets cover (1) with the

blow-by filter and tighten the M5x10 screws (2).

SECTION 3 - INDUSTRIAL APPLICATION

29

PrintP2D32F005 E Base - A

il 2009

Page 78

30

p

r

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Rotary feed pump disassembly and assembly procedure

NOTE

This procedure prescribes that:

- the fuel pipes (from the pumping elements to

the injectors, recovering blow-by from the

injectors to the pump and the supply from the

priming pump) have all been removed;

- the electrical c onnections have been

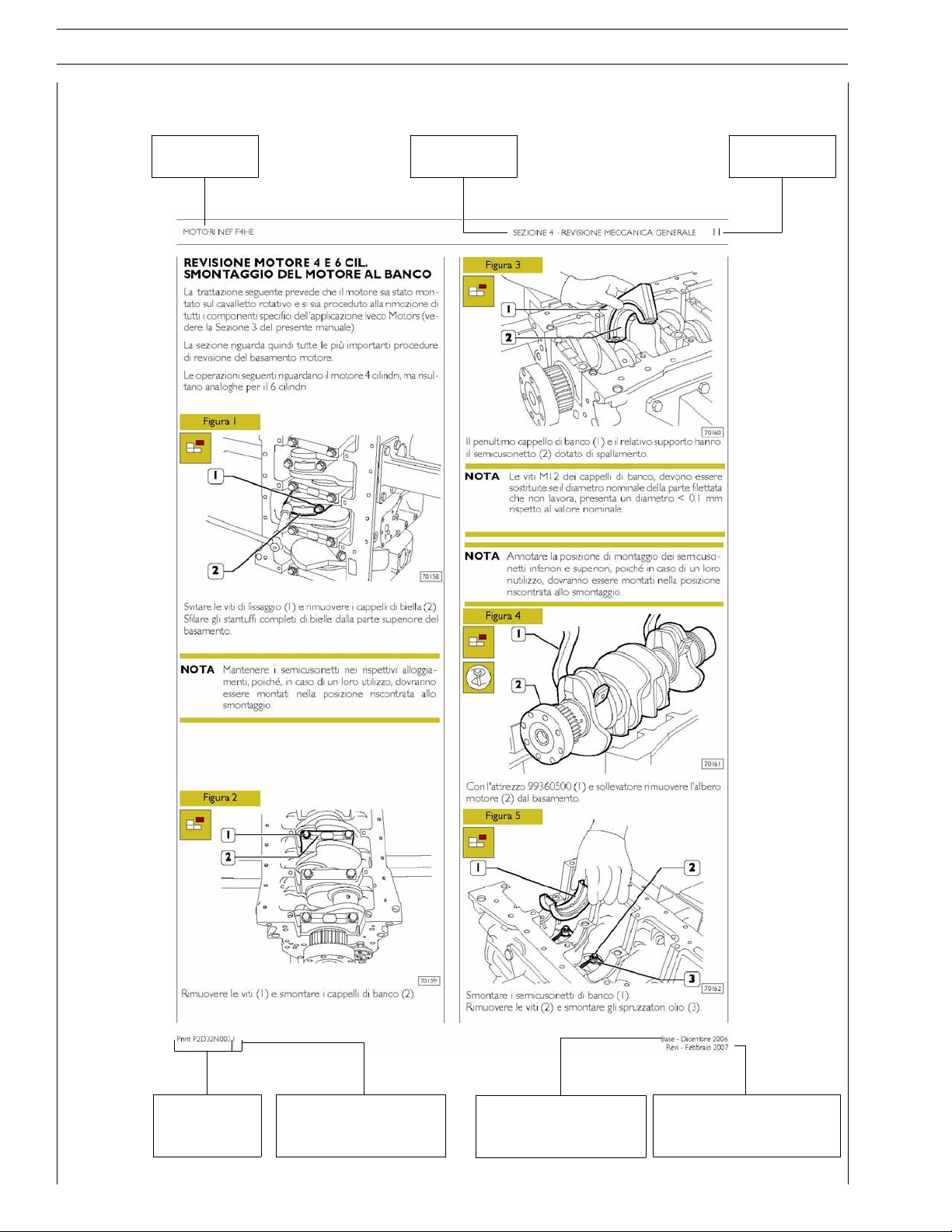

disconnected.