Page 1

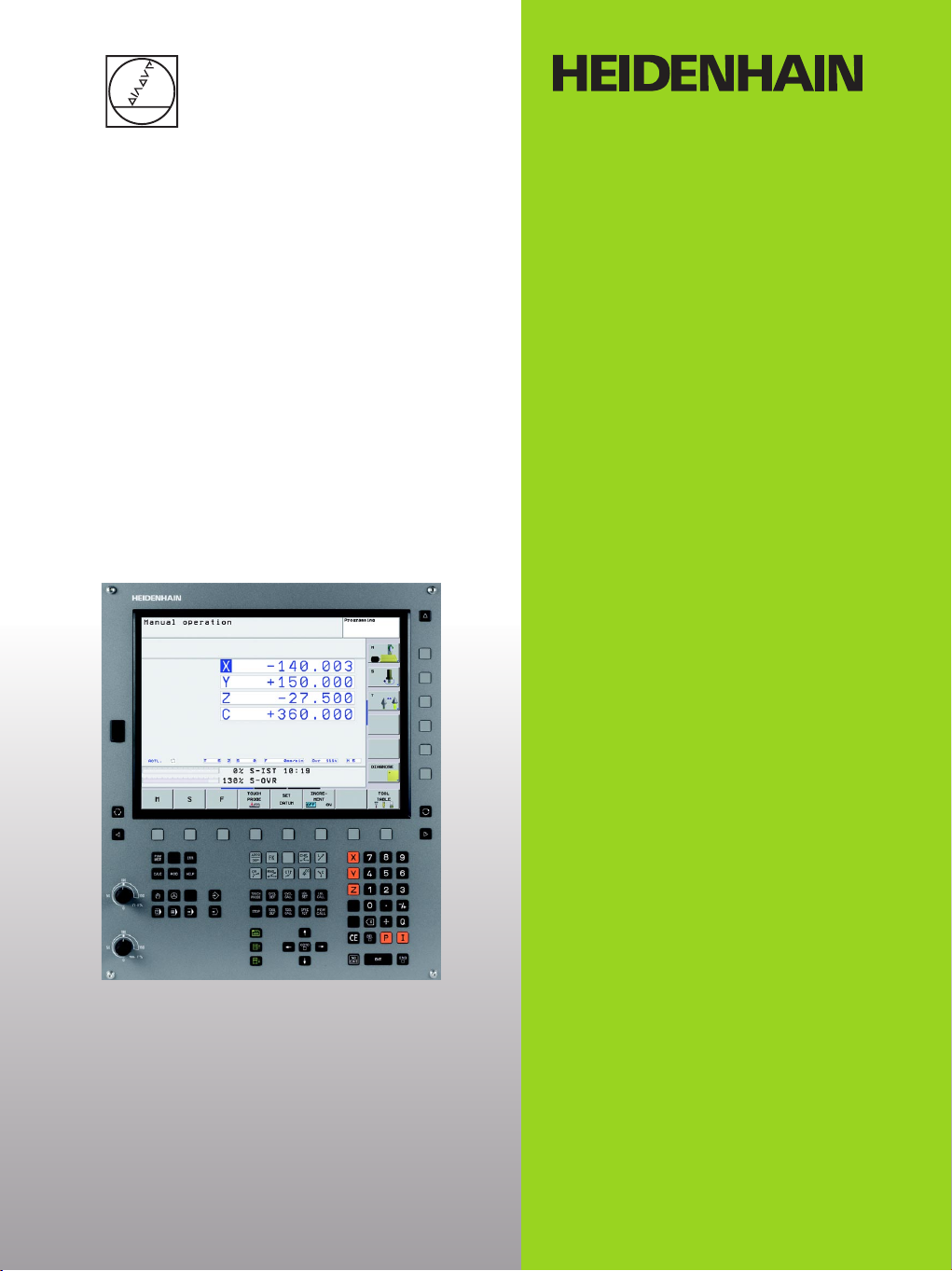

Technical Manual

TNC 620

NC Software

340 56x-02

October 2010

Page 2

2 HEIDENHAIN Technical Manual TNC 620

Page 3

Contents

1 Update Information

1.1 General Information..........................................................................19

1 Update Information No. 1

1.1 Overview............................................................................................21

1.1.1 Released Service Packs ......................................................21

1.1.2 Released NC Software........................................................21

1.2 NC Software 340 560-01...................................................................22

1.3 NC Software 340 551-04 / NC Software 340 560-02 ......................23

1.3.1 Important Notes on Updating Software ..............................23

1.3.2 Description of the New Functions.......................................28

1.4 NC Software 340 554-xx (TNC 320 Programming Station) ...........44

1.4.1 Description of the New Functions.......................................44

1.5 Hardware ...........................................................................................45

1.5.1 MC 6110 Computer Unit with ProfiBus Interface...............45

1 Update Information No. 2

1.1 Overview............................................................................................47

1.1.1 Released service packs.......................................................47

1.2 Hardware ...........................................................................................47

1.2.1 MC 6110 main computer of the TNC 620...........................47

1 Update Information No. 3

1.1 Overview............................................................................................49

1.1.1 Released service packs.......................................................49

1.2 NC software 340 56x-02 Service Pack 8..........................................49

1.2.1 Description of important changes.......................................49

1.3 Hardware ...........................................................................................50

1.3.1 UEC 11x controller unit with inverter and PLC I/O..............50

October 2010 3

Page 4

2Introduction

2.1 Meaning of the Symbols Used in this Manual...............................53

2.2 Proper Operation...............................................................................53

2.3 Trained Personnel .............................................................................53

2.4 General Information..........................................................................54

2.4.1 HSCI interface.....................................................................57

2.5 Overview of Components ................................................................58

2.5.1 MC main computer, CFR memory card and SIK .................58

2.5.2 CC 6106 controller unit .......................................................60

2.5.3 UEC 11x controller unit with integrated inverter and

PLC......................................................................................61

2.5.4 PLC input/output systems with HSCI interface ..................63

2.5.5 PSL 130 low-voltage power supply unit..............................67

2.5.6 MB 620 Machine Operating Panel......................................69

2.5.7 Handwheels ........................................................................70

2.5.8 Key symbols........................................................................73

2.5.9 Touch probes ......................................................................78

2.5.10 Other accessories ...............................................................80

2.5.11 Documentation....................................................................80

2.6 Brief Description................................................................................81

2.7 Software ............................................................................................93

2.7.1 Designation of the software................................................93

2.7.2 PLC software ......................................................................93

2.7.3 Enabling additional axes or software options......................94

2.7.4 Upgrade functions (Feature Content Level) ........................97

2.7.5 NC software exchange on the TNC 620 .............................98

2.7.6 Installing a service pack ....................................................103

2.7.7 Reversing a software update ............................................104

2.7.8 Special features of the software.......................................105

2.7.9 Firmware update on HSCI devices....................................106

2.7.10 Monitoring hardware changes ..........................................108

2.7.11 Data backup ......................................................................108

2.8 Software Releases ..........................................................................109

2.8.1 NC Software 340 560-xx...................................................109

2.8.2 NC software 340 561-xx ...................................................109

4 HEIDENHAIN Technical Manual TNC 620

Page 5

3 Mounting and Electrical Installation

3.1 General Information........................................................................111

3.1.1 Safety precautions.............................................................111

3.1.2 Degrees of protection .......................................................112

3.1.3 Electromagnetic compatibility ...........................................112

3.1.4 ESD protection..................................................................113

3.2 Environmental Conditions .............................................................115

3.2.1 Heat generation and cooling..............................................115

3.2.2 Humidity............................................................................116

3.2.3 Installation elevation..........................................................116

3.2.4 Mechanical vibration..........................................................116

3.2.5 Mounting Attitude with MC 6110 .....................................117

3.2.6 Mounting Attitude of CC 61xx, UV xxx, UM xxx,

UE 2xx B............................................................................118

3.3 Overview of Hardware....................................................................119

3.4 HSCI..................................................................................................120

3.4.1 Introduction.......................................................................120

3.4.2 Topology............................................................................121

3.4.3 HSCI interface...................................................................122

3.5 Connection Overview for TNC 620...............................................124

3.5.1 MC 6110 main computer ..................................................124

3.5.2 CC 6106 modular controller unit........................................125

3.5.3 UEC 11x: Compact Controller Unit with Inverter and

PLC I/Os ............................................................................126

3.5.4 UEC 11x: Digital PLC inputs/outputs.................................133

3.5.5 PLB 62xx and PLB 61xx ....................................................136

3.5.6 Switching inputs and outputs 24 V– (PLC)........................140

3.5.7 PLB 6xxx: Digital PLC Inputs/Outputs...............................141

3.5.8 PLB 6xxx: Analog PLC Inputs/Outputs..............................143

3.5.9 X121: PROFIBUS connection............................................145

3.5.10 Configuring the PLC Inputs/Outputs with IOconfig...........146

3.6 Power Supply for the TNC 620 ......................................................147

3.6.1 PSL 130 low-voltage power supply unit............................153

3.7 Power Supply for PLC Outputs......................................................161

3.8 Power Supply for PLB 6xxx............................................................162

3.9 Power Supply for Control-Is-Ready Signal...................................163

3.10 Drive Controller Enable ..................................................................164

3.11 Buffer Battery ..................................................................................165

3.12 Encoder Connections .....................................................................166

3.12.1 General information...........................................................166

3.12.2 Position Encoder Input .....................................................167

3.12.3 Input of speed encoder ...................................................169

October 2010 5

Page 6

3.13 Adapters for Encoder Signals ........................................................174

3.14 Connecting the Motor Power Stages (Only CC 61xx) .................178

3.15 Touch Probe Systems.....................................................................179

3.16 Data Interfaces ................................................................................182

3.16.1 USB Interface....................................................................185

3.17 MB 620 Machine Operating Panel .................................................186

3.18 Handwheel Input.............................................................................190

3.18.1 HR 410 portable handwheel..............................................190

3.18.2 HR 130 panel-mounted handwheel...................................192

3.18.3 HRA 110 handwheel adapter ............................................193

3.19 Cable Specifications........................................................................195

3.20 Dimensions......................................................................................196

3.20.1 MC 6110 ...........................................................................197

3.20.2 MB 620 .............................................................................198

3.20.3 CC 6106 ............................................................................199

3.20.4 UEC 11x ............................................................................200

3.20.5 PL 6xxx..............................................................................201

3.20.6 PSL 130.............................................................................201

3.20.7 Adapter block for the data interface..................................202

3.20.8 USB hub............................................................................203

3.20.9 Line-drop compensator .....................................................204

3.20.10 Handwheels ......................................................................204

3.20.11 Touch probes ....................................................................208

3.21 HSCI Connection Overview of the TNC 620 with CC 61xx..........215

3.22 HSCI Connection Overview of the TNC 620 with UEC 11xx .......216

3.23 Grounding diagram for TNC 620 with Modular

HEIDENHAIN Inverter System .......................................................217

3.24 Basic Circuit Diagram for TNC 620 ................................................218

3.25 Cable Overview for TNC 620 with CC 6106 ..................................219

3.26 Cable Overview for TNC 620 with UEC 11x..................................220

3.27 Cable Overview for TNC 620—Accessories ..................................221

6 HEIDENHAIN Technical Manual TNC 620

Page 7

4 Machine Parameters

4.1 General Information........................................................................223

4.2 The “Machine Parameter” Mode of Operation............................225

4.2.1 Calling the configuration editor..........................................225

4.2.2 Entering and Changing Machine Parameters....................227

4.2.3 Accessing Machine Parameters via MP Numbers............238

4.2.4 Managing configuration files .............................................241

4.2.5 Sort File Content ...............................................................241

4.2.6 Attribute Information.........................................................242

4.2.7 Access Protection / Options..............................................244

4.2.8 Update rules......................................................................245

4.2.9 Remove Syntax Error ........................................................255

4.2.10 Resets the update version ................................................255

4.2.11 Backup of Parameters.......................................................256

4.3 User Parameters..............................................................................257

4.3.1 Configuration of the user parameters ...............................258

4.3.2 Example:............................................................................260

4.3.3 XML commands for creating the layout files ....................262

4.4 The KeySynonym function.............................................................265

4.5 Allocation of Configuration Data ..................................................267

4.6 Structure of a Parameter File.........................................................269

4.7 Machine-Parameter Subfiles..........................................................272

4.7.1 Syntax of Machine-Parameter Subfile...............................272

4.7.2 Activating the Machine-Parameter Subfile........................272

4.7.3 Displaying/Editing Data Records in the Configuration

Editor.................................................................................275

4.8 Read or Change Machine Parameters via a PLC Module ............277

4.9 Overview of Machine Parameters .................................................283

4.9.1 “System” Group ...............................................................283

4.9.2 “Channels” Group.............................................................292

4.9.3 “Axes” group....................................................................295

4.9.4 “KeySynonym” group.......................................................300

4.10 Parameter Overview Sorted by MP Numbers..............................301

4.10.1 System configuration and miscellaneous..........................302

4.10.2 Channel-specific parameters.............................................322

4.10.3 Axis-specific parameters ...................................................327

4.10.4 Parameters for configuring the parameter sets ................329

4.11 Overview: iTNC 530 MP Numbers <–> TNC 620 MP

Numbers ..........................................................................................336

4.11.1 Measuring systems and machine axes.............................337

4.11.2 Positioning and regulation.................................................339

4.11.3 PWM interface (DSP) ........................................................341

4.11.4 Spindle control (1st spindle) ..............................................344

4.11.5 Integrated PLC ..................................................................345

4.11.6 Serial interface...................................................................346

4.11.7 Touch probe ......................................................................346

4.11.8 Tool touch probe for tool measurement............................347

4.11.9 Tapping..............................................................................347

4.11.10 Display and programming..................................................348

4.11.11 Machining and Program Run.............................................349

4.11.12 Hardware...........................................................................350

October 2010 7

Page 8

5 Modules and PLC Operands

5.1 Overview of Modules......................................................................351

5.2 Overview of the PLC Operands......................................................357

5.2.1 PLC Operands of the “General Data” Group....................357

5.2.2 PLC Operands of the “Operating Mode Group”

Group ................................................................................359

5.2.3 PLC Operands of the “Machining Channels” Group ........360

5.2.4 PLC Operands of the “Axis” Group..................................362

5.2.5 PLC Operands of the “Spindle” Group.............................364

6 Configuring the Axes and Spindle

6.1 Machine Structure ..........................................................................365

6.1.1 Adapting the control to the machine.................................365

6.1.2 Definition of axes ..............................................................366

6.2 Configuration of Machining Channels ..........................................368

6.2.1 Configuring a machining channel ......................................368

6.2.2 Traversing the reference marks ........................................373

6.2.3 Returning to the contour/block scan .................................374

6.3 Configuration of Axes.....................................................................378

6.3.1 Axis designations and coordinates....................................380

6.3.2 Programmable axes ..........................................................383

6.3.3 Physical axes.....................................................................386

6.3.4 Display of axes on the screen...........................................394

6.3.5 Hirth coupling....................................................................398

6.3.6 Kinematics properties of axes...........................................400

6.3.7 Manual axis (counter axis).................................................402

6.3.8 Introducing a new NC axis into the system ......................404

6.4 Encoders ..........................................................................................415

6.4.1 Type of the position encoder ............................................415

6.4.2 Signal period of encoders..................................................418

6.4.3 Distance-coded reference marks ......................................422

6.4.4 Connecting the encoders, PWM output on the

CC 61xx.............................................................................424

6.4.5 Connecting the encoders to the UEC 11x.........................429

6.4.6 Defining the traverse direction..........................................431

6.4.7 Encoder monitoring...........................................................433

6.4.8 Linear and torque motors..................................................437

6.5 Reading and Writing Axis Information .........................................439

6.5.1 Reading axis information...................................................439

6.5.2 Writing axis information – activating and deactivating

axes...................................................................................445

6.6 Traverse Ranges..............................................................................454

6.6.1 Overwrite software limit switches....................................455

6.7 Lubrication Pulse.............................................................................456

6.8 Controlling Axes by PLC (PLC Axes) .............................................458

8 HEIDENHAIN Technical Manual TNC 620

Page 9

6.9 Axis Error Compensation ...............................................................468

6.9.1 Backlash compensation.....................................................470

6.9.2 Linear axis error compensation .........................................474

6.9.3 Nonlinear axis error compensation....................................476

6.9.4 Compensation of thermal expansion.................................483

6.9.5 Compensation of static friction .........................................485

6.9.6 Compensation of sliding friction........................................486

6.10 Machine Kinematics........................................................................488

6.10.1 Configuring the machine kinematics.................................491

6.10.2 Find/activate kinematics through the PLC.........................511

6.11 Tilting Axes......................................................................................513

6.11.1 “Tilting the working plane” function

(software option 1)............................................................513

6.12 Parallel Axes ....................................................................................518

6.13 Synchronized Axes (Option 24) .....................................................520

6.13.1 Gantry axes .......................................................................520

6.13.2 Master-slave torque control ..............................................530

6.14 Reference Marks..............................................................................541

6.14.1 Definition...........................................................................541

6.14.2 Traversing the reference marks ........................................542

6.14.3 Defining the process of traversing the reference

marks.................................................................................545

6.14.4 “Pass Over Reference Point” operating mode.................552

6.15 The Control Loop ............................................................................556

6.15.1 Block diagram of control loop............................................556

6.15.2 Relation between jerk, acceleration, velocity and

distance.............................................................................557

6.15.3 Geometry filter ..................................................................559

6.15.4 Look-ahead........................................................................561

6.15.5 Interpolator........................................................................571

6.15.6 Nominal position value filter..............................................572

6.15.7 Feed-rate smoothing (software option 2)..........................583

6.15.8 Position controller..............................................................585

6.15.9 Activating and deactivating position control loops ............594

6.15.10 Feed-rate enable................................................................597

6.15.11 Speed controller ................................................................599

6.15.12 Filters in the speed controller and position controller

when using the CC 61xx and CC 424................................603

6.15.13 CC 61xx/CC 424: filter order for separate low-pass

filter in the speed controller ..............................................607

6.15.14 CC 61xx/CC424: peculiarities in weakened-field

operation ...........................................................................608

6.15.15 Active damping of low-frequency oscillations...................610

6.15.16 Acceleration feedforward control......................................612

6.15.17 IPC, holding torque, following error in the jerk phase .......615

6.15.18 HSCI: switching drives on and off, enabling the drive

controller ...........................................................................620

6.15.19 Current controller ..............................................................630

6.15.20 Braking the drives for an EMERGENCY STOP and a

power fail...........................................................................635

6.15.21 Power and torque limiting .................................................638

6.15.22 Controller parameters for manual traverse........................645

6.15.23 Switching parameter sets .................................................646

October 2010 9

Page 10

6.15.24 Synchronous motors in field weakening range .................659

6.15.25 Motor with wye/delta switchover .....................................661

6.15.26 Speed-dependent switching of the PWM frequency ........663

6.15.27 TRC – torque ripple compensation....................................666

6.15.28 Torsion compensation.......................................................669

6.16 Monitoring Functions .....................................................................671

6.16.1 Monitoring the drives........................................................671

6.16.2 Position monitoring ...........................................................673

6.16.3 Movement monitoring ......................................................677

6.16.4 Standstill monitoring .........................................................679

6.16.5 Positioning window...........................................................680

6.16.6 Monitoring of the power supply unit ................................684

6.16.7 Temperature monitoring ...................................................687

6.16.8 I

2

t monitoring ....................................................................691

6.16.9 Momentary utilization of drive motors ..............................702

6.16.10 Status of HEIDENHAIN hardware and software...............704

6.16.11 Motor brake.......................................................................708

6.16.12 Emergency stop monitoring..............................................709

6.16.13 Monitoring functions when using the CC 61xx and

CC 424 ..............................................................................714

6.17 Spindles ...........................................................................................716

6.17.1 Configuring spindles..........................................................716

6.17.2 Position encoder of the spindle.........................................717

6.17.3 Spindle speed encoder......................................................718

6.17.4 Filtering the acceleration values........................................720

6.17.5 Controlling the spindle ......................................................721

6.17.6 Oriented spindle stop (spindle point stop) ........................732

6.17.7 Tapping with floating tap holder and coded

spindle-speed output.........................................................736

6.17.8 Switching the modes of operation ....................................738

6.17.9 Stop spindle at trip dog position........................................740

6.17.10 Spindle of the kinematics model.......................................743

6.17.11 Gear shifting......................................................................744

6.17.12 Tapping..............................................................................744

6.17.13 Operating a second spindle...............................................744

6.17.14 C-axis operation.................................................................746

6.17.15 Volts-per-hertz control mode.............................................748

6.18 Configuring the Controller Unit and Drive Motors......................749

6.18.1 Structure of the CC 61xx and UEC 11x controller

units ..................................................................................749

6.18.2 CC61xx: single-speed and double-speed (software

option #49) ........................................................................751

6.18.3 PWM frequencies with the CC 61xx.................................755

6.18.4 PWM frequency with INDRAMAT “POWER DRIVE”

inverters ...........................................................................757

6.18.5 PWM frequency with SIEMENS “SIMODRIVE”

inverters ............................................................................757

6.18.6 Comparison of the CC 61xx and CC 424 controller

units ..................................................................................760

6.18.7 Configuring the servo motor .............................................763

6.18.8 Field orientation – fundamentals.......................................766

6.18.9 Ascertaining the field angle with the CC 61xx or

CC 424 ..............................................................................768

10 HEIDENHAIN Technical Manual TNC 620

Page 11

6.19 Current Controller Adjustment......................................................776

6.20 Integrated Oscilloscope..................................................................778

6.20.1 Fundamentals....................................................................778

6.20.2 Prepare recording..............................................................780

6.20.3 Record signals...................................................................784

6.20.4 Analyze recording..............................................................786

6.20.5 Saving and loading recordings...........................................789

6.20.6 Circular interpolation test with the integrated

oscilloscope.......................................................................790

6.20.7 Configure the colors of the oscilloscope display...............791

7 Machine Integration

7.1 Display and Operation....................................................................795

7.1.1 Position and status display................................................795

7.1.2 Unit of measurement for display and operation................803

7.1.3 Conversational language ...................................................804

7.1.4 Format of NC programs and cycle display.........................809

7.1.5 Settings for the programming mode of operation.............811

7.1.6 Binary file management ....................................................817

7.1.7 Access rights to drives and directories .............................819

7.1.8 Code numbers...................................................................821

7.1.9 Programming station mode...............................................822

7.1.10 Operating modes / control operation in the operating

mode group.......................................................................825

7.1.11 Control operation in the machining channel ......................829

7.1.12 Error messages and log files.............................................846

7.1.13 TNCguide – context-sensitive help system (user

documentation) .................................................................871

7.1.14 Table editor........................................................................882

7.1.15 Machine datum .................................................................885

7.1.16 Cycles................................................................................888

7.1.17 Window manager (XFCE) ..................................................892

7.2 Small PLC window..........................................................................896

7.3 PLC Soft Keys ..................................................................................900

7.4 Switching the Control On/Off........................................................901

7.4.1 Powering up the control....................................................901

7.4.2 Shutting down the control.................................................904

7.5 Keystroke Simulation .....................................................................911

7.5.1 Control keyboard...............................................................911

7.5.2 Machine operating panel...................................................918

7.6 Electronic Handwheel.....................................................................920

7.6.1 Serial handwheel...............................................................920

7.6.2 Handwheel at position encoder input................................925

7.6.3 Traverse per handwheel revolution ...................................930

7.6.4 Assigning a handwheel to an axis.....................................931

7.6.5 HR 410 portable handwheel..............................................935

7.6.6 HR 150 panel-mounted handwheels with HRA 110

handwheel adapter............................................................937

October 2010 11

Page 12

7.7 Override ...........................................................................................939

7.7.1 Override devices ...............................................................939

7.7.2 Compensation for potentiometers ....................................941

7.7.3 Override functions.............................................................942

7.8 PLC Inputs/Outputs........................................................................946

7.8.1 Diagnosis of the external PL .............................................946

7.8.2 24 V– switching input/outputs ..........................................950

7.8.3 Analog inputs ....................................................................954

7.8.4 Analog outputs..................................................................957

7.9 Incremental Jog Positioning..........................................................959

7.10 Operating Times and System Times.............................................961

7.10.1 Measuring operating times ...............................................961

7.10.2 System time......................................................................967

7.11 Tool Changer ...................................................................................969

7.11.1 Tool and pocket number ...................................................969

7.11.2 Automatic Tool Recognition............................................1000

7.11.3 Controlling the Tool Changer...........................................1001

7.12 Touch Probe...................................................................................1007

7.12.1 Using the Touch Probes..................................................1010

7.12.2 Touch Probe Cycles ........................................................1015

7.12.3 Tool measurement..........................................................1022

7.13 Commissioning .............................................................................1035

7.13.1 Power Module Table and Motor Table............................1035

7.13.2 Preparation......................................................................1044

7.13.3 Commissioning of Digital Axes .......................................1047

7.13.4 Commissioning the Spindle ............................................1064

7.14 Diagnosis with the Online Monitor (OLM) .................................1068

7.14.1 Introduction.....................................................................1068

7.14.2 Using the OLM................................................................1069

7.14.3 Screen Layout .................................................................1071

7.14.4 Group of NC Axes ...........................................................1074

7.14.5 Group of Spindle Commands ..........................................1094

7.14.6 Group of NC Channels ....................................................1096

7.14.7 Hardware Group..............................................................1101

7.14.8 Group of Drive Commands .............................................1114

7.14.9 Auxiliary Group................................................................1115

7.14.10 PLC Group.......................................................................1121

7.14.11 Queue-Trace....................................................................1124

7.14.12 Frequent Causes of Error ................................................1126

12 HEIDENHAIN Technical Manual TNC 620

Page 13

8 PLC Programming

8.1 PLC functions.................................................................................1127

8.1.1 The API 3.0 symbolic memory interface.........................1128

8.1.2 HEIDENHAIN PLC basic program ...................................1134

8.1.3 Selecting the plc programming mode of operation .........1135

8.1.4 PLC main menu...............................................................1136

8.1.5 File management.............................................................1138

8.1.6 The API DATA function ...................................................1139

8.1.7 The WATCH LIST function ..............................................1141

8.1.8 The TABLE function ........................................................1143

8.1.9 The TRACE function........................................................1145

8.1.10 The COMPILE function ...................................................1147

8.1.11 The EDIT function............................................................1148

8.1.12 Diagnostic functions........................................................1151

8.1.13 BUS diagnostics..............................................................1171

8.2 Configure PLC input/output systems .........................................1176

8.3 Operands........................................................................................1178

8.3.1 Overview of operands.....................................................1178

8.3.2 Operand addressing (byte, word, double word)..............1181

8.3.3 Timers and counters .......................................................1182

8.3.4 Fast PLC inputs...............................................................1192

8.4 Data Organization.........................................................................1194

8.4.1 Data organization on the CFR memory card....................1194

8.4.2 Compressing graphic files...............................................1196

8.4.3 Configuring the displayed drives and directories in

the file manager ..............................................................1197

8.4.4 PLC system files ...........................................................1199

8.5 M Functions (M Strobe)................................................................1207

8.5.1 Assigning M functions to the machining channels..........1207

8.5.2 Configuration of M functions...........................................1208

8.5.3 Overview of M functions of the TNC ..............................1216

8.6 S Function (S Strobe) ...................................................................1222

8.6.1 Assigning S functions to the machining channels...........1222

8.6.2 Configuration of S function..............................................1223

8.7 T Functions (T Strobe)..................................................................1233

8.7.1 Assigning T functions to the machining channels ...........1233

8.7.2 Configuration of T functions............................................1234

8.8 Alias Functions (Alias Strobe).....................................................1241

8.8.1 Assigning alias functions to the machining

channels ..........................................................................1241

8.8.2 Configuration of alias functions.......................................1242

8.9 Options for the PLC Run-Time System.......................................1244

October 2010 13

Page 14

8.10 Tables.............................................................................................1247

8.10.1 Creating a new table type ...............................................1248

8.10.2 Defining a table prototype...............................................1259

8.10.3 Creating a new table with the file manager ....................1260

8.10.4 Inserting additional columns in an existing table.............1261

8.10.5 Deleting columns from an existing table.........................1262

8.10.6 Removing column names and column descriptions .......1263

8.10.7 Defining the path for OEM tables ...................................1264

8.10.8 Symbolic names for tables..............................................1264

8.10.9 Editing tables via the PLC ..............................................1266

8.10.10 Access to tables via SQL commands..............................1277

8.10.11 PLC modules for the SQL statements ............................1290

8.11 Data Transfer NC => PLC, PLC => NC..........................................1309

8.11.1 Introduction.....................................................................1309

8.11.2 Data transfer NC program => PLC ("FN19: PLC =" or

"FN29: PLC =").................................................................1310

8.11.3 Q parameters ..................................................................1312

8.11.4 Data transfer NC program => NC (FN17:

SYSWRITE) .....................................................................1314

8.11.5 Data transfer NC => NC program (FN18: SYSREAD).......1326

8.11.6 Data transfer machine parameters => PLC ....................1339

8.11.7 Interrogate PLC operands in the NC program (FN20:

WAIT FOR)......................................................................1341

8.12 Program Creation..........................................................................1342

8.12.1 ASCII editor.....................................................................1342

8.12.2 Program format...............................................................1342

8.12.3 Program structure ...........................................................1343

8.13 Command Set................................................................................1344

8.13.1 Overview.........................................................................1344

8.13.2 LOAD (L) .........................................................................1347

8.13.3 LOAD NOT (LN) ..............................................................1349

8.13.4 LOAD TWO’S COMPLEMENT (L–).................................1351

8.13.5 LOAD BYTE (LB) .............................................................1352

8.13.6 LOAD WORD (LW) .........................................................1352

8.13.7 LOAD DOUBLE WORD (LD)...........................................1353

8.13.8 ASSIGN (=)......................................................................1353

8.13.9 ASSIGN BYTE (B=)..........................................................1354

8.13.10 ASSIGN WORD (W=)......................................................1355

8.13.11 ASSIGN DOUBLE WORD (D=) .......................................1355

8.13.12 ASSIGN NOT (=N)...........................................................1356

8.13.13 ASSIGN TWO’S COMPLEMENT (=–) .............................1356

8.13.14 SET (S).............................................................................1357

8.13.15 RESET (R)........................................................................1358

8.13.16 SET NOT (SN)..................................................................1359

8.13.17 RESET NOT (RN).............................................................1360

8.13.18 AND (A) ...........................................................................1361

8.13.19 AND NOT (AN) ................................................................1363

8.13.20 OR (O) .............................................................................1365

8.13.21 OR NOT (ON) ..................................................................1367

8.13.22 EXCLUSIVE OR (XO).......................................................1369

8.13.23 EXCLUSIVE OR NOT (XON)............................................1371

8.13.24 ADDITION (+)..................................................................1373

8.13.25 SUBTRACTION (–)...........................................................1374

8.13.26 MULTIPLICATION (X)......................................................1375

8.13.27 DIVISION (/).....................................................................1376

14 HEIDENHAIN Technical Manual TNC 620

Page 15

8.13.28 REMAINDER (MOD) .......................................................1377

8.13.29 INCREMENT (INC)...........................................................1377

8.13.30 DECREMENT (DEC)........................................................1378

8.13.31 EQUAL TO (==)...............................................................1378

8.13.32 LESS THAN (<)................................................................1379

8.13.33 GREATER THAN (>) ........................................................1380

8.13.34 LESS THAN OR EQUAL TO (<=) ....................................1381

8.13.35 GREATER THAN OR EQUAL TO (>=).............................1382

8.13.36 NOT EQUAL (<>) ............................................................1383

8.13.37 AND [ ] (A[ ]) ....................................................................1384

8.13.38 AND NOT [ ] (AN[ ]) .........................................................1385

8.13.39 OR [ ] (O[ ]) ......................................................................1385

8.13.40 OR NOT [ ] (ON[ ]) ...........................................................1386

8.13.41 EXCLUSIVE OR [ ] (XO[ ])................................................1386

8.13.42 EXCLUSIVE OR NOT [ ] (XON[ ]) .....................................1386

8.13.43 ADDITION [ ] (+[ ])...........................................................1386

8.13.44 SUBTRACT [ ] (–[ ]) ..........................................................1387

8.13.45 MULTIPLY [ ] (x[ ])...........................................................1387

8.13.46 DIVIDE [ ] (/[ ])..................................................................1388

8.13.47 REMAINDER [ ] (MOD[ ]) ................................................1388

8.13.48 EQUAL TO [ ] (==[ ])........................................................1388

8.13.49 LESS THAN [ ] (<[ ]).........................................................1389

8.13.50 GREATER THAN [ ] (>[ ]).................................................1390

8.13.51 LESS THAN OR EQUAL TO [ ] (<=[ ]) .............................1390

8.13.52 GREATER THAN OR EQUAL TO [ ] (>=[ ])......................1390

8.13.53 NOT EQUAL [ ] (<>[ ]).....................................................1390

8.13.54 SHIFT LEFT (<<)..............................................................1391

8.13.55 SHIFT RIGHT (>>)...........................................................1392

8.13.56 BIT SET (BS)....................................................................1393

8.13.57 BIT CLEAR (BC)...............................................................1394

8.13.58 BIT TEST (BT)..................................................................1395

8.13.59 PUSH DATA ONTO THE DATA STACK (PS) ...................1396

8.13.60 PULL DATA FROM THE DATA STACK (PL)....................1397

8.13.61 PUSH LOGIC ACCUMULATOR ONTO THE DATA

STACK (PSL)....................................................................1397

8.13.62 PUSH WORD ACCUMULATOR ONTO THE DATA

STACK (PSW)..................................................................1398

8.13.63 PULL LOGIC ACCUMULATOR FROM THE DATA

STACK (PLL)....................................................................1398

8.13.64 PULL WORD ACCUMULATOR FROM THE DATA

STACK (PLW) ..................................................................1399

8.13.65 UNCONDITIONAL JUMP (JP).........................................1399

8.13.66 JUMP IF LOGIC ACCUMULATOR = 1 (JPT)...................1400

8.13.67 JUMP IF LOGIC ACCUMULATOR = 0 (JPF)...................1401

8.13.68 CALL MODULE (CM)......................................................1401

8.13.69 CALL MODULE IF LOGIC ACCUMULATOR = 1

(CMT)...............................................................................1401

8.13.70 CALL MODULE IF LOGIC ACCUMULATOR = 0

(CMF)...............................................................................1402

8.13.71 END OF MODULE, END OF PROGRAM (EM)................1403

8.13.72 END OF MODULE IF LOGIC ACCUMULATOR = 1

(EMT)...............................................................................1403

8.13.73 END OF MODULE IF LOGIC ACCUMULATOR = 0

(EMF)...............................................................................1403

8.13.74 LABEL (LBL)....................................................................1403

October 2010 15

Page 16

8.14 INDEX Register (X Register).........................................................1404

8.15 Commands for String Processing................................................1406

8.16 LOAD STRING (L) ..........................................................................1408

8.17 ADD STRING (+) ............................................................................1408

8.18 STORE STRING (=)........................................................................1408

8.19 OVERWRITE STRING (OVWR) .....................................................1409

8.20 EQUAL TO Command for String Processing (==) ......................1410

8.21 LESS THAN Command for String Processing (<).......................1410

8.22 GREATER THAN Command for String Processing (>)...............1410

8.23 LESS THAN OR EQUAL TO Command for String

Processing (<=)..............................................................................1411

8.24 GREATER THAN OR EQUAL TO Command for String

Processing (>=)..............................................................................1411

8.25 NOT EQUAL Command for String Processing (<>)....................1412

8.26 Modules for String Processing ....................................................1413

8.27 Submit programs..........................................................................1416

8.28 Calling the Submit Program (SUBM)..........................................1417

8.29 Interrogating the Status of a Submit Program (RPLY)..............1417

8.30 Canceling a Submit Program (CAN)............................................1418

8.31 Cooperative Multitasking.............................................................1420

8.31.1 Starting a Parallel Process (SPAWN)...............................1420

8.31.2 Control of events.............................................................1421

8.32 Constants Field (KF)......................................................................1427

8.33 Program Structures ......................................................................1428

8.33.1 IF ... ELSE ... ENDI structure...........................................1429

8.33.2 REPEAT ... UNTIL Structure............................................1429

8.33.3 WHILE ... ENDW structure .............................................1430

8.34 CASE branch..................................................................................1430

8.35 Linking Files...................................................................................1432

8.36 USES STATEMENT (USES)..........................................................1432

8.37 GLOBAL Statement (GLOBAL) ....................................................1434

8.38 EXTERN STATEMENT (EXTERN).................................................1434

8.39 PLC Modules..................................................................................1435

8.39.1 Markers, Bytes, Words, and Double Words ...................1435

8.39.2 Number conversion.........................................................1438

16 HEIDENHAIN Technical Manual TNC 620

Page 17

9 Data Interfaces

9.1 Introduction...................................................................................1443

9.2 The Ethernet Interface..................................................................1444

9.3 Connecting the Control to the Network.....................................1445

9.3.1 Configuring the control’s network address .....................1445

9.3.2 Configuring network access to other devices

(mount)............................................................................1447

9.3.3 Overview of functions for configuring the network ........1449

9.4 HSCI Interface................................................................................1451

9.5 The USB Interface of the Control (USB 1.1) ...............................1453

9.6 The Serial Interface of the Control ..............................................1456

9.6.1 RS-232-C/V.24 interface..................................................1456

9.7 Configuring the Serial Interface...................................................1459

9.7.1 Control characters...........................................................1459

9.7.2 Configuration of interfaces..............................................1460

9.8 Data Transmission Protocols.......................................................1472

9.8.1 Standard communications protocol.................................1472

9.8.2 Communications protocol with block check

character..........................................................................1474

9.8.3 LSV2 transmission protocol.............................................1477

9.9 Saving and Loading Files .............................................................1478

9.10 Configuring the Control for TeleService 2.0...............................1479

9.11 Data Transfer by PLC ....................................................................1482

9.11.1 PLC modules...................................................................1482

10 Index

October 2010 17

Page 18

18 HEIDENHAIN Technical Manual TNC 620

Page 19

1 Update Information

1.1 General Information

Update Information for the TNC 620 appears at irregular intervals, often as part

of a new software version. This is preliminary information in PDF format,

containing brief descriptions of new software functions as well as new

hardware components. After the Update Information has been published, the

new items are included in the TNC 620 Technical Manual.

Each Update Information is saved in the HEIDENHAIN FileBase on the

Internet, where registered users can access it under http://

filebase.heidenhain.de.

Registered users of the HEIDENHAIN FileBase on the Internet receive an

e-mail notification when a new Update Information appears.

November 2009 1.1 General Information 19

Page 20

20 HEIDENHAIN Technical Manual TNC 620

Page 21

1 Update Information No. 1

1.1 Overview

1.1.1 Released Service Packs

The following service packs have been released for NC software 340 56x-01:

Service pack 1: 340 56x-01 SP1 First release: September 2008

Service pack 2: 340 56x-01 SP2 October 2008

Service pack 3: 340 56x-01 SP3 December 2008

1.1.2 Released NC Software

The following NC software has been released:

NC software 340 560-02

NC software 340 561-02

NC software 340 564-02

November 2009 1.1 Overview 21

Page 22

1.2 NC Software 340 560-01

Warning

Service packs

When needed, HEIDENHAIN prepares service packs for the various

versions of the NC software. Registered customers can download these

service packs from the HEIDENHAIN FileBase on the Internet. Installation

of a service pack in addition to the already installed NC software

implements important error fixes. Please ensure that the NC software

always contains the latest service pack before you ship the machine.

Perform all tests required of the machine or the NC software again after

having installed the service pack.

The following service packs have been released for NC software 340 560-01:

Service pack 1 NC software Release

340 560-01 SP1 340 560-01 First release in

Service pack 2 NC software Release

340 560-01 SP2 340 560-01 October 2008

Service pack 3 NC software Release

340 560-01 SP3 340 560-01 December 2008

September 2008

22 HEIDENHAIN Technical Manual TNC 620

Page 23

1.3 NC Software 340 551-04 / NC Software 340 560-02

Note

Note

Note

Note

1.3.1 Important Notes on Updating Software

Please remember the following important information when updating the

software versions listed below:

TNC 320: 340 551-03 to 340 551-04 or

TNC 620: 340 560-01 to 340 560-02

If you are using linear encoders with EnDat interface or motor encoders

with EnDat interface for position measurement on your machine, you must

carry out the following step.

Move the EnDat axes to known positions before the update:

A function for monitoring the SRAM contents for consistency will be

introduced with new NC software. After the software update, all EnDat axes

will therefore display the error message S-RAM contents of axis are

invalid. At the same time, the control will display a dialog box for

confirmation, in which the current (the displayed) position of the axis is

compared with the physical (switch-off) position.

Move the axes to known positions before the update.

Write down the switch-off positions.

After the control has booted with the new software for the first time,

confirm the positions of the EnDat axes.

HEIDENHAIN recommends:

Making a backup of the control (e.g. with TNCbackup), before updating the

NC software.

Saving your current machine configuration. The configuration editor (DATA

BACKUP soft key) can be used for this purpose.

If you later want to undo the software update and return to the previous

software version, you need the saved configuration data of the old version!

Please perform the update of the NC software as described in the Technical

Manual in Chapter 2 "NC Software Exchange".

Be sure to remember the important information about the software update,

which is provided on the following pages.

November 2009 1.3 NC Software 340 551-04 / NC Software 340 560-02 23

Page 24

Checking and saving new machine parameters:

Warning

After having installed the new NC software and rebooted the control, you

must check and confirm the new machine parameters. The MOD dialog box

appears on the screen:

Enter the MP code number 95148 and confirm your entry with the ENT key.

Press the MORE FUNCTIONS soft key.

Press the UPDATE RULES soft key.

Check the listed update rules. Each entry in the list stands for a new

parameter that was added to the system by the update.

Exit the UPDATE RULES with the END soft key.

Press the CONFIG DATA soft key.

Before the configuration editor opens, an informational window is displayed,

reporting the removal of the CfgRestorePosition machine parameter. Press

the NEXT soft key.

All new machine parameters are marked with a red exclamation point in the

configuration editor. The control indicates if certain machine parameters are

faulty. Please ignore these messages for the time being.

Important step: Press the SAVE soft key.

The Configuration data changed dialog box opens. Press the SAVE soft key

again. The new machine parameters are now automatically saved in the

*.cfg files.

Press the END soft key and exit the Machine Parameter Programming

operating mode by pressing the END soft key again.

The control then continues booting.

When the control has booted up for the first time after the software update,

the internal firmware of HSCI components must be updated.The control

displays the error message Firmware update required.

After you have acknowledged the displayed error message, the control will

start the update process automatically.

Never shut down the control while the firmware is being updated –

otherwise the control will need servicing!

After the update is finished, the control displays another message on the

screen. After you have acknowledged the message, the control will shut

down automatically. Switch off the machines and restart the control.

24 HEIDENHAIN Technical Manual TNC 620

Page 25

Note

Due to a software update regarding the evaluation of parameter

Note

MP_signCorrNominalVal (400002), you must check whether the spindle

turns in the correct direction:

Check the direction of spindle rotation, and correct it if required:

After the booting process, the control displays the error message Check the

parameter for the direction of spindle rotation!.

Acknowledge the error message.

It is essential that you check now whether the spindle turns in the correct

direction. Program a function, such as M3 or M19, and observe the direction

of spindle rotation.

If required, use parameter MP_signCorrNominalVal (400002) or

MP_signCorrActualVal (400001) to define the direction of spindle rotation

correctly, see „Defining the Traverse Direction“ on page 419.

In the first TOOL CALL after the software update, the control may display

the warning Pocket table might be inconsistent. In this case, please note

the following information:

Check the pocket table and correct it if required:

Up to now, the control allowed you to enter „0“ for zero tool T0 in the

spindle pocket. This entry is no longer permissible with the new NC

software. The control issues the warning mentioned above. The column

location for the zero tool in the spindle pocket must now be empty. Proceed

as follows to correct the pocket table:

Open the pocket table and press the EDITING ON soft key.

Delete the entry "0" for zero tool T0.

November 2009 1.3 NC Software 340 551-04 / NC Software 340 560-02 25

Page 26

Note

The definition file of the symbolic programming interface API 3.0 has been

Note

expanded. You must perform the step described below in order for the PLC

program to be compiled successfully after the update.

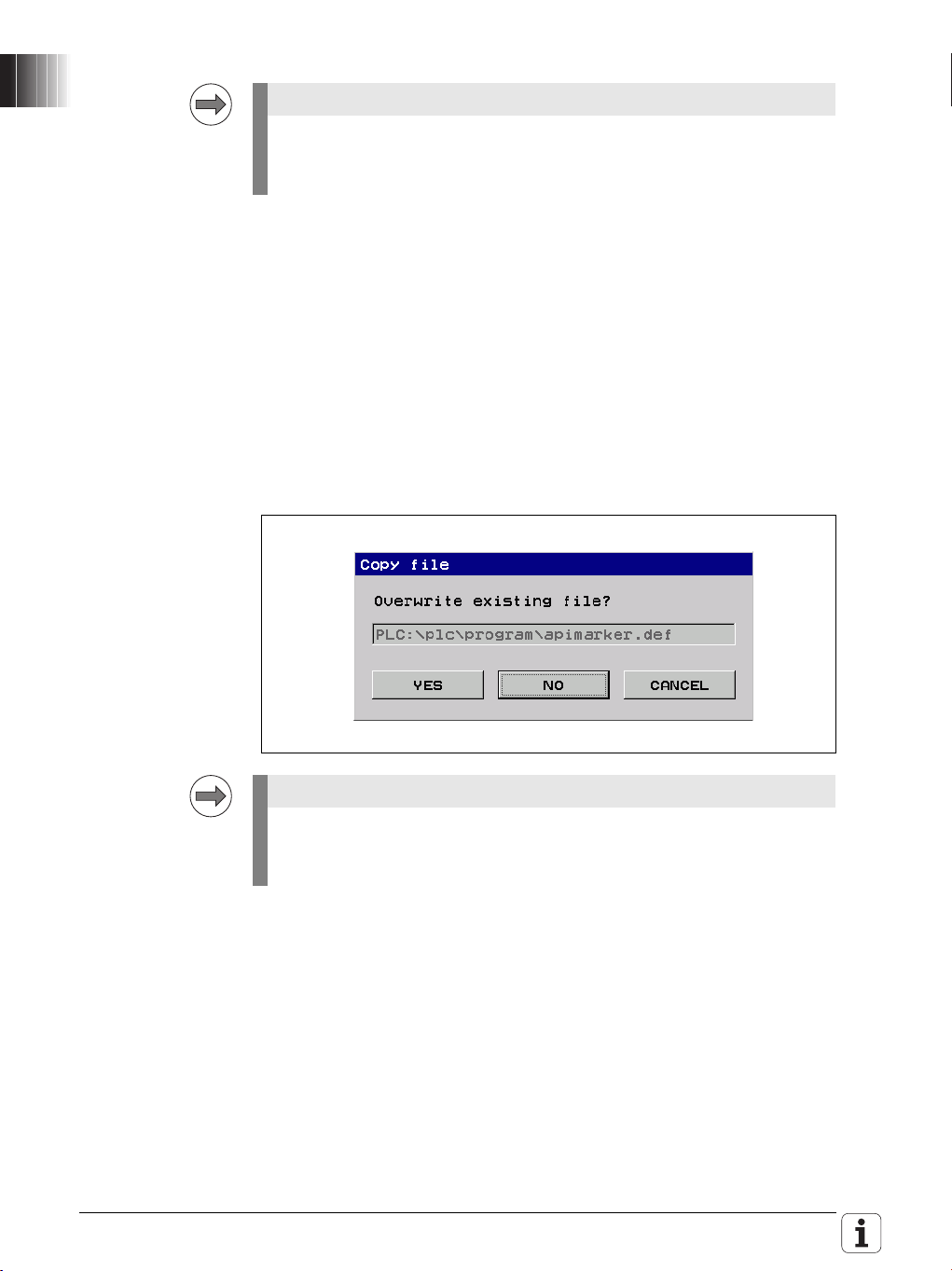

Replace the apimarker.def file:

During the update of the NC software, a new version of the apimarker.def

file was automatically copied to the PLC partition of the control. Proceed as

follows:

Switch to the Programming mode of operation.

Enter the MOD code number 807667 to switch to the PLC Programming

mode of operation.

Open the File Manager with the PGM MGT key.

Switch to the PLC:\proto\plc directory.

Copy the apimarker.def file to the program directory of your PLC program.

Overwrite the existing apimarker.def file:

Please also copy the apimarker.def file to your PC as well, and add it to the

PLCdesignNT project. Otherwise, during the next transfer of PLC project

files to the control, the file might be overwritten by the old version.

26 HEIDENHAIN Technical Manual TNC 620

Page 27

Note

Please observe the following note if you

are using the HEIDENHAIN PLC Basic Program.

It is essential that you check and modify the PLC program:

The behavior of the symbolic API marker NN_ChnProgCancel (NC program

cancellation) has been changed: NN_ChnProgCancel will now be set every

time the NC program is canceled. For a normal end of program,

NN_ChnProgEnd will be set. The NN_ChnProgCancel marker remains set

during the complete Cancel cycle and beyond the program end until the next

NC program is started.

When a program is canceled, the NN_ChnProgEnd marker will not be set.

The end of program run, including the execution of a Cancel cycle, has been

reached when NN_ChnControlInOperation is reset. NN_ChnProgCancel

and NN_ChnProgEnd will be reset when NN_ChnControlInOperation is

set again.

If both NN_ChnProgCancel and NN_ChnControlInOperation are set, this

indicates that the Cancel cycle is being executed.

Module 9429 or 9320 can be used to inquire the reason for the program

cancellation.

Please check the PLC basic program and make the following changes if

necessary:

German: Biblioth.src

;External/Internal STOP

L ApiChn.NN_ChnProgCancel

AN ML_Internal_STOP

= MG_Impuls_Internal_STOP

L ApiChn.NN_ChnProgCancel

= ML_Internal_STOP

English: Library.src

;External/Internal STOP

L ApiChn.NN_ChnProgCancel

AN ML_Internal_STOP

= MG_pulse_internal_stop

L ApiChn.NN_ChnProgCancel

= ML_Internal_STOP

November 2009 1.3 NC Software 340 551-04 / NC Software 340 560-02 27

Page 28

1.3.2 Description of the New Functions

New software

options

You can enable the following new software options by entering a code

number. HEIDENHAIN can give you the code number after having been

informed of the SIK number:

Option Description ID

#24 Gantry Axes

In gantry axes, two servo-controlled axes are coupled

so that they can only move simultaneously. The

gantry axes behave like a single drive. The main axis

is referred to as the master, and the tracking axis as

the slave.

#41 Additional Language

Enabling of additional conversational languages. The

languages listed below can be ordered. Please

contact HEIDENHAIN if you required additional

conversational languages.

Slovenian 530 184-01

Slovak 530 184-02

Latvian 530 184-03

Norwegian 530 184-04

Korean 530 184-06

Estonian 530 184-07

Turkish 530 184-08

Romanian 530 184-09

Lithuanian 530 184-10

#46 Python OEM Process

Possibility of running Python processes on the

control.

670 455-01

579 650-01

Enhanced software option:

Option Description ID

#9 Software Option 2 (only TNC 620):

If there are especially high requirements on the

surface quality, a filter for smoothing the feed rate

(MP_filterFeedTime) and two new axis-specific jerk

parameters (MP_axPathJerk and MP_axPathJerkHi)

are available.

28 HEIDENHAIN Technical Manual TNC 620

617 921-01

Page 29

Overview of the

Note

improvements

A summary of the improvements in NC software 340 551-04 and 340 560-02

is given below. For more detailed information, please refer to the Technical

Manual sections indicated in the brief descriptions given below.

Machine

Configuration

New: Search for the iTNC MP number in the configuration editor

For numerous machine parameters, the compatible iTNC MP number is

stored in the help text in the configuration editor. Up to now, it has not been

possible to search the configuration for these numbers. The search function

of the configuration editor now enables you to search for the iTNC MP

number (selection: MP number). See “Finding / Replacing” on page 236.

New: Separate parameter numbers for OEM parameters

In order for the OEM to group the parameters in the configuration editor

according to his own needs, or to make them easier to find, there is now a

separate number range for the OEM. Numbers 900000 to 999999 are

reserved for the OEM. For those parameters for which an OEM number is

defined, this number is shown instead of the HEIDENHAIN number. The

numbers are to be defined in the

%OEM%\config\layout\PlcUniqueNumbers.xml file. If the file is missing or

empty, no OEM numbers will be displayed. For more information, see „User

Parameters“ on page 257

Expanded: OEM motor table (only digital control, TNC 620)

Until now, if the OEM-specific motor table (path:

PLC:\table\motor_oem.mot) was missing, a warning was issued and the

user had to create the table himself. Now no warning will be issued. The

control itself creates a new blank table as soon as the MP_motName

(401301) parameter is edited. If the OEM motor table exists but columns are

missing, then the columns that exist in the SYS motor table will be added

when copying. The control indicates which columns were not copied.

Expanded: Saving update rules

If the user tries to exit the configuration editor without saving the changes

made by the update rules, a dialog window appears prompting the user to

save the data. The configuration editor cannot be exited until the data are

saved, see "Update rules" on page 245.

The first restart of the control after the update cannot be continued without

saving the configuration changes made by the update rules.

November 2009 1.3 NC Software 340 551-04 / NC Software 340 560-02 29

Page 30

Machine

parameters

new/expanded/

changed

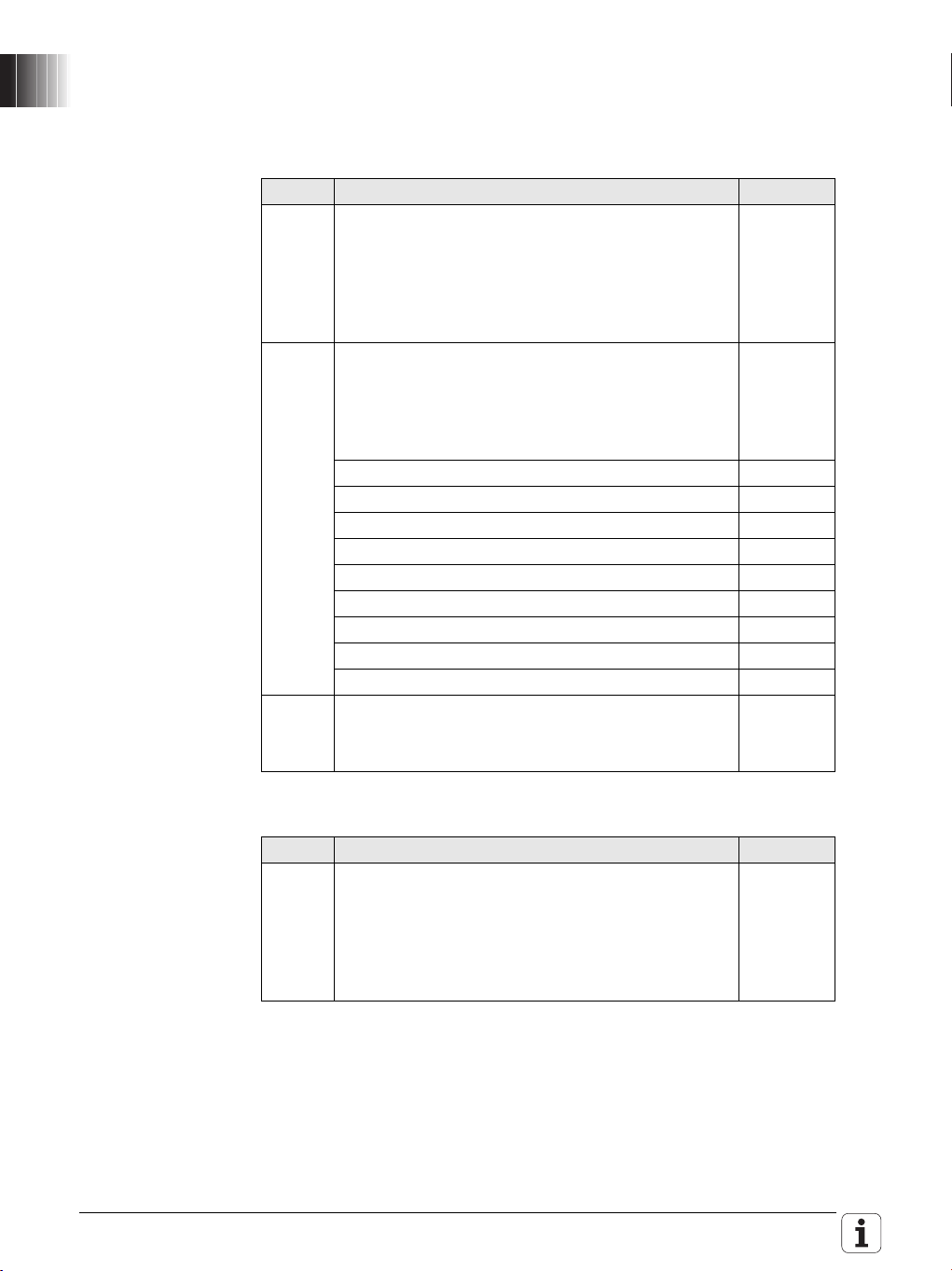

MP number Config object Parameter Description of change

100201 CfgMachineSimul MP_simMode When the new value Delivery is

102902 CfgFileType MP_standardEditor "TEXT-EDITOR“ can now be selected

103502 CfgPlcTimer MP_value The input range of the parameter was

104300

104400

105201 CfgSystemTime MP_offsetToUTC Values with decimal places can now

114103 CfgTool

201203 CfgRotWorkPlane MP_planeCalcMode Parameter removed – obsolete

CfgPlcOverrideDev

CfgPlcOverrideS

Measurement

Expanded/changed machine parameters

set, during startup of the control all

axes are set to the test mode, and a

switch-on of the axes is prevented.

The user should then be able to

start the control, even with an

incomplete or faulty axis

configuration in order to put the

axes into operation. After the

configuration of all axes has been

completed, the control can be

switched to full operation

(FullOperation).

If Delivery, CcAndExt or CcOnly is

set, the control now no longer

outputs any analog nominal values.

in order to assign the ASCII editor of

the control to a file type.

expanded from 1 000 to 1 000 000

seconds (corresponds to approx. 11.5

days).

– The reaction of the parameters under

CfgPlcOverrideDev, CfgPlcOverrideS,

CfgPlcOverrideF and

CfgPlcOverrideR was changed from

NOTHING to RESET. The control

must now be rebooted after a

parameter change.

be entered for time differences to

universal time (GMT). This is

necessary for parts of Australia (+8.5

and +9.5 hours) and Kazakhstan (+3.5

hours), for example. Also, the

maximum value was extended from

+13 to +14 [hours].

MP_probingDirRadial The parameter defines the probing

direction for tool radius

measurement. Z_Positive and

Z_Negative can now also be selected,

because the control now also

supports mounting the TT tool touch

probe in these axis directions, see

page 1024.

30 HEIDENHAIN Technical Manual TNC 620

Page 31

MP number Config object Parameter Description of change

201205 CfgRotWorkPlane MP_autoMoveAxes Parameter MP_autoPosOfRotAxes

was renamed to MP_autoMoveAxes.

Extended description, see page 514

400011 CfgAxisHardware MP_posEncoder

Resistor

New machine parameters:

MP number Config object Parameter Description

101608 CfgShutDown MP_powerOffDevice Optional parameter – Number of a

101609 MP_powerOffSlot Optional parameter - Slot number of

102907 CfgFileType MP_protect Disables filtering or editing of a file

104018 CfgPlcSStrobe MP_cuttingSpeed Optional parameter – If parts of the

105409 CfgEditorSettings MP_blockIncrement Setting the block number increment

105410 MP_useProgAxes Specifies which axis configuration is

105411 MP_enableStraightCut This optional parameter is used to

114205 CfgTTRoundStylus MP_stylusAxis This optional parameter is used to

The default value of the parameter

was changed from without to

120 ohm.

device in the HSCI string (PL, MB) on

which the control is to set an output

during shutdown, see page 908.

the HSCI device specified in

MP_powerOffDevice on which the

control is to set the output after

shutdown, see page 908.

type, see page 1252.

configuration indicate the symbolic

name or number of a word marker to

which the cutting speed is copied.

of ISO programs between 0 and 250.

Extended description, see page 815.

used in the Programming mode of

operation. Extended description, see

page 816

enable (TRUE) or disable (FALSE)

paraxial positioning blocks. As a

default, paraxial positioning blocks are

allowed. Extended description, see

page 816

specify the orientation of the TT tool

touch probe in the working space, see

page 1027.

November 2009 1.3 NC Software 340 551-04 / NC Software 340 560-02 31

Page 32

MP number Config object Parameter Description

106501 CfgConfigSettings MP_undoListSize Defines the number of entries in the

parameter change list, see page 235.

106502 MP_suppressUsrMsg This parameter is used to suppress

the warning Key is non-functional,

see page 870.

106503 MP_dispParam

Numbers

106504 MP_hideWrite

Protected

116601 CfgDiagnosis MP_osTraceFileSize Maximum log file size for diagnostic

116602 MP_tcpTraceFileSize Maximum log file size for diagnostic

116603 MP_krnlTraceFileSize Maximum log file size for diagnostic

116604 MP_traceDir Target directory for log files, see page

116605 MP_ncTraceFileSize File size for diagnostic messages

201206 CfgRotWorkPlane MP_rotPreference Cycle 19 and Plane function: Define

201513 CfgLaPath MP_filterFeedTime Time constant of the filter for

201719 CfgPlcToolChange MP_sequText Script for tool-change sequence.

201720 MP_sequTint Script for tool-change sequence.

202904 CfgKinCompos

Model

300205 CfgAxisPropKin MP_parAxComp Definition of compensation for parallel

401414 CfgController

Comp

MP_tiltingAllowed This optional parameter is used to

MP_compSwitchOff TRC (Torque Ripple Compensation)

Specifies whether MP numbers or

symbolic names are displayed in the

parameter change list, see page 235.

If the parameter is set to TRUE,

write-protected parameters are

hidden in the configuration editor, see

page 244.

messages of the operating system,

see page 869.

messages of the network, see page

869.

messages of NC kernel, see page

870.

868

from the NC software, see page 869

the realization of the tilt position.

Extended description, see page 515

smoothing the feed rate (software

option 2), see page 584.

Defines the tool-change sequence for

calling an external tool without

loading it in the spindle

Defines the tool-change sequence for

calling an internal tool without loading

it in the spindle

define whether tilting the working

plane is allowed for the kinematics

model, see page 498.

minor axes, see page 518.

can be switched off by setting bit 0,

see page 668.

32 HEIDENHAIN Technical Manual TNC 620

Page 33

MP number Config object Parameter Description

401703 CfgLaAxis MP_axPathJerk (only software option 2)

Axis-specific maximum jerk on the

path. This value limits the jerk in

traverse direction, see page 568

401704 MP_axPathJerkHi (only software option 2)

Axis-specific maximum jerk on the

path for feed rates greater than

MP_maxG1Feed, see page 568.

402301 CfgAxisCoupling MP_masterAxis Synchronized axes: Assign a master

axis to the slave axis, see page 525.

402302 MP_mode Synchronized axes: Mode of the

coupling, see page 525.

402303 MP_type Synchronized axes: Type of coupling,

see page 525.