Page 1

FANUC AC SERVO MOTOR @* series

FANUC AC SERVO MOTOR #

FANUC LINEAR MOTOR L

FANUC SY

BUILT-IN SERVO MOTOR D

NCHRONOUS

*S series

PARAMETER MANUAL

* series

*S series

B-65270EN/06

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

The parameters described in this manual must be set correctly according to the relevant

descriptions. If the parameters are not set correctly, vibrations and unpredictable motions

can occur. When setting and updating the parameters, place top priority on safety in

operation by taking actions, such as lowering the torque limit value, excessive error level,

and operation speed, and performing an operation so that an emergency stop can be

initiated immediately, until the settings are confirmed to be appropriate.

Page 3

B-65270EN/06 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

- Read this manual carefully, and store it in a safe place.

s-1

Page 4

Page 5

B-65270EN/06 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE .................................s-1

1 OVERVIEW .............................................................................................1

1.1 SERVO SOFTWARE AND SERVO CARDS SUPPORTED BY EACH NC

MODEL.......................................................................................................... 2

1.2 ABBREVIATIONS OF THE NC MODELS COVERED BY THIS MANUAL .... 4

1.3 RELATED MANUALS.................................................................................... 5

2 SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS......................7

2.1 INITIALIZING SERVO PARAMETERS.......................................................... 8

2.1.1 Before Servo Parameter Initialization ......................................................................8

2.1.2 Parameter Initialization Flow ...................................................................................9

2.1.3 Servo Parameter Initialization Procedure...............................................................10

2.1.4 Setting Servo Parameters when a Separate Detector for the Serial Interface is

Used........................................................................................................................29

2.1.5 Setting Servo Parameters when an Analog Input Separate Interface Unit is

Used........................................................................................................................40

2.1.6 Setting Parameters when an α

2.1.7 Setting Parameters when the PWM Distribution Module is Used .........................48

2.1.8 Actions for Illegal Servo Parameter Setting Alarms ..............................................51

iCZ Sensor is Used.................................................42

3 αiS/αiF/βiS SERIES PARAMETER ADJUSTMENT........................... 63

3.1 SERVO TUNING SCREEN.......................................................................... 64

3.2 ACTIONS FOR ALARMS ............................................................................ 67

3.3 ADJUSTING PARAMETERS FOR HIGH-SPEED AND HIGH-PRECISION

MACHINING ................................................................................................ 76

3.3.1 Servo HRV Control Adjustment Procedure ...........................................................76

3.3.2 High-Speed Positioning Adjustment Procedure.....................................................99

3.3.3 Rapid Traverse Positioning Adjustment Procedure..............................................102

3.3.4 Vibration in the Stop State ...................................................................................107

3.3.5 Vibration during Travel........................................................................................109

3.3.6 Stick Slip ..............................................................................................................111

3.3.7 Overshoot .............................................................................................................112

4 SERVO FUNCTION DETAILS ............................................................113

4.1 SERVO HRV CONTROL ........................................................................... 114

c-1

Page 6

TABLE OF CONTENTS B-65270EN/06

4.1.1 Servo HRV2 Control ............................................................................................117

4.2 HIGH-SPEED HRV CURRENT CONTROL............................................... 122

4.2.1 Servo HRV3 Control ............................................................................................122

4.2.2 Servo HRV4 Control ............................................................................................128

4.2.3 High-speed HRV Current Control........................................................................133

4.3 CUTTING/RAPID SWITCHING FUNCTION.............................................. 134

4.4 VIBRATION SUPPRESSION IN THE STOP STATE................................. 140

4.4.1 Velocity Loop High Cycle Management Function ..............................................140

4.4.2 Acceleration Feedback Function ..........................................................................142

4.4.3 Variable Proportional Gain Function in the Stop State ........................................144

4.4.4 N Pulses Suppression Function ............................................................................148

4.5 MACHINE RESONANCE ELIMINATION FUNCTION ............................... 150

4.5.1 Torque Command Filter (Middle-Frequency Resonance Elimination Filter) ......150

4.5.2 Resonance Elimination Filter Function

(High-Frequency Resonance Elimination Filter) .................................................152

4.5.3 Disturbance Elimination Filter Function

(Low-Frequency Resonance Elimination Filter) ..................................................158

4.5.4 Observer Function ................................................................................................162

4.5.5 Current Loop 1/2 PI Control Function .................................................................166

4.5.6 Vibration Damping Control Function ..................................................................168

4.5.7 Dual Position Feedback Function (Optional function).........................................170

4.5.8 Machine Speed Feedback Function......................................................................176

4.6 CONTOUR ERROR SUPPRESSION FUNCTION ....................................179

4.6.1 Feed-forward Function .........................................................................................179

4.6.2 Advanced Preview Feed-forward Function..........................................................183

4.6.3 RISC Feed-forward Function ...............................................................................186

4.6.4 Cutting/Rapid Feed-forward Switching Function ................................................188

4.6.5 Feed-forward Timing Adjustment Function.........................................................190

4.6.6 Backlash Acceleration Function...........................................................................193

4.6.7 Two-stage Backlash Acceleration Function.........................................................199

4.6.8 Static Friction Compensation Function................................................................214

4.6.9 Torsion Preview Control Function .......................................................................217

4.7 OVERSHOOT COMPENSATION FUNCTION ..........................................227

4.8 HIGH-SPEED POSITIONING FUNCTION ................................................ 233

4.8.1 Position Gain Switching Function........................................................................233

4.8.2 Low-speed Integral Function................................................................................237

4.8.3 Fine Acceleration/Deceleration (FAD) Function .................................................239

c-2

Page 7

B-65270EN/06 TABLE OF CONTENTS

4.9 SERIAL FEEDBACK DUMMY FUNCTIONS .............................................248

4.9.1 Serial Feedback Dummy Functions......................................................................248

4.9.2 How to Use the Dummy Feedback Functions for a Multiaxis Servo Amplifiers

when an Axis is not in Use...................................................................................250

4.10 BRAKE CONTROL FUNCTION................................................................. 251

4.11 QUICK STOP FUNCTION ......................................................................... 255

4.11.1 Quick Stop Type 1 at Emergency Stop ................................................................255

4.11.2 Quick Stop Type 2 at Emergency Stop ................................................................257

4.11.3 Lifting Function Against Gravity at Emergency Stop..........................................258

4.11.4 Quick Stop Function for Hardware Disconnection of Separate Detector.............262

4.11.5 Quick Stop Function at OVL and OVC Alarm ....................................................264

4.11.6 Overall Use of the Quick Stop Functions.............................................................265

4.12 UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION

(Optional function) .....................................................................................266

4.12.1 Unexpected Disturbance Torque Detection Function ..........................................266

4.12.2 Cutting/Rapid Unexpected Disturbance Torque Detection Switching Function..277

4.13 FUNCTION FOR OBTAINING CURRENT OFFSETS AT EMERGENCY

STOP......................................................................................................... 279

4.14 LINEAR MOTOR PARAMETER SETTING................................................ 280

4.14.1 Procedure for Setting the Initial Parameters of Linear Motors ............................280

4.14.2 Detection of an Overheat Alarm by Servo Software when a Linear Motor and

a Synchronous Built-in Servo Motor are Used.....................................................307

4.14.3 Smoothing Compensation for Linear Motor ........................................................310

4.15 SYNCHRONOUS BUILT-IN SERVO MOTOR PARAMETER SETTING ... 320

4.15.1 Procedure for Setting the Initial Parameters of Synchronous Built-in Servo

Motors ..................................................................................................................320

4.15.2 Detection of an Overheat Alarm by Servo Software when a Synchronous

Built-in Servo Motor are Used .............................................................................346

4.15.3 Smoothing Compensation for Synchronous Built-in Servo Motor ......................346

4.16 TORQUE CONTROL FUNCTION .............................................................351

4.17 TANDEM DISTURBANCE ELIMINATION CONTROL

(POSITION TANDEM) (Optional function)................................................. 354

4.18 SYNCHRONOUS AXES AUTOMATIC COMPENSATION........................ 362

4.19 TORQUE TANDEM CONTROL FUNCTION (Optional function) ............... 366

4.19.1 Preload Function ..................................................................................................372

4.19.2 Damping Compensation Function........................................................................375

4.19.3 Velocity Feedback Average Function ..................................................................377

c-3

Page 8

TABLE OF CONTENTS B-65270EN/06

4.19.4 Servo Alarm 2-axis Simultaneous Monitor Function...........................................377

4.19.5 Motor Feedback Sharing Function .......................................................................379

4.19.6 Full-closed Feedback Sharing Function ...............................................................380

4.19.7 Adjustment ...........................................................................................................381

4.19.8 Cautions for Controlling One Axis with Two Motors..........................................385

4.19.9 Block Diagrams....................................................................................................387

4.20 SERVO TUNING TOOL SERVO GUIDE................................................... 388

4.20.1 SERVO GUIDE ...................................................................................................388

5 DETAILS OF PARAMETERS .............................................................400

5.1 DETAILS OF THE SERVO PARAMETERS FOR Series 30i, 31i, 32i,

15i, 16i, 18i, 21i, 0i, 20i, Power Mate i (SERIES 90D0, 90E0, 90B0,

90B1, 90B6, 90B5, AND 9096).................................................................. 401

6 PARAMETER LIST ............................................................................. 427

6.1 PARAMETERS FOR HRV1 CONTROL .................................................... 428

6.2 PARAMETERS FOR HRV2 CONTROL .................................................... 438

6.3 PARAMETERS FOR HRV1 CONTROL (FOR Series 0i-A)....................... 451

APPENDIX

A ANALOG SERVO INTERFACE SETTING PROCEDURE.................. 457

B PARAMETERS SET WITH VALUES IN DETECTION UNITS ............ 464

B.1 PARAMETERS FOR Series 15i ................................................................ 465

B.2 PARAMETERS FOR Series 16i, 18i, AND 21i .......................................... 467

B.3 PARAMETERS FOR THE Power Mate i ................................................... 469

B.4 PARAMETERS FOR Series 30i, 31i, AND 32i .......................................... 471

C FUNCTION-SPECIFIC SERVO PARAMETERS ................................. 473

D PARAMETERS RELATED TO HIGH-SPEED AND

HIGH PRECISION OPERATIONS ......................................................481

D.1 MODEL-SPECIFIC INFORMATION ..........................................................482

D.1.1 Series 15i-MB.......................................................................................................482

D.1.2 Series 16i/18i/21i/0i/0i Mate-MB, 0i/0i Mate-MC/20i-FB ..................................485

D.1.3 Series 30i/31i/32i-A, 31i-A5 ................................................................................495

D.2 SERVO PARAMETERS RELATED TO HIGH-SPEED AND

HIGH PRECISION OPERATIONS............................................................. 498

E VELOCITY LIMIT VALUES IN SERVO SOFTWARE .........................505

F SERVO FUNCTIONS .......................................................................... 510

c-4

Page 9

B-65270EN/06 TABLE OF CONTENTS

G PARAMETERS FOR α AND OTHER SERIES ...................................513

G.1 MOTOR ID NUMBERS OF α SERIES MOTORS...................................... 514

G.2 MOTOR ID NUMBERS OF β SERIES MOTORS ...................................... 516

G.3 MOTOR ID NUMBERS OF CONVENTIONAL LINEAR MOTORS ............ 517

G.4 PARAMETERS FOR SERVO HRV2 CONTROL ....................................... 518

G.5 HRV1 CONTROL PARAMETERS FOR α SERIES, β SERIES, AND

CONVENTIONAL LINEAR MOTORS........................................................ 519

G.6 HRV2 CONTROL PARAMETERS FOR βM SERIES MOTORS................ 528

H DETAILS OF HIGH-SPEED AND HIGH-PRECISION

ADJUSTMENT .................................................................................... 530

I SERVO CHECK BOARD OPERATING PROCEDURE ...................... 555

c-5

Page 10

Page 11

B-65270EN/06 1.OVERVIEW

1 OVERVIEW

This manual describes the servo parameters of the CNC models using

FANUC AC SERVO MOTOR α

descriptions include the servo parameter start-up and adjustment

procedures. The meaning of each parameter is also explained.

iS, αiF, and βiS series. The

- 1 -

Page 12

1.OVERVIEW B-65270EN/06

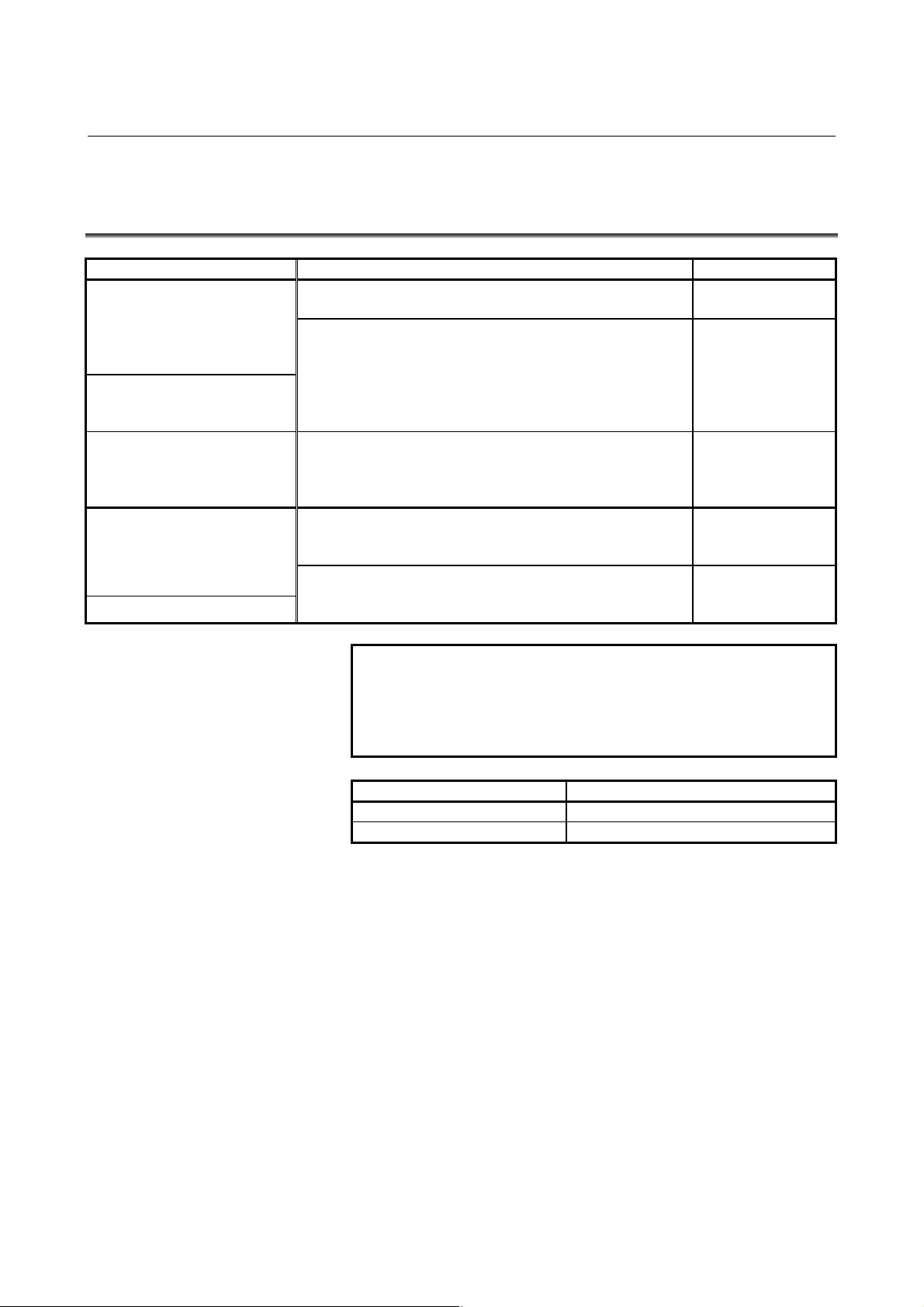

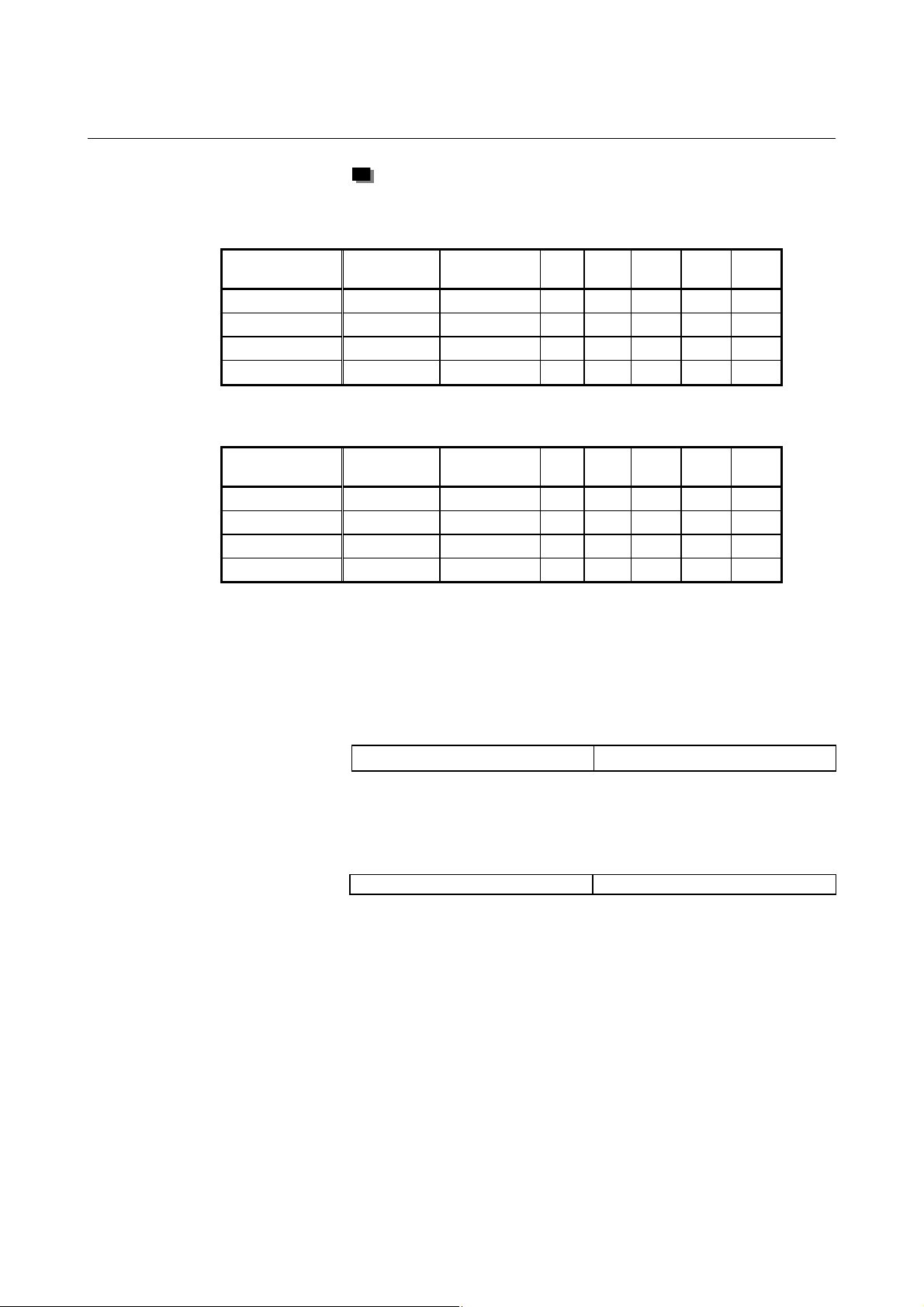

1.1 SERVO SOFTWARE AND SERVO CARDS SUPPORTED

BY EACH NC MODEL

NC product name Series and edition of applicable servo software Servo card

Series 21i-MODEL B (Note1)

Series 0i-MODEL B (Note1)

Series 0i Mate-MODEL B (Note1)

Power Mate i-MODEL D (Note1)

Power Mate i-MODEL H (Note1)

Series 15i-MODEL B

Series 16i-MODEL B

Series 18i-MODEL B

Series 0i-MODEL C

Series 0i Mate-MODEL C

Series 20i-MODEL B

Series 30i-MODEL A

Series 31i-MODEL A

Series 32i-MODEL A

Series 9096/A(01) and subsequent editions

(Supporting i series CNC and SERVO HRV1 control) (Note2)

Series 90B0/H(08) and subsequent editions

Series 90B6/A(01) and subsequent editions

(Supporting i series CNC and SERVO HRV1, 2, and 3 control)

(Note3)

Series 90B1/A(01) and subsequent editions (Note3)

Series 90B5/A(01) and subsequent editions

(Supporting i series CNC and SERVO HRV1, 2, and 3 control)

(Note4)

Series 90D0/A(01) and subsequent editions

(Supporting i series CNC and SERVO HRV4 control)

(Note5, Note6)

Series 90E0/A(01) and subsequent editions

(Supporting i series CNC and SERVO HRV2 and 3 control)

(Note6)

320C52 servo card

320C5410 servo card

320C5410 servo card

Servo card for FS30i

servo HRV4 control

Servo card for FS30i

servo HRV2 and 3

control

NOTE

1 The servo software series of the Series

21i-MODEL B, 0i-MODEL B, 0i Mate MODEL B, or

Power Mate i-MODEL D/H depends on the

incorporated servo card, as shown below:

Servo software Servo card

Series 9096 320C52 servo card

Series 90B0 or Series 90B6 320C5410 servo card

- 2 -

Page 13

B-65270EN/06 1.OVERVIEW

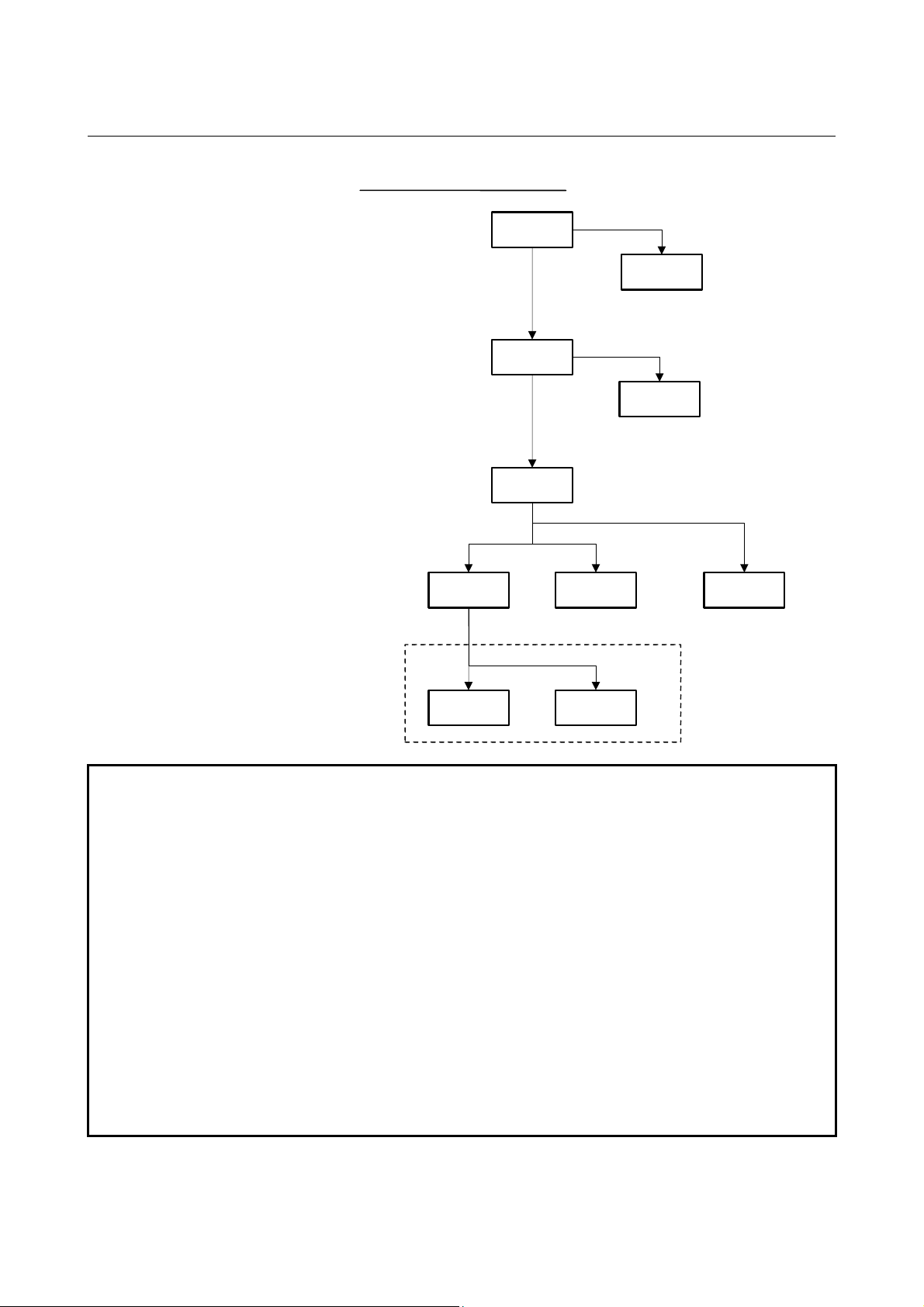

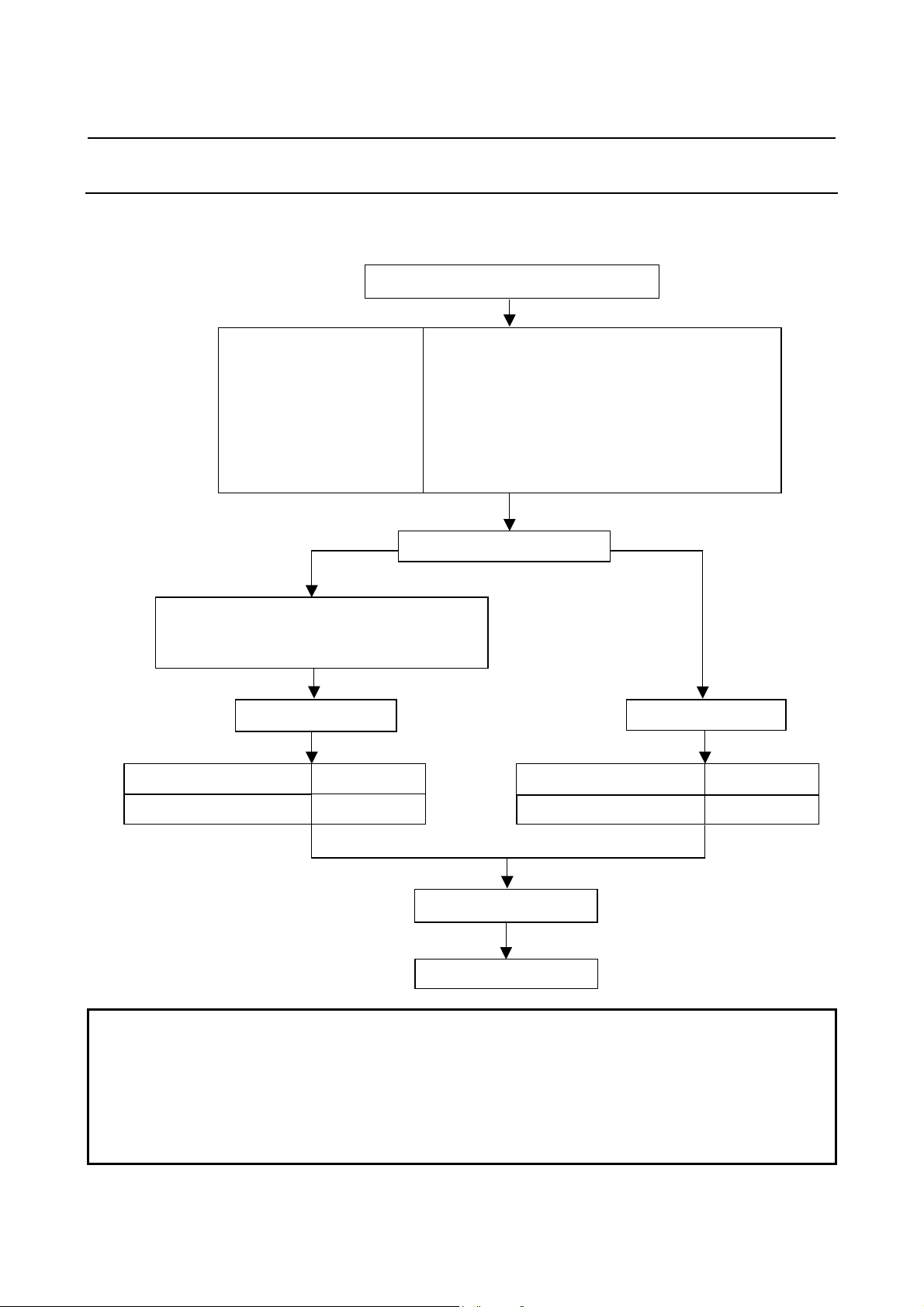

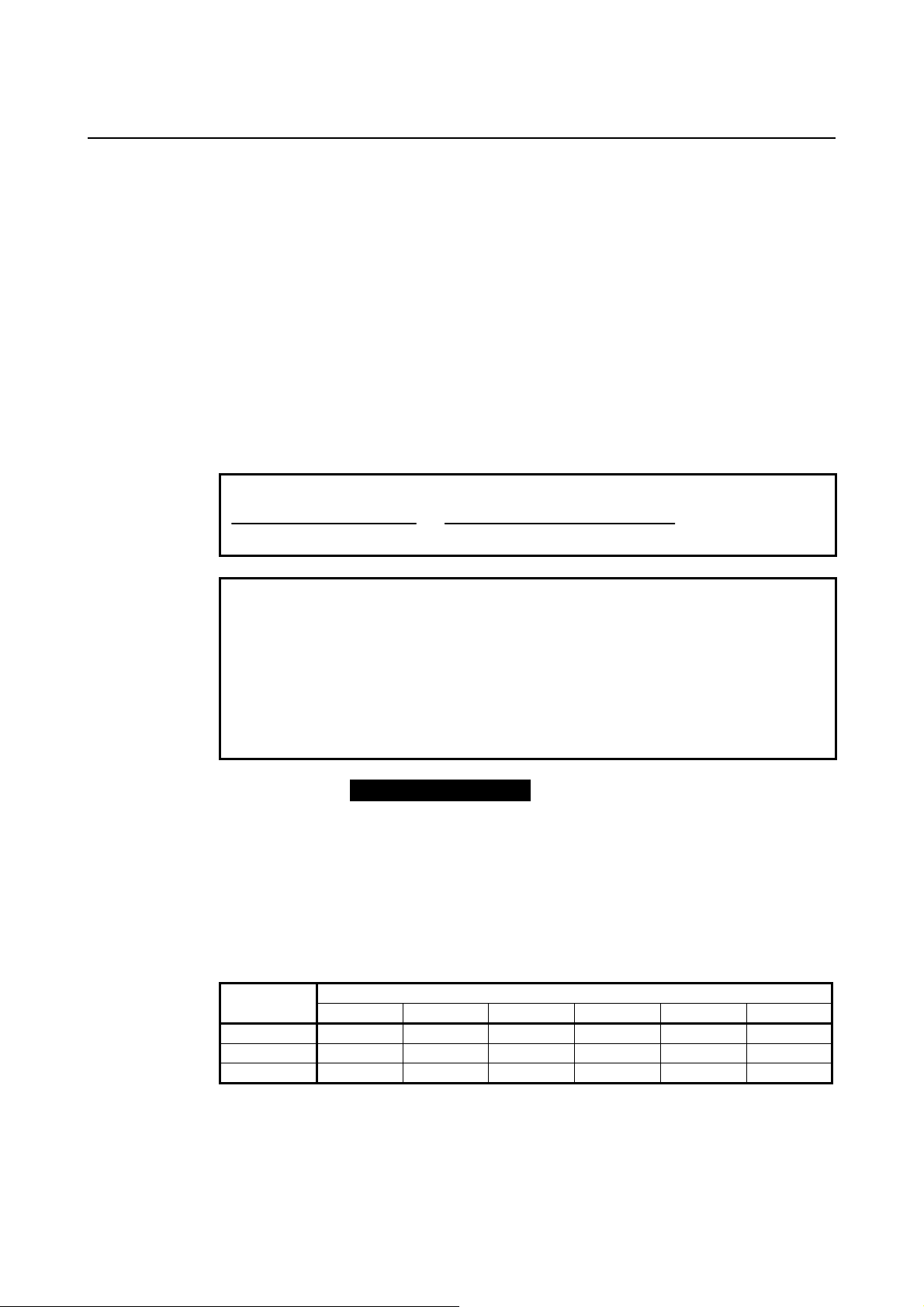

α

Servo software series map

HRV1 supported,

i not supported

For Series 16i ,

and so on

For Series 30i ,

and so on

9090

HRV2 supported, αi not supported

90A0

HRV3 supported, αi supported

90B0

HRV1 supported,

αi supported

9096

90A6

For Series 0i-C

90B1 90B6 90B5

HRV4

supported

90D0 90E0

NOTE

1 The servo software Series 9096 is compatible with the conventional servo software

Series 9090 except for the following function:

- Electric gear box (EGB) function can not be used.

2 The servo software Series 90B0 is upwardly compatible with the conventional servo

software Series 90A0. Series 90B6 is a successor of Series 90B0. Series 90B1 is a

special series compatible with Series 90B0 and is required when a PWM

distribution module or pulse input DSA is used.

3 Servo software Series 90B5, which is a successor of Series 90B0 and supports the

same functions as Series 90B6, is used in the Series 0i-MODEL C,

0i Mate-MODEL C, and 20i-MODEL B.

4 When using servo HRV4 control with Series 30i-MODEL A and 31i-MODEL A, use

Series 90D0.

5 Servo software Series 90D0 and 90E0 is upwardly compatible with conventional

servo software Series 90B0 except the following functions:

- Fine Acc./Dec. (FAD) function can not be used.

- HRV1 control can not be used.

- 3 -

Page 14

1.OVERVIEW B-65270EN/06

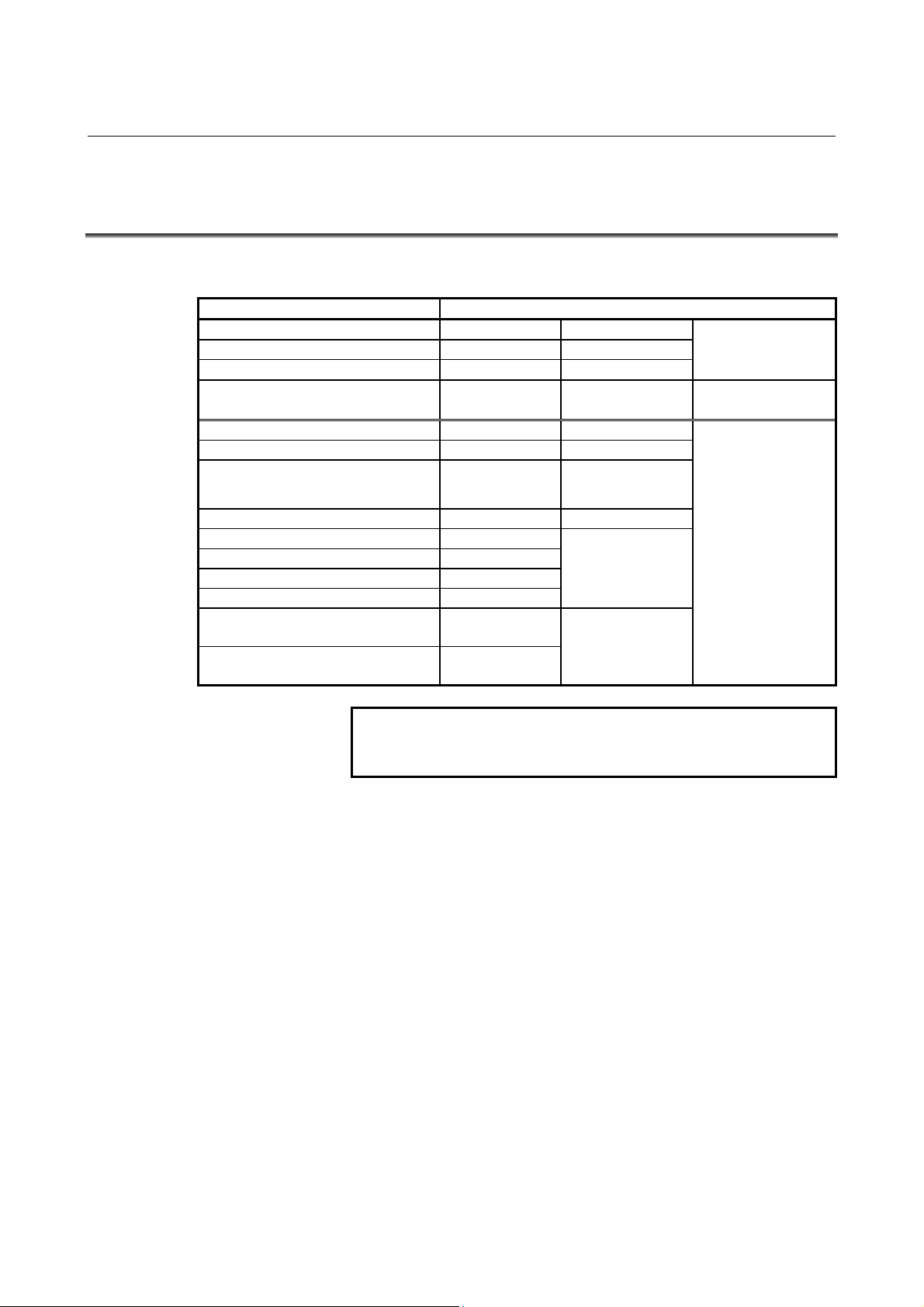

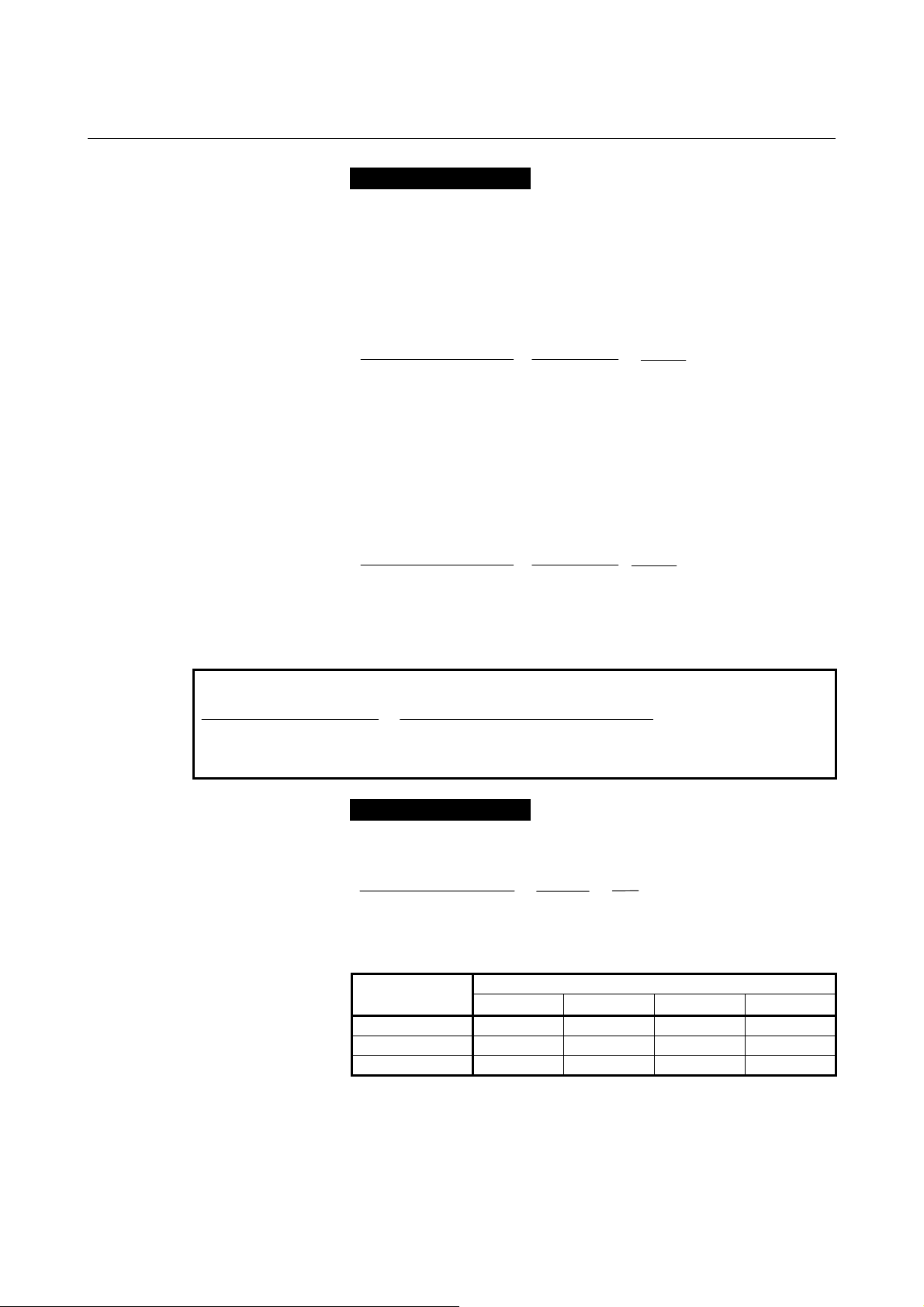

1.2 ABBREVIATIONS OF THE NC MODELS COVERED BY

THIS MANUAL

In this manual, the NC product names are abbreviated as follows.

NC product name Abbreviations

FANUC Series 30i-MODEL A Series 30i-A Series 30i

FANUC Series 31i-MODEL A Series 31i-A Series 31i

FANUC Series 32i-MODEL A Series 32i-A Series 32i

FANUC Series 15i-MODEL B Series 15i-B Series 15i

FANUC Series 16i-MODEL B Series 16i-B Series 16i

FANUC Series 18i-MODEL B Series 18i-B Series 18i

FANUC Series 20i-MODEL B Series 20i-B

FANUC Series 21i-MODEL B Series 21i-B Series 21i

FANUC Series 0i-MODEL C Series 0i-C

FANUC Series 0i Mate-MODEL C Series 0i Mate-C

FANUC Series 0i-MODEL B Series 0i-B

FANUC Series 0i Mate-MODEL B Series 0i Mate-B

FANUC Power Mate i-MODEL D

FANUC Power Mate i-MODEL H

Power Mate i-D

PMi-D

Power Mate i-H

PMi-H

Series 20i

FS20i

Series 0i

FS0i

Power Mate i

Power Mate i-D/H

NOTE

In this manual, Power Mate i refers to the Power

Mate i-D, and Power Mate i-H.

(Note 1)

Series 30i

FS30i

Series 15i

FS15i

Series 16i and so on

Series 16i etc.

FS16i and so on

FS16i etc.

- 4 -

Page 15

B-65270EN/06 1.OVERVIEW

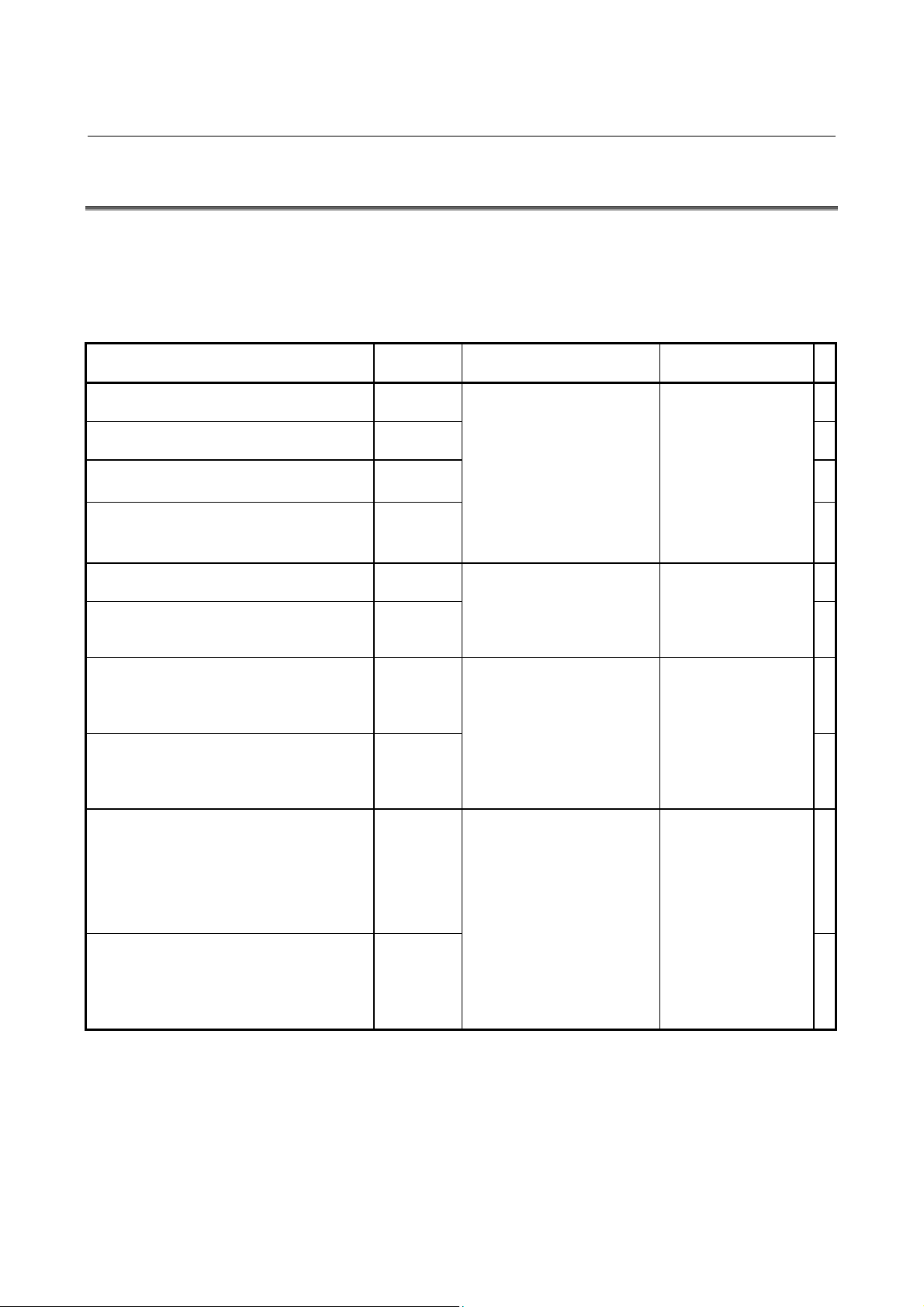

1.3 RELATED MANUALS

The following seven kinds of manuals are available for FANUC AC

SERVO MOTOR α

In the table, this manual is marked with an asterisk (*).

Table 1.3 Related manuals of SERVO MOTOR αiS/αiF/βiS series

Document name

FANUC AC SERVO MOTOR αi series

DESCRIPTIONS

FANUC AC SERVO MOTOR βi series

DESCRIPTIONS

FANUC LINEAR MOTOR LiS series

DESCRIPTIONS

FANUC SYNCHRONOUS BUILT-IN SERVO

MOTOR D

DESCRIPTIONS

FANUC SERVO AMPLIFIER αiSV series

DESCRIPTIONS

FANUC SERVO AMPLIFIER βiSV series

DESCRIPTIONS

FANUC AC SERVO MOTOR αi series

FANUC AC SPINDLE MOTOR αi series

FANUC SERVO AMPLIFIER αi series

MAINTENANCE MANUAL

FANUC AC SERVO MOTOR βi series

FANUC AC SPINDLE MOTOR βi series

FANUC SERVO AMPLIFIER βi series

MAINTENANCE MANUAL

FANUC AC SERVO MOTOR αi series

FANUC AC SERVO MOTOR βi series

FANUC LINEAR MOTOR L

FANUC SYNCHRONOUS BUILT-IN SERVO

MOTOR D

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR αi series

FANUC AC SPINDLE MOTOR βi series

FANUC BUILT-IN SPINDLE MOTOR

Bi series

PARAMETER MANUAL

iS series

iS series

iS series

Document

number

B-65262EN

B-65302EN

B-65222EN

B-65332EN

B-65282EN

B-65322EN

B-65285EN

B-65325EN

B-65270EN *

B-65280EN

iS, αiF or βiS series.

Major contents Major usage

• Specification

• Characteristics

• External dimensions

• Connections

• Specifications and functions

• Installation

• External dimensions and

maintenance area

• Connections

• Start up procedure

• Troubleshooting

• Maintenance of motor

• Initial setting

• Setting parameters

• Description of parameters

• Selection of motor

• Connection of motor

• Selection of amplifier

• Connection of

amplifier

• Start up the system

(Hardware)

• Troubleshooting

• Maintenance of

motor

• Start up the system

(Software)

• Turning the system

(Parameters)

- 5 -

Page 16

1.OVERVIEW B-65270EN/06

Other manufactures’ products referred to in this manual

* IBM is registered trademark of International Business Machines

Corporation.

* MS-DOS and Windows are registered trademarks of Microsoft

Corporation.

All other product names identified throughout this manual are

trademarks or registered trademarks of their respective companies.

In this manual, the servo parameters are explained using the following

notation:

(Example)

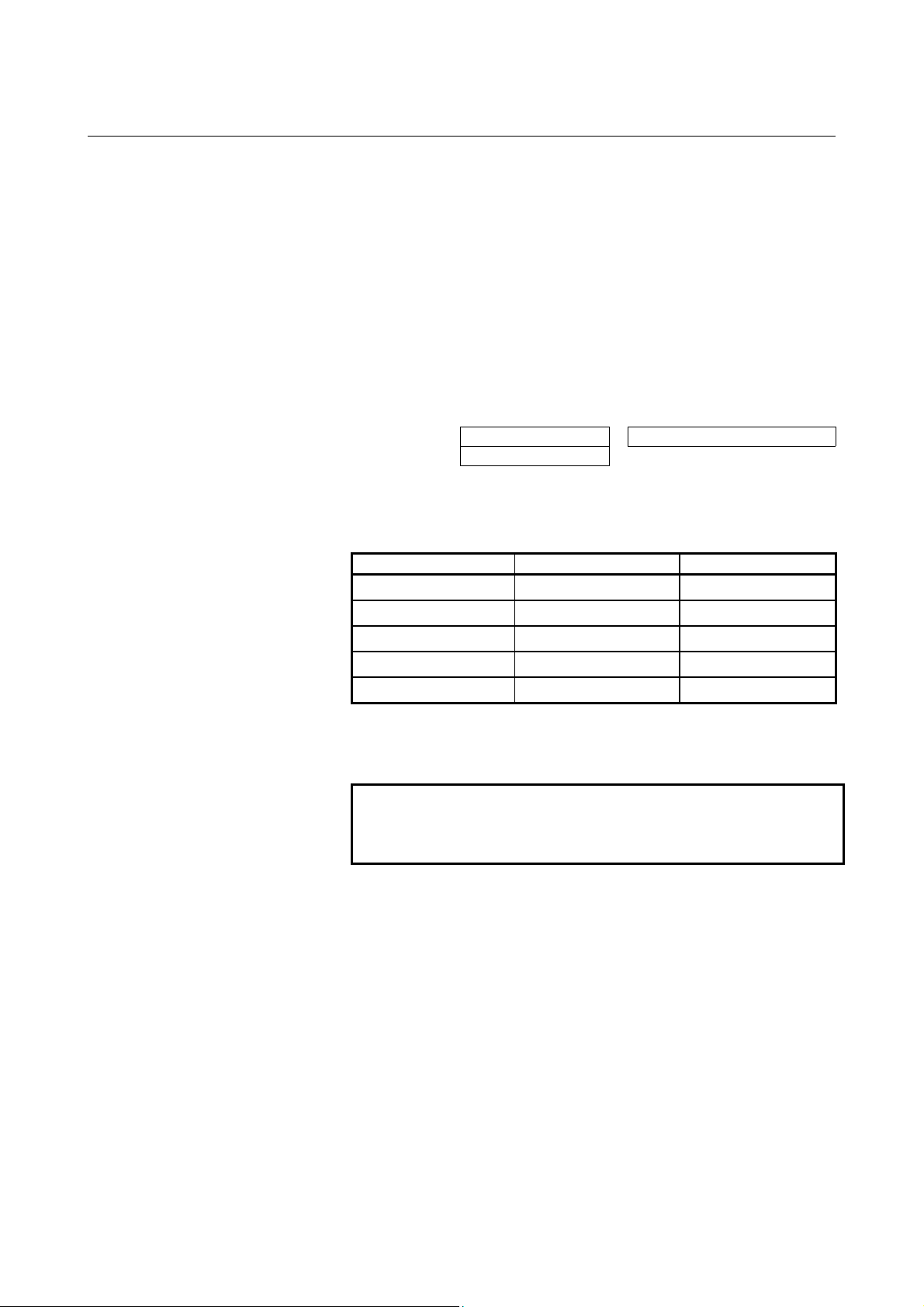

Series 15i Servo parameter function name

No.1875(FS15i)

No.2021(FS30i, 16i)

Series 30i, 31i, 32i, 16i, 18i, 21i, 0i, Power Mate i

The following α

i/βi Pulsecoders are available.

Pulsecoder name Resolution Type

αiA1000

αiI1000

αiA16000

βiA128

βiA64

1,000,000 pulse/rev Absolute

1,000,000 pulse/rev Incremental

16,000,000 pulse/rev Absolute

131,072 pulse/rev Absolute

65,536 pulse/rev Absolute

When parameters are set, these pulse coders are all assumed to have a

resolution of 1,000,000 pulses per motor revolution.

NOTE

Load inertia ratio

The effect of α

iA16000 can be increased when

used together with AI nano contour control.

- 6 -

Page 17

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

2 SETTING αiS/αiF/βiS SERIES SERVO

PARAMETERS

- 7 -

Page 18

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

2.1 INITIALIZING SERVO PARAMETERS

2.1.1 Before Servo Parameter Initialization

Before starting servo parameter initialization, confirm the following:

<1> NC model (ex.: Series 16i-B)

<2> Servo motor model (ex.: α

<3> Pulsecoder built in a motor (ex.:

<4> Is the separate position detector used? (ex.: Not used)

<5> Distance the machine tool moves per revolution of the motor

(ex.:10 mm per one revolution)

<6> Machine detection unit (ex.:0.001 mm)

<7> NC command unit (ex.:0.001 mm)

iF8/3000)

αiA1000)

- 8 -

Page 19

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

A

)

2.1.2 Parameter Initialization Flow

On the servo setting and servo adjustment screens, set the following:

In emergency stop state, switch on NC.

Initialization bits

Motor ID No.

MR

CMR

Move direction

Reference counter

Velocity gain

Make settings for using separate detector.

No. 1807#3 = 1, 1815#1 = 1 (Series 15i)

No. 1815#1 = 1 (Series 30i, Series 16i and so on)

Set flexible feed gear.

Number of velocity pulses

8192

00000000 See (2) and (8)-(b)-3 in Subsec. 2.1.3.

See (3) in Subsec. 2.1.3.

See (4) in Subsec. 2.1.3.

See (5) in Subsec. 2.1.3.

See (7) in Subsec. 2.1.3.

See (9) in Subsec. 2.1.3.

Set 150% if the machine inertia is unknown.

(Equivalent to load inertia ratio parameter)

Semi-closed loop Closed loop

Which system is being used?

← See (6) in Subsec. 2.1.3. →

Number of velocity pulses

Set flexible feed gear.

8192

Number of position pulses

Ns (Note 1

Number of position pulses

Turn power off then on.

End of parameter setting

12500

NOTE

1 When a separate detector of A/B phase parallel type and a serial linear scale are

used, Ns indicates the number of feedback pulses per motor revolution, sent from

the separate detector.

When a serial rotary scale is used, the number of pulses is calculated using

following expression: 12500 × (gear reduction ratio between the motor and table)

See (8)-(b)-2 in Subsec. 2.1.3.

- 9 -

Page 20

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

2.1.3 Servo Parameter Initialization Procedure

(1) Preparation

Switch on the NC in an emergency stop state.

Enable parameter writing (PWE = 1).

Initialize servo parameters on the servo setting screen.

For a Power Mate i with no CRT, specify a value for an item number

on the servo setting screen. See Fig. 2.1.3.

To display the servo setting screen, follow the procedure below, using

the key on the NC.

- Series 15i

Press the

SYSTEM

key several times, and the servo setting screen will

appear.

- Series30i,31i,32i,16i,18i,21i,20i,0i

→ [SYSTEM] → [ ] → [SV-PRM]

If no servo screen appears, set the following parameter as shown, and

switch the NC off and on again.

#7 #6 #5 #4 #3 #2 #1 #0

3111 SVS

SVS (#0) 1: Displays the servo screen.

When the following screen appears, move the cursor to the item you

want to specify, and enter the value directly.

Power Mate

No.2000

No.2020

No.2001

No.1820

No.2084

No.2085

No.2022

No.2023

No.2024

No.1821

X axis

16

2

1

100

111

8192

12500

10000

01000 N0000

Z axis

00001010

16

00000000

2

1

100

111

8192

12500

10000

Servo set

INITIAL SET BITS

Motor ID No.

AMR

CMR

Feed gear N

(N/M) M

Direction Set

Velocity Pulse No.

Position Pulse No.

Ref. counter

Fig. 2.1.3 Servo setting screen Correspondence of Power Mate i

00001010

00000000

- 10 -

Page 21

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

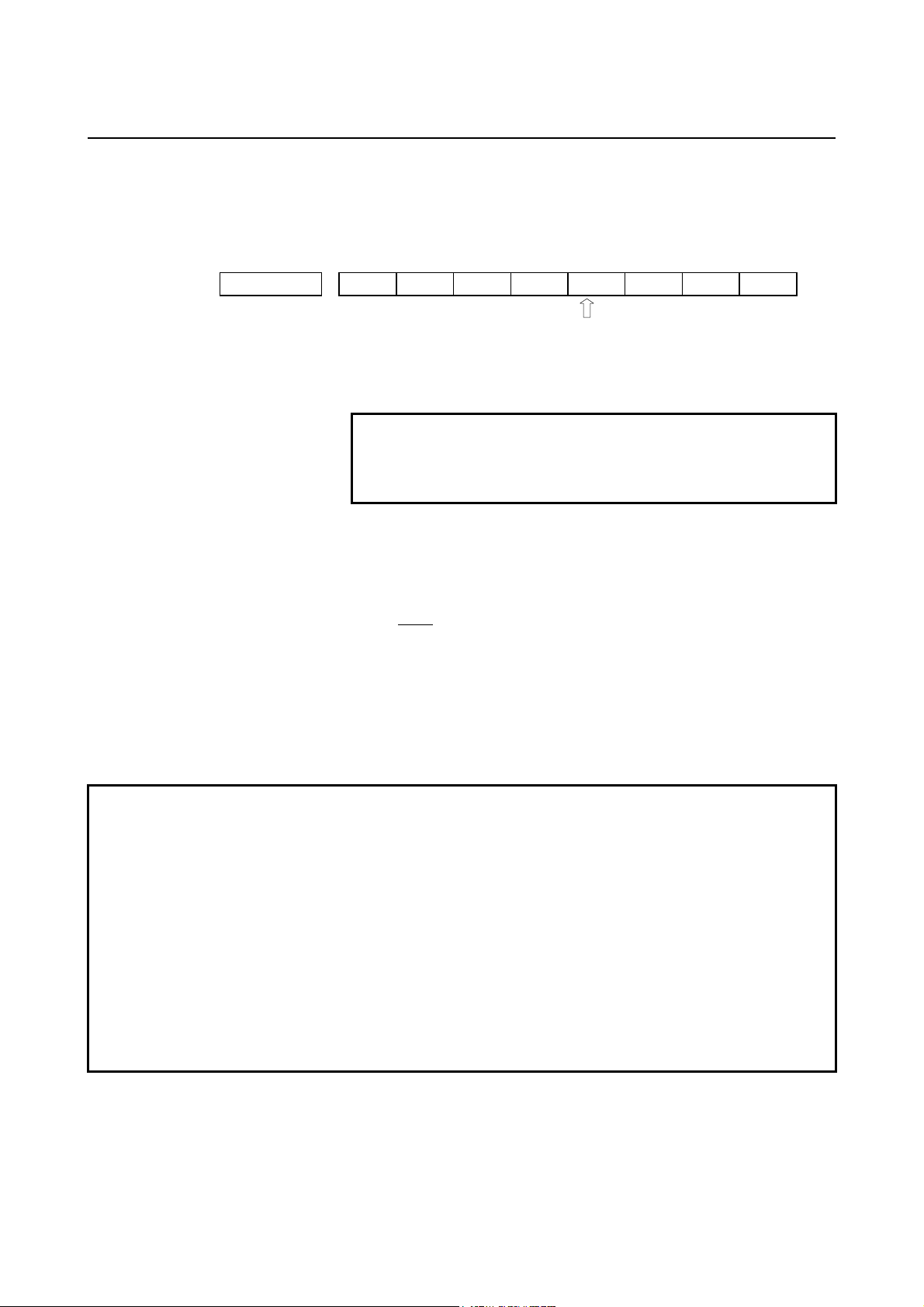

(2) Initialization

Start initialization.

Do not power off the NC until step (11).

#7 #6 #5 #4 #3 #2 #1 #0

INITIAL SET BIT PRMC DGPR PLC0

( Note)

Reset initialization bit 1 to 0.

DGPR(#1)=0

After initialization is completed, DGPR (#1) is set to 1.

NOTE

Once initialization has been completed, bit 3

(PRMC) for initialization is automatically set to 1.

(Except Series 30i, 31i and 32i)

(3) Motor ID No. setting

Specify the motor ID number.

Select the motor ID number of a motor to be used according to the

motor model and motor specification (the middle four digits in

A06B-****

When using servo HRV3 or HRV4 control, please use the motor ID

number for servo HRV2 control. It is available with the series and

editions listed in the table and later editions.

The mark "x" indicates a value that varies depending on the used

options.

The mark "-" indicates that automatic loading of standard parameters

is not supported as of December, 2005.

NOTE

• Series 30i, 31i and 32i

Specify the motor ID number for servo HRV2 control.

• Other than the Series 30i, 31i and 32i

When a pair of the values set in parameter No. 1023 (servo axis number) are

consecutive odd and even numbers, set motor ID numbers for servo HRV control of

the same type.

(Correct examples)

Servo axes when parameter No.1023= 1,2: Motor ID number for servo HRV2 control

Servo axes when parameter No.1023= 3,4: Motor ID number for servo HRV1 control

(Wrong examples)

Servo axes when parameter No.1023= 1: Motor ID number for servo HRV2 control

Servo axes when parameter No.1023= 2,3: Motor ID number for servo HRV1 control

-B***) listed in the following tables.

- 11 -

Page 22

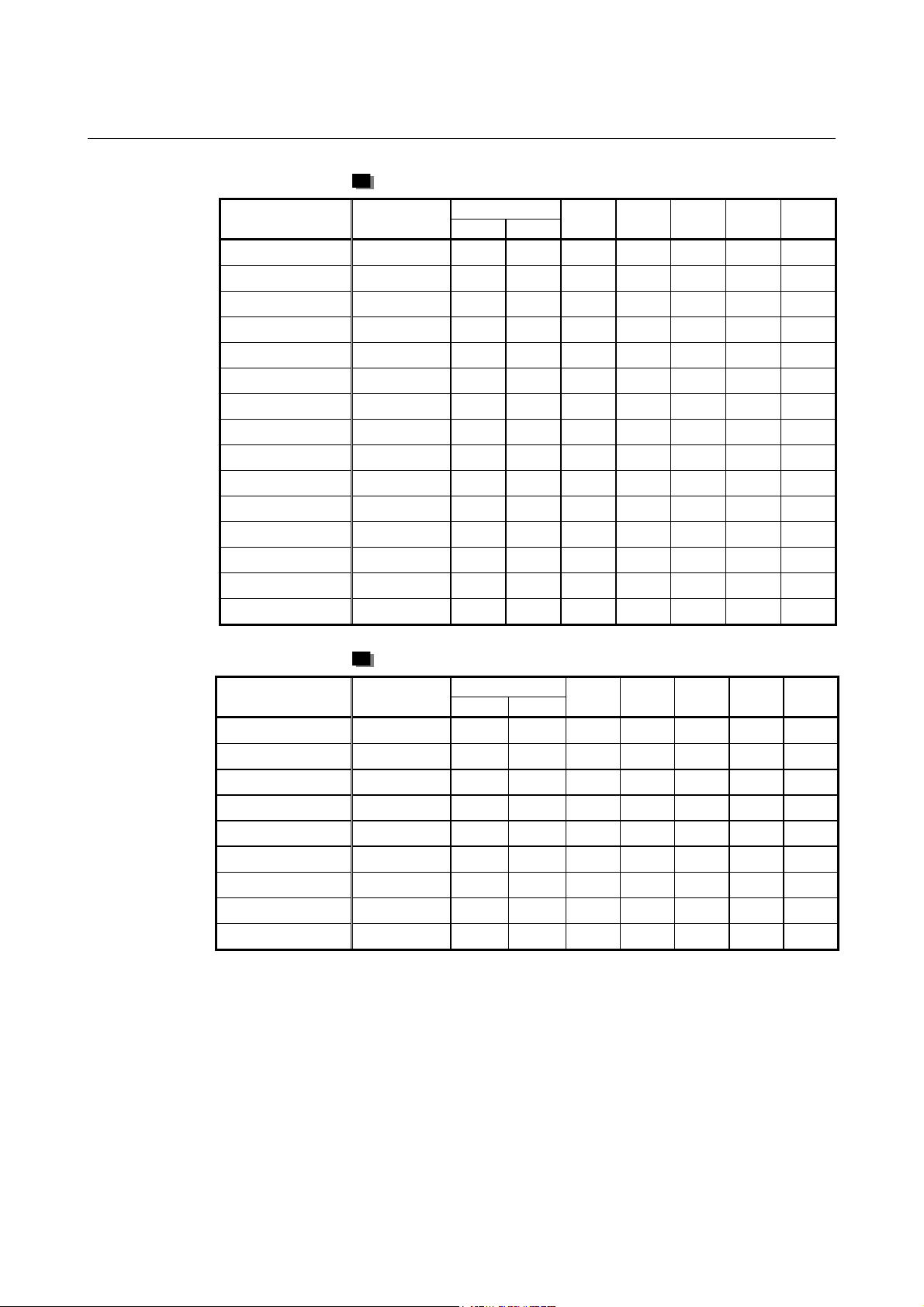

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

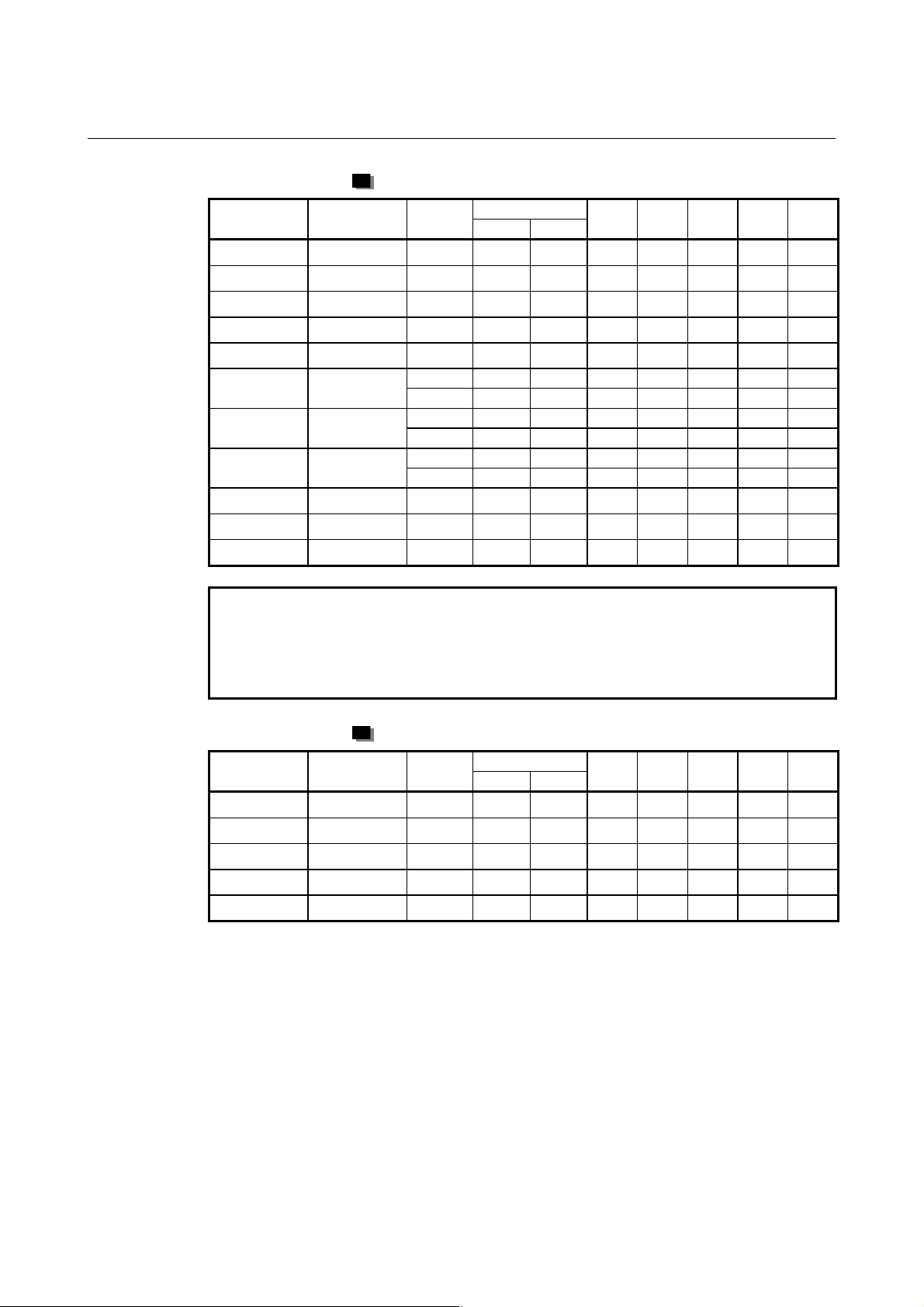

αiS series servo motor

Motor model

αiS2/

5000

αiS

2/6000

αiS4

/5000

αiS

8/4000

αiS

8/6000

αiS

12/4000

αiS

22/4000

αiS

30/4000

αiS

40/4000

αiS5

0/3000

αiS

50/3000 FAN

αiS

100/2500

αiS

200/2500

αiS

300/2000

αiS

500/2000

Motor

specification

0212 162 262 A H A A A

0218 - 284 G - B B -

0215 165 265 A H A A A

0235 185 285 A H A A A

0232 - 290 G - B B -

0238 188 288 A H A A A

0265 215 315 A H A A A

0268 218 318 A H A A A

0272 222 322 A H A A A

0275-Bx0x 224 324 B V A A F

0275-Bx1x 225 325 A N A A D

0285 235 335 A T A A F

0288 238 338 A T A A F

0292 115 342 B V A A -

0295 245 345 A T A A F

Motor ID No.

HRV1 HRV2

90D0

90E0

90B0

90B5

90B6

90B1 9096

Motor model

αiF1/5000

αiF2/5000

αiF4/4000

αiF8/3000

αiF12/3000

αiF22/3000

αiF30/3000

αiF40/3000

αiF40/3000

FAN

αiF series servo motor

Motor

specification

0202 152 252 A H A A A

0205 155 255 A H A A A

0223 173 273 A H A A A

0227 177 277 A H A A A

0243 193 293 A H A A A

0247 197 297 A H A A A

0253 203 303 A H A A A

0257-Bx0x 207 307 A H A A A

0257-Bx1x 208 308 A I A A C

Motor ID No.

HRV1 HRV2

90D0

90E0

90B0

90B5

90B6

90B1 9096

- 12 -

Page 23

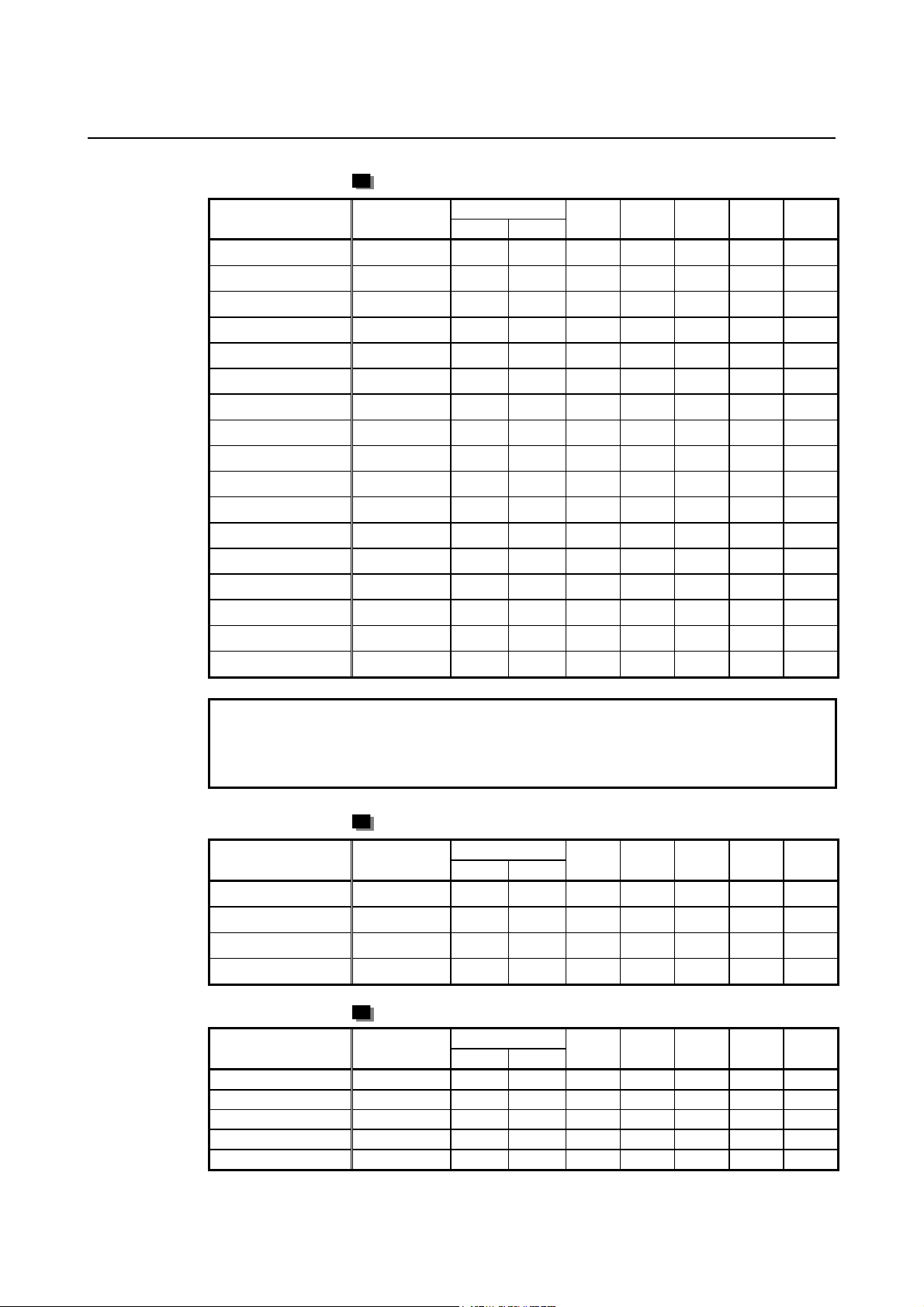

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

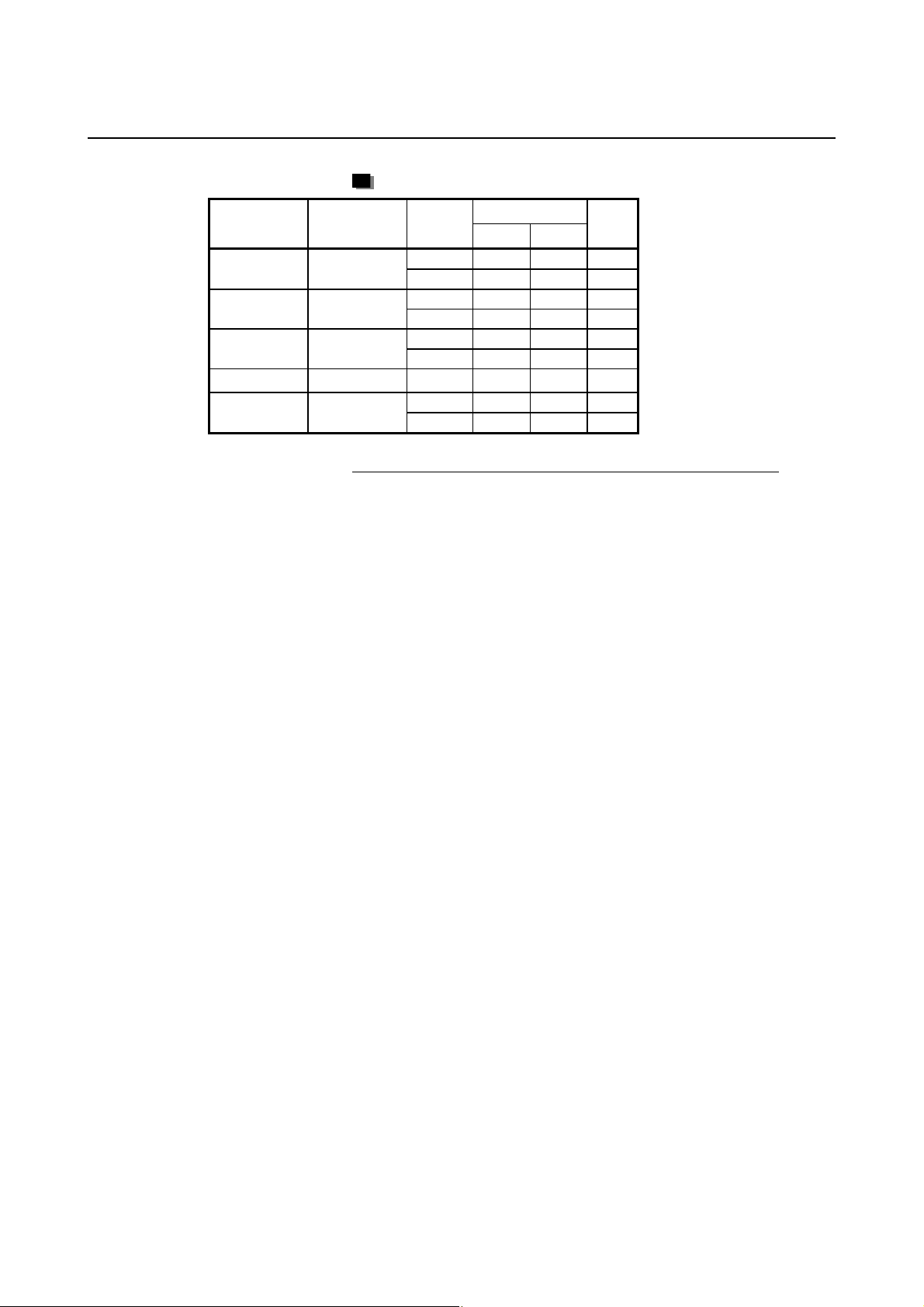

αiS series servo motor (for 400-V driving)

Motor model

αiS2/

αiS

2/6000HV

αiS

4/5000HV

αiS

8/4000HV

αiS

8/6000HV

αiS

12/4000HV

αiS

22/4000HV

αiS

30/4000HV

αiS

40/4000HV

αiS

50/3000HV FAN

αiS

50/3000HV

αiS

100/2500HV

αiS

200/2500HV

αiS

300/2000HV

αiS

500/2000HV

αiS

1000/2000HV

αiS

2000/2000HV

5000HV

(Note 1)

Motor

specification

0213 163 263 A Q A A D

0219 - 287 G - B B -

0216 166 266 A Q A A D

0236 186 286 A N A A D

0233 - 292 G - B B -

0239 189 289 A N A A D

0266 216 316 A N A A D

0269 219 319 A N A A D

0273 223 323 A N A A D

0276-Bx1x 226 326 A N A A D

0276-Bx0x 227 327 B V A A F

0286 236 336 B V A A F

0289 239 339 B V A A F

0293 243 343 B V A A F

0296 246 346 B V A A F

0298 248 348 B V A A F

0091 - 340 J - B B -

Motor ID No.

HRV1 HRV2

90D0

90E0

90B0

90B5

90B6

90B1 9096

NOTE

1 The model needs manual setting. (See Subsection 2.1.7, "Setting

Parameters when the PWM Distribution Module is used".)

When using the torque control function, contact FANUC.

Motor model

αiF

4/4000HV

αiF

8/3000HV

αiF

12/3000HV

αiF

22/3000HV

Motor model

αC4/3000i

αC8/2000i

αC12/2000i

αC22/2000i

αC30/1500i

αiF series servo motor (for 400-V driving)

Motor

specification

0225 175 275 A Q A A E

0229 179 279 A Q A A E

0245 195 295 A Q A A E

0249 199 299 A Q A A E

Motor ID No.

HRV1 HRV2

90D0

90E0

90B0

90B5

90B6

90B1 9096

αCi series servo motor

Motor

specification

0221 171 271 A H A A A

0226 176 276 A H A A A

0241 191 291 A H A A A

0246 196 296 A H A A A

0251 201 301 A H A A A

Motor ID No.

HRV1 HRV2

90D0

90E0

90B0

90B5

90B6

90B1 9096

- 13 -

Page 24

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

A

A

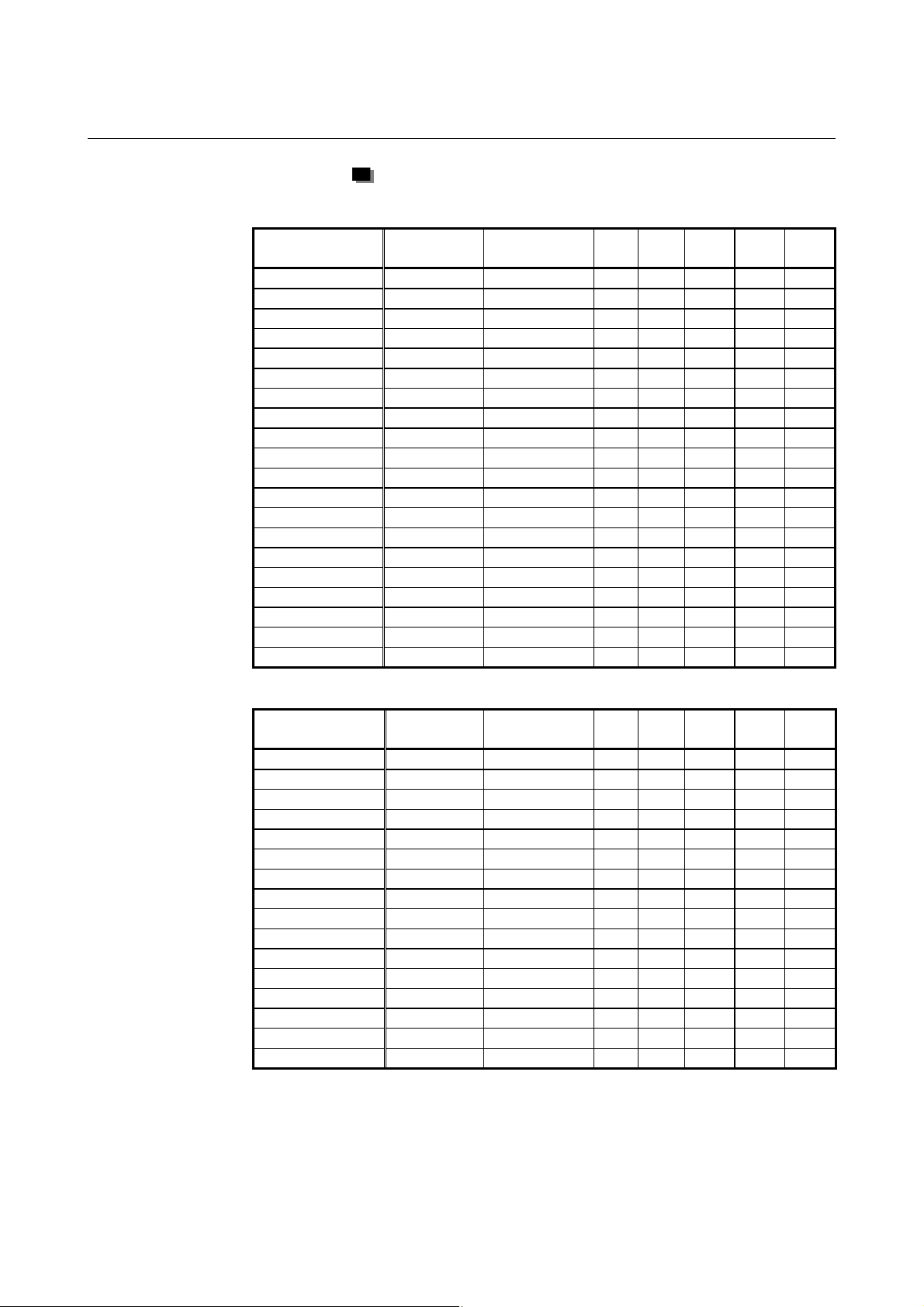

βiS series servo motor

Motor model

βiS0.2/

5000

βiS0.3/

5000

βiS0.4/

5000

βiS0.5/

6000

βiS1/

6000

βiS2/

4000

βiS4/

4000

βiS8/

3000

βiS12/

2000

βiS12/

3000

βiS22/

2000

Motor

specification

(Note 1)

0111

(Note 1)

0112

(Note 1)

0114

0115 20A 181 281 G - B B -

0116 20A 182 282 G - B B -

(Note 2)

0061

(Note 2)

0063

(Note 2)

0075

(Note 2)

0077

0078 40A 172 272 B V A A F

0085 40A 174 274 B V A A F

mplifier

driving

4A - 260 A N A A

4A - 261 A N A A

20A - 280 A N A A

20A 153 253 B V A A F

40A 154 254 B V A A F

20A 156 256 B V A A F

40A 157 257 B V A A F

20A 158 258 B V A A F

40A 159 259 B V A A F

20A 169 269 - - D - -

Motor ID No.

HRV1 HRV2

90D0

90E0

90B0

90B5

90B6

90B1 9096

*

*

*

NOTE

1 HRV1 control cannot be used with these motors. So, these motors

cannot be used with Series 9096.

2 For a motor specification suffixed with “-Bxx6”, be sure to use

parameters dedicated to FS0i.

Motor model

βiS2/

4000HV

βiS4/4

000HV

βiS8/3000HV

βiS12/

3000HV

βiS22/

2000HV

βiS series servo motor (for 400-V driving)

Motor

specification

0062 10A 151 251 J - B C -

0064 10A 164 264 J - B C -

0076 10A 167 267 J - B C -

0079 20A 170 270 J - B C -

0086 20A 178 278 J - B C -

mplifier

driving

Motor ID No.

HRV1 HRV2

90D0

90E0

90B0

90B5

90B6

90B1 9096

The mark "-" indicates that automatic loading of standard parameters

is not supported as of December, 2005.

- 14 -

Page 25

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

A

βiS series servo motor (dedicated to FS0i)

Motor model

βiS2/

4000

βiS4/

4000

βiS8/

3000

βiS12/2

βiS22/

000

1500

Motor

specification

0061-Bxx6

0063-Bxx6

0075-Bxx6

0077-Bxx6

0084-Bxx6

mplifier

driving

20A 206 306 D

40A 210 310 D

20A 211 311 D

40A 212 312 D

20A 183 283 D

40A 194 294 D

20A

20A 202 302 D

40A 205 305 D

Motor ID No.

HRV1 HRV2

198 298 D

90B5

The motor models above can be driven only with Series 90B5.

- 15 -

Page 26

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

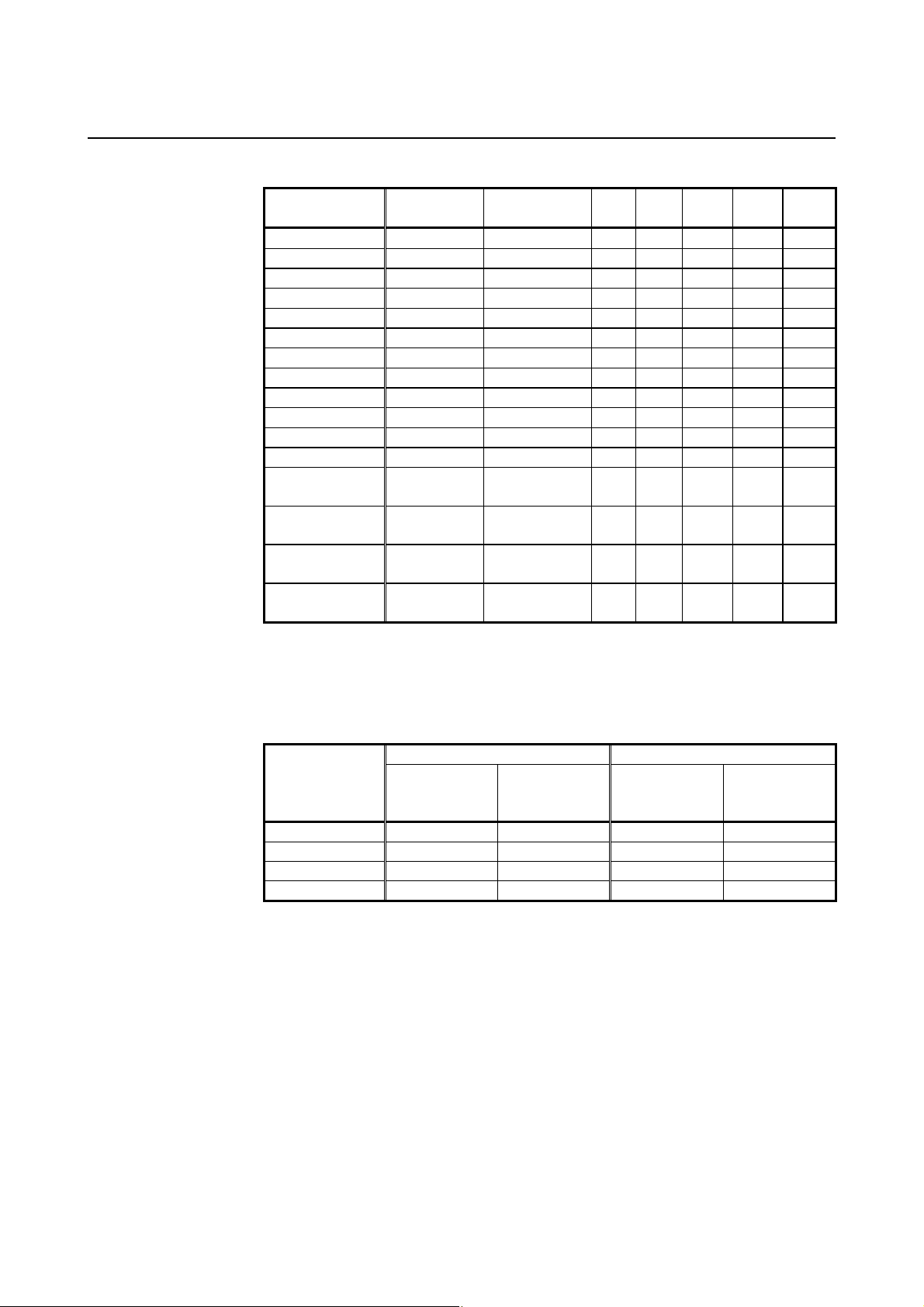

Linear motor

Linear motor parameters for servo HRV2 control

Note: The following linear motors are driven by 200V.

Motor model

LiS300A1/4

LiS600A1/4

LiS900A1/4

LiS1500B1/4

LiS3000B2/2

LiS3000B2/4

LiS4500B2/2

LiS6000B2/2

LiS6000B2/4

LiS7500B2/2

LiS7500B2/4

LiS9000B2/2

LiS9000B2/4

LiS3300C1/2

LiS9000C2/2

LiS11000C2/2

LiS15000C2/2

LiS15000C2/3

LiS10000C3/2

LiS17000C3/2

Note: The following linear motors are driven by 400V.

Motor model

LiS1500B1/4

LiS3000B2/2

LiS4500B2/2HV

LiS4500B2/2

LiS6000B2/2HV

LiS6000B2/2

LiS7500B2/2HV

LiS7500B2/2

LiS9000B2/2

LiS3300C1/2

LiS9000C2/2

LiS11000C2/2HV

LiS11000C2/2

LiS15000C2/3HV

LiS10000C3/2

LiS17000C3/2

Motor

specification

0441-B200 351 G - B B 0442-B200 353 G - B B 0443-B200 355 G - B B 0444-B210 357 G - B B 0445-B110 360 G - B B 0445-B210 362 G - B B 0446-B110 364 G - B B 0447-B110 368 G - B B 0447-B210 370 G - B B 0448-B110 372 G - B B 0448-B210 374 G B B 0449-B110 376 G - B B 0449-B210 378 G - B B

0451-B110 380 G - B B 0454-B110 384 G - B B 0455-B110 388 G - B B 0456-B110 392 G - B B 0456-B210 394 G - B B 0457-B110 396 G - B B 0459-B110 400 G - B B -

Motor

specification

0444-B210 358 G - B B 0445-B110 361 G - B B 0446-B010 363 G - B B 0446-B110 365 G - B B 0447-B010 367 G - B B 0447-B110 369 G - B B 0448-B010 371 G - B B 0448-B110 373 G - B B 0449-B110 377 G - B B 0451-B110 381 G - B B 0454-B110 385 G B B

0455-B010 387 G - B B 0455-B110 389 G - B B 0456-B010 391 G - B B 0457-B110 397 G - B B 0459-B110 401 G - B B -

Motor ID No.

Motor ID No.

90D0

90E0

90D0

90E0

90B0

90B0

90B5

90B6

90B5

90B6

90B1 9096

90B1 9096

- 16 -

Page 27

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

Linear motor parameters for servo HRV1 control

Motor model

LiS1500B1/4

LiS3000B2/2

LiS6000B2/2

LiS9000B2/2

LiS1500C2/2

LiS3000B2/4

LiS6000B2/4

LiS9000B2/4

LiS15000C2/3

LiS300A1/4

LiS600A1/4

LiS900A1/4

LiS6000B2/4

LiS9000B2/2

LiS9000B2/4

LiS15000C2/2

Motor

specification

0444-B210 90 A A A A A

0445-B110 91 A A A A A

0447-B110 92 A A A A A

0449-B110 93 A A A A A

0456-B110 94 A A A A A

0445-B210 120 A A A A A

0447-B210 121 A A A A A

0449-B210 122 A A A A A

0456-B210 123 A A A A A

0441-B200 124 A A A A A

0442-B200 125 A A A A A

0443-B200 126 A A A A A

0412-B811

0413

0413-B811

0414

Motor ID No.

127

(160-A driving)

128

(160-A driving)

129

(360-A driving)

130

(360-A driving)

90D0

90B0

90E0

A R A A D

A N A A D

A Q A A D

A Q A A D

90B5

90B6

90B1 9096

(Reference)

The parameter table presented in Chapter 6 has two motor ID Nos. for

the same linear motor. One of the two is for driving the α series servo

amplifiers (130A and 240A). Be careful not to use the wrong ID No.

αi servo amplifier driving

Amplifier

maximum

current [A]

Motor ID No.

Motor model

LiS6000B2/4

LiS9000B2/2

LiS9000B2/4

LiS15000C2/2

α servo amplifier driving

Amplifier

maximum

current [A]

240 121 160 127

130 93 160 128

240 122 360 129

240 94 360 130

Motor ID No.

- 17 -

Page 28

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

Synchronous built-in servo motor

Synchronous built-in servo motor for servo HRV2 control

NOTE: The following synchronous built-in servo motors are

driven by 200V.

Motor model

DiS85/400

DiS110/300

DiS260/600

DiS370/300

Motor

specification

0483-B20x 423 K - - - -

0484-B10x 425 K - - - -

0484-B31x 429 K - - -

0484-B40x 431 K - - -

Motor ID No.

90D0

90E0

90B0

90B5

90B6

90B1 9096

-

-

NOTE: The following synchronous built-in servo motors are

driven by 400V.

Motor model

DiS85/400

DiS110/300

DiS260/600

DiS370/300

Motor

specification

0483-B20x 424 K - - - -

0484-B10x 426 K - - - -

0484-B31x 430 K - - -

0484-B40x 432 K - - -

Motor ID No.

90D0

90E0

90B0

90B5

90B6

90B1 9096

-

-

(4) AMR setting

For AMR, set 00000000. When using a linear motor, set AMR

according to the description in Section 4.14, "LINEAR MOTOR

PARAMETER SETTING". When using a synchronous built-in servo

motor, set AMR according to the description in Section 4.15,

"SYNCHRONOUS BUILT-IN SERVO MOTOR PARAMETER

SETTING".

αiS/αiF/βiS motor

00000000

(5) CMR setting

Set, as CMR, a specified magnification for the amount of movement

from the NC to the servo system.

CMR = Command unit / Detection unit

CMR 1/2 to 48 Setting value = CMR × 2

Usually, set CMR with 2, because command unit = detection unit

(CMR = 1).

- 18 -

Page 29

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

(6) Flexible feed gear setting

Specify the flexible feed gear (F⋅FG). This function makes it easy to

specify a detection unit for the leads and gear reduction ratios of

various ball screws by changing the number of position feedback

pulses from the Pulsecoder or separate detector. It converts the

incoming number of pulses from the position detector so that it

matches the commanded number of pulses. When using a linear motor,

set F⋅FG according to the description in Section 4.14, "LINEAR

MOTOR PARAMETER SETTING". When using a synchronous

built-in servo motor, set F⋅FG according to the description in Section

4.15, "SYNCHRONOUS BUILT-IN SERVO MOTOR

PARAMETER SETTING".

(a) Semi-closed feedback loop

Setting for the αi Pulsecoder

↓ (Note 1) Necessary position feedback pulses

F⋅FG numerator (≤ 32767) per motor revolution

= (as irreducible fraction)

F⋅FG denominator (≤ 32767) 1,000,000 ← (Note 2)

NOTE

1 For both F⋅FG numerator and denominator, the maximum setting

value (after reduced) is 32767.

2 αi Pulsecoders assume one million pulses per motor revolution,

irrespective of resolution, for the flexible feed gear setting.

3 If the calculation of the number of pulses required per motor

revolution involves π, such as when a rack and pinion are used,

assume π to be approximately 355/113.

Example of setting

If the ball screw used in direct coupling has a lead of 5 mm/rev and

the detection unit is 1 µm

The number of pulses generated per motor turn (5 mm) is:

5/0.001 = 5000 (pulses)

Because the αi Pulsecoder feeds back 1000000 pulses per motor turn:

FFG = 5000 / 1000000 = 1 / 200

Other FFG (numerator/denominator) setting examples, where the gear

reduction ratio is assumed to be 1:1

Ball screw lead Detection

unit

1µm 6 / 1000 8 / 1000 10 / 1000 12 / 1000 16 / 1000 20 / 1000

0.5µm 12 / 1000 16 / 1000 20 / 1000 24 / 1000 32 / 1000 40 / 1000

0.1µm 60 / 1000 80 / 1000 100 / 1000 120 / 1000 160 / 1000 200 / 1000

6mm 8mm 10mm 12mm 16mm 20mm

- 19 -

Page 30

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

r

N

Example of setting

If the gear reduction ratio between the rotary axis motor and table is

10:1 and the detection unit is 1/1000 degrees

The table rotates through 360/10 degrees when the motor makes one

turn.

The number of position pulses necessary for the motor to make one

turn is:

360/10 ÷ (1/1000) = 36,000 pulses

F⋅FG numerato

36,000 36

= =

F⋅FG denominator 1,000,000 1,000

If the gear reduction ratio between the rotary axis motor and table is

300:1 and the detection unit is 1/10000 degrees

The table rotates through 360/300 degrees when the motor makes one

turn.

The number of position pulses necessary for the motor to make one

turn is:

360/300 ÷ (1/10000) = 12,000 pulses

F⋅FG numerator 12,000 12

= =

F⋅FG denominator 1,000,000 1,000

(b) Full-closed feedback loop

Setting for use of a separate detector (full-closed)

Number of position pulses corresponding

F⋅FG numerator (≤ 32767) to a predetermined amount of travel

= (as irreducible fraction)

F⋅FG denominator (≤ 32767) Number of position pulses corresponding

to a predetermined amount of travel from

a separate detector

Example of setting

To detect a distance of 1-µm using a 0.5-µm scale, set the following:

(L represents a constant distance.)

umerator of F⋅FG L/1 1

= =

Denominator of F⋅FG L/0.5 2

Other FFG (numerator/denominator) setting examples

Detection unit

1µm 1 / 1 1 / 2 1 / 10 1 / 20

0.5µm - 1 / 1 1 / 5 1 / 10

0.1µm - - 1 / 1 1 / 2

1 µm 0.5 µm 0.1 µm 0.05 µm

Scale resolution

- 20 -

Page 31

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

NOTE

The maximum rotation speed allowable with servo

software depends on the detection unit. (See

Appendix E, "VELOCITY LIMIT VALUES IN SERVO

SOFTWARE".) Select a detection unit that enables a

requested maximum rotation speed to be realized.

When a speed of up to 6000 revolutions is used as a

live tool in the direct motor connection mode, in

particular, use a detection unit of 2/1000 deg (IS-B

setting, CMR=1/2, flexible feed gear=18/100).

(7) Motor rotation direction setting

Set the direction in which the motor is to turn when a positive value is

specified as a move command. For linear motors, set the parameter

according to the description in Section 4.14, "LINEAR MOTOR

PARAMETER SETTING". For synchronous built-in servo motors, set

the parameter according to the description in Section 4.15,

"SYNCHRONOUS BUILT-IN SERVO MOTOR PARAMETER

SETTING".

111 Clockwise as viewed from the Pulsecoder

−111 Counterclockwise as viewed from the Pulsecoder

Counterclockwise as

viewed from the

Pulsecoder

Set -111.

FANUC

Clockwise as viewed from

the Pulsecoder

Set 111.

(8) Specify the number of velocity pulses and the number of position pulses.

Set the number of velocity pulses and the number of position pulses

according to the connected detector. For linear motors, set these

parameters according to the description in Section 4.14, "LINEAR

MOTOR PARAMETER SETTING". For synchronous built-in servo

motors, set these parameters according to the description in Section

4.15, "SYNCHRONOUS BUILT-IN SERVO MOTOR

PARAMETER SETTING".

(a) Number of velocity pulses

Set the number of velocity pulses to 8192.

αiS/αiF/βiS motor

8192

- 21 -

Page 32

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

(b) Number of position pulses

(b)-1 Number of position pulses for semi-closed feedback loop

Set the number of position pulses to 12500.

Number of position pulses

(αiS/αiF/βiS motor, semi-closed feedback loop)

12500

(b)-2 Number of position pulses for full-closed feedback loop

(See Subsections 2.1.4 and 2.1.5)

Set the number of position pulses to the number of pulses fed back

from the separate detector when the motor makes one turn. (The

flexible feed gear has nothing to do with the calculation of the number

of position pulses).

Number of position pulses

(full-closed feedback loop)

When using a serial rotary scale with a resolution of 1,000,000 pulses

per revolution, set a value assuming that 12500 is equivalent to

1,000,000 pulses.

Number of position pulses

(full-closed feedback loop)

(*) 1,000,000 pulses / rev

Example 1:

Parallel type, serial linear scale

If the ball screw used in direct coupling has a lead of 10 mm and

the separate detector used has a resolution of 0.5 µm per pulse

Number of position pulses = 10 / 0.0005 = 20,000

Example 2:

Serial rotary scale

If the motor-table gear reduction ratio is 10:1,

Number of position pulses = 12,500 × (1/10) = 1250

Number of pulses fed back from the separate

detector when the motor makes one turn

12,500 ×(motor-table gear reduction ratio)

- 22 -

Page 33

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

(b)-3 If the setting for the number of position pulses is larger than 32767

Conventionally, initialization bit 0 (high resolution bit) must be

changed according to the command unit. For the current

i series CNC,

however, there is no mutual dependence between the command unit

and initialization bit 0.

Of course, the conventional setting method is applicable, but using the

conversion coefficient for the number of position feedback pulses

makes the setting easier.

2628 (FS15i)

2185 (FS30i,16i)

Conversion coefficient for the number of position feedback pulses

Series 90E0, Series 90D0, Series 90B0, Series 90B5, Series 90B6,

Series 90B1 :

Set the number of position pulses with a product of two

parameters, using the conversion coefficient for the number of

position feedback pulses.

Number of feedback pulses per motor revolution, sent from the

separate detector

= Number of position pulses × Conversion coefficient for the

number of position feedback pulses

Series 9096 :

No conversion coefficient for the number of position feedback

pulses can be used. As usual, set the initialization bit 0 to 1, and

set the number of velocity pulses and the number of position

pulses to 1/10 the respective values stated earlier.

Number of feedback pulses per motor revolution, sent from the

separate detector

= Number of position pulses × 10

→ See Supplementary 3 of Subsection 2.1.8.

(9) Reference counter setting

Specify the reference counter.

The reference counter is used in making a return to the reference

position by a grid method.

(a) Semi-closed loop

(Linear axis)

Count on the reference

counter

(Rotary axis)

Count on the reference

counter

* When the motor-table gear reduction ratio is M/N (M and N are integers,

and M/N is a fraction that is reduced to lowest terms.)

Number of position pulses corresponding to a

=

single motor revolution or the same number

divided by an integer value

Number of position pulses corresponding to a

=

single motor revolution/M, or the same

number divided by an integer value

- 23 -

Page 34

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

NOTE

1 If the calculation above results in a fraction, a

setting can be made with a fraction.

See (a)-1.

2 If the rotation ratio between the motor and table on

the rotary axis is not an integer, the reference

counter capacity needs to be set so that the point

(grid point) where the reference counter equals 0

appears at the same position relative to the table.

So, with the rotary axis, the number of position

pulses per motor revolution needs to be multiplied

by 1/M.

Example of setting

αi Pulsecoder and semi-closed loop (1-µm detection)

Ball screw lead

(mm/revolution)

10

20

30

Necessary number of

position pulses

(pulse/revolution)

10000

20000

30000

Reference

counter

10000

20000

30000

Grid width

(mm)

10

20

30

When the number of position pulses corresponding to a single motor

revolution does not agree with the reference counter setting, the

position of the zero point depends on the start point.

In such a case, set the reference counter capacity with a fraction to

change the detection unit and eliminate the error in the reference

counter. (Except Series 9096)

Example of setting

System using a detection unit of 1 µm, a ball screw lead of 20

mm/revolution, and a gear reduction ratio of 1/17

(a)-1 Method of specifying the reference counter capacity with a fraction (except

Series 9096)

The number of position pulses necessary for the motor to make one

turn is: 20000/17

Set the following parameter as stated below.

1896 (FS15i)

1821 (FS30i, 16i)

[Valid data range] 0 to 99999999

Reference counter capacity (numerator)

Set the numerator of a fraction for the reference counter capacity.

- 24 -

Page 35

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

2622 (FS15i)

2179 (FS30i, 16i)

Reference counter capacity (denominator)

[Valid data range] 0 to 32767

A value up to around 100 is assumed to be set as the denominator of

the reference counter capacity. Note that if a larger value is set, the

grid width becomes too small, which makes it difficult to perform

reference position return by grid method.

The denominator parameter is not indicated in the servo setting screen,

so it must be set in the parameter screen.

In this example, set the numerator and denominator, respectively, to

20000 and 17.

NOTE

Even if a setting is made with a fraction, set the

number of position pulses per motor revolution/M for

a semi-closed loop rotary axis when the reduction

ratio is M/N.

Reference counter =

Number of position pulses per motor revolution/M, or

The same number divided by an integer

(a)-2 Method of changing the detection unit

The number of position pulses necessary for the motor to make one

turn is: 20000/17

In this case, increase all the following parameter values by a factor of

17, and set the detection unit to 1/17 µm.

Parameter modification

FFG

CMR

Reference counter

Effective area

Position error limit in traveling

Position error limit in the stop state

Backlash

Changing the detection unit from 1 µm to 1/17 µm requires

multiplying each of the parameter settings made for the detection unit

by 17.

CAUTION

In addition to the above parameters, there are

some parameters that are to be set in detection

units. For details, see Appendix B.

Making these modifications eliminates the difference between the

number of position pulses corresponding to a single motor revolution

and the reference counter setting.

Number of position pulses corresponding to a single motor revolution

= 20000

Reference counter setting = 20000

Series 30i,15i,16i,0i, Power Mate i,

and so on

Servo screen

Servo screen

Servo screen

Nos. 1826, 1827

No. 1828

No. 1829

Nos. 1851, 1852

- 25 -

Page 36

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

(b) Full-closed loop (See Subsections 2.1.4 and 2.1.5)

Reference

counter setting

Z-phase (reference-position) interval divided by the

=

detection unit, or this value sub-divided by an integer

value

NOTE

If the separate detector-table rotation ratio for the

rotary axis is not an integer, it is necessary to set

the reference counter capacity in such a way that

points where reference counter = 0 (grid points)

appear always at the same position for the table.

Example of setting

Example 1) When the Z-phase interval is 50 mm and the detection

unit is 1 µm:

Reference counter setting = 50,000/1 = 50,000

Example 2) When a rotary axis is used and the detection unit is

0.001°:

Reference counter setting = 360/0.001 = 360,000

Example 3) When a linear scale is used and a single Z phase exists:

Set the reference counter to 10000, 50000, or another

round number.

If the calculated value of the reference counter capacity is not an

integer, the reference counter capacity can be set as a fraction as in the

case of a semi-closed loop. For details of parameters, see (a)-1.

NOTE

The following value can be set as a reference

counter capacity:

(For linear axis)

Number of position pulses corresponding to the

Z-phase interval of a separate detector (or the

same number divided by an integer)

(For rotary axis)

Number of position pulses per revolution of a

separate detector/M (or the same number divided

by an integer)

(*) When the rotation ratio between the table and

separate detector is M/N (M and N are integers,

and M/N is a fraction that is reduced to lowest

terms.)

- 26 -

Page 37

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

(10) Full-closed system setting (go to (11) if a semi-closed system is in use)

For a full-closed system, it is necessary to set the following function

bit.

(a) Series15i only

#7 #6 #5 #4 #3 #2 #1 #0

1807 (FS15i)

2002 (FS30i, 16i)

PFSE

↑ To be specified only for the Series 15i

PFSE(#3) The separate position detector is:

0: Not to be used

1: To be used

CAUTION

Specify this parameter only for the Series 15i.

(b) Series30i,15i,16i, 0i,Power Mate i, and so on

#7 #6 #5 #4 #3 #2 #1 #0

1815 OPTX

↑To be specified for

every NC.

OPTX(#1) The separate position detector is:

0: Not to be used

1: To be used

NOTE

For the Series 30i, 16i, 0i, Power Mate i, and so

on, specifying this parameter automatically sets bit

3 of parameter No. 2002 to 1.

(11) NC restart

Switch the NC off and on again.

This completes servo parameter initialization.

If an invalid servo parameter setting alarm occurs, go to Subsec. 2.1.8.

If a servo alarm related to Pulsecoders occurs for an axis for which a

servo motor or amplifier is not connected, specify the following

parameter.

#7 #6 #5 #4 #3 #2 #1 #0

1953 (FS15i)

2009 (FS30i, 16i)

DMY (#0) The serial feedback dummy function is: (See Section 4.9, “SERIAL

DMY

FEEDBACK DUMMY FUNCTIONS” for function detail)

0 : Not used

1 : Used

- 27 -

Page 38

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

(12) Absolute position detector setting

When you are going to use an αi/βi Pulsecoder as an absolute

Pulsecoder, use the following procedure.

Procedure

1. Specify the following parameter, then switch the NC off.

#7 #6 #5 #4 #3 #2 #1 #0

1815 APCx

APCx (#5) The absolute position detector is:

0: Not used

1: Used

2. After making sure that the battery for the Pulsecoder is connected,

turn off the CNC.

3. A request to return to the reference position is

displayed.

4. Cause the servo motor to make one turn by jogging.

5. Turn off and on the CNC.

6. A request to return to the reference position is

displayed.

7. Do the reference position return.

These steps

were added

for the α

Pulsecoder.

i/βi

- 28 -

Page 39

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

2.1.4 Setting Servo Parameters when a Separate Detector for the

Serial Interface is Used

(1) Overview

When a separate detector of the serial output type is used, there is a

possibility that the detection unit becomes finer than the detection unit

currently used. Accordingly, a few modifications are made to the

setting method and values of servo parameters.

When using a separate detector of the serial output type, follow the

method explained below to set parameters.

(2) Series and editions of applicable servo software

(Series 30i,31i,32i)

Series 90D0/A(01) and subsequent editions

Series 90E0/A(01) and subsequent editions

(Series 15

Series 90B0/A(01) and subsequent editions

Series 90B1/A(01) and subsequent editions

Series 90B6/A(01) and subsequent editions

(Series 0

Series 90B5/A(01) and subsequent editions

(3) Classification of serial detectors and usable detector examples

Usable separate detectors for the serial interface are classified into

four major types as shown below. Note that parameter settings vary

with these types.

(a) Serial output type linear encoder

Minimum resolution Model Backup

Mitutoyo Co., Ltd.

HEIDENHAIN

(b) Analog output type linear encoder + FANUC high-resolution serial output

circuit

Signal pitch Model Backup

Mitutoyo Co., Ltd.

HEIDENHAIN

Sony Precision Technology Inc.

(c) Serial output type rotary encoder

Minimum resolution

FANUC 220 pulse/rev αA1000S Required

i-B,16i-B,18i-B,21i-B,0i-B,0i Mate-B,Power Mate i)

i-C,0i Mate-C,20i-B)

0.05µm

0.05µm/0.1µm

0.05µm/0.1µm

20µm

20µm

20µm

(Note 1)

AT353, AT553 Not required

LC191F

LC491F

AT402 Required

LS486, LS186 Required

SH12 Required

Model Backup

Not required

Not required

- 29 -

Page 40

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

(d) RCN220, RCN223, RCN723, and RCN727 manufactured by HEIDENHAIN

Minimum resolution

HEIDENHAIN 220 pulse/rev

23

2

pulse/rev

27

2

pulse/rev

(Note 1)

Model Backup

RCN220

RCN223, 723

RCN727

Not required

Not required

Not required

NOTE

1 The minimum resolution of a rotary encoder is the resolution of the

encoder itself. For the FANUC systems, however:

One million pulses/rev for a minimum resolution of 220 pulses/rev

23

Eight million pulses/rev for a minimum resolution of 2

Eight million pulses/rev for a minimum resolution of 2

pulses/rev

27

pulses/rev

(4) Setting parameters

Set the following parameters according to the type of the detector

(described in the previous item).

(a) Parameter setting for a linear encoder of a serial output type

(Parameter setting method)

In addition to the conventional settings for a separate detector (bit 1 of

parameter No. 1815 (Series30

i), bit 3 of parameter No. 1807 (Series 15i), and if needed, FSSB),

note the following parameters:

[Flexible feed gear]

Parameter Nos. 1977 and 1978 (Series 15i) or Nos. 2084 and 2085

(Series 30

i, 16i and so on)

Flexible feed gear (N/M) =

Minimum resolution of detector [µm] / controller detection unit [µm]

[Number of position pulses]

Parameter No. 1891 (Series 15i) or No. 2024 (Series 30i, 16i and so

on)

Number of position pulses =

Amount of movement per motor revolution [mm] /

detection unit of the sensor [mm]

* If the result of the above calculation does not fall in the setting

range (0 to 32767) for the number of position pulses, use

“position feedback pulse conversion coefficient” to specify the

number of position pulses according to the following procedure.

Number of position pulses to be set = A × B

Select B so that A is within 32767. Then, set the following:

A: Position pulses parameter (32767 or less)

No.1891 (Series15

B: Position pulses conversion coefficient parameter

No.2628 (Series15

i,15i,16i,18i,21i,20i,0i, and Power Mate

i), No.2024 (Series 30i, 16i and so on)

i), No.2185 (Series 30i, 16i and so on)

- 30 -

Page 41

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

(Example of parameter setting)

[System configuration]

• The Series 16i is used.

• A linear scale with a minimum resolution of 0.1 µm is used.

• The least input increment of the controller is 1 µm.

• The amount of movement per motor revolution is 16 mm.

[Parameter setting]

• To enable a separate detector, set bit 1 of parameter No. 1815 to

1.

• Calculate the parameters for the flexible feed gear.

Because flexible feed gear (N/M) = 0.1 µm/1 µm = 1/10:

No. 2084 = 1 and No. 2085 = 10

• Calculate the number of position pulses.

Number of position pulses = 16 mm/0.0001mm = 160000

Because this result does not fall in the setting range (0 to 32767),

set A and B, respectively, with the "number of position pulses"

and "position pulses conversion coefficient" by assuming:

160,000 = 10,000 × 16 → A = 10,000 and B = 16

No.2024 = 10,000, No.2185 = 16

(b) Parameter setting for analog output type linear encoder +

FANUC high-resolution serial output circuit

(Parameter setting method)

In addition to the conventional separate detector settings (bit 1 of

parameter No. 1815 (Series15

i), bit 3 of parameter No. 1807 (Series 15i), and, if necessary, FSSB

setting), pay attention to the following parameter settings.

First check the type of the FANUC high-resolution output circuit to be

coupled to the linear encoder, and then determine the settings of the

following function bits.

[Function bit]

i,30i,16i,18i,21i,20i,0i, and Power Mate

Circuit Specification

High-resolution serial output circuit A860-0333-T501 512

High-resolution serial output circuit H A860-0333-T701 2048

High-resolution serial output circuit C A860-0333-T801 2048

Interpolation

magnification

- 31 -

Page 42

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

#7 #6 #5 #4 #3 #2 #1 #0

2687 (FS15i)

2274 (FS30i, 16i)

HP2048(#0) The 2048-magnification interpolation circuit (high-resolution serial

HP2048

output circuit H or C) is:

1: To be used

0: Not to be used

NOTE

1 When high-resolution serial output circuit H is used,

set the setting pin SW3 inside the circuit to "Setting

B" usually.

2 This function bit can be used with the following

series and editions:

(Series 30i, 31i, 32i)

Series 90D0/A(01) and subsequent editions

Series 90E0/A(01) and subsequent editions

(Series 15i-B, 16i-B, 18i-B, 21i-B, 0i-B, 0i Mate-B,

Power Mate i)

Series 90B0/Q(17) and subsequent editions

Series 90B1/A(01) and subsequent editions

Series 90B6/A(01) and subsequent editions

(Series 0i-C, 0i Mate-C, 20i-B)

Series 90B5/A(01) and subsequent editions

If this bit is specified, the minimum resolution

setting of the detector is assumed to be:

Encoder signal pitch/512 [µm]

If the minimum resolution (signal pitch/2048 [µm])

is necessary as the detection unit, specify:

Flexible feed gear = 4/1

3 When high-resolution serial output circuit H is used,

and the input frequency 750 kHz needs to be

supported, set the following:

- Set the setting pin SW3 to "Setting A".

- Set HP2048=1.

- Set the minimum resolution of the detector as:

Encoder signal pitch/128 [µm]

(Related report: TMS03/16)

[Minimum resolution of the detector]

In the following calculation of a flexible feed gear and the number of

position pulses, the minimum detector resolution to be used is:

(Linear encoder signal pitch/512 [µm])

(Specifying the above function bit appropriately makes it unnecessary

to take the difference in the interpolation magnification among the

high-resolution serial output circuits into account. So always use 512

for calculations.)

- 32 -

Page 43

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

[Flexible feed gear]

Parameters Nos. 1977 and 1978 (Series 15i) or Nos. 2084 and 2085

(Series 30

i, 16i, and so on)

Flexible feed gear (N/M)

= minimum resolution of the detector [µm] /

detection unit of controller [µm]

[Number of position pulses]

Parameter No. 1891 (Series 15i) or No. 2024 (Series 30i, 16i, and so

on)

Number of position pulses

= Amount of movement per motor revolution [mm] /

minimum resolution of the detector [mm]

* If the result of the above calculation does not fall in the setting

range (0 to 32767) for the number of position pulses, use

“position feedback pulse conversion coefficient” to specify the

number of position pulses according to the following procedure.

Number of position pulses to be set = A × B

Select B so that A is within 32767. Then, set the following:

A: Position pulses parameter (32767 or less)

No.1891 (Series15

i), No.2024 (Series 30i, 16i, and so on)

B: Position pulses conversion coefficient parameter

No.2628 (Series15

i), No.2185 (Series 30i, 16i, and so on)

(Example of parameter setting)

[System configuration]

• The Series 16i is used.

• A linear encoder with a signal pitch of 20 µm is used.

• The linear encoder is coupled with high-resolution serial output

circuit H.

• The least input increment of the controller is 1 µm.

• The amount of movement per motor revolution is 16 mm.

[Parameter setting]

• To enable a separate detector, set bit 1 of parameter No. 1815 to

1.

• To use high-resolution serial output circuit H, set bit 0 of

parameter No. 2274 to 1.

Minimum resolution of the detector = 20 µm/512

= 0.0390625 µm

• Calculate the parameters for the flexible feed gear.

Because flexible feed gear (N/M)=(20/512µm)/1µm=5/128

No.2084=5, No.2085=128

• Calculate the number of position pulses.

Number of position pulses = 16 mm/(20/512µm) = 409,600

Because this result does not fall in the setting range (0 to 32767),

set A and B, respectively, with the "number of position pulses"

and "position pulses conversion coefficient" by assuming:

409,600 = 25,600 × 16 → A = 25,600, B = 16

No.2024 = 25,600, No.2185 = 16

- 33 -

Page 44

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

(c) Parameter setting for the serial output type rotary encoder

* For explanations about the rotary encoders RCN220, RCN223,

RCN723, and RCN727 made by HEIDENHAIN, see "Parameter

setting for the rotary encoders RCN220, RCN223, RCN723, and

RCN727 made by HEIDENHAIN."

(Parameter setting method)

In addition to the conventional settings for a separate detector (bit 1 of

parameter No. 1815 (Series15

i), bit 3 of parameter No. 1807 (Series 15i), and if needed,

Mate

FSSB), note the following parameters:

[Flexible feed gear]

Parameters Nos. 1977 and 1978 (Series 15i) or Nos. 2084 and 2085

(Series 30

Flexible feed gear (N/M) =

(Amount of table movement [deg] per detector revolution) /

[Number of position pulses]

Parameter No. 1891 (Series 15

on)

Number of position pulses = 12500×(motor-to-table deceleration ratio)

* If the result of the above calculation does not fall in the setting

Number of position pulses to be set = A × B

Select B so that A is within 32767. Then, set the following:

i, 16i and so on)

(detection unit [deg]) / 1,000,000

range (0 to 32767) for the number of position pulses, use

“position feedback pulse conversion coefficient” to specify the

number of position pulses according to the following procedure.

A: Position pulses parameter (32767 or less)

No.1891 (Series15

B: Position pulses conversion coefficient parameter

No.2628 (Series15

i, 30i, 16i, 18i, 21i, 20i, 0i, and Power

i) or No. 2024 (Series 30i, 16i and so

i), No.2024 (Series 30i, 16i and so on)

i), No.2185 (Series 30i, 16i and so on)

(Example of parameter setting)

[System configuration]

• The Series 16i is used.

• The least input increment of the controller is 1/1000 degree.

• The amount of movement per motor revolution is 180 degrees

(deceleration ratio: 1/2)

• Table-to-separate-encoder reduction ratio = 1/1

- 34 -

Page 45

B-65270EN/06 2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS

[Parameter setting]

• To enable a separate detector, set bit 1 of parameter No. 1815 to

1.

• Calculate the parameters for the flexible feed gear.

Because flexible feed gear (N/M)

=360 degrees /0.001 degrees /1,000,000 =36/100

No.2084=36, No.2085=100

• Calculate the number of position pulses.

Because number of position pulses = 12500 × (1/2)=6250

No.2024=6250

- 35 -

Page 46

2. SETTING αiS/αiF/βiS SERIES SERVO PARAMETERS B-65270EN/06

(d) Parameter setting for the rotary encoders RCN220, RCN223, RCN723, and

RCN727 made by HEIDENHAIN

(Series and editions of applicable servo software)

To use the high-resolution rotary encoders RCN220, RCN223,

RCN723, and RCN727 manufactured by HEIDENHAIN as separate

detectors, the following servo software is required:

[RCN220,223,723]