DishDrawer

Models

DD601v2 DD601Iv2

DS601v2 DS601Iv2

599039

Contents

1.0 SERVICE REQUIREMENTS 1

1.1 Health & Safety 1

1.2 Specialised Tools 3

2.0 DIMENSIONS & SPECIFICATIONS 4

3.0 TECHNICAL OVERVIEW 5

3.1 Electronics 5

3.2 Motor 5

3.3 Cabinet 5

3.4 Filling 6

3.5 Dispensing Detergent 7

3.6 Lid Seal 7

3.7 Wash Cycle 8

3.8 Heating 8

3.9 Filter Plate 9

3.10 Drain Cycle 9

3.11 Drying Cycle 10

3.12 Deflating 10

3.13 Lockring Nut 10

3.14 Wiring Cover 11

4.0 DIAGNOSTICS 12

4.1 Setup & Diagnostics 12

4.2 Fault Modes 12

4.3 Diagnostic Modes 13

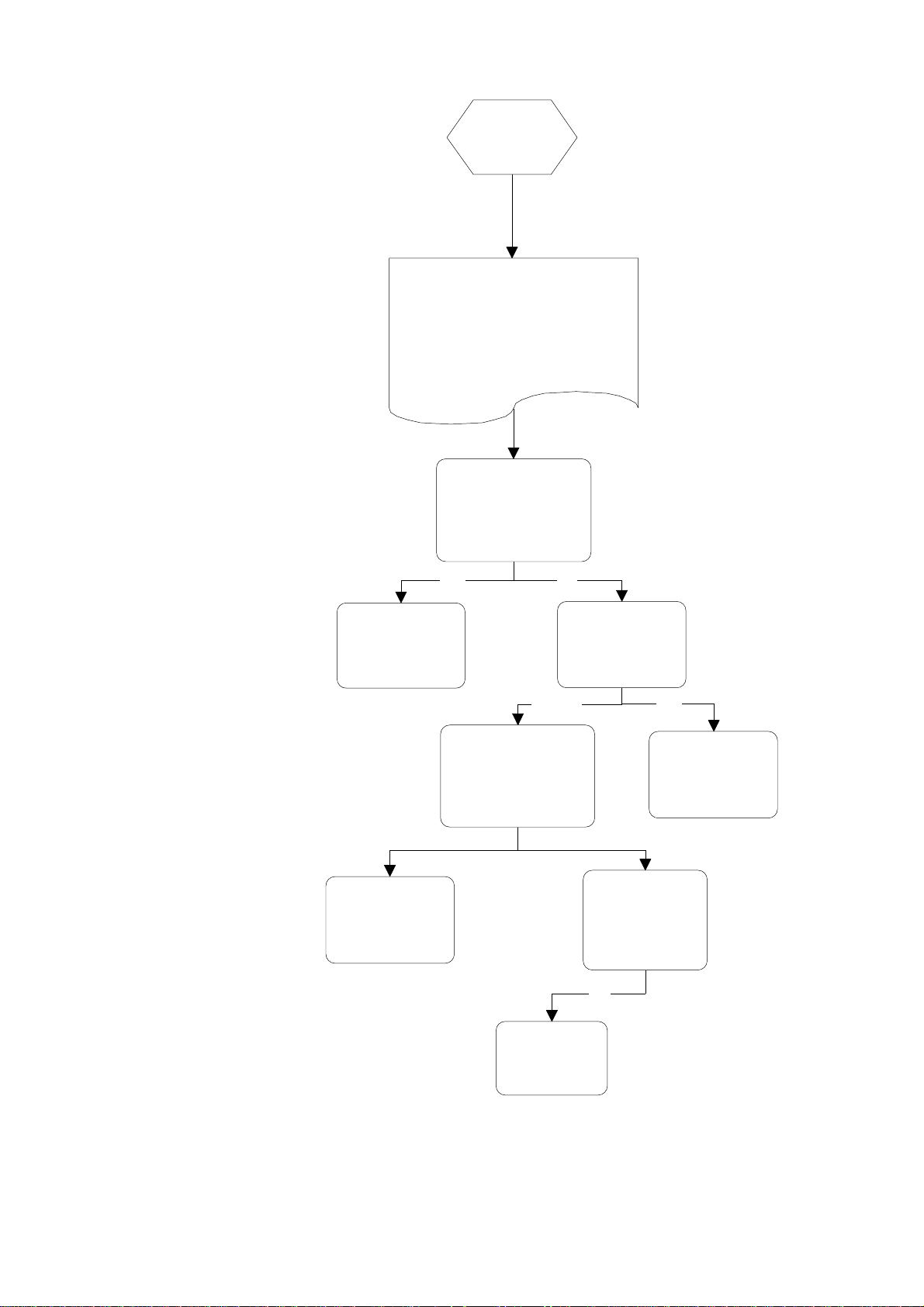

4.4 Diagnostics Quick Reference Flow Chart 18

4.5 Fault Codes 20

5.0 WIRING DIAGRAM 33

- i -

6.0 SERVICE PROCEDURES 34

6.1 Drawer Front Removal 34

6.2 Handle and LCD Display Removal 34

6.3 Drying Fan Removal 34

6.4 Detergent Dispenser 35

6.5 Electronic Controller 35

6.6 Top Kick Strip Removal 35

6.7 Lower Kick Strip Removal 36

6.8 Wiring Cover Removal 36

6.9 Filter Plate Removal 36

6.10 Rotor Assembly Removal 36

6.11 Tub Removal 37

6.12 Locking Ring, Element Plate & Motor Assembly Removal 37

6.13 Lid Assembly Removal 38

6.14 Lid Seal Replacement 38

6.15 Slide Runner Replacement 39

6.16 Front Trim Replacement 39

6.17 Sound Gasket Replacement 39

6.18 Link Assembly Removal 40

6.19 Air Pump Removal 40

6.20 Exhaust Valve Removal 41

6.21 Water Valve Removal 41

6.22 Flood Switch Removal 41

6.23 EMI Filter Removal 42

6.24 Tub Microswitch Removal 42

- ii -

1.0 SERVICE REQUIREMENTS

1.1 Health & Safety

Note: When servicing the dishdrawer, health and safety issues must

be considered at all times. Specific safety issues are listed

below with their appropriate icon. These are illustrated

throughout the service information to remind service people of

the issues.

1.1.1 Electrical Safety

Ensure the mains power has been disconnected before

servicing the DishDrawer. If the mains supply is required to be

on to service the DishDrawer, make sure it is turned off when

removing any electrical component or connection to avoid

electrical shock.

1.1.2 Electrostatic Discharge

An anti-static strap is to be used as electrical static discharge

(ESD) protection when servicing electronic components.

1.1.3 Good Working Practices

Ensure the work area is in a tidy and orderly condition at all

times so as not to cause a hazard while service work is being

completed. Always clean and tidy the DishDrawer and work

area after service is completed.

1.1.4 Isolate Water Supply

Turn off the water connection tap before servicing.

1.1.5 Water Leak Check

Check for water leaks as part of the testing after the service

has been completed.

- 1 -

1.1.6 Insulation Test

Megger test to check insulation.

Warning: Short together the phase and neutral pins on the

plug so as not to damage any electronic circuitry.

1.1.7 Solvent and Excessive Heat Damage

Plastic surfaces can be damaged by solvents and excessive

heat.

1.1.8 Sheet Metal Edges

When working around cut sheet metal edges use appropriate

gloves or protection to eliminate the chance of receiving a

laceration.

1.1.9 Diagnostics

While in diagnostics some safety devices are bypassed.

D

Ensure you do not run components unattended. They may

overheat, flood, burnout or cause water damage.

- 2 -

1.2 Specialised Tools

For servicing this product Specialised tools are required.

1.2.1 Static Strap:

To be used as ESD protection when replacing or handling

electronic components.

1.2.2 Down Load Pen Connection: P/N 425930C.

To be used to retrieve data from the electronic controller along

with the diagnostic program on your laptop.

1.2.3 Down Load Serial Connection: P/N 425376C.

To be used to retrieve and download data from the electronic

controller along with the diagnostic program on your laptop.

1.2.4 Perspex Test Lid: P/N 525826.

To be used on the drawer while extended to observe water fill,

wash and drain operations.

1.2.5 Air Gauge and Plumbing. P/N 525819.

To be used to measure the air pressure in the lid seal and

plumbing.

- 3 -

2.0 DIMENSIONS & SPECIFICATIONS

Product Size (mm) Minimum Cavity Size

Height 817-877mm 820-880mm

Width 595mm 600mm

Depth 570mm 580mm

Drawer Open (incl cab) 1080mm

Electrical 230-240V AC 50Hz 10amp max.

Specifications

Lid Seal

P/N525878

Exhaust Valve

P/N525415

Lid Seal Air Pump

P/N525430

Water Inlet Valves

P/N525113 Dual

P/N525842 Single

Flood Switch

P/N525941

EMI Filter

P/N525908P

Motor

Drain

Wash

30-40 Kpa

12 Volt ac

70 ± 5 Ohms

5 Volt ac

16 ± 2 Ohms

24Volt dc

70 ± 5 Ohms

5 Lt/min

24Volt dc

Double Pole

240Volt ac

40 Volt dc 3 Phase

4200RPM

2300-2850RPM

Detergent

Dispenser

P/N525675

Rinse Aid

Dispenser

Electronic P.C.B.

P/N525832P

Control Panel Std

P/N525192P

24 volt dc

70 ± 5 Ohms

5 grams

10 grams

15 grams

5 gram pre-rinse

24 Volt dc

70 ± 5 Ohms

50 mls

25 reg. Washes

approx

230-240 Volt Input

Outputs: 230 Volt ac

40 Volt dc

24 Volt dc

24 Volt dc

Stator

P/N525933

Rotor

P/N525736

Temperature Sensor

(Part of Heater

Plate)

Inlet Hose

P/N525151

Drain Hose

P/N525435

P/N525495

2.5 ± 0.2 Ohms

per winding

962-Ohms @ 20°C

1000-Ohms@ 30°C

1202-Ohms @ 60°C

1.7m

960Kpa

2.0m from rear of

cabinet

2.5m bottom tub

2.9m top tub

- 4 -

Control Panel

Integrated

P/N525185P

Heater Plate

P/N525169

24 Volt dc

240 Volt ac

55 ± 5 Ohms

3.0 TECHNICAL OVERVIEW

3.1 Electronics

The DD601 electronic controller has two separate micro controllers on the main

printed circuit board. One is for motor control and output switching and the other is

for controlling interface and console functions.

The user interface comprises a printed circuit board for front controls and a touch

switch panel for internal controls.

The electronics can connect to a computer service tool via a serial communications

port for fault finding and product information.

All output peripherals (solenoids, fans etc), except the heating element, are run on low

voltage (24v).

The power for all low voltage devices comes from a 100w switchmode power supply,

which is cooled by a heatsink and when necessary the drying fan.

The element is switched by a relay and protected by a fail safe relay.

3.2 Motor

The motor is a fully electronically controlled 40V 60w 3 phase 6 pole brushless

DC motor, running at approximately 2300-2850 depending on wash cycle selected,

2500 rpm on Normal, Fast, and Rinse cycles, 2300 on Delicate and 2850 on Heavy

Wash, 4200 rpm on Drain.

3.3 Cabinet

3.3.1 Chassis

On the double drawer the double chassis is one complete assembly composed of 5 steel

metal components locked together by a proprietry riveting process. The chassis

exterior is made of white prepaint, while other components are made of

electrogalvanised material. On the single drawer four bolts and washers are used to

secure the chassis to the shelf using the steel inserts.

Unlike most other dishwashers, the chassis assembly is a load carrying structure

designed to impart stiffness to the product and to ensure deflection is minimised.

The feet of the cabinet are assembled into the chassis by means of four steel inserts

which are clinched in place to form a permanent threaded connection.

- 5 -

The tub extends 510mm out of the cabinet by travelling along two rigidly attached

slides on either side of the tub.

3.3.2 Drawer Fronts

Prefinished drawer fronts are formed from a prepainted blank of steel. The drawer

fronts are attached to the tub by means of formed hooks and two pins which are

inserted through either side of the tub.

On the integrated model, the front panel supplied on each drawer is the mounting panel

for the joinery finished drawer front. The joinery finished drawer front is supplied by

the customer.

3.4 Filling

3.4.1 Cold Inlet

The tub of the dishwasher fills by a cold water inlet hose only. From the connection to

the cold water pipe in the kitchen, the inlet hose enters the cabinet of the dishwasher at

the base, onto a dual water valve. Each tub is supplied water independently via one of

the dual valve coils and a fill hose that runs through customised link assemblies at the

back of the tub and travels along the base of the tub under the wiring cover to the

front. At the front of the tub, the fill hose connects to the detergent dispenser which

allows water to enter the tub, firstly through the pre rinse section of the dispenser for

the pre rinse cycle and secondly through the main wash section for all other cycles.

3.4.2 Mixing the Detergent

Filling cold water enters the detergent dispenser, flushing the detergent from the cup,

through the dispenser into the tub.

3.4.3 Amount of Water

The tub fills with approximately 2.2 litres of water, level with the base of the spray arm

attachment. Once this level is reached, the wash pump (which has sensed the fill at 30

second intervals during the fill), becomes primed and pumps the water through the

spray arm which will then rotate.

The water level is monitored by sensing the motor load through the electronics.

- 6 -

3.5 Dispensing Detergent

The dispenser is mounted in the front wall of the wash tub.

The detergent dispenser consists of two detergent chambers, one for pre wash and the

other for the main wash.

The detergent dispenser door is opened manually for detergent loading and then

manually closed ready for the detergent to be transported to the wash tub by the inlet

water. To enable each detergent chamber to be dispensed separately, an inlet water

diverter valve controlled by the electronics is necessary.

Additionally a positive displacement pump unit and storage tank are incorporated

within the dispenser to supply rinse aid. The rinse aid dispensed volume is adjusted

utilising the dishwasher electronic controller. A glowing red light on the tank filler cap

indicates an empty rinse aid tank.

3.6 Lid Seal

3.6.1 When Activated

At the beginning of each wash cycle, the lid seal inflates while the pre wash drain cycle

removes any residue water from the tub. This runs for approximately 60 seconds, then

the tub fills.

3.6.2 What is the Lid Seal

The lid seal is a static plastic moulding retained in the lid which provides a dynamic

seal to the tub. The dynamic seal is created by a bellows section gasket bridging

between the top flange of the tub and the lid. The dynamic seal also locks the

tub/drawer during washing.

3.6.3 During Wash

The bellows section gasket is inflated by a solenoid activated diaphragm air pump.

This cycles during the complete cycle at timed intervals to maintain a 35kpa sealing

pressure.

- 7 -

3.7 Wash Cycle

3.7.1 Tub

The tub is the main cavity where all the wash activity occurs. The tub is a plastic

recepticle which has a wash pump and sprayarm at the base. The tub also has guide

vanes around its walls which direct falling water from the wash cycle in a clockwise

direction around the filter plate. This clears the filter plate of food particles into the

sump where they can be trapped or pumped out during the drain cycle.

3.7.2 Rotor

The rotor is a four pole permanent magnet rotor with a graphite bearing at each end of

the vertical shaft. At the lower end of the rotor shaft is the drain impellor and at the

upper end is the wash impellor.

3.7.3 Spray Arm

The spray arm is shaped for most efficient waterflow. The holes are positioned for

best penetration into the washload, with the water jets angled to ensure the sprayarm

rotates at the most efficient speed.

3.8 Heating

3.8.1 The Element

The heater plate is an element consisting of a porcelain enamelled steel plate with a

thick film resistive circuit written onto the dry side. The element is clamped in place by

a lockring nut and supports the motor at the base of the tub.

3.8.2 Heating the Water

The heater plate lies beneath the filter plate. This creates a flow through water heating

system during the wash cycle by allowing water to flow through the filter plate, over

the surface of the element and into the wash pump.

3.8.3 Maintaining the Temperature

Attached to the element is a sub printed circuit board with a temperature sensitive

thermistor . This connects by means of a RAST 2.5 connector system to the wiring

harness of the element. Sensor components are unservicable.

- 8 -

3.8.4 Overheating Control

The heater plate is only activated during the wash cycles. It is not used for drying.

The temperature is maintained by the thermistor. The element circuit is continuously

monitored by the electronic controller and will switch a fail safe relay if a fault is

detected in the heater circuit. The element is thermally monitored by the thermistor on

the element through the electronic controller.

3.9 Filter Plate

The filter plate is a stainless steel disk which lies below the dishrack and sprayarm and

completely encompasses the base of the tub.

3.9.1 The Filter System

The tub is designed with vanes which swirl the water around and over the filter plate.

At the front of the tub, located as part of the filter plate, is the drain filter. Large soils

collect in the drain filter and only 1.5mm or smaller soils flow through its micro mesh

filter, eliminating re-depositing of soil during the wash. Only soils up to 6mm pass

through the drain filter during the drain cycle. This requires the drain filter to be

regularly emptied and cleaned.

3.9.2 Removing and Cleaning the Filter Plate

The drain filter can be emptied with the dishrack in place by removing the cutlery

basket and opening the plastic section of the dishrack. The filter plate is removable for

cleaning by removing the dishrack and sprayarm and unlocking the lockring nut anticlockwise.

3.10 Drain Cycle

The drain pump is a self priming centrifugal pump which only pumps when the motor

is rotating in the drain direction (anti-clockwise). It has a five bladed impellor made

from acetal pushed into a spline on the end of the rotor shaft. The drain cycle is a 60

second timed drain period.

The drain pump housing, which incorporates an inlet and outlet pipe, is welded to the

motor housing, hence captivating the motor.

The inlet pipe plugs straight into the sump and is sealed there by a small ‘o’ ring.

The outlet pipe has a non return flap valve to prevent soiled water returning to the tub.

The drain hose is an extruded blow mould hose which is routed over the link assembly

and exits out of the base of the product and is connected to a domestic drain.

- 9 -

3.11 Drying Cycle

Immediately after water from the final hot rinse has been drained from the tub, the

drying system begins operation.

The fan draws air through the tub, where it absorbs water from the dishload. The

moisture laden air is then mixed with a larger quantity of ambient air (from the

kitchen), to minimise the amount of vapour visible when exiting from the drawer front.

The fan runs continuously during the drying cycle and will restart if the tub is opened

and closed again. After the drying cycle is complete, the fan continues to run for 30

minutes, but will not restart if the tub is opened.

The fan is pulsed when needed throughout the entire wash cycle. This draws ambient

air through the electronics heatsink to maintain the electronics components within their

specified operating temperatures.

3.12 Deflating

3.12.1 Lid Seal

The lid seal is a static plastic moulding retained in the lid which provides a dynamic

seal to the tub during the washing cycles.

3.12.2 When the Lid Seal Deflates

At the end of the dishwasher programme, or a pause in the programme, an exhaust

valve releases the air pressure from the bellows section gasket. This deflates the seal

and unlocks the tub and drawer.

3.13 Lockring Nut

The lockring nut holds the heater plate into the base of the tub and motor housing

assembly to form a watertight seal. It does this by compressing two large ‘o’ rings

between the heater plate and tub and between the heater plate and the motor assembly.

It has clips which hold the drain hose, fill hoses and the wiring loom in place.

Another function of the lockring nut is to support the wiring cover with three clips.

- 10 -

3.14 Wiring Cover

The wiring cover protects the customer from the 240V mains supply which passes over

the link assembly and under the lockring to the front of the tub. It also serves to

protect the motor assembly, drain and fill hoses from damage when opening and

closing drawers. The wiring cover acts as a cosmetic part of the product.

- 11 -

4.0 DIAGNOSTICS

4.1 Setup & Diagnostics

The DishDrawer comes with comprehensive fault codes and built in diagnostics, to

save the user & service person time and worry, if the dishwasher ever exhibits a fault.

4.2 Fault Modes

The faults are displayed in the LCD as one of 8 F (fatal) faults or one of 3 U (user)

faults. A Fatal fault will usually require the assistance of a qualified service person,

while many User a faults are simply blockages or installation errors, easily fixed by the

user. In the Integrated models, an LCD is not available, and faults are indicated by a

Red center LED, with the fault number indicated on the touch switch panel with Red

LED’s. The indication below for the Touch Switch Panel is from left to right, with ‘_’

meaning the LED is Off, and ‘#’ meaning the LED is On. A fatal fault is accompanied

by a continuous pulsating beep, while a user fault is accompanied by a more pleasant

continuous pulsating tone pattern. The last two faults are logged into EE memory,

with 8 bytes of information logged to aid location of the fault. These bytes are

available for interrogation by a PC if required. The fault codes shown on Pages 20/21

have been implemented in the DishDrawer.

To clear any fault press the Power button. It the fault is still present then it cannot be

cleared.

- 12 -

4.3 Diagnostic Modes

4.3.1 Temperature Display Mode

During a wash cycle, the current water temperature can be displayed on the LCD

instead of the time remaining. To enter temperature display mode, start a wash cycle

as normal. Initiate a keylock by pushing and holding the Keylock button for 4

seconds.

Once in keylock mode push and hold Start/Pause for 8 seconds to enter temperature

display mode. The temperature is now displayed and the MIN symbol is switched off.

Keylock mode can now be exited.

To cancel temperature display mode, either repeat the above procedure or enter power

off mode by pressing Power. Temperature display mode is automatically cancelled at

the end of a wash program (even in CC mode).

4.3.2 Rinse Aid / Tub-Open Beep Water Pressure Setup Mode

To enter this setup mode, hold the Programme and Eco touch switches

simultaneously for 5 seconds. Once the setup mode is entered a beep is emitted and

the LCD is red with ‘HP’ displayed.

Push Power at any time to exit this setup mode.

4.3.3 Rinse Aid Setup

The current rinse aid setting is shown using orange LED’s on the touch switch panel.

The amount of rinse aid dispensed into a rinse cycle can be varied to suit the level of

hardness of the local water supply. It is adjusted for 1 - 5 dispenser levels

(1 = approx 1ml of rinse aid , 5 = approx. 5mls of rinse aid).

Push Programme to advance the rinse aid setting. Once the desired setting is

achieved, push Power to exit. The rinse aid index is stored in EE memory, so even

with the power removed, the rinse aid level is retained.

4.3.4 Tub-Open Beep Setup

The beep sequence that occurs when the tub is opened can be turned on or off using

the Keylock button. If the Smily Face on the LCD is On then the beep sequence will

occur when the tub is Opened. If the Smiley face is Off then no beeps will occur when

the tub is Opened. Push Power to exit when the desired setting has been selected.

The Integrated Model will sound a single beep when turning this option off, while the

actual beep sequence is sounded when turning this option on. The DishDrawer will

default to 'beeps on' if the mains power is removed.

- 13 -

4.3.5. Water Pressure Set Up

The DishDrawer can be set to either High(Standard) or Low inlet water pressure. The

LCD displays the current water pressure setting.

If “HP” is displayed then the setting is High Pressure.

If “LP” is displayed then the setting is Low Pressure. Low pressure is generally less

than 50kPa or equivalent to that supplied by a ceiling tank.

Push the Start/Pause button to alternate between HP and LP.

Integrated: A high beep is sounded when changing the HP, and a low beep is sounded

when changing to LP. Push Power to exit when the desired setting has been selected.

4.3.6 Dishwasher Diagnostics

Dishwasher Diagnostics can only be entered in Power Off mode, ie. When there is no

display on the LCD or the badge LED’s are off. Diagnostics is entered by holding the

Keylock and Start/Pause buttons simultaneously for 6 seconds. Ensure that Keylock

is pushed first to prevent the dishwasher from starting a wash, from a Start/Pause

keypress.

There are currently four levels of diagnostics. To move to next level push Power.

Once a mode has been entered, pushing Power will exit diagnostics completely

(except Display & Show Off modes). If no mode is entered then the display will cycle

through the four levels and exit after the last. On entering diagnostic mode the first

level is Download Mode.

4.3.7 Display / Download Mode

In this mode all LED’s (except Rinse program) and LCD segments (except keylock)

are illuminated.

4.3.8 Optical LED Download / Fault Display

An optical data download is available here to download all EE data to a PC via the

Rinse Program Red LED. Hold the reader pen over the Rinse Program LED and press

Start / Pause to initiate the download. A short beep indicates the start and finish of

download.

The last two faults are displayed on the LCD during the optical download, with the

Current Fault code displayed first followed by the Previous Fault Code.

- 14 -

4.3.9 Clearing Fault Logs

To Clear the current Fault press the Keylock button until a beep is sounded. This

action moves the Current Fault into the Previous Fault while clearing the Current

Fault. To Clear the Previous Fault press Keylock once more until the beep is

sounded. Warning: Once a fault has been cleared it is permanently removed from

Memory and cannot be recovered.

Press Power to advance to the next mode.

4.3.10 Show Off Mode

This mode initiates a shop show off display and operation demonstration. The LCD

display is Red backlight ‘Ad’. The touch switch LED’s are - Grn Grn __ Grn Grn.

Press Power to skip show off mode and move onto the next mode.

Press Start/Pause to initiate show off mode:

A short series of tones indicates that Show Off mode has been entered. The Show Off

display cycles through every LED, & LCD segment. If any front panel key is pressed

the dishwasher will re-initiate a series of short tones.

Once Show Off mode has been initiated, the mains power must be removed to exit out

of Show Off mode.

4.3.11 Hardware Output Diagnostic Test Mode

This mode tests all the hardware outputs and inputs. The LCD display is Red

backlight and ‘HO’.

Press Power to skip hardware diagnostics and advance to the next mode.

Press Start/Pause to enter hardware diagnostics.

Once hardware diagnostics has been entered the current hardware output being tested

is indicated in green on the touch switch panel, using binary encoding, and also on the

LCD as shown below.

Any combination of outputs can be switched on or off. Load sensing is enabled when

the motor is running.

Press Start/Pause to advance to next hardware output.

Press Keylock to turn the currently displayed output On or Off. If the currently

displayed output has a green backlight then that output has been switched on, and if

the backlight is red then that output is off.

Press Power to Exit at any time (All outputs will be switched off on exit).

The LCD display and touch switch panel green LED’s are illuminated to correspond to

a particular hardware device. The following table details the display order of the test.

- 15 -

LCD Heavy Norm Fast Deli Hardware Output

------------------------------------------------------------------------------------------EU Off Off Off On Exhaust Valve

FU Off Off On Off Fill Water Valve

dd Off Off On On Detergent Diverter Valve

LS Off On Off Off Lid Seal Pump

rd Off On Off On Rinse Aid Dispenser (dispenses

current setting)

P1 Off On On Off Motor Wash direction

(2300-2850 rpm)

P2 Off On On On Motor Drain direction

(4200 rpm)

dF On Off Off Off DC drying fan (On

100% duty)

Er On Off Off On Element Relay

‘temp’ On Off On Off Displays current water

temperature.

WARNING : As there is no protection in this mode it is possible to turn the element

on with no water in the tub. It is advisable to avoid turning on the element without

water in the tub.

NB : No Fault codes will come up while in diagnostics mode.

Tub Open Microswitch Test: At any time during HO test mode the Rinse red LED

indicates the tub position. On = Open, Off = Closed.

Note : There maybe a short delay (up to 0.5sec) from when the tub has changed state

to the position that is indicated on the LED. This is due the communication delays

between the two micro-controllers.

4.3.12 Continuous Cycle Life Test Mode

In this mode the dishwasher can be run continuously in any wash cycle. Once the cycle

has finished, the dishwasher automatically restarts the same wash cycle.

The LCD is Red backlight and display CC. The touchswitch panel is Red Red __ Red Red.

To exit diagnostic mode push Power.

To initiate a continuous cycle press Start/Pause. The dishwasher will enter standby

mode. Choose the required cycle and operate the dishwasher as normal. Continuous

cycling can be canceled at any time by pushing the Power button, or removing the

mains power. Continuous cycling is indicated by the backlight alternating between

green and orange.

In continuous cycle a delay occurs when a cycle has finished before the next cycle

starts. This delay is currently 1 min. During this time the LCD displays a finish cycle

display, and the backlight alternates between RED and OFF.

- 16 -

Cycle Count Retrieval

To display the cycle count on the LCD screen, Pause the dishwasher while running a

Continuous Cycle. The two bytes of the cycle count will be displayed alternately, in

syncronisation with the changing backlight.

The Low byte is displayed when the backlight is Green.

The High byte is displayed when the backlight is Orange.

To calculate the Total diswasher cycle count use the formula below.....

Cycle_Count = ((200 x High_byte) + Low_byte).

Eg. Low_byte = 156

High_byte = 21

Cycle_count = ((200 x 21) + 156) = 4,356.

- 17 -

4.4 Diagnostics Quick Reference Flow Chart

again you will remove

Start/Pause buttons

previous fault code will

LCD

test mode

mode

Press and hold

Keylock, then

for 6 seconds

#1 Display

Press Power

button

#2 Show Off/Demo Mode

Press Power

Button

#3 Hardwre Output Test

LED Heavy Normal Light Delicate

EU Off Off Off On

FU Off Off On Off

dd Off Off On On

LS Off On Off Off

rd Off On Off On

P1 Off On On Off

P2 Off On On On

dF On Off Off Off

Er On Off Off On

temp On Off On Off

All LED's &

LCD segments

except Keylock

are illuminated

Press

Start/Pause

button

Press

Start/Pause

button

Press

Start/Pause

button

Press Keylock

button to turn

output On/Off

Initiate Pen upload via

Rinse program LED.

At the same time, first

the current, then the

be displayed in the

Cycles

through every

LED & LCD

segment

Hardware

output

diagnostic

EU = Exhaust valve

FU = Water Inlet Valve

dd = Detergent diverter valve

Er = Element relay

LS = Lid seal pump

rd = Rinse aid dispenser

P1 = Wash pump motor

P2 = Drain pump motor

dF = Drying fan

temp = currentwater temperature

Display green = output on

Note:

Display red = output off

Tub microswitch can be tested at

any time. Rinse LED on = Open

Rinse LED off =Closed

To clear the current

fault code press the

Keylock once. Note if

you press Keylock

the previous fault.

Disconnect

power supply to

exit Show Off

See Next

- 18 -

4.4 Diagnostics Quick Reference Flow Chart cont'd

#4 Continuous Cycle Test Mode

Press Key Lock.

Machine Beeps

Smiley Face off &

Smiley Face on &

water pressure

water pressure

pressure setting to 'LP'.

LCD is Rd backlight

Press Power

Button

Press

Start/Pause

button

Once a mode has been entered, press Power to exit diagnostics

except Display and Show Off modes) which require the plug to be removed from the power socket.

Continuous

cycle

Stand - by

mode

and displays CC.

Touchswitch panel is

Red Red Red Red

Select desired cycle and

operate as normal.

Continuous cycle is indicated

by backlight alternating

between green & orange. In

this mode the cycle count is

displayed.

Rinse Aid Adjustments/Tub Open Beep/Water Pressure Setup

LCD Display on. Hold

the Programme and

Eco Touch Switches

simultaneously for

5 seconds

Water Pressure option

is available if water

pressure is below

50kPa and a 'U1'fault

occurs during wash

cycles. If this happens

then change water

Press Key Lock

Press

Start/Pause

and "HP" is

displayed in

the LCD.

This turns the

deactivates Tub

Open

beeps.

This turns the

activates Tub

Open

beeps.

This adjusts

set up from high

to low.

Push Wash

Programme Selection

Touch Switch to select

dose of Rinse Aid.

Each LED = 1cc.

Press Power to Exit.

Press Power to

exit

(Factory setting is 'HP'.)

Press

Start/Pause

This adjusts

set up from

low to high

- 19 -

4.5 Fault Codes

Fault Code LED Display Fault Possible Causes

F1 ----# The flood switch has

been activated.

F2 ---#- The motor is not

rotating.

F3 ---## The water temperature is

greater than 80°C.

F4 --#-- No temperature increase

has been recorded when

the element is on.

F6 --##- Communications Baud

rate error.

F7 --### Communications Time-

Out error.

F8 -#--- RAM fault.

• A leak has occurred in the base of

the dishwasher.

• The fill valve has failed open.

• The flood switch is faulty.

• Excessive water has been added

to a wash sub cycle, indicating

leaking seal or siphoning.

• Foreign matter has jammed the

motor.

• The motor drive electronics or

power supply have failed.

• The rotor is faulty or missing.

• The hall sensor is faulty or

missing.

• The element has failed on.

• The temperature sensor has failed.

• The electronics ADC has failed.

• The incoming water temperature

is greater than 80°C.

• The element is not connected.

• The element has gone open

circuit.

• Temperature sensor or electronics

ADC has failed.

• The motor control micro has

communications set at an

incorrect baud rate.

• Communication echo bytes are

consistently incorrect (perhaps

due to noise).

• External master device has

incorrect baud rate.

• The motor control micro has

crashed and is not responding to

communications requests.

• The hardware communications

link from console to motor micro

has broken.

• An external device is holding the

communications line low.

• The electronic controller has

RAM fault.

- 20 -

Fault Code LED Display Fault Possible Causes

U1 #---# Fill fault. The motor has

not primed after a given

time.

U2 #--#- Tub open fault.

U3 #--## Time to fill was too

short, indicating water

was still in the tub.

• The water supply is not turned on.

• The machine is siphoning.

• The sprayarm is not in place.

• Excessive foaming.

• The fill valve has failed closed.

• The machine is set to 'HP' on a

low pressure water supply.

• The drawer has been forced open

during a wash cycle.

• The drawer microswitch has

failed.

• The exhaust valve has failed open

circuit.

• Drain pump is blocked.

• Drain hose is blocked.

• Sprayarm or rotor not turning

freely.

• Motor electronics have failed.

• Machine set to 'LP' on a high

pressure water supply.

- 21 -

F1

Monitored while mains

power is on. When one

drawer leaks this cuts out

both drawers. F1 is not

monitored in diagnostics.

Does the water

through the

back air vent?

No Yes

Look for a leak

from the lid, tub

& hoses (refer

Page 32)

No

Check the spray

arm for a split or

water deflection

Not OK

overflow

Check the fill valve

for an electrical or

Yes

Is the water level

in the tub above

the spray arm?

Note*

Yes

mechanical fault

OK

Did a flood

occur & activate

the flood switch?

No

Has the switch or

polystyrene float

been mislocated

No Yes

Check the flood

switch wiring and

switch for a

closed circuit

Not OK

No

Machine may be

syphoning and has

topped up too

many times

Check non-return

valve and drain

hose height

Was the

machine

tilted?

Yes

Check load

Replace

valves

Note: Has the spray arm floated off

affecting load sensing or is the product

programmed for low pressure fill on a high

pressure installation? Reprogramme?

sensing through a

serial download

connection

Test the flood

switch connections

for a closed circuit

OK Not OK

Repair the

wiring or

connections

- 22 -

Relocate float

Replace the

flood switch

F2

This fault is monitored when the

motor is running. It is looking for 10

stalls in a row. It is not monitored

during diagnostics.

The rotor has not

been sensed as

rotating. Is the rotor

jammed?

Note*

Yes No

Free or replace

the rotor. Check

the rotor housing.

Repair or replace

wiring,

connections or

stator.

*Note: Has the spray arm caused the

rotor to jam by being interfered with by

an object falling through the basket?

Not OK

Check the stator

connections and

wiring. See

specification chart for

stator readings.

Not OK

Replace the

RPS.

Substitute Rotor

OK

Replace Rotor

OK

Substitue the

rotor position

sensor on the

stator.

OK

- 23 -

F3

This fault is monitored

every 6 seconds while the

mains power is connected.

It is not monitored during

diagnostics.

Water sensed

at greater than

80°C

Yes

Replace the

electronic

controller

Is the element

on all the

time?

Check the wiring &

connections to the

element and sensor

PCB

Not OK OK

Is the incoming

No Yes

water greater

than 80° C?

No

Turn the power

off at the supply

and then retest

Is the element

heating all the

time?

Adjust the

incoming water

temperature

YesNo

Repair or replace

the wiring or

connections

Replace the

heater plate

Check the

resistance of the

sensor at the PCB.

See chart.

Not OK

- 24 -

Replace the

electronic

controller

F4

No temperature

increase has been

sensed while the

element is on.

Does the

element heat in

diagnostics?

Test the resistance

of the element at the

controller as per the

specifications

Not OK OK

Test the edge

connectors

and wiring

OK

Test the

resistance at

the element

Not OK

NO YES

Turn the power to

the dishdrawer off

at the supply. Then

retest.

Repair the

wiring or

connections

Test the resistance

of the sensor as per

OK Not OK

Replace the

electronic

controller

the temperature

chart

Check the wiring

and connections

to the sensor

OK

Replace the

Heater Plate

Not OK

Replace the

element plate

- 25 -

F6

F7

Inter-communication fault.

Replace the electronic

controller. If this occurs while

you are servicing the

Dishdrawer, you may have

induced the fault , so ignore it.

F8

RAM fault.

Replace the

electronic

controller

- 26 -

U1

which time the fill valve operates

valve activate in

at the controller to

wiring and valve.

resistance of the

Replace the valve.

repair the wiring

No

No

Motor runs for 15 seconds, during

for 2 seconds. This occurs three

times. If prime is not detected

then the fill valve is operated

continually until prime is reached.

Is the water

pressure

above 50Kpa?

Yes

Does the water

diagnostics?

Yes

Sprayarm not

in place.

OK

Not OK

Below 50kPa water

pressure change the

programme from

'HP' to 'LP' as per

Page 14

Check the voltage

the valve. 24vdc

Not OK

Replace the

electronic

controller

Refit spray

arm

OK

Is the tap turned

on or the water

inlet filters

blocked?

Check the

continuity of the

OK

It must have a

mechanical fault.

OK

Not OK

Check for a

kinked hose

Check the

valve at the

valve.

Not OK

Replace the

valve.

Check and

or connections

OK

The wash

impellor is

slipping or

missing

OK

Machine

siphoning

Not OK

Not OK

Replace the

rotor

assembly

Check the

drain length

and height

OK

- 27 -

Foaming

Check for

incorrect use of

detergent or

rinse aid leak.

U2

The tub drawer has been

working in

No

sensed as open during

the cycle or the exhaust

valve is open circuit.

Is the drawer

open?

Yes

Shut the drawer.

Check the

mechanical

operation of the

the slides.

OK Not OK

Test the exhaust

valve for an open

circuit.

Note: Tub home microswitch is located on the rear

of the left slide runner and is connected in series with

the exhaust valve.

Check the

microswitch is

diagnostics.

OK Not OK

Replace the

microswitch.

Adjust the slides.

- 28 -

Check locknut on

filter plate is

locked in

correctly

U3

The motor has sensed

prime too quickly

Has the

dishdrawer

drained?

No Yes

Check for pump

blockage or drain

impellor failure

Free sprayarm

or rotor

Check the

rotor/sprayarm

are turning freely

Not

OK

OK

Possibilty of

electronics incorrectly

sensing the load but

not likely

Has it been

programmed for low

pressure? Refer

Page 14 for

Re-programming.

- 29 -

Poor Dry

Performance

Rinse aid not

being

dispensed

In Diagnostics, does

the Dispenser pump

run?

Is there rinse aid in

the dispesner?

OK

Replace dispenser.

Yes

Repair wiring or

connection.

Replace dispenser.

No

Check the continuity of

the wiring and pump

solenoid by removing

the connections at the

PCB and testing with a

meter.

Not

OK

OK

OK

Check the voltage

(24 Volts dc) at the

PCB.

Not

OK

- 30 -

Replace the PCB

water now exits the other side of

Test voltage at

Check the continuity of the

wiring and diverter solinoid

Not OK

No

Poor Wash

Performance

Detergent not

flushing out of

Pre Wash or Main

Wash chambers

In Diagnostics active the fill valve

and note which side of the

dispenser the water comes out.

Then turn off the fill valve and

activate the diverter valve(dd),

re-active the fill valve to see if the

the dispenser.

OK

Not OK

Replace

dispenser

by removing the

connections at the PCB.

and testing with a meter.

OK

the PCB

(24 volt)

Not OK

- 31 -

Replace

Electronic

PCB

Remove drawer

fronts and note

that this happens

during cycle

Yes

May have

intermitent

bockage in

dispenser

Enter Diagnostics

must reach between

connection. Pressure

joints for leaks

OK

Not OK

and seal for correct

Tub Lid

No

Leak

Fit test

gauge to Air

pump

and activate

Exhaust valve

then air pump

Run pump for 60

seconds. Pressure

30 - 40 Kpa.

Switch

Pump off

Leave for 2 min.

Is there a

pressure loss?

No

Check lid & tub for

correct alignment

installation.

Yes

Check the lid

gasket and

Yes

Pinch plumbing

above the exhaust

valve connection.

Pressure creases?

No

Yes

Pinch plumbing

above the test gauge

creases?

Replace

Exhaust

Valve

Replace air

pump

- 32 -

5.0 WIRING DIAGRAM

- 33 -

6.0 SERVICE PROCEDURES

6.1. Drawer Front Removal

6.1.1 Slide open drawer.

6.1.2 Locate draw pin on either side of the tub.

6.1.3 Using a sharp pair of long nose pliers or slip jaw pliers grasp the

center dividing web of the pin and pull away from the tub to remove

the pin.

Support the drawer front with your hand while doing this.

Note: The pin web is vertical.

6.1.4 With both pins removed the bottom of the drawer front can now be

eased down and forward so as to clear the microswitch lever.

6.1.5 Now carefully pull the drawer front down to allow it to come free

from the top locating slots.

6.1.6 This allows the drawer front to come away with the handle insert and

insulation.

6.1.7 Refit in reverse manner insuring the drawer slides are right forward

and the pin secures through the hook on the front end of the slide.

Note: When reinserting the pins make sure the dividing web is

vertical.

6.2. Handle and LCD Display Removal

6.2.1 Remove the drawer front as per instructions in 6.1.

6.2.2 The handle clips under two location inserts either side of the tub. Pull

forward on the handle tabs and this will release them from the

location inserts.

6.2.3 Disconnect the seven wire harness from the electronic controller to

the LCD or Badge.

6.2.4 The handle may now be lifted clear.

The LCD display is held in place by a spring tab on one end. Using a

small blade screwdriver slip it down the end of the LCD with the

single tab. This will release the LCD.

6.2.6 The wiring harness can now be unplugged from the LCD.

6.2.7 Push pads can now be removed. The LCD display holds these in

place.

6.2.8 Refit in reverse manner.

6.3 Drying Fan Removal

6.3.1 Remove the drawer front as per instructions in 6.1.

6.3.2 Slide forward the drying fan duct and remove.

6.3.2 Disconnect the two wire harness from the electronic controller

6.3.3 Release the three securing tabs that hold the drying fan in place while

applying forward pressure on the drying fan.

6.3.4 The drying fan will now come free.

6.3.5 Refit in reverse manner.

- 34 -

6.4 Detergent Dispenser

6.4.1 Remove the drawer front and handle as per instructions in 6.1.& 6.2

6.4.2 Disconnect the two wiring loom connections off the dispenser coils.

Note: Push back locking tabs to allow connectors to release.

6.4.3 Unclip the retainer flap at the bottom center of the dispenser and

slide out the rinse aid level LED.

6.4.4 Unclip the fill hose on the dispenser

6.4.5 While holding the dispenser unscrew the six T10 Torx drive screws

securing the brackets around the dispenser.

6.4.6 The dispenser can now be removed from inside the tub.

6.4.7 The coils can be replaced as a spare part by sliding them off the

armature.

6.4.8 To open up the dispenser door fully, first open the door using the

release catch then squeeze the top sides of the door. This will release

the door to the fully open position. This can be done with the

dispenser in place.

6.4.9 Refit in reverse manner ensuring the dispenser gasket is located

correctly.

6.5 Electronic Controller

6.5.1 Remove the drawer front and handle as per instructions in 6.1.& 6.2.

6.5.2 Placing a finger either side of the top sides of the controller, pull it

forward until the controller clears the top edge of the tub.

6.5.3 Disconnect the wiring connectors down the left side of the

controller.

6.5.4 The controller can now be tipped down to 90° from it’s original

position. This will allow the disconnection off the lower wiring

connectors and the two and three wire looms from their wire duct.

6.5.6 The controller can now be lifted clear.

6.5.7 Refit in reverse manner.

6.6 Top Kick Strip Removal

6.6.1 Pull out the lower drawer.

6.6.2 Place both hands under the top kick strip.

6.6.3 Pull the bottom of the top kickstrip forward quickly.

6.6.4 Tipping it right up will allow the top locating tabs to drop out of the

tub inserts.

6.6.5 Refit in reverse manner ensuring it is clipped into place.

- 35 -

6.7 Lower Kick Strip Removal

6.7.1 Remove the top kick strip as per instructions in 6.6.

6.7.2 Insert a flat blade screwdriver into the two inserts in the trim above

the lower kick strip and twist.

6.7.3 This will unclip the lower kick strip from the chassis.

6.7.4 Refit by locating the lower kick strip pins into the chassis clips and

foot retainer clips.

6.7.5 Push on the face of the lower kick strip to locate home the lower

kickstrip pins.

6.8 Wiring Cover Removal

6.8.1 Remove the drawer front as per instructions in 6.1.

6.8.2 Unclip the front two legs of the wiring cover from under the

electronic controller and the front left hand side of the tub.

6.8.3 Release the three clips on the underside of the tub which retain the

wiring cover.

6.8.4 The wiring cover may now be moved forward to release it from the

link assembly at the rear.

6.8.5 To reassemble first ensure that the wiring harnesses, drain hose and

fill hose are clipped into their correct position.

6.8.6 Then refit in reverse manner.

6.9 Filter Plate Removal

6.9.1 Remove the lower racks from the tub.

6.9.2 Remove the drain filter assembly.

6.9.3 Rotate the filter plate locknut anti-clockwise to release the filter plate

from the rotor assembly.

6.9.4 Lift the filter plate clear.

6.9.5 Refit in reverse manner.

6.10 Rotor Assembly Removal

6.10.1 Remove filter plate as per instructions 6.9.

6.10.2 Rotate the rotor locking ring anti clockwise to release it from the

motor assembly.

6.10.3 This assembly is not serviceable.

6.10.4 Refit in reverse manner.

- 36 -

6.11 Tub Removal

6.11.1 Remove the drawer front as per instructions in 6.1.

6.11.2 Remove the wiring cover as per instructions in 6.8.

6.11.3 Disconnect the fill hose from the dispenser (water may drip)

6.11.4 Disconnect the mains harness and chassis harness connectors from

the electronic controller.

6.11.5 Unclip the drain hose cuff from the motor assembly.

6.11.6 From the under side of the tub now unclip the drain hose, fill hose

and the wiring looms which go to the link assembly. Disconnect the

earth wire off the element plate.

6.11.7 The link assembly can now be unhooked from the rear of the tub by

pressing the spigots back through the tub connection point.

6.11.8 The tub may now be lifted at the front and slipped forward off the

slide runners.

6.11.9 Refit in reverse manner.

6.12 Locking Ring, Element Plate and Motor Assembly Removal

6.12.1 Remove the drawer front, tub, filter plate and rotor assembly as per

instructions in 6.1,6.9, 6.10 & 6.11.

6.12.2 Disconnect the wiring connectors off the heater plate and motor

(mark motor wire location). To release the motor connections push

a fine blade screwdriver down alongside the wiring connection to

release the locking barb on the terminal.

6.12.3 Disconnect the rotor position sensor from the motor housing.

6.12.4 While lifting the tab on the locking ring, rotate the ring anticlockwise

until it comes free of tub tabs.

6.12.5 This also releases the motor housing from the locking ring.

6.12.6 Holding the pump housing on the motor assembly lift the locking

ring, heating plate and motor clear of the tub.

6.12.7 The suction pipe of the drain molding will slide out of the tub drain

area.

6.12.8 You may now lift the locking ring clear of the motor assembly. This

will allow the heater plate and motor assembly to come apart

6.12.9 Be careful of the two ‘O’ rings which seal between the motor

assembly and heater plate and the heater plate and tub, these and the

tub sealing area must be clean and put in the correct place before

reassembly takes place.

6.12.10 Check both the drain cuff ‘O’ ring and suction pipe ‘O’ ring for

deformation and damage. Lubricate and if necessary replace ‘O’ rings

before reassembly.6.12.11 Reassemble in reverse manner

ensuring all locking ring tabs are engaged.

- 37 -

6.13 Lid Assembly Removal

6.13.1 Remove tub assembly as per instructions in 6.11

6.13.2 Disconnect the lid plumbing off the exhaust valve and air pump

above the ‘Y’ joint.

6.13.3 Release two locking tabs securing the front of the lid to the chassis.

6.13.4 To do this, push back the tab in the center of the rectangular slot at

the front of the lid molding, using a blade screwdriver, then apply

downward pressure to the lid while holding the tab back.

6.13.5 The lid will now drop into the chassis opening and this will allow it

to be slid forward out of the chassis area.

6.13.6 Refit in reverse manner being careful not to damage the seal when

fitting the lid in through the chassis. Ensure the location tab at the

right rear of the lid locates to the right of the rear chassis support.

Note: The bottom lid has a strengthening bar at the rear.

6.14 Lid Seal Replacement

6.14.1 Remove Lid assembly as per instructions 6.13.

6.14.2 Remove the seal by grasping hold of it in the middle and easing it

away from the lid. This will release the fir tree part of the gasket

from the retaining slot.

6.14.3 Ease the gasket away from the air plumbing connector joint at the

rear of the lid.

6.14.4 Fit the new up to the shoulder on the plumbing connection. Slide

both ends of the lid seal into place ensuring they rest against the

stops.

6.14.5 Lay the gasket in the approximate position around the lid.

6.14.6 Press the gasket into position at each corner. The fir tree section

pushes into the lid slot.

6.14.7 Now the rest of the gasket can be pushed in around the lid section.

Note: This is a push in seal and does not require a sealant.

6.14.8 Testing the gasket with an extension piece of air plumbing, air gauge

and air supply before fitting would be advisable. Pump the gasket up

to 40Kpa and then pinch off the supply. The pressure should not

drop below 30Kpa over a 60 second period.

6.14.9 Refit lid as per instructions in 6.13.6.

- 38 -

6.15 Slide Runner Replacement

6.15.1 Remove the Tub as per instructions 6.11

6.15.2 Bottom slide runners only. Remove the two large Philips head screws

securing the slide runner at the front. The backing plate that the

screws locate into may come loose. This does not matter. It can be

realigned on reassembly.

6.15.3 Tap the slide runner from underneath at the front. This will knock the

slide runner up and free from its location in the chassis.

Note: On the bottom lefthand slide runner the water valve

mounting bracket will come away as well. This will mean

the water and electrical connections will have to be

disconnected first.

6.15.4 The slide runner may now be pulled forward to release it from its

location in the rear of the chassis.

6.15.5 Refit in reverse manner.

6.16 Front Trim Replacement

6.16.1 The trim has to be removed by breaking the retaining clips.

6.16.2 This can be done by slipping a blade screwdriver between the trim

and the chassis and twisting the blade to snap the clips. Protect the

cabinet from chipping and remove the broken clips.

6.16.3 Line up the clips on the replacement trim with the holes in the chassis

and push home.

6.17 Sound Gasket Replacement

6.17.1 Remove the sound gasket by grasping it in the middle with your

fingers and pulling it out of the trim.

6.17.2 To refit, feed the ends of the sound gasket into the ends of the

trim slot.

6.17.3 Push the middle section of the sound gasket into the slot then work

the rest in.

6.17.4 Roll the sound gasket with a coin to get it even.

- 39 -

6.18 Link Assembly Removal

6.18.1 Remove tub as in instructions 6.11.

6.18.2 Release clips on side of link assembly to allow the lid of the assembly

to hinge open.

6.18.3 Using a blade screw driver to wedge out the spigots in the hinge

point of the bracket connecting to the rear of the dishwasher.

6.18.4 With both assembly lid open and the hinge point free the assembly

may be released from the drain hose, fill hose and wiring harnesses

(mark on the harnesses and hoses the location of these to the lid so

that when reassembling they are put back in the same location).

6.18.4 To replace the link assembly bracket, release the wire and hose

retaining clip to free these items, then slide the bracket up and out of

rear panel.

6.18.5 Refit in reverse manner.

6.19 Air Pump Removal

Note: This component maybe serviced by two Methods.

6.19.1 Method 1: Remove appropriate tub assembly as per instructions in

6.11.

6.19.2 Method 2: Remove lower kick strip as per instructions in 6.7

6.19.3 Remove the clip pegs from the slide retainers.

6.19.4 Slide the dishdrawer from the cavity to allow servicing from the rear.

6.19.5. Remove the screw securing the rear service panel.

6.19.6 Fit a screwdriver through the hole in the rear service panel and

lift or tap the shaft of the screwdriver up so to disengage the panel

from its retainers.

6.19.7 The service procedures from now on are the same for both methods.

6.19.8 Disconnect the air plumbing from the air pump.

6.19.9 The air pump can now be released from the rubber mount (if sliding

the rubber mount off the exhaust valve be careful not to lose the steel

core which will fall out of the exhaust valve. The exhaust valve core

is fitted with the rubber end upper most ).

6.19.10 Disconnect the wiring connector from the coil.

6.19.11 Refit in reverse manner. Ensure the pump hangers are correctly

located.

- 40 -

6.20 Exhaust Valve Removal

Note: This component maybe serviced by two Methods.

6.20.1 Method 1: Remove tub assembly as per instructions in 6.11.

6.20.2 Method 2: Remove lower kick strip as per instructions in 6.7.

6.20.3 Remove the clip pegs from the slide retainers.

6.20.4 Slide the dishdrawer from the cavity to allow servicing from the rear.

6.20.5 Remove the screw securing the rear service panel.

6.20.6 Fit a screwdriver through the hole in the rear service panel and

lift or tap the shaft of the screwdriver up so to disengage the panel

from its retainers.

6.20.7 The service procedures from now on are the same for both

directions.

6.20.8 Lift the exhaust valve up to disengage the mounting from the

chassis.

6.20.9 Disconnect the air plumbing from the exhaust valve.

6.20.10 Remove the exhaust valve from the rubber mount (be careful not to

lose the steel core which will fall out of the exhaust valve. The

exhaust valve core is fitted with the rubber end upper most).

6.20.11 Disconnect the wiring connection from the exhaust valve.

6.20.12 Refit in reverse manner. Ensure the pump hangers are correctly

located.

6.21 Water Valve Removal

6.21.1 Remove the lower tub as per instructions in 6.11.

6.21.2 The water valve is located at the rear on the lefthand side.

6.21.3 Disconnect the wiring connections to both solenoids. Release the

locking tabs for the connectors with a blade screwdriver while doing

this.

6.21.4 Disconnect the inlet hose connection.

6.21.5 The water valve may now be slid forward off the mounting bracket.

6.21.6 Disconnect the two fill hoses off the valve noting which hose goes to

the top and tub and which goes to the bottom tub.

6.21.7 Refit in reverse manner.

6.22 Flood Switch Removal

6.22.1 Remove the lower tub as per instructions in 6.11

6.22.2 The flood switch is located on the base of the chassis.

6.22.3 Remove the wiring connections to the switch noting each connection

location.

6.22.4 The switch is released from the chassis by squeezing together the

pins on the legs of the switch with a fine blade screwdriver.

6.22.5 Refit in reverse manner.

- 41 -

6.23 EMI Filter Removal

6.23.1 Remove the lower tub as per instructions in 6.11.

6.23.2 The EMI filter is located at the rear left hand side of the chassis base.

6.23.3 Remove the screw in the rear access panel of the chassis..

6.23.4 Raise the insulating cover to expose the EMI filter.

6.23.5 The EMI filter can now be replaced or serviced.

6.23.6 Refit in reverse manner.

6.24 Tub Microswitch Removal

Note: Located on the rear of the left slide runner and connected in series

with the exhaust valve, this component can be serviced by two

methods.

6.24.1 Method 1:

Remove the slide runner as per instructions in 6.15.

6.24.2 Method 2:

Remove lower kickstrip as per instructions in 6.7.

6.24.3 Remove the clip pegs from the slide runners.

6.24.4 Slide the DishDrawer from the cavity to allow servicing from the

rear.

6.24.5 Remove the screw securing the rear service panel.

6.24.6 Fit a screwdriver through the hole in the rear service panel and lift or

tap the shaft of the screwdriver up so as to disengage the panel from

its retainers.

6.24.7 The service procedures from now on are the same for both methods.

6.24.8 Disconnect the wiring to the microswitch.

6.24.9 Release the microswitch from the retaining clips on latch retaining

mechanism on the drawer slide.

6.24.10 Refit in reverse manner.

- 42 -

Loading...

Loading...