Page 1

Page 2

This user manual describes all proceedings concerning the

operations of this CNC system in detail as much as possible. However, it is

impractical to give particular descriptions for all unnecessary or unallowable

system operations due to the manual text limit, product specific applications

and other causes. Therefore, the proceedings not indicated herein should

be considered impractical or unallowable.

This user manual is the property of GSK CNC Equipment Co., Ltd. All

rights are reserved. It is against the law for any organization or individual

to publish or reprint this manual without the express written permission of

GSK and the latter reserves the right to ascertain their legal liability.

- -

I

Page 3

Installation and Connection Manual of GSK218MC CNC System

Preface

Your Excellency,

It’s our pleasure for your patronage and purchase of this

GSK218MC Series Machining Center CNC System made by GSK CNC

Equipment Co., Ltd.

This manual is the part of the “Installation and Connection”, which

is introduced the installation and connection and the PLC

programming method of the machining center CNC of the

GSK218MC.

In order to guarantee the product is operated with a safe, normal and

effective situation, it is necessary to carefully read this manual before installing

and using this product.

Chinese version of all technical documents in Chinese and English

languages is regarded as final.

II

Page 4

Preface and Precaution

Security Precaution

Accident may occur by improper connection and operation !This

system only can be operated by authorized and qualified personnel.

Please carefully read this manual before using!

Especially prompt: The power installed on/inside the main cabinet

is a special one offering by our company CNC system.

Never attempt to use for other purposes by this power.

Otherwise, huge hazard may occur.

III

Page 5

Installation and Connection Manual of GSK218MC CNC System

Warning, Notice and Explanation

Statement!

z In this manual we have tried as much as possible to describe all

various matters. However, we cannot describe all the matters which

must not be done, or which cannot be done, because there are so

many possibilities. Therefore, matters which are not especially

described as possible in this manual should be regarded as

“impossible”.

Warning!

z Before installing, programming and operating the machine, thoroughly

read this manual and user manual issued by the machine

manufacturer, and rigidly operate the machine based upon the

requirement of this manual, otherwise, possibly causing damage to

the workpiece and/or machine itself, or injury to the user.

z The product functions and technical indexes (such as accuracy,

velocity) described in this manual are only for this machine, which

installs the CNC system of this product. The actual function

configuration and technical capacity are determined by the machine

manufacturer, and the function configurations of the CNC machine

and technical indexes are subjected on the manual issued by the

machine builder.

All specifications and designs are subject to change without notice.

Notice!

IV

Page 6

Preface and Precaution

Safety Precautions

■ Transportation and Storage

z Do not pile up the carton over 6 layers.

z Do not climb, stand on the carton, and as well not place the heave objects on it.

z Do not drag or move the product using the cables connected with the product.

z Do not crash or scratch the panel and display screen.

z Avoid damp, sunshine and raining on the product carton.

■ Open carton to inspect

z Ensure that it is your purchased product after opening the carton.

z Check whether the product is damaged during transporting.

z Confirm whether each part is prepared or damaged based upon the packing list.

z Contact our company immediately if the product type is inconsistent with the

packing list, lack of accessories or damage in transportation.

■ Wiring

z The person who attends the wiring and check should have the corresponding

professional capacity.

z The product should be reliably grounded, and its resistance should be less than

0.1Ω and can not be used the neutral conductor (zero cable) to replace the

ground wire.

z The wiring should be correct and firm, otherwise, possibly causing the

malfunction in product or unexpectable result.

z The surge absorb diode connected with the product should be linked based upon

the described direction, otherwise, it may damage the product.

z Before Inserting/pulling out the plug or opening the main cabinet of the product, it

is important to cut off the product’s power.

■ Inspection and maintenance

z Cut off the power before inspecting and maintaining or changing the

components.

z Check the malfunction when the short-circuit or overloading occurs. The

computer can be started after the malfunction is eliminated.

z Do not power ON/OFF frequently for the product, if you want to turn on the

power again after power off, its interval time is 1min. at least.

V

Page 7

Installation and Connection Manual of GSK218MC CNC System

Volume Ⅰ Programming Description

Introduce the technical specification, product type series and parameter

configuration, command code and program format of 218MC series machining center

CNC system.

Volume Ⅱ Function Description

Introduce the main function of the GSK218MC series machining center CNC

system.

Volume Ⅲ Operation Description

Introduce the operations of the GSK218MC series machining center CNC

system

Volume Ⅳ Installation and Connection

Introduce the installation, connection and setting methods of the GSK218MC

series machining center CNC system.

Appendix

Introduce the use explanations of the GSK218MC series machining center CNC

system and the appendix

VI

Page 8

Preface and Precaution

Security Responsibility

Security responsibility of the manufacturer

——Manufacturer should take responsibility for the design and structure danger of the

motor and the accessories which have been eliminated and/or controlled.

——Manufacturer should take responsibility for the security of the motor and

accessories.

——Manufacturer should take responsibility for the offered information and

suggestions for the user.

Security responsibility of the users

——User should know and understand about the contents of security operations by

learning and training the security operations of the motor.

——User should take responsibility for the security and danger because of increasing,

changing or modifying the original motor or accessory by themselves.

——User should take responsibility for the danger without following the operations,

maintenances, installations and storages described in the manual.

This manual is stored by the last user.

Sincerely thanks for your friendly supporting of GSK’s

products!

VII

Page 9

Installation and Connection Manual of GSK218MC CNC System

VIII

Page 10

Contents

CONTENTS

VOlUME Ⅰ PROGRAMMING......................................................................................0H1

CHAPTER ONE THE COMPILATION SCHEDULE OF SEQUENCE PROGRAMMING ...........

1.1 GSK218MC Series PLC Specification .....................................................................................

1.2 The Concept of the Sequence Programming ......................................................................... 3H3

1.3 Distribution Interface (Step one) ...............................................................................................

1.4 Ladder Diagram Programming (Step two)............................................................................... 5H4

1.5 Sequence Programming Debugging (Step 3)......................................................................... 6H4

CHAPTER TWO SEQUENCE PROGRAMMING.......................................................................

2.1 Performance Process of Sequence Programming ................................................................

2.2 The Performance of the Cycle ..................................................................................................

2.3 The Priority Sequence of the Performance (the 1st Level, the 2nd level).......................... 10H6

2.4 Sequence Programming Structure ...........................................................................................

2.5 The Treatment of the Input/output Signal ................................................................................ 12H8

2.6 Interlocking.................................................................................................................................

CHAPTER THREE PLC ADDRESS.........................................................................................

3.1 Machine → PLC address (X)..................................................................................................

3.2 PLC → Address of the Machine Tool Side (Y) .................................................................

3.3 PLC →CNC Address (G) ........................................................................................................

3.4 CNC →PLC Address (F) .........................................................................................................

3.5 Internal Replay Address (R) ....................................................................................................

3.6 Nonvolatile Relay Address (K) ................................................................................................

3.7 Information Display Request Address (A) ............................................................................. 21H16

3.8 Counter Timer (C) ..................................................................................................................... 22H17

3.9 Counter Preset Value Address (DC) ......................................................................................

3.10 Timer Address (T) ................................................................................................................... 24H17

3.11 Presetting Value Address of the Timer (DT)........................................................................

3.12 Data Table Address (D) ..........................................................................................................

3.13 Sign Address (L)......................................................................................................................

3.14 Subprogram Number (P) .......................................................................................................

CHAPTER FOUR PLC BASIS CODE......................................................................................

4.1 RD, RD.NOT, WRT, and WRT.NOT Codes...........................................................................

4.2 AND, AND.NOT Codes............................................................................................................. 31H19

4.3 OR, OR.NOT Codes.................................................................................................................

4.4 OR. STK Code........................................................................................................................... 33H20

4.5 AND. STK Code ........................................................................................................................ 34H20

CHAPTER FIVE PLC FUNCTION CODE ................................................................................

st

5.1 END1 (End of the 1

5.2 END2 (The End of the 2

Level Sequence Program) ................................................................. 36H22

nd

Sequence Program) ................................................................... 37H23

5.3 CALL (Call Subprogram)..........................................................................................................

5.4 CALLU (Call Subprogram Without Condition) ......................................................................

5.5 SP (Subprogram) ......................................................................................................................

5.6 SPE (End of Subprogram).......................................................................................................

1H3

2H3

4H4

7H5

8H5

9H6

11H7

13H10

14H11

15H11

16H13

17H14

18H15

19H15

20H16

23H17

25H17

26H17

27H17

28H17

29H18

30H18

32H19

35H22

38H23

39H23

40H24

41H24

IX

Page 11

Installation and Connection Manual of GSK218MC CNC System

5.7 SET (Replacement/Setting) .....................................................................................................42H25

5.8 RST (Resetting) .........................................................................................................................43H25

5.9 JMPB (Mark Number Skip) ......................................................................................................44H26

5.10 LBL (Mark Number).................................................................................................................

45H26

5.11 TMR (Timer) .............................................................................................................................46H27

5.12 TMRB (Fixed Timer)................................................................................................................47H28

5.13 TMRC (TIMER)........................................................................................................................

48H28

5.14 CRT (Binary Counter).............................................................................................................49H29

5.15 DEC (Binary Decoding) ..........................................................................................................50H30

5.16 COD (Binary System Code Conversion) .............................................................................51H31

5.17 COM (Concentric Line Control).............................................................................................

52H33

5.18 COME (Concentric Line Control End)..................................................................................53H33

5.19 ROT (Binary Rotation Control) ..............................................................................................54H33

5.20 SFT (Register Displacement/Shifting)..................................................................................

55H35

5.21 DIFU (Rising Edge Detection)...............................................................................................56H36

5.22 DIFD (Descending Edge Detection) .....................................................................................57H37

5.23 COMP (The Comparison of the Binary Number)................................................................

58H38

5.24 COIN (Consistency Comparison) ......................................................................................... 59H38

5.25 MOVN (Data Transmission)...................................................................................................60H39

5.26 MOVB (Transmission of 1 Byte)............................................................................................

61H40

5.27 MOVW (Transmission of Two Bytes) ...................................................................................62H40

5.28 XMOV (Binary Indexed Data Transmission) .......................................................................63H41

5.29 DSCH (Binary Data Index).....................................................................................................

64H42

5.30 ADD (Binary Addition).............................................................................................................65H43

5.31 SUB (Binary Subtraction).......................................................................................................66H44

5.32 ANDF (Bit-by-bit AND)............................................................................................................67H45

5.34 NOT (Bit-by-bit NOT)..............................................................................................................

68H47

5.35 EOR (Exclusive OR) ...............................................................................................................69H47

CHAPTER SIX THE COMPILATION LIMIT OF THE LADDER DIAGRAM ..............................

70H49

VOLUME II FUNCTION EXPLANATION.................................................................... 71H51

CHAPTER ONE CONTROLLABLE AXIS ................................................................................

1.1 The output of the axis movement............................................................................................

1.2 Servo Ready Signal ..................................................................................................................

CHAPTER TWO READY FOR OPERATION...........................................................................

2.1 ESP..............................................................................................................................................

2.2 CNC Overtravel Signal .............................................................................................................

2.3 Alarm Signal ...............................................................................................................................

2.4 Selection of the Operation Method .........................................................................................79H56

2.5 State Output Signal ................................................................................................................80H57

CHAPTER THREE MANUAL OPERATION.............................................................................

3.1 JOG Feed/Incremental Feed ...................................................................................................

3.2 MPG (Manual Pulse Generator) / Single Step Feed............................................................

CHAPTER FOUR REFERENCE POSITION RETURN ...........................................................

4.1 Manual Reference Position Return.........................................................................................

4.2 Return to the Reference Position Detection Signal..............................................................

4.3 Area Detection Signal ...............................................................................................................87H62

X

72H53

73H53

74H54

75H55

76H55

77H55

78H56

81H58

82H58

83H59

84H60

85H60

86H61

Page 12

Contents

CHAPTER FIVE AUTOMATICAL OPERATION .......................................................................88H64

5.1 Cycle Start/ Feed Hold .............................................................................................................

5.2 Reset...........................................................................................................................................

5.3 Program test .............................................................................................................................. 91H66

5.4 Skip Optional Block................................................................................................................... 92H68

CHAPTER SIX FEEDRATE CONTROL...................................................................................

6.1 Rapid Traverse Rate.................................................................................................................

6.2 Feedrate Override..................................................................................................................... 95H71

6.3 Override Cancellation...............................................................................................................

CHAPTER SEVEN MISCELLANEOUS FUNCTION................................................................

7.1 M Code Miscellaneous Function.............................................................................................

7.2 S Code Miscellaneous Function .............................................................................................

7.3 T Code Miscellaneous Function.............................................................................................. 100H74

7.4 Miscellaneous Function Lock .................................................................................................. 101H76

CHAPTER EIGHT SPINDLE SPEED FUNCTION...................................................................

8.1 Spindle Speed Control Method ...............................................................................................

8.2 Rigid Tapping .............................................................................................................................

CHAPTER NINE PROGRAMMING CODE ..............................................................................

9.1 User Macro Program ................................................................................................................

9.2 Canned Cycle ............................................................................................................................

CHAPTER TEN DISPLAY/SETTING .......................................................................................

10.1 Clock Function.........................................................................................................................

10.2 Display the Operation Record............................................................................................... 110H85

10.3 Help Function .......................................................................................................................... 111H85

CHAPTER ELEVEN MEASURING ..........................................................................................

11.1 Skip Function ...........................................................................................................................

CHAPTER TWELVE PANEL LOCK SETTING.........................................................................

89H64

90H65

93H70

94H70

96H71

97H72

98H72

99H72

102H78

103H78

104H80

105H81

106H81

107H83

108H85

109H85

112H86

113H86

114H87

VOLUME III OPERATION EXPLANATION.................................................................115H93

CHAPTER ONE PLC INTERFACE DISPLAY ..........................................................................

1.1 GSK218MC The Automatic Operation in PLC ON............................................................

1.2 Programmable Interface Display ............................................................................................ 118H95

CHAPTER TWO PLC PROGRAMMING OPERATION ..........................................................

2.2 Basis Code...............................................................................................................................

2.3 The Operation Explanation of the Ladder Diagram ...........................................................

2.4 Function Code .........................................................................................................................

2.5 Command Table ...................................................................................................................... 123H108

2.6 Compilation Command........................................................................................................... 124H109

2.7 PLC Operation Steps..............................................................................................................

CHAPTER THREE PLC ADDRESS AND PARAMETER SETTING.......................................

3.1 Nonvolatile/Hold Relay............................................................................................................

3.2 Timer ............................................................................................................................... ...........128H112

3.3 Data List ....................................................................................................................................129H113

3.4 Counter ......................................................................................................................................130H114

3.5 M function corresponding to the F address..........................................................................

CHAPTER FOUR THE USER EXPLANATION OF THE LADDER DIAGRAM SOFTWARE

EDIT .........................................................................................................................................

116H95

117H95

119H103

120H104

121H105

122H107

125H109

126H111

127H111

131H115

132H117

XI

Page 13

Installation and Connection Manual of GSK218MC CNC System

4.1 Brief ............................................................................................................................... ............ 133H117

4.2 Software Introduction.............................................................................................................. 134H117

4.3 Software Operation ................................................................................................................. 135H119

VOLUME Ⅳ INSTALLATION AND CONNCETION................................................. 136H127

CHAPTER ONE THE SYSTEM CONFIGURATION AND INSTALLATION.............. 137H129

1.1 Composition of the System ................................................................................................

1.2 The System Installation and Connection ............................................................................139H129

1.3 CNC System Installation Dimension Figure .......................................................................

1.4 The Additional Panel Figure ...............................................................................................

138H129

140H131

141H136

CHAPTER TWO CONNECTION BETWEEN EQUIPMENTS .................................. 142H137

2.1 Connection Diagram of the External System......................................................................143H137

2.1.1 The Layout of Interface Position ........................................................................................

2.1.2 The Connection Diagram ....................................................................................................

2.2 Connection between the System and the Drive Unit ..........................................................

2.2.1 The System Interface Figure ..............................................................................................

2.2.2 The Interface Signal List .....................................................................................................148H140

2.2.3 Introduction of Signals.........................................................................................................149H140

2.2.4 The Cable Connection Diagram.........................................................................................

2.3 RS232 Standard Series Interfaces .....................................................................................

2.4 Connection between MPG and Handhold Unit...................................................................

2.4.1 Interface Signal Diagram ....................................................................................................

2.4.2 Introduction of Interface Signals ........................................................................................154H145

2.5 Connection of the Spindle Units .........................................................................................

2.5.1 List of the Interface Signals ................................................................................................

2.5.3 The Connection Circuit of DAP03 Interfaces ................................................................... 157H148

2.6 The System Power Supply Interface ..................................................................................

2.7 The Control Interface of the External Power Supply...........................................................

144H137

145H138

146H139

147H139

150H142

151H144

152H144

153H144

155H147

156H147

158H149

159H149

CHAPTER THREE THE MACHINE CONTROL I/O INTERFACE ............................ 160H150

3.1 The Interface Signal List.....................................................................................................

3.2 The Input Interfaces ...........................................................................................................

3.2.1 The Circuit Principle of the Input Interface .......................................................................

3.2.2 The Interface Definition of the Input Signals....................................................................

3.3 The Output Interface ..........................................................................................................

3.3.1 The Circuit Principle of the Output Interface....................................................................

3.3.2 The Definitions of the Output Signal Interfaces...............................................................167H155

161H150

162H151

163H151

164H152

165H154

166H154

CHAPTER FOUR MACHINE DEBUGGING............................................................. 168H157

4.1 Debugging Ready...............................................................................................................

4.2 System Power-on ...............................................................................................................

4.3 Emergency Stop and Limit .................................................................................................

4.4 Changing the Gear Ratio....................................................................................................

4.5 Backlash Compensation.....................................................................................................173H162

4.6 Setting the Drive Unit .........................................................................................................

XII

169H157

170H158

171H158

172H161

174H164

Page 14

Contents

4.7 The Machine Screw Pitch Compensation...........................................................................175H165

4.8 Mechanical Zero Return (Machine Zero Return) ................................................................

176H167

4.9 Controlling the Input and Output Signals during the Spindle CW and CCW Rotation.........177H171

4.10 The Spindle Automatic Gear Change Control ...................................................................

178H172

4.11 The External Cycle Start and Feed Hold...........................................................................179H173

4.12 The External Editing Lock and the External Operation Panel Lock ..................................

180H174

4.13 Cooling, Lubricating and Chip Removal Control...............................................................181H175

4.14 Setting the Relative Feedrate ...........................................................................................

182H176

4.15 Setting the Relative Tapping Parameters .........................................................................183H178

APPENDIX ..................................................................................................................184H181

APPENDIX ONE THE USAGE GUIDE OF THE LADDER DIAGRAM OF GSK218MC

WITH THE TURRET MAGAZINE ................................................................................

185H183

1. Points for Attention during Using the Ladder Diagram when GSK218MC with the Turret

Magazine..................................................................................................................................186H183

2. The Allocation and Definitions of I/O Address and Internal Software Components in CNC PLC

of GSK218MC ..........................................................................................................................

3. Usage and Maintenance of GSK218MC CNC System with the Turret Magazine......................

187H183

188H212

APPENDIX TWO THE USAGE GUIDE OF LADDER DIAGRAM OF GSK218MC WITH

THE DISC MAGAZINE ................................................................................................189H221

1. Points for Attention of Using the Disc Magazine: ..................................................................190H221

2. The Allocation and Definition of PMC, I/O Address and the Internal Software Components in

GSK218MC CNC System.........................................................................................................

3. Usage and Maintenance of GSK218MC CNC SYSTEM with the Disc Magazine ................

191H222

192H254

4. Note of GSK218MC CNC System with the Disc Magazine Macro Program.........................193H262

APPENDIX THREE THE ALLOCATED FILE FORMAT OF THE LADDER DIAGRAM

....................................................................................................................................194H263

1. M Code M00—Meaning of F Signal in M99..........................................................................

2. “%” in a Single Line Meaning Saving M Code Information End ............................................196H263

3. X signal X0.0---The Code and Meaning of X6.7 ...................................................................

4. Y Signal Y0.0—The Code and Meaning of Y5.7...................................................................198H263

5. K signal K6.0---The Code and Meaning of K63.7 .................................................................

6. A signal A0.0---The Code and Meaning of A31.7..................................................................200H264

7. End// End Symbol.................................................................................................................201H264

195H263

197H263

199H264

XIII

Page 15

Installation and Connection Manual of GSK218MC CNC System

XIV

Page 16

Chapter One The Compilation Schedule of the Sequence Programming

Volume I Programming

VOlUME Ⅰ PROGRAMMING

1

Page 17

Installation and Connection Manual of GSK218MC CNC System

Volume I Programming

VolumI Programming

2

Page 18

Chapter One The Compilation Schedule of the Sequence Programming

CHAPTER ONE THE COMPILATION SCHEDULE OF SEQUENCE

PROGRAMMING

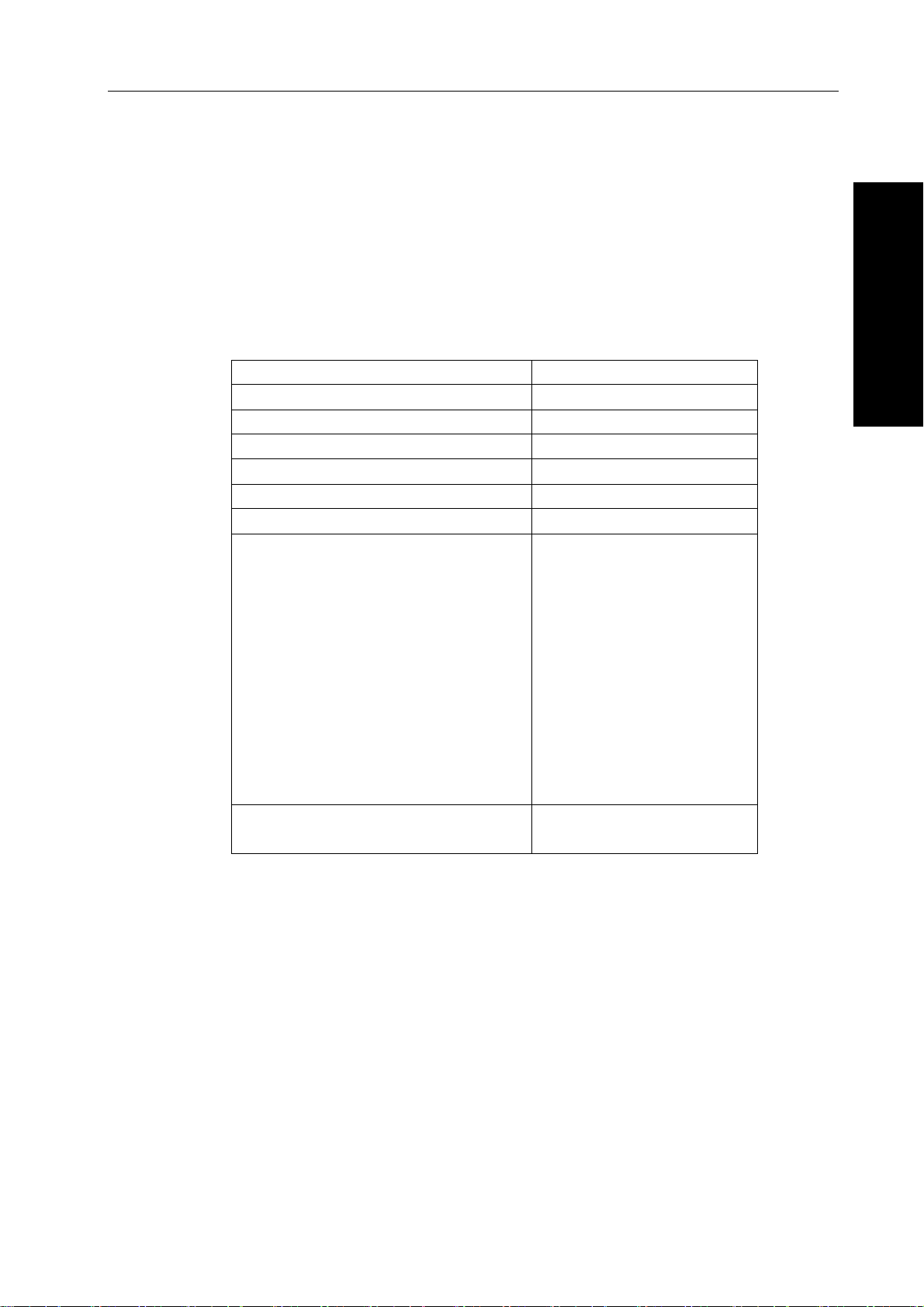

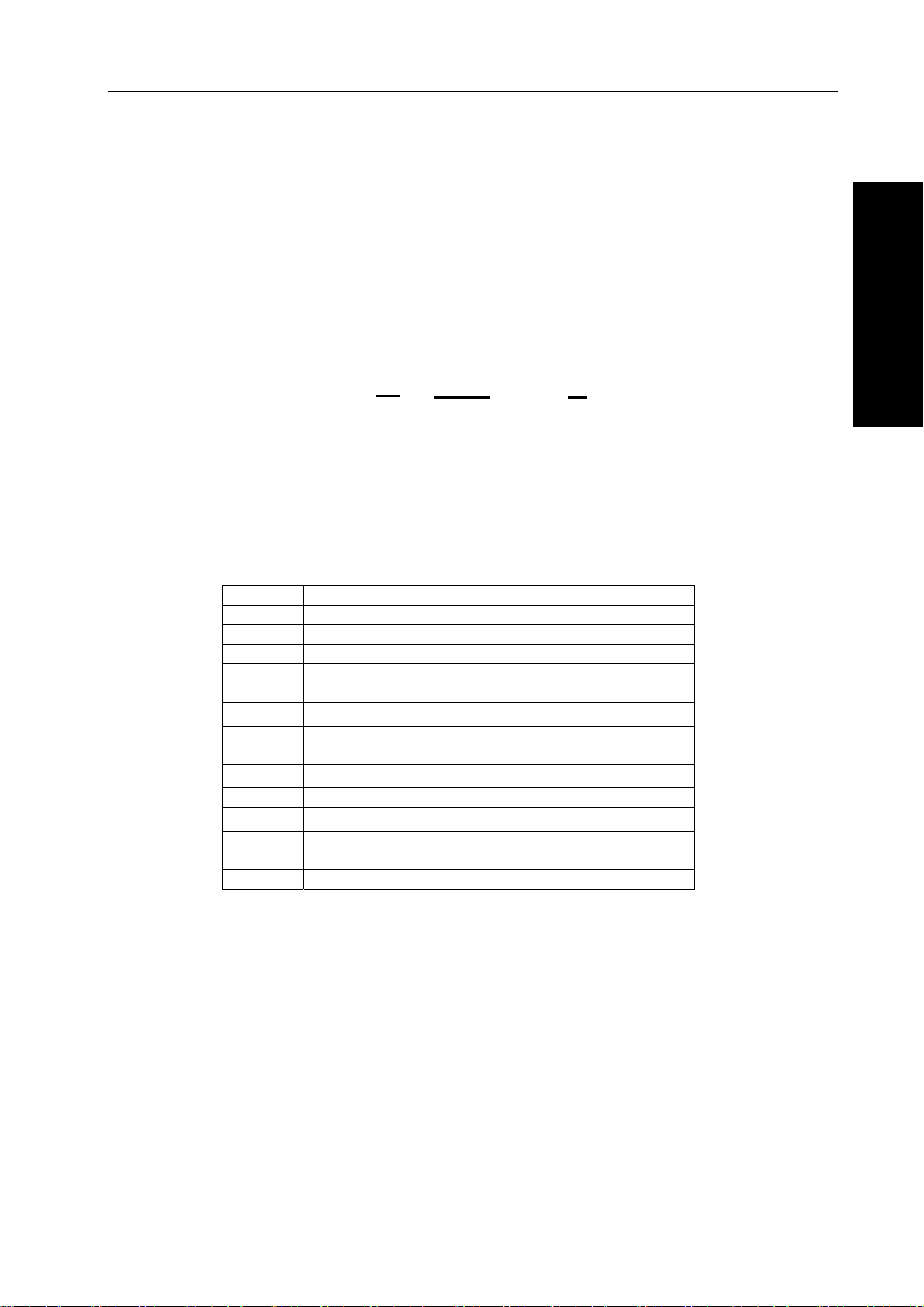

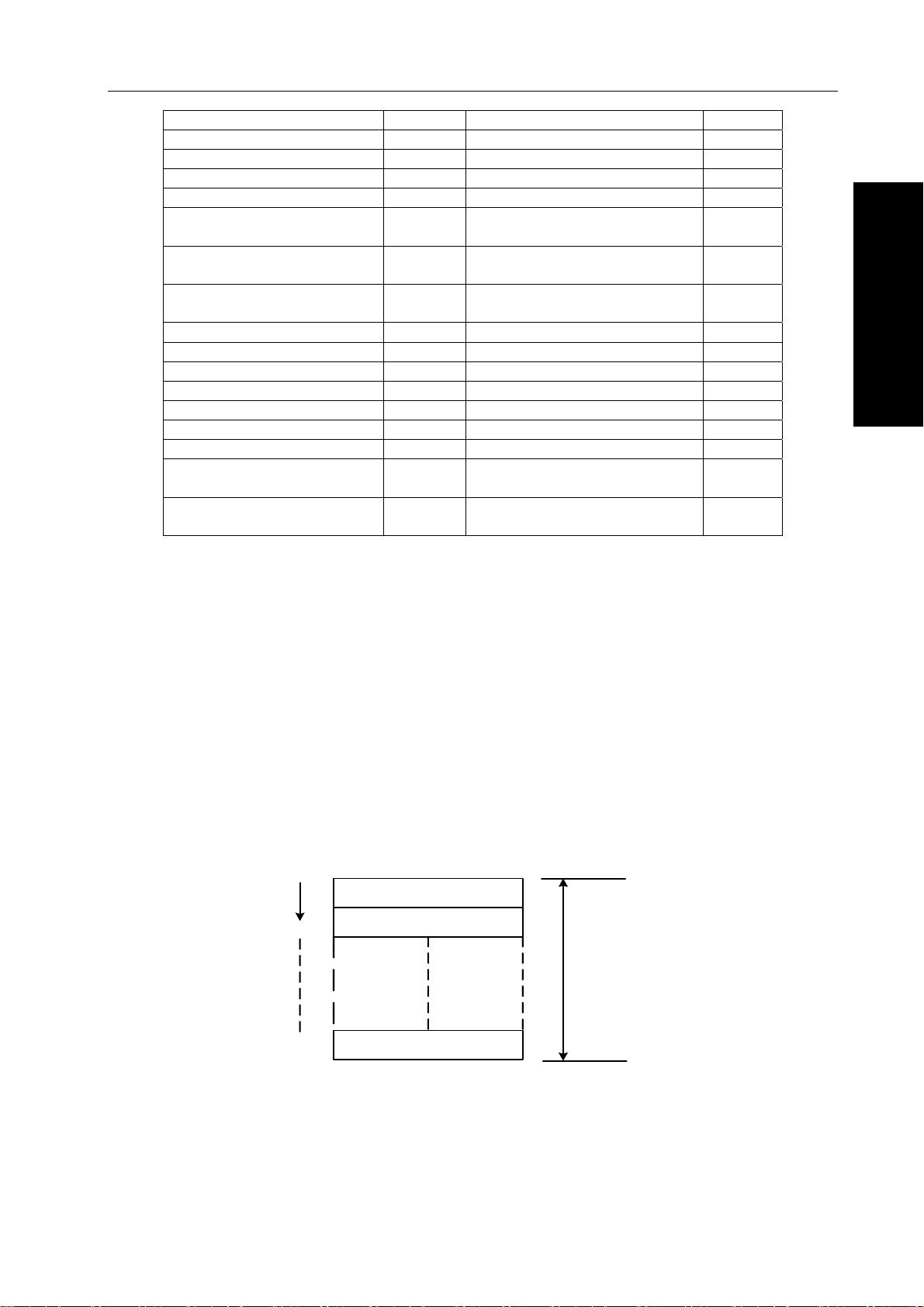

1.1 GSK218MC Series PLC Specification

GSK218MC series PLC specification is shown below:

Table 1-1-1

Specification GSK218MC Series PLC

Programming language Ladder

Program level 2

The 1st level program execution cycle 8ms

Basis code average treatment time 5μs

Programming capacity 4700 steps

Code Basis code + function code

Internal relay (R)

PLC alarm detection (A)

Nonvolatile memory area

Timer (T)

Counter (C)

Data base (D)

Nonvolatile relay (K)

Counter prevalue data register (DC)

Timer prevalue data register (DT)

Subprogram (P)

Mark (L)

Input signal of NC side (F)

Signal outputs to the NC side (G)

Volume I Programming

0~511 (byte)

0~31 (byte)

0~127 (word)

0~127 (word)

0~255 (word)

0~63 (byte)

0~127 (word)

0~127 (word)

0~99

0~99

0~63 (byte)

0~63 (byte)

I/O module (X)

(Y)

0~63 (byte)

0~47 (byte)

1.2 The Concept of the Sequence Programming

The programming is performed a logic control to the machine tool and its relative equipments, which

is called sequence programming.

After the programming is converted into some kind of format, CPU can be performed the code and

calculation treatment for it, and its fruits can be memorized to RAM. CPU can be rapidly read each

code stored in the memory, which can be performed the programming according to the calculation

operation.

The compiling of the sequence programming starts with developing of the ladder diagram

3

Page 19

Installation and Connection Manual of GSK218MC CNC System

1.3 Distribution Interface (Step one)

The interface can be distributed after confirming the controlled object and calculating the points of the

Volume I Programming

corresponding input/output signal.

Refer to the Chapter Four Input/output interface signal table in the part of the Installation and

Connection when distributing the interface.

VolumI Programming

1.4 Ladder Diagram Programming (Step two)

The control operation required by the machine tool can be expressed by the ladder diagram with the

on-line compiling of the GSK218MC. The functions, such as the timer and counter, can not be

expressed by relay symbols, which can be indicated by the specified function code symbols.

The compiled ladder diagram should be stored and converted into the corresponding PLC codes

before operating, namely, the so-called instruction list.

1.5 Sequence Programming Debugging (Step 3)

The sequence programming can be debugged using the following methods:

1) Debugging with emulator

The machine tool can be replaced by an emulator (it composes of the lights and switches). The

input signal state of the machine tool can be expressed by the ON or OFF of the switches; and

the output signal state can be indicated by the ON or OFF of the light.

2) Debugging with actual operation

Debug on the actual machine tool. It is better to prepare the precautions before debugging, due

to an unexpected behavior may occur.

4

Page 20

Chapter Two Sequence Programming

CHAPTER TWO SEQUENCE PROGRAMMING

The operating principle is different with the common relay, because the PLC sequence controlling is

carried out by compiling the on-line diagram. And therefore, it is better to thoroughly understand the

sequence controlling principle when designing the PLC sequence programming.

2.1 Performance Process of Sequence Programming

In the general relay controlling circuits, each of them can be simultaneously operated. When the relay

A is operated in the following figure, the replay D and E can be operated (when the contactor A and B

are closed) at the same. Each replay in the PLC sequence control is operated in turn. The relay D is

operated before relay A, and then the relay E operates (refer to the following figure). Namely, each

relay is operated based upon the sequence of the ladder diagram (compiling sequence).

A

A

Fig. 2.1 (a) Circuit illustration

B

D

C

E

Volume I Programming

The differences between the relay circuit and PLC programming operation are shown below in the Fig.

2.1 (b) and Fig. 2.1 (c).

A

A

C

B

C

Fig. 2.1 (b)

A

C

A

C

B

Fig. 2.1 (c)

(1) Relay circuit

Both Fig. 2.1 (b) and Fig. 2.1 (c) are shared a same operation. B and C are switched on after A is

turned on. B is cut off after C is ON.

5

Page 21

Installation and Connection Manual of GSK218MC CNC System

(2) PLC program

A same relay is shared a same circuit, refer to the Fig. 2.1 (b); B and C are switched on after A is

turned on. B is cut off after one cycle of the PLC program is performed. In the Fig. 2.1 (c), C is ON

instead of B, after C is turned on.

Volume I Programming

2.2 The Performance of the Cycle

VolumI Programming

PLC performs from the beginning to the end of the ladder diagram. It performs again from the

beginning of the ladder diagram after this diagram is performed, which is called cycle performance.

The performance time from the beginning to the end of the ladder diagram is abbreviated as a period

of a cycle treatment. The shorter of the treatment period is, the stronger of the response capacity of

the signal is.

2.3 The Priority Sequence of the Performance (the 1st Level, the 2nd

level)

GSK218MC PLC program are composed of two parts: the 1st level program and the 2nd level program,

which are inconsistent with the performance period.

st

The 1

level program performs once each 8ms, which can be treated some fast corresponding and

short pulse.

nd

The 2

may divide the 2

program performs once each 8*nms. N is the partition value of the 2nd level program. PLC

nd

level program into N parts when the 2nd level program is executed. It is performed

one part for each 8ms.

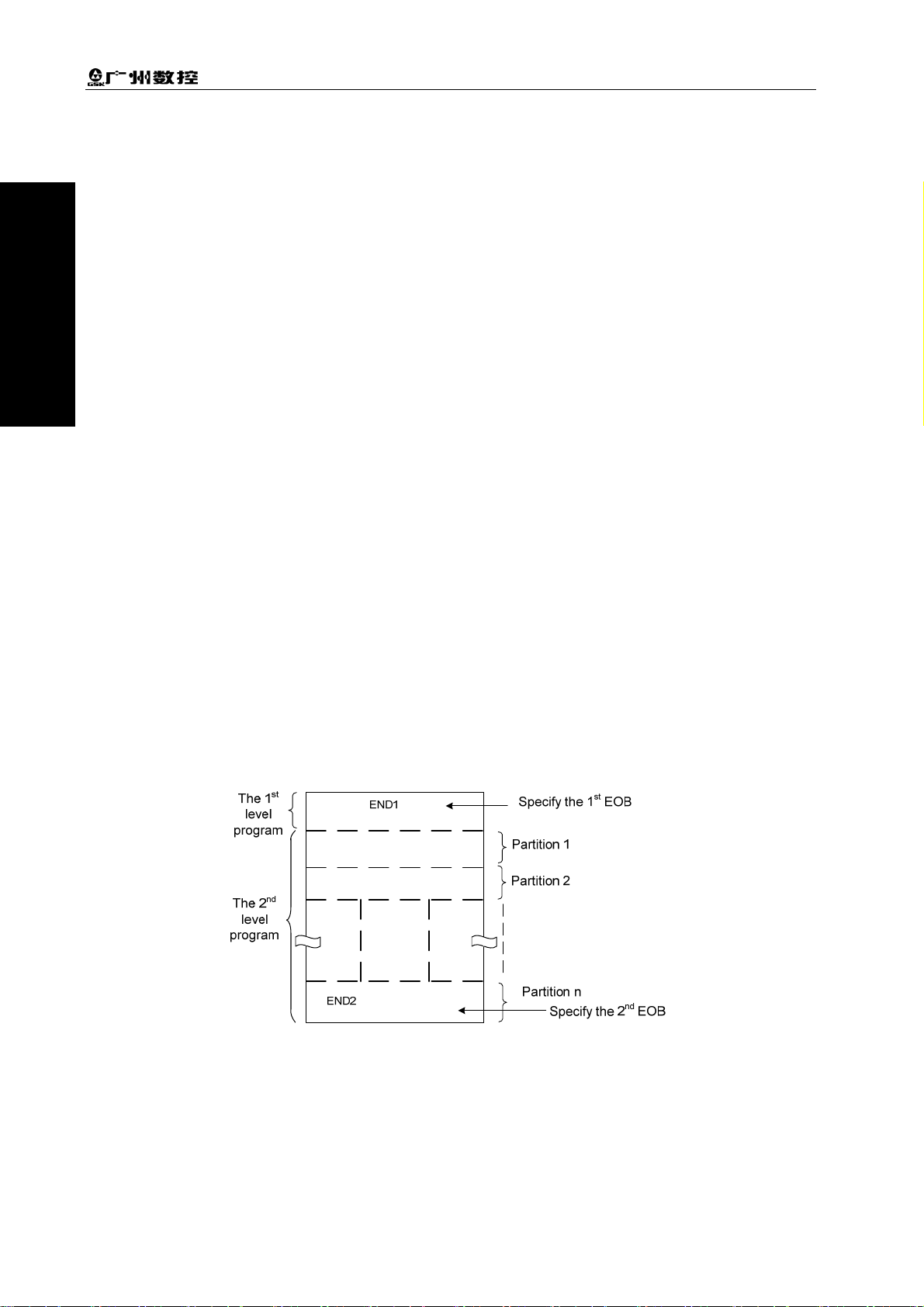

Fig. 2-3-1

PLC in the GSK218MC is separately performed in the PLC-AVR SCM. The 1ms of each 8ms is the

communication time for reading the PLC data from the CNC. The 5ms is that the PLC gains the

system control signal (F. X), and uploads the control result data (G, Y parameter) external port I/O.

PLC is always performed the ladder diagram calculation other than the interruption of the response

exchange data.

6

Page 22

Chapter Two Sequence Programming

Fig. 2-3-2

nd

When the last partition value of the 2

executed from the beginning of the program. In this case, when the partition value is n, the

performance time of one cycle is 8*n ms. The 1

program performs once each 8*n ms. If its steps of the 1

the steps of the 2

nd

level program within 8ms should be reduced correspondingly; the partition value

may be increased, and the treatment time of the overall program will be longer. So, the compiling of

st

level program should be shorter.

the 1

level program of the n is performed, the program is then

st

level program performs once each 8ms; the 2nd level

st

level program is increased, and therefore

Volume I Programming

2.4 Sequence Programming Structure

The ladder diagram is compiled with sequence in the traditional PLC. It owns the following

advantages in the ladder diagram language allowing the structured programming:

1. The program is easy to comprehend and compile.

2. It is more convenient to find the faults during the programming.

3. It is easy to find some reasons when the operation malfunction occurs.

The methods of the main structure programming are shown below:

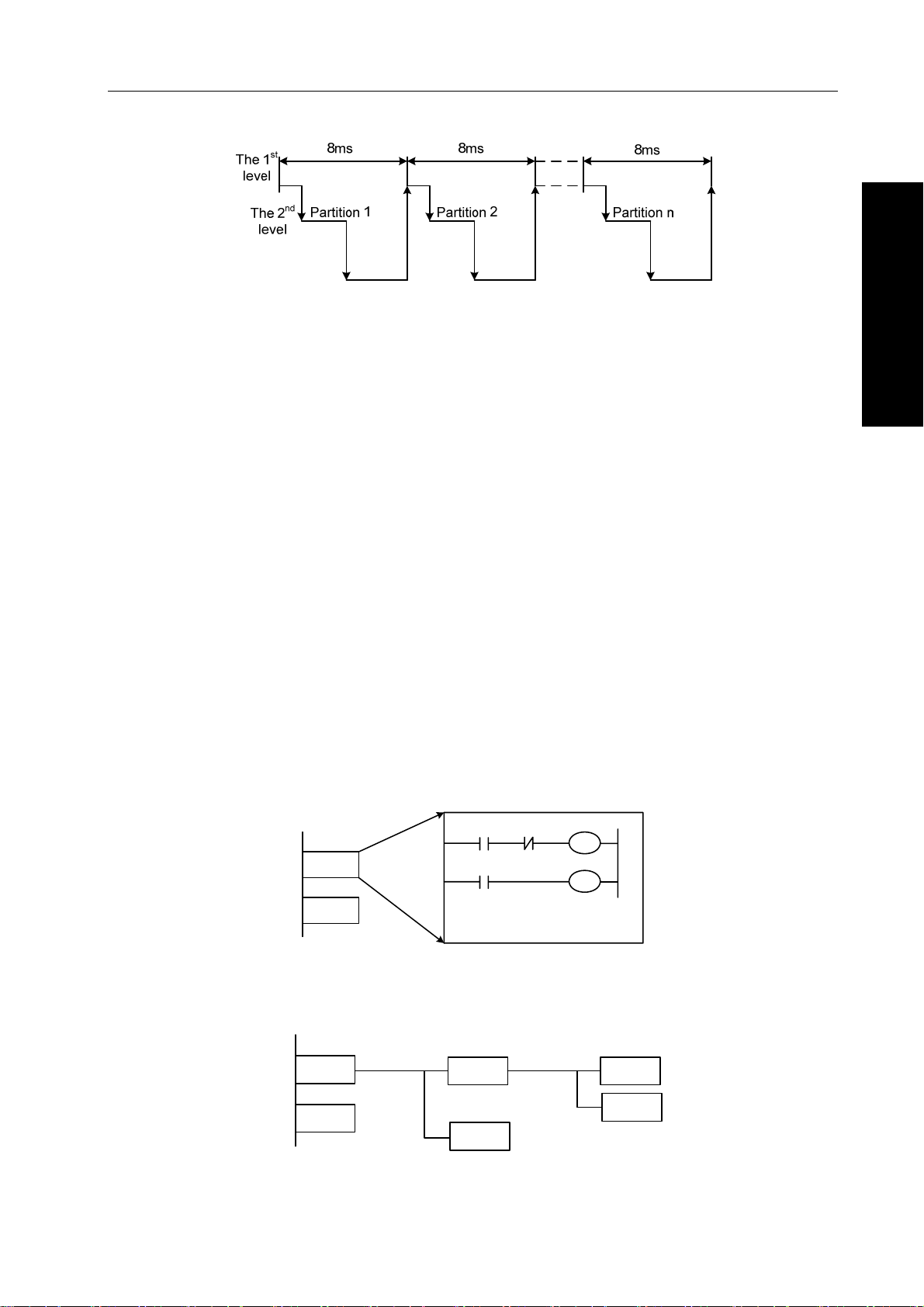

1) Sub-program

The subprogram is regarded as a treatment unit based on the ladder diagram.

C

A

Task A

Task B

A

.

.

.

.

Fig. 2-4-1

2) Nesting

One subprogram can be performed the task by calling another one.

B

C

Main program

Task A

Task B

Subprogram 1 Subprogram 2

Task A1

Task An

Task A11

Task A12

Fig. 2-4-2

7

Page 23

Installation and Connection Manual of GSK218MC CNC System

3) Conditional branch

The main program is performed circularly, and checks whether its conditions are suitable. The

corresponding subprograms are performed under these conditions, vice versa.

Volume I Programming

VolumI Programming

Fig. 2-4-3

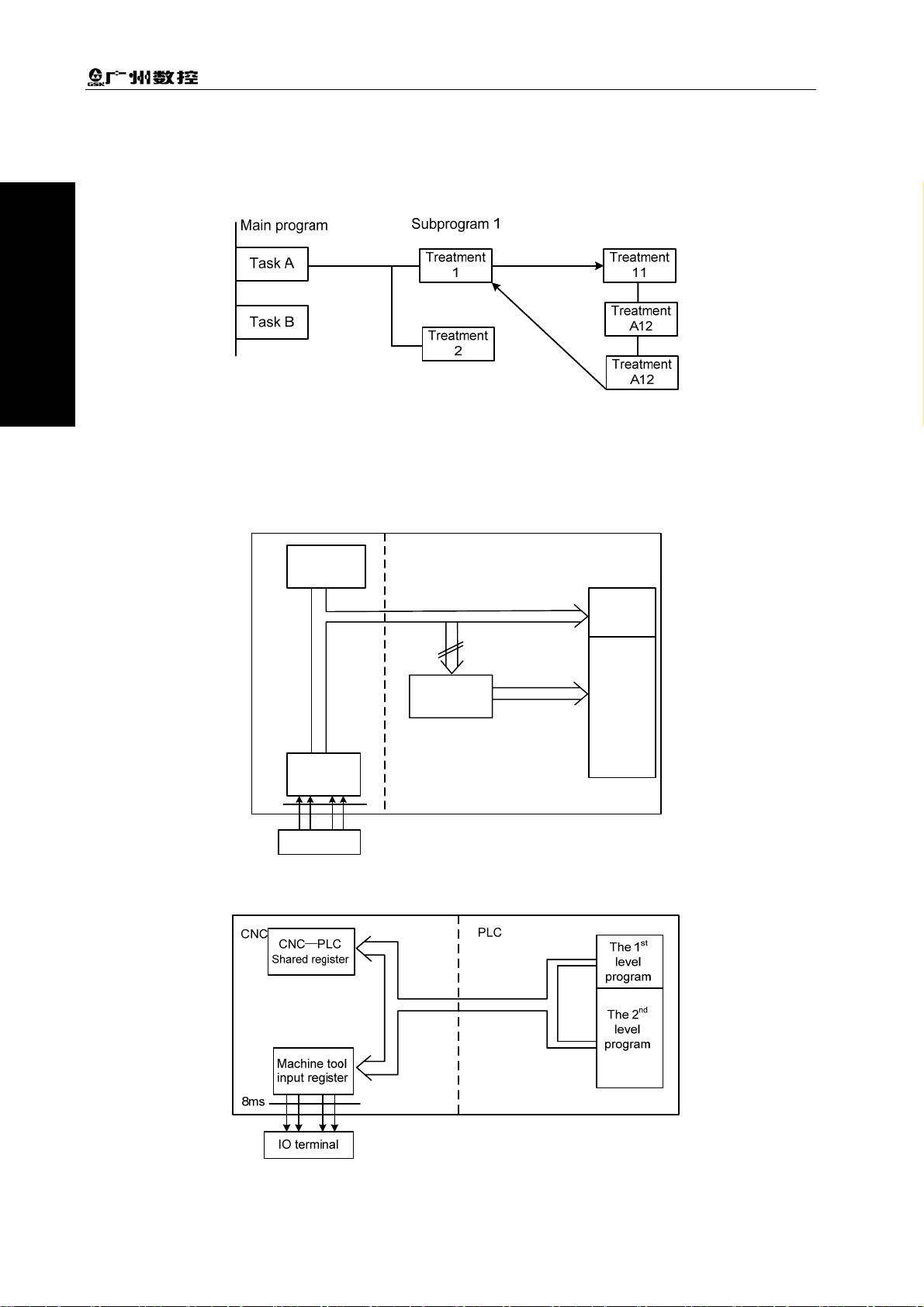

2.5 The Treatment of the Input/output Signal

The treatment of the input signal:

CNC

CNC—PLC

Shared register

Latched at the

beginning of the

nd

level

2

nd

The 2

program input

signal latch

Machine tool

input register

8ms

IO terminal

Fig. 2-5-1

The 1stlevel

program

The 2ndlevel

program

The treatment of the output signal:

8

Fig. 2-5-2

Page 24

Chapter Two Sequence Programming

2.5.1 Input Signal Treatment

(1) NC input register

The NC input signals from the NC are memorized into the NC input register, which are transferred to

st

PLC each 8ms. The 1

signals.

(2) Machine tool input register

The machine tool input register is scanned and memorized its input signal from the machine each

8ms. The 1st level program is also performed the corresponding treatment by using this signals

directly.

nd

(3) The 2

level program input register

The 2nd level program input signal register is also called the 2nd level program synchronic input signal

register. Wherein, the stored input signal is treated by the 2nd level program. This signal state in the

register is synchronic with the 2

The signals both in the NC and machine tool input register can be locked to the 2

input latch, as long as the 2nd level program performs. The signal state in this latch keeps invariable

during the performance of the 2

level program performs the corresponding treatment using state of these

nd

level one.

nd

level program

nd

level program.

Volume I Programming

2.5.2 The Treatment of the Output Signal

(1) NC output register

The output signal transfers to the NC output register from the PLC each 8ms.

(2) Machine tool output register

The signal memorized in the machine tool output register conveys to the machine tool each 8ms.

Note: The signal states, such as the NC input register, NC output register, machine input register and machine output

register, which can be displayed by the self-diagnosis function. The diagnosis number is the address number in

the sequence programming.

2.5.3 The Distinguish of the Signal State Between the 1st Level and the

2nd Level Program

As for the same input signal, their states may different between the 1st and 2nd level programming,

that is the reason that different registers are used between two levels programming. Namely, the input

nd

signal used with the 2

signal in the 2nd level program is later than the 1st level one. At the worst case, one 2nd level program

performance cycle can be lagged.

It is better to remember this point when programming the ladder diagram.

level program is the one of the 1st level who is locked. And therefore, the

A

A

.

.

.

.

END1

.

.

.

.

B

C

It belongs to the 2nd partition

of the 2

nd

level program

Fig. 2-5-3-1

9

Page 25

Installation and Connection Manual of GSK218MC CNC System

A=1 performs the 1st level program when the 1st 8ms is performed, then B=1. And therefore, the 2nd

nd

level program is performed, the A=1 is latched to the 2

level program, and then the first partition of

the 2nd level program is completed.

Volume I Programming

A turns into 0 to perform the 1

nd

therefore, the 2

partition of the 2nd level program is performed; in this case, the state of the A is still

st

level program when the 2nd 8ms is performed, then B=0. And

latched as the one last time. So, C=1.

VolumI Programming

In this way, the state both B and C are different.

2.6 Interlocking

In the sequence control, the interlocking is very important from the safety issue.

It is necessary to use the interlocking in the sequence control programming. Simultaneously, the hard

interlocking is used in the relay control circuit of the strong electric cabinet of the machine tool sides.

This is the reason that the interlocking is disabled when the hardware of the performance sequence

programming malfunctions, even if the interlocking is logically used in the sequence program

(software). And therefore, the interlocking can be ensured the safety for the user, and prevent the

machine tool from damaging in the strong electric cabinet of the machine sides.

10

Page 26

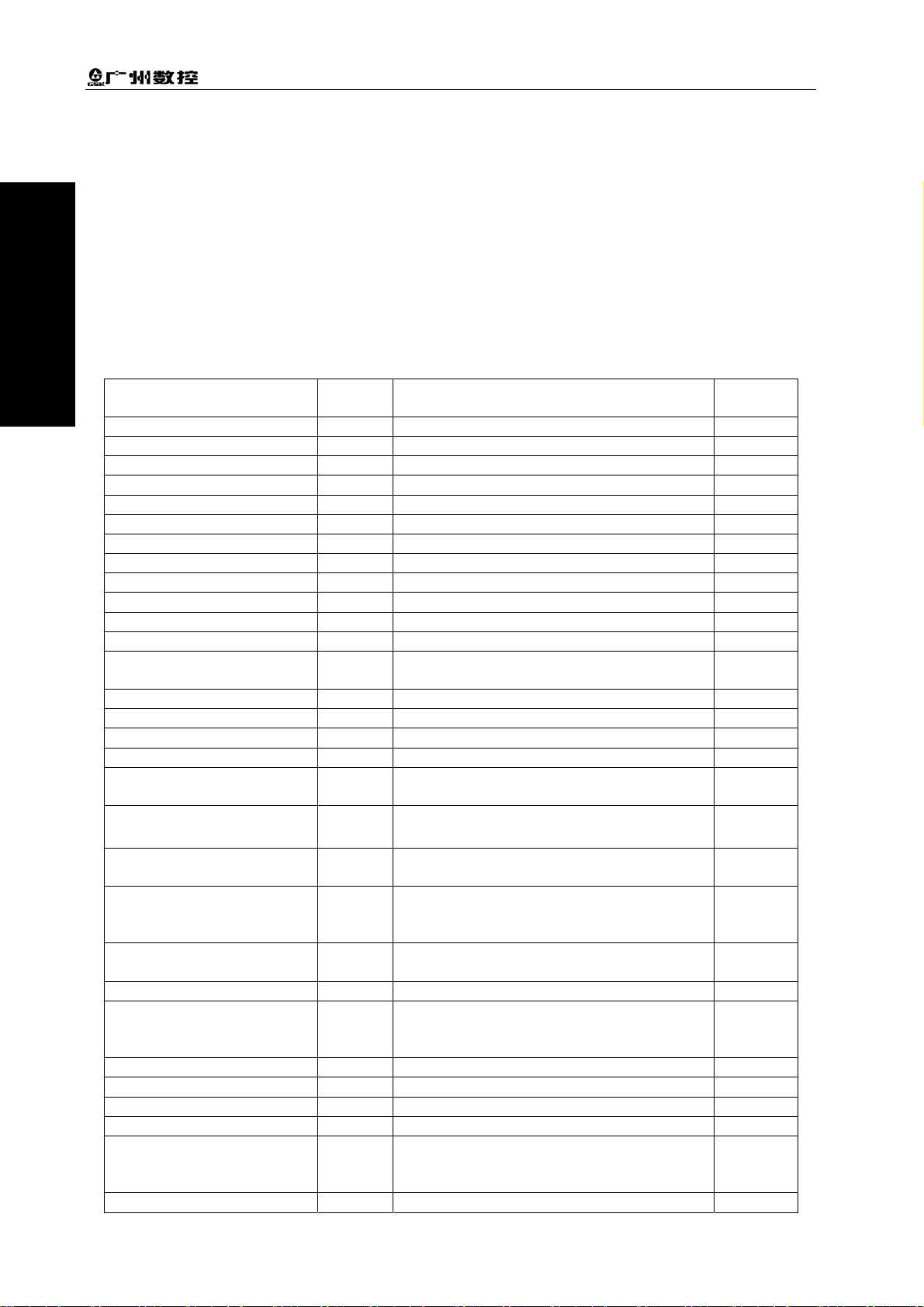

Chapter Three PLC Address

CHAPTER THREE PLC ADDRESS

Address distinguishes signal. Different address is separately corresponding to the I/O signal at the

side of the machine tool, the I/O signal at the side of the CNC, the internal relay, the counter, the timer,

the keep relay and the data list. Each address is composed of the address number and bit number,

and its number is as shown below:

Address number rules:

Address number consists of address type, address number and bit number.

Type Address number Bit number

Address type: X, Y, R, F, G, K, A, D, C and T

Address number: Decimal number means one byte.

Bit number: Octonary number system, 0~7 are separately indicated the bytes (0~7 bits) in the front

of the address number.

The address type of the GSK218MC PLC is shown below:

Address Address explanation Length

X Machine →PLC (64 bytes) INT8U

Y PLC → machine tool (48 bytes) INT8U

F CNC → PLC (64 bytes) INT8U

G PLC → CNC (64 bytes) INT8U

R Intermediate relay (512 bytes) INT8U

D

DC

C

A PLC alarm detection INT8U

T

DT

K Keep relay (64 types) INT8U

Data register (0~255)

The data register of the counter

preset value

Counter (0~127)

Timer (0~127)

The data register of the timer preset

value

X 000 . 6

Table 3-1

INT16U

INT16U

INT16U

INT16U

INT16U

Volume I Programming

INT8U data type is 8-bit character type without symbol, INT16U data type is 16-bit integral type

without symbol.

3.1 Machine → PLC address (X)

The X address of the GSK218MC PLC composes of two types:

1. The X address is assorted with the three I/O input terminals, namely, XS40, XS41 and XS42.

2. The X address is assorted with the input button on the MDI panel of the system.

3.1.1 X Address on the I/O Input

The addresses (48 addresses) are defined as INT8U from X0 to X5, which are distributed on the

three I/O input terminals, for example, XS40, XS41 and XS42.

11

Page 27

Installation and Connection Manual of GSK218MC CNC System

Users can define the signal significance of the X address of the I/O ports based upon the actual cases,

which can be connected the machine tool and compiled the corresponding ladder diagram. Refer to

the appendix one (GSK218MC CNC system PLC I/O address) and the configuration and definition of

the internal software components for the initial definition of the input address.

Volume I Programming

3.1.2 X Address on the MDI Panel

There are 11 types from the addresses X20 ~ X30 of which these addresses are corresponding with

the button input on the MDI panel one by one. User can not modify its signal definition. The buttons

VolumI Programming

on the MDI panel should be firstly responded by CNC, and then conveys the X signal to PLC.

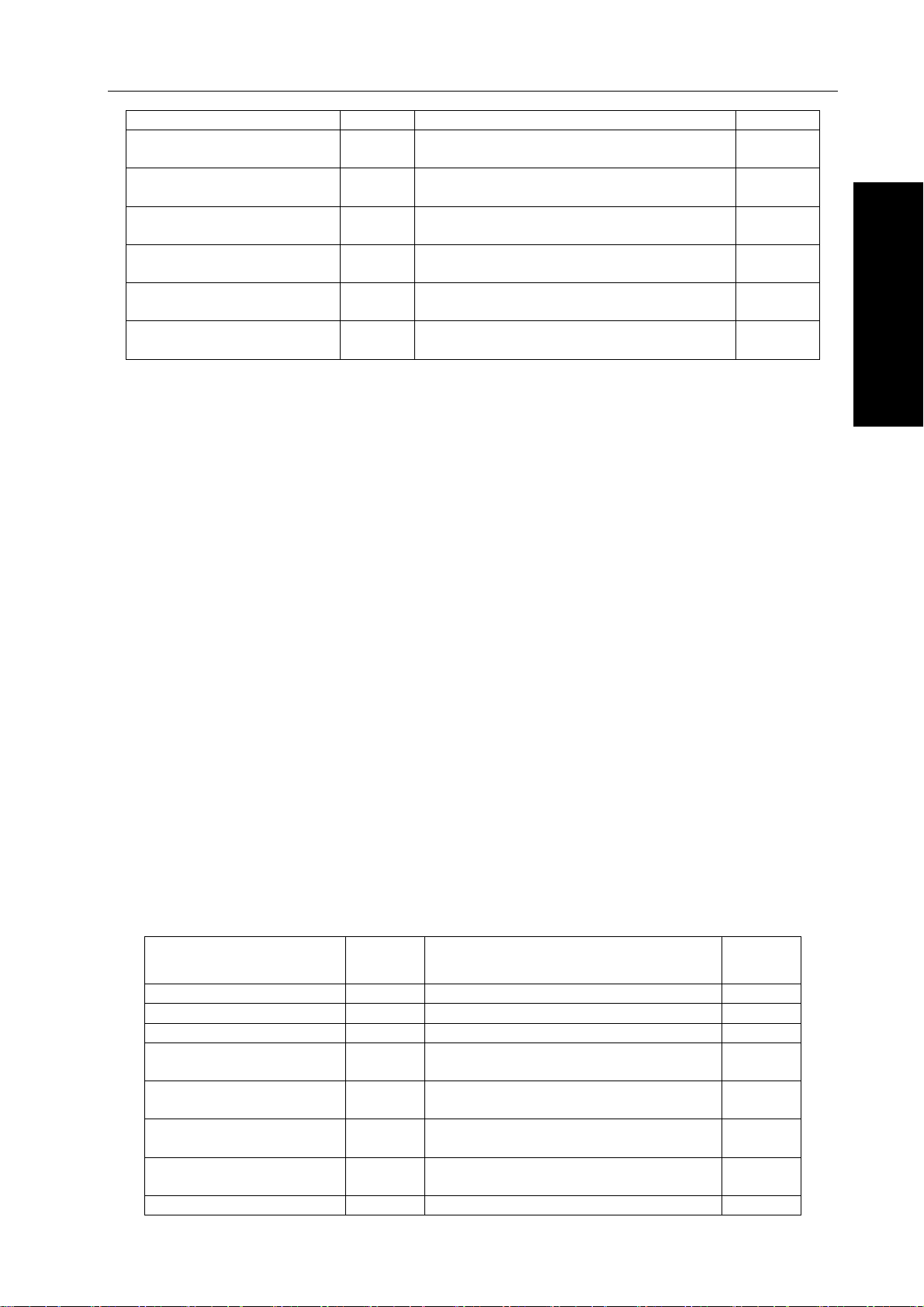

The corresponding relationships are shown below:

Table 3-1-2-1

Button input

Edit X20.0 Rapid Fo X25.0

Auto X20.1 Rapid 25% X25.1

MDI X20.2 Rapid 50% X25.2

Zero return X20.3 Rapid 100% X25.3

Single step X20.4 Increment step 0.001 X26.0

Manual X20.5 Increment step 0.01 X26.1

MPG X20.6 Increment step 0.1 X26.2

DNC X20.7 Increment step 1 X26.3

Skip X21.0 Manual feed shaft +X X27.0

Single step X21.1 Manual feed shaft +Y X27.1

Dry run X21.2 Manual feed shaft +Z X27.2

M.S.T Lock X21.3 Manual feed shaft +Nth X27.3

Machine tool lock X21.4

Selection stop X21.5 Manual feed shaft -X X28.0

Program restart X21.6 Manual feed shaft -Y X28.1

Working light X21.7 Manual feed shaft -Z X28.2

Spindle CCW X22.0 Manual feed shaft -Nth X28.3

Spindle stop X22.1

Spindle CW X22.2

Spindle negative override

(218MC integration)

Spindle override

cancellation

(218MC integration)

Spindle positive override

(218MC integration)

Spindle JOG X22.6 Tool magazine CW X29.3

Spindle override

cancellation (218MC-H/-V

is the channel selection)

Lubrication X23.0 Tool pivoting (tool infeed) X29.5

Cooling X23.1 Tool back (tool retracting) X29.6

Chip-removal X23.2 Tool changer X29.7

ESP X23.5 Overtravel release X30.0

Cycle start X23.6

Feed hold X23.7 Spindle override cancellation X31.1

PLC

address

Spindle positive override

(218MC-H/-V is N axis +)

Spindle negative override

(218MC-H/-V is N axis -)

Spindle blowing (218MC 一

integration)

X22.3 Spindle orientation X29.0

X22.4 Tool magazine zero return X29.1

X22.5 Tool clamping/releasing X29.2

X22.7 Tool magazine CCW X29.4

Spindle negative override

(218MC-H/-V is the spindle override

SOV1)

Button input

PLC

address

X27.4

X28.4

X28.7

X31.0

12

Page 28

Chapter Three PLC Address

(218 MC-H/-V is spindle override SOV2)

User 1 X24.0

User 2 X24.1

User 3 X24.2

User 4 X24.3

User 5 X24.4

Rapid switch X24.7

Spindle positive override

(218MC-H/-V is spindle override SOV4)

Feed negative override

(218MC-H/-V is the feed override FOV1)

Feed override cancellation

(218MC-H/-V is the feed override FOV2)

Feed positive override

(218MC-H/-V is the feed override FOV4)

Feed override FOV8

(218MC-H/-V)

Feed override FOV16

(218MC-H/-V)

X31.2

X31.3

X31.4

X31.5

X31.6

X31.7

3.2 PLC → Address of the Machine Tool Side (Y)

The Y address of the GSK218MC PLC composes of two types:

1. The Y address is assorted with the three I/O input terminals, namely, XS43, XS44 and XS45.

2. The Y address is assorted with the indicator on the MDI panel of the system.

3.2.1 Y Address on the I/O Output Port

Volume I Programming

The addresses (48 addresses) are defined as INT8U from Y0 to Y5, which are distributed on the

three I/O input terminals, for example, XS43, XS44 and XS45.

Users can define the signal significance of the Y address of the I/O ports based upon the actual cases,

which can be connected the machine tool and compiled the corresponding ladder diagram. Refer to

the appendix one (GSK218MC CNC system PLC I/O address) and the configuration and definition of

the internal software components for the initial definition of the input address.

3.2.2 Y Address on the MDI Panel

There are 8 types from the addresses Y12 ~ Y19 of which these addresses are corresponding with

the button input on the MDI panel one by one. User can not modify its signal definition. PLC system

reports to the CNC system keyboard module after calculating, and it is used for displaying the

indicator signal.

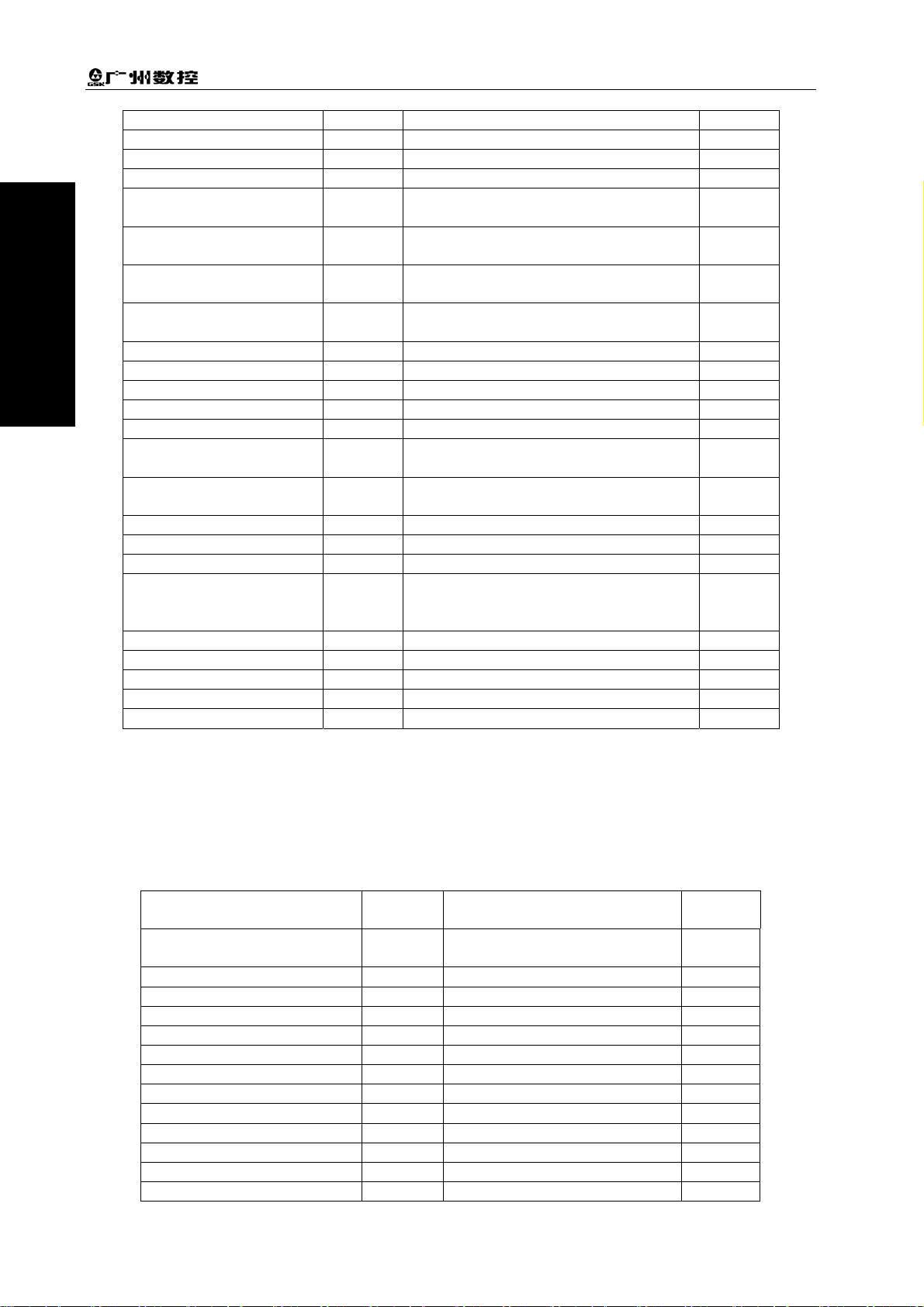

The corresponding relationships of each prompt light:

Table 3-2-2-1

Key-board indicator

output

Edit key indicator Y12.0 Spindle orientation indicator Y15.7

Auto key indicator Y12.1 Tool magazine zero return indicator Y16.0

MDI key indicator Y12.2 Tool magazine CW indicator Y16.1

Zero return key

indicator

Single step key

indicator

Manual key indicator

MPG key indicator

DNC key indicator Y12.7 Tool magazine tool changer Y16.6

PLC

address

Y12.3 Tool magazine CCW indicator Y16.2

Y12.4

Y12.5

Y12.6

Key-board indicator output

Tool magazine (tool pivoting) (tool

infeed) indicator

Tool magazine (tool retraction)

indicator

Tool magazine clamping/releasing

indicator

PLC

address

Y16.3

Y16.4

Y16.5

13

Page 29

Installation and Connection Manual of GSK218MC CNC System

Spindle CCW indicator Y13.0 USER3 indicator Y16.7

Spindle CW indicator Y13.1 +X key indicator Y17.0

Volume I Programming

VolumI Programming

Spindle stop indicator Y13.2 +Y key indicator Y17.1

Y axis zero return

indicator

Y axis zero return

indicator

Z axis zero return

indicator

The 4th axis zero return

indicator

DEF indicator Y13.7 (218MC integration) Y17.7

Skip indicator Y14.0 -X key indicator Y18.0

Single-step indicator Y14.1 -Y key indicator Y18.1

Dry run indicator Y14.2 -Z key indicator Y18.2

M.S.T lock indicator Y14.3 -4TH key indicator Y18.3

Machine tool lock

indicator

Machine tool lighting

indicator

Lubrication indicator Y14.6 Tunnel selection key indicator Y18.6

Cooling indicator Y14.7 JOG key indicator Y18.7

Chip-removal indicator Y15.0 Overtravel end key indicator Y19.0

The indicator of feed

override cancellation

key

Rapid switch indicator Y15.2 Cycle start key indicator Y19.2

0.001/F0 key indicator Y15.3 Tool magazine zero point indicator Y19.3

0.01/25% key indicator Y15.4 Selection stop indicator Y19.4

0.1/50% key indicator Y15.5 Program re-start indicator Y19.5

1/100% key indicator Y15.6

indicator

Y13.3 +Z key indicator Y17.2

Y13.4 +4TH key indicator Y17.3

Y13.5 USER1 key indicator Y17.4

Y13.6 N axis + key indicator Y17.5

Y14.4 USER2 key indicator Y18.4

Y14.5 N axis - key indicator Y18.5

Y15.1 Feed dwell key indicator Y19.1

3.3 PLC →CNC Address (G)

The addresses from G0 to G63, its definition type: INT8U, totally 64 bytes.

The operation panel key signal is shown below:

Table 3-3-1

Operation panel key signal PLC

address

Edit mode G20.0

Auto mode G20.1 Rapid switch G24.7

MDI mode G20.2 Rapid Fo G25.0

Zero return mode G20.3 Rapid 25% G25.1

Single step mode G20.4 Rapid 50% G25.2

Manual mode G20.5 Rapid 100% G25.3

MPG mode G20.6 Increment step length 0.001 G26.0

DNC mode G20.7 Increment step length 0.01 G261

Skip G21.0 Increment step length 0.1 G26.2

Single block G21.1 Increment length 1 G26.3

Dry run G21.2 MPG step length 0.001 G26.4

M.S.T lock G21.3 MPG step length 0.01 G26.5

Machine lock G21.4 MPG step length 0.1 G26.6

Operation panel key signal

Feed negative override

(218MC integration)

PLC

address

G24.2

14

Page 30

Chapter Three PLC Address

o

Selection stop G21.5 Manual feed axis + X G27.0

Program re-start G21.6 Manual feed axis +Y G27.1

Spindle CCW (positive) G22.0 Manual feed axis +Z G27.2

Spindle stop G22.1 Manual feed axis +4Th G27.3

Spindle CW (negative) G22.2 Manual feed axis –X G28.0

Spindle negative override

(218MC integration)

Spindle override cancellati

(218MC integration)

Spindle positive override

(218MC integration)

Spindle JOG G22.6 Spindle orientation G29.0

Tunnel selection signal G22.7 Tool magazine zero return G29.1

Lubrication G23.0 Tool clamping/release G29.2

Cooling G23.1 Tool magazine positive G29.3

Chip removal G23.2 Tool magazine negative G29.4

Cycle start G23.6 Tool pivoting (Tool infeed) G29.5

Feed hold G23.7 Tool return (tool retraction ) G29.6

Feed positive override

(218MC integration)

Feed override cancellation

(218MC integration)

G22.3 Manual feed axis -Y G28.1

G22.4 Manual feed axis -Z G28.2

Th

G22.5 Manual feed axis -4

G28.3

G24.0 Tool changer G29.7

G24.1 Overtravel release G30.0

Volume I Programming

The signal of G63 bytes are used inside the system, the G63.0, G63.1 and G63.2 are the answer

signal inside the system separately performed by M, S and T.

3.4 CNC →PLC Address (F)

The addresses from F0 to F63 are defined as: INT9U, totally 64 bytes.

Refer to the Chapter Two Function for details.

3.5 Internal Replay Address (R)

The address area is reset when the system is turned on. R510 and R511 are used by the system.

Its definition type is: INT8U, totally 512 bytes.

Address

number

R0

6

7

3

45

012

R511

Fig. 3-5-1

System program administration area

R510

The signal of R510.0 address is set to 1 when PLC starts and restarts, which is used the signal set by

the initial user. The R510.0 is reset to 0 after the ladder diagram is performed once.

15

Page 31

Installation and Connection Manual of GSK218MC CNC System

R511 (System timer) The following four signals can be used for system timer:

R511

Volume I Programming

76 5

432

1

0

Always cut off

Always power on

VolumI Programming

(104ms ON, 96ms OFF)

(504ms ON, 496ms OFF)

200ms period

signal

1s period signal

Fig. 3-5-2

3.6 Nonvolatile Relay Address (K)

This address area is used for nonvolatile replay and PLC parameter setting. This area is called

nonvolatile relay area, namely, the content inside the register will not lose even if the system is turned

off. K000~~K005 are used by the system, which is used to protect the PLC system parameter, it is

very convenient for user to control PLC in the CNC system.

Its definition type: INT8U, totally 64 bytes.

Address

number

K0

K1

K63

Note: When PLC address K005.2 =1, PLC enters the debugging mode. All of the external alarms are cancelled, and

the machine interlocking signals are then cancelled, the tool-change code can not be performed. The parameter

can be modified only when comprehending the parameter, so that the damage in the machine tool or injury of

the person may occur.

6

7

3

45

Fig. 3-6-1

012

K relay

area

3.7 Information Display Request Address (A)

This address area is reset when the system is turned on

Its definition type: INT8U, totally 32 bytes.

Fig. 3-7-1

16

Page 32

Chapter Three PLC Address

3.8 Counter Timer (C)

This area is used for placing the current count value of the counter. The data is reset after the system

is turned off.

Its definition type: 128 addresses.

3.9 Counter Preset Value Address (DC)

This address area is used for storing the counter preset, which is a nonvolatile storage area, that is,

the memorized content may not loose even the system is power off.

Its definition type: 128 addresses. The setting value of the DC is only read instead of writing.

3.10 Timer Address (T)

This address area is used for storing the current numerical value of the timer. The data initial is

presetting value after the system is power off. Current data is presetting value when it is set to 0.

Its definition type: 128 addresses

3.11 Presetting Value Address of the Timer (DT)

Volume I Programming

This address area is used for placing the timer preset value. This area is nonvolatile register area,

namely, the content inside the register will not lose even if the power of the system is turned off.

Its definition type: 128 addresses. The setting value of the DT is only read instead of writing.

3.12 Data Table Address (D)

The content inside the memory will not lose even if the power of the system is turned off.

Its definition type: totally 256 addresses. Wherein, D240~247 are used by the system, users can not

define by themselves.

3.13 Sign Address (L)

It is used to specify signs both skip object and the LBL code in the JMPB code.

Its range: 0~99

3.14 Subprogram Number (P)

It is used to specify the called object subprogram number in the CALL code and the subprogram

number in the SP code.

Its range: 0~99

17

Page 33

Installation and Connection Manual of GSK218MC CNC System

CHAPTER FOUR PLC BASIS CODE

Volume I Programming

The design of the sequence program begins from the compiling of the ladder diagram. The ladder

diagram consists of relay contact and function code. The logic relationship in the ladder diagram

composes of sequence program. There are two methods of the sequence program input: one is that

the input method uses the mnemonic symbol language (The system is not temporarily supported the

VolumI Programming

PLC command code of the RD, AND and OR); the other one that is used the relay symbol. The

programming can be compiled using ladder diagram, and do not comprehend the PLC code based

upon the latter.

Actually, the sequence program inside the system can be converted into corresponding PLC code

even if it is input by the relay symbol.

The basis codes are commonly used codes when designing the sequence programming, which are

performed one-digit calculation.

The basis command codes of the GSK218MC are shown below:

Table 4-1

Code name Function

RD Left shift one bit of the content of the register, the signal state specified by

address set to ST0

RD.NOT Left shift one bit of the content of the register, the signal state specified by

address is set to ST0 after its state is set to NOT.

WRT Output the logic calculation result to the specified address

WRT.NOT Output the logic calculation result after NOT to the specified address.

AND Logic AND

AND.NOT Logic AND after the specified state is set to NOT.

OR Logic OR

OR.NOT Logic OR after the specified state is set to NOT.

OR. STK Right shift one bit of the stacked memory after ST0 and ST1 logic OR

AND.STK Right shift one bit of the stacked memory after ST0 and ST1 logic AND

4.1 RD, RD.NOT, WRT, and WRT.NOT Codes

Mnemonic symbol and function

Table 4-1-1

Mnemonic

symbol

RD Left shift one bit of the content of the register, the signal state specified by

address is set to ST0.

RD.NOT Left shift one bit of the content of the register, the signal state specified by

address is set to ST0 after it is set to NOT.

WRT Output the logic calculation result to the specified address

Function

WRT.NOT Output the logic calculation result after NOT to the specified address

18

Page 34

Chapter Four PLC Basis Code

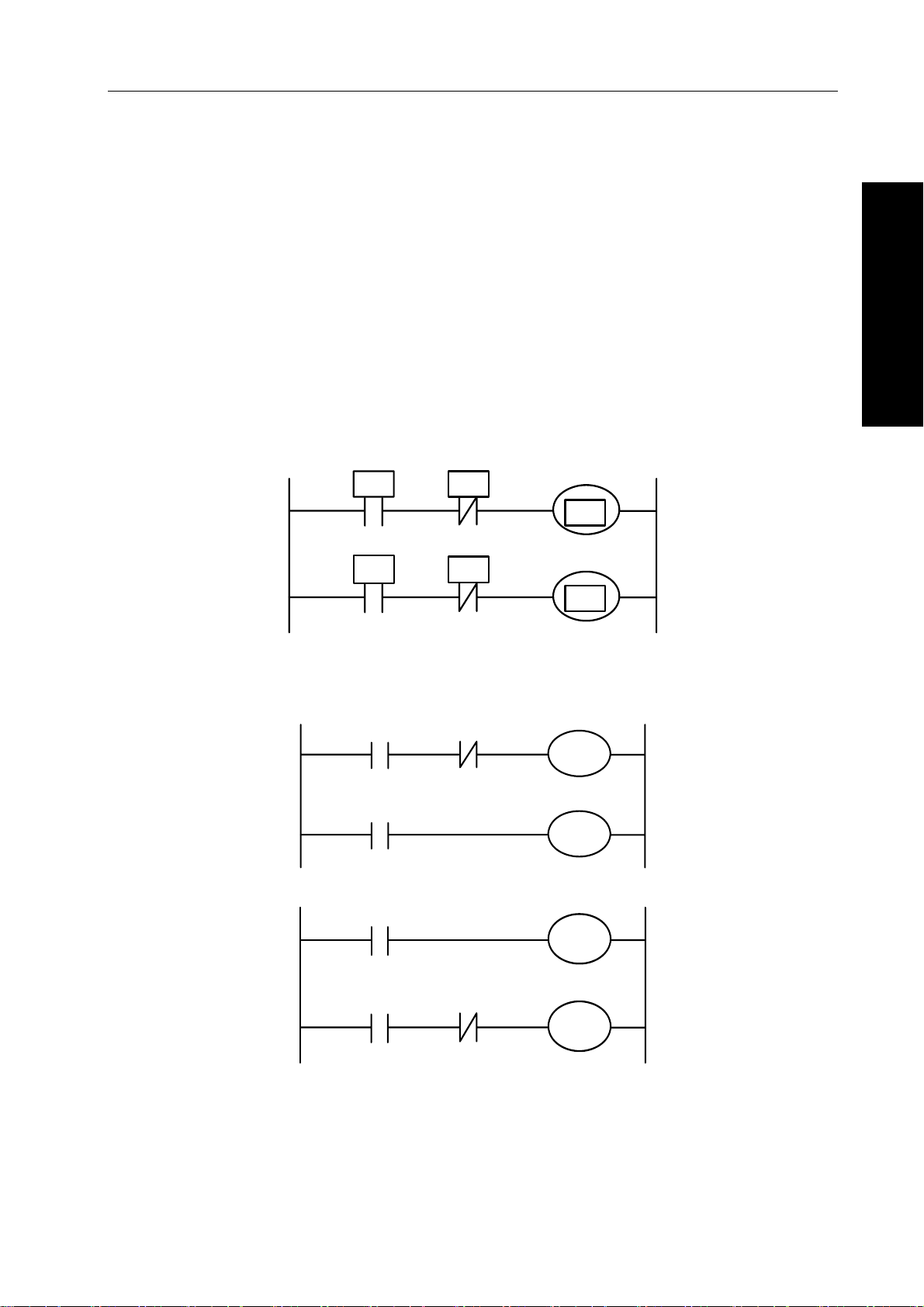

Code explanation

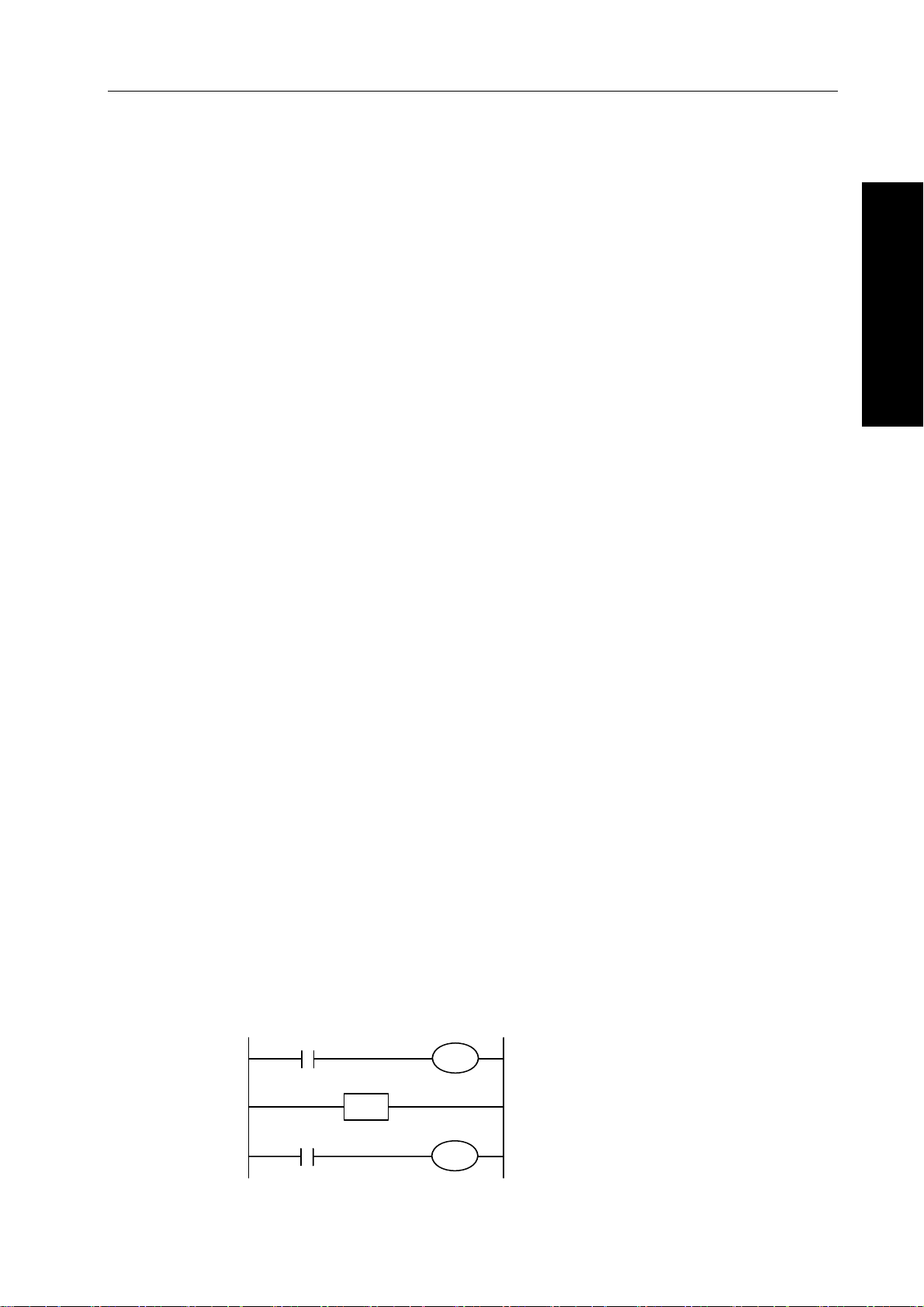

z WRT and WRT.NOT codes are the coil drive code of the output relay and internal relay, but

the input relay can not be used.

z The paratactic WRT command can be used multiply, but it can not output with double coil.

Refer to the following programming:

RD X002.1

X002.1 Y003.7

( )

F100.3 G120.0

( )

WRT Y003.7

RD.NOT F100.3

WRT G120.0

Fig. 4-1-1

4.2 AND, AND.NOT Codes

Mnemonic symbol and function

Table 4-2-1

Volume I Programming

Mnemonic symbol Function

AND Logic AND

AND.NOT Logic AND after the specified

state is NOT

Code explanation

z Connect 1 contact with series connection by using AND, AND.NOT code. The numbers of

series connection contacts are unconstrained, and this code can be used for dozens of times.

Refer to the following programming:

RD X002.1

X002.1 Y003.7

F100.3 X008.6

( )

AND.NOT F100.3

AND X008.6

WRT Y003.7

Fig. 4-2-1

4.3 OR, OR.NOT Codes

Mnemonic symbol and function

Table 4-3-1

Mnemonic symbol Function

OR Logic OR

OR.NOT Logic OR after the specified state is NOT

Code explanation

z Connect 1 contact with series connection using the OR and OR.NOT code.

19

Page 35

Installation and Connection Manual of GSK218MC CNC System

z OR, OR.NOT is started from the step of this code; it can be connected with series connection

with the abovementioned RD, RD.NOT code step.

Refer to the following programming:

Volume I Programming

X002.1 Y003.7

F100.3

VolumI Programming

4.4 OR. STK Code

Mnemonic symbol and function

Mnemonic symbol Function

OR. STK

Code explanation

z OR.STK code is the separate code without any address.

Refer to the following programming:

X002.1 Y003.7

1

F100.3

2

R022.1

3

X002.2

F100.6

( )

RD X002.1

OR.NOT F100.3

WRT Y003.7

Fig. 4-3-1

Table 4-4-1

Right shift one bit of the stacked register after

ST0 and ST1 logic OR

( )

Node N1

OR.STK

OR

RD X002.1

AND.NOT X002.2

RD.NOT F100.3

AND F100.6

OR.STK

OR R 022 .1

W R T Y 003.7

Fig. 4-4-1

There are three branches , and from the left bus to the node N1. The branches and are ①② ③ ① ②

series connection circuit block. When the series connection circuit block is performed between bus to

node or among the nodes, other than the first branch, use the RD code when the following branch is

ended. The branch is not a series connection circuit block, which can be used by the OR code.③

OR. STK and AND. STK are the code without operation component, which indicates the OR , AND

relationships between circuit blocks.

4.5 AND. STK Code

Mnemonic symbol and function

Table 4-5-1

Mnemonic symbol Function

AND.STK

Code explanation

Right shift one bit of the stacked memory after ST0 and

ST1 logic AND

20

Page 36

Chapter Four PLC Basis Code

z Use the AND. STK coded when the branch circuit (parallel circuit block) is connected with

series connection with the front of the circuit. The start of the branch is used RD, RD.NOT

code. Use the AND. STK code is connected with series connection with the front of the circuit

Volume I Programming

after the series connection circuit block is executed.

z AND. STK code is the separate code without any address.

Refer to the following programming:

X002.1 Y003.7

R100.0

R100.3

( )

F100.3

G003.3

R009.7

X011.0

Block

1

Block

2

RD X 002 .1

OR.NOT F100.3

OR.NOT X011.0

RD R 10 0.0

AND.NOT R100.3

RD G 00 3.3

AND R009.7

OR .S T K (1)

AND.STK (2)

Fig. 4-5-1

As for the abovementioned ladder diagram and command table, OR.STK indicates parallel ⑴

connection of the series connection circuit block in the block , AND.STK expresses the series ②⑵

connection between circuit block and .①②

21

Page 37

Installation and Connection Manual of GSK218MC CNC System

CHAPTER FIVE PLC FUNCTION CODE

Volume I Programming

When the basis command code is not easy to compile some operations of the machine tool, the

function command codes can be simplified it.

Table 5-1 (218MC PLC function command code)

VolumI Programming

Serial

number

1 END1

2 END2

3 CALL Call subprogram 21 DIFU Rising edge detection

4 CALLU

5 SP Subprogram 23 COMP Binary number comparison

6 SPE End of subprogram 24 COIN Consistency comparison

7 SET Setting 25 MOVN Data transfer

8 RST Resetting 26 MOVB Transfer of one byte

9 JMPB Sign skip 27 MOVW Transfer of two bytes

10 LBL Sign 28 XMOV

11 TMR Timer 29 DSCH Binary data search

12 TMRB Regular timer 30 ADD Binary addition

13 TMRC Timer 31 SUB Binary subtraction

Name Function

st

The 1

program end

The 2

level sequence

nd

level sequence

program end

Call the subprogram

without any condition

Serial

number

Name Function

19 ROT Binary rotation control

20 SFT Register shift

22 DIFD Trailing edge detection

Binary indexed data

transfer

14 CTR Binary counter 32 ANDF Logic AND

15 DEC Binary decode 33 ORF Logic OR

16 COD Binary code conversion 34 NOT Logic NOT

17 COM

18 COME

Control of the concentric

line

End of the concentric line

control

35 EOR Exclusive OR/ XOR

5.1 END1 (End of the 1st Level Sequence Program)

Function

This function can be specified once in sequence program at the end of the 1

can be performed at the beginning of the 2

nd

level program when the 1st level program does not

execute. The first program can be compiled up to 500 steps.

st

level program, or it

22

Page 38

Format

Chapter Five PLC Function Code

Fig. 5-1-1

5.2 END2 (The End of the 2nd Sequence Program)

Function

It specifies at the end of the 2nd level program.

Format

END2

Fig. 5-2-1

5.3 CALL (Call Subprogram)

Function

Call one specified subprogram

It owns the following characters and limitations:

Subprogram can be nested and called other subprograms up to 18 layers, as for the endless

repetition caused by the closure call, the system may alarm. The system allows that the maximum

subprogram call number is 100 for controlling the performance data value. The subprogram call can

st

not be performed at the 1

SPE, or before SP, the system can not be performed, and then alarms.

level program. The code or network wrote between END2 AND SP, or after

Volume I Programming

Format

Control condition

Parameter

indicated as 0~99.

ACT

CALL

ACT=0, next code after performing CALL

ACT=1, call subprogram of the specified subprogram number

Subprogram

number

Fig. 5-3-1

Subprogram number: specify the called subprogram number. The subprogram number is

5.4 CALLU (Call Subprogram Without Condition)

Function

Call one specified subprogram without any condition

23

Page 39

Installation and Connection Manual of GSK218MC CNC System

It owns the following characters and limitations:

Subprogram can be nested and called other subprograms up to 18 layers, as for the endless

repetition caused by the closure call, the system may alarm. The system allows that the maximum

subprogram call number is 100 for controlling the performance data value. The subprogram call can

Volume I Programming

not be performed at the 1

SPE, or before SP, the system can not be performed, and then alarms.

st

level program. The code or network wrote between END2 AND SP, or after

Format

VolumI Programming

CALLU

Parameter

Subprogram serial number: specify the called subprogram number, its range is 0~99.

Subprogram

number

Fig. 5-4-1

5.5 SP (Subprogram)

Function

SP is used to generate a subprogram. The subprogram number is regarded as its name. The range of

the subprogram is specified by the SP code and the aftermentioned SPE code together.

Notice

1. The subprogram should be compiled after END2.

2. Another subprogram can not be set inside one subprogram.

Format

SP

Parameter

Subprogram number: specify a called subprogram mark number, its range is 0~99.

Subprogram

number

Fig. 5-5-1

5.6 SPE (End of Subprogram)

Function

* Specify the range of the subprogram when the SPE and SP are used together.

* The control will return to the main program of the called subprogram when this function code

is performed.

* The subprogram should be compiled after END2.

Figure format

SPE

Fig. 5-6-1

24

Page 40

For example

Chapter Five PLC Function Code

CALL P33

END2

SP P33

SPE

5.7 SET (Replacement/Setting)

Function:

Set 1 in the specified address.

Format:

Volume I Programming

Fig. 5-6-2

ACT

SET

Controllable condition