Interlogix 521NCSXT, 541NB, 541NCSRH Installation Guide

ESL 500N Series C U¤ L US

LISTED

Smoke Detector

Installation Instructions

WARNING

This document is intended for licensed electricians/ alarm installers. GE Interlogix cannot provide technical support to unqualified persons.

If you have questions, call GE Interlogix at 1-800-648-7424.

Description

The ESL 500N Series conventional 2-wire and 4-wire photoelectric smoke detectors have intelligent software and digitally processed sensing capabilities. This intelligence coupled with the ESL patented optical sensing chamber means the ESL 500N Series quickly and accurately detects smoke. CleanMe® compatible software, selfdiagnostics, and dust (drift) compensation are standard in every unit. The ESL 500N Series offers application flexibility with optional auxiliary relays, rate-of-rise/fixed temperature heat sensors, isolated heat sensors and/or 85dBa temporal 3 sounders.

All models ship standard with the following features:

Detector/base lock

Discourages unauthorized removal of the smoke detector by requiring a screwdriver to remove the detector from the base.

Self-diagnostics

Auxiliary and end-of-line relays

Auxiliary relays are form C and operate at 1A @ 30VDC to allow for the addition of auxiliary notification devices to the smoke loops. Products with an “R” in the suffix signify the auxiliary relay feature.

An end-of-line relay operates as a power supervision relay and is normally energized and will release with the loss of power. Products with an “E” in the suffix signify the end-of-line feature.

Heat sensors

Some models come with both a rate-of-rise and fixed temperature heat sensors which allows the unit to detect changes in temperature that may signal a fire event. Models with an “XT” in the suffix have a heat sensor included.

Some models are available with an isolated heat sensor. If the unit senses a temperature change it will alert the panel and signal an alarm independent of smoke in the photoelectric chamber. The heat alarm output is on the alarm relay and the smoke alarm output is on the auxiliary relay. Models with an “H” in the suffix have an isolated heat sensor which is both rate- of-rise and fixed temperature.

Convertible inputs

The 2-wire 500N Series can be converted using the ESL 505 module to a 4-wire input on the control panel. The 500N Series is UL Listed as compatible with the 505 module and will be fully UL compliant with any UL listed 24 VDC control panel and panels that do not operate below 12V. Up to 20 ESL 500N Series smoke detectors can be accomodated on each 505 module. See the 505 module installation instructions for more information.

Includes automatic sensitivity testing. Once a day and immediately upon first power up, each 500N Series detector performs a full diagnostic test that includes a dynamic test of the sensing chamber and internal electronics. This meets NFPA 72 field sensitivity testing requirements without the need for external meters.

Drift compensation (dust compensation)

Compatibility

Please refer to the ESL Compatibility Index for a complete listing of control panels and proper identifiers. For a copy of the Compatibility Index, call 1-800-648-7424 or visit www.sentrol.com for a copy to download. Remember,

4-wire smoke detectors do not require a compatibility listing.

The detectors automatically adjust sensitivity, up to a maximum of 1.0%/ft., as the detectors become dirty.

Automatic voltage range selection for UL 2-wire compatibility

The 2-wire 500N Series detectors automatically determine if the detector is connected to a 6/12V panel or a 12/24V panel. There are no switches to set.

Depending on the model, the smoke detector provides the following features:

CleanMe®

Enables the control panel to receive a warning signal via a 505 module, or CleanMe compatible panel, indicating that the optical chamber needs to be replaced. This feature is available on the 500N Series 2-wire detectors only.

The 500N Series 2-wire detectors enable the CleanMe function by recognizing voltage polarity at installation. If the + and - terminal connections are reversed, the CleanMe function is enabled. New 500N Series detectors are compatible on the same loop with previous 500 Series detectors if proper wiring is observed. See Figure 5.

Dining |

Kitchen |

Bedroom |

Bedroom |

Room |

|

|

|

1A |

|

|

|

|

Living Room |

Bedroom |

|

|

Dining |

Kitchen |

Bedroom |

|

Room |

|

|

1 B |

TV Room |

|

|

|

|

|

|

|

Living Room |

Bedroom |

|

|

|

|

|

|

Bedroom |

|

|

Integral Temporal 3 Sounder |

|

|

|

|

|

|

|

|

|

|

|

In the 500N models with sounder, a piezoelectric horn produces an |

1 C |

Bedroom |

|

Bedroom |

|

||||||

interrupted 85dBa tone when the detector alarms or when the polarity |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

is reversed. Sounder follows input voltage in reverse polarity. |

|

Living |

|

|

|

|

|

|

|

Dining |

|

|

|

|

|

|

|

|

|

|

|||

In order for all sounders to activate when the panel alarms, the panel |

|

Room |

|

|

|

|

|

|

|

Room |

|

|

|

|

|

|

|

|

|

|

|

|

|

must reverse the supply voltage polarity to the loop on alarm. If the |

|

|

|

|

|

|

|

|

|

|

|

panel does not implement polarity reversal, an ESL 405 Polarity |

|

Basement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reversal Relay Module must be used. (Refer to the installation |

= Required smoke detectors |

|

|

|

|||||||

instructions for the ESL 405 Polarity Reversal Relay Module.) |

|

|

|

||||||||

= Additional smoke detectors required for new construction |

|||||||||||

|

Figure 1. Detector placement |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

ESL 500N Series |

|

|

|

|

|

|

|

|

1 |

||

Selecting a Location

Selecting a suitable location is critical to the operation of smoke detectors. This equipment should be installed in accordance with the National Fire Protection Association’s (NFPA) Standard 72.

A-8-1.2.1.a Where to Locate the Required Smoke Detectors in Existing Construction. The major threat from fire in a family living unit occurs at night when everyone is asleep. The principal threat to persons in sleeping areas comes from fires in the remainder of the unit. Therefore, a smoke detector(s) is best located between the bedroom areas and the rest of the unit. In units with only one bedroom area on one floor, the smoke detector(s) should be located as shown in Figure 1 A.

In family living units with more than one bedroom area or with bedrooms on more than one floor, more than one smoke detector is required, as shown in Figure 1 B.

In addition to smoke detectors outside of the sleeping areas, the installation of a smoke detector on each additional story of the family living unit, including the basement, is required. These installations are shown in Figure 1 C. The living area smoke detector should be installed in the living room or near the stairway to the upper level, or in both locations. The basement smoke detector should be installed in close proximity to the stairway leading to the floor above. Where installed on an open-joisted ceiling, the detector should be placed on the bottom of the joists. The detector should be positioned relative to the stairway to intercept smoke coming from a fire in the basement before the smoke enters the stairway.

A-8-1.2.1.b Where to Locate the Required Smoke Detectors in New Construction. All of the smoke detectors specified in A-8-1.2.1.a for existing construction are required and, in addition, a smoke detector is required in each bedroom.

A-8-1.2.1.c Are More Smoke Detectors Desirable?

The required number of smoke detectors might not provide reliable early warning protection for those areas separated by a door from the areas protected by the required smoke detectors. For this reason, it is recommended that the householder consider the use of additional smoke detectors for those areas for increased protection. The additional areas include the basement, bedrooms, dining room, furnace room, utility room, and hallways not protected by the required smoke detectors. The installation of smoke detectors in kitchens, attics (finished or unfinished), or garages is not normally recommended, as these locations occasionally experience conditions that can result in improper operation.

Important: Regulations pertaining to smoke detector installations vary from state to state. For more information, contact your local fire department or local authority having jurisdiction.

In addition to NFPA 72, use the following location guidelines to optimize performance and reduce the chance of false alarms from the detector:

Installing the Detector

All wiring must conform to the National Electric Code (NEC) and/ or local codes having jurisdiction. Use 12 to 24 AWG (16 to 22AWG recommended) wire to install the detector.

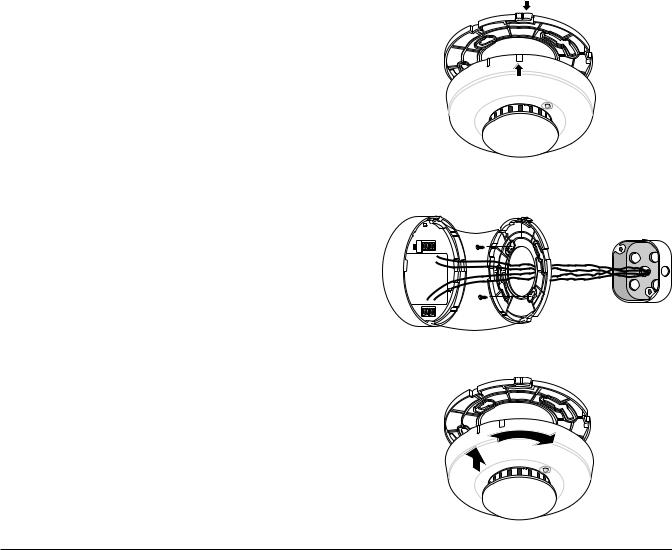

1.If you are using the detector/base lock, remove the detector knockout and break off the tab on the mounting base. See Figure 2.

2.Remove the red plastic cover from the detector. The detector is shipped with a cover for protection against construction site dust.

3.Run system wiring to the detector location and mount electrical boxes if necessary. The detector fits standard single gang boxes and 3 1/2” and 4” round ceiling boxes.

4.Line up and attach the mounting base to the electrical box, wall or ceiling using the screws provided. Use the wall anchors if necessary. See Figure 3.

5.Strip the system wires and connect them to the appropriate terminals on the detector. See Figure 5.

6.Attach the detector to the mounting base as follows:

-Line up the raised tab on the side of the detector with the arrow on the mounting base. See Figure 4.

-Insert the smoke detector into the base and turn clockwise approximately 15 degrees. It should snap firmly into place.

7.Apply power and test the detector. See Smoke Testing the Detector.

Figure 2. Detector/base lock

•Locate ceiling-mounted smoke detectors in the center of a

|

room or hallway at least 4 inches (10cm) from any walls or |

Figure 3. Detector installation |

|

|

|

|

partitions. |

|

• |

Locate wall-mounted smoke detectors so the top of the |

|

|

detector is 4 to 12 inches (10 to 30cm) below the ceiling. |

|

• |

Do not locate detectors in or near bathrooms or kitchens. |

|

• |

Locate in a suitable environment as follows: |

|

|

- Temperature between 32°F (0°C) and 100°F (37°C) |

|

|

- Humidity between 0 and 95% non-condensing |

|

• |

Locate away from air conditioners, heating registers, and any |

|

|

other ventilation source that may interfere with smoke |

|

|

entering the detector. |

|

• |

Mount smoke detectors on a firm permanent surface. |

Figure 4. Mounting |

|

|

|

2 |

|

ESL 500N Series |

Loading...

Loading...