Iveco CURSOR EURO 4 Repair Manual

CURSOR

EURO 4 ENGINES

Vehicle application

C78

C78 ENT C

C10

C10 ENT C

C13

C13 ENT C

Technical and Repair manual

This publication describes the characteristics, data and correct

methods for repair operations on each component of the vehicle.

If the instructions provided are followed and the specified

equipment is used, correct repair operations in the programmed time will be ensured, safeguarding against possible

accidents.

Before starting to perform whatever type of repair, ensure that

all accident prevention equipment is available and efficient.

All protections specified by safety regulations, i.e.: goggles,

helmet, gloves, boot, etc. must be checked and worn.

All machining, lifting and conveying equipment should be inspected before use.

The data contained in this publication was correct at the time

of going to press but due to possible modifications made by

the Manufacturer for reasons of a technical or commercial nature or for adaptation to the legal requirements of the different countries, some changes may have occurred.

No part of this publication, including the pictures, may be reproduced in any form or by any means.

Publication edited by

Iveco Motors

Iveco SpA

PowerTrain

Mkt. Advertising & Promotion

Viale dell’Industria, 15/17

20010 Pregnana Milanese

Milano (Italy)

Print P1D32C002 E -1

st

Ed. 09.2006

Produced by:

B.U. TECHNICAL PUBLISHING

Iveco Technical Publications

Lungo Stura Lazio, 15/19

10156 Turin - Italy

CURSOR EURO 4 ENGINES

1

CURSOR EURO 4 ENGINES

F2B Cursor engines Part 1

F3A Cursor engines Part 2

F3B Cursor engines Part 3

Print P1D32C002 E Base - September 2006

2

CURSOR EURO 4 ENGINES

Base - September 2006 Print P1D32C002 E

CURSOR EURO 4 ENGINES

3

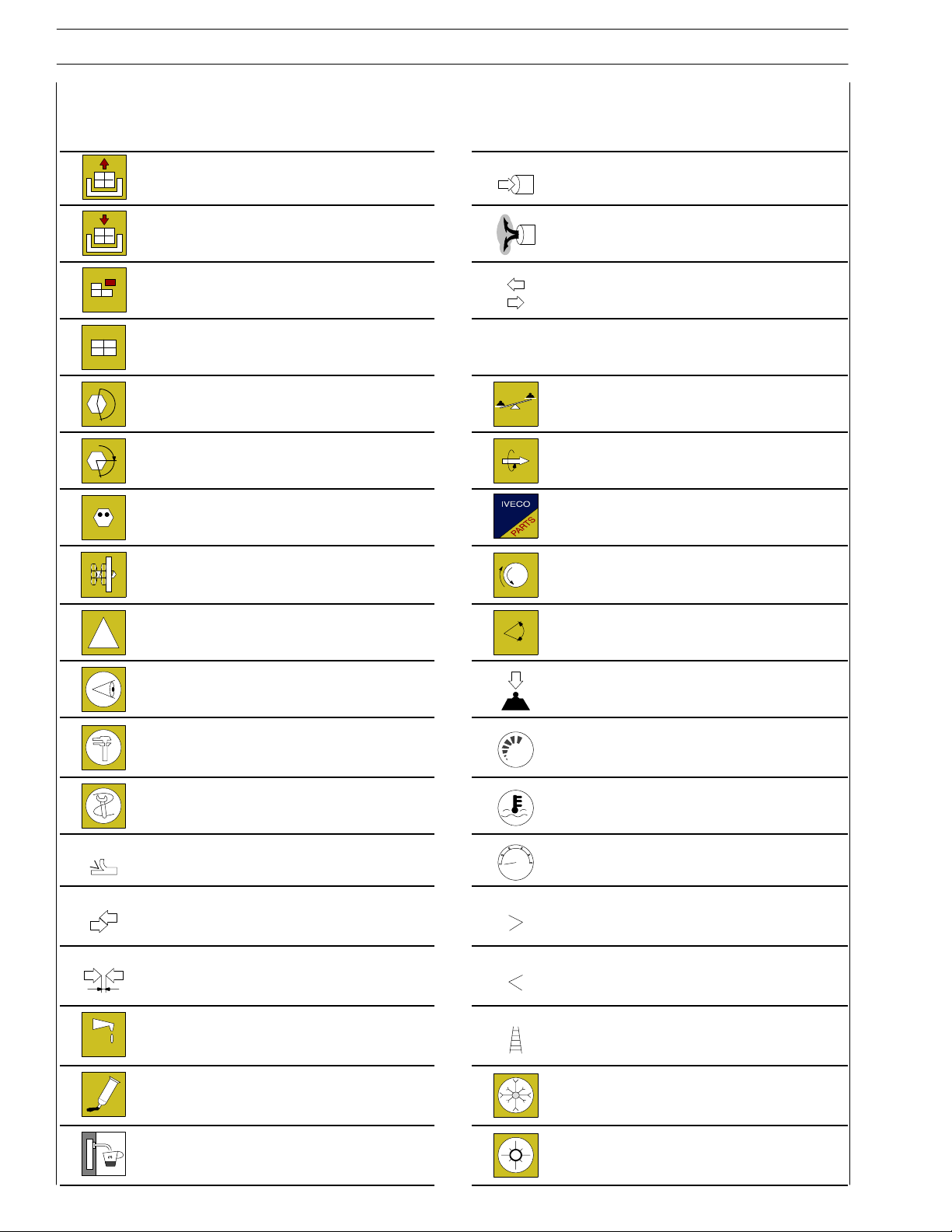

SPECIAL REMARKS

The subjects usually dealt with in each section are:

Technical data table, Driving torques, Equipment, Diagnostic, Removal and Fitting in place, Repair operations.

Where possible, the same sequence of procedures has been followed for easy reference.

Diagrams and symbols have been widely used to give a clearer and more immediate illustration of the subject being dealt with, (see

next page) instead of giving descriptions of some operations or procedures.

Example

∅

Ø 1 = housing for connecting rod small end bush

1

Ø 2 = housing for connecting rod bearings

∅

2

Tighten to torque

Tighten to torque + angular value

α

Print P1D32C002 E Base - September 2006

4

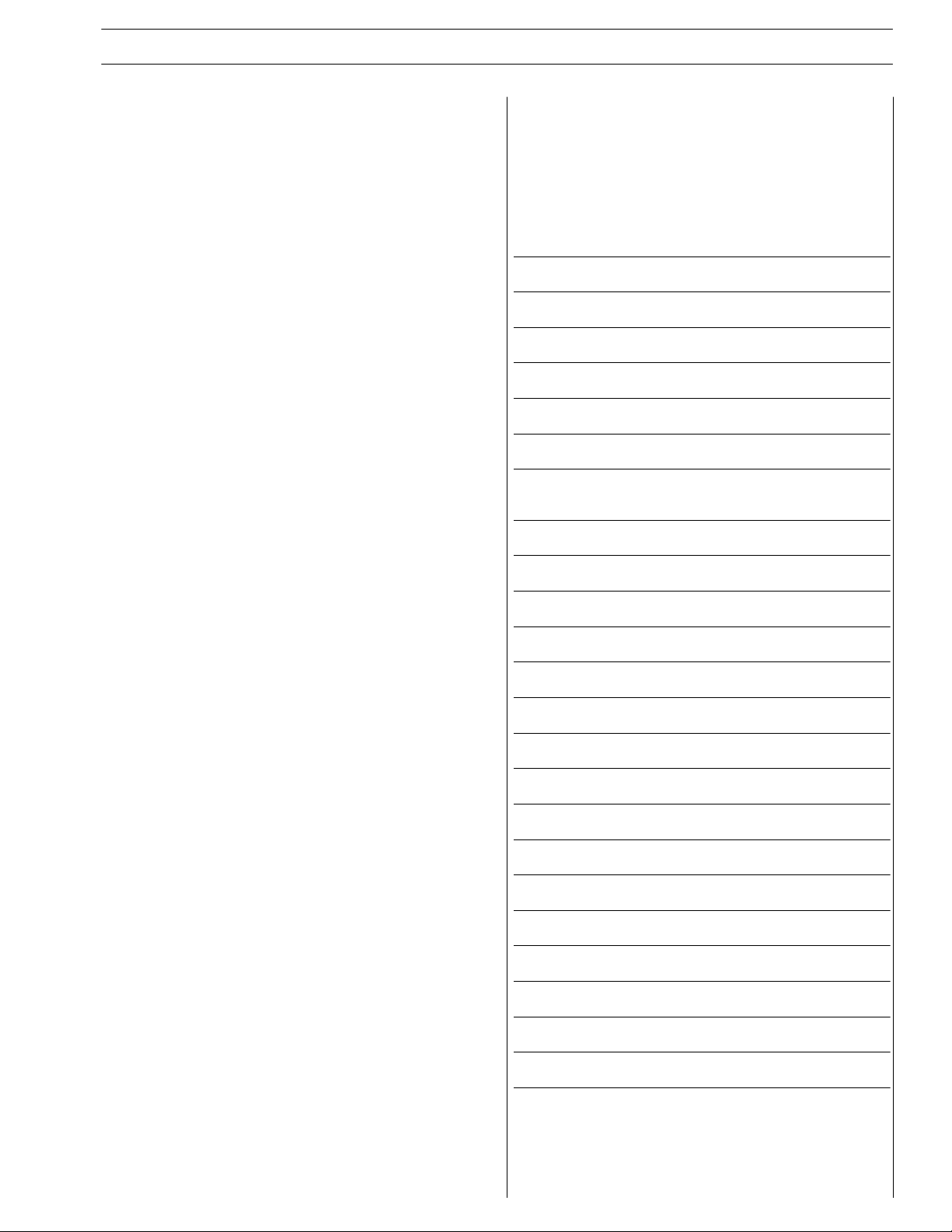

Graph and symbols

CURSOR EURO 4 ENGINES

Removal

Disconnection

Refitting

Connection

Removal

Disassembly

Fitting in place

Assembly

Tighten to torque

Tighten to torque + angle value Rolling torque

α

Press or caulk

Regulation

Adjustment

ρ

Intake

Exhaust

Operation

Compression ratio

Tolerance

Weight difference

Replacement

Original spare parts

Rotation

!

Warning

Note

Visual inspection

Fitting position check

Measurement

Value to find

Check

Equipment Temperature

Surface for machining

Machine finish

Interference

Strained assembly

Thickness

Clearance

Lubrication

Damp

Grease

Sealant

Adhesive

Air bleeding

bar

Angle

Angular value

Preload

Number of revolutions

Pressure

Oversized

Higher than….

Maximum, peak

Undersized

Less than….

Minimum

Selection

Classes

Oversizing

Temperature < 0 °C

Cold

Winter

Temperature > 0 °C

Hot

Summer

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

1

Part 1

F2B CURSOR EURO 4 ENGINES

Section

General specifications

Fuel 2

Vehicle application 3

General overhaul 4

Tools 5

Safety prescriptions Appendix

1

PREFACE TO USER’S GUIDELINE MANUAL

Section 1 describes the F2B engine illustrating its features

and working in general.

Section 2 describes the type of fuel feed.

Section 3 relates to the specific duty and is divided in four separate parts:

1. Mechanical part, related to the engine overhaul,

limited to those components with different characteristics

based on the relating specific duty.

2. Electrical part, concerning wiring harness, electrical

and electronic equipment with different characteristics

based on the relating specific duty.

3. Maintenance planning and specific overhaul.

4. Troubleshooting part dedicated to the operators who,

being entitled to provide technical assistance, shall have simple

and direct instructions to identify the cause of the major inconveniences.

Sections 4 and 5 illustrate the overhaul operations of the engine overhaul on stand and the necessary equipment to execute

such operations.

The appendix reports general safety prescriptions to be followed by all operators whether being in-charge of installation or

maintenance, in order to avoid serious injury.

Print P1D32C002 E Base - September 2006

2

F2B CURSOR EURO 4 ENGINES

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

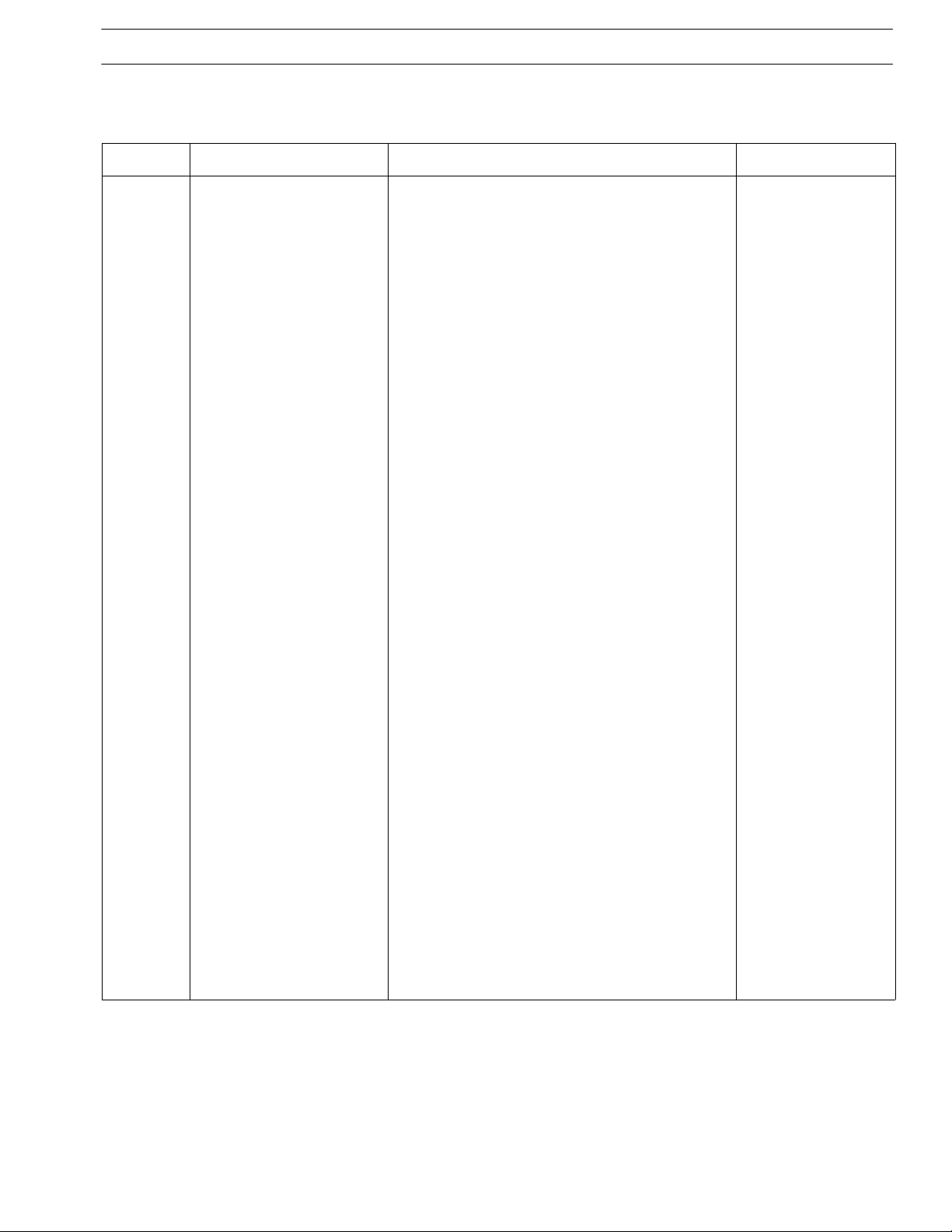

UPDATING

Section Description Page Date of revision

3

Print P1D32C002 E Base - September 2006

4

F2B CURSOR EURO 4 ENGINES

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

SECTION 1 - GENERAL SPECIFICATIONS

SECTION 1

General specifications

CORRESPONDENCE BETWEEN TECHNICAL CODE

AND COMMERCIAL CODE 3.............

ENGINE SECTIONS 5......................

LUBRICATION 7..........................

- Oil pump 8.............................

- Overpressure valve 8.....................

- Oil pressure control valve 9................

- Heat exchanger 9........................

- By-pass valve inside the filter support/heat

exchanger assembly 10.....................

1

Page

- Thermostatic valve 10......................

- Engine oil filters 10........................

- Valve integrated in piston cooling nozzle 11.....

COOLING 12..............................

- Description 12............................

- Operation 12............................

- Water pump 13..........................

- Thermostat 13...........................

TURBOCHARGING 14......................

VGT TURBOCHARGER 14...................

- Actuator 15..............................

- Solenoid valve for VGT control 15............

DENOX SYSTEM 2 16.......................

- General remarks 16........................

- Tank 18.................................

- AdBlue fluid level gauge control 18............

Print P1D32C002 E Base - September 2006

2

SECTION 1 - GENERAL SPECIFICATIONS

- By-pass valve 18..........................

- Pump module 19.........................

- Dosing module 19........................

- Catalyst 19..............................

- Exhaust gas temperature sensor 20...........

- Humidity detecting sensor 21................

F2B CURSOR EURO 4 ENGINES

Page

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

SECTION 1 - GENERAL SPECIFICATIONS

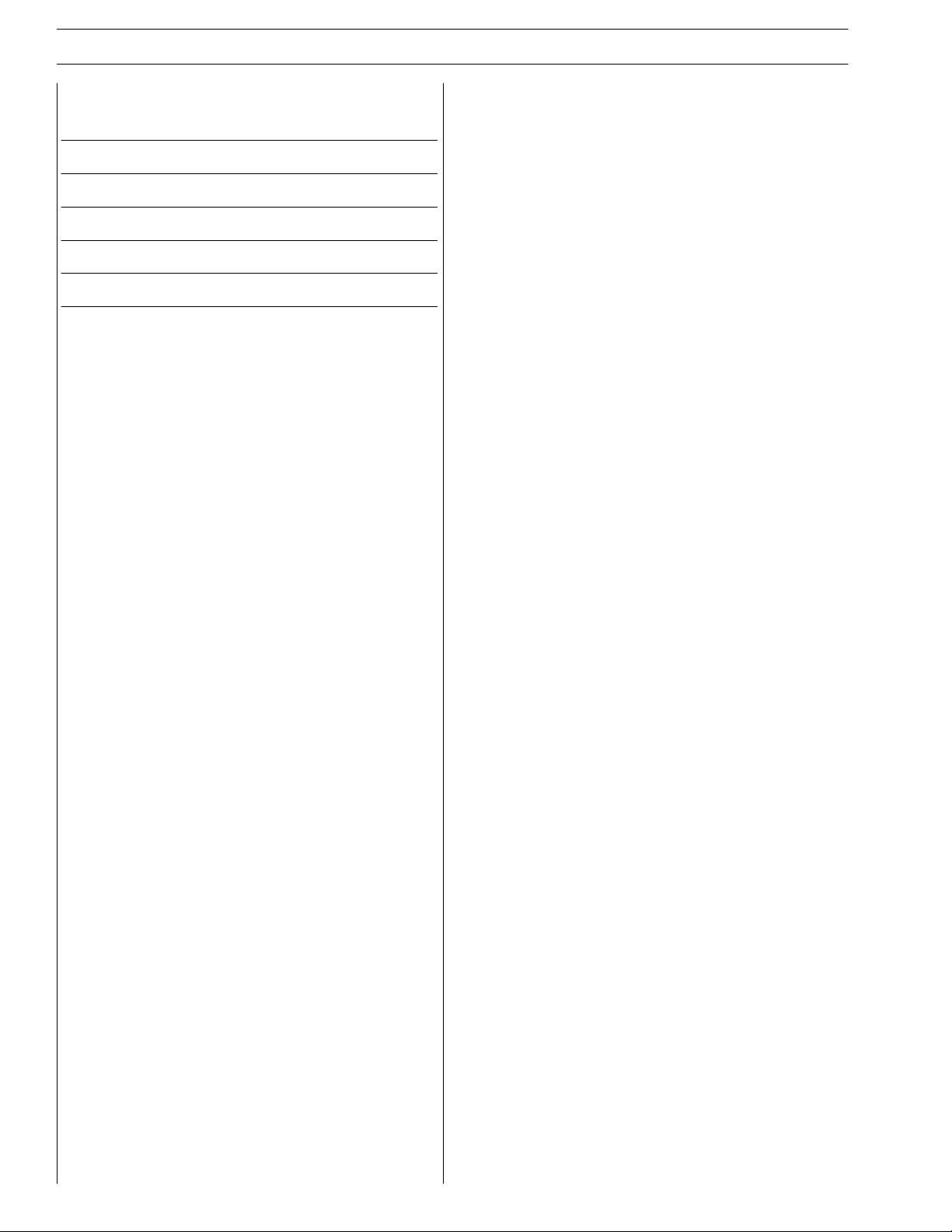

CORRESPONDENCE BETWEEN TECHNICAL CODE AND COMMERCIAL CODE

Technical Code Commercial Code

F2BE3681C C78 ENT C

F2BE3681B C78 ENT C

F2BE3681A C78 ENT C

3

Print P1D32C002 E Base - September 2006

4

SECTION 1 - GENERAL SPECIFICATIONS

F2B CURSOR EURO 4 ENGINES

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

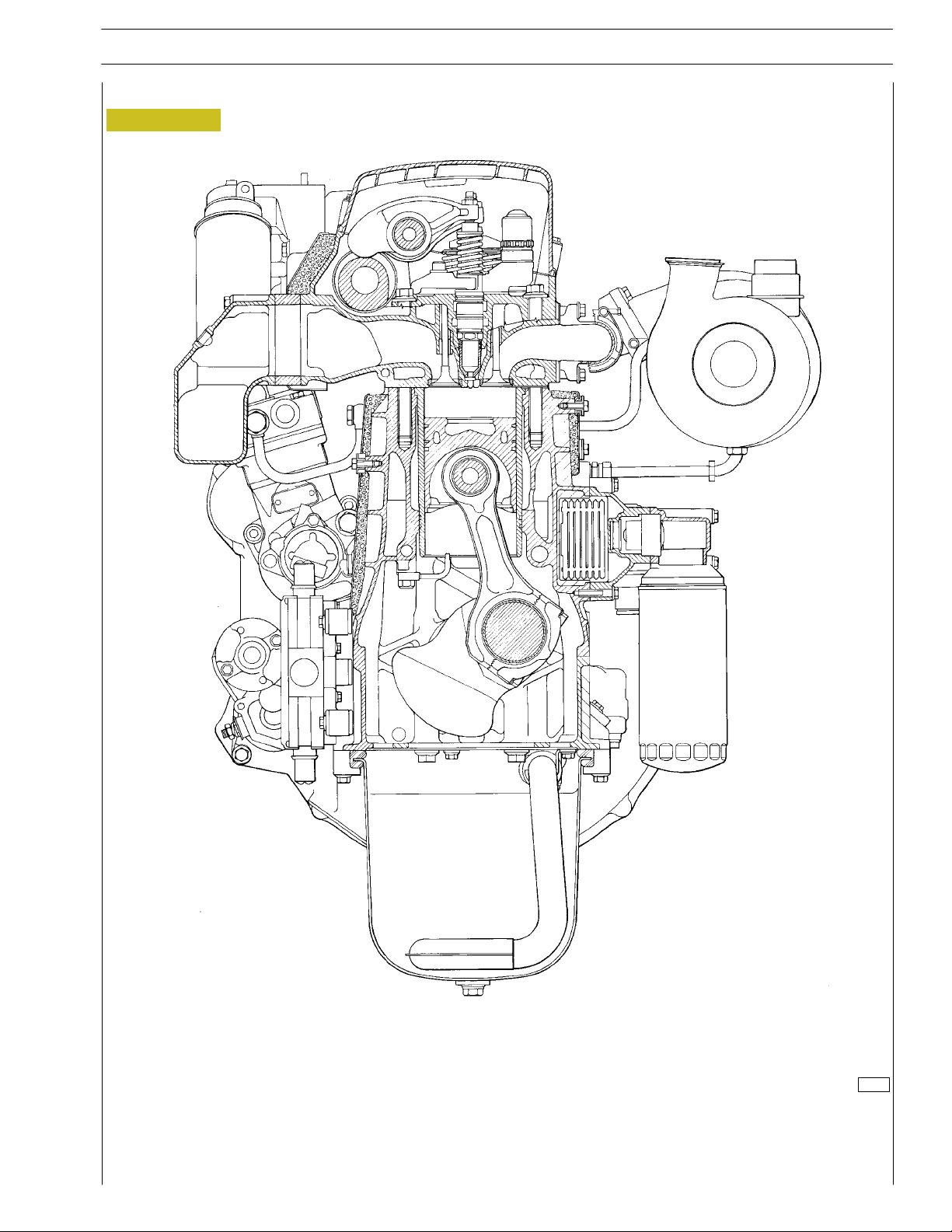

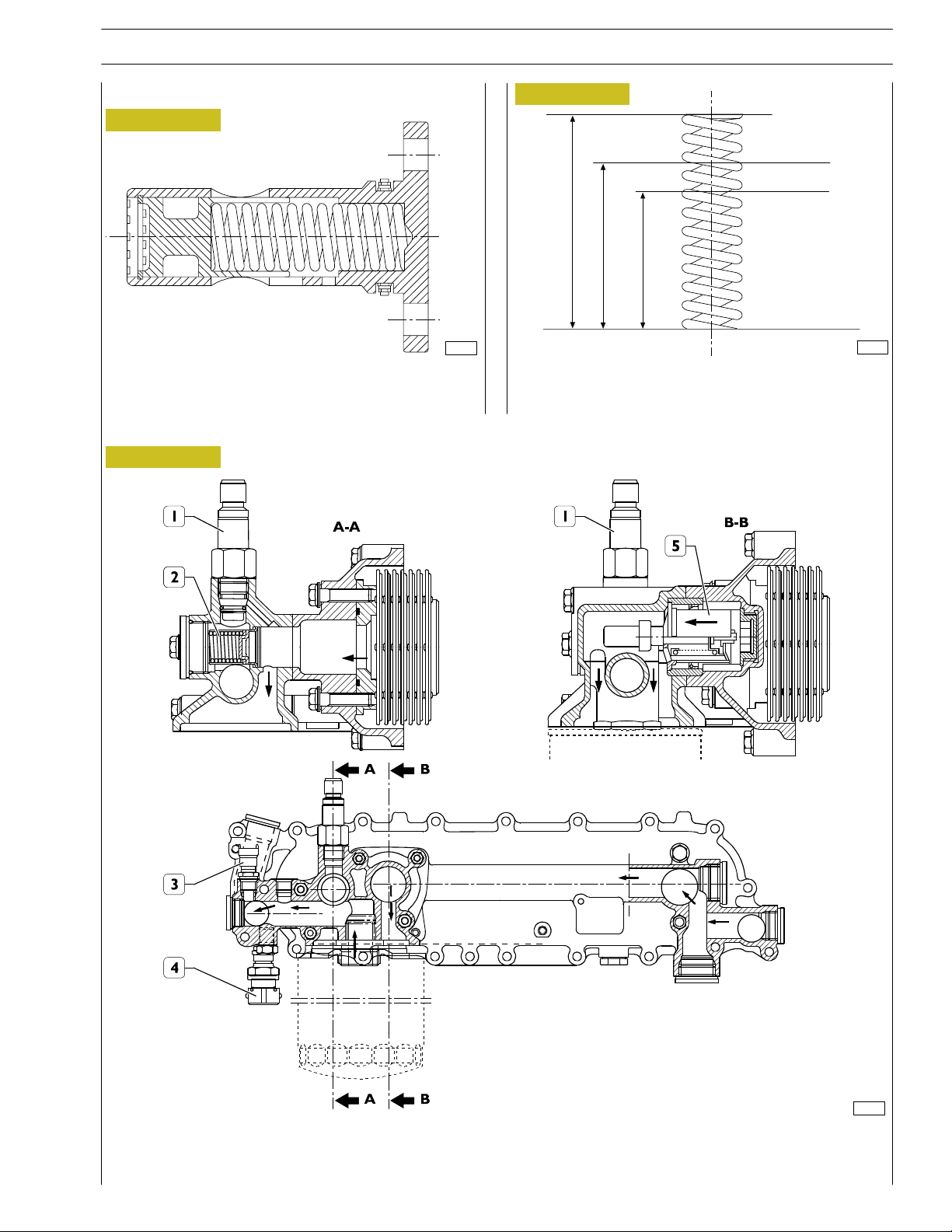

ENGINE SECTIONS

Figure 1

SECTION 1 - GENERAL SPECIFICATIONS

5

78841

ENGINE - CROSS SECTION

Print P1D32C002 E Base - September 2006

6

SECTION 1 - GENERAL SPECIFICATIONS

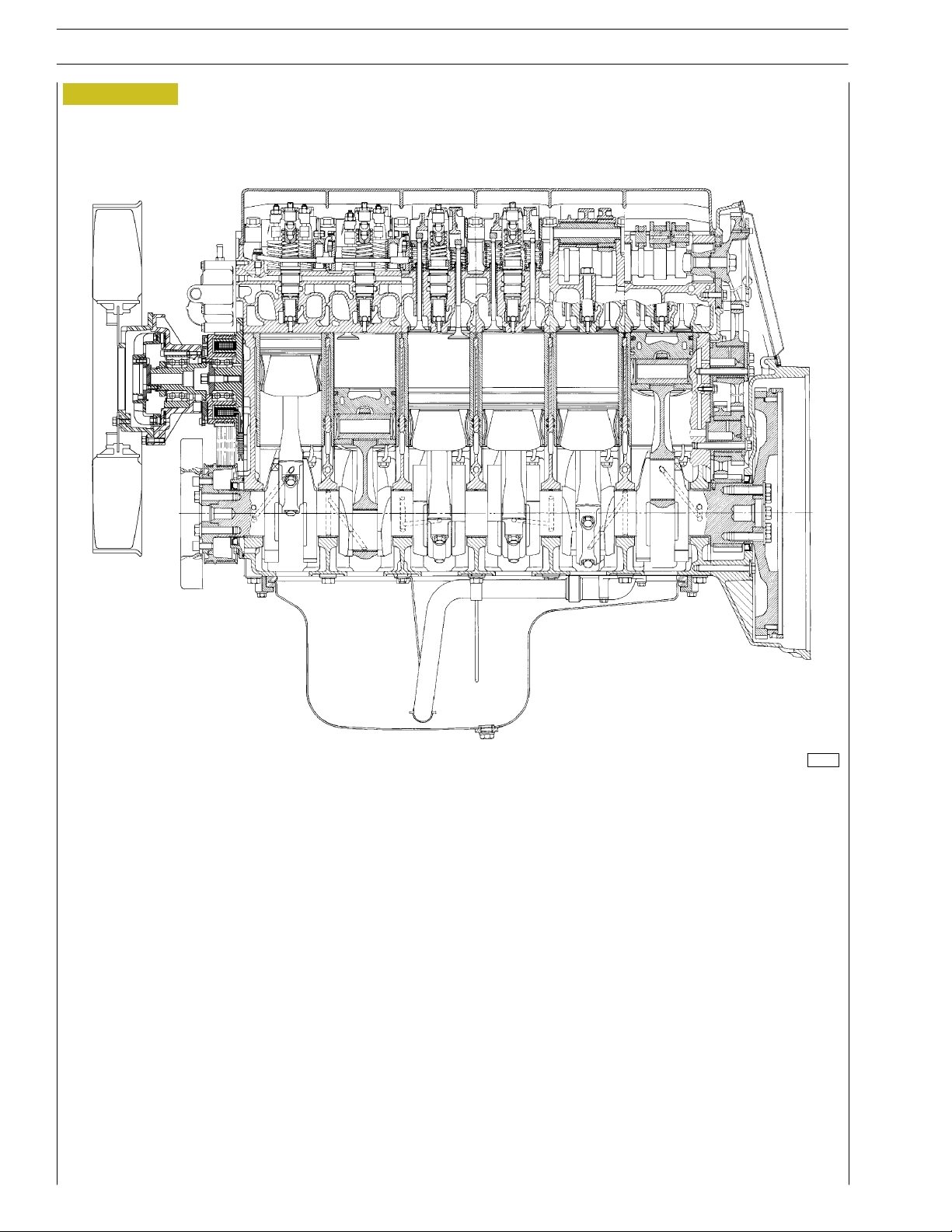

Figure 2

F2B CURSOR EURO 4 ENGINES

78839

ENGINE - LONGITUDINAL SECTION

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

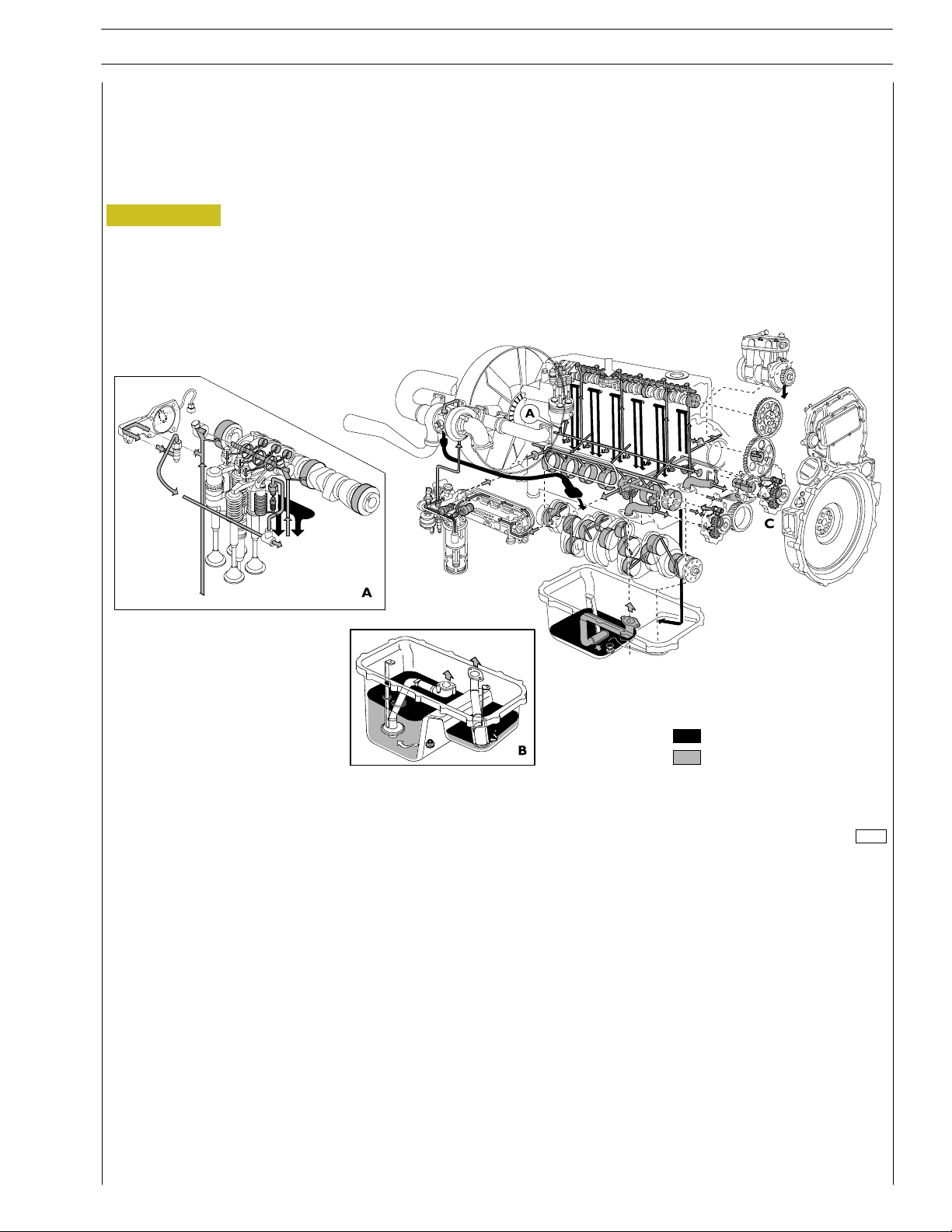

LUBRICATION

Engine lubrication is obtained with a gear pump driven by the crankshaft via gears.

A heat exchanger governs the temperature of the lubricating oil.

The oil filter, signalling sensors and safety valves are installed in the intercooler.

Figure 3

SECTION 1 - GENERAL SPECIFICATIONS

7

B. Engine oil sump (auxiliary oil pump version)

C. Auxiliary oil pump

Dropping oil

Pressure oil

86930

LUBRICATION CIRCUIT

Print P1D32C002 E Base - September 2006

8

SECTION 1 - GENERAL SPECIFICATIONS

F2B CURSOR EURO 4 ENGINES

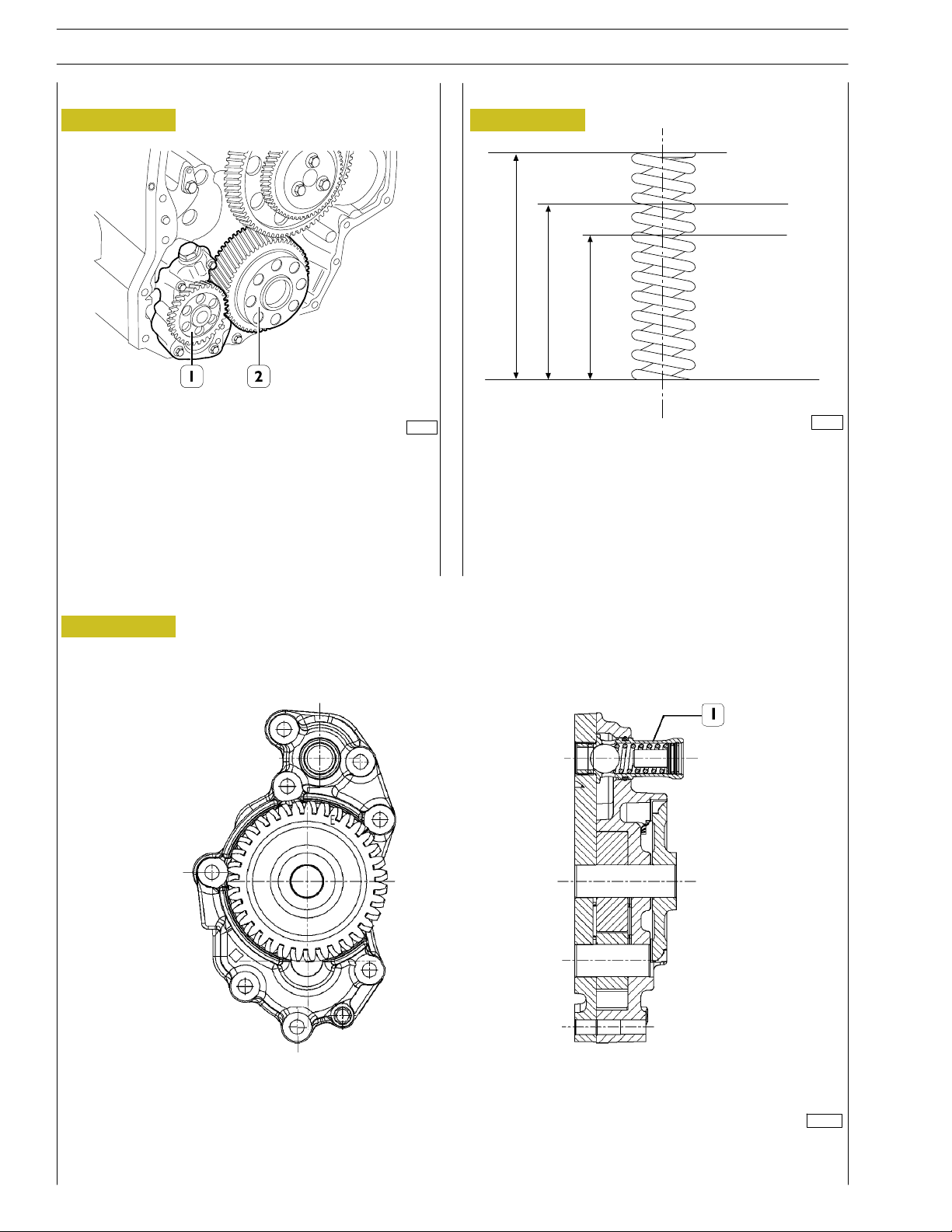

Oil pump

Figure 4

60560

The oil pump (1) cannot be overhauled. On finding any

damage, replace the oil pump assembly.

See under the relevant heading for replacing the gear (2) of

the crankshaft.

Overpressure valve

Figure 6

190 ± 6N

324 ± 9N

43,65

33,5

22,95

77820

MAIN DATA TO CHECK THE OVERPRESSURE

VALVE SPRING

Figure 5

112327

OIL PUMP CROSS-SECTION

1. Overpressure valve — Start of opening pressure 10.1 ± 0.7 bars

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

SECTION 1 - GENERAL SPECIFICATIONS

9

Oilpressurecontrolvalve

Figure 7

73542

The oil pressure control valve is located on the left-hand side

of the crankcase.

Start of opening pressure 5 bars.

Heat exchanger

Figure 9

Figure 8

168 ± 9

308 ± 15

63

51

36,4

88819

MAIN DATA TO CHECK THE OIL PRESSURE

CONTROL VALVE SPRING

77818

HEAT EXCHANGER

The following elements are fitted on the intercooler: 1. Transmitter for low pressure warning lamp - 2. By-pass valve - 3. Oil

temperature sensor - 4. Oil pressure sensor for single gauge - 5. Heat valve. Number of intercooler elements: 7

Print P1D32C002 E Base - September 2006

10

SECTION 1 - GENERAL SPECIFICATIONS

F2B CURSOR EURO 4 ENGINES

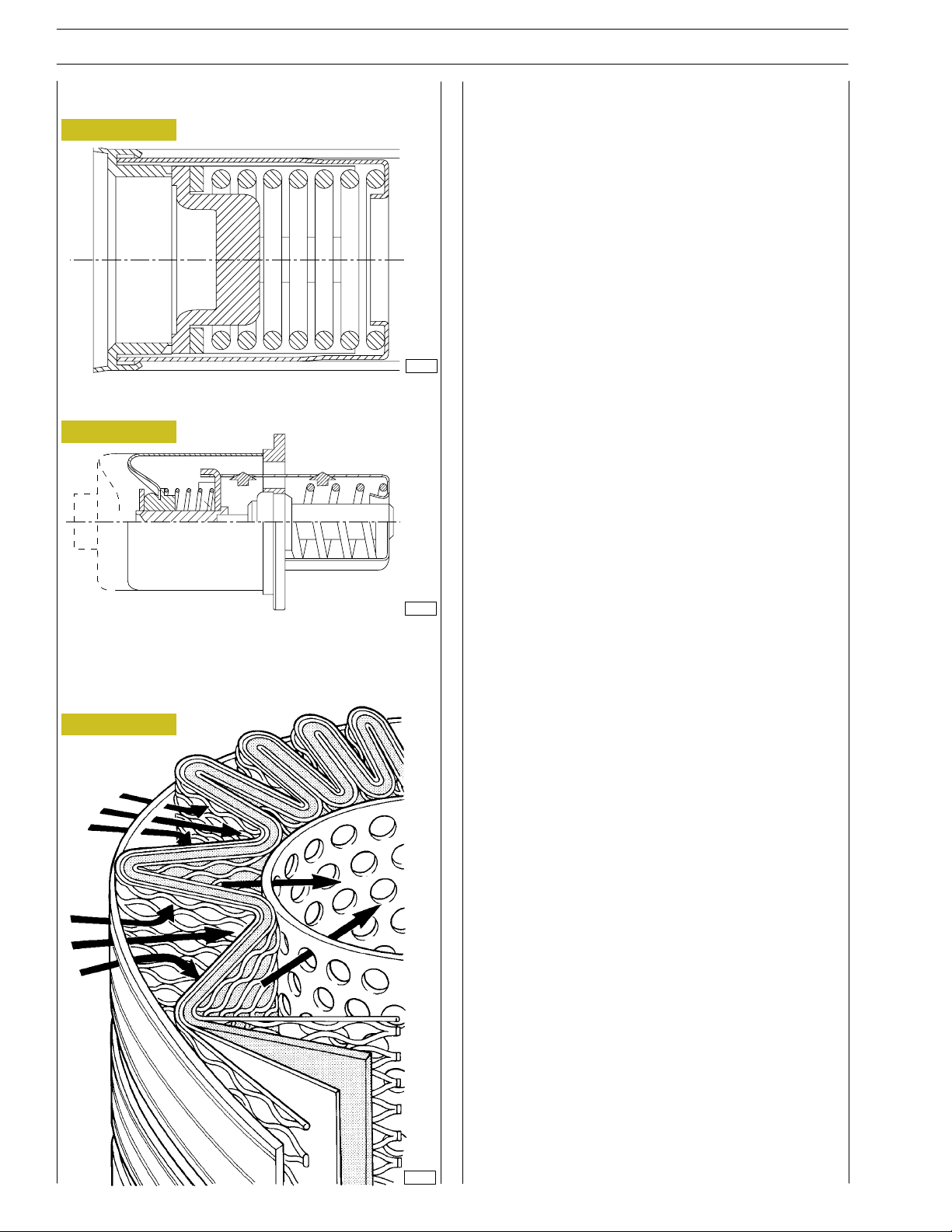

By-pass valve inside the filter support/heat exchanger assembly

Figure 10

73545

The valve quickly opens at a pressure of: 3 bars.

Thermostatic valve

Figure 11

This is a new generation of filters that permit much more

thorough filtration as they are able to holder back a greater

amount of particles of smaller dimensions than those held

back by conventional filters with a paper filtering element.

These high-filtration devices, to date used only in industrial

processes, make it possible to:

- reduce the wear of engine components over time;

- maintain the performance/specifications of the oil and

thereby lengthen the time intervals between changes.

External spiral winding

The filtering elements are closely wound by a spiral so that

each fold is firmly anchored to the spiral with respect to the

others. This produces a uniform use of the element even in the

worst conditions such as cold starting with fluids with a high

viscosity and peaks of flow. In addition, it ensures uniform

distribution of the flow over the entire length of the filtering

element, with consequent optimization of the loss of load and

of its working life.

Mount upstream

To optimize flow distribution and the rigidity of the filtering

element, this has an exclusive mount composed of a strong mesh

made of nylon and an extremely strong synthetic material.

Start of opening:

- travel 0.1 mm at a temperature of 82 ± 2°C

End of opening:

- travel 8 mm at a temperature of 97°C

.

Engine oil filters

Figure 12

Filtering element

73546

.

Composed of inert inorganic fibres bound with an exclusive

resin to a structure with graded holes, the element is

manufactured exclusively to precise procedures and strict

quality control.

Mount downstream

A mount for the filtering element and a strong nylon mesh

make it even stronger, which is especially helpful during cold

starts and long periods of use. The performance of the filter

remains constant and reliable throughout its working life and

from one element to another, irrespective of the changes in

working conditions.

Structural parts

The o-rings equipping the filtering element ensure a perfect

seal between it and the container, eliminating by-pass risks and

keeping filter performance constant. Strong corrosion-proof

bottoms and a sturdy internal metal core complete the

structure of the filtering element.

When mounting the filters, keep to the following rules:

- Oil and fit new seals.

- Screw down the filters to bring the seals into contact with

the supporting bases.

- Tighten the filter to a torque of 35÷40 Nm.

47447

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

Valve integrated in piston cooling nozzle

Figure 13

109080

The valve allows oil to enter only above the threshold pressure

of 1.7 ± 0.2 bar. This permits filling the circuit and therefore

lubricating the most stressed parts even when working at

lower pressures.

SECTION 1 - GENERAL SPECIFICATIONS

11

Print P1D32C002 E Base - September 2006

12

SECTION 1 - GENERAL SPECIFICATIONS

F2B CURSOR EURO 4 ENGINES

COOLING

Description

The engine cooling system is of the closed-circuit, forced circulation type.

It consists mainly of the following components:

- expansion tank, not supplied (by IVECO);

- a heat exchanger to cool down lubrication oil;

- a water pump with centrifugal system incorporated in the cylinder block;

- fan, not supplied;

- a 2-way thermostat controlling the coolant circulation.

Operation

The water pump is actuated by the crankshaft through a poli-V belt and sends coolant to the cylinder block, especially to the cylinder

head (bigger quantity). When the coolant temperature reaches and overcomes the operating temperature, the thermostat is

opened and from here the coolant flows into the radiator and is cooled down by the fan.

The pressure inside the system, due to temperature change, is adequately controlled through the expansion vessel.

Figure 14

Water leaving the thermostat

Water circulating in the engine

Water entering the pump

92824

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

Water pump

Figure 15

44915

WATER PUMP SECTION

The water pump consists of: rotor, seal bearing and control

pulley.

Make sure that the pump casing has no cracking or

water leakage; otherwise, replace the entire pump.

!

SECTION 1 - GENERAL SPECIFICATIONS

13

Thermostat

THERMOSTAT OPERATION VIEW

Figure 16

TO THE HEATER

TO BY-PASS FROM THE HEAD

Water circulating in the engine

Figure 17

TO THE HEATER

45357

TO RADIATOR

TO EXPANSION TANK

FROM THE HEAD

45358

Water issuing from thermostat

Check thermostat operation, in case of doubts, replace it.

Start of stroke temperature 84 _C ± 2 _C

Minimum stroke 15 mm at 94 _C ± 2 _C

Print P1D32C002 E Base - September 2006

14

SECTION 1 - GENERAL SPECIFICATIONS

TURBOCHARGING

The turbocharging system consists of:

- air filter;

- a variable geometry or a fixed geometry turbocharger;

- “intercooler” radiator.

Figure 18

F2B CURSOR EURO 4 ENGINES

Engine exhaust gas

Intake air

Compressed air (hot)

Compressed air (cooled)

DIAGRAM OF SUPERCHARGING WITH THE VGT TURBOCHARGER

VGT TURBOCHARGER

Operating principle

The variable geometry turbocharger (VGT) consists of a

centrifugal compressor and a turbine, equipped with a mobile

device which adjusts the speed by changing the area of the

passing section of exhaust gases to the turbine.

Thanks to this solution, gas velocity and turbine speed can be

high even when the engine is idling.

If the gas is made to go through a narrow passage, in fact, it

flows faster, so that the turbine rotates more quickly.

44916

The movement of the device, choking the exhaust gas flowing

section, is carried out by a mechanism, activated by a

pneumatic actuator.

This actuator is directly controlled by the electronic control

unit by a proportional solenoid valve.

The device is in maximum closing condition at idle speed.

At high engine operating speed, the electronic control system

is activated and increases the passing section, in order to allow

the in-coming gases to flow without increasing their speed.

A toroidal chamber is obtained during the casting process in

the central body for the passage of the coolant.

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

SECTION 1 - GENERAL SPECIFICATIONS

15

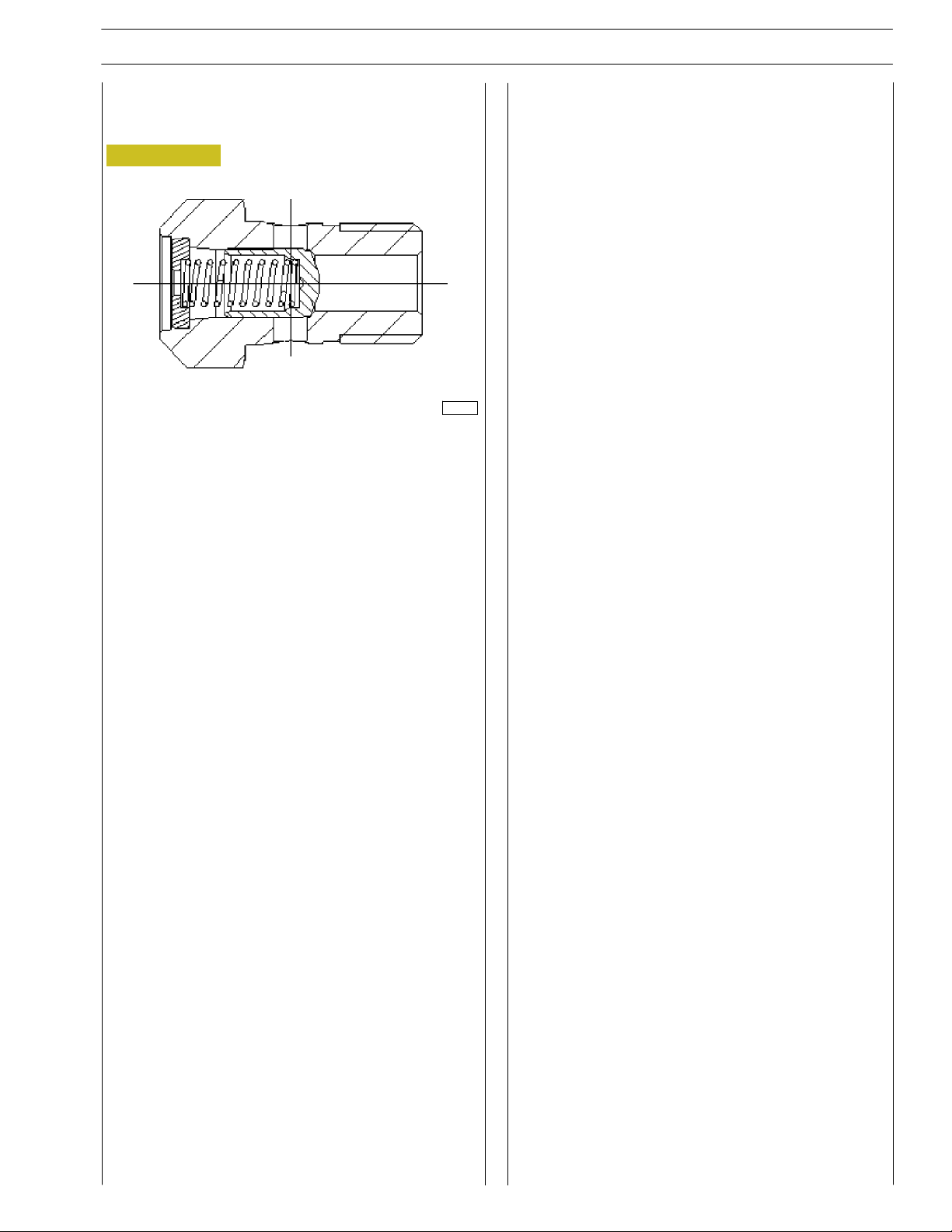

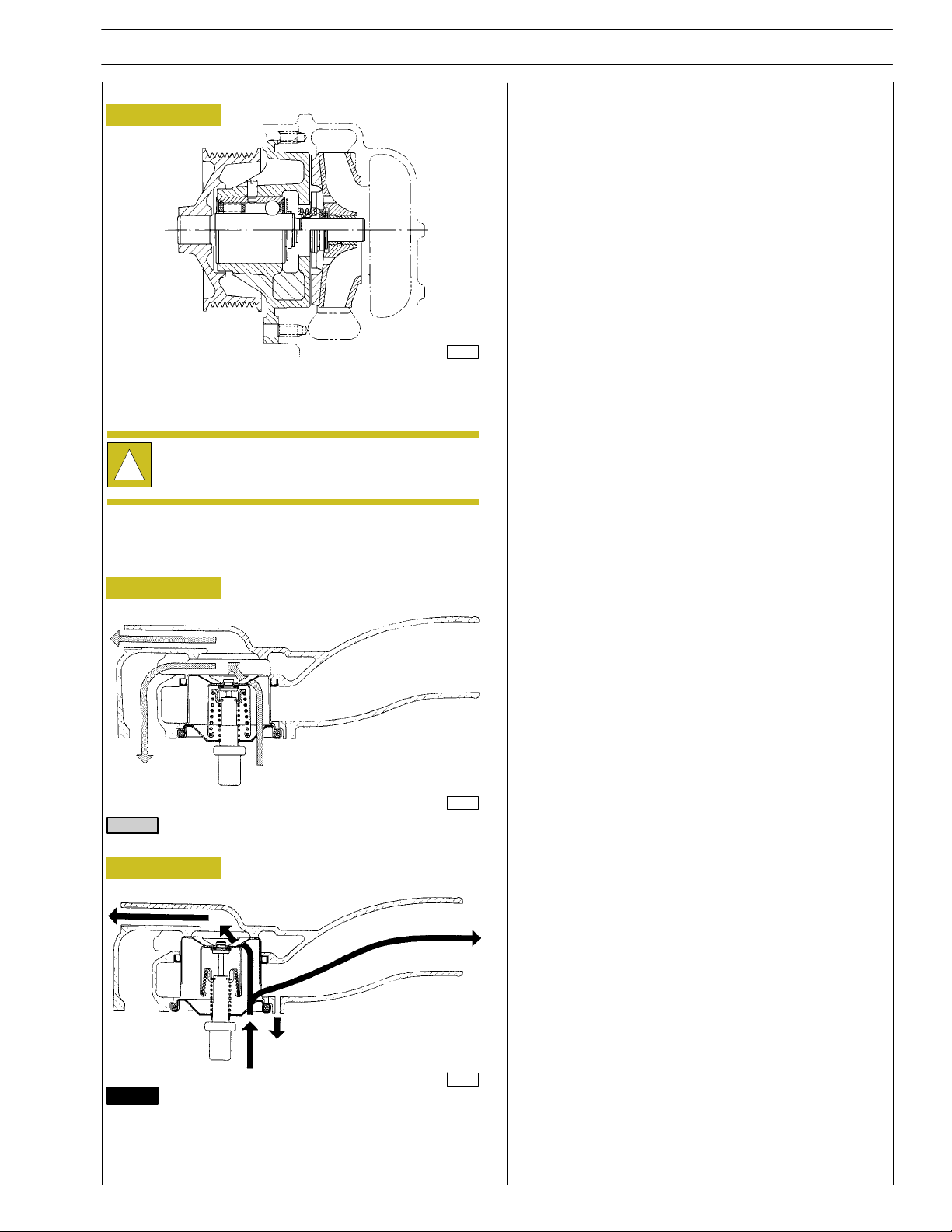

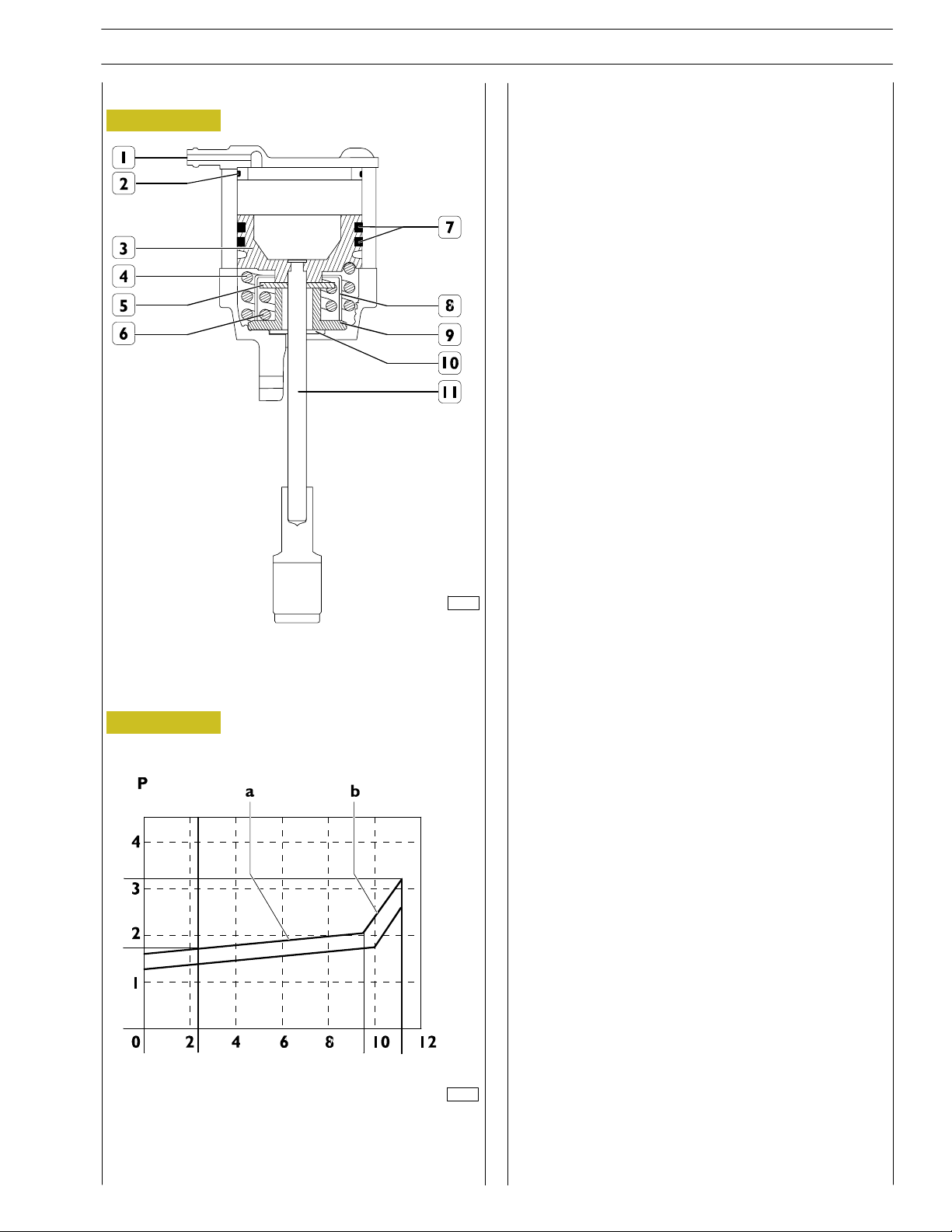

Actuator

Figure 19

Working principle (See Figure 19)

The actuator piston, connected to the drive rod, is controlled

with the compressed air introduced through the air inlet (1)

on the top of the actuator.

Modulating the air pressure varies the movement of the piston

and turbine control rod. As the piston moves, it progressively

compresses the external spring (4) until the base of the piston

reaches the disc (5) controlling the internal spring (6).

On further increasing the pressure, the piston, via the disc (5),

interferes with the bottom limit stop (10).

Using two springs makes it possible to vary the ratio between

the piston stroke and the pressure. Approximately 85% of the

stroke of the rod is opposed by the external spring and 15%

by the internal one.

Solenoid valve for VGT control

This N.C. proportional solenoid valve is located on the

left-hand side of the crankcase under the turbine.

The electronic control unit, via a PWM signal, controls the

solenoid valve, governing the supply pressure of the turbine

actuator, which, on changing its position, modifies the

cross-section of the flow of exhaust gases onto the blades of

the impeller and therefore its speed.

The resistance of the coil is approx. 20-30 Ohms.

71834

1. Air inlet - 2. Gasket - 3. Piston - 4. External spring -

5. Internal spring control disc - 6. Internal spring -

7. O-ring - 8. Spring holder - 9. Limit stop - 10. Dust seal -

11. Control rod.

Figure 20

[bar]

Stroke [mm]

72421

a Gradient characterized by the effect of the external spring

(4, Figure 19).

b Gradient characterized by the effect of the external (4,

Figure 19) and internal (6) springs.

Print P1D32C002 E Base - September 2006

16

SECTION 1 - GENERAL SPECIFICATIONS

F2B CURSOR EURO 4 ENGINES

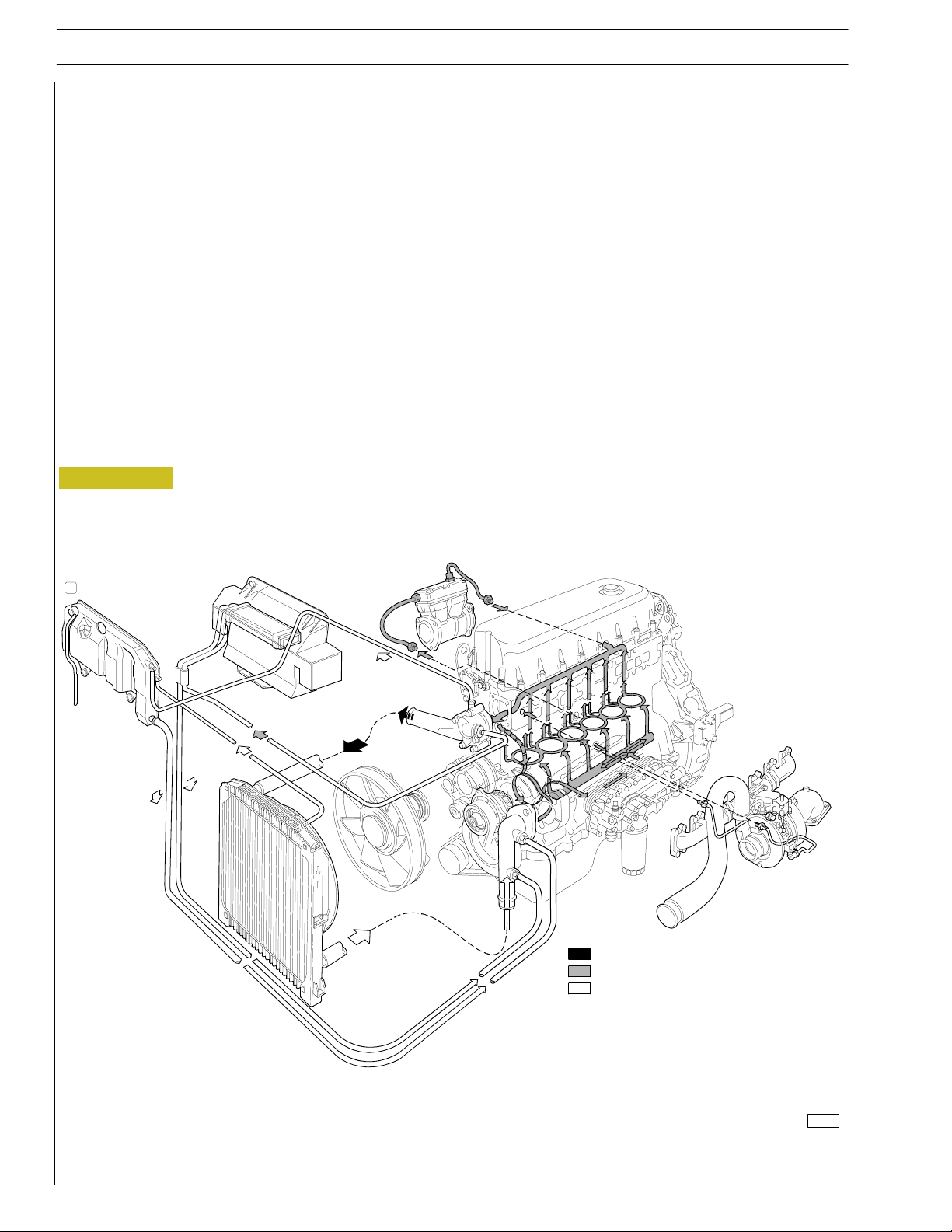

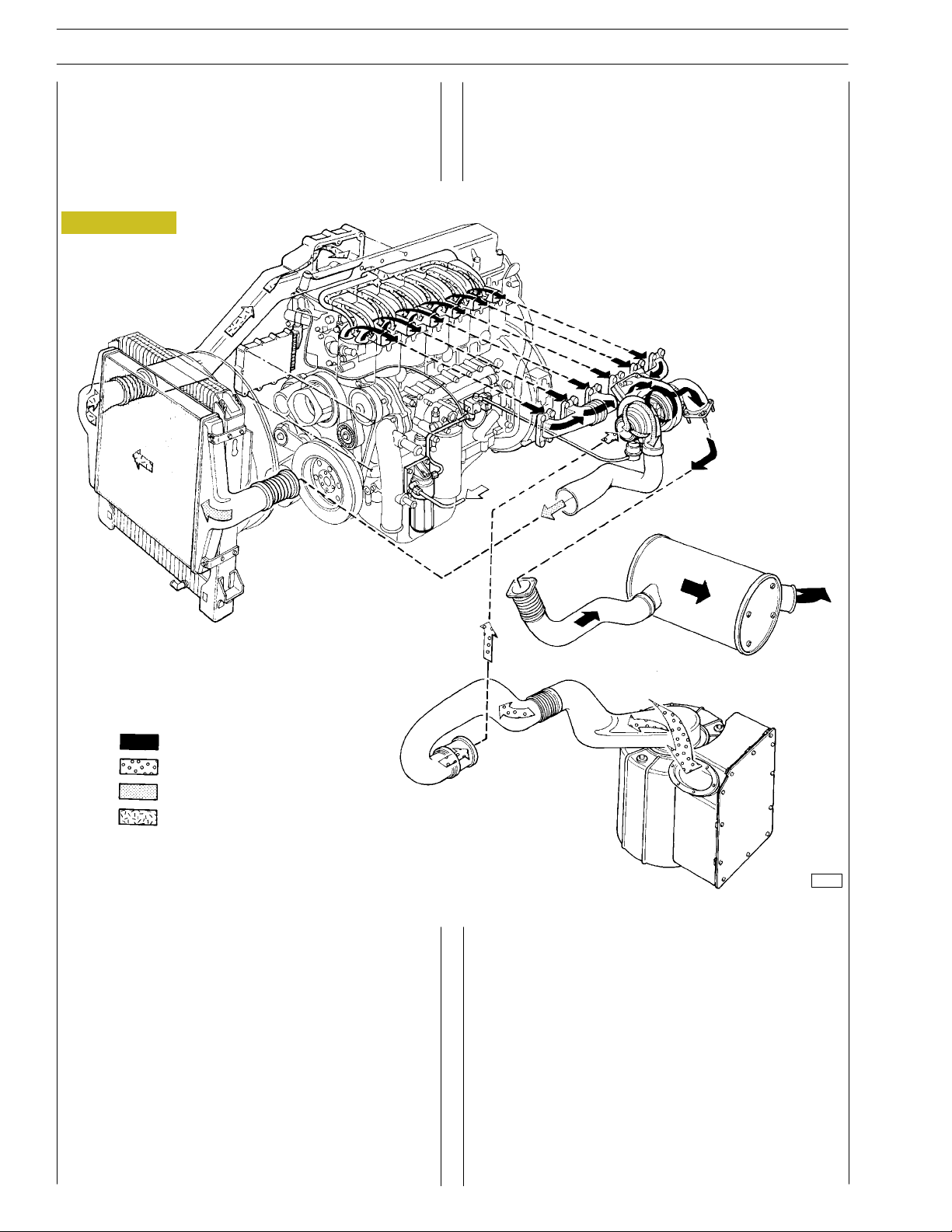

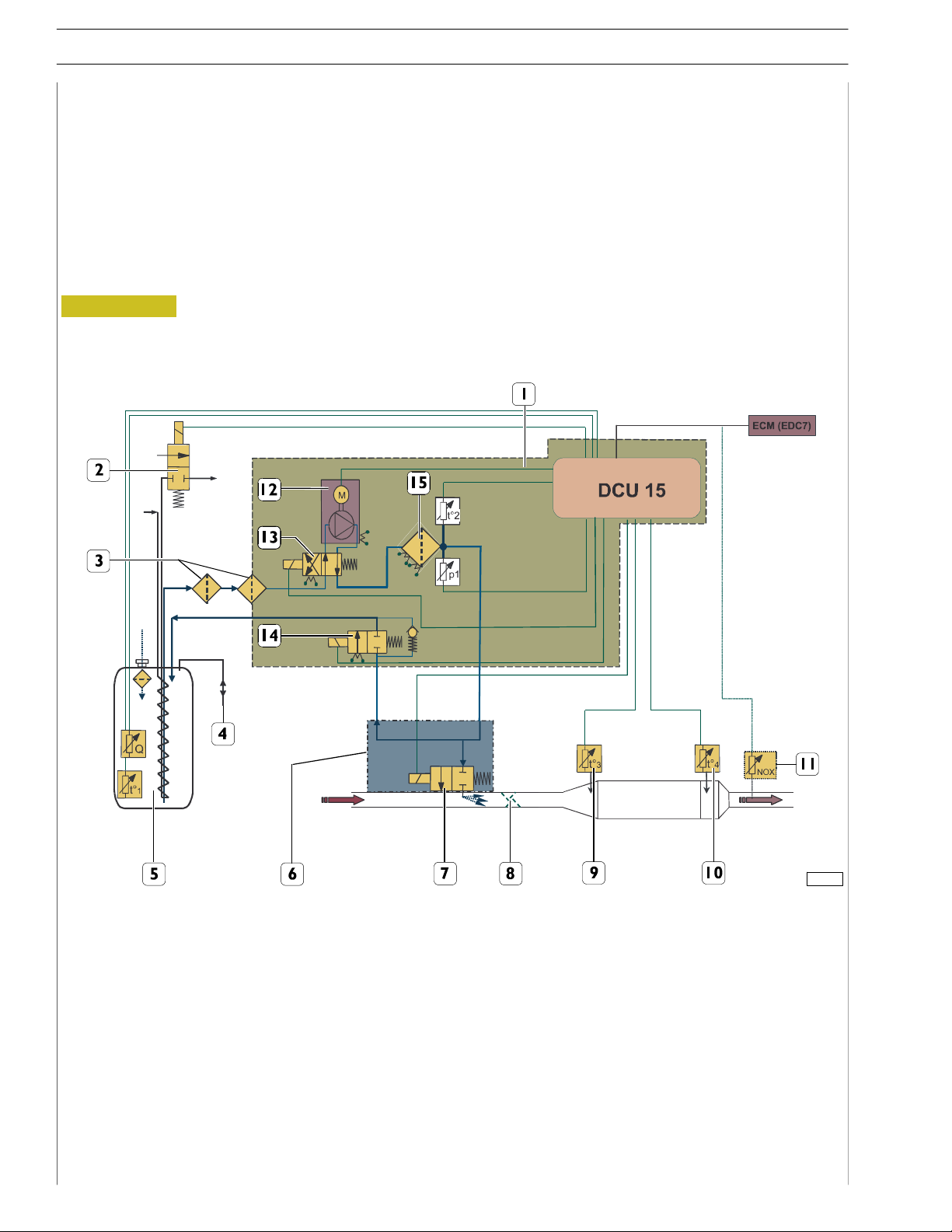

DeNOxSYSTEM 2

General remarks

In order to keep the exhaust emission values of nitric oxides (NOx) within the limits prescribed by the Euro 4 standard, with low

fuel consumption, a system for post-processing of the above substances found in exhaust gas has been fitted to the vehicles. This

system essentially consists of an electronic-control oxidizing catalyst.

The system converts, through the SCR (Selective Catalytic Reduction) process, nitric oxides (NO

nitrogen (N

)andwatervapour(H2O).

2

The SCR process is based on a series of chemical reactions, which leads, due to ammonia reacting with exhaust gas oxygen, to

a reduction of nitric oxides (NO

) found in exhaust gas.

x

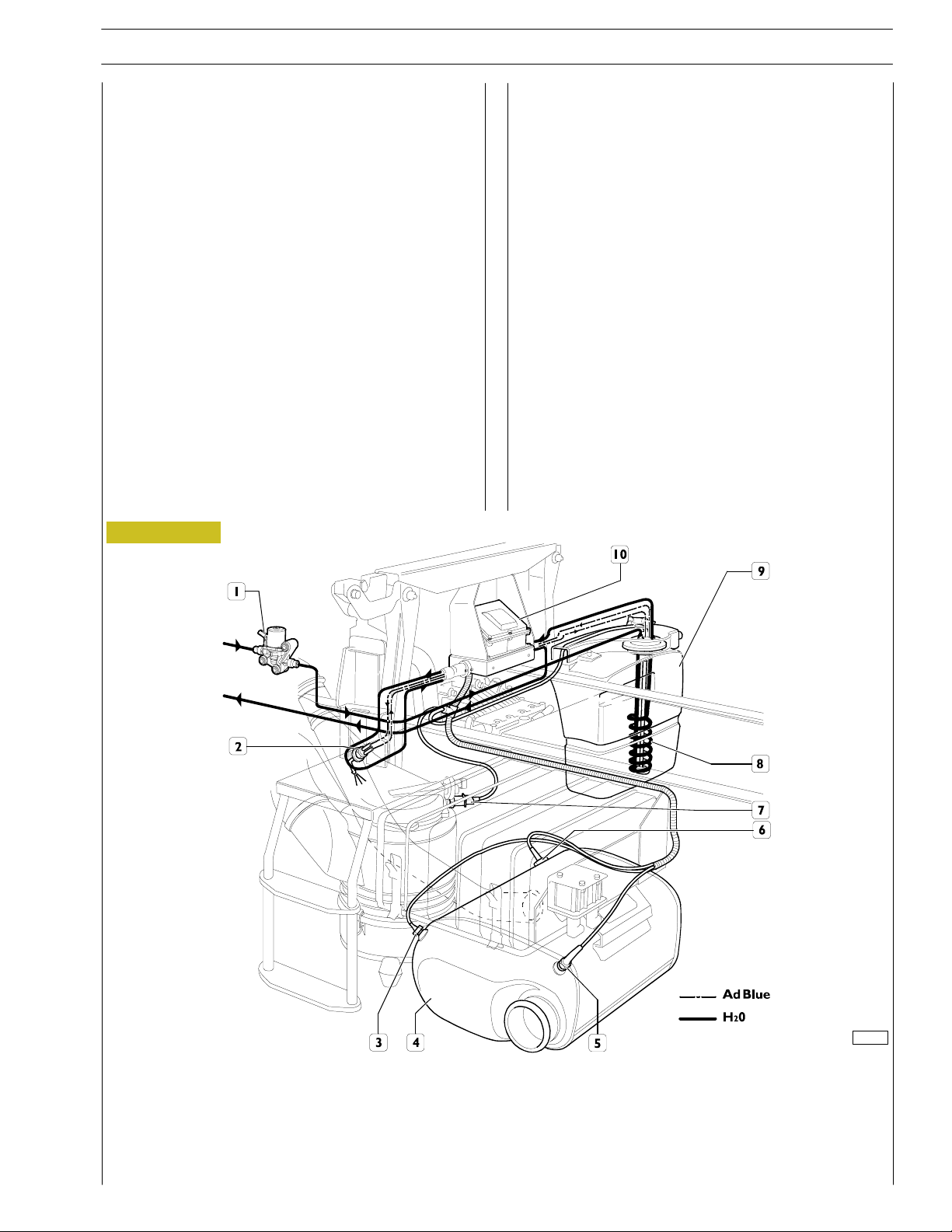

Figure 21

) into inert compounds: free

x

115785

SCR SYSTEM DIAGRAM

A. PUMP MODULE - B. MEASURING OUT MODULE

1. Supply module - 2. MV4 - 3. Pre-filters - 4. Tank vent - 5. AdBlue tank with gridle - 6. Dosing module - 7. MV2 - 8. Mixer -

9. - 10. Temperature sensors - 11. Nox sensor (*) - 12. Membrane pump - 13. MV1 - 14. MV3 - 15. Main filter.

* Future application

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

SECTION 1 - GENERAL SPECIFICATIONS

17

The system is essentially made up of:

- a tank (9) for reagent solution (water - urea: AdBlue),

equipped with level gauge (8);

- an H2O diverter valve (1);

-pumpmodule(10);

- a mixing and injection module (2);

- catalyst (4);

- two exhaust gas temperature sensors (5, 6) on catalyst

output (4);

- a moisture detection sensor (7) fitted on the engine air

intake pipe downstream from the air cleaner.

SCR system is electronically managed by DCU (Dosing Control Unit) incorporated into pump module (10); depending on

engine rpm, supplied torque, exhaust gas temperature, quantity of nitrogen oxides and humidity of air sucked in, the control unit regulates the flow rate of AdBlue solution to be let

into the system.

Figure 22

Pump module (10) takes reagent solution out of tank (9), then

sends it under pressure into measuring out module (2); finally,

the reagent solution is injected into the exhaust pipe upstream

of catalyst (4).

Here, the first phase of the process is realized: the reagent solution will vaporize immediately, due to the exhaust gas temperature, and will be converted into ammonia (2NH

carbon dioxide (CO

), owing to hydrolysis. At the same time,

2

)and

3

vaporization of the solution will cause a decrease in the exhaust gas temperature: the latter will get near the optimum

temperature required for the process.

Exhaust gas added with ammonia - and at the reaction temperature - will flow into catalyst where the second phase of

the process will be realized: ammonia will, by reacting with the

exhaust gas oxygen, convert into free nitrogen (N) and water

vapour (H

2

O).

108125

POSITION OF SCR SYSTEM COMPONENTS ON THE VEHICLE

1. H

O valve - 2. Dosing module - 3. Nitric oxide detecting sensor (*) - 4. Catalyst -

2

5. Outlet temperature sensor - 6. Inflow exhaust gas temperature sensor - 7. Sucked air humidity

and temperature sensor - 8. Level gauge - 9. Water-urea solution (AdBlue) tank - 10. Pump module.

* Future application

Print P1D32C002 E Base - September 2006

18

SECTION 1 - GENERAL SPECIFICATIONS

F2B CURSOR EURO 4 ENGINES

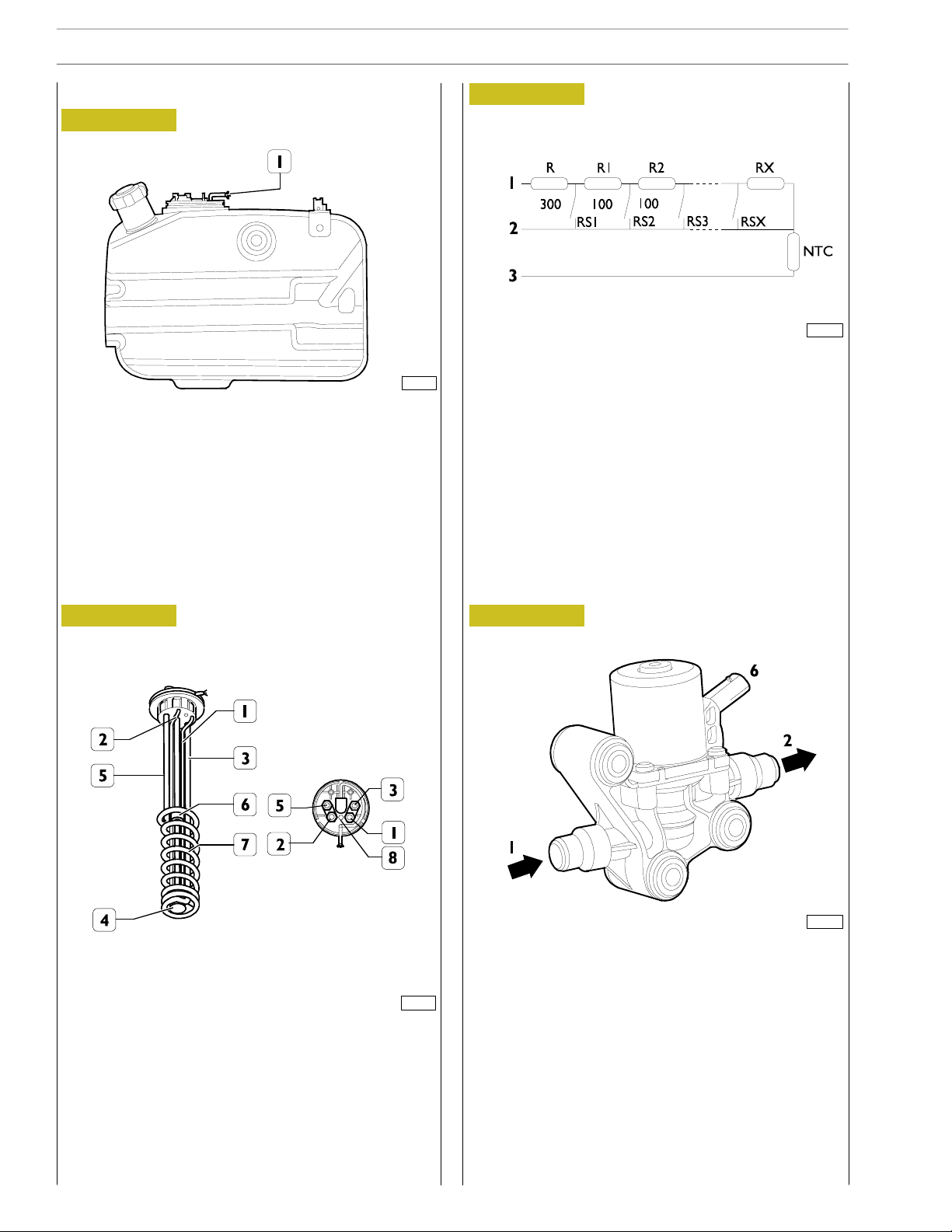

Tank

Figure 23

102295

The tank equipped with level gauge control (1) contains the

reducing substance required for the SCR process, which

consists of a 35%-urea and water solution called AdBlue.

Figure 25

102308

FUNCTIONAL WIRING DIAGRAM

The AdBlue fluid level gauge control consists of a device made

up of a set of resistors, a float, a NTC temperature sensor, and

a coil used to heat the fluid under low temperature conditions.

It informs the control unit of any current change due to the

resistor determined by the float position with respect to the

AdBlue fluid level.

AdBlue fluid l evel gauge control

Figure 24

1. AdBlue fluid suction pipe - 2. AdBlue fluid return

pipe - 3. Engine cooling hot fluid inlet pipe -

4. AdBlue (NTC) temperature sensor -

5. Engine cooling hot fluid outlet pipe - 6. Float -

7. AdBlue fluid heating coil - 8. AdBlue air vent.

116181

By-pass valve

Figure 26

108127

FUNCTIONAL WIRING DIAGRAM

1. Coolant inlet - 2. Coolant outlet -

6. Electrical connection.

The valve, which is a Normally Closed type valve, allows

AdBlue tank to be heated by engine coolant.

The NTC temperature sensor controls the by-pass valve

which closes or opens (depending on temperature) the

passage of the engine cooling hot fluid into the heating coil.

Base - September 2006 Print P1D32C002 E

F2B CURSOR EURO 4 ENGINES

SECTION 1 - GENERAL SPECIFICATIONS

19

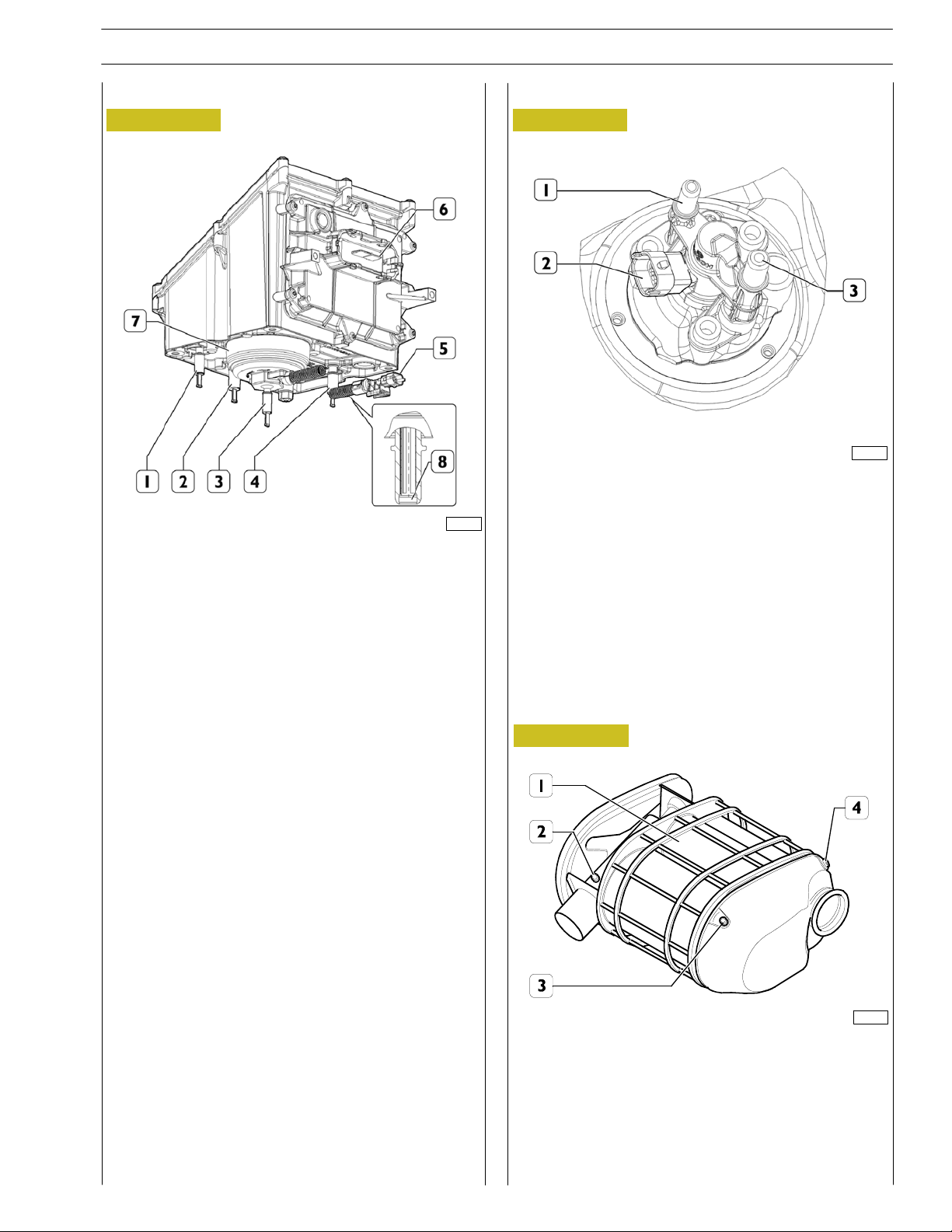

Pump module

Dosing module

Figure 27 Figure 28

108128

The function of this module is to dose the AdBlue solution to

1. AdBlue return pipe to the tank - 2. AdBlue return pipe

be conveyed to the injector.

from dosing module - 3. AdBlue solution outlet - 4. AdBlue

solution infeed - 5. Electrical connection - 6. DCU control

unit connector - 7. Filter - 8. Prefilter.

108129

1. AdBlue infeed - 2. Electrical connection -

3. AdBlue outlet.

Catalyst

Figure 29

102301

Catalyst (1), equipped with sound-proofing material, replaces

the exhaust silencer.

Inside the catalyst, the exhaust gas nitric oxides are, by reacting

with ammonia, converted into free nitrogen and water vapour.

Temperature sensors (2 & 3) and nitric oxide detecting sensor

(4) are fitted onto catalyst (1).

Print P1D32C002 E Base - September 2006

20

SECTION 1 - GENERAL SPECIFICATIONS

Exhaust gas temperature sensor

Figure 30

F2B CURSOR EURO 4 ENGINES

102303

Figure 31

102304

FUNCTIONAL WIRING DIAGRAM

1.Supplyvoltage-2.Variableoutputvoltage-3.Connector-4.Signalcable(grey)-5.Earthcable(white)-6.Sensor.

The function of this sensor is to send the control unit the catalyst inlet and outlet exhaust gas temperature values required to

calculate the amount of urea to be injected into the system.

Base - September 2006 Print P1D32C002 E

Loading...

Loading...