Page 1

EXIT MANUAL

ALLEN BRADLEY

7/16/97

Click here to

Click here to

EXIT Manual

EXIT Manual

SERVICE MANUAL

Page 2

Attention symbols

Some of the warnings, instructions and advice in this manual are so

important that we used the following special symbols to draw attention

to them:

Warnings

This symbol indicates a warning. Injury or even death may

result if you do not heed it.

This symbol is also used to mark out safety components

etc. See section ”Safety devices, a survey” in chapter

”Introduction” in the OPERATOR MANUAL or chapter

”Maintenance” in the SERVICE MANUAL.

Instructions

EXIT MANUAL

Advice

This symbol indicates instructions which are important, for

example to prevent damage to the s terilizer and/or the load.

This symbol indicates important advice and hints that

make it easier to work with the sterilizer.

Page 3

SERVICE MANUAL

TABLE OF CONTENTS

Attention symbols

1. FUNCTIONAL CHECK

Prior to Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. MAINTENANCE

Safety devices, a survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

After commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Air filter sterilization program. . . . . . . . . . . . . . . . . . . . . . . . . . 5

Suggested Preventative Maintenance Schedule . . . . . . . . . . . . . . . . 7

EXIT MANUAL

3. GENERAL ADVICE

Manual interference in the sterilizing process . . . . . . . . . . . . . . . . . 1

Manual stepping with key switch . . . . . . . . . . . . . . . . . . . . . . . . 1

Fault with an analog transducer . . . . . . . . . . . . . . . . . . . . . . . . 2

Manual control by actuating the control valves . . . . . . . . . . . . . . . . . 3

Open the door manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. THE DOOR

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Adjusting the door motion . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Adjusting the door position . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The door seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Lubricating the door seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Replacing the door seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Replacing the door cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Replacing the piston seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Door safety arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Blocking the start an d o pening the door . . . . . . . . . . . . . . . . . . . .11

Emergency stop button . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5. CONTROL UNIT ALLEN BRADLEY

Operating panel SLC 504 . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Push Buttons/ Indicator Lights - Load Side . . . . . . . . . . . . . . . . . . . 4

Push Buttons/Indicator Lights - Unload Side . . . . . . . . . . . . . . . . . . 5

Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Detailed screen displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Page 4

Alarm and System Messages - Troubleshooting . . . . . . . . . . . . . . . .26

System Interlocks - Horizontal Doors . . . . . . . . . . . . . . . . . . . . . .36

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6. STERILIZER SPECIFICATION

7. P&ID DIAGRAM

8. ELECTRICAL WIRING

9. INSTALLATION DRAWING

10. PHASE LIST

11. COMPONENTS

Illustration on drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Panel-Mounted Thermal Printer, Model PRNTR0001 . . . . . . . . . . . . . 2

Vacuum pump LEM 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Solenoid valve block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Piston valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

PT-100 Sensors (RTD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Soldered plate heat excha ngers . . . . . . . . . . . . . . . . . . . . . . . .12

EXIT MANUAL

Page 5

1. FUNCTIONAL CHECK

Prior to Commissioning

Prior to use, check that all service media are correct connected at their dedicated connection points.

• Check that all electric wire connection screws are tig htened.

• Open the valves for compressed air, water and steam.

• Check the safety valves by li fting the lever when they are pressurized. Steam or air should blow out.

EXIT MANUAL

Use protective gloves. Blowing steam and hot lever can

cause burns.

• Check for leakage on both supply and sterilizer pipes, for cabinet

units remove the co ver plates and panels.

• Check the door (doors) according to instructions given under the

headline DOOR in the Service Manual.

Check and, if necessary, adjust the supply of sealing water and leak

•

air to the vacuum pump. See the Vacuum pump sect ion in the C OMPONENTS chapter.

Perform all safety checks as described in the DO OR chapter.

•

• Check and adjust if necessary the air leak and sealing water flow to

the vacuum pump.

Run all processes while checking pressure temperatures, times and

function of sign al lig ht s. Set po ints will be fou nd in th e pha se li st. Save

all Printouts for record.

1.1

Page 6

2. MAINTENANCE

To be made by trained technicians only!

Safety devices, a survey

The panels of the sterilizer shall prevent the operator access to the inner

parts of the sterilizer. Only speci ally trained personnel have acc ess to

the inner parts.

Safety components

Every sterilizer is equipped with a number of compo nents the purpose

of which is to specifically guarantee human safety. These items are

marked with the sign below:

EXIT MANUAL

General

•

Electric diagrams

•

Piping diagrams

These components have been subject to special tests before being

accepted as safety components and must therefore not be substituted by

any make or execution not approved by Getinge/Castle, Inc. It is of

greatest importance that these components are kept in good working

order to maintain a safe function during the sterilizer life time. The signs

are used not only to point out important components, but also to emphasize such other safety factors requiring special attention as measurements, tolerances, material etc.

Beware of the risks for squeezing, jamming, cutting and burning as

well as the risks with electrical shock when removing and working

behind the panels.

The demand for main tenance depends, above all, on the usage rate of

the sterilizer. How o ften steps shou ld be taken to prevent ma lfunction

therefore will vary from case to case. We recommend the following

maintenance t o be performed at intervals state d for a sterilizer that is

fully utilized .

2.1

Page 7

After commissioning

After one month's oper ation, deposits and pa rticles of dirt from new

pipes will have co ll e ct ed in filters, stra in ers a n d other sensitive components. If they ar e not remo ved , t hey w ill r esult in re liab ility p robl ems,

leaks and reduced performan ce.

Clean all strainers, including the filters, in the cold water, steam and

•

drain lines.

Check that all flow rat es are correct, and rectify them if not.

•

Clean all steam traps. Remove deposits on their seats and floats.

•

Check that all pipe joints in the service supply and the sterilizer are

•

tight.

Check that all electric terminal screws are properly tightened, partic-

•

ularly on power conn e c ti on s .

Once a week

EXIT MANUAL

Check that the door clo sing motion (vertical doors) can be stopped

•

by gently pushing, the squeeze protection plate in the door opposite

direction.

Monthly

Check the door seal. If needed, lubricate as described in chapter

•

Door.

Check ink ribbon or pens of any printers or recorders and r e place if

•

necessary. Th ermal printer s d o n ot require this routine maint e na n ce .

After the first month of operation

Clean all filters and strainers.

•

Clean all steam traps.

•

Perform a leak rate test using the appropriate program. See Operator

•

Manual.

Every three months

•

•

Overhaul as stated under Monthly.

Check that the safety valve lead seal is intact.

2.2

Page 8

EXIT MANUAL

•

In case the seal isn't intact, the valve has to be replaced. Alternatively, call for an authorized person from the pressure vessel authorities, who will check the valve and seal it.

If the seals is broken, the set-pressure of the valve might

have been manipulated. Autoclaves with broken safety

valve-seals are not to be used.

•

Sterilizers with safety valves for compressed air or water are checked

by lifting the lever of the safety valve while having pressure in the

chamber.

•

Check that the safety valve is not leaking steam, air or water.

•

Make a leak test using the appropriate program, as described in

Chamber Leak Test in the Operator Manual.

•

Check that the RTD Pt 100 is located in the center of the drain tube

with the tip 70-75 mm below the chamber bottom or positioned in the

flow of the drain piping.

Every six month

•

Overhaul as stated under ”Every three months”.

•

During a process the temperature and pressure sensors connected to

the control system shall be checked against an independent system.

For calibration of th e se nsors, see the CONTROL Chapter of this

Manual.

The pressure deviation, at 1 bar(a), may not be greater than

±10 mbar. For pressure above 1 bar(a) the deviation may not be

greater than 0.01 x P (abs).

• Carry out the foll ow in g me a s ure s fo llowing descripti on under the

heading Door:

· Make the check as described in Adjusting the door moti on .

· Make the safety check as described in Door safety arrangements

· Make the safety check as described in Blocking the start and

opening the door .

· Make the safety check as described in Blocking the admittance of

mediums to the chamber.

· Make the safety check as described in Safety check, chamber

pressure switch.

·

Make the check as described in Emergency st op button.

•

Replace the air filter. The f ilter should be changed more frequently

if the air contains high amount of particles or hum idity,

2.3

Page 9

Once a year

•

Overhaul as stated under Every six m on ths .

•

Make the check as described in Checking and adjusting the door

position.

•

Make the safety check as described in Safety check, door seal groove

pressure switch.

•

Check for leaks on pi pe joints and fittings.

•

Check that all electric connection screws are tightened.

•

Clean all filters and strainers

•

Clean all steam traps.

•

Run all processes and check pressure, temp erature, times and pilot

lamp functions. Save all recorder diagrams from tests made.

EXIT MANUAL

2.4

Page 10

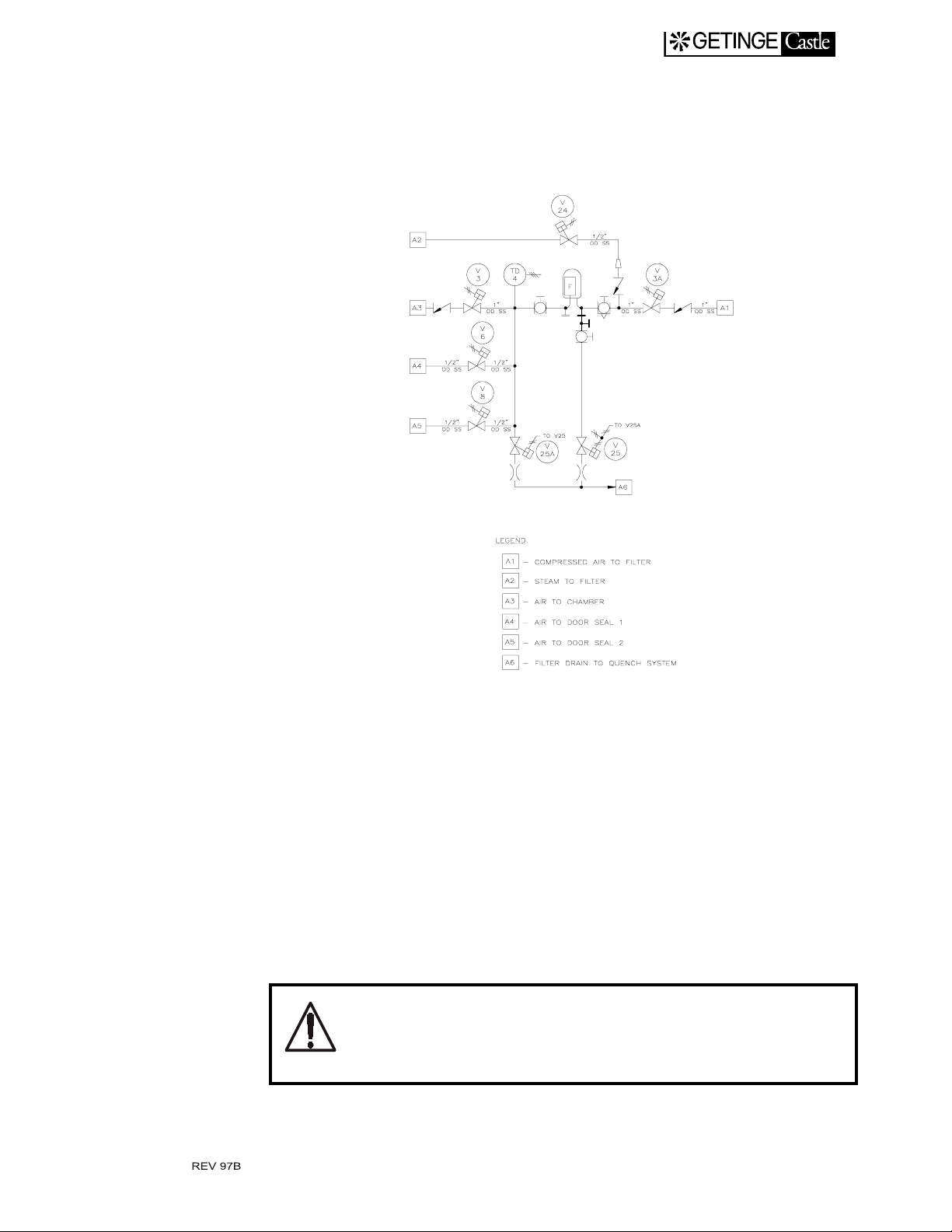

Air filter sterilization program.

The sterilizer is equipped with a program for automatic in-line sterilization of the air filt e r .

EXIT MANUAL

1. Val ves 3, 3A, 6 & 8 will clo se, and va lves 24 , 25 & 25A ope n. The

filter housing will be depressurized.

2. By operating valve 24, the system will be sterilized at 121

minutes. This is monitored by a resistive temperature detector,

TD4.

3. Af ter sterilization the system wil l be cooled down. Thi s i s d on e b y

closing valve 24 an d op e ni ng valve 3A letting the co mpressed air

cool the filter. Valves 25 and 25A remai n open to enhance the drying. The drying cycle runs for 10 minutes.

Prior to removal of filter housing, internal pressure of the filter hous ing and piping must be relieved.

o

C for 15

2.5

Page 11

Service

Spare parts

EXIT MANUAL

Contact your local Getinge representative

or

Getinge/Castle, Inc.

Scientific Division

Service Department

Phone: 1-732-370-8800 Ext. 214

Fax: 1-732-367-7994

Contact your local Getinge representative

or

Getinge/Castle, Inc.

Scientific Division

Parts Department

Phone: 1-732-370-8666

Fax: 1-732-367-7994

2.6

Page 12

Suggested Preventative Maintenance Schedule

QUARTERLY VIS IT:

1st 2nd 3rd 4th

EXIT MANUAL

Check door Reversal safety

operation

Check door limit switches [ ][ ][ ][ ]

Test 2 PSI chamber safety

switch

Check & adjust doors to

appropriate door gap

Check door seal regulator at

28 PSIG

Check chamber temperature at

sterilization +/- 0.5

Check pressure transducer for

correct readings and linear ity

Test gauges +/- 2 PSI (+/- 1

GMP)

Test vacuum pump operation

& lubricate if applicabl e

o

C

[ ] [ ] [ ] [ ]

[ ] [ ] [ ] [ ]

[ ]

[ ] [ ]

[ ][ ][ ][ ]

[ ] [ ]

[ ][ ][ ][ ]

[ ] [ ] [ ] [ ]

Relubricate & rotate door

seals

Replace door seals [ ] [ ]

Test that safety valves lift at

rated pressure

Adjust main compressed air

regulator filter to 80 PSIG

Adjust door motor air regula-

tor to 25 PSIG

Clean strainers [ ] [ ] [ ] [ ]

Check steam traps for leakage.

Clean or replace if necessary

Check air admit filter for

blockage (Non-biological test)

Change air admit filter [ ]

[ ][ ][ ][ ]

[ ] [ ] [ ] [ ]

[ ][ ][ ][ ]

[ ][ ][ ][ ]

[ ] [ ] [ ]

[ ] [ ]

2.7

Page 13

Suggested Preventative Maintenance Schedule Continued:

QUARTERLY VIS IT:

1st 2nd 3rd 4th

Check retraction of door seal [ ] [ ] [ ] [ ]

Verify Controls:

A. Check exposure /dry time rs [ ] [ ]

EXIT MANUAL

B. Check all lamps and buttons

C. Check operation of load

probes

D. Verify abort routine and

Emergency stop activation

E. Verify program settings [ ] [ ] [ ] [ ]

Check valve operations/out-

puts

Test operation of cycles in

accordance with program

combination sheet

Check & adjust alignment of

loading equipment

Perform chamber vacuum lead

test (HV units: <1”/hr or .035

BAR/hr)

Check dip switch settings on

mircoprocessors, printers

[ ] [ ] [ ] [ ]

[ ][ ][ ][ ]

[ ] [ ] [ ] [ ]

[] [ ] [ ] [ ]

[ ] [ ]

[ ] [ ]

[ ]

[]

Check all cable & wire connection

Check for plumbing leaks [ ] [ ] [ ] [ ]

Polish exterior stainless panels [ ] [ ] [ ] [ ]

Check operation of utility

switches if equipped

[ ] [ ] [ ] [ ]

[ ][ ][ ][ ]

2.8

Page 14

3. GENERAL ADVICE

Manual interference in the sterilizing process

When an error like supply medium o r component failure occurs dur ing

a sterilizing process, the process may , after an alarm is emitted, get

stuck in a phase from which the con trol unit can not go further.

The operator can, in some cases, restart the process by pressing the start/

restart button. If this isn 't po ssible or doesn't so lve the alarm, a tr ained

technician must override the buil t in safety condi tions by manu al stepping.

Manual stepping with key switch

EXIT MANUAL

When stepping forward in a process program by means of the button C/

F9 after setting the key switch, all parameters are controlled by the automatic control unit whereby no dangerous situations can occur. The manually stepping means that the proce ss goes from one process phase to

another without time, temperature or pressure conditions being fulfilled.

For safety reasons, the possi bility t o go past a co oling p hase or a pressure equalization is blocked , except in some cases when a fault with an

analog transducer has occurred . Stepping should preferably be carri ed

out with the process still in alarm phase and befo re restarting the process.

When stepping past a cooling phase or a pressure equalization, there no longer exists any blockages to prevent

dangerous situations from arising. The technician himself

has to decide which steps are to be taken.

The manual stepping must only be used by a technician

who is well acquainted with the process, the properties of

the sterilized goods and the function of the individual ster ilizer components.

3.1

Page 15

Fault with an analog transducer

Fault with an analog pressure t ransducer or temperat ure sens or stops a

proceeding process. In case of a pr essure transd ucer fault , the operato r

therefore has to step past the pressure conditions at post vacuum, evacuation, natural cooling and pressure equalization. With temperature

sensor fault the operator has to step past the corresponding temperature

conditions.

Fault with an analog pressur e transduce r or temperat ure sensor is indi cated only once per process by th e control unit.

Pressure transducer fault

Program with post vacuum.

Step to the post vacuum phase.

•

(NOTE! The process will perform a normal post vacuum. If a ramp

is needed it has to be cont rolled by manually operating the vacuum

valve.)

EXIT MANUAL

When a required vacuum is reached, step to the pressure equalization

•

phase.

Raise the chamber pressure to atmospheric pressure by opening the

•

valve to the air-in filter or the valve for support pressure. (Refer to

Solenoid Block in COMPONENTS SECTION) Check the chamber

pressure gauge.

Step past the pressure equalization phase.

•

(NOTE! possible only w ith pressure transducer fault)

Program with cooling

Step to the coolin g phase.

•

Restart the process.

•

Control the chamber pressure, by manually operating the solenoid

•

valve for support pressu re. When the load is cooled down, the process will automatically go to pressure equalization phase.

Pressure equalize the chamber to atmospheric pressure by manually

•

operating the soleno id valve controlling the Fast Exha ust drain

valve. (Refer to Soleno id Block in Components Section) Check the

chamber pressure gauge

Step past the pressure equalization phase.

•

(NOTE! possible only w ith pressure transducer fault).

Temperature Sensor fault

The process can be restarted if only one of the load sensors is bro ken.

The process will then disregard the faulty sensor and go on from the

point where the fault occurred.

3.2

Page 16

EXIT MANUAL

Follow the instructions below if there is only one load sensor or more

than one is fault y.

Program with post vacuum

•

Step to the post vacuum phase.

•

Restart the process.

•

The process will be automatically ended.

Program with cooling

•

Step to the coolin g phase.

•

Restart the process.

•

Make sure that the load has been cooled down to a safe temperature

when the minimum cooling time has expired.

•

Step past the cooling phase

(NOTE! possible only w ith pressure transducer fault)

•

The process will end automatically.

Sensor fault, independent system

In case the process is sto pped in a co oling or do or opening phase, due

to failure of the independent sensors, the safety system can be by-passed

by manual operation of the safety relays.

See the electric wiring diagram.

Manual control by actuating the control valves

Manual actuating of control valves can be done when a system error

occurs which keeps the process stuck in one phase.

When using this method, there no longer exists any blockages to prevent dangerous situations from arising. The

technician himself has to decide which steps are to be

taken.

The above captioned method must only be used by a tec hnician who is well acquainted with the process, the properties of the sterilized goods and the function of the

individual sterilizer components.

3.3

Page 17

Open the door manually

The following, important steps, have to be taken into consideration before a door is manually opened

1. Make sure, beyond all doubts, that the valve you are going to

manipulate is the correct one.

2. Drain the chamber from liquid s that might flow out when opening

a door by manually opening a drain valve

3. Relieve pressure from the chamber by manually opening a drain

valve.

4. If sterilizer load consists of liquids, make sure that the temperature

of the liquid is well below its boiling point.

Calibration

Analog sensors/transducers must be calibrated, for example when

replaced.

EXIT MANUAL

When using an oil bath, note the following points:

A Accuracy must meet the specified requirements.

B Compounds or condensation in the oil may cause coatings and thus

severely reduced the accuracy of measurement. Change the oil at

regular interva ls!

C Use an oil bath with a large capacity, preferably more than five

litres.

D Allow the measuring instru ment to stabilize for one to two hours

after the bath has reached the set temperature.

E Allow the oil bath to stabil ize for at least 30 minutes after the sen-

sors are lowered into the bath and the bath has regained its set temperature.

F Clean the sensors thorou ghly to remove the oil after calibration.

See the calibration menus section in the CONTROL UNIT chapter.

3.4

Page 18

4. THE DOOR

General

The opening and closing motion of the door is executed by a pneumatic

cylinder. As a safety measure there is a squeeze protection integrated in

the top of the door.

When the door is closed, a mechanical lock will bl ock the door. This

lock activates a switch which makes it possible to pressurize the groove

behind the door seal.

The doors are kept c losed by the automat ic control unit and the above

mentioned lock while cycl es are in progress and also when su pply

media fail. The doors do not open until the condition chamber pressure

= atmospheric pressure is fulfilled, not even in case o f an electric failure causing an opening command.

EXIT MANUAL

The door closing system comprises a number of parts and

components which cooperate in a tested, safe way from

personnel and material point of view. These items must not

be subject to violence or improper influence of any kind

which alter their initial function.

Adjustments on doors and associated equipment must be

made by authorized personnel only.

Seal between door and chamber

The door seal is a continuous, thick-walled silicon rubber tube, movable

in a groove and pushed ag ainst the door by means of steam, gas or air

pressure. To enable for the door to move freely, the sealing tube can be

sucked back from the door surface int o its groove by a vacuum device.

Media to chamber

Before entering media to the chamber, all following requirement s have

to be fulfilled:

A Emergency stop not activated.

B Doors are closed.

C The door seals are pressurized.

4.1

Page 19

D The control system gives signals for operating the media valves.

Adjusting the door motion

The door speed is controlled by a variable restriction in the air line supplying the door cylinder with compressed air. Changing the closing

speed will result in a correspo nding influence on the openin g speed.

1. Adjust the restriction so that the door will close in about 15-18 sec-

onds.

2. Check that the motion is even and free from je rks.

3. Check that the door does not scrape against closely situated metal

components. Advise for corrections are given under the head line

”Adjusting the door position”.

EXIT MANUAL

Adjusting the door position

A. VERTICALLY

This adjustment becomes n ecessary if the d istance between t he top of

the open door and the ch amber bottom is not = 10 mm.

1. Measure the door adjustment required.

2. Lift away the door covering lower front plate after removing its two

screws near the floor (see chapter INSTA LLATI ON).

3. Close the door by activating its pilot valve by hand.

4. Lower and prop up the door until it rests upon the prop.

Make sure the door is resting securely on the prop!

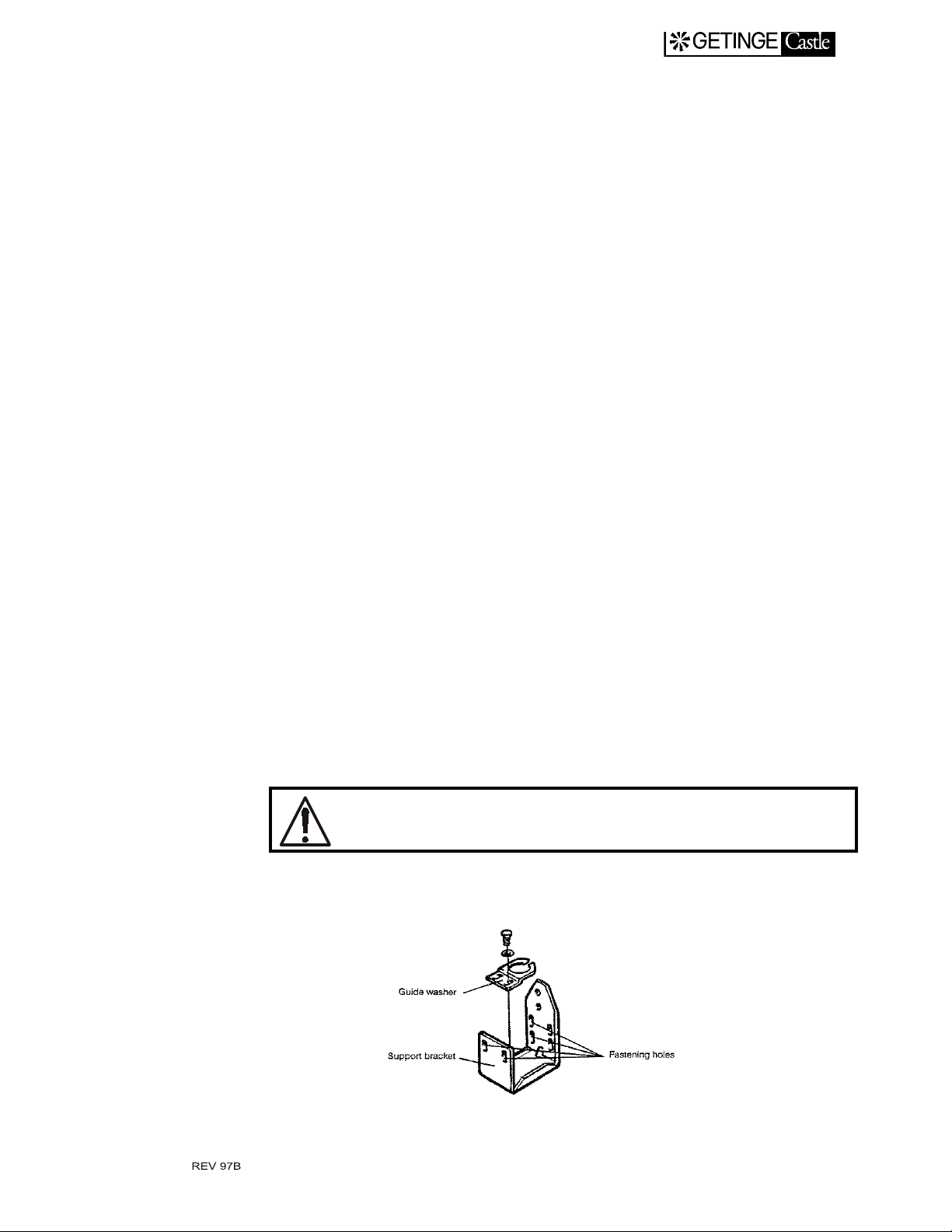

5. Loosen the support bracket, adjust it in accordanc e with th e mea-

sured requirements and tighten the screws.

4.2

Page 20

B. SIDEWAYS

EXIT MANUAL

6. Pressurize the cylinder, remove the prop and lower the door. Check

the level in rela ti on to the sterilizer bo tt om.

7. Check that the closed door covers the door seal groove completely

(small piston stroke margins).

8. Check that the upper end of the door is horizontal. When needed,

move the lower end of the cylinder piston sideways after the attachment screws of the guide washer has been loosene d. Tigh ten the

screws when the washer is in correct position.

9. Assemble dismantled parts.

10. Remove the front plates as described in the INSTALLATION chap-

ter under the headline Transportation.

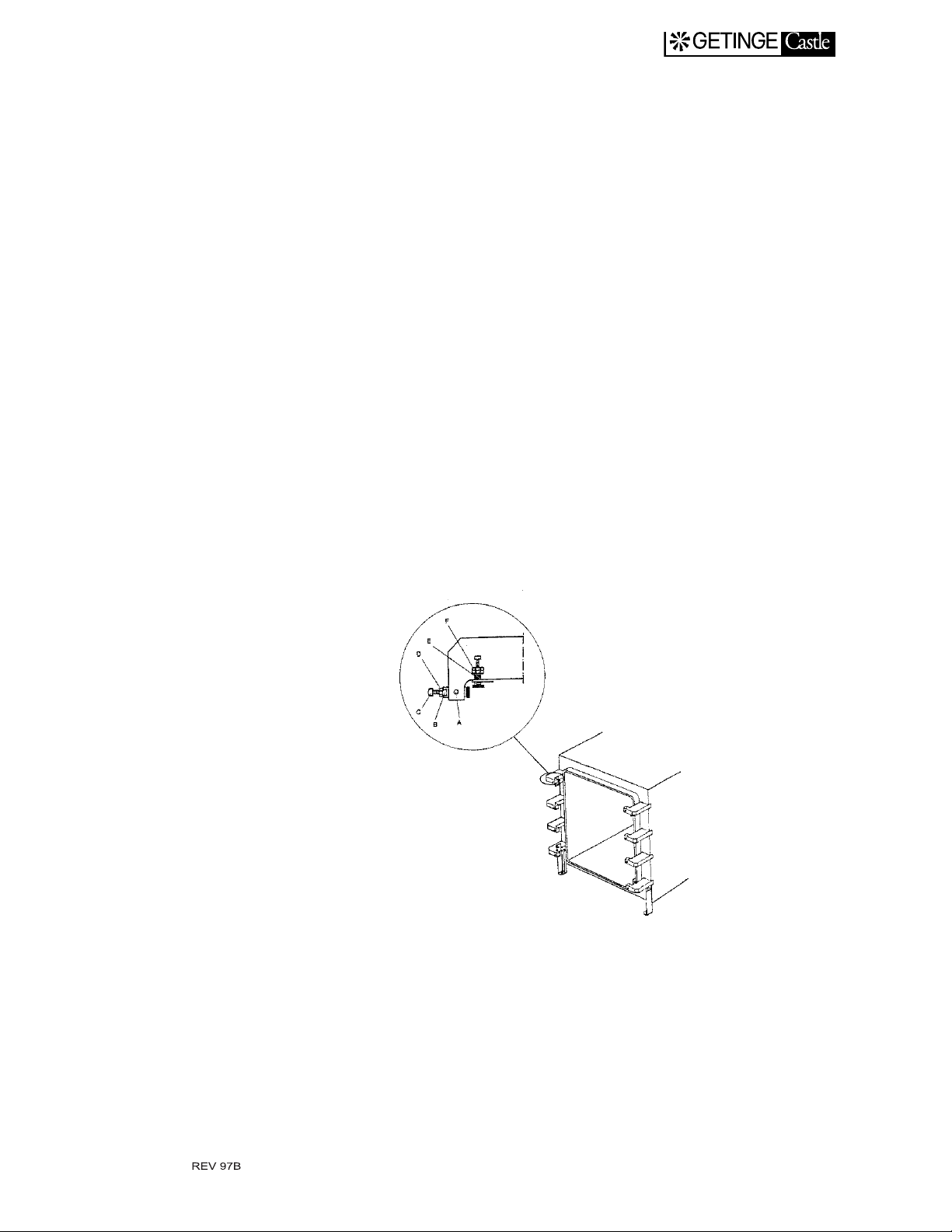

1. Partly loosen the side guide attachment nut F.

2. Adjust the door sideways by means of the screws E so as to form a

clearance space to the guides of 23 mm.

3. The door should be symmetrically located in front of the chamber

opening with the small deviations required for clearance to the trim

plates.

4. Fasten the side guides upon completed adjustment.

C. AXIALLY

1. The clearance space between the door surface and th e door seal

groove should be about 2.5 mm.

2. Remove the front plates as described in the INSTALLATION

chapter under the headline Transportation.

4.3

Page 21

3. Partly loosen the locking screws A and the locking nut D.

4. If needed, loosen the screws B and insert a 2.5 mm thick plate strip

5. Adjust B until the plate strips are squeezed lightly between door

All screws have to be firmly tightened. The screws are an

integrated part of the pressure vessel.

6. Tighten A and D.

7. Remove the plate strips.

Removing the door

1. Remove the lower front panel and both side front panels.

EXIT MANUAL

between door and seal groove at each corner.

and seal groove.

2. Place a prop or similar to stop the door about 150 mm from its end

position when lowered .

Make sure the door is resting securely on the prop!

3. Lower the door.

4. Remove the air hose fitting from the foot of the piston end.

5. Loosen the eight nuts D and remove the screws C together with the

two brass guides.

4.4

Page 22

EXIT MANUAL

6. Lean the top of the door away from the sterilizer and lift it out. The

weight of the doo r is approx. 75 kg (165 lb).

4.5

Page 23

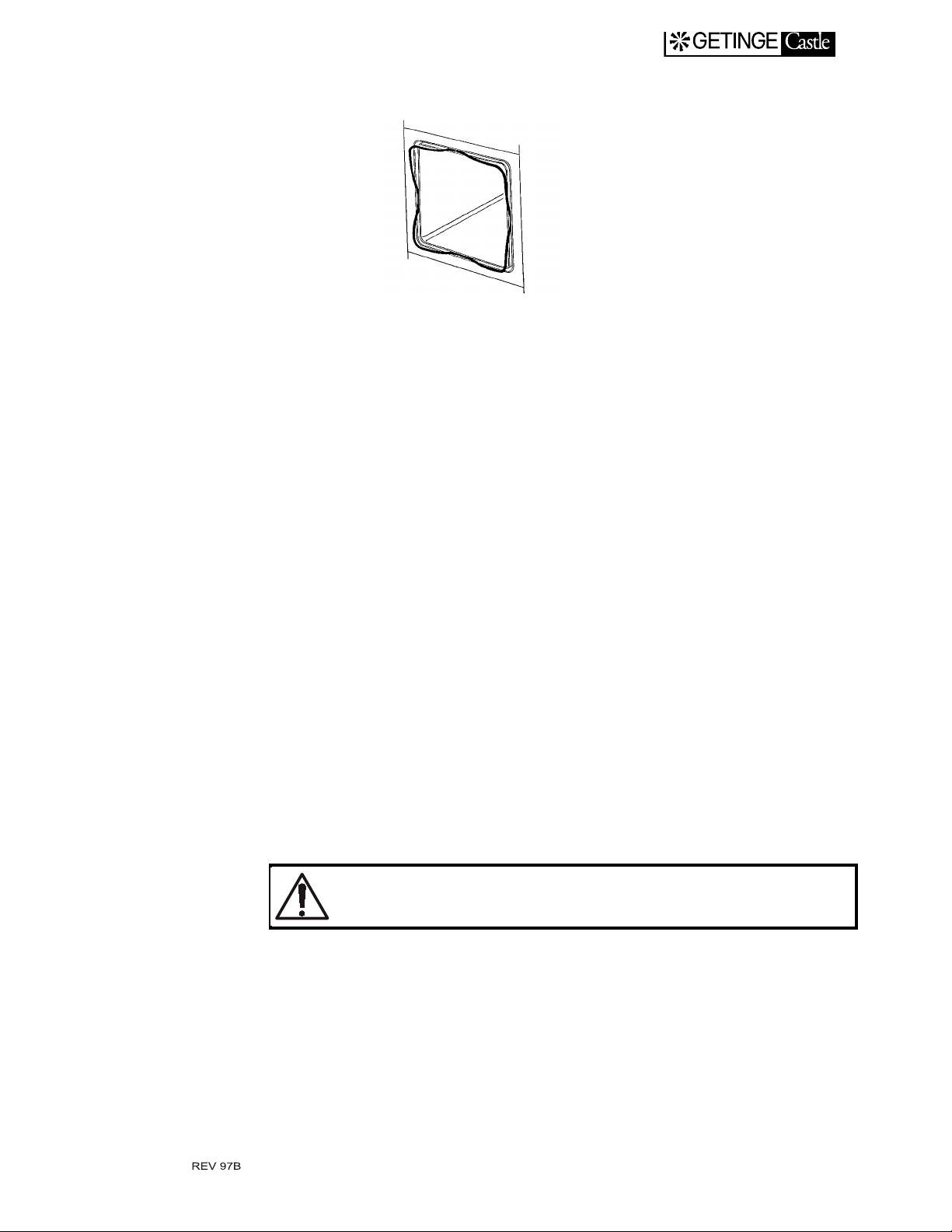

The door seal

Care

EXIT MANUAL

The door seal is that part of the pr essure v essel tha t is mo st expo sed to

wear and tear. The comp osit ion o f th e mate ri al, the d esign o f th e seal ,

its fitting and care are of extreme importance for reliable operation and

long life of the seal. Getinge's d oor seal consists of a special silicone

material, and its physical design is intended to make best use of its special characteristics.

Use only genuine Getinge door seals. Remember that each

seal is an integral part of the pressure vessel.

There are several negative factors that adversely affect the life of the

door seal. By avoiding them as far as possible, the life of the seal can

be considerably extend ed.

Avoid leaving the sterilizer switched on in the standby mode during

•

the night. Al though th e door seal materia l can with stand co ntinuou s

temperatures of more than 200 °C, it slowl y d egrades where it is in

contact with the seal groove. Leaving the ster ilizer continuously

energized will shorten the life of the seal by about 60 %.

If the sterilizer has a steam generator, the generator must be drained

•

at the prescribed interval s. Any feed water other than de-i onised

feed water will gradually build up a concentration of mine r a ls and

other substances. At high concentrat ions, several of t hese substances

are carried over with the steam and precipitated on the seal as weak

acids.

If the sterilizer is connected to a central steam system, the quality of

•

the steam is decisive in determining the life of the seal. Chemicals

are often added to the feed water for such purposes as protecting

pipes against corrosion. Undesirable chemical characteristics of the

steam include high hyd razine or carbon dioxide contents.

Keep the seal lubricating layer intact and the sealing groove clean.

•

The lubricating layer not only assists the seal in sliding, but is also an

effective barrier again s t long-term chemical breakdo wn. See also

under the 'Lubrication of the door seal' heading.

Lubricating the door seal

At delivery the door seal is prepa red wi th a dr y lu bric ant wh ich resu lt s

in a graphite grey appearance. The lubricating film has to be renewed in

order to maintain the safe function of the seal. Renewal of the lubricating layer must not be made with the seal in place. Repeated spraying in

4.6

Page 24

EXIT MANUAL

the groove will build u p layers which ev entually wil l cause t he gasket

to leak.

Disconnect the air supply or similar to make it impossible

for the door to close while the work is carried out.

When applicable, see also chapter ”Special advice for sterilizer with

automatic loader”.

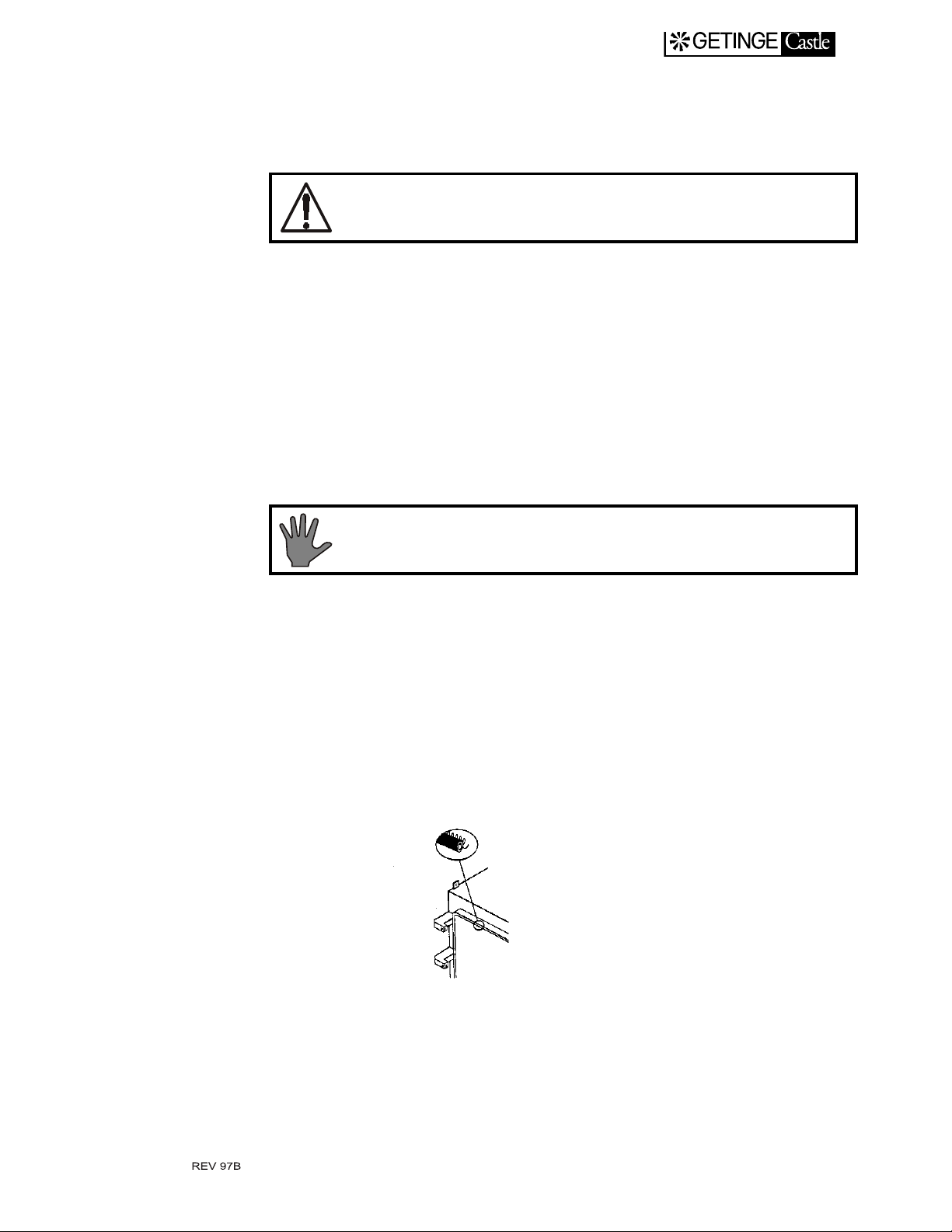

•

Remove one of the safety plate screws and push the plate towards the

empty screw hole until it becomes free at the opposite end (Vertical

door system only).

•

By means of a 6 mm allen-key, loosen the four cylinder attachment

screws six turns each (Vertical Door System Only).

CAUTION! Do not tamper with the four smaller screws

which have now become loose.

•

Remove the gasket from the groove. Be careful with gasket and

groove.

•

Clean the groove of anyth ing that may interfere with subsequent

sealing.

•

Clean the gasket with alco hol until its surface is felt absolut e ly

smooth.

•

Spray the gasket all over with dry lubricant, Dow Corning Molykote

321 recommended.

•

Check that the helix is in place at the bottom of the groove.

4.7

Page 25

•

Press the gasket joint into the middle of the upper horizontal part of

the groove.

•

Press the middle of the gasket loop into the middle of the lower horizontal part of th e groove and finally th e middle of the two rem aining

loops into the middle of the vertical parts of the groove.

•

Push the gasket into th e groove. Alwa ys work towards th e corners to

make these collect the excess length of the gasket.

•

Tighten the four cylind er attachment screws.

•

Fit the safety plate by pushing it to the side with the missing screw,

press it down and hook it up at the opposite end. Tighten the fixing

screw and check the function.

EXIT MANUAL

Replacing the door seal

Proceed as describe d under Lubricating the door seal bu t skip se ction s

concerning cleani ng seal and spraying seal.

Replacing the door cylinder

1. Close the door by operating its air solenoid valve by hand.

2. Place a prop or similar to stop the door about 150 mm from its end

position when lowered manu a l.

Beware of the danger of insufficient support

3. Remove the cylinder air hose fitting located on the piston stand and

remove prop to comple tely lower the door.

4. Remo ve one of the safety plate atta c hment screws and push the

plate towards the empty screw hole until it loosens at the opposite

end.

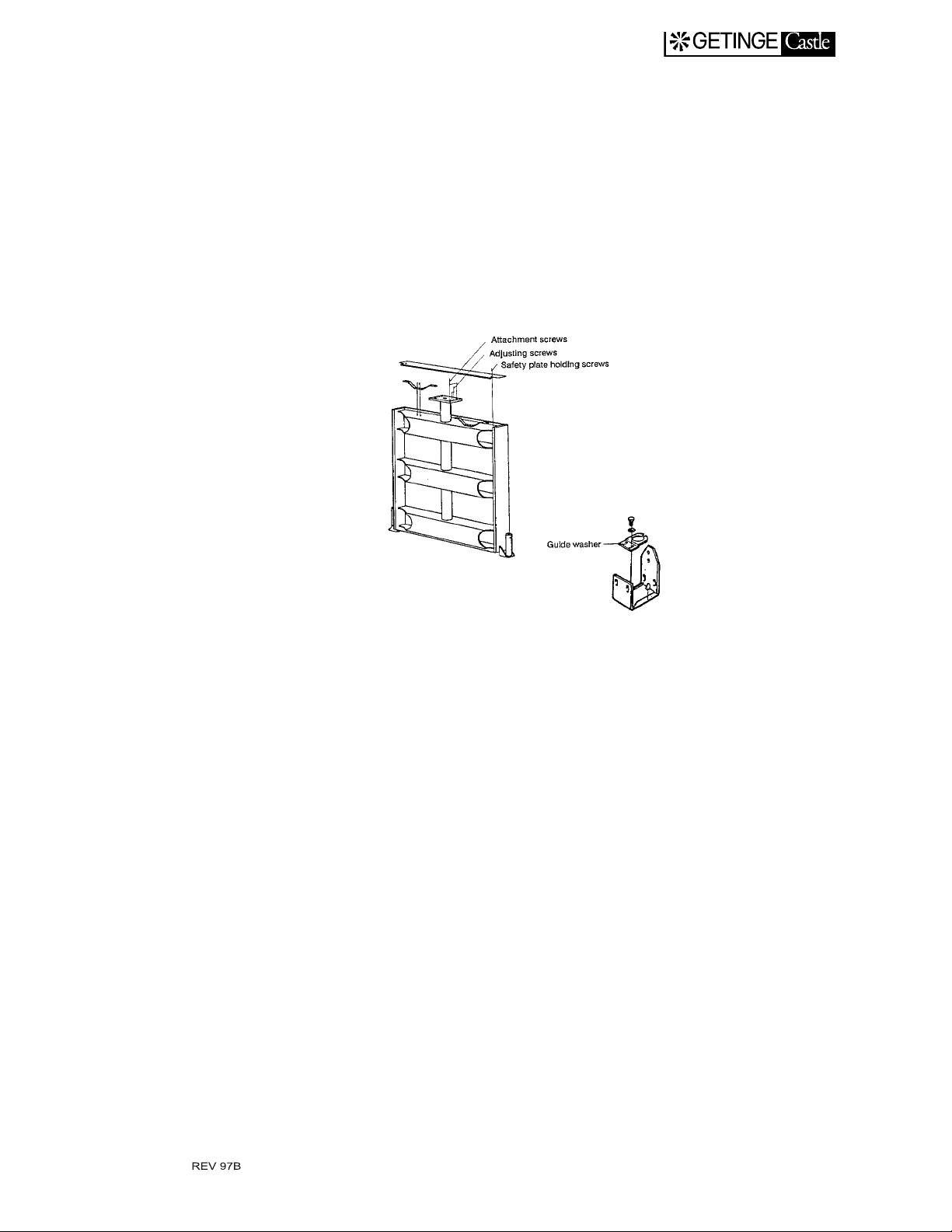

5. By means of a 6 mm allen-key, remove the four cylinder attachment

screws.

4.8

Page 26

EXIT MANUAL

6. Prevent the piston from moving out of the cylinder by keepin g the

safety valve at its bottom closed (pull ed out). Lift away the cylinder.

7. Attach the nipple and hose to the piston of the new cylinder.

8. Fit the cylinder into the door . Prevent the piston from m oving out

of the cylinder as described ea rlier or with a piece of string.

9. Attach it by means of the four allen-screws. With the four adjusting

screws, make the cylinder align with the center line of the notches

of the stiffening bars.

10. Attach the piston end guide washer in that position which makes the

door move in the most proper way.

Replacing the piston seal

A worn-out piston seal can not be replaced as separate unit but the

whole piston has to be replaced.

First perform ”Replacement of door cylinder”, section 1-7.

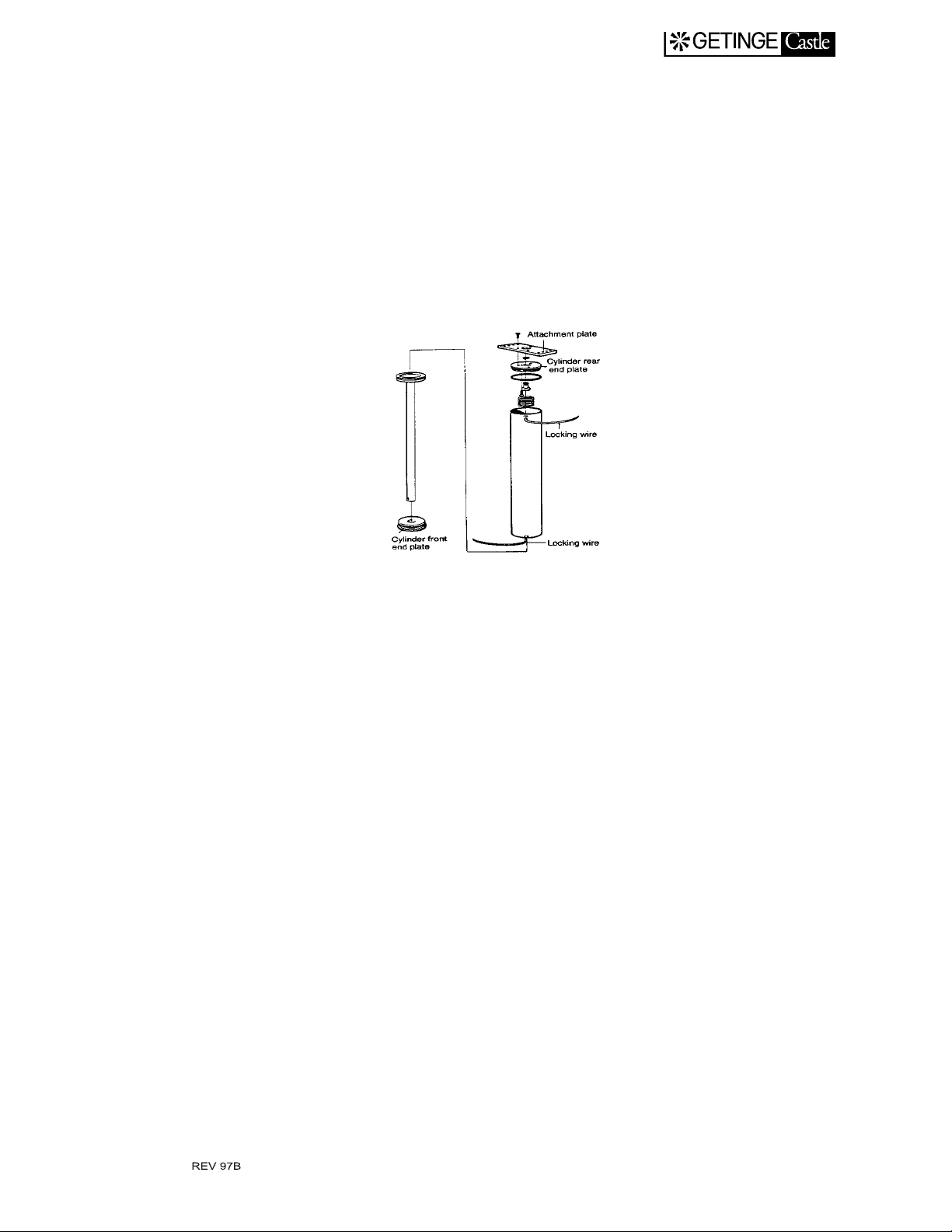

1. Fix the cylinder carefully in a v ice jaw.

2. Remove the cylinder attachment plate.

3. Twist the cylinder end plate until the end of the locking wire

appears in the locking wir e hole.

4. Twist the cylinder end plate in that directi on which feeds the lock-

ing wire out of the hole. The wire may need help from a tool to ent er

the edge of the hole.

5. Pull out the bent end of the locking wire from its driver hole.

6. Remove the cylinder end plate and replace its O-ring in connection

with the replacement of the piston even if it appears to be free from

damage.

7. Push out the piston and fix it in a vi ce jaw.

4.9

Page 27

EXIT MANUAL

8. Protect the piston rod from tool marks with a piece of weak plate

around its lower part, whi ch is stiffened up by an insert piece of

brass, while gripping there, but no whe re el se, with a pipe wrench

or similar tool.

9. Twist the piston rod to thread off. If sticky, apply heat carefully to

soften the thread sealing compound. Clean the piston rod thread s

with a wire brush.

10. Apply ”Lo c ti t e 54 2" hy dr a ul ic seal ing compound on the threads

and screw the new piston on to the piston rod.

11. Assemble the cylinder and install it according to the points 8-11

under the head line ”Replacing the door cylinder”.

Door safety arrangements

Squeeze protection

The door motion is executed by a pneumatic cylinder the air inlet of

which is considerably choked. An air exhaust valve having much larger

flow capacity is arranged at the free cylinder end which is directed

upwards. Any obstruction present during door closing exerts pressure

on a plate running the entire length of the upper edge of the door at

which this plate makes t he exhaust valve open, thereby s topping the

upward motion immedi ately. This will preven t personnel injuries an d

material damage.

Safety check

The safety check shall be performed in the early stage of the door closing operation. This reduces the risk for injuries due to squeezing.

1. Check that the air supply pressure is maximum perm issible 8 bar

(100 PSIG).

2. Open the door speed control valve entire ly.

4.10

Page 28

3. Close manually the door cylinder exhaust valve and open the inlet

valve to make the door close.

4. Push downwards by hand and check that the plate moves freely.

This enables the valve to open for a force on any spot of the plate

without use of extreme force.

Blocking the start and opening the door

To prevent the door from opening by its own weight in case the pneumatic door cylinder sho uld become depressurized, a brace underneath

the door keeps it in closed position. The brace is brought in the stop

position under the door by spring-force 20 seconds after a door closing

command has been given. A limit switch senses the position of the brace

thereby stoppi ng the process from b eing started and medi ums being

admitted to the chamber before the door is compl etely closed.

EXIT MANUAL

Safety check

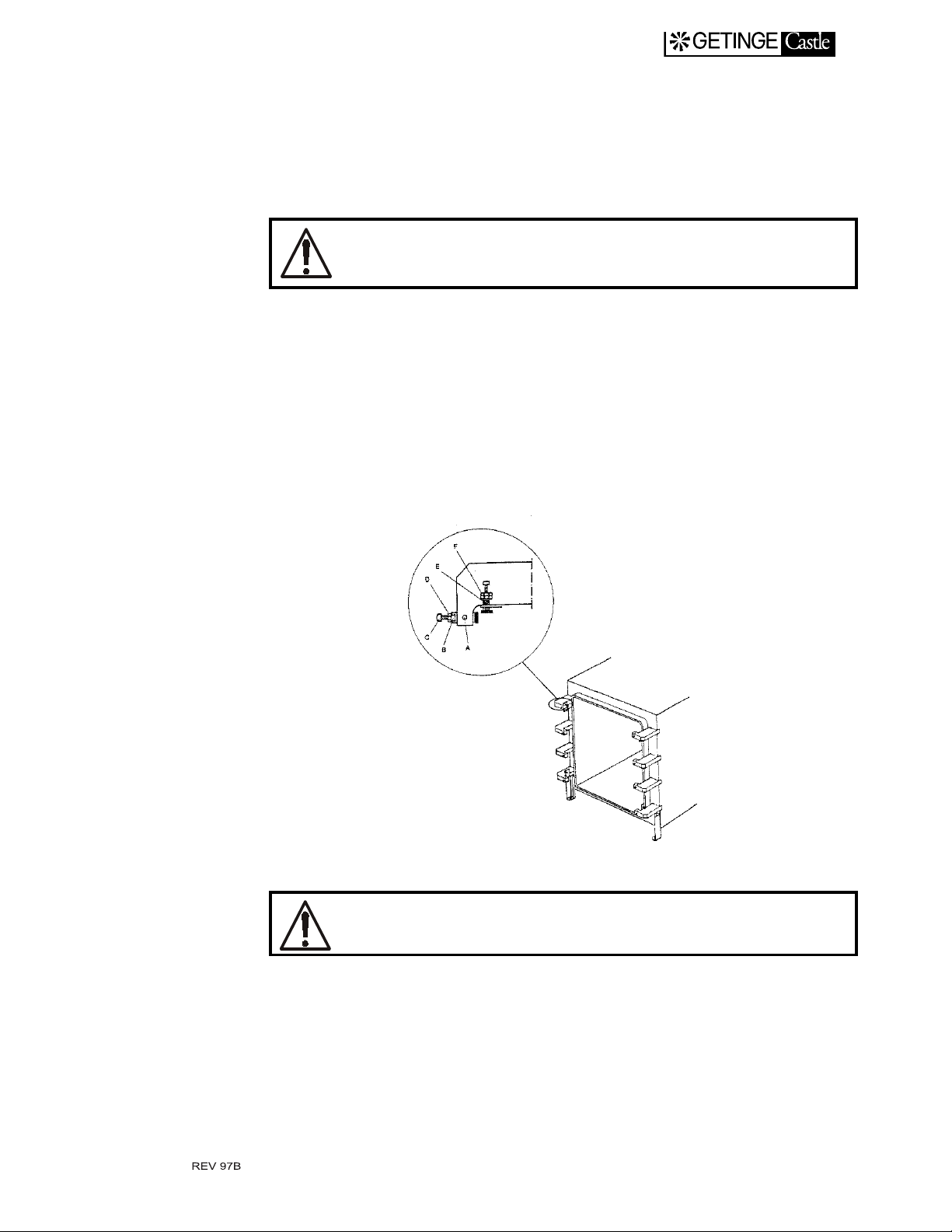

1. Check that the air pressure is minimum permissible 6 bar (80

PSIG).

2. Admit compressed air to make the door close.

a

3. Check that the measurement ”a” is 3-4 mm.

Adjust the height of the brace when needed.

4. Check that the end of the brace is well within the cylinder circum-

ference. (”b” = 12-17 mm)

b

5. Check by listening that the contact of the limi t switch does not

change over until the brace is sa fely under the pneumatic cyli nder.

Beware of the danger of squeezing, while manipulating the

brace.

4.11

Page 29

6. Check that the retaining pin is in place, preventing the limit switch

operating cone from moving on th e thread.

7. Operate the brace cylinder air valve repeatedly to che ck that the

motion of the piston is smooth an d free from jerks.

8. Check while the door is moving that it stops and remains stopped

when pushing the EMERGENCY STOP-button.

Safety check, door seal groove pressure switch

A pressure switch senses the pressure in the seal groove and breaks the

connection with those valves which control the admittance of steam,

compressed air, water and gases whenever the seal groove pressure falls

below the set point.

For double door sterilizers there are always two pressure switches,

one for each door.

•

Check the P&I diagram to identify and the pressure switch(es) for the

door seal groove(s).

EXIT MANUAL

•

Start a process.

•

Stop the process using the main power switch, when full pressure is

reached in the seal groove.

•

Connect a measuring device (Ohm-meter) over the connection points

of the pressure switch.

•

Keep the sterilizer main power switch switched off. Due to condensation of steam, the pressure in the groove will decrease.

•

Note the pressure at which con tact change-over takes place. Right

value shall be 1.9 bar(g) ± 0.1 (28 PSI).

•

After the check, disconnect the measuring device.

•

Switch the main power on and end the process (See section Alarm in

OPERATION Chapter in the Service Manual).

Emergency stop button

When the emergency stop button is activated , the following fun ctions

are blocked:

•

Media to chamber.

•

Air supply for open ing and closing door.

4.12

Page 30

Safety check

EXIT MANUAL

Further, the control system will enter the alarm phase.

A Open a door. While the door is moving, press the em ergency stop

button. The door shall stop and the contr ol system give an alarm.

Reset the alarm and reset the emergency stop button. Open the door

by pressing the ”open door” button.

B Close the door and start a sterilizing cycle.

C Press the emergency stop button when steam is entering the cham-

ber. The steam valve shall close and the system shall go i nto the

alarm phase. The printer (if connected) prin ts ”Process Stop” and

the stop is indicated on the display of the co ntrol system.

D Reset the alarm and reset the emergency stop button.

E End the sterilization cycle.

In case above described functions do not work according

to the description, let a well trained technician check the

system.

F Make above safety check also for emergency stop button at the sec-

ond door.

4.13

Page 31

EXIT MANUAL

5. CONTROL UNIT - ALLEN BRADLEY

The object of the control system is to produce command s and transmit

information to the sterilizer componen ts enabli ng for a number of sterilization processes to be accompli shed in accordance with a predicted

pattern. The command signals are generated by the control unit computer program in combination with measurements of the process parameter values. The latter consist mainly of times, temperatures and

pressures.

Various equipment can be connected to the control unit for programming, monitoring and recording the sterilization processes.

The operator communicates with the control unit via a control panel.

The entire process is controlled by an Allen Bradley SLC 504 microprocessor control system.

The Allen Bradley SLC 504 control system is made up of the Control

Processing Unit (CPU) and a Panelview504 Operator Interface Panel.

This panel contains status indi cator ligh ts and display while servi ng as

the operator interface for cy cle selection and cycle parameter inp ut.

Visual indication of the process appears as a read-out on the display.

Documentation of programs, system definitions and process data can be

made by connecting a pri nter. A host computer can also be connected

direct to the control unit CPU.

The computer contains a program section for calibration of temperature

and pressure transducers. Correction constants, when known, may be

entered manually. Among available test functions there are facilities for

activating analog and digital outputs and monitoring analog and digital

inputs. The maximum programmable digits are 9999.

The hardware of the steri lizer control system contains the operating

panels easily locate in a suitable place. The CPU and po wer pack are

placed in a separate electrical enclosure, connected to the operating panels.

Some terms of the branch

STERILIZATION means the whole series of treatments to form a process in order to attain total killing of all viable organisms. This is in connection with autoclaves usually made up by air removal, heat treatment

and a drying phase.

STERILIZING means the actual killin g part, th e heat treatmen t, of the

total process.

Analogous to the two expressions above, STERILIZATION TIME

means the durability of the total process from the start until the goods

can be unloaded. PROCESS TIME is equal to sterilization time.

5.14

Page 32

EXIT MANUAL

STERILIZING TIME represents that part of the process on ly during

which the programmed STERILIZING TEMPERATURE prevails in

the chamber.

PARAMETER in this context means the ELEMENTS WHICH

INFLUENCE the sterilization course. Examples of parameters in the

sterilization process are temperature, pressure, time, gas concentration,

etc. The PARAMETER VALUES may be fixed in the program or operator adjustable.

F

-VALUE is a time defined by the equ ation

0

t

T

k1–

t

()

------------------k

2

F

10

=

∫

0

0

t = Time in minutes

×

dt

T(t) =

= Constant within the range 0.0 - 150.0 oC. Usually 121.1 oC

k

1

= Constant withi n the range 0.0 - 99.9 oC. Usually 10.0 oC

k

2

The F

Load temperature at time t

. value is based upon the sterilizing time, required for the temper-

0

ature prevailing in each moment, being recalculated to the base temperature for steam sterilization, 121.1

The use of F

value is most common in the pharmaceutical field, where

0

often the time control of sterilization processes is based upon this value,

thereby utilizing t he heat appl ied du ring heat ing u p and cooli ng down .

By this method, heat sensitive products do not need to be exposed to

high temperatures for a longer period of time than required in obtaining

a sterile result.

Operating panel SLC 504

By means of the SLC 504, the operator selects program, alter parameter

values, starts and monitors the processes and receives information about

possible errors occurring with the sterilizer.

o

C

5.15

Page 33

EXIT MANUAL

The SLC 504 control p an el will not allow for su ch programming of the

cycle, such as making new processes or altering programs already resident in the CPU.

Display

Front Panel

Rear Panel

The 256 x 128 pixel displa y is the liqu id cryst al type. The back light i s

field replaceable to extend the life of the terminal.

The SLC 504 control panel consists of multiple touch keys for operator

interface.

•

Numeric keypad with decimal and underline.

•

Function keys for F1 through F10 selection.

•

Scroll arrow keys to move the cursor left or right

down

ÏÐ

.

•

ENTER key

•

Backspace key

The back of the SLC 504 cont rol panel c ontains tw o I/O Termina l Ports.

↵

.

Í

ÍÎ

and up or

•

Remote I/O port to connect a remote I/O Network.

•

RS-232 port al lowing c onnecti on to a R S-232 port of a comp uter for

information transfer .

5.16

Page 34

Push Buttons/Indicator Lights - Load Side

EXIT MANUAL

Emergency

Stop/ Abort

Alarm

Acknowledge

Control Power

ON/OFF

This push button is used to discontinue a

cycle. Once depressed, the outputs of the

control system will be turned off disabling

the sterilizer. At this time, a key must be

used to unlock the emergency stop button.

To unlock the emergency stop, turn the

key. The button will m ove outward to

reset. The operator must then acknowledge the alarm via the function keys

located on the Allen Bradley display.

This push button is pressed to acknowledge any alarm prior to continuing or

aborting a cycle. This push button is also

used to acknowledge that the sterilizer is

unloaded after closing the door on the

unload side.

This selector switch controls power to the

OFF position, all digital outputs are turned

off disabling the sterilizer. During normal

operation, the switch should be in the ON

position.

Open Door This push button is used to open the steril-

izer door after a cycle has ended. When

illuminated, it signals to the operator that

the door can be opened.

Close Door

This push button is used to close the door.

It must be pressed and held the entire time

that the door is in motion. The door will

reverse to the open position if the button is

not held.

5.17

Page 35

Push Buttons/Indicator Lights - Unload Side

EXIT MANUAL

Emergency

Stop/ Abort

Alarm

Acknowledge

Open Door

Close Door This push button is used to close the door.

This push button is used to discontinue a

cycle. Once depressed, the outputs of the

control system will be turned off disabling

the sterilizer. At this time, a key must be

used to unlock the emergency stop button.

To unlock the emergency stop, turn the

key. The button will m ove outward to

reset. The operator must then acknowledge the alarm via the function keys

located on the Allen Bradley display.

This push button is pressed to acknowledge any alarm prior to continuing or

aborting a cycle. This push button is also

used to acknowledge that the sterilizer is

unloaded after closing the door on the

unload side.

This push button is used to open the sterilizer door after a cycle has ended. When

illuminated, it signals to the operator that

the door can be opened.

It must be pressed and held the entire time

that the door is in motion. The door will

reverse to the open position if the button is

not held.

Cycle In

Progress

This indicator light iden tifies the cycle is

in progress.

5.18

Page 36

Passwords

EXIT MANUAL

Six passwords exist in the Allen Bradley and consists of five digits 0000

- 99999. The password sections are:

Parameters

•

Cycle Start

•

Cycle Time & Date

•

Service

•

Calibration

•

Master Password

•

Passwords at delivery:

The passwords set in the con trol system is revealed in a special docu ment delivered in a sealed envelope together with the sterilizer manuals.

Detailed screen displays

Main Menu

Upon start-up of the sterilizer, the main menu of the display will appear

as shown below. Functions such as cycle selection, start cycle, runtime

screen, change cycle parameters, alarms, and service information can be

accessed through the main menu.

Us the up or down arrows located on the panelview keypad to select the

next display frame. Press return to acknowledge and advance to the

selected display frame.

5.19

Page 37

Load Door Main Screen

EXIT MANUAL

This screen allows for the selection of the Validation Password Screen

to allow the operation of a cycle from the opposite door. The correct

password must be entered for the following displayed on the Unload

Door.

Unload Door Main Screen

5.20

Page 38

EXIT MANUAL

.

5.21

Page 39

Cycle Selection/Start Cycle

In the Cycle Selection menu screen, select the type of cycle to be run by

pressing the appropriate function key (F1, F2, etc.). The type of cycle

selected will appear in the highlighted box. Press F5 to start the cycle.

.

EXIT MANUAL

5.22

Page 40

Cycle Start

EXIT MANUAL

The display will then ask the operator to verify start of the cycle. Press

F3 to acknowledge the start of th e cycle. The sterilizer’s door will then

be sealed and locked initia ting the cycle.

.

Following the selection of F3, the following confirmation screen will

appear:

5.23

Page 41

Runtime Screen

EXIT MANUAL

The Runtime screen a llo ws th e opera tor to o bserve t he co nd ition s d uring the sterilizer cycle such as temperatur e, pressure, etc. This d isplay

is accessed through the main menu via the up or down arrow keys followed by pressing the return button

.

5.24

Page 42

Cycle Parameters

EXIT MANUAL

The Change Cycle Parameter d isplay screen is us ed to alter par ameter

setpoints of the cycle to be run such as st erilization time and temper ature. This display is accessed through the main menu. Use the up or

down arrow keys followed by pressing the return key to access this display. A password is req uired to access the Cha nge Parameter display.

Press F1 to enter the password. Enter the password using the numeric

keys followed by pressi ng the return key.

.

Select the cycle in which the parameters are to be altered. Use the up or

down arrow key to select the cycle followed by pressing the return key.

.

5.25

Page 43

Change Parameter

In the Change Parameter display, the current parameter settings will be

displayed. To alter a pa rame t e r, pr e ss th e app ropriate function ke y ( F1,

F2, etc.). Enter the parameter value using the numeric keys followed by

pressing the return key. Decimal points are not required in en tering the

new value. A cycle may be started from this display screen by pressing

F5.

Textile Cycle:

.

EXIT MANUAL

Insitu Cycle:

.

5.26

Page 44

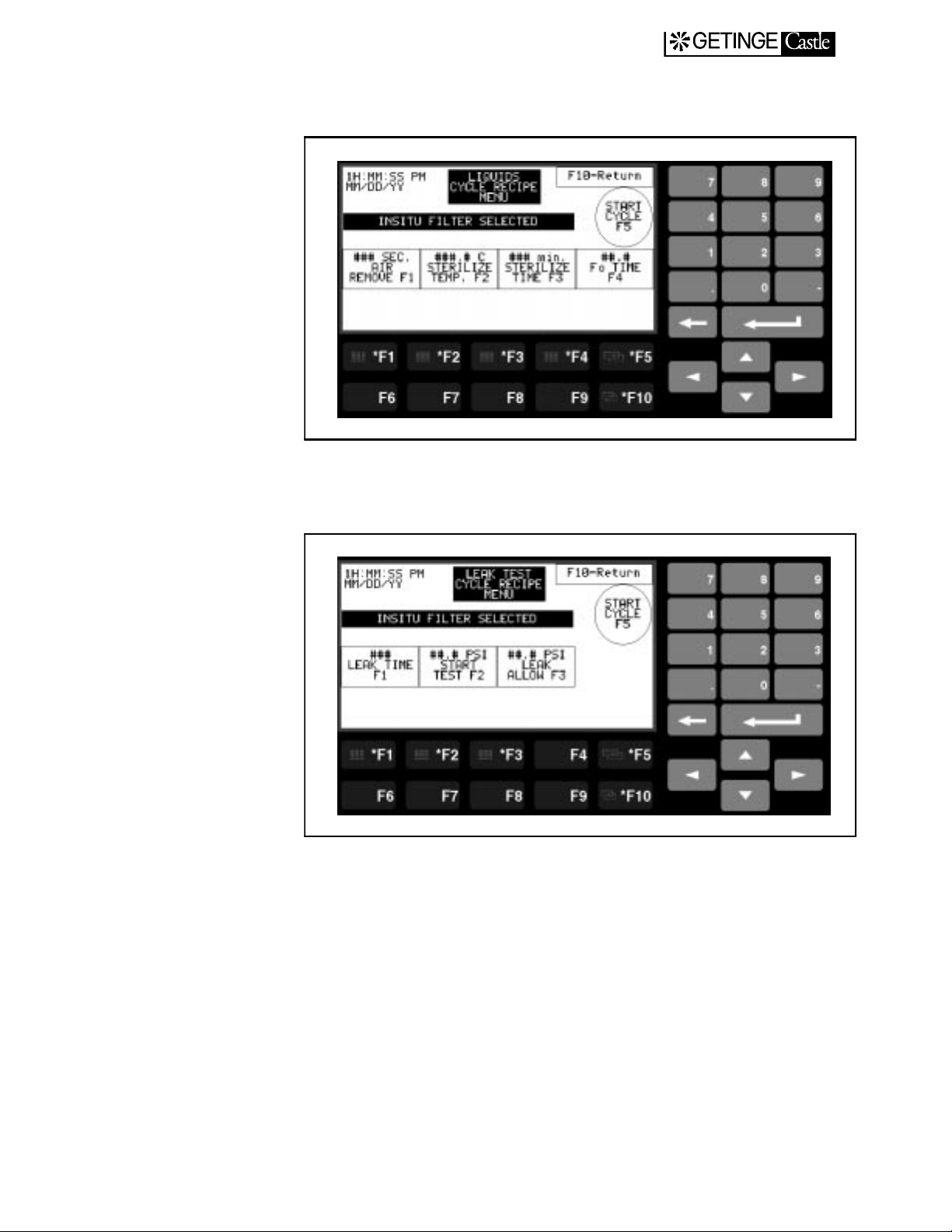

Liquid Cycle:

.

EXIT MANUAL

Leak Test Cycle:

.

5.27

Page 45

Parameter Password Screen

In the Change Password Screen, the operator can set or change the

parameter password. To set or change the parameter password, press

F1. Enter the password by using the numbered keys followed by pressing the return key.

.

EXIT MANUAL

5.28

Page 46

Alarm Display

EXIT MANUAL

In the event an alarm condition occurs during a cycle, the Alarm display

screen will appea r. The type of alarm will be displayed in the high lighted box. Any al arm or aborte d cycle must be ackn owledged to the

control system. Acknowledge the alarm by pressing F3. The system will

then ask the operator to conti nue the cyc le or abort the cycle. Press F3

to abort the present cycle or F5 to continue the present cycle.

Emergency Stop Alarm Screen:

5.29

Page 47

System Information

The System Information display screen will identify informa tion about

the cycle progress.

EXIT MANUAL

5.30

Page 48

Service Screen

EXIT MANUAL

The Service display screen is used for service and maintenance functions such as monitoring control v alue, I/O ch ecks and man ual contr ol

of the sterilizers. The service display screen is accessed through the

main menu by the use of the up or down arrow keys followed by pressing the return key. A service password is required to access the service

display screens. Press F1 to enter the service password. Enter the password by using the numeric keys followed by pressing the return key.

In the Service display screen, the up or down arrow keys are used to

select the sterilizer components to be monitored and/or altered. Press

the return key to access the display screen s for th ese functions.

5.31

Page 49

Service Screen Passwords

In this display scree, the user can change the service password. To

change the current service password, press F1. Enter the new password

using the numeric keys followed by pressing the RETURN key to enter

the password. The system will then ask the user to verify the password.

Re-enter the password followed by pressing the RETURN key.

EXIT MANUAL

5.32

Page 50

Digital Inputs

EXIT MANUAL

In the Digital Input display, the user can observe the system’s digital

inputs as they are energized. An illuminated box ind icates that the

device is on and providing input to the controller.

.

5.33

Page 51

Digital Outputs

EXIT MANUAL

In the Digital Outpu t display, the user can manually overrid e devices,

such as opening valves, once the device is in the manual mode. For each

digital output display, the left-hand column and associated function

keys will place the selected dev ice in the manual mode when pressed.

The right-hand column and associated function keys will physically

turn the devic e on or off when p ressed. A n illumi nated bo x represe nts

the device in ON.

.

5.34

Page 52

EXIT MANUAL

5.35

Page 53

EXIT MANUAL

.

5.36

Page 54

EXIT MANUAL

.

5.37

Page 55

PID Control

EXIT MANUAL

In either the Jacket PID or the Chamber PID display screen, the user can

observe the operation of the valve which controls steam to the chamber

or jacket. The proportional ga in an d reset valu es used to maint ain temperature control can be altered fr om this display. To alter one of the

parameters, press the appropriate function key. PRess F3 to alter the

PROPORTIONAL GAIN value or F2 to alter the RESET value. Enter

the new value using the numerical keys followed by pressing the

RETURN key to enter the value.

Jacket PID

Chamber PID

5.38

Page 56

Alarm and System Messages - Troubleshooting

Note:

All alarms and system messages must be acknowledged to silence the

alarm and clear the display. Fatal errors will interru pt the cycle. The

cycle will not be interrupted whe n a non-fatal error occurs. Ackn owledging the error will not interrupt the cycle. When troubleshooting,

ALWAYS refer to the wiring diagram for the unit being serviced. Also

see the Input/Output table in the Appendix.

SERVICE TO BE PERFO RMED BY QUALIFIED PER SONNEL

ONLY.

EXIT MANUAL

5.39

Page 57

Information Text

The following messages are displayed on the display panel. Typically

the “CYCLE RESTARTED” and “CYCLE ABORTED” messages will

also be printed to the printer

CYCLE ABORT This message will be displayed if, following pu shing

Emergency Stop butt on and then restori ng the power, t he

operator elects to abort the current cycle by pushing the

OPEN DOOR button. S ee Emergency Stop below.

SEALING DOOR #1 This message will be d isplayed on the display panel once

all start conditions are satisfied and the start button is

pressed. When Door #1 is fully sealed, the message is no

longer displayed.

EXIT MANUAL

SEALING DOOR #2 This message will be displayed on ce all start conditions

are satisfied and the Start butt on is pressed. When Door

#2 is fully sealed, the message is no longer display ed.

UNSEALING DOOR #1 During the Cycle End phase, this message will be dis-

played as the Load Door is unsealed.

UNSEALING DOOR #2 During the Cycle End phase, this message will be dis-

played as the Unload Door is unsealed.

CYCLE COMPLETE During the Cycle End phase, this message will be dis-

played after the chamber has returned to atmospheri c

pressure.

CYCLE RESTARTED This message will be displ ayed if, foll owing pu shing th e

Emergency Stop butt on and then restori ng the power, t he

operator elects to continue the cur rent cycle by pushing

the CONTINUE button on the Alarm Display. See Emergency Stop below.

UNLOADING This message will be displayed du ring the Cycle End

phase while the unload door is opened.

PRESS OPEN - LOAD This message will be displayed du ring the Cycle End

phase once the unload door has been closed again following unloading the Load Door may be opened.

OPEN DOOR This message will be displayed du ring the Cycle End

phase once the Load Door seal has been pulled and the

door is ready to be opened.

5.40

Page 58

Alarm List

EMERGENCY STOP

Message Display:

EMERGENCY STOP

This alarm is activated when the Emergency Stop pushbutton is activated from the fascia panel. All digital outputs except for the alarm and

Acknowledge Alarm lamp will be turned off. The alarm will sound and

the Acknowledge Alarm lamp will flash. It will also activate the emergency stop alarm scr een on the PanelView 9 00 operator terminal . The

alarm will be printed if the unit is in cycle.

Operator Acknowledgement:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm lamp will stop flashing, but remain illuminated.

All outputs remain off.

EXIT MANUAL

The Emergency Stop button must be reset by inserting the key and

twisting in the clockwise direction. The cycle may be aborted or continued by pressing the appropriate button area of the touch screen display.

When a cycle is abor ted, the sterilizer will advance to the post condi tioning phase of the cycle allowing the sterilizer to advance to a safe

condition. When a cycle is continued, the process will return to the condition at the point when the alarm was activated and continue the cycle.

CHAMBER TEMPERATURE SENSOR ERROR

Alarm Condition:

The probe is out of the allowable range of -5.0

Message Display:

CHAMBER TEMP OUT OF RANGE

This alarm will turn off all digital outputs except for the alarm and

Acknowledge Alarm lamp. The alarm will sound and the Acknowledge

Alarm lamp will flash. It will also activate the alarm screen of the PanelView 900. The alarm shall be printed.

Operator Acknowledge:

o

C to 150oC

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present. All outputs remain off.

The alarm must be cleared by repair or replacement of the defective

component. When the sensor returns to within the allowable range, the

process will return to the co ndition when the alarm was activ ated. The

Alarm Acknowledge lamp will extinguish.

5.41

Page 59

PRESSURE SENSOR ERROR

Alarm Condition:

The sensor is out of the allowable range of 0 PSIA to 50.0 PSIA.

Message Display:

CHAMBER PRESSURE OUT OF RANGE

This alarm will turn off all digital outputs except for the alarm and

Acknowledge Alarm lamp. The alarm will sound and the Acknowledge

Alarm lamp will flash. It will also activate the alarm screen of the PanelView 900. The alarm shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present. All outputs remain off.

The alarm must be cleared by repair or replacement of the defective

component. When the sensor returns to within the allowable range, the

process will return to the co ndition when the alarm was activ ated. The

Alarm Acknowledge lamp will extinguish.

EXIT MANUAL

INSITU FILTER TEMPERATURE SENSOR ERROR

Alarm Condition:

The probe is out of the allowable range of -5.0

Message Display:

INSITU FILTER TEMP OUT OF RANGE

This alarm will turn off all digital outputs except for the alarm and

Acknowledge Alarm lamp. The alarm will sound and the Acknowledge

Alarm lamp will flash. It will also activate the alarm screen of the PanelView 900. The alarm shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present. All outputs remain off.

The alarm must be cleared by repair or replacement of the defective

component. When the sensor returns to within the allowable range, the

process will return to the co ndition when the alarm was activ ated. The

Alarm Acknowledge lamp will extinguish.

o

C to 150oC

5.42

Page 60

LOAD TEMPERATURE SENSOR ERROR

Alarm Condition:

The probe is out of the allowable range of -5.0

Message Display:

LOAD TEMP OUT OF RANGE

This alarm will turn off all digital outputs except for the alarm and

Acknowledge Alarm lamp. The alarm will sound and the Acknowledge

Alarm lamp will flash. It will also activate the alarm screen of the PanelView 900. The alarm shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present. All outputs remain off.

The alarm must be cleared by repair or replacement of the defective

component. When the sensor returns to within the allowable range, the

process will return to the co ndition when the alarm was activ ated. The

Alarm Acknowledge lamp will extinguish.

o

C to 150oC

EXIT MANUAL

DOORS NOT CLOSED

Alarm Condition:

The door limit switch input is on.

Message Display:

DOORS NOT CLOSED

This alarm will turn off all digital outputs except for the alarm and

Acknowledge Alarm lamp. The alarm will sound and the Acknowledge

Alarm lamp will flash. It will also activate the alarm screen of the PanelView 900. The alarm shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present. All outputs remain off.

The alarm must be cleared by repair or replacement of the defective

component. When the repai r is complete, the process wi ll return to the

condition when the alarm was activated. The Alarm Acknowledge lamp

will extinguish.

5.43

Page 61

DOORS NOT SEALED

Alarm Condition:

The door seal pressure switch reads low (off) for mor e than 2 minutes.

Message Display:

DOORS NOT SEALED

The alarm will sound and the Acknowledge Alarm lamp will flash. It

will also activate the alarm screen of the PanelView 900. The alarm

shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present.

Check that required steam pressure is being supplied to the unit. The

alarm must be cleared by repair or replacement of the defective component or providing required steam pressure. When the repair is complete,

the process will return to the condition when the alarm was activated.

The Alarm Acknowledge lamp will extinguish.

EXIT MANUAL

DOORS 1 SEAL LEAK

Alarm Condition:

The door 1 seal flow switch reads high for more that 20 seconds.

Message Display:

DOORS 1 SEAL LEAK

The alarm will sound and the Acknowledge Alarm lamp will flash. It

will also activate the alarm screen of the PanelView 900. The alarm

shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present.

Check that required steam pressure is being supplied to the unit. The

alarm must be cleared by repair or replacement of the defective component or providing required steam pressure. When the repair is complete,

the process will return to the condition when the alarm was activated.

The Alarm Acknowledge lamp will extinguish.

5.44

Page 62

DOORS 2 SEAL LEAK

Alarm Condition:

The door 2 seal flow switch reads high for more that 20 seconds.

Message Display:

DOORS 2 SEAL LEAK

The alarm will sound and the Acknowledge Alarm lamp will flash. It

will also activate the alarm screen of the PanelView 900. The alarm

shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present.

Check that required steam pressure is being supplied to the unit. The

alarm must be cleared by repair or replacement of the defective component or providing required steam pressure. When the repair is complete,

the process will return to the condition when the alarm was activated.

The Alarm Acknowledge lamp will extinguish.

EXIT MANUAL

POWER FAILURE

Alarm Condition:

The processor detect there has been a loss of power.

Message Display:

POWER FAILURE

The alarm will sound and the Acknowledge Alarm lamp will flash. It

will also activate the alarm screen of the PanelView 900. The alarm

shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Ala rm lamp wi ll ex ti ng ui sh.

5.45

Page 63

HIGH CHAMBER PRESSURE

Alarm Condition:

The chamber pressure transducer reads greater than 60 PSIA

Message Display:

HIGH CHAMBER PRESSURE

This alarm will turn off all digital outputs except for the alarm and

Acknowledge Alarm lamp. The alarm will sound and the Acknowledge

Alarm lamp will flash. It will also activate the alarm screen of the PanelView 900. The alarm shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present. All outputs remain off.

The alarm must be cleared by repair or replacement of the defective

component. When the sensor returns to within the allowable range, the

process will return to the co ndition when the alarm was activ ated. The

Alarm Acknowledge lamp will extinguish.

EXIT MANUAL

VACUUM SYSTEM TIMEOUT

Alarm Condition:

The chamber pressure did not achiev e the necessary vacuum level

within 60 minutes.

Message Display:

VACUUM SYSTEM TIMEOUT

The alarm will sound and the Acknowledge Alarm lamp will flash. It

will also activate the alarm screen of the PanelView 900. The alarm

shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present.

The alarm must be cleared by repair or replacement of the defective

component. When the sensor returns to within the allowable range, the

process will return to the co ndition when the alarm was activ ated. The

Alarm Acknowledge lamp will extinguish.

5.46

Page 64

LOW STERILIZATION TEMPERATURE

Alarm Condition:

The controlling temperature device reads less than one degree C

o

(1.0

C) than the set sterilization temperature for more than 10 seconds.

Message Display:

LOW STERILIZATION TEMPERATURE

The alarm will sound and the Acknowledge Alarm lamp will flash. It

will also activate the alarm screen of the PanelView 900. The alarm

shall be printed.

The sterilization timer is reset t o ze r o (0:00) minutes and t he ti mer will

not restart until the temperature is regained.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present.

EXIT MANUAL

The alarm will clear when the sensor returns to the set sterilization temperature. The Alarm Acknowledge lamp will extinguish.

HIGH STERILIZATION TEMPERATURE

Alarm Condition:

The controlling temperature device reads more than two degree C

o

(2.0

C) than the set sterilization temperat ure for more than 2 minutes.

Message Display:

HIGH STERILIZATION TEMPERATURE

The alarm will sound and the Acknowledge Alarm lamp will flash. It

will also activate the alarm screen of the PanelView 900. The alarm

shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present.

The alarm will clear when the sensor return s to less than two degrees

above the set sterilization tempera ture. The Alarm Ackno wledge lamp

will extinguish.

5.47

Page 65

HIGH WATER LEVEL IN DRAIN

Alarm Condition:

The drain high water level switch (LS10) is on for more than 30 seconds

Message Display:

HIGH WATER

The fast exhaust valve shall open to clear the water from the drain.

When the switch detects no water in the drain, the fast exhaust valve

will close.

The alarm will sound and the Acknowledge Alarm lamp will fla sh. It

will also activate the alarm screen of the PanelView 900. The alarm

shall be printed.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. The

Acknowledge Alarm l amp will sto p flashi ng a nd r emain illu min ated i f

the alarm condition is still present.

EXIT MANUAL

The alarm will clear when the switch detects no water in the drain. The

Alarm Acknowledge lamp will extinguish.

LEAK TEST FAILURE

Alarm Condition:

The chamber pressure rises above th e allowable leak amount. The

leak amount set point is dete rmi ned by ad ding th e chamber pre ssure at

the start of the leak test to the allow able leak amount.

Message Display:

LEAK TEST FAILURE

The alarm will sound and the Acknowledge Alarm lamp will flash. It

will also activate the alarm screen of the PanelView 900. The alarm

shall be printed and the process will automatically advance to the air

admission phase to end the cycle.

Operator Acknowledge:

Press the Acknowledge Alarm button to silence the alarm. Determine

the cause of the lead and run another lead test cycle.

5.48

Page 66

INPUT/OUTPUT LIST

EXIT MANUAL

NAME DESIGNATION

DOOR 1 NOT FULL OPEN LS1A I:1/0

DOOR 1 NOT FULL CLOSED LS1B I:1/1

DOOR 1 SAFETY SWITCH OK PS11A I:1/2

DOOR 1 SEALED PS1 I:1/3

DOOR 2 NOT FULL OPEN LS2A I:1/4

DOOR 2 NOT FULL CLOSED LS2B I:1/5

DOOR 2 SAFETY SWITCH OK PS11B I:1/6

DOOR 2 SEALED PS2 I:1/6

CHAMBER PRESSURE SWITCH PS6 I:1/7

RUPTURE DISK FAILURE PS4 I:1/8

EMERGENCY STOP PB4D1 I:1/10

HIGH DRAIN WATER LEVEL LT1 I:1/11

CONDENSER TEMP HIGH TS1 I:1/12

VACUUM PUMP TRIPPED MS3D2 I:1/13

MEMORY

LOCATION

120VAC POWER SUPPLY OK N/A I:1/14

OPEN DOOR PB200 I:2/0

CLOSE DOOR PS201 I:2/1

OPEN DOOR 2 PB202 I:2/2

CLOSE DOOR 2 PB203 I:2/3

ALARM ACKNOWLEDGE PB204 I:2/4

5.49

Page 67

Technical data

EXIT MANUAL

5.50

Page 68

EXIT MANUAL

5.51

Page 69

6. STERILIZER SPECIFICATION

EXIT MANUAL

Page 70

7. P&I DIAGRAM

EXIT MANUAL

Page 71

8. ELECTRIC WIRING

EXIT MANUAL

Page 72

9. INSTALLATION DRAWING

EXIT MANUAL

Page 73

10. PHASE LIST

EXIT MANUAL

Page 74

11. COMPONENTS

Illustration on drawings

• Electric wiring diagrams ar e drawn with power off.

• Apparatus and components are illustrated in their basic position.

• Pressure switches are illustrated in the position they take for atmos-

pheric pressure.

• Thermal switches are illustrated in the position they take for room

temperature.

Departure from these ru les are indicated on the diagrams.

EXIT MANUAL

11.1

Page 75

EXIT MANUAL

Panel-Mounted Thermal Printer, Model PRNTR0001

The Getinge panel printer is a completely maintenance-free thermal

printer, specially developed to withstand the severe conditions associated with front mounting. The thermal paper has been specially developed for the Getinge panel printer in order to withstand particularly

severe requirements in respect of heat resistance, resistance to fading

and permanent documentat ion.

Loading the paper

Use only genuine Getinge paper for the best printout durability.

The thermal paper i s of hi gh quali ty, supp lie d o n 50 m m ( 2”) d iamet er

rolls with a width of 60 mm (2.4”).

Do not replace the paper without being properly grounded.

If not, static electricity can destroy the microprocessor if

you touch it, or any of the connections.

Turn off the cont rol unit power supp ly switch. The prin ter lamp goes

•

out.

Pull the upper edge of the transparent paper collector outwards in

•

order to release it.

Release the bl ac k printer cov er in the same w a y and remove the ol d

•

paper roll.

Load a new roll of paper with the tongue upwards, as shown in Fig-

•

ure 1. This will automatically posit ion the recording side correctly

in the printer.

Position the roll co rrectly, pull out some of it and close the printer

•

cover so that it clicks into position.

Turn on the sterilizer control power supply switch and feed out about

•

10 mm (1/2”) of paper using the paper feed pushbutton on the printer.

Refer to Figure 2. Check that the paper is being fed correctly through

the opening in th e pr inter cover.

Lift the paper collector into position. The p rinter is ready for use.

•

11.2

Page 76

Operation

Maintenance

•

Data is recorded automatically as the cycle progresses. The steady

red light on th e lower left of the fron t panel in dicates the po wer is on