Ford Mondeo 1996, Mondeo 1993 User Manual

Ford Mondeo

Service and Repair Manual

Jeremy Churchill and A K Legg LAE MIMI

(1923-304-10X3)

Models covered

All Ford Mondeo models with four-cylinder petrol engines, including special/limited editions

1597 cc, 1796 cc and 1988 cc

Does not cover Diesel or V6 engines, or four-wheel-drive models

© Haynes Publishing 1996

A book in the Haynes Service and Repair Manual Series

All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or by any information storage or retrieval system, without permission in writing from the copyright holder.

ISBN 1 85960 167 7

British Library Cataloguing in Publication Data

A catalogue record for this book is available from the British Library.

Printed by J H Haynes & Co. Ltd, Sparkford, Nr Yeovil,

Somerset BA22 7JJ

Haynes Publishing

Sparkford, Nr Yeovil, Somerset BA22 7JJ, England

Haynes North America, Inc

861 Lawrence Drive, Newbury Park, California 91320, USA

Editions Haynes S.A.

147/149, rue Saint Honoré, 75001 PARIS, France

Contents

LIVING WITH YOUR FORD MONDEO

Introduction |

Page |

0•4 |

Safety First! |

Page |

0•5 |

|

|

|

General dimensions and weights |

Page |

0•6 |

|

|

|

MOT Test Checks

Checks carried out from the driver’s seat |

Page |

0•7 |

Checks carried out with the vehicle on the ground |

Page |

0•8 |

|

|

|

Checks carried out with the vehicle raised |

Page |

0•9 |

|

|

|

Checks carried out on your vehicle’s exhaust emission system |

Page |

0•10 |

|

|

|

Roadside Repairs

Jacking, towing and wheel changing |

Page |

0•11 |

Booster battery (jump) starting |

Page |

0•12 |

|

|

|

Identifying leaks |

Page |

0•13 |

|

|

|

Conversion factors |

Page |

0•14 |

|

|

|

Routine Maintenance

Routine maintenance and servicing |

Page |

1•1 |

Lubricants, fluids and capacities |

Page |

1•2 |

|

|

|

Maintenance schedule |

Page |

1•3 |

|

|

|

Weekly checks |

Page |

1•6 |

|

|

|

Every 10 000 miles or 12 months |

Page |

1•11 |

|

|

|

Every 20 000 miles or 2 years |

Page |

1•20 |

|

|

|

Every 30 000 miles or 3 years |

Page |

1•22 |

|

|

|

Every 60 000 miles |

Page |

1•26 |

|

|

|

Every 3 years |

Page |

1•26 |

|

|

|

Contents

REPAIRS & OVERHAUL

Engine and Associated Systems

In-car engine repair procedures |

Page |

2A•1 |

Engine removal and general engine overhaul procedures |

Page |

2B•1 |

|

|

|

Cooling, heating and air conditioning systems |

Page |

3•1 |

|

|

|

Fuel and exhaust systems |

Page |

4•1 |

|

|

|

Engine electrical systems |

Page |

5•1 |

|

|

|

Emissions control systems |

Page |

6•1 |

|

|

|

Transmission

Manual transmission |

Page |

7A•1 |

Automatic transmission |

Page |

7B•1 |

|

|

|

Clutch and driveshafts |

Page |

8•1 |

|

|

|

Brakes

Braking system Page 9•1

Suspension

Suspension and steering systems Page 10•1

Body Equipment

Bodywork and fittings Page 11•1

Electrical

Body electrical systems |

Page |

12•1 |

Wiring Diagrams |

Page |

12•24 |

|

|

|

REFERENCE

Tools and Working Facilities |

Page |

REF• 1 |

|

General Repair Procedures |

Page |

REF• 4 |

|

|

|

|

|

Buying spare parts and vehicle identification numbers |

Page |

REF• |

5 |

|

|

|

|

Fault Finding |

Page |

REF• |

6 |

|

|

|

|

Glossary of Technical Terms |

Page |

REF•13 |

|

|

|

|

|

Index

Page REF•17

0•4 Introduction

Introduction to the Ford Mondeo

Introduced in March 1993, the Ford Mondeo models are available in four-door Saloon, five-door Hatchback and five-door Estate configurations. All feature a high standard of equipment, with driver/passenger safety in accidents being a particularly high design priority; all models are fitted with features such as side impact bars in all doors, “anti-submarine” seats combined with “seat

belt grabbers” and pre-tensioners, and an airbag fitted to the steering wheel. Vehicle security is enhanced, with an in-built alarm system and engine immobiliser being fitted as standard, as well as double-locking doors with shielded locks, and security-coded audio equipment.

The four-cylinder petrol engine is a new design, available in 1.6, 1.8 and 2.0 litre

Ford Mondeo 2.0 Ghia Saloon

Ford Mondeo 1.8 GLX Estate

capacities. It is controlled by a sophisticated engine management system, which combines multi-point sequential fuel injection and distributorless ignition systems with evaporative emissions control, exhaust gas recirculation and a three-way regulated catalytic converter (with a pulse-air system for rapid warm-up) to ensure that the vehicle complies with the most stringent of the emissions control standards currently in force, and yet provides the levels of performance and fuel economy expected.

The transversely-mounted engine drives the front roadwheels through either a fivespeed manual transmission with a cableoperated clutch, or through an electronicallycontrolled four-speed automatic transmission.

The fully-independent suspension is by MacPherson strut on all four roadwheels, located by transverse lower arms at the front, and by transverse and trailing arms at the rear; anti-roll bars are fitted at front and rear. The Estate rear suspension is of a different design, to give maximum loadspace inside the vehicle, with self-levelling suspension units available as an option. On some models, the suspension is electronically-controlled through the Adaptive Damping System.

The steering is power-assisted, the pump being belt-driven from the engine, and the rack-and-pinion steering gear mounted behind the engine.

The vacuum servo-assisted brakes are disc at the front, with drums at the rear on most models; disc rear brakes and an electronically-controlled Anti-lock Braking System (ABS) are available on some models, with a Traction Control System (TCS) available as a further option where ABS is fitted.

Acknowledgements

Thanks are due to Champion Spark Plug, who supplied the illustrations showing spark plug conditions. Certain other illustrations are the copyright of the Ford Motor Company, and are used with their permission. Thanks are also due to Sykes-Pickavant Limited, who provided some of the workshop tools, and to all those people at Sparkford who helped in the production of this manual.

Project vehicles

The main project vehicle used in the preparation of this manual, and appearing in many of the photographic sequences, was a 1993-model Ford Mondeo 2.0 Si Hatchback. Additional work was carried out and photographed on a 1993-model 2.0 Si Saloon and a 1993-model 2.0 Ghia Estate (with automatic transmission).

Safety First! 0•5

Working on your car can be dangerous. This page shows just some of the potential risks and hazards, with the aim of creating a safety-conscious attitude.

General hazards

Scalding

•Don’t remove the radiator or expansion tank cap while the engine is hot.

•Engine oil, automatic transmission fluid or power steering fluid may also be dangerously hot if the engine has recently been running.

Burning

• Beware of burns from the exhaust system and from any part of the engine. Brake discs and drums can also be extremely hot immediately after use.

Crushing

•When working a raised vehicle, supplement the jack with axle stands, or use drive-on ramps

Never venture under a car which is only supported by a jack.

•Take care if torque nuts Initial loosening be done with

Fire

•Fuel is highly explosive.

•Don’t let fuel

•Do not smoke (including pilot vehicle being creating sparks (electrically or by

•Fuel vapour is work on the fuel an inspection pit

•Another cause overload or short repairing or

•Keep a fire suitable for use

Electric shock

• Ignition HT voltage can be dangerous, especially to people with heart problems or a pacemaker. Don’t work on or near the ignition system with the engine running ignition switched

• Mains voltage is also dangerous. Make sure that any mains-operated equipment is correctly earthed. Mains power points should be protected by a residual current device (RCD) circuit breaker.

Fume or gas intoxication

•Exhaust fumes are poisonous; they contain carbon monoxide, which is rapidly fatal if inhaled Never run the engine in a

confined space such as a garage with the doors shut

•Fuel vapour is also poisonous, as are cleaning solvents

your pocket.

• Air conditioning poisonous gas if (including a cigarette) burns on contact.

Special hazards

Hydrofluoric acid

• This extremely corrosive acid is formed when certain types of synthetic rubber, found in some O-rings, oil seals, fuel hoses etc, are exposed to temperatures above 4000C. The

charred or sticky acid. Once formed,

for years. If it be necessary to

.

vehicle which has components salvaged

protective gloves

.

• Batteries contain sulphuric acid, which attacks clothing, eyes and skin. Take care

carrying the battery. off by the battery cause a spark or

. Be careful when battery

if they go off when removing the

. Special storage

instructions may apply.

Diesel injection equipment

• Diesel injection pumps supply fuel at very high pressure. Take care when working on the fuel injectors and fuel pipes.

Asbestos

• Asbestos dust can |

Warning: Never expose the |

or swallowed. |

hands, face or any other part of |

gaskets and in brake |

the body to injector spray; the |

When dealing with |

fuel can penetrate the skin with |

safest to assume |

potentially fatal results. |

Remember... |

A few tips |

|

DO |

DON’T |

|

• Do use eye protection when using power |

• Don’t attempt to lift a heavy component |

|

tools, and when working under the vehicle. |

which may be beyond your capability – get |

|

• Do wear gloves or use barrier cream to |

assistance. |

|

• Don’t rush to finish a job, or take |

||

protect your hands when necessary. |

||

• Do get someone to check periodically |

unverified short cuts. |

|

• Don’t use ill-fitting tools which may slip |

||

that all is well when working alone on the |

||

vehicle. |

and cause injury. |

|

• Do keep loose clothing and long hair well |

• Don’t leave tools or parts lying around |

|

out of the way of moving mechanical parts. |

where someone can trip over them. Mop |

|

• Do remove rings, wristwatch etc, before |

up oil and fuel spills at once. |

|

• Don’t allow children or pets to play in or |

||

working on the vehicle – especially the |

||

electrical system. |

near a vehicle being worked on. |

|

• Do ensure that any lifting or jacking |

|

|

equipment has a safe working load rating |

|

|

adequate for the job. |

|

|

|

|

0•6 General Dimensions & Weights

Dimensions

Overall length: |

|

Saloon, Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4481 mm |

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4631 mm |

Overall width - including mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1925 mm |

Overall height - at kerb weight: |

|

Saloon, Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1403 to 1435 mm |

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1416 to 1501 mm |

Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2704 mm |

Front track - all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1503 mm |

Rear track: |

|

Saloon, Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1486 to 1487 mm |

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1504 mm |

Turning circle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10.9 m |

Weights

Kerb weight: |

|

|

1.6 |

Saloon, Hatchback models . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1215 to 1250 kg |

1.6 |

Estate models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1265 to 1275 kg |

1.8 |

Saloon, Hatchback models: |

|

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1225 to 1260 kg |

|

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1260 to 1280 kg |

|

1.8 |

Estate models: |

|

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1275 to 1285 kg |

|

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1305 kg |

|

2.0 |

Saloon, Hatchback models: |

|

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1250 to 1310 kg |

|

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1285 to 1340 kg |

|

2.0 |

Estate models: |

|

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1295 to 1335 kg |

|

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1330 to 1415 kg |

|

Maximum gross vehicle weight: |

|

|

Saloon, Hatchback: |

|

|

1.6 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1725 kg |

|

1.8 Saloon models, automatic transmission . . . . . . . . . . . . . . . . . |

1750 kg |

|

2.0 models, automatic transmission . . . . . . . . . . . . . . . . . . . . . . . |

1800 kg |

|

All others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1775 kg |

|

Estate: |

|

|

1.6 models, 2.0 models with manual transmission . . . . . . . . . . . . |

1900 kg |

|

All others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1925 kg |

|

Maximum roof rack load: |

|

|

Estate models with integral roof rack . . . . . . . . . . . . . . . . . . . . . . . . |

100 kg |

|

All others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

75 kg |

|

Maximum towing weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1500 kg |

|

Trailer nose weight limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

75 kg |

|

MOT Test Checks 0•7

This is a guide to getting your vehicle through the MOT test. Obviously it will not be possible to examine the vehicle to the same standard as the professional MOT tester. However, working through the following checks will enable you to identify any problem areas before submitting the vehicle for the test.

Where a testable component is in borderline condition, the tester has discretion in deciding whether to pass or fail it. The basis of such discretion is whether the tester would be happy for a close relative or friend to use the vehicle with the component in that condition. If the vehicle presented is clean and evidently well cared for, the tester may be more inclined to pass a borderline component than if the vehicle is scruffy and apparently neglected.

It has only been possible to summarise the test requirements here, based on the regulations in force at the time of printing. Test standards are becoming increasingly stringent, although there are some exemptions for older vehicles. For full details obtain a copy of the Haynes publication Pass the MOT! (available from stockists of Haynes manuals).

An assistant will be needed to help carry out some of these checks.

The checks have been sub-divided into four categories, as follows:

1Checks carried out |

|

2Checks carried out |

|

3Checks carried out |

|

4Checks carried out on |

FROM THE DRIVER’S |

|

WITH THE VEHICLE |

|

WITH THE VEHICLE |

|

YOUR VEHICLE’S |

SEAT |

|

ON THE GROUND |

|

RAISED AND THE |

|

EXHAUST EMISSION |

|

|

|

|

WHEELS FREE TO |

|

SYSTEM |

|

|

|

|

TURN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1Checks carried out

FROM THE DRIVER’S SEAT

Handbrake

MTest the operation of the handbrake. Excessive travel (too many clicks) indicates incorrect brake or cable adjustment.

MCheck that the handbrake cannot be released by tapping the lever sideways. Check the security of the lever mountings.

Footbrake

M Depress the brake pedal and check that it does not creep down to the floor, indicating a master cylinder fault. Release the pedal, wait a few seconds, then depress it again. If the pedal travels nearly to the floor before firm resistance is felt, brake adjustment or repair is necessary. If the pedal feels spongy, there is air in the hydraulic system which must be removed by bleeding.

MCheck that the brake pedal is secure and in good condition. Check also for signs of fluid leaks on the pedal, floor or carpets, which would indicate failed seals in the brake master cylinder.

MCheck the servo unit (when applicable) by operating the brake pedal several times, then keeping the pedal depressed and starting the engine. As the engine starts, the pedal will move down slightly. If not, the vacuum hose or the servo itself may be faulty.

Steering wheel and column

MExamine the steering wheel for fractures or looseness of the hub, spokes or rim.

MMove the steering wheel from side to side and then up and down. Check that the steering wheel is not loose on the column, indicating wear or a loose retaining nut. Continue moving the steering wheel as before, but also turn it slightly from left to right.

MCheck that the steering wheel is not loose on the column, and that there is no abnormal

movement of the steering wheel, indicating wear in the column support bearings or couplings.

Windscreen and mirrors

M The windscreen must be free of cracks or other significant damage within the driver’s field of view. (Small stone chips are acceptable.) Rear view mirrors must be secure, intact, and capable of being adjusted.

0•8 MOT Test Checks

Electrical equipment

MSwitch on the ignition and check the operation of the horn.

MCheck the windscreen washers and wipers, examining the wiper blades; renew damaged or perished blades. Also check the operation of the stop-lights.

M Inspect both front brake flexible hoses for cracks or deterioration of the rubber. Turn the steering from lock to lock, and ensure that the hoses do not contact the wheel, tyre, or any part of the steering or suspension mechanism. With the brake pedal firmly depressed, check the hoses for bulges or leaks under pressure.

Seat belts and seats

Note: The following checks are applicable to all seat belts, front and rear.

MExamine the webbing of all the belts (including rear belts if fitted) for cuts, serious fraying or deterioration. Fasten and unfasten each belt to check the buckles. If applicable, check the retracting mechanism. Check the security of all seat belt mountings accessible from inside the vehicle.

MThe front seats themselves must be securely attached and the backrests must lock in the upright position.

Doors

M Both front doors must be able to be opened and closed from outside and inside, and must latch securely when closed.

2Checks carried out

WITH THE VEHICLE ON THE GROUND

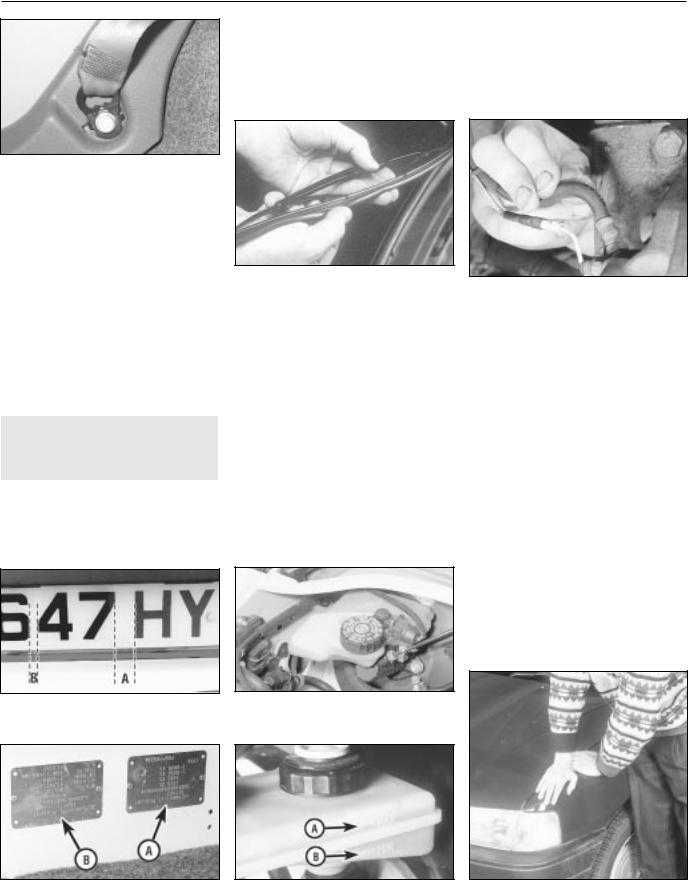

Vehicle identification

M Number plates must be in good condition, secure and legible, with letters and numbers correctly spaced – spacing at (A) should be twice that at (B).

M The VIN plate (A) and homologation plate

(B) must be legible.

MCheck the operation of the sidelights and number plate lights. The lenses and reflectors must be secure, clean and undamaged.

MCheck the operation and alignment of the headlights. The headlight reflectors must not be tarnished and the lenses must be undamaged.

MSwitch on the ignition and check the operation of the direction indicators (including the instrument panel tell-tale) and the hazard warning lights. Operation of the sidelights and stop-lights must not affect the indicators - if it does, the cause is usually a bad earth at the rear light cluster.

MCheck the operation of the rear foglight(s), including the warning light on the instrument panel or in the switch.

Footbrake

M Examine the master cylinder, brake pipes and servo unit for leaks, loose mountings, corrosion or other damage.

M The fluid reservoir must be secure and the fluid level must be between the upper (A) and lower (B) markings.

Steering and suspension

MHave your assistant turn the steering wheel from side to side slightly, up to the point where the steering gear just begins to transmit this movement to the roadwheels. Check for excessive free play between the steering wheel and the steering gear, indicating wear or insecurity of the steering column joints, the column-to-steering gear coupling, or the steering gear itself.

MHave your assistant turn the steering wheel more vigorously in each direction, so that the roadwheels just begin to turn. As this is done, examine all the steering joints, linkages, fittings and attachments. Renew any component that shows signs of wear or damage. On vehicles with power steering, check the security and condition of the steering pump, drivebelt and hoses.

MCheck that the vehicle is standing level, and at approximately the correct ride height.

Shock absorbers

M Depress each corner of the vehicle in turn, then release it. The vehicle should rise and then settle in its normal position. If the vehicle continues to rise and fall, the shock absorber is defective. A shock absorber which has seized will also cause the vehicle to fail.

MOT Test Checks 0•9

Exhaust system

M Start the engine. With your assistant holding a rag over the tailpipe, check the entire system for leaks. Repair or renew leaking sections.

3Checks carried out

WITH THE VEHICLE RAISED AND THE WHEELS FREE TO TURN

Jack up the front and rear of the vehicle, and securely support it on axle stands. Position the stands clear of the suspension assemblies. Ensure that the wheels are clear of the ground and that the steering can be turned from lock to lock.

Steering mechanism

MHave your assistant turn the steering from lock to lock. Check that the steering turns smoothly, and that no part of the steering mechanism, including a wheel or tyre, fouls any brake hose or pipe or any part of the body structure.

MExamine the steering rack rubber gaiters for damage or insecurity of the retaining clips. If power steering is fitted, check for signs of damage or leakage of the fluid hoses, pipes or connections. Also check for excessive stiffness or binding of the steering, a missing split pin or locking device, or severe corrosion of the body structure within 30 cm of any steering component attachment point.

Front and rear suspension and wheel bearings

M Starting at the front right-hand side, grasp the roadwheel at the 3 o’clock and 9 o’clock positions and shake it vigorously. Check for free play or insecurity at the wheel bearings, suspension balljoints, or suspension mountings, pivots and attachments.

Now grasp the wheel at the 12 o’clock and o’clock positions and repeat the previous inspection. Spin the wheel, and check for roughness or tightness of the front wheel

bearing.

M If excess free play is suspected at a component pivot point, this can be confirmed by using a large screwdriver or similar tool and levering between the mounting and the component attachment. This will confirm whether the wear is in the pivot bush, its retaining bolt, or in the mounting itself (the bolt holes can often become elongated).

M Carry out all the above checks at the other front wheel, and then at both rear wheels.

MThe same general checks apply to vehicles fitted with other suspension types, such as torsion bars, hydraulic displacer units, etc. Ensure that all mountings and attachments are secure, that there are no signs of excessive wear, corrosion or damage, and (on hydraulic types) that there are no fluid leaks or damaged pipes.

MInspect the shock absorbers for signs of serious fluid leakage. Check for wear of the mounting bushes or attachments, or damage to the body of the unit.

Driveshafts

(fwd vehicles only)

M Rotate each front wheel in turn and inspect the constant velocity joint gaiters for splits or damage. Also check that each driveshaft is straight and undamaged.

Braking system

M If possible without dismantling, check brake pad wear and disc condition. Ensure that the friction lining material has not worn excessively, (A) and that the discs are not fractured, pitted, scored or badly worn (B).

Springs and shock absorbers

MExamine the suspension struts (when applicable) for serious fluid leakage, corrosion, or damage to the casing. Also check the security of the mounting points.

MIf coil springs are fitted, check that the spring ends locate in their seats, and that the spring is not corroded, cracked or broken.

MIf leaf springs are fitted, check that all leaves are intact, that the axle is securely attached to each spring, and that there is no deterioration of the spring eye mountings, bushes, and shackles.

MExamine all the rigid brake pipes underneath the vehicle, and the flexible hose(s) at the rear. Look for corrosion, chafing or insecurity of the pipes, and for signs of bulging under pressure, chafing, splits or deterioration of the flexible hoses.

MLook for signs of fluid leaks at the brake calipers or on the brake backplates. Repair or renew leaking components.

MSlowly spin each wheel, while your assistant depresses and releases the footbrake. Ensure that each brake is operating and does not bind when the pedal is released.

0•10 MOT Test Checks

MExamine the handbrake mechanism, checking for frayed or broken cables, excessive corrosion, or wear or insecurity of the linkage. Check that the mechanism works on each relevant wheel, and releases fully, without binding.

MIt is not possible to test brake efficiency without special equipment, but a road test can be carried out later to check that the vehicle pulls up in a straight line.

Fuel and exhaust systems

MInspect the fuel tank (including the filler cap), fuel pipes, hoses and unions. All components must be secure and free from leaks.

MExamine the exhaust system over its entire length, checking for any damaged, broken or missing mountings, security of the retaining clamps and rust or corrosion.

Wheels and tyres

M Examine the sidewalls and tread area of each tyre in turn. Check for cuts, tears, lumps, bulges, separation of the tread, and exposure of the ply or cord due to wear or damage. Check that the tyre bead is correctly seated on the wheel rim, that the valve is sound and

properly seated, and that the wheel is not distorted or damaged.

MCheck that the tyres are of the correct size for the vehicle, that they are of the same size and type on each axle, and that the pressures are correct.

MCheck the tyre tread depth. The legal minimum at the time of writing is 1.6 mm over at least three-quarters of the tread width. Abnormal tread wear may indicate incorrect front wheel alignment.

Body corrosion

MCheck the condition of the entire vehicle structure for signs of corrosion in loadbearing areas. (These include chassis box sections, side sills, cross-members, pillars, and all suspension, steering, braking system and seat belt mountings and anchorages.) Any corrosion which has seriously reduced the thickness of a load-bearing area is likely to cause the vehicle to fail. In this case professional repairs are likely to be needed.

MDamage or corrosion which causes sharp or otherwise dangerous edges to be exposed will also cause the vehicle to fail.

4Checks carried out on

YOUR VEHICLE’S EXHAUST EMISSION SYSTEM

Petrol models

MHave the engine at normal operating temperature, and make sure that it is in good tune (ignition system in good order, air filter element clean, etc).

MBefore any measurements are carried out, raise the engine speed to around 2500 rpm, and hold it at this speed for 20 seconds. Allow the engine speed to return to idle, and watch

for smoke emissions from the exhaust tailpipe. If the idle speed is obviously much too high, or if dense blue or clearly-visible black smoke comes from the tailpipe for more than 5 seconds, the vehicle will fail. As a rule of thumb, blue smoke signifies oil being burnt (engine wear) while black smoke signifies unburnt fuel (dirty air cleaner element, or other carburettor or fuel system fault).

M An exhaust gas analyser capable of measuring carbon monoxide (CO) and hydrocarbons (HC) is now needed. If such an instrument cannot be hired or borrowed, a local garage may agree to perform the check for a small fee.

CO emissions (mixture)

M At the time or writing, the maximum CO level at idle is 3.5% for vehicles first used after August 1986 and 4.5% for older vehicles. From January 1996 a much tighter limit (around 0.5%) applies to catalyst-equipped vehicles first used from August 1992. If the CO level cannot be reduced far enough to pass the test (and the fuel and ignition systems are otherwise in good condition) then the carburettor is badly worn, or there is some problem in the fuel injection system or catalytic converter (as applicable).

HC emissions

MWith the CO emissions within limits, HC emissions must be no more than 1200 ppm (parts per million). If the vehicle fails this test at idle, it can be re-tested at around 2000 rpm; if the HC level is then 1200 ppm or less, this counts as a pass.

MExcessive HC emissions can be caused by oil being burnt, but they are more likely to be due to unburnt fuel.

Diesel models

M The only emission test applicable to Diesel engines is the measuring of exhaust smoke density. The test involves accelerating the engine several times to its maximum unloaded speed.

Note: It is of the utmost importance that the engine timing belt is in good condition before the test is carried out.

M Excessive smoke can be caused by a dirty air cleaner element. Otherwise, professional advice may be needed to find the cause.

Roadside Repairs 0•11

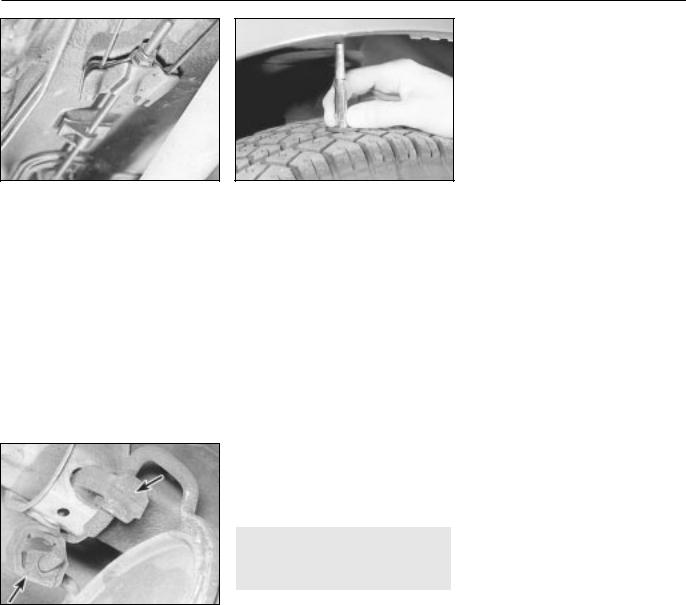

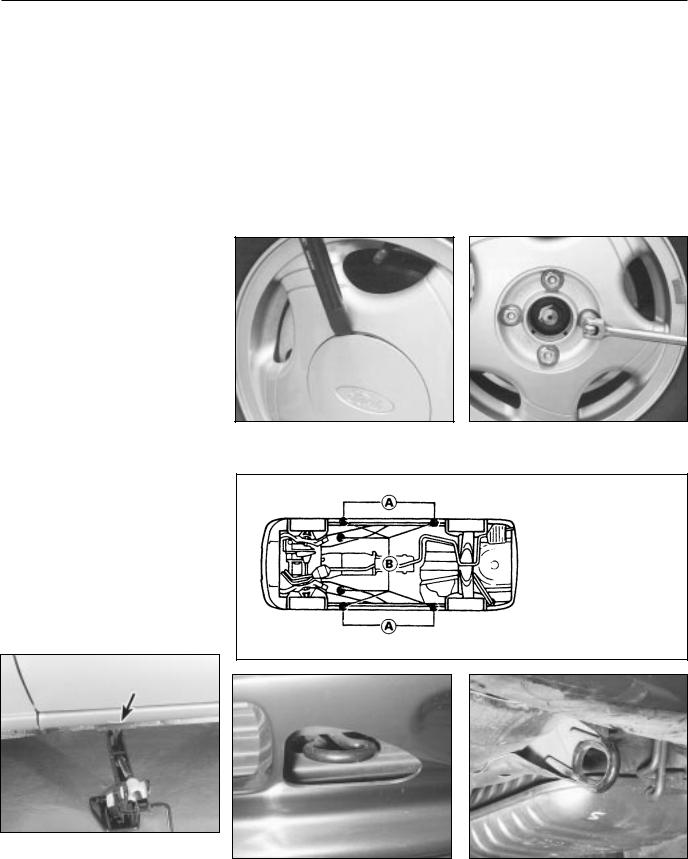

Jacking, towing and wheel changing

To change a wheel, remove the spare wheel and jack, apply the handbrake, and chock the wheel diagonally opposite the one to be changed. On manual transmission models, select first or reverse gear; on automatic transmission models, place the selector lever in “P”. Make sure that the vehicle is located on firm level ground. Use the flat end of the wheelbrace carefully to remove the trim covering the wheel nuts, then slightly loosen the wheel nuts with the brace (see illustrations). Locate the jack head in the jacking point nearest to the wheel to be changed, ensuring that the channel in the jack head fits over the body flange (see illustrations) and turn its handle to raise the jack. When the wheel is clear of the ground, remove the nuts and lift off the wheel. Fit the spare wheel, and moderately tighten the nuts. Lower the vehicle, then tighten the nuts fully and refit the trim. With the spare wheel in position, remove the chock, and stow the jack and tools.

When jacking up the vehicle to carry out repair or maintenance tasks, position the jack as follows.

If the front of the vehicle is to be raised, either place the jack head under the sump, with a block of wood to prevent damage, or place a jacking beam across the two front points “B” shown in the accompanying illustration, and lift the vehicle evenly.

To raise the rear of the vehicle, place a jacking beam across the two rear points “B” shown in the accompanying illustration, and lift the vehicle evenly.

To raise the side of the vehicle, place the jack head under the appropriate point indicated in the accompanying illustration - if a trolley jack or similar is used on the points “A” provided for the vehicle’s jack, make up a wooden spacer with a groove cut in it to accept the underbody flange, so that there is

no risk of the jack slipping or buckling the flange. Never work under, around or near a raised vehicle unless it is adequately supported in at least two places with axle stands or suitable sturdy blocks.

The vehicle may be towed, for breakdown recovery purposes only, using the towing eyes positioned at the front and rear of the vehicle (see illustrations). These eyes are intended for towing loads only, and must not be used for lifting the vehicle, either directly or indirectly.

Use flat end of wheelbrace to remove trim covering roadwheel nuts

If the vehicle is equipped with automatic transmission, the following precautions must be observed if the vehicle is to be towed, particularly if any kind of transmission fault is suspected. Preferably, a front-end-suspended tow should be used (ie with the front wheels off the ground). If this is not possible, place the selector lever in “N” and tow the vehicle - forwards only, never backwards - for a distance of no more than 30 miles (50 km), and at speeds no greater than 30 mph (50 km/h).

Slacken roadwheel nuts in diagonal sequence

Jacking and supporting points

AJacking points (for vehicle jack in roadside use) - support points (for axle stands in servicing/overhaul work)

BJacking points (for trolley jack or workshop hoist in servicing/overhaul work) - additional support points

With jack base on firm ground, locate jack |

|

|

head in jacking point - indentations |

Front towing eye |

Rear towing eye |

(arrowed) in sill identify jacking points |

0•12 Roadside Repairs

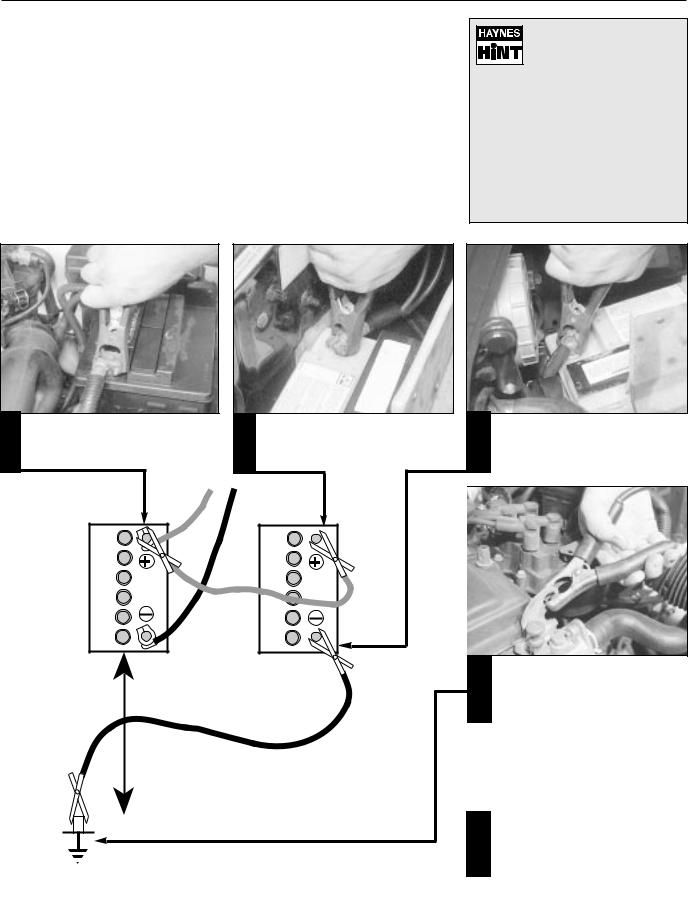

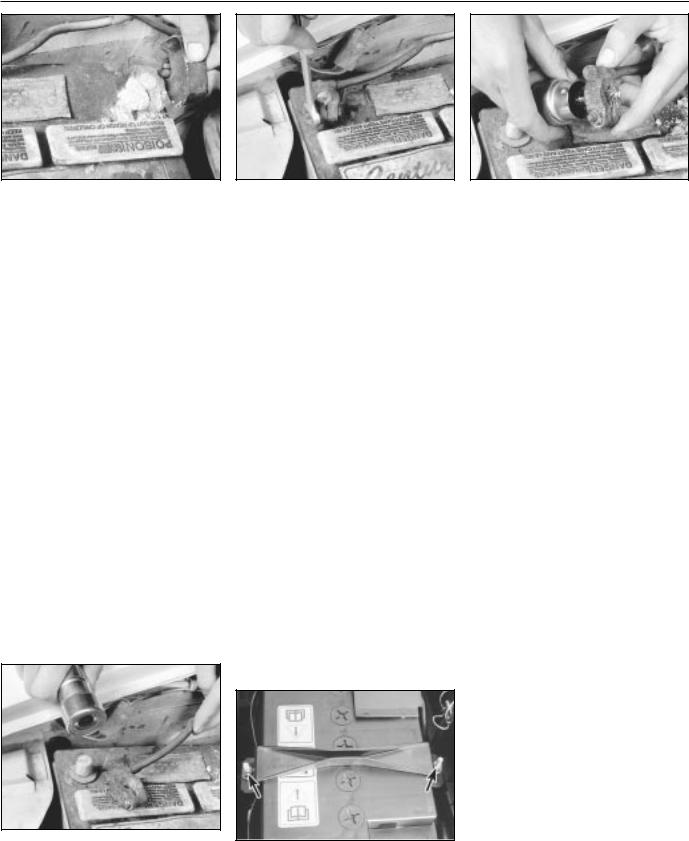

Booster battery (jump) starting

When jump-starting a car using a booster battery, observe the following precautions:

A)Before connecting the booster battery, make sure that the ignition is switched off.

B)Ensure that all electrical equipment (lights, heater, wipers, etc) is switched off.

C)Make sure that the booster battery is the same voltage as the discharged one in the vehicle.

D)If the battery is being jump-started from the battery in another vehicle, the two vehcles MUST NOT TOUCH each other.

E)Make sure that the transmission is in neutral (or PARK, in the case of automatic transmission).

Jump starting will get you out of trouble, but you must correct

whatever made the battery go flat in the first place. There are three possibilities:

1The battery has been drained by repeated attempts to start, or by

leaving the lights on.

2The charging system is not working properly (alternator drivebelt slack

or broken, alternator wiring fault or alternator itself faulty).

3The battery itself is at fault (electrolyte low, or battery worn out).

1

the positive (+) terminal of the flat battery

2 Connect the other end of the red lead to the positive (+) terminal of the booster battery.

3 Connect one end of the black jump lead to the negative (-) terminal of the booster battery

4 jump lead to a bolt or bracket on the

|

|

|

|

|

engine block, well away from the |

|

|

|

|

|

battery, on the vehicle to be started. |

|

|

|

|

|

Make sure that the jump leads will not |

|

|

|

|

5 |

|

|

come into contact with the fan, drive- |

||||

|

|

|

|

|

belts or other moving parts of the |

|

|

|

|

|

engine. |

|

|

|

|

|

Start the engine using the booster |

|

|

|

|

|

|

|

6 |

||||

|

battery, then with the engine running at |

||||

|

|||||

idle speed, disconnect the jump leads in the reverse order of connection.

Roadside Repairs 0•13

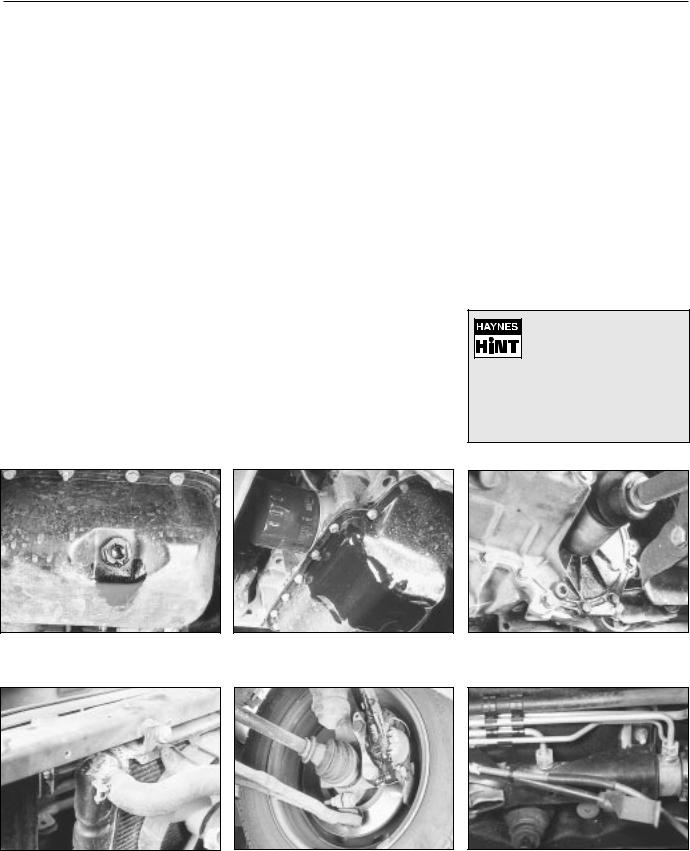

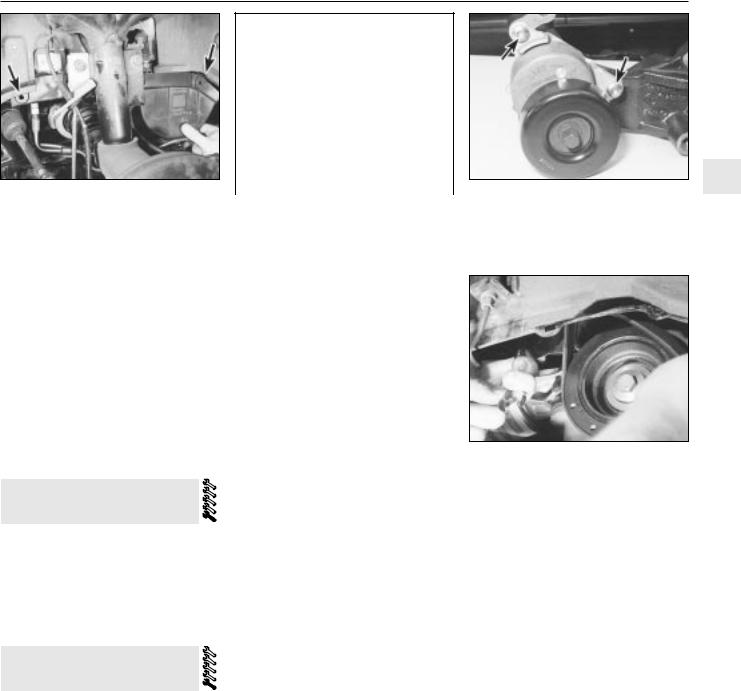

Identifying leaks

Puddles on the garage floor or drive, or obvious wetness under the bonnet or underneath the car, suggest a leak that needs investigating. It can sometimes be difficult to decide where the leak is coming from, especially if the engine bay is very dirty already. Leaking oil or fluid can also be blown rearwards by the passage of air under the car, giving a false impression of where the problem lies.

Warning: Most automotive oils and fluids are poisonous. Wash them off skin, and change out of contaminated clothing, without delay.

The smell of a fluid leaking from the car may provide a clue to what’s leaking. Some fluids are distictively coloured.

It may help to clean the car carefully and to park it over some clean paper overnight as an aid to locating the source of the leak.

Remember that some leaks may only occur while the engine is running.

Sump oil

Engine oil may leak from the drain plug...

Antifreeze

Oil from filter

...or from the base of the oil filter.

Brake fluid

Gearbox oil

Gearbox oil can leak from the seals at the inboard ends of the driveshafts.

Power steering fluid

Leaking antifreeze often leaves a crystalline deposit like this.

A leak occurring at a wheel is almost certainly brake fluid.

Power steering fluid may leak from the pipe connectors on the steering rack.

0•14 Conversion Factors

Length (distance)

Inches (in) |

x 25.4 |

= |

Millimetres (mm) |

x |

0.0394 = |

Inches (in) |

|

Feet (ft) |

x 0.305 |

= |

Metres (m) |

x |

3.281 |

= |

Feet (ft) |

Miles |

x 1.609 |

= |

Kilometres (km) |

x |

0.621 |

= |

Miles |

Volume (capacity)

Cubic inches (cu in; in3) Imperial pints (Imp pt) Imperial quarts (Imp qt) Imperial quarts (Imp qt) US quarts (US qt) Imperial gallons (Imp gal) Imperial gallons (Imp gal) US gallons (US gal)

x |

16.387 = |

Cubic centimetres (cc; cm3) |

|

x |

0.568 |

= |

Litres (l) |

x |

1.137 |

= |

Litres (l) |

x 1.201 |

= |

US quarts (US qt) |

|

x |

0.946 |

= |

Litres (l) |

x |

4.546 |

= |

Litres (l) |

x |

1.201 |

= |

US gallons (US gal) |

x |

3.785 |

= |

Litres (l) |

x |

0.061 |

= Cubic inches (cu in; in3) |

x |

1.76 |

= Imperial pints (Imp pt) |

x |

0.88 |

= Imperial quarts (Imp qt) |

x |

0.833 |

= Imperial quarts (Imp qt) |

x 1.057 |

= US quarts (US qt) |

|

x |

0.22 |

= Imperial gallons (Imp gal) |

x |

0.833 |

= Imperial gallons (Imp gal) |

x |

0.264 |

= US gallons (US gal) |

Mass (weight)

Ounces (oz) |

x |

28.35 |

= |

Grams (g) |

x |

0.035 |

= |

Ounces (oz) |

Pounds (lb) |

x |

0.454 |

= |

Kilograms (kg) |

x |

2.205 |

= |

Pounds (lb) |

Force

Ounces-force (ozf; oz) |

x |

0.278 |

= |

Newtons (N) |

x |

3.6 |

= |

Ounces-force (ozf; oz) |

Pounds-force (lbf; lb) |

x |

4.448 |

= |

Newtons (N) |

x |

0.225 |

= |

Pounds-force (lbf; lb) |

Newtons (N) |

x |

0.1 |

= |

Kilograms-force (kgf; kg) |

x |

9.81 |

= |

Newtons (N) |

Pressure

Pounds-force per square inch |

x |

0.070 |

= |

Kilograms-force per square |

x |

14.223 = |

Pounds-force per square inch |

|

(psi; lbf/in2; lb/in2) |

|

|

|

centimetre (kgf/cm2; kg/cm2) |

|

|

|

(psi; lbf/in2; lb/in2) |

Pounds-force per square inch |

x 0.068 |

= |

Atmospheres (atm) |

x |

14.696 = |

Pounds-force per square inch |

||

(psi; lbf/in2; lb/in2) |

|

|

|

|

|

|

|

(psi; lbf/in2; lb/in2) |

Pounds-force per square inch |

x |

0.069 |

= |

Bars |

x |

14.5 |

= |

Pounds-force per square inch |

(psi; lbf/in2; lb/in2) |

|

|

|

|

|

|

|

(psi; lbf/in2; lb/in2) |

Pounds-force per square inch |

x |

6.895 |

= |

Kilopascals (kPa) |

x |

0.145 |

= |

Pounds-force per square inch |

(psi; lbf/in2; lb/in2) |

|

|

|

|

|

|

|

(psi; lbf/in2; lb/in2) |

Kilopascals (kPa) |

x |

0.01 |

= |

Kilograms-force per square |

x |

98.1 |

= |

Kilopascals (kPa) |

|

|

|

|

centimetre (kgf/cm2; kg/cm2) |

|

|

|

|

Millibar (mbar) |

x |

100 |

= |

Pascals (Pa) |

x |

0.01 |

= |

Millibar (mbar) |

Millibar (mbar) |

x |

0.0145 = |

Pounds-force per square inch |

x |

68.947 = |

Millibar (mbar) |

||

|

|

|

|

(psi; lbf/in2; lb/in2) |

|

|

|

|

Millibar (mbar) |

x |

0.75 |

= |

Millimetres of mercury (mmHg) |

x |

1.333 |

= |

Millibar (mbar) |

Millibar (mbar) |

x |

0.401 |

= |

Inches of water (inH2O) |

x |

2.491 |

= |

Millibar (mbar) |

Millimetres of mercury (mmHg) |

x |

0.535 |

= |

Inches of water (inH2O) |

x |

1.868 |

= |

Millimetres of mercury (mmHg) |

Inches of water (inH2O) |

x |

0.036 |

= |

Pounds-force per square inch |

x |

27.68 |

= |

Inches of water (inH2O) |

|

|

|

|

(psi; lbf/in2; lb/in2) |

|

|

|

|

Torque (moment of force)

Pounds-force inches |

x |

1.152 |

= |

Kilograms-force centimetre |

x |

0.868 |

= |

Pounds-force inches |

(lbf in; lb in) |

|

|

|

(kgf cm; kg cm) |

|

|

|

(lbf in; lb in) |

Pounds-force inches |

x 0.113 |

= |

Newton metres (Nm) |

x 8.85 |

= |

Pounds-force inches |

||

(lbf in; lb in) |

|

|

|

|

|

|

|

(lbf in; lb in) |

Pounds-force inches |

x |

0.083 |

= |

Pounds-force feet (lbf ft; lb ft) |

x |

12 |

= |

Pounds-force inches |

(lbf in; lb in) |

|

|

|

|

|

|

|

(lbf in; lb in) |

Pounds-force feet (lbf ft; lb ft) |

x |

0.138 |

= |

Kilograms-force metres |

x |

7.233 |

= Pounds-force feet (lbf ft; lb ft) |

|

|

|

|

|

(kgf m; kg m) |

|

|

|

|

Pounds-force feet (lbf ft; lb ft) |

x |

1.356 |

= |

Newton metres (Nm) |

x |

0.738 |

= Pounds-force feet (lbf ft; lb ft) |

|

Newton metres (Nm) |

x 0.102 |

= |

Kilograms-force metres |

x 9.804 |

= |

Newton metres (Nm) |

||

|

|

|

|

(kgf m; kg m) |

|

|

|

|

Power

Horsepower (hp) x 745.7 = Watts (W) x 0.0013 = Horsepower (hp)

Velocity (speed)

Miles per hour (miles/hr; mph) x 1.609 = Kilometres per hour (km/hr; kph) x 0.621 = Miles per hour (miles/hr; mph)

Fuel consumption*

Miles per gallon (mpg) x 0.354 = Kilometres per litre (km/l) x 2.825 = Miles per gallon (mpg)

Temperature

Degrees Fahrenheit = (°C x 1.8) + 32 Degrees Celsius (Degrees Centigrade; °C) = (°F - 32) x 0.56

* It is common practice to convert from miles per gallon (mpg) to litres/100 kilometres (l/100km), where mpg x l/100 km = 282

1•1

1

Chapter 1 Routine maintenance and servicing

Contents

Air conditioning system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Air filter element renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . . 7 Automatic transmission linkage lubrication . . . . . . . . . . . . . . . . . . . 18 Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . . . . . . . . . . . 11 Battery check, maintenance and charging . . . . . . . . . . . . . . . . . . . . 9 Brake check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Clutch pedal adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 28 Door and bonnet check and lubrication . . . . . . . . . . . . . . . . . . . . . . 24 Driveshaft rubber gaiter and CV joint check . . . . . . . . . . . . . . . . . . . 20 Electrical system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Engine compartment wiring check . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Engine oil and filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Idle speed and mixture check and adjustment . . . . . . See Chapter 4

Ignition timing check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 5 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Manual transmission oil level check . . . . . . . . . . . . . . . . . . . . . . . . . 16 Positive Crankcase Ventilation (PCV) system check

and filter cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Power steering fluid level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Roadwheel nut tightness check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Seat belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . See end of Chapter Steering, suspension and roadwheel check . . . . . . . . . . . . . . . . . . . 19 Timing belt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Tyre and tyre pressure checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Underbody and fuel/brake line check . . . . . . . . . . . . . . . . . . . . . . . . 22 Underbonnet check for fluid leaks and hose condition . . . . . . . . . . 12 Ventilation system pollen filter renewal . . . . . . . . . . . . . . . . . . . . . . . 27 Windscreen/tailgate washer system and wiper blade check . . . . . . 6

Degrees of difficulty

Easy, suitable for |

Fairly easy, suitable |

Fairly difficult, suitable |

Difficult, suitable for |

Very difficult, |

novice with little |

for beginner with |

for competent DIY |

experienced DIY |

suitable for expert DIY |

experience |

some experience |

mechanic |

mechanic |

or professional |

1•2 Lubricants, Fluids & Capacities

Lubricants and fluids

Component or system |

Lubricant type/specification |

Engine |

Multigrade engine oil to specification API SG/CD or better, viscosity range 5W/50 to 10W/30 |

Manual transmission |

Gear oil to Ford specification ESD-M2C-186-A |

Automatic transmission |

Transmission fluid to Ford specification ESP-M2C-166-H |

Power steering |

Transmission fluid to Ford specification ESP-M2C-166-H |

Cooling system |

Soft water, and antifreeze (ethylene glycol-based, suitable for use in mixed-metal cooling systems) to |

|

Ford specification ESD-M97B-49-A |

Braking system |

Hydraulic fluid to Ford specification ESD-M6C-57-A, Super DOT 4 or equivalent |

Driveshaft joints |

Long-life grease to Ford specification SQM-1C 9004-A |

Capacities

Engine oil:

At oil and filter change . . . . . . . . . . . . . . . . . . . . . . . 4.25 litres Dry - at engine overhaul . . . . . . . . . . . . . . . . . . . . . . 4.50 litres Difference between dipstick minimum and

maximum level notches . . . . . . . . . . . . . . . . . . . . . . 0.5 to 1.0 litre Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61.5 litres

Cooling system:

Manual transmission models . . . . . . . . . . . . . . . . . . 6.6 litres Automatic transmission models . . . . . . . . . . . . . . . 7.1 litres Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6 litres

Automatic transmission:

Total, including fluid cooler . . . . . . . . . . . . . . . . . . . 7.2 litres Drain and refill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6 litres

Maintenance schedule 1•3

Ford Mondeo maintenance schedule

The manufacturer’s recommended maintenance schedule for these vehicles is as described below - note that the schedule starts from the vehicle’s date of registration. These are the minimum maintenance intervals recommended by the factory for Mondeos driven daily, but subjected only to “normal” use. If you wish to keep your vehicle in peak condition at all times, you may wish to perform some of these procedures even more often. Because frequent maintenance enhances the efficiency, performance and resale value of your vehicle, we encourage you to do so. If your usage is not “normal”, shorter intervals are also recommended - the most important examples of these are noted in the schedule. These shorter intervals apply particularly if you drive in dusty areas, tow a caravan or trailer, sit with the engine idling or drive at low speeds for extended periods (ie, in heavy traffic), or drive for short distances (less than four miles) in below-freezing temperatures.

When your vehicle is new, it should be serviced by a Ford dealer service department to protect the factory warranty. In many cases, the initial maintenance check is done at no cost to the owner. Note that this first free service (carried out by the selling dealer 1500 miles or 3 months after delivery), although an important check for a new vehicle, is not part of the regular maintenance schedule, and is therefore not mentioned here.

Weekly checks

mCheck the engine oil level, and top-up if necessary (Section 3)

mCheck the brake fluid level, and top-up if necessary (Section 3). If repeated topping-up is required, check the system for leaks or damage at the earliest possible opportunity (Sections 12 and 22)

mCheck the windscreen/tailgate washer fluid level, and topup if necessary (Section 3)

mCheck the tyre pressures, including the spare (Section 4)

mVisually check the tyres for excessive tread wear, or damage (Section 4)

mCheck the operation of all (exterior and interior) lights and the horn, wipers and windscreen/tailgate washer system (Sections 6 and 8). Renew any blown bulbs (Chapter 12), and clean the lenses of all exterior lights

Monthly checks

mCheck the coolant level, and top-up if necessary (Section 3)

mCheck the battery electrolyte level, where applicable (Section 3)

mCheck the power steering fluid level, and top-up if necessary (Section 5)

mVisually check all reservoirs, hoses and pipes for leakage (Section 12)

mCheck the operation of the air conditioning system (Section 14)

mCheck the operation of the handbrake (Section 23)

mCheck the aim of the windscreen/tailgate/headlight washer jets, correcting them if required (Section 6)

mCheck the condition of the wiper blades, renewing them if worn or no longer effective - note that the manufacturer recommends renewing the blades as a safety precaution, irrespective of their apparent condition, at least once a year (Section 6)

Every 10 000 miles or 12 months, whichever occurs first

Note: If the vehicle is used regularly for very short (less than |

|

10 miles), stop/go journeys, the oil and filter should be renewed |

|

between services (ie, every 5000 miles/6 months). |

|

m Check the electrical system (Section 8) |

|

m Check the battery (Section 9) |

|

m Check the seat belts (Section 10) |

1 |

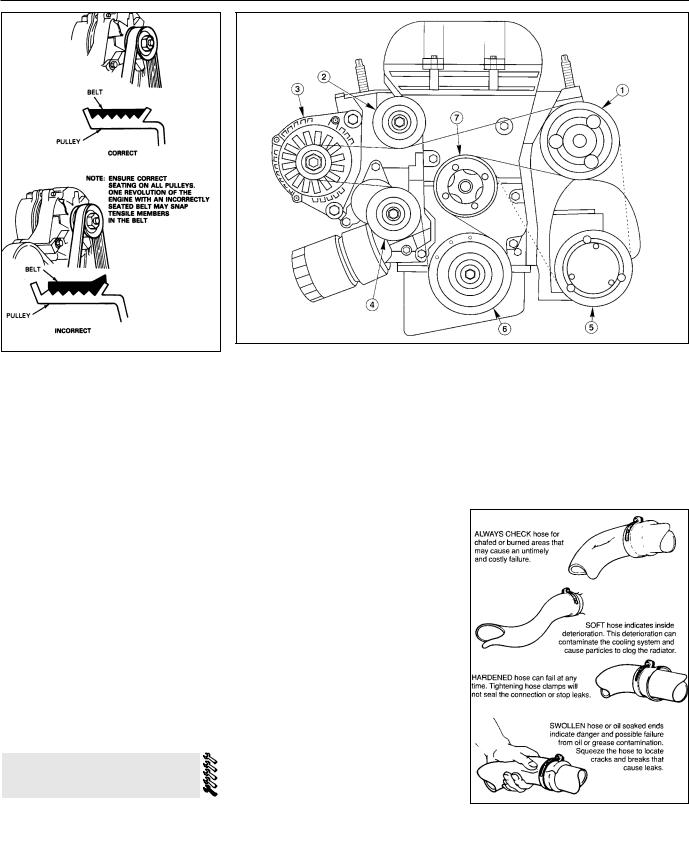

m Check the auxiliary drivebelt (Section 11) |

mCheck for fluid leaks and hose condition (Section 12)

mCheck the condition of all wiring (Section 13)

mCheck all air conditioning components (Section 14)

mChange the engine oil and filter (Section 15)

mCheck the manual transmission oil level (Section 16)

mCheck the adjustment of the clutch pedal (Section 17)

mLubricate the automatic transmission linkage (Section 18)

mCheck the steering, suspension and wheels (Section 19)

mCheck the driveshaft gaiters and CV joints (Section 20)

mCheck the exhaust system (Section 21)

mCheck the underbody, and all fuel/brake lines (Section 22)

mCheck the brake system (Section 23)

mCheck and lubricate the doors and bonnet (Section 24)

mCheck the security of all roadwheel nuts (Section 25)

mRoad test (Section 26). Check the level of the automatic transmission fluid with the engine still hot, after the road test (Section 7)

Every 20 000 miles or 2 years, whichever occurs first

Carry out all operations listed above, plus the following:

mRenew the ventilation system pollen filter (Section 27)

mRenew the coolant (Sections 2 and 28)

Every 30 000 miles or 3 years, whichever occurs first

Carry out all operations listed above, plus the following:

mRenew the air filter element (Section 29). Note that this task must be carried out at more frequent intervals if the vehicle is used in dusty or polluted conditions

mCheck the Positive Crankcase Ventilation (PCV) system, and clean the filter (Section 30)

mRenew the spark plugs (Section 31)

Every 60 000 miles

Carry out all operations listed above, plus the following:

mRenew the timing belt (Section 32)

mRenew the fuel filter (Section 33)

Every 3 years (regardless of mileage)

m Renew the brake fluid (Section 34)

1•4 Maintenance procedures

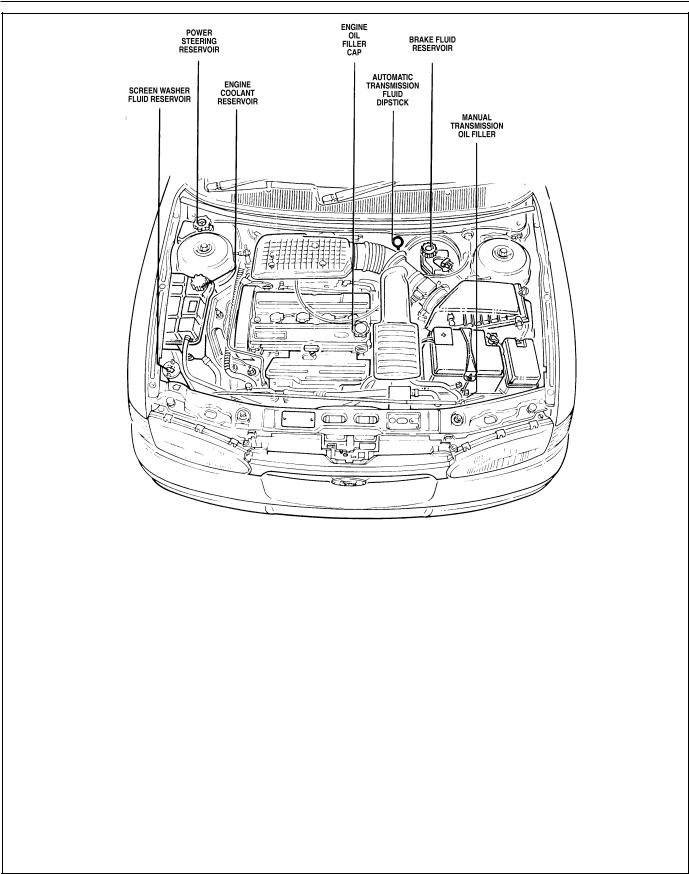

Engine compartment components

1 Spark plugs (Section 31)

2 Engine oil filler cap (Section 3)

3 Brake fluid reservoir (Section 3)

4 Auxiliary fusebox (Chapter 12)

5 Air cleaner assembly (Section 29)

6 Battery (Section 9)

7 Cooling system expansion tank (Section 28)

8 Ventilation system pollen filter - under cowl grille panel (Section 27)

9 Air intake resonator (Chapter 4)

10 Radiator top hose (Section 12)

11 Cooling system expansion tank filler cap (Section 3)

12 Air intake plenum chamber (Chapter 4)

13 Engine oil dipstick (Section 3)

14 Vehicle Identification Number (VIN) plate

15 Windscreen/tailgate washer fluid reservoir (Section 3)

16 Auxiliary drivebelt (Section 11)

17 Power steering fluid reservoir (Section 5)

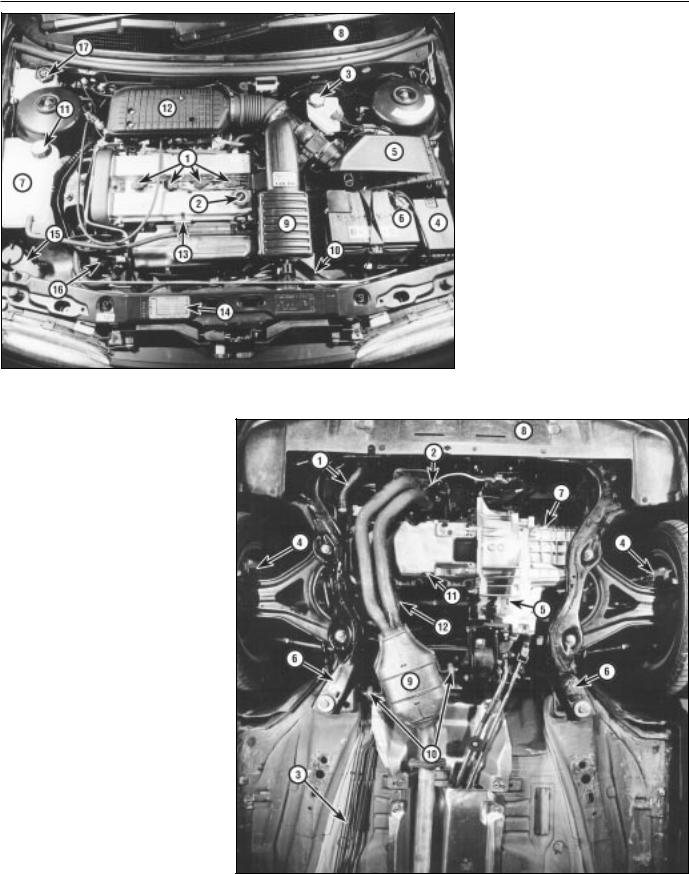

Front underbody view

1Radiator bottom hose (Section 12)

2Exhaust gas oxygen sensor (Chapter 6)

3Braking system, fuel and emission control system lines (Section 22)

4Front disc brake (Section 23)

5Manual transmission drain plug (Chapter 7, Part A)

6Front suspension subframe (Chapter 2, Part B)

7Manual transmission filler/level plug (Section 16)

8Radiator undershield (Section 28)

9Catalytic converter (Section 21)

10Exhaust system rubber mountings (Section 21)

11Engine oil drain plug (Section 15)

12Engine oil filter (Section 15)

Maintenance procedures 1•5

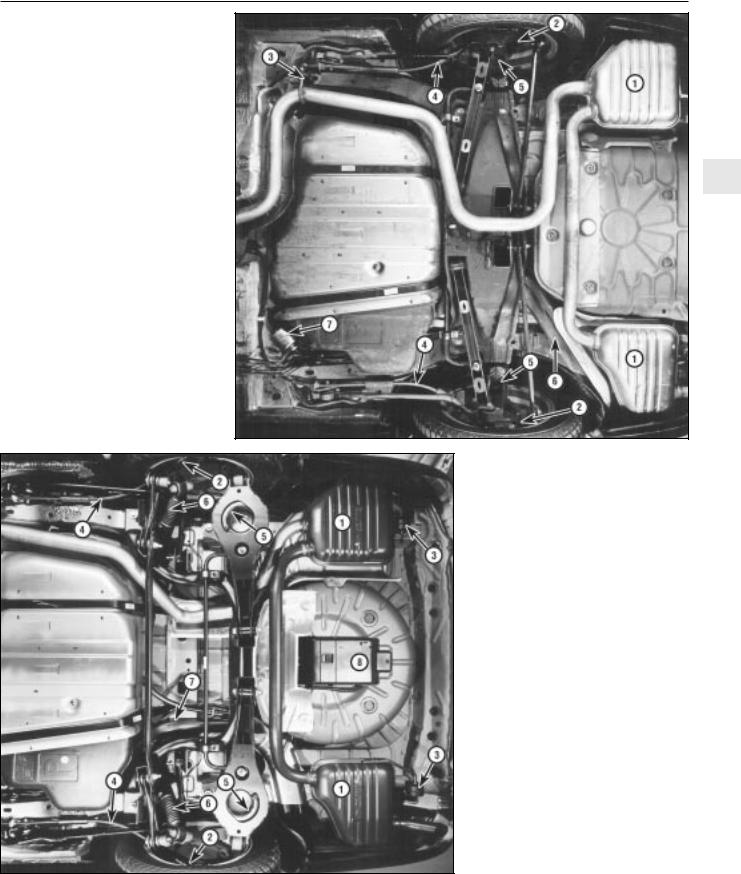

Rear underbody view - Saloon and

Hatchback models

1

1Silencers (Section 21)

2Rear brakes (Section 23)

3Exhaust system rubber mounting (Section 21)

4Handbrake cables (Section 23)

5Suspension struts and springs (Section 19)

6Fuel tank filler neck (Section 22)

7Fuel filter (Section 33)

Rear underbody view - Estate models

1 Silencers (Section 21)

2 Rear brakes (Section 23)

3 Exhaust system rubber mounting (Section 21)

4 Handbrake cables (Section 23)

5 Suspension springs (Section 19)

6 Suspension shock absorbers (Section 19)

7 Fuel tank filler neck (Section 22)

8 Evaporative emissions control system charcoal canister (Chapter 6)

1•6 Weekly checks

1 Introduction

This Chapter is designed to help the home mechanic maintain the Ford Mondeo models for peak performance, economy, safety and long life.

On the following pages are Sections dealing specifically with each item on the maintenance schedule. Visual checks, adjustments, component replacement and other helpful items are included. Refer to the accompanying illustrations of the engine compartment and the underside of the vehicle for the location of various components.

Servicing your Mondeo in accordance with the mileage/time maintenance schedule and the following Sections will provide it with a planned maintenance programme, which should result in a long and reliable service life. This is a comprehensive plan, so maintaining some items but not others at the specified service intervals will not produce the same results.

As you service your Mondeo, you will discover that many of the procedures can - and should - be grouped together, because of the nature of the particular procedure you’re performing, or because of the close proximity to one another of two otherwise-unrelated components.

For example, if the vehicle is raised for any

reason, you should inspect the exhaust, suspension, steering and fuel systems while you’re under the vehicle. When you’re checking the tyres, it makes good sense to check the brakes and wheel bearings, especially if the roadwheels have already been removed.

Finally, let’s suppose you have to borrow or hire a torque wrench. Even if you only need to tighten the spark plugs, you might as well check the torque of as many critical fasteners as time allows.

The first step of this maintenance programme is to prepare yourself before the actual work begins. Read through all the Sections which are relevant to the procedures you’re planning to carry out, then make a list of, and gather together, all the parts and tools you will need to do the job. If it looks as if you might run into problems during a particular segment of some procedure, seek advice from your local parts man or dealer service department.

2 Coolant renewal

Ford state that, where antifreeze to specification ESD-M97B-49-A (the type with which the vehicle’s cooling system would have been filled on production at the factory) is used, it will last the lifetime of the vehicle.

This is subject to it being used in the recommended concentration, unmixed with any other type of antifreeze or additive, and topped-up when necessary using only that antifreeze mixed 50/50 with clean water. If any other type of antifreeze is added, the lifetime guarantee no longer applies; to restore the lifetime protection, the system must be drained and thoroughly reverse-flushed before fresh coolant mixture is poured in.

If the vehicle’s history (and therefore the quality of the antifreeze in it) is unknown, owners who wish to follow Ford’s recommendations are advised to drain and thoroughly reverse-flush the system, as outlined in Section 28, before refilling with fresh coolant mixture. If the appropriate quality of antifreeze is used, the coolant can then be left for the life of the vehicle.

If any antifreeze other than Ford’s is to be used, the coolant must be renewed at regular intervals to provide an equivalent degree of protection; the conventional recommendation is to renew the coolant every two years.

The above assumes the use of a mixture (in exactly the specified concentration) of clean, soft water and of antifreeze to Ford’s specification or equivalent. It is also assumed that the cooling system is maintained in a scrupulously-clean condition, by ensuring that only clean coolant is added on topping-up, and by thorough reverse-flushing whenever the coolant is drained (Section 28).

Weekly checks

3 Fluid level checks

General

1 Fluids are an essential part of the lubrication, cooling, braking and other systems. Because these fluids gradually become depleted and/or contaminated during normal operation of the vehicle, they must be periodically replenished. See “Lubricants and fluids and capacities” at the beginning of this Chapter before adding fluid to any of the following components. Note: The vehicle must be on level ground before fluid levels can be checked.

Engine oil

2 The engine oil level is checked with a dipstick located at the front of the engine; it can be identified by its yellow/black plastic grip (see illustration). The dipstick extends through a metal tube, from which it protrudes down into the sump at the bottom of the engine.

3 The oil level should be checked before the vehicle is driven, or about 5 minutes after the engine has been switched off.

If the level is checked

immediately after driving the

immediately after driving the

vehicle, some of the oil will remain in the engine upper

vehicle, some of the oil will remain in the engine upper

components, producing an inaccurate dipstick reading.

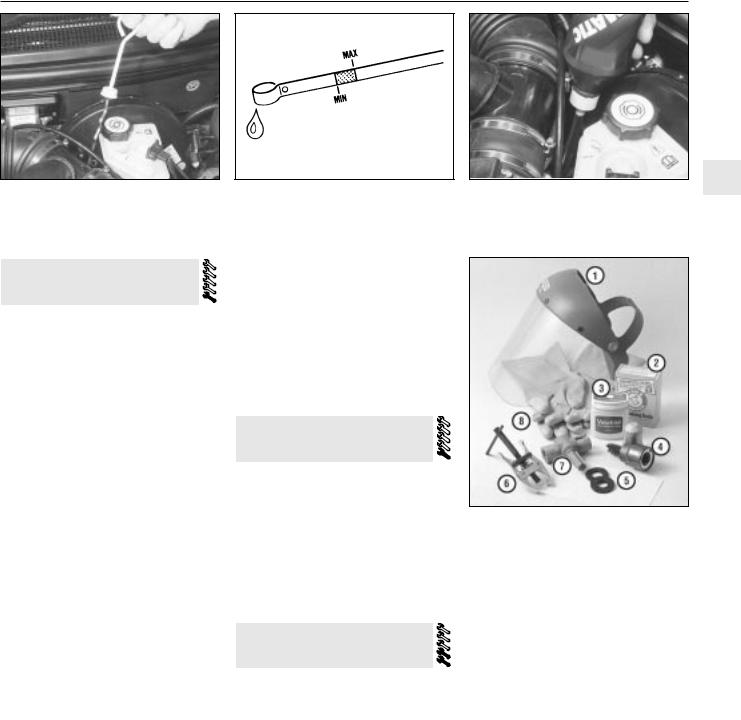

4 Pull the dipstick from the tube, and wipe all the oil from the end with a clean rag or paper towel; note the dipstick’s maximum and minimum levels, indicated by notches (see

3.2 The engine oil dipstick (arrowed) is located at the front of the engine - note yellow/black plastic grip

illustration). Insert the clean dipstick all the way back into its metal tube, and pull it out again. Observe the oil on the end of the dipstick; its level should be between these two notches.

5 Do not allow the level to drop below the minimum level notch, or oil starvation may cause engine damage. Conversely, overfilling the engine (adding oil above the maximum level notch) may cause oil-fouled spark plugs, oil leaks or oil seal failures.

6 The yellow/black plastic oil filler cap is screwed into the left-hand front end of the

3.4 The oil level should be at or near the maximum level notch (A) - if not, add enough oil to correct the level. It takes approximately 0.5 to 1.0 litre of oil to raise the level from the minimum level notch (B) to the maximum

Weekly checks 1•7

1

3.6 The yellow/black oil filler cap is screwed into the cylinder head cover. Always make sure the area around the opening is clean before unscrewing the cap, to prevent dirt from contaminating the engine

cylinder head cover; unscrew it to add oil (see illustration). When topping-up, use only the correct grade and type of oil, as given in the Specifications Section of this Chapter; use a funnel if necessary to prevent spills. It takes approximately 0.5 to 1.0 litre of oil to raise the level from the dipstick’s minimum level notch to its maximum level notch. After adding the oil, refit the filler cap hand-tight. Start the engine, and allow it to idle while the oil is redistributed around the engine - while you are waiting, look carefully for any oil leaks, particularly around the oil filter or drain plug. Stop the engine; check the oil level again, after the oil has had enough time to drain from the upper block and cylinder head galleries.

7 Checking the oil level is an important preventive maintenance step. A continuallydropping oil level indicates oil leakage through damaged seals and from loose connections, or oil consumption past worn piston rings or valve guides. If the oil looks milky in colour, or has water droplets in it, the cylinder head gasket may be blown - the engine’s compression pressure should be checked immediately (see Chapter 2A). The condition of the oil should also be checked. Each time you check the oil level, slide your thumb and index finger up the dipstick before wiping off the oil. If you see small dirt or metal particles clinging to the dipstick, the oil should be changed (Section 15).

Coolant

Warning: Do not allow antifreeze to come in contact with your skin or painted surfaces of the

vehicle. Flush contaminated areas immediately with plenty of water. Don’t store new coolant, or leave old coolant lying around, where it’s accessible to children or pets - they’re attracted by its sweet smell. Ingestion of even a small amount of coolant can be fatal! Wipe up garage-floor and drip-pan spills immediately. Keep antifreeze containers covered, and repair cooling system leaks as soon as they’re noticed.

3.10 The cooling system expansion tank is located on the right-hand side of the engine compartment. The coolant level must be between the tank “MAX” and “MIN” level lines (arrowed) when the engine is cold

8 All vehicles covered by this manual are equipped with a sealed, pressurised cooling system. A translucent plastic expansion tank, located on the right-hand side of the engine compartment, is connected by a hose to the thermostat housing. As the coolant heats up during engine operation, surplus coolant passes through the connecting hose into the expansion tank; a connection to the radiator bottom hose union allows coolant to circulate through the tank and back to the water pump, thus purging any air from the system. As the engine cools, the coolant is automatically drawn back into the cooling system’s main components, to maintain the correct level.

9While the coolant level must be checked regularly, remember therefore that it will vary with the temperature of the engine. When the engine is cold, the coolant level should be between the “MAX” and “MIN” level lines on the tank, but once the engine has warmed up, the level may rise to above the “MAX” level line.

10For an accurate check of the coolant level, the engine must be cold. The level must be between the “MAX” and “MIN” level lines on the tank (see illustration). If it is below the “MIN” level line, the coolant must be toppedup as follows.

11First prepare a sufficient quantity of coolant mixture, using clean, soft water and antifreeze of the recommended type, in the specified mixture ratio. If you are using antifreeze to Ford’s specification or equivalent (see the note at the beginning of Section 2 of this Chapter), mix equal quantities of water and antifreeze to produce the 50/50 mixture ratio specified when topping-up; if using any other type of antifreeze, follow its manufacturer’s instructions to achieve the correct ratio. If only a small amount of coolant is required to bring the system up to the proper level, plain water can be used, but repeatedly doing this will dilute the antifreeze/water solution in the system, reducing the protection it should provide against freezing and corrosion. To maintain

3.13 Remove the cap to add coolant only when the engine is cold - top-up to the “MAX” level line using the specified coolant mixture

the specified antifreeze/water ratio, it is essential to top-up the coolant level with the correct mixture, as described here. Use only ethylene/glycol type antifreeze, and do not use supplementary inhibitors or additives.

Warning: Never remove the expansion tank filler cap when the engine is running, or has just

been switched off, as the cooling system will be hot, and the consequent escaping steam and scalding coolant could cause serious injury.

12If topping-up is necessary, wait until the system has cooled completely (or at least 10 minutes after switching off the engine, if lack of time means it is absolutely necessary to top-up while the engine may still be warm). Wrap a thick cloth around the expansion tank filler cap, and unscrew it one full turn. If any hissing is heard as steam escapes, wait until the hissing ceases, indicating that pressure is released, then slowly unscrew the filler cap until it can be removed. If more hissing sounds are heard, wait until they have stopped before unscrewing the filler cap completely. At all times, keep your face, hands and other exposed skin well away from the filler opening.

13When the filler cap has been removed, add coolant to bring the level up to the “MAX” level line (see illustration). Refit the cap, tightening it securely.

14With this type of cooling system, the addition of coolant should only be necessary at very infrequent intervals. If topping-up is regularly required, or if the coolant level drops within a short time after replenishment, there may be a leak in the system. Inspect the radiator, hoses, expansion tank filler cap, radiator drain plug and water pump. If no leak is evident, have the filler cap and the entire system pressure-tested by your dealer or suitably-equipped garage; this will usually show up a small leak not otherwise visible. If significant leakage is found at any time, use an antifreeze hydrometer to check the concentration of antifreeze remaining in the coolant.

1•8 Weekly checks

3.17 Topping-up the windscreen washer reservoir

15 Coolant hydrometers are available at most automotive accessory shops. If the specific gravity of a sample taken from the expansion tank (when the engine is switched off and fully cooled down) is less than that specified, the coolant mixture strength has fallen below the minimum. If this is found, either the coolant strength must be restored by adding neat antifreeze to Ford’s specification (if that is what is in the system) or by draining and flushing the system, then refilling it with fresh coolant mixture of the correct ratio (if any other type of antifreeze is being used).

16 When checking the coolant level, always note its condition; it should be relatively clear. If it is brown or rust-coloured, the system should be drained, flushed and refilled. If antifreeze has been used which does not meet Ford’s specification, its corrosion inhibitors will lose their effectiveness with time; such coolant must be renewed regularly, even if it appears to be in good condition, usually at the intervals suggested at the beginning of Section 2 of this Chapter.

Windscreen/tailgate and headlight washer fluid

17 Fluid for the windscreen/tailgate washer system (and where applicable the headlight washer system) is stored in a plastic reservoir, which is located at the right front corner of the engine compartment. In milder climates, plain water can be used to top-up the reservoir, but the reservoir should be kept no more than two-thirds full, to allow for expansion should the water freeze. In colder climates, the use of a specially-formulated windscreen washer fluid, available at your dealer or any car accessory shop, will help lower the freezing point of the fluid (see illustration). Do not use regular (engine) antifreeze - it will damage the vehicle’s paintwork.

Battery electrolyte

18 On models not equipped with a sealed battery (see Section 9), check the electrolyte level of all six battery cells. The level must be approximately 10 mm above the plates; this may be shown by maximum and minimum level lines marked on the battery’s casing (see

3.18 On non-sealed batteries, keep the electrolyte level of all the cells in the battery between the maximum and minimum levels (arrowed) - ie, 10 mm above the plates. Use only distilled water, and never overfill

illustration). If the level is low, use a coin to release the filler/vent cap, and add distilled water. Install and securely retighten the cap.

Caution: Overfilling the cells may cause electrolyte to spill over during periods of heavy charging, causing corrosion or damage.

Refer also to the warning at the beginning of Section 9.

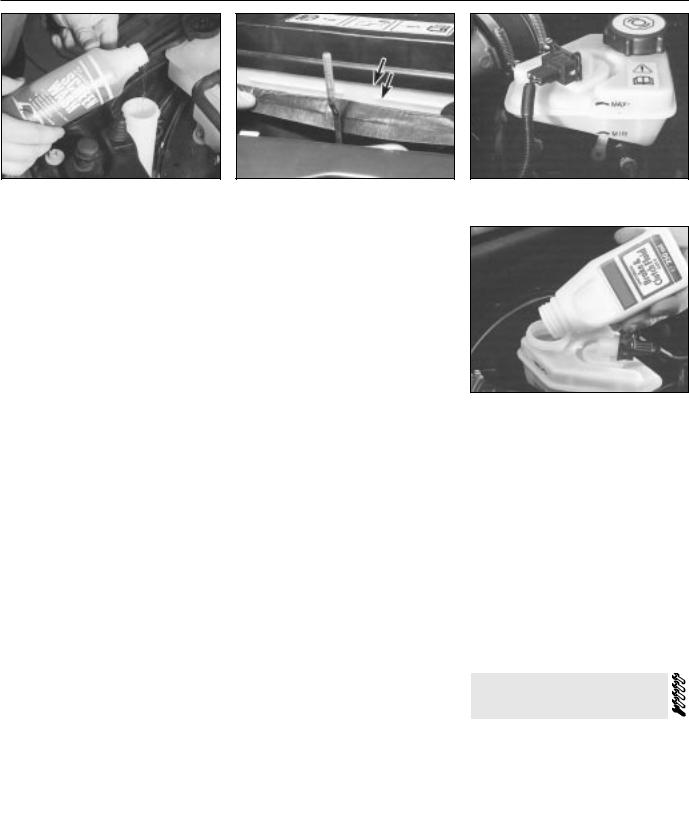

Brake fluid

19The brake fluid reservoir is located on the top of the brake master cylinder, which is attached to the front of the vacuum servo unit. The “MAX” and “MIN” marks are indicated on the side of the translucent reservoir, and the fluid level should be maintained between these marks at all times (see illustration).

20The brake fluid inside the reservoir is readily visible. With the vehicle on level ground, the level should normally be on or just below the “MAX” mark.

21Progressive wear of the brake pads and brake shoe linings causes the level of the brake fluid to gradually fall; however, when the brake pads are renewed, the original level of the fluid is restored. It is not therefore necessary to top-up the level to compensate for this minimal drop, but the level must never be allowed to fall below the minimum mark.

22If topping-up is necessary, first wipe the area around the filler cap with a clean rag before removing the cap. When adding fluid, pour it carefully into the reservoir, to avoid spilling it on surrounding painted surfaces (see illustration). Be sure to use only the specified hydraulic fluid (see “Lubricants, fluids and capacities” at the start of this Chapter) since mixing different types of fluid can cause damage to the system.

Warning: Brake hydraulic fluid can harm your eyes and damage painted surfaces, so use extreme caution when handling and

pouring it. Wash off spills immediately with plenty of water. Do not use fluid that has been standing open for some time, as it absorbs moisture from the air. Excess

3.19 Brake fluid reservoir, showing “MAX” and “MIN” marks

3.22 Topping-up the brake fluid reservoir

moisture can cause corrosion and a dangerous loss of braking effectiveness.

23When adding fluid, it is a good idea to inspect the reservoir for contamination. The system should be drained and refilled if deposits, dirt particles or contamination are seen in the fluid.

24After filling the reservoir to the correct level, make sure that the cap is refitted securely, to avoid leaks and the entry of foreign matter.

25If the reservoir requires repeated replenishing to maintain the correct level, this is an indication of an hydraulic leak somewhere in the system, which should be investigated immediately.

Power steering fluid

26 See Section 5 of this Chapter.

4 Tyre and tyre pressure checks

1Periodic inspection of the tyres may spare you from the inconvenience of being stranded with a flat tyre. It can also provide you with vital information regarding possible problems in the steering and suspension systems before major damage occurs.

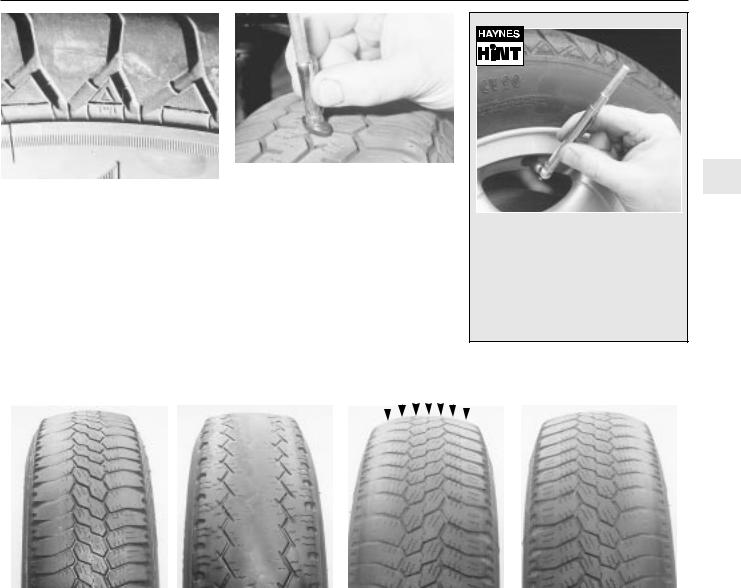

2The original tyres on this vehicle are equipped with tread wear indicator (TWI) bands, which will appear when the tread depth reaches approximately 1.6 mm. Most tyres have a mark around the tyre at regular intervals to indicate the location of the tread

Weekly checks 1•9

|

|

|

|

|

4.2B A tyre tread depth indicator should |

4.2A The TWI mark on the side of the tyre |

|

be used to monitor tyre wear - they are |

|

available at accessory shops and service |

|

shows the position of the tread wear |

|

|

|

stations, and cost very little |

|

indicator bands |

|

|

|