Page 1

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East 1978 Foreman Dr.

Flow Control Division Provo, Utah 84606 Cookeville, TN 38501

www.flowserve.com Phone: 801 373 3028 Phone: 931 432 4021

LV1 Lockout and Vent Valve

The LV1 Lockout and vent valve is a NAMUR

mounted module for the Automax SuperNova

actuator, with two primary uses. The LV1 may be used

as a compact bypass valve for use with a manual

override to shut off supply air and vent actuator ports.

The LV1 may also be used as a lockout valve which,

when properly implemented, will satisfy OSHA

Standard 1910.47, “The Control of Hazardous

Energy.” The LV1 may be sandwich mounted with

other Automax NAMUR accessories or may be used

with the NPT adapter.

Installation Instructions

Automax sandwich NAMUR mount accessories are

easily installed to the SuperNova actuator, simply by

stacking one on top of the other and bolting the entire

stack to the actuator NAMUR mounting surface.

Orientation of LV1:

The LV1 should be mounted to the actuator with

NAMUR O-ring grooves toward the actuator. The

spool shift lockout knob may be oriented either left or

right. Standard mounting is to the left, with the

exhaust port facing down. Automax recommends

orientation such that water or other contaminants

cannot drip into exhaust port.

To Install:

1. Follow order of installation below in stacking

accessories. If an accessory is not required, skip

it and proceed to the next accessory.

4. Mount entire stack to SuperNova NAMUR mounting

face, using appropriate bolt kit shown in chart on back

page of IOM. Apply Locktite Threadlocker 222 or equal

to screws prior to assembly.

Operation

The LV1 functions as a lockable block and bleed valve for

use as a manual override bypass valve or as a air supply

lockout valve. Under normal operation, air flows freely to

the actuator. The spool is shifted to block pressure ports

and exhaust actuator air pressure. A lock may be inserted

into the spool in the block and bleed position.

SuperNova Actuator

A25N Solenoid

Valve

Order of Installation:

a. LV1 Lockout and vent valve

b. FC1, FCDA, or FCSR flow control

c. APS1 or APS2* air purge system

or NPT1* NAMUR-NPT adapter block

d. A25N* solenoid valve

*One of these accessories should be the

last accessory in the stack. The NPT1

block provides 1/4’ NPT ports in cases

where FC1, FCDA, FCSR or LV1 would

be last accessory in stack.

2. Properly orient NAMUR accessory (see

appropriate IOM.)

3. Insert O-rings into O-ring grooves on back face of

accessory.

LV1Lockout and Vent Valve in

Automatic Operation

Used with manual override, the LV1 exhausts internal

actuator pressure to atmosphere, while blocking supply

pressure. Without internal pressure on the pistons, the

actuator may be freely manually operated. The single

exhaust port on the LV1 allows the piston chambers to

draw clean air from each other, rather than drawing

outside air as the actuator is being manually cycled back

and forth. This feature keeps possible corrosive

atmospheres from entering the actuator.

L V1 Valve

B00058-4 (AUTO-17) 3/02 Page 1 of 2

©

2002, Flowserve Corporation, Printed in USA

Page 2

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East 1978 Foreman Dr.

Flow Control Division Provo, Utah 84606 Cookeville, TN 38501

www.flowserve.com Phone: 801 373 3028 Phone: 931 432 4021

LV1 Lockout and Vent Valve

Operation (cont.)

Locking spool shaft in block and bleed position prevents

air pressure from operating the actuator. The intent of

this application is to satisfy OSHA requirements for

control of hazardous energy. With air supply to actuator

blocked, the actuator cannot be operated. The valve

mounted to the actuator is effectively “locked out” from

automatic operation.

Temperature: -20 F to 180

Pressure: 20 psig to 120 psig

Media: Dry or lubricated non-corrosive gas

compatible with nitrile/viton seals.

Estimated c

: 1.75

v

o

Maintenance

The LV1 module is factory lubricated for long lif e.

Should any problems arise with the LV1, consult factory.

If the valve is to be stored for extended periods of

time, periodically operate the spool to keep seals from

taking a set.

How to Order

Order part number LV1 with appropriate NAMUR mount

bolt kit from chart at right.

Example:

with A25N solenoid valve, order

To order LV1 to be sandwich NAMUR mounted

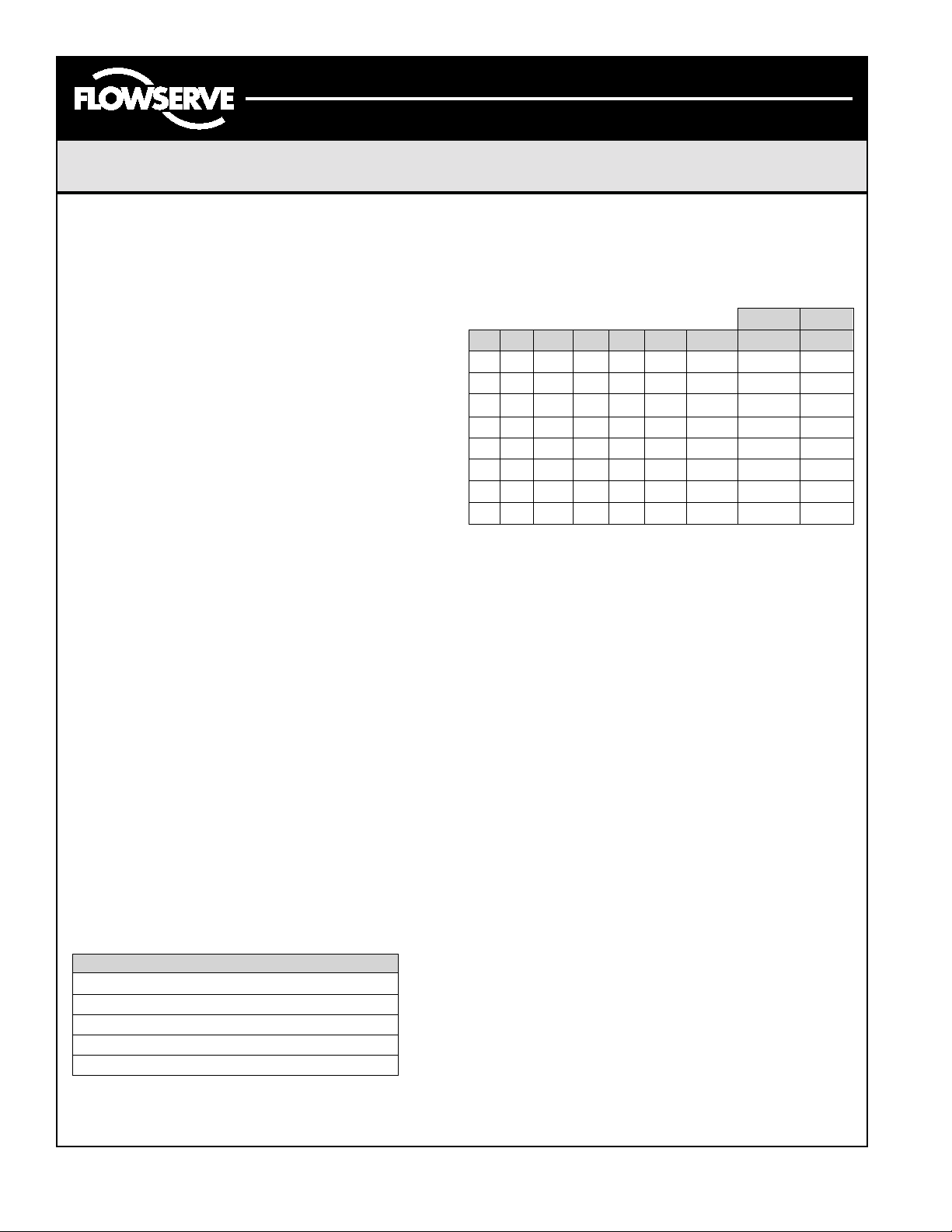

NAMUR Accessory Bolt Chart

FC1 / FCDA FCSR

LV1 FC# APS1 APS2 NPT1 A25N Bolt Kit Bolt Kit Bolt Kit

√ √ NBK40 NBK25 NBK40

√ √ √ NBK50 NBK65

√ √ NBK60 NBK50 NBK60

√ √ NBK55 NBK45 NBK55

√ √ √ NBK70 NBK80

√ √ √ NBK65 NBK55 NBK65

√ √ √ √ NBK80 NBK90

√ √ √ NBK75 NBK85

Other NAMUR accessories:

• EC1 - Sandwich mount flow control-one

direction.

• FCDA - Sandwich mount flow control-dual

direction for DA actuators.

• FCSR - Sandwich mount flow control-dual

direction for SR actuators.

• APS1 - Air purge system for spring return

actuators sandwich mount with A25N

solenoid valve.

• APS2 - Air purge system for spring return

actuators Namur mount for remote/line

mount solenoid valves.

• NPT1 - 1/4” NPT adapter plate.

• A25N - NAMUR mount solenoid valve.

Note:

see appropriate IOM’s for additional

information on above NAMUR accessories.

LV1 and NBK55.

How to Specify

The lockable block and bleed valve shall be an

Bill of Material

Item Material

Body Aluminum, Anodized

Spool Aluminum, Anodized

Endcap Aluminum, Anodized

Seals Nitrile, viton

Knob Plastic

B00058-4 (AUTO-17) 3/02 Page 2 of 2

©

2002, Flowserve Corporation, Printed in USA

Automax LV1 module, capable of being sandwich

NAMUR mounted with other NAMUR mount

accessories. The body shall be anodized aluminum.

Spool shall have extension shaft with knob and hole

capable of accepting a standard lock. In normal

position, valve shall allow free air flow. In locked

position, valve shall block external pressure, and vent

actuator pressure with internal air purging of the

cylinder bore during manual gear operation.

Loading...

Loading...