Page 1

TNC 640

User’s Manual

Cycle Programming

NC Software

340590-05

340591-05

340595-05

English (en)

1/2015

Page 2

Page 3

Fundamentals

Page 4

Fundamentals

About this Manual

About this Manual

The symbols used in this manual are described below.

This symbol indicates that important information

about the function described must be considered.

WARNING This symbol indicates a possibly

dangerous situation that may cause light injuries if

not avoided.

This symbol indicates that there is one or more

of the following risks when using the described

function:

Danger to workpiece

Danger to fixtures

Danger to tool

Danger to machine

Danger to operator

This symbol indicates that the described function

must be adapted by the machine tool builder. The

function described may therefore vary depending on

the machine.

This symbol indicates that you can find detailed

information about a function in another manual.

Would you like any changes, or have you found any errors?

We are continuously striving to improve our documentation for you.

Please help us by sending your requests to the following e-mail

address: tnc-userdoc@heidenhain.de.

4

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 5

TNC model, software and features

TNC model, software and features

This manual describes functions and features provided by TNCs as

of the following NC software numbers.

TNC model NC software number

TNC 640 340590-05

TNC 640 E 340591-05

TNC 640 Programming Station 340595-05

The suffix E indicates the export version of the TNC. The export

version of the TNC has the following limitations:

Simultaneous linear movement in up to 4 axes

The machine tool builder adapts the usable features of the TNC to

his machine by setting machine parameters. Some of the functions

described in this manual may therefore not be among the features

provided by the TNC on your machine tool.

TNC functions that may not be available on your machine include:

Tool measurement with the TT

Please contact your machine tool builder to become familiar with

the features of your machine.

Many machine manufacturers, as well as HEIDENHAIN, offer

programming courses for the TNCs. We recommend these courses

as an effective way of improving your programming skill and

sharing information and ideas with other TNC users.

User's Manual:

All TNC functions that have no connection with

cycles are described in the User's Manual of the TNC

640. Please contact HEIDENHAIN if you require a

copy of this User's Manual.

ID of User's Manual for conversational programming:

892904-xx.

ID of User’s Manual for DIN/ISO programming:

892910-xx.

TNC 640 | User's Manual Cycle Programming | 1/2015

5

Page 6

Fundamentals

TNC model, software and features

Software options

The TNC 640 features various software options that can be enabled by your machine tool builder. Each option is to

be enabled separately and contains the following respective functions:

Additional Axis (option number 0 to option number 7)

Additional axis

Advanced Function Set 1 (option 8)

Expanded functions Group 1 Machining with rotary tables

Advanced Function Set 2 (option 9)

Expanded functions Group 2 3-D machining:

Additional control loops 1 to 8

Cylindrical contours as if in two axes

Feed rate in distance per minute

Coordinate transformations:

Tilting the working plane

Interpolation:

Circle in 3 axes with tilted working plane (spatial arc)

Motion control with minimum jerk

3-D tool compensation through surface normal vectors

Using the electronic handwheel to change the angle of the swivel

head during program run without affecting the position of the tool

point. (TCPM = Tool Center Point Management)

Keeping the tool normal to the contour

Tool radius compensation perpendicular to traversing direction and

tool direction

Interpolation:

Linear in 5 axes (subject to export permit)

Touch Probe Functions (option 17)

Touch probe functions

HEIDENHAIN DNC (option number 18)

Display Step (Option #23)

Display step Input resolution:

Touch probe cycles:

Compensation of tool misalignment in automatic mode

Datum setting in the Manual Operation mode

Datum setting in automatic mode

Automatically measuring workpieces

Tools can be measured automatically

Communication with external PC applications over COM component

Linear axes down to 0.01 µm

Rotary axes to 0.00001°

6

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 7

Dynamic Collision Monitoring – DCM (Option #40)

TNC model, software and features

Dynamic Collision Monitoring

DXF Converter (Option #42)

DXF converter

Adaptive Feed Control – AFC (Option #45)

Adaptive Feed Control

KinematicsOpt (Option #48)

Optimizing the machine

kinematics

The machine manufacturer defines objects to be monitored

Warning in Manual operation

Program interrupt in Automatic operation

Includes monitoring of 5-axis movements

Supported DXF format: AC1009 (AutoCAD R12)

Adoption of contours and point patterns

Simple and convenient specification of reference points

Select graphical features of contour sections from conversational

programs

Recording the actual spindle power by means of a teach-in cut

Defining the limits of automatic feed rate control

Fully automatic feed control during program run

Backup/restore active kinematics

Test active kinematics

Optimize active kinematics

Mill-Turning (Option #50)

Milling and turning modes Functions:

Switching between Milling/Turning mode of operation

Constant surface speed

Tool-tip radius compensation

Turning cycles

Extended Tool Management (Option #93)

Extended tool management Python-based

Spindle Synchronism (Option #131)

Spindle synchronization Synchronization of milling spindle and turning spindle

Remote Desktop Manager (Option #133)

Remote operation of external

computer units

Synchronizing Functions (Option #135)

Synchronization functions Real Time Coupling – RTC:

Windows on a separate computer unit

Incorporated in the TNC interface

Coupling of axes

TNC 640 | User's Manual Cycle Programming | 1/2015

7

Page 8

Fundamentals

Cross Talk Compensation – CTC (Option #141)

TNC model, software and features

Compensation of axis couplings

Position Adaptive Control – PAC (Option #142)

Adaptive position control

Load Adaptive Control – LAC (Option #143)

Adaptive load control

Active Chatter Control – ACC (Option #145)

Active chatter control Fully automatic function for chatter control during machining

Determination of dynamically caused position deviation through axis

acceleration

Compensation of TCP (Tool Center Point)

Changing of the control parameters depending on the position of

the axes in the working space

Changing of the control parameters depending on the speed or

acceleration of an axis

Automatic determination of workpiece weight and frictional forces

Changing of control parameters depending on the actual mass of

the workpiece

8

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 9

TNC model, software and features

Feature Content Level (upgrade functions)

Along with software options, significant further improvements

of the TNC software are managed via the Feature Content Level

upgrade functions. Functions subject to the FCL are not available

simply by updating the software on your TNC.

All upgrade functions are available to you without

surcharge when you receive a new machine.

Upgrade functions are identified in the manual with FCL n, where n

indicates the sequential number of the feature content level.

You can purchase a code number in order to permanently enable

the FCL functions. For more information, contact your machine tool

builder or HEIDENHAIN.

Intended place of operation

The TNC complies with the limits for a Class A device in

accordance with the specifications in EN 55022, and is intended for

use primarily in industrially-zoned areas.

Legal information

This product uses open source software. Further information is

available on the control under

Programming and Editing operating mode

MOD function

LICENSE INFO softkey

TNC 640 | User's Manual Cycle Programming | 1/2015

9

Page 10

Fundamentals

Optional parameters

Optional parameters

The comprehensive cycle package is continuously further

developed by HEIDENHAIN. Every new software version thus

may also introduce new Q parameters for cycles. These new Q

parameters are optional parameters, some of which have not been

available in previous software versions. Within a cycle, they are

always provided at the end of the cycle definition. You will find an

overview of the optional Q parameters that have been added with

this software version in the "New and changed cycle functions of

software 34059x-05" section. You can choose whether to define

optional parameters or delete them with the NO ENT key. You can

also adopt the default value. If you have accidentally deleted an

optional Q parameter or if you would like to extend cycles in your

existing programs after a software update, you can include optional

Q parameters in cycles when needed. The following steps describe

how this is done:

To insert optional Q parameters in existing programs:

Call the cycle definition

Press the right arrow key until the new Q parameters are

displayed

Apply the default value or enter a value

To transfer the new Q parameter, exit the menu by pressing

the right arrow key once again or by pressing END

If you do not wish to apply the new Q parameter, press the

NO ENT key

Compatibility

The majority of part programs created on older HEIDENHAIN

contouring controls (TNC 150 B and higher) can be executed with

this new software version of the TNC 640. Even if new, optional

parameters ("Optional parameters") have been added to existing

cycles, you can normally continue running your programs as usual.

This is achieved by using the stored default value. The other way

round, if a program created with a new software version is to be

run on an older control, you can delete the respective optional

Q parameters from the cycle definition with the NO ENT key.

In this way you can ensure that the program will be downward

compatible. If NC blocks contain invalid elements, the TNC will

mark them as ERROR blocks when the file is opened.

10

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 11

New cycle functions of software 34059x-04

New cycle functions of software 34059x-04

The character set of the fixed cycle 225 Engraving was

expanded by more characters and the diameter sign see

"ENGRAVING (Cycle 225, DIN/ISO: G225)", page 300

New fixed cycle 275 Trochoidal Milling see "TROCHOIDAL SLOT

(Cycle 275, DIN ISO G275)", page 211

New fixed cycle 233 Face Milling see "FACE MILLING (Cycle

233, DIN/ISO: G233)", page 167

In Cycle 205 Universal Pecking you can now use parameter

Q208 to define a feed rate for retraction see "Cycle parameters",

page 92

In the thread milling cycles 26x an approaching feed rate was

introduced see "Cycle parameters", page 119

The parameter Q305 NUMBER IN TABLE was added to Cycle

404 see "Cycle parameters", page 462

In the drilling cycles 200, 203 and 205 the parameter Q395

DEPTH REFERENCE was introduced in order to evaluate the T

ANGLE see "Cycle parameters", page 92

Cycle 241 SINGLE-LIP DEEP HOLE DRILLING was expanded

by several input parameters see "SINGLE-LIP DEEP-HOLE

DRILLING (Cycle 241, DIN/ISO: G241)", page 97

The probing cycle 4 MEASURING IN 3-D was introduced see

"MEASURING IN 3-D (Cycle 4)", page 567

TNC 640 | User's Manual Cycle Programming | 1/2015

11

Page 12

Fundamentals

New and changed cycle functions of software 34059x-05

New and changed cycle functions of

software 34059x-05

New Cycle 880 GEAR HOBBING (software option 50), see

"GEAR HOBBING (Cycle 880, DIN/ISO: G880)", page 425

New Cycle 292 CONTOUR TURNING INTERPOLATION

(software option 96), see "CONTOUR TURNING

INTERPOLATION (Cycle 292, DIN/ISO: G292, software option

96)", page 286

New Cycle 291 COUPLING TURNING INTERPOLATION

(software option 96), see "COUPLING TURNING

INTERPOLATION (Cycle 291, DIN/ISO: G291, software option

96)", page 295

New Load Adaptive Control (LAC) cycle for the load-dependent

adaptation of control parameters (software option 143), see

"ASCERTAIN THE LOAD (Cycle 239, DIN/ISO: G239, software

option 143)", page 309

Cycle 270: CONTOUR TRAIN DATA was added to the cycle

package (software option 19), see "CONTOUR TRAIN DATA

(Cycle 270, DIN/ISO: G270)", page 210

Cycle 39 CYLINDER SURFACE (software option 1) Contour was

added to the cycle package, see "CYLINDER SURFACE (Cycle

39, DIN/ISO: G139, software option 1)", page 232

The character set of the fixed cycle 225 Engraving was

expanded by the CE, ß and @ characters and the system time,

see "ENGRAVING (Cycle 225, DIN/ISO: G225)", page 300

Cycles 252 to 254 were expanded by the optional parameter

Q439, see "Cycle parameters", page 148

Cycle 22 was expanded by the optional parameters Q401 and

Q404, see "ROUGHING (Cycle 22, DIN/ISO: G122)", page 199

Cycles 841, 842, 851 and 852 were expanded by the plunging

feed rate Q488, see "Cycle parameters", page 372

Cycle 484 was expanded by the optional parameter Q536, see

"Calibrate the wireless TT 449 (Cycle 484, DIN/ISO: G484 Touch

Probe Functions)", page 619

Eccentric turning with Cycle 800 is possible with option 50, see

"ADAPT ROTARY COORDINATE SYSTEM(Cycle 800, DIN/ISO:

G800)", page 322

12

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 13

Contents

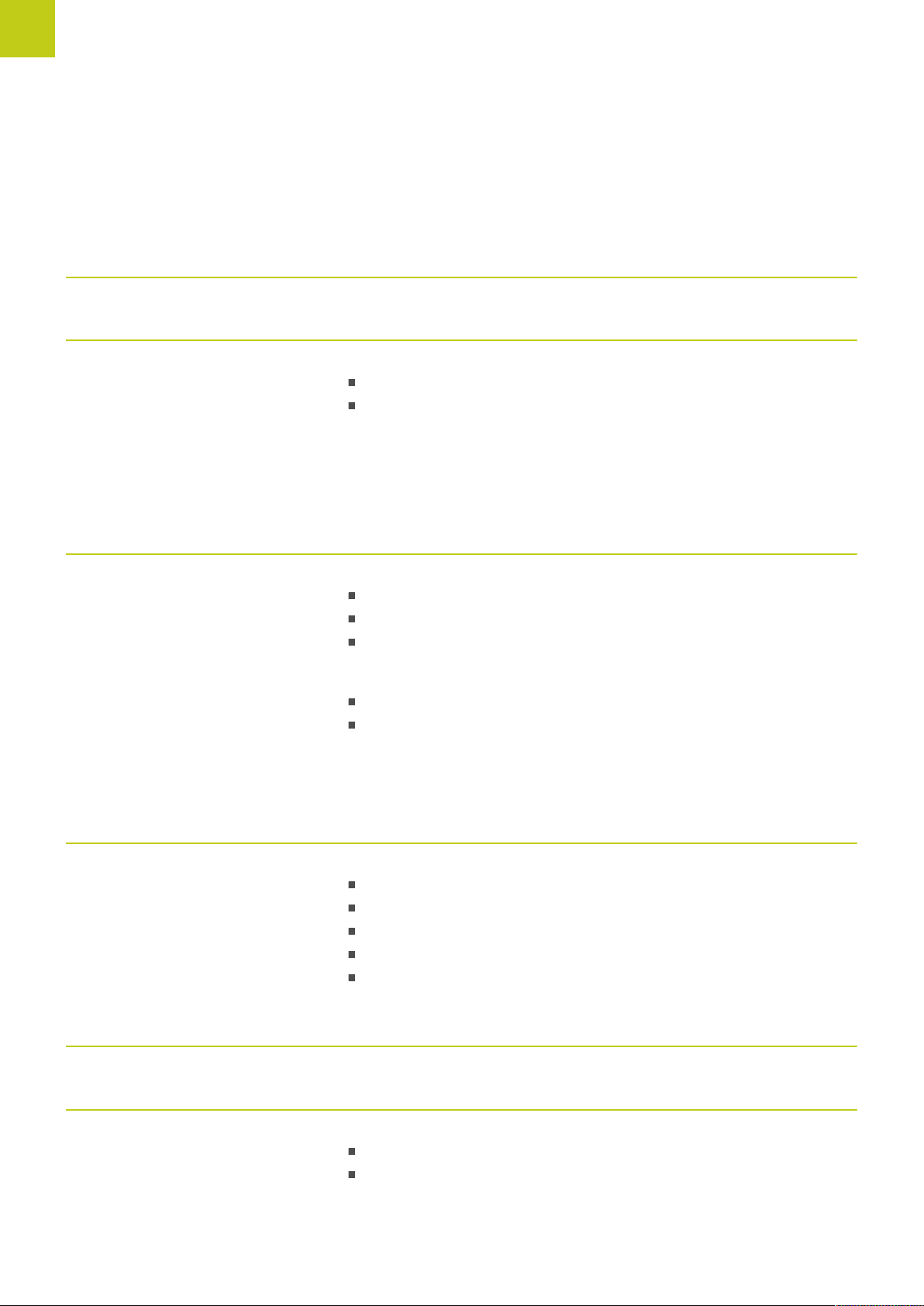

1 Fundamentals / Overviews............................................................................................................49

2 Using Fixed Cycles......................................................................................................................... 53

3 Fixed Cycles: Drilling......................................................................................................................73

4 Fixed Cycles: Tapping / Thread Milling...................................................................................... 103

5 Fixed Cycles: Pocket Milling / Stud Milling / Slot Milling........................................................139

6 Fixed Cycles: Pattern Definitions................................................................................................ 177

7 Fixed Cycles: Contour Pocket......................................................................................................187

8 Fixed Cycles: Cylindrical Surface................................................................................................ 221

9 Fixed Cycles: Contour Pocket with Contour Formula...............................................................239

10 Cycles: Coordinate Transformations...........................................................................................253

11 Cycles: Special Functions............................................................................................................ 277

12 Cycles: Turning..............................................................................................................................315

13 Using Touch Probe Cycles........................................................................................................... 437

14 Touch Probe Cycles: Automatic Measurement of Workpiece Misalignment.......................... 447

15 Touch Probe Cycles: Automatic Datum Setting........................................................................ 469

16 Touch Probe Cycles: Automatic Workpiece Inspection.............................................................521

17 Touch Probe Cycles: Special Functions......................................................................................563

18 Touch Probe Cycles: Automatic Kinematics Measurement......................................................579

19 Touch Probe Cycles: Automatic Tool Measurement..................................................................611

20 Tables of Cycles............................................................................................................................ 627

TNC 640 | User's Manual Cycle Programming | 1/2015

13

Page 14

Contents

14

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 15

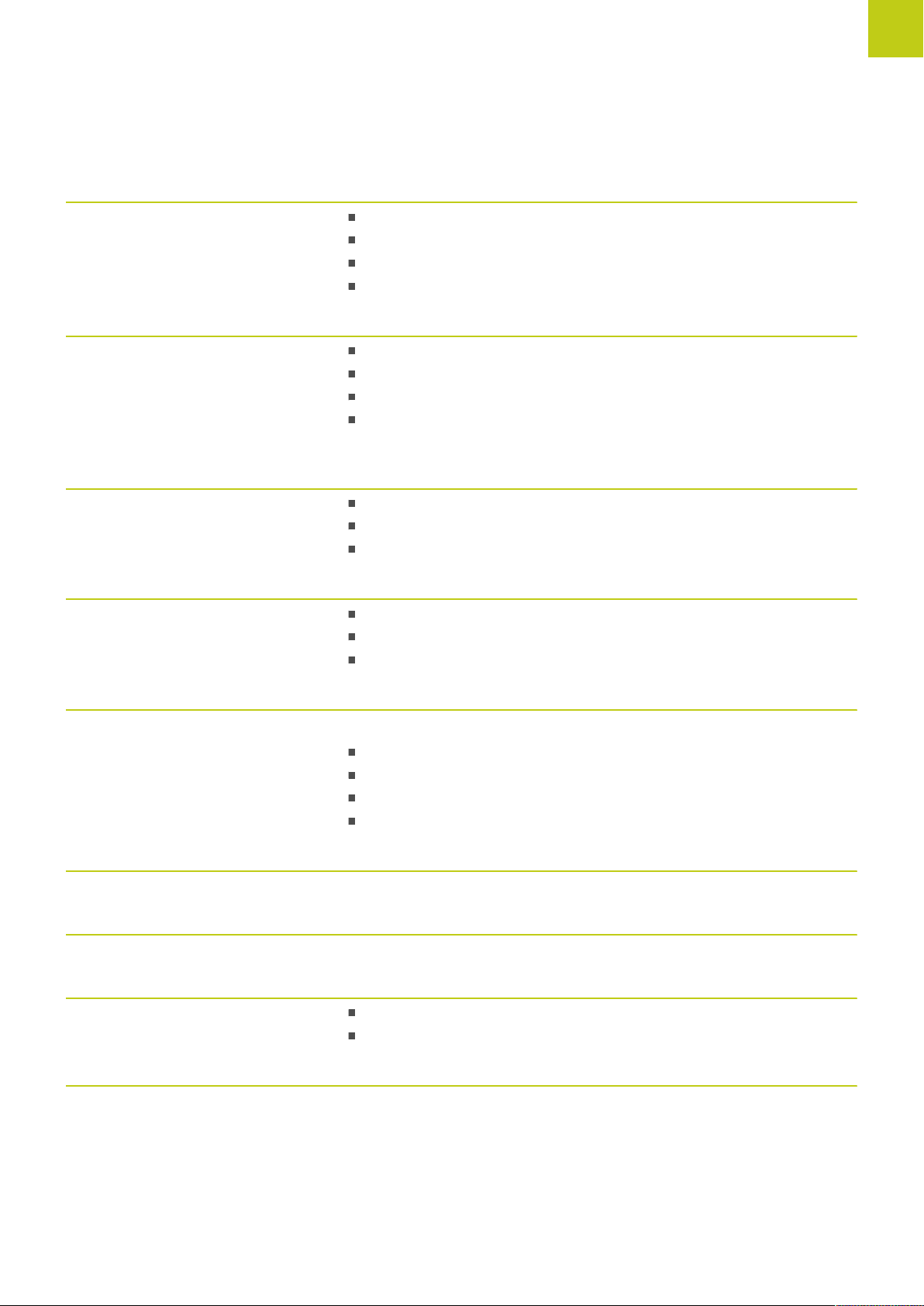

1 Fundamentals / Overviews............................................................................................................49

1.1 Introduction............................................................................................................................................50

1.2 Available Cycle Groups.........................................................................................................................51

Overview of fixed cycles........................................................................................................................ 51

Overview of touch probe cycles.............................................................................................................52

TNC 640 | User's Manual Cycle Programming | 1/2015

15

Page 16

Contents

2 Using Fixed Cycles......................................................................................................................... 53

2.1 Working with fixed cycles....................................................................................................................54

Machine-specific cycles...........................................................................................................................54

Defining a cycle using soft keys.............................................................................................................55

Defining a cycle using the GOTO function............................................................................................. 55

Calling a cycle......................................................................................................................................... 56

2.2 Program defaults for cycles................................................................................................................. 58

Overview................................................................................................................................................. 58

Entering GLOBAL DEF............................................................................................................................58

Using GLOBAL DEF information............................................................................................................ 59

Global data valid everywhere..................................................................................................................60

Global data for drilling operations........................................................................................................... 60

Global data for milling operations with pocket cycles 25x..................................................................... 60

Global data for milling operations with contour cycles...........................................................................61

Global data for positioning behavior....................................................................................................... 61

Global data for probing functions........................................................................................................... 61

2.3 PATTERN DEF pattern definition......................................................................................................... 62

Application...............................................................................................................................................62

Entering PATTERN DEF.......................................................................................................................... 63

Using PATTERN DEF...............................................................................................................................63

Defining individual machining positions.................................................................................................. 64

Defining a single row..............................................................................................................................64

Defining a single pattern.........................................................................................................................65

Defining individual frames.......................................................................................................................66

Defining a full circle................................................................................................................................67

Defining a pitch circle............................................................................................................................. 68

2.4 Point tables............................................................................................................................................69

Application...............................................................................................................................................69

Creating a point table............................................................................................................................. 69

Hiding single points from the machining process.................................................................................. 70

Selecting a point table in the program................................................................................................... 70

Calling a cycle in connection with point tables...................................................................................... 71

16

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 17

3 Fixed Cycles: Drilling......................................................................................................................73

3.1 Fundamentals........................................................................................................................................ 74

Overview................................................................................................................................................. 74

3.2 CENTERING (Cycle 240, DIN/ISO: G240)............................................................................................ 75

Cycle run................................................................................................................................................. 75

Please note while programming:............................................................................................................75

Cycle parameters.................................................................................................................................... 76

3.3 DRILLING (Cycle 200)............................................................................................................................77

Cycle run................................................................................................................................................. 77

Please note while programming:............................................................................................................77

Cycle parameters.................................................................................................................................... 78

3.4 REAMING (Cycle 201, DIN/ISO: G201)................................................................................................79

Cycle run................................................................................................................................................. 79

Please note while programming:............................................................................................................79

Cycle parameters.................................................................................................................................... 80

3.5 BORING (Cycle 202, DIN/ISO: G202)...................................................................................................81

Cycle run................................................................................................................................................. 81

Please note while programming:............................................................................................................82

Cycle parameters.................................................................................................................................... 83

3.6 UNIVERSAL DRILLING (Cycle 203, DIN/ISO: G203)...........................................................................84

Cycle run................................................................................................................................................. 84

Please note while programming:............................................................................................................84

Cycle parameters.................................................................................................................................... 85

3.7 BACK BORING (Cycle 204, DIN/ISO: G204)........................................................................................87

Cycle run................................................................................................................................................. 87

Please note while programming:............................................................................................................88

Cycle parameters.................................................................................................................................... 89

3.8 UNIVERSAL PECKING (Cycle 205, DIN/ISO: G205)........................................................................... 90

Cycle run................................................................................................................................................. 90

Please note while programming:............................................................................................................91

Cycle parameters.................................................................................................................................... 92

TNC 640 | User's Manual Cycle Programming | 1/2015

17

Page 18

Contents

3.9 BORE MILLING (Cycle 208).................................................................................................................. 94

Cycle run................................................................................................................................................. 94

Please note while programming:............................................................................................................95

Cycle parameters.................................................................................................................................... 96

3.10 SINGLE-LIP DEEP-HOLE DRILLING (Cycle 241, DIN/ISO: G241)....................................................... 97

Cycle run................................................................................................................................................. 97

Please note while programming:............................................................................................................97

Cycle parameters.................................................................................................................................... 98

3.11 Programming Examples..................................................................................................................... 100

Example: Drilling cycles........................................................................................................................ 100

Example: Using drilling cycles in connection with PATTERN DEF........................................................101

18

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 19

4 Fixed Cycles: Tapping / Thread Milling...................................................................................... 103

4.1 Fundamentals...................................................................................................................................... 104

Overview............................................................................................................................................... 104

4.2 TAPPING with a floating tap holder (Cycle 206, DIN/ISO: G206)...................................................105

Cycle run............................................................................................................................................... 105

Please note while programming:..........................................................................................................106

Cycle parameters.................................................................................................................................. 107

4.3 RIGID TAPPING without a floating tap holder (Cycle 207, DIN/ISO: G207)................................... 108

Cycle run............................................................................................................................................... 108

Please note while programming:..........................................................................................................109

Cycle parameters.................................................................................................................................. 110

Retracting after a program interruption................................................................................................ 110

4.4 TAPPING WITH CHIP BREAKING (Cycle 209, DIN/ISO: G209)........................................................ 111

Cycle run............................................................................................................................................... 111

Please note while programming:..........................................................................................................112

Cycle parameters.................................................................................................................................. 113

4.5 Fundamentals of Thread Milling....................................................................................................... 115

Prerequisites..........................................................................................................................................115

4.6 THREAD MILLING (Cycle 262, DIN/ISO: G262).................................................................................117

Cycle run............................................................................................................................................... 117

Please note while programming:..........................................................................................................118

Cycle parameters.................................................................................................................................. 119

4.7 THREAD MILLING/COUNTERSINKING (Cycle 263, DIN/ISO:G263)................................................120

Cycle run............................................................................................................................................... 120

Please note while programming:..........................................................................................................121

Cycle parameters.................................................................................................................................. 122

4.8 THREAD DRILLING/MILLING (Cycle 264, DIN/ISO: G264).............................................................. 124

Cycle run............................................................................................................................................... 124

Please note while programming:..........................................................................................................125

Cycle parameters.................................................................................................................................. 126

TNC 640 | User's Manual Cycle Programming | 1/2015

19

Page 20

Contents

4.9 HELICAL THREAD DRILLING/MILLING (Cycle 265, DIN/ISO: G265)...............................................128

Cycle run............................................................................................................................................... 128

Please note while programming:..........................................................................................................129

Cycle parameters.................................................................................................................................. 130

4.10 OUTSIDE THREAD MILLING (Cycle 267, DIN/ISO: G267)................................................................ 132

Cycle run............................................................................................................................................... 132

Please note while programming:..........................................................................................................133

Cycle parameters.................................................................................................................................. 134

4.11 Programming Examples..................................................................................................................... 136

Example: Thread milling........................................................................................................................136

20

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 21

5 Fixed Cycles: Pocket Milling / Stud Milling / Slot Milling........................................................139

5.1 Fundamentals...................................................................................................................................... 140

Overview............................................................................................................................................... 140

5.2 RECTANGULAR POCKET (Cycle 251, DIN/ISO: G251)..................................................................... 141

Cycle run............................................................................................................................................... 141

Please note while programming:..........................................................................................................142

Cycle parameters.................................................................................................................................. 143

5.3 CIRCULAR POCKET (Cycle 252, DIN/ISO: G252)..............................................................................145

Cycle run............................................................................................................................................... 145

Please note while programming:..........................................................................................................147

Cycle parameters.................................................................................................................................. 148

5.4 SLOT MILLING (Cycle 253, DIN/ISO: G253)......................................................................................150

Cycle run............................................................................................................................................... 150

Please note while programming:..........................................................................................................151

Cycle parameters.................................................................................................................................. 152

5.5 CIRCULAR SLOT (Cycle 254, DIN/ISO: G254)................................................................................... 154

Cycle run............................................................................................................................................... 154

Please note while programming:..........................................................................................................155

Cycle parameters.................................................................................................................................. 156

5.6 RECTANGULAR STUD (Cycle 256, DIN/ISO: G256)......................................................................... 159

Cycle run............................................................................................................................................... 159

Please note while programming:..........................................................................................................160

Cycle parameters.................................................................................................................................. 161

5.7 CIRCULAR STUD (Cycle 257, DIN/ISO: G257)...................................................................................163

Cycle run............................................................................................................................................... 163

Please note while programming:..........................................................................................................164

Cycle parameters.................................................................................................................................. 165

5.8 FACE MILLING (Cycle 233, DIN/ISO: G233)......................................................................................167

Cycle run............................................................................................................................................... 167

Please note while programming:..........................................................................................................171

Cycle parameters.................................................................................................................................. 172

TNC 640 | User's Manual Cycle Programming | 1/2015

21

Page 22

Contents

5.9 Programming Examples..................................................................................................................... 175

Example: Milling pockets, studs and slots........................................................................................... 175

22

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 23

6 Fixed Cycles: Pattern Definitions................................................................................................ 177

6.1 Fundamentals...................................................................................................................................... 178

Overview............................................................................................................................................... 178

6.2 POLAR PATTERN (Cycle 220, DIN/ISO: G220).................................................................................. 179

Cycle run............................................................................................................................................... 179

Please note while programming:..........................................................................................................179

Cycle parameters.................................................................................................................................. 180

6.3 LINEAR PATTERN (Cycle 221, DIN/ISO: G221)................................................................................. 182

Cycle run............................................................................................................................................... 182

Please note while programming:..........................................................................................................182

Cycle parameters.................................................................................................................................. 183

6.4 Programming Examples..................................................................................................................... 184

Example: Polar hole patterns................................................................................................................ 184

TNC 640 | User's Manual Cycle Programming | 1/2015

23

Page 24

Contents

7 Fixed Cycles: Contour Pocket......................................................................................................187

7.1 SL Cycles..............................................................................................................................................188

Fundamentals........................................................................................................................................188

Overview............................................................................................................................................... 189

7.2 CONTOUR (Cycle 14, DIN/ISO: G37).................................................................................................190

Please note while programming:..........................................................................................................190

Cycle parameters.................................................................................................................................. 190

7.3 Superimposed contours..................................................................................................................... 191

Fundamentals........................................................................................................................................191

Subprograms: overlapping pockets.......................................................................................................191

Area of inclusion................................................................................................................................... 192

Area of exclusion.................................................................................................................................. 193

Area of intersection.............................................................................................................................. 194

7.4 CONTOUR DATA (Cycle 20, DIN/ISO: G120).....................................................................................195

Please note while programming:..........................................................................................................195

Cycle parameters.................................................................................................................................. 196

7.5 PILOT DRILLING (Cycle 21, DIN/ISO: G121)..................................................................................... 197

Cycle run............................................................................................................................................... 197

Please note while programming:..........................................................................................................198

Cycle parameters.................................................................................................................................. 198

7.6 ROUGHING (Cycle 22, DIN/ISO: G122)............................................................................................. 199

Cycle run............................................................................................................................................... 199

Please note while programming:..........................................................................................................200

Cycle parameters.................................................................................................................................. 201

7.7 FLOOR FINISHING (Cycle 23, DIN/ISO: G123)..................................................................................203

Cycle run............................................................................................................................................... 203

Please note while programming:..........................................................................................................204

Cycle parameters.................................................................................................................................. 204

7.8 SIDE FINISHING (Cycle 24, DIN/ISO: G124)..................................................................................... 205

Cycle run............................................................................................................................................... 205

Please note while programming:..........................................................................................................206

Cycle parameters.................................................................................................................................. 207

24

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 25

7.9 CONTOUR TRAIN (Cycle 25, DIN/ISO: G125)...................................................................................208

Cycle run............................................................................................................................................... 208

Please note while programming:..........................................................................................................208

Cycle parameters.................................................................................................................................. 209

7.10 CONTOUR TRAIN DATA (Cycle 270, DIN/ISO: G270).......................................................................210

Please note while programming:..........................................................................................................210

Cycle parameters.................................................................................................................................. 210

7.11 TROCHOIDAL SLOT (Cycle 275, DIN ISO G275)............................................................................... 211

Cycle run............................................................................................................................................... 211

Please note while programming:..........................................................................................................212

Cycle parameters.................................................................................................................................. 213

7.12 Programming Examples..................................................................................................................... 215

Example: Roughing-out and fine-roughing a pocket............................................................................. 215

Example: Pilot drilling, roughing-out and finishing overlapping contours..............................................217

Example: Contour train......................................................................................................................... 219

TNC 640 | User's Manual Cycle Programming | 1/2015

25

Page 26

Contents

8 Fixed Cycles: Cylindrical Surface................................................................................................ 221

8.1 Fundamentals...................................................................................................................................... 222

Overview of cylindrical surface cycles..................................................................................................222

8.2 CYLINDER SURFACE (Cycle 27, DIN/ISO: G127, software option 1)............................................... 223

Cycle run............................................................................................................................................... 223

Please note while programming:..........................................................................................................224

Cycle parameters.................................................................................................................................. 225

8.3 CYLINDER SURFACE Slot milling (Cycle 28, DIN/ISO: G128, software option 1)......................... 226

Cycle run............................................................................................................................................... 226

Please note while programming:..........................................................................................................227

Cycle parameters.................................................................................................................................. 228

8.4 CYLINDER SURFACE Ridge milling (Cycle 29, DIN/ISO: G129, software option 1).......................229

Cycle run............................................................................................................................................... 229

Please note while programming:..........................................................................................................230

Cycle parameters.................................................................................................................................. 231

8.5 CYLINDER SURFACE (Cycle 39, DIN/ISO: G139, software option 1)..............................................232

Cycle run............................................................................................................................................... 232

Please note while programming:..........................................................................................................233

Cycle parameters.................................................................................................................................. 234

8.6 Programming Examples..................................................................................................................... 235

Example: Cylinder surface with Cycle 27............................................................................................. 235

Example: Cylinder surface with Cycle 28............................................................................................. 237

26

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 27

9 Fixed Cycles: Contour Pocket with Contour Formula...............................................................239

9.1 SL cycles with complex contour formula.........................................................................................240

Fundamentals........................................................................................................................................240

Selecting a program with contour definitions.......................................................................................242

Defining contour descriptions............................................................................................................... 242

Entering a complex contour formula.................................................................................................... 243

Superimposed contours........................................................................................................................ 244

Contour machining with SL Cycles.......................................................................................................246

Example: Roughing and finishing superimposed contours with the contour formula...........................247

9.2 SL cycles with simple contour formula............................................................................................250

Fundamentals........................................................................................................................................250

Entering a simple contour formula....................................................................................................... 252

Contour machining with SL Cycles.......................................................................................................252

TNC 640 | User's Manual Cycle Programming | 1/2015

27

Page 28

Contents

10 Cycles: Coordinate Transformations...........................................................................................253

10.1 Fundamentals...................................................................................................................................... 254

Overview............................................................................................................................................... 254

Effect of coordinate transformations.................................................................................................... 254

10.2 DATUM SHIFT (Cycle 7, DIN/ISO: G54)............................................................................................. 255

Effect..................................................................................................................................................... 255

Cycle parameters.................................................................................................................................. 255

10.3 DATUM SHIFT with datum tables (Cycle 7, DIN/ISO: G53)............................................................. 256

Effect..................................................................................................................................................... 256

Please note while programming:..........................................................................................................257

Cycle parameters.................................................................................................................................. 257

Selecting a datum table in the part program........................................................................................258

Edit the datum table in the Programming mode of operation..............................................................258

Configuring the datum table................................................................................................................. 260

To exit a datum table............................................................................................................................ 260

Status displays...................................................................................................................................... 260

10.4 DATUM SETTING (Cycle 247, DIN/ISO: G247)..................................................................................261

Effect..................................................................................................................................................... 261

Please note before programming:........................................................................................................ 261

Cycle parameters.................................................................................................................................. 261

Status displays...................................................................................................................................... 261

10.5 MIRRORING (Cycle 8, DIN/ISO: G28)................................................................................................ 262

Effect..................................................................................................................................................... 262

Please note while programming...........................................................................................................263

Cycle parameters.................................................................................................................................. 263

10.6 ROTATION (Cycle 10, DIN/ISO: G73)................................................................................................. 264

Effect..................................................................................................................................................... 264

Please note while programming:..........................................................................................................265

Cycle parameters.................................................................................................................................. 265

10.7 SCALING (Cycle 11, DIN/ISO: G72.................................................................................................... 266

Effect..................................................................................................................................................... 266

Cycle parameters.................................................................................................................................. 266

28

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 29

10.8 AXIS-SPECIFIC SCALING (Cycle 26).................................................................................................. 267

Effect..................................................................................................................................................... 267

Please note while programming:..........................................................................................................267

Cycle parameters.................................................................................................................................. 268

10.9 WORKING PLANE (Cycle 19, DIN/ISO: G80, software option 1).....................................................269

Effect..................................................................................................................................................... 269

Please note while programming:..........................................................................................................270

Cycle parameters.................................................................................................................................. 270

Resetting............................................................................................................................................... 271

Positioning the axes of rotation............................................................................................................ 271

Position display in the tilted system.....................................................................................................272

Workspace monitoring.......................................................................................................................... 272

Positioning in a tilted coordinate system..............................................................................................273

Combining coordinate transformation cycles........................................................................................273

Procedure for working with Cycle 19 WORKING PLANE..................................................................... 274

10.10 Programming Examples..................................................................................................................... 275

Example: Coordinate transformation cycles......................................................................................... 275

TNC 640 | User's Manual Cycle Programming | 1/2015

29

Page 30

Contents

11 Cycles: Special Functions............................................................................................................ 277

11.1 Fundamentals...................................................................................................................................... 278

Overview............................................................................................................................................... 278

11.2 DWELL TIME (Cycle 9, DIN/ISO: G04)...............................................................................................279

Function.................................................................................................................................................279

Cycle parameters.................................................................................................................................. 279

11.3 PROGRAM CALL (Cycle 12, DIN/ISO: G39).......................................................................................280

Cycle function........................................................................................................................................280

Please note while programming:..........................................................................................................280

Cycle parameters.................................................................................................................................. 281

11.4 SPINDLE ORIENTATION (Cycle 13, DIN/ISO: G36)...........................................................................282

Cycle function........................................................................................................................................282

Please note while programming:..........................................................................................................282

Cycle parameters.................................................................................................................................. 282

11.5 TOLERANCE (Cycle 32, DIN/ISO: G62)..............................................................................................283

Cycle function........................................................................................................................................283

Influences of the geometry definition in the CAM system..................................................................283

Please note while programming:..........................................................................................................284

Cycle parameters.................................................................................................................................. 285

11.6 CONTOUR TURNING INTERPOLATION (Cycle 292, DIN/ISO: G292, software option 96)............ 286

Cycle run............................................................................................................................................... 286

Please note while programming:..........................................................................................................288

Cycle parameters.................................................................................................................................. 290

Machining variants.................................................................................................................................291

Defining the tool................................................................................................................................... 293

11.7 COUPLING TURNING INTERPOLATION (Cycle 291, DIN/ISO: G291, software option 96)............295

Cycle run............................................................................................................................................... 295

Please note while programming:..........................................................................................................296

Cycle parameters.................................................................................................................................. 297

Defining the tool................................................................................................................................... 298

30

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 31

11.8 ENGRAVING (Cycle 225, DIN/ISO: G225)..........................................................................................300

Cycle run............................................................................................................................................... 300

Please note while programming:..........................................................................................................300

Cycle parameters.................................................................................................................................. 301

Allowed engraving characters............................................................................................................... 302

Characters that cannot be printed........................................................................................................ 302

Engraving system variables...................................................................................................................303

11.9 FACE MILLING (Cycle 232, DIN/ISO: G232)...................................................................................... 304

Cycle run............................................................................................................................................... 304

Please note while programming:..........................................................................................................306

Cycle parameters.................................................................................................................................. 307

11.10 ASCERTAIN THE LOAD (Cycle 239, DIN/ISO: G239, software option 143).................................... 309

Cycle run............................................................................................................................................... 309

Please note while programming:..........................................................................................................310

Cycle parameters.................................................................................................................................. 310

11.11 Programming examples..................................................................................................................... 311

Example: Interpolation Turning Cycle 291.............................................................................................311

Example: Interpolation Turning Cycle 292.............................................................................................313

TNC 640 | User's Manual Cycle Programming | 1/2015

31

Page 32

Contents

12 Cycles: Turning..............................................................................................................................315

12.1 Turning Cycles (software option 50)..................................................................................................316

Overview............................................................................................................................................... 316

Working with turning cycles................................................................................................................. 319

Blank form update (FUNCTION TURNDATA)........................................................................................ 320

12.2 ADAPT ROTARY COORDINATE SYSTEM (Cycle 800, DIN/ISO: G800)............................................322

Application.............................................................................................................................................322

Effect..................................................................................................................................................... 325

Please note while programming:..........................................................................................................325

Cycle parameters.................................................................................................................................. 326

12.3 RESET ROTARY COORDINATE SYSTEM (Cycle 801, DIN/ISO: G801).............................................328

Please note while programming:..........................................................................................................328

Effect..................................................................................................................................................... 328

Cycle parameters.................................................................................................................................. 328

12.4 Fundamentals of Turning Cycles....................................................................................................... 329

12.5 TURN SHOULDER LONGITUDINAL (Cycle 811, DIN/ISO: G811).....................................................330

Application.............................................................................................................................................330

Roughing cycle run................................................................................................................................330

Finishing cycle run................................................................................................................................ 331

Please note while programming:..........................................................................................................331

Cycle parameters.................................................................................................................................. 332

12.6 TURN SHOULDER LONGITUDINAL EXTENDED (Cycle 812, DIN/ISO: G812)................................333

Application.............................................................................................................................................333

Roughing cycle run................................................................................................................................333

Finishing cycle run................................................................................................................................ 334

Please note while programming:..........................................................................................................334

Cycle parameters.................................................................................................................................. 335

12.7 TURN, LONGITUDINAL PLUNGE (Cycle 813, DIN/ISO: G813)........................................................ 337

Application.............................................................................................................................................337

Roughing cycle run................................................................................................................................337

Finishing cycle run................................................................................................................................ 338

Please note while programming:..........................................................................................................338

Cycle parameters.................................................................................................................................. 339

32

TNC 640 | User's Manual Cycle Programming | 1/2015

Page 33

12.8 TURN, LONGITUDINAL PLUNGE EXTENDED (Cycle 814, DIN/ISO: G814)....................................340

Application.............................................................................................................................................340

Roughing cycle run................................................................................................................................340

Finishing cycle run................................................................................................................................ 341

Please note while programming:..........................................................................................................341

Cycle parameters.................................................................................................................................. 342

12.9 TURN CONTOUR LONGITUDINAL (Cycle 810, DIN/ISO: G810)......................................................344

Application.............................................................................................................................................344

Roughing cycle run................................................................................................................................344

Finishing cycle run................................................................................................................................ 345

Please note while programming:..........................................................................................................345

Cycle parameters.................................................................................................................................. 346

12.10TURN CONTOUR-PARALLEL (Cycle 815, DIN/ISO: G815)............................................................... 348

Application.............................................................................................................................................348

Roughing cycle run................................................................................................................................348

Finishing cycle run................................................................................................................................ 349

Please note while programming:..........................................................................................................349

Cycle parameters.................................................................................................................................. 350

12.11TURN SHOULDER FACE (Cycle 821, DIN/ISO: G821)...................................................................... 352

Application.............................................................................................................................................352

Roughing cycle run................................................................................................................................352

Finishing cycle run................................................................................................................................ 353

Please note while programming:..........................................................................................................353

Cycle parameters.................................................................................................................................. 354

12.12TURN SHOULDER FACE EXTENDED (Cycle 822, DIN/ISO: G822).................................................. 355