Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 15 / 150 – Model B

Macro Compiler/Executer

Programming Manual

GFZ-62073E-2/03 September 1995

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1995 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B–62073E–2/03

Table of contents

PROGRAMMING

1. GENERAL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 OUTLINE 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 FEATURES 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. MACRO COMPILER 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 OUTLINE 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 FLOW FOR CREATING, REGISTERING AND SAVING PROGRAMS 7. . . . . . . . . . . . . . . . . . . . .

2.3 USE OF MACRO COMPILER 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Registering a P–CODE Program in F–ROM Using a Memory Card

2.3.2 Registering the P–CODE Program in F–ROM Using a ROM Cassette

2.3.3 Compiling and Registering Custom Macro Programs in F–ROM Using the Series 15–B 19. . . . . . . . . .

2.3.4 P–CODE Program 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.5 F–ROM 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 COMPILE PARAMETER 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 ERROR CODE LIST 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(When Compiled with a Personal Computer) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(When the P–CODE Program has been Compiled with the System P or a Personal Computer) 14. . . . .

3. EXECUTION MACRO 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 INTERFACE WITH USER PROGRAM AND

EXECUTION MACRO IN P–CODE PROGRAM 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Call Code and Program No. 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Variables 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Argument Designation 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 LIMITATION FOR EXECUTION MACRO 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Argument Specification 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Macro call 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Variable 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Custom Macro Commands 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 NC Commands Which Cannot be Used in Automatic Operation 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 Modal Call from Execution Macro 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.7 Calling a P–CODE Program from an Execution Macro Using the G, M, S, T, or B User Code 45. . . . . .

3.2.8 Calling a User Program Using an Execution Macro 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.9 Specifying of the G Code for Macro Calls of P–CODE Programs 45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.10 Calling a Macro Using a T Code 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.11 Macro and Subprogram Multiplexity in Execution Macro 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 DISPLAYING AND SETTING VARIABLES 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 User Program Common Variables (#100–#199, #500–#999) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 P–CODE Program Common Variable (#100–#199, #500–#999) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 P–CODE Program Local Variable (#1–#33) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Variable Name Setting (SETVN) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 CAUTIONS 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. CONVERSATIONAL MACRO FUNCTION 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 OVER VIEW 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 CONVERSATIONAL MACRO FUNCTION 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 AUXILIARY MACRO FUNCTION 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 COORDINATE SYSTEM SCREEN 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Character Coordinate System 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of contents

4.4.2 Graphic Coordinate System 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62073E–2/03

4.5 VARIABLE, FUNCTION AND CONTROL CODE 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 System Variable 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 P–CODE Program Exclusive Local Variables 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.3 Conversational Macro P–CODE Common Variables 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.4 UI and UO Signal Separation for User and P–CODE Programs 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.5 Conversational Macro Special Variables (#30000–) 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.6 Expanded Conversational Macro Exclusive Variable (#40000 –) 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.7 Reference and Writing System Common Variables 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.8 Execution Control Variable 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.9 Key Input Control Variable 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.10 Character String Registered Program Control Variable #8509 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.11 Arrangement Type Processing of Conversational Macro Exclusive Variable 69. . . . . . . . . . . . . . . . . . . .

4.5.12 Reference of Arrangement of Conversational Macro Exclusive Variables 70. . . . . . . . . . . . . . . . . . . . . .

4.5.13 Refer to and Read CNC Program with Conversation Macro 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.14 Reading of Cutting Time and Cutting Distance by Conver–Sational Macro, and Preset Functions 79. . .

4.5.15 PMC Axis Control by Conversational Macro 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.16 Torque Limit Override Control 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.17 A/D Converter Data Reading by Conversational Macro 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.18 Conversational Macro Variable Window Function 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.19 Reading Relative Coordinates by Conversational Macro, and Preset 96. . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.20 Address Function 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.21 Screen Display Control Codes 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.22 Execution Control Code 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.23 RS–232–C Control by Conversational Macro 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.24 File Control 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.25 Functions of PMC Address 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.26 PMC Address Control Code (G310) 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.27 Variable for Reading Remaining Shift Amount 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.28 Referring to NC Parameter 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 CONVERSATIONAL MACRO DEBUG FUNCTION 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.1 Overview 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.2 Displaying Macro Variables 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.3 Conversational Macro Debugger Function 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. PARAMETER 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. Macro Program Example 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 DESCRIPTION OF PROGRAMS 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 DESCRIPTION OF MACRO VARIABLES 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 SOURCE PROGRAM 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 FLOW CHART 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5 PROGRAM EXPLANATION 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.6 PROGRAM DESCRIPTION 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.7 LIST OF KANJI AND HIRAGANA CODES 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.8 MACRO EXECUTOR FUNCTIONS 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

PROGRAMMING

Page 6

B–62073E–2/03

1

GENERAL

1.GENERAL

1.1

OUTLINE

NC programs include those which are prepared by custom macro and very

seldom altered and those which may differ from one another according to

relevant machining such as part programs. This function is that which converts

the created custom macro program to execu–

at the machine tool builder and executes it. Further, the conversational

macro can also be executed independently in parallel with a normal NC

program by means of converting the conversational macro program to

execution format (P–CODE program).

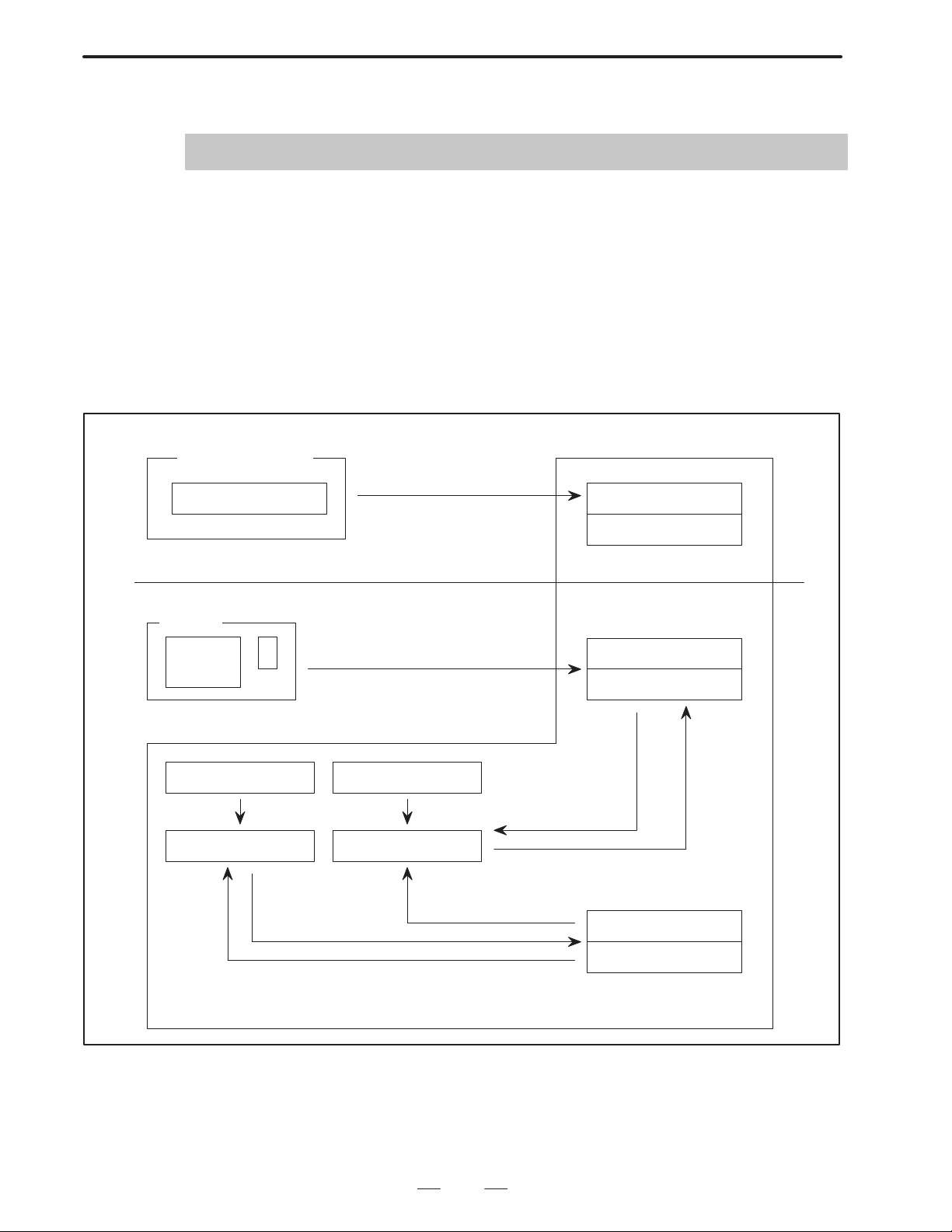

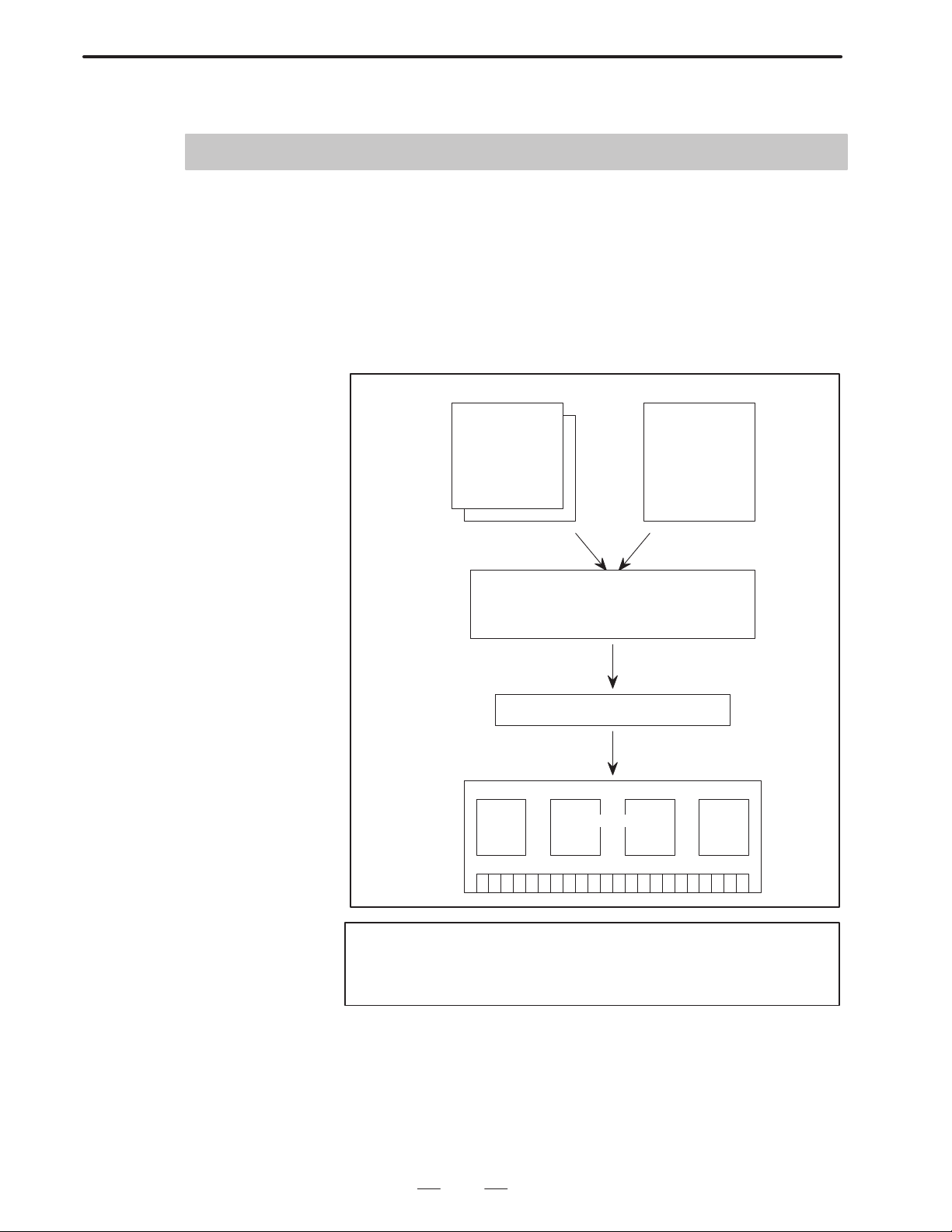

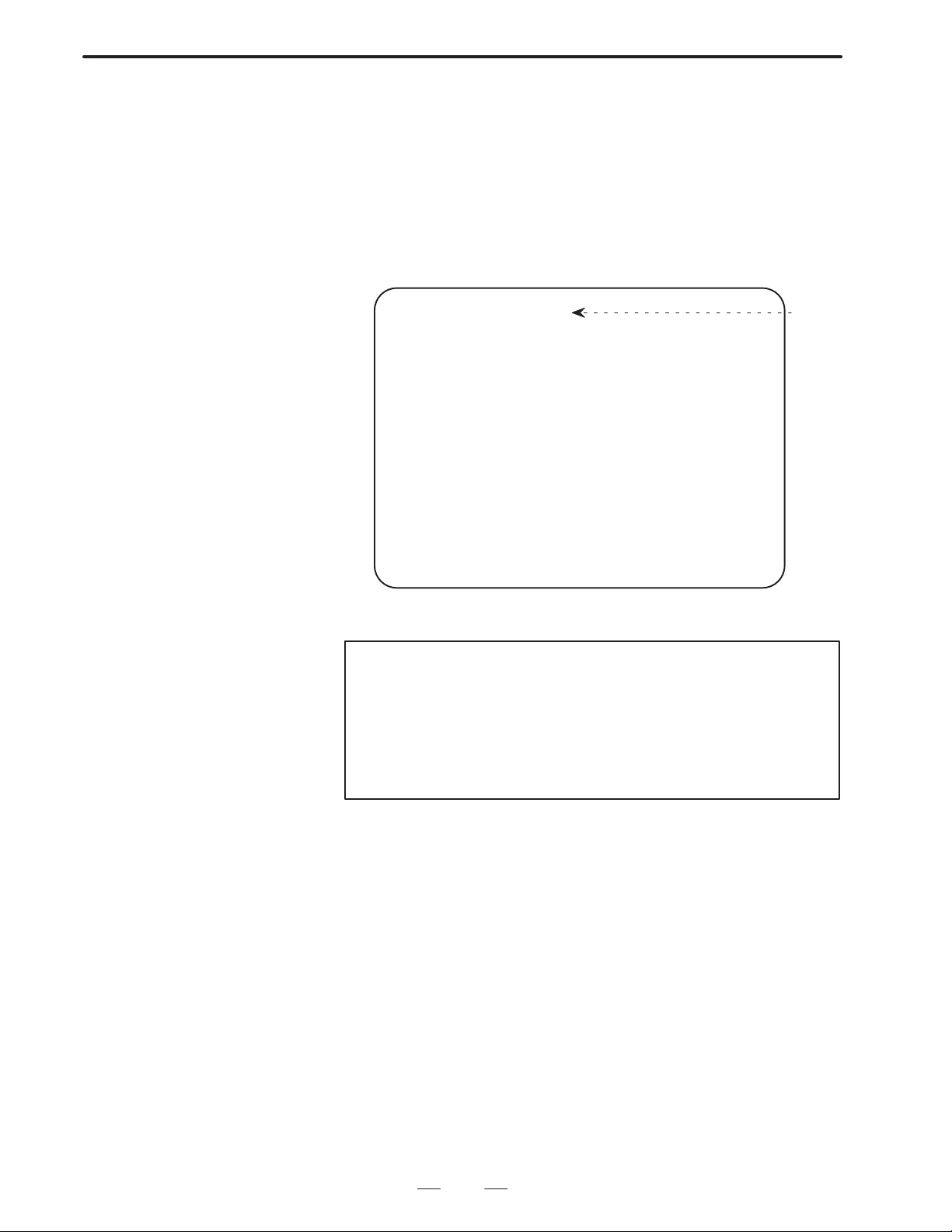

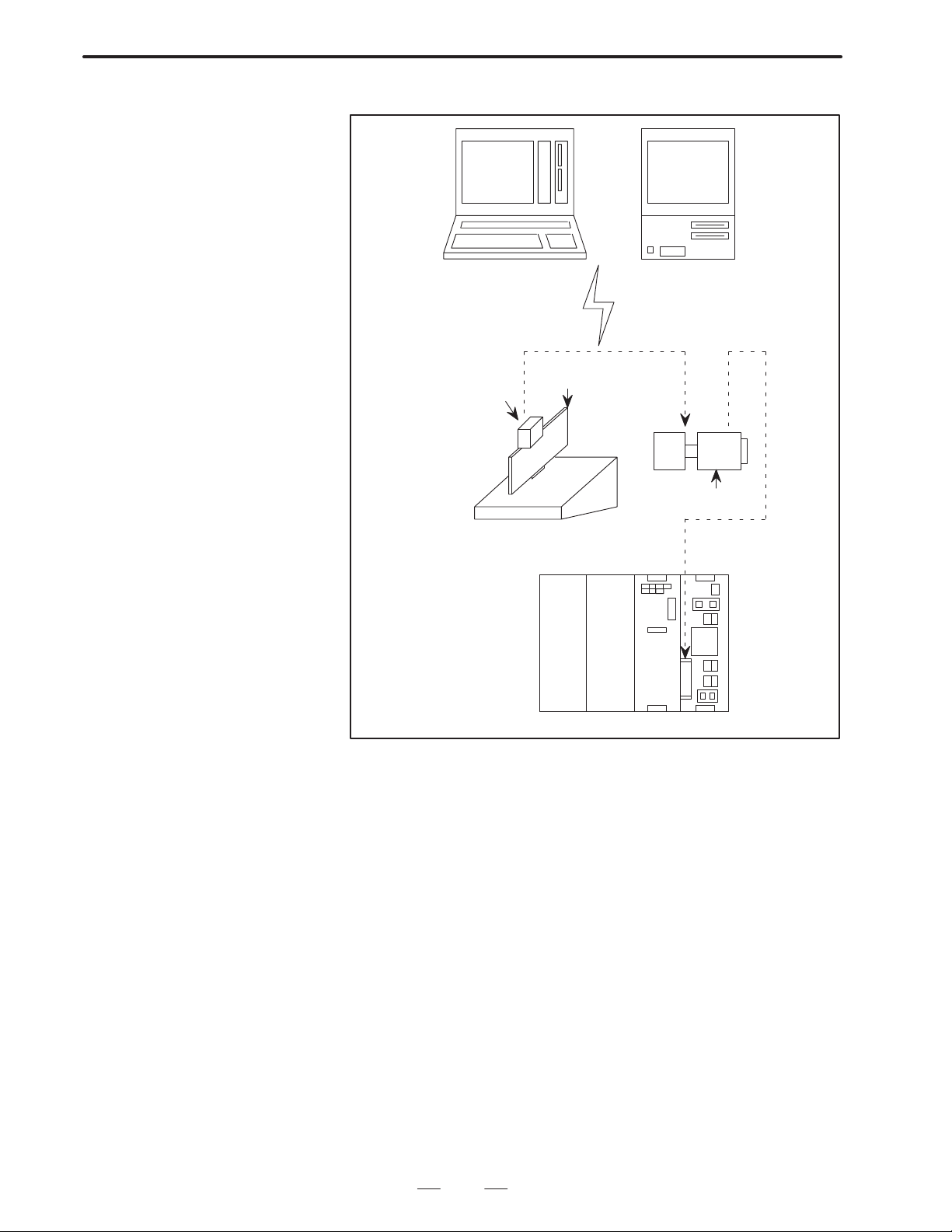

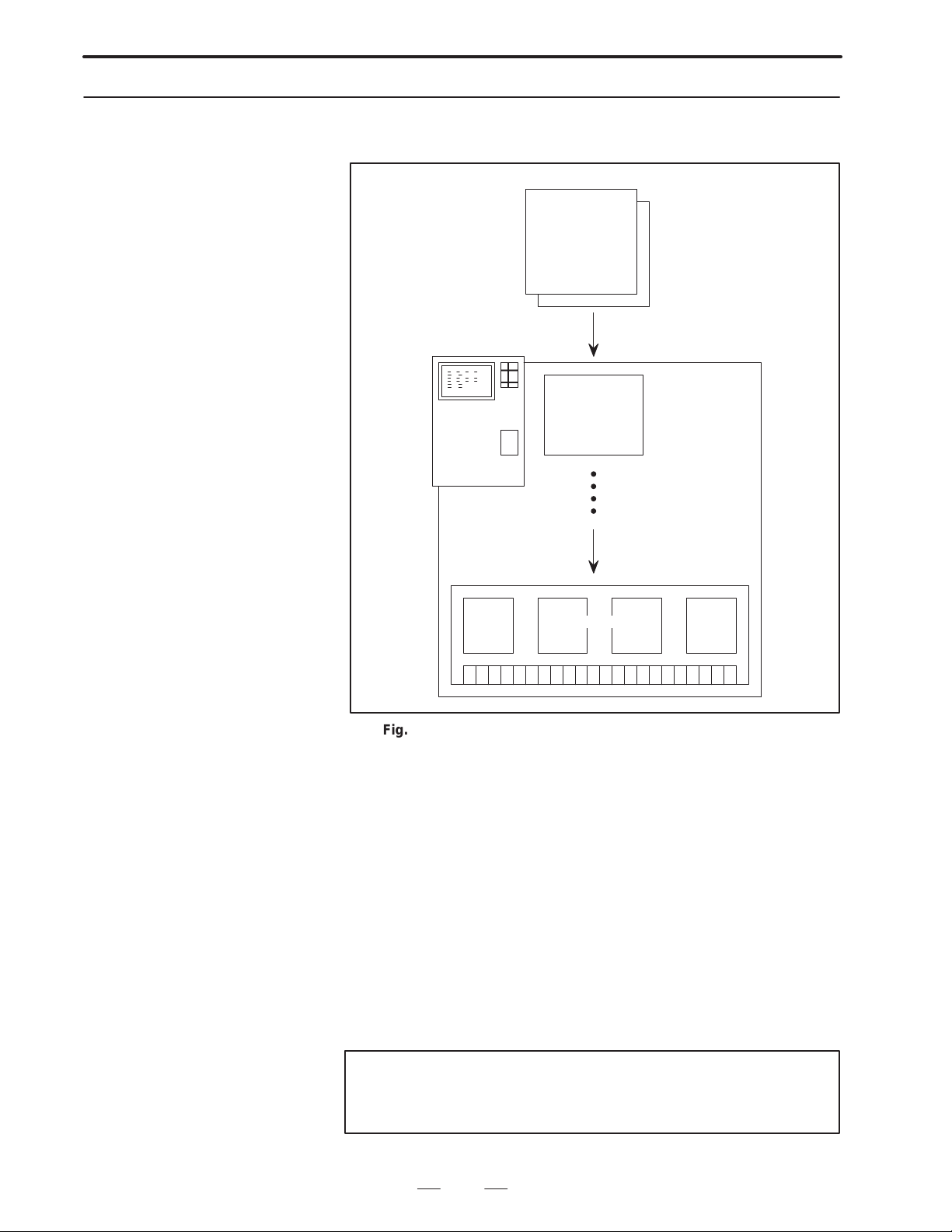

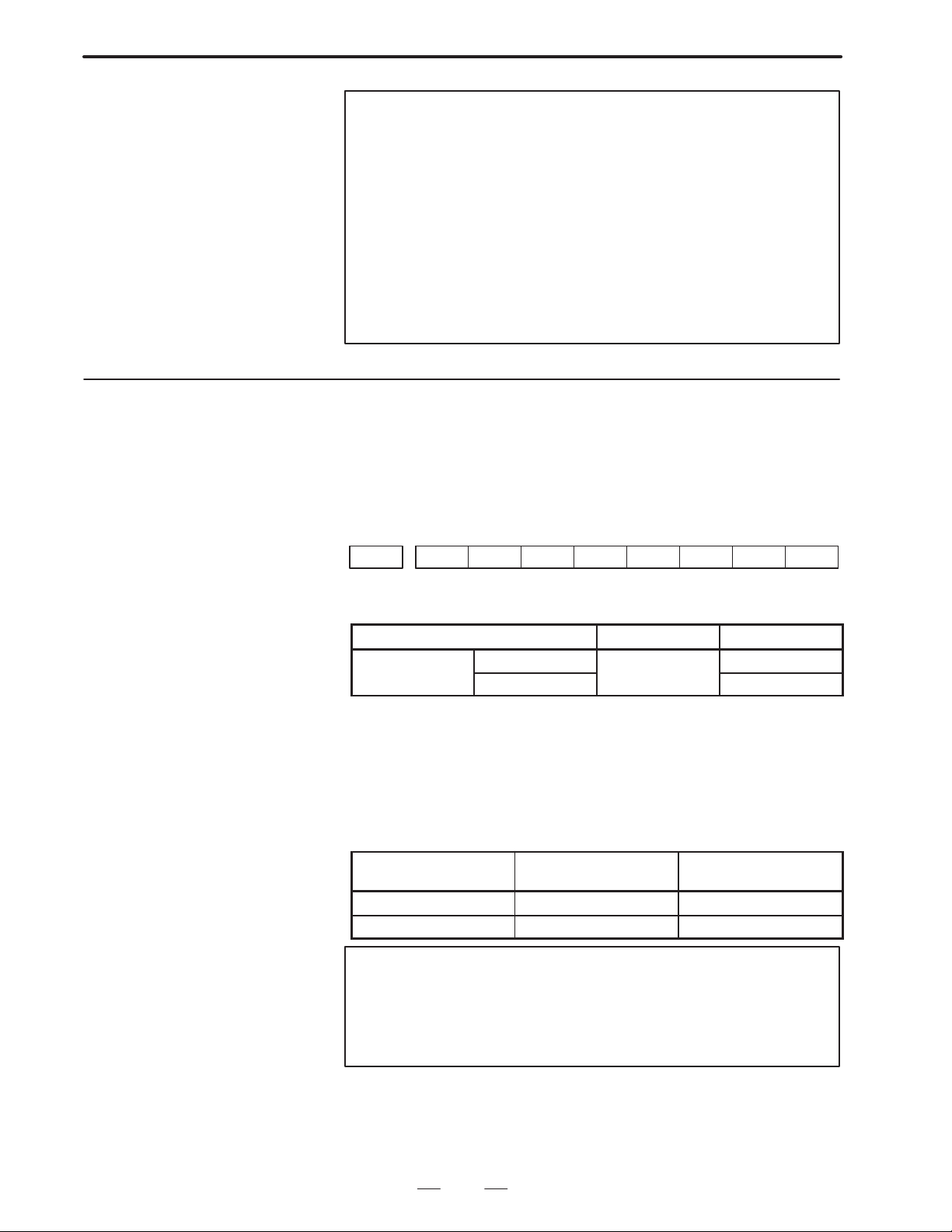

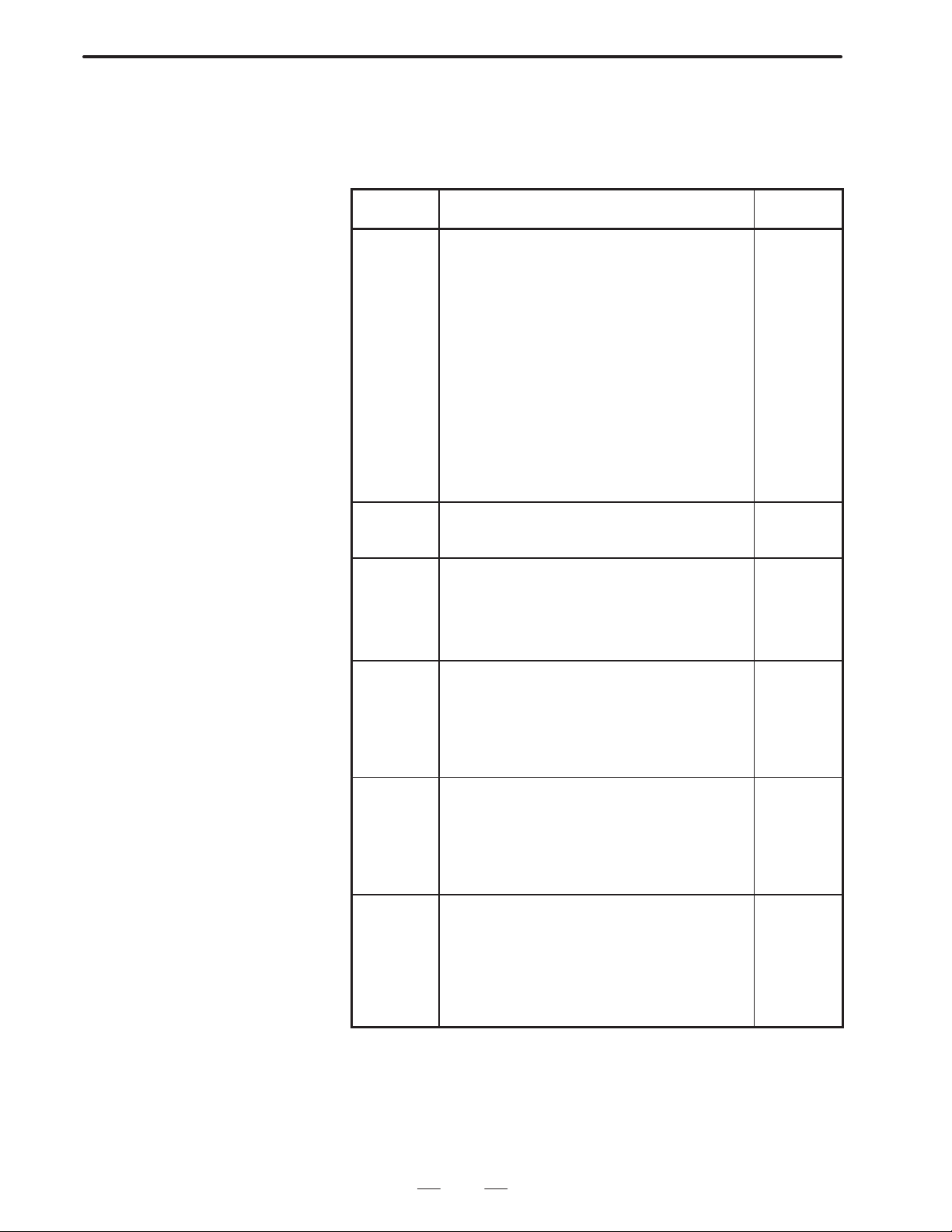

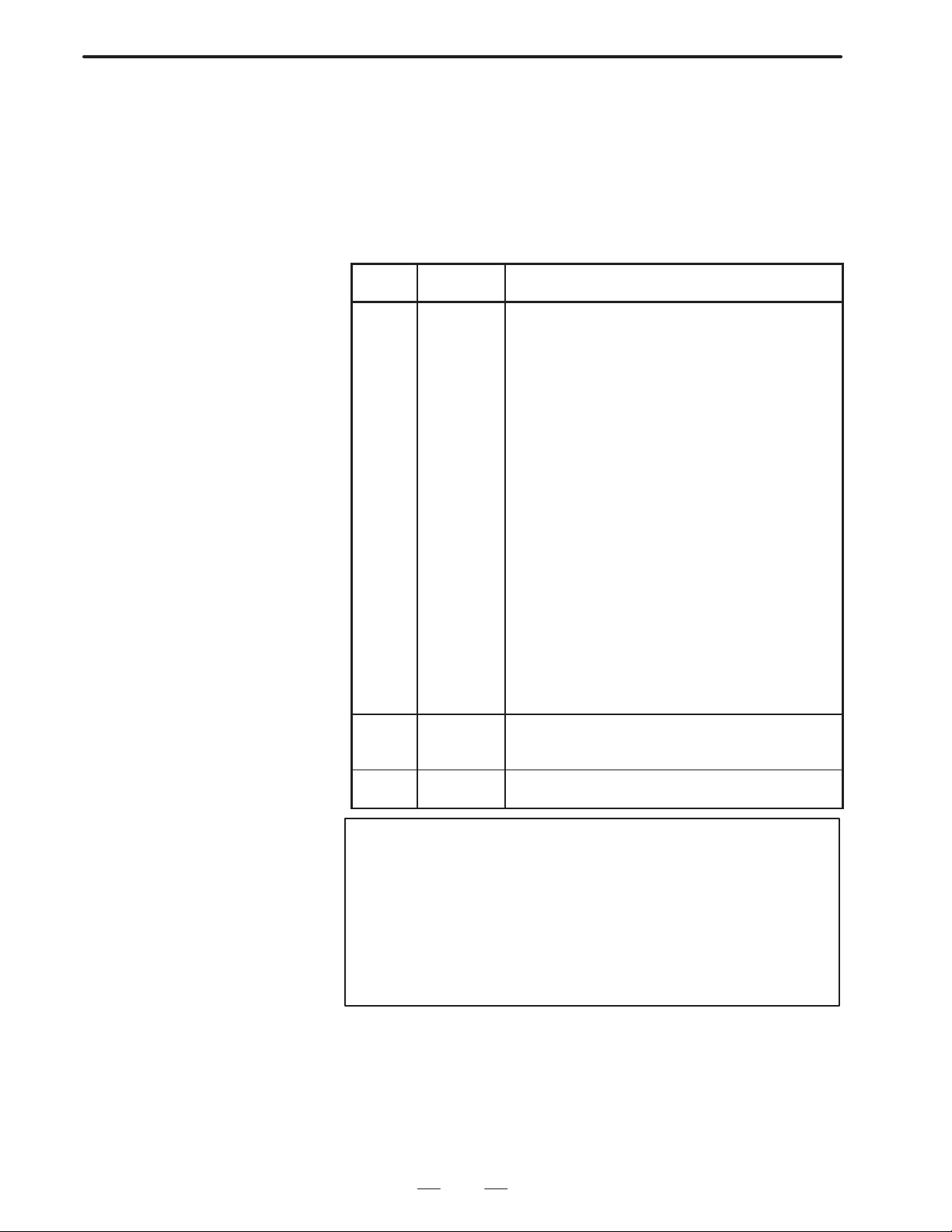

Macro compiler basic outline diagram

Part program strage

User program Execution macro

(Memory operation execution level)

CRT/MDI

M/T/G code call

Software key call

tion format (P–CODE program)

executer

Conversational macro

executer

Parameter 8537 Parameter 8536

(when switching on power)

Control variable #8600 Control variable #8500

Startup by

system variable

Program number change

Program number change

Program

number

change

Auxiliary macro

executer

Startup

by system

variable

3

Page 7

1. GENERAL

Series 15B

B–62073E–2/03

The words used in the explanation are defined as follows.

“P–CODE program” –––––

Execution type macroprogram prepared by machine tool builders,

being compiled and registered to ROM.

“Execution macro” –––

Program to operate machine in P–CODE program.

“Conversational macro” –––

Program operated screen in P–CODE program.

“User program” –––––

Program prepared by end–user for program edit memory.

This manual describes the following products.

Model name Abbreviation

FANUC Series 15–TB 15–TB

FANUC Series 15–MB 15–MB

4

Page 8

B–62073E–2/03

1.GENERAL

1.2

FEATURES

(1) Since the custom macro is converted into an execution format and

registered, the execution speed is high. This will shorten the

machining time and improve the machining accuracy.

(2) The registration to the ROM eliminates prevents custom macro

damage through misoperation. This will improve the reliability.

(3) Since the converted program into execution format is not indicated

on the program display, the machine tool builder’s knowhow can be

protected.

(4) Since the execution format program is registered in the ROM, the

program edit memory can effectively be used.

(5 ) The user can call the execution format program (P–CODE program)

with an easy call procedure without being conscious of the registered

program.

(6) Using the conversational function and conversational macro,

execution can be performed.

(7) There is an auxiliary macro for executing regardless of the selected

mode and screen.

(8) Compiling the NC program, and ROM output can be performed by

the Series 15 itself.

(9) When compiled in Series 15, without writing the execution format

program to ROM, it can be started up as it is and execution/debug can

be performed.

5

Page 9

2. MACRO COMPILER

MACRO COMPILER

2

B–62073E–2/03

2.1

OUTLINE

A custom macro program is converted to executable form (hereafter

called a P–CODE programs), then registered in flash ROM (hereafter

called F–ROM). The registered P–CODE program can be called from the

user programs and executed by using the G, M or T code (execution

Macro) or by setting the program number in the associated parameter

(conversational macro execution).

Custom macro programs

O9000 ;

#1=#2+#5 ;

:

:

M99 ;

Macro compiler (FANUC System P)

(Personal computer)

(FANUC Series 15–B)

Compile parameters

8500=10000001

8501=00000001

:

:

:

8550=50

Set parametersRegister programs

Compile

P–CODE programs and executer

Write to ROM

F–ROM

Note

The executer executes the P–CODE program generated by

compiling a custom macro program with the macro compiler.

6

Page 10

B–62073E–2/03

2.MACRO COMPILER

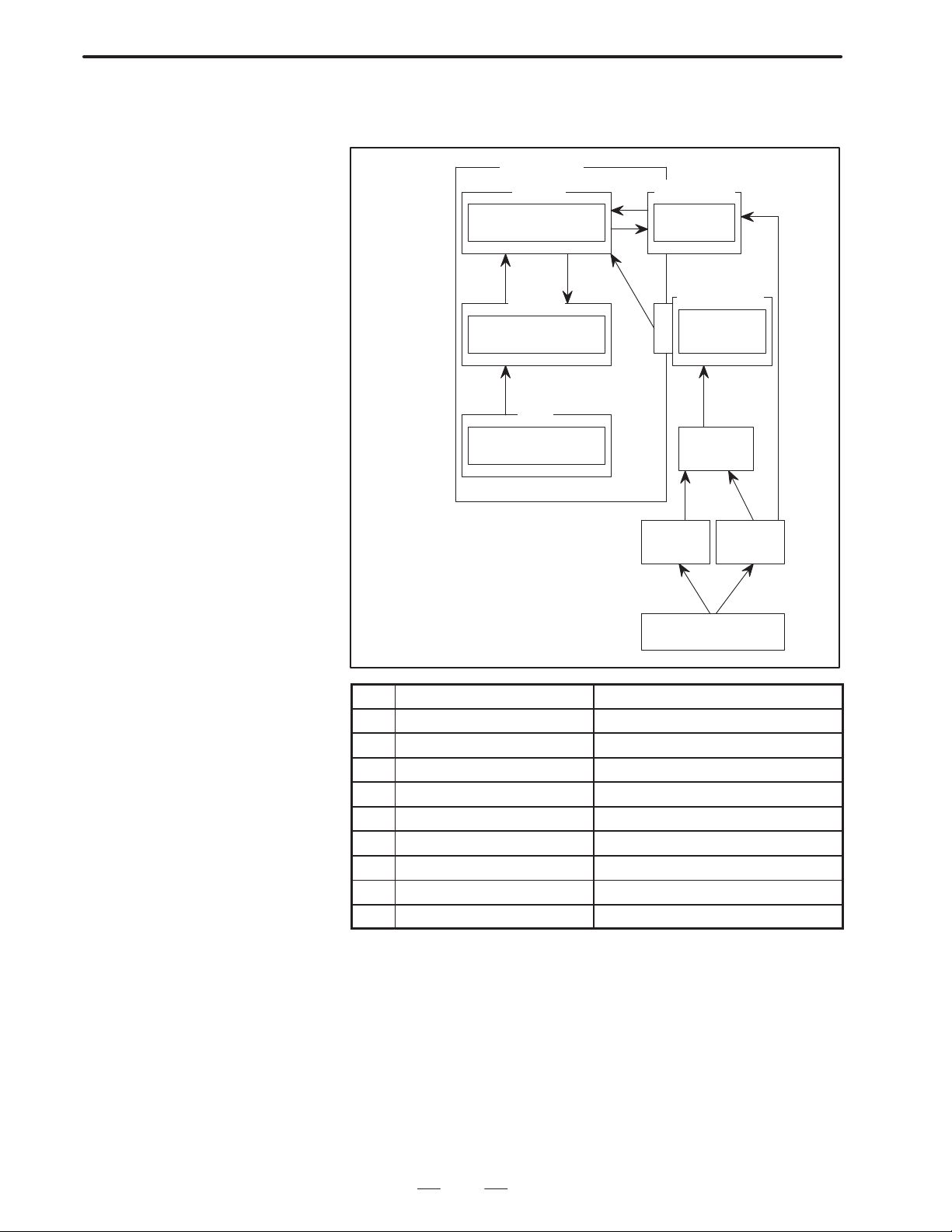

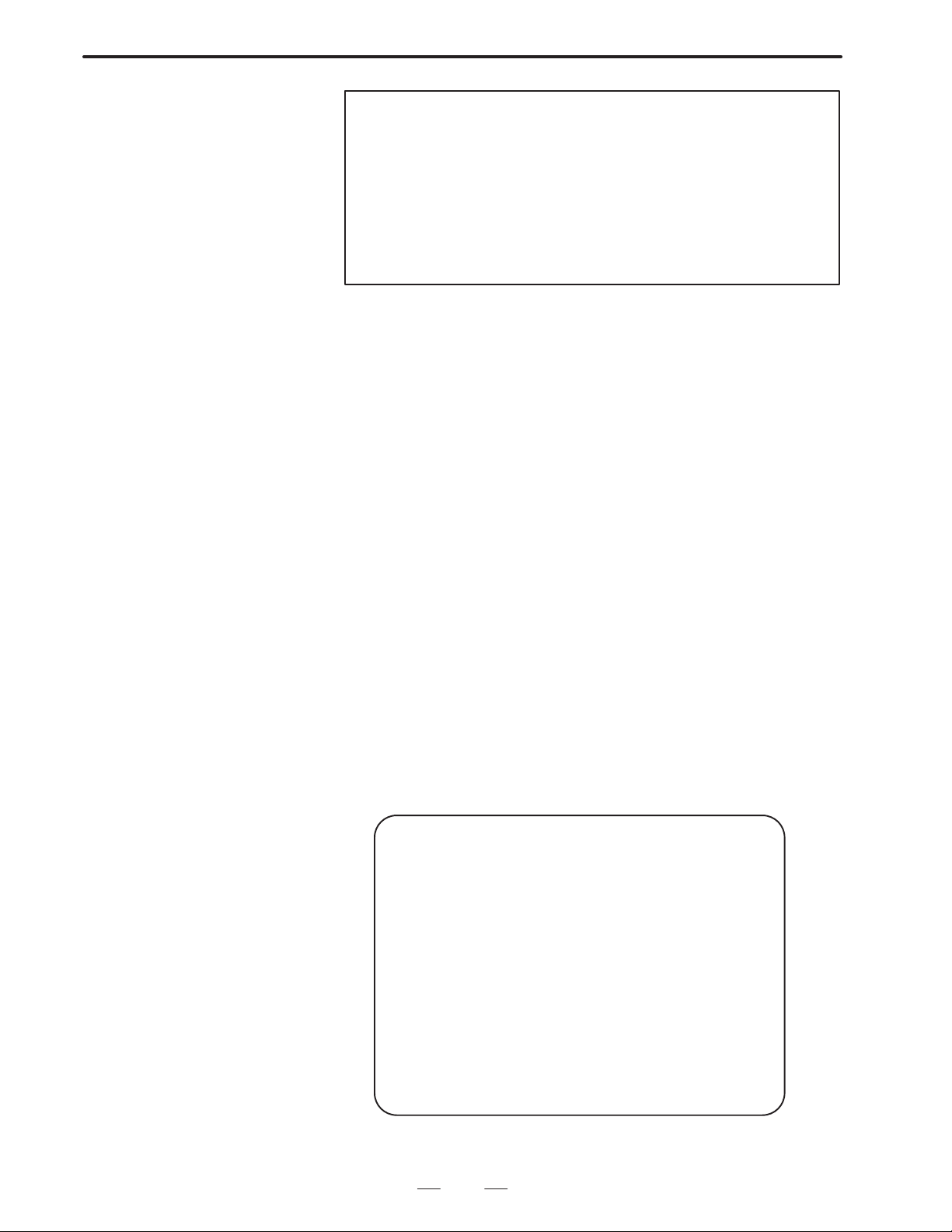

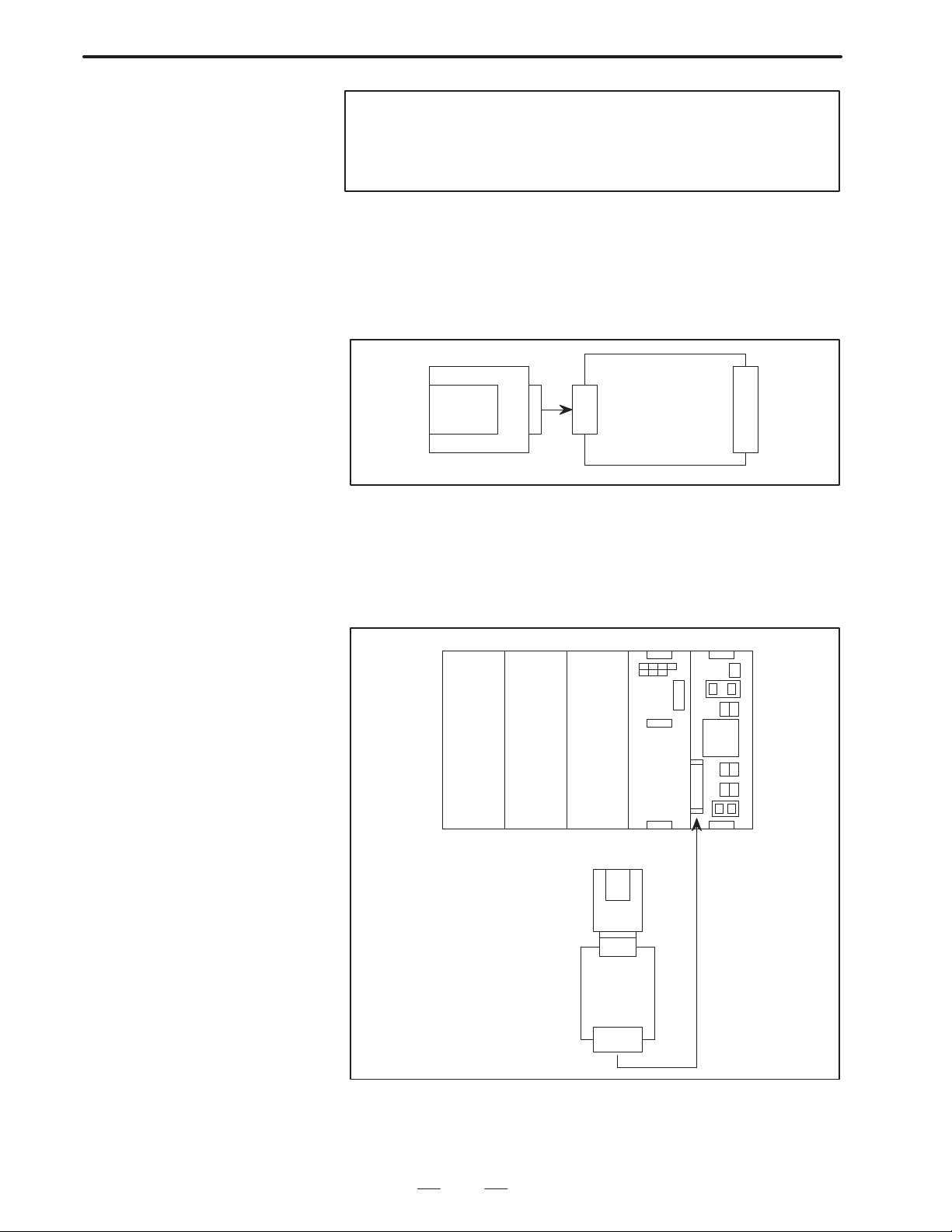

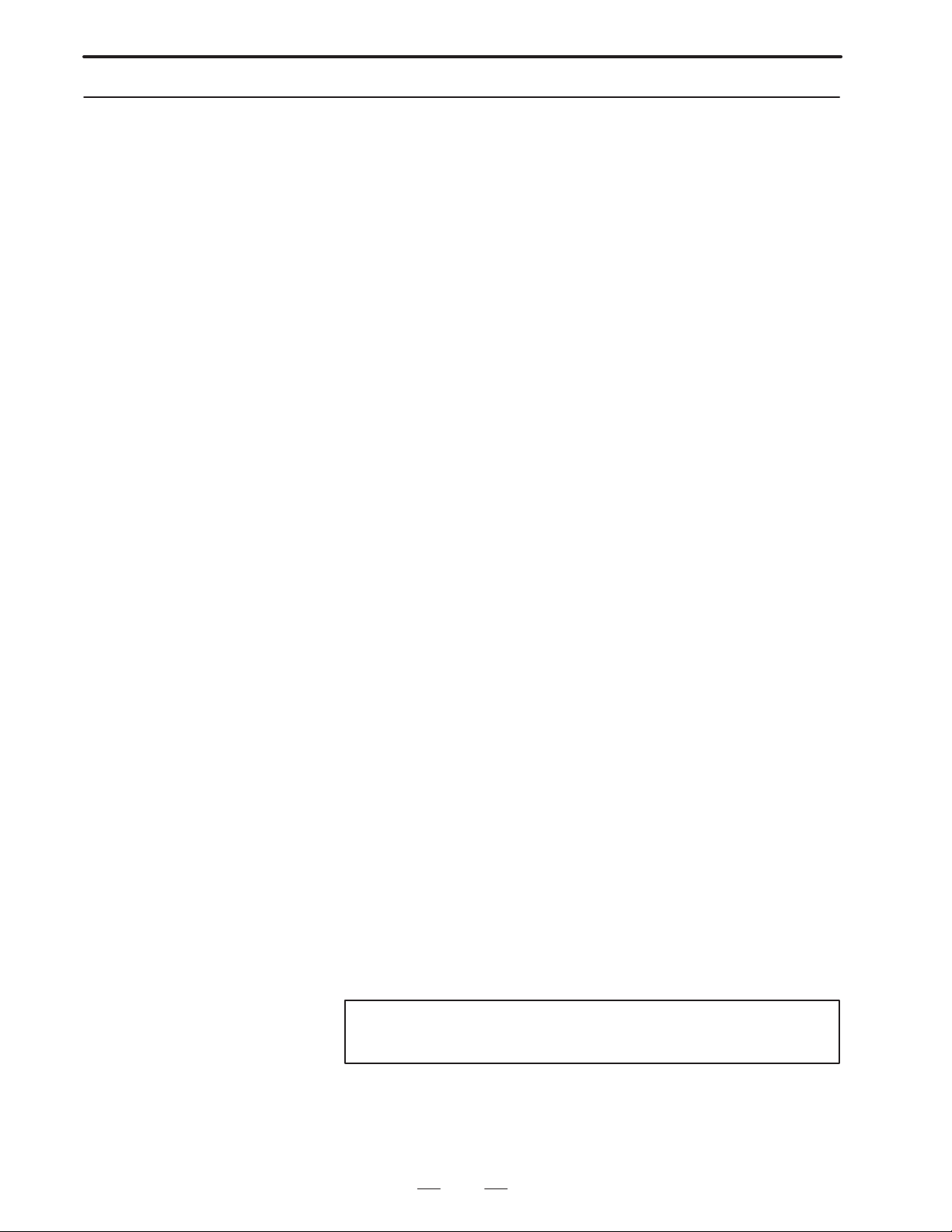

2.2

FLOW FOR

CREATING,

REGISTERING AND

SAVING PROGRAMS

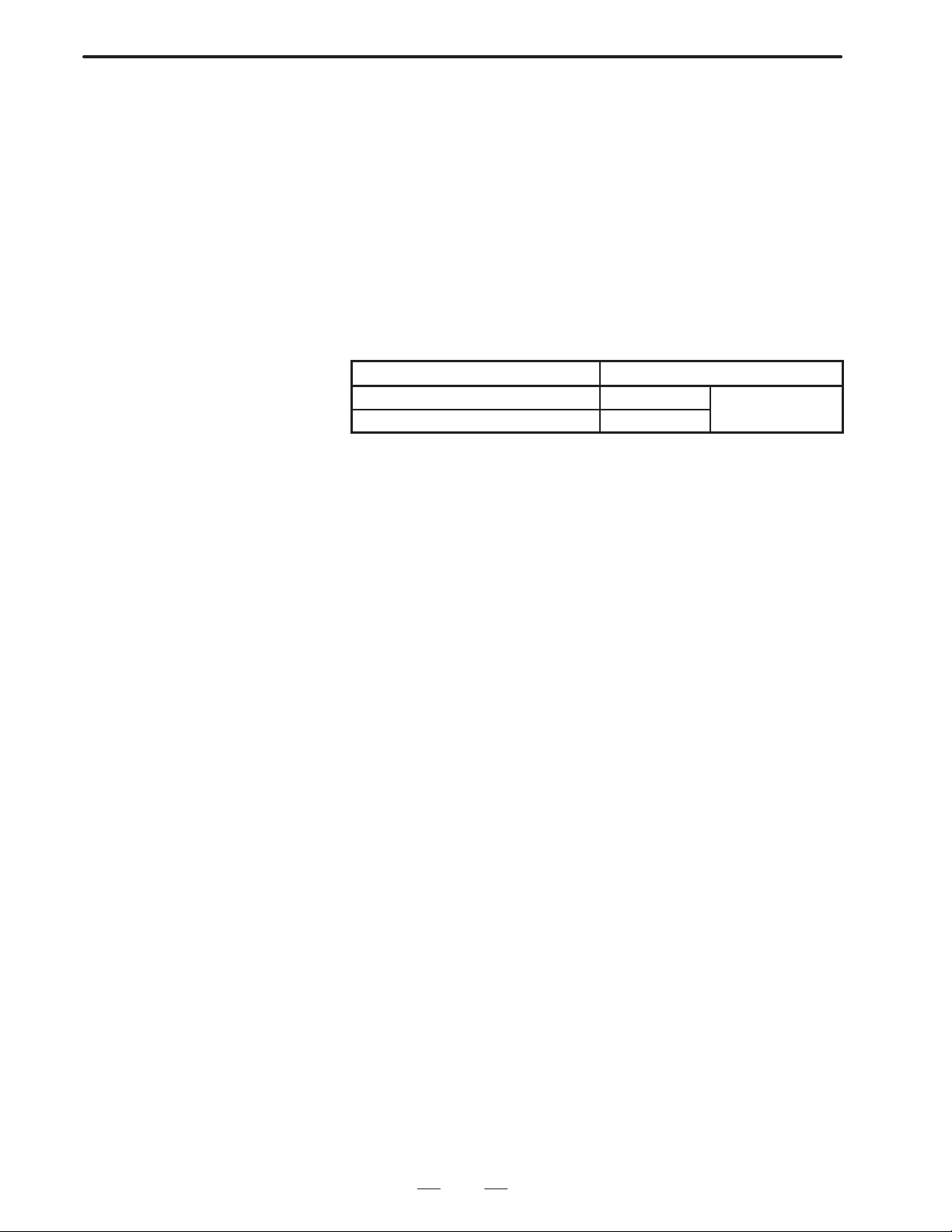

In Series 15–B, custom macro and P–CODE programs are created,

registered and saved as follows.

Series 15–B

F–ROM

P–CODE program

(2) (3)

D–RAM

P–CODE program

(1)

T ape

Custom macro

program

(4)

(5)

(6)

System P

Memory card

P–CODE file

ROM cassette

P–CODE

program

(7) or (8)

PMC–

writer

(7)

(9)

(8)

Personal

computer

(7)

Custom macro program

(8) or (9)

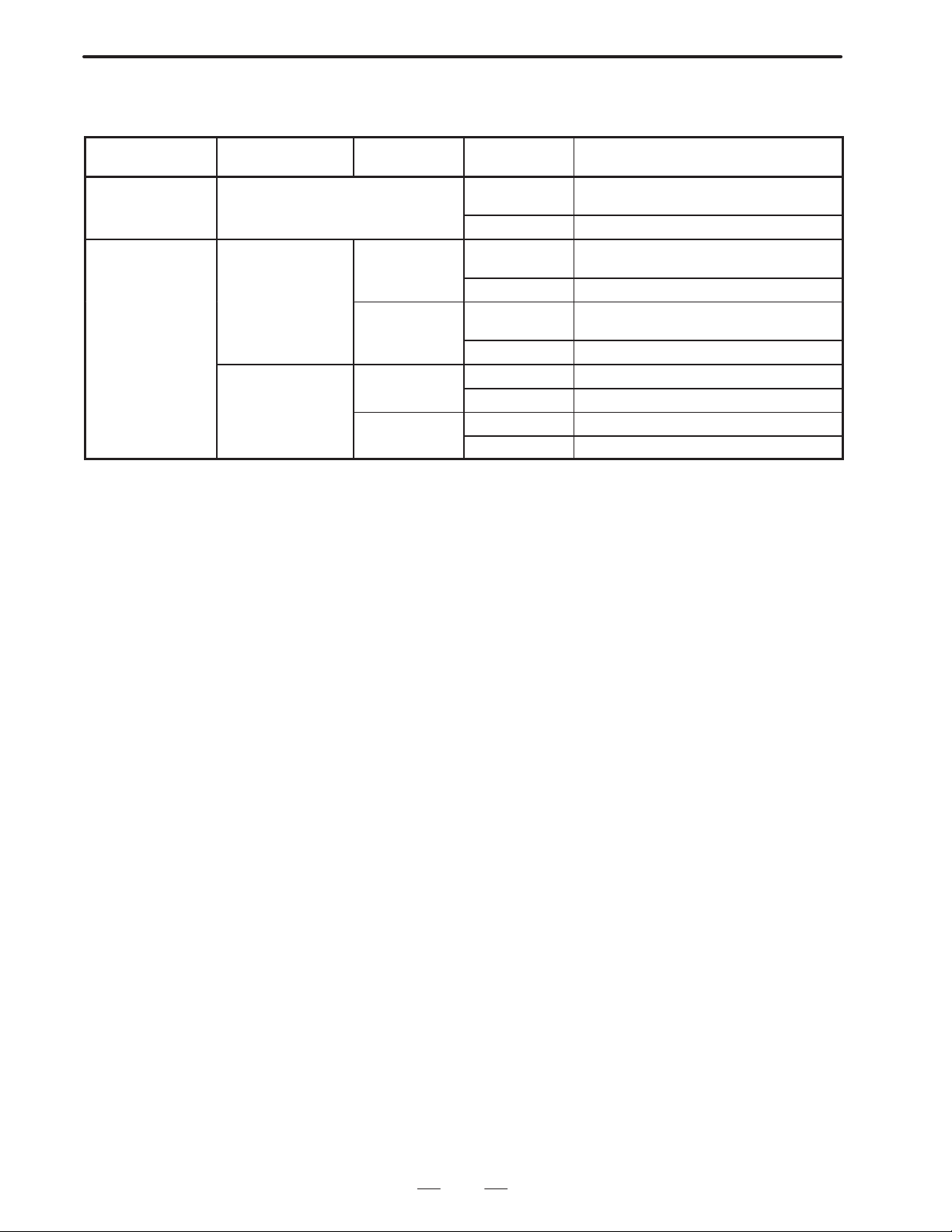

No. Process Performed by

(1) Compile Series 15–B macro compiler

(2) ROM write Series 15–B macro compiler

(3) Activate P–CODE program CNC

(4) Load Boot system

(5) Save Boot system

(6) Load Boot system

(7) Compile System P macro compiler

(8) Compile Personal computer macro compiler

(9) Compile Personal computer macro compiler

7

Page 11

2. MACRO COMPILER

B–62073E–2/03

2.3

USE OF MACRO

COMPILER

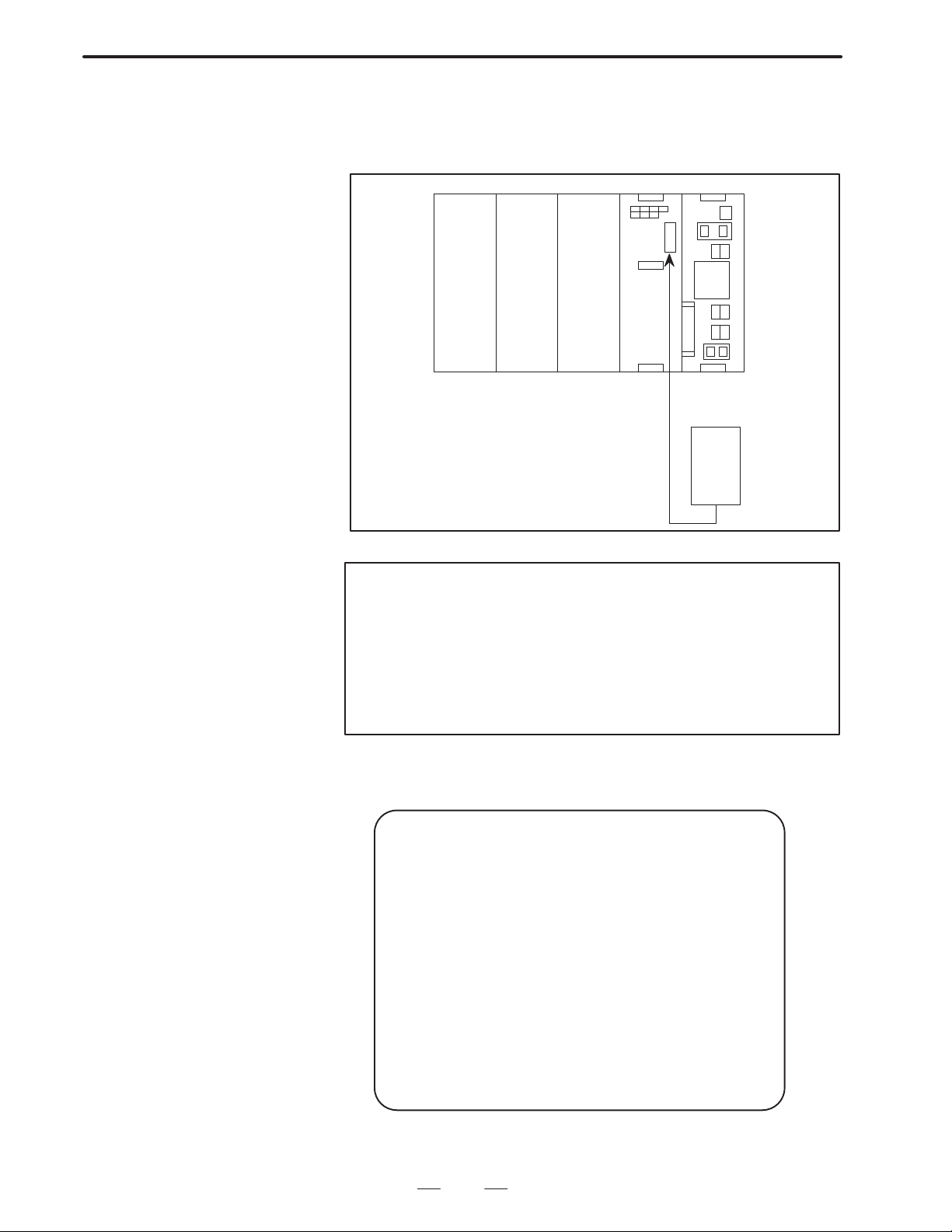

2.3.1

Registering a P–CODE

Program in F–ROM

Using a Memory Card

(When Compiled with a

Personal Computer)

The P–CODE program created by compiling a custom macro program

can be registered in F–ROM in any one of the following ways:

(1) When the P–CODE program is compiled with a personal computer,

it can be registered in F–ROM using a memory card.

(2) When the P–CODE program is compiled with a personal computer

or System P, it can be registered in F–ROM using a ROM cassette.

(3) Series 15–B can compile the P–CODE program for registration in

F–ROM.

Note

The P–CODE program resident in F–ROM can be saved

onto a memory card via the boot system and copied to

another F–ROM unit.

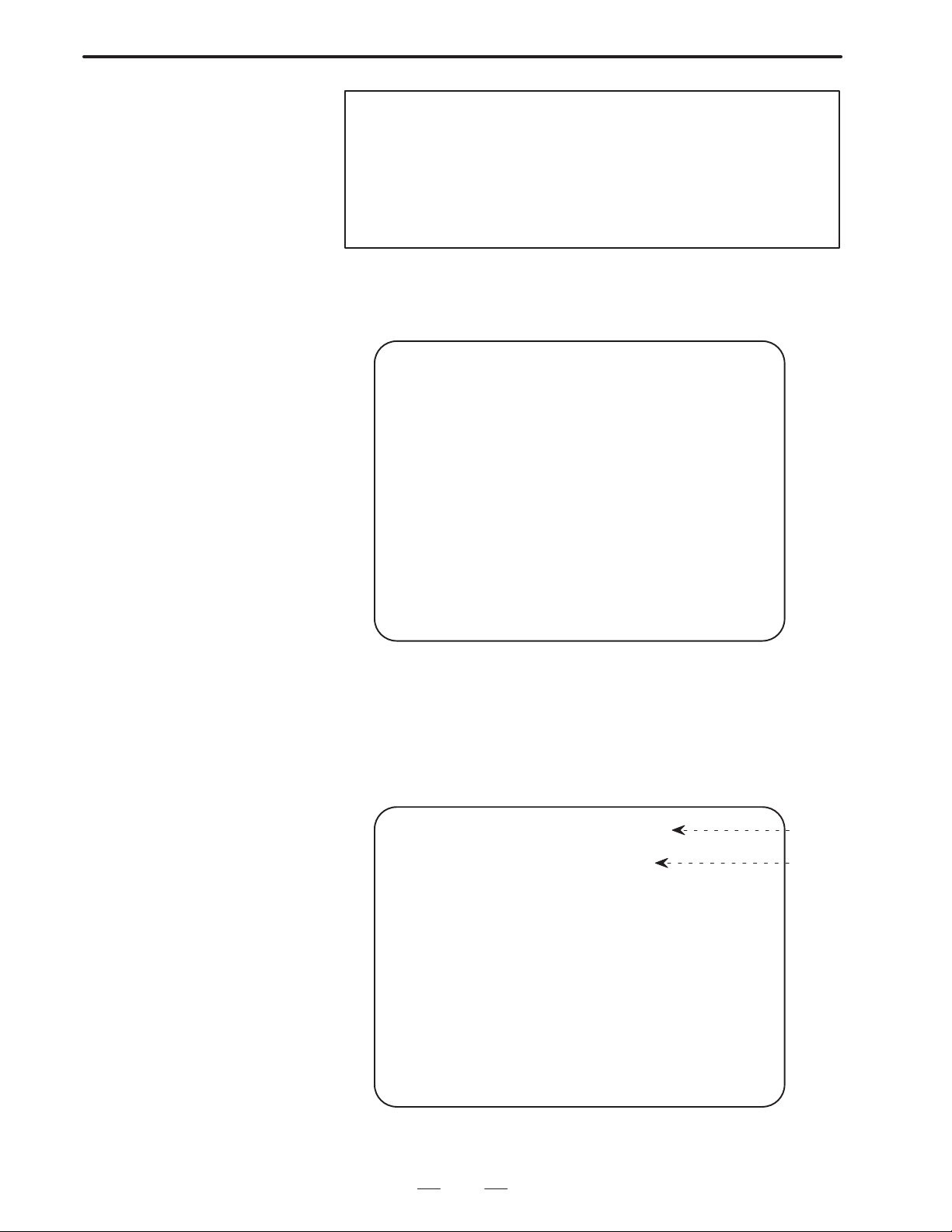

This method uses a memory card to register a P–CODE program

compiled with a personal computer in the F–ROM unit of Series 15–B.

For how to compile a program, refer to the FAPT Macro Compiler (for

Personal Computer) Programming Manual (B–66102E).

Custom macro programs

Personal

computer

O9000 ;

#1=#2+#5 ;

:

:

M99 ;

Compile custom macro programs

into the P–CODE program.

Memory card

Boot system

Register

F–ROM

Save

Fig.2.3.1 (a) P–CODE Program Registration Using a Memory Card

8

Page 12

B–62073E–2/03

2.MACRO COMPILER

(1) Procedure for registering a P–CODE program in a memory card to

F–ROM

1) Insert the memory card in the memory card interface of the CNC

unit.

PMC PSU

Series 15–B

Memory card

Fig.2.3.1 (b) Mounting of a Memory Card

Note

The PMC slot is used as the memory card interface. The

memory card can be inserted or removed while the power

is turned on. When the boot system is active, make sure that

the main menu [see Fig. 2.3.1(c)] is displayed on the screen

before inserting or removing the memory card. Otherwise,

proper access is not made, and the contents of the memory

card files may be destroyed.

2) Turn on the power of the CNC unit while holding down the

page–up and page–down keys. The boot system is activated, and

the following screen appears.

SYSTEM MONITOR

1. SYSTEM DATA LOADING

2. SYSTEM DATA CHECK

3. SYSTEM DATA SAVE

4. FILE DATA BACKUP

5. END

*** MESSAGE ***

SELECT MODE AND HIT INPUT KEY

Fig.2.3.1 (c) Boot System Main Menu

9

Page 13

2. MACRO COMPILER

B–62073E–2/03

3) Select ”2. SYSTEM DATA CHECK” using the cursor keys and

press the input key. The contents of F–ROM are retrieved, and

the following information is displayed on the screen:

SYSTEM DATA CHECK

FILE DIRECTORY

1. OPTIONA3 ( 2)

2. HELP MSG ( 2)

3. DG SERVO ( 1)

4. NC BASIC (10)

5. PCD 256A ( 2)

6. PMC–NA0B ( 1)

7. MCR–CMPA ( 2)

END

*** MESSAGE ***

SELECT FILE AND HIT INPUT KEY

Fig.2.3.1 (d) DATA CHECK DIRECTORY Screen

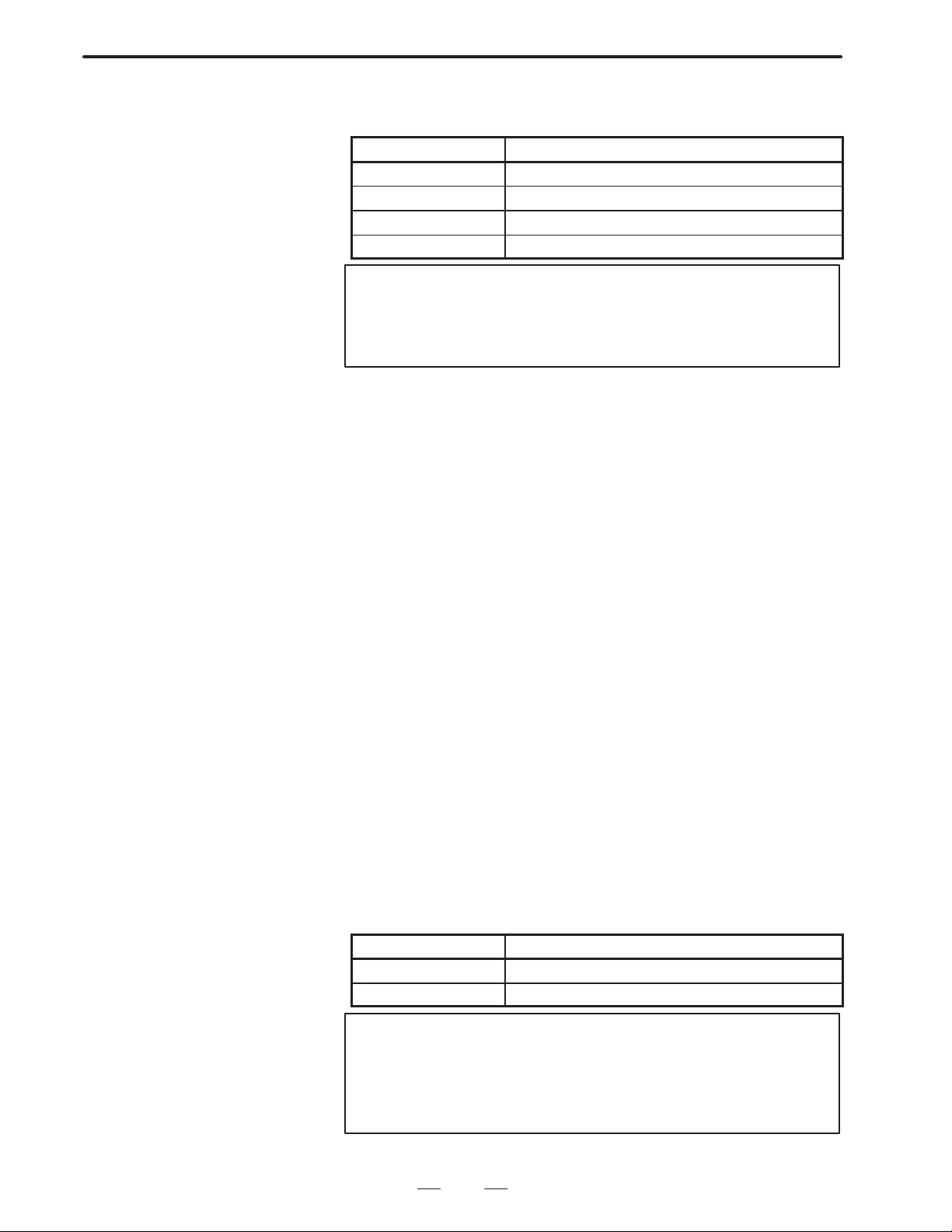

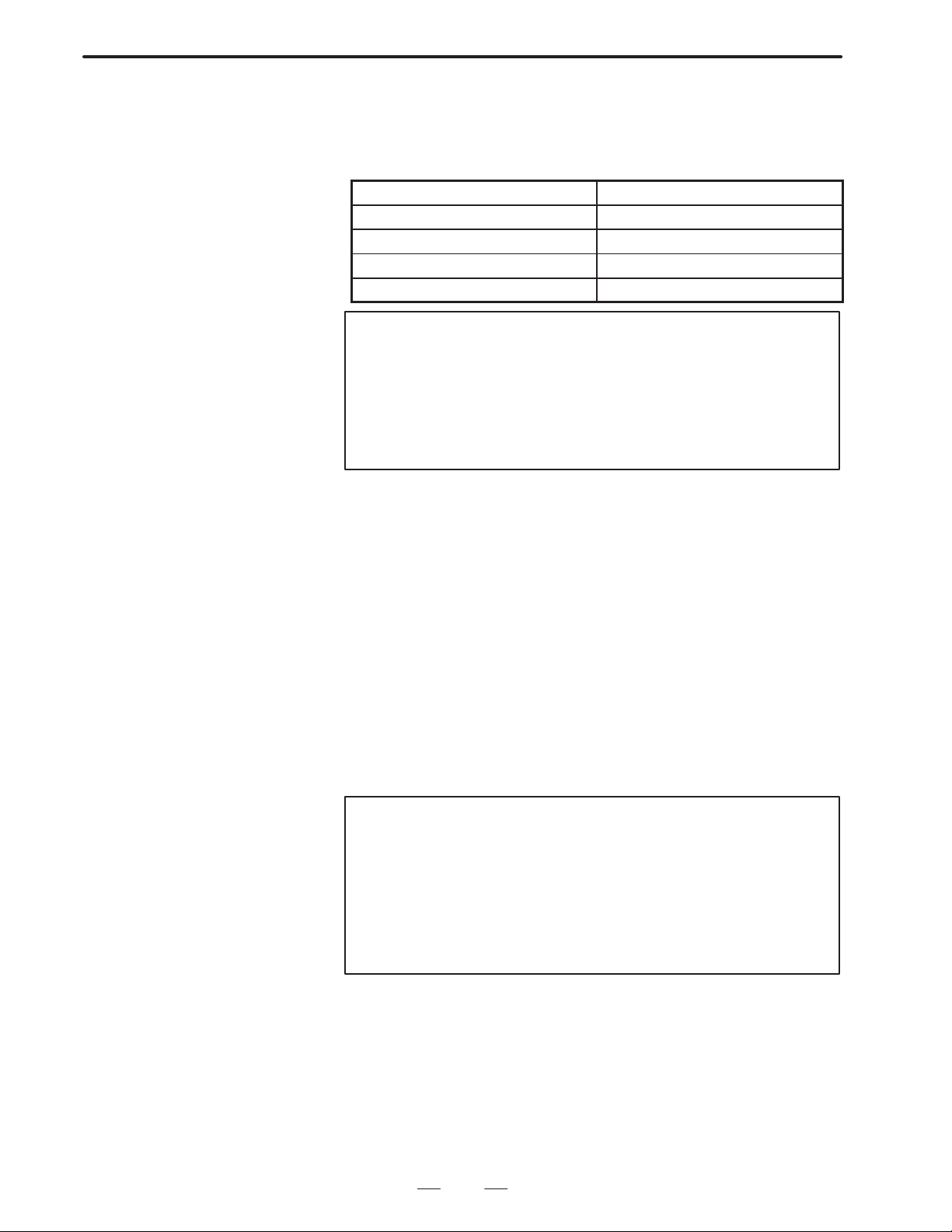

Check this screen to see if any P–CODE programs are registered. If a

P–CODE program is already registered, its file name is displayed (see the

table below).

2.3.1 P–CODE File Names)

File name

PCD 256A For systems without a sub–CPU (256K bytes)

PCD 512A For systems without a sub–CPU (512K bytes)

PCD 256M For systems with a sub–CPU (256K bytes)

PCD 512M For systems with a sub–CPU (512K bytes)

Description

4) If a P–CODE file is already registered, delete it. To delete a

P–CODE file, select it with the cursor, then press the ”delete” key .

When no P–CODE file is registered, proceed to step 7.

5) The message “DELETE OK?” appears. Make sure that the selected

file is a P–CODE file, then press the input key. If the wrong file has

been selected, press the cancel key. The DATA CHECK

DIRECTORY screen [Fig. 2.3.1(d)] is then displayed again.

Note

When an attempt is made to delete a system file, such as

a CNC program or the macro compiler, the message

”PROTECT FILE” appears on the screen and the attempt is

rejected. However, the system deletes user files, such as

the PMC ladder, without asking for confirmation. Once

deletion has started, the process cannot be halted. If no

backup file exists on a memory card or another storage

medium, the contents of the file cannot be restored in any

way. To avoid such inadvertent deletion of files, make sure

that the correct file has been selected before deleting it.

Also, back up user files at appropriate intervals.

10

Page 14

B–62073E–2/03

2.MACRO COMPILER

6) When the file has been successfully deleted, the message “DELETE

COMPLETED” appears. Press the input key. The DA TA CHECK

DIRECTORY screen [Fig. 2.3.1(d)] 1 is then displayed again.

Confirm that the P–CODE file is no longer listed.

7) Select ”END” and press the input key. The main menu [Fig.

2.3.1(c)] is then displayed again.

8) Select “1. SYSTEM DATA LOADING” using the cursor keys,

then press the input key . The directories in the memory card are

listed on the screen.

SYSTEM DATA LOADING

FILE DIRECTORY

1. LADDER1. ROM

2. LADDER2. ROM

3. TEST. DAT

4. MACRO. ROM

END

*** MESSAGE ***

SELECT FILE AND HIT INPUT KEY

Fig.2.3.1 (e) DATA LOADING DIRECTORY SCREEN

Note

If a ROM cassette error occurs, check the title. When the

boot system has been activated by holding down the

page–up and page–down keys, the title should read:

SYSTEM DATA LOADING.

If this title is not displayed, turn off the system power once,

then turn it on again.

Title

For the functions of the boot system, see 2.3.5, (1) Methods of starting up

the boot system and the corresponding main menu functions.

9) Select the P–CODE file using the cursor keys, then press the

input key.

10)The message ”OK? INPUT/CANCEL” appears. To register the

selected program, press the input key . T o not register the selected

file cancel, press the ”cancel” key. The DATA LOADING

DIRECTOR Y screen [see Fig. 2.3.1 (e)] is then displayed again.

11

Page 15

2. MACRO COMPILER

B–62073E–2/03

Note

The boot system registers any file having the acceptable

format. Once registration has started, it cannot be halted.

If no backup file exists on a memory card or another storage

medium, the previously saved data of the file cannot be

restored in any way. To avoid such inadvertent registration

of files, make sure that the correct file has been selected

before registering it. Also, back up files at appropriate

intervals.

11)When the file has been successfully registered, the message

”PROGRAM COMPLETED” appears. Press the input key . The

DATA LOADING DIRECTORY screen [see Fig. 2.3.1 (e)] is

then displayed again.

12)Select “END” and press the input key. The main menu [Fig. 2.3.1

(c)] is then displayed again.

13)Select “2. SYSTEM DATA CHECK” to retrieve the contents of

F–ROM. After confirming that the P–CODE file has been

registered, press the input key to return the main menu [Fig. 2.3.1

(c)].

14)Select “END” on the main menu and press the input key. The

blinking message “LOADING CNC DAT A” appears. The CNC

starts up about ten seconds later.

15)Make sure that the registered P–CODE file operates normally.

16)Remove the memory card from the memory card interface. The

card can be removed even when the CNC power is on.

(2) Procedure for registering a P–CODE program in F–ROM to a

memory card

1) Insert the memory card in the memory card interface of the CNC

unit to activate the boot system. See steps 1 and 2 of 2.3.1 (1),

Procedure for registering a P–CODE program in a memory card

to F–ROM.

2) Select “3. SYSTEM DATA SAVE” using the cursor keys, then

press the input key. The contents of F–ROM are retrieved, and

the following information is displayed on the screen:

SYSTEM DATA SAVE

FILE DIRECTORY

1. OPTIONA1 ( 2)

2. HELP MSG ( 2)

3. DGTL SRV ( 1)

4. NC BASIC (10)

5. PCD 256A ( 2)

6. PMC–NA0B ( 1)

7. MCR–CMPA ( 2)

END

*** MESSAGE ***

SELECT FILE AND HIT INPUT KEY

Fig.2.3.1 (f) DATA SAVE DIRECTORY SCREEN

12

Page 16

B–62073E–2/03

2.MACRO COMPILER

3) Select one of the P–CODE files listed below using the cursor,

then press the input key.

File name Description

PCD 256A For systems without a sub–CPU (256K bytes)

PCD 512A For systems without a sub–CPU (512K bytes)

PCD 256M For systems with a sub–CPU (256K bytes)

PCD 512M For systems with a sub–CPU (512K bytes)

Note

System files, such as the CNC program or the micro

compiler, cannot be saved (if you attempt to save one of

these files, the message ”PROTECT FILE” is displayed).

4) The message “INPUT FILE NAME” appears. Input the file name

using the MDI key . A file must be named according to MS–DOS

file naming rules; that is, a file name consisting of up to eight

characters followed by a three–character or shorter extension.

During file name input:

The cursor can be moved using the cursor ( and ) keys.

The cancel key functions as the backspace key.

Pressing the reset key displays the DATA SAVE

DIRECTORY screen [Fig. 2.3.1 (f)] again.

Characters are input in the overwrite mode.

5) After inputting the file name, press the input key to save the file.

6) If the save operation terminates normally, the message “SAVE

COMPLETED” appears. Press the input key . The DATA SAVE

DIRECTORY screen [Fig. 2.3.1 (f)] is then displayed again.

7) Select “END” and press the input key . The main menu [Fig. 2.3.1

(c)] is then displayed again.

(3) Specifications and limitations of the memory card

(a) Specifications

The boot system of Series 15–B permits the use of commercially

available memory cards conforming to the following

specifications:

Standards : JEIDA Ver.4 or later

Capacity : 512K bytes or more

(b) P–CODE file size

When a P–CODE file is saved onto a memory card, its size is as

follows:

File capacity Size on memory card

256K#bytes 262272#bytes (256K#bytes + 128#bytes)

512K#bytes 524416#bytes (256K#bytes + 128#bytes)

Note

A P–CODE file cannot be divided and saved onto two or

more memory cards. Prepare a memory card having

enough capacity to save the whole file. Two or more

P–CODE files can be saved onto the same card.

13

Page 17

2. MACRO COMPILER

B–62073E–2/03

(c) Limitations

The boot system is capable of handling only root directory files.

Subdirectory files are not accessible. A void using a memory card

with a subdirectory for the boot system.

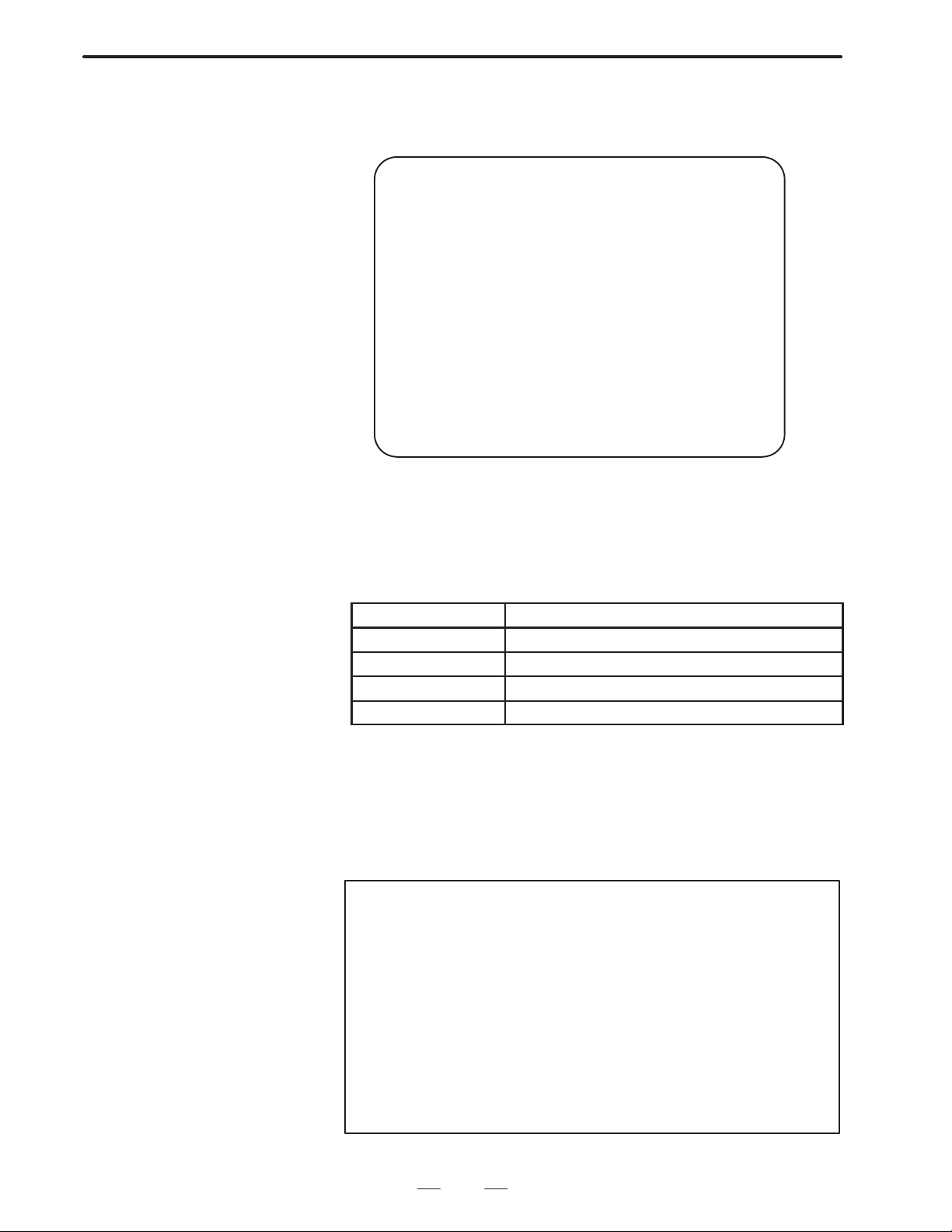

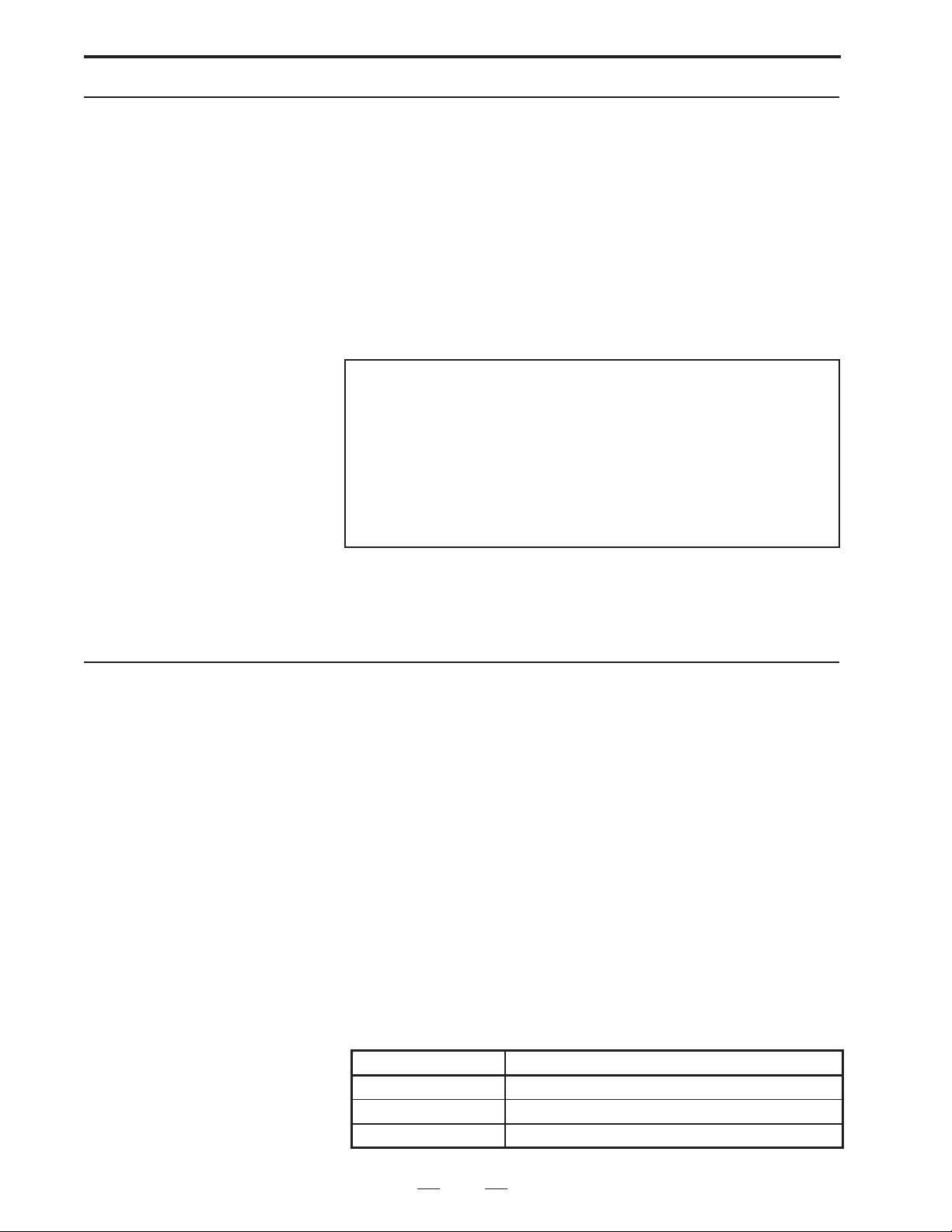

2.3.2

Registering the

P–CODE Program in

F–ROM Using a ROM

Cassette (When the

P–CODE Program has

been Compiled with

the System P or a

Personal Computer)

A P–CODE program compiled with the System P or a personal computer

can be registered in F–ROM of Series 15–B by using a ROM cassette.

For how to compile and write programs to ROM, refer to F ANUC System

P series FAPT Macro Compiler Operator’s Manual (B–66032E) and

FAPT Macro Compiler (for Personal Computer) Programming Manual

(B–66102E).

Custom macro programs

O9000 ;

#1=#2+#5 ;

:

:

M99 ;

System P

or

Personal

computer

Writing the P–CODE

program into ROM

ROM cassette

Boot system

Register

F–ROM

Fig.2.3.2 (a) Registering the P–CODE Program Using a ROM Cassette

14

Page 18

B–62073E–2/03

(1) Writing data into a ROM cassette

2.MACRO COMPILER

System P

ROM cassette

or

Printed circuit board for

the ROM cassette adapter

PMC writer

Personal

computer

RS–232–C

POM cassette adapter

Series 15–B

Fig.2.3.2 (b) Writing Data into a ROM Cassette

The following are required to write data into a ROM cassette:

1) System P or a personal computer

2) RS–232–C cable

3) PMC writer (A13B–0126–B002)

4) Printed circuit board for the ROM cassette adapter

(A16B–1212–0182)

5) ROM cassette: A02B–0094–C163 for 1M–bit ROM (256K

bytes)/A02B–0094–C164 for 2M–bit ROM (512K bytes)

6) Compiler for System P: COMPILER (A08B–0035–J720 for

P–G Mate/A08B–0036–J720 for P–G Mark II)/LIBRARY

(A08B–0036–J721 for both P–G Mate and P–G Mark II)

or F APT macro compiler for a personal computer (A08B – 9001 – J540

#EN03) /FAPT macro library (A08B–9001–J640#ZZ03)

7) ROM cassette adapter (A20B–2000–0760)

15

Page 19

2. MACRO COMPILER

B–62073E–2/03

Note

Items 1) to 5) were required when compiling programs for

Series 15–A using System P or a personal computer. Items

6) and 7) have been required for Series 15–B additionally.

(2) Procedure for registering a P–CODE program in a ROM cassette to

F–ROM

1) Connect the ROM cassette into which the program has been

written using System P or a personal computer to the ROM

cassette adapter (A20B–2000–0760).

ROM

cassette

Fig.2.3.2 (c) Connection of the ROM Cassette to

the ROM Cassette Adapter

ROM cassette adapter

(A20B–2000–0760)

2) T urn off the power of the CNC unit, then insert the ROM cassette

adapter into the mini slot of the CNC unit. The mini slot is on

the PSU and is protected with a cover when not in use.

PMC PSU

Series 15–B

ROM cassette

ROM cassette adapter

Fig.2.3.2 (d) Connection of the ROM Cassette Adapter to the CNC Unit

16

Page 20

B–62073E–2/03

2.MACRO COMPILER

Note

Be sure to turn off the power of the CNC unit before inserting

or removing the adapter. Inserting or removing the adapter

while the CNC power is on can not only damage the CNC

unit and the ROM cassette but can also destroy

battery–retained data, such as NC programs and

parameters.

3) T urn on the power of the CNC unit while holding down the cursor

( and ) keys. The boot system is activated, and the following

screen appears:

SYSTEM MONITOR

1. SYSTEM DATA LOADING

2. SYSTEM DATA CHECK

3. SYSTEM DATA SAVE

4. FILE DATA BACKUP

5. END

*** MESSAGE ***

SELECT MODE AND HIT INPUT KEY

4) Check the contents of F–ROM. If a P–CODE program is already

registered, delete it. For the deletion procedure, see 2.3.1 (1)

Procedure for registering a P–CODE program in a memory card

to F–ROM, steps 3 to 7.

5) Select ”SYSTEM DATA LOADING” using the cursor keys, then

press the input key. The following contents of the ROM cassette

are read and displayed on the screen:

SYSTEM DATA LOADING (CASSETTE)

P–CODE 256K (WITHOUT SUB–CPU)

Title

ROM

type

*** MESSAGE ***

SELECT FILE AND HIT INPUT KEY

Fig.2.3.2 (e) DATA LOADING DIRECTORY SCREEN (for ROM Cassette)

17

Page 21

2. MACRO COMPILER

B–62073E–2/03

The type of mounted ROM cassette (P–CODE file) is displayed

(see the table below). If the displayed ROM cassette type does not

agree with that of the connected ROM cassette, check the ROM

cassette.

ROM cassette/P–CODE file Display

1M–bit ROM without a sub–CPU P–CODE 256K (without sub–CPU)

2M–bit ROM without a sub–CPU P–CODE 512K (without sub–CPU)

1M–bit ROM with a sub–CPU P–CODE 256K (with sub–CPU)

2M–bit ROM with a sub–CPU P–CODE 512K (with sub–CPU)

Note

If an alarm related to the memory card occurs or when

displaying memory card directories, confirm the title. When

the CNC unit has been activated with the cursor ( and )

keys pressed down, the title should read:

SYSTEM DATA LOADING (CASSETTE)

If this title is not displayed, activate the CNC unit again.

6) The message “OK? INPUT/CANCEL” appears. To register the

P–CODE file, press the input key. To not resister the P–CODE

file, press the “cancel” key. Then the main menu [Fig. 2.3.1 (c)]

is then displayed again.

7) When the file has been successfully registered, the message

“PROGRAM COMPLETED” appears. Press the input key . The

main menu [Fig. 2.3.1 (c)] is then displayed again.

8) Select “2. SYSTEM DATA CHECK” to retrieve the contents of

F–ROM. After confirming that the P–CODE file has been

registered in F–ROM. Press the input key to return the main

menu [Fig. 2.3.1 (c)].

9) Turn off the power of the CNC unit, and remove the ROM

cassette adapter from the mini slot. After removing the adapter,

place the cover over the slot to protect it.

Note

Avoid using the CNC unit while the ROM cassette remains

in its mini slot. If the CNC unit is used without removing the

ROM cassette, the data stored in the ROM cassette takes

precedence, disabling the use of the micro compiler and

P–CODE program resident in F–ROM.

For more information, see 2.3.4 (3), Priority of the micro

compiler and P–CODE program.

10)Make sure that the registered P–CODE program operates

normally.

18

Page 22

B–62073E–2/03

2.MACRO COMPILER

2.3.3

Compiling and

Registering Custom

Macro Programs in

F–ROM Using the

Series 15–B

Custom macro programs resident in the part–program edit memory can

be compiled and registered in F–ROM using the Series 15–B.

Custom macro programs

O9000 ;

#1=#2+#5 ;

:

:

M99 ;

Part–program

edit memory

Series 15–B

Compile

Register

F–ROM

Fig.2.3.3 (a) Compilation and Registration Using the Series 15–B

(1) Procedure for operating the micro compiler

1) In part–program edit memory register all the custom macro

programs to be compiled into the P–CODE program.

Be sure to compile a program into one P–CODE file at a time.

Compiling a custom macro program into several P–CODE files

and then combining them into one file is not allowed.

The compiler only checks programs for basic syntax error.

2) Set the compile parameters.

Specify parameters necessary for program compilation, including

those related to the conditions for P–CODE program generation and

the correspondence between call codes and program numbers. The

alarm message “POWER MUST BE OFF” may be displayed on the

screen while changing the compile parameters; ignore the message

and proceed with the parameter setting.

Note

For details about the compile parameters, see 2.4, Compile

Parameters.

19

Page 23

2. MACRO COMPILER

B–62073E–2/03

3) When all the parameters have been set, turn off the power of the

CNC.

4) T urn on the power of the CNC unit while holding down MDI keys

4 and 6. The utility is activated, and the following screen appears:

FANUC SERIES 15

1. MACRO COMPILER

2. TROUBLE GUIDANCE

3. END

?

Fig.2.3.3 (b) Utility Screen

5) Select “1. MACRO COMPILER” from the menu by typing ”1”,

then press the input key . The macro compiler is activated, and the

menu screen appears.

FANUC SERIES 15 NC PROGRAM COMPILER

1. COMPILE

2. COMPILE AND ROM WRITE

3. COMPILE AND VERIFY ROM

4. END

?

Fig.2.3.3 (c) Menu Screen

6) Select the desired operation from the menu.

1 COMPILE: Compile custom macro programs. The

P–CODE file is not registered in F–ROM.

2 COMPILE AND ROM WRITE: Compile custom macro

programs and register the P–CODE file in F–ROM.

3 COMPILE AND VERIFY ROM: Compile custom macro

programs and verify the compiled file with the P–CODE file

in F–ROM.

4 END: T erminate the compiler and return to the utility screen

[Fig. 2.3.3 (b)].

20

Page 24

B–62073E–2/03

2.MACRO COMPILER

Note

Since the compiled P–CODE file is also written on RAM of

the CNC unit, the P–CODE program can be executed after

the complier is terminated, irrespective of whether it is

registered in F–ROM. While the selected operation is being

performed, its number is displayed next to the question

mark (?). The question mark disappears when the

operation is completed.

7) The status of the operation being performed is displayed in the

status indication area on the screen.

FANUC SERIES 15 NC PROGRAM COMPILER

1. COMPILE

2. COMPILE AND ROM WRITE

3. COMPILE AND VERIFY ROM

4. END

The following data items are displayed here depending on the selected

operation, one of COMPILE, F–ROM

ERASE & BLANK CHECK, F–ROM WRITE, and

F–ROM VERIFY.

Status indication area

Fig.2.3.3 (d) Status Indication Area

(1) COMPILE

Compilation can be suspended while it is in progress by pressing the

reset key.

COMPILE

PROGRAM NO. 9010 (Note 1)

BLOCK NO. 120 (Note 2)

P–CODE SIZE 00012EF0 (Note 3)

ALARM NO. 0000 (Note 4)

DIAGNOSIS 110 (Note 5)

Fig.2.3.3 (e) Status Indication (COMPILE)

(2) F–ROM ERASE & BLANK CHECK

The displayed indication remains unchanged while this operation is

being performed. This operation cannot be suspended while it is in

progress.

21

Page 25

2. MACRO COMPILER

F–ROM ERASE & BLANK CHECK

ADDRESS 00000000 (Note 6)

ALARM NO. 0000 (Note 4)

DIAGNOSIS 140 (Note 5)

Fig.2.3.3 (f) Status Indication (ERASE)

B–62073E–2/03

(3) F–ROM WRITE

Writing of F–ROM can be suspended while it is in progress by

pressing the reset key. However, avoid suspending this operation

while it is in progress since doing so will shorten the life of the

F–ROM unit.

F–ROM WRITE

ADDRESS 00027A00 (Note 6)

ALARM NO. 0000 (Note 4)

DIAGNOSIS 150 (Note 5)

Fig.2.3.3 (g) Status Indication (WRITE)

(4) F–ROM VERIFY

Verification of F–ROM can be suspended while it is in progress by

pressing the reset key suspending this processing does not affect the

life of the F–ROM unit.

F–ROM VERIFY

ADDRESS 00027A00 (Note 6)

ALARM NO. 0000 (Note 4)

DIAGNOSIS 160 (Note 5)

Fig.2.3.3 (h) Status Indication (VERIFY)

22

Page 26

B–62073E–2/03

O tion

256K#bytes

2.3.4

P–CODE Program

2.MACRO COMPILER

Notes

1 Number of the custom macro program being compiled

(number preceded by an O)

2 Block number assigned by the macro compiler

3 Total size of the compiled P–CODE file

4 Alarm number of the error. If an error occurs, the micro

compiler suspends its operation. For details, see 2.5,

ERROR CODE LIST.

5 This information is displayed for maintenance purposes

only. No special attention is required.

6 Address in F–ROM to which data is being written or for

which verification is being performed

(1) P–CODE file size

The size of a P–CODE file can be either 256K bytes or 512K bytes.

Whether the size is 256K bytes on 512K bytes depends on the setting

of parameter No.8500 (P512) and whether the option (macro executor

user program memory) is used.

#7 #6 #5 #4 #3 #2 #1 #0Address

8500 P512

Bit No.

Option : Macro executer user program memory with a

capacity of 512K bytes (A02B–0162–J607)

P512 0 1

p

Used

Not used

512K#bytes

Error

Error : If 1 is specified for P512 when the option is not used,

the P–CODE file size selection error (error number

4109) occurs. For details, see 2.3.5 (3), F–ROM

errors and corrective action.

(2) P–CODE program size

The maximum size of a P–CODE program to be created depends on

the selected P–CODE file size as shown in the table below.

File size

256K#bytes 192K#bytes 128K#bytes

512K#bytes 416K#bytes 384K#bytes (Note)

System without

sub–CPU

System with sub–CPU

Note

When a file size of 512K bytes is selected for a system with

a sub–CPU, a total of 384K bytes is allocated as the

P–CODE program area. Of these 384K bytes, 128K bytes

are used for the execution macro.

(3) Priority of the macro compiler and P–CODE program

The priority of the macro compiler and P–CODE program is as

follows.

23

Page 27

2. MACRO COMPILER

1. P–CODE program in resident ROM cassette

2. P–CODE program in resident F–ROM

3. Macro compiler

}

Priority changes depending on how the CNC unit is activated.

B–62073E–2/03

P–CODE program

in ROM cassette

Resident No effect on priority no ope The P–CODE program in the ROM cas-

Not resident Resident Resident no ope The P–CODE program in F–ROM is acti-

no ope : Turn on the power of the CNC unit.

“4”, “6” : Hold down MDI keys 4 and 6 while turning on the power of the CNC unit.)

P–CODE program

in F–ROM

Not resident Resident no ope The P–CODE program in not activated.

Macro

compile

Not resident no ope The P–CODE program in F–ROM is acti-

Not resident no ope The P–CODE program in not activated.

How to

activate CNC

sette is activated.

“4”, “6” The compiler is not activated.

vated.

“4”, “6” The compiler is activated.

vated.

“4”, “6” The compiler is not activated.

“4”, “6” The compiler is activated.

“4”, “6” The compiler is not activated.

Result

24

Page 28

B–62073E–2/03

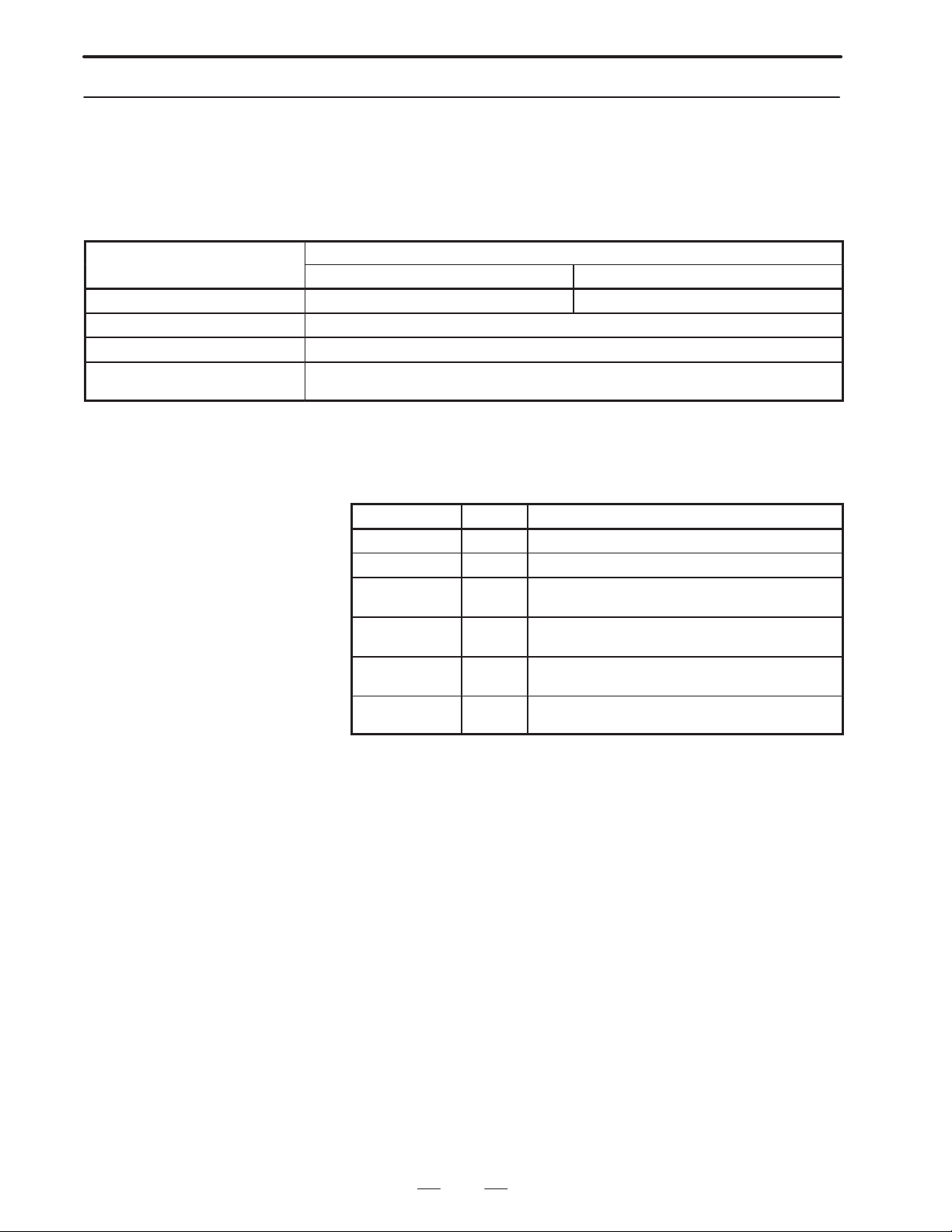

Main menu item

2.MACRO COMPILER

2.3.5

F–ROM

SYSTEM DATA LOADING Load files from memory card to F–ROM. Load files from ROM cassette to F–ROM.

SYSTEM DATA CHECK List files registered in F–ROM and check ROM data.

SYSTEM DATA SAVE Save files registered in F–ROM to memory card.

FILE DATA BACKUP Save battery–retained data (NC programs, parameters, etc.) to memory card and

(1) Methods of starting up the boot system and the corresponding main

menu functions

The following table lists the main menu items and their functions.

(The function of SYSTEM DA TA LOADING changes depending on

how the boot system is started up.)

How to start up the boot system

“page up key”. “page down key” “”, “”

restore these data.

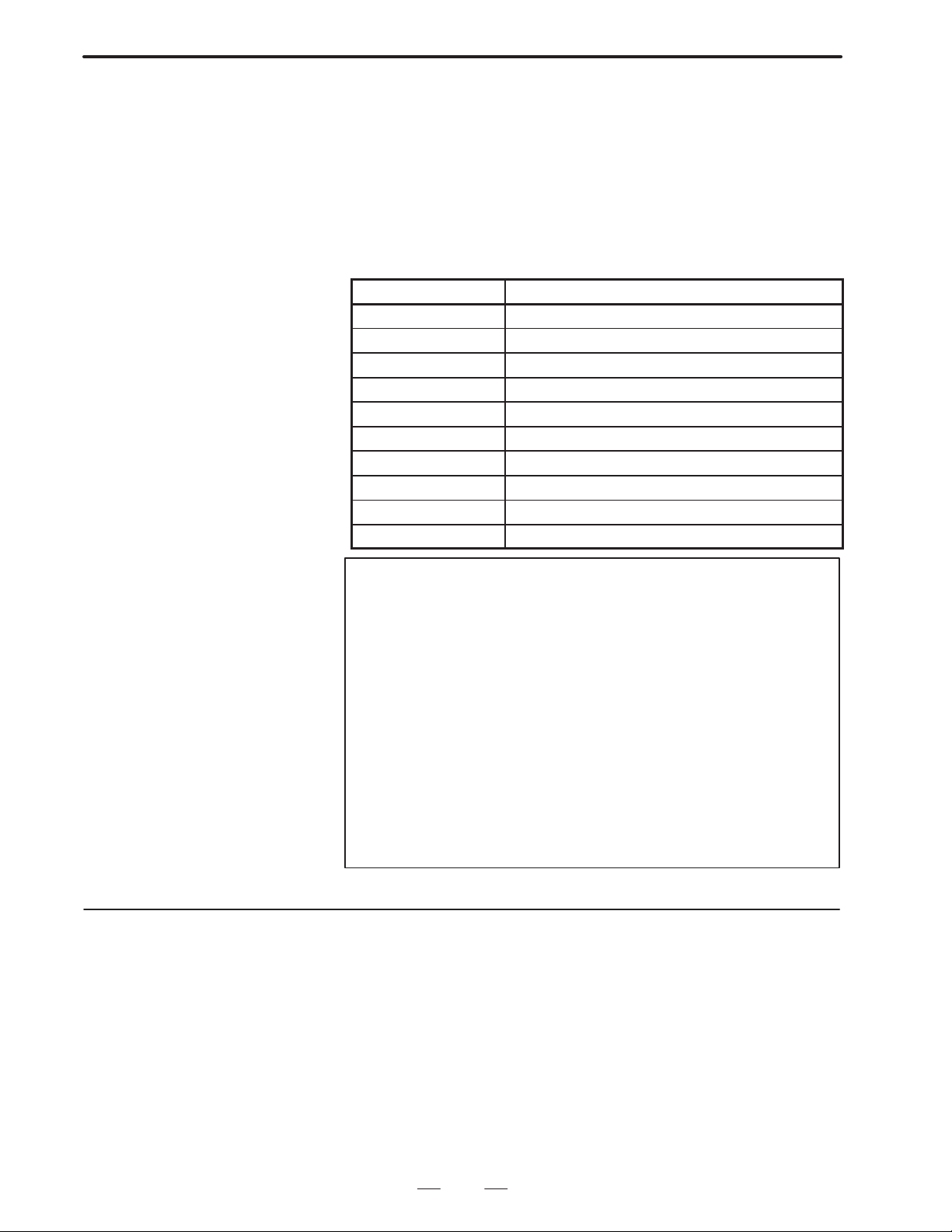

(2) Files in F–ROM

The following table lists the files shown on the SYSTEM DATA

CHECK DIRECTORY screen that are related to the micro compiler

executer.

File name Type Description

MCR–CMPA S Micro compiler for systems without a sub–CPU

MCR–CMPM S Micro compiler for systems with a sub–CPU

PCD 256A U P–CODE file for systems without a sub–CPU

PCD 512A U P–CODE file for systems without a sub–CPU

PCD 256M U P–CODE file for systems with a sub–CPU

PCD 512M U P–CODE file for systems with a sub–CPU

(256K bytes)

(512K bytes)

(256K bytes)

(512K bytes)

File type

S : System files provided by FANUC.

Note) These files are used to compile custom macro programs with

the Series 15–B.

The following operations cannot be performed for these files:

Saving files to memory card

Deleting files from F–ROM

U : User–defined data files. These files are accessible in every

operation.

25

Page 29

2. MACRO COMPILER

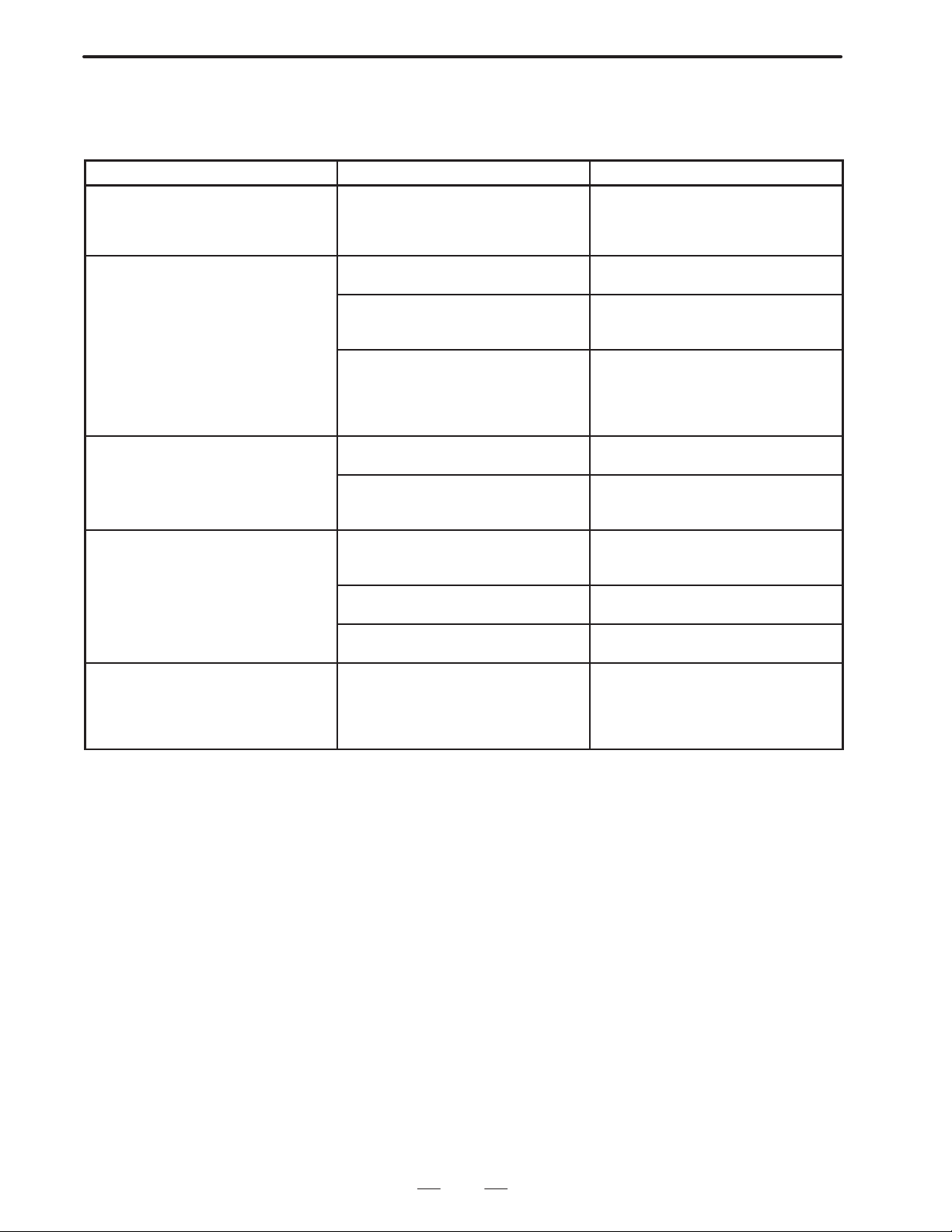

(3) F–ROM errors and corrective action

The following table lists F–ROM errors caused by erroneous

operations and the corrective actions to be taken for then.

Error Cause Corrective action

Error code 4109 is output. Parameter No.8500 is set to 512K

The compiler is not activated when the

CNC is powered up with MDI keys 4

and 6 pressed down.

The newly registered P–CODE program is not activated. The old one is

activated instead.

The P–CODE program does not operate at all.

The meassage ”USER FILE

(P–CODE): ILLEGAL KIND FILE” is

displayed when the CNC power is

turned on.

bytes when the option (user program

memory with a capacity of 512K bytes)

is not used.

The ROM cassette is still in the slot. Turn off the CNC power and remove

The compiler is not registered in

F–ROM.

The wrong compiler is registered. The

compiler for systems without a sub–

CPU is inadvertently registered for

systems with a sub–CPU, or vice

versa.

The ROM cassette is still in the slot. Turn off the CNC power and remove

”COMPILE AND VERIFY ROM” was

selected instead of ”COMPILE AND

ROM WRITE” when compiling files

The P–CODE program is not registered in F–ROM.

The compiler was terminated before

compilation was completed.

Parameters are not set. Set the parameters correctly , then re–

The P–CODE program for the wrong

system is registered. The program for

systems without a sub–CPU is inadvertently registered for systems with a

sub–CPU, or vice versa.

B–62073E–2/03

Check and correct the parameter.

the cassette.

Check the SYSTEM DATA CHECK

DIRECTORY screen. If the compiler is

not listed there, register it.

Check the SYSTEM DATA CHECK

DIRECTORY screen. If the wrong

compiler is listed there, register the

correct one.

the cassette.

Select ”COMPILE AND ROM WRITE”

and execute it.

Check the SYSTEM DATA CHECK

DIRECTORY screen. If the P–CODE

program is not listed there, register it.

Re–execute compilation.

execute compilation.

Check the SYSTEM DATA CHECK

DIRECTORY screen. Delete the registered P–CODE program, then register

the correct one or compile the programs.

26

Page 30

B–62073E–2/03

2.MACRO COMPILER

2.4

COMPILE PARAMETER

#7 #6 #5 #4 #3 #2 #1 #0Address

Bit No.

8500 0 P512 VERY

Parameter input

Data format : bit type

VERY When “COMPILE AND ROM WRITE” is executed, F–ROM is

0 : not verified

1 : verified

P512 The size of the P–CODE program to be output to F–ROM is

0 : 256K bytes (the same size as that used in the 1M bit ROM

cassette)

1 : 512K bytes (the same size as that used in the 2M bit ROM

cassette)

#4 Always specify a “0.”

#7 Always specify a “1.”

#7 #6 #5 #4 #3 #2 #1 #0Address

8501 SEQN

Parameter input

Data format : bit type

SEQN Outputs sequence number to P–CODE program

0 : does not

1 : does

#7 #6 #5 #4 #3 #2 #1 #0Address

8502 NPEF TMCC EUI0 DMV2 DBG SBK VAR DIR

Parameter input

Data format : bit type

DIR Displays directory of P–CODE program.

0 : does not

1 : does

VAR In case of debug mode, displays macro variable for macro

compiler

0 : does not

1 : does

SBK Single block stop when conversational macro is started up in

debugging function of conversational macro

0 : does not

1 : does

DBG Execution of macro compiler in debug mode

0 : does not perform

1 : performs

Note) DIR, VAR, SBK are enabled only when debugging mode (DBG

= 1).

Auxiliary macro cannot be executed during debugging mode

DMV2 When not in the debug mode, micro compiler variables are

0 : not displayed

27

Page 31

2. MACRO COMPILER

B–62073E–2/03

1 : displayed

EUI0 For the P–CODE program (execution, conversational, and

auxiliary macros), the UI and UO signals range from

0 : UI00/UO00 to UI15/UO15

1 : EUI00/EUO00 to EUI15/EUO15

TMCC Macro calls by T codes are

0 : invalid

1 : valid

NPEF In RS–232–C control by conversational macros, the end of file

(EOF) mark (%) is

0 : output

1 : not output

#7 #6 #5 #4 #3 #2 #1 #0Address

8503 VR7 VR6 VR5 VR4 VR3 VR2 VR1 VR0

Parameter input

Data format: bit type

VR0 Macro variable for macro compiler (#100–149)

0 : uses the same as normal custom macro

1 : uses one for macro compiler

VR1 Macro variable for macro compiler (#150–199)

0 : uses the same as normal custom macro

1 : uses one for macro compiler

VR2 Macro variable for macro compiler (#500–549)

0 : uses the same as normal custom macro

1 : uses one for macro compiler

VR3 Macro variable for macro compiler (#550–599)

0 : uses the same as normal custom macro

1: uses one for macro compiler

VR4 Macro variable for macro compiler (#600–699)

0 : uses the same as normal custom macro

1 : uses one for macro compiler

VR5 Macro variable for macro compiler (#700–799)

0 : uses the same as normal custom macro

1 : uses one for macro compiler

VR6 Macro variable for macro compiler (#800–899)

0 : uses the same as normal custom macro

1 : uses one for macro compiler

VR7 Macro variable for macro compiler (#900–999)

0 : uses the same as normal custom macro

1 : uses one for macro compiler

#7 #6 #5 #4 #3 #2 #1 #0Address

8507 PMC–NB STDM ECAN

Parameter input

Data type: Bit type

ECAN While data receiving (G335) or data sending (G336) is in the

wait state under conversational macro RS–232–C control,

pressing the CANCEL key on the MDI/CRT panel:

28

Page 32

B–62073E–2/03

2.MACRO COMPILER

0 : Does not suspend data sending or receiving.

1 : Cancels the wait state for data sending or receiving.

STDM On the conversational macro screen, status display (mode and

status display) is:

0 : Not masked.

1 : Masked.

PMC-NB If the system features PMC–NB, writing or reading of

two–byte or four–byte data by G310 is done in the:

0 : PMC–NA format.

Two–byte data :

The high–order byte is assigned A. The low–order byte is

assigned A + 1.

Four–byte data :

The bytes are read or written in a sequence such that the

high–order byte is assigned the lowest address A, while the

low–order byte is assigned the highest address A + 3.

1 : PMC–NB format.

Two–byte data :

The low–order byte is assigned A. The high–order byte is

assigned A + 1.

Four–byte data :

The bytes are read or written in a sequence such that the

low–order byte is assigned the lowest address A, while the

high–order address is assigned the highest address A + 3.

2 bytes 4 bytes

A

A+1

#7 #6 #5 #4 #3 #2 #1 #0Address

8508 EXT1 CUTL BCAL ONMK SCAL TCAL ACL2 ACL1

A

A+1

A+2

A+3

Parameter input

Data format: bit type

ACL1 Sub program call by designated code (O9004/#146)

0 : disabled

1 : enabled

ACL2 Sub program call by designated code (O9005/#147)

0 : disabled

1 : enabled

TCAL Sub program call by T code (O9000/#149)

0 : disabled

1 : enabled

SCAL Sub program call by S code (O9029/#147)

0 : disabled

1 : enabled

ONMK O,N number display in conversational macro screen

29

Page 33

2. MACRO COMPILER

B–62073E–2/03

0 : performs

1 : does not perform

BCAL Sub program call by B code (O9028/#146)

0 : disabled

1 : enabled

CUTL Cutting distance

0 : does not integrate

1 : integrates

EXT1 Reference/writing of CNC program, reading/ preset of cutting

distance function, and circuit control function

0 : does not perform

1 : performs

#7 #6 #5 #4 #3 #2 #1 #0Address

8509 PGMP PTCR MODC EVF2 EVF1

Parameter input

Data format: bit type

EVF Expanded conversational macro exclusive variable (#40000–) is

0: floating decimal point format

1: fixed decimal point format

EVF2 Format of conversational macro special variables (#30000 to

#39999)

0: Floating–point

1: Fixed–point

MODC Macro modal call

0: Call after move (corresponding to G66)

1: Block–by–block call (corresponding to G66.1)

PTCR CR code output after LF at the time of macro variable data

output

0: Outputs no CR code.

1: Outputs a CR code twice.

PGMP

Calling a P–CODE by using an M code, S code, T code, B code, M

codes specifying a range, or a specific code during a P–CODE call by

a G code, and calling a G code during a P–CODE call by using an M

code, S code, T code, B code, M codes specifying a range, or a

specific code are:

0 : permitted

1 : not permitted (codes are executed in the normal way)

Address

8510 Sub program M–CODE for calling 09001

8511 Sub program M–CODE for calling 09002

8512 Sub program M–CODE for calling 09003

Parameter input

Data format : word type

Data range : 0 to 9999

Specifies M–CODE to perform sub program call by M–CODE.

30

Page 34

B–62073E–2/03

Address

8513 Custom macro G–CODE for calling O9010

8514 Custom macro G–CODE for calling O9011

8522 Custom macro G–CODE for calling O9019

2.MACRO COMPILER

Parameter input

Data format : word type

Data range : 1 to 255 (except for 65 to 67)

Specifies G–CODE to perform macro call by G–CODE.

Address

8523 Custom macro M code to call O9020

8524 Custom macro M code to call O9021

8532 Custom macro M code to call O9029

Parameter input

Data format : word type

Data range : 0 to 9999

Specifies M–CODE to perform macro call by M code.

Address

8533 M code for calling a user program

Parameter input

Data type : Word

Valid data range : 0 to 99

Note) M00, M01, M02, M30, M98, and M99 cannot be used to call a user

program.

A P–CODE program (execution macro program) called by a user program

can call another user program as a subprogram, according to the specified

M code.

Address

8536

Value of conversational macro execution control variable 1 when turning on power

Parameter input

Data format : word type

Data range : 0 to 9999

Sets the program number of the first conversational macro to be executed

after power–on. This value is set in conversational macro execution

control variable 1 (#8500).

Address

8537

Value of conversational macro execution control variable 2 when turning on power

Parameter input

Data format : word type

Data range : 0 to 9999

31

Page 35

2. MACRO COMPILER

B–62073E–2/03

Sets the program number of the auxiliary macro to be executed at

power–on. This value is set in conversational macro execution control

variable 2 (#8600).

Address

8538 Calls by range specified M–CODE, lower limit M–CODE

8539 Calls by range specified M–CODE, upper limit M–CODE

Parameter input

Data format : word type

Data range : 0 to 9999

Specifies the upper limit/lower limit value of the M–CODE for sub

program call by range specified M–CODE.

Note) The special M–CODES M00, M01, M02, M30, M99 cannot be

used even when inside the range.

Address

8540 Timeout period (seconds) for data receiving (G335) or data sending (G336)

under conversational macro RS–232C control

Parameter input

Data type : Word

Units of data : Seconds

Valid data range : 0 to 180

Note) If zero is set, no timeout occurs in either data sending or receiving.

Address

8541 Conversational macro debug start key

Parameter input

Data format : byte type

Data range : 1 to 21

After the single block stop of the conversational body macro, when in

conversational macro debug mode, set the key code for restarting. Refer

to (Note) for the correspondence between the key code to be set and the

key.

Address

8542 Conversational macro debug single block switching key

Parameter input

Data format : byte type

Data range : 1 to 21

Set the key code for switching ON/OFF the single block of the

conversational body macro when in conversational macro debug mode.

Refer to (Note) for the correspondence between the key code to be set and

the key.

Address

8543 Conversational macro debug trigger point setting key

Parameter input

Data format : byte type

Data range : 1 to 21

32

Page 36

B–62073E–2/03

2.MACRO COMPILER

Set the key code for executing the conversational body macro up to trigger

point when in conversational macro debug mode. Refer to (Note) for the

correspondence between the key note to be set and the key.

Note) Setting the MDI/CRT key for the conversational macro debug

function is as follows.

PAGE ± : 1 SOFT FUNCTION KEY 3:14

PAGE ° : 2 SOFT FUNCTION KEY 4:15

CURSOR LEFT : 5 SOFT FUNCTION KEY 5:16

CURSOR RIGHT : 6 SOFT FUNCTION KEY 6:17

INPUT : 8 SOFT FUNCTION KEY 7:18

SOFT FUNCTION KEY RIGHT : 11 SOFT FUNCTION KEY 8:19

SOFT FUNCTION KEY 1 : 12 SOFT FUNCTION KEY 9:20

SOFT FUNCTION KEY 2 : 13 SOFT FUNCTION KEY 10:21

SOFT FUNCTION KEY LEFT, POS, OFSET, and other keys used to

directly select a screen have specific functions. The functions of these

keys cannot be changed.

POS, OFSET, etc: Clears the current screen and displays the

corresponding NC screen.

SFT KEY LEFT: Terminates the conversational macro.

The 14” CRT can be set as SOFT FUNCTION KEY 1–SOFT

FUNCTION KEY 10,

and the 9” CRT can be set as SOFT FUNCTION KEY 1–SOFT

FUNCTION KEY 5. Further, set without giving importance to the key

setting.

Address

8544 Address to call O9004 (argument #146)

Parameter input

Data format : byte type

Data range : “A” to “Z” (character code)

Calls O9004 by the set address when parameter No. 8508 ALC1 is 1. The

command value of that address is stored as an argument in #146.

Address

8545 Address to call O9005 (argument #147)

Parameter input

Data format : byte type

Data range : “A” to “Z” (character code)

Calls O9005 by the set address when parameter No. 8508 ALC2 is 1. The

command value of that address is stored as an argument in #147.

Address

8546 Quantity

Parameter input

Data type : Byte

Valid data range : 0 to 40

Sets the number of G codes to be added for calling P–CODE macros.

33

Page 37

2. MACRO COMPILER

Address

8547 Conversational macro Trigger program number

B–62073E–2/03

Parameter input

Data format : long type

Data range : 0 to 9999

Set the trigger program number of the conversational macro when in

conversational macro debugging mode.

Address

8548 Conversational macro Trigger sequence number

Parameter input

Data format : long type

Data range : 0 to 99999

Set the trigger sequence number of the conversational macro when in

conversational macro debugging mode.

Address

8549 A number of conversational macro exclusive variables (#30000–)

Parameter input

Data format : word type

Data range : 0 to

The upper limit of the conversational macro exclusive variables is

0 : 30000+ (value of parameter No. 8549) 40–1

1 : 30000+ (value of parameter No. 8549) 100–1

Address

8550 A number of conversational macro exclusive variables (#40000–)

Parameter input

Data format : word type

Data range : 0 to

The upper limit of the conversational macro exclusive variables is

40000+ (value of parameter No. 8550)10–1

when parameter No. 8509 EVF is 0, and

40000+ (value of parameter No. 8550)30–1

when parameter No. 8509 EVF is 1.

Address

8551 First G–code number among the G codes to be called

Parameter input

Data type : Word

Valid data range : 0 to 9999

Sets the first G–code number among the G codes to be used to add G codes

for calling P–CODE macros.

34

Page 38

B–62073E–2/03

Address

8552 First program number among the programs to be called

2.MACRO COMPILER

Parameter input

Data range : Word

Valid data range : 0 and 9000 to 9999

Sets the first program number among the programs to be called by the G

codes added for calling P–CODE macros.

35

Page 39

2. MACRO COMPILER

Ô

B–62073E–2/03

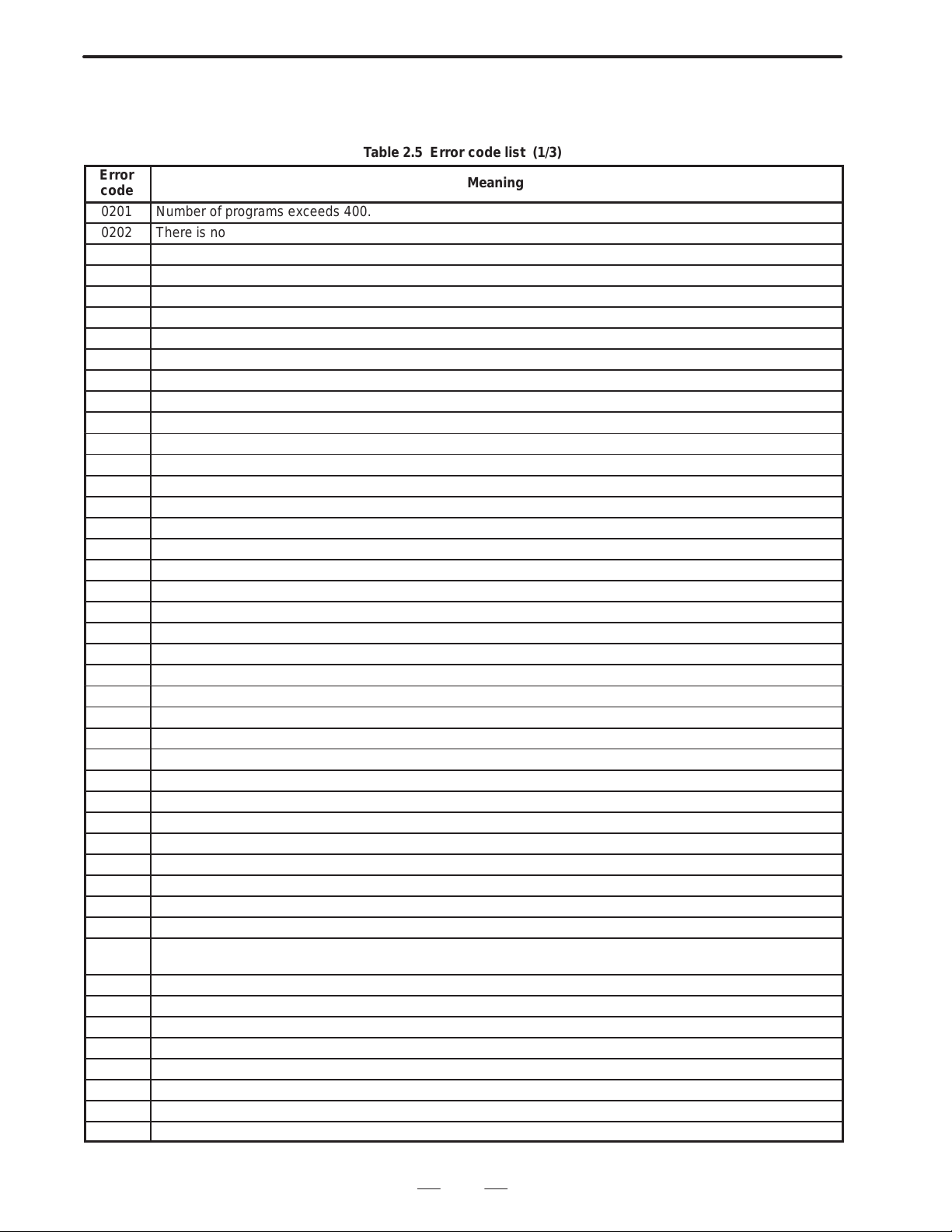

2.5

ERROR CODE LIST

ФФФФФФФФФФФФФФФФФФФФФФФФФФФФФФФ

Error

code

The meanings of error codes which should occur in compilation are given

below.

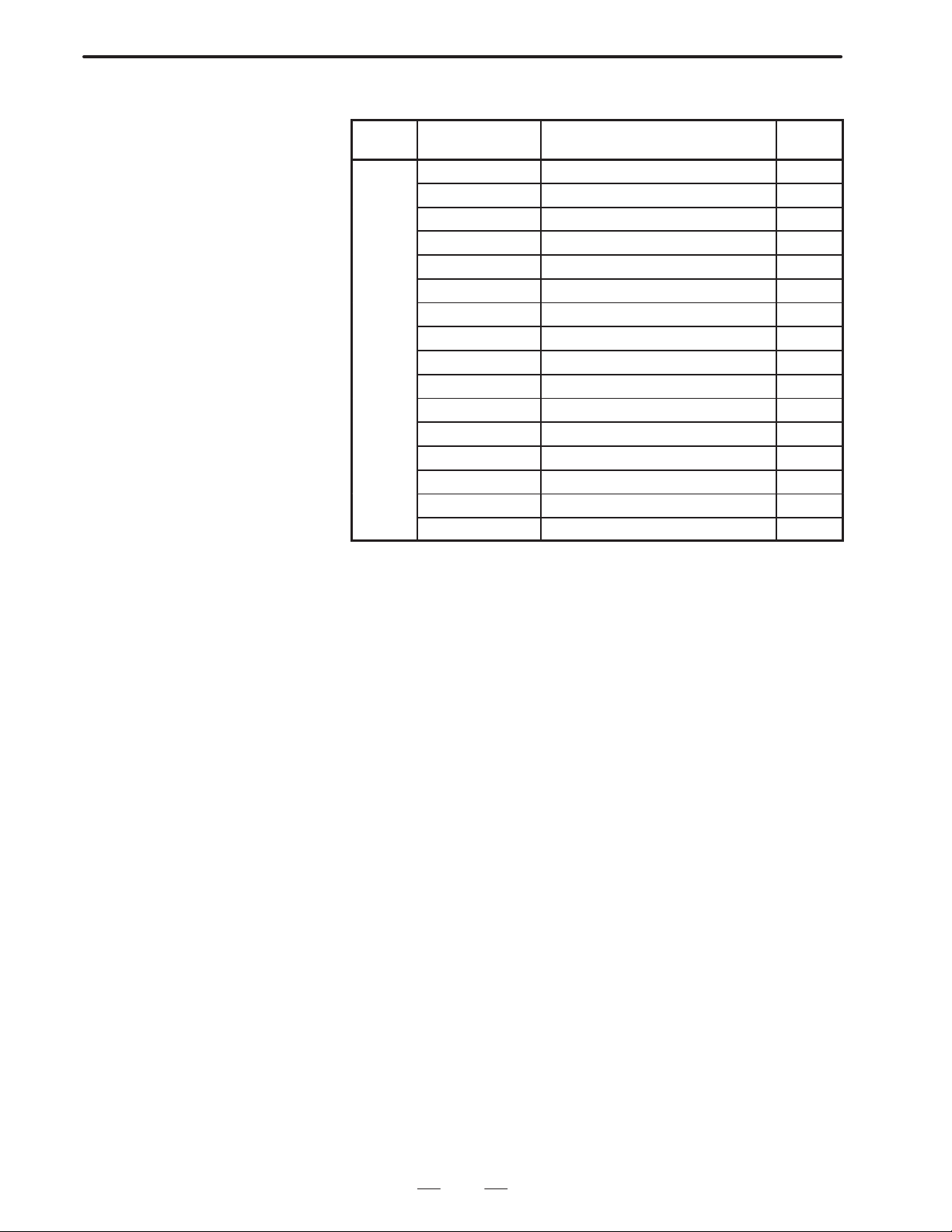

T able 2.5 Error code list (1/3)

Meaning

0201 Number of programs exceeds 400.

0202 There is not program.

1001 Block delete No. is provided with decimal point.

1002 Block delete No. is other than 1–9.

1003 The program No. is placed but not at the program head.

1004 The sequence No. is placed but not at the block head.

1005 There is an error in the NC statement format.

1006 Code other than EOB is placed at the end of the macro statement.

1007 The equal sign of macro statement is missing.

1008 The multiplexity of DO exceeds 3.

1009 The relational operator in the conditional expression is missing.

100A GOTO is missing after IF.

100B ’]’ of IF [<conditional expression>] is missing.

100A GOTO is missing after IF.

100B ’]’ of IF [<conditional expression>] is missing.

100C There is code other than EOB after GOTO n.

100D There is code other than EOB after DO m.

100E There is code other than EOB after END m.

100F The identification No. of END does not correspond to DO.

1010 There is no END corresponding to DO.

1011 DO after WHILE is missing.

1012 ’]’ of WHILE [<Conditional expression>] is missing.

1013 There is a block which is judged neither as an NC statement nor as a macro sentence.

1014 There is no DO corresponding to END.

1015 The directory program No. does not correspond to the program No. in the program.

1016 Program No. is missing at the head of program.

1201 The multiplexity of parentheses exceeds 5.

1202 ’]’ of #[expression>] is missing

1203 ’]’ of [<expression>] is missing.

1204 The second ’[’ of ATAN [<Expression>]/[<Expression>] is missing.

1205 ’/’ of ATAN [<Expression>]/[<Expression>] is missing.

1206 The first ’]’ of ATAN [<Expression>] is missing.

1207 ’]’ of the function [<Expression>] is missing.

1208 There is an error in the format of <Expression>.

1209 There is an error in the format of the <Expression> to the left of the substitution statement.

120A There is an error in the format of the <Expression> in <Address> [<Expression>], or <Address>–[<Expres-

sion>], or GOTO [<expression>].

1401 The numeric word exceeds 8 digits.

1402 There is code other than a numeric code after decimal point.

1403 The variable No. of the macro variable exceeds 6 digits.

1404 Something found after # is neither a numeric code nor ’[’.

1405 The pro ram No. exceeds 4 digits.

1406 The sequence No. exceeds 4 digits.

1407 ’[’ of the function IF [<Expression>] is missing.

1408 ’[’ of IF [<Conditional expression>] or WHILE (<Conditional expression>] is missing.

36

Page 40

B–62073E–2/03

Error

code

1409 m of ”DO m” or ”END m” exceeds 1 digit.

140A m of ”DO m” or ”END m” is another than 1–3.

140B A code other than a numeric code is found behind DO or END.

140C There is an alphabetic spelling other than a control command and a function.

140D There is an alphabetic spelling of more than 5 characters.

140E EOR is missing at the program end.

140F There is a code which is not used in the program.

1410 The length of the character string exceeds 255.

1411 The internal code exceeds 4 digits.

1412 The internal code is not of a hexadecimal expression.

1413 A non–displayable internal code is commanded.

1414 The command of the character string starting with ’(*’ is not terminated ith ’*)’.

1415 There is an unallowable character between ’(’ and ’)’.

1601 The area of temporary variable used by the executor is insufficient. There are too many addresses including

<Expression> in 1 block NC sentence.

1602 The destination of GOTO is too far. Reduce the program size.

1603 The number of addresses in 1 block NC statement exceeds 50.

1604 The macro variable No. exceeds 6 digits.

1605 The macro variable No. is negative.

1606 There is a decimal point in the macro variable No.

1607 The numeric code after GOTO exceeds 4 digits.

1608 There is a decimal point in the numeric code after GOTO.

1681 GOTO sentences directly designating the sequence No. exceed 100 in one program.

1682 The sequence No. to which jump is commanded by GOTO is missing.

1683 WHILE statement exceed 100 in number in one program.

1684 There are several sequence Nos. to which a jump is commanded by GOTO.

1801 The ROM cassette overflows.

2001 Time has run out for receiving from the PMC writer.

2002 A parity error occurred during receiving from the PMC writer.

2003 An overrun error occurred during receiving from the PMC writer.

2004 A framing error occurred during receiving from the PMC writer.

2005 The PMC writer is not ready. Or the reader/puncher interface cable is not connected.

2006 An error occurred at a transfer to the PMC writer.

2007 A parity error occurred at a transfer to the PMC writer.

2008 The ROM is not erased.

2009 A ROM writing error occurred.

200A A ROM verify error occurred.

200B The ROM cassette is not set.

200C Another ROM cassette than order–made macro is set.

200D The PMC writer edition is wrong.

200E An error occurred in the PMC writer.

200F RESET key is depressed during processing.

2010 An odd number is designated as address or the length for the PMC writer.

2011 Writing was tried exceeding the capacity of ROM cassette connected.

2012 The baud rate is inadequately set.

3000 Normal termination

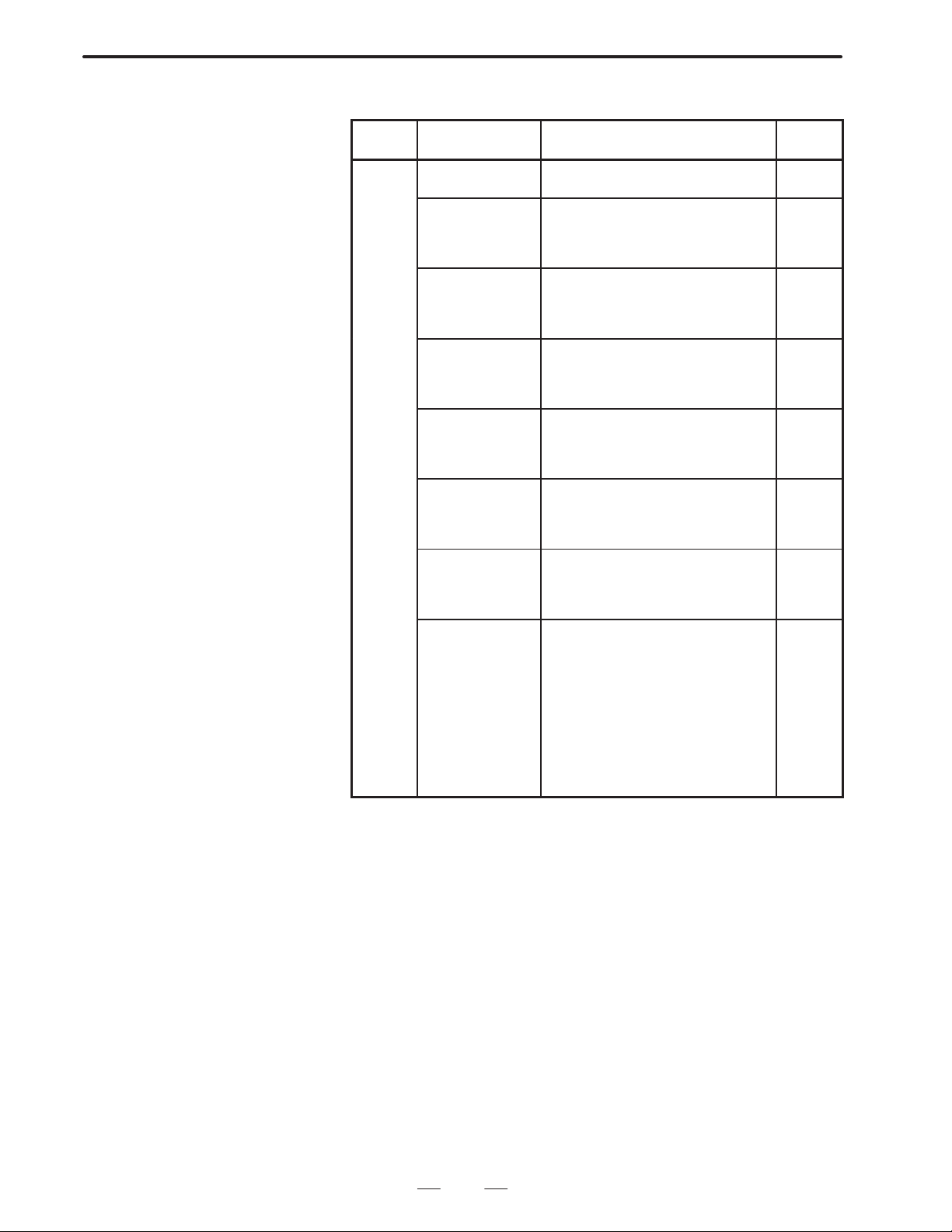

T able 2.5 Error code list (2/3)

Meaning

2.MACRO COMPILER

37

Page 41

2. MACRO COMPILER

T able 2.5 Error code list (3/3)

Error

code

3001 There is no receive data.

PC–writer is busy.

3002 Number of characters in transmitted data does not match.

3003 Parity error occurred during transmission.

3004 ROM is not erased.

3005 ROM program error occurred.

3006 Verification error with ROM occurred.

3007 Error other than those indicated above occurred with PC–writer.

3008 Power to PC–writer is turned off.

RS–232–C cable is not connected.

Cable is not connected to logical channel specified in parameter.

3009 Carry signal was driven low during data transmission.

300A Overrun error occurred.

300B Framing error occurred.

300C Ten or more characters were entered after termination request.

300D Invalid instruction was issued to ACI–IOS.

300E Reset key was pressed.

300F RS–232–C interface is already opened.

3010 Baud rate other than 4800 bps is set.

3011 P.C.B is not set.

3012 Another ROM cassette is set.

ROM cassette is not set.

3013 Odd–numbered address or size is set.

3014 Size larger than ROM size was specified.

3015 Parameter is not set correctly.

4000 Normal termination.

40FB A file type that cannot be output to F–ROM is specified.

40FE An invalid command was input for F–ROM.

40FF The reset key was pressed (canceled).

4101 The file cannot be written to F–ROM.

4102 The file cannot be read from F–ROM.

4103 The file cannot be deleted from F–ROM.

4104 An attempt was made to read a file from a position which is beyond the file size.

4105 No file is resident in F–ROM.

4106 An attempt was made to write a file having a size which exceeds the specified size.

4107 A verification error occurred.

4108 The ROM number range was exceeded.

4109 A file size of 512K bytes is specified when the option is not used.

Meaning

B–62073E–2/03

38

Page 42

B–62073E–2/03

3

EXECUTION MACRO

3. EXECUTION MACRO

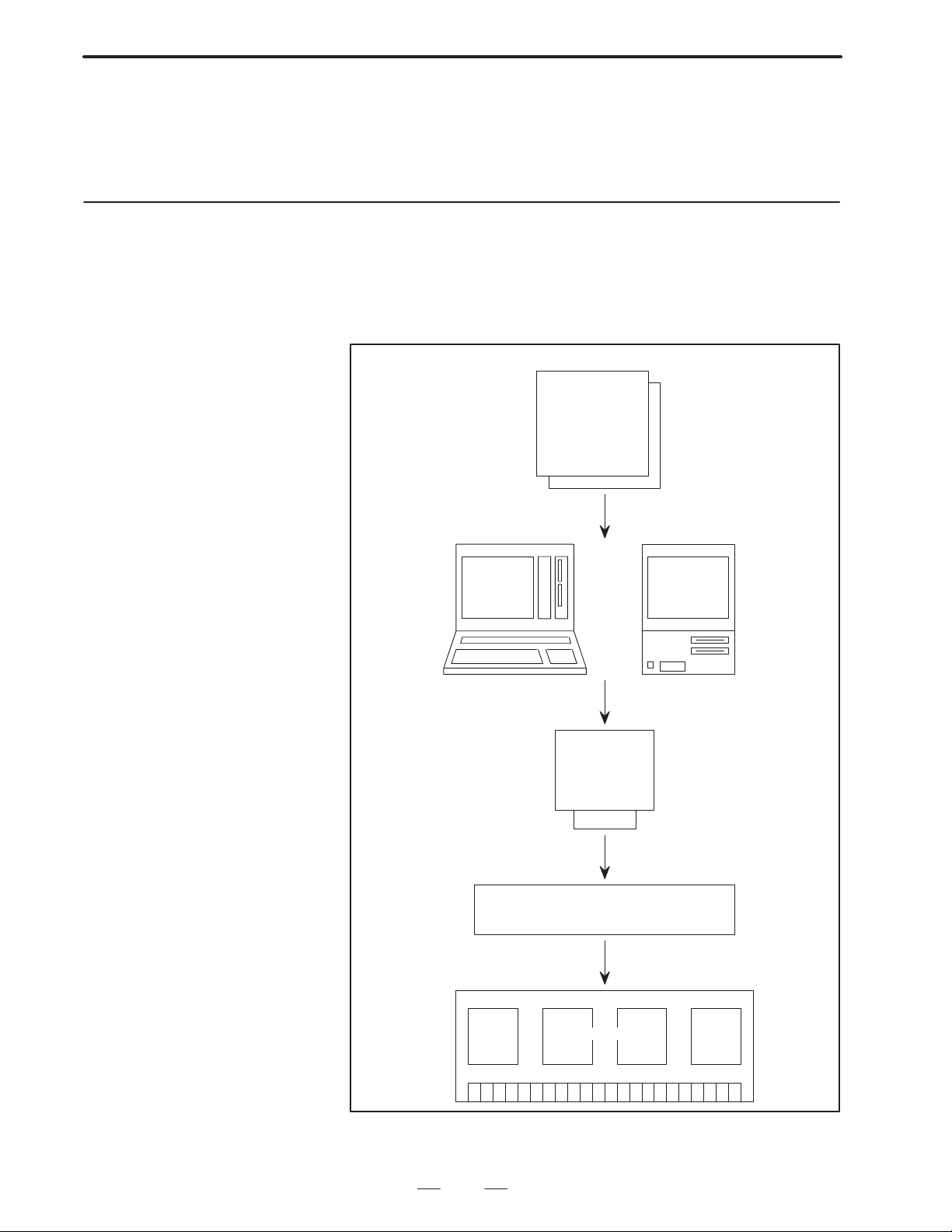

3.1

INTERFACE WITH

USER PROGRAM

AND EXECUTION

MACRO IN P–CODE

PROGRAM

Only a registered P–CODE program cannot be executed. It is called from

the user program by G, M, T code, or specified code by parameter setting,

and executed. In case of macro call, argument designation is possible, and

it is compared as a local variable at the P–CODE (execution macro) side.

Further, for the specification method for the argument, in the same manner

as the normal NC macro, there are possible 2 types of specification

methods, argument specification I, argument specification II, or a

mixture of argument specification I and II. Regarding argument

specification I and argument specification II, refer to FANUC Series

OPERATOR’S MANUAL (macro call command). Moreover , if a minus

value is set at parameter as for macro call by G code, modal call of

P–CODE program can be done by corresponding G code.

User program

(Program edit memory)

O0001 ;

G92X0Y0 ;

G00X100. Y100. ;

G101

<Argument>

G–CODE call

M–CODE call

T–CODE call

S–CODE call

B–CODE call

P–CODE program inside

macro ROM cassette

(execution macro)

O9010 ;

#100=#100+10 ;

M99 ;

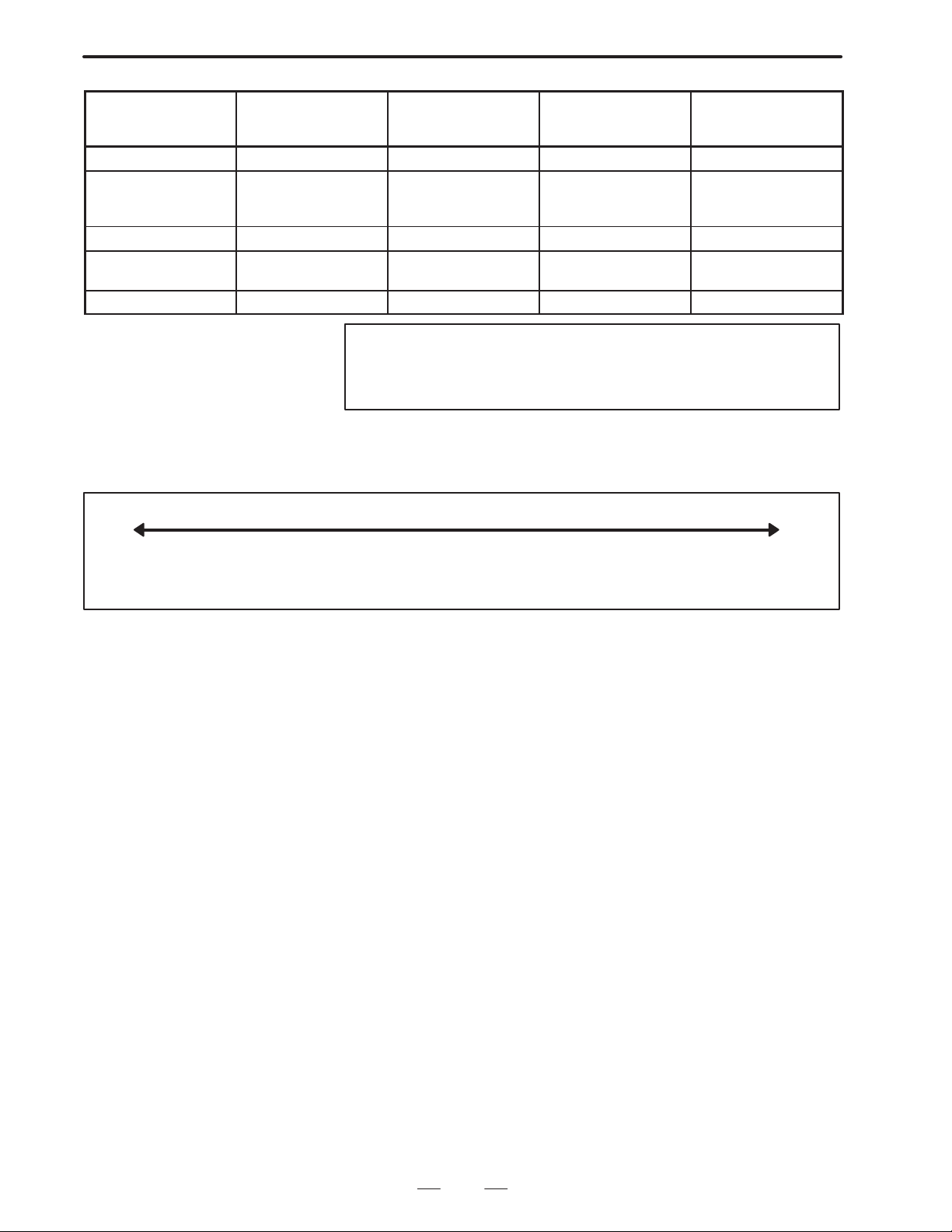

3.1.1

Call Code and Program

No.

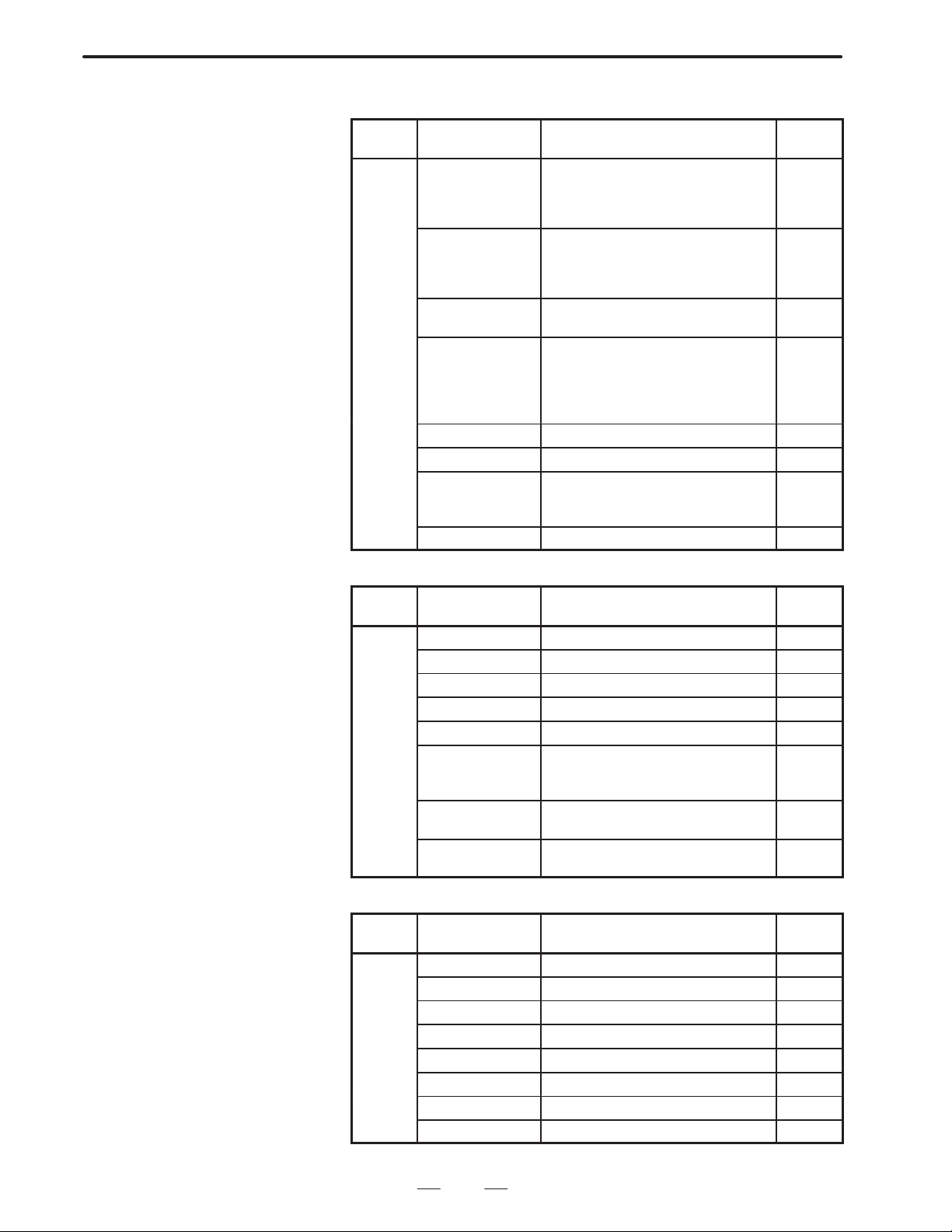

Call code Call mode

T Subprogram call 9000 #149 TCAL (No. 8508#2)

M Subprogram call 9001–9003 Unused No. 8510–8512

S Subprogram call 9029 #147 SCAL (No. 8508#3)

(Second miscella-

B

neous function code)

G Macro call Continuous

Subprogram call 9028 #146 BCAL (No. 8508#5)

call

M02 ;

Parameter

8513 101

To call a P–CODE program from the user program, call with G, M, or T

code as indicated above.)

Called program

number

9010–9019 Unused No. 8513–8522

Variable number in

which the specified

code is stored

Parameter to be spe-

cified

No. 1030

MODC (No. 8509#2)

39

Page 43

3. EXECUTION MACRO

B–62073E–2/03

Call code

M Macro call 9020–9029 Unused No. 8523–8532

Special Subprogram call 9004, 9005 #146, #147 ACL1, ACL2 (No.

Range–designation M Subprogram call 9009 #148 No. 8538, 8539

Range–designation G Macro call Specified in the

T Macro call 9008 #27 TMCC (No. 8502#6)

Call mode

Called program

number

parameter

Variable number in

which the specified

code is stored

Unused No.8546

Parameter to be spe-

cified

8508#0, #1) No. 8544,

8545

No. 8551, 8552

Note

If the system features a SUB–CPU, only programs 9000 to

9999 can be stored and executed as execution macros.

The priorities of calling custom macros by G, M, S, T , and B, and calling

macro executors by G, M, S, T, and B are as follows:

High LowPriority

Calling custom

macros by G, M, S,

T, and B

Calling macro

executors by G, M,

>>>

S, T, and B

Calling macro

executors by special

codes

Calling macro

executors by

M–code with range

specified

Call of each macro, comparison of subprogram call code and program

number to be called is determined by a compile parameter.

(1) The return sequence number definition for returning to the user’s

program

When operational control is returned to the user’s program from

the P–CODE program, control passes to the sequence number of the

user’s program defined by address P.

(2) Macro modal call is enabled by setting a negative value in the

G–CODE parameters (Nos. 8513 to 8522) for macro call. For

example, –11 set in a parameter represents G1 1 for a modal call state.

Whether the modal call state corresponds to G66 or G66.1 depends

on parameter No. 8509, MODC.

The macro modal call function can be used to call a P–CODE program

from a CNC program. The function cannot be used to call a P–CODE

program from a P–CODE program.

G67 is used for modal call cancellation.

For the detailed specifications, refer to the description of macro call

using G–CODEs in the FANUC Series 15 operator’s manual.

Example

When parameter No. 8513=–100, and parameter No. 8509 MODC=0

CNC program

G91 G01 F100. ;

40

Page 44

B–62073E–2/03

G100 ; Modal call state ON

X10.; Calls O9010 after move.

X10.; Calls O9010 after move.

G90; Does not call O9010.

Y20.; Calls O9010 after move.

G67; Modal call state OFF

P–CODE program

09010;

Z5.;

Z–5.;

M99;