Page 1

®

Worthington

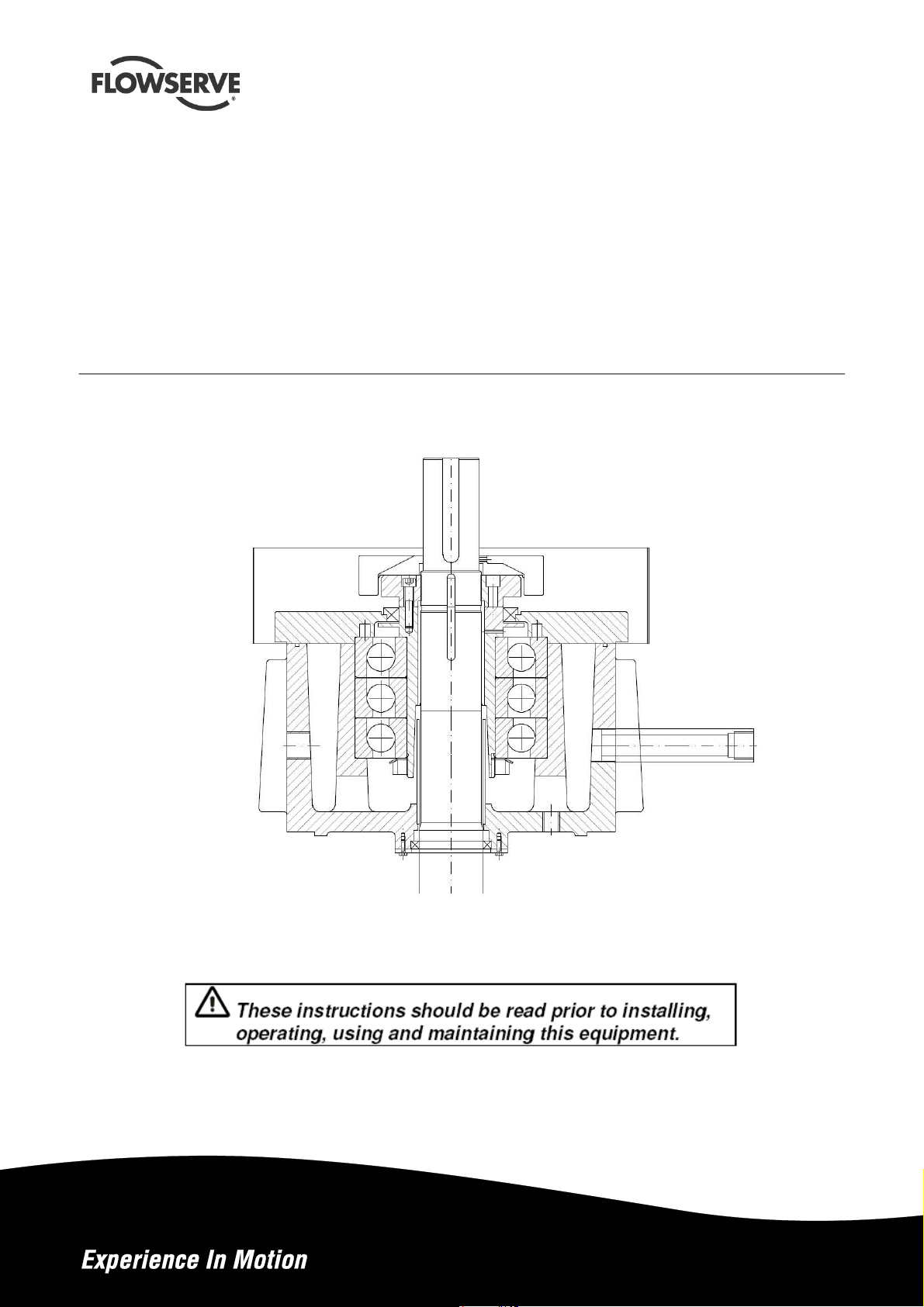

N-Series of Thrust Pot

for Vertical, Multistage Pumps

USER INSTRUCTIONS

Installation

Operation

Original Instructions

PCN= 26999948 07-14 (E)

Maintenance

Page 2

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

CONTENTS

PAGE

1.0 INTRODUCTION AND SAFETY ............................ 3

1.1 G

ENERAL

1.2 CE

1.3 D

ISCLAIMER

1.4 C

OPYRIGHT

1.5 D

UTY CONDITIONS

1.6 S

AFETY

................................................................. 3

MARKING AND APPROVALS

................................ 3

............................................................. 3

............................................................. 3

................................................... 3

.................................................................... 4

2.0 TRANSPORT AND STORAGE ............................. 7

2.1 C

ONSIGNMENT RECEIPT AND UNPACKING

2.2 H

ANDLING

2.3 L

IFTING

2.4 S

TORAGE

2.5 R

ECYCLING AND END OF PRODUCT LIFE

................................................................ 7

.................................................................... 7

................................................................. 7

............... 7

................. 7

3.0 COMMISSIONING START-UP, OPERATION

AND SHUTDOWN .......................................................... 8

3.1 P

UMP LUBRICANTS

3.2 O

PERATION

.................................................. 8

............................................................ 10

4.0 MAINTENANCE ..................................................... 10

4.1 G

ENERAL

4.2 M

AINTENANCE SCHEDULE

4.3 S

PARE PARTS

4.4 R

ECOMMENDED SPARES

4.6 D

ISASSEMBLY

4.7 A

SSEMBLY

............................................................... 10

..................................... 10

........................................................ 10

....................................... 11

........................................................ 12

............................................................. 12

5.0 FAULTS; CAUSES AND REMEDIES ................ 13

6.0 PARTS LIST AND DRAWINGS ........................... 14

6.1 A

6.2 A

6.3 A

SSEMBLY

SSEMBLY

SSEMBLY

0N-1N ................................................. 14

3N-7N ................................................. 15

8N ....................................................... 16

7.0 CERTIFICATION .................................................... 17

8.0 OTHER RELEVANT DOCUMENTATION AND

MANUALS ..................................................................... 17

8.1 S

UPPLEMENTARY USER INSTRUCTIONS

8.2 C

HANGE NOTES

8.3 A

DDITIONAL SOURCES OF INFORMATION

8.4 A

BBREVIATIONS

..................................................... 17

..................................................... 18

................ 17

.............. 17

Page 2 of 20

Page 3

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

1.0 INTRODUCTION AND SAFETY

instructions. Where applicable this document

incorporates information relevant to these Directives.

To establish Approvals and if the product itself is CE

Marked check the serial number plate and the

Certification.

1.1 General

These Instructions must always be kept

close to product's operating location or directly

with the product.

Flowserve's products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great care

and commitment to continuous quality control,

utilizing sophisticated quality techniques, and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not take

into account local regulations; ensure such regulations

are observed by all, including those installing the

product. Always coordinate repair activity with

operations personnel, and follow all plant safety

requirements and applicable safety and health

laws/regulations.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The equipment

must not be put into service until all the conditions

relating to safety, noted in the instructions, have

been met. Failure to follow and apply the present

user instructions is considered to be misuse.

Personal injury, product damage, delay or failure

caused by misuse are not covered by the Flowserve

warranty.

1.3 Disclaimer

Information in these User Instructions is believed to

be complete and reliable. However, in spite of all of

the efforts of Flowserve Corporation to provide

comprehensive instructions, good engineering and

safety practice should always be used.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality

Assurance organizations. Genuine parts and

accessories have been designed, tested and

incorporated into the products to help ensure their

continued product quality and performance in use. As

Flowserve cannot test parts and accessories sourced

from other vendors the incorrect incorporation of such

parts and accessories may adversely affect the

performance and safety features of the products. The

failure to properly select, install or use authorized

Flowserve parts and accessories is considered to be

misuse. Damage or failure caused by misuse is not

covered by Flowserve's warranty. In addition, any

modification of Flowserve products or removal of

original components may impair the safety of these

products in their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without prior

permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

1.2 CE marking and approvals

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

Marking Directives covering Machinery and, where

applicable, Low Voltage Equipment, Electromagnetic

Compatibility (EMC), Pressure Equipment Directive

(PED) and Equipment for Potentially Explosive

Atmospheres (ATEX).

Where applicable the Directives, and any additional

Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory

provision of technical documents and safety

Page 3 of 20

The product must not be operated beyond

the parameters specified for the application. If

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial number.

If the conditions of service on your purchase order

are going to be changed (for example liquid pumped,

temperature or duty) it is requested that the user

seeks Flowserve´s written agreement before start up.

Page 4

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

1.6 Safety

1.6.1 Summary of safety markings

These user instructions contain specific safety

markings where non-observance of an instruction

would cause hazards. The specific safety markings

are:

This symbol indicates electrical safety instructions

where non-compliance will involve a high risk to

personal safety or the loss of life.

This symbol indicates safety instructions

where non-compliance would affect personal safety

and could result in loss of life.

This symbol indicates "hazardous and toxic

fluid" safety instructions where non-compliance would

affect personal safety and could result in loss of life.

instructions where non-compliance will involve some

risk to safe operation and personal safety and would

damage the equipment or property.

field" safety instructions where non-compliance would

affect personal safety, pacemakers, instruments or

stored data sensitive to magnetic fields.

This symbol indicates explosive atmosphere

marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

indicates an important instruction in the assembly

process.

This symbol indicates potential risks

connected with extremely high temperatures.

This symbol indicates safety

This symbol indicates "strong magnetic

The sign is not a safety symbol but

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the manufacturer / supplier

to provide applicable training.

Always co-ordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws/regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

help prevent injury to personnel and damage to

the environment and to equipment. For products

used in potentially explosive atmospheres

section 1.6.4 also applies.

NEVER DO MAINTENANCE WORK WHILST THE

UNIT IS CONNECTED TO POWER

GUARDS MUST NOT BE REMOVED WHILE

PUMP IS OPERATIONAL

MOTOR ROTATION WITH COUPLING ELEMENT/

PINS REMOVED

Starting in reverse direction of rotation will damage

the pump.

LUBRICATION (See section 3.0, Commissioning,

startup, operation and shutdown.)

ABNORMALLY HIGH OR LOW FLOW RATES

Operating at a flow rate higher than normal or at a flow

rate with no back pressure on the pump may overload

the motor and cause cavitation. Low flow rates may

cause a reduction in pump/bearing life, overheating of

the pump, instability and cavitation/vibration.

ONLY CHECK DIRECTION OF

ENSURE CORRECT

NEVER RUN THE PUMP DRY

DO NOT RUN THE PUMP AT

This symbol indicates potential risks

connected with extremely low temperatures.

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lbs) use a crane

Page 4 of 20

HANDLING COMPONENTS

Page 5

Temperature class

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

corresponding to the mass and in accordance with

current local regulations.

HOT AND COLD PARTS

If hot or freezing components or auxiliary heating

supplies can present a danger to operators, they

must be shielded to avoid accidental contact. If

complete protection is not possible, the machine

access must be limited to maintenance staff only.

Bearing housings must not be insulated

and drive motors and bearings may be hot.

If the temperature is greater than 80 °C (175 °F) o r

below -5 °C (20 °F) in a restricted zone, or

exceeds local regulations, action as above shall

be taken.

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

• Avoid excess temperature

• Prevent dry running

• Prevent the generation of sparks

• Maintain the pump to avoid hazard

The following instructions for pumps and pump units

when installed in potentially explosive atmospheres

must be followed to help ensure explosion protection.

For ATEX, both electrical and non-electrical equipment

must meet the requirements of European Directive

94/9/EC. Always observe the regional legal Ex

requirements eg Ex electrical items outside the EU may

be required certified to other than ATEX eg IECEx, UL.

1.6.4.1 Scope of compliance

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive

coupling assembly, seal and pump equipment are

suitably rated and/or certified for the classification of the

specific atmosphere in which they are to be installed.

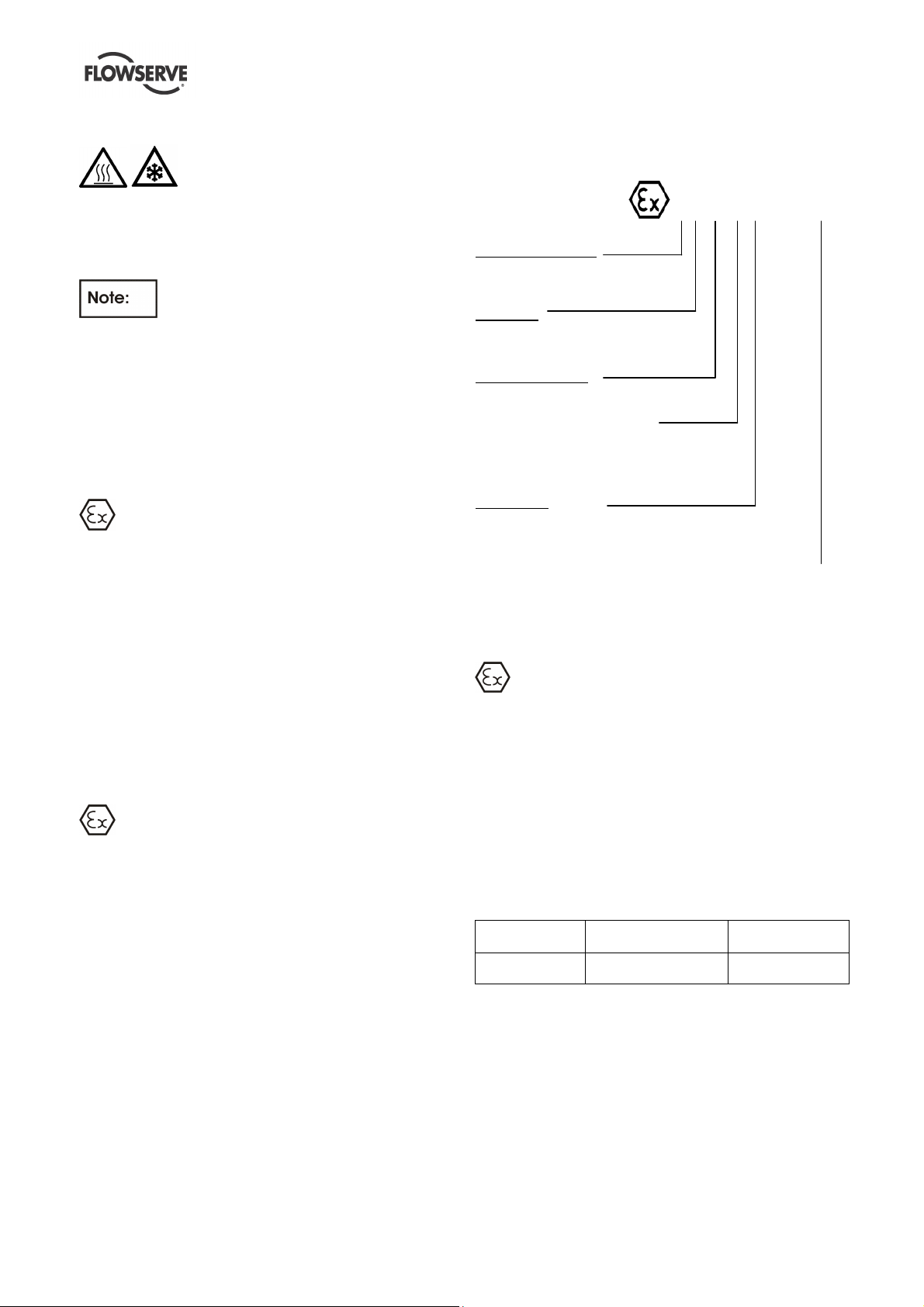

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

II 2 GD c IIC135ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = High level protection

3 = normal level of protection

Gas and/or Dust

G = Gas; D= Dust

c = Constructional safety

(in accordance with EN13463-5)

b = Control of ignition source

(in accordance with EN13463-6)

Gas Group

IIA – Propane (Typical)

IIB – Ethylene (Typical)

IIC – Hydrogen (Typical)

Maximum surface temperature (Temperature Class)

(see section 1.6.4.3)

1.6.4.3 Avoiding excessive surface

temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

Pumps have a temperature class as stated in the

ATEX Ex rating on the nameplate. These are based

on a maximum ambient of 40 ºC (104 ºF); refer to

Flowserve for higher ambient temperatures.

The surface temperature on the pump is influenced

by the temperature of the liquid handled. The

maximum permissible liquid temperature depends on

the temperature class and must not exceed the

values in the table that follows.

to EN13463-1

T6

T5

* The table only takes the ATEX temperature class into consideration.

Pump design or material, as well as component design or material,

may further limit the maximum working temperature of the liquid.

Maximum surface

temperature permitted

85 °C (185 °F)

100 °C (212 °F)

Temperature limit of

liquid handled *

Consult Flowserve

Consult Flowserve

The temperature rise at the seals and bearings and

due to the minimum permitted flow rate is taken into

account in the temperatures stated.

The responsibility for compliance with the

specified maximum liquid temperature is with the

plant operator.

Temperature classification “Tx” is used when the

liquid temperature varies and the pump could be

Page 5 of 20

Page 6

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

installed in different hazarous atmospheres. In this

case the user is responsible for ensuring that the

pump surface temperature does not exceed that

permitted in the particular hazardous atmosphere.

If an explosive atmosphere exists during the

installation, do not attempt to check the direction of

rotation by starting the pump unfilled. Even a short

run time may give a high temperature resulting from

contact between rotating and stationary components.

Where there is any risk of the pump being run against

a closed valve generating high liquid and casing

external surface temperatures, fit an external surface

temperature protection device.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips, temperature monitor or a

power monitor and make routine vibration monitoring

checks.

In dirty or dusty environments, make regular checks

and remove dirt from areas around close clearances,

bearing housings and motors.

1.6.4.4 Preventing dry running

adversely affect the ambient conditions. Where there

is a risk from such tools or materials, maintenance

must be conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted. (See section 4.0,

Maintenance.)

ENSURE THAT THE THRUST POT IS

PROPERLY FILLED ANS DOES NOT RUN DRY

Ensure that the oil level is as per section 3.1.4.

The bearing temperature shall be monitored by

means of a PT 100, surface contact type.

1.6.4.5 Preventing sparks

To prevent a potential hazard from mechanical

contact, the coupling guard must be non-sparking.

To avoid the potential hazard from random induced

current generating a spark, the baseplate must be

properly grounded.

Avoid electrostatic charge: do not rub non-metallic

surfaces with a dry cloth; ensure cloth is damp.

For ATEX application sthe coupling must be selected

to comply with 94/9/EC. Correct coupling alignment

must be maintained.

1.6.4.6 Maintenance to avoid the hazard

CORRECT MAINTENANCE IS REQUIRED TO

AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

The responsibility for compliance with maintenance

instructions is with the plant operator.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting

materials used must not give rise to sparking or

Page 6 of 20

Page 7

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

2.0 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery/shipping documents for

its completeness and that there has been no damage

in transportation. Any shortage and/or damage must

be reported immediately to Flowserve Pump Division

and must be received in writing within one month of

receipt of the equipment. Later claims cannot be

accepted.

Check any crate, boxes or wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to side

walls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as well

as when ordering spare parts or further accessories.

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork lift vehicles or slings dependent on their

size and construction.

2.3 Lifting

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

regulations at all times.

A crane must be used for all pump sets in

excess of 25 kg (55 lb.). Fully trained personnel must

carry out lifting, in accordance with local regulations.

Before lifting the driver alone, refer to the

manufacturer’s instructions.

2.4 Storage

Store the unit in a clean, dry location

away from vibration. Leave protective covers and

plugs in place to keep dirt and other foreign material

out of the unit. Turn shaft at intervals to prevent false

brinelling of the bearings.

The unit may be stored as above for up to 6 months.

Consult Flowserve for preservative actions when a

longer storage period is needed.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and local requirements. If the

product contains substances that are harmful to the

environment, these should be removed and disposed

of in accordance with current regulations. This also

includes the liquids and/or gases that may be used in

the "seal system" or other utilities.

Page 7 of 20

Page 8

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

3.0 COMMISSIONING START-UP,

OPERATION AND SHUTDOWN

These operations must be

carried out by fully qualified personnel.

3.1 Pump Lubricants

3.1.1 Lubrication

The bearing housing shall be filled with proper

lubricating oil prior to start up. If the pump will be

started after a longer storage period, the bearing

housing should be first flushed and cleaned with

gasoline. It is not necessary to remove the

preservation oil as this will mix up thoroughly with the

lubrication oil.

Lubrication is provided by the pumping effect of the

rotating ball bearings. Maintaining the correct oil level

(middle of the oil sight glass) ensures that the lower

ball bearing is covered with oil.

As option a ¼” NPT connection for a purge oil mist

lubrication is provided (refer to General Arrangement

Drawing).

For recommended lubricating oils refer to the

lubrication table.

3.1.2 Purge oil mist lubrication

For preventing, that dirt or humidity get into the bearing

housing, this pump is equipped with a ¼“ NPT

connection for air or nitrogen supply.

Also at standstill the air or nitrogen supply shall be

maintained.

The pressure shall be between

0.01 bar (0.14 psi) and 0.02 bar (0.29 psi), otherwise

you have to consider an oil leakage and as a result a

bearing damage .

The provided flow rate shall be 0,1 SCFM.

The supplied air or nitrogen shall be clean and dry.

3.1.3 Oil change

After first start up, the oil shall be changed after 200

service hours.

Every further oil change shall take place after about

2000 service hours or at least every 6 month.

3.1.4 Oil level

The correct oil level is in the middle of the oil sight glass

and shall be checked when pump is not in operation.

Periodically check if the lubricating oil is mixed with any

condensed water. Careful opening of the oil drain

during a stop of the pump will show any water.

During operation the level will decrease

due to circulation of the oil through the bearings.

A too high oil level will result in higher bearing

temperatures and therefore poorer lubrication.

3.1.5 Oil quality

Oil used for lubrication should only be of high quality.

The viscosity of the oil at working temperature must

be at least 10 cSt. The pouring point of the oil must

be in accordance with the lowest expected

temperature of the bearing housing during a stop of

the pump. For recommended lubricating oils refer to

the lubrication table.

Having selected the corresponding oil quality the

actual oil temperature at the bearing housing must be

checked after two service hours of the pump.

Considering this measured oil temperature the actual

viscosity must be determined by using the data sheet

of the oil, to verify the minimum required viscosity of

10 cSt. Do not forget, the oil temperature in the

bearing itself is about 10 °C ( ∆ 18°F) higher than the

oil temperature at the bearing housing. On the

following table the oil viscosity is given at 40 °C

(104 °F). Determining the correct lubricating oil one

must take into consideration that all bearings will

have higher temperatures during the first 20 service

hours. In constant operation the bearing temperature

will decrease about 10 °C (50 °F). The oil

temperature shall be lower than 85 °C (185 °F) afte r

this running-in time. The bearing outer race

temperature should not exceed 95°C (204°F). If the

temperature is higher, the reason may be a wrong oil

quality, wrong oil level or overload of the pump

because of excessive wear.

If the humidity at the site is high, the roller bearings

become easily rusty during stand still periods. To

avoid that, we recommend mixing the lubricating oil

with a corrosion inhibitor contact your lubrication oil

supplier for proper additives inhibitors.

3.1.6 Oil quantity

Bearing size is shown on the name plate of the

pump, and with this the correct thrust bearing frame

can be selected according to the following table.

Thrust bearing No. Oil quantity l (Fl.oz.) Bearing size

0 N 0.5 (16.9) 7210 BECBJ

1 N 1.5 (50.7) 7313 BECBJ

3 N 2 (67.6) 7315 BECBJ

4 N 2.5 (84.5) 7317 BECBJ

5 N 3 (101.4) 7318 BECBJ

6 N 5 (169) 7322 BECBM

7 N 6.5 (219.8) 7326 BCBM

8 N 6.5 (219.8)

7232 BCBM

7330 BCBM

Page 8 of 20

Page 9

2000 hours or at least every

2000 hours or at least every

2000 hours or at least every

2000 hours or at least every

3.1.7 Lubrication Table

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

Lubrication service

Ambient temperature

Oil temperature range*

Viscosity

mm²/s 40°C [cSt]

First Oil Change 200 hours

Centrifugal Pump Lubrication

Further Oil Changes

Designation according to

DIN51502 ISO VG

CASTROL -

(for oil mist)

Oil Companies and Lubricants

Oil

Type

°C (°F)

°C (°F)

BP -

OMV -

Aral -

Esso LSC

Mobil -

Shell -

Texaco -

-5 to 65

(23 to 149)

200 hours

6 months

BP Energol HL32

BP Energol HLP32

Hyspin AWS 32

Perfecto T32**

OMV turb HTU 32**

Aral Vitam GF 32

NUTO H32

LSO 32

Synthetic oil

Mobil Nuto H32

Mobil DTE13M

Mobil DTE24

Shell Tellus 32

Shell Turbo T32**

Rando HD 32

Oil Bath and Purge Oil Mist Lubrication

Mineral Oil

(Petroleum Based)

-20 to 35

(-4 to 95)

up to 85

(up to 185)

32

32

46

200 hours

6 months

46

BP Energol HL46

BP Energol HLP46

Hyspin AWS 46

Perfecto T46**

OMV turb HTU 46**

Aral Vitam GF 46

NUTO H46

LSO 46

Synthetic oil

Mobil Nuto H46

Mobil DTE15M

Mobil DTE25

Shell Tellus 46

Shell Turbo T46**

Rando HD 46

Ball bearing

35 to 60

(95 to 140)

up to 100

(up to 212)

68

200 hours

6 months

68

BP Energol HL68

BP Energol HLP68

Hyspin AWS 68

Perfecto T68

OMV turb HTU 68

Aral Vitam GF 68

NUTO H68

LSO 68

Synthetic oil

Mobil Nuto H68

Mobil DTE16M

Mobil DTE26

Shell Tellus 68

Shell Turbo T68

Rando HD 68

Pure Oil Mist

Lubrication

Mineral Oil

(Petroleum Based)

-5 to 60

(23 to 140)

15 and above

(59 and above)

6 months

LSO 100

Synthetic oil

100

100

Total -

Wintershall

(BASF Group)

* Note that it normally takes 2 hours for bearing temperature stabilize and the final temperature will depend on the ambient, r/min, pumpage temperature and pump

size. Viscosity index shall be at least 95.

** For ambient temperature from -12°C (10 °F) upwar ds

Azolla ZS32

Wiolan HN32

Wiolan HS32

Azolla ZS46

Wiolan HN46

Wiolan HS46

Azolla ZS68

Wiolan HN68

Wiolan HS68

-

For temperatures below -5 °C (-23 °F) use lubri cation oil class SAE 5W-50 or API-SJ.

Barrier/Buffer Fluid for

Mech. Seal

Tandem Seal to -60°C (-76 °F) Ethanol/Propanol

The sequence of the suppliers of the lubricants does not represent any indication of their superiority.

¹ Viscosity at 40 °C (104 °F) in cSt [mm²/s] DIN 5 1562

Seal System / Pumped Liquid Quench-Oil General Features

Tandem Seal to -40 °C (-40 °F)

Back to back Seal with gascoffer-dam

Conventional back to back Seal

- Raffinated Hydraulic Oil

- Synthetic Oil

- Mixture of water / glykol

ATTENTION:

Do not use Methanol

appr. 10-15 cST at 40°C

(104 °F)

below -40°C (-40 °F)

Pourpoint vaporization

above 80°C (176 °F)

Page 9 of 20

Page 10

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

3.2 Operation

a) The bearing housing temperature shall not exceed

80 °C (176 °F). If higher bearing temperature is

observed, check the viscosity grade of the used

lubrication oil.

The minimum viscosity is 10

cSt at the expected oil temperature.

(Oil temperature = bearing gland temperature +

10°C (18°F))

4.0 MAINTENANCE

Never use air or compressed inert gas to clean

clothes.

Before working on the pump, take measures to

prevent an uncontrolled start. Put a warning board

on the starting device with the words:

"Machine under repair: do not start".

With electric drive equipment, lock the main switch

open and withdraw any fuses. Put a warning board

on the fuse box or main switch with the words:

"Machine under repair: do not connect".

Never clean equipment with inflammable solvents or

carbon tetrachloride. Protect yourself against toxic

fumes when using cleaning agents.

4.1 General

It is the plant operator's responsibility to

ensure that all maintenance, inspection and

assembly work is carried out by authorized and

qualified personnel who have adequately familiarized

themselves with the subject matter by studying this

manual in detail.

Any work on the machine must be performed when it

is at a standstill.

On completion of work all guards and safety devices

must be re-installed and made operative again.

Oil and grease leaks may make the ground

slippery. Machine maintenance must always

begin and finish by cleaning the ground and the

exterior of the machine.

If platforms, stairs and guard rails are required for

maintenance, they must be placed for easy access to

areas where maintenance and inspection are to be

carried out. The positioning of these accessories

must not limit access or hinder the lifting of the part to

be serviced.

When air or compressed inert gas is used in the

maintenance process, the operator and anyone in the

vicinity must be careful and have the appropriate

protection.

Do not spray air or compressed inert gas on skin.

Do not direct an air or gas jet towards other people.

4.2 Maintenance schedule

a) Check bearing lubricant level, and if the hours

run show a lubricant change is required.

b) Check vibration, noise level and surface

temperature at the bearings to confirm

satisfactory operation.

c) Check dirt and dust is removed from areas

around close clearances, bearing housings and

motors.

Our specialist service personnel can help with

preventative maintenance.

If any problems are found the following sequence of

actions should take place:

a) Ensure equipment complies with the

recommendations in this manual.

b) Contact Flowserve if the problem persists.

4.2.1 Routine Inspection (daily/weekly)

The following checks should be

made and the appropriate action taken to remedy any

deviations.

a) Check operating behavior; ensure noise,

vibration and bearing temperatures are normal.

4.3 Spare parts

4.3.1 Storage of spares

Spares should be stored in a clean dry area away from

vibration. Inspection and retreatment of metallic

surfaces (if necessary) with preservative is

recommended at a 6 monthly interval.

Page 10 of 20

Page 11

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

(A 193 Gr.B7M,

Carbon Steel

(A 193 Gr. B7,

4.4 Recommended spares

Part Normal Maintenance

Bearings complete (antifriction, radial) 1

Bearings complete (antifriction, thrust) 1

Bearing pads only (hydrodynamic, thrust) 1

Gaskets, O-rings (set) 1

Spares Recommended

4.5 Fastener torques

Tightening torque MA Nm (lbf.ft)

Size of

screw

M 4 2,4 (1,8) 2,8 (2,1)

M 5 4,8 (3,6) 5,6 (4,1)

M 6 8,3 (6,1) 9,7 (7,1)

M 8 19,8 (14,6) 23,1 (17)

M 10 39 (28,8) 45,4 (33,5)

M 12 67,8 (50) 78,8 (58,2)

M 14 107,5 (79,3) 125,1 (92,3)

M 16 164,5 (121,4) 191,4 (141,3)

M 18 230 (170) 267 (197)

M 20 321 (237) 373 (276)

M 22 431 (318) 502 (370)

M 24 553 (408) 644 (475)

Above mentioned torques are for all screwed unions, which works under dynamical load. For all other

connections you can use a corresponding smaller torque.

Carbon Steel (NACE)

A 320 Gr. L7M)

A 320 Gr. L7, 8.8)

Page 11 of 20

Page 12

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

4.6 Disassembly

4.6.1 Dismantling of the thrust bearing

Thrust bearing No. Bearing size

0 N 7210 BECBJ

1 N 7313 BECBJ

3 N 7315 BECBJ

4 N 7317 BECBJ

5 N 7318 BECBJ

6 N 7322 BECBM

7 N 7326 BCBM

8 N

4.6.1.1 Bearing housing 3N – 8N

1) Remove the bearing assembly consisting of the

thrust ball bearing [3013.1], bearing adaptor

sleeve [2471], spacer ring [2510] and the bearing

lock nut [3712] as a cartridge.

2) Open the bearing lock nut [3712] and pull off the

thrust ball bearing [3013.1]

4.6.1.2 Bearing housing 0N – 1N

1) Remove the bearing assembly consisting of the

thrust ball bearing [3013.1], bearing adaptor

sleeve [2471] and the bearing lock nut [3712] as

a cartridge.

Open the bearing lock nut [3712] and pull off the

thrust ball bearing [3013.1].

7232 BCBM

7330 BCBM

4.7 Assembly

Ensure threads, gasket and O-ring mating faces are

clean.

4.7.1 Assembly of the thrust bearing

Thrust bearing No. Bearing size

0 N 7210 BECBJ

1 N 7313 BECBJ

3 N 7315 BECBJ

4 N 7317 BECBJ

5 N 7318 BECBJ

6 N 7322 BECBM

7 N 7326 BCBM

8 N

4.7.1.1 Bearing housing 3N – 8N

1) Heat up the first angular contact bearing, and put

it on the bearing adaptor sleeve [2471] as shown

in the section drawing.

2) Install the spacer ring [2510]. Warm up the other

two bearings and install it according to the

section drawing. Put on the lockwasher [6541] for

bearing nut and the bearing lock nut [3712]. After

tightening secure the bearing lock nut [3712] with

the lockwasher [6541] for bearing nut.

4.7.1.2 Bearing housing 0N – 1N

1) Heat up the two bearings and install it according

to the section drawing.

2) Put on the lockwasher [6541] for bearing nut and

the bearing lock nut [3712]. After tightening

secure the bearing lock nut [3712] with the

lockwasher [6541] for bearing nut.

7232 BCBM

7330 BCBM

Page 12 of 20

Page 13

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

PROBABLE CAUSES

POSSIBLE REMEDIES

MECHANICAL TROUBLES

ELECTRICAL TROUBLES

5.0 FAULTS; CAUSES AND REMEDIES

FAULT SYMPTOM

Bearings have short life

⇓⇓⇓⇓

⇓⇓⇓⇓

Shaft bent. Check shaft runouts within acceptable values

Rotating part rubbing on stationary part

internally.

Bearings worn Replace bearings

Shaft running off center because of worn

bearings or misalignment.

Excessive grease in ball bearings. Check method of regreasing

Lack of lubrication for bearings.

Improper installation of bearings

Damaged bearings due to contamination. Check contamination source and replace damaged bearings

Motor running too slow, Check motor terminal box connections

Check for signs of this and consult Flowserve if necessary

Check misalignment and correct if necessary. If alignment satisfactory

check bearings for excessive wear

Check hours run since last change of lubricant, the schedule and its

basis

Check method of assembly, possible damage or state of cleanliness

during assembly and type of bearing used

Page 13 of 20

Page 14

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

6.0 PARTS LIST AND DRAWINGS

6.1 Assembly 0N-1N

For 2 pole speed the bearing assembly is delivered with axial fan. No cowl is required.

Page 14 of 20

Page 15

6.2 Assembly 3N-7N

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

The standard design is delivered with radial fan. For that design a cowl is necessary. For special

customer requirements (e.g. temperature limits below the API 610 limits) axial fan may be installed that do not

require cowl.

Page 15 of 20

Page 16

6.3 Assembly 8N

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

The standard design is delivered with radial fan. For that design a cowl is necessary. For special

customer requirements (e.g. temperature limits below the API 610 limits) axial fan may be installed that do not

require cowl.

Page 16 of 20

Page 17

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

7.0 CERTIFICATION

Certificates determined from the contract

requirements are provided with these instructions

where applicable. Examples are certificates for CE

marking, ATEX marking etc. If required, copies of

other certificates sent separately to the Purchaser

should be obtained from the Purchaser for retention

with these User Instructions.

8.0 OTHER RELEVANT

DOCUMENTATION AND MANUALS

8.1 Supplementary user instructions

Supplementary instructions determined from the

contract requirements for inclusion into user

Instructions such as for a driver, instrumentation,

controller, sub-driver, seals, sealant system, mounting

component etc are included in the Data Book. If

further copies of these are required they should be

obtained from the supplier for retention with these

user instructions.

Where any pre-printed set of user instructions are

used, and satisfactory quality can be maintained only

by avoiding copying these, they are included at the

end of these user instructions such as within a

standard clear polymer software protection envelope.

8.2 Change notes

If any changes, agreed with Flowserve, are made to

the product after its supply, a record of the details

should be maintained with these User Instructions.

8.3 Additional sources of information

Reference 1:

NPSH for Rotordynamic Pumps: a reference guide,

Europump Guide No. 1, Europump & World Pumps,

Elsevier Science, United Kingdom, 1999.

Reference 2:

Pump Handbook, 2nd edition, Igor J. Karassik et al,

McGraw-Hill Inc., New York, 1993.

Reference 3:

ANSI/HI 1.1-1.5

Centrifugal Pumps - Nomenclature, Definitions,

Application and Operation.

Reference 4:

ANSI B31.3 - Process Piping.

Page 17 of 20

Page 18

8.4 Abbreviations

Quantity ISO unit

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

ISO unit

abbreviation

Multiplication

Factor 1

US unit

US unit

Abbreviation

Area

Capacity or

Flow rate

Force Newton N 0.2248 Pound force lbf

Head meter m 3.28084 feet ft

Heat Energy kilo joule kJ 0.9478

Length

Mass

Moment of

Inertia

Noise 4 decibel dBA

Power kilowatt kW 1.34102 horsepower hp

Pressure 2 bar bar 14.5 pounds/in.² psi

Rotational

Speed

Stress

Temperature

square meter

square centimeter

Cubic

meter/hour

meter

millimeter

micrometer

kilogram

gram

kilogram

square meter

revs per minute r/min

Newton/square

millimetre

degrees

Celsius

m²

cm²

m³/h 4.4033

m

mm

µm

kg

g

kg.m² 23.73

N/mm² 145.0 pounds/in.² psi

°C (1.8 x °C) + 32

10.764

0.155

3.28084

0.03937

0.00003937

2.20462

0.035274

square feet

square inch

US Gallons/

minute

British

thermal unit

feet

inch

inch

pounds

ounces

pounds

square feet

degrees

Fahrenheit

ft²

in.²

US gpm

Btu

ft

in.

in.

lb.

oz.

lb.ft²

°F

Torque Newton meter Nm 0.7376 pound.feet lbf.ft

Unbalance gram millimeter g.mm 0.001389 ounce-inch oz-in.

Velocity

Vibration 3

Viscosity

Volume

meter/second

millimeter/second

millimetre/

second

square millimetre/

second or centiStoke

cubic meter

liter

m/s

mm/s

mm/s

cSt

m³

l

3.28084

0.03937

0.03937

264.2

33.81

feet/second

inches/second

inches/

second

US Gallons

fluid ounce

ft/sec

in./sec

in./sec

US gal.

Fl.oz.

1

multiply the ISO unit by the multiplication factor to obtain US units

2

where pressure is not stated to be absolute it is gauge

3

where not stated to be peak it is r.m.s.

4

sound pressure level LpA, re 1m - 20microPa, or sound power level LwA re 1 pW when sound power is

applicable

Page 18 of 20

Page 19

OUR ADRESS

Flowse

rve (Austria) GmbH

MESSAGES CAN BE LEFT ALSO ON OUR A

NSWERING MACHINE

Please quote your service:

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

AFTERMARKET DIRECTORY

Tel: +43 / 2236 / 31530

Industriestraße B/6 Fax: +43 / 2236 / 33430

A-2345 Brunn/Geb., AUSTRIA Mail: flowserve-brunn@flowserve.com

IMPORTANT NOTES:

PLEASE NOTE, THAT WARRANTY EXPIRES:

- USE OF NON GENUINE FLOWSERVE AUSTRIA PARTS FOR MAINTENANCE AND REPAIRS

- NO USE OF OUR SERVICE PERSONAL IN CASE OF REPAIRS DURING WARRANTY PERIOD

RECOMMENDATION:

-PLEASE ASK FOR OUR SPECIAL RATES

- PLEASE ALSO ASK OUR SERVICE PERSONAL ABOUT REPAIRING AND SERVICING YOUR

PUMPS AFTER THE WARRANTY PERIOD

Name of Company: ………………………… Pumpdata:

Contact person:.……………………….. Type: ………………….

Telephone: …………….…………........... Serialno.: …….......…….....

Fax: ...…………………………………....

e-mail: ………………………………………

Country: ………………………………………

Page 19 of 20

Page 20

N-SERIES OF THRUST POT USER INSTRUCTIONS ENGLISH 07/14

Your Flowserve factory contacts:

Flowserve (Austria) GmbH

Industriestraße B6

2345 Brunn am Gebirge

Austria

Telefon: +43 2236 31530

Fax: +43 2236 33430

E.mail: flowserve-brunn@flowserve.com

FLOWSERVE REGIONAL

SALES OFFICES:

USA and Canada

Flowserve Corporation

5215 North O’Connor Blvd.

Suite 2300

Irving, Texas 75039-5421, USA

Telephone: +1 937 890 5839

Europe, Middle East, Africa

Flowserve Corporation

Parallelweg 13

4878 AH Etten-Leur

The Netherlands

Telephone: +31 76 502 8100

Latin America

Flowserve Corporation

Martín Rodriguez 4460

B1644CGN-Victoria-San

Fernando

Buenos Aires, Argentina

Telephone: +54 11 4006 8700

Telefax: +54 11 4714 1610

Asia Pacific

Flowserve Pte. Ltd.

10 Tuas Loop

Singapore 637345

Telephone: +65 6771 0600

Telefax: +65 6862 2329

Loading...

Loading...