Page 1

USER INSTRUCTIONS

MX/QX Profibus DP / PA Field Unit

FCD LMENIM2336-03 – 12/12

Installation

Operation

Maintenance

Experience In Motion

Page 2

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Contents

1 Introduction 5

1.1 Purpose 5

1.2 How to Use this Manual 5

1.3 User Safety 6

1.4 User Knowledge 6

1.5 MX/QX PB System Capabilities and Features 7

1.5.1 General Network Specification 10

2 System Components and Installation 12

2.1 Introduction 12

2.2 Hardware 13

2.2.1 MX/QX Actuator 14

2.2.2 MX/QX PB Field Unit 14

2.2.3 Network Host Station 15

2.2.4 Network Cabling for PROFIBUS DP 16

2.2.5 Network Cabling for PROFIBUS PA 20

2.3 Other Network Components 23

2.4 Site and Network Cable Preparation 24

2.4.1 Site Preparation 24

2.4.2 Network Cable Preparation 25

2.4.3 MX/QX PB Device Installation 30

2.5 MX/QX PB Device Setup 31

2.5.1 Proportional Band 33

2.5.2 Deadband 33

2.5.3 Valve Data 33

2.6 MX/QX PB Device Description, Capabilities and Device Type Manager File Installation 34

2.6.1 MX/QX PB Device Description 34

2.6.2 MX/QX PB Device Type Manager 34

2.7 Installation Verification 34

2.7.1 Network Cabling Installation Verification 34

2.7.2 MX/QX PB Device Installation Verification 35

2.8 Configuration Confirmation 35

2.8.1 Checking Connections 35

2.8.2 View Settings 35

2.8.3 Checking the Normal Display 36

3 Software 38

3.1 PROFIBUS Protocol 38

3.2 PROFIBUS Function, Transducer, and Physical Blocks 38

3.3 Analog Input (AI) Function Block 41

3.4 Analog Output (AO) Function Block 44

3.5 Discrete Input (DI) Function Block 48

3.6 Discrete Output (DO) Function Block 50

3.7 Transducer Block 52

3.8 GSD and Electronic Device Description, and DTM Files 53

2

4 Associated Documents 54

Page 3

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

5 How to Order Parts 55

A Appendix – Wiring Diagrams 56

B Appendix – Feature Definitions 62

C Appendix – PROFIBUS Function Block 80

Glossary 85

Tables

Table 2.1 – Maximum Segment Length 17

Table 2.2 – Total Network Length (with up to nine repeaters) 17

Table 2.3 – Recommended PROFIBUS DP Cable Parameters 17

Table 2.4 – Recommended PROFIBUS DP Cable Types 18

Table 2.5 – Recommended PROFIBUS PA Cable Parameters (Type A – shielded twisted-pair) 20

Table 2.6 – Recommended PROFIBUS PA Cable Types 20

Table 2.7 – Recommended Lengths of PROFIBUS PA Spurs (Stubs) 21

Table 2.8 – Details of Terminal Block Cable Assignments 29

Table 3.1 – Description of the Function Blocks 40

flowserve.com

3

Page 4

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Figures

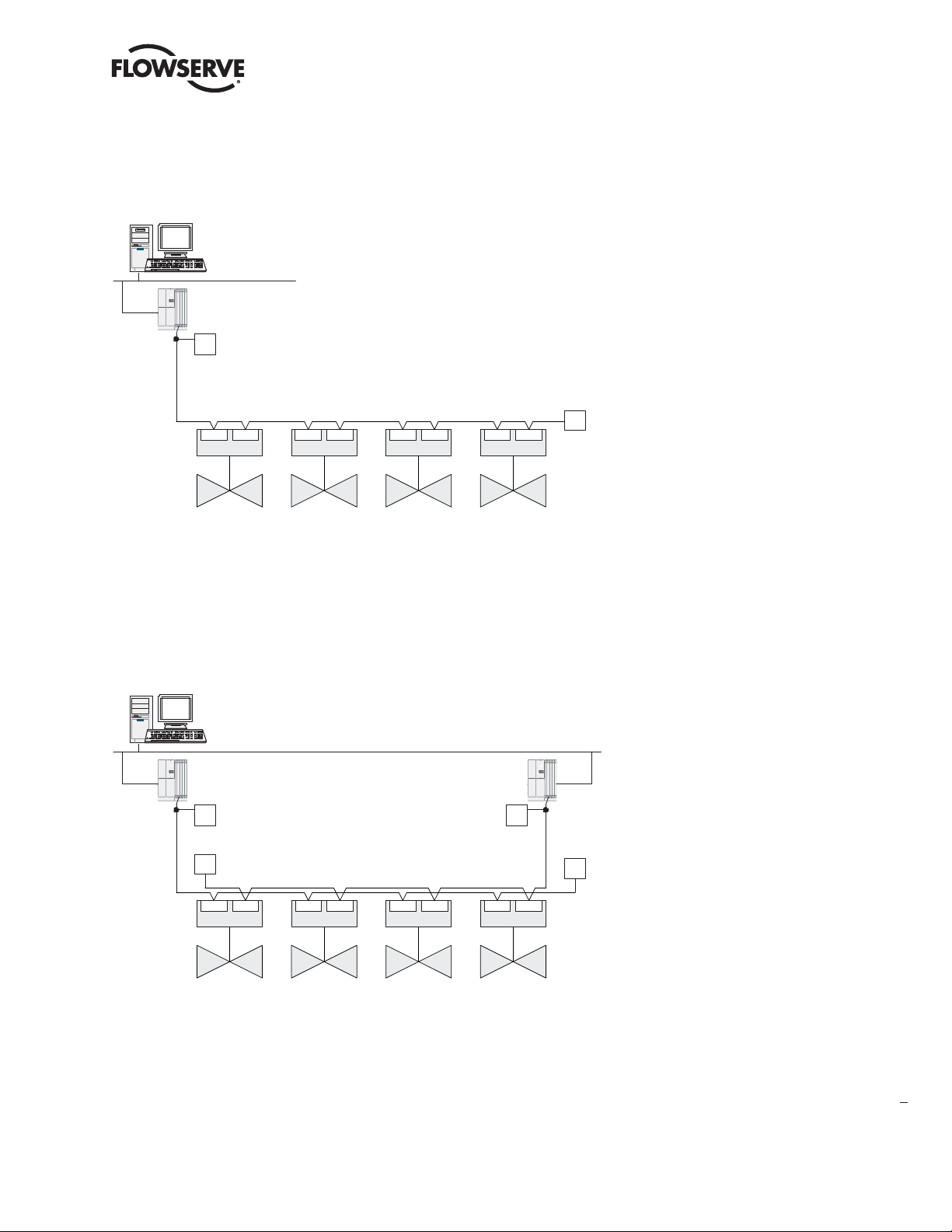

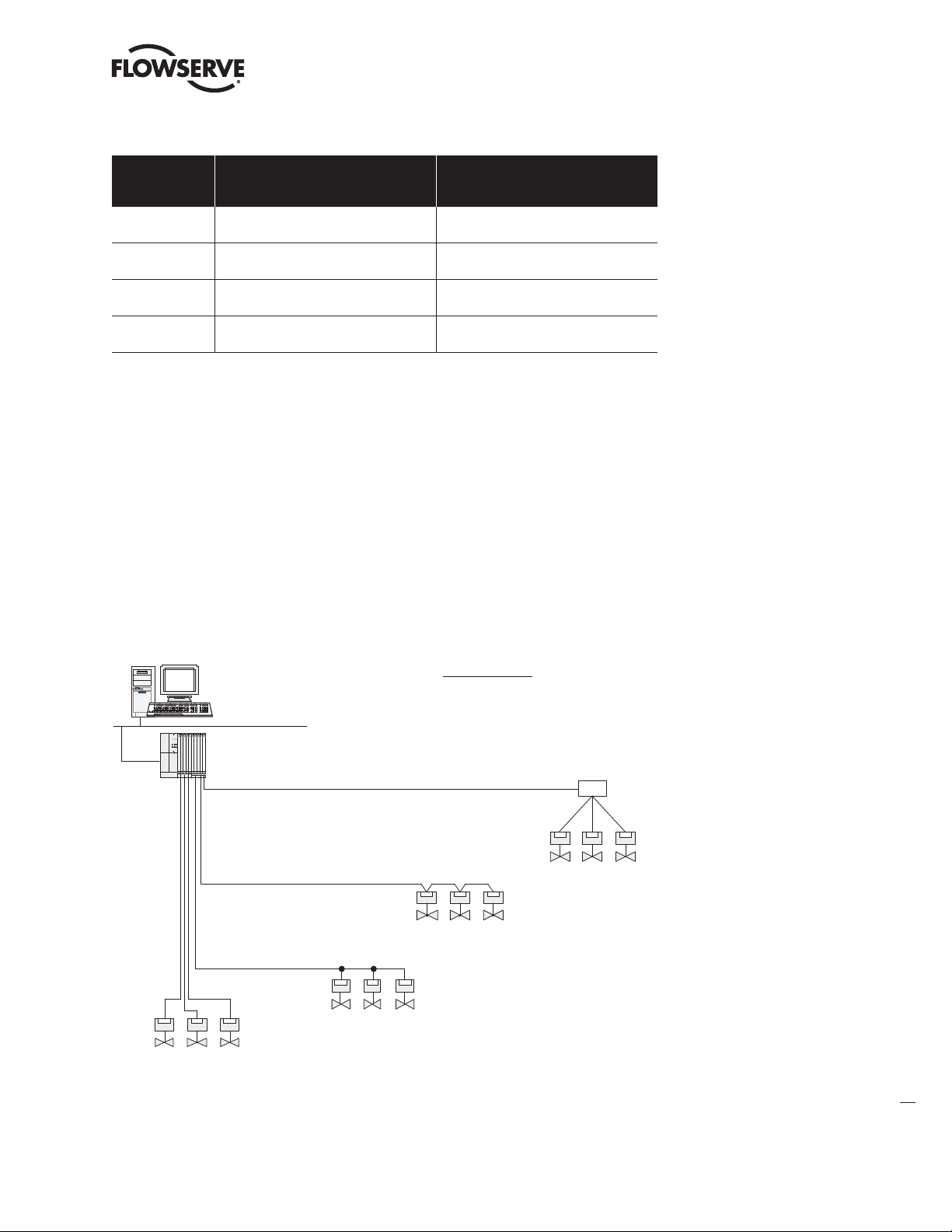

Figure 1.1 – Typical PROFIBUS DP Network with DCS or PLC as the Host System 8

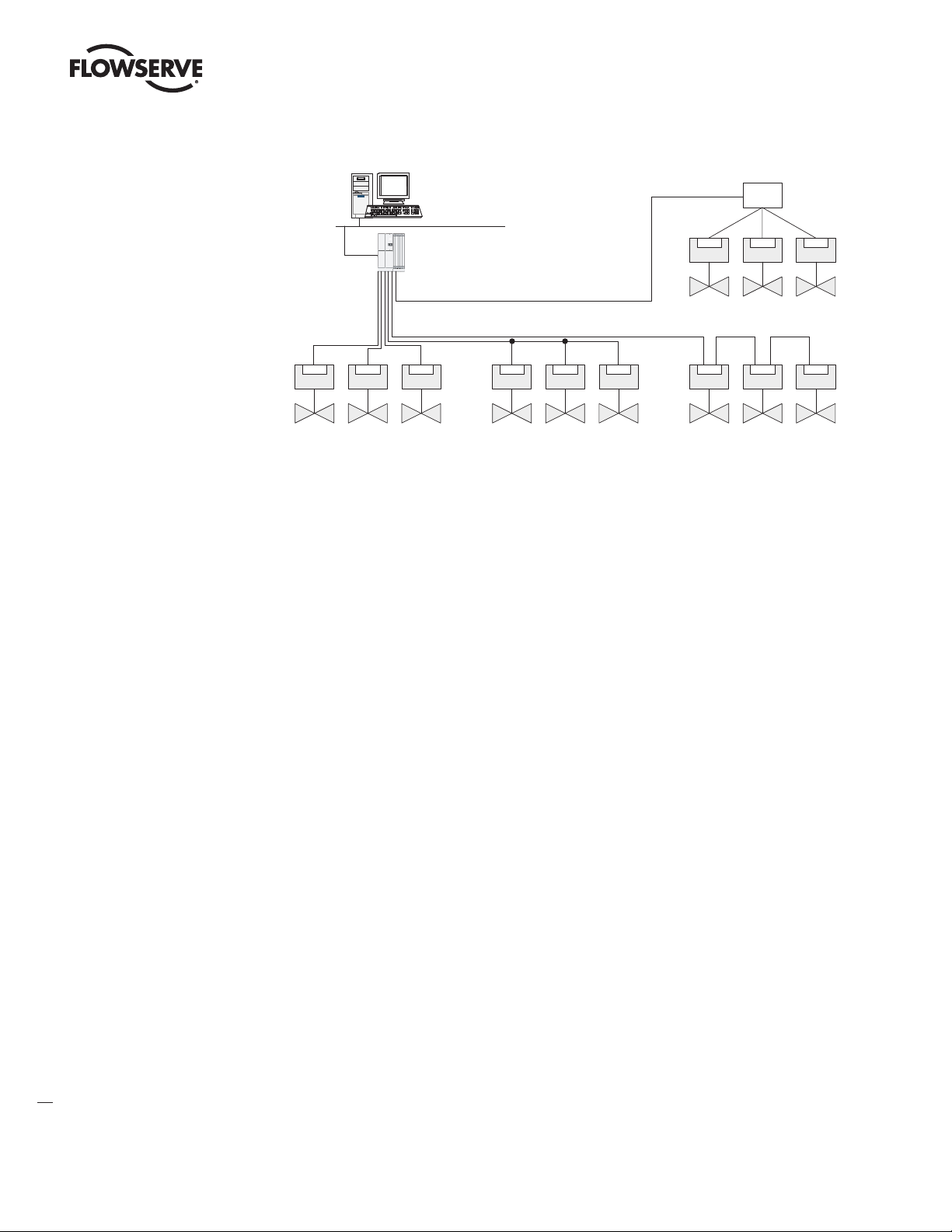

Figure 1.1a – Typical PROFIBUS DP Network with Redundancy Option (Single Master) 9

Figure 1.1b – Typical PROFIBUS DP Network with Redundancy Option (Dual Master) 9

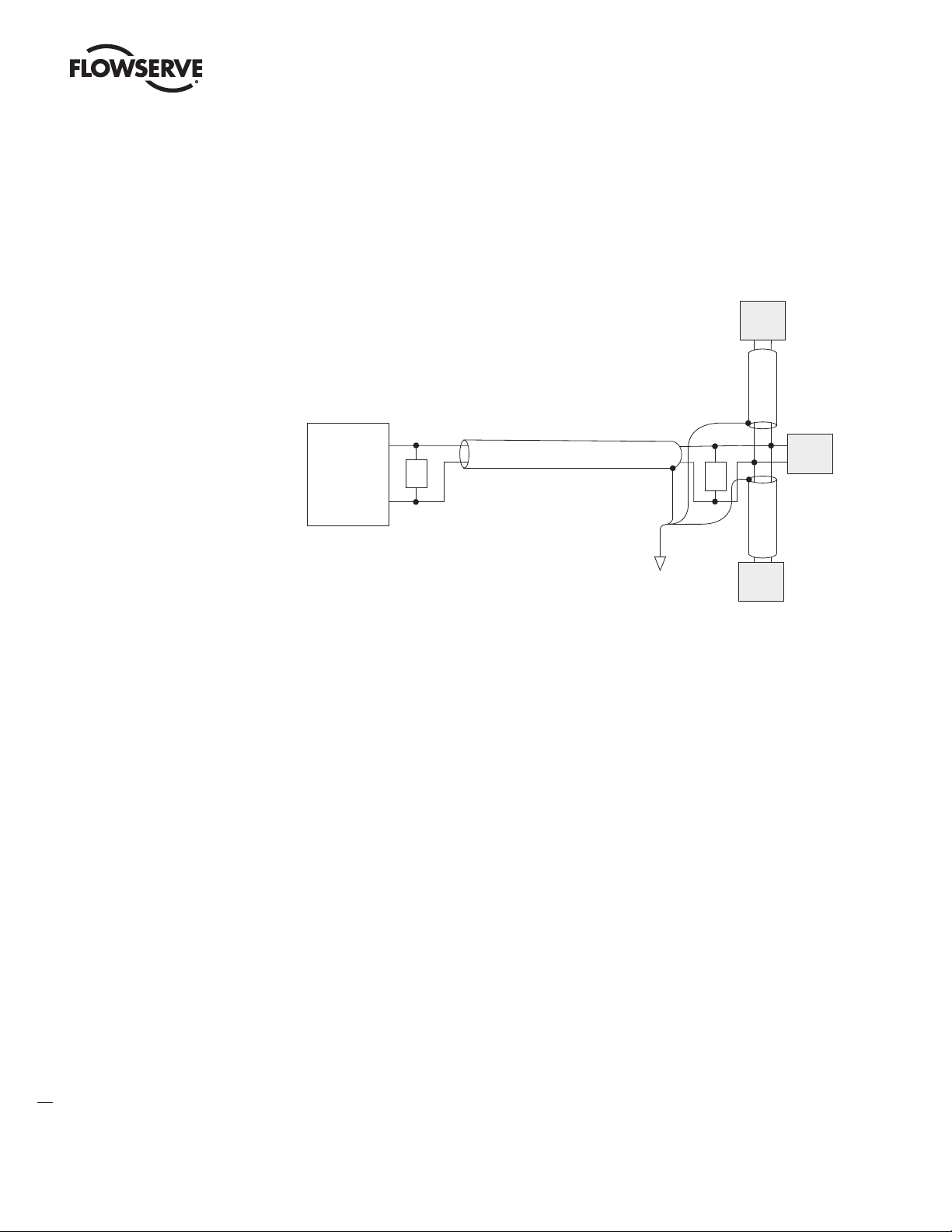

Figure 1.2 – Typical PROFIBUS PA Network with DCS or PLC as the Host System 10

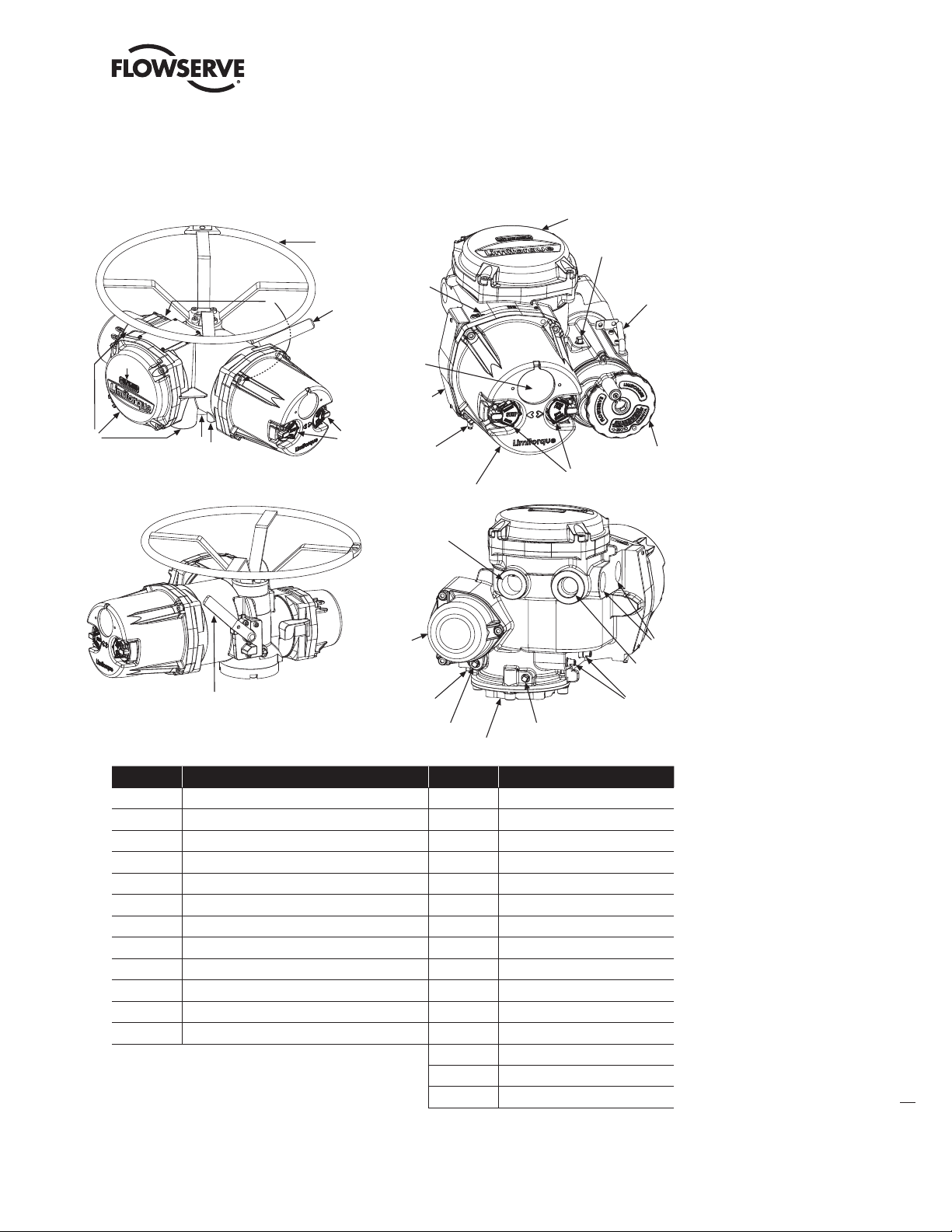

Figure 2.1 – MX/QX-05 Actuator 13

Figure 2.2 – MX/QX PB DP Field Unit 14

Figure 2.3 – MX/QX PB PA Field Unit 15

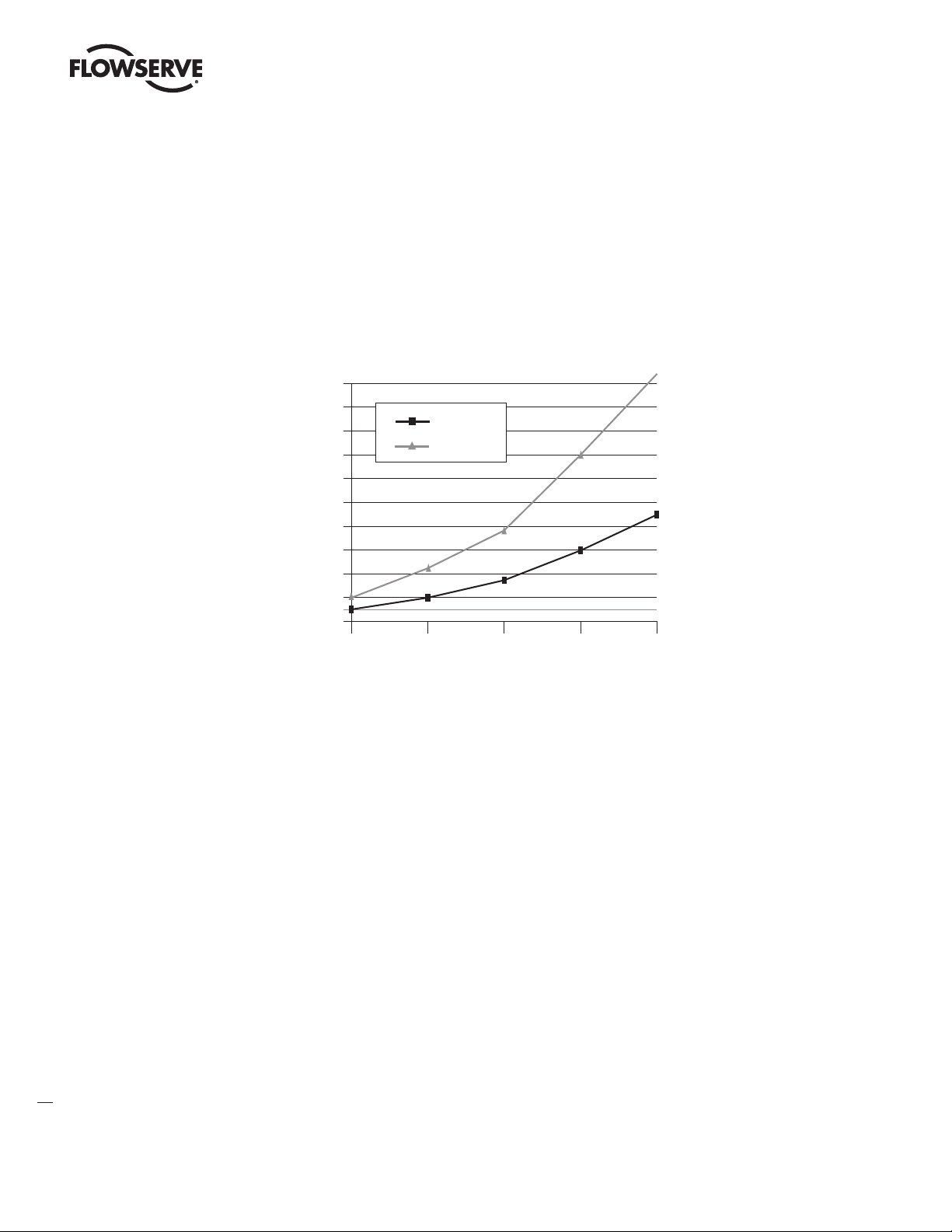

Figure 2.4 – Typical Cycle Time (Each Station with 2 Bytes I/O) 16

Figure 2.5 – Copper PROFIBUS Distance vs. Baud Rate Chart 18

Figure 2.6 – Cable Topologies 19

Figure 2.7 – Use of Shielded Cable in PROFIBUS DP 19

Figure 2.8 – PROFIBUS PA Cable Topologies 21

Figure 2.9 – Use of Shielded Cable in PROFIBUS PA 22

Figure 2.10 – PROFIBUS PA Power Supply 23

Figure 2.11 – PROFIBUS Segments 24

Figure 2.12a – PROFIBUS DP Cable Connections 25

Figure 2.12b – PROFIBUS DP Cable Connections (Redundancy Option with Single Master) 25

Figure 2.12c – PROFIBUS DP Cable Connections (Redundancy Option with Dual Master) 26

Figure 2.13 – PROFIBUS PA Cable Connections to Terminal Blocks 26

Figure 2.14 – Removing Outer Plastic Jacket 27

Figure 2.15 – Separating Cable Parts 27

Figure 2.16 – Stripping Conductors 28

Figure 2.17 – Applying Heat-Shrink Tubing 28

Figure 2.18 – Ring Tongue Connectors 29

Figure 2.19 – Connecting Network Cable to the MX/QX Terminal Block 30

Figure 2.20a – MX/QX PB DP Primary Board Mounted to MX/QX Main Board 30

Figure 2.20b – MX/QX PB DP Primary and Redundant Boards Mounted to MX/QX Main Board 30

Figure 2.21 – MX/QX PB DP Setup Sequence 31

Figure 2.22 – MX/QX PB PA Setup Sequence 32

Figure 2.23 – Normal Display, Field Unit is Communicating with Host 36

Figure 2.24a – No Communications 36

Figure 2.24b – No Communications 37

Figure 2.25 – Hardware Failure, No Communication, Bus Power Lost 37

Figure 3.1 – MX/QX Actuator Block Overview 39

Figure 3.2 – Summary of the Parameters of the Analog Input Function Block 41

Figure 3.3 – Analog Input Block 42

Figure 3.4 – Analog Input Block Scaling and Filtering 43

Figure 3.5 – Summary of the Parameters of the Analog Output Block 44

Figure 3.6 – Analog Output Function Block 45

Figure 3.7 – Analog Output Block Scaling 47

Figure 3.8 – Summary of the Parameters of the Discrete Input Function Blocks 49

Figure 3.9 – Discrete Input Function Block 49

Figure 3.10 – Summary of the Parameters of the Discrete Output Function Block 50

4

Figure 3.11 – Discrete Output Function Block 51

Figure 3.12 – PROFIBUS PA Configuration Requirements 53

Page 5

1

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Introduction

1.1 Purpose

This manual explains how to install and operate the Flowserve Limitorque MX/QX PROFIBUS field

unit, referred to as the MX (Multi-turn)/QX (Quarter-turn) PB (PROFIBUS) field unit. Actuators

containing the PB field unit may be connected by shielded twisted-pair, or shielded two-wire cable to

form a PROFIBUS communication system network. The name PROFIBUS is derived from Process

Fieldbus. The PROFIBUS communication system is a digital, serial, two-way open bus system that

supports a variety of communication rates. The MX/QX PB unit supports a communication rate up to

1.5 Mbit/sec. This system allows a network host station such as a distributed control system (DCS)

or a programmable logic controller (PLC) to control and monitor the actuators, including the acquisition of status and alarm data from each MX/QX.

1.2 How to Use this Manual

Each section provides the MX/QX PB user with information on installing and operating the MX/QX PB

field unit.

Section 1. Introduction The introduction details user safety and knowledge requirements, system

capabilities, and features.

Section 2. System Components and Installation The system components section focuses on the

description of the PROFIBUS system hardware and software components, and provides details for

installing and configuring a field unit.

Section 3. Software The software section provides details regarding the software that the MX/QX

PB uses to communicate.

Section 4. Associated Documents This section provides a list of documents on related subjects for

additional MX/QX and PROFIBUS system information.

Section 5. How to Order Parts This section provides part numbers and ordering contact

information.

flowserve.com

5

Page 6

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Appendix A – Wiring Diagram This section contains the detailed wiring connection information for

the MX/QX field unit.

Appendix B – Feature Definitions This section contains the Flowserve Limitorque actuator

Transducer Block I/O (Input/Output) channels and parameters.

Appendix C – PROFIBUS Function Block This section contains the PROFIBUS Function Block

parameters and descriptions.

Glossary The glossary contains a terminology list of abbreviations, acronyms and their

descriptions.

1.3 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal

injury and damage to the equipment. The user must read and be familiar with these instructions

before attempting installation, operation, or maintenance. Failure to observe these precautions could

result in serious bodily injury, damage to the equipment, warranty void, or operational difficulty. The

user must follow all applicable local and state safety regulations.

Safety notices are presented in this manual in three forms:

WARNING: Refers to personal safety and alerts the user to potential danger. Failure to follow

c

warning notices could result in personal injury or death.

CAUTION: Direct the user’s attention to general precautions that, if not followed, could result

a

in personal injury and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the actuator’s installation and

operation.

1.4 User Knowledge

It is recommended that the user read this manual in its entirety before the MX/QX PB field unit is

installed and operated.

The user needs to have a fundamental knowledge of electronics and an understanding of valve

actuators and digital control systems. Refer to the Glossary for information regarding the terms used

throughout this manual.

The following websites have documents on PROFIBUS and electric actuators:

www.PROFIBUS.com

www.flowserve.com

www.iec.ch

For PROFIBUS technology and cabling information, refer to the following documents:

6

• PROFIBUS DP Specification, IEC 61158 Type 3 and IEC 61784.

• PROFIBUS Profile – PROFIBUS PA – Profile for Process Control Devices, Version 3.02, November

2008, PROFIBUS International Order No. 3.042.

Page 7

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

• Installation Guidelines for PROFIBUS – FMS/DP Version 1.0, PROFIBUS International Order No.

2.112.

• Profibus Installation Guideline For Cabling and Assembly, Version 1.0.6, PROFIBUS International

Order No. 8.022.

• Profibus Installation Guideline For Commissioning, Version 1.0.2, PROFIBUS International Order

No. 8.032.

• Technical Guideline: PROFIBUS PA User & Installation Guideline, Version 2.2, February 2003.

• PROFIBUS Specification - Slave Redundancy Version 1.2, PROFIBUS International Order No. 2.212,

November 2004.

1.5 MX/QX PB System Capabilities and Features

Flowserve Limitorque’s MX/QX PROFIBUS (PB) field unit conforms to the open fieldbus standard

EN50170. It is suitable for use on PROFIBUS and uses a twisted-pair or two-conductor shielded cable

for connection to the network. A PROFIBUS device is an intelligent device within the actuator that

can send multiple variables to the control system over a high-resolution and distortion-free digital

communication network. The device provides control and self-test capabilities, which allow abnormal

conditions to be easily and immediately identified before an unplanned shutdown.

The MX/QX PB unit may command its actuator to: open, stop, close, move to a set position, perform

an emergency shutdown operation, read and control relays, monitor analog inputs and position,

and monitor modes and alarms. Commands to the unit come over the network from the master

network host station, which may be a Personal Computer (PC), Distributed Control System (DCS),

Programmable Logic Controller (PLC), or some other microprocessor-based device. The master is

defined as an active network node which means that it has addressing, and read and write privileges

to slave devices that are assigned to it.

Additional features and capabilities are:

• The system reduces the cost of wiring and installation by using existing wiring and multi-drop

connections, if it meets PROFIBUS requirements. It is also possible to have more than one

PROFIBUS communication network on the same cabling.

• Multiple-master operations through the use of the PROFIBUS token being passed between masters

(active nodes). Each master has its own set of slaves and may only write to those slaves.

• Master-slave operations where the master, active node, has the right to address, and send or fetch

messages from the slaves (passive nodes).

• The devices are interoperable, as devices from different suppliers communicate with one another

on the same network.

The PROFIBUS communication system supports up to 32 devices per segment, with up to 126

addressable devices with the use of repeaters.

Segmentation is used for the following reasons:

• Isolation is desired between two areas or buildings.

• Media conversion (copper to fiber or fiber to copper) is desired.

• The maximum of 32 nodes has been reached (31 + repeater).

• The maximum distance has been reached.

• It is desirable to “reform” the signal to full voltage levels (noisy environment).

7

flowserve.com

Page 8

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

The devices used to create a segment are Repeaters for copper networks, Optical Link Modules for

glass or plastic-coated glass fiber-optic networks, and Optical Bus Terminals for plastic fiber-optic

networks. Each of these devices provides either electrical or optical isolation between segments.

The MX/QX PB field unit fits in the actuator in the sealed electrical housing compartment. There

are two different communication board options for the MX/QX PB field unit: MX/QX PB DP, which

supports PROFIBUS DP (Decentralized Periphery) RS-485 physical layer and MX/QX PB PA, which

supports PROFIBUS PA (Process Automation) IEC 1158 physical layer. The MX/QX PB DP field unit is

available with Flying and System Redundancy.

PROFIBUS DP ensures high-speed data transmission of user data, and is designed especially for

communication between a master host station and distributed devices at the field level.

PROFIBUS PA uses the expanded PROFIBUS DP protocol for data transmission and implements the

PA profile that specifies the characteristics of the field device. This transmission technique ensures

intrinsic safety and powers the field devices over the bus. PROFIBUS PA is designed for high-speed

and reliable communications, with the ability to link sensors and actuators to a common fieldbus line,

even in potentially explosive areas.

PROFIBUS PA devices can be integrated into PROFIBUS DP networks using segment couplers.

The adjustments to the MX/QX PB settings may be made locally at the actuator and over the

PROFIBUS network using a DPV1 network configuration tool.

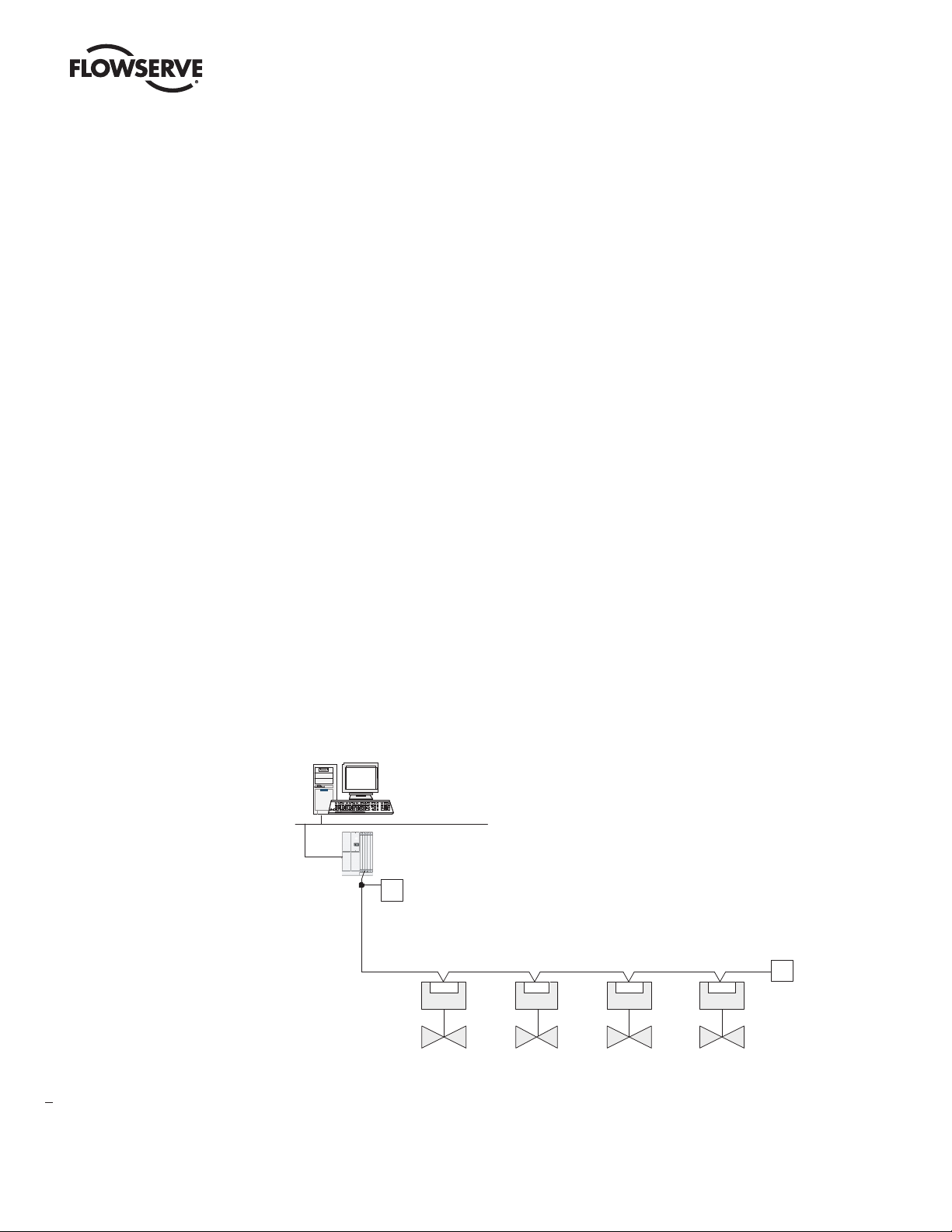

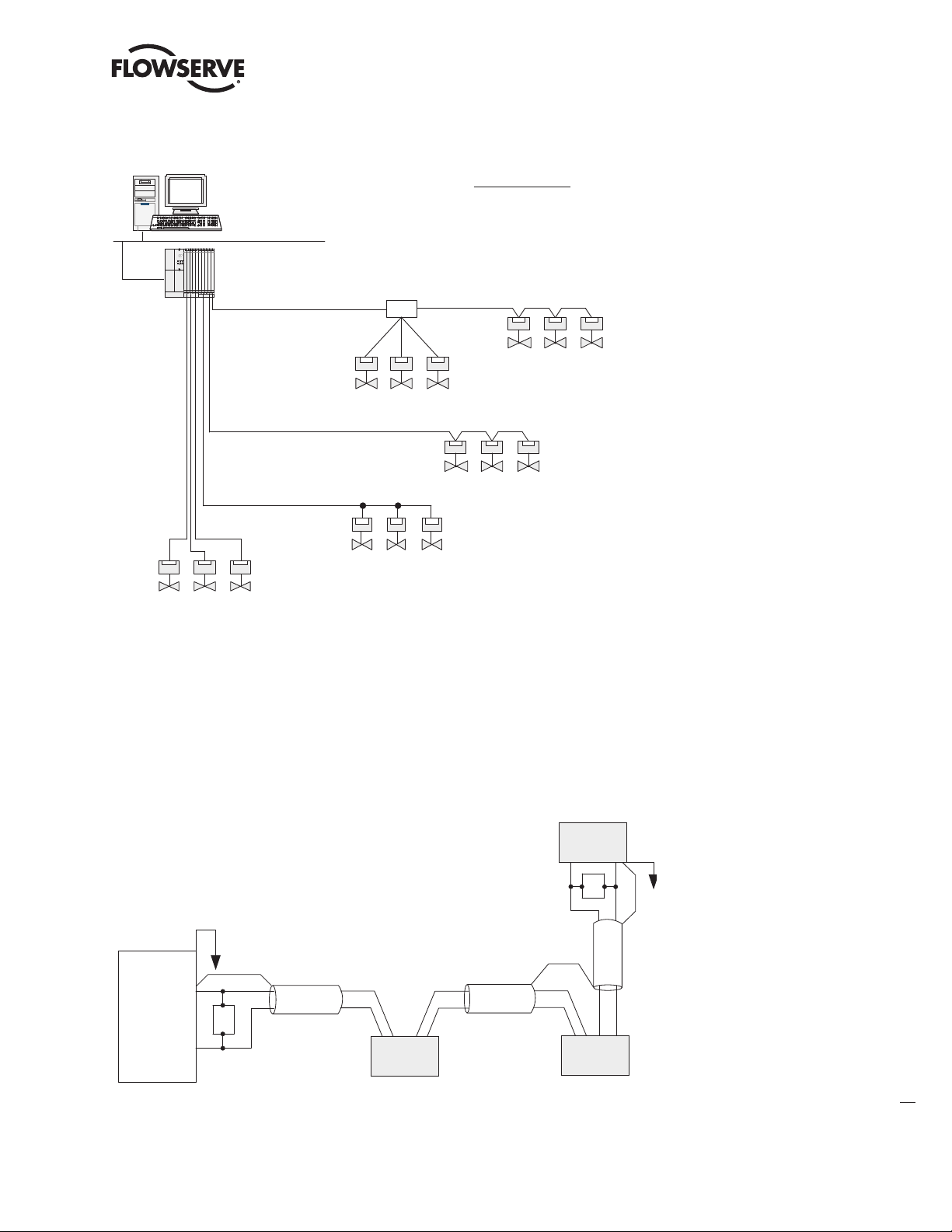

A typical MX/QX PB DP system is shown in Figure 1.1 in a Master/Slave Configuration, Figure 1.1a

shows a typical PROFIBUS DP network with redundancy option in a single master configuration,

Figure 1.1b shows a typical PROFIBUS DP network with redundancy option in a dual master

configuration, and Figure 1.2 shows a typical MX/QX PB PA system.

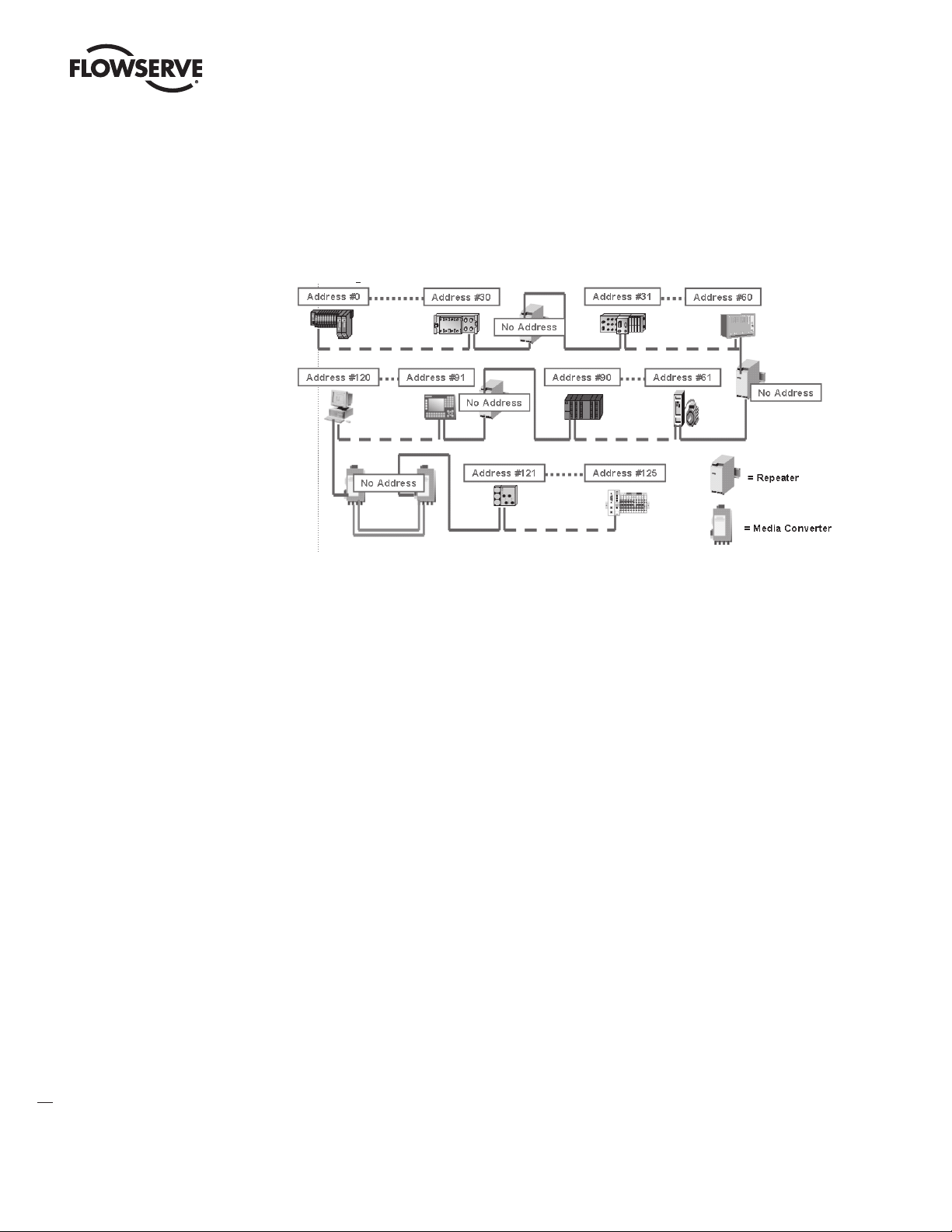

Figure 1.1 – Typical PROFIBUS DP Network with DCS or PLC as the Host System

Distributed Control

System (Host)

Control Highway

PROFIBUS DP-V1

Interface

T Terminator

Power for the fieldbus devices and cable shield

grounding are discussed in Sections 2.4 and 2.5.

PROFIBUS DP Network

Terminator

T

Actuator Actuator Actuator

PBPBPBPB

Actuator

8

Page 9

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Figure 1.1a – Typical PROFIBUS DP Network with Redundancy Option (Single Master)

Distributed Control

System (Host)

Control Highway

PROFIBUS DP-V1

Interface

Terminator

T

PROFIBUS DP Network

PBDP-A PBDP-B

Actuator

PBDP-A PBDP-B

Actuator

PBDP-A PBDP-B

Actuator

PBDP-A PBDP-B

Actuator

Figure 1.1b – Typical PROFIBUS DP Network with Redundancy Option (Dual Master)

Distributed Control

System (Host)

Control Highway

PROFIBUS DP-V1

Interface-1

Terminator

T Terminator T

Terminator

T

PROFIBUS DP Network

PBDP-A PBDP-B

Actuator

PBDP-A PBDP-B

Actuator

PBDP-A PBDP-B

Actuator

PROFIBUS DP-V1

Interface-2

PBDP-A PBDP-B

Actuator

Terminator

T

Terminator

T

flowserve.com

9

Page 10

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Figure 1.2 – Typical PROFIBUS PA Network with DCS or PLC as the Host System

Distributed Control

System (Host)

Control Highway

PROFIBUS PA

Interface

PA

ActuatorPAActuatorPAActuator

Point to Point Bus with spurs (or drops) Daisy Chain

Power for the fieldbus

devices and cable shield

grounding are discussed

in Sections 2.4 and 2.5.

PA

ActuatorPAActuatorPAActuator

1.5.1 General Network Specification

System Specifications:

• Communicates using the PROFIBUS DP or PROFIBUS PA protocol.

• PROFIBUS DP is V1 compliant.

• Employs high-speed communication.

• Complies with EN50170 fieldbus standard.

• PA Physical Layer with IEC1158-2.

• DP Physical Layer with RS-485.

Junction Box

PA

ActuatorPAActuatorPAActuator

Tree

PA

ActuatorPAActuatorPAActuator

10

Network Specification:

Several topologies are available including point-to-point, bus, tree, ring, or a combination of these.

Network features include:

• PROFIBUS DP high-speed communications up to 1.5 Mbit/sec.

• PROFIBUS PA communications are 31.25kbits/sec (segment coupler side).

• Master/slave communications.

• Multiple-master network systems.

• Redundant PROFIBUS DP with single or multiple-master communications.

MX/QX Field Unit Specification:

The field unit mounts inside the actuator, is software controlled, and has the following features:

• Input and Output Function Blocks.

• Device descriptions – describes device and parameters.

• Network communication – compliant with EN50170.

• Configurable by user – locally and via network.

Page 11

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

PROFIBUS Master Specification

The PROFIBUS master is the network system host, and can be a PC, DCS, PLC, or some other

microprocessor-based device. The master is defined as the network node that has addressing, and

read/write privileges to slave devices that are assigned to it. A PROFIBUS network can have more

than one master, but one, and only one, token is active at a given time. The token provides the right

to access the transmission medium, as is passed between the active nodes (masters) with a token

telegram. The master host station acts as the bus arbiter, and does the following:

• Recognizes and adds new devices on the link.

• Removes non-responsive devices from the link.

• Distributes a priority-driven token for unscheduled cyclic transmissions between masters.

• Ensures cyclic data transferred on a periodic basis.

• Issues requests for process data from the field devices.

• Issues commands to the field devices.

High Speed Data Exchange – Startup Sequence

• Power ON / Reset – Power on / Reset of master or slave.

• Parameterization – download of parameters into the field device (selected during configuration by

the user).

• I/O Configuration – download of I/O configuration into the field device (selected during configuration by the user).

• Data Exchange – cyclic data exchange (I/O Data) and field device reports diagnostics.

NOTE: In the application profile definition, only Function Blocks may have cyclic parameters. Physical

Blocks and Transducer Blocks do not have cyclic parameters. PROFIBUS DP/V1 is part of the

requirement to access Acyclic parameters through the Function Block specification and is composed

of a slot number and an index number. Acyclic services are performed between two data exchange

cycles. A PROFIBUS Class 2 Master is required for acyclic data exchange (Function Blocks). An

Electronic Device Descriptor File is used in the configuration tool of the Master to gain access to the

Function Block parameters (refer to Chapter 3, Software).

Device Configuration Tool Requirements

Generally, the device configuration tool can be executed independently of the control system configuration tool. The general requirements are as follows:

• A PROFIBUS DP or PA network is inserted as an object of a control system project (or independent

project).

• Within that network, a device is logically attached along with object name, PROFIBUS DP/PA

address, and how many objects are to be attached.

• Editing this device will allow the user to select the type of device (actuator, sensor, etc.).

• The configuration tool will then display the extended parameters with initial values.

• These parameters may be uploaded from the device to display the actual values (if a network

connection is possible).

• New values can be entered and then downloaded to the device through the network connection.

• There will also be a method for monitoring the online parameter values.

11

flowserve.com

Page 12

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

System Components

2

and Installation

2.1 Introduction

This section is an overview of the components used in the PROFIBUS system and their integration

with the MX/QX actuator. The MX/QX PB field unit is installed in the control compartment of the

actuator as shown in Figures 2.1a and 2.1b. The PROFIBUS network cable from the host control

station connects to the fieldbus unit at the actuator terminal block.

The Network Cabling section of this chapter is broken into two sections; PROFIBUS DP and

PROFIBUS PA.

Refer to Appendix A for detailed wiring connections.

12

Page 13

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

2.2 Hardware

Figure 2.1a – MX-05 Actuator Figure 2.1b – QX-05 Actuator

10

1

3

11

13

5

12

2

9

OPTIONAL

15

1

9

7

4

9

3

14

8

6

3

3

11

10

9

12

4

8

7

2

2

5

6

Item Description Item

1 Handwheel 1 Handwheel

2 Declutch lever 2 Declutch lever (QX-05)

3 Oil fills (dotted arrow depicts fill on declutch side) 3 Oil fill

4 Controls compartment (field unit location) 4 Controls cover

5 LCD display 5 LCD display

6 Control knobs 6 Control knob

7 Ground lug 7 Ground lug

8 Thrust/torque base 8 Baseplate

9 Conduit entries 9 Conduit entry

10 Terminal compartment 10 Terminal compartment

11 Electric motor 11 Motor

12 Nameplate 12 Certification nameplate

13 Tag nameplate

14 Oil plug

15 Stem nut stops

13

flowserve.com

Page 14

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

2.2.1 MX and QX Actuators

The MX and QX actuators are designed for operation of ON-OFF and modulating valve applications.

The MX is a multi-turn actuator, while the QX is a quarter-turn actuator.

Both the MX and QX include the following features:

• Non-intrusive setup.

• Separately sealed terminal compartment.

• Unique absolute encoder for valve position sensing (no battery required).

• 32-character LCD for indication and calibration.

• Enhanced electronic control, monitoring, and diagnostic capabilities with Built-In Self Test (BIST)

and LimiGard™ technology.

NOTE: Recommended storage procedures are detailed in the MX and QX Maintenance and Spare

Parts Manual LMENIM2314 and LMENIM3314 respectively. Failure to comply with recommended

procedures will void the warranty. For longer-term storage, contact Flowserve for procedure and

recommendations.

2.2.2 MX/QX PB Field Unit

The MX/QX PB field unit interface board is installed in the actuator controls compartment (Figure

2.1). The MX/QX PB DP version is shown in Figure 2.2, and the MX/QX PB PA version is shown in

Figure 2.3. Each unit permits the actuator to be controlled as a slave by one or more master host

stations over their respective PROFIBUS network. The MX/QX PB DP version supports two forms of

redundancy when two PB DP field unit boards are installed in a single actuator:

a. Flying redundancy provides slave hardware redundancy in the form of an active and standby PB

DP field unit installed in each actuator. This form is commonly utilized in applications where a single

master is present.

b. System redundancy provides for both slave hardware redundancy, in the form of an active and

standby PB field unit installed in each actuator, and cable redundancy in the form of dual masters

connected to the active and standby PB DP field units.

Figure 2.2 – MX/QX PB DP Field Unit

14

Note: Field unit board jumpers, JP1 and JP2, are set to “A” position on Primary board and “B” position on Redundant board.

Page 15

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Figure 2.3 – MX/QX PB PA Field Unit

The following commands and feedback information are transmitted through this unit:

• OPEN, CLOSE, and STOP commands.

• ESD (Emergency Shutdown) commands.

• Go-to-position commands.

• Redundancy switch-over commands (Profibus DP Redundancy option).

• Position feedback.

• Actuator status, alarm, and diagnostic messages.

• User analog input feedback.

• Discrete input feedback.

• Discrete output relays.

2.2.3 Network Host Station

The PROFIBUS master is considered to be the network host station, which is typically a DCS, PC,

PLC or other microprocessor-based PROFIBUS-compliant device. In a mono-master network, the

network host device is the only active network node. This is common in a standard Master-Slave

PROFIBUS network. In a multi-master network, there are two or more active nodes. This is managed

in a token ring, where the token, a uniquely structured message, circulates continuously among the

active network nodes. In the case of multiple Masters, only one Master has read/write privileges to

its Slaves (passive nodes) at any one time, and the control token is passed continuously in ascending

order to all other active network nodes.

2.2.3.1 Token Bus and Token Passing in a Multi-Master Network

During the bus initialization and startup, the bus access control creates the token ring by recognizing

the active network nodes in ascending order. The bus access control automatically determines the

addresses of all active nodes on the bus, and records them together with its own node address,

creating a List of Active Stations. The Lowest Station Address (LSA) begins with the active token,

allowing it to fetch and send data messages to its passive slaves (referred to as polling). At completion of its request frame (polling telegram), and acknowledgement or response frame returned from

the slave, the token is passed to the Next Station (NS) with a token telegram. The active node from

which the node was passed is called the Previous Station (PS). This continues until the token is being

passed from the Highest Station Address (HSA). At completion of the HSA polling telegram, the token

is passed to the LSA. The List of Active Stations is required during network operation to remove a

faulty active node, or to add a node, without disturbing data on the bus.

15

flowserve.com

Page 16

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

2.2.3.2 Token Rotation Time

The time required for the rotation of the token to all active nodes is the token rotation time. The Time

Target Rotation (TTR) is adjustable, and is used to specify the maximum allowed time of one rotation.

2.2.3.3 Bus Cycle Time

Based on the number of slaves attached to each master and the amount of data to be transferred, a

Bus Cycle Time is calculated by the master. This is the amount of time required for a master to poll all

slaves. This, along with the Token Rotation Time, makes PROFIBUS network access deterministic.

Figure 2.4 – Typical Cycle Time (Each Station with 2 Bytes I/O)

20.0

18.0

16.0

14.0

12.0

10.0

8.0

Cycle Time (ms)

6.0

4.0

2.0

0.0

2.0

0.9

4.6

1.5 MBaud

500 kBaud

2.0

51

Number of Slaves

7.7

3.3

10 20

14.1

8.8

6.1

30

16

2.2.4 Network Cabling for PROFIBIS DP

Network cabling should be in accordance with PROFIBUS Decentralized Periphery (DP) guidelines.

To achieve immunity to electromagnetic interference, ensuring high data integrity, certain cables and

guidelines are recommended. Additionally, the following items should be taken into account when

planning the network:

• Transmission rate – Within a network, only one transmission rate can be used; the MX/QX PB DP

works at baud rates up to 1.5 Mbps.

• The level of Master and Slave redundancy, if any.

• The required number of nodes.

• The type of network components needed – terminals, connectors, connecting cables, termination.

• The type of cable to be used and its characteristics.

• The number of segments and/or repeaters.

• The overall span of the network – adding repeaters and long cable lengths can increase transmis-

sion time.

• Cable termination – active termination resistors are required at the ends of all segments.

In general, the following rules apply for PROFIBUS networks:

• The higher the baud rate, the shorter the distance allowed between nodes.

• The higher the baud rate, the shorter the maximum distance of a segment.

• The higher the baud rate, the shorter the maximum distance of an entire network.

Page 17

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

These distance rules (or limitations) are based on the physical characteristics of the RS-485 topology

and are not a limitation of the PROFIBUS protocol. If the distance required between two stations or

the total network distance is greater than allowed by the PROFIBUS specifications for copper cable, a

conversion to fiber-optic cable may be required. Figure 2.5 shows the baud rate versus copper cable

distance using PROFIBUS.

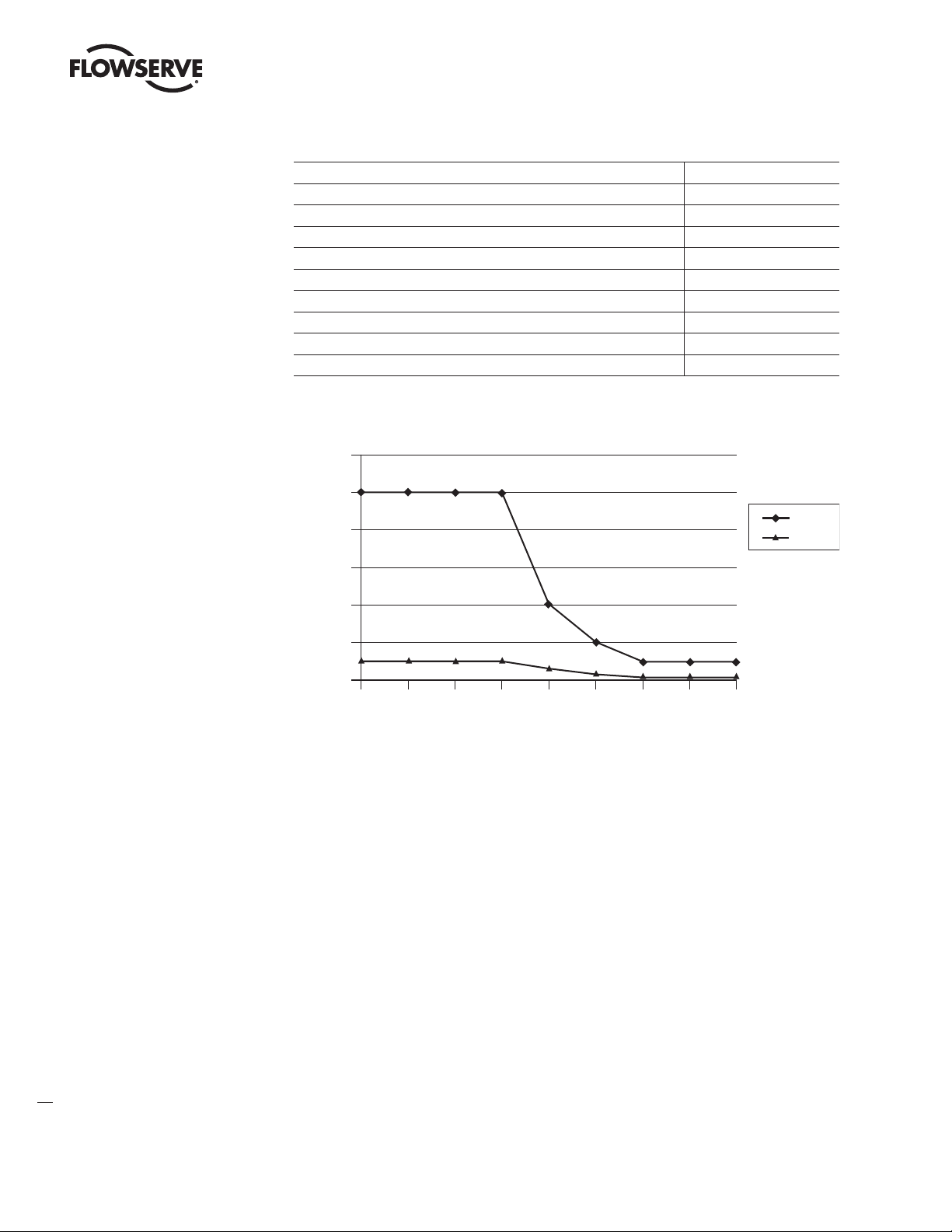

Table 2.1 provides the guidelines for maximum segment length versus baud rate.

Table 2.1 – Maximum Segment Length

Baud Rate 9600 to 187.5K 500K 1.5M

Maximum Segment Length (meters) 1,000 400 200

Table 2.2 provides the guidelines for maximum network length versus baud rate (assuming the use of

up to 9 repeaters).

Table 2.2 – Total Network Length (with up to nine repeaters)

Baud Rate 9600 to 187.5K 500K 1.5M

Total Network Length (meters) 10,000 4,000 2,000

NOTE: The maximum lengths are estimates and depend on the condition of the actual cable.

Tables 2.3 and 2.4 detail the various types of cable which can be used for network cabling. For

additional guidelines, see the following publications:

• PROFIBUS Networks SIMATIC NET 6GK1970-5CA20-0AA1.

• PROFIBUS Technical Guideline for PROFIBUS-DP/FMS, Version 1.0, September 1998; PROFIBUS

Guideline, Order No. 2.112.

There are different types of electrical data transfer cables:

• Standard bus cable.

• Standard bus cable with halogen-free sheath (type FRNC).

• Cable with PE sheath for use in the food and drug manufacturing industries.

• Direct buried cable with additional protective sheath for buried service.

• Trailing cable – This is a special cable type which is used where parts of the machine move

occasionally or continuously.

• Festooned cable – Comparable to a trailing cable, but has an additional strain relief element.

NOTE: Cable must meet the requirements as listed in table 2.3 to ensure reliable network

communications.

Table 2.3 – Recommended PROFIBUS DP Cable Parameters

Characteristic impedence at 3-20 MHz (ohms) 135-165

Operating capacitance (pF/m) < 30

Loop resistance (ohms/km) ≤ 110

Core diameter (mm) > 0.64

2

Core cross-section (mm

) > 0.34

17

flowserve.com

Page 18

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Table 2.4 – Recommended PROFIBUS DP Cable Types

FC Standard Cable (Siemens AG) 6XV1 830-0EH10

FRNC Cable (Siemens AG) 6XV1 830-0CH10

FC Food Cable (Siemens AG) 6XV1 830-0GH10

FC Ground Cable (Siemens AG) 6XV1 830-3FH10

FC Trailing Cable (Siemens AG) 6XV1 830-3EH10

Festoon Cable (Siemens AG) 6XV1 830-3GH10

PROFIBUS Data Cable (Belden Wire and Cable) 3079A/3076F

PROFIBUS DP Cable (Moeller GmbH) ZB4-900-KB1

PROFIBUS DP Cable (Kerpenwerk GmbH) 7422/7436

PROFIBUS DP Cable (ABB Automation GmbH) NDC110-NO

Figure 2.5 – Copper PROFIBUS Distance vs. Baud Rate Chart

12,000

10,000

8,000

Network

Segment

6,000

4,000

Distance (m)

2,000

1,000 1,000 1,000

0

9.6

19.2

93.75

1,000

187.5

Baud Rate (kBaud)

400

500

200

1,500 3,000

100

1,000 1,000

100

12,000

6,000

100

There are several topologies available for both redundant and non-redundant PROFIBUS networks:

• Point-to-point – A single cable from master to slave.

• Daisy chain – A single cable daisy chained in and out of each field unit device. End of segment

devices only have one incoming cable.

• Tree – Cables and electronic devices (such as repeaters or link modules) are used to branch out

from different points.

• Ring – Often implemented with fiber-optic cable which forms a circle or ring when used with

Optical Link Modules. This topology yields redundancy so that any single component fault or cable

break does not affect the network (except for the component).

• Combination of the above.

NOTE: Bus with Spurs, also referred to as stub lines, are not recommended by PROFIBUS as they can

create parallel resistance and cause disturbances and reflections on the main trunk or bus line.

18

Page 19

Figure 2.6 – Cable Topologies

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

PROFIBUS

Interface

Point-to-point

Distributed Control

System (Host)

Network

Schematic topology: Details such

as terminators and power supplies

not shown

Repeater

Daisy Chain

Tree

Daisy Chain

Bus with spurs

(or drops)

2.2.4.1 Cable Shielding and Grounding for PROFIBUS DP

For best performance, PROFIBUS DP cables should be shielded. Per PROFIBUS Technical Guidelines,

the cable shield should be connected at the beginning and end of the segment. Alternatively, a 10-12

AWG ground wire may be run to each MX/QX.

In Figure 2.7, the grounding point is shown at the junction of the field devices and at each field device.

Figure 2.7 – Use of Shielded Cable in PROFIBUS DP

Field

Device

T

PROFIBUS

Interface

T

Field

Device

Field

Device

19

flowserve.com

Page 20

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

2.2.5 Network Cabling for PROFIBUS PA

Network cabling should be in accordance with PROFIBUS Process Automation (PA) guidelines using

twisted-pair shielded cable. The data line is normally also used to supply power to the field devices.

PROFIBUS PA is a combination of the PROFIBUS-DP V1 protocol and the IEC 61158-2 transmission

technique.

The following items should be taken into account when planning the network:

• Transmission rate – Within a network, only one transmission rate can be used; typical restrictions

of PA are 31.25kbits/sec.

• The required number of nodes.

• The type of network components needed – Terminals, connectors, connecting cables, termination.

• The type of cable to be used and its characteristics.

• The number of segments and/or repeaters.

• The overall span of the network – Adding repeaters and long cable lengths can increase transmis-

sion time.

• Cable termination – Active termination resistors are required at the ends of all segments.

Tables 2.5 and 2.6 detail the recommended cable parameters and various types of cable that can be

used for network cabling. For additional guidelines, see the following publications:

• PROFIBUS Networks SIMATIC NET 6GK1970-5CA20-0AA1

• Technical Guideline – PROFIBUS PA User and Installation Guideline Version 2.2 February 2003,

PROFIBUS Guideline Order No. 2.092

Table 2.5 – Recommended PROFIBUS PA Cable Parameters (Type A – shielded twisted-pair)

Characteristic impedence 100 ohms ±20%

Maximum capacitance 2 nF/km

Loop resistance 44 ohms/km

2

Conductor cross-sectional area 0.8 mm

Maximum length of network (including spurs) 1900 m

(AWG 18)

Table 2.6 – Recommended PROFIBUS PA Cable Types

PA, Ex and Non-Ex

(ABB Automation Products GmbH)

PA, Ex and Non-Ex

(ABB Automation Products GmbH)

PROFIBUS FC Process Cable (Siemens AG) 6XV1 830-5.H10

PROFIBUS Data Cable (Beldon Wire & Cable) 3079A & 3076F

UNITRONICS Bus PA (Lapp Kabel GmbH) 2170 235 1x2x1.0

NPC080-NO

NPC150-NO

20

Page 21

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Table 2.7 – Recommended Lengths of PROFIBUS PA Spurs (Stubs)

Number of Spur

Cables

19 to 24 30 30

15 to 18 30 60

13 to 14 30 90

1 to 12 30 120

Length of Spur Cable

Intrinsically Safe (m)

Length of Spur Cable

Non-Intrinsically Safe (m)

NOTE: The maximum lengths are estimates and depend on the condition of the actual cable.

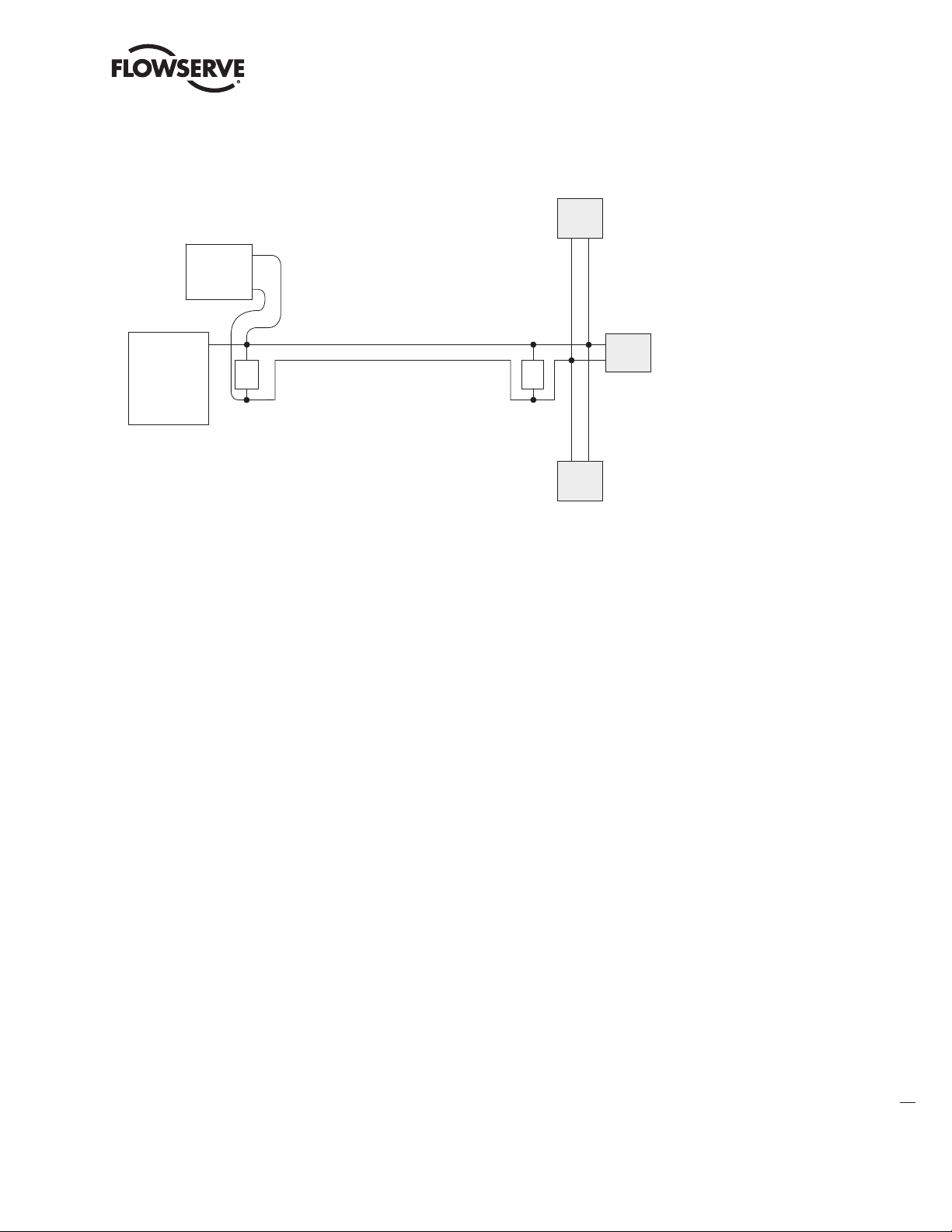

There are several topologies for PROFIBUS networks:

• Daisy Chain – A single cable daisy chained in and out of each device. End devices only have one

cable.

• Tree – Cables and electronic devices (such as repeaters or link modules) are used to branch out

from different points.

• Star – Similar to a Tree configuration but the cables all originate from one centralized point that is

comprised of electronic devices (such as repeaters or link modules).

• Combination of the above.

Figure 2.8 – PROFIBUS PA Cable Topologies

Distributed Control

System (Host)

Control Highway

PROFIBUS

Interface

Point-to-point

Schematic topology: Details such

as terminators and power supplies

not shown

Junction

Box

Tree

Daisy Chain

Bus with spurs

(or drops)

flowserve.com

21

Page 22

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

2.2.5.1 Cable Shielding and Grounding for PROFIBUS PA

For best performance, PROFIBUS PA cables must be shielded. When using shielded cable, connect

each cable shield to the trunk shield, and connect the overall shield to the PROFIBUS power supply

ground.

In Figure 2.9, the grounding point is shown at a connection point of power supply return.

Figure 2.9 – Use of Shielded Cable in PROFIBUS PA

Field

Device

Shielded Wire Pair

Field

PROFIBUS

Interface

T

T

Device

Connect Shield

to Ground at one

place only

Field

Device

2.2.5.2 PROFIBUS PA Power Supply

The MX/QX PB/PA board requires a nominal 24 VDC (9-32 VDC) on the PA bus to power the MX/QX

PB/PA board and make the actuator visible on the network. The required power supply is typically

connected to a segment coupler to the bus, usually located at the host end of the cable. Validate the

requirements of the segment coupler to determine actual power and voltage.

NOTE: If the actuator does not have three-phase power and the network is active, the MX/QX PB/PA

board will report this condition to the host.

22

Page 23

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Figure 2.10 shows a typical PROFIBUS PA power supply arrangement.

Figure 2.10 – PROFIBUS PA Power Supply

Fieldbus

Power

Supply

+

-

Field

Device

PROFIBUS PA

Interface

Shielded Wire Pair

T

NOTE: Bus power supply may be integrated

with the PROFIBUS PA bus interface.

T

Field

Device

Field

Device

2.3 Other Network Components

In addition to the network cables, the following components may be used in the PROFIBUS network.

Each network is designed based on its application and therefore may not require all of these

components.

• Bus Terminal Blocks/Junction Box – Provides multiple connections to the bus (network).

• Active Bus Terminal – Provides active termination so that other stations may be powered down for

service without affecting the network.

• Connectors – Enable connections to junction boxes, terminators or other connectors. Useful in

installations where devices will be periodically disconnected or when a device is only going to be

temporarily disconnected. Some PROFIBUS connectors also include termination resistors for line

termination.

• Couplers – Provide one or several connection points to a network segment.

• Repeaters – The PROFIBUS Physical Layer (RS-485) dictates that no more than 32 nodes can exist

in a shielded twisted-pair (copper) segment. A node is defined as any station, active or passive,

that is connected to the network. Media converters (copper to fiber-optic, fiber-optic to copper) and

repeaters do not have PROFIBUS addresses and, therefore, are not included in the 126 possible

addressable nodes.

RS-485 repeaters may be used to extend the recommended distance of a segment and “reform”

the signal to full voltage levels. Repeaters are included in the total number of allowable nodes per

segment; therefore, a segment that begins with a repeater and ends with a repeater may have 30

nodes between them. The maximum number of repeaters allowed in a PROFIBUS network is nine.

(Refer to Figure 2.11.)

• Terminators – Used at each end of a PROFIBUS segment to prevent signal reflections.

• Power Supplies – Different types of power supplies can be used in a PROFIBUS network:

• Non-intrinsically safe power supply.

• Standard linear or switching power supply used with a power conditioner.

• Intrinsically safe power supply (9-32 VDC; nominal 24 VDC for PA).

23

flowserve.com

Page 24

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

For cable connecting information on these components, refer to the following:

• Installation Guidelines for PROFIBUS – FMS/DP Version 1.0, PROFIBUS International Order No.

2.112.

• Technical Guideline: PROFIBUS PA User & Installation Guideline, Version 2.2, February 2003.

Figure 2.11 – PROFIBUS DP Segments

24

2.4 Site and Network Cable Preparation

2.4.1 Site Preparation

Prepare the installation site and associated equipment for operation of the MX/QX PB-controlled

actuators as follows:

1. Prepare a detailed site plan consisting of the following:

• Actuator locations and tag numbers.

• Junction boxes and terminal strip locations and tag numbers.

• Terminators and power supplies/conditioners, and repeaters.

2. Provide free access to the MX/QX control panel and terminal block for setup, configuration, and

troubleshooting.

3. Prepare the cable and label all wires. See Section 2.4.2.

4. Install power and control wires in separate conduits.

5. Install and verify earth grounds. The cable shields should be tied together. Ground the bus shield

at the end of each segment. The MX/QX PB unit should not connect either conductor of the cable

to ground at any point in the network. Refer to Sections 2.2.4.1 and 2.2.5.1.

NOTE: An effective local earth ground is defined as a low impedance (less than 5 ohms) path to

either:

• A ground electrode placed in the close vicinity of the actuator, free of any ground loop currents OR

Page 25

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

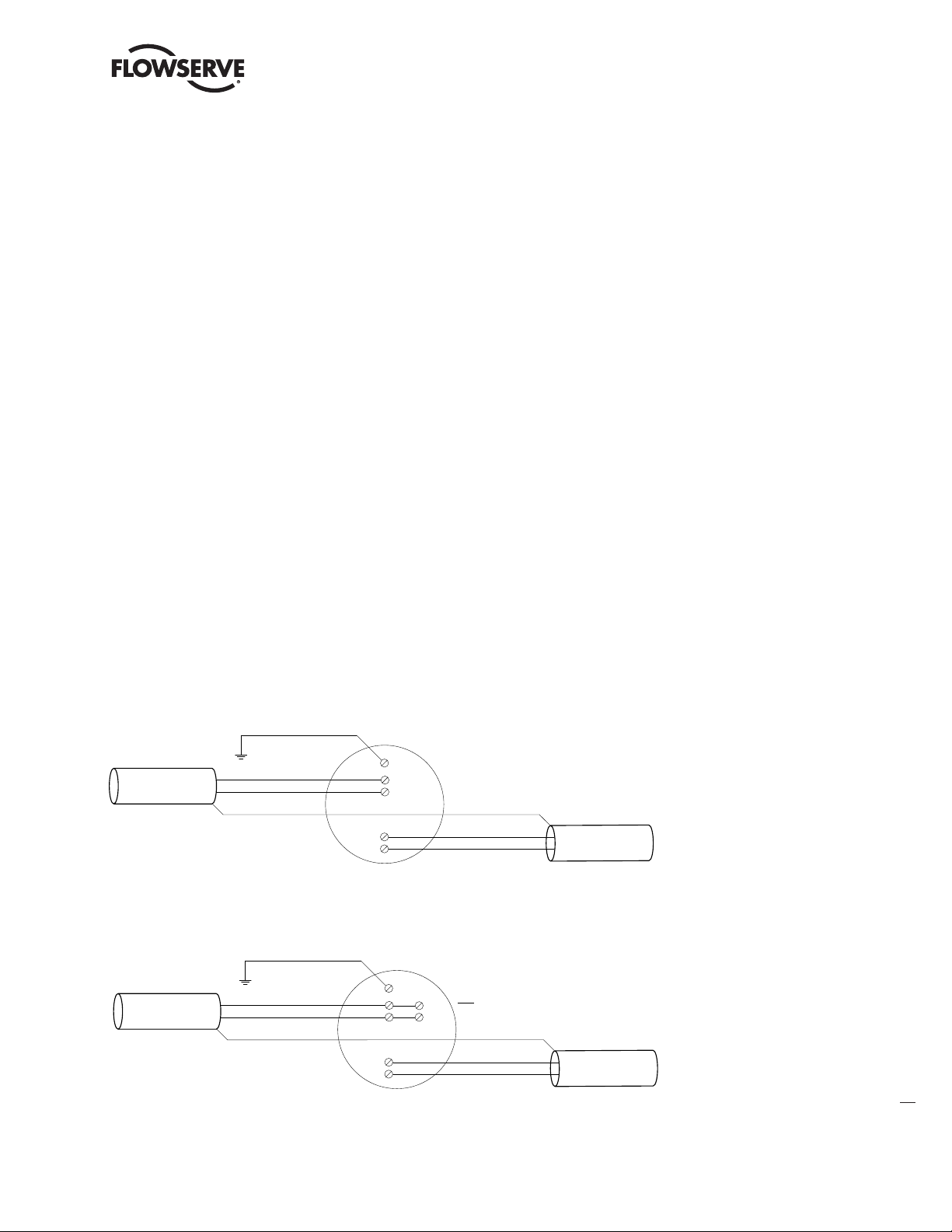

Figure 2.12(a) – PROFIBUS DP Cable Connections to Terminal Blocks

Figure 2.12(b) – PROFIBUS DP Cable Connections (Redundancy option with single master) to Terminal Blocks

• A safety ground, free of ground loop currents, running from the actuator back to the system

ground electrode. If the signal wiring is run on aerial cable where it may be exposed to

high-energy electrostatic discharge (such as lightning), a low impedance path to ground which

is capable of high current must be provided a short distance from the actuator as described

above OR

• A power distribution grid identifying the impact of power isolation to a particular actuator or

group of actuators.

2.4.2 Network Cable Preparation

Care must be taken during cable preparation:

• When stripping the insulation, use wire strippers that do not nick the wire.

• Use crimp ferrules to prevent stranded wires from getting loose and shorting to other wires.

• Use vibration-resistant wiring terminals that hold the ferrule securely.

2.4.2.1 Network Cable Connection to the MX/QX PB Unit

The field device is connected to the PROFIBUS network through the MX/QX terminal block.

The PROFIBUS DP network cable is connected to the terminal block as shown in Figure 2.12.

NOTE: The MX/QX PB DP device is sensitive to polarity. Cable polarity should be maintained through

all connection points.

The PROFIBUS PA network cable is connected to the terminal block as shown in Figure 2.13.

NOTE: The MX/QX PB PA device is equipped with automatic polarity identification. It is not polarity

sensitive.

Figure 2.12a – PROFIBUS DP Cable Connections to Terminal Blocks

Earth ground

Network data PBDP-A (-)

Network data PBDP-A (+)

3

14

IN

13

4

OUT

5

Network data PBDP-A (-)

Network data PBDP-A (+)

Figure 2.12b – PROFIBUS DP Cable Connections (Redundancy option with single master)

to Terminal Blocks

Earth ground

Network data PBDP-A (-)

Network data PBDP-A (+)

3

14

IN

13

Note: External jum per connection requi red between

15

16

a) Termi nals 14 & 15

b) Termi nals 13 & 16

4

OUT

5

Network data PBDP-A (-)

Network data PBDP-A (+)

25

flowserve.com

Page 26

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

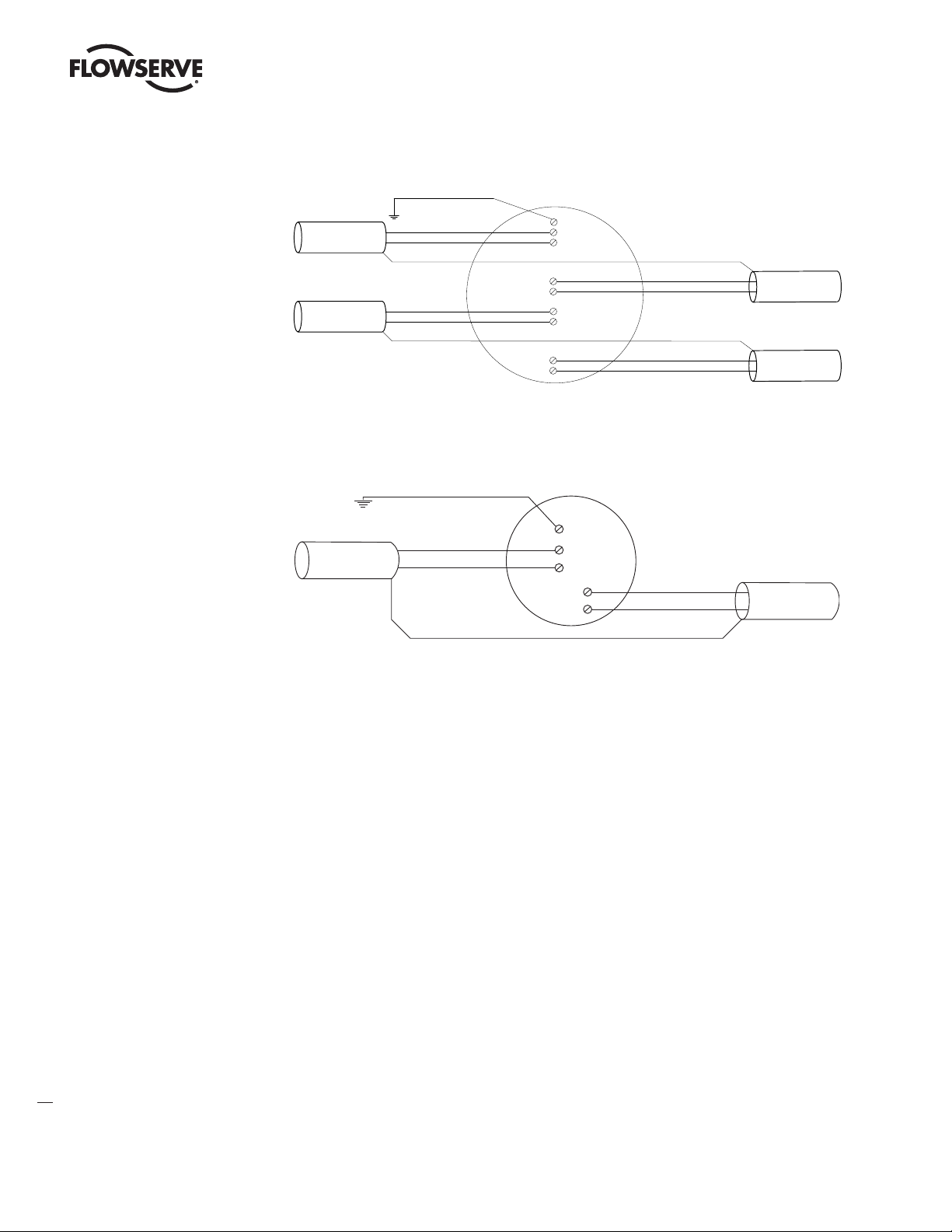

Figure 2.12(c) – PROFIBUS DP Cable Con nections (Redundancy option with dual master) to Terminal Blocks

Figure 2.12c – PROFIBUS DP Cable Connections (Redundancy option with dual master)

to Terminal Blocks

Earth ground

OUT

3

14

IN

13

4

OUT

5

1

2

15

IN

16

Network data PBDP -A(-)

Network data PBDP -A(+)

Network data PBDP -B(-)

Network data PBDP -B(+)

Figure 2.13 – PROFIBUS PA Cable Connections to Terminal Blocks

Earth ground

Network data PBPA1(-)

Network data PBPA1(+)

3

4

5

14

13

Network data PBPA1(-)

Network data PBPA1(+)

Network data PBDP -A(-)

Network data PBDP -A(+)

Network data PBDP -B(-)

Network data PBDP -B(+)

26

Page 27

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

• Shielded twisted-pair cables in compliance to PROFIBUS standards must be used.

• Shields are connected to earth ground.

PB/DP connects at the ends of each segment.

PB/PA connects at only a single point in the segment.

• Clean earth-ground connection (less than 5 ohms) provides noise protection and a clear, safe path

for surge currents.

Prepare the network cable for connection to the MX/QX terminals as follows:

CAUTION: Strip stranded conductors carefully, do not damage the strands. This will weaken

a

the conductor and can cause the conductor to break. This type of damage may not be

apparent and failure can occur without warning.

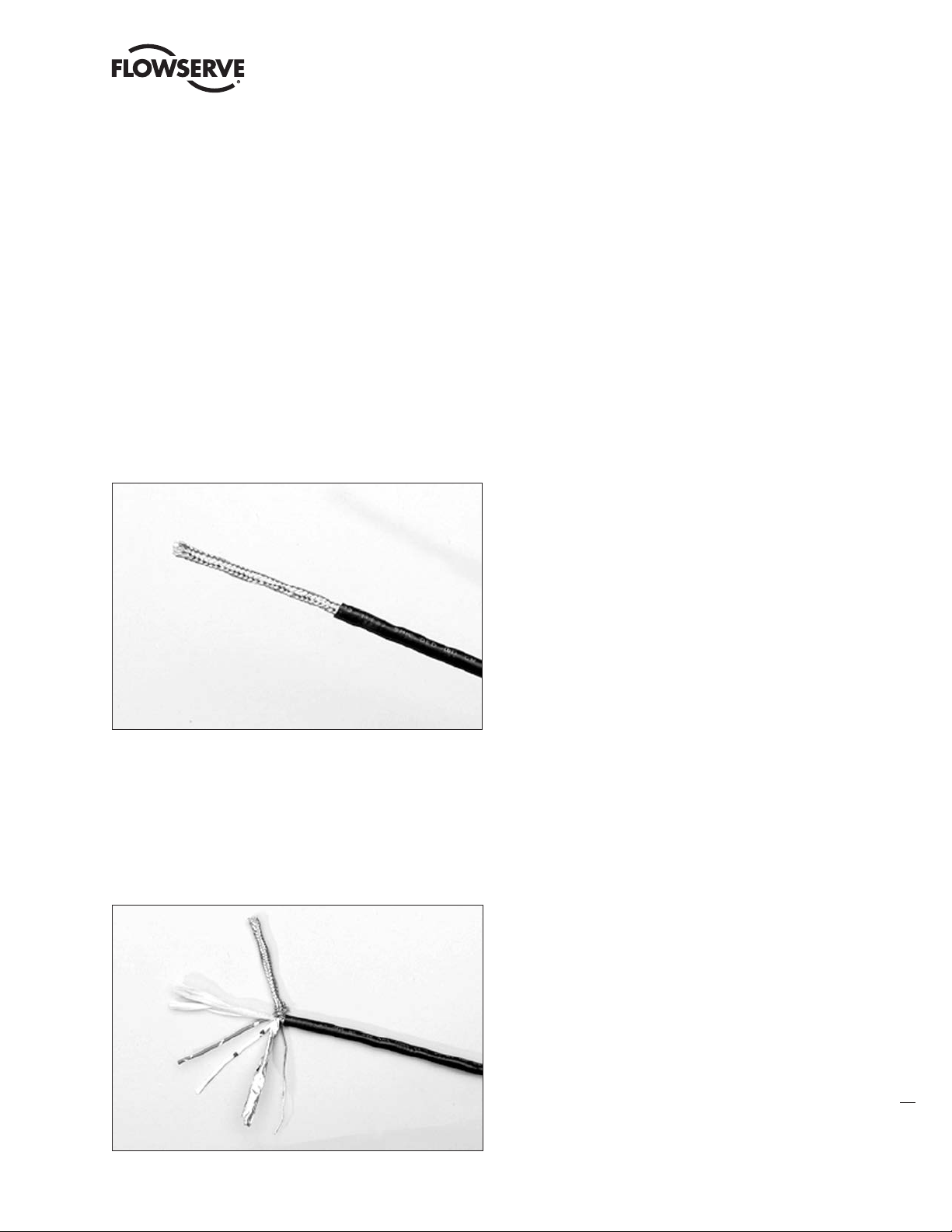

1. Remove two to three inches (5 to 8 cm) of the outer jacket of the cable as shown in Figure 2.14.

Do not cut or nick the shield or the insulated conductors.

Figure 2.14 – Removing Outer Plastic Jacket

NOTE: Excess cable should be cut and removed, not coiled or looped, to prevent noise induction into

the network.

2. Separate the cable parts. Unbraid the shield and peel back the shield to the same point where the

outer jacket was removed as shown in Figure 2.15.

Figure 2.15 – Separating Cable Parts

27

flowserve.com

Page 28

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

3. Cut away the foil shield. Strip the insulation from the conductors approximately 0.4 inch (1 cm)

as shown in Figure 2.16.

Figure 2.16 – Stripping Conductors

4. Apply heat-shrink tubing to insulate the braided shield and to provide stress relief to the cable as

shown in Figure 2.17.

Figure 2.17 – Applying Heat-Shrink Tubing

CAUTION: Do not melt the insulation during the application of heat-shrink tubing.

a

5. Install ring tongue connectors as shown in Figure 2.18.

NOTE: Flowserve recommends the use of Thomas and Betts #RZ22-6 for optimum results.

28

Page 29

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Figure 2.18 – Ring Tongue Connectors

6. Connect the network cables to the MX/QX terminal block as shown in Figure 2.19.

Table 2.8 – Details of Terminal Block Cable Assignments

Terminal Block

Number

1 PBDP-B (-) Out N/A

2 PBDP-B (+) Out N/A

3 Surge/Ground Surge/Ground

4 PBDP-A (-) Out PBPA1 (-)

5 PBDP-A (+) Out PBPA1 (+)

13 PBDP-A (+) In PBPA1 (+)

14 PBDP-A (-) In PBPA1 (-)

15 PBDP-B (-) In N/A

16 PBDP-B (+) In N/A

DP Connection PA Connection

NOTE: Terminal 3 must be connected to earth ground in each actuator for field unit surge

suppression.

NOTE: Ground each segment of the cabling at each field device unit. See Section 2.2.4.1 and

2.2.5.1. Verify the actuator is properly grounded.

7. Connect the cable shields to each other inside the unit. Do not connect them to the unit in any

way. The network shield should be grounded at the end of each segment. For surge suppression,

Terminal 3 must be tied to earth ground in both DP and PA applications.

29

flowserve.com

Page 30

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Figure 2.19 – Connecting Network Cable to the MX/QX Terminal Block

2.4.2.2 Network Cable Connection to the Host System

For instructions on connecting to the host system, see the applicable host system/station. There are

several topologies for the network detailed in Installation Guideline for PROFIBUS-DP/FMS, Version

1.0, September 1998 and PROFIBUS PA User and Installation Guideline, Version 2.2, February 2003.

2.4.3 MX/QX PB Device Installation

The MX/QX PB board is located in the electrical housing of the actuator unit. The PB board has four

standoffs and mounts on top of the main processor board as shown in Figure 2.20. An optional

redundant PB DP board or Input/Output (I/O) board may also be present. The PB and I/O boards

may be inserted in any order on top of the main processor board. For detailed installation instructions, refer to the MX or QX Maintenance and Spare Parts Manuals, LMENIM2314 or LMENIM3311,

respectively.

Figure 2.20a – MX/QX PB DP Primary Figure 2.20b – MX/QX PB DP Primary and

Board Mounted to MX/QX Main Board Redundant Boards Mounted to MX/QX

Main Board

30

Note: Field unit board jumpers, JP1 and JP2, are set to “A” position on Primary board

and “B” position on Redundant board.

Page 31

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Figure 2.21 – PROFIBUS DP Setup Sequence

2.5 MX/QX PB Device Setup

The MX/QX PB option enables the actuator to be controlled by a PROFIBUS communications signal.

If the option has been purchased, it is automatically enabled.

NOTE: If the PB option has not been purchased, the screens for changing PB will not be available. To

add the option, please consult Flowserve Limitorque service at (434) 528-4400.

Figure 2.21 – MX/QX PB DP Setup Sequence

YES

NO

CHA NGE

PB/DP ?

PB DP- A STA TUS

(ON) - OK ?

NO

YES

ES D AC TION

(IGNORE )-OK?

(CLOSE )

NO

(OPEN )

(STOP)

(POSITION )

*

ES D MOVE TO

(X XX%) - OK ?

(0-100% )

Figure 2.21 illustrates the setup sequence for the MX/QX PB DP field unit. For proper operation, either

Position Mode or Open/Close Mode must be selected.

Follow these steps to enter and configure the setup mode:

1. Proceed through the Setup to the CHANGE PBDP? display.

2. Select YES to proceed to the PBDP-A STATUS (ON)-OK? display. PBDP-A Status enables the

user to change from the default condition to turn on and off the digital control capability of the

actuator.

3. Select YES to proceed to the PBDP-B STATUS (ON)-OK? display. PBDP-B Status enables the user

to change from the default condition to turn on and off the redundant digital control capability of

the actuator, if installed.

YES

NO

PB DP-B STATU S

(ON) -OK ?

YES

NO

COMM LOSS

AC TION

(NONE) –OK ?

(CLO SE)

(OP EN)

(S TOP)

(P OSITION )

YES

NO

YES

RE DUND ANT

MAS TER

(Y ES) - OK ?

*

MOVE TO

(X XX% ) - O K?

(0-100% )

NO

NO

YES

YES

MONITOR

STA NDB Y PB

(ON) -OK ?

COMM LOSS

DE LAY

60 SE CS-O K?

(0-4095)

YES

PB ADD RES S 1

OK?

(0-1 25)

NO

Unit incremen ts

YES YES

OPE N/CLOSE

MODE - OK?

NO

NO

POS ITION

MODE - OK?

NO

YES

YES

AN ALOG S CALE

0-10 0-OK?

(0-255)

(0-4095)

CHA NGE PROP/

DE AD B AND?

NO

YES

NO

YES

(1%-100 %)

1% Incr ements

PR OP BA ND

(15% ) - OK?

NO

If P OSITION is cho sen, as action,

*

this menu will appear.

YES

DE ADB AN D

(2% ) - OK?

(1%-50% )

1% Incr ements

YES

NO

4. Select YES to proceed to the REDUNDANT MASTER (YES)-OK? display. Selecting REDUNDANT

MASTER will allow for System Redundancy with two independent connections to Profibus

masters. REDUNDANT MASTER must be set to NO for Flying Redundancy (single Profibus

master connection).

5. If YES is selected, MONITOR STANDBY PB (ON)-OK? is displayed.

6. To allow the standby Profibus master to monitor the health of the actuator’s standby PB DP

board, select YES.

31

flowserve.com

Page 32

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

7. The unit will display PB ADDRESS 1–OK? If OK, select YES. If NO, select different address

(1-125).

8. Select YES to proceed to the ANALOG SCALE display.

9. From ANALOG SCALE, if the default value of 0-100 is OK, select YES. If not, select NO.

10. If YES is selected, ESD ACTION (IGNORE) – OK? is displayed.

11. For ignoring ESD ACTION, select YES. For setting ESD ACTION, select NO. If POSITION is chosen

as action, ESD MOVE TO (XXX%)-OK? is displayed. Select NO to set desired position.

12. If YES is selected, COMM LOSS ACTION (NONE) – OK? is displayed.

13. For no COMM LOSS ACTION, select YES. For setting COMM LOSS ACTION, select NO. If

POSITION is chosen, as action, MOVE TO XXX% OPEN is displayed. Select NO to set desired

position.

14. If YES is selected, COMM LOSS DELAY (60 SEC) – OK? is displayed.

15. For a 60-second delay, select YES. Otherwise, select NO until the required value is displayed.

16. If YES is selected, OPEN/CLOSE MODE-OK? is displayed.

NO

CHANGE

PB/PA?

YES

ESD ACTION

(IGNORE)-OK?

(CLOSE)

(OPEN)

(STOP)

(POSITION)

STATUS

(ON)-OK?

NO

17. For OPEN/CLOSE MODE, select YES. For POSITION MODE, select NO. In position mode, the host

device can set the valve position to any desired value; in OPEN/CLOSE MODE the host can only

fully open or fully close the valve. The user must locally configure one of these two modes.

18. Proceed to configure the proportional band and deadband as discussed in sections 2.5.1 and

2.5.2, respectively.

Figure 2.22 – MX/QX PB PA Setup Sequence

YES

PB ADDRESS

NO(OFF)

YES

XXX% OPEN

(0-100%)

(1)-OK?

MOVE TO

YES

ANALOG SCALE

(1-125)

NO

Unit Increments

COMM LOSS ACTION

YES

(POSITION)

NO

0-100-OK?

(NONE)-OK?

(CLOSE)

(OPEN)

(STOP)

YES

NO

YES YES

COMM LOSS DELAY

(60 SEC)-OK?

MOVE TO

XXX% OPEN

YES

NO

(0-4095)

NO

**

(0-100%)

YES

OPEN/CLOSE

MODE-OK?

NO

NO

POSITION

MODE-OK?

CHANGE PROP/

DEADBAND?

YESYES YES

PROP BAND

(15%)-OK?

(1%-100%)

NO NO

1% Increments

DEADBAND

(2%)-OK?

(1%-50%)

1% Increments

If POSITION is chosen, as action,

*

this menu will appear.

YES

NO

32

Figure 2.22 illustrates the setup sequence for the MX/QX PB PA. For proper operation, either Position

Mode or Open/Close Mode must be selected.

Follow these steps to enter and configure the setup mode:

Page 33

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

1. Proceed through the Setup to the CHANGE PB/PA? display.

2. Select YES to proceed to the STATUS (ON)-OK? display. PB Status enables the user to change

from the default condition to turn on and off the digital control capability of the actuator.

3. The unit will display PB ADDRESS 1–OK? If OK, select YES. If NO, select different address

(1-125).

4. Select YES to proceed to the ANALOG SCALE display.

5. From ANALOG SCALE, if the default value of 0-100 is OK, select YES. If not, select NO.

6. If YES is selected, ESD ACTION (IGNORE) – OK? is displayed.

7. For ignoring ESD ACTION, select YES. For setting ESD ACTION, select NO. If POSITION is

chosen as action, ESD MOVE TO XXX% OPEN is displayed. Select NO to set desired position.

8. If YES is selected, COMM LOSS ACTION (NONE) – OK? is displayed.

9. For no COMM LOSS ACTION, select YES. For setting COMM LOSS ACTION, select NO. If

POSITION is chosen, as action, MOVE TO XXX% OPEN is displayed. Select NO to set desired

position.

10. If YES is selected, COMM LOSS DELAY (60 SEC) – OK? is displayed.

11. For a 60-second delay, select YES. Otherwise, select NO until the required value is displayed.

12. If YES is selected, OPEN/CLOSE MODE-OK? is displayed.

13. For OPEN/CLOSE MODE, select YES. For POSITION MODE, select NO. In position mode, the host

device can set the valve position to any desired value; in OPEN/CLOSE MODE the host can only

fully open or fully close the valve. The user must locally configure one of these two modes.

14. Proceed to configure the proportional band and deadband as discussed in the next sections.

2.5.1 Proportional Band

Proportional band is the range of errors between the position and demand signal that will produce

reduced speed (pulsing). The default value is 15%.

To change from the default value, select NO until the required value is displayed. The value is adjustable between 1% and 100%, in 1% increments.

2.5.2 Deadband

The default deadband value is 2%. For error signals less than this, no motion occurs.

The deadband should be wide enough to prevent “hunting” of the actuator, but as low as possible to

give adequate response to changes in the error signal. To change from the default, select NO to adjust

the value between 1% and 50%, in 1% increments to suit the application.

2.5.3 Valve Data

Valve data may be stored in the MX/QX PB transducer block for use by the host system. Refer to

Bulletin LMENIM2306 (MX) or LMENIM3306 (QX), respectively for instructions to edit data for the

valve serial number, model and type.

33

flowserve.com

Page 34

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

2.6 MX/QX PB Device Description, Capabilities

and Device Type Manager File Installation

2.6.1 MX/QX PB Device Description

A Configuration File (a GSD or EDD file) describes the communication objects in a PROFIBUS device.

In the host system, the configuration device can use Electronic Device Description (EDD) files or CF

files to configure a PROFIBUS system without having the device online. Some host systems need

both EDD and CF files. Refer to your host system and software documentation for the files that are

needed. Please contact Flowserve Limotorque for EDD files.

The GSD (characteristics) files are downloaded from the PROFIBUS website into the host system.

These files are required by the host system for proper configuration and addressing.

The PROFIBUS website is: www.profibus.com

Alternatively, the files can be downloaded from the Flowserve website: www.flowserve.com.

2.6.2 MX/QX PB Device Type Manager

The Device Type Manager (DTM) provides an interface between its specific application software and

a Network Host Station’s Field Device Tool (FDT) frame. The DTM can be integrated into FDT frame

applications to allow users to perform offline and online parameterization, configuration, and status

and diagnostic retrieval. A separate GSD file download is unnecessary when using the DTM. The DTM

file can be downloaded from the Flowserve website: www.flowserve.com.

2.7 Installation Verification

2.7.1 Network Cabling Installation Verification

After installation is complete and prior to operation, inspect the network cable and its connection to

each field device.

NOTE: Units should be disconnected from power. The network should be disconnected from the host

device.

Check for the following:

1. There should not be:

Nicks in the insulation – this can cause a short to the grounded shield.

Cut strands in a stranded conductor – this can cause a poor connection and eventually an open

circuit.

34

2. Cable armor shorted to the cable shield/drain wire. This may not be at ground potential and could

be subject to lightning surges.

3. Shield/drain wires grounded only at one point in the segment to avoid ground loop problems.

4. Ground/earth connections should be at true ground potential and effective at all times. See

Section 2.4.1 for details.

Page 35

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

2.7.2 MX/QX PB Device Installation Verification

Verify the field device is installed as follows:

1. Enter the Setup mode as detailed in the MX or QX Installation and Operation Manual,

LMENIM2306 or LMENIM3306 respectively.

2. In the Setup mode, use the black control knob to select YES to the main menu selection VIEW

DIAGNOSTICS?

3. Select YES to the display VIEW HARDWARE? The VIEW HARDWARE routine will enable some

of the actuator components to be reviewed for integrity. These components are continuously

monitored.

4. Select YES to scroll through the menu selections. For a PB PA field unit the display will eventually

read PBPA (OK) – NEXT? For a PB DP field unit, the display will eventually read PBDP-A (OK) Next? If a redundant PB DP field unit is installed, and board jumpers JP1 and JP2 are in the “B”

position, the display will read PBDP-B (OK) - Next?

NOTE: PB PA field unit: If the PB PA (OK) – NEXT? does not appear, verify PB PA bus power is

applied. If PA bus power is applied, contact Flowserve for assistance. PB DP field unit: If the

PBDP-A (OK)-NEXT? or PBDP-B (OK)-NEXT? (for redundant units) does not appear, verify field

unit board jumper JP1 and JP2 settings are in “A” position for primary unit and “B” position for

redundant unit.

5. To return to the normal display, use the red knob to select either LOCAL or REMOTE.

2.8 Configuration Confirmation

Field device operation cannot be verified until the complete PROFIBUS system is operational.

However, routine checks can be performed to verify many functions.

2.8.1 Checking Connections

Verify that all connections, including network data wires, shield ground, discrete inputs, discrete

outputs, analog inputs and analog outputs are in accordance with MX/QX wiring diagrams and

MX/QX PB device diagrams in Section 2.4.

2.8.2 View Settings

Refer to the MX or QX Installation and Operation Manual, LMENIM2306 or LMENIM3306 respectively, to access the view settings menu. Verify the settings as follows:

1. From the VIEW SETTINGS display, scan to the VIEW PB/DP or VIEW PB/PA? display depending

on which option is installed.

2. From the VIEW PB/DP or VIEW PB/PA? display, select YES and check that the PB/DP or PB/PA

status is ON. This confirms that PB/DP or PB/PA is enabled.

3. If the MX/QX contacts are to be controlled via the network to control external equipment, from

the VIEW PB/DP or VIEW PB/PA? display, select NO and obtain the VIEW STATUS AND ALARM

CONTROL? display. Verify that the digital outputs, S-1 and S-2 are set for “Network” control.

35

flowserve.com

Page 36

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

2.8.3 Checking the Normal Display

Place the selector switch in LOCAL or REMOTE position. The valve position will be indicated at the

top of the display. For a PB PA field unit, STATUS OK or PB COMM LOSS should be indicated at the

bottom of the display. For a PB DP field unit, STATUS OK or PBDP COMM LOSS should be indicated

at the bottom of the display.

2.8.3.1 STATUS OK

If STATUS OK is displayed, then the field device is sufficiently powered and communicating with the

host system.

Figure 2.23 illustrates the field unit with a normal display.

Figure 2.23 – Normal Display, Field Unit is Communicating with Host

Remot e

or

Local

100% OPEN

STATUS OK

2.8.3.2 COMM LOSS

If PB COMM LOSS is displayed, no communication is occurring between the PB PA field unit and the

Host. If PBDP COMM LOSS is displayed, no communication is occurring between the PB DP field

unit and the Host. This could be due to a number of factors, including problems with the host/master

station and/or the network. Check all local connections and configurations. If these are correct and

the PB COMM LOSS is still displayed, then the solution to this problem must await full system

commissioning.

If PB COMM LOSS is displayed, bus power is present but no communication to the host exists. If

HARDWARE FAIL is displayed, then the bus power is not present.

Figure 2.24a illustrates the PB PA field unit with a COMM LOSS display.

Figure 2.24a – No Communications

Remot e

36

or

Local

100% OPEN

PB COMM LOSS

Page 37

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Figure 2.24b illustrates the PB DP field unit with a COMM LOSS display.

Figure 2.24b – No Communications

Remot e

or

Local

100% OPEN

PBDP COMM LOSS

2.8.3.3 HARDWARE FAILURE

If HARDWARE FAILURE is displayed, either the device or the bus power supply has failed. Check the

bus power supply voltage and the wiring connections.

Figure 2.25 illustrates the field unit with a BUS display.

Figure 2.25 – Hardware Failure, No Communication, Bus Power Lost

Remot e

or

Local

100% OPEN

HARDWARE

flowserve.com

37

Page 38

3

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Software

3.1 PROFIBUS Protocol

This fieldbus system uses the PROFIBUS fieldbus protocol to communicate over the PROFIBUS

network with other PROFIBUS devices. The signals are encoded using the Non-Return to Zero

(PROFIBUS DP) and Manchester Biphase-L (PROFIBUS PA) technique. The signals are called

synchronous serial because the clock information is embedded in the serial stream. The protocol

uses built-in error checking rules when processing data.

3.2 PROFIBUS Function, Transducer,

and Physical Blocks

The MX/QX Actuator is designed to comply with the PROFIBUS PA Profile, Version 3.0. This profile

provides the user with a standard interface for control and management.

This standard profile provides the following blocks for the network user. Details of each block are

described in the following paragraphs.

• One Physical Block

• One Transducer Block

• Several Function Blocks

The Physical Block is used for general device management. A device contains only one Physical

Block. Physical Blocks are usually used during commissioning and maintenance, and contain

parameters such as:

38

• Manufacturer’s Name

• Device Name (ID)

• Device Serial Number

• Identification and Maintenance (I&M) Functions

Page 39

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

The Transducer Block is used to convert signals from the actuator hardware to a digital format usable

by Function Blocks and the network host. It also conveys data from network users and Function

Blocks, sending this data to the actual hardware.

Function Blocks contains two types of parameters. The first type, Configuration parameters, are

used during commissioning to configure specifically what data the function block will use and how

it will process the data before sending it to its final destination. These configuration parameters are

sometimes called Acyclic parameters, because they are only read or written when needed.

The second type of parameter in a Function block is the Process parameter type. These parameters

provide the process data to the device or network user when the process is running. When the

process is running these parameters are updated in a periodic cyclic manner and are therefore

sometimes referred to as Cyclic data parameters.

The Function Blocks provide the network user with a standard interface for setting and obtaining

process data in the device. Function blocks can be connected together through the host to perform

the specific control functions of the process. The host device also monitors the function blocks to

supervise the entire control system.

The figure below provides a block diagram view of the various standard “blocks” in the MX/QX

actuator for use by the network user.

The Analog Output and Discrete Output function blocks accept commands from the network user and

force the actuator to perform some kind of action, i.e., open, close, modulate, set network ESD, etc.

The Analog Input and Discrete Input bunction blocks provide the network user with information from

the actuator such as current position alarms, faults, etc. The following sections provide further details

about each function block.

Figure 3.1 – MX/QX Actuator Block Overview

MX/QX Actuator Block Overview

One AI Blocks

PROFIBUS

Networks

Communication

Physical Block

One AO Blocks

Four DI Blocks

Two DO Blocks

One

Transducer

Block

Actuator

Hardware

flowserve.com

39

Page 40

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

The following table provides generic descriptions of how the various blocks are used in the

PROFIBUS Profile Version 3.0 standard.

Table 3.1 – Description of the Function Blocks

Function Block Name

Analog Input AI 1

Analog Output AO 1

Discrete Input DI 4

Discrete Output DO 2

Transducer Block 1

Number of

Blocks

Description

Processes field device measurements and makes

them available to other function blocks; supports

alarming, filtering, signal status, mode control,

and simulation.

Assigns an analog setpoint value to a field device

through a transducer block I/O channel; supports

mode control, signal status calculation, and

simulation.

Processes a single discrete input from a field

device and makes it available to other function

blocks; supports alarming, signal status propagation, mode control, and simulation.

Processes a discrete setpoint and outputs it to a

specified I/O channel to produce an output signal;

supports mode control, output tracking, and

simulation.

A custom block to monitor and control the

actuator; connects function blocks to actuator

hardware.

40

Physical Block 1

A standard block to provide general management

of the device.

Standard PROFIBUS parameters used in these blocks are listed in Appendix C.

Each Function Block contains a “Mode” parameter, defining the operating behavior of the function

block. There are two main parts to the Mode parameter. The Target mode is the mode of operation

desired by the network user. The Actual mode is the block’s actual current mode.

The effect of mode on the operation of the Function Block is summarized as follows:

Out of Service (O/S) The block is not being evaluated. The output will maintain the last value or be

a value defined by the user in the case of a power loss.

Local Override (LO) In the Local Override mode, the block output tracks the value of the input

parameter.

Manual (Man) The block output is not being calculated. It is directly set by the network user.

Automatic (Auto) The block output is calculated using the input from the transducer block in the

case of an input function block and using a setpoint value provided by the host or network user in the

case of an output function block. For physical blocks and transducer blocks, this mode indicates that

the block functions are enabled for operation.

Remote Cascade (RCas) The block setpoint is being set by the control application (host) through

the remote cascade parameter RCAS_IN.

Page 41

PB DPV1 / PA Field Unit Installation and Maintenance FCD LMENIM2336-03 – 12/12

Execution of a function block, physical block or transducer block will be controlled by the mode

parameter. Mode sub-index values are defined as follows:

1. Target – This is the mode requested by the operator. Only one mode from those allowed by the

permitted mode parameter may be requested.

2. Actual – This is the current mode of the block, which may differ from the target based on

operating conditions. Its value is calculated as part of block execution.

3. Permitted – Defines the modes which are allowed for an instance of the block. The permitted

mode is configured by the block design group, i.e., is defined for every block in the according

data sheet. Any mode change request will be checked by the device to ensure that the request