Page 1

DAILY M.Y. 2012

BODYBUILDERS INSTRUCTIONS

LIGHT RANGE

ISSUE 2012

Page 2

IVECO S.p.A.

Technical Application

Strada delle Cascinette, 424/34

10156 Torino (TO) - I taly

www.iveco.com

Printed 603.95.241 -2

nd

ed. 02/2012

Revi - 10/2012

Page 3

DAILY

Bodybuilders instructions

Printed 603.95.241 - 2

Base - 02/2012

UPDATE DATA

Section Paragraph Description Revision date

3 Index Modification to text October 2012

3 3.4.2 Modification to text October 2012

3 3.9 Modification to table 3.11 and text October 2012

3 3.14.3 Modification to text

5 5.4.9 Modification to table 5.19 October 2012

Appendix B Index Modification to text October 2012

Appendix B B.4.1 Modification to text October 2012

nd

ed.

Modification to figure 3.23

October 2012

Update data

Printed 603.95.241 Base - 02/2012

Revi - 10/2012

Page 4

Update data

Base - 02/2012 Printed 603.95.241

Page 5

Foreword

This publication provides data, specifications and instructions for fitting out and converting vehicles. Its contents are directed at

qualified and specialised personnel.

The Bodybuilder is responsible for the project and its execution and must guarantee conformity with the both legal requirements

and those given in this publication.

Any modification, conversionor outfitting not listed in this manual andwhich is not expressly authorised inwriting by Iveco shall result

in theexclusion of any responsibilityfor Iveco, and, inparticular, where the vehicleis covered by aguarantee, shall result inan immediate lapse of the guarantee.

IVECO is available to provide any information necessary for the work to be performed and to provide instructions for any cases

and situations not covered in this publication.

Before commencing any work, it is necessary to:

- check manuals and documentation are at hand for the vehicle model on which work is to be performed;

- ensure that all personal protection devices (goggles, helmet, gloves, shoes etc.), as well as tools and equipment, lifting and trans-

port equipment, etc., are available and in good working order;

- ensure that the vehicle is parked in a safe condition.

When any work has been completed, the conditions of functionality, efficiency and safety required by IVECO must be restored.

Contact the Assistance Network if any adjustments or fine tuning of the vehicle are necessary.

The information contained in this publication may not becompletely in line with modifications which IVECO may see fit tointroduce

at any time for technical or commercial reasons, or to ensure vehicles meet new legal requirements.

In the event of disagreement between the information contained herein and the actual vehicle, please contact the relevant Product

Manager before performing any work.

Symbols - warnings

Danger for persons

Missing or incomplete observance of these prescriptions can cause serious danger for persons’ safety.

Danger of serious damage for the vehicle

Partial orcomplete nonobservance of theseprescriptions can causeserious damagesto the vehicleand sometimesguarantee lapse too.

General danger

!

It includes the dangers of above described signals.

Environment protection

It indicates correct behaviour in order that vehicle use is environmentally friendly as much as possible.

It indicates an additional explanation for a piece of information.NOTE

Foreword

Printed 603.95.241 Base - 02/2012

Page 6

Page header and footer interpretation

Vehicle type Section title

Section number -

page number

Print

number

Foreword

Base - 02/2012 Printed 603.95.241

Chapter title

Basic edition -

month year

Page 7

INDEX OF SECTION

Section

General specifications

Chassis modifications 2

Fitting superstructures 3

Power Take Offs 4

Special instructions for electronic subsystems 5

Appendix A - Daily PASSENGER TRANSPORT A

Appendix B - Daily CNG and CNG with Recovery Mode B

1

Index of section

Printed 603.95.241 Base - 02/2012

Page 8

Index of section

Base - 02/2012 Printed 603.95.241

Page 9

DAILY

Index

GENERAL SPECIFICATIONS

SECTION 1

General specifications

1.1 Aim of the requirements 1-3

1.2 Technical documentation available via computer 1-3

1.3 IVECO authorisation 1-3

1.4 Request for approval 1-4

1.5 Liabilities 1-4

1.6 Legal provisions 1-4

1.7 Multi Stage Type Approval - Collaboration (only for EU nations, Switzerland and Turkey) 1-5

1.8 Guarantees 1-6

1-1

Page

1.9 Quality System management 1-6

1.10 Prevention of accidents 1-7

1.11 Choice of material to use: Ecology - Recycling 1-7

1.12 Vehicle management c/o Bodybuilder 1-8

1.12.1 Acceptance of the chassis 1-8

1.12.2 Maintenance 1-8

1.12.3 Delivery of the vehicle to the final Customer 1-8

1.13 Vehicles identification 1-9

1.14 Trademarks and logos 1-9

1.15 Dimensions and masses 1-10

1.15.1 General specifications 1-10

1.15.2 Determining the centre of gravity of the body and payload 1-11

1.15.3 Observing the permitted weights 1-15

1.16 Instructions for correct operation of vehicle components and accessibility 1-16

1.17 Conventions 1-17

Index

Printed 603.95.241 Base- 02/2012

Page 10

1-2

GENERAL SPECIFICATIONS

D

AILY

Index

Base - 02/2012 Printed 603.95.241

Page 11

DAILY

Aimof the requirements

GENERAL SPECIFICATIONS

1-3

1.1 Aim of the requirements

The aim of this publication is to supply data, specifications and instructions for fitting out and converting original IVECO vehicles

in order to guarantee their operation, safety and reliability.

These Requirements also indicate the following for Bodybuilders:

- the quality level to be attained;

- work safety obligations;

- their obligations in respect of objective product liability.

Remember that collaboration with IVECO startswith the assumptionth at the Bodybuilderwill use their technical and organisational

capacities to the maximum and that work will be performedin a technically perfect fashion. What follows is by no means exhaustive

and is limited to indicating the basic rules and precautions allowing the technical in itiative to be developed.

Any faults or defects caused by complete or partial failure to comply with these Requirements shall not be covered by guarantees

on the chassis and mechanical assemblies.

1.2 Technical documentation available via computer

The following technical documents are available on the Internet at www.thbiveco.com:

- Directives for transformation and equipping of vehicles;

- technical cards;

- chassis cab diagrams;

- chassis diagrams;

- other specifications concerning the vehicle ran ge.

The Body Builder shall submit the modification and/or fitting to the competent authorities for approval.

1.3 IVECO authorisation

Modifications or conversions listed in and performed with full respect for these Requirements do not require specific

authorisation.

On the contrary, the following can be performed only with IVECO authorisation:

- particular modifications of the wheelbase;

- work on the brake system;

- modifications to the steering;

- modifications to the stabiliser bars and the suspension;

- changes to the cab, cab supports, locking and tipping devices;

- changes to the intake systems, engine exhaust and SCR components;

- fitting of retarders;

- fitting of PTOs;

- changing tyre size;

- modifications to coupling devices (hooks, articulations).

Aim of the requirements

Printed 603.95.241 Base- 02/2012

Page 12

1-4

GENERAL SPECIFICATIONS

Request forapproval

D

AILY

1.4 Request for approval

Requests for authorisation, when necessary, must be sent to the relevant IVECO market departments.

The Bodybuilder must supply vehicle data (c ab, wheelbase, protrusion, ch assis no.) with suitable supporting documentation

(drawings, calculations, technical report etc.) illustrating the proposed work, mission and conditions of use for the vehicle. Anything

which differs from these instructions must also be highlighted on the drawings.

When work has been finished, the Bodybuilder will then be responsible for obtaining definitive approval from the relevant authorities.

1.5 Liabilities

IVECO authorisation exclusively regards the tech nical/conceptual feasibility of the proposed modifications and/or outfitting.

The Bodybuilder is therefore responsible for:

-theproject;

- the choice of materials;

-thework;

- the project and work meeting any specific requirements supplied by IVECO as well as regulations in force in the country the

vehicle is destined for;

- any effects on th e vehicle’s operation, safety, reliability and, in general, the good performance of the vehicle;

- of the supply of spare parts for a minimum period of 10 years starting with the latest preparation of an order and for all parts

and components that are installed.

1.6 Legal provisions

The Bodybuilder must ensure that the finished product conforms, without exception, with all applicable laws both at

municipal/autonomous/national level for each country in which it is to be registered or driven (Highway Codes, Official Regulation s

etc.) and at an international level (European Union directives, UN/Geneva ECE regulations etc.). It must also respect all the

requirements concerning accident prevention, instructions for assistance, the environment, etc.

Requirements regarding prevention of accidents or legislative indications given in these Requirements may be considered the most

important, but in no case do they replace or eliminate the Bodybuilder’s obligation and responsibility to keep th emselves correctly

informed.

For this reason, IVECO shall not be held responsible for consequences due to errors caused by incorrect understanding or

interpretation of any laws in force.

Request for approval

Base - 02/2012 Printed 603.95.241

Page 13

DAILY

Multi Stage Typ eAp proval ---Collaborati on (only for EU nati ons, Switz erland and Tu rkey)

GENERAL SPECIFICATIONS

1-5

1.7 Multi Stage Type Approval - Collaboration (only for EU nations, Switzerland and Turkey)

Annex XVII to Direc tive 2007/46/EC deals with Multi Stage Type Approval.

This procedure requires each Manufacturer to be responsible for type approval and production conformity of systems,components

and ”independent technical units” produced or installed on the vehicle by them.

The Manufacturer of the base vehicle is defined as ”First stage Manufacturer”,while the Bodybuilder is defined as the ”Second stage

Manufacturer” or later.

Figure 1.1

IVECO (Dealer) Bodybuilder Customer

166680

A specific contract, known as a ”Technical Agreement” must be drawn up on the basis of this Directive between IVECO

(Manufacturer of the base vehicle) and a Bodybuilder who intends to apply for Multi Stage Type Approval; this details the contents

and reciprocal obligations.

Consequently:

a) IVECO has th e responsibility to make available, in agreed form, type-approval documentation (EC/ECE type approval) and

technical information necessary for correct realisation of the outfitting and/or conversion of the vehicle (manuals, drawings,

specifications);

b) the Bodybuilder has the following responsibilities:

• design and realisation of modifications on the base vehicle received from IVECO,

• re-attainment of type approval for systems previously approved when such type approvals must be updated due to modifica-

tions made to the base vehicle,

• ensuring all national/international laws and regu lations are complied with for all modifications performed, in particular as

regards the country which the vehicle is destined for,

• presenting the modifications made to a technical service for evaluation,

• appropriate documentation of modifications made, giving clear evidence that the aforementioned laws and regulations have

been respected (e.g. type-approval/testing documentation).

Before signing the Technical Agreement, IVECO reserves the right to visit the Bodybuilder in order to ensure they are qualified to

perform the outfitting/conversion requested by the agreement.

The contents of the Technical Agreement can be evaluated in detail upon request to the person responsible for relations with

Bodybuilders in the relevant market.

Multi Stage Type Approval - Collaboration (only for EU nations, Switzerland and Turkey)

Printed 603.95.241 Base- 02/2012

Page 14

1-6

GENERAL SPECIFICATIONS

Guarante es

D

AILY

1.8 Guarantees

A guarantee that work has been performed to required standards must be given by the Bodybuilder who realised the

superstructure or modifications to the ch assis, in full respect of the requirements listed in these Directives.

IVECO reserves the right to declare void its own warran ties for the vehicles where:

- unauthorised outfitting or conversions have been performed;

- an unsuitable frame has been used for the required conversion or application;

- the regulations, specifications and instructions which IVECO provides for work to be performed correctly have not been

respected;

- original spare parts or components made available by IVECO for specific operations have not been used;

- safety requirements are not respected;

- the vehicle is used for any other purpose than that for which it was designed.

1.9 Quality System management

For some time I VE CO has been promoting Q uality System development and train in g for Bodybuilders.

This is a requirement due not only to regulations on product responsibility, but also to ever increasing quality requirements, new

organizational forms in the various sectors and the never-ending drive for greater efficiency.

IVECO therefore consider that Bodybuilders should have:

- organization charts for func tions and responsibilities;

- quality objectives and indicators;

- technical design documentation;

- process documentation, including testing;

- product improvement plan, obtained also with correct ive actions;

- after sales service;

- staff training;

ISO 9001 certification, while not obligatory, is considered by IVECO to be extremely important.

Guarantees

Base - 02/2012 Printed 603.95.241

Page 15

DAILY

Preventi onof accide nts

GENERAL SPECIFICATIONS

1.10 Prevention of accidents

Do no allow unauthorised personnel to work on or operate the vehicle.

It is forbidden to use the vehicle if its safety devices have been tampered with or damaged.

Structures and devices applied to the vehicles must conform to current requirements for accident

prevention and safety regulations in each Country where the vehicles are to be used.

All technical precautions must also be taken to avoid functional faults and defects.

Compliance with these regulations will be the responsibility of the manufacturers of the structures and devices.

Seats, upholstery, seals, protective panels etc. can represent a potential fire hazard if exposed to an

intense heat source.

!

Arrange for their removal before working with welding equipment and flames.

1-7

1.11 Choice of material to use: Ecology - Recycling

The choice of materials to be used must be carefully considered in the stu dy an d design phase also from an ecological and

recycling point of view.

In this regard, the following should be kept in mind:

- the use of materials which are damaging to health, or in any case potentially hazardous is forbidden, for example those containing

asbestos, lead, halogen additives, CFCs, c admium, mercury, hexavalent chromium etc.;

- it is recommended to u se materials which produce a limited quantity of waste when worked and which allow easy recycling

after their first use;

- mutually compatible components should be usedfor compositesynthetic materials, also providing for potential use with salvaged

components. Arrange for markings required by current regulations;

- batteries contain substances which are very damaging to the environment. The Service Network can be contacted when

replacing batteries they are equipped for correct disposal of old batteries in full compliance with the law.

In order to comply with directive 2000/53 EC (ELVs), IVECO forbids installation of components

containing lead, mercury, cadmium and hexavalent chromium; exceptions are made for the cases

allowed for by Annex II of this directive.

Prevention of accidents

Printed 603.95.241 Base- 02/2012

Page 16

1-8

GENERAL SPECIFICATIONS

Vehicl em anagement c/oBod ybuilde r

D

AILY

1.12 Vehicle management c/o Bodybuilder

1.12.1 Acceptance of the chassis

Bodybuilders receiving a chassis/vehicle from IVECO or a Dealer must perform a preliminary check, notifying th em of any missing

accessories or damage ascribable to the transporter.

1.12.2 Maintenance

To keep the c hassis/vehicle in full working order even when in the workshop for an extended period, maintenance operations

set out for pre-established times may be necessary.

The expenses for performing these operations are borne by whoever owns the vehicle at that time (Bodybuilder, Dealer or

Customer).

If the vehicle is not to be used for an extended period, it is recommended to disconnect the battery’s

negative terminal in order to maintain optimum charge.

1.12.3 Delivery of the vehicle to the final Customer

Before delivering t he vehicle, the Bodybuilder must:

- prepare your execution (vehicle and/or equipment) and check its functionality and safety;

- perform the checks laid out in the Pre-Delivery Inspection (PDI) list available from the IVECO network for the items regarding

the work performed (obviously the other items in the ODI will remain the responsibility of the Dealer as per guarantee booklet);

- measure the voltage of the batteries using a digital multimeter (2 digit decimal), bearing in mind that:

a) the optimum value is 12.5 V,

b) between 12.1 V and 12.49 V, the battery must be trickle charged,

c) with values lower t han 12.1 V the battery must be c hanged.

The batteries must be maintained at regular intervals (refer to IVECO Std 20-1812 and/or IVECO Std 20-1804) until delivery

to the Customer/Dealer in order to avoid problems such as insufficient charge, short circuit or c orrosion.

IVECO reserves the right to invalidate the battery guarantee if the required maintenance procedures are not respected.

- perform (in the case of vehicle conversion) an on-the-road functional test. IVECO Service must be notified of any defects or

snags in order to check if th ere are valid conditions for insertion in the PDI expenses;

- prepare and deliver to the end Cust omer t he necessary instructions for servicing and maintenance of the conversion and any

additional components installed;

- record the new data on the plates provided;

- give confirmation that the jobs done correspond to the indications supplied by the vehicle Manufacturer and to the legal

requirements;

- draft a warranty the regards the modifications introduced.

Vehicle management c/o Bodybuilder

Base - 02/2012 Printed 603.95.241

Page 17

DAILY

Vehicl es iden tificati on

GENERAL SPECIFICATIONS

1.13 Vehicles identification

The commercial designation of IVECO vehicles is not the same as the type approval (homologation) designation. Two types

of commercial designation are shown below with the meaning of the codes used:

1-9

GVW

(t x 10)

Class Engine

rating

Version Suspension

(HP : 10)

2 9 L 1 0

3 5 S 1 2 D - P

5 0 C 1 5 C N G - P

Class Rear wheels GVW (t) Version

L single 2.8 — 3.3 - Truck

S single 3.5 D Crewcab 6+1

C twin 3.5 — 7.0 V Van

CCombi

CV City Version

Suspension SV Semi-Windowed Van

- mechanic CA Cab without rear wall

/P pneumatic CC Chassis

CCS Lightened chassis

AAutomatic

CNG CNG engine

1.14 Trademarks and logos

Factory branding, marks and names must not be altered or removed from their original positions, since the originality of the

vehicle’s image must be protected.

Application of branding for the conversion or outfitting must be authorised. If present, th ey may not be placed immediately next

to IVECO branding.

IVECO reserves the right to withdraw branding and markings whenever the outfitting or transformation should bear characteristics

which do not conform with those required; the Bodybuilder shall t ake full responsibility for the vehicle in this case.

Instruction for added assemblies

The Bodybuilder must provide necessary instruct ions for servicing and maintenance of additional installed

components/assemblies upon delivery of the vehicle.

All units making up a single order must be equipped with components of the same brand, model and quality.

Vehicles identification

Printed 603.95.241 Base- 02/2012

Page 18

1-10

GENERAL SPECIFICATIONS

Dimensionsandmasses

D

AILY

1.15 Dimensions and masses

1.15.1 General specifications

The vehicle dimensions and permitted weights on the axles are shown on the drawings, on the technical descriptions and more

generally on the documents on the IVECO official website. The kerb weights refer to vehicles with standard equipment. Special

equipment may in volve considerable modification to the weight and its distribution on the axles.

Weighing the chassis

It must be remembered that variations in mass of ±5% for 29L, 35S, 35C models and ±3% for 40C to 70C models are possible.

It is therefore, advisable to weigh the vehicle in the chassis cab condition before fitting the body and equipment and establish the

weight distribution on the axles.

Body conversions

The body building limits for each model are mainly defined by the following:

- weight distribution on the axles;

- width of the mirrors used;

- position of the rear under run-bar.

Greatervalues in compliancewith the weights permittedon the axlesmay beauthorized byIVECO aftermodifyingsuch components

as the chassis, un der run-bar, mirrors, etc.

Positioning of lights and side mirrors is normally expected for widths up to 2350 mm.

Dimensions and masses

Base - 02/2012 Printed 603.95.241

Page 19

DAILY

GENERAL SPECIFICATIONS

1-11

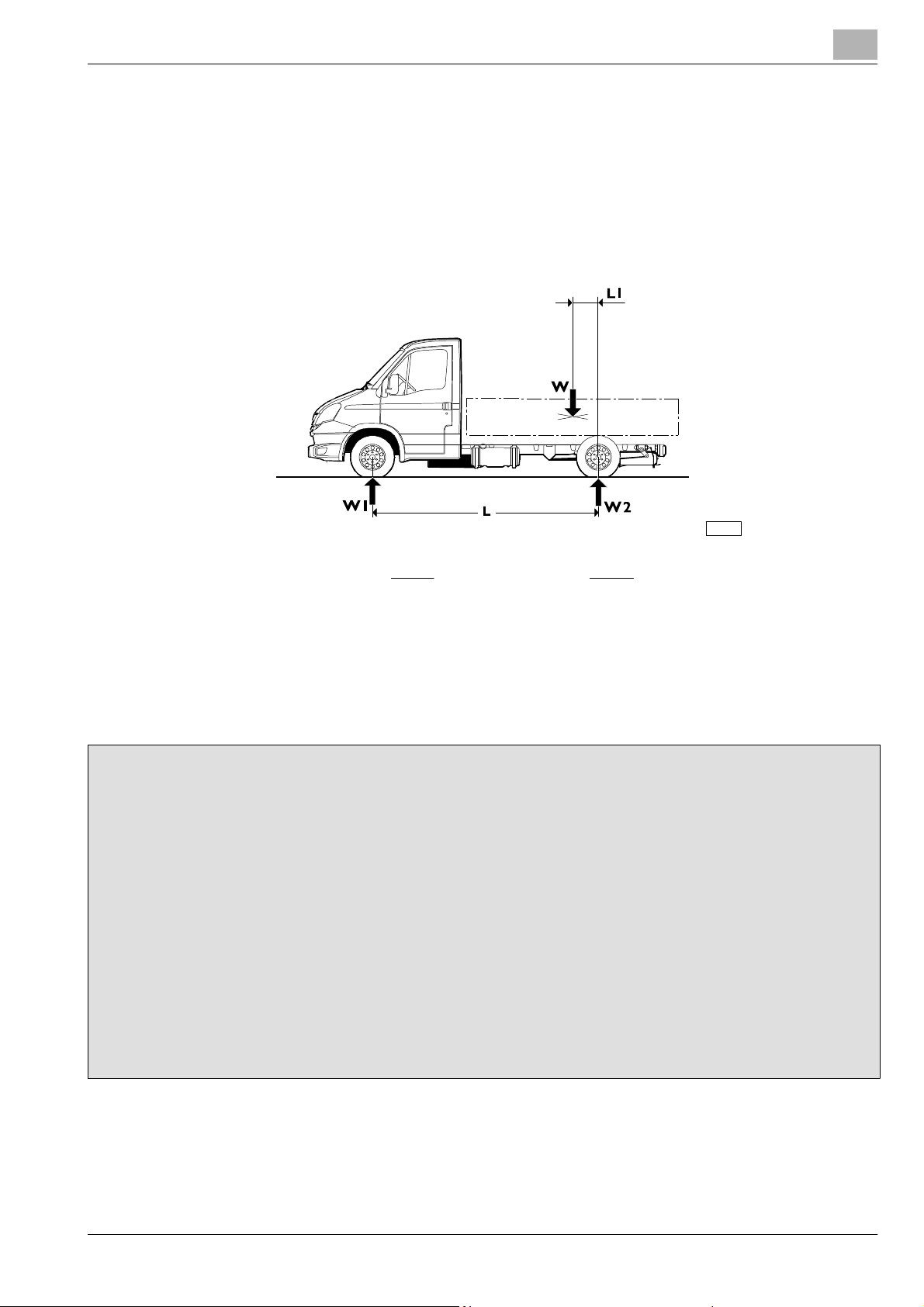

1.15.2 Determining the centre of gravity of the body and payload

Positioning on the longitudinal plane

The examples given below may be used to determine the position of the superstructure’s centre of gravity and the payload.

The technical documentation specific to each model(chassis cab drawing)give the positions permitted with thevehicle in itsstan dard

form. The masses and positioning of the single components of the vehicle are given in the chassis and weight distribution diagram.

Figure 1.2

166681

W

⋅ L

1

=

L

1

W = Body + payload (kg)

W1 = Reaction to portion of W bearing on front axle (kg)

W2 = Reaction to portion of W bearing on rear axle centre line (kg)

L1 = Distance of the centre of gravity from the rear axle centre line (mm)

L = Wheelbase (mm)

respectively L1 = L −

W

W2 ⋅ L

W

Example of calculation of the load barycentre position

Consider a 40C13 vehicle with a wheelbase of 3,450 mm with:

1. GWW = 4,200 kg (permitted maximum: 1,900 kg on the front and 3,100 kg on the rear)

2. KERB WEIGHT = 1,955 kg (1,340 kg on the fro nt axle, 615 kg on the rear)

The permitted maximum load (body + payload) will be W = 4,200 - 1,955 = 2,245 kg. Let us calculate the position of the center

of gravity in which the maximum permitted on the front axle is achieved. Let us assume an uniform distributed load .

In this case, out of 2,245 kg. W

= 1,900 - 1,340 = 560 kg will affect the front axle, while the remaining W2= 2,245 - 560 = 1,685

1

kg will affect the rear axle.

Thus, the following will be obtained:

1

= 560 kg

1. W

2. L = 3450 mm

3. W = 2245 kg

=W1x L / W = 860 mm

L

1

The center of gravity of the load (Body + payload) must not be more than 860 mm far from the rear axle; otherwise, the front

axle would be overloaded.

Dimensions and masses

Printed 603.95.241 Base- 02/2012

Page 20

1-12

GENERAL SPECIFICATIONS

D

AILY

In terms of the effects of dividing the payload on the axles, consider that it is evenly distributed, with the exception of cases where

the shape of the loading bed would result in it being distributed differently.

Regarding any equipment, the actual position of the centre of gravity must be used.

When creating the superstructure or containers, loading and unloading systems for goods must be created which avoid excessive

variations on the payload distribution and/or excessive loads on the axles, with instru ctions supplied for end users if necessary.

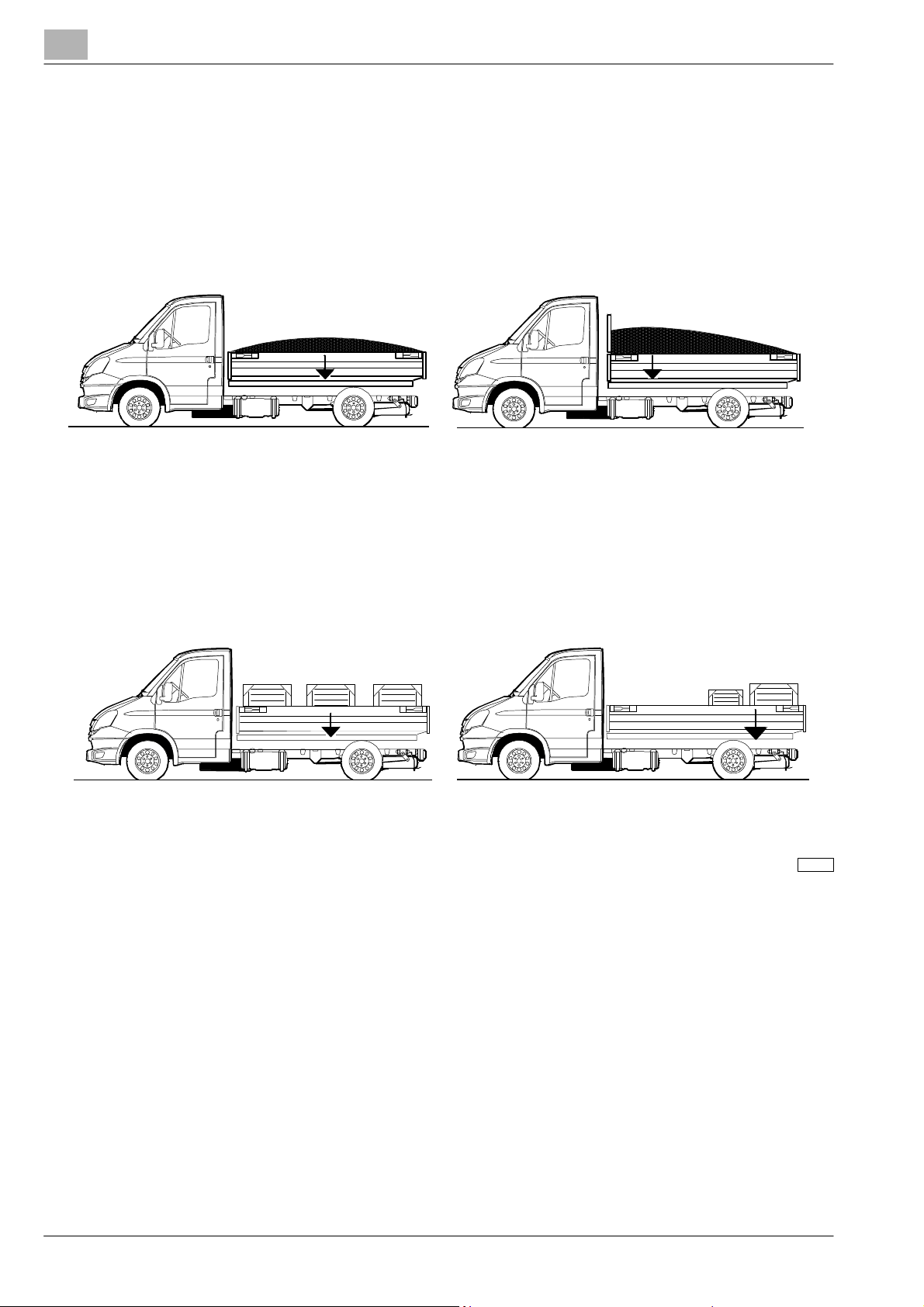

Figure 1.3

Uniform load distribution Uneven load distribution

Figure 1.4

Uniform load distribution Uneven load distribution

(beware of axle loads and minimum axle ratio)

166682

Dimensions and masses

Base - 02/2012 Printed 603.95.241

Page 21

DAILY

GENERAL SPECIFICATIONS

1-13

Height of centre of gravity

For chassis cab and unladen vehicles, the height of the centre of gravity is given on the specific technical documentation for each

model (chassis cab diagram).

When the vehicle is complete with a superstructure and fully laden, this h eight must co mply with the maximum values permitted

by national or international regulations, particularly ECE Directive 13 on longitudinal stability and ECE Directive 111 on transverse

stability while in motion.

The following cases may arise:

a) fixed loads

b) mobile loads

c) loads that involve high aerodynamic actions

a) Fixed loads

:

Check when fully laden:

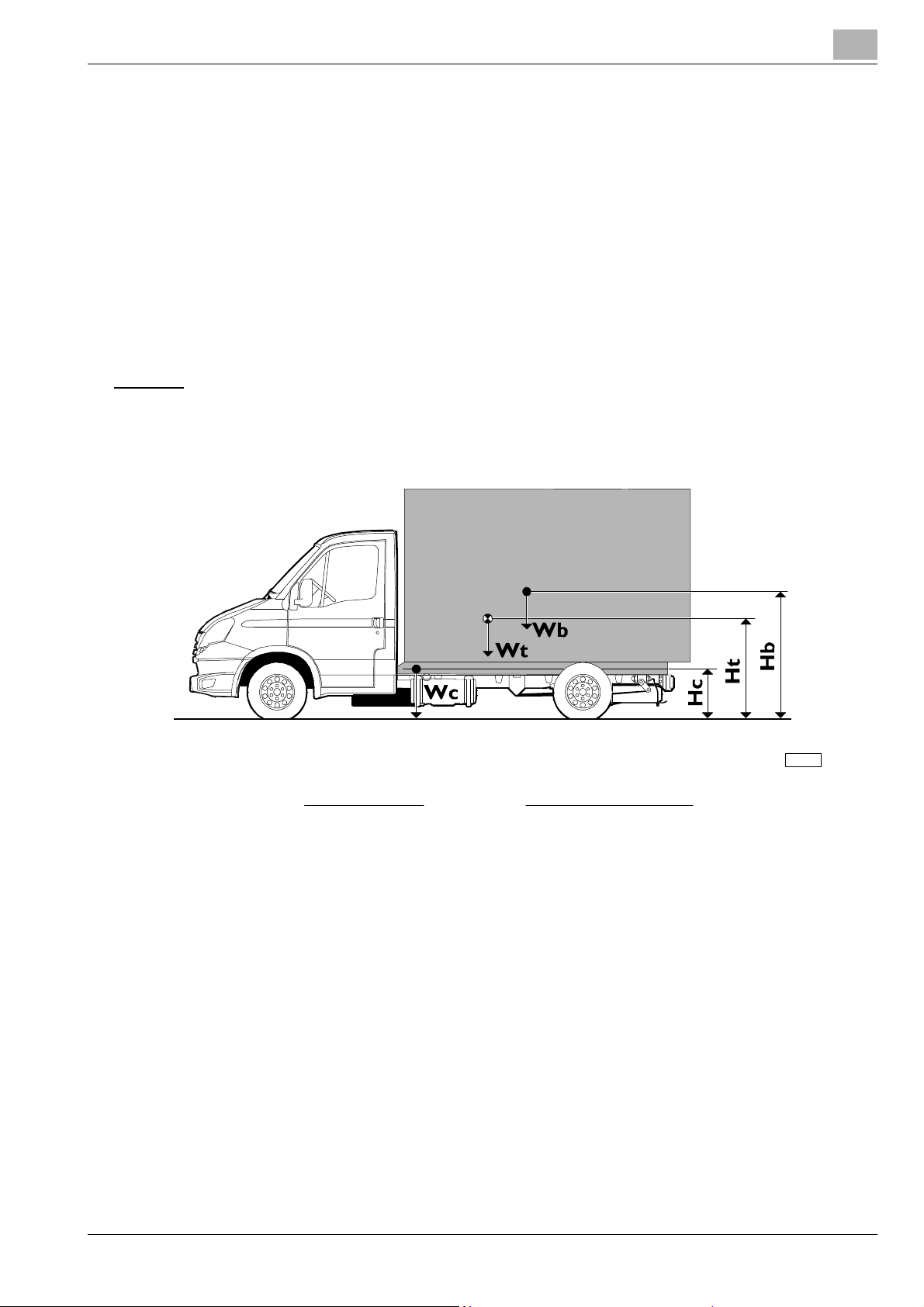

Figure 1.5

Wc . Hc + Wb . Hb

Ht =

Wc + Wb

(Wc + Wb) . Ht − Wc . Hc

Hb =

Wb

166683

Wc = Chassis cab vehicle kerb weight

Hc = Height of centre of gravity of chassis cab vehicle (laden condition)

Wb = Body and payload

Hb = Height of centre of gravity of body and payload in relation to ground

Wt = Vehicle weight when fully loaded

Ht = Height of centre of gravity of vehicle with full load

To check the vehicle with its body but no payload use the above formula but for Wb use only the vehicle unladen weight (The

position for Hc will depend on the load and deflection of the suspension).

Dimensions and masses

Printed 603.95.241 Base- 02/2012

Page 22

1-14

GENERAL SPECIFICATIONS

D

AILY

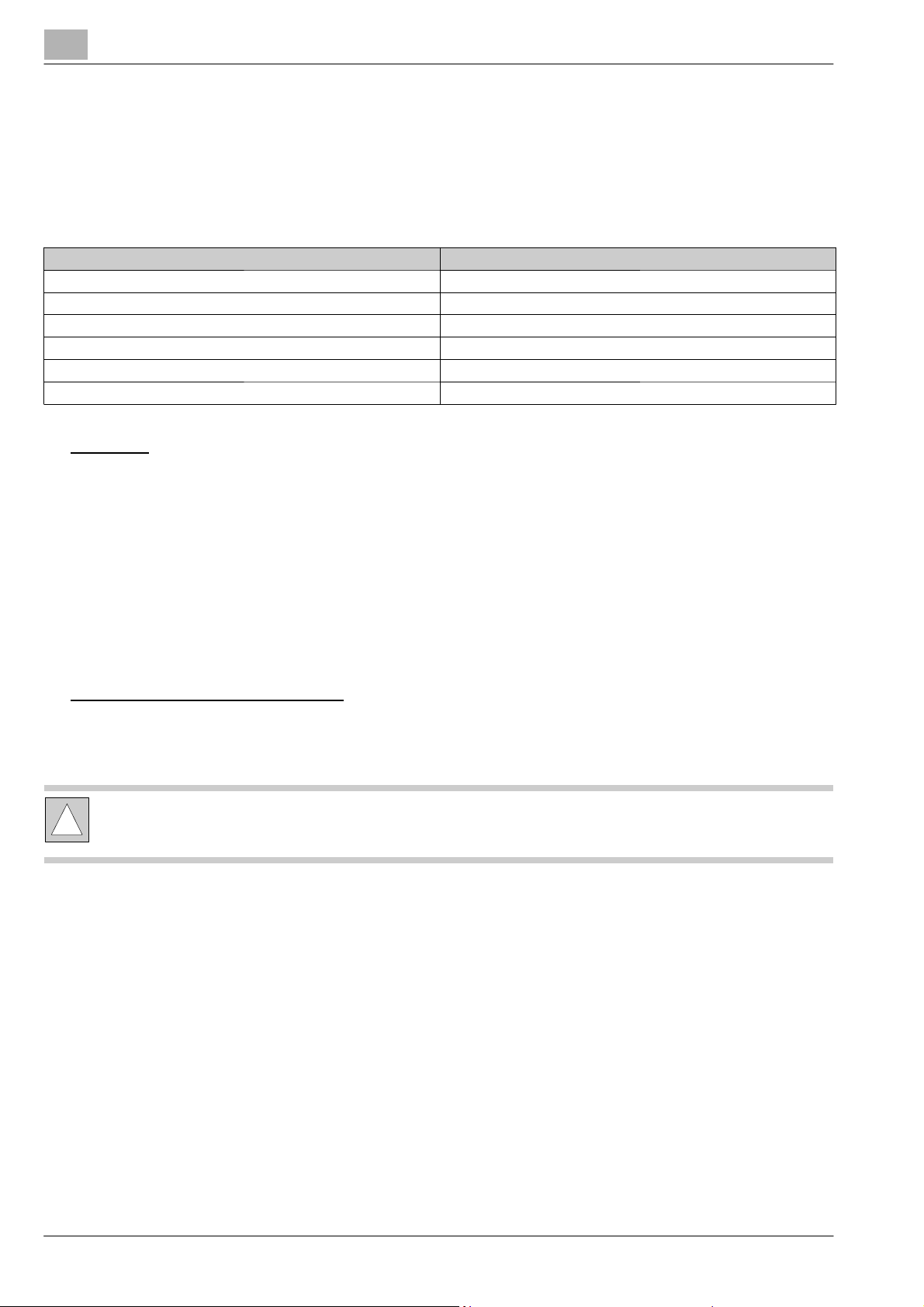

The following table shows the maximum approximate heights indicating the overall cent re of mass (payload + body and/or

equipment), with reference to the vehicle’s transverse stability.

Table 1.1

Models Centre of mass height (mm)

29L 1400

35S 1500

35C (front transverse leaf spring) 1800

35C (front longitudinal bar) - 40C 1900

45C - 50C 1950

60C - 65C - 70C 2050

b) Mobile loads

In specifications where the load may move laterally when cornering (e.g. suspended loads, liquid transport, animal transport, etc.),

dynamic transverse forces may be generated that are high enough to affect vehicle stability.

With reference to regulation ECE 111, particular attention must therefore be paid:

- to defining the height of the centre of gravity of a converted vehicle that is fully laden;

- to evaluating dynamic thrust and lateral movement of the centre of gravity;

- in considering (for liquids) the density;

- to recommending due caution in driving behaviour.

Any cases that are difficult to assess must be submitted to IVECO for approval.

c) Loads that involve hi gh aerodynamic

actions

To conversions characterised by large height and surface area (e.g.: vehicles with large advertising panels); the height of the centre

of thrust determined by high winds must be calculated very carefully.

Even with a low centre of gravity, a converted vehicle presenting a high side area may not guarantee

!

sufficient transverse stability and may be exposed to the danger of rolling over.

Particular attention must therefore be paid;

- to defining the height of the centre of gravity of a converted vehicle that is fully laden;

- to evaluating aerodynamic thrust;

- to recommending due caution in driving behaviour.

Any cases that are difficult to assess must be submitted to IVECO for approval.

Using stabiliser bars

The application of supplementary or reinforced stabiliser bars, spring reinforcements or rubber parts (with respect to point 2.11)

may allow higher values for the height of the payload CG, to be defined for each individual case.

Work must be carried out after careful evaluation of the charac teristics of the conversion, the wheelbase and the division of

transverse forces on the suspension, generally regarding both the front and the rear. Work on the front axle may be necessary with

loads concentrated behind the cab (e.g. cranes) or with highly rigid superstructures (e.g.: van bodies).

Dimensions and masses

Base - 02/2012 Printed 603.95.241

Page 23

DAILY

GENERAL SPECIFICATIONS

1-15

1.15.3 Observing the permitted weights

All limits given in IVECO documentation must be respected. It is essential that the maximum weight on the front axle is not

exceeded, under any loa d condition, so as to ensure the correct steering and braking characteristics regardless of the road surface

conditions.

Special attention must be paidto vehicles with loads concentrated on the rear protrusion (e.g. cranes, tail lift, trailers) and to vehi cles

with short wheelbase and high CG.

NOTE

Correct transverse division of loads must be ensured when positioning auxiliary units and the

superstructure. A variation of ± 4% of nominal load is permitted for each wheel (50% of the

corresponding axle load, e.g.: permitted load on axle 3000 kg, 1440 to 1560 kg load permitted for each

wheel) respecting what is permitted by the tyres, without compromising the vehicle’s braking

characteristics and stability.

Unless specifically stated otherwise for individual vehicles, the weight on the front axle must be

considered to have a minimum value of 28% of the actual weight of the vehicle (whether with

uniformly distributed loads or with loads concentrated on the rear overhang or derived from a

possible trailer).

Variations in the permissible weight

Special dispensations for maximum allowable masses may be given for special u ses; nevertheless, precise usage limitations an d

in some cases compulsory reinforcements to the vehicle have been established for these cases.

If these dispensations should exceed legal limits they must be Authorised by the Relevant Authorities.

When requesting authorisation, the following must be indicated:

- vehicle type, wheelbase, identification number, designated use;

- unladen weight on the axles (e.g. vehicles equipped with cran e) in c luding positions for the centre of gravity of the payload;

- proposals concerning the reinforcement of the vehicle components where necessary.

The reduction ofpermissiblevehicle weight(downrating) mayrequire workon some components such as thesuspension and brakes

and may require new weight calibration for the braking corrector; in these cases the necessary indications can be supplied.

Dimensions and masses

Printed 603.95.241 Base- 02/2012

Page 24

1-16

GENERAL SPECIFICATIONS

Instructionsforcorrectoperationof vehiclecomponentsandaccessibility

D

AILY

1.16 Instructions for correct operation of vehicle components and accessibility

When converting vehicles or installing any type of equipment, n o alterations must be made which would compromise correct

operation of the vehicle assemblies and components in their various work conditions.

For example:

- free access must be guaranteed to points requiring inspection, maintenance or periodic checks (e.g. replacement of battery,

accessto air suspensioncompressor)and, with closedsuperstructures,appropriate compartments andhatches must beavailable;

- the possibility to remove the various assemblies for servicing must be maintained. Work on the transmission/clu tch or

adjustments (e.g. suspension bars) must be possible without removing important elements of the added structure;

- cooling (grille, radiator, air passages, coolin g circuit etc.), fuel supply (position of pump, filters, tubing diameters etc.) and engine

air intake must not be altered;

- soundproofing panels must not be altered or removed in order not to change the approved noise emission levels. Whenever

openings are to be made (e.g. for th e passage of lon gitudinal chassis members), they must be re-closed using materials with fireand sound-proofing characteristics equivalent to the original materials;

- adequate brake and battery case ventilation must be maintained (in particular for vans);

- when positioning mudguards and wheel arches, free movement of rear wheels must be guaranteed, also when used with snow

chains;

- when the conversion is finished,the vehicle’s headlights mustbe checked in order to ensure they are correctly adjusted.Proceed

according to the indications given in the use and maintenance manual for adjustment;

- the Bodybuilder must carefully ch oose the positioning of any loose elements (e.g. spare wheel, chocks) so as to ensure they are

safely and accessibly positioned in full respect of an y national regulations.

Instructions for correct operation of vehicle components and accessibility

Base - 02/2012 Printed 603.95.241

Page 25

DAILY

Convention

GENERAL SPECIFICATIONS

1.17 Conventions

The following conventions are used in this document:

- Wheelbase: distance between the centre line of the steering axle and that of the rear axle.

This definition differs from the definition of wheelbase indicated in EC Directives.

- Rear overhang: distance between the centre line of the rear axle and the rearmost point of the chassis side members.

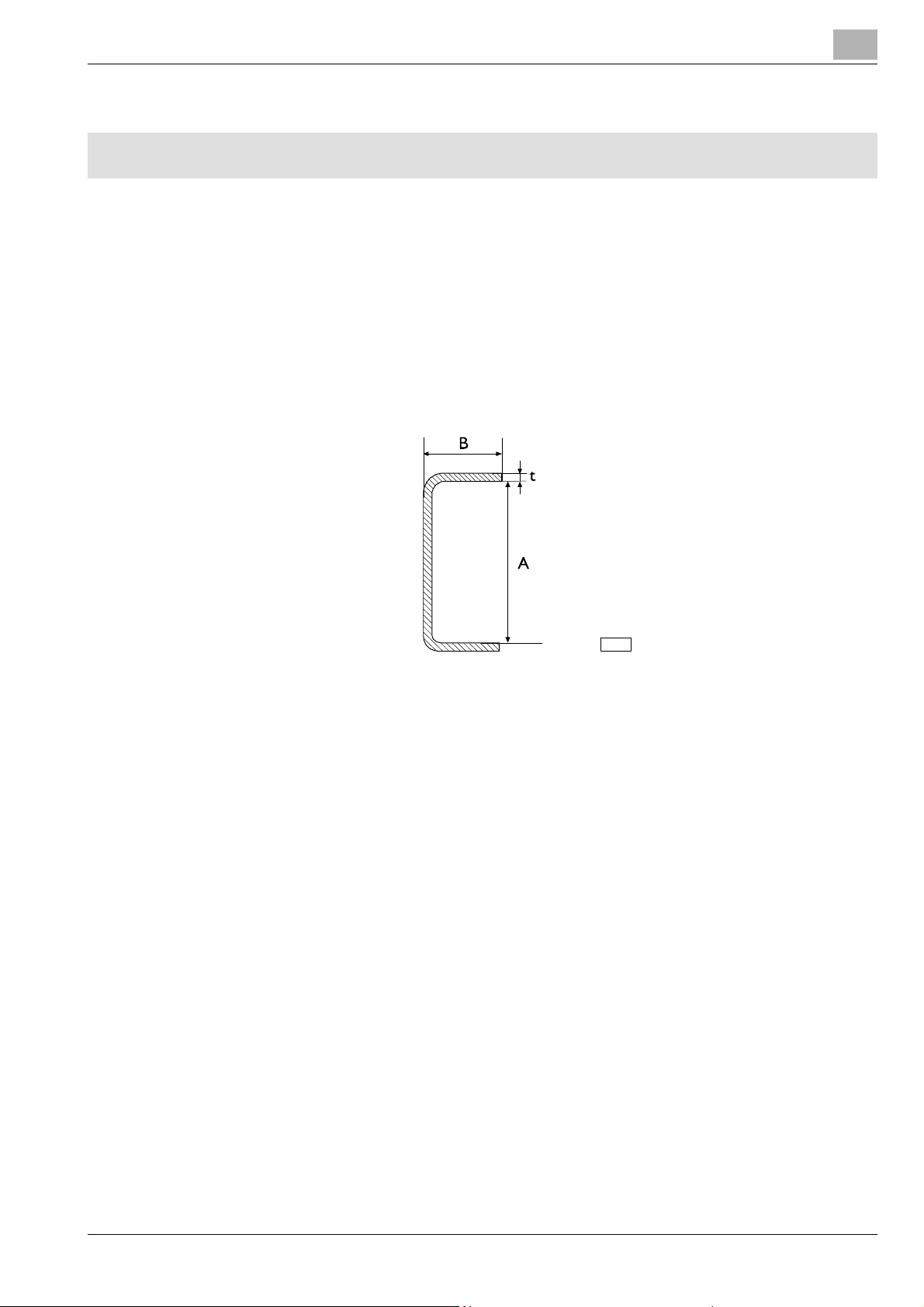

- Dimensions A, B and t of the chassis section: see the figure.

Figure 1.6

1-17

91473

Convention

Printed 603.95.241 Base- 02/2012

Page 26

1-18

GENERAL SPECIFICATIONS

D

AILY

Convention

Base - 02/2012 Printed 603.95.241

Page 27

DAILY

Index

CHASSIS MODIFICATIONS

SECTION 2

Chassis modifications

2.1 General standards regarding changes to the chassis 2-5

2.1.1 Particular precautions 2-5

2.1.2 Characteristics of the material to be used when modifying the chassis 2-6

2.1.3 Stress o n the chassis 2-7

2.2 Drills on the chassis 2-8

2.2.1 Hole positioning and dimensions 2-8

2.2.2 Screws and nuts 2-9

2.2.3 Welds 2-10

2.2.4 Closing holes by welding 2-12

2-1

Page

2.3 Rust protection and paint 2-13

2.3.1 Original vehicle components 2-13

2.3.2 Added or modified parts 2-16

2.3.3 Precautio ns 2-17

2.4 Modification of the wheelbase 2-18

2.4.1 General information 2-18

2.4.2 Authorisation 2-18

2.4.3 Influence on steering 2-18

2.4.4 Influence on braking 2-19

2.4.5 Procedure 2-19

2.4.6 Checking chassis stress 2-20

2.4.7 Cross members 2-20

2.4.8 Chassis reinforcements 2-21

2.4.9 Changes to the transmissions 2-21

2.5 Change of the rear overhang 2-22

2.5.1 General information 2-22

2.5.2 Authorisation 2-22

2.5.3 Shortening 2-22

Index

Printed 603.95.241 Base — 02/2012

Page 28

2-2

CHASSIS MODIFICATIONS

D

Page

2.5.4 Elongat ion 2-22

2.6 Application of the towing hook 2-24

2.6.1 Adjusting the vehicle for t owing 2-24

2.6.2 Precautions for installation 2-24

2.6.3 Hook types 2-24

2.6.4 Towing hook for central axle trailers 2-25

2.6.5 Rear cross member in a lowered position 2-27

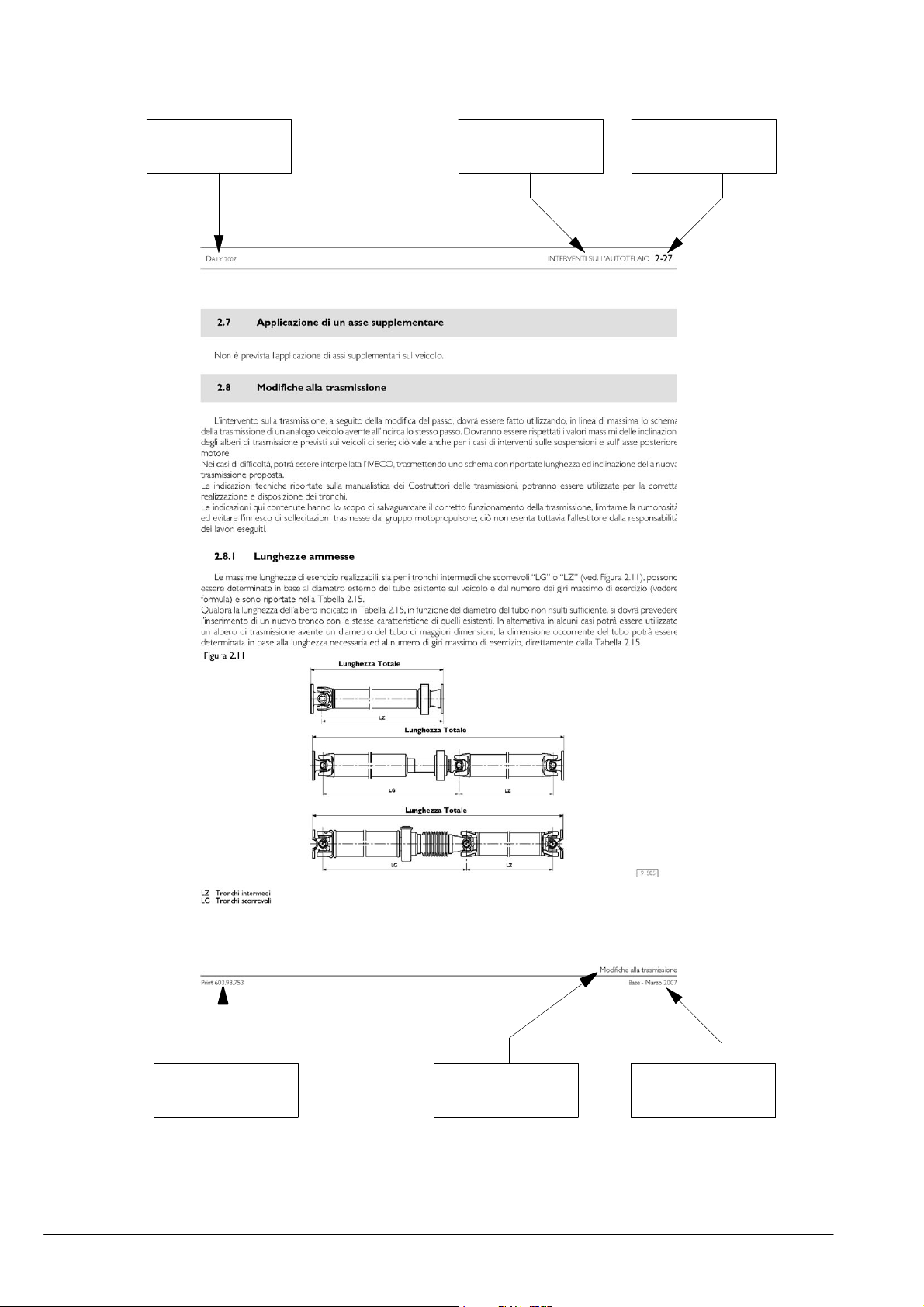

2.7 Application of a supplementary axle 2-29

2.8 Changes to the transmission 2-29

2.8.1 Permitted lengths 2-29

2.8.2 Sect i on positioning 2-32

2.9 Changes to the air intake and engine exhaust systems 2-34

AILY

2.9.1 Intake 2-34

2.9.2 Engine exhaust 2-34

2.10 Changes to the engine cooling system 2-35

2.11 Operations on the suspensions 2-36

2.12 Changes to the heating/cooling sy stem 2-38

2.12.1 Installation of a supplementary heating system 2-38

2.12.2 Installation of an air conditioning system 2-40

2.13 Operations on sheet metal 2-41

2.13.1 General information 2-41

2.13.2 Operations on the cab 2-42

2.13.3 Operations on the body (vans and c ombi) 2-44

2.13.4 Creating deep cabs 2-51

2.13.5 Occupant protection 2-52

2.14 Changing tyre size 2-53

2.15 Work on the brake system 2-55

2.15.1 Piping 2-55

2.15.2 Braking corrector 2-59

2.15.3 ESP (Electronic Stability Program) 2-61

Index

Base — 02/2012 Printed 603.95.241

Page 29

DAILY

CHASSIS MODIFICATIONS

2.15.4 ESP system down grading 2-62

2.16 Electrical system: work and current draws 2-64

2.17 Moving components and fastening supplementary units and equipment 2-65

2.18 Road transport of hazardous goods (ADR) 2-68

2.19 Application of a retarder 2-69

2.20 Changes to the under-run protection bar 2-70

2.21 Rear under-run protection and wheelhouses 2-70

2.22 Mudflaps 2-71

2.23 Side protections 2-71

2.24 Chocks 2-71

2-3

Page

Index

Printed 603.95.241 Base — 02/2012

Page 30

2-4

CHASSIS MODIFICATIONS

D

AILY

Index

Base — 02/2012 Printed 603.95.241

Page 31

DAILY

2222.2

Gener al standards re garding change s tothe chas sis

CHASSIS MODIFICATIONS

2-5

2.1 General standards regarding changes to the chassis

Keep the following in mind:

- welding is absolutely prohibited on the load bearing structures of the chassis (with the exception of what is specified in

paragraphs 2.2.3, 2.4, and 2.5);

- drilling is not permitted on the side member wings (with the exception of what is specified in paragraphs 2.2.3, 3.1.1 and 3.14.3);

- if it is permitted to make changes to the con nections implemented with rivets, they may be replaced with flanged head screws

and nuts or with c lass 8.8 hexagonal head screws with the next highest diameter and nuts with loosening prevention systems.

Screws larger than M12 must not be used (maximum hole diameter 13 mm), unless otherwise specified;

- if connections are restored that use screws, it is mandatory to check the suitability of the screws before reusing them and to

tighten them to a suitable torque;

If safety components are reassembled, it is prohibited to reuse already used screws and it is mandatory

to tighten to the specifically specified torque (contact the Service Network for information about the

!

value).

- ifsafety componentsare reassembledand when rivets arereplacedwith screws,the closure ofthe connection mustbe rechecked

after driving approx. 500 - 1000 km.

2.1.1 Particular precautions

During welding, drilling, grinding and cutting operations near brake pipes or electric cables, take

suitable precautions to protect them, disassembling them if necessary (follow the instructions

!

provided in chapters 2.15 and 5.4).

Figure 2.1

91444

General standards regarding changes to the chassis

Printed 603.95.241 Base — 02/2012

Page 32

2-6

CHASSIS MODIFICATIONS

D

AILY

Precautions for the alternator and the electric/electronic components

In order to prevent damage to the rectifier with diodes, the batteries must never be disconnected (and the disconnecting switch

must not be opened) while the engine is running.

If the vehicle must be started by means of towing (which is strongly advised against), make sure that the battery is charged an d

connected in order to provide the ECU engine control unit with the minimum operating voltage.

If the battery must be charged, it must be disconnected fromthe vehicle circuit. If the engine must be startedusing external charging

devices, do not use the ”start” function (if the equipment has this function) in order to prevent peaks of current that could damage

the electric and electronic components.

The start-up must o nly be carried out using an external battery carriage, being careful to respect the polarity.

Ground connections

In general, the vehicle’s original ground connections must not be changed. If it is necessary to move these connections or create

additional ground points, use the holes already existing in the c hassis if possible, being careful to:

- remove mechanically, through filing and/or with a suitable chemical product, the paint from both the c h assis and terminal sides,

creating a contact surface that is smooth and even;

- apply suitable paint with high electric conductivity between the terminal and the metalsurface (e.g. zinc basedpaint Part number

IVECO 459622 from the company PPG);

- connect the ground within 5 minutes of applying the paint.

For signal level ground connections (e.g.: low absorption sensors or devices), do not use the standardised IVECO points ”m1” (on

the engine block, near the starter motor) or ”m2” and make the ground connections of the signal cables on points separate from

the power cables and cables used as radiofrequency shields.

For electronic equipment, avoid making ground connections between devices in a linked manner, foreseeing individually wired

ground connections, optimising the length (prefer a shorter path).

Braking and electrical system

For more information about the braking and electrical systems, see chapters 2.15 and 5.4.

2.1.2 Characteristics of the material to be used when modifying the chassis

When making changes to the vehicle chassis (all models and all wheelbases) and when applying reinforcements directly on the

side members, the material to be used must comply with what was used originally for the chassis with regard to quality (Table 2.1)

and thickness (Table 2.2).

If it is not possible to find material that has the indicated thickness, material may be used with the next highest standard thickness.

Table 2.1 - Material to be used when making changes to the Standard IVECO chassis 15-2110 and 15-2812

Steel name

IVECO FEE420

Europe S420MC

Germany S420MC

UK S420MC

Ultimate tensile

strength

(N/mm

2

)

530 420 23

Yield strength

(N/mm

2

)

Elongation

(%)

N.B. For 70C vehicles only, the material must be FEE490 with:

- Ultimate tensile strength 610 N/mm

- Yield strength 490 N/mm

- Elongation 19%

General standards regarding changes to the chassis

Base — 02/2012 Printed 603.95.241

2

2

Page 33

DAILY

CHASSIS MODIFICATIONS

Table 2.2 - Section dimension and thickness of the chassis

2-7

Class Type Wheelbase [mm]

truck

29L - 35S

35C

van

lightened

campe r

3950 (camper) 1825

3000 short overhang 840

3000 long overhang 1240

3000 (1) 1240

35C-50C truck

4100 (1) 1715

4750 (2) 2350

3000 short overhang 840

35C - 40C van

3000 long overhang 1240

3000 short overhang 840

45C - 50C van

60C - 65C -

truck

3000 long overhang 1240

70C

van 3950 1825

(1) = only 35C - 40C

(2) = only 45C - 50C

Chassis rear

overhang

[mm]

3000 920

3450 1355

3750 1665

3300 1460

3950 1825

3750 1665

3950 1825

3450 1355

3750 1665

4350 1885

3300 1460

3950 1825

3300 1460

3950 1825

3450 1355

3750 1665

4350 1890

4750 2350

AxBxt

section wheelbase

area side member

[mm]

AxBxt

section rear

overhang area side

member [mm]

144 X 56 X 3 94 X 56 X 3

144 X 56 X 3 94 X 56 X 3

174 X 70 X 4 114 X 70 X 4

174 X 69 X 3 114 X 69 X 3

174 X 70 X 4 114 X 70 X 4

174 X 69 X 5 174 X 69 X 5

2.1.3 Stress on the chassis

In no case it is allowed to exceed the following stress values under static conditions:

Table 2.3

Range Static stress permitted on the chassis σ amm (N/mm2)

Road use Off-road use

Daily 120 80

In any case, comply with the most restrictive limits defined by national regulations.

Welding operations cause a deterioration of the material characteristics, therefore, when checking the stress in the thermally altered

area, consider a reduction of approx. 15% of the resistance characteristics.

General standards regarding changes to the chassis

Printed 603.95.241 Base — 02/2012

Page 34

2-8

CHASSIS MODIFICATIONS

Drillsonthechassis

D

AILY

2.2 Drills on the chassis

When it is necessary to fit auxiliary parts or assemblies to the c hassis, th e existing holes made in the factory should be used if

possible.

Drilling the flanges of the vehicle side members is strictly prohibited, with the exception of what is

indicated in paragraph 3.3.1.

!

In special cases (application ofbrackets, angle irons, etc.) where new holes haveto be drilled, these holes shallbe made on the vertical

rib of the side member and shall be accurately burred and bored.

2.2.1 Hole positioning and dimensions

The new holes shall not be drilled in the areas subjected to greater stress (e.g. spring supports) and areas where the side member

section changes.

The diameter of the holesshould be suitable forthe thickness of the panel andmust not exceed 13 mm (unless otherwise specified).

The distance of the hole axis from the edges of the side member must n ot be less than 30 mm, and the axes of the holes must not

be between them, or less than 30 mm with respect to the existing ones.

Theholesmustbeoffset,asshownintheFigure2.2.

The original drilling diagrams must be followed when moving spring supports or cross members.

Figure 2.2

102420

Drills on the chassis

Base — 02/2012 Printed 603.95.241

Page 35

DAILY

CHASSIS MODIFICATIONS

2-9

2.2.2 Screws and nuts

In general, it is recommended to make connections of the the same type and class as those foreseen for similar fastenings on

the original vehicle (Table 2.4).

Screws of class 8.8 and 10.9 must be hardened and tempered and, for applications with diameter

use stainless steel parts.

The foreseen coatings are Geomet and galvanisation. If the screws are subjected to welding, the Geomet coating is not

recommended.

If space permits, use screws and nuts wit h a flanged head.

Use nuts with loosening prevention systems and remember that the tightening torque must be applied to the nut.

Table 2.4 - Screw resistance classes

≤ 6 mm, it is recommended to

Resistance class Use

Ultimate tensile strength

(N/mm

2

)

4.8 Non-load bearing screws 400 320

5.8 Low resistance screws 500 400

Medium resistance screws

8.8

(cross members, cut

800 640

resistance plates, brackets)

High resistance screws (spring

10.9

mounts, stabilizer bars and

1000 900

shock absorbers)

Yield strength (N/mm2)

Drills on the chassis

Printed 603.95.241 Base — 02/2012

Page 36

2-10

CHASSIS MODIFICATIONS

2.2.3 Welds

The welds must only be made by qualified personnel with suitable equipment, and always to

professional standards (see standard EN 287). Any operation performed that does not comply with the

!

instructions provided by IVECO could seriously damage the on-board systems, jeopardise vehicle

safety and cause damage not covered by the warranty.

Welds are permitted:

- in side member joints, when lengthening and shortening;

- when applying angular reinforcements in the area involved with th e side member modification, as specified below

(see Figure 2.3).

Figure 2.3

D

AILY

91448

In the event of electrical arc welding, observe the following instructions to protect the electric components and electronic control

units:

- before disconnecting the power cables ensure there are no active electric users;

- if an electric circuit breaker (main switch) is present, wait for it to complete the cycle;

- disconnect the battery negative pole;

- disconnect the positive battery pole without grounding it, and DO NOT short circuit it with the negative pole;

- disconnect the c onnectors from electronic control units and proceed carefully, avoiding touching the pins of control unit

connectors;

- if welds are to be made near an electronic control unit, disconnect the control unit from the vehicle;

- connect the welding machine ground directly to the piece to be welded;

- protect the plastic pipes from heat sources, removing them if necessary;

- when welding near leaf springs or air springs, protect their surfaces appropriately from welding sprays;

- avoid touching the spring leafs with the electrodes or pliers.

Drills on the chassis

Base — 02/2012 Printed 603.95.241

Page 37

DAILY

CHASSIS MODIFICATIONS

2-11

Welding procedures

a) Carefully remove any paint and traces of oxidation from the parts of the chassis involved with the welding as well as those that

must be covered with reinforcements.

b) Cut the side members with a slanted or vertical cut. The side membersmust not be cut at the points wherethe chassiscontour

and width changes or where stress is greater (e.g. spring mounts). The separation line must not involve the holes on the side

member (see Figure 2.4).

Figure 2.4

YES

NO

YES

NO

YES

YES

YES

YES

91446

c) Make a 60° V shaped chamfer on the parts to join on the inner side of the side member along the entire length of the area

to be welded (see Figure 2.5).

Figure 2.5

91447

d) Perform arc welding with several passes using carefully dried basic electrodes.

Avoid current overload; the weld must be free from marginal cuts and waste material.

e) Repeat in the other direction and make the weld as specified in point d).

f) Allow the side members to cool slowly and uniformly. They must not be cooled using an air jet, water or another method.

g) Grind off the excess material.

h) Apply angular steel reinforcements on the inside, with the same specifications as the steel used in the chassis. The approximate

minimum dimensions are specified in Figure 2.3.

The reinforcements may only be secured on the vertical rib of the side member and may be implemented with welding beads,

false spots, screws or rivets (also Huck rivets).

The welding bead section and length, as well as the number and arrangement of false spots, screws or rivets, must be suitable

to transmit the bending and cutting moments of the section.

i) When the work is completed, protect with rust proofing (see paragraph 2.3.2).

Drills on the chassis

Printed 603.95.241 Base — 02/2012

Page 38

2-12

CHASSIS MODIFICATIONS

2.2.4 Closing holes by welding

When making new holes, and if they are too close to already existing holes (see Figure 2.2), the latter can be closed by welding

them.

To ensure that this operation will be suc cessful:

- smooth the external edge of the hole;

- apply a strip of copper inside the side member to retain the weld material;

- perform the welding on both sides of the side member and remove the residues.

In order to close holes with a diameter greater than 20 mm, rounded washers can also be used, welding on both sides.

D

AILY

Drills on the chassis

Base — 02/2012 Printed 603.95.241

Page 39

DAILY

Rust protecti on and paint

2.3 Rust protection and paint

CHASSIS MODIFICATIONS

2-13

NOTE

All components assembled on the chassis must be painted according to IVECO Standard 18-1600

colour IC444 RAL 7021 70/80 gloss.

2.3.1 Original vehicle components

Table 2.5 shows the protection and painting classes required for the original vehicle components; Table 2.6 sh ows the classes

for non painted or aluminium parts and Table 2.7 shows the parts for the painted classes.

Table 2.5 - Class of protection - IVECO Standard 18 - 1600 (Table I)

Class Part requirements Examples of involved parts

Body - Rear-view mirrors - Windscreen wipers - Sun visor

A Parts in direct contac t with atmospheric agents.

B

B2

Parts in direct contact with atmospheric agents with

mainly structural characteristics, in direct view.

B1 Only for rear and front axles

C

Parts in direct contact with atmospheric agents, not in

direct view.

D Parts not in direct contact with atmospheric agents.

metal structure - Metal bumper - Cab hook-up lock Door stop device - Body fixing elements (screws, bolts,

nuts, washers), etc.

Chassis and relative parts, including fastening elements.

Parts under the grille (class B).

Running boards outside the cab.

Engine and relative parts

Pedal assemblies - Seat frames - Fastening elements - etc.,

installed inside the cab.

NOTE

The parts must be supplied only with cataphoresis or a rust inhibitor (Table III). The enamel will be

applied during the chassis finishing phase.

Rust protection and paint

Printed 603.95.241 Base — 02/2012

Page 40

2-14

CHASSIS MODIFICATIONS

Table 2.6 - Various unpainted, aluminium parts and components - IVECO Standard 18 - 1600 (Table IV)

D

AILY

Type of protection

IVECO

standard

A B-B1-B2 C D

Classes

Stainless steel ¡ 18-0506 yes - - -

GEO 321-8

GEO 500-8

GEO 321-8 PM

GEO 321-8 PML

yes -

GEO 321-8 PL

Geomet

(HHH)

GEO 500-8 PL

GEO 321-5

18-1101

- -

GEO 500-5

GEO 321-5 PM

GEO 321-5 PML

GEO 321-5 PL

-

yes

yes

Class B1

GEO 500-5 PL

wheel studs

FE/ZN 12 II

- - yes yes

- - yes yes

Galvanisation

(HH)

FE/ZN 7 IV

FE/ZN 12 IV

FE/ZN 7 IV LUB

18-1102

FE/ZN 7 IV S

- yes yes yes

yes yes yes

yes

Aluminium

FE/ZN 12 IV S

Anodic

oxidation

Painting

18-1148 yes

See

Table III

¡ Coupling with other metal materials must not cause a ”pile effect”.

(

HH) Coatings free of hexavalent chromium.

HHH) Coatings free of chromium salts.

(

Rust protection and paint

Base — 02/2012 Printed 603.95.241

Page 41

DAILY

CHASSIS MODIFICATIONS

Table 2.7 - Painted parts - IVECO Standard 18 - 1600 (Table III)

2-15

Cycle phase description

MECHANICAL SURFACE

CLEANING¡

PRETREATMENT

CATAPHORESIS

RUST PROOFING

STONE RESISTANT BOTTOM

ENAMEL

Classes

A B § B1¤ B2 C D

Sandblasting/shotblasting -

yes L - yes L yes L yes LBrushing

Sanding

yes L

Iron phosphating (only for

ferrous materials that are not

previously coated)

yes L - yes L yes L yes L

Zinc phosphating l yes

High thickness (30-40 μm) yes ©

Medium thickness (20-30 μm) yes ¢

yes L

¥

yes L

Finishing acrylic (>35 μm) - Bi-component (30-40 μm)

Single-component (30-40 μm) - yes Single (130 °C)

or bi-component (30-40 μm)

Single (130 °C)

or bi-component (30-40 μm)

-

yes ¢ - - - - -

yes

yes - yes

yes L -

Powders (40-110 μm) yes £

Single-component at low

temperature (30-40 μm)

- - yes

yes L

¥

¨¥

yes L

¨

- yes L

yes L

¥

yes L

yes L

¦

¡ = Operation to be performed if there are shearing burrs, oxidation, welding scraps, laser cut surfaces.

© = Two-layer body cycle.

¢ = Three-layer body cycle.

£ = As an alternative to single or bi-component enamel only for body parts (windscreen wipers, rear-view mirrors, etc.).

¤ = Rear and front axles only.

¥ = Exclusions of parts that cannot be immersed in pretreatment or paint baths as their functionality could be jeopardised (e.g.: mechanical parts).

¦ = Only if the colour is defined on the drawing according to I.C.

§ = For fuel tanks in ferrous or precoated plate.

¨ = Only parts to be installed on the engine.

l = For galvanised plate or aluminium, specific phosphates must be used.

L = Alternative products and cycles for the same phase, providing they are compatible with the parts to be treated.

Rust protection and paint

Printed 603.95.241 Base — 02/2012

Page 42

2-16

CHASSIS MODIFICATIONS

D

AILY

2.3.2 Added or modified parts

All the vehicle parts (body, chassis, equipment, etc.) that are added or that are changed must be protected against oxidation

and corrosion.

Areas without protection are not accepted on ferrous materials.

Tables 2.8 and 2.9 indicate the minimum treatments to which the modified or added components must be subjected when it is not

possibleto protect them using the same protection used for the original components. Different treatments are permitted providing

that the same oxidation and c orrosion protection is guaranteed.

Do not use powder enamels directly after degreasing.

Parts in light alloy, brass and copper are not protected.

Table 2.8 - Added or modified painted parts

Cycle phase description

Mechanical surface cleaning (including the removal of

burrs/oxidation and cleaning cut parts)

A-B-D(1)

Brushing/sanding/sandblasting

Pretreatment Degreasing

Rust proofing Bi-component (30-40 μm) (2)

Enamel Bi-component (30-40 μm) (3)

Class

(1) = Changes on rear axles, front axles and engine (classes B1 and C) not permitted

(2) = Preferably epoxy

(3) = Preferably polyurethane.

Table 2.9 - Added or modified unpainted or aluminium parts

Class

Type of protection

A-B(1) D

Stainless steel

Geomet -

yes

Galvanising (1) - yes

(1) = Free of hexavalent chromium.

-

Rust protection and paint

Base — 02/2012 Printed 603.95.241

Page 43

DAILY

CHASSIS MODIFICATIONS

2.3.3 Precautions

a) On the vehicle

Suitable precautions must be taken to protect the parts for which paint may be harmful for con servation and operation:

- rubber o r plastic flexible pipes for pneumatic and hydraulic systems;

- gaskets, parts in rubber or plastic;

- propeller shaft and power take-off flanges;

-radiators;

- shock absorber, hydraulic or pneumatic cylinder stems;

- air bleeder valves (mechanical units , air tanks, thermostarter preheating tan ks, etc.);

- fuel sediment filter;

-plates,acronyms.

If painting is necessary after disassembling the wheels, proceed as follows:

- protect the wheel rim contact surfaces on the hubs and the stud/fixing nut contact areas;

2-17

- ensure suitable protection for the brake discs.

Electronic components and modules must be removed.

b) Engines and their electrical and electronic components

Suitable precautions must be taken to protect:

- engine and vehicle wiring, including ground contacts;

- sensor/actuator side and wiring side connectors;

- sensors/actuators on the flywheel, on the flywheel rev sensor support bracket;

- the plastic and metal pipes in the entire diesel circuit;

- the complete diesel filter base;

- the electronic control unit and its base;

- the entire inner part of the soundproofing cover (injectors, rail, pipes);

- the common rail pump with regulator;

- the vehicle’s electrical pump;

- the tank;

- the front belt coil and relative pulleys;

- the power steering pump and relative pipes.

When the painting operation is complete and before drying in the oven (max. temperature 80 °C), all

the parts that may be harmed by exposure to heat must be removed or protected.

!

Rust protection and paint

Printed 603.95.241 Base — 02/2012

Page 44

2-18

CHASSIS MODIFICATIONS

Modificati onof the whe elbase

D

AILY

2.4 Modification of the wheelbase

2.4.1 General information

Any change to the wheelbase that involves the electrical circuits and/or the relocation of the

electrical/electronic components requires approval and must be performed in compliance with the

!

instructions in chapter 5.4.

In general, the wheelbase must be changed by working on a standard production wheelbase that is as close as possible to the

onetobecreated.

If permitted by the dimension of the superstructure, it is preferable to create wheelbases that are equal to those foreseen by normal

production, as this makes it possible to use original propeller shafts and predefined cross member positions.

Please note that if y ou want to create a size that is smaller than the approved minimum or greater than the approved maximum,

authorisation must be requested from IVECO.

For vehicles equipped with an ESP system, see paragraph 2.15.3.

!

2.4.2 Authorisation

The wheelbase may be changed without specific IVECO approval only when:

- implementing one of the lengths foreseen in the catalogue for the type of vehicle to be transformed;

- replicating the structure (side member section; number, type and positions of the cross members), the circuits and systems on

the standard chassis corresponding to this length.

If both these conditions do not exist simultaneously , with which th e diagram of the transformed chassis is identical to the diagram

of an original chassis, the c hange must be submitted for approval.

The workshop that makes the transformation must provide sufficient guarantees from a technological and control point of view

(qualified personnel, suitable operating processes, etc.).

The work must be carried out in compliance with th ese directives, in accordance with suitable regulations and adaptations, as well

as proper precautions (e.g. check the need to reset the control unit parameters, positioning of the exhaust pipe, compliance with

the minimum tare on the rear axle, etc.) foreseen for corresponding original wheelbases.

2.4.3 Influence on steering

In general, lengthening the wheelbase has a negative influence on steering characteristics.

When required by regulations, do not exceed the limits required for the swing-out radius, the forces on the steering wheel and the

relative inscribability times (e.g. ECE Regulation or EC Directive in force).

Table 2.10 specifies the maximum wheelbase lengthening values possible with standard steering, the maximum load permitted on

the front axle and the required tyres for the vehicle.

If longer wheelbases are necessary, specific approval must be requested and measures must be adopted to improve steering, such

as the reduction of the maximum load on the front axle or the creation of an offset with lower values.

Also the use of a supplementary pump must be authorised, whereas for the subsequent installation, a specialised company must

be used.

Modification of the wheelbase

Base — 02/2012 Printed 603.95.241

Page 45

DAILY

CHASSIS MODIFICATIONS

Table 2.10 - Maximum permitted wheelbase elongation

2-19

Model Front suspension

Maximum wheelbase

(mm)

29L, 35S Transverse 4100

35C, 40C, 45C, 50C Transverse (maximum permitted 1800 kg) 4100

35C, 40C, 45C, 50C Torsion bar (maximum permitted 1900 kg) 4750

60C, 65C, 70C Torsion bar 4750

2.4.4 Influence on braking

In general, shortening the wheelbase has a negative influence on braking characteristics.

Table 2.11shows the limits for wheelbase modification.Checkwith the IVECO - Homologation & Technical Applicationdepartment

about the conditions (brake cylinders, minimum tares, technically permissible weights, tyres, height of the centre of gravity) with

which these values are permitted.

Table 2.11 - Braking, limits for wheelbase modification

Model Version

Minimum (mm) Maximum (mm)

29L, 35S Truck, van 3000 3950

35C, 40C Truck, van 3000 4100

45C, 50C Van 3000 4750

45C, 50C Truck 3450 4750

60C, 65C, 70C Truck, van 3300 4750

Wheelbase

In the case of vehicles equipped with an ASR system, the setting data must be updated.

!

2.4.5 Procedure

To obtain a good result, proceed as follows:

- position the vehicle so that the chassis is perfectly flat, using suitable stands;

- disconnect the propeller shafts, the brake system pipes, wiring and anything else that could prevent the work from being

performed correctly;

- identify the reference points on the chassis (e.g. pilot holes, suspension mounts);

- markthe reference pointswitha light punching line on the upper wings of both side members, after checking that the connecting

one is perfectly perpendicular to the vehicle’s longitudinal axis;

- if moving the suspension mounts, identify the new position using the previously determined references;

- check that the new dimensions are identical on the left and right sides; the diagonal check, for minimum lengths of 1500 mm,

must not detect deviations greater than 2 mm;

- make the new drill holes using the mounts and cross member plates as a mask if other equipment is not available;

- fasten the mounts and the cross members using rivets or screws; if screws are used, ream the holes and use calibrated screws,

class 10.9, with nuts with loosening prevention systems; if their dimensions permit it, flanged head screws and nuts can be used;

- if cutting the chassis (to be carried out according to the instructions on page 2-11, point b) determine a second line of reference

points so that the area to be worked on is contained between these and the previous ones (ensure a minimum distance of 1500

mm after the operation is complete). Move the points relative to the cutting area inside the two lines of reference, proceeding

according to the in structions in paragraph 2.2.3;

Modification of the wheelbase

Printed 603.95.241 Base — 02/2012

Page 46

2-20

CHASSIS MODIFICATIONS

D

AILY

- beforeweldingcheck that the side members,including anypart that wasadded,are perfectly alignedand thenperform thecontrol

measurement on the two sides and diagonally, as previously indicated.

Apply the reinforcements according to t he instructions in paragraph 2.2.3.

Additional information

- Protect the surfaces from oxidation as specified in paragraph 2.3.2.

- Restore the braking and electrical systems according to what is specified in chapters 2.15 and 5.4.

- For operations on the transmission, follow the instructions in chapter 2.8.

2.4.6 Checking chassis stress

When lengthening the wheelbase, in addition to providing local reinforcement in corresponding of the side member joint, the

fitter must also foresee reinforcements in order to create, for the entire wheelbase length, resistance modules of a section no less

than what is foreseen by IVECO for the same wheelbase or the next highest one. Alternatively, if permitted by local regulations,

larger sized sections of th e sub-frame may be adopted.

The fitter must check that the stress limits required by national regulations are observed. The stress may not exceed the stress on

the chassis in the original wheelbase, in the case of a uniformly distributed load and with the chassis considered as a beam placed

in correspondence of the suspension mounts.

If elongation is done starting from a longer original wheelbase, the reinforc ements must be provided in fu n ction of not only the

amount of elongation but also of the type of bodywork that is created and the vehicle use.

2.4.7 Cross members

The need to use one or more cross members depends on:

- the amount of the elongation;

- the position of the transmission support;

- the welding area;

- the point of application of the forces coming from the superstructures;

- conditions of vehicle use.

If there is a supplementary cross member, it must have the same characteristics of the ones already on the chassis (resistance to

bending and torsion, material quality, connections to side members, etc.).

Figure 2.6 shows an implementation example.

An additional cross member must be provided for extensions greater than 600 mm.

In general, the distance between the two cross members must not exceed 1000 ÷1200 mm.

The minimum distance between two cross members, particularly for ”heavy duty use” must not be less than 600 mm; this limitation

excludes the ”light” cross member for transmission and shock absorber support.

Figure 2.6

102421

Modification of the wheelbase

Base — 02/2012 Printed 603.95.241

Page 47

DAILY

CHASSIS MODIFICATIONS

2-21

2.4.8 Chassis reinforcements

Figure 2.7 shows some examples of solutions that can be implemented.

The reinforcements must be continuous and must involve the entire length of the vehicle chassis to the cab. For their connection

tothesidemember,inthecaseofanangularsection,rivetsorscrews with a resistance class of 8.8 must be used; the diameter and

distribution must make it possible for the section to provide the foreseen contribution to resistance.

In the rear overhang area, and for about half of the wheelbase (in any case no less than 2 m from the front axle) it is recommend e d

to make a shear-resistant connection.

Bending stresses must be foreseen on the transformed chassis that are no greater than those on the chassis of the original vehicle,

in the corresponding sections.

Figure 2.7

102422

1. Bracket - 2. Plate - 3. Screws or rivets

To prevent consequences on the resistance of the original sections, it is not permitted to apply reinforcement plates directly on

the wings of the side members using holes filled with welding.

Alternatives may be authorised by IVECO only when demonstrated requirements exist, connected to the subsequent phase of

installing the superstructure.

In these c ases, due to the deteriorationcaused by welding, it is a good idea to consider a reduction in material characteristics of

approx. 15%.

When sizing the reinforcements use the material suggested in Table 2.1 and the static stress values on the chassis specified in

Table 2.3 may not be exceeded.

In any case, comply with the most restrictive limits defined by national regulations.

2.4.9 Changes to the transmissions

To check the permitted changes, refer to chapter 2.8.

Modification of the wheelbase

Printed 603.95.241 Base — 02/2012

Page 48

2-22

CHASSIS MODIFICATIONS

Change of the rear overh ang

D

AILY

2.5 Change of the rear overhang

2.5.1 General information

When changing the rear overhang, keep in mind the impact this has on the effects of the distribution of useful load on the axles,

with respect to the loads specified by IVECO (see chapter 1.15). It is necessary to comply with the limits specified by national

regulations as well as the maximum distances from the rear structure edge and the heights off the ground, defined for the towing

hook and the under-run protection. The distance from the chassis end to the rear edge of the superstructure must not normally

exceed 350 ÷ 400 mm.

If it is necessary to move the rear cross member fixed with screws, it is necessary to maintain the same type of standard connection

(number of screws, dimensions, resistance class).

If a towing hook is to be applied, sufficient distance (approx. 350 mm) must be left between the rear cross member and the nearest

one for possible hook assembly and disassembly operations.

If the work is done up to professional standards and in accordance wit h the instructions provided here, theo riginally defined towable

weight can remain unvaried.

The party who c arries out the work is responsible for it.

2.5.2 Authorisation

The rear elongations of the chassis as well as shortening to a value shorter than what is foreseen standard for each model, if

implemented according to the instructions provided here, do not need to be specifically authorised.

For vehicles intended for special use, where load distribution is predefined and fixed, the rear overhang can be lengthened with values

greater than60% of the wheelbase, providing that they comply with the conditionsset forth in Paragraph 1.15.3,Directive EEC97/27

and the relative national implementations with regard to the swing-out radius.

2.5.3 Shortening

When shortening the rear overhang of the chassis, the last cross member must be moved forward.

When the rear cross member results as being located too near to an existing one, the latter can be removed if it is not involved

with the suspension mounts.

For vehicles equipped with an ESP system, see paragraph 2.15.3.

!

2.5.4 Elongation

The possible solutions, based on the amount of elongation, are shown in Figures 2.8, 2.9 and 2.10.

Also a straight cut is permitted for the chassis. The minimum dimensions of the reinforcements to be applied to the area involved

with the change, are specified in Figure 2.3.

Figures 2.8 and 2.9 show the solution foreseen for elongations that do not exceed 300 ÷ 350 mm; in this case the reinforcement

angle bars, which also provide a connection between the cross member and the chassis, must h ave the same thickness and width

of the original connection plate. The connect ion between the cross member and plates, which was originally implemented using

rivets, can be done using 8.8 class screws with the next highest diameter, and nuts with loosening prevention systems.

For vehicles equipped with an ESP system, see paragraph 2.15.3.

!

Change of the rear overhang

Base — 02/2012 Printed 603.95.241

Page 49

DAILY

The solution foreseen for elongations greater than 350 mm is shown in Figure 2.10.

Figure 2.8

Figure 2.9

CHASSIS MODIFICATIONS

2-23

Figure 2.10

102427

If the amount of the elongation is con siderable, it is necessary to assess on a case by case basis if a supplementary cross member

is needed in order to ensure suitable torsional rigidity for the chassis. A supplementary cross member, with the standard

characteristics, must be inserted when the distance between the two cross members is greater than 1200 mm.

Change of the rear overhang

Printed 603.95.241 Base — 02/2012

Page 50

2-24

CHASSIS MODIFICATIONS

Applicati onof the towi nghook

D

AILY

2.6 Application of the towing hook

2.6.1 Adjusting the vehicle for towing

The transformation from a non-towing version to an approved towing version is permitted without the specific need for

authorisation by IVECO.

A vehicle that is not originally setup for towing can be adjustedfor this purpose by adding a specific ”towing section”, which means