Page 1

Gibbs and Associates

323 Science Drive

Moorpark, CA 93021

(805) 523-0004

March 1999

GEOMETRY CREATION

USER MANUAL

Page 2

PROPRIETARY NOTICE

This document contains propriety information of Gibbs and Associates and is to be used only

pursuant to and in conjunction with the license granted to you with respect to the accompanying Gibbs

and Associates licensed software. Except as expressly permitted in the license, no part of this document

may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language

or computer language, in any form or by any means, electronic, magnetic, optical, chemical, manual or

otherwise, without the prior written permission from a duly authorized representative of Gibbs and

Associates.

It is strongly advised that you carefully review the license in order that you understand your

rights and obligations related to the licensed software and the accompanying user documentation.

Use of the computer software and the user documentation has been provided pursuant to a

Gibbs and Associates license agreement.

© Copyright 1996 Gibbs and Associates, Inc.

All Rights Reserved

Acknowledgements:

Written by Shannon McConville.

Thanks to Tim Alvord, Sean Canterbury, Gary Esser, Bill Gibbs, Charles Haden, Tom Hubina, Pete

Jackson, Kristin Kelley, Michael Kelley, Israel Klain, James Moore, Jeff Myers and Robb Weinstein for

their input and assistance.

Trademarks:

Windows NT, Windows 95 and Windows 98 are trademarks of Microsoft Corporation

Macintosh is a trademark of Apple Computer, Inc.

Printed in the United States of America

◆

Geometry Creation User Manual GFK-1 7 0 3

Page 3

Table of Contents

CHAPTER 1

:

INTRODUCTION III

How to Learn the System . . . . . . . . . . . . . . . . . . . . . . . . . iii

Balloons and Prompting . . . . . . . . . . . . . . . . . . . . . . . . . iii

Operating Systems Glossary . . . . . . . . . . . . . . . . . . . . . . . . iii

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

CHAPTER 2

:

INTERFACE 1

Cursors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Clipboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CHAPTER 3

:

PART SET-UP 13

Document Control Dialog . . . . . . . . . . . . . . . . . . . . . . . . . 13

CHAPTER 4

:

GEOMETRY CREATION 16

Geometry Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Geometry Creation Palette . . . . . . . . . . . . . . . . . . . . . . . . . 17

Geometry Expert. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Free Form CAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Text Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Curve Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Workgroups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Shapes and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Modify Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

File Import . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

File Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Workgroup Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Printing the Part Geometry . . . . . . . . . . . . . . . . . . . . . . . . . 57

GFK-1703 Table of Contents

◆

i

Page 4

◆

Geometry Creation User Manual GFK-1 7 0 3

ii

CHAPTER 5

:

GEOMETRY EXPERT EXERCISES 58

Exercise #1: Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Exercise #2: Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Exercise #3: Shuttle . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Exercise #4: Lathe Tutorial . . . . . . . . . . . . . . . . . . . . . . . . 106

Exercise #5: Doodle . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Exercise #6: Bell Crank . . . . . . . . . . . . . . . . . . . . . . . . . . 122

CHAPTER 6

:

FREE FORM CAD EXERCISES 135

Exercise #1: Shapes and Connectors . . . . . . . . . . . . . . . . . . . . . 135

Exercise #2: Mill Tutorial . . . . . . . . . . . . . . . . . . . . . . . . . 150

Exercise #3: Lathe Tutorial . . . . . . . . . . . . . . . . . . . . . . . . . 181

Exercise #4: Shuttle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Exercise #5: Text Creation . . . . . . . . . . . . . . . . . . . . . . . . . 232

Exercise #6: Overlapping Features . . . . . . . . . . . . . . . . . . . . . . 237

CHAPTER 7

:

COMBINATION EXERCISES 245

Exercise #1: Loading Shapes ..................................................256

Exercise #2: Mill Tutorial ....................................................257

Exercise #3: Gear Housing ....................................................272

APPENDIX 1

:

OPERATING SYSTEMS 277

Launching the System........................................................277

Operating Systems Glossary ...................................................277

File Compatibility ...........................................................278

Standard Extensions .........................................................278

Post Processor Formats .......................................................279

APPENDIX 2

:

PART PRINTS 280

Part Print #1: Shaft ..........................................................280

Part Print #2: Chassis ........................................................281

Part Print #3: Shuttle.........................................................282

Part Print #4: Lathe Tutorial ...................................................283

Part Print #5: Doodle ........................................................284

Part Print #6: Mill Tutorial ....................................................285

Part Print #7: Gear Housing ...................................................286

Part Print #8: Bell Crank......................................................287

INDEX 288

Page 5

GFK-1703 Introduction

◆

iii

CHAPTER 1

:

Introduction

HOW TO LEARN THE SYSTEM

Congratulations on purchasing the most productive programming system available! It is rec-

ommended that the Geometry Creation Manual be reviewed before moving on to either the Mill or

Lathe Module Manuals. The best way to learn the system is to read the reference information and

complete the geometry exercises. Then complete the tutorials provided in the module specific manuals. For simple explanations of on-screen items and their purpose, use Balloons and Prompting pro-

vided in the Help menu.

BALLOONS AND PROMPTING

Balloons and Prompting are built-in documentation and training information, also known as

CAT (Computer Aided Training). They can be turned on from selections under the Help menu.

Balloons provide reference information about any object that the cursor is placed over. Prompting

extends certain palettes in the system to provide useful suggestions about how to proceed. They are

very useful.

OPERATING SYSTEMS GLOSSARY

The Windows NT®, Windows 95/98® and MacOS® operating systems use different terminology for certain common items. A short list has been provided to help eliminate possible confusion.

Refer to the Operating Systems Appendix for additional information on the differences between the

Windows NT, Windows 95/98 and Macintosh operating systems.

EQUIVALENT TERMS

file = document

program = application

directory = folder

backspace key (not delete or del) = delete key (not del)

Operating system symbol : This symbol appears throughout the manual to indicate when

there are variations in specific system functions depending on the operating system.

O

S

Page 6

◆

Geometry Creation User Manual GFK-1 7 0 3

iv

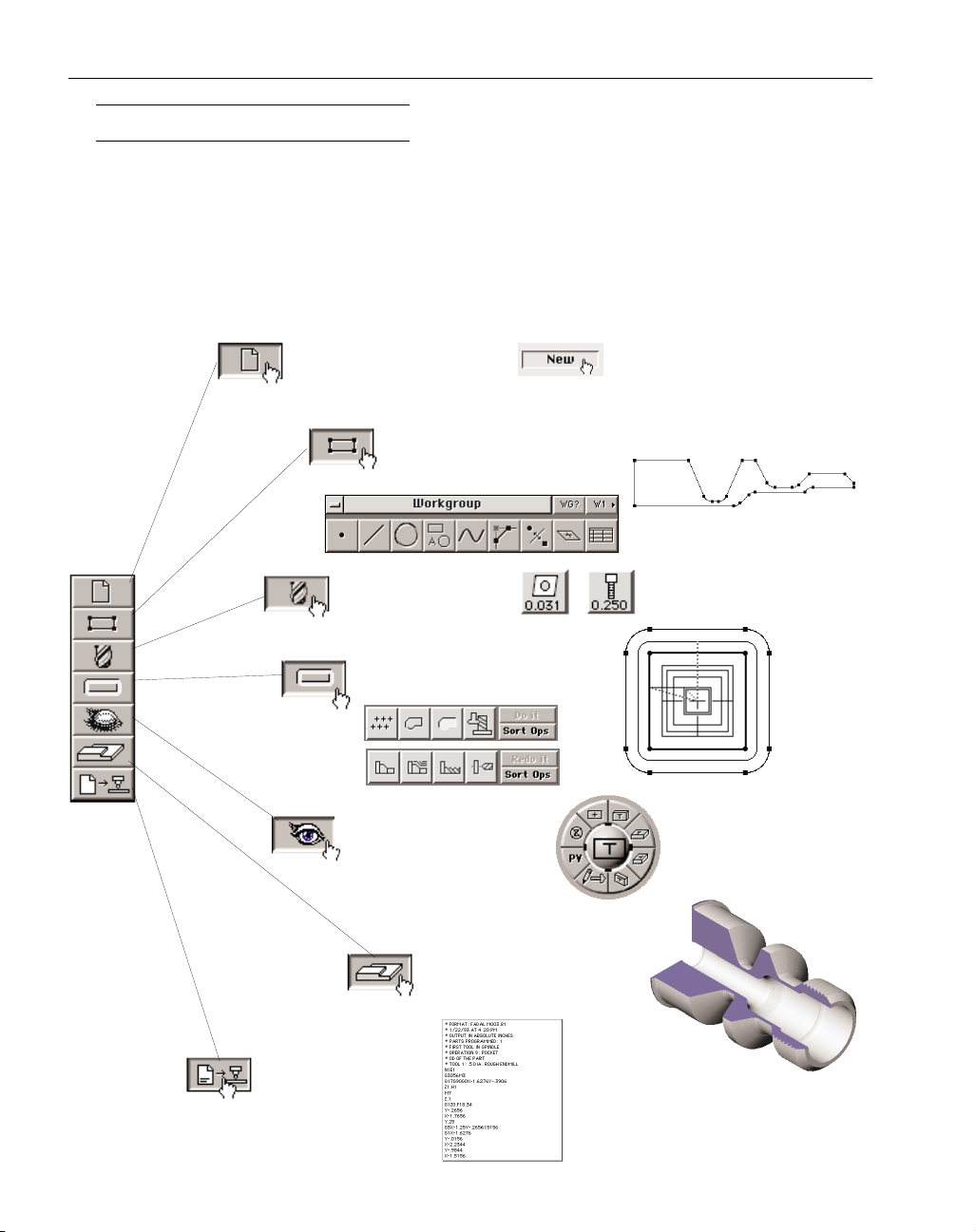

SYSTEM OVERVIEW

This system is designed to be extremely flexible, to allow the user the freedom to create parts

in any way that comes naturally. The "modeless" interface allows the user to have geometry creation, tools, machining capabilities and post processing functions available at all times. However,

there are certain basic elements required to create a part. There must be geometry, a tool, and a

toolpath (an operation) created before post processing. The Top Level palette is organized in a logical manner for building a part. A part does not have to be created in this order, it only serves as a

guideline.

Create a new file.

Create part geometry.

Create a tool.

Create a toolpath.

Cut Part Render

Post Process.

Change the view.

Page 7

GFK-1703 Interface

◆

1

CHAPTER 2

:

Interface

This system uses a Graphic User Interface (GUI). This simply means that pictures or symbols

are used in place of text whenever possible. This section of the manual describes the different interface objects and their uses.

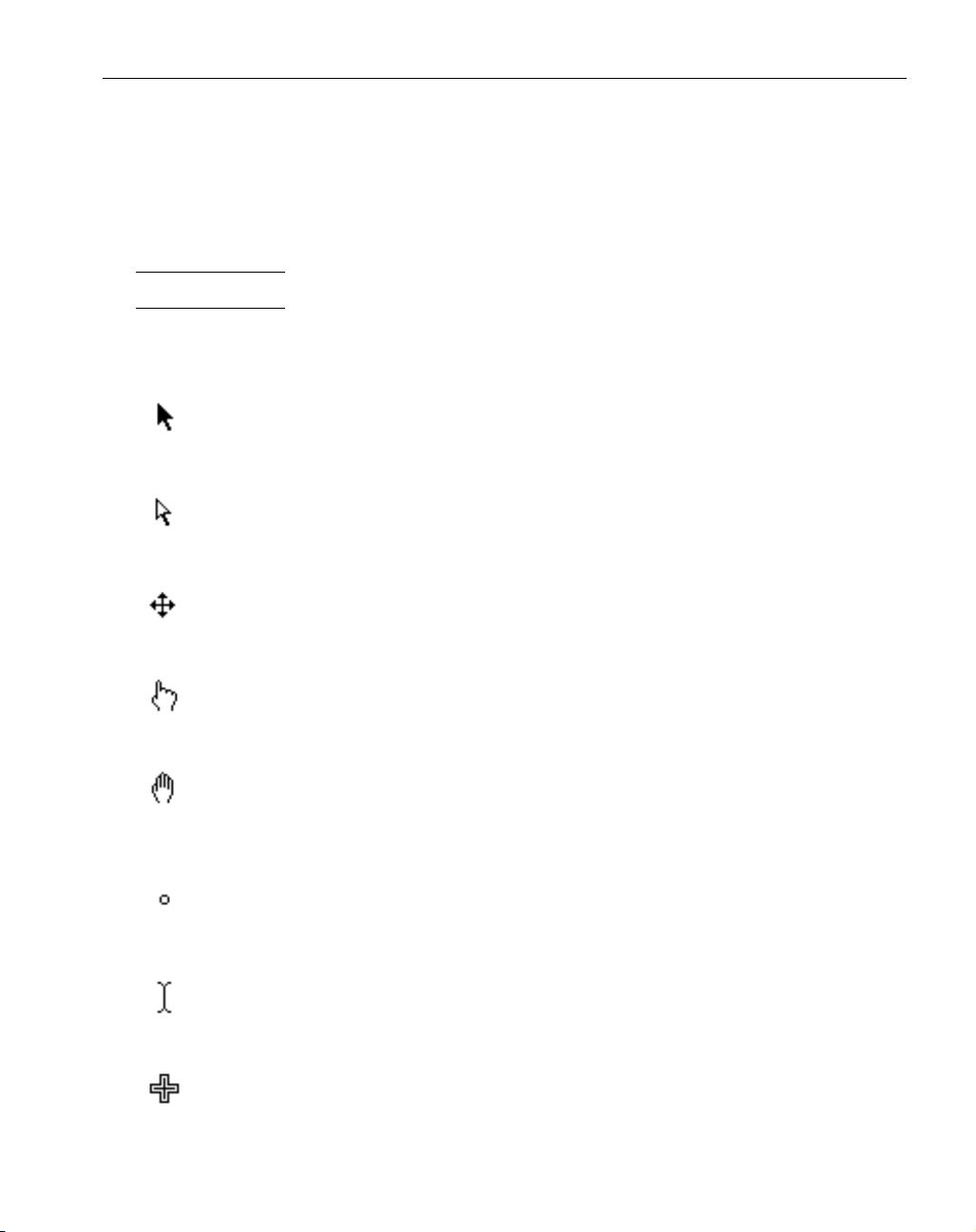

CURSORS

The cursor is the object moved with the mouse. Its appearance changes depending on its location. The appearance of the cursor dictates its usage.

Black Pointer : This cursor is used to select objects and geometry by clicking on them. Zoom

by dragging a rectangle around an area on the screen.

White Pointer : This cursor functions the same as the black pointer, except it is in multiple

selection mode. The white pointer appears when the Shift key is held down or when a geometry sub-palette is open. It allows more than one item to be selected at a time.

Mover Tool : This indicates that the cursor is placed on the edge of a palette or in a dialog’s

title bar. Move the palette or dialog by holding the mouse button down and dragging it to a

different location.

Pointing Finger : This indicates that the cursor is over a button. Push the button by clicking on

it.

Hand : This indicates that the cursor is over a draggable object such as a tile. Move the object

by clicking on it once and dragging it to the desired location. This cursor is also used to roll

the trackball.

Spot : The cursor changes to this while rolling the trackball.

I Beam : This indicates that the cursor is in a location where text input is accepted. It is a

flashing cursor.

Area Select : The cursor changes to this while doing a mouse drag or zooming in on an area.

Page 8

◆

Geometry Creation User Manual GFK-1 7 0 3

2

ACTIONS

There are a number of actions used throughout the system.

• Moving the cursor : The cursor is moved and positioned with the mouse.

• Click : A quick tap on any mouse button.

• Double-click : Two quick taps on the mouse button.

• Type : Using the keyboard.

• Drag : Position cursor, hold mouse button down, reposition cursor, release mouse button.

• Shift-click : Hold shift key down while clicking the mouse.

• Shift-double-click, Ctrl-click, Ctrl-double-click, etc. : Hold down stated key and

click (or double-click).

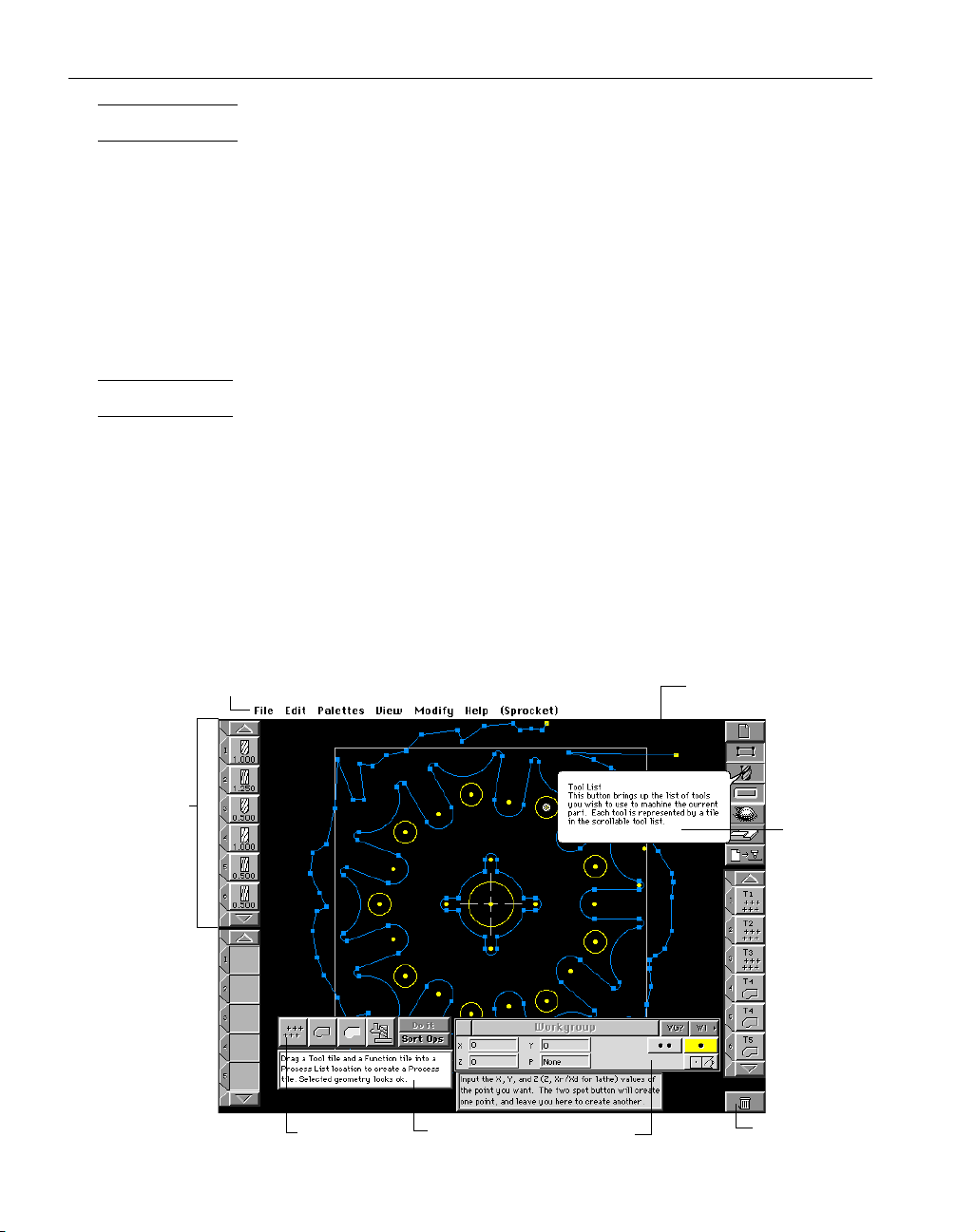

OBJECTS

There are several interface objects used throughout the system. The Tile Lists and Machining

Markers will be described in the machining manuals for the Mill and Lathe modules.

• Drawing Window

• Palettes

• Dialogs

• Tile Lists

• Menus

• Machining Markers

• Balloons/Prompts

• Wastecan

g

Menu Bar

Drawing

Window

Tile List

Balloon

Palette

Prompt

Dialo

Wastecan

Page 9

GFK-1703 Interface

◆

3

DRAWING WINDOW

The drawing window is the full size of the screen. All drawing of geometry, toolpaths, and

rendered images appear in the drawing window. It is not moveable. All other interface objects

appear in front of the drawing window.

PALETTES

A palette is a collection of functions grouped together in a logical manner for the user. Some

palettes are moveable, others are not.

Top Level Palette: This palette is made up of buttons. These buttons can be either “on”

(depressed) or “off” (raised). Clicking once on a button turns it on and accesses the appropriate dialog or palette. Another click will turn the button off and put any dialogs or

palettes away. The top level palette cannot be moved.

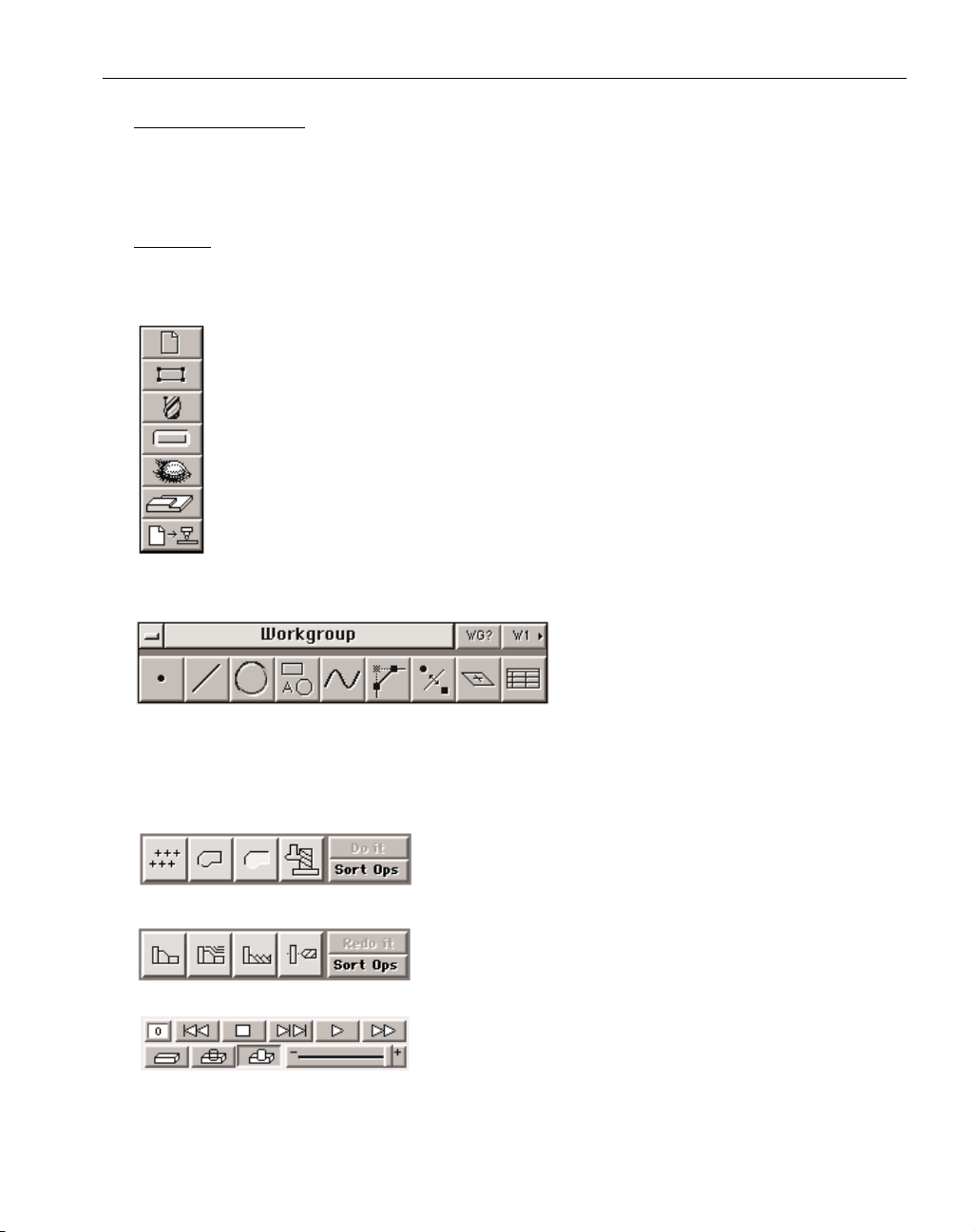

Geometry Creation Palette: This palette is also

made up of a group of buttons. However,

when one of the buttons is clicked on, it does

not stay depressed. Instead, it brings up a

sub-palette or the Geometry Expert

Spreadsheet. The Geometry Creation Palette can be moved to any location on the screen. Move the

palette by placing the cursor in the title bar of the palette. When the cursor changes to the mover

tool, hold the mouse button down and move the palette. This action is called “dragging the edge”.

Mill

Machining Palette: This palette is made up of Function Tiles and

buttons. The four Function Tiles are moveable objects that can

be dragged to the Process List to create operations. The

Lathe Machining Palette can be moved to any location on the screen.

Render palette: This palette provides control over the cut part

rendering process. It allows the user to control rendering

speed, the operations that will be rendered, and the way the

tool will be displayed. This is also a moveable palette.

Page 10

◆

Geometry Creation User Manual GFK-1 7 0 3

4

View Control Palette (Trackball) : The View Control Palette allows the user to easily change the current view of the part. The buttons around the outside provide

standard view changes, redraws and unzooms. The center ball operates like a

trackball and rolls to allow the part to be viewed from any orientation. When

the cursor is placed over the ball, it changes into a hand, which indicates that

the ball can be rolled. Holding the mouse button down and moving the mouse

will roll the trackball. The black outlined box on the ball represents the orien-

tation of the part. The "T" identifies the top surface of the part. The dimensions of the box do not change with the actual part size. Once the desired view is obtained, and the

mouse button is released, the part is redrawn in the new view. The ball has four small solid black

rectangles around it, inside the ring of buttons (located at 12:00, 3:00, 6:00, 9:00). These are called

ball "handles". Drag these handles for a single axis view change. The trackball is a moveable

palette, drag its edge to move it.

DIALOGS

Dialogs are used when information is needed from the user. This information is conveyed

through text boxes, radio buttons, yes/no buttons, and pop-up menus.

Text boxes: Items that require keyboard input

have a box next to them. If you click once in

a text box, a flashing text cursor will appear

where you clicked. Any typed input will

begin at the flashing text cursor. To move

the text cursor, simply click the desired location. Double clicking in a text box will select (highlight) everything in the text box. Anything

typed at this point will completely replace the current contents of the box. To select only portions of

the contents of the text box, click before or after the text to be edited, hold the mouse button down

and drag.

Moving from one text box to another can be accomplished by clicking or double clicking in

the desired box, or hitting the Tab key. Hitting the Tab key moves the cursor from box to box, and

highlights the entire contents of each box.

The contents of all text boxes can be cut, copied and pasted to and from the Clipboard by

choosing items from the Edit Menu.

Math Input in a Text box: All number input boxes will accept the four standard math function symbols

(+ - x / ), as well as a number of special functions, (both * and x are used for multiplication).

Hitting the equal key or tab key on the keyboard will display the final value. Special math functions

include:

r = squareroot

s= sine

c= cosine

t= tangent

a= arctangent

m= convert from inch to millimeter (x 25.4)

i= convert from millimeter to inch (/ 25.4)

Text Box

Page 11

GFK-1703 Interface

◆

5

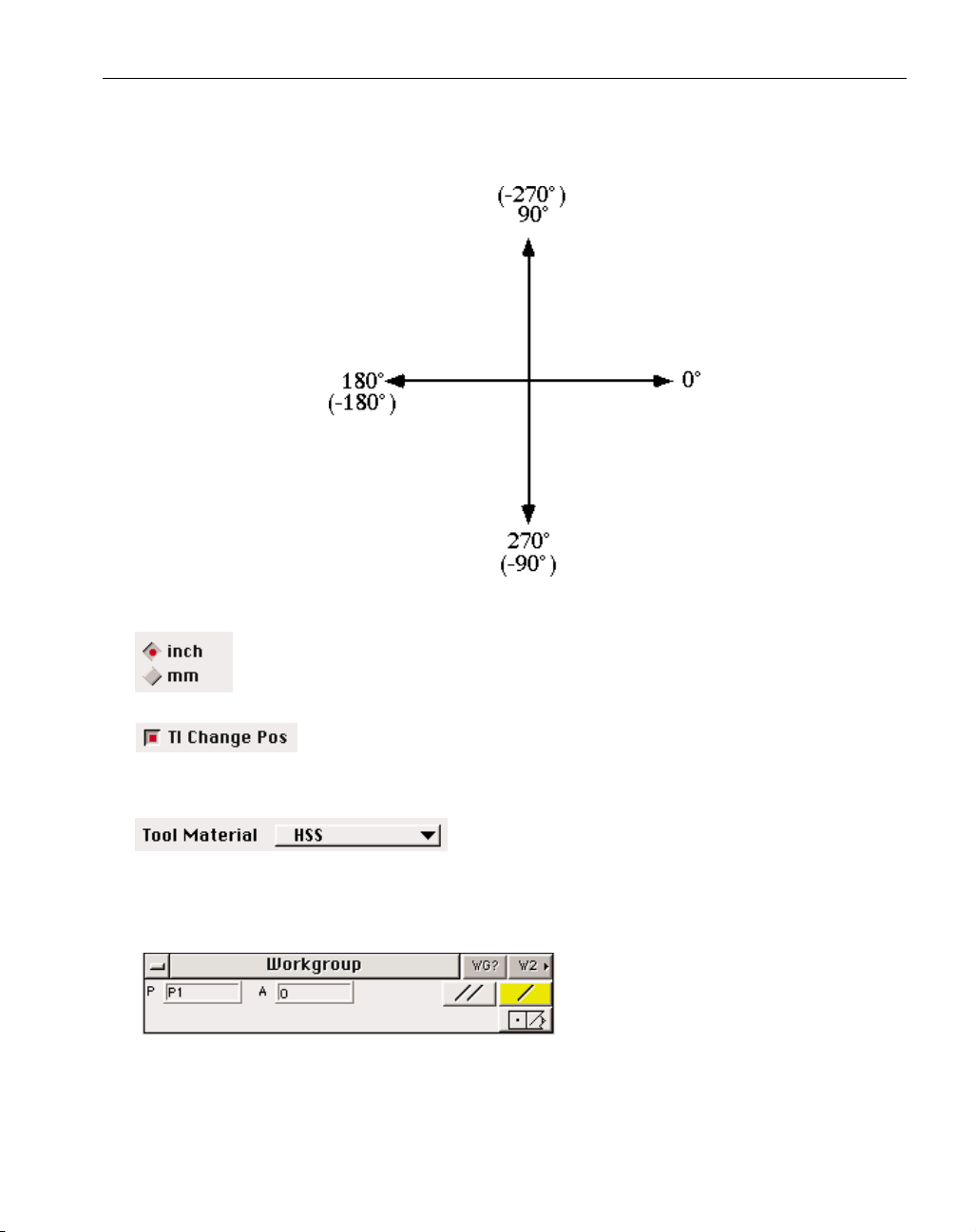

Angle values follow the standard Cartesian coordinate system, as shown below. Negative val-

ues are acceptable as input.

Radio buttons: Radio buttons come in groups. When one of the buttons in the group

is depressed (turned "on"), the other buttons in the group are "off." The button that

is depressed displays a small red dot or "light" to indicate that it is "on".

Yes/No buttons:Yes/No buttons come one per option. Depress the button for

yes, pop it up for no. The button that is depressed displays a small red dot or

"light" to indicate that it is "on".

Pop-Up menus : Pop-up menus provide multiple choices. A

pop-up menu looks like a button, but has an arrow indicating that there are more choices available. The menu is accessed by depressing it and dragging the

cursor down to scroll through the list. When the desired item is highlighted, release the mouse button to select it.

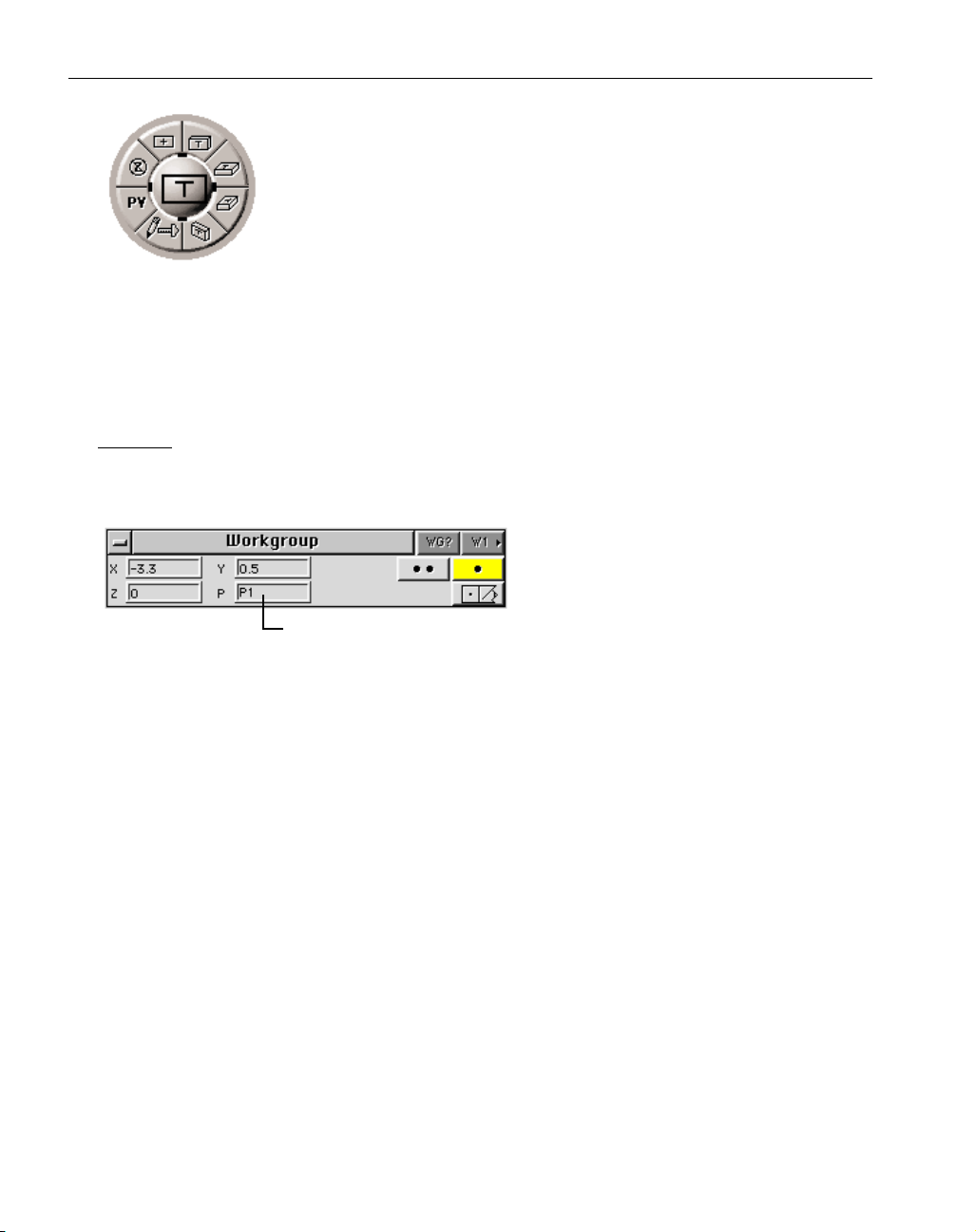

Geometry Dialog : Geometry Dialogs are

used for input of specific geometry information when creating shapes. All Geometry

Dialogs contains buttons that access the

Workgroup Information and Selection

Dialogs.

Page 12

◆

Geometry Creation User Manual GFK-1 7 0 3

6

Moveable dialogs : Some dialogs

may be moved around on the

screen. The area at the top of the

dialog is called the title bar. The

title bar shows the name of the

dialog. Drag the title bar to move

the dialog. The small box in the

upper left corner of the window is

the close box. Clicking in this box

puts the dialog away. Doubleclicking on the title bar will hide

the dialog and leave only the title

bar. An additional double-click

will restore the dialog. This is

useful for conserving screen

space. Most of the dialogs in the

system can be shrunk to the title

bar in this manner.

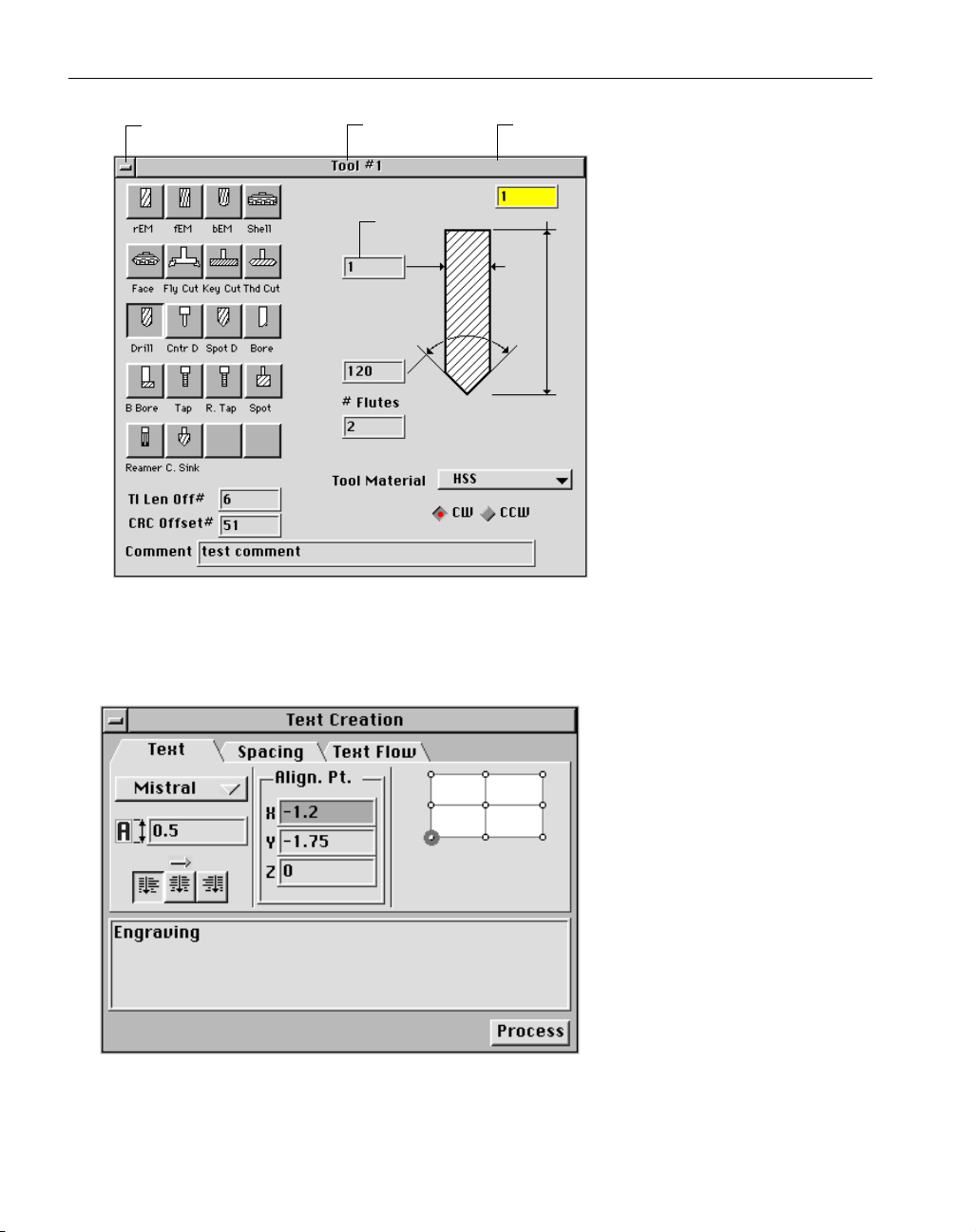

Text Creation Dialog : The Text

Creation Dialog contains “tabs” that

allow the user to access the Text,

Spacing, and Text Flow windows

contained within the dialog. Click

on the tabs to access the desired

window. The bottom portion of the

dialog where text can be entered

and the Process button remain available regardless of what window is

currently being viewed.

Close box

Dialog Name Title Bar

Page 13

GFK-1703 Interface

◆

7

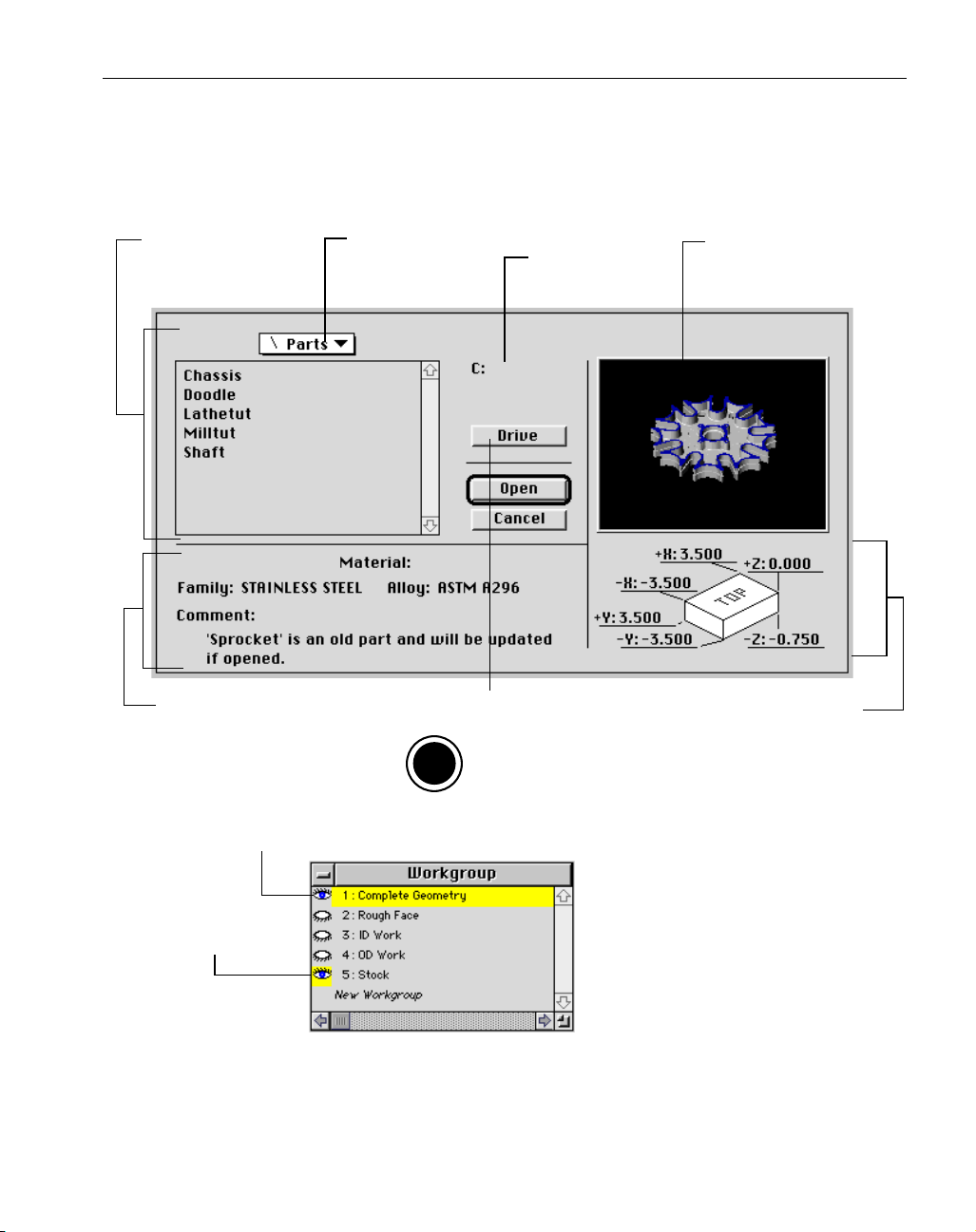

Open Dialog : The Open Dialog is used to locate, view, and open files. It comes up when Open is

selected from the File menu, or the Open button is depressed in the Document Control Dialog. The

part dimensions shown in the dialog below are for a mill part. If a lathe part is being opened, the

part dimension picture will change accordingly.

Workgroup Selection Dialog : The

Workgroup Selection Dialog is used to

create new workgroups, switch between

workgroups and select workgroups to

be viewed as background workgroups.

The current workgroup is highlighted in

yellow. Double-clicking on an eyeball

will change the viewing of a back-

ground workgroup. Geometry contained

in background workgroups will be drawn in gray, and cannot be edited or selected as a cut shape to

create machining operations. To select multiple workgroups to be viewed as background workgroups, use the Show Selected WG item in the View Menu. Holding down the Shift key will allow

more than one eye icon to be selected at a time to be viewed.

Current Directory/Folder:

displays a list of all

available files in the

current directory

Material Information

and Part Comment

Pop-up menu to

access a higher level

directory; displays

current directory

Button used to access the available drives

and disks contained on the system.

O

S

Name of the

current disk

On DOS, Windows NT an Windows 95

systems, it is the Drive button as

shown above. On Macintosh systems,

it is the Desktop button.

Part Preview:

displays the last

rendered image

of the part

Part Dimensions

Current Workgroup

Background Workgroup

Page 14

◆

Geometry Creation User Manual GFK-1 7 0 3

8

MENUS

Menu Bar: The menu bar, shown below, is located at the top of the screen. It is available to the user

at all times. To access the menu bar, position the cursor over the menu bar title, hold the mouse button down, drag the cursor down until the desired item is highlighted, and release the mouse button.

If a menu item is grayed out it cannot be selected. Selecting geometry or some other appropriate

item on the screen may change the menu item so that it becomes black and can be selected. Some

menu items are grayed out because certain modules of the software are not installed with the system.

Keyboard Shortcuts : Many menu items can also be accessed

by the keyboard. The symbol and letter next to the menu

item indicate that depressing a modifier key along with the

letter will access that menu item.

The modifier keys used to perform certain shortcuts in the system vary depending on the

operating system. The Shortcuts information card or the Shortcuts Appendix provide complete listings of the specific modifier keys used on each operating system.

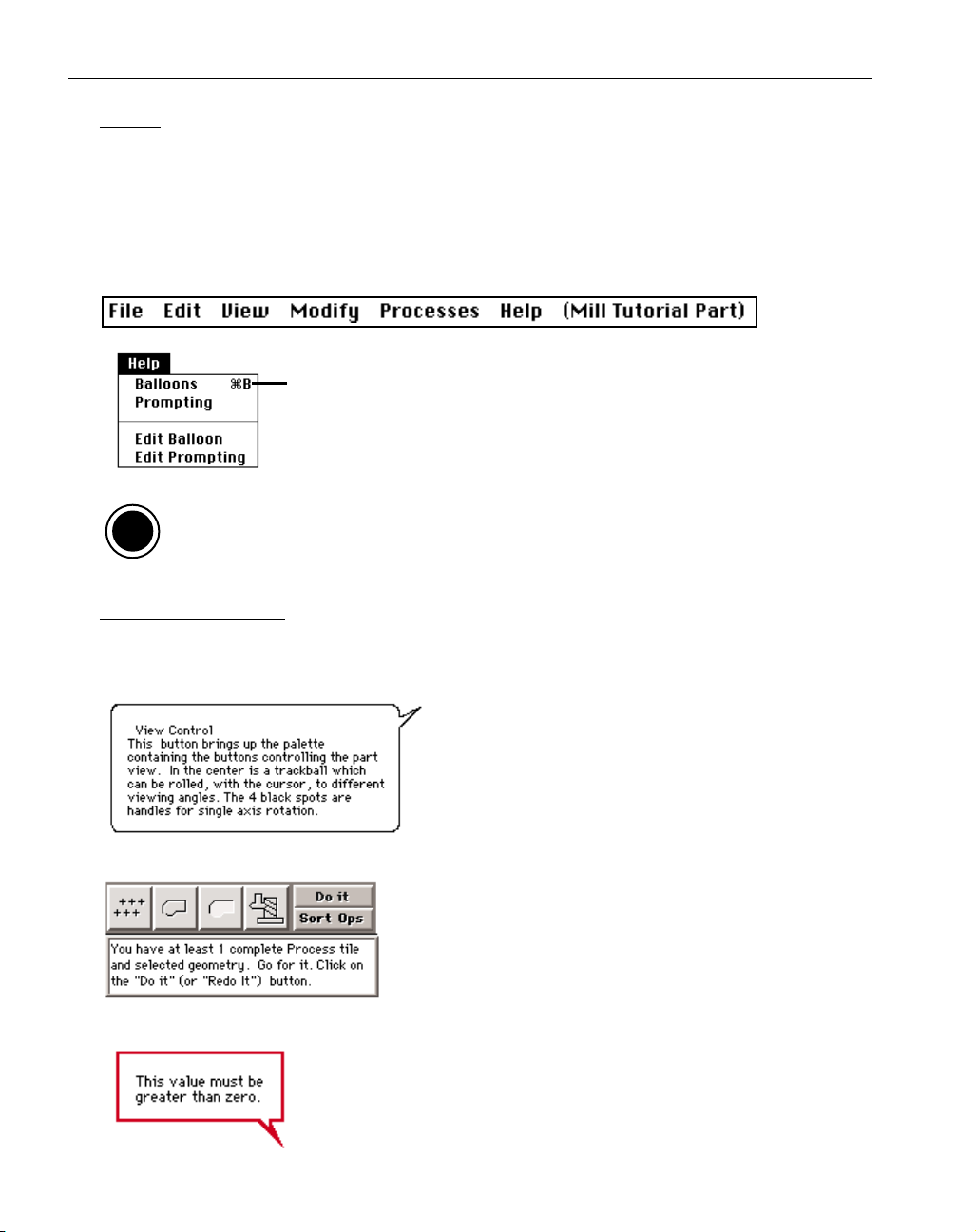

BALLOONS/PROMPTS

Balloons and prompts provide on-line reference information about the objects and functions in

the system.

Balloons: Balloons are turned on in the Help menu. A bal-

loon containing reference information will appear when

the cursor is placed over an object on the screen.

Prompting: Prompting is also turned on in the Help menu.

Prompting extends the geometry and machining palettes to

include useful suggestions on how to use the software.

Error Balloons: Error balloons alert the user whenever an invalid value has

been entered. They are outlined in red and disappear when a valid entry is

made.

Keyboard Shortcut

O

S

Page 15

GFK-1703 Interface

◆

9

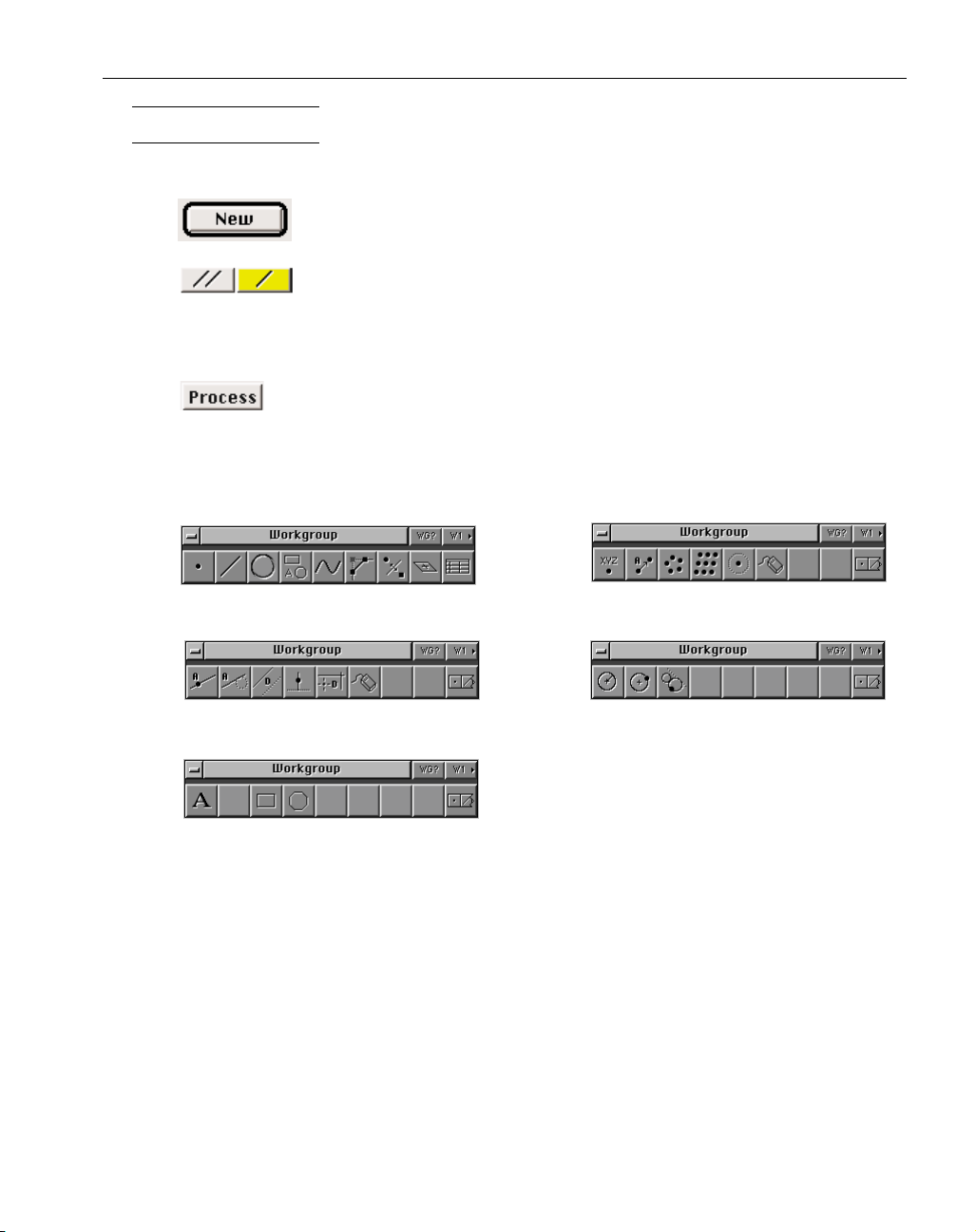

SHORTCUTS

Button Shortcuts : In some cases, buttons may be depressed by actions other than clicking on them.

When a button has a black outline around it, it can be depressed by hitting the

enter or return key.

Geometry Dialogs give the user a choice of single or multiple feature cre-

ation. To create only one feature (a line, for example), click on the single line

button. To create more than one line, click on the multiple line button. One of the buttons will

always be highlighted. The highlighted button can be depressed by clicking on it, hitting the

space bar, the enter key, or the return key.

The Process button is found in some dialogs, primarily those found in the Modify

menu. It can be depressed by clicking on it, or by hitting the enter or return keys.

Palette Shortcuts: There are some keyboard shortcuts for functions other than menu choices in the

system. Simply hit the appropriate number to activate the button.

Geometry Creation Palette Point Sub-Palette

Line Sub-Palette Circle Sub-Palette

Auto-shape Sub-Palette

The system contains many other shortcuts that are described on platform specific Shortcuts

information cards and in the Shortcuts Appendix.

1234 5 7 986

12345 6

12345 6

123

123

Page 16

◆

Geometry Creation User Manual GFK-1 7 0 3

10

SELECTION

Three classes of objects may be selected in the system: text, geometry features and tiles. Text

and geometry can be cut, copied, and pasted to and from the clipboard within the same file by using

items in the Edit Menu. Selection techniques are described below.

TEXT SELECTION

To select text:

•

Click and drag the cursor over some text.

The text will become selected.

•

Double-click in a text box.

All text in the box will become selected.

•

Hit the tab key to move from text box to another.

All text in the box will become selected.

GEOMETRY SELECTION

To select a single geometry feature:

•

Click on a feature.

The feature will become selected. If any other features were selected, they will

become deselected.

To select multiple geometry features:

•

Shift-click on a feature.

If the feature was unselected, it will become selected and added to any other currently

selected features. If the feature was selected, it will become deselected and removed from

the currently selected group.

Holding down the shift key changes the cursor to multiple selection mode which

allows more than one geometry feature to be selected at a time.

To select an entire connected shape:

•

Double-click on a feature of the shape.

All connected features will become selected.

To select certain types of geometry:

•

Use the Select items found under the Edit menu.

All geometry that matches the selected type will become selected and added to the

currently selected group.

TILE SELECTION

To select a single tile:

•

Click on a tile.

The tile will become selected. If any other tiles were selected, they will become deselected.

To select multiple tiles:

•

Shift-click on a tile.

Page 17

GFK-1703 Interface

◆

11

If the tile was unselected, it will become selected and added to any other currently

selected tiles. If the tile was selected, it will become deselected and removed from the currently selected group.

Holding down the shift key changes the cursor to multiple selection mode which

allows more than one tile to be selected at a time.

For additional selection shortcuts, refer to the Shortcuts information card or the Shortcuts

Appendix.

COLORS

The system uses colors to graphically display different items drawn on the screen. The color

scheme for geometry, toolpaths and rendering is listed below.

GEOMETRY

Yellow Unconnected Geometry

Dashed Yellow Unconnected Rapid Geometry

Light Blue Connected Geometry

Dashed Light Blue Connected Rapid Geometry

Gray Geometry viewed as a background workgroup

TOOLPATHS

Dark Blue Cut Shape; selected area of a shape to be machined

Solid Orange Feed Move in a Toolpath

Dashed Orange Rapid Move in a Toolpath

Dashed Gray Rapid Move used for positioning moves and tool changes

Solid Gray Approach Feed Move

RENDERING

Blue Stock

Yellow Rendering of selected operations, and/or selected tools

Gray Rendering of unselected operations and/or unselected tools

Red Tool Interference

CLIPBOARD

The clipboard is used as a temporary storage place for geometry and text. Using the Cut option

from the Edit menu will delete whatever items are selected and replace the contents of the clipboard

with them. Using Copy will leave the selected items in their current location and replace the contents of the clipboard with a duplicate of them. Choosing Paste can do two things. If something is

selected it will replace that selection with the contents of the clipboard. If nothing is selected the

contents of the clipboard will be pasted in either the drawing window or in an active text box

depending on whether the clipboard contains text or geometry. The clipboard can only hold one

selection at a time. This means that it can hold either text or geometry, but not both. If text is copied

into a clipboard holding geometry, the geometry in the clipboard will be lost. The contents of the

clipboard will also be lost, when a file is closed, the software is quit out of, or the computer is shut-

Page 18

◆

Geometry Creation User Manual GFK-1 7 0 3

12

down.

It is possible to cut and paste geometry within a part file between different workgroups.

However, geometry cannot be cut, copied or pasted between different part files because the contents

of the clipboard are deleted when the part file is closed.

Page 19

GFK-1703 Part Set-Up

◆

13

CHAPTER 3

:

Part Set-Up

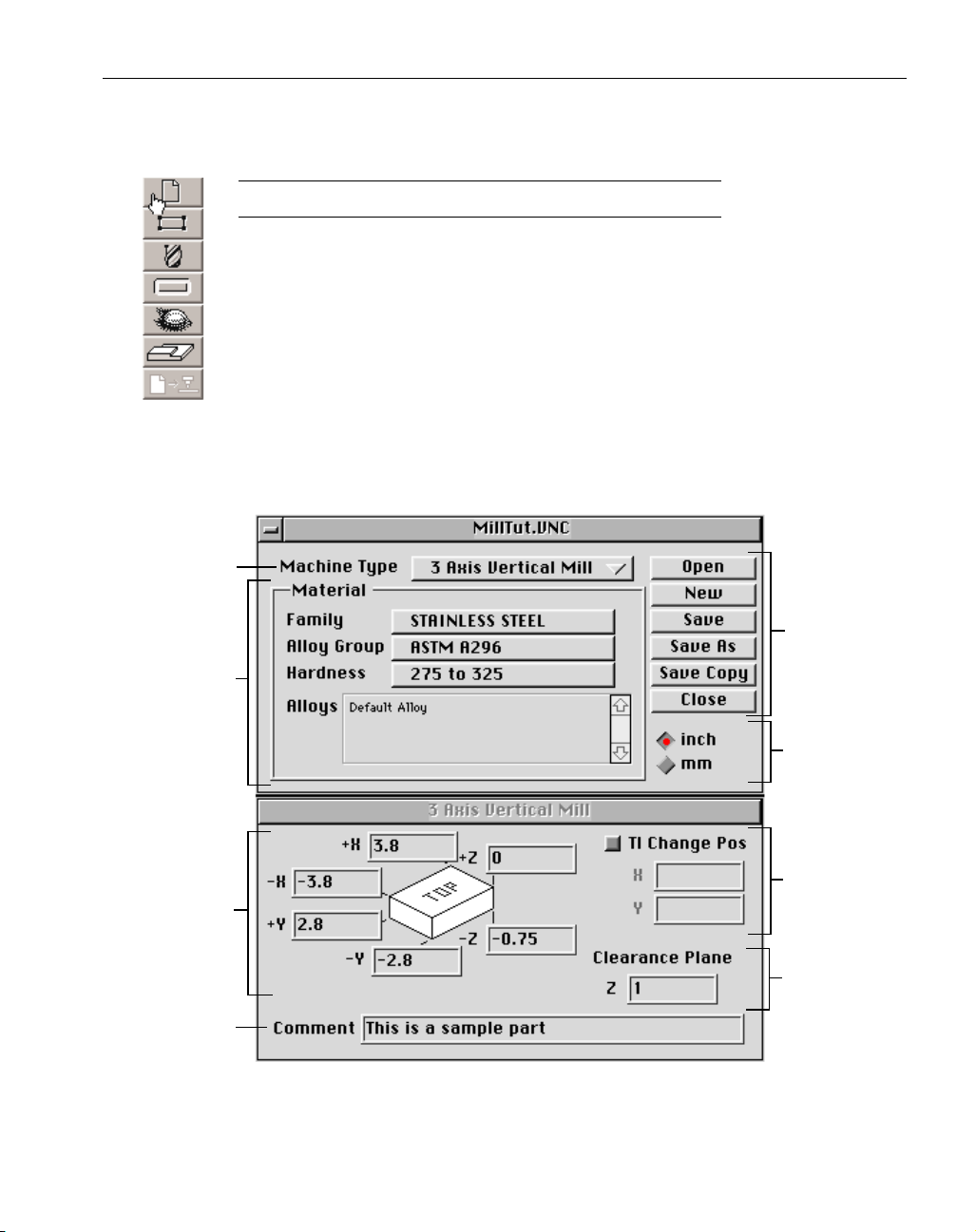

DOCUMENT CONTROL DIALOG

Clicking on the Document Control Button will bring up the Document Control

Dialog. This dialog is actually a combination of two linked dialogs. The top dialog

contains general information about the file and gives the user control over where it is

stored on the computer. The top dialog is the same for both the Mill and Lathe modules. All of the items in the top dialog, except for Material information, will be

described in this section. The Material database will be outlined in the machining

manuals for the Mill and Lathe modules.

The bottom dialog changes according to the Machine Type selected in the top

dialog. The bottom dialog contains information on stock size, clearance positioning

and tool change position. Only the stock size information will be explained in this section, while all

information on clearance planes, tool change, and automatic clearance (lathe only) will be described

in the appropriate machining manual.

Machine

Type

File

Management

Material

Information

Stock

Diagram

Comment

Measurement

Type

Tool Change

Position

Clearance

Position

Page 20

◆

Geometry Creation User Manual GFK-1 7 0 3

14

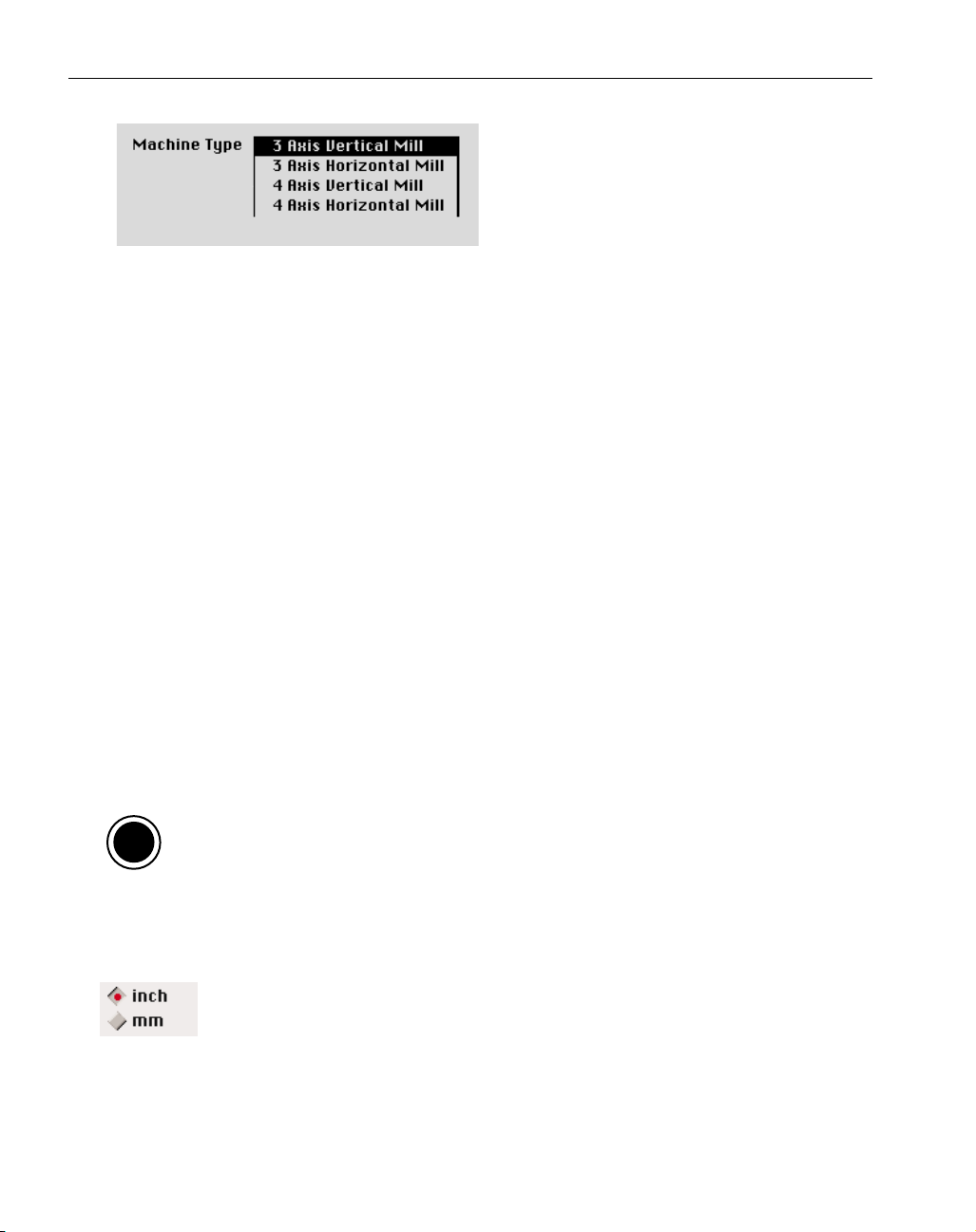

Machine Type: Clicking on the Machine Type

pop-up menu will produce a list of all machines

the system is set up to handle. The available

selections depend on which modules of the software that have been installed. There are both

horizontal and vertical selections for mills. The

shank size on the lathe selections refers to the standard tool holder size on a lathe. These shank sizes

are used to limit the number of inserts and holders in the tool database. If the Advanced Milling

module is installed, there will also be selections for four and five axis machines.

The buttons used for file management, described below, are also available under the File menu.

Open Button: Clicking on the Open button will bring up the Open Dialog which allows the user to

select which file to open. If a file is currently open, it will be closed and the selected file will be

opened.

New Button: This button will create a new file by opening a dialog and asking for a file name and a

location to save the new file. If there is a file open, it will be closed.

Save Button: If there have been any changes made while the file was open, this button will save the

changes.

Save As Button: This button will open a dialog asking for a file name and a location to save the current file. The changes made since the last Save command will be written into the new file. The original file will not be affected. The new file will become the current, open file.

Save a Copy Button: This button is very similar to the the Save As button. The system will create a

duplicate copy of the open file. The original file remains the current, open file. The name of the

duplicate file can be changed.

On Macintosh, Windows NT and Windows 95 systems, the word “copy”will be added at

the end of the file name to distinguish it from the original.

Close Button: This button closes the current file. If the file has not been saved before clicking on the

Close Button, a dialog will come up asking if the file should be saved.

Measurement Type: These two radio buttons determine whether values input will be

based on an English or metric standard and entered in inches or millimeters. The

measurement type used by the post processor is determined by the post processor

itself. There are English and metric post processors. If an English post is used on a metric part, the

posted numbers will be converted from millimeters to inches. Likewise, metric posts will convert

values from inches to millimeters.

O

S

Page 21

GFK-1703 Part Set-Up

◆

15

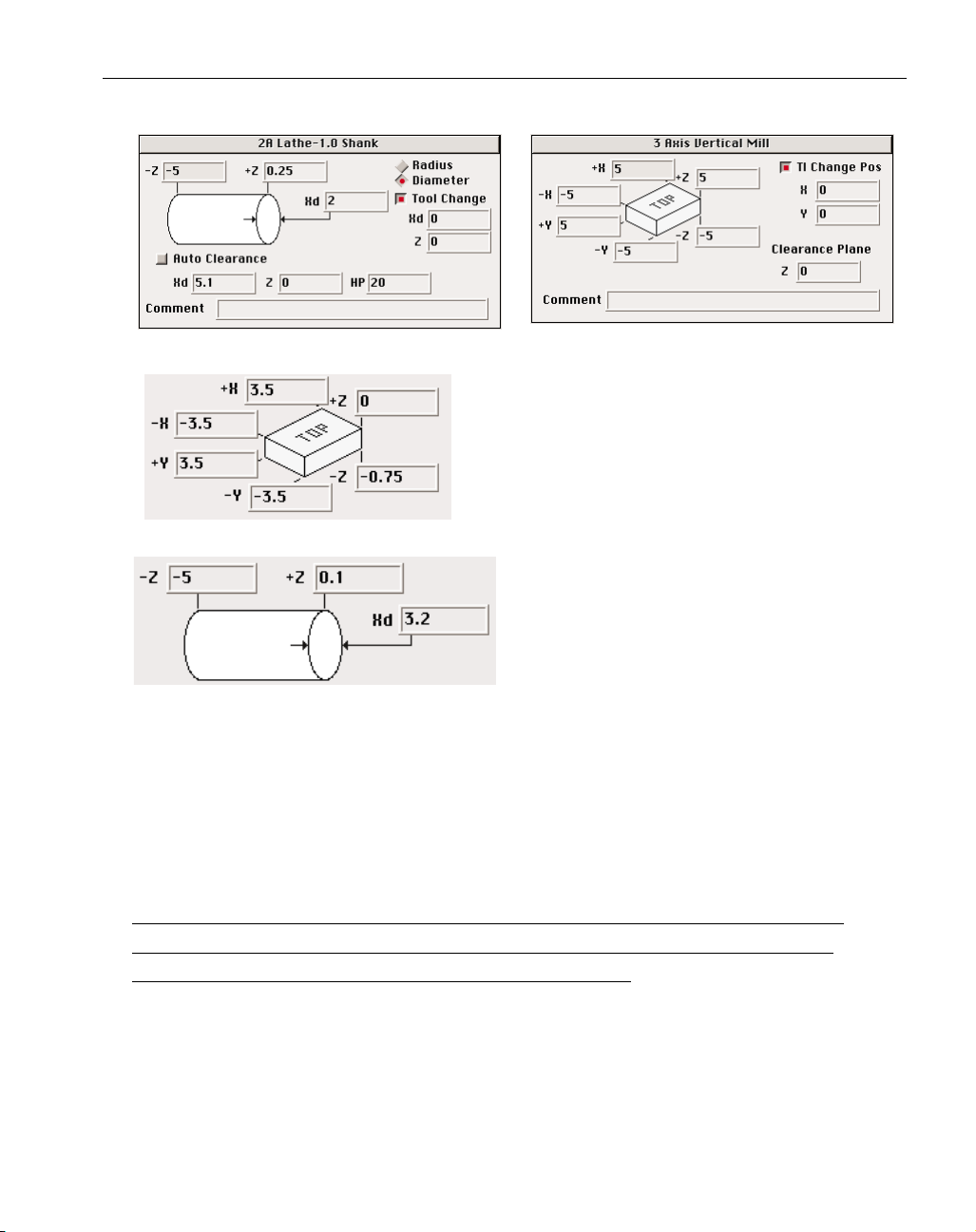

Lathe Mill

Mill Stock Size Diagram: This section of the dialog is used

to specify the starting size of the part stock. The numbers

will be used to draw the stock outline and origin marker

correctly, and to draw the stock during the rendering

process. These values will not affect the programming of

the part, but it is recommended that they closely correspond to the actual stock being used.

Lathe Stock Size diagram: This section of the dialog is

used to specify the starting size of the part stock.

The stock size entered here will be used by the system to determine positioning moves when the Auto

Clearance option is turned on, and toolpath moves

when the Material Only option is selected in a

process. If a custom stock shape has been created in

one of the workgroups, the system will use the custom stock size for toolpath and positioning

moves. In that case, the values entered here will only be used to draw the stock outline and origin

marker, correctly. The text box for the X dimension will be a radius or diameter value depending

on which option is selected for the X Dimension Style.

Comment: Any text entered as a part comment will be shown in the part preview section of the Open

dialog.

THE OTHER INFORMATION CONTAINED IN THIS DIALOG, SUCH AS CLEARANCE PLANE

VALUES AND TOOL CHANGE POSITION WILL BE DESCRIBED IN THE ACCOMPANYING

MACHINING MANUALS FOR THE LATHE AND MILL MODULE.

Page 22

◆

Geometry Creation User Manual GFK-1 7 0 3

16

CHAPTER 4

:

Geometry Creation

GEOMETRY OVERVIEW

Geometry must be created in order to machine a part. All part geometry is created using the Geometry Creation palette or imported through the Exchange option.

Creating geometry using the Geometry Creation palette can be accomplished in

three ways; using the Geometry Expert spreadsheet which combines the creation and

connection of all geometry features in one easy to use method, using the free form

CAD tools and connecting the independent features together, or using a combination

of these two.

This chapter details the different functions available for geometry creation and

provides detailed explanations of how shapes are created using the system. To gain practical

knowledge of the concepts outlined in this chapter, complete the exercises provided in the following chapters.

GEOMETRY EXPERT

Geometry Expert is a method of geometry creation which facilitates the fast creation of simple parts and the simplified creation of more complex parts, along with being very easy to learn

and use. Geometry Expert is designed to create a single, continuous, shape. It allows the user to

define, create and connect shape features while following along the path of the part.

Geometry Expert has a tabular format which operates much like a standard spreadsheet.

Features are defined by entering dimensions into the cells (text boxes) of the feature rows. Each

row creates a different feature. Features are defined in the same order as they are encountered

along the shape path.

Creating a shape using Geometry Expert is akin to “walking” around the path of the shape,

indicating such items as location, direction and the distance being traveled. While this is similar to

standard shape creation techniques, Geometry Expert goes one step further. It applies its inherent

knowledge of geometric principles and follows a logical course which allows for the creation of

complete, connected, geometrically correct shapes, requiring the least amount of input from the

user.

Geometry Expert, as the name implies, provides the user with a built-in consultant on the

rules and principles of geometry. The system makes the creation of simple parts as quick, easy,

and painless as possible. At the same time, it makes the creation of more complex parts as simple

as possible by calculating, creating and connecting shape features based on whatever part dimensions are provided.

The associative capabilities of Geometry Expert make editing any existing shape a very easy

process. The system handles the dimension changes while maintaining all the proper connections

and relationships between pieces of geometry (eg. intersections and tangencies). Geometry Expert

frees the user from needing to understand complex geometrical relationships and calculate feature

dimensions. Instead, the user can simply enter the specifications provided on the part blueprint

and let Geometry Expert do the rest.

Page 23

GFK-1703 Geometry Creation

◆

17

FREE FORM CAD

The free form CAD tools included in the system are also very powerful and easy to use.

Creating points and features is as easy as clicking on buttons and entering values. Likewise, connecting features to form shapes that can be machined simply involves selecting the intersecting

features and clicking on a button. Several different options are provided for creating points, lines,

circles, fillets, and chamfers making it possible to create any shape regardless of how the blueprint

is dimensioned. The free form CAD tools are particularly useful with parts requiring construction

geometry.

COMBINATION

Using both Geometry Expert and the free form CAD capabilities to create a part shape is a

very powerful combination. For example, a simple shaft with chamfers can be created in minutes

by using Geometry Expert to create the horizontal and vertical lines, and the automatic

fillet/chamfer option in the Geometry Creation palette to create the chamfers.

Additionally, Geometry Expert allows for the loading of any shape into its spreadsheet format. Loading an existing shape into Geometry Expert, whether it was created using Geometry

Expert, free form CAD, or imported using the Exchange option, is as easy as double-clicking on

any part of the shape while the Geometry Expert spreadsheet is open on the screen. All features of

the shape are listed and dimensioned in the rows of the spreadsheet where they can be checked

and changed. This provides the user with a quick and easy verification method and editing tool.

GEOMETRY CREATION PALETTE

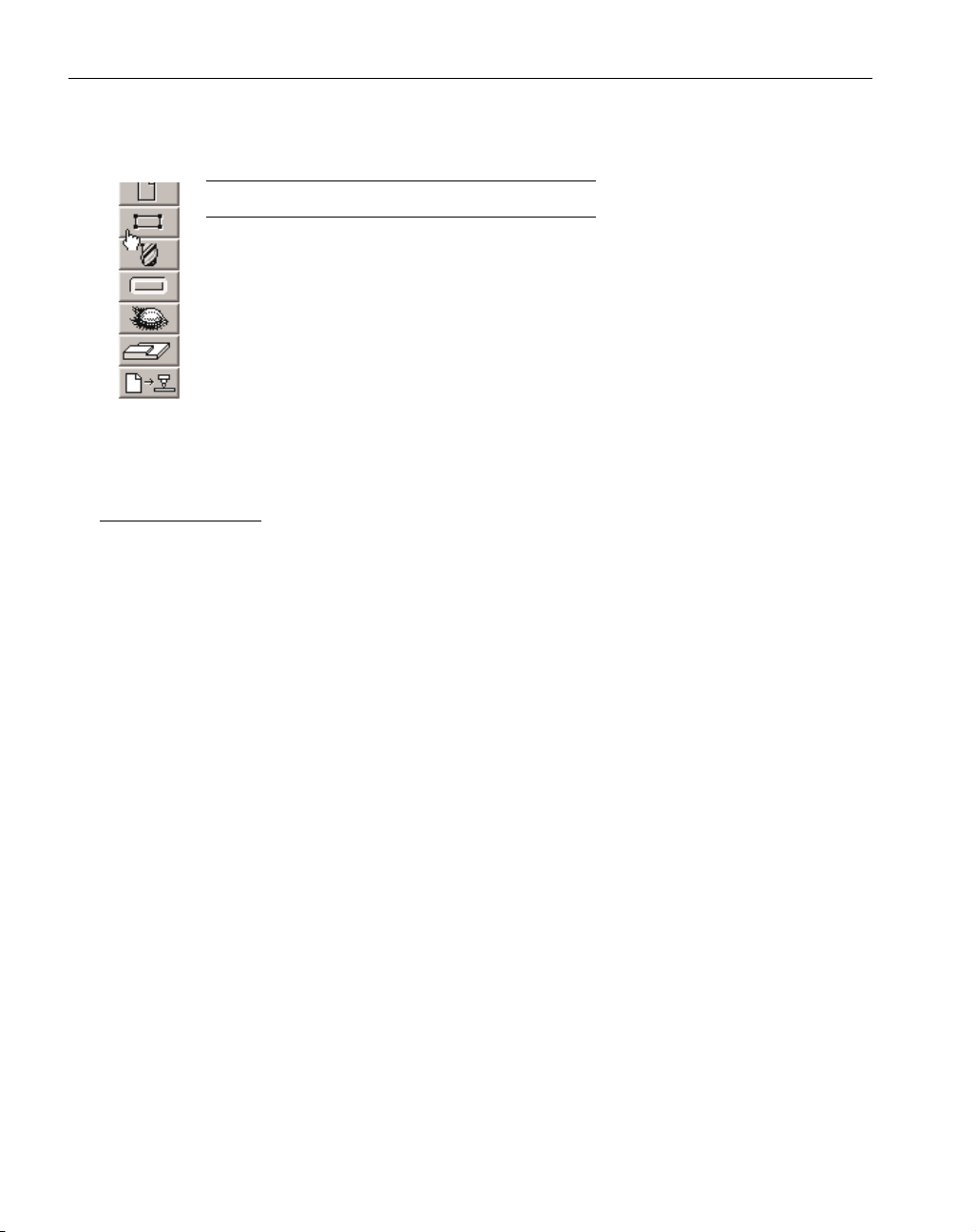

Depressing the Geometry Creation button will bring up the Geometry Creation palette. The

Point, Line, Circle, Fillet-Chamfer and Auto-shape buttons access sub-palettes which provide various options for creating the selected type of geometry. The Geometry Expert button accesses the

Geometry Expert spreadsheet which allows the user to enter feature information and quickly

define a continuous shape. The Connect/Disconnect button allows the user to manually connect or

disconnect features. This palette also accesses different workgroups (layers) of the file and creates

new workgroups. For more information on workgroups, refer to the Workgroups section later in

this chapter.

All buttons in the Geometry Creation palette can be accessed from the keyboard by typing

the number of their position in the palette, (eg. type a 1 instead of clicking on the Point button, a 2

for the Line button, etc). The Geometry Creation palette can be moved (“dragged”) to any loca-

Spline

Button

Fillet-Chamfer

Button

Connect/Disconnect

Button

Workgroup Info

Button

Workgroup Selection

Button

Geometry Expert

Button

Coordinate System Button

(Adv. Milling only)

Title Bar

Line

Button

Auto-shape

Button

Close Box

Point

Button

Circle

Button

Page 24

◆

Geometry Creation User Manual GFK-1 7 0 3

18

tion on the screen by placing the cursor on the title bar of the palette so that the cursor changes to

the mover tool. Then, while holding down the mouse button, drag the dotted outline of the palette

to a different location, and let go of the mouse button.

When a sub-palette is open, the cursor will change to the selection cursor. This means that

any geometry that is clicked on will become part of the current selection. If the geometry is

already selected when it is clicked on, it will become deselected. This is the same as holding

down the shift key when not in a sub-palette.

GEOMETRY EXPERT

There are four general ways that Geometry Expert can be utilized as a geometry creation

tool. First, the creation of simple shapes, containing primarily horizontal and vertical lines, such

as shafts, is almost effortless using Geometry Expert. The default settings and automatic angle

toggling allow the user to create alternating, intersecting, horizontal and vertical lines in the fastest

manner possible. The user only needs to enter one value in order to define the line.

Second, the creation of more complex shapes, containing multiple arcs and angled lines, is

greatly simplified due to the fact that Geometry Expert constantly applies its built in logic and

knowledge of geometry to guide the user through the process.

Third, the user can doodle or sketch a rough part outline using the Mouse Line tool, and then

load the shape into Geometry Expert to properly dimension it. The associative capabilities of the

system will adjust the shape according the the new values entered, while still maintaining all the

correct connections and relational data to the other features of the shape.

Finally, Geometry Expert is a very powerful editing tool. Feature dimensions can be adjusted by simply changing the values in the spreadsheet. Geometry Expert handles all of the calculations and adjustments to the other features that are affected by the changes. Any shape, regardless

of how it was created, can be loaded into Geometry Expert, making it ideal for verifying and

adjusting imported IGES and DXF files, old CAD files, or frequently changing part files.

HOW GEOMETRY EXPERT WORKS

Geometry Expert is set up much like a standard spreadsheet. Feature specifications are

entered into cells which are contained in rows. Each row of the spreadsheet defines a feature.

Features are defined in the order that they appear along the path of the shape. When the

Geometry Expert spreadsheet is open on the screen the user can create fully connected shapes by

entering feature specifications in each of the rows. Because Geometry Expert creates connected

shapes, each feature is dependent on and aware of the preceding and following features.

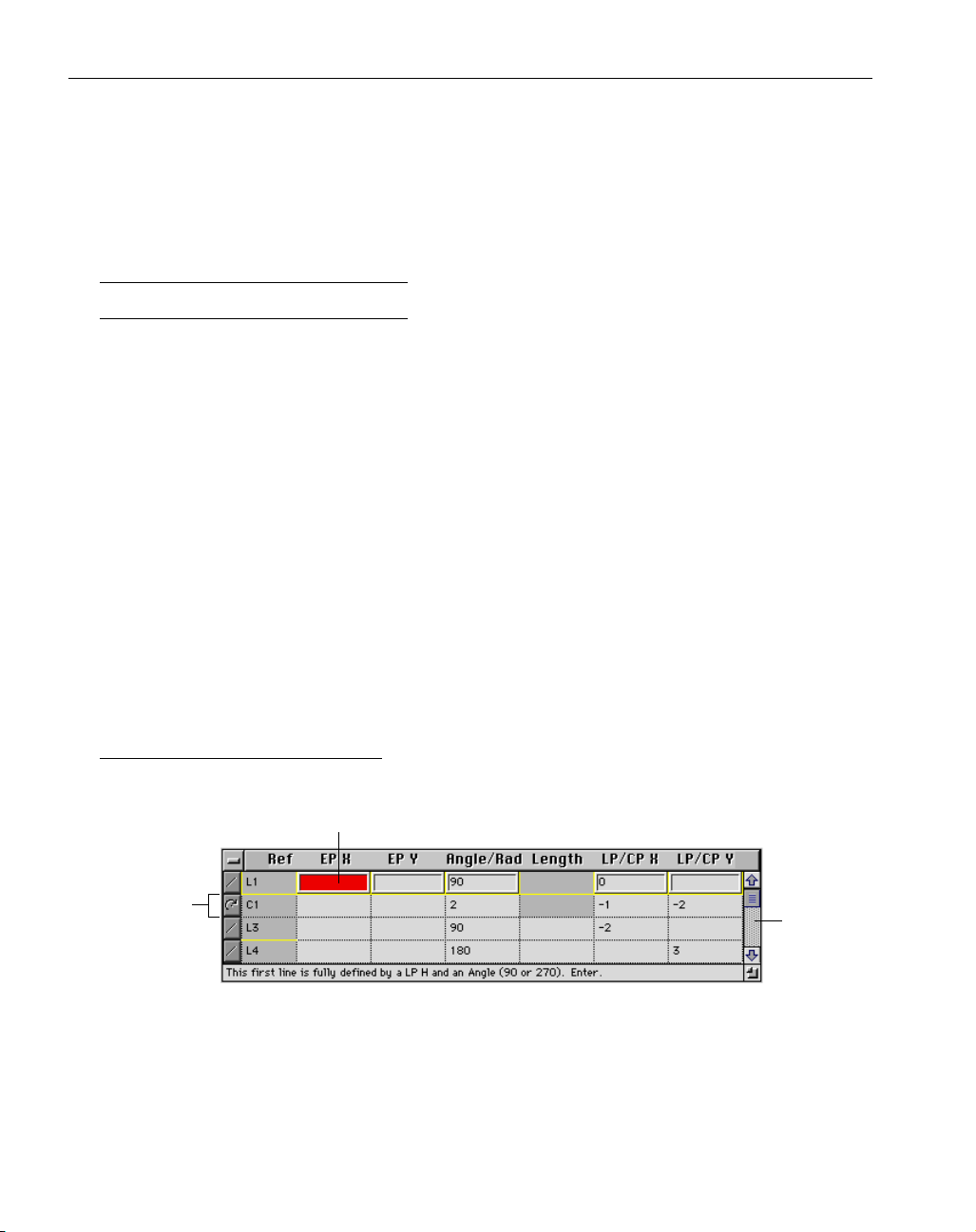

The feature row that is being worked on at any given time is referred to as the “current row”.

The current row has an upraised frame and is outlined in either yellow or black. When the current

row contains adequate information, it is outlined in yellow. The prompt at the bottom of the

Cell

Feature Row

Scroll Bar

Page 25

GFK-1703 Geometry Creation

◆

19

spreadsheet, which gives the status of the current row, will indicate what will happen when the

row is entered.

The current row will be outlined in black if it does not contain enough information. The

prompt will indicate what additional information is needed to define the row. If the user attempts

to enter a row that does not contain enough information, an error balloon will come up, again indicating what other information is required. When the current feature row contains the appropriate

information, the row is entered into the spreadsheet by hitting the enter or return key. Entering a

new row moves the cursor down to the next row in the spreadsheet, which will now be the current

row. The enter and return keys only move the current row down in the spreadsheet if a new row is

being created. Otherwise, the arrow keys or the cursor must be used to maneuver through the

rows in the spreadsheet.

Each feature is drawn on the screen as soon as the spreadsheet contains the necessary information. Some features cannot be drawn until later features are defined. These are referred to as

“floating features” and are explained later in this section.

Creating part geometry with Geometry Expert is accomplished by walking along the path of

a shape, and defining features as they are encountered. In this way, all features are automatically

connected to the preceding and following features. Because of this methodology, sometimes it is

necessary to specify the correct direction of a feature, in addition to indicating its magnitude.

For arcs, the selected feature type indicates the direction, either clockwise or counter-clockwise. For lines, the angle value indicates the direction. For example, a horizontal line can either

be defined with an angle value of 0° or 180°; both will draw the same line, but in the opposite

direction. Specifying the correct line direction is only an issue if the previous or next feature is

going to be an arc. When that is the case, it is necessary to indicate to the system what direction

the line is moving. Again, checking the line direction should only be necessary when the line is

being connected to an arc.

CREATING SHAPES USING GEOMETRY EXPERT

When creating a part using Geometry Expert, the first thing that must be decided is the starting feature and the direction to travel around the part, either clockwise or counter-clockwise.

When the spreadsheet is first opened, the first row will default to a line with an angle of 90°. The

information in this row will need to be added to and/or changed in order to define the first feature.

The prompts indicate what additional information can be entered to define the feature. As

soon as the first row contains enough information to fully define the feature, the frame of the row

will become yellow. When the frame is yellow, the prompting information tells the user how the

feature will be created. A yellow frame around the row indicates that the user can press enter

without getting an error message. Hitting enter or return will create the feature and start a new

row. The reference number of the feature that was created will be placed in the Ref cell in its row.

The new row’s feature type will default to a line, and the angle will default to either 0°/180°

or 90°/270°. The angle value of the line will automatically toggle between either 0°/180° or

90°/270°. Once again, the prompt will indicate what information can be added to further define

the line.

In this case, and many others, the frame of the row will be yellow even if the row does not

contain enough information to fully define the feature. This is because it is still possible to add

information in subsequent rows that will fully define the feature. At this point, information can be

added to or removed from the row to define the next feature of the shape as dimensioned on the

print. When the information is correct, the feature is created by hitting the enter or return key.

Page 26

◆

Geometry Creation User Manual GFK-1 7 0 3

20

This process continues until the last feature of the shape is defined. When the last feature of

the shape is created it should intersect with the first feature of the shape. At this point the feature

must be connected using the Close Shape feature type.

Geometry Expert button: The Geometry Expert button is located in the last position in the

Geometry Creation palette. Clicking on this button brings up the Geometry Expert

spreadsheet, shown below, which allows the user to create connected shapes by entering

feature dimensions in the rows of the spreadsheet.

Feature Type: There are seven options available for the

feature type. They are (from left to right): line, chamfer,

fillet, clockwise arc, counter-clockwise arc, close shape, and macro. Each row must have a

feature type selected. To select the feature type, click on the feature type button which will

access the possible selections. Drag the mouse to the desired feature so that the button

appears depressed, and let go of the mouse button. That feature will now appear as the

feature type for the row. In some cases, depending on the previous feature, some of the

feature type options may be grayed out to indicate they are not valid selections. Also,

depending on the feature type selected, some cells may be grayed out indicating that the

selected feature type does not require that dimension. The feature type can also be selected

using keyboard shortcuts. Refer to the Shortcuts information card or the Shortcuts Appendix

found in the Machining Module Manuals for information on keyboard shortcuts for

Geometry Expert.

Reference #: Every feature that is created is assigned a reference number by the system. The

letter indicates what type of feature it is, L for line, C for circle, and the number indicates the

creation order. These reference numbers may change during the course of creating geometry,

but will not affect the shape.

Close box

Reference #

Feature Type

Current Row

Prompt

Horizontal coordinate

of Endpoint

(Z in Lathe, X in Mill)

Angle of Line/

Radius of Circle

Vertical coordinate

of Endpoint (Xd/Xr in

Lathe,Y in Mill)

Horizontal coordinate of

Line point/Centerpoint

(Z in Lathe, X in Mill)

Length of line

or chamfer Size box

Vertical coordinate of

Line point/ Centerpoint

(Xd/Xr in Lathe,Y in Mill)

Page 27

GFK-1703 Geometry Creation

◆

21

NOTE

For lathe parts, the horizontal coordinate is a Z value, the vertical coordinate is an Xd or Xr

value. For mill parts, the horizontal coordinate is an X value and the vertical coordinate is a Y

value.

EP Z (X): The number entered in this cell is the horizontal coordinate of the endpoint of the

current feature. When a feature is defined with an endpoint, the system will draw the feature

and trim it at the specified endpoint. Endpoint specifications are required if the next feature

needs a start point in order to be correctly defined.

EP Xd/Xr(Y): The number entered in this cell is the vertical coordinate of the endpoint of the

current feature.

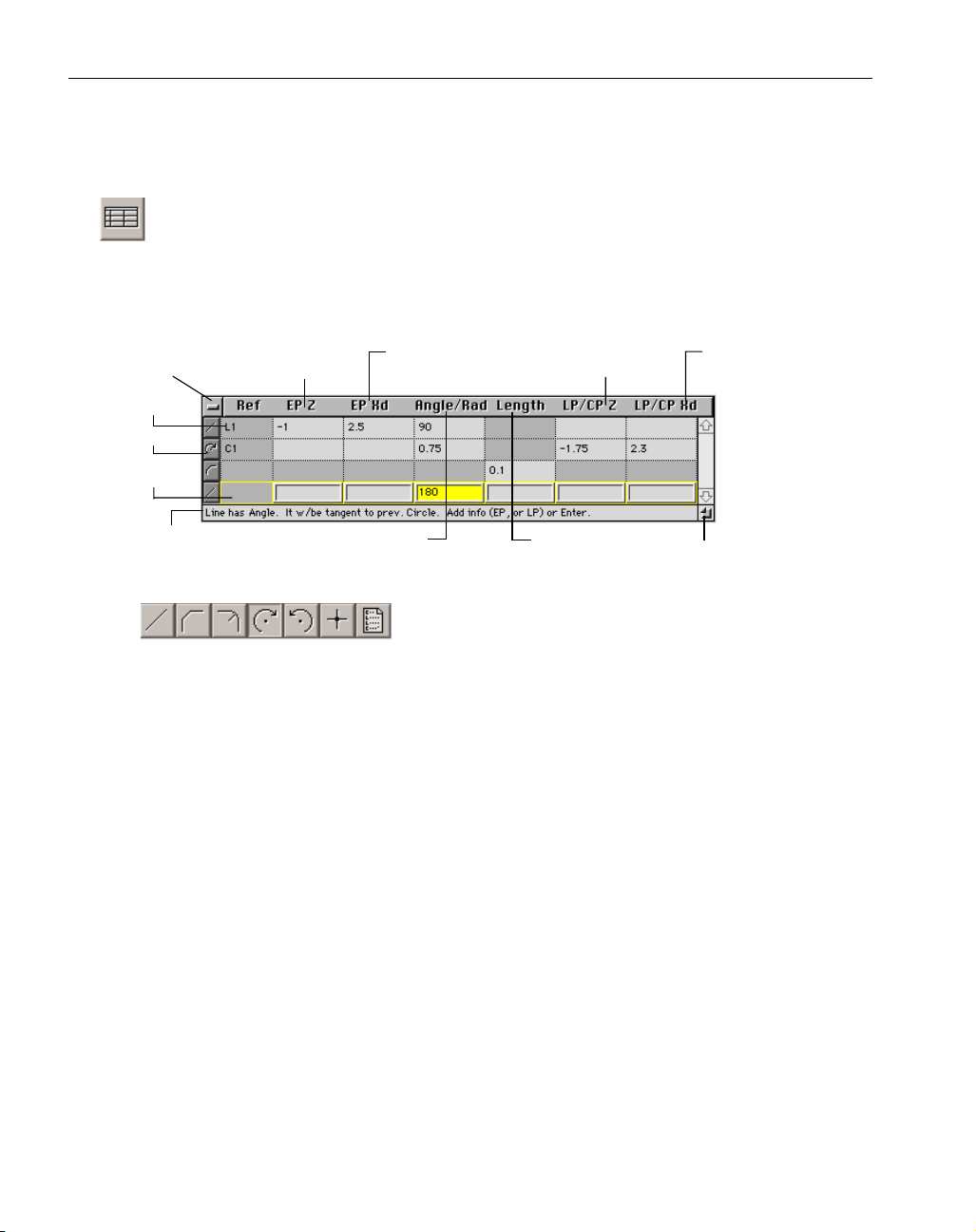

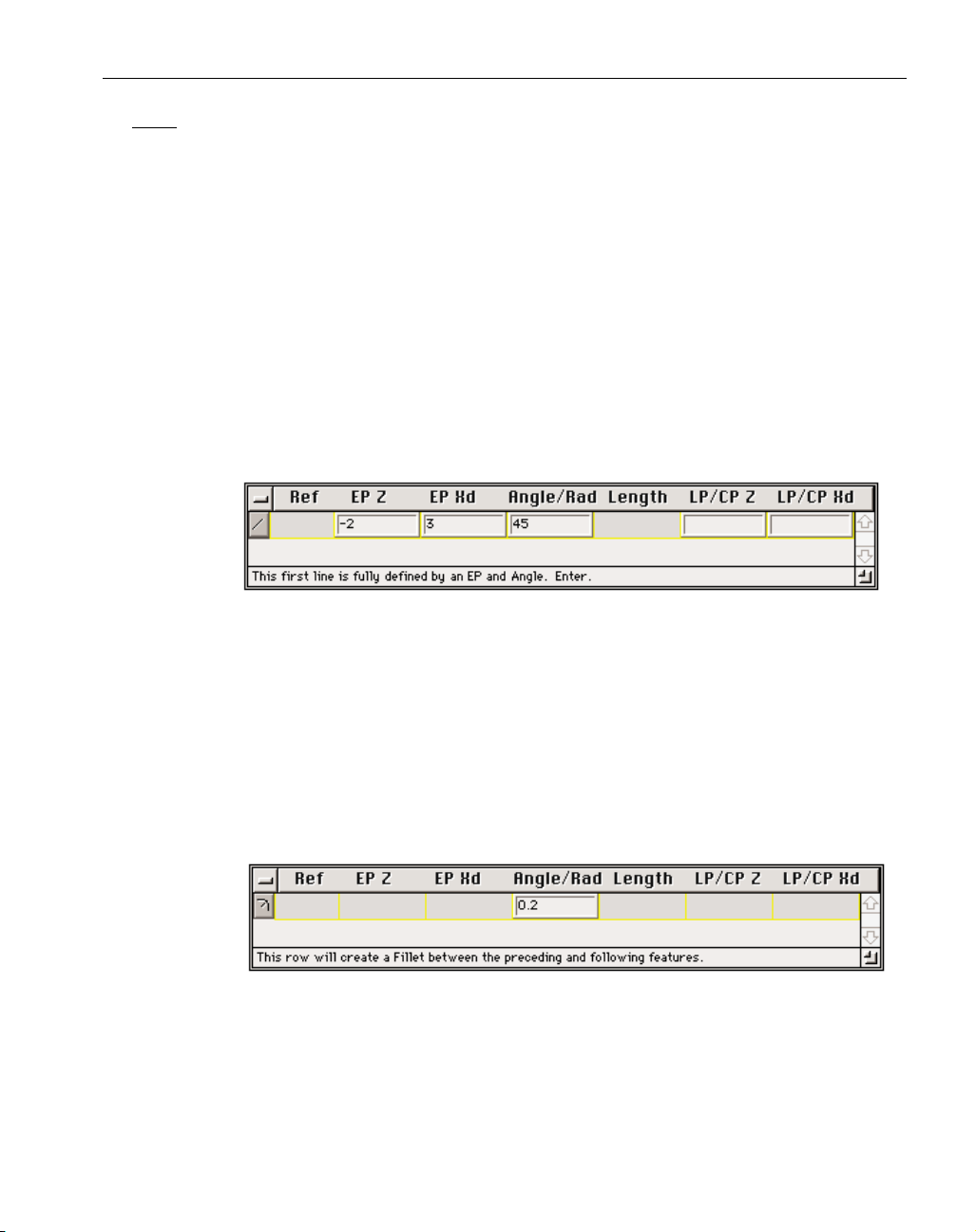

EXAMPLE: The row shown below will create a 45° line with an endpoint drawn at

Z -2, Xd 3. The next feature that is defined in the spreadsheet will start at the end

point of this feature.

Angle/Rad: The number entered in this cell is dependent on the feature type selected.

If the feature type is a line, this number specifies the angle of the line. The angle value for a

line defaults to either 90°/270° or 0°/180° allowing for the creation of vertical or horizontal

lines, respectively. The system toggles between these angle values which makes the creation

of intersecting horizontal and vertical lines a very quick and easy process. The user can

change the default values by simply entering the new numbers in the cells. If the feature

type is a arc or fillet, this number specifies the radius.

EXAMPLE: The row shown below will create a fillet between the previous and following feature with a radius of 0.2.

Length: The number entered in this cell is the length of the current feature. The length cell

is only active if the feature type is either a line or a chamfer.

Page 28

◆

Geometry Creation User Manual GFK-1 7 0 3

22

LP/CP Z (X): The number entered in this cell is dependent on the feature type selected.

If the feature type selected is a line, this number is the horizontal coordinate of a line point

(LP). A line point is simply any point that lies somewhere on the line. Line points are only

used to draw and calculate the line, they are not part of the shape. Line points are not drawn

on the screen. Geometry Expert defaults to the LP/CP cell so it is more efficient when

creating lines to use line points whenever possible in order to reduce the number of key

strokes necessary. If the feature type selected is a circle, this number is the horizontal coordinate of the centerpoint of the circle.

LP/CP Xd/Xr (Y): The number entered in this cell is dependent on the feature type selected.

If the feature type selected is a line, this number is the vertical coordinate of a line

point. If the feature type selected is a circle, this number is the horizontal coordinate of the

centerpoint of the circle.

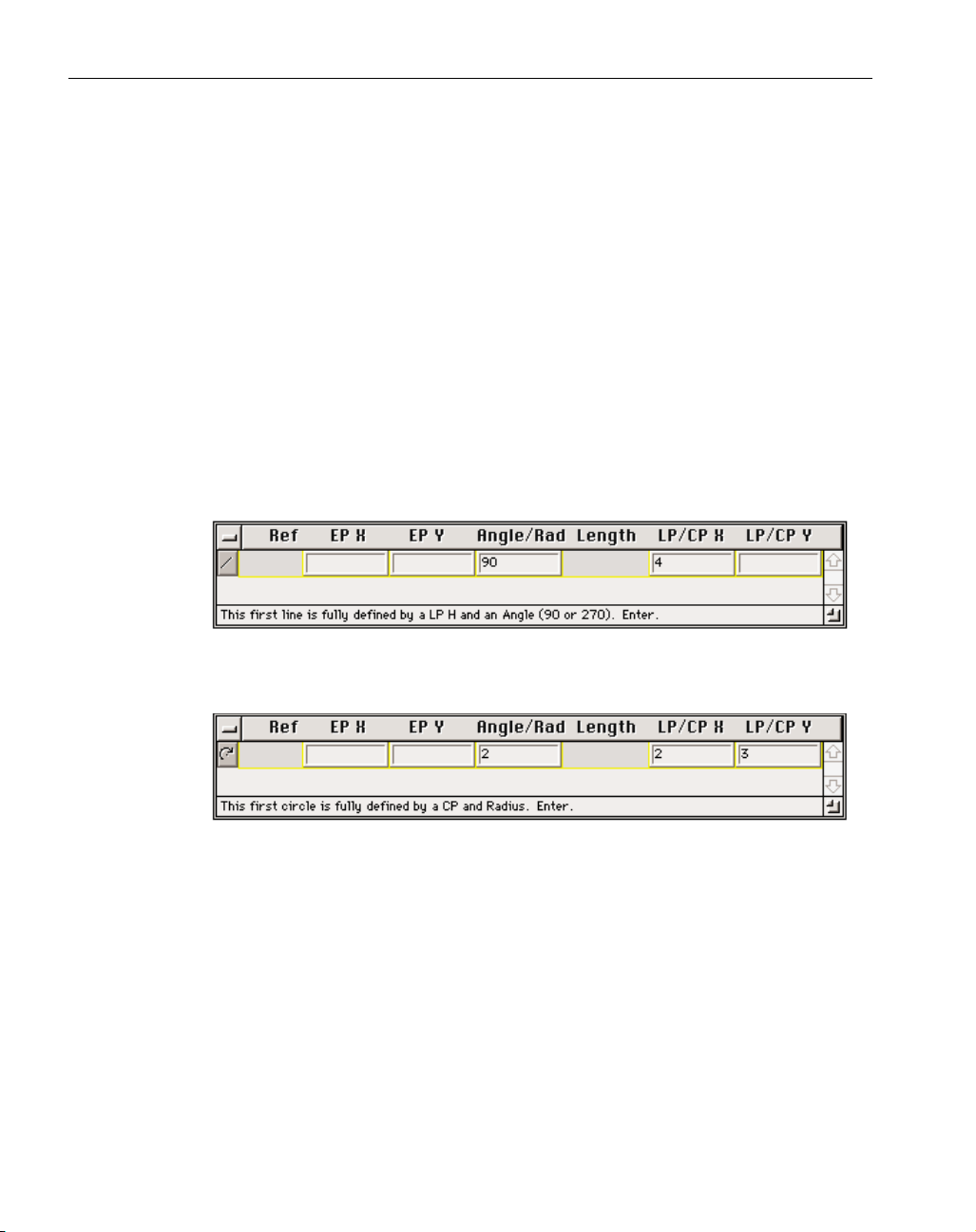

EXAMPLE: The row shown below will create a 90° (vertical) line that goes through

the point at X 4. When defining either horizontal (0°/180°) or vertical (90°/270°)

lines, only one LP coordinate is required. Refer to the section on Half Points in this

chapter for more information.

EXAMPLE: The row shown below will create a circle with a radius of 2 and a

centerpoint at X 2, Y 3.

Prompt: The information contained in the prompt indicates the status of the current row.

When a feature row is outlined in yellow, the prompt tells the user what specifications have

been entered for this feature and what will happen when the row is entered. If the feature row

is outlined in black indicating that more information is required, the prompt will tell the

user what additional information is required. The prompt also indicates if the system has automatically deleted a cell value because the feature row contained too much information that

overdefined the feature. This aspect of Geometry Expert is referred to as the “auto delete”

function which is explained in the Expert Aids section of this chapter.

Page 29

GFK-1703 Geometry Creation

◆

23

Close box: Clicking in this box will close Geometry Expert and allow the user to use the free

form CAD tools contained in the Geometry Creation palette. When Geometry Expert is closed,

all information is cleared out of the spreadsheet. When the Geometry Expert button is

depressed again, the spreadsheet will come up empty. In order to load or reload a shape into

the spreadsheet, simply double click on any feature of the shape while the spreadsheet is open

on the screen.

Size box: The size box allows the user to adjust the size of the Geometry Expert spreadsheet.

To adjust the size of the spreadsheet, click in the Size box and drag the window to the desired

size. The width cannot be changed, but the length can be adjusted.

Scroll Bar: The scroll bar and arrows allow the user to scroll through the rows contained in

the spreadsheet to make adjustments and check the values entered. This is useful if the spreadsheet needs to stay relatively small to fit on the screen, and/or if it contains many features.

EXPERT AIDS

There are several items built in to Geometry Expert that are designed to guide the user

through geometry creation. They include prompting, auto delete, and error balloons.

Prompting

The prompting information appears across the bottom of the Geometry Expert spreadsheet.

The prompt tells the user what actions are being taken by the system based on the information provided by the user. The user should be able to follow the prompts through the creation process to

get a good idea of what is happening.

Auto Delete

The auto delete function of Geometry Expert is intended to reduce errors resulting from features being overdefined because too much information has been entered in the feature row.

Geometry Expert is designed so that the user need only enter the minimum amount of information

to define a feature. The system will automatically delete the first entry made in the feature row

when the feature is overdefined. Auto delete is necessary in order to facilitate the associative

capabilities of Geometry Expert. Note that the default values, such as the line angle, are considered the first entry rather than any information entered by the user. The prompt will indicate what

information is being deleted.

Error Balloons

Geometry Expert also contains Error Balloons which appear on the screen whenever a problem occurs. The most common error messages appear when the system requires more information

for a feature being entered. For example, if a line needs another value for an end point, an Error

Balloon will come up indicating that a V or H value is needed to calculate the end point. The

Error Balloons and Prompting use the letters V and H, indicating Vertical and Horizontal, rather

than using X and Y (for Mill) or Xd/Xr and Z (for Lathe.) This way the error messages remain the

same regardless of what module is being used.

Another common error message indicates that the feature being defined cannot intersect with

the previous feature. The non-intersecting feature can still be created, but the message indicates to

Page 30

◆

Geometry Creation User Manual GFK-1 7 0 3

24

the user that the continuity of the shape has been broken and the subsequent features being created

will not connect to the existing shape.

ADDITIONAL INFORMATION

Defaults

When entering features in the Geometry Expert spreadsheet, the system contains defaults for

the feature type and line angle. The standard feature type default is a line. When Geometry

Expert defaults to a line, it also enters an angle value, either 90°/270° or 0°/180°, depending on

the angle of the last line entered. Sometimes a line is not a possible feature type option, in which

case the system defaults to an arc. This only occurs when the previous feature is a floating line.

Geometry Expert dimensions the line according the preceding and following feature specifications.

Floating features are not drawn on the screen until the system contains the necessary information.

Post Targeting

Despite all of its expertise, Geometry Expert can’t always know the correct intersection point

to use for a connector. When there are two or more, equally valid points of intersection, the system will draw both points. This is referred to as post targeting. When post targeting is required, a

dialog will come up that asks the user to select the appropriate point and click on the OK button.

Once the user has selected the desired intersection point, Geometry Expert will make the appropriate connection and continue along in the spreadsheet defining and connecting features.

The Edit menu contains an item that will change the intersection point selected in a post targeting dialog to the other possible point of intersection. The menu item toggles between Use

Intersection #1 and Use Intersection #2, depending on the point selected and where it lies along

the path of the shape. This option will be an active item when a feature that required post targeting is selected on the screen.

Half Points

In certain cases, only one coordinate, either the horizontal or vertical, is required to define

the feature. This is referred to as a half point case. Half points are valid when Geometry Expert is

able to calculate the other half of the coordinate value from information contained in the spreadsheet. (Either preceding or following features.)

When a valid half point is entered, the row will be highlighted in yellow, allowing the user to

enter the feature row. If the half point entered is not valid, the row will be highlighted in black

and the prompt will indicate what additional information is necessary to enter the row. If an

incomplete row is entered, an error ballon will come up indicating what additional information is

required. There are three cases where half points are valid. They are listed and explained below.

Half Line Point: A half line point is valid only when creating either a horizontal line (angle

value = 0° or 180°) or vertical line (angle value = 90° or 270°). If creating a horizontal line, a

V coordinate must be given for a valid half line point. If creating a vertical line, an H coordi-

nate must be given for a valid half line point. Line points are not part of the shape, but are

only used to calculate the position of the line.

Half End Point: A half end point is only valid if the line is otherwise completely defined.

Given either the vertical or horizontal coordinate of the end point along with the other informa-

tion that defines the line, the system can calculate the other half of the end point. If a half end

point is used in the case of 0°/180° or 90°/270° lines, the half end point will function like a

half line point, in that an end point will not be drawn, although the correct line will be created.

Page 31

GFK-1703 Geometry Creation

◆

25

Half Center Point: A half center point is valid when a circle has a radius value and is tangent to

the preceding feature. (There must be a preceding feature.) Given the radius and the vertical

or horizontal component of the centerpoint, the system can calculate the other half of the

centerpoint by the assumed tangencies.

Floating Features

Floating features are features whose defining row does not contain all of the information necessary to draw the feature. Floating feature rows are different from incomplete feature rows. With

floating feature rows, the information contained in the current feature row and the preceding rows

is inadequate to completely define the feature and draw it. However, subsequent features, defined

in following rows, should provide the necessary information to define the floating feature.

Floating feature rows are outlined in yellow and can be entered.

Incomplete feature rows do not contain enough information to create the feature, and no

amount of information entered in following rows will make the feature definable. Incomplete feature rows are outlined in black and cannot be entered without getting error messages.

Again, the row outline and the prompting information will indicate if the feature row can be

entered, and if it is, how the floating feature will be incorporated into the shape after later features

have been defined.

Inserting and Deleting Rows

The Edit menu contains options for inserting and deleting rows in the spreadsheet. When

inserting rows in the spreadsheet, the system will create a new row above the current row. To

insert a row, select the row beneath the row to be inserted. Then, select the Insert row option in

the Edit menu. When an inserted row is entered, the system will recalculate the shape and attempt

to incorporate the new feature into the existing shape, if possible.

To delete a row, simply select the row to be removed, and choose the Delete Row option in

the Edit menu. When rows are deleted, Geometry Expert will recalculate the shape, and attempt

to keep it continuous and connected. If that is not possible, error balloons will appear indicating

that features do not intersect and the shape cannot be connected.

Arcs vs. Fillets

Arcs with only a radius value and fillets appear to be very similar at first glance, but actually

use two completely different methods for calculating the circles. A fillet takes a sharp point produced by an intersection between two other features and changes it into a radius. It is created after

the intersection between the two features is completed. Because of this, it is dependent on the

intersection of the other two features to exist. This means that the system cannot use the fillet to

calculate features that follow it in the spreadsheet. As the prompts indicate, Geometry Expert

completely ignores fillets (and chamfers) when calculating what information is necessary to define

features. When the prompt displays information about the interaction between the current feature

and the previous feature, fillets will be ignored.

An arc with only a radius value is created tangent to two other features. These two features

do not have to intersect. The arc is treated as an actual feature and can be used when calculating

other features of the shape.

This is particularly important when dealing with floating lines (lines with limited information) that have specific tangency requirements. Geometry Expert assumes that floating lines are

going to be made tangent to the preceding feature. In most cases this is adequate, but sometimes a

Page 32

◆

Geometry Creation User Manual GFK-1 7 0 3

26

floating line is supposed to intersect the previous circle and be tangent to the next circle. This is

called a "forward" tangency.

In the case of forward tangencies, if there is a radius between the previous circle and the

floating line, then an arc, rather than a fillet, must be used in order to allow for the necessary tangency calculation. The line will be made tangent to both the arc used as a fillet and the next arc.

A fillet cannot be used in this case because the fillet will be ignored by the system until the intersection is completed, and the correct intersection cannot be created without the arc. If there is no

fillet, an arc with a radius of zero will need to be created. This will allow the system to create the

line tangent to the following circle, while creating a sharp point at the intersection of the previous

feature.

For a practical example of forward tangencies, refer to Exercise # 3 in the Combination

Exercises Chapter.

FREE FORM CAD

The free form CAD tools are contained in the Geometry Creation palette. The buttons in the

palette access sub-palettes and dialogs that allow the user to enter feature specifications and create

shapes. The buttons, sub-palettes and dialogs are described below.

Point button: Clicking on this button brings up the Point sub-palette, shown below, which

consists of a group of buttons containing the construction tools for creating points.

Point sub-palette: This sub-palette con-

tains buttons which allow the user to

create points in 3D space in a variety

of ways. When each is depressed,

a geometry dialog appears on the

screen. Geometry dialogs are used for input of specific geometric (numerical) information in

the creation of points and features. If two features are selected before the Point button is

depressed, the Point sub-palette will be skipped and a dialog providing for the creation of a

point between the two features will appear instead. Likewise, once the Point button has been

depressed, two features can be selected without depressing a button of the sub-palette, and a

dialog will automatically appear allowing for the creation of a point between the two features

selected. If only the Lathe module is installed, the Bolt Circle button and the Matrix Point but

ton will be grayed out because they have no applications in lathe.

XYZ button: Create a point by typing in the coordinate values for the point.

For Mill, X,Y, and Z coordinates. For lathe, Xd or Xr (depending on the X

Dimension style) and Z coordinates.

Polar Point button: Create a point at some angle and distance from an existing

point.

Page 33

GFK-1703 Geometry Creation

◆

27

Bolt Circle Point button: Create a circular pattern of points by entering the

appropriate information in the dialog shown below.

Matrix Point button: Create a parallelogram pattern of points by entering the

required information in the dialog shown below.

Centerpoint button: Create a point at the center of an existing circle.

Mouse Point button: Create a point wherever the cursor is clicked with a user-

defined grid spacing.

Return button: This button appears at the far right end of geometry sub-

palettes and dialogs, and returns the user to the Geometry Creation palette.

It can also be activated by hitting the escape key on the keyboard.

X Coordinate of

Pattern Centerpoint

Y Coordinate of

Pattern Centerpoint

Radius of

Circle Pattern

Z Depth

of Points

Creation Order Direction

(CCW or CW)

Angle to 1st Point

# of Points

in Pattern

Side 1

Change in X

Side 1

Change in Y

# of points

in Side 1

Y Coordinate

of 1st Point

X Coordinate

of 1st point

Side 2

Change in Y

Side 2

Change in X

Z Depth

of Points

# of Points

in Side 2

Page 34

◆

Geometry Creation User Manual GFK-1 7 0 3

28

Line button: Clicking on this button brings up the Line sub-palette, shown below, which provides for the creation of lines.

Line sub-palette: This sub-palette con-

tains buttons which provide different

methods to create lines. All buttons in

this palette are active choices. If

two features and/or points are selected before the Line button is depressed and those points

and/or features can have a line created through or tangent to them, the Line sub-palette will be

skipped and a dialog asking to create a line between the two features and/or points will appear

instead. Likewise, once the Line button has been depressed, two features and/or points can be

selected without depressing a button of the sub-palette, and a geometry dialog will automatically appear allowing for the creation of a line between the two features and/or points selected.

Point-Angle button: Create a line through an existing point at some specified

angle.

Tangent-Angle button: Create a line tangent to an existing circle at some speci-

fied angle.

Parallel Line button: Create a line parallel to an existing line at some specified

distance.

Perpendicular Line button: Create a line perpendicular to an existing line

through a specified point.

Parallel to Axis button: Create either a horizontal or vertical line, parallel to

an axis, at a specified distance from the axis.

Mouse Line button: Create connected lines using the mouse. Endpoints will be

made whenever you click on the mouse button, and will snap to a predefined grid of the users choice.

Circle button: Clicking on this button accesses the Circle sub-palette, shown below, which

provides options for the creation of circles.

Circle sub-palette: This sub-palette con-

tains a group of buttons for creating

circles. If two features and/or points

are selected before the Circle button is

depressed and those points and/or features can have a circle created tangent to them, the Circle

sub-palette will be skipped and a dialog asking to create a circle tangent to the features and/or

points will appear instead. Likewise, once the Circle button has been depressed, features

and/or points can be selected without depressing a button of the sub-palette, and dialog will

automatically appear allowing for the creation of a line between the two features and/or points

selected.

Page 35

GFK-1703 Geometry Creation

◆

29

Centerpoint-Radius button: Create a circle using a selected point for the centerpoint and defining a radius.

Centerpoint-Circumference button: Create a circle by choosing a point for the

centerpoint and another as a point on the circumference of the circle.

Three Elements button: Create a circle by selecting any combination of three

points, lines or circles for the circle to intersect or be tangent to.

Auto-shape button: Clicking on this button brings up the Auto-shape sub-palette which provides options for automatically generating shapes including text, rectangles, and polygons.

Auto-shape sub-palette: This sub-palette

provides options for quickly creating

text, rectangles and polygons. Each

button in the sub-palette accesses a

dialog specific to the type of shape

that will be created.

Text Creation button: This button accesses the Text Creation dialog which creates spline geometry from any TrueType font. For more information on Text

Creation refer to the Text Creation section later in this chapter.

Rectangle button: This button accesses the Rectangle dialog which creates rectangles and squares.

Rectangle dialog: This dialog specifies the length of

each side of the rectangle

and the center position of

the shape. There is also a

radio button at the bottom

of the dialog which

allows the user to specify

a fillet radius which will

be added at each corner

of the shape. Clicking on

the Process button creates

the defined shape.

Page 36

◆

Geometry Creation User Manual GFK-1 7 0 3

30

Polygon button: This button accesses the Polygon dialog which creates multi-

sided shapes (polygons).

Polygon dialog: This

dialog specifies the

number of sides, the

center position, the distance from the centerpoint to either the flat

side or the corder.

There is also a radio

button at the bottom of

the dialog which

allows the user to specify a fillet radius which

will be added at each

corner of the shape.

Curve button: Clicking on this button accesses the Curve sub-palette which provides options

for creating curves through a series of selected points.

Curve sub-palette: This sub-palette pro-

vides three different methods for cre-

ating curves through a series of pre-

defined points. Those methods

include Line Fit, Curve Fit, and Control Point. The Curve sub-palette changes in appearance

depending on the selected creation method. For more information on Curve Creation refer to

the Curve Creation section later in this chapter.

Fillet-Chamfer button: When this button is depressed, the Fillet-Chamfer sub-palette appears

on the screen. The options available in this menu can only be used on fully connected

points. Normally the button is grayed out, however, when a point(s) is selected, the button becomes black and allows the user to access the sub-palette. If the point is not a connector

point the sub-palette will come up on the screen, but no fillets or chamfers will be created.

Multiple fillets and chamfers can be created at one time by using this option when multiple points

are selected.

Fillet-Chamfer sub-palette: This subpalette provides options for creating

fillets and chamfers. The first button

provides for the creation of fillets.

The remaining three buttons allow

the user to create chamfers by specifying the chamfer size using different methods of defin

ition. The pictures on the chamfer creation buttons clearly display the meaning of the value

entered for the chamfer size.

Page 37

GFK-1703 Geometry Creation

◆

31

Fillet button : Create a fillet by selecting a connector point(s), entering a

radius value and clicking on the single circle button.

Chamfer-Side button: Create a chamfer by selecting a connector point(s),

entering a side value and clicking on the single line button.

Chamfer-Depth button: Create a chamfer by selecting a connector point(s),

entering a depth value and clicking on the single line button.

Chamfer-Length button: Create a chamfer by selecting a connector point(s),

entering a length value and clicking on the single line button.

Connect/Disconnect button: This button does not access any sub-palettes or dialogs. It

becomes an available option (black instead of gray) when a point is selected. To change a

plain point to a connector point, the point and the two features that intersect at that point

must be selected prior to clicking on this button. To disconnect or break a connection, only the

point needs to be selected prior to clicking on the button. Refer to the Shapes and Connectors section in this chapter for details.

TEXT CREATION