Page 1

GAGE-CHEK 2000

Operating Instructions

Evaluation Unit

English (en)

12/2018

Page 2

Contents

Contents

1 Fundamentals..................................................................................................................................11

2 Safety...............................................................................................................................................21

3 Transport and storage....................................................................................................................27

4 Mounting......................................................................................................................................... 33

5 Installation.......................................................................................................................................39

6 Basic operation...............................................................................................................................51

7 Commissioning............................................................................................................................... 73

8 Setup..............................................................................................................................................107

9 Measuring......................................................................................................................................137

10 File management..........................................................................................................................147

11 Settings..........................................................................................................................................155

12 Service and maintenance............................................................................................................191

13 What to do if ............................................................................................................................... 199

14 Removal and disposal..................................................................................................................205

15 Specifications................................................................................................................................207

16 Index...............................................................................................................................................213

17 List of figures................................................................................................................................215

2

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 3

Contents

1 Fundamentals..................................................................................................................................11

1.1 Overview............................................................................................................................................... 12

1.2 Information on the product................................................................................................................ 12

1.3 Demo software for the product..........................................................................................................12

1.4 Documentation on the product..........................................................................................................13

1.4.1 Validity of the documentation..................................................................................................13

1.4.2 Notes on reading the documentation......................................................................................14

1.4.3 Storage and distribution of the documentation.......................................................................15

1.5 About these instructions.....................................................................................................................15

1.5.1 Document category................................................................................................................. 15

1.5.2 Target groups for the instructions........................................................................................... 15

1.5.3 Target groups according to user types....................................................................................16

1.5.4 Contents of the chapters.........................................................................................................16

1.5.5 Notes in this documentation................................................................................................... 18

1.5.6 Symbols and fonts used for marking text............................................................................... 19

2 Safety...............................................................................................................................................21

2.1 Overview............................................................................................................................................... 22

2.2 General safety precautions................................................................................................................. 22

2.3 Intended use......................................................................................................................................... 22

2.4 Improper use........................................................................................................................................ 23

2.5 Personnel qualification........................................................................................................................ 23

2.6 Obligations of the operating company..............................................................................................24

2.7 General safety precautions................................................................................................................. 24

2.7.1 Symbols on the product.......................................................................................................... 24

2.7.2 Electrical safety precautions....................................................................................................25

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

3

Page 4

Contents

3 Transport and storage....................................................................................................................27

3.1 Overview............................................................................................................................................... 28

3.2 Unpacking............................................................................................................................................. 28

3.3 Items supplied and accessories..........................................................................................................28

3.3.1 Items supplied......................................................................................................................... 28

3.3.2 Accessories..............................................................................................................................29

3.4 In case of damage in transit...............................................................................................................31

3.5 Repackaging and storage....................................................................................................................32

3.5.1 Repackaging the product.........................................................................................................32

3.5.2 Storage of the product............................................................................................................ 32

4 Mounting......................................................................................................................................... 33

4.1 Overview............................................................................................................................................... 34

4.2 Assembly of the product.................................................................................................................... 34

4.2.1 Mounting on Multi-Pos stand.................................................................................................. 36

4.2.2 Mounting on Multi-Pos holder.................................................................................................37

5 Installation.......................................................................................................................................39

5.1 Overview............................................................................................................................................... 40

5.2 General information............................................................................................................................. 40

5.3 Product overview................................................................................................................................. 41

5.4 Connecting encoders........................................................................................................................... 43

5.5 Connecting touch probes.................................................................................................................... 44

5.6 Wiring switching inputs and outputs................................................................................................ 45

5.7 Connecting a printer............................................................................................................................47

5.8 Connecting input devices....................................................................................................................48

5.9 Connecting a network peripheral.......................................................................................................48

5.10 Connecting the line voltage................................................................................................................49

4

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 5

Contents

6 Basic operation...............................................................................................................................51

6.1 Overview............................................................................................................................................... 52

6.2 Using the touchscreen and input devices......................................................................................... 52

6.2.1 Touchscreen and input devices............................................................................................... 52

6.2.2 Gestures and mouse actions...................................................................................................52

6.3 General operating elements and functions.......................................................................................54

6.4 GAGE-CHEK 2000 – switch-on and switch-off.................................................................................. 56

6.4.1 Switching on GAGE-CHEK 2000..............................................................................................56

6.4.2 Activating and deactivating the energy saving mode..............................................................56

6.4.3 Switching off GAGE-CHEK 2000...............................................................................................57

6.5 User login and logout......................................................................................................................... 57

6.5.1 User login.................................................................................................................................58

6.5.2 User logout.............................................................................................................................. 58

6.6 Setting the language........................................................................................................................... 59

6.7 Performing the reference mark search after startup........................................................................ 59

6.8 User interface....................................................................................................................................... 60

6.8.1 User interface after switch-on................................................................................................. 60

6.8.2 Main menu of the user interface............................................................................................ 61

6.8.3 Measure menu.........................................................................................................................62

6.8.4 File management menu...........................................................................................................63

6.8.5 User login menu...................................................................................................................... 64

6.8.6 Settings menu..........................................................................................................................65

6.8.7 Switch-off menu....................................................................................................................... 66

6.9 Position display.................................................................................................................................... 66

6.9.1 Operating elements of the position display............................................................................ 66

6.10 Working in the workspace..................................................................................................................67

6.10.1 Adjusting the display of the workspace.................................................................................. 67

6.11 Using the Inspector............................................................................................................................. 68

6.11.1 Operating elements of the Inspector...................................................................................... 68

6.11.2 Function elements................................................................................................................... 68

6.11.3 Adjusting settings in the quick access menu..........................................................................69

6.12 Messages and audio feedback............................................................................................................70

6.12.1 Messages.................................................................................................................................70

6.12.2 Wizard...................................................................................................................................... 71

6.12.3 Audio feedback.........................................................................................................................72

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

5

Page 6

Contents

7 Commissioning............................................................................................................................... 73

7.1 Overview............................................................................................................................................... 74

7.2 Logging in for commissioning............................................................................................................74

7.2.1 User login.................................................................................................................................74

7.2.2 Performing the reference mark search after startup............................................................... 75

7.2.3 Setting the language................................................................................................................75

7.2.4 Changing the password...........................................................................................................76

7.3 Steps for commissioning.................................................................................................................... 76

7.3.1 Basic settings...........................................................................................................................76

7.3.2 Configuring the axes................................................................................................................81

7.3.3 Configuring a touch probe..................................................................................................... 100

7.4 OEM area............................................................................................................................................ 101

7.4.1 Adding documentation...........................................................................................................101

7.4.2 Adding a startup screen........................................................................................................ 102

7.4.3 Configuring the unit for screenshots.....................................................................................103

7.5 Back up settings.................................................................................................................................104

7.6 Back up user files...............................................................................................................................104

8 Setup..............................................................................................................................................107

8.1 Overview............................................................................................................................................. 108

8.2 Logging in for setup.......................................................................................................................... 108

8.2.1 User login...............................................................................................................................108

8.2.2 Performing the reference mark search after startup............................................................. 109

8.2.3 Setting the language..............................................................................................................109

8.2.4 Changing the password.........................................................................................................110

8.3 Single steps for setup....................................................................................................................... 110

8.3.1 Basic settings.........................................................................................................................110

8.3.2 Adding function elements......................................................................................................123

8.3.3 Creating a preset table.......................................................................................................... 124

8.3.4 Configuring the MinMax function..........................................................................................126

8.3.5 Configuring the measured value output................................................................................ 127

8.4 Back up settings.................................................................................................................................135

8.5 Back up user files...............................................................................................................................136

6

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 7

Contents

9 Measuring......................................................................................................................................137

9.1 Overview............................................................................................................................................. 138

9.2 Conducting a measurement............................................................................................................. 138

9.2.1 Preparing a measurement..................................................................................................... 138

9.2.2 Selecting a preset..................................................................................................................140

9.2.3 Measuring lengths and angles.............................................................................................. 142

9.2.4 Measuring with a touch probe.............................................................................................. 143

9.2.5 Capturing the minimum, maximum, and range.....................................................................144

9.2.6 Sending measured values to a computer..............................................................................145

10 File management..........................................................................................................................147

10.1 Overview............................................................................................................................................. 148

10.2 File types.............................................................................................................................................149

10.3 Managing folders and files............................................................................................................... 149

10.4 Opening and viewing files................................................................................................................ 152

10.5 Exporting files.................................................................................................................................... 153

10.6 Importing files.................................................................................................................................... 154

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

7

Page 8

Contents

11 Settings..........................................................................................................................................155

11.1 Overview............................................................................................................................................. 156

11.1.1 Overview of the Settings menu............................................................................................ 157

11.2 General................................................................................................................................................ 158

11.2.1 Device information.................................................................................................................158

11.2.2 Screen.................................................................................................................................... 158

11.2.3 Display....................................................................................................................................159

11.2.4 Input devices..........................................................................................................................159

11.2.5 Sounds................................................................................................................................... 160

11.2.6 Printers................................................................................................................................... 160

11.2.7 Properties............................................................................................................................... 161

11.2.8 Add printer............................................................................................................................. 161

11.2.9 Remove printer...................................................................................................................... 162

11.2.10 Date and time........................................................................................................................162

11.2.11 Units.......................................................................................................................................163

11.2.12 Copyrights.............................................................................................................................. 164

11.2.13 Service info............................................................................................................................164

11.2.14 Documentation.......................................................................................................................164

11.3 Sensors................................................................................................................................................165

11.3.1 Touch probe............................................................................................................................165

11.4 Interfaces.............................................................................................................................................166

11.4.1 Network..................................................................................................................................166

11.4.2 Network drive........................................................................................................................ 167

11.4.3 USB........................................................................................................................................ 168

11.4.4 RS-232....................................................................................................................................168

11.4.5 Data transfer.......................................................................................................................... 169

11.4.6 Wireless LAN hotspot........................................................................................................... 169

11.4.7 Switching functions................................................................................................................170

11.5 User......................................................................................................................................................171

11.5.1 OEM....................................................................................................................................... 171

11.5.2 Setup...................................................................................................................................... 172

11.5.3 Operator................................................................................................................................. 173

11.5.4 Adding a User........................................................................................................................ 173

11.6 Axes..................................................................................................................................................... 174

11.6.1 Reference marks....................................................................................................................174

11.6.2 Information............................................................................................................................. 175

11.6.3 Error compensation................................................................................................................175

11.6.4 Nonlinear error compensation (NLEC)................................................................................... 176

11.6.5 Squareness error compensation (SEC)..................................................................................176

11.6.6 Axes X, Y .............................................................................................................................. 177

11.6.7 Axis Q.................................................................................................................................... 177

8

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 9

Contents

11.6.8 Encoder.................................................................................................................................. 178

11.6.9 Reference marks (Encoder)....................................................................................................182

11.6.10 Reference point displacement............................................................................................... 183

11.6.11 Linear error compensation (LEC)...........................................................................................183

11.6.12 Segmented linear error compensation (SLEC)...................................................................... 184

11.6.13 Create table of supporting points..........................................................................................184

11.7 Service................................................................................................................................................. 185

11.7.1 Firmware information.............................................................................................................185

11.7.2 Back up and restore.............................................................................................................. 186

11.7.3 Firmware update....................................................................................................................187

11.7.4 Reset......................................................................................................................................187

11.7.5 OEM area...............................................................................................................................188

11.7.6 Documentation.......................................................................................................................188

11.7.7 Software options....................................................................................................................189

12 Service and maintenance............................................................................................................191

12.1 Overview............................................................................................................................................. 192

12.2 Cleaning...............................................................................................................................................192

12.3 Maintenance plan...............................................................................................................................193

12.4 Resuming operation...........................................................................................................................193

12.5 Updating the firmware......................................................................................................................194

12.6 Restore settings................................................................................................................................. 196

12.7 Restore user files............................................................................................................................... 197

12.8 Reset all settings................................................................................................................................198

12.9 Reset to shipping conditions............................................................................................................198

13 What to do if ............................................................................................................................... 199

13.1 Overview............................................................................................................................................. 200

13.2 System or power failure....................................................................................................................200

13.2.1 Restoring the firmware..........................................................................................................200

13.2.2 Restore settings.....................................................................................................................201

13.3 Malfunctions....................................................................................................................................... 201

13.3.1 Troubleshooting...................................................................................................................... 202

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

9

Page 10

Contents

14 Removal and disposal..................................................................................................................205

14.1 Overview............................................................................................................................................. 206

14.2 Removal...............................................................................................................................................206

14.3 Disposal...............................................................................................................................................206

15 Specifications................................................................................................................................207

15.1 Overview............................................................................................................................................. 208

15.2 Product data....................................................................................................................................... 208

15.3 Product dimensions and mating dimensions................................................................................. 210

15.3.1 Product dimensions with Duo-Pos stand.............................................................................. 211

15.3.2 Product dimensions with Multi-Pos stand.............................................................................211

15.3.3 Product dimensions with Multi-Pos holder............................................................................212

16 Index...............................................................................................................................................213

17 List of figures................................................................................................................................215

10

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 11

1

Fundamentals

Page 12

1

GAGE-CHEK xxxx

2

3

1

Fundamentals | Overview

1.1 Overview

This chapter contains information about the product and these instructions.

1.2 Information on the product

Product designation ID Firmware version Index

GAGE-CHEK 2000 1089181-xx 1248580.1.0.x ---

The ID label is provided on the back of the product.

Example:

1

Product designation

2

Index

3

Part number (ID)

1.3 Demo software for the product

GAGE-CHEK 2000 Demo is software you can install on a computer independently

of the device. GAGE-CHEK 2000 Demo helps you to become familiar with, try out

or present the functions of the device.

You can download the current version of the software here: www.heidenhain.de

To download the installation file from the HEIDENHAIN Portal, you

need access rights to the Software portal folder in the directory of the

appropriate product.

If you do not have access rights to the Portal's Software folder, you can

request the access rights from your HEIDENHAIN contact person.

12

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 13

Fundamentals | Documentation on the product

1.4 Documentation on the product

1.4.1 Validity of the documentation

Before using the documentation and the product, you need to verify that the

documentation matches the product.

Compare the ID number and the index indicated in the documentation with the

corresponding data given on the ID label of the product

Compare the firmware version given in the documentation with the firmware

version of the product

Further information: "Device information", Page 158

If the ID numbers and indexes as well as the firmware versions match, the

documentation is valid

If the ID numbers and indexes do not match, so that the documentation

is not valid, you will find the current documentation for the product at

www.heidenhain.de.

1

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

13

Page 14

1

Fundamentals | Documentation on the product

1.4.2 Notes on reading the documentation

WARNING

Fatal accidents, personal injury or property damage caused by noncompliance with the documentation!

Failure to comply with the documentation may result in fatal accidents, personal

injury or property damage.

Read the documentation carefully from beginning to end

Keep the documentation for future reference

The table below lists the components of the documentation in the order of priority

for reading.

Documentation Description

Addendum An addendum supplements or supersedes

the corresponding contents of the Operating

Instructions and, if applicable, of the Installation

Instructions.

If an addendum is included in the shipment, it has

the highest priority for reading. All other contents

of the documentation retain their validity.

Installation Instructions The Installation Instructions contain all of the infor-

mation and safety precautions needed for the

proper mounting and installation of the product.

The Installation Instructions are contained as an

excerpt from the Operating Instructions in every

delivery.

The Installation Instructions have the second

highest level of priority for reading.

Operating Instructions The Operating Instructions contain all the infor-

mation and safety precautions needed for the

proper operation of the product according to its

intended use. The Operating Instructions are

included on the supplied storage medium and can

also be downloaded in the download area from

www.heidenhain.de. The Operating Instructions

must be read before the unit is put into service.

The Operating Instructions have the third highest

level of priority for reading.

14

Have you found any errors or would you like to suggest changes?

We are continuously striving to improve our documentation for you. Please help us

by sending your suggestions to the following e-mail address:

userdoc@heidenhain.de

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 15

Fundamentals | Documentation on the product

1.4.3 Storage and distribution of the documentation

The instructions must be kept in the immediate vicinity of the workplace and must

be available to all personnel at all times. The operating company must inform the

personnel where these instructions are kept. If the instructions have become

illegible, the operating company must obtain a new copy from the manufacturer.

If the product is given or resold to any other party, the following documents must

be passed on to the new owner:

Addendum (if supplied)

Installation Instructions

Operating Instructions

1.5 About these instructions

These instructions provide all the information and safety precautions needed for

the safe operation of the product.

1

1.5.1 Document category

Operating Instructions

These instructions are the Operating Instructions for the product.

The Operating Instructions

Are oriented to the product life cycle

Contain all information and safety precautions needed for the proper operation

of the product according to its intended use

1.5.2 Target groups for the instructions

These instructions must be read and observed by every person who performs any

of the following tasks:

Mounting

Installation

Commissioning and configuration

Operation

Service, cleaning and maintenance

Troubleshooting

Removal and disposal

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

15

Page 16

1

Fundamentals | About these instructions

1.5.3 Target groups according to user types

The target groups of these instructions refer to the various user types of the

product and their authorizations.

The product features the following user types:

OEM user

The OEM (Original Equipment Manufacturer) user has the highest level of

permissions. This user is allowed to configure the product's hardware (e.g.

connection of encoders and sensors). He can create Setup and Operator-type

users, and configure the Setup and Operator users. The OEM user cannot be

duplicated or deleted. This user cannot be logged in automatically.

Setup user

The Setup user configures the product for use at the place of operation. This user

can create Operator-type users. The Setup user cannot be duplicated or deleted.

This user cannot be logged in automatically.

Operator user

The Operator user is permitted to use the basic functions of the product.

An Operator-type user cannot create additional users, but is allowed to edit

various operator-specific settings, such as his name or the language. A user of the

Operator group can be logged in automatically as soon as the product is switched

on.

1.5.4 Contents of the chapters

The table below shows:

from which chapters these instructions are derived from

which information the chapters of the instructions contain

to which target groups the chapters of the instructions mainly apply

Section Contents

1 "Fundamentals"

This chapter contains information about…

... this product

... these instructions

Target

group

OEM

Setup

✓ ✓ ✓

Operator

16

2 "Safety"

3 "Transport and storage"

4 "Mounting"

5 "Installation"

... Safety regulations and safety measures

for mounting the product

for installing the product

for operating the product

... transporting the product

... storing the product

... items supplied with the product

... accessories for the product

... correct mounting of the product

... correct installation of the product

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

✓ ✓ ✓

✓ ✓

✓ ✓

✓ ✓

Page 17

Fundamentals | About these instructions

1

Section Contents

This chapter contains information about…

... the operating elements of the product user

6 "Basic operation"

7 "Commissioning"

8 "Setup"

9 "Measuring"

10 "File management"

11 "Settings"

12 "Service and

maintenance"

interface

... the user interface of the product

... basic functions of the product

... commissioning the product

... correct setup of the product

... the performance of a measurement

... the transmission of measured values to a computer

(measured value output)

... the functions of the "File management" menu

... setting options and associated setting parameters

for the product

... general maintenance work on the product

Target

group

OEM

Setup

✓ ✓ ✓

✓

✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

Operator

✓

13 "What to do if ..."

14 "Removal and disposal"

15 "Specifications"

16 "Index"

... causes of faults or malfunctions of the product

... corrective actions for faults or malfunctions of the

product

... disassembly and disposal of the product

... environment protection specifications

... the technical data of the product

... product dimensions and mating dimensions

(drawings)

This chapter enables accessing the content of these

instructions according to specific topics.

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

17

Page 18

1

Fundamentals | About these instructions

1.5.5 Notes in this documentation

Safety precautions

Precautionary statements warn of hazards in handling the product and provide

information on their prevention. Precautionary statements are classified by hazard

severity and divided into the following groups:

DANGER

Danger indicates hazards for persons. If you do not follow the avoidance

instructions, the hazard will result in death or severe injury.

WARNING

Warning indicates hazards for persons. If you do not follow the avoidance

instructions, the hazard could result in death or serious injury.

CAUTION

Caution indicates hazards for persons. If you do not follow the avoidance

instructions, the hazard could result in minor or moderate injury.

NOTICE

Notice indicates danger to material or data. If you do not follow the avoidance

instructions, the hazard could result in things other than personal injury,

such as property damage.

Informational notes

Informational notes ensure reliable and efficient operation of the product.

Informational notes are divided into the following groups:

The information symbol indicates a tip.

A tip provides additional or supplementary information.

The gear symbol indicates that the function described depends on the

machine, e.g.

Your machine must feature a certain software or hardware option

The behavior of the functions depends on the configurable machine

settings

18

The book symbol represents a cross reference to external

documentation, e.g. the documentation of your machine tool builder or

other supplier.

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 19

Fundamentals | About these instructions

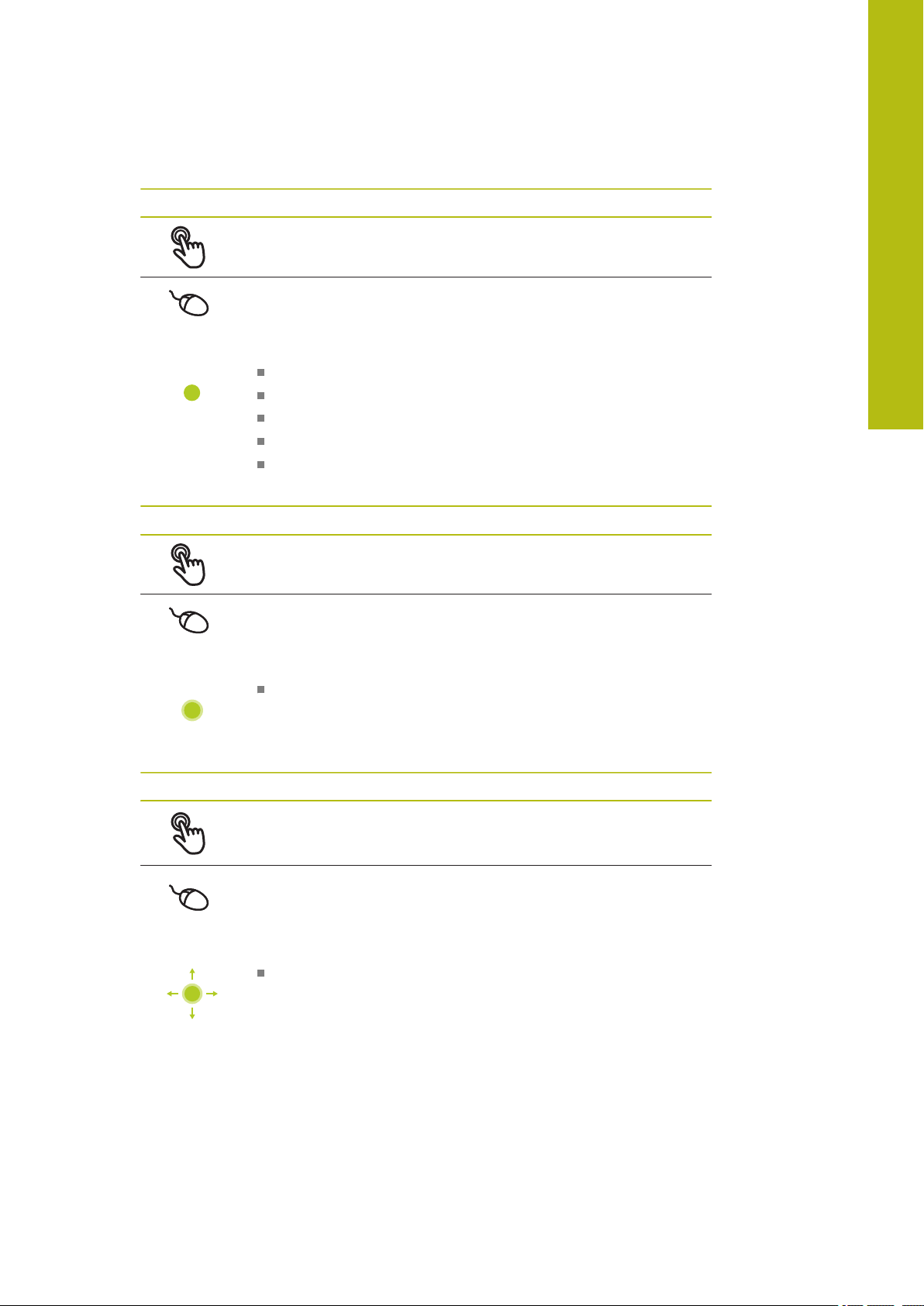

1.5.6 Symbols and fonts used for marking text

In these instructions the following symbols and fonts are used for marking text:

Depiction Meaning

1

Bold

...

...

...

...

Identifies an action and the result of this action

Example:

Tap OK

The message is closed

Identifies an item of a list

Example:

TTL interface

EnDat interface

...

Identifies menus, displays and buttons

Example:

Tap Shut down

The operating system shuts down

Turn the power switch off

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

19

Page 20

Page 21

2

Safety

Page 22

2

Safety | Overview

2.1 Overview

This chapter provides important safety information needed for the proper operation

of the unit.

2.2 General safety precautions

General accepted safety precautions, in particular the applicable precautions

relating to the handling of live electrical equipment, must be followed when

operating the system. Failure to observe these safety precautions may result in

personal injury or damage to the product.

It is understood that safety rules within individual companies vary. If a conflict

exists between the material contained in these instructions and the rules of a

company using this system, the more stringent rules take precedence.

2.3 Intended use

The products of the GAGE-CHEK 2000 series are advanced digital evaluation

electronics for the measurement of exact measured values and for positioning

tasks in metrology applications. The products are used primarily on measuring

machines, and positioning equipment.

The products of this series

must only be used in commercial applications and in an industrial environment

must be mounted on a suitable stand or holder to ensure the correct and

intended operation of the product

are intended for indoor use in an environment in which the contamination

caused by humidity, dirt, oil and lubricants complies with the requirements of

the specifications

The products support the use of peripheral devices from different

manufacturers. HEIDENHAIN cannot make any statements on the

intended use of these devices. The information on their intended use,

which is provided in the respective documentation, must be observed.

22

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 23

Safety | Improper use

2.4 Improper use

In particular, the products of the GAGE-CHEK 2000 series must not be used in the

following applications:

Use and storage outside the operating conditions specified in "Specifications"

Outdoor use

Use in potentially explosive atmospheres

Use of the products of the GAGE-CHEK 2000 series as part of a safety function

2.5 Personnel qualification

The personnel for mounting, installation, operation, service, maintenance and

removal must be appropriately qualified for this work and must have obtained

sufficient information from the documentation supplied with the product and with

the connected peripherals.

The personnel required for the individual activities to be performed on the product

are indicated in the respective sections of these instructions.

The personnel groups are specified in detail as follows with regard to their

qualifications and tasks.

2

Operator

The operator uses and operates the product within the framework specified for the

intended use. He is informed by the operating company about the special tasks

and the potential hazards resulting from incorrect behavior.

Qualified personnel

The qualified personnel are trained by the operating company to perform advanced

operation and parameterization. The qualified personnel have the required technical

training, knowledge and experience and know the applicable regulations, and are

thus capable of performing the assigned work regarding the application concerned

and of proactively identifying and avoiding potential risks.

Electrical specialist

The electrical specialist has the required technical training, knowledge and

experience and knows the applicable standards and regulations, and is thus

capable of performing work on electrical systems and of proactively identifying and

avoiding potential risks. Electrical specialists have been specially trained for the

environment they work in.

Electrical specialists must comply with the provisions of the applicable legal

regulations on accident prevention.

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

23

Page 24

2

Safety | Obligations of the operating company

2.6 Obligations of the operating company

The operating company owns or leases the product and the peripherals. At all

times, the operating company is responsible for ensuring that the intended use is

complied with.

The operating company must:

Assign the different tasks to be performed on the product to suitable, qualified

and authorized personnel

Verifiably train the personnel in the authorizations and tasks

Provide all materials and means necessary in order for the personnel to

complete the assigned tasks

Ensure that the product is operated only when in perfect technical condition

Ensure that the product is protected from unauthorized use

2.7 General safety precautions

The safety of any system incorporating the use of this product is the

responsibility of the assembler or installer of the system.

The product supports the use of a wide variety of peripheral devices

from different manufacturers. HEIDENHAIN cannot make any

statements on the specific safety precautions to be taken for

these devices. The safety precautions provided in the respective

documentation must be observed. If there is no documentation at

hand, it must be obtained from the manufacturers concerned.

The specific safety precautions required for the individual activities to be

performed on the product are indicated in the respective sections of these

instructions.

2.7.1 Symbols on the product

The following symbols are used to identify the product:

Symbol Meaning

Observe the safety precautions regarding electricity and the

power connection before you connect the product.

24

Functional ground connection as per IEC/EN 60204-1. Observe

the information on installation.

Product seal. Breaking or removing the product seal will result

in forfeiture of warranty and guarantee.

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 25

Safety | General safety precautions

2.7.2 Electrical safety precautions

Hazard of contact with live parts when opening the unit.

This may result in electric shock, burns or death.

Never open the housing

Only the manufacturer is permitted to access the inside of the product

Hazard of dangerous amount of electricity passing through the human

body upon direct or indirect contact with live electrical parts.

This may result in electric shock, burns or death.

2

WARNING

WARNING

Work on the electrical system and live electrical components is to be

performed only by trained specialists

For power connection and all interface connections, use only cables and

connectors that comply with applicable standards

Have the manufacturer exchange defective electrical components

immediately

Regularly inspect all connected cables and all connections on the product.

Defects, such as loose connections or scorched cables, must be removed

immediately

NOTICE

Damage to internal parts of the product!

If you open the product, the warranty and the guarantee will be void.

Never open the housing

Only the product manufacturer is permitted to access the inside of the

product

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

25

Page 26

Page 27

3

Transport and

storage

Page 28

3

Transport and storage | Overview

3.1 Overview

This chapter contains information on the transportation and storage of the product

and provides an overview of the items supplied and the available accessories for

the product.

The following steps must be performed only by qualified personnel.

Further information: "Personnel qualification", Page 23

3.2 Unpacking

Open the top lid of the box

Remove the packaging materials

Unpack the contents

Check the delivery for completeness

Check the delivery for damage

3.3 Items supplied and accessories

3.3.1 Items supplied

The following items are included in delivery:

Name Description

Addendum (optional) Supplements or supersedes the contents of

the Operating Instructions and, if applicable,

of the Installation Instructions.

Operating Instructions PDF issue of the Operating Instructions on

a memory medium in the currently available

languages

Product Evaluation Unit GAGE-CHEK 2000

Installation Instructions Printed issue of the Installation Instructions

in the currently available languages

28

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 29

Transport and storage | Items supplied and accessories

3.3.2 Accessories

Software options need to be enabled on the product via a license key.

Before you can use the associated hardware components, you need to

enable the respective software option.

Further information: "Activating the Software options", Page 78

The following accessories are optionally available and can be ordered from

HEIDENHAIN:

3

Accessories

For operation

For installation

Name Description ID

GAGE-CHEK 2000 AEI1

software option

GAGE-CHEK 2000 AEI1

Trial software option

Foot switch Foot switch for external

KT 130 edge finder Touch probe for probing

Power cable Power cable with European

RS-232 connecting cable RS-232 connecting cable,

Enabling of an additional

encoder input

Enabling of an additional

encoder input, test version

for a limited time (60 days)

operation with two freely

assignable keys; cable

length 2.4 m

a workpiece (for setting

presets)

plug (type F), length: 3 m

complete with two 9-pin Dsub connectors (female)

1089226-01

1089226-51

681041-04

283273-xx

223775-01

366964-xx

Adapter cable for touchprobe connection, DIN 5pin female

Adapter connector 11

µApp

Adapter connector 1 Vpp Conversion of the 1 V

TS 248 touch probe Touch probe for probing

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Conversion of the pin layout

from HEIDENHAIN touch

probe interface to Renishaw

touch probe interface

Conversion of the 11 µA

interface from installa-

tion in D-sub connector,

2-row, female, 9-pin to Dsub connector, 2-row, with

locking screws, male, 15-pin

interface from installation in D-sub connector,

2-row, male, 15-pin to Dsub connector, 2-row, with

locking screws, male, 15-pin

a workpiece (for setting

presets), axial cable outlet

PP

PP

1095709-xx

1089213-01

1089214-01

683110-xx

29

Page 30

3

Transport and storage | Items supplied and accessories

Accessories

For mounting

Name Description ID

TS 248 touch probe Touch probe for probing

USB connecting cable USB connecting cable for

2 Vpp adapter connector Pin layout conversion from

Adapter connector for

TTL

Cables For information on connect-

Multi-Pos holder Holder for fastening the

a workpiece (for setting

presets), radial cable outlet

connector type A to type B

HEIDENHAIN 1 VPP to

Mitutoyo-2 V

Conversion of the pin layout

from HEIDENHAIN TTL to

RSF TTL and Renishaw TTL

ing cables, see "Cables

and Connectors for

HEIDENHAIN Products"

brochure.

device on an arm, continuously tiltable within an

angle of 90°, fixing hole

pattern 50 mm x 50 mm

PP

683112-xx

354770-xx

1089216-01

1089210-01

---

1089230-08

Duo-Pos stand Stand for rigid mounting,

inclination angle 20° or 45°,

fixing hole pattern 50 mm x

50 mm

Multi-Pos stand Stand for continuously

variable tilting with a tilting

range of 90°, fixing hole

pattern 50 mm x 50 mm

1089230-06

1089230-07

30

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 31

Transport and storage | Items supplied and accessories

Recommended RS-232 adapters

The product supports only RS-232 adapters of the DIGITUS® brand

from the manufacturer ASSMANN Electronic GmbH.

HEIDENHAIN recommends the following RS-232 adapters from ASSMANN

Electronic GmbH:

Part no. Model designation Interface Conversion

DA-70156 DIGITUS USB serial adapter USB 2.0 Serial

3.4 In case of damage in transit

Have the shipping agent confirm the damage

Keep the packaging materials for inspection

Notify the sender of the damage

Contact the distributor or machine manufacturer for replacement parts

3

If damage occurred during transit:

Keep the packaging materials for inspection

Contact HEIDENHAIN or the machine manufacturer

This applies also if damage occurred to requested replacement parts

during transit.

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

31

Page 32

3

Transport and storage | Repackaging and storage

3.5 Repackaging and storage

Repackage and store the product carefully in accordance with the conditions

stated below.

3.5.1 Repackaging the product

Repackaging should correspond to the original packaging as closely as possible.

Re-attach all mounting parts and dust protection caps to the product as

received from the factory, or repackage them in the original packaging as

received from the factory

Repackage the product in such a way that

it is protected from impact and vibration during transit

it is protected from the ingress of dust or humidity

Place all accessories that were included in the shipment in the original

packaging

Further information: "Items supplied and accessories", Page 28

Enclose all the documentation that was included in the original packaging

Further information: "Storage and distribution of the documentation", Page 15

If the product is returned for repair to the Service Department:

Ship the product without accessories, without encoders and without

peripherals

3.5.2 Storage of the product

Package the product as described above

Observe the specified ambient conditions

Further information: "Specifications", Page 207

Inspect the product for damage after any transport or longer storage times

32

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 33

4

Mounting

Page 34

4

50

50

Mounting | Overview

4.1 Overview

This chapter describes the mounting of the product. It contains instructions about

how to correctly mount the product on stands or holders.

The following steps must be performed only by qualified personnel.

Further information: "Personnel qualification", Page 23

4.2 Assembly of the product

General mounting information

The mount for the mounting variants is provided on the rear panel. The mounting

hole pattern corresponds to a grid of 50 mm x 50 mm.

34

Figure 1: Dimensions of rear panel of the product

The material for attachment of the mounting variants on the device is included in

delivery.

You will also need the following:

Torx T20 screwdriver

Torx T25 screwdriver

Allen key, size 2.5 (Duo-Pos stand)

Material for mounting on supporting surface

The unit must be mounted to a stand or a holder to ensure the correct

and intended use of the product.

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 35

Mounting | Assembly of the product

Mounting on Duo-Pos stand

You can fasten the Duo-Pos stand to the product at a 20° or 45° angle.

If you screw the Duo-Pos stand into the product at a 45° angle, you

must attach the product at the upper end of the mounting slots. Use a

power cable cable with an angled connector.

Use the provided M4 x 8 ISO 7380 hexagon socket screws to fasten the stand

to the lower threaded holes on the rear panel

Comply with the permissible tightening torque of 2.6 Nm

Using the mounting slots (width = 4.5 mm), screw the stand to a supporting

surface

or

Set up the device freely at the desired location

Route the cable from behind through the two supports of the stand and then

through the lateral openings to the connections

4

Figure 2: Product mounted on Duo-Pos

stand Figure 3: Cable routing on Duo-Pos stand

Further information: "Product dimensions with Duo-Pos stand", Page 211

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

35

Page 36

4

Mounting | Assembly of the product

4.2.1 Mounting on Multi-Pos stand

Use the provided M4 x 8 ISO 14581 countersunk head screws (black) to fasten

the stand to the threaded holes on the rear panel

Comply with the permissible tightening torque of 2.6 Nm

Using two M5 screws, you can also optionally screw the stand to a supporting

surface from the bottom

Adjust the desired angle of inclination

To fix the stand: Tighten the T25 screw

Comply with the tightening torque for screw T25

Recommended tightening torque: 5.0 Nm

Maximum permissible tightening torque: 15.0 Nm

Route the cable from behind through the two supports of the stand and then

through the lateral openings to the connections

Figure 4: Product mounted on Multi-Pos

stand Figure 5: Cable routing on Multi-Pos stand

Further information: "Product dimensions with Multi-Pos stand", Page 211

36

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 37

Mounting | Assembly of the product

4.2.2 Mounting on Multi-Pos holder

Use the provided M4 x 8 ISO 14581 countersunk head screws (black) to fasten

the holder to the threaded holes on the rear panel

Comply with the permissible tightening torque of 2.6 Nm

Mount the holder with the supplied M8 screw, the washers, the handle and the

M8 hexagon nut to an arm

Adjust the desired angle of inclination

To fix the holder in place: Tighten the T25 screw

Comply with the tightening torque for screw T25

Recommended tightening torque: 5.0 Nm

Maximum permissible tightening torque: 15.0 Nm

4

Route the cable from behind through the two supports of the holder and then

through the lateral openings to the connections

Figure 6: Product mounted on Multi-Pos

holder

Further information: "Product dimensions with Multi-Pos holder", Page 212

Figure 7: Cable routing on Multi-Pos

holder

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

37

Page 38

Page 39

5

Installation

Page 40

5

Installation | Overview

5.1 Overview

This chapter describes the Installation of the product. It contains information about

the product's connections and instructions about how to correctly connect the

peripheral devices.

The following steps must be performed only by qualified personnel.

Further information: "Personnel qualification", Page 23

5.2 General information

NOTICE

Interference from sources of high electromagnetic emission!

Peripheral devices, such as frequency inverters or servo drives, may cause

interference.

To increase the noise immunity to electromagnetic influences:

Use the optional functional ground connection as per IEC/EN 60204-1

Use only USB peripherals with continuous shielding, e.g. by metalized film

and metal braiding or a metal housing. The degree of coverage provided by

the braiding must be 85 % or higher. The shield must be connected around

the entire circumference of the connectors (360° connection).

NOTICE

Damage to the device from the engaging and disengaging of connecting

elements during operation!

Damage to internal components may result.

Do not engage or disengage any connecting elements while the unit is under

power

NOTICE

Electrostatic discharge (ESD)!

40

This product contains electrostatic sensitive components that can be destroyed

by electrostatic discharge (ESD).

It is essential to observe the safety precautions for handling ESD-sensitive

components

Never touch connector pins without ensuring proper grounding

Wear a grounded ESD wristband when handling product connections

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 41

Installation |

Damage to the product due to incorrect wiring!

The incorrect wiring of inputs or outputs can cause damage to the unit or to

peripheral devices.

Comply with the pin layouts and specifications of the product

Assign only pins or wires that will be used

Further information: "Specifications", Page 207

5.3 Product overview

The connections on the rear panel of the device are protected by dust protection

caps from contamination and damage.

5

NOTICE

NOTICE

Contamination or damage may result if the dust protection caps are

missing!

If no dust protection caps are fitted to unused connections, this may impair the

proper functioning of the contacts or destroy them.

Remove dust protection caps only when connecting measuring devices or

peripherals

If you remove a measuring device or peripheral, re-attach the dust protection

cap to the connection

The type of connections for encoders may vary depending on the

product version.

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

41

Page 42

5

AC 100 V ... 240 V

50 Hz ... 60 Hz

(max. 38 W)

HEIDENHAIN

X113

X3

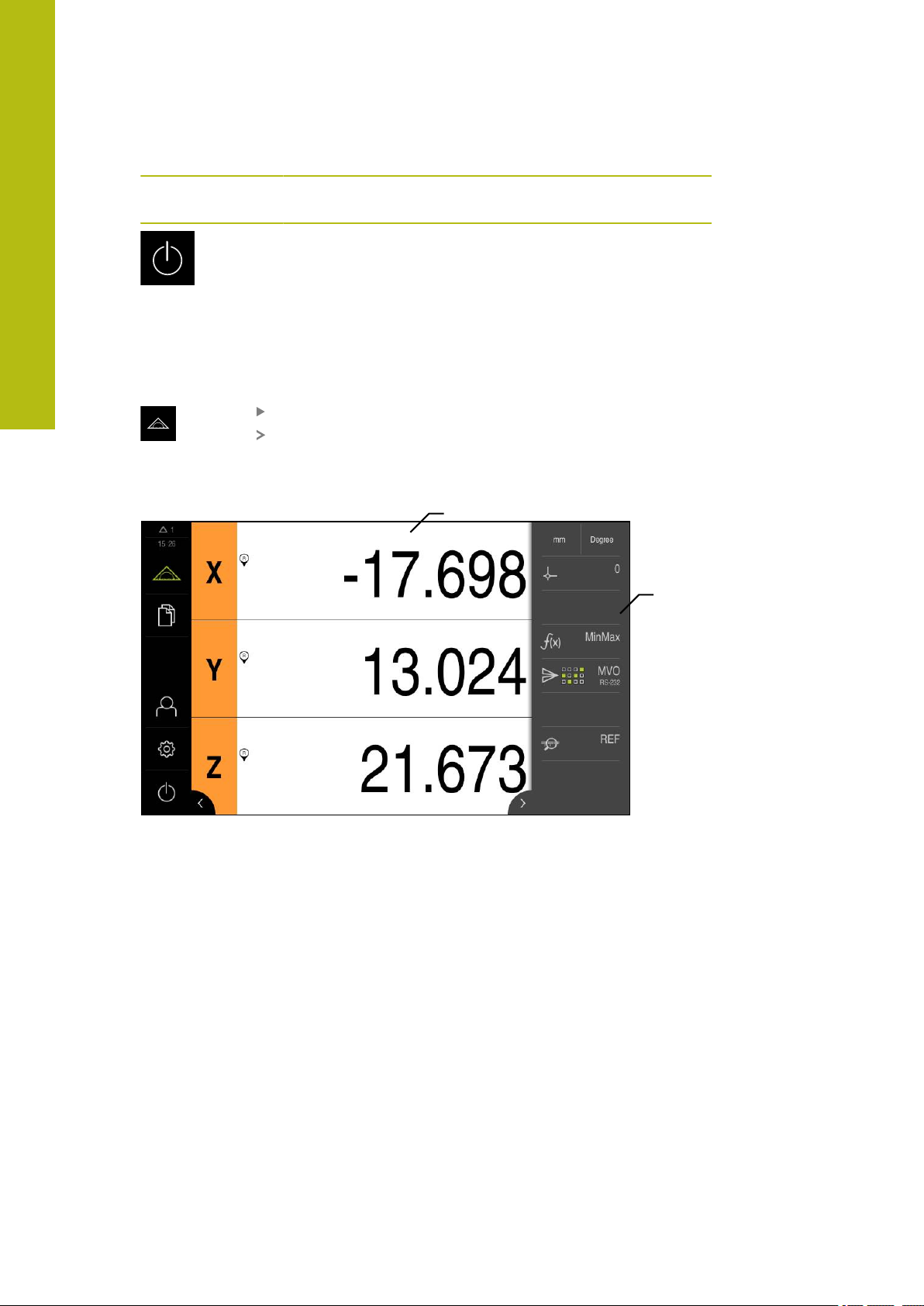

X2

X1

X116

X10 0

X32

4

5

6

7

89

10

Installation | Product overview

Rear panel without dust protection caps

Figure 8: Rear panel on devices with ID 1089181-01

Connections:

5 D-sub connections for encoders, one input enabled by default, another two inputs can

be enabled optionally

X1 to X3: device variant with 15-pin D-sub connections for encoders with 1 VPP,

11 μAPP or EnDat 2.2 interface

X21 to X23: Device variant with 9-pin D-sub connections for encoders with a

TTL interface

X1, X2, X21: Device variant with two 15-pin D-sub connections for encoders with

1 VPP interface and one 9-pin D-sub connection for encoders with TTL interface

7 X32: USB 2.0 Hi-speed connection (type A) for printers, input devices or USB mass

storage

10 Speaker

8 Functional ground connection as per IEC/EN 60204-1

6 X116: RJ45 Ethernet connection for communication and data exchange with subse-

quent systems or PC

4 X113: 15-pin D sub connection for touch probes (e.g., HEIDENHAIN touch probe)

9 X100: Power switch and power connection

42

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 43

Installation | Connecting encoders

5.4 Connecting encoders

For encoders with an EnDat 2.2 interface: If the corresponding encoder

input has already been assigned to an axis in the device settings, then

the encoder is automatically detected upon restart, and the settings are

adapted. Alternatively, you can assign the encoder input after you have

connected the encoder.

Comply with the pin layout

Remove and save the dust protection cap

Route the cables depending on the mounting variant

Further information: "Assembly of the product", Page 34

Connect the encoder cables tightly to the respective connections

Further information: "Product overview", Page 41

If the cable connectors include mounting screws, do not overtighten them

5

Pin layout of X1, X2, X3

1 VPP, 11 µAPP, EnDat 2.2

1 2 3 4 5 6 7 8

1 V

PP

11 μA

A+ B+ / / R– /

I

PP

1+

0 V

EnDat /

9 10 11 12 13 14 15

1 V

PP

A– B- / R+ /

Sense

0 V

11 μA

PP

I

1-

EnDat /

Pin layout of X21, X22, X23

U

P

I

2+

/ I

Inter-

0+

/

nal

/

DATA

shield

/ CLOCK

Sense

U

I

2-

/

P

/ I

DATA / CLOCK

0+

/

TTL

1 2 3 4 5 6 7 8 9

/ U

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

a1

U

a1

U

a2

U

a2

0 V U

p

U

a0

U

a0

43

Page 44

5

Din 0...3

X113

GND

DC 5 V

Dout 0

GND

X113

DC 5 V

TTL

TP

X113

GND

DC 5 V

Installation | Connecting touch probes

5.5 Connecting touch probes

The following touch probes can be connected to the unit:

HEIDENHAIN TS 248 touch probe

HEIDENHAIN KT 130 edge finder

Renishaw touch trigger probe

Further information: "Items supplied and accessories", Page 28

Comply with the pin layout

Remove and save the dust protection cap

Route the cables depending on the mounting variant

Further information: "Assembly of the product", Page 34

Connect the touch probe firmly

Further information: "Product overview", Page 41

If the cable connectors include mounting screws, do not overtighten them

Pin layout of X 113

1 2 3 4 5 6 7 8

LED+ B 5 V B 12 V Dout 0 DC 12 V DC 5 V Din 0 GND

9 10 11 12 13 14 15

Din 1 Din 2 TP GND TP Din 3 LED–

B – Probe signals, readiness

TP – Touch Probe, normally closed

Digital inputs: Digital outputs:

44

Touch probe:

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 45

Installation | Wiring switching inputs and outputs

5.6 Wiring switching inputs and outputs

Depending on the peripherals to be connected, the connection work

may need to be carried out by an electrical specialist.

Example: Safety Extra Low Voltage (SELV) exceeded

Further information: "Personnel qualification", Page 23

The product fulfills the requirements of standard IEC 61010-1 only if the

power to the peripheral devices is supplied from a secondary circuit

with current limitation as per IEC 61010-1

power limitation as per IEC 60950-1

secondary circuit as specified in UL1310.

In place of IEC 61010-1

of standards DIN EN 61010-1, EN 61010-1, UL 61010-1 and CAN/CSAC22.2 No. 61010-1can be used, and, in place of IEC 60950-1

Section 2.5, the corresponding sections of standards DIN EN 60950-1,

EN 60950-1, UL 60950-1, CAN/CSA-C22.2 No. 60950-1 can be applied.

3rd Ed.

, Section 9.4, the corresponding sections

3rd Ed.

2nd Ed.

, Section 2.5 or from a Class 2

, Section 9.4 or with

2nd Ed.

5

,

Wire switching inputs and outputs in accordance with the following pin layout

Remove and save the dust protection cap

Route the cables depending on the mounting variant

Further information: "Assembly of the product", Page 34

Connect the connecting cables of the peripherals tightly to their connectors

Further information: "Product overview", Page 41

If the cable connectors include mounting screws, do not overtighten them

The digital or analog inputs and outputs must be assigned in the device

settings of the respective switching function.

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

45

Page 46

5

Din 0...3

X113

GND

DC 5 V

Dout 0

GND

X113

DC 5 V

TTL

TP

X113

GND

DC 5 V

Installation | Wiring switching inputs and outputs

Pin layout of X 113

1 2 3 4 5 6 7 8

LED+ B 5 V B 12 V Dout 0 DC 12 V DC 5 V Din 0 GND

9 10 11 12 13 14 15

Din 1 Din 2 TP GND TP Din 3 LED–

B – Probe signals, readiness

TP – Touch Probe, normally closed

Digital inputs: Digital outputs:

Touch probe:

46

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 12/2018

Page 47

Installation | Connecting a printer

4

3 2 1

1 2 3 4 5 6 7 8

5.7 Connecting a printer

Connecting a USB printer

Comply with the pin layout

Remove and save the dust protection cap

Route the cables based on the mounting variant

Further information: "Assembly of the product", Page 34

Connect USB printer to USB Type-A port (X32). Make sure the USB cable

connector is fully inserted

Further information: "Product overview", Page 41

Pin layout X32

5

1 2 3 4

DC 5 V Data (–) Data (+) GND

Connecting an Ethernet printer

Comply with the pin layout

Remove and save the dust protection cap

Route the cables based on the mounting variant

Further information: "Assembly of the product", Page 34