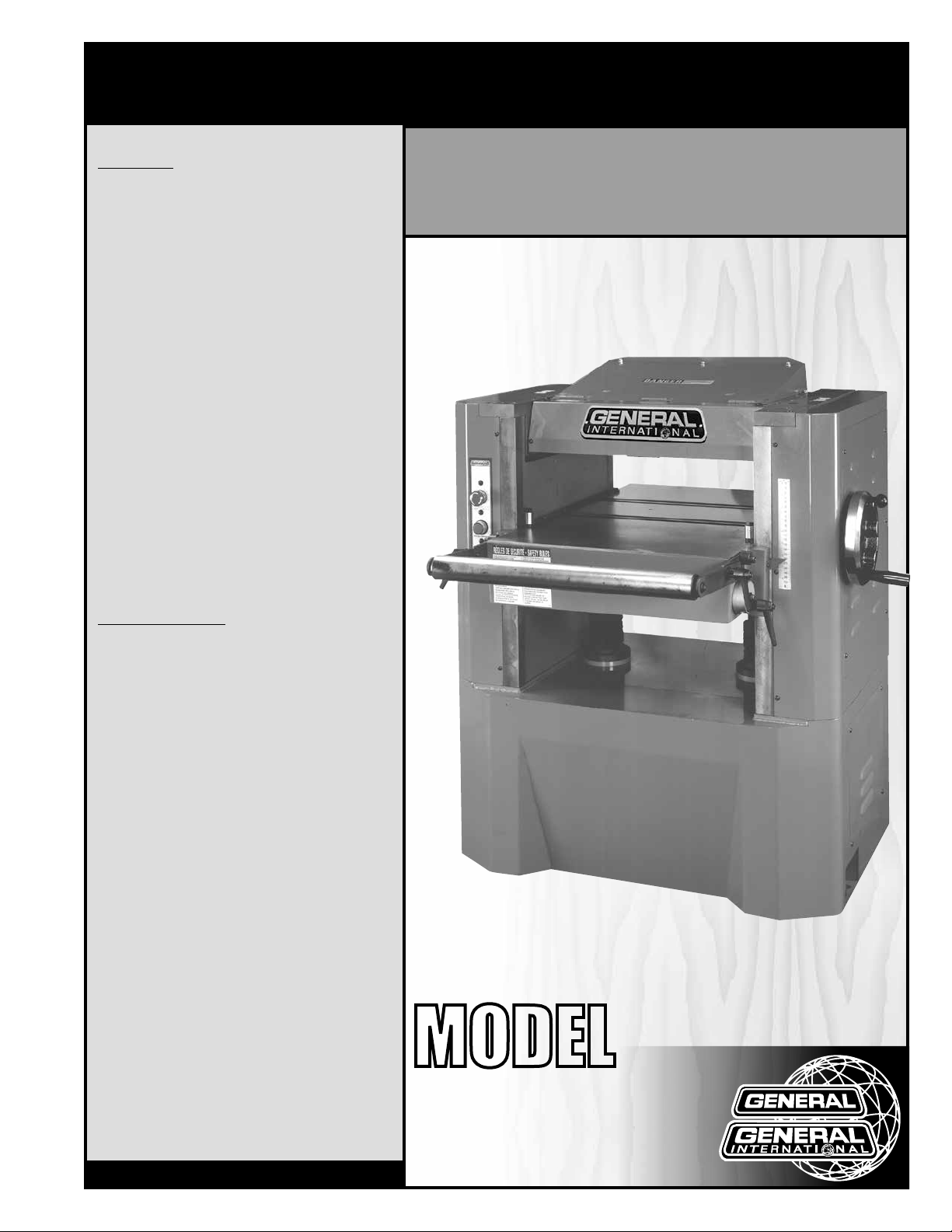

Page 1

SETUP & OPERATION MANUAL

FEATURES

Positive gear design for quick and accurate

table adjustments.

5” dust collection hood.

Cast-iron table and head.

Four cutter knives result in easier cutting and

longer motor life, (helical cutter head model

available: #30-360HC).

Built-in table rollers reduce friction.

Large 8” handwheel quickly adjusts table

height.

Comes with magnetic safety switch.

Graduated scale in both inches and metric to

indicate workpiece thickness.

Anti-kickback fingers at the front of the infeed

roller to ensure maximum operator safety.

Vertical adjustment handle for table rollers.

Equipped with a sectioned infeed roller and a

rubber outfeed roller.

One front-mounted exterior table roller.

20” SINGLE SURFACE PLANER

SPECIFICATIONS

• Table size

32” x 20” (813 x 508 mm)

• Maximum planing width

20” (508 mm)

• Min/Max thickness of stock

3/16” (5 mm) / 8” (204 mm)

• Minimum length of stock

8 1/4” (210 mm)

• Maximum cutting depth (full width)

1/8” (3 mm)

• Maximum cutting depth (width 8 1/2” or less)

1/4” (6 mm)

• Cutter head diameter

3 3/4” (97 mm)

• Cutter head speed

4500 rpm

• Feed speeds

(2) 22 & 28 fpm

• Cuts per inch (not applicable for HC model)

68.17 at 22 fpm & 53.5 at 28 fpm

• Number of knives / Inserts

4 - 30-360 / 58 - 30-460HC

• Base dimensions (l x w)

36” x 22” (914 x 559 mm)

• Motor

M1: 7 1/2 HP, 220 V, 1 Ph, 31 A

M2: 7 1/2 HP, 220 V, 3 Ph, 20 A

M3: 7 1/2 HP, 600 V, 3 Ph, 10 A

• Weight

1392 lbs (633 kg) - 30-360

1397 lbs (635 kg) - 30-360HC

Version #1_Revision #2 - November 2015

© Copyright General International

*With helical cutter head

MODEL

#

30-360

#

30-360HC*

Page 2

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU

for choosing this General® International model 30-360/30360HC 20” single surface planer. This planer has been carefully tested and inspected before

shipment and if properly used and maintained, will provide you with years of reliable service.

For your safety, as well as to ensure optimum performance and trouble-free operation, and to

get the most from your investment, please take the time to read this manual before assembling,

installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and

features of this planer as well as the set-up, maintenance and identification of its parts and

components. This manual is not intended as a substitute for formal woodworking instruction,

nor to offer the user instruction in the craft of woodworking. If you are not sure about the safety

of performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

DISCLAIMER: The information and specifications

in this manual pertain to the unit as it was supplied

from the factory at the time of printing. Because we

are committed to making constant improvements,

General® International reserves the right to make

changes to components, parts or features of this unit

as deemed necessary, without prior notice and without

obligation to install any such changes on previously

delivered units. Reasonable care is taken at the factory

to ensure that the specifications and information in this

manual corresponds with that of the unit with which it

was supplied. However, special orders and “after factory”

modifications may render some or all information in

this manual inapplicable to your machine. Further,

as several generations of this model of single surface

planer and several versions of this manual may be in

circulation, if you own an earlier or later version of this

unit, this manual may not depict your unit exactly. If you

have any doubts or questions contact your retailer or

our support line with the model and serial number of

your unit for clarification.

Page 3

GENERAL® INTERNATIONAL WARRANTY

All component parts of General® International and Excalibur by General International® products

are carefully inspected during all stages of production and each unit is thoroughly inspected upon

completion of assembly.

Limited Lifetime Warranty

Because of our commitment to quality and customer satisfaction, General® International agrees to

repair or replace any part or component which upon examination, proves to be defective in either

workmanship or material to the original purchaser for the life of the tool. However, the Limited Lifetime

Warranty does not cover any product used for professional or commercial production purposes nor

for industrial or educational applications. Such cases are covered by our Standard 2-year Limited

Warranty only. The Limited Lifetime Warranty is also subject to the “Conditions and Exceptions” as listed

below.

Standard 2-Year Limited Warranty

All products not covered by our lifetime warranty including products used in commercial, industrial

and educational applications are warranted for a period of 2 years (24 months) from the date of

purchase. General® International agrees to repair or replace any part or component which upon

examination, proves to be defective in either workmanship or material to the original purchaser during

this 2-year warranty period, subject to the “conditions and exceptions” as listed below.

To file a Claim

To file a claim under our Standard 2-year Limited Warranty or under our Limited Lifetime Warranty,

all defective parts, components or machinery must be returned freight or postage prepaid to

General® International, or to a nearby distributor, repair center or other location designated by

General® International. For further details call our service department at 1-888-949-1161 or your local

distributor for assistance when filing your claim.

Along with the return of the product being claimed for warranty, a copy of the original proof of purchase

and a “letter of claim” must be included (a warranty claim form can also be used and can be obtained,

upon request, from General® International or an authorized distributor) clearly stating the model and

serial number of the unit (if applicable) and including an explanation of the complaint or presumed

defect in material or workmanship.

CONDITIONS AND EXCEPTIONS:

This coverage is extended to the original purchaser only. Prior warranty registration is not required but

documented proof of purchase i.e. a copy of original sales invoice or receipt showing the date and

location of the purchase as well as the purchase price paid, must be provided at the time of claim.

Warranty does not include failures, breakage or defects deemed after inspection by

General® International to have been directly or indirectly caused by or resulting from; improper use,

or lack of or improper maintenance, misuse or abuse, negligence, accidents, damage in handling or

transport, or normal wear and tear of any generally considered consumable parts or components.

Repairs made without the written consent of General® International will void all warranty.

Page 4

TABLE OF CONTENTS

Rules for safe operation ..................................................................................................... 5

Electrical requirements ...................................................................................................... 6

Identification of main parts and components .................................................................. 7

Unpacking .......................................................................................................................... 8

Basic functions ................................................................................................................... 8

Cleaning............................................................................................................................. 9

Placement within the shop ................................................................................................ 9

Assembly instructions ........................................................................................................ 9

Knife setting jig .................................................................................................................................................... 9

Attach the depth of cut adjustment handwheel .......................................................................................... 10

Installing the lifting hooks ................................................................................................................................ 10

Installing the table roller and adjustment lever ............................................................................................ 10

Installing the dust chute ................................................................................................................................... 10

Connecting to a dust collector ....................................................................................................................... 10

Basic adjustments and controls ................................................................................. 11-13

Connecting to a power source .......................................................................................................................11

Magnetic safety switch .................................................................................................................................... 11

Overload protection ......................................................................................................................................... 11

Adjusting table roller height ............................................................................................................................ 12

Using the table extension roller ....................................................................................................................... 12

Immobilizing the machine .............................................................................................................................. 12

Operating instructions ................................................................................................ 13-16

Basic principles of planing .............................................................................................................................. 13

Selecting boards suitable for planing ............................................................................................................ 13

Rated limits of this planer ................................................................................................................................. 13

Adjusting the depth of cut ............................................................................................................................... 14

Adjusting feed speed ....................................................................................................................................... 14

Checklist before starting .................................................................................................................................. 14

Planing step by step ......................................................................................................................................... 15

Maintenance ............................................................................................................... 16-26

Adjusting cutter head parallel to the table ................................................................................................... 16

Adjusting the infeed & outfeed rollers ............................................................................................................ 17

Adjusting the chipbreaker ............................................................................................................................... 18

Aligning the table rollers .................................................................................................................................. 18

leveling the extension roller to the table .......................................................................................................18

Periodic maintenance ..................................................................................................................................... 19

Inspecting cutter head knives/inserts ............................................................................................................ 19

Inspecting cutter head (model 30-360 only) ................................................................................................ 20

Knife setting or replacement (model 30-360 only) ....................................................................................... 21

Helical cutter head insert reversal/Replacement (model 30-360HC only) ............................................... 22

Replacing the gear box ................................................................................................................................... 23

Lubrication ......................................................................................................................................................... 24

Cleaning anti-kickback fingers ....................................................................................................................... 25

Adjusting belt tension/changing the belts .................................................................................................... 26

Recommended optional accessories ............................................................................. 27

Parts list & diagram .................................................................................................... 28-37

Contact information ........................................................................................................ 38

Page 5

RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations,

as well as potential hazards. General

harmless for any injury that may result from the improper use of it’s equipment.

1. Do not operate this planer when tired, distracted, or

under the effects of drugs, alcohol or any medica tion that impairs reflexes or alertness.

2. The work area should be well lit, clean and free

of debris.

3. Keep children and visitors at a safe distance when

the planer is in operation; do not permit them to

operate the planer.

4. Childproof and tamper proof your shop and all

machinery with locks, master electrical switches

and switch keys, to prevent unauthorized or unsu pervised use.

5. STAY ALERT! Give your work your undivided attention.

Even a momentary distraction can lead to serious

injury.

6. Fine particulate dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area

and whenever possible use a dust collector. Wear

face, eye, ear, respiratory and body protection

devices.

®

International disclaims any real or implied warranty and holds itself

13. Do not push or force stock into the cutter head. The

planer will perform better and safer when working at

the rate for which it was designed.

14. Kickback is when the workpiece is ejected at high

speeds by the force of the cutter head. To minimize

the risk of injury from kickback, use proper feeding

technique and stand to one side, out of the path of

a potential kickback.

15. Select appropriate feed speed for the stock being

planed: high speed for softwood and slow for hard woods.

16. Place stock firmly against the table and use suitable

in-feed and out-feed support if stock is too long.

17. Keep guards in place and in working order. If a

guard must be removed for maintenance or clean ing make sure it is properly attached before using

the machine again.

18. Use of parts and accessories NOT recommended

by General

malfunction or risk of injury.

®

International may result in equipment

7. Do not wear loose clothing, gloves, bracelets, neck laces or other jewelry while the planer is in ope ration. Wear protective hair covering to contain long

hair and wear non-slip footwear.

8. Be sure that adjusting wrenches, tools, drinks and

other clutter are removed from the machine and/or

the table surface before operating.

9. Keep hands well away from knives and all moving

parts. Use a push stick to feed stock, and a brush,

not hands, to clear away chips and dust.

10. Be sure that the knives are securely installed in the

cutter head.

11. Always use clean, properly sharpened knives. Dirty

or dull knives are unsafe and can lead to accidents.

12. Inspect stock and remove all foreign objects be fore planing. Make sure that any stock you plane

is clean and free of any dirt, nails, staples, tiny rocks

or any other foreign objects that may damage the

planer knives. Only process natural solid wood

boards. Never plane MDF, particle board, plywood,

laminates or other synthetic materials.

19. Never stand or lean on machinery. Serious injury

could result if the tool is tipped over or if the cutting

tool is unintentionally contacted.

20. Always disconnect the tool from the power source

before servicing or changing accessories such as

knives, or before performing any maintenance or

cleaning, or if the machine will be left unattended.

21. Make sure that the switch is in the “OFF” position be fore plugging in the power cord.

22. Make sure the tool is properly grounded. If equipped

with a 3-prong plug it should be used with a three pole receptacle. Never remove the third prong.

23. Do not use this planer for any purpose other than

its intended use. If used for other purposes, General

International disclaims any real or implied warranty

and holds itself harmless for any injury, which may

result from that use.

®

5

Page 6

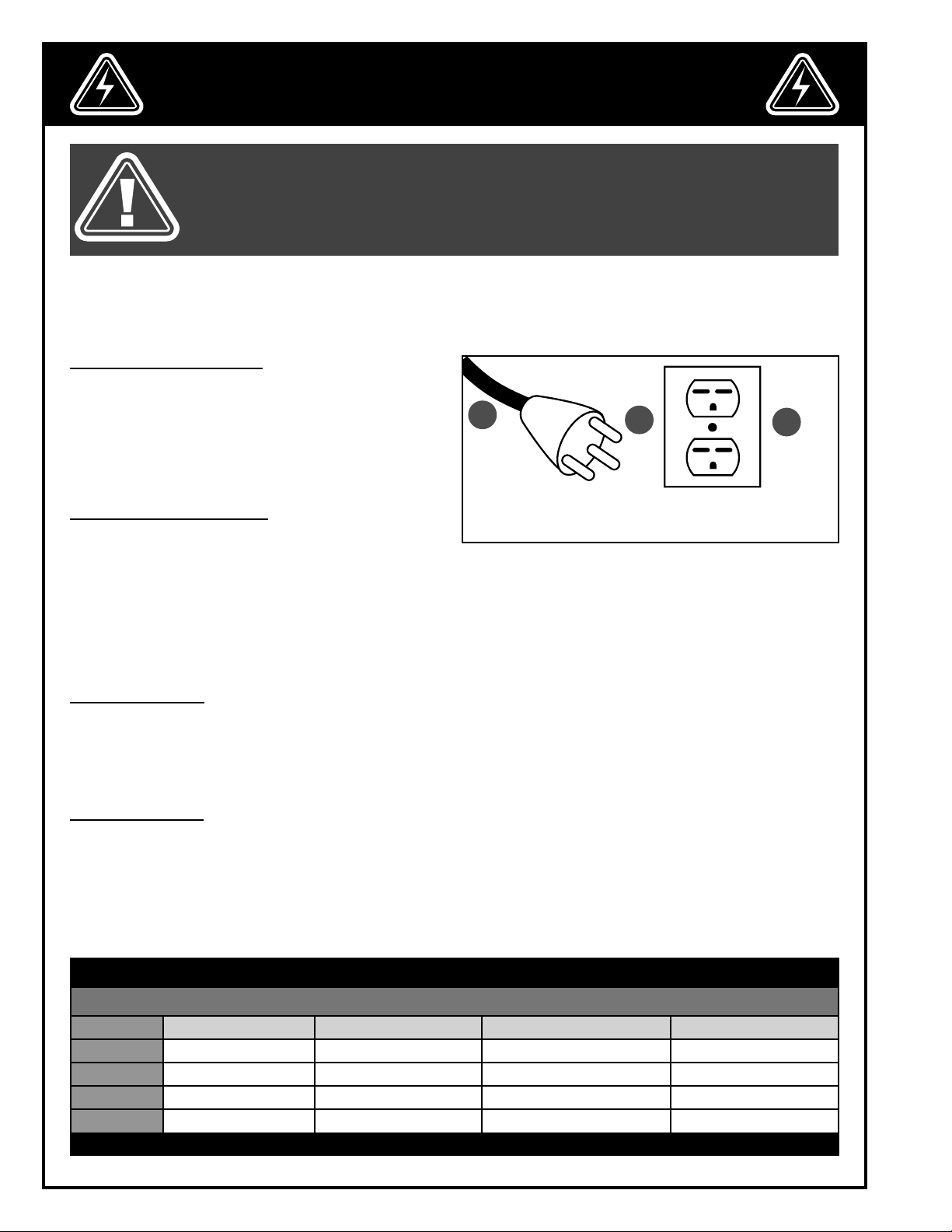

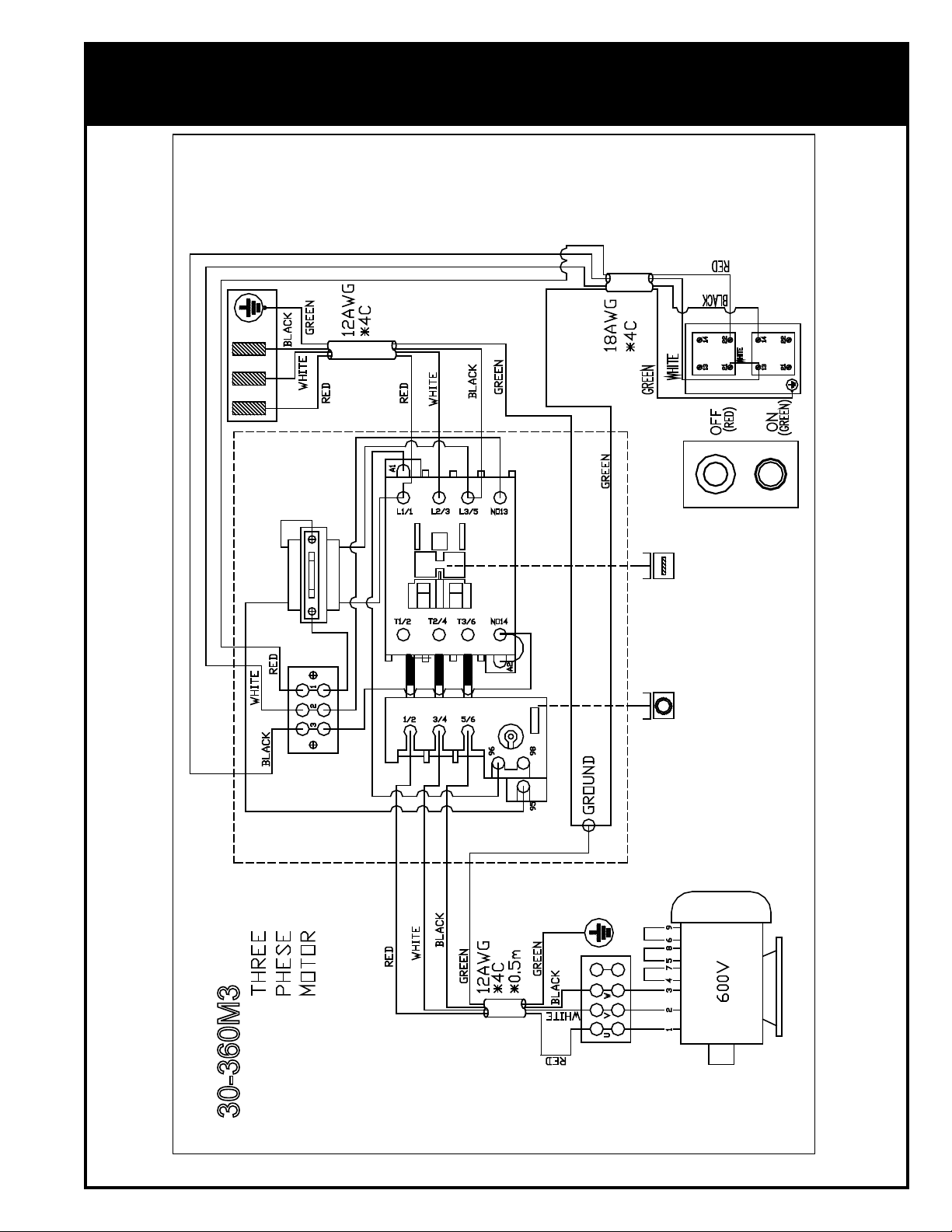

ELECTRICAL REQUIREMENTS

BEFORE CONNECTING THE MACHINE TO THE POWER SOURCE, VERIFY THAT THE VOLTAGE OF YOUR POWER SUPPLY CORRESPONDS WITH THE VOLTAGE SPECIFIED ON THE MOTOR I.D. NAMEPLATE. A POWER SOURCE WITH

GREATER VOLTAGE THAN NEEDED CAN RESULT IN SERIOUS INJURY TO THE USER AS WELL AS DAMAGE TO THE

MACHINE. IF IN DOUBT, CONTACT A QUALIFIED ELECTRICIAN BEFORE CONNECTING TO THE POWER SOURCE.

THIS TOOL IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO RAIN OR USE IN WET OR DAMP LOCATIONS.

Note: voltage requirements and amperage draw for M2 & M3 3-phase motors may not be fully

described in this manual. For complete electrical requirements refer to the motor I.D. name

plate on the machine. If in doubt consult a licensed qualified electrician before proceeding.

ELECTRICAL CONNECTIONS

Both a manual circuit breaker (or similar device) as well

as an electrical plug (similar to the one shown) are recommended and SHOULD BE INSTALLED BY A QUALIFIED

ELECTRICIAN.

Use locally approved wire A that includes a separate

grounding wire and a 3 prong grounding type plug B

with a matching receptacle C.

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short circuit,

grounding reduces the risk of electric shock to the operator. The motor of the “M1” model of this machine is wired for 220 V single phase operation.As with many stationary

industrial type machines, because each installation situation is unique, this machine is supplied without a power

cord or plug.

The installation of an appropriate power cord and plug must be performed by a qualified electrician. The machine must be connected to an electrical source using a power cord that has a grounding wire, which must also

be properly connected to the grounding prong on the plug. The outlet must be properly installed and grounded

and all electrical connections must be made in accordance with all local codes and regulations.

CIRCUIT CAPACITY

Make sure that the wires in your circuit are capable of handling the amperage draw from your machine, as well as

any other machines that could be operating on the same circuit. If you are unsure, consult a qualified electrician.

If the circuit breaker trips or the fuse blows regularly, your machine may be operating on a circuit that is close to its

amperage draw capacity. However, if an unusual amperage draw does not exist and a power failure still occurs,

contact a qualified technician or our service department.

EXTENSION CORDS

The use of an extension cord is not generally recommended for 220 V equipment. If you find it necessary, use only

3-wire extension cords that have 3-prong grounding plug and a matching 3-pole receptacle that accepts the

tool’s plug. Repair or replace a damaged extension cord or plug immediately. Make sure the cord rating is suitable

for the amperage listed on the motor I.D. plate.

An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The accompanying

chart shows the correct size extension cord to be used based on cord length and motor I.D. plate amp rating. If in

doubt, use the next heavier gauge.

A

B

C

AMPERES 50 feet 100 feet 200 feet 300 feet

< 5

6 to 10

10 to 12

12 to 16

*NR = Not Recommended

6

TABLE - MINIMUM GAUGE FOR CORD

EXTENSION CORD LENGTH

18 16 16 14

18 16 14 12

16 16 14 12

14 12 *NR *NR

Page 7

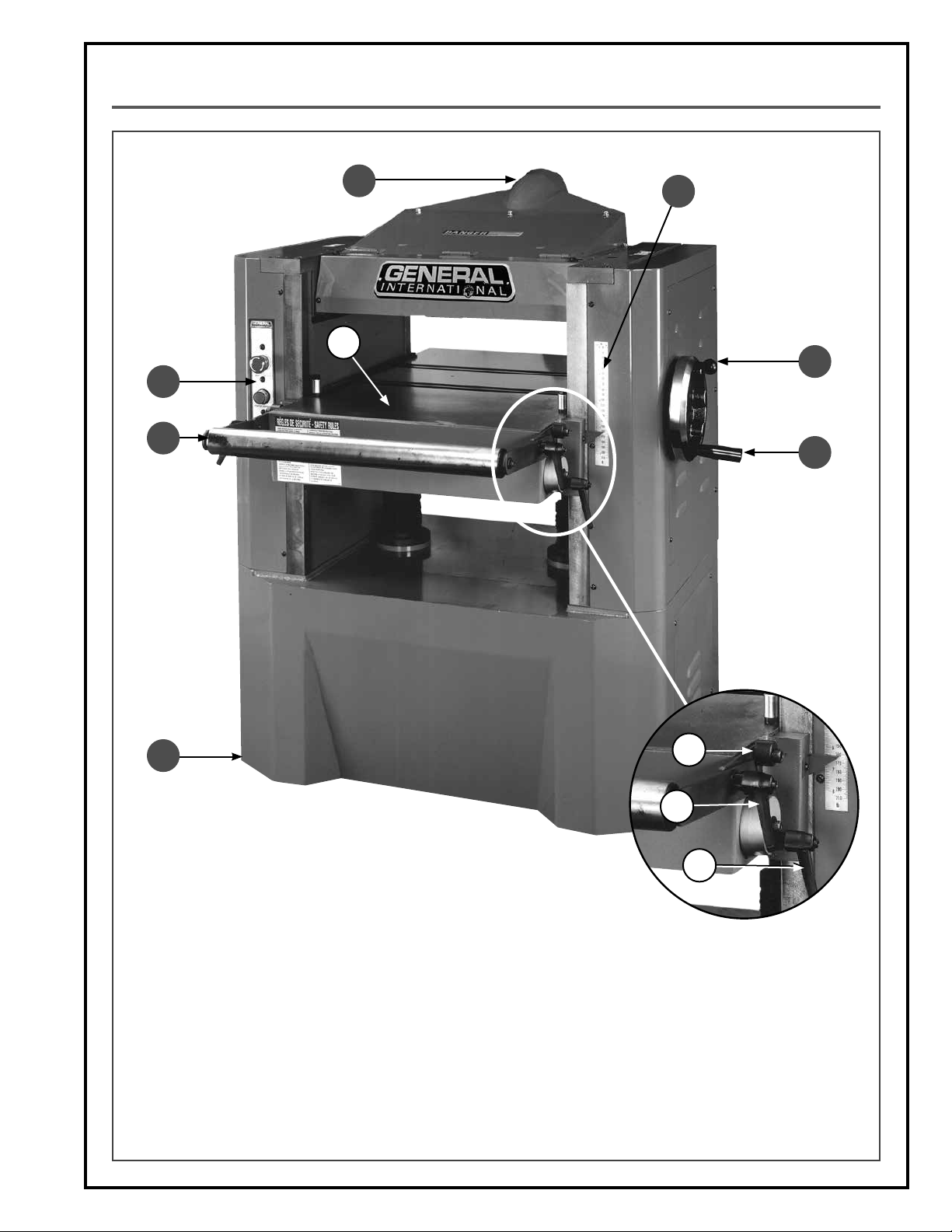

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

C

B

D

E

F

G

H

A

A. FRAME

B. EXTENSION ROLLER

C. ON/OFF SWITCH

D. MAIN TABLE

E. DUST CHUTE

F. GRADUATED SCALE

G. FEED SPEED ADJUSTMENT KNOB

H. DEPTH OF CUT ADJUSTMENT HANDWHEEL

I. ECCENTRIC BLOCK

J. EXTENSION ROLLER LOCK LEVERS (2)

K. TABLE ROLLER ADJUSTMENT LEVER

I

J

K

7

Page 8

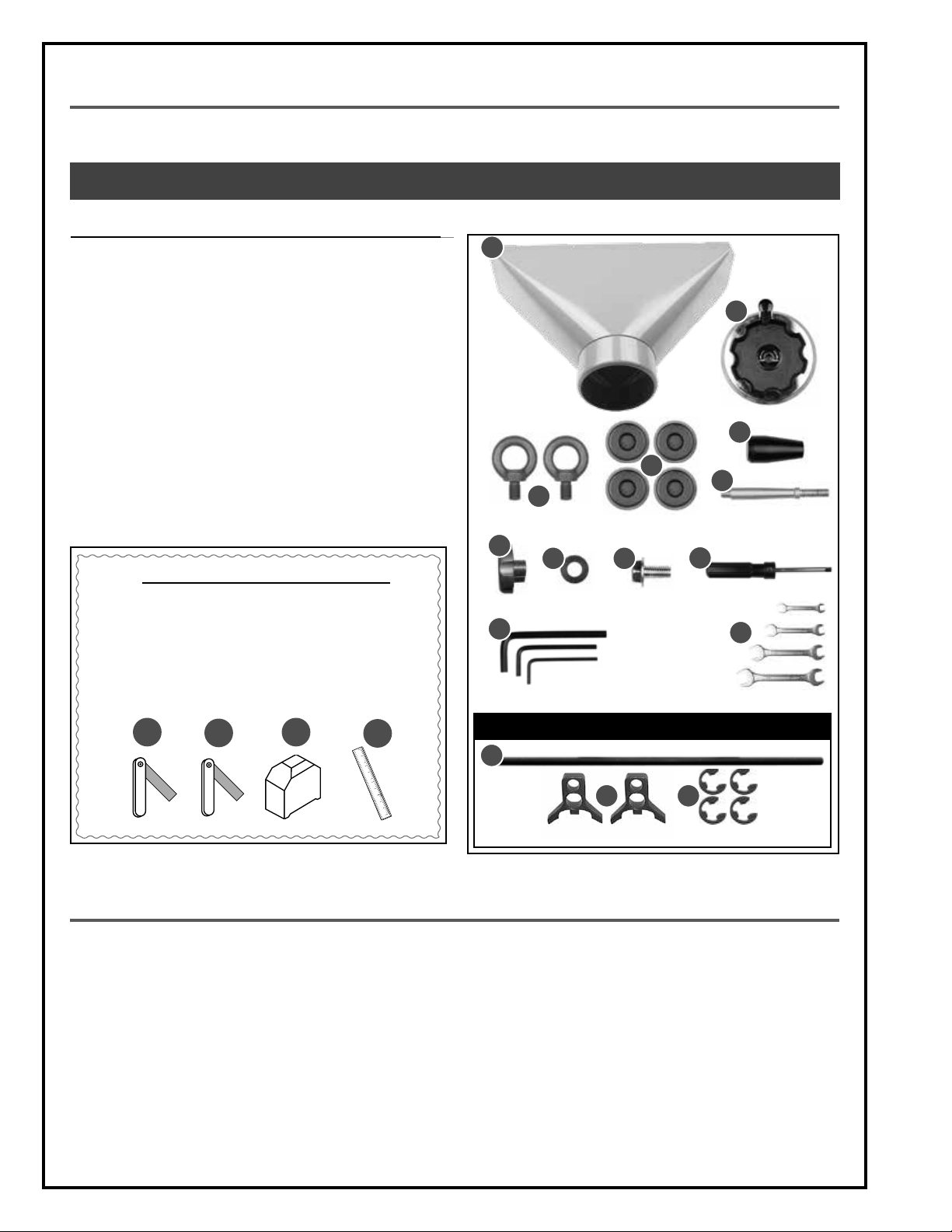

UNPACKING

Carefully unpack and remove the unit and its components from the box and check for missing or damaged items

as per the list of contents below.

NOTE: PLEASE REPORT ANY DAMAGED OR MISSING ITEMS TO YOUR GENERAL® INTERNATIONAL DISTRIBUTOR IMMEDIATELY.

LIST OF CONTENTS QTY

A. DUST CHUTE ............................................................................. 1

B. HANDWHEEL (DEPTH OF CUT ADJUSTMENT) .......................... 1

C. LIFTING HOOK ......................................................................... 2

D. FOOT PAD ................................................................................ 4

E. HANDLE (TABLE ROLLER ADJUSTMENT LEVER) ....................... 1

F. THREADED ROD (TABLE ROLLER ADJUSTMENT LEVER)........... 1

G. LOCK KNOB (DEPTH OF CUT ADJUSTMENT HANDWHEEL) .... 1

H. FLAT WASHER (DEPTH OF CUT ADJUSTMENT HANDWHEEL) ... 1

I. FLANGE BOLT (DUST CHUTE) ................................................... 6

J. SCREWDRIVER ......................................................................... 1

K. 3, 4, 6 MM ALLEN KEYS ............................................................ 1

L. 10,14,19, 24 MM WRENCHES .................................................. 1

M. KNIFE SETTING BAR* ................................................................ 1

N. KNIFE SETTING PAD* ................................................................ 2

O. RETENTION RING* ................................................................... 4

ADDITIONAL REQUIREMENTS FOR SET UP

A

B

E

D

C

G

H I

F

J

A. 0,02” FEELER GAUGE

B. 0,004” FEELER GAUGE

K

L

C. GAUGE BLOCK

D. STRAIGHT EDGE

A

0.0

2

”

B

0

.0

0

4

”

C

D

M

*Not included and not needed for 30-360HC

KNIFE SETTING JIG*

N O

BASIC FUNCTIONS

This 20” heavy-duty planer is designed for thickness planing of solid wood only. The unit is not designed nor should

it be used to surface or prepare, plywood, wood paneling, particleboard, MDF nor any other wood based byproducts nor any non-wood based materials.

This unit has the capacity to plane boards of up to 20” wide having a maximum thickness of 8” and a minimum

thickness of 3/16”.

The unit is offered with 2 different cutter head options as follows:

• Model 30-360 M1 – 20” planer with 4-knife cutter head;

• Model 30-360HC M1 - 20” planer with General International’s unique “Magnum” style helical cutter head con-

taining 58 reversible two-sided, quick-change carbide inserts.

8

Page 9

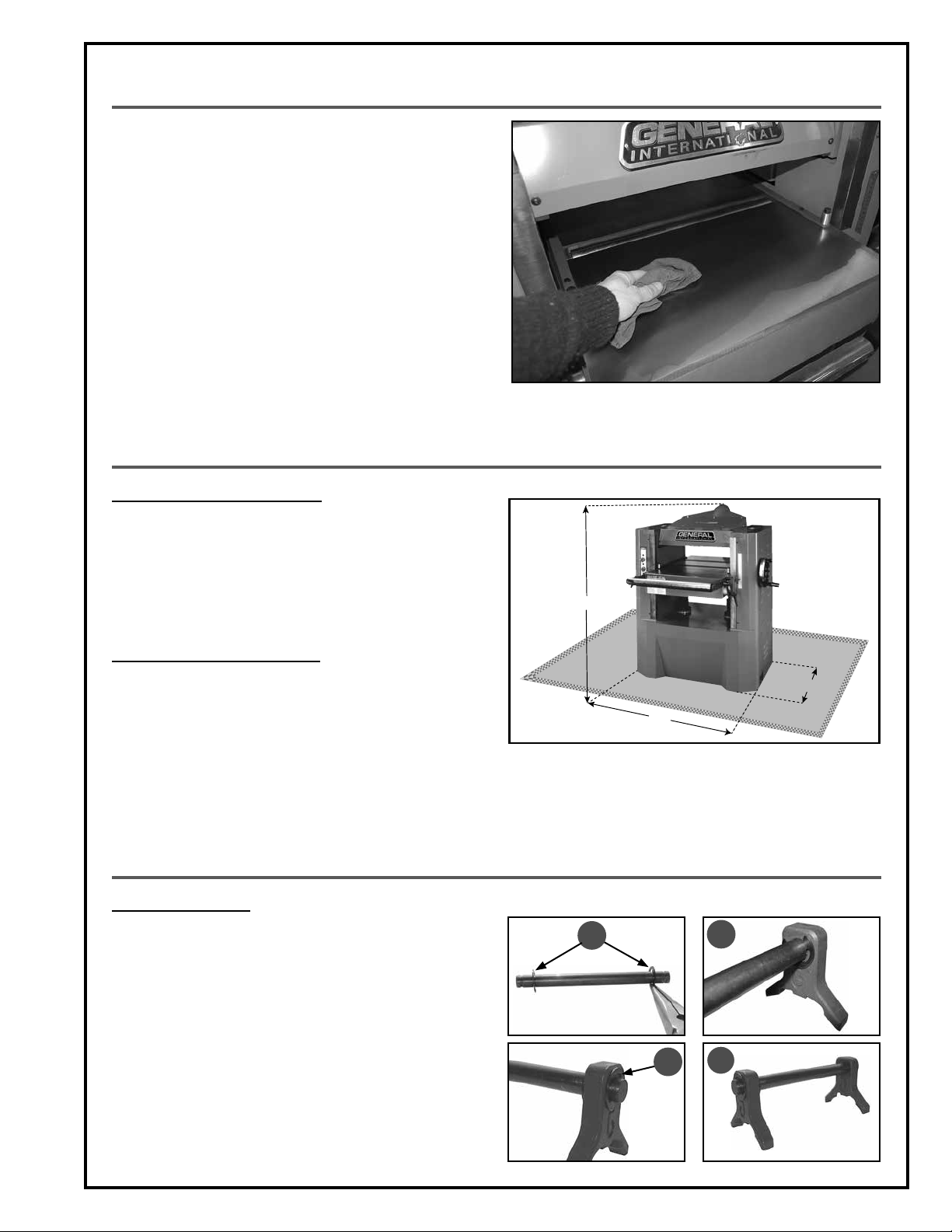

CLEANING

The protective coating on the table prevents rust from

forming during shipping and storage. Remove it by

rubbing with a rag dipped in kerosene, mineral spirits

or paint thinner. (Dispose of potentially flammable solvent-soaked rags according to manufacturer’s safety

recommendations).

A putty knife, held flat to avoid scratching the surface,

may also be used to scrape off the coating followed

by clean-up with solvent. Avoid rubbing the machine’s

painted surfaces, as many solvent-based products will

remove paint.

To prevent rust, apply a light coating of paste wax or

use regular applications of any after-market surface

protectant or rust inhibitor.

PLACEMENT WITHIN THE SHOP / SAFETY ZONE

PLACEMENT WITHIN THE SHOP

This machine should be installed and operated only

on a solid, flat and stable floor that is able to support

the weight of the machine (1397 lbs - 635 kg) and the

operator. Using the dimensions shown as a guideline,

plan for placement within your shop that will allow the

operator to work unencumbered and unobstructed by

foot traffic (either passing shop visitors or other shop

workers) or other tools or machinery.

ESTABLISHING A SAFETY ZONE

For shops with frequent visitors or multiple operators,

it is advisable to establish a safety zone around shop

machinery. A clearly defined “no-go” zone on the floor

around each machine can help avoid accidents that

could cause injury to either the operator or the shop

visitor. It is advisable to take a few moments to either paint (using non-slip paint) or using tape, define on the floor

the limits or perimeter of each machines safety zone. Take steps to ensure that all operators and shop visitors are

aware that these areas are off limits whenever a machine is running for everyone but the individual operating the

unit.

48"

22"

36"

ASSEMBLY INSTRUCTIONS

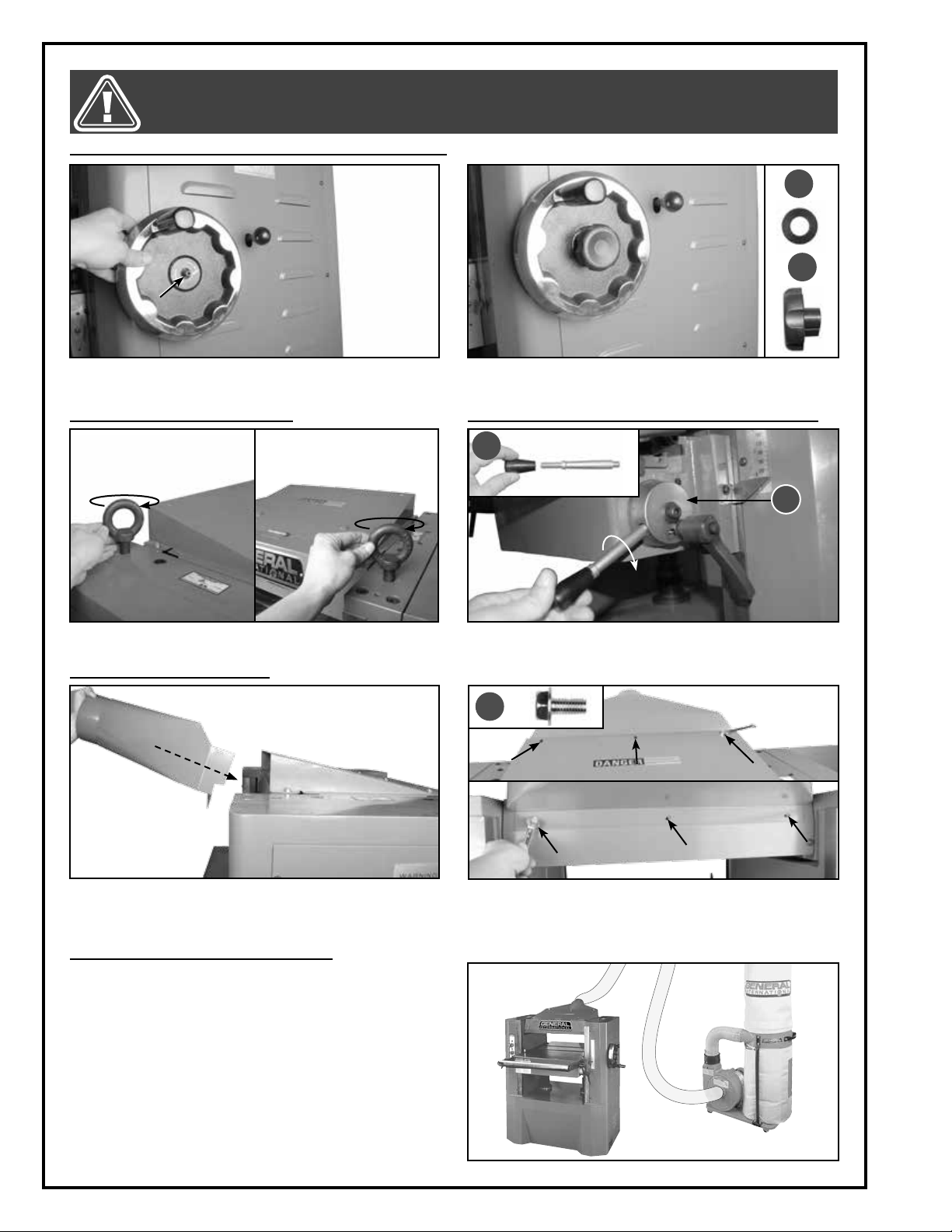

KNIFE SETTING JIG*

1. Using a pair of pliers, push a retention ring into the

inner grooves on each end of the knife setting jig

rod as shown A.

2. Slide one foot onto one end of the rod as shown B.

3. Secure the foot on the rod by pushing a retention

ring into the exposed groove in the rod as shown

C.

4. Repeat step 2 and 3 to install the other foot as

shown D. Set the jig aside for use whenever knife

settings need to be verified or adjusted.

*Not included and not needed for 30-360HC

A

C

B

D

9

Page 10

BEFORE ASSEMBLING, MAKE SURE THAT THE SWITCH IS IN THE “OFF” POSITION AND THAT THE POWER CORD IS

UNPLUGGED. DO NOT PLUG IN OR TURN ON THE MACHINE UNTIL YOU HAVE COMPLETED THE ASSEMBLY AND

INSTALLATION STEPS DESCRIBED IN THIS SECTION OF THE MANUAL.

ATTACH THE DEPTH OF CUT ADJUSTMENT HANDWHEEL

A

B

1. Slide the handwheel onto the arbor.

2. Slide the flat washer A onto the arbor, then secure

it in place with by tightening the lock knob B.

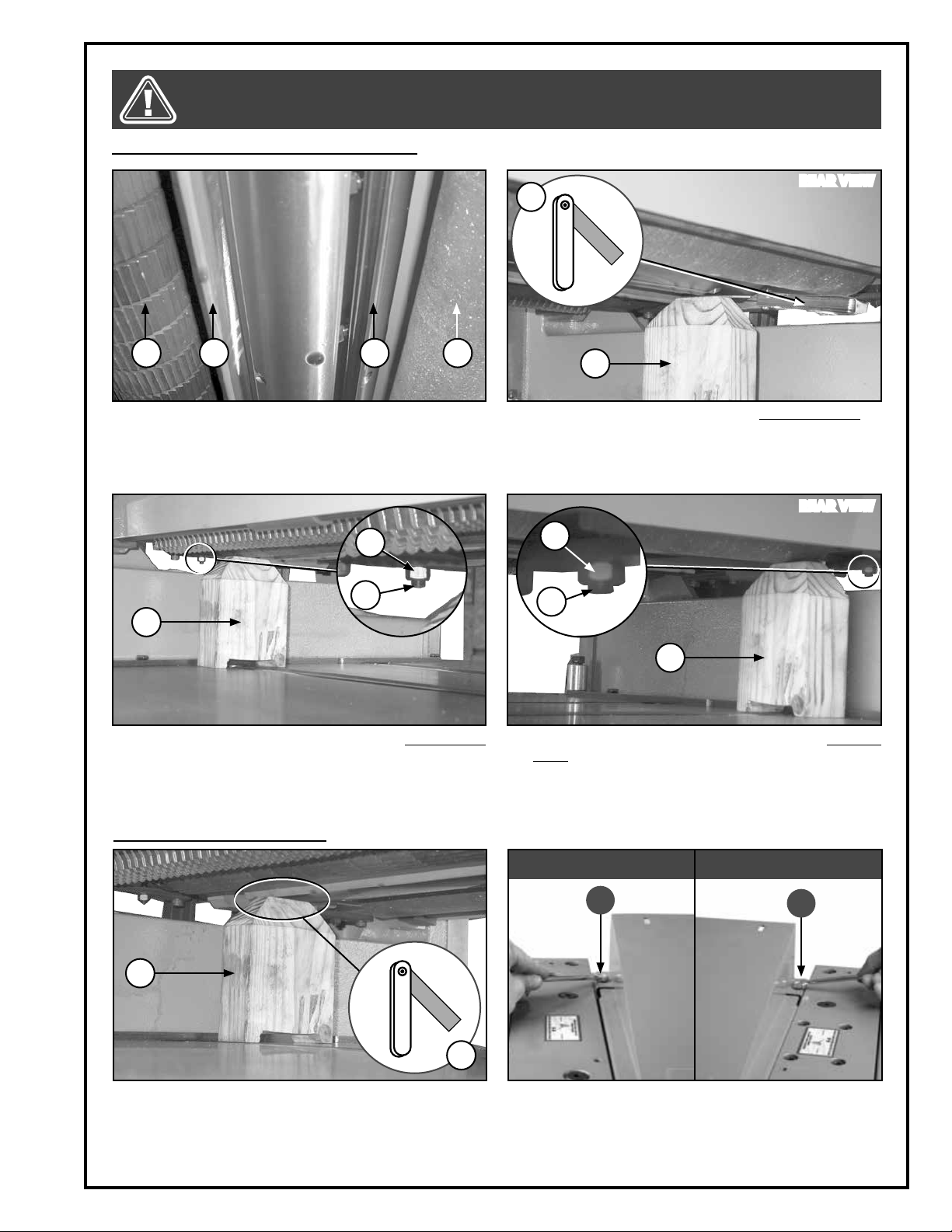

INSTALLING THE LIFTING HOOKS INSTALLING THE TABLE ROLLER ADJUSTMENT LEVER

C

D

If needed, install the lifting hooks on the top of the machine.

INSTALLING THE DUST CHUTE

Tighten the handle onto the shaft C, then tighten the

assembly into the bracket D.

E

1. Place the dust chute against the opening in the

back of the machine.

CONNECTING TO A DUST COLLECTOR

A dust chute that fits 5” hose is provided to accommodate connection to a dust collector (not included). Be

sure to use appropriate sized hose and fittings (not included).

Check that all connections are sealed tightly to help

minimize airborne dust. If you do not already own

a dust collection system consider contacting your

General® International distributor for information on

our complete line of dust collection systems and accessories or visit our Web Site at www.general.ca.

10

2. Align the mounting holes in the dust chute with the

corresponding holes in the machine, then secure

it with 6 flange bolts E using a 10 mm wrench.

Page 11

BASIC ADJUSTMENTS & CONTROLS

TO REDUCE THE RISK OF SHOCK OR FIRE DO NOT OPERATE THE UNIT WITH A DAMAGED POWER CORD OR PLUG. REPLACE DAMAGED CORD OR PLUG IMMEDIATELY. TO AVOID UNEXPECTED OR UNINTENTIONAL START-UP, MAKE SURE

THE POWER SWITCH IS IN THE OFF POSITION BEFORE CONNECTING TO A POWER SOURCE.

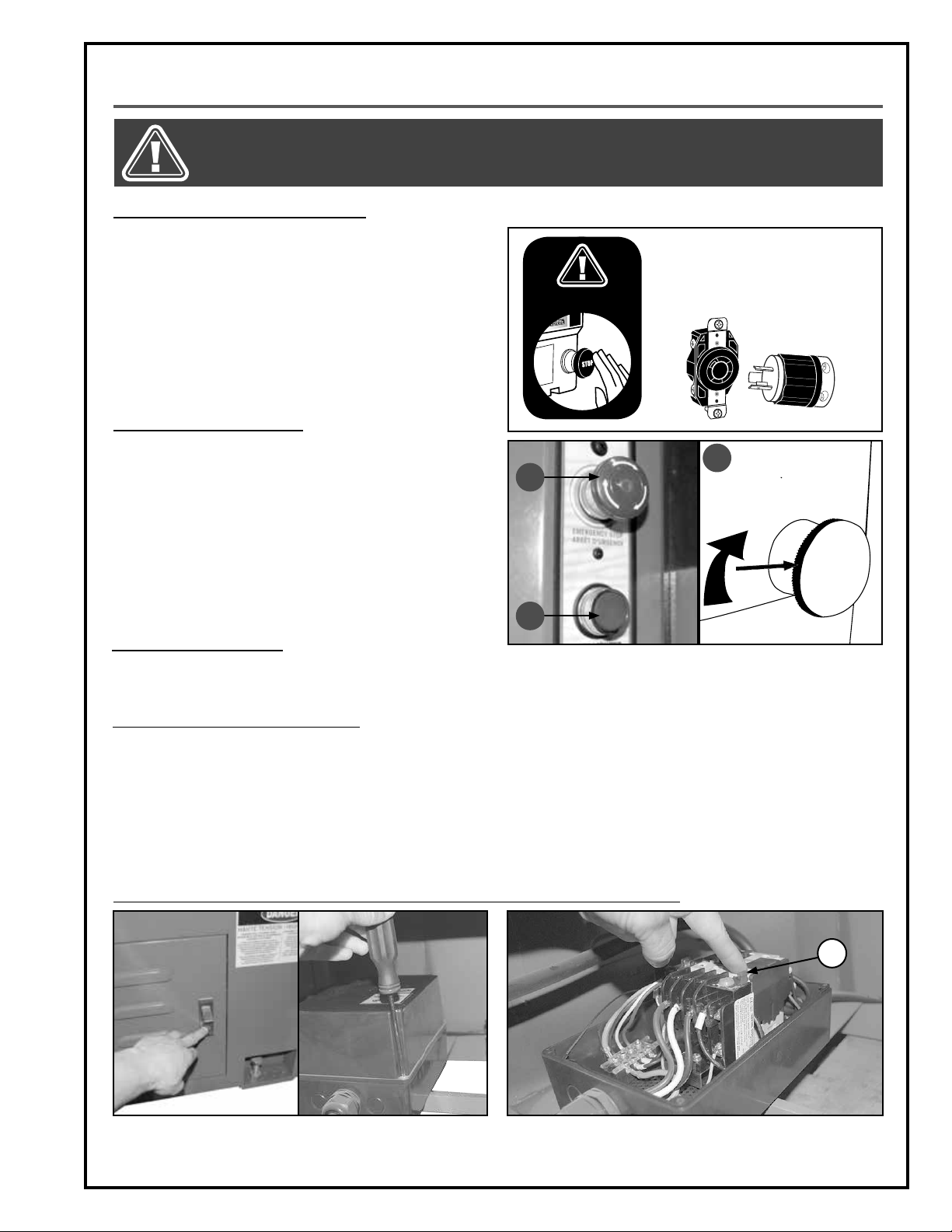

CONNECTING TO A POWER SOURCE

Once the assembly steps have been completed, plug

the power cord into an appropriate outlet.

Refer back to the section entitled “Electrical Require

ments” and make sure all requirements and grounding

instructions are followed.

When operations have been completed unplug the

machine from the power source.

MAGNETIC SAFETY SWITCH

This machine is equiped with a magnetic safety switch

designed to protect the the user from unintentional startup. The switch assembly is equipped with a GREEN “START”

button A and a RED spring loaded “STOP” button B.

Once the RED “STOP” button has been pressed, the machine can only be restarted by turning the inner part of

the button to the right to release the stop button, C.

-

SWITCH OFF

B

TO AVOID UNEXPECTED OR UNINTENTIONAL START-UP, MAKE SURE

THAT THE POWER SWITCH IS IN

THE OFF POSITION BEFORE CONNECTING TO A POWER SOURCE.

C

A

OVERLOAD PROTECTION

The magnetic safety switch on this machine is equipped with an overload protection feature. To prevent an electrical overload from damaging the motor, in the event of a spike in line voltage or amperage draw, the internal

overload protector will automatically be tripped, thereby cutting off power to the motor.

Common causes of such overloads:

• Overworking the motor by forcing the machine, particularly with thicker denser material, thereby causing an

increase in power consumption and a spike in amperage draw.

• An electrical extension cord that is too long or not the correct gauge of wire, which can also cause an increase in amperage draw. If an electric extension cord must be used, follow the instructions and refer to the

chart in the electrical requirements section at the beginning of this manual.

• Overworked circuit caused by operating on a circuit that is close to its amperage draw capacity. Make sure

thecircuit being used is capable of handling the amperage draw from this machine as well as any other electrical devices operating on the same circuit. If you are unsure, consult a qualified electrician.

To reset the overload protection switch after it has been tripped proceed as follows:

D

1. Unplug the machine. Open the motor door in the

back of the machine and remove electrical box

cover a Phillips screwdriver.

2. Press the button D to reset the overload protection.

Before to start the machine, retighten the cover box

and close the motor door.

11

Page 12

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

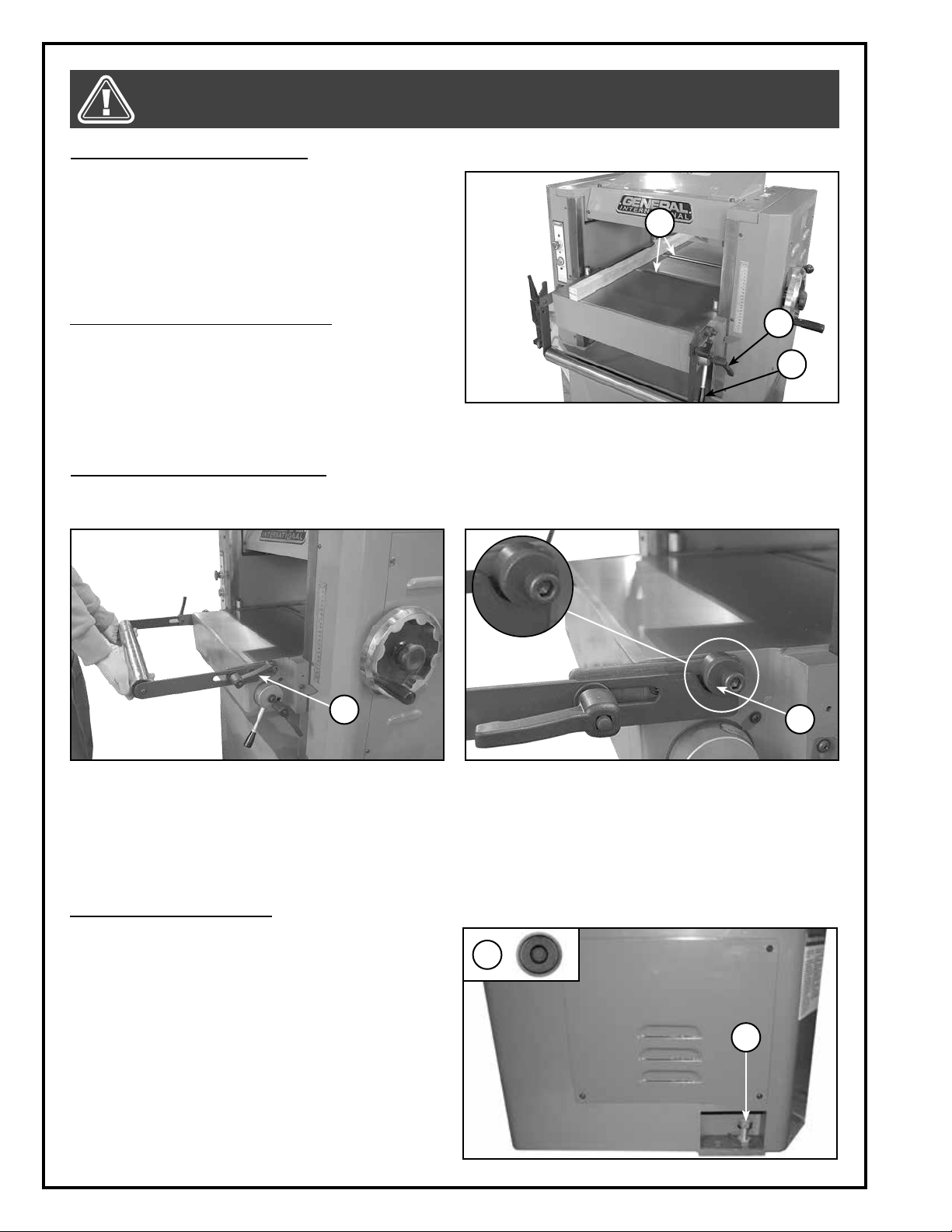

ADJUSTING TABLE ROLLER HEIGHT

The two adjustable table rollers A are designed to help

reduce friction when feeding stock through the planer.

The height of the rollers can be set based on personal

preference as well as the type of stock being fed into

the machine.

As a general rule when planing rough stock the rollers

should be set higher, and when planing smooth stock

they should be set lower.

To adjust the height of the table rollers:

1. Loosen the lock lever B and then turn the adjustment lever C up or down as needed. Tighten the

lock lever B to secure the rollers at the desired

height.

USING THE TABLE EXTENSION ROLLER

The infeed table extension roller is designed to support the workpiece as well as to help reduce friction when feeding longer stock through the planer.

A

B

C

D

1. Loosen the levers (right & left) D , then lift the table

extension into the horizontal position and push it all

the way. Tighten the levers D to lock the roller in position.

IMMOBILIZING THE MACHINE

Machine vibration during operation may cause the

machine to move, particularly when installed on uneven surfaces.

The pads F and anchor bolts G can be used to help

keep the machine immobilized by either lowering the

bolts against pads on the floor to act as points of contact with the floor, or for permanent installations, by drilling into the floor and bolting the machine in place.

E

Note: Make sure the extension roller plates are against the

eccentric nuts E.

F

G

12

Page 13

OPERATING INSTRUCTIONS

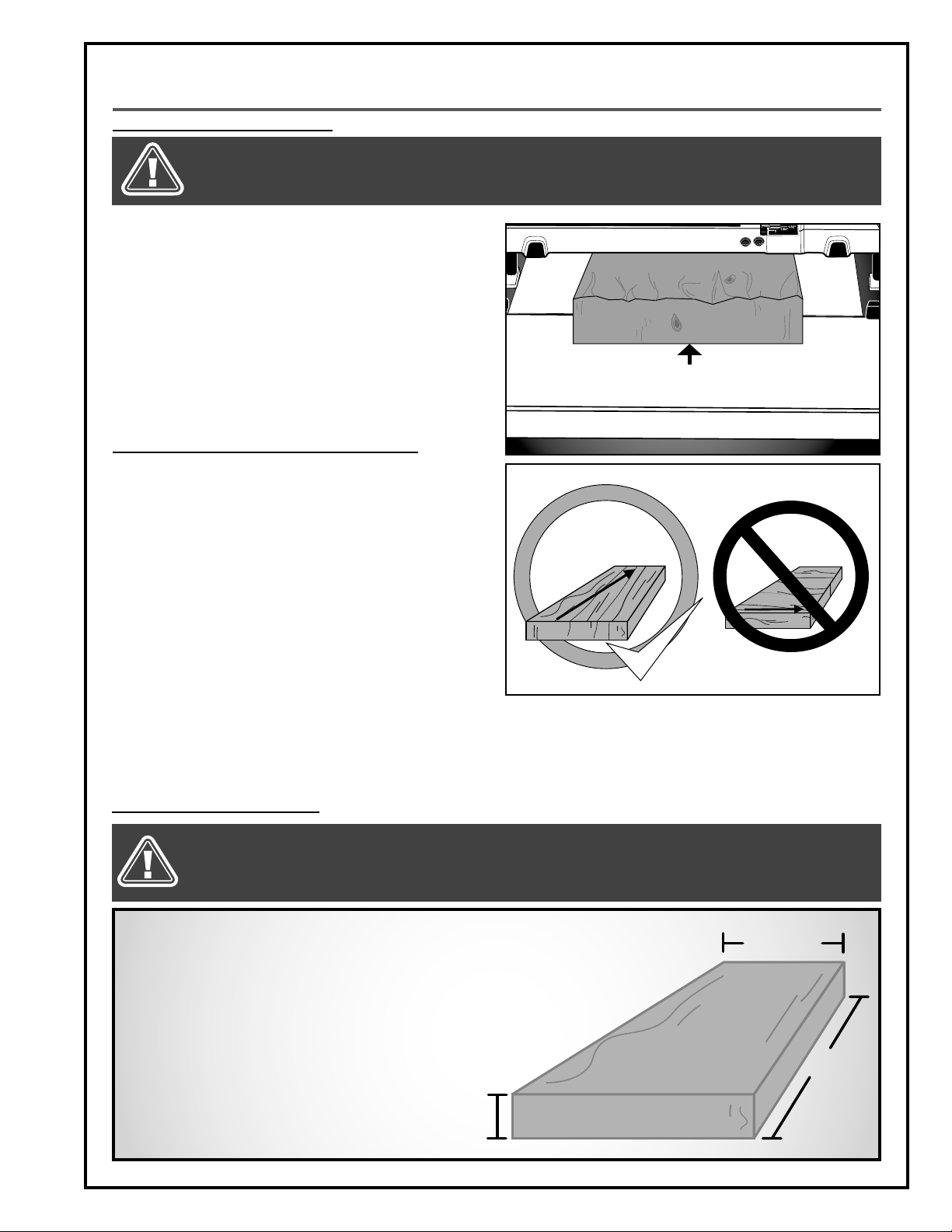

GRAIN DIRECTION

BASIC PRINCIPLES OF PLANING

ALWAYS PLANE IN THE GENERAL DIRECTION OF THE GRAIN. PLANING AGAINST THE GRAIN OR PLANING END GRAIN

IS DANGEROUS AND MAY CAUSE THE WORKPIECE TO SHATTER.

This planer is designed to remove material from the top

face of a board in order to bring the board (or a series

of boards) down to a specific desired shape or profile

and thickness.

To obtain uniform results across the length of a board,

the stock being planed must have one face that has

already been machined perfectly flat (usually on a

jointer) and the stock should be fed with this flat face

against the table.

SELECTING BOARDS SUITABLE FOR PLANING

This planer is intended for use with solid woods or MDF

only, and should not be used to plane or mold any

other materials. The workpiece should always be fed

through the machine in the general direction of the

grain in the wood. Before being fed through the planer

all lumber should be inspected for debris and foreign

objects such as staples or nails.

Foreign objects stuck to, or embedded in your workpiece can be ejected from the machine at high speed

and cause serious injury or damage cutter knives.

Make sure to remove all such foreign objects from

the wood before running it through the planer. Select

lumber carefully and avoid workpieces with loose or

protruding knots. Workpieces that are twisted, severely

deformed or warped should also be avoided.

Warped, twisted, damaged or fragile stock runs an increased risk of jamming in or damaging the machine or cutters. There is also a much greater risk of injury to the operator or bystanders from kickback, where the workpiece is

forcefully or violently ejected from the machine due to a jam, whenever working with such damaged or warped

wood.

FLAT SIDE DOWN

GRAIN DIRECTION

GRAIN DIRECTION

RATED LIMITS OF THIS PLANER

RESPECT THE RATED LIMITS OF THIS MACHINE IGNORING THESE LIMITS AND FEEDING NON COMPATIBLE STOCK INTO

THIS PLANER CAN LEAD TO SERIOUS INJURY TO THE USER OR SHOP BYSTANDERS, AND CAUSE DAMAGE TO THE WORKPIECE AND/OR THE MACHINE. IF THE STOCK YOU WISH TO PLANE DOES NOT MEET OR COMPLY WITH THE LIMITATIONS

LISTED ABOVE, FIND ANOTHER SAFER WAY TO PERFORM THE REQUIRED TASK.

Maximum planing width: 20”

Maximum workpiece thickness: 8”

Minimum workpiece thickness: 3/16”

Minimum workpiece length: 8 1/4”

Max. 20”

Min. 8 1/4”

Max. 8”

Min. 3/16”

13

Page 14

ADJUSTING THE DEPTH OF CUT

The depth of cut is adjustable by using the handwheel

A. Remind that the maximum depth of cut on full

width planing is 1/8” and lowering the head assem-

bly. It is recommended that for both hard and soft wood:

removing less material per pass and taking multiple

passes is always preferred to more aggressive planing.

1. turn off the machine.

2. Position the board under the infeed roller and ad-

just the position of the table work with the handwheel A so that the infeed roller is in contact with

the board.

3. Remove the board and adjust the cutting depth using the scale B by turning the handwheel A clockwise.

ADJUSTING FEED SPEED

Two rollers turn and feed the stock. The feed motor

speed ranges from 22 to 28 fpm (feet per minute). The

feed speed adjustment knob is located on the right

hand side of the machine.

Select appropriate feed speed for the stock being

plane: high speed for softwood and slow for hardwood.

Experiment with feed speeds based on the workpiece

material and its width as well as the depth of cut, to find

which setting work best for your needs.

- To increase the feed rate at 28 fpm, pull the knob C

out.

- To decrease the feed rate at 22 fpm, push the knob

C back.

- For zero speed, set the knob C in neutral position.

B

A

22 fpm

28 fpm

0

C

NOTE: TO AVOID DAMAGE TO THE GEARBOX, SPEED CHANGES SHOULD ONLY BE MADE WHILE THE MACHINE IS RUNNING.

CHECKLIST BEFORE STARTING

• Make sure the board has been inspected and is suitable for planing as explained in section “Selecting boards

suitable for planing”.

• Make sure you and any assistants are wearing safe appropriate workshop attire. Roll up long sleeves, secure

long hair and remove any jewelry: watches, rings, bracelets or anything that could become caught in the moving parts, potentially causing serious injury.

• Make sure to have on safety glasses as well as hearing and respiratory protection at all times when using the

planer.

• To reduce the risk of damage to the planer or the workpiece, as well as a potential for personal injury, after initial

set-up as well as before each use, make sure that everything is securely installed and that all fasteners and moving parts on this machine are locked in place before starting the machine.

• If multiple boards are to be planed, collect all workpieces together and set them nearby on a table or bench

within easy reach D. To limit the potential for injury in the event of a kickback, avoid having to step or reach in

front of the machine to pick up the next workpiece E.

D

E

AVOID HAVING TO STEP

OR REACH IN FRONT OF

THE MACHINE!

14

Page 15

PLANING STEP-BY-STEP

GRAIN DIRECTION

A

1. With the planer turned off, position the workpiece

on the infeed table with the flat face down and the

face to be planed facing up.

B

22 fpm028 fpm

3. Set the board aside, then turn the planer on B. Ad-

just the speed.

GRAIN DIRECTION

GRAIN DIRECTION

2. Adjust the depth of cut A (see section “Adjusting

depth of cut).

TO LIMIT THE POTENTIAL FOR INJURY IN THE EVENT

OF A KICKBACK, AVOID STANDING DIRECTLY IN LINEWITH THE FRONT OR BACK OF THE PLANER WHENEVERA BOARD IS ENGAGED IN THE CUTTER HEAD.

4. Stand to one side of the machine and set the board

back on the infeed table with the face to be planed

facing up.

5. Align the board laterally so that it will be fed through

the planer in the general direction of the grain, and

allow the workpiece enough clearance to feed

properly without rubbing or catching on either side

of the machine.

7. Release the board allowing the feed roller to auto-

matically feed the board through the planer.

6. Slowly slide the workpiece forward until the infeed

roller “grips” the board.

NEVER PUSH, PULL OR OTHERWISE TRY TO MOVE OR REPOSITION THE WORKPIECE ONCE IT IS IN THE CONTROL

OF THE AUTOMATIC FEED ROLLERS.

8. Step to the rear of the machine and recover the planed

board on the outfeed table once it has cleared the

outfeed roller and has stopped advancing.

15

Page 16

MAINTENANCE

Note: It is recommended to verify the following before starting any new project. To do this will require: A straight edge, a

feeler gauge, a gauge block (see below).

GAUGE BLOCK

You may use a home made gauge block made of hardwood. The gauge block can be made by following the dimensions in the illustration. If you prefer, precision aluminum gauge blocks are available from

General International under item #30-040.

1/2"

45°

4"

1/2"

1½"

1/4"

2"

3"

4"

ADJUSTING CUTTER HEAD PARALLEL TO THE TABLE

The cutter head has been pre-set parallel to the table at the factory, therefore, except in some rare cases (important maintenance, transport handling) no further adjustments are required.

If adjustments are required follow these procedures:

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

C

A

B

1. Disconnect the machine from the power source.

2. Place the gauge block A on table directly under cutter head. Lower the cutter head until the it just touches the

gauge block A.

3. Move the gauge block A to opposite end of the table and make sure it just touches the cutter head at the

other end as well.

If not, leave the gauge in place and follow the instructions below.

4. Under the table, loosen the three screws B using the a 6 mm Allen key, insert a screwdriver in the hole located

in the lead screw housing C, and then turn the shaft clockwise or counterclockwise so that the gauge block A

just touches the cutter head.

5. Position the gauge block A to the other side to make sure the table is now parallel to the cutter head and

retighten the bolts B.

16

Page 17

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORM-

0.0

2

”

0

.0

0

4

”

ING ANY MAINTENANCE OR ADJUSTMENTS.

ADJUSTING THE INFEED & OUTFEED ROLLERS

A B

C

D

1. Begin by take note of all the components in order

to make required adjustments: A infeed roller; B

chipbreaker; C cutter head with knife/insert; D outfeedroller.

G

H

E

F

REAR VIEW

E

2. Place the gauge block E under the knife/insert C,

adjust the table height until you can only slide a

0.02” feeler gauge F between the block and the

cutter. Once finished, do not move the height of the

table.

REAR VIEW

I

J

3. Place the block E under the end of the infeed roller

A as shown. Loosen the nut G, turn the screw H until

the roller touches the top of the block, and then retighten the nut G. Repeat for the other end.

ADJUSTING THE CHIPBREAKER

E

1. Place the block E under a knive/insertion and ad-

just the table height until you can slide only a 0,004”

feeler gauge K between the block E and the knive/

insertion. Then place the block under the chipbreaker B.

E

4. Place the block E under the end of the outfeed

roller D. Loosen the nut I, turn the screw J until the

roller touches the top of the block, and then retighten the nut I. Repeat for the other end.

LEFT SIDE RIGHT SIDE

L

L

K

2. Remove the dust chute, remove the two bolts L with

a 10 mm wrench, and then lift the chip deflector

cover in order to access the cutter head.

17

Page 18

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

ADJUSTING THE CHIPBREAKER (CONTINUED)

3. Loosen the two jam nuts M using a 10 mm wrench.

4. Turn the set screws N using a 4 mm Allen key in the

direction required so that the chipbreaker (see reference B in a previous page) touches the top of

the block.

Note: Start with the set screw N located on the same side

as the gauge block, then move the block to the other end

and adjust the other set screw.

M

5. Retighten the two jam nuts using a 10 mm wrench.

Re-install the chip deflector and the dust chute before starting the machine.

N

ALIGNING THE TABLE ROLLERS

The table rollers are set parallel at the factory and under normal circumstances should not require alignment

upon initial installation. However with use over time, it may become necessary to re-align the rollers.

If so proceed as follows:

A

1. Disconnect the machine from the power source.

Place a straight edge across the rollers A in up position.

LEVELING THE EXTENSION ROLLER TO THE TABLE ROLLERS

1. Place a straight edge across the table rollers and

the extension roller in up position.

2. Verify visibly that the extension roller is leveled to

the table rollers.

To level:

3. Loosen two eccentric blocks using a 4 mm Allen

key, then turn the eccentric blocks in the direction

required until the extension roller is leveled to the

table rollers.

B

C

2. Using a 10 mm wrench, loosen the jam nuts B lo-

cated at each end table roller under the table, then

turn the bolts C to the direction required to raise or

lower the roller. Retighten the bolts B and repeat

with the other roller.

Note: Always make sure the rollers are parallel to the table

and at the same height.

D

18

Page 19

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

PERIODIC MAINTENANCE

• Inspect/test the ON/OFF switches before each use. Do not operate the planer with a damaged switch; replace

a damaged switch immediately.

• Keep the machine as well the table clean and free of saw dust, woodchips, pitch or glue.Vacuum or brush off

any loose debris and wipe down the machine and the table occasionally with a damp rag.

• An occasional light coating of paste wax can help protect the table surface and reduce workpiece friction.

Ask your local distributor for suggestions on aftermarket surface cleaners, protectant and dry lubricants based

on what is readily available in your area.

• Avoid using silicon based products that may affect or react with wood finishing products such as oil, solvent or

water-based stains, varnishes and lacquers.

• Periodically inspect the power cord and plug for damage. To minimize the risk of electric shock or fire, never

operate the planer with a damaged power cord or plug. Replace a damaged power cord or plug at the first

visible signs of damage.

• The drive gears, chain and elevation screws should be cleaned of woodchips, dust, debris and old grease.

After cleaning, re-apply a generous coating of any common automotive bearing grease.

• Regularly inspect planed workpieces for signs of knife/inserts damage or wear and replace damaged or

worn knives immediately.

• Wipe the chains with a lubricated cloth for medium to slow speed operation.

• If excessive build-up of dust, dirt or wood shavings occur ; coat chain with a light film of oil (never pour directly

on chain). Over oiling defeats the purpose of the lubrication, the chain will overly accelerate , and will require

constant replacement.

• The bearings on the cutter head are factory lubricated and sealed, therefore they require no further attention.

INSPECTING CUTTER HEAD KNIVES/INSERTS

Cutter head knives (blades)/inserts are installed in the

planer at the factory. With usage and normal wear over

time, it will eventually become necessary to replace

A

EFFECT EXAGGERATED FOR CLARITY

the knives, or to reverse the inserts if applicable. When

needed, replacement knives (sold in sets of 3) or inserts

(sold in sets of 10) can be ordered through your local

General International distributor under part #30-362

or #30-364 (for model 30-360) or 30-443 (for model 30-

360HC). Observing planed workpieces as they come

out of the machine and looking for signs of knife damage or wear is the best method to help you to determine when knives/insertions are due to be changed.

Signs to look for include:

1. A raised ridgeline in the workpiece that runs a

straight line from beginning to end of the board A.

B

EFFECT EXAGGERATED FOR CLARITY

This is generally an indication that one or all of the

knives/inserts has been nicked or damaged by a

for-eign object such as a nail, staple or other hard

ob-ject hidden or embedded in the workpiece.

2. A slight washboard or chatter effect, B, which can

be an indication of uneven knife wear/insertions or

causing one knife/several inserts to cut just deeper than the other.

3. Rough, irregular, torn or fuzzy grain on a freshly planed surface may be a sign of worn or dull blades/inserts

causing the wood to tear out. Sharp blades cut crisply and leave a relatively smooth finish.

Note: fuzzy grain can also be a sign of high moisture content in the workpiece. If knives have recently been changed or

if you suspect that moisture content and not dull knives is the cause, set the workpiece aside and test by planing other

boards with known or acceptable moisture content. If the planed results using a different workpiece are smooth, then

moisture content in your wood is the problem - no adjustments can be made to the machine for this. Set the “wet” stock

aside and simply work with drier wood. To maintain even knife wear always replace all knives each time knife replacement is required (only for the model 30-360).

19

Page 20

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

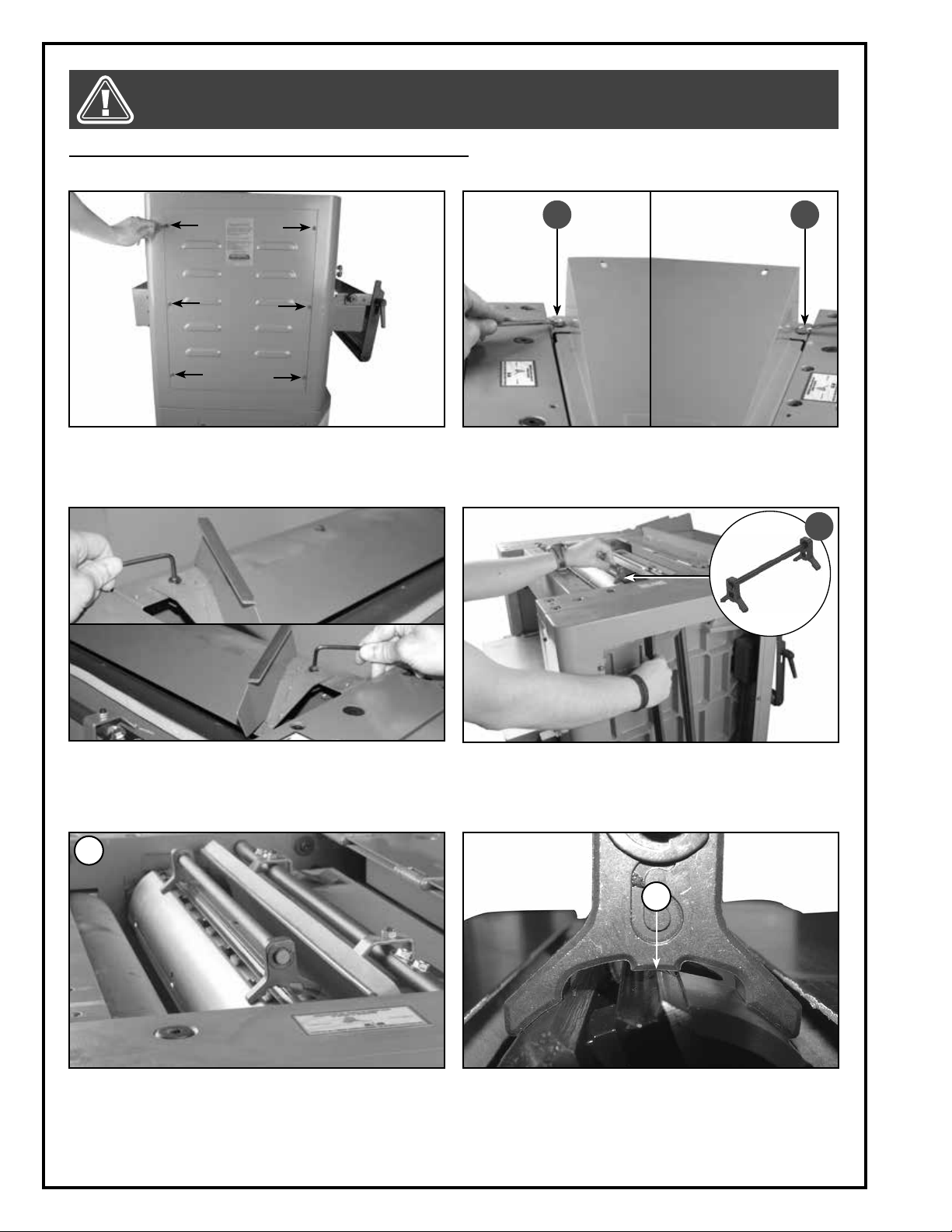

INSPECTING CUTTER HEAD KNIVES (MODEL 30-360 ONLY)

Note: To make sure the knives are properly adjusted, use the jig provided to check each of the four knives.

A A

1. Unscrew the 6 screws and remove the left panel us-

ing a 4 mm Allen key.

RIGHT SIDE

2. Remove the dust chute and the chip deflector bolts

A using a 10 mm wrench. Then tilt up the chip de-

flector cover.

B

LEFT SIDE

3. Remove the chip deflector using a 4 mm Allen key. 4. Position one of the four knives on top by manually

turning the cutter head belt and setting the gauge

B on the cutter head as shown C.

C

D

Ideal knife position has the gauge sitting flush on the cutter head and the knife barely touching the center reference pads on the gauge D.

Make sure the other knives are positioned properly and in a good condition. Should any (or all) of the knives need

adjusting, follow the instructions in the section “Knife setting or replacement”. Once the verifications are done, reinstall the chip deflector, chip deflector cover and the left panel before starting the machine.

20

Page 21

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

KNIFE SETTING OR REPLACEMENT (MODEL 30-360 ONLY)

Properly setting all four knives is essential to achieving accurate results. Properly set knives will last longer and also

keep their edge (sharpness) longer by equally sharing the cutting workload. You may use the supplied knife setting jig to help you set the knives to the correct height whenever re-setting or

A

Note: If you prefer you may also find other “aftermarket”

gauges, jigs or knife setting tools that are to your liking –

ask your local tool distributor for information on any such

tools that may be available in your market.

changing knives.

The cutter head on this unit is supplied with both adjustment springs and jack screws A providing you with two

options for setting the knives.

We suggest you try each method at least once or twice

and decide for yourself which method works best and

fastest for you.

Tip: To avoid potentially costly downtime, consider having

a spare set of replacement knives/inserts on hand and

ready for use when needed.

KNIVES ARE VERY SHARP. USE CARE WHEN HANDLING KNIVES.

1. Refer to section “Inspecting cutter head knives”

and perform steps 1 to 3 before following the instructions below.

2. Turn the cutter head pulley by hand to rotate the

cutter head to access one of the knives as shown B.

3. Loosen the 6 the gib bolts C using a 10 mm wrench

– start in the center and alternate sides. Position the

jig over the selected knife D.

Note: If replacing an old or damaged knife, loosen the

bolts until the knife can be removed and install a new

sharpened knife.

To use the adjustment springs to set the knife height:

Push the knife down with the jig so that the edge of the

knife is touching the center reference pads on the jig E.

Hold the jig down and tighten the bolts C to secure the

knife in place. Repeat for the 3 other knives.

To use the Jack Screws to set the knife height:

Use a 4 mm Allen key to turn the three screws F to raise

or lower the knife as needed until the knife touches the

center reference pads with the jig sitting flush on the

cutter head and the knife barely touching the center reference pads on the jig E. Repeat for the 3 other

knives.

6. Re-check the height on all the knives and reset if

necessary.

7. Re-install the left panel, the chipbreaker, the chip

deflector and the dust chute.

Note: After changing or resetting the knives, the depth cut

must be readjusted.

B

F

C

D

E

21

Page 22

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

HELICAL CUTTER HEAD INSERT REVERSAL / REPLACEMENT (MODEL 30-360HC ONLY)

To be sure that the inserts are in good condition, simply make a visual inspection by manually turning the cutter

head.

There are 58 reversible carbide inserts (knives) B installed in the helical cutter head A (#360H) at the factory. With

use and normal wear over time, it will eventually become necessary to reverse and/or replace the inserts.

To maintain even insert wear always reverse or replace all 58 inserts each time knife replacement is required. When

needed, replacement inserts B can be ordered through your local General International distributor under part

#30-443 (sold by sets of ten).

A B

NOTE: THE DISASSEMBLY OF THE CUTTING HEAD IS NOT REQUIRED FOR THIS OPERATION. THE IMAGE ABOVE IS FOR ILLUSTRATION ONLY.

C

D

E

1. Using one of the two supplied Allen keys, loosen but

do not remove the nut and screw C and remove

the knife-holder/chip breaker D and insert E.

I

G

IMPORTANT! TO PREVENT KNIFE

HEIGHT DISCREPENCIES, THE

KNIFE HOLDERS /CHIP BREAKERS AND INSERTS MUST BE

CLEAN AND FREE OF DEBRIS.

3. Thoroughly clean the knife-holders/chip breakers

G and inserts H using a lacquer thinner and small

brush. Reverse or replace the insert and re-install it

along with the knife-holder/chip breaker into the

slot, then partially retighten the nut and screw I.

H

F

2. Thoroughly clean the housing F before reinstalling

a knife-holder/chip breaker and insert.

J

4. Center the knife-holder/chip breaker with the flat

edge of the nut J and fully tighten the nut and

screw. Repeat with all other 57 inserts.

22

Page 23

Important! The nut and screw that secures the knife-holder/chip breakers and inserts in the cutter head

does not have to be removed for blade reversal/replacement, only loosened. If the nuts and screws have to

be replaced or if they have been removed instead of loosened, follow the instructions below to make sure

that the knife-holder/chip breakers are all secured at the same height into the cutter head.

1. Place the screw in the threaded hole but don’t

start tightening it yet.

3. Holding nut with, tighten the screw. This will

tighten both the screw and nut simultaneously.

REPLACING THE GEAR BOX OIL (EVERY 2500 HOURS OF OPERATION):

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

2. Place the nut on top of the screw but don’t start

tightening the screw yet.

Do not thread the nut onto the screw before

tightening the screw into the threaded hole in

the cutter head.

C

E

B

A

1. Remove the depth of cut handwheel A. Unscrew

and remove the feed speed knob B. Remove the

right panel to access the gear box C.

D

2. Place a container under the plug D and remove

it with a 14 mm wrench. Once the gear box is

drained, re-install the plug D, and then remove the

plug E using a14 mm open wrench.

3. Fill the gear box with a 80W/90 oil until it reaches

the hole, then re-install the plug E. Re-install the panel, the handwheel and the feed speed adjustment

knob.

23

Page 24

LUBRICATION

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

LUBRICATION REFERENCE CHART

REFERENCE

A

B

C

D

E

F

PART

ELEVATION SCREWS ALL PURPOSE GREASE ONCE A MONTH

SLIDING SURFACES ALL PURPOSE OIL ONCE A MONTH

CHAINS ALL PURPOSE GREASE ONCE A MONTH

CHAIN ALL PURPOSE GREASE ONCE A MONTH

CHAIN ALL PURPOSE GREASE ONCE A MONTH

ROLLER SPRINGS ALL PURPOSE OIL

TYPE OF LUBRICANT FREQUENCY TASK

EVERY 30 HOURS OF

SERVICE

Remove old lubrificant and dust

deposits by wiping with a dry rag,

then apply generous dabs of the

lubricant required.

Lubricate the spring rollers with

the lubricant required via the four

set screws.

BA

C

D

E

24

F

F

Page 25

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

CLEANING ANTI-KICKBACK FINGERS

The anti-kickback fingers on this planer are designed

to reduce the risk of injury due to kick-back by preventing the workpiece from being violently ejected from the

machine.

In order for the anti-kickback fingers to move freely and

operate correctly, you must clean off any dust, particles

or residue left behind.

ALIGNING THE BELTS

A

B

1. Remove the left panels using a 4 mm Allen key B.

2. Using a straight edge C, verify that the pulleys are

properly aligned.

To align the pulleys, proceed as follows:

3. Open the motor access door.

4. Loosen the two nuts D and the four nuts E using 24

mm & 14 mm wrenches, then slide the motor on its

mounting plate so that the pulleys are aligned.

5. Retighten the four nuts E and the belt tension nuts D.

Note: check tension by pushing the belt with your finger. The

belt should not move more than 1/2”.

6. Close the motor access door and re-install the pan-

els before starting the machine.

C

E

E

D

25

Page 26

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

ADJUSTING BELT TENSION/CHANGING THE BELTS

Inspect the belts afler every 100 hours of use. Belts that show visible signs of wear such as cracks or fraying at the edges

should be replaced immediately.

A B

To adjust the belt tension:

1. Remove the left panel A using a 4 mm Allen key.

2. Check the belt tension by pushing the belt with your

finger. The belt should not move more than 1/2”. If

not proceed as follows:

3. Open the motor access door C.

4. Loosen the two jam nuts D and then raise or lower

the two nuts E with a 19 mm wrench to tighten or

loosen the belt as needed.

5. Retighten the jam nuts D against the motor mount-

ing plate.

6. Close the motor access door.

To change the belts:

7. Remove the left panels A & B.

8. Remove the nuts E.

9. Place a piece of wood under the motor base as

shown F.

10. Step on the wood to pivot the motor up, and then

remove the belts from the upper pulley G.

11. Install new belts starting with the lower pulley. Re-

install the nuts E.

12. Follow steps 2, 4 and 5 to adjust the tension belt.

13. Re-install the left panels and close the motor ac-

cess door before starting the machine.

C

E

D

G

26

F

Page 27

RECOMMENDED OPTIONAL ACCESSORIES

Here is a sampling of optional accessories available from your local General International dealer that can be

used with this product. For more information about our products, please visit our website at www.general.ca

DUST COLLECTORS

Dust collectors contribute to a cleaner more

healthful workshop environment.

We offer a wide selection of top quality dust

collectors to suit all your

shop needs.

Item #30-025

MAGNETIC, MICRO-ADJUSTABLE KNIFE ALIGNMENT GAUGE

Set of two gauges. Suitable for all planer knives from

6” – 26” in length (for model 30-360).

Item #30-040

CUTTER HEAD ALIGNMENT BLOCKS

Aluminum guide block

used to align the cutter

head parallel to the table

(set of 2).

50-167S

50-170

50-150

Item #360H

20” “MAGNUM” HELICAL

CUTTER HEAD FOR

MODEL 30-360 HC

4 rows, total: 58 inserts.

Item #50-150/ 167S/170

ROLLER STANDS

We offer a selection of

roller stands for added infeed or outfeed support

when working with longer stock

Item #30-050

DIAL-GAUGE

MICROMETER FOR

PLANER KNIFE ALIGNMENT

Precision built, easy to adjust, mounted on enamel

finished alloy steel. Designed to rest squarely

on the cutter head for fast

accurate knife alignment.

Dial is easy to read and

adjust (for model 30-360).

Item #30-443

REPLACEMENT CARBIDE

INSERTS FOR MODEL 30360 HC

Set of 10 inserts.

Item #30-444

SCREW FOR CARBIDE INSERTS FOR “MAGNUM”

HELICAL HEAD

For 30-360HC only.

Item #30-362

REPLACEMENT KNIVES

FOR MODEL 30-360

Set of 4 20” hi-speed steel

blades.

Item #30-364

REPLACEMENT KNIVES

FOR MODEL 30-360

Set of 4 20” carbide

blades.

Item #10-140

HEAVY-DUTY POLYETHYLENE FLEXIBLE HOSES

6” X 50’

27

Page 28

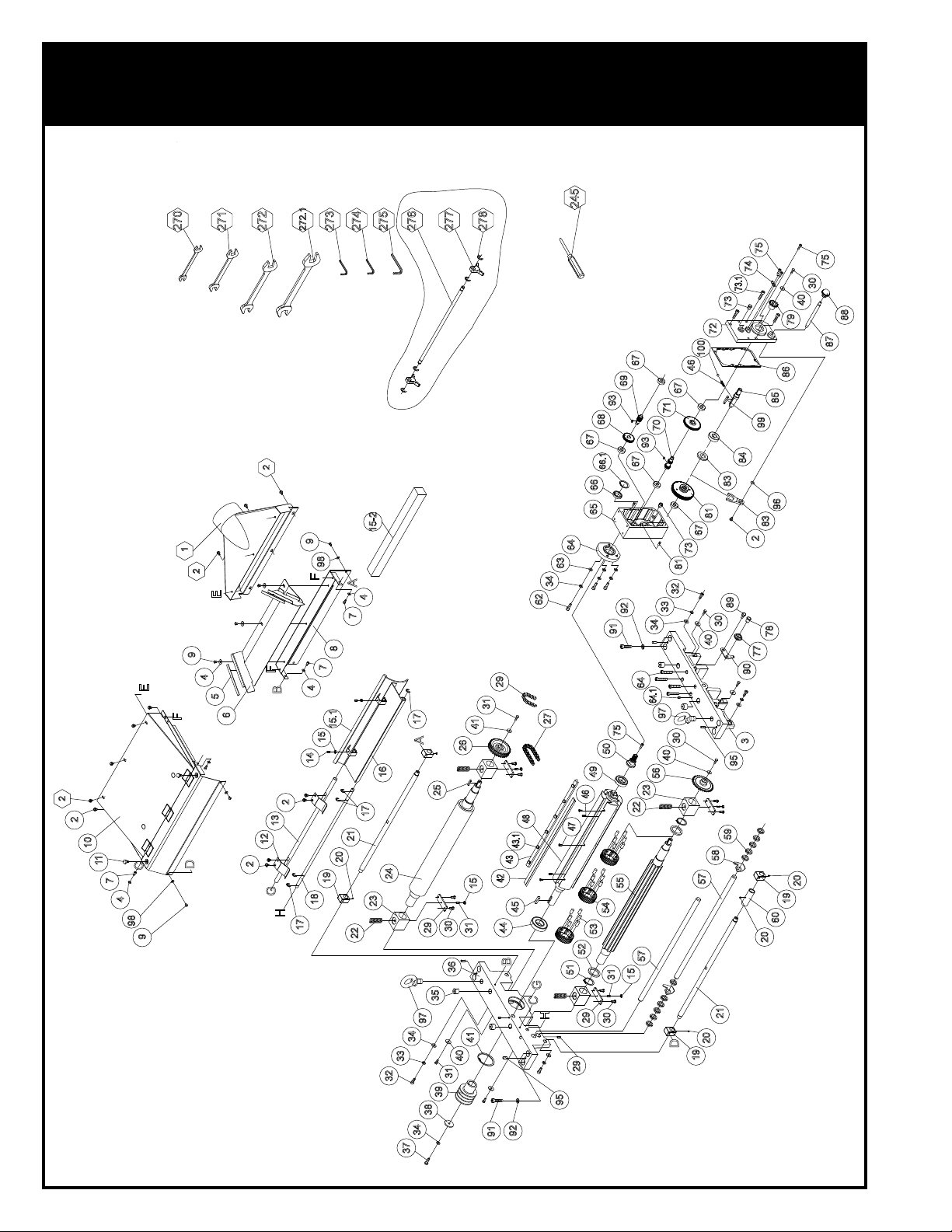

DIAGRAM

HEAD - 30-360

245

270

271

272

2

1

2

E

9

E

4

5

F

2

2

10

11

C

7

4

98

9

D

F

B

6

13

12

2

G

H

273

272.1

9

14

2

17

274

275

15-2

98

F

A

4

7

8

7

4

15.1

15

16

17

21

20

19

18

24

23

22

33

32

37

276

17

34

34

277

278

75

74

73.1

73

72

67

69

93

68

67

66

65

64

63

34

62

29

31

A

29

97

38

41

26

25

42

15

30

31

36

35

41

40

31

39

91

27

49

46

48

47

43.1

43

45

44

B

53

52

51

G

C

H

29

29

95

92

66.1

54

93

67

92

34

91

64

64.1

75

50

23

22

55

57

15

31

30

100

46

67

71

70

83

81

67

73

81

32

33

97

40

56

30

40

30

59

58

57

21

20

D

19

85

99

84

96

83

2

89

78

77

90

3

95

60

20

75

30

40

79

86

20

19

88

87

28

Page 29

DIAGRAM

FRAME - 30-360

131

152

130

101

128

127

101

148.1

148

126

105

104

125

124

123

122

121

120

119

153

134

117

118

135

102

126

138

136

120

137

139

140

106

141

106

147

104

143

149

133

129

146

145

144

133.1

118

101

107

108

101

109

142

128

117

118

153

110

151

115

53

117

118

132

110

111

112

113

114

101

101

150

154

*

29

Page 30

DIAGRAM

TABLE - 30-360

164

165

166

174

167

175

176

178

162

159

179

185

180

185

208

156

177

181

182

183

177

183

186

187

188

156

167

191

195

178

159

189

190

159

165

193

162

167

168

169

170

171

157

172

173

184

159

192

158

161

196

163

207

197

198

160

199

200

202

201

203

155

206

205

204

30

Page 31

DIAGRAM

STAND - 30-360

251

255

*

258

266

226

226

266

267

223

265

225

224

229

225

230

224

227

216

231

229

212

223

211

239

230

210

218

232

238

231

220

236

231

211

215

221

214

232

233

217

235

231

234

269

214

222

249.1

249

237

250

233

268

234

252

264

284

261

219

213

223

263

*

254

263

260

209

241

222

*

248

245

244

235

263

262

227

228

215

209

241

240

242

235

244

245

31

Page 32

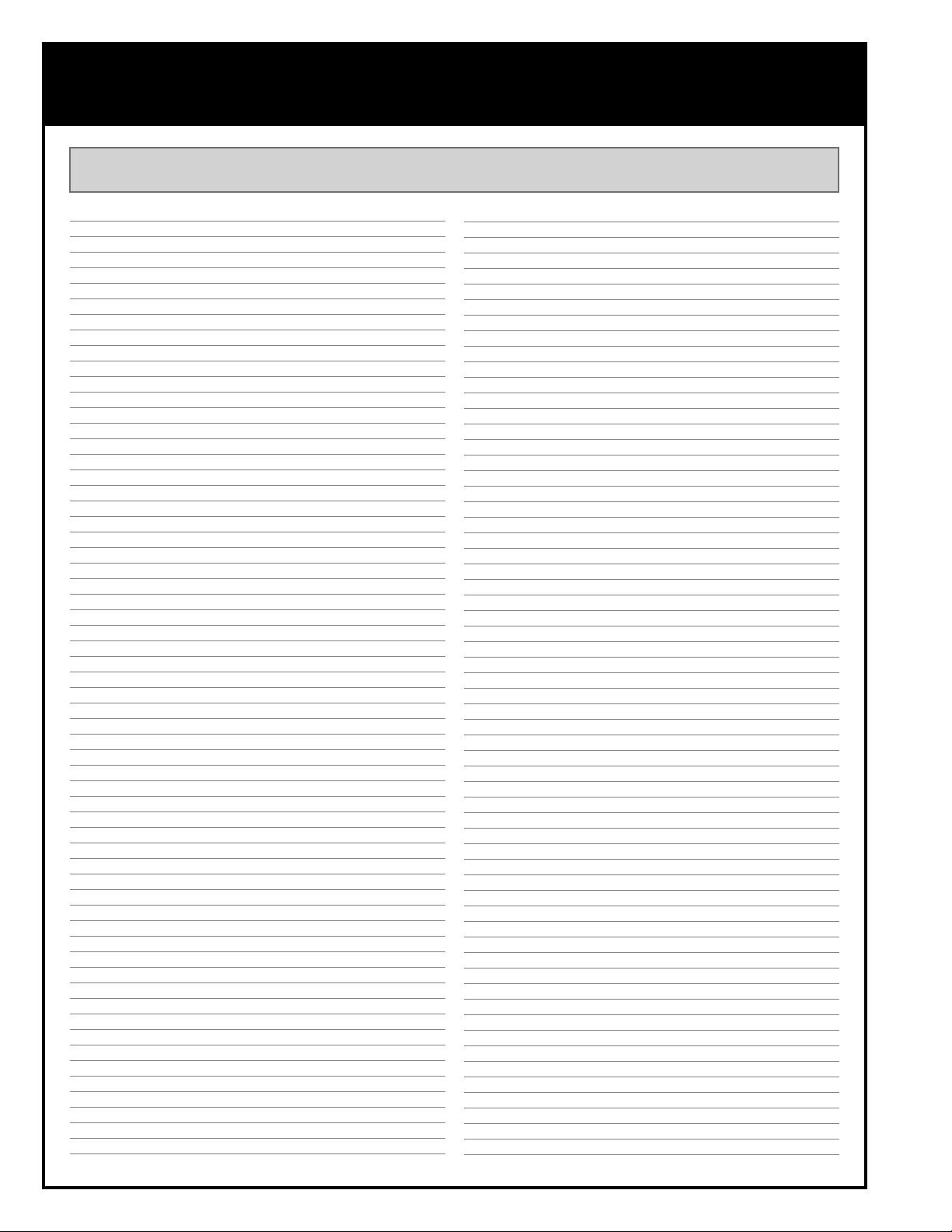

PARTS LIST

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PART # DESCRIPTION SPECIFICATIONS QTY

30360-01 DUST CHUTE 1

30360-02 FLANGE BOLT M6X1.0PX12L 13

30360-03 RIGHT SUPPORT SHAFT 1

30360-04 WASHER 6.7X19X2.0T 8

30360-05 FOAM 2

30360-06 CHIP DEFLECTOR 1

30360-07 CAP SCREW M6X1.0PX12L 4

30360-08 REAR TOP COVER 1

30360-09 ROUND HEAD SCREW M6X1.0PX10L 7

30360-10 FRONT TOP COVER 1

30360-11 SHOCK ABSORBER 2

30360-12 PLATE FLAP 2

30360-13 SHAFT 1

30360-14 SET SCREW M6X1.0PX14L 2

30360-15 NUT M6X1.0P 4

30360-15-1 SPONGE PAD 3/8”X1/2”X525L 1

30360-15-2 SPONGE PAD 1

30360-16 CHIP BREAKER 1

30360-17 RETENTION RING ETW-10 2

30360-18 SHAFT 1

30360-19 FIXING PLATE 4

30360-20 SET SCREW M5X0.8PX5L 5

30360-21 FIXING SHAFT 2

30360-22 SPRING 4

30360-23 BUSHING 4

30360-24 OUTFEED ROLLER 1

30360-25 KEY 1

30360-26 SPROCKET 1

30360-27 CHAIN 06BX76P 1

30360-28 CHAIN 06BX52P 1

30360-29 PLATE 4

30360-30 NUT M6X1.0PX16L 5

30360-31 SET SCREW M6X1.0PX16L 4

30360-32 CAP SCREW M8X1.25PX20L 6

30360-33 LOCK WASHER 8.2X15.4 7

30360-34 WASHER 8.5X22X2T 4

30360-35 SCREW 4

30360-36 LEFT SUPPORT SHAFT 1

30360-37 HEX HEAD BOLT M8X1.25PX20L 1

30360-38 WASHER 8X40X4T 1

30360-39 UPPER PULLEY 1

30360-40 WASHER 6.5X23X3T 7

30360-41 RETENTION RING RTW-72 1

30360-42 KNIFE (ITEM #30-364 OU #30-362) 4

30360-43 KNIFE LOCKING BAR 4

30360-43-1 HEX HEAD BOLT M8X1.25PX10 6

30360-44 BEARING 6207-2NSE 1

30360-45 KEY 8X8X40 1

30360-46 SPRING 9

30360-47 HEX HEAD BOLT M5X0.8PX12L 12

30360-48 CUTTERHEAD FOR 30-360 OR #360H FOR 30-360HC 1

30360-49 BEARING 6006-2NSE 1

30360-50 GEAR 1

30360-51 SET SCREW M10X1.5PX12L 4

30360-52 SPACER 2

30360-53 RUBBER PIN 120

30360-54 INFEED ROLLER 20

30360-55 INFEED ROLLER SHAFT 1

30360-56 SPROCKET 1

30360-57 ANTI-KICK BACK SHAFT 2

30360-58 ANTI-KICK BACK PLATE 56

30360-59 SPACER 66

30360-60 FIXING PLATE 1

30360-61 CAP SCREW M8X1.25PX25L 3

30360-62 WASHER 8.5X16X2T 3

30360-63 BEARING HOUSING 1

30360-64 CAP SCREW M8X1.25PX50L 4

30360-64-1 SET SCREW M6X1.0PX6 2

30360-65 GEAR BOX 1

30360-66 OIL SEAL TC28X40X8 1

30360-66-1 RETENTION RING RTW-40 1

30360-67 BEARING 6201Z 5

30360-68 GEAR 1

30360-69 SHAFT 1

30360-70 SHAFT 1

30360-71 GEAR 1

30360-72 GEAR BOX COVER 1

30360-73 OIL SCREW PT1/4”-19T 2

30360-73-1 CAP SCREW M6X1.0PX25 5

30360-74 HOOK 1

30360-75 CAP SCREW M6X1.0PX20L 4

30360-76 SHAFT 1

30360-77 IDLE PULLEY 2

30360-78 BRACKET 2

30360-79 SPROCKET 1

30360-80 PIN 2

30360-81 GEAR ASSEMBLY 1

30360-82 CLUTCH 1

30360-83 OIL SEAL SC25X47X6 1

30360-84 BEARING 6204Z 1

30360-85 SHAFT 1

30360-86 PACKING PIECE 1

30360-87 LEVER 1

30360-88 KNOB 1

30360-89 SHAFT 1

30360-90 BRACKET 1

30360-91 CAP SCREW M10X1.5PX30L 8

30360-92 LOCK WASHER 10.2X18.5 8

30360-93 KEY 5X5X10 2

30360-94 WASHER 10.3X22X2L 8

30360-95 FIXING PIN 4

30360-96 OIL RING P12 1

30360-97 SCREW M20X2.5PX30 2

30360-98 WASHER 60X40X0.05T 4

30360-99 KEY 6X6X40 1

30360-100 BALL _6 1

30360-101 ROUND HEAD SCREW M6X1.0PX10L 24

30360-102 SET SCREW M5X0.8PX5L 2

30360-103 SPROCKET WASHER BW-4 1

30360-104 LOCK WASHER 8.2X15.4 5

30360-105 CAP SCREW M8X1.25PX25L 3

30360-106 WASHER 8.5X16X2T 4

30360-107 LEFT SIDE COVER 1

30360-108 LEFT SIDE SUPPORT COVER 1

30360-109 LEFT SUPPORT 1

30360-110 WASHER 5.3X12X1T 4

30360-111 ROUND HEAD SCREW M5X0.8PX15L 2

30360-112 STOP SWITCH 1

30360-113 ROUND HEAD SCREW M4X0.7PX12L 1

30360-114 START SWITCH 1

30360-115 NUT M5X0.8P 2

32

Page 33

PARTS LIST

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

30360-116 SWITCH BOX 1

30360-117 LOCK WASHER 10.2X18.5 12

30360-118 WASHER 10X25X3T 13

30360-119 RIGHT SUPPORT PLATE 1

30360-120 BEARING 6004ZZ 2

30360-121 SPROCKET 3

30360-122 KEY 5X5X10 1

30360-123 HANDWHEEL SHAFT 1

30360-124 KEY 1

30360-125 HANDWHEEL BUSHING 1

30360-126 BEARING 6005ZZ 2

30360-127 RIGHT SIDE SUPPORT COVER 1

30360-128 RIGHT SIDE PANEL 1

30360-129 HEX HEAD BOLT M6X1.0PX12L 1

30360-130 HANDWHEEL 1

30360-131 HANDLE 1

30360-132 WASHER 4.3X10X1.0T 1

30360-133 NUT M10X1.5P 1

30-360-133-1 KNOB 1

30360-134 FIXING PIN 1

30360-135 SHAFT 1

30360-136 SPROCKET 1

30360-137 RETENTION RING STW-25 1

30360-138 BEVEL GEAR 25T 1

30360-139 KEY 5X5X16 1

30360-140 KEY 8X7X18 1

30360-141 SHAFT 1

30360-142 NUT M4X0.7P 1

30360-143 BRACKET 1

30360-144 IDLE 1

30360-145 IDLE FIXING SHAFT 1

30360-146 CAP SCREW M8X1.25PX35L 1

30360-147 CAP SCREW M8X1.25PX16L 1

30360-148 RETENTION RING RTW-47 1

30360-148-1 SPACER 1

30360-149 WASHER 10.3X22X2L 2

30360-150 CONNECT CORD 14A/1CX0.25M 1

30360-151 RELIEF BUSHING SB9R-2 1

30360-152 CHAIN #40-100P 1

30360-153 HEX HEAD BOLT M10X1.5PX30L 12

30360-154 SWITCH CORD 18AWG/4C 1

30360-155 ROUND HEAD SCREW M6X1.0PX10L 2

30360-156 SET SCREW M5X0.8PX5L 4

30360-157 NUT M6X1.0PX16L 2

30360-158 LOCK WASHER 8.2X15.4 3

30360-159 WASHER 8.5X22X2T 6

30360-160 CAP SCREW M10X1.5PX30L 1

30360-161 WASHER 10X25X3T 1

30360-162 KEY 5X5X10 3

30360-163 HEX HEAD BOLT M6X1.0PX12L 2

30360-164 ROLLER BASE 4

30360-165 BEARING 4

30360-166 TABLE ROLLER 2

30360-167 NUT M8X1.25P 6

30360-168 SET SCREW M8X1.25PX40L 6

30360-169 GIB 2

30360-170 NUT M8X1.25PX16L 2

30360-171 LEAD PLATE 2

30360-172 HEX HEAD BOLT M10X1.5PX50L 2

30360-173 FIXING POINT 2

30360-174 HEX HEAD BOLT M8X1.25PX20L 4

30360-175 MAIN TABLE 1

30360-176 SPRING PIN 4

30360-177 CONNECT PLATE 3

30360-178 CAP SCREW M8X1.25PX16L 5

30360-179 CAM LOCK SHAFT 4

30360-180 CAM LOCK 4

30360-181 BAR 2

30360-182 FLANGE SCREW 1

30360-183 FLANGE SCREW 2

30360-184 POINTER 1

30360-185 ROUND HEAD SCREW M5X0.8PX10L 6

30360-186 SHAFT 1

30360-187 KEY 5X5X15 1

30360-188 BUSHING 1

30360-189 ADJUSTMENT HANDWHEEL 1

30360-190 HANDLE 1

30360-191 FIXING PLATE 1

30360-192 CAP SCREW M10X1.5PX20L 1

30360-193 HANDLE 1

30360-194 SHAFT 1

30360-195 FIXING PLATE 1

30360-196 CAP SCREW M8X1.25PX45L 6

30360-197 WASHER 2

30360-198 FIXING BUSH 4

30360-199 SCREW W/WASHER M4X0.7PX8/4X10X0.8T 8

30360-200 EXTENSION PLATE 2

30360-201 WASHER 13.5X28X2T 6

30360-202 HANDLE 2

30360-203 SUPPORT PLATE 2

30360-204 EXTENSION SHAFT 1

30360-205 EXTENSION ROLLER 1

30360-206 ROLLER CAP 2

30360-207 FIXING SHAFT 2

30360-208 POINTER 1

30360-209 ROUND HEAD SCREW M6X1.0PX10L 8

30360-210 CAP SCREW M8X1.25PX20L 6

30360-211 CAP SCREW M8X1.25PX25L 6

30360-212 WASHER 8.5X16X2T 2

30360-213 LOCK WASHER 10.2X18.5 4

30360-214 SPROCKET 2

30360-215 KEY 5X5X10 2

30360-216 NUT M10X1.5P 1

30360-217 KEY 5X5X16 1

30360-218 BRACKET 1

30360-219 NUT M10X1.5P 4

30360-220 IDLE 1

30360-221 IDLE FIXING SHAFT 1

30360-222 ROUND HEAD SCREW M5X0.8PX10L 7

30360-223 WASHER 10.3X22X2L 9

30360-224 FIXING BUSH 2

30360-225 SCREW W/WASHER M4X0.7PX8/4X10X0.8T 4

30360-226 WASHER 13.5X28X2T 4

30360-227 EXPANSION BEND 2

30360-228 LEAD SCREW 1

30360-229 RETENTION RING RTW-68 2

30360-230 BEARING 6008-2NSE 2

30360-231 BEARING 51105 4

30360-232 BUSHING 2

30360-233 WASHER _25 2

30360-234 NUT M25X1.5P 2

30360-235 CHAIN #40-78P 1

33

Page 34

PARTS LIST

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

30360-236 LEAD SCREW 1

30360-237 BEVEL GEAR 50T 1

30360-238 REAR DOOR 1