Page 1

GSK218MC SERIES M ACHINING CENTER CNC SYSTEM

Product Brief:

*GSK 218MC series is a high-level machining center system and the newest

man-machine design of which its machining efficiency and cleanness can be compared

favorably with the imported medium system. It is very convenient to connect the standard

configuration GSK-LINK Ethernet bus and absolute motor (It is the mechanical memory

encoder, regardless of that t he data may lose out of battery) .

Product Characteris t ic:

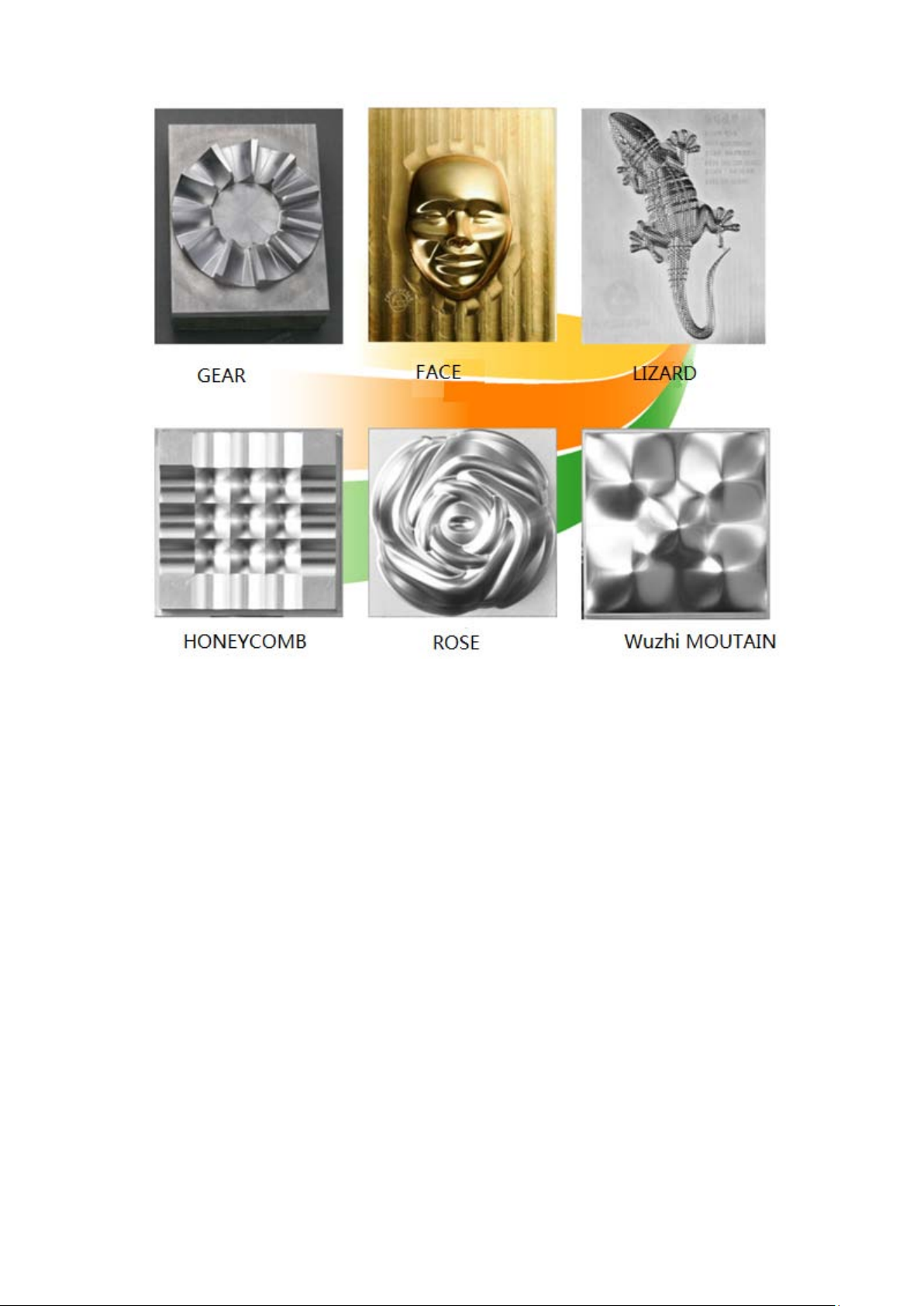

* Five-axis & Five-axis Linkage Function

It owns the five-axis contr ol functi ons, su ch as t he five-axis RTCP (Tool center control)

and non-RTCP, sloping surface (3+2 positioning) (4+1 and absolute five-axis) machining.

The five-axis linkage high-speed and high-accuracy interpolation function can be carried

out the complicated curved surface high speed and accuracy machining to guarantee the

quality of the machining precision and surface, simultaneously, improve the machining

efficiency. And therefore, the surface of the machining workpiece is with clear veins, and

stable at the corner of the transition, clear and activate pointednes s char acteristic, as well

without overcutting and un der cut t ing.

1

Page 2

* High-Speed & High-accuracy Function

It adopts the high-speed interpolation technology; the complicated curved surface

machining efficiency velocity is 8m/min; the optimal machining velocity is 4m/min. Up to

1000 of the pre-treatment sections; it also owns the prospective function, rapid,

high-precision and perfect cleanness.

2

Page 3

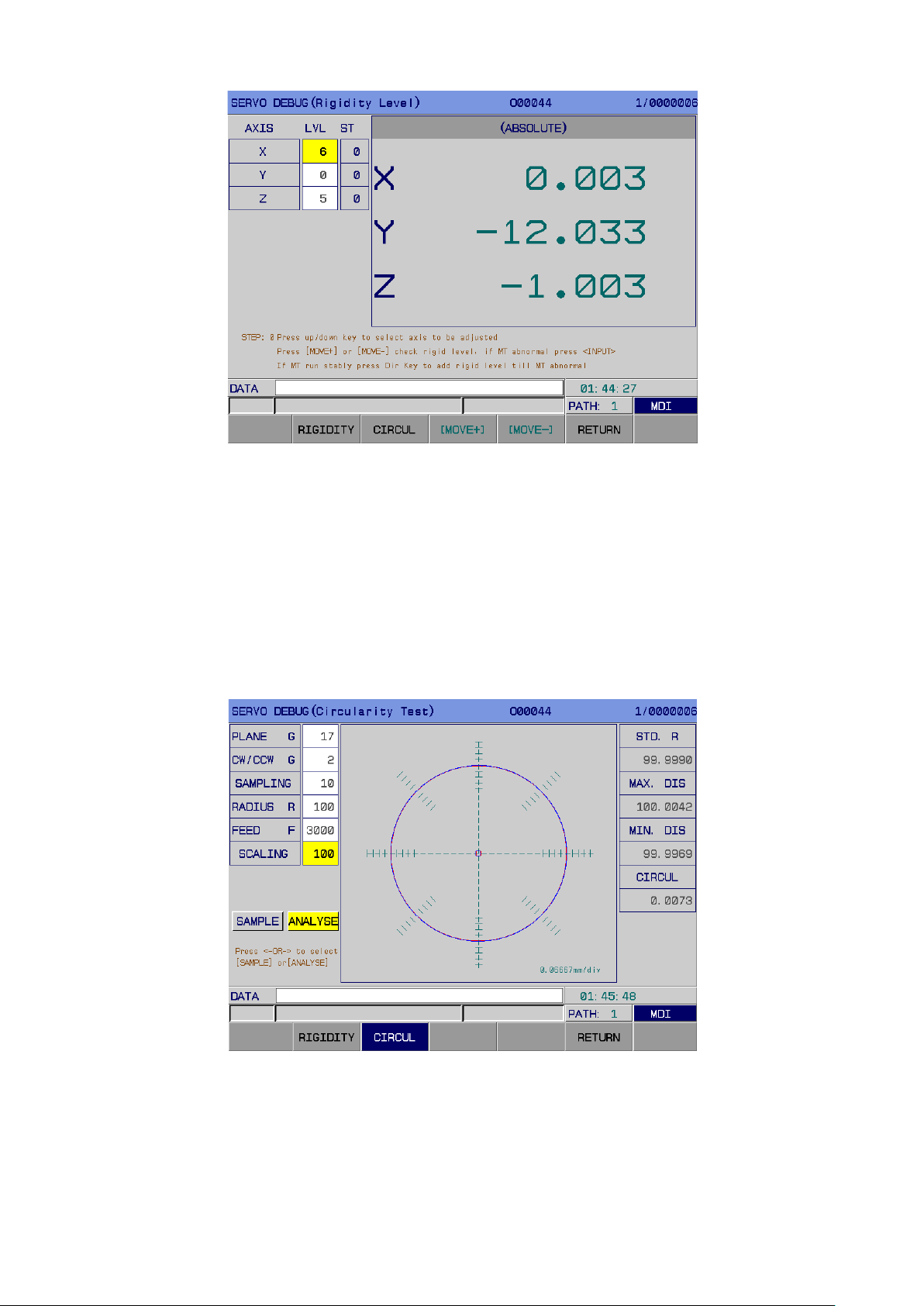

* Convenient Debugging Method

The on-line rigidity level debugging function of the bus configuration can further

enhanced the machine tool rigidity adjustment and parameter optimization for the

machine machining performa nce, instead of debugging the drive’s parameter one by one,

it is simplified accordingly. Also, it has the majorization function of which the system can

be optimized a group of para meter by itself to reserve the high-rigidity of the machine.

3

Page 4

总线配置在线圆度测试分析功能,圆度测试可模拟圆周切削运动圆并以此采集电

机码盘位置信息来判断机床各伺服轴响应的同步性和响应速度。

The on-line circular-degree testing analysis function of the bus configuration in

which the circular-degree testing can be judged the responsive synchronism and its

velocity of each servo axis for the machine tool by imitating the circle to cut a movement

round and then collect the motor’s en coder position informatio n based upon it.

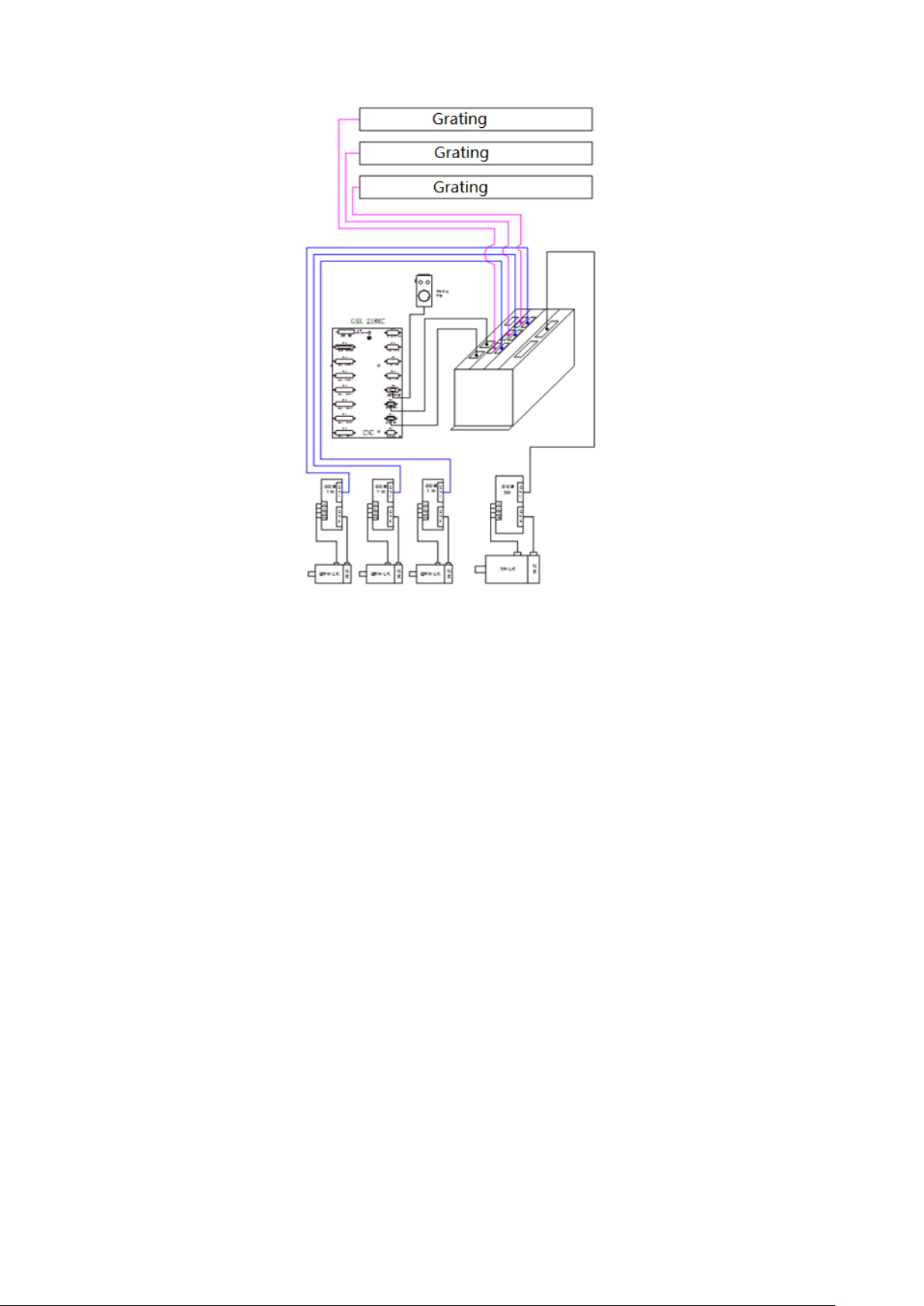

* Convenient Extension Function

I/O board —— extend the I / O point

Spindle board —— Multi-spindle extension, 4-circuit analogy voltage, 4-circuit

rigidity tapping

4

Page 5

Servo board —— Multi-feed-axis extension, pulse conversion from pulse

Acquisition board —— Connect the grating etc. measurement feedback

equipment

Analogy board —— It can be accepted the multi-circuit analogy input/output

voltage.

5

Page 6

* Dual-Drive Calibration, Grating Detection Function

It has the grating read function: grating bar detects and then adjusts the levelness of

the cross beam to guarantee t he lev el accuracy during mach in ing.

It has precision stop interpolation and corner smooth treatment function to prevent

the corner from overcutting.

It has the automatic calibration dual-driving function: The synchronism error between

2 motors can be detected out by the feedback of each motor, and perform the

synchronism error compensation. The alarm generates when the synchronism error

exceeds the setting value to stop the axis movement and then inspect the synchronism

error value.

6

Page 7

* Adapt the Automatic Tool-setting Center Apparatus to Carry out the

Corresponding Function

Further, enhance the integral automation utility regardless of the calibration for each

tool length alone any more to improve the accuracy of the workpiece center. The

tool-setting center can be carrie d out by increas ing t he auto mat ic too l-settin g a pparatus t o

improve the integrated efficiency.

7

Page 8

Installation Dimensi on:

GSK 218MC

8

Page 9

GSK 218MC System installation dimension figure

开 图 缩开 图 缩开 图 缩

9

Page 10

Additional panel (Optional)

10

Page 11

GSK 218MC-H

开孔安装示意图

GSK 218MC-H host machine unit installation dimension figure

11

Page 12

开孔及安装尺寸示意图

GSK 218MC-H operation panel in st allation dimension figure

12

Page 13

GSK 218MC-V

开孔安装示意图

GSK 218MC-V host machine unit installation dimension figure

13

Page 14

开孔安装示意图

GSK 218MC-V operation panel instal lation dimension figure

Other Explanations:

* The application in the standard machine tool.

Item Type

CNC system 218MC series CNC system

Machine VMC850 ver t ical an d horizontal

Spindle GSK ZJY series

Tool magazine Disk manipulator

Spindle GS3075Y

Drive

Motor

X axis GE2075-LA1

Y axis GE2075-LA1

Z axis GE2075-LA1

Spindle ZJY208-7.5B

X axis 175SJT-M150D(A4I)

Y axis 175SJT-M150D(A4I)

Z axis 175SJT-MZ150D(A4I)

14

Page 15

The cutting feedrate is F5000mm/min when machining the above-mentioned mold

(The material is mold st eel ) and its oper at ion is stab le. The cut ter threa d at t he circular arc

corner is clear, no overcutting, no undercutting and distortion etc., as well clear

pointedness (closed angle) characteristic, sharp and without inactivation at the

pointedness (closed angle) transition; up to Ra0.8um for the roughness on the cavity

surface.

* Three-Axis Linkage Gear Machining Application

Three-axis linkage (Z, X and C) can be carried out the single-head, multi-head

variable pitch and variable -diameter (reducing) defor me d scr ew rod machining

The special-purpose G07 parabolic screw interpolation command can be machined

the constant and variable pitch s crew rod.

The system can be performed the lead screw reverse interval compensation and

dual-direction pitch error com pensation to ensure the mach ining accuracy;

Up to Ra3.2 for the machining roughness, the screw rod leading error is

0.08mm/300m.

15

Page 16

* Five-Axis Circular Gear Machining Application

Five CNC axes: B— Hobbing cutter spindle revolving movement, C— Workpiece

revolving movement, X— Radial feed movement, Y— Tangential feed movement,

Z— axial feed movement;

It can be carried out each kind of gear machining such as the direct gear, helical gear,

tapering helical gear, conical gear, drum-type gear, chamfering slick gear, worm-gear

etc.

It can be ac hi eved multi-gear machin ing such as the gear-milling a nd gr oove etc.

Up to the 4 lev els for the gear machin ing precision.

16

Page 17

* The Application of the High Velocity Drilling & Tapping Machine Tool

40M/MIN rapid positioning velocity, multi-tapping calculation; immediately performs

the tool-retraction after tapping to the bottom of a hole with high velocity; and it greatly

improves the machining efficiency;

Up to 4000 revolutions effective velocity of the spin dle tapping;

It contents to the tapp ing r equ ireme nt fro m M 0.8 to M24, as we l l to the mat erials s uc h

as the steel, iron, aluminu m, iron casting and aluminum alloy etc.

Up to 0.005mm for the repeated positioning accuracy; ensure the batch tapping

quality.

17

Page 18

* Dual-Channel Function Application

It is used the bus technology to carried out t he dual-channel; each of the cha nnel can

be realized the five-axis & five-axis linkage;

It can be equipped with the dual tool-magazine to carry out that each channel owns

the tool-change function.

It can be configured the grating to c ar ry out the closed-loop cont r ol o f each channel.

18

Page 19

19

Loading...

Loading...