Fisher & Paykel DD24STI9N Installation manual

SINGLE DISHDRAWERTM DISHWASHER

DD24SI, DD24STI & DD24SHTI models

INSTALLATION GUIDE

US CA

59186 A 08.17

1 SAFETY AND WARNINGS

!

WARNING!

Electrical Shock Hazard

Before installing the dishwasher, remove the house fuse or open the circuit

breaker. If permanently connecting the dishwasher, be sure the power is

isolated and the dishwasher unplugged.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of a malfunction or breakdown,

grounding will reduce the risk of electric shock by providing a path of least

resistance for electric current. This appliance is equipped with a cord having

an equipment-grounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is installed and grounded in

accordance with all local codes and ordinances. WARNING - Improper

connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualified electrician or service representative if

you are in doubt as to whether the appliance is properly grounded.

If the dishwasher is installed as a permanently connected appliance:

GROUNDING INSTRUCTIONS - This appliance must be connected to a

grounded metal, permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the appliance.

Do not modify the power supply plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a qualified electrician. Do

not use an extension cord, adapter plug or multiple outlet box.

Failure to follow this advice may result in electrical shock or death.

IMPORTANT SAFETY INSTRUCTIONS

●

Installation of this dishwasher requires basic mechanical and electrical skills.

●

Be sure to leave these Instructions with the Customer.

●

Installation must comply with your local building, electricity, and plumbing regulations.

●

At the completion of the dishwasher installation, the Installer must perform the Final

Checklist.

●

Remove all packaging materials supplied with the dishwasher.

●

This dishwasher is manufactured for indoor use only.

●

Ensure all water connections are turned OFF. It is the responsibility of the plumber and

electrician to ensure that each installation complies with all Codes and Regulations.

●

The dishwasher MUST be installed to allow for future removal from the enclosure if service

is required.

●

The switched power outlet must be outside the dishwasher cavity, so that it is accessible

after installation.

●

Care should be taken when the appliance is installed or removed to reduce the likelihood

of damage to the power supply cord and hoses.

●

If the dishwasher is to be relocated from one installation to another it must be kept

upright to avoid damage from water spillage.

●

Make sure only new hoses are used for connection (supplied with the dishwasher). Old

hoses should not be reused.

●

Failure to install the dishwasher correctly could invalidate any warranty or liability claims.

●

If the product is installed in a motor vehicle, boat or similar mobile facility, you must bring

the vehicle, boat or mobile facility containing the product to the service shop at your

expense or pay the service technician’s travel to the location of the product.

●

This dishdrawer is intended for connection to the hot-water supply.

●

Failure to install the dishwasher correctly could invalidate any warranty or liability claims.

!

WARNING!

Fitting integrated front panels requires access to electrical service areas.

This work must be performed and certified by a qualified electrical service technician.

Electrical Shock Hazard

WARNING: To reduce the risk of electrical shock, fire, or injury to persons, the

installer must ensure that the dishwasher is completely enclosed at the time

of installation.

Before fitting the front panels and connecting the ‘knock to pause’ module (if

necessary), the installer must ensure that the dishwasher is disconnected from

the power supply.

After installing the front panels, the installer must ensure that the following

components are electrically grounded: the panel bracket and any custom

metal component (e.g. handle) that extends past the rubber seal.

Failure to follow these warnings may result in electrical shock, injury or fire.

!

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

1

●

Ensure the product is not plugged in when fitting custom panels.

●

Installation of custom panels requires basic mechanical and electrical skills.

●

Installation must comply with your local building and electricity regulations.

●

Failure to install the custom panels correctly could invalidate any warranty or liability

claims.

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to

change at any time. For current details about model and specification availability in your country,

please go to our website www.fisherpaykel.com or contact your local Fisher & Paykel dealer.

2 PARTS SUPPLIED

Drain hose

support (1)

Phillips

16 mm

screws (7)

Drain hose

joiner (1)

38 mm

bottom fixing

screws & metal

washers (2)

Rubber washer

for inlet hose (1)

(comes already

fitted)

Wire clip (1)

(for securing

Drain hose joiner)

Clamp (1)

(for securing

Drain hose joiner)

Moisture protection

tape (1)

(to prevent moisture

damage to cabinetry)

Side mounting

bracket kit

(A and B) (2)

OPTIONAL

Cavity Bracket Kit (1)

(supplied with Tall

Height Models only)

(fitted before installation

in order to conceal

the gap at the top of

the cavity left after

installation.)

Top

mounting

brackets (2)

OPTIONAL

Edge Protector (1)

(If the services hole

is through a metal

partition, the hole must

be protected with the

Edge Protector supplied

to prevent damage to the

power cord or hoses.)

Panel bracket (1)

& Knock-to-Pause Module (1)

(shipped fixed to product)

If the Drain hoses supplied are not long enough to reach your services, you must use a Drain Hose Extension Kit P/N 525798 which will extend the drain

hoses by 11’ 10” (3.6m). The kit is available from the nearest Fisher & Paykel Authorized Service Center, or Toll free 1.888.936.7872 or www.fisherpaykel.com

Panel mounting

screws (6)

External Venting kit (1)

2

3 OPTIONALLY HARD WIRING PRIOR TO INSTALLATION

3-A REMOVE THE DRAWER 3-B REMOVE THE ACCESS COVER & REMOVE POWER

To prevent kinked hoses

Either sit the drawer down on the left

hand side (recommended) or rotate the

drawer clockwise, resting it on its side after

1

removal.

Clip

1

Clip

1

3

2

3

4” (100mm)

Press the release tabs in

on either side and push

back to release drawer

from runners.

Lift drawer off runners.

Sit the drawer down

Rotate the drawer

clockwise (max. 90

and rest on side.

4

Push drawer

runners back

in on either

side.

4

Push drawer

runners back in

on either side.

o

)

1 With a flat-bladed screwdriver, push

in the clips and slide out the access

cover.

2 Unscrew the electronics module

cover.

3 Carefully pull out the electronics

module and rest on the chassis base

out of the way.

4 With a screwdriver, unclip the plastic

harness cover and hinge open.

5 Slide the terminal block cover

sideways to unlock and hinge open

to access the terminal block.

6 Unscrew the Live, Neutral and Earth

wires as shown.

7 Unscrew the three screws on the

base as shown and remove the cord

from the product.

Access cover

5

4

Remove existing

power cord

7

6

2

Electronics

module

Terminal

Block cover

7

3

3-C TERMINATE MAINS WIRING AS SHOWN AND REPLACE MODULE AND COVERS

8

9

IMPORTANT!

Ensure the mains wires are routed

UNDERNEATH all other harness

wiring from the electronics module.

3 OPTIONALLY HARD WIRING PRIOR TO INSTALLATION

12

13

11

10

14

8 Fit a suitable cable clamp for the

conduit through the metal knockout.

Ensure wiring is routed through or

under under housing ribs.

9 Screw down the Live, Neutral and

Earth wires correctly.

10 Push the plastic harness cover back

over. It should clip back into place

11 Fold down and slide back the

terminal block cover.

12 Refit the electronics module back

into position, being careful of wiring.

13 Replace the screw securing the

electronics module.

14 Slide the access cover back,

ensuring the 2 clips shown are fully

locked in place.

NOTE: Use copper conductors

only.

Before refitting the

drawer, ensure the hoses

are not twisted and the

latches at the rear of

each drawer runner are

facing forward.

2

3-D REFIT THE DRAWER ONTO THE RUNNERS & CLOSE

Lift or rotate counterclockwise the

drawer back onto the drawer runners

on either side.

4” (100 mm)

3

1

Release tab

4

Pull the release tabs forward on both

sides 4” (100 mm). Ensure the tabs are

fully pulled forward and click into place.

4

4 PRODUCT DIMENSIONS

E

B

PLAN

A

H

D

I

C

F

PROFILEFRONT

PRODUCT DIMENSIONS INCHES (MM) INCHES (MM)

Overall height of product

A

Overall width of product

B

Overall depth of product

C

Depth of chassis (to back of front drawer panel)

D

Depth of drawer front panel

E

Height of drawer front panel min. 16 1/16” (408)

F

Height of chassis

G

Ventilation gap below drawer front panel

H

Maximum extension of drawer

I

1

includes 1 ⁄16” (2mm) high bracket slots 2 assuming a front panel thickness of 11/16” (18mm)

3

recommended for a 1 ⁄16” (2mm) ventilation gap below panel, if cavity height is 16 1/4” (412mm)

4

recommended for a 1 ⁄16” (2mm) ventilation gap below panel

1

1

2

2

G

STANDARD

HEIGHT

MODELS

DD24SI

16 1/8” (410) min. 17 7/8” (454)

23 9/16” (599) 23 9/16” (599)

22 1/2” (571) 22 1/2” (571)

21 3/4” (553) 21 3/4” (553)

5/8” - 13/16” (16-20) 5/8” - 13/16” (16-20)

3

min. 17 13/16” (452)

16 1/8” (410) 17 7/8” (454)

min. 1/6” (2) min. 1/6” (2)

21 7/16” (545) 21 7/16” (545)

TALL

HEIGHT

MODELS

DD24STI

DD24SHTI

4

5

K

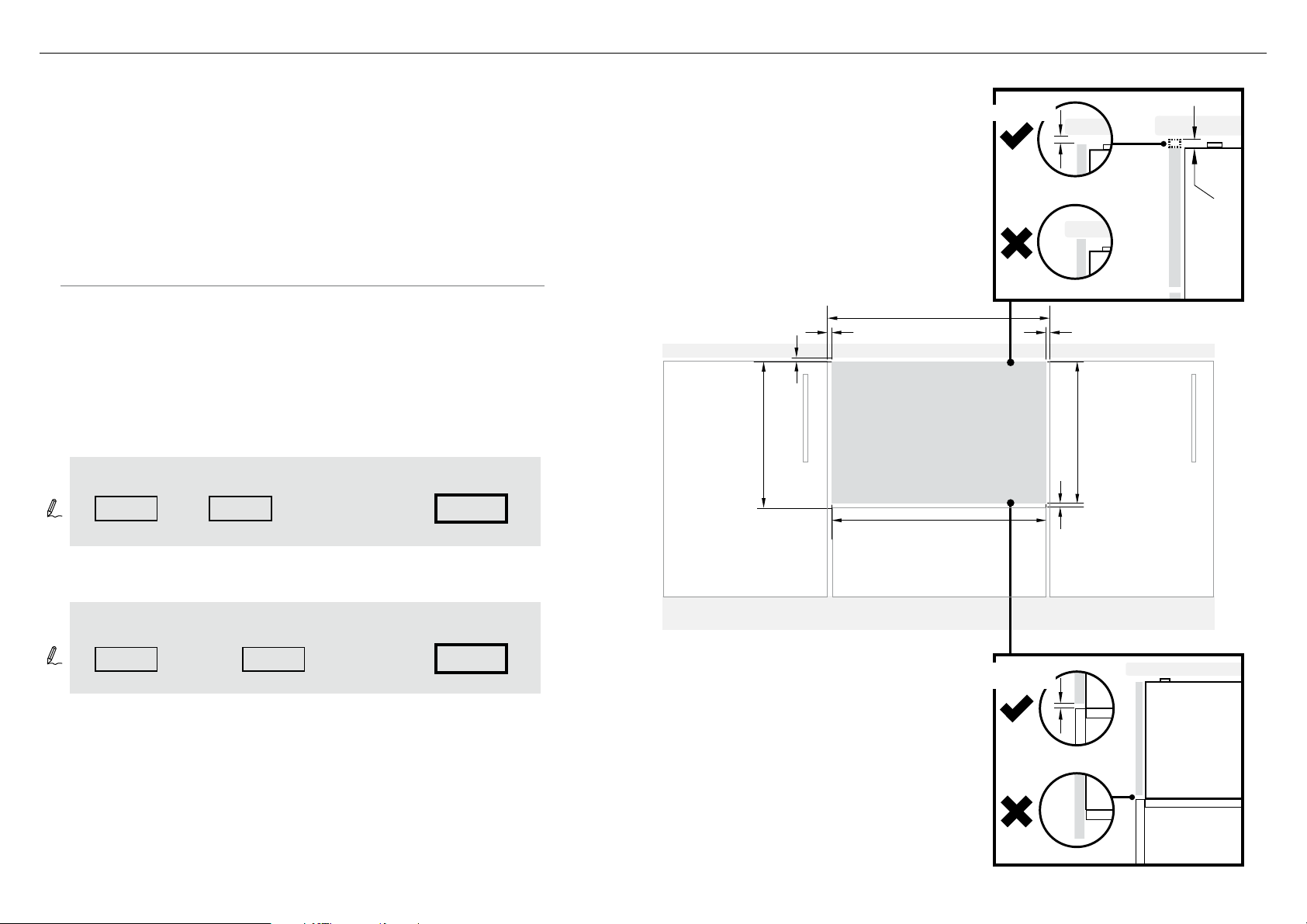

5 CABINETRY DIMENSIONS

L

Bracket slots

PLAN

STANDARD

HEIGHT

MODELS

DD24SI

CABINETRY DIMENSIONS INCHES (MM) INCHES (MM)

Inside height of cavity

J

Inside width of cavity

K

Inside depth of cavity

L

min. 16 1/4” (412) min. 18” (456)

23 5/8” (600) 23 5/8” (600)

min. 22 1/16” (560) min. 22 1/16” (560)

Minimum clearances from adjacent cabinetry

TALL

HEIGHT

MODELS

DD24STI

DD24SHTI

J

PROFILE

Custom Filler Panel

J

min. 1/2” (13 mm)

clearance from a

corner cupboard

min. 1/16” (2 mm)

clearance to adjacent

cupboard door

If your cavity height leaves a visible gap

under your countertop when you open

the drawer:

Fit the supplied cavity bracket (or

a custom cavity filler panel) before

installation in order to conceal any

gap at the top of the cavity left after

installation.

PROFILE

6

6 CUSTOM DRAWER PANEL SPECIFICATIONS

FRONT PANEL MATERIAL SPECIFICATIONS

●

5/8 - 13/16” (16 - 20mm) panel thickness

●

Adequately sealed to withstand moisture (122OF/50OC @ 80% RH)

Because of it being a hot and wet environment generally, the back and sides of the

panel should be completely sealed with a waterproof vapour barrier (ie polyurethane)

to prevent damage to the panel.

●

The back of the panel (including any integrated handle) should be completely flush so

that the seal between the panel and the rubber trim is maintained.

●

Installation outside these specs may result in condensation on cabinetry surfaces.

●

Maximum weight of panel: 20lb (9kg)

The following calculations assume the top of the upper panel is

aligned with the top of the adjacent cabinetry.

WIDTH OF THE PANEL

Measure A (the width between adjacent door/drawer fronts)

and write it in the first box below, then complete the equation.

Clearance to adjacent

A

cabinet front

WIDTH OF PANEL

- 2x =

(min. 1/16” (2mm))

HEIGHT OF THE PANEL

(23 7/16”-24 3/16” (596-615mm))

1/16” (2mm)

Note: when the top of the dishwasher

has to be lower than the adjacent

cabinetry, the top of the panel can

extend above the chassis where required,

however a min. 1/16” (2mm) gap to

the benchtop must be maintained.

A

min. 1/16” (2mm) min. 1/16” (2mm)

min. 1/16” (2mm)

B

PANEL

WIDTH OF PANEL

HEIGHT OF

PANEL

Ventilation Gap

min. 1/16” (2mm)

with External Venting

Kit installed

B

Ventilation Gap

(min. 1/16” (2mm))

HEIGHT OF PANEL

=-

Ventilation Gap (min. 1/16” (2mm))

with External Venting Kit installed

7

Loading...

Loading...